Page 1

LMC5022C-R3 LMC5110C-R3 LMC5116C-R3 LMC5182C-R3

LMC5023C-R3 LMC5111C-R3 LMC5117C-R3

LMC5026C-R3 LMC5113C-R3 LMC5180C-R3

LMC5027C-R3 LMC5114C-R3 LMC5181C-R3

High-Density Media Converter System II Layer 2 Modules

True Layer 2 conversion enables

you to extend your network

up to 40 kilometers over duplex fiber.

Page 2

FCC and IC RFI Statements

FCC and Industry Canada RF Interference Statements

Class B Digital Device. This equipment has been tested and found to comply with

the limits for a Class B computing device pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation. This equipment generates,

uses, and can radiate radio frequency energy, and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. If this equipment does cause harmful interference to radio or

telephone reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult an experienced radio/TV technician for help.

CAUTION

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

To meet FCC requirements, shielded cables and power cords are required to

connect this device to a personal computer or other Class B certified device.

This digital apparatus does not exceed the Class B limits for radio noise

emission from digital apparatus set out in the Radio Interference Regulation of

Industry Canada.

Page 2 724-746-5500 | blackbox.com LMC5022C-R3

Page 3

Certifications

Certifications

Class 1 Laser product, Luokan 1 Laserlaite,

Laser Klasse 1, Appareil A’Laser de Classe

European Directive 2002/96/EC (WEEE) requires that any equipment that

bears this symbol on product or packaging must not be disposed of with

unsorted municipal waste. This symbol indicates that the equipment should be

disposed of separately from regular household waste. It is the consumer’s

responsibility to dispose of this and all equipment so marked through

designated collection facilities appointed by government or local authorities.

Following these steps through proper disposal and recycling will help prevent

potential negative consequences to the environment and human health. For

more detailed information about proper disposal, please contact local

authorities, waste disposal services, or the point of purchase for this equipment.

LMC5022C-R3 724-746-5500 | blackbox.com Page 3

Page 4

Table of Contents

Table of Contents

Part Numbers ..................................................................................................5

1. Specifications............................................................................................6

2. Overview: About the High-Density Media Converter System II Layer 2

Modules........................................................................................................... 7

3. Configuration............................................................................................. 8

4. Install the High-Density Media Converter System II Layer 2 Modules.....9

4.1 Managed Modules .................................................................................... 9

4.1.1 Configuration Control and SNMP Management.................................9

4.2 Unmanaged Modules..............................................................................10

4.3 FX LinkLoss, TX LinkLoss, Link Fault Pass-Through, Far End Fault and

FiberAlert....................................................................................................... 11

4.3.1 Link Integrity.....................................................................................11

4.3.2 FX LinkLoss (FXLL).......................................................................... 12

4.3.3 TX LinkLoss (TXLL).......................................................................... 12

4.3.4 Link Fault Pass-Through (LFPT)......................................................12

4.3.5 FiberAlert and Far End Fault............................................................ 13

4.4 Auto Negotiation on High-Density Media Converter System II Layer 2

Modules......................................................................................................... 15

4.5 AutoCross Feature for Twisted Pair Connection ....................................15

5. Operation................................................................................................16

5.1 LED Operation........................................................................................16

6. Troubleshooting......................................................................................17

7. Contacting Black Box..............................................................................18

8. Fiber Optic Cleaning Guidelines............................................................. 19

Electrostatic Discharge Precautions.............................................................. 19

Page 4 724-746-5500 | blackbox.com LMC5022C-R3

Page 5

Part Numbers

Part Number Description

LMC5022C-R3 TX/FX-MM1300-ST

LMC5023C-R3 TX/FX-MM1300-SC

LMC5026C-R3 TX/FX-SM1310/PLUS-ST

LMC5027C-R3 TX/FX-SM1310/PLUS-SC

LMC5110C-R3 TX/FX-SM1310/LONG-SC

LMC5111C-R3 TX/FX-SM1310/LONG-ST

LMC5113C-R3 TX/SSFX-SM1310-SC (1310xmt/1550rcv)

LMC5114C-R3 TX/SSFX-SM1550-SC (1550xmt/1310rcv)

LMC5116C-R3 TX/SSFX-SM1310/PLUS-SC (1310xmt/1550rcv)

LMC5117C-R3 TX/SSFX-SM1550/PLUS-SC (1550xmt/1310rcv)

LMC5180C-R3 TX/FX-SM1550/LONG-SC

LMC5181C-R3 TX/FX-MM850-SC

LMC5182C-R3 TX/FX-MM850-ST

Part Numbers

LMC5022C-R3 724-746-5500 | blackbox.com Page 5

Page 6

Chapter 1: Specifications

1. Specifications

DC Input L2 w/LFPT: 0.80 Amp @ 5V

Operating Temperature: +32° F to +122° F (0° C to +50° C)

Storage Temperature: 0° F to +122° F (-20° C to +70° C)

Humidity: 5 - 95% (non-condensing)

Fiber Optic Specifications For fiber optic specifications, please visit:

http://www.blackbox.com

Page 6 724-746-5500 | blackbox.com LMC5022C-R3

Page 7

Chapter 2: Overview

2. Overview: About the High-Density Media Converter System II Layer 2

Modules

The L2 is a Fast Ethernet module which provides a single conversion between

100BASE-TX twisted pair and 100BASE-FX/SX single-mode or multi-mode

fiber. Each L2 includes one RJ-45 connector and one pair of ST or SC fiber

optic connectors

Also available in a single-strand fiber version, L2 TX/SSFX allows two

wavelengths to share one fiber strand — Full-Duplex data travels on different

wavelengths, for example (1310 nm and 1550 nm) — doubling the capacity of

fiber.

The L2 is SNMP-manageable and can be installed into the modular, SNMPmanageable High-Density Media Converter System II Layer 2 chassis, which is

unmanaged.

LMC5022C-R3 724-746-5500 | blackbox.com Page 7

Page 8

Chapter 3: Configuration

3. Configuration

The L2 has user-configurable features (e.g., FiberAlert (FA), TX LinkLoss

(TXLL), FX LinkLoss (FXLL), Link Fault Pass-Through (LFPT) and Far End

Fault (FEF)). Refer to the Managed Media Converter Module DIP Switch

Configuration Table for information on available features. Instructions for

installing and configuring both managed (via an SNMP-compatible

management application like iView²) and unmanaged modules follow.

Page 8 724-746-5500 | blackbox.com LMC5022C-R3

Page 9

Chapter 4: Install the High-Density Media Converter System II Layer 2

Modules

4. Install the High-Density Media Converter System II Layer 2 Modules

The Managed Media Converter Modules install in Black Box SNMP

manageable High-Density Media Converter System II chassis.

NOTE

All modules are hot-swappable.

To install a Managed Media Converter Module:

1. Remove the blank bracket covering the slot where the module is to be

installed by removing the screws on the outside edges of the bracket.

2. Slide the Managed Media Converter Modules into the chassis, via the

cardguides, until the module is seated securely in the connector.

3. Secure the module to the chassis by tightening the captive screw.

4. Save any “blanks” removed during installation for future use if the

configuration requirements change

4.1 Managed Modules

To manage one or more L2(s), an SNMP agent must be present in the chassis.

To configure Managed Modules, install the module first, and then configure

using the management software.

All Fiber Type information is now loaded into the NVRAM during manufacturing.

This is viewed only via iView² software, within the modules details.

Requirements:

• SNMP Firmware version C2

• iView² 1.8.6 or higher

4.1.1 Configuration Control and SNMP Management

Some High Density L2 Modules offer Configuration Control; labels on the front

faceplate are identified as such. Configuration Control has been implemented

to assist the end user by retaining the latest configuration regardless of how

that configuration was implemented (via DIP Switch settings or SNMP), when

an SNMP Management Module is present in a managed chassis.

Historically, if an SNMP Management Module was installed in a chassis, SNMP

would override the DIP Switch settings of a module. Using Configuration

Control, the end user has three conditions under which the configuration of an

SNMP Manageable Module may be impacted:

• Changing or installing an SNMP Management Module into a chassis with a

High Density L2 Modules with Configuration Control populated in a chassis

- The High Density L2 Module with Configuration Control will transfer its

saved configurations to the SNMP Management Module. If there is no

LMC5022C-R3 724-746-5500 | blackbox.com Page 9

Page 10

Chapter 4: Install the High-Density Media Converter System II Layer 2

Modules

SNMP Management Module, the High Density L2 Module with

Configuration Control will function based on its DIP Switch settings. If

the DIP Switches have not been changed, the stored configuration will

be used. The stored configuration can be extracted from the SNMP

Management Module or the DIP Switches.

• Replacing the same type of a High Density L2 Module with Configuration

Control

- If the DIP Switch settings are the same as the settings on the removed

High Density L2 Module, the new High Density L2 Modules with

Configuration Control gets its configuration settings from the SNMP

Management Module.

- If the DIP Switch settings are different, then the configuration of the

module is determined by the DIP Switch settings. (The settings are

forwarded to the SNMP Management Module and the values are

saved.)

• Installing a different model of a High Density L2 Module with Configuration

Control

- If another type of module is installed into the same slot in a chassis, the

SNMP Management Module clears the memory of the previous

configuration for that slot; the installed SNMP Manageable Module

configures itself, and its configuration is forwarded to the SNMP

Management Module, where the values are saved.

The SNMP Write Lock switch does not impact any High Density L2 Module or

High Density L2 Module with Configuration Control. Removing and installing a

new SNMP Management Module will no longer impact these modules either.

However, if there is a mixture of High Density L2 Modules with and without

Configuration Control, the Write Lock Switch and a new SNMP Management

Module must be taken into consideration.

If the command cleandb is applied to an SNMP Management Module, all the

settings for the modules will be removed, but the Configuration Control modules

will still be based on the last change made, while those without Configuration

Control will be set to their default settings.

4.2 Unmanaged Modules

Before installing, configure the L2 modules for desired features. The table on

the next page indicates the available features and settings for the L2 modules.

After configuring the DIP Switches for the desired settings, install the module

and connect the appropriate cables (refer to the Installating a High-Density

Media Converter System II Layer 2 section for more information).

Page 10 724-746-5500 | blackbox.com LMC5022C-R3

Page 11

Chapter 4: Install the High-Density Media Converter System II Layer 2

Modules

DIP Switch on S1 Feature Default Setting

1

2

3

4

5

6

7

8

Auto Negotiation (AN) ON

Far End Fault (FEF) OFF

FX LinkLoss (FXLL) OFF

TX LinkLoss (TXLL) OFF

FiberAlert (FA) OFF

Factory Default OFF

Factory Default OFF

Factory Default OFF

4.3 FX LinkLoss, TX LinkLoss, Link Fault Pass-Through, Far End Fault

and FiberAlert

L2 modules include the troubleshooting features FiberAlert, TXLL, FXLL, FEF

and LFPT that help locate silent failures on a network. Before attempting to

install the module(s), understand how these features work and react to a

specific network configuration.

4.3.1 Link Integrity

During normal operation, link integrity pulses are transmitted by all point-topoint Ethernet devices. When a Black Box media converter receives valid link

LMC5022C-R3 724-746-5500 | blackbox.com Page 11

Page 12

Chapter 4: Install the High-Density Media Converter System II Layer 2

Modules

pulses, it knows that the device to which it is connected is up and sending

pulses, and that the copper or fiber cable coming from that device is intact. The

appropriate “LNK” (link) LED is lit to indicate this.

The Black Box media converter also sends out link pulses from its copper and

fiber transmitters, but normally has no way of knowing whether the cable to the

other device is intact and the link pulses are reaching the other end. The

combination of FiberAlert and LinkLoss allows this information to be obtained

even when physical access to a remote device (and its link integrity LED) is not

available.

4.3.2 FX LinkLoss (FXLL)

FX LinkLoss is a troubleshooting feature. When enabled, if a fault occurs on

the fiber segment of a conversation, FX LinkLoss detects the fault and passes

this information to the twisted pair segment. If a media converter is not

receiving a fiber link, FX LinkLoss disables the transmitter on the media

converter’s twisted pair port. This results in a loss of link on the device

connected to the twisted pair port.

4.3.3 TX LinkLoss (TXLL)

TX LinkLoss is a troubleshooting feature. When enabled, if a fault occurs on

the twisted pair segment of a conversion, TX LinkLoss detects the fault and

passes this information to the fiber segment. If a media converter is not

receiving a twisted pair link, TX LinkLoss disables the transmitter on the media

converter's fiber port. The result is in a loss of the link on the device connected

to the fiber port.

4.3.4 Link Fault Pass-Through (LFPT)

Link Fault Pass-Through (LFPT) is a troubleshooting feature that combines TX

and FX LinkLoss from both the local and remote L2 modules. LFPT is enabled

by turning on both FX and TX LinkLoss on both modules. This feature allows

either end of the conversion to detect a link fault occurring at the other end of

the media conversion chain.

Page 12 724-746-5500 | blackbox.com LMC5022C-R3

Page 13

Chapter 4: Install the High-Density Media Converter System II Layer 2

Modules

Regardless if there is a break in segment 1, 2 or 3, the link will drop on the

switches at both ends. The link fault is passed through the media conversion

and is observed at each end. It acts just like it would if the devices were

directly connected.

For more information on LinkLoss/FiberAlert, visit the Black Box Web site at

http://www.blackbox.com. If unsure of how to implement these features in a

specific configuration, contact Black Box Technical Support at 877-877-2269.

4.3.5 FiberAlert and Far End Fault

Modules ship from the factory with troubleshooting features disabled.

FiberAlert (FA)

FiberAlert minimizes the

problems associated with

the loss of one strand of

fiber. If a strand is

unavailable, the Black

Box device at the receiver

end notes the loss of link.

The device will then stop transmitting data and the link signal until a signal or

link pulse is received. The result is that the link LED on BOTH sides of the fiber

connection will go out indicating a fault somewhere in the fiber loop. Using

FiberAlert, a local site administrator is notified of a fault and can quickly

determine where a cable fault is located.

LMC5022C-R3 724-746-5500 | blackbox.com Page 13

Page 14

Chapter 4: Install the High-Density Media Converter System II Layer 2

Modules

WARNING

Enable FiberAlert at the remote side of a media conversion only. Enabling it on both

sides would keep both transmitters disabled indefinitely.

By default FA is disabled. When enabled if, a fault occurs on the fiber line,

affecting data in one direction, FA stops sending signal in the opposite

direction. FXLL will act on this lack of signal, propagating the loss of like to the

copper port when FXLL is enabled.

Far End Fault

By default, FEF is disabled. When enabled, and a fault occurs on the fiber line,

affecting data in one direction, an FEF signal will be sent in the opposite

direction, indicating the fault. FXLL will act on this signal propagating the loss of

link to the copper port when FXLL is enabled.

FEF versus FA

FEF is preferred when the devices at both ends of the fiber can interpret the

FEF signal. This allows FEF to be turned on at both ends, which will engage

the FEF regardless of which direction the fault occurs. (Please refer to diagram

on previous page) For example if a fault should occur on segment 2 in the

direction of segment 1 to 3, FEF would be engaged on the L2 between

segment 2 and 3. This would then send a signal back to the L2 between

segment 1 and 2. If the L2 between segment 1 and 2 is in a managed chassis,

the chassis would send a trap that the port is down. Alternatively, if the L2 is

not in a managed chassis, FXLL could be engaged to propagate the fault onto

the copper port; this would cause segment 1 to show no link on both end s.

FA is used when connecting to a device that does not support FEF. If an FEF

signal is sent to a device that does not support FEF, the device acts as if there

is still a good connection. The FEF signal is mistaken for data. FA works

similar to FEF, in that when there is a fault in one direction of the fiber, it acts

on the fiber in the opposite direction. But unlike FEF, FA sends no signal.

Because of this, FA can not be enabled on both ends. If it is enabled and a

fault occurs, FA will turn signal off in the opposite direction; the device on the

other side of the fiber will see the loss of signal and engage FA, turning off

signal. The net result will be the signal turned off in both directions, even after

the fault has been repaired.

It is highly recommended that only one is chosen, either FEF or FA. If both are

selected FA will take precedence over FEF.

Page 14 724-746-5500 | blackbox.com LMC5022C-R3

Page 15

Chapter 4: Install the High-Density Media Converter System II Layer 2

Modules

4.4 Auto Negotiation on High-Density Media Converter System II Layer 2

Modules

L2 modules include the feature Auto Negotiation. When Auto Negotiation is

enabled, the module negotiates as a 100 Mbps full-duplex device. If the

connected device can operate at 100 Mbps full-duplex, a link is established.

Auto Negotiation (DIP Switch #1) is enabled by default.

If the twisted pair port on the other device does not have the ability to Auto

Negotiate or if the 100 Mbps half-duplex connection is desired, then Auto

Negotiation must be disabled. Half- and full-duplex settings must be set

manually and match on both devices.

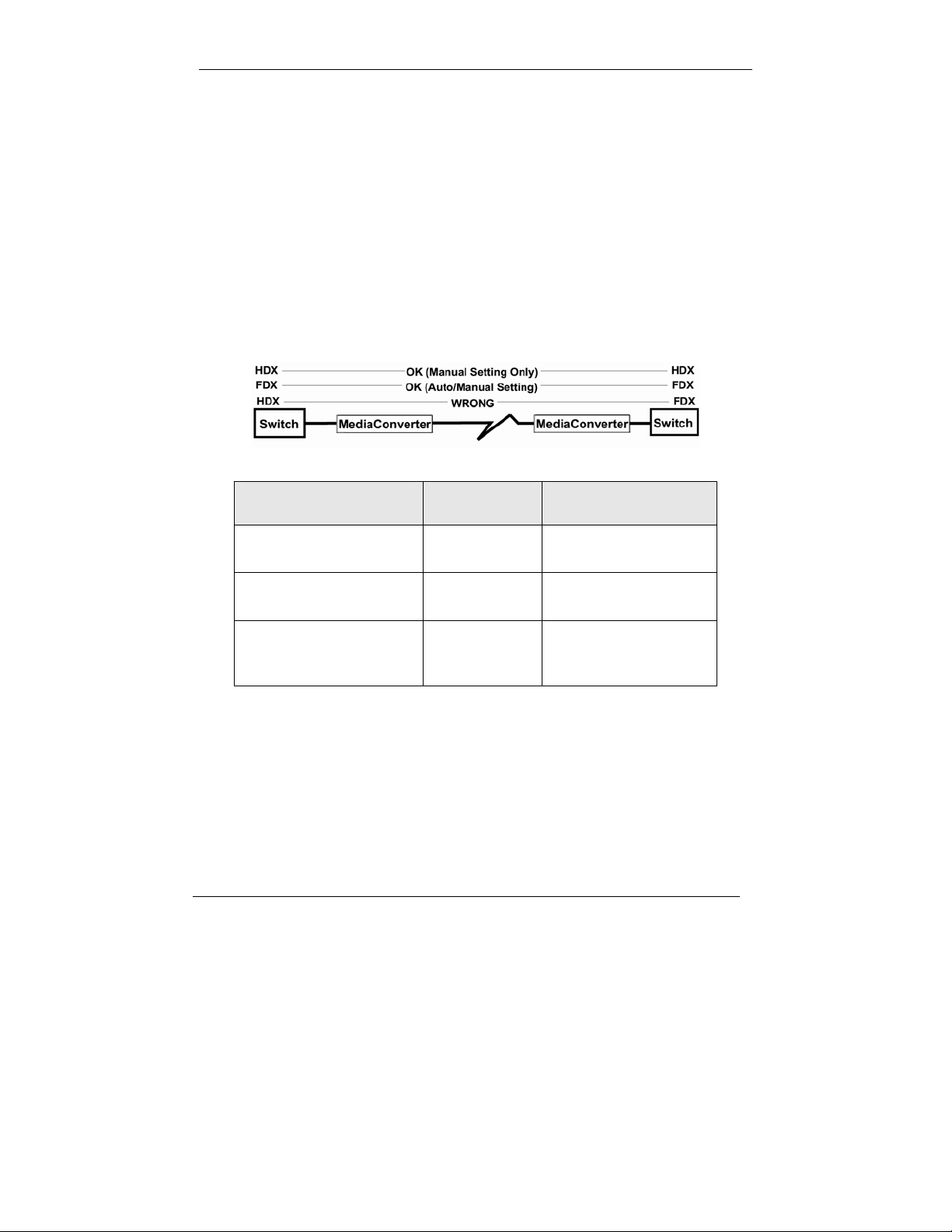

The following diagram shows a typical application and with three possible

configurations.

End-to-End

Switch TX/FX

Connection

Half-Duplex Configure

HDX manually

Full-Duplex Configure

FDX manually

Full-Duplex Auto

Negotiation is

Auto Negotiation is

OFF

Auto Negotiation is

OFF

Auto Negotiation is

ON

ON

Configure Auto Negotiation on a L2 by adjusting the DIP Switch setting (for

unmanaged modules) or via the management software. Refer to the DIP

Switch table for switch location and settings.

4.5 AutoCross Feature for Twisted Pair Connection

All twisted pair ports on the L2 includes AutoCross, a feature that automatically

selects between a crossover workstation and a straight-thro ugh connection

depending on the connected device.

LMC5022C-R3 724-746-5500 | blackbox.com Page 15

Page 16

Chapter 5: Operation

5. Operation

5.1 LED Operation

Each L2 module features diagnostic LEDs that provide information on features

and ports.

Upgrade LED Stacks

Upper Function State

FEF

TXLL

LNK

DIS

Upper Function State

FA

FXLL

LNK

DIS

Fiber Far End Fault ON Green

TX LinkLoss/Blink if Active ON Green

FiberLink is valid/Flash on Activity ON Green

Software Disabled TX Port On Yellow

FiberAlert enabled/Blink Active ON Green

FX LinkLoss/Blink if Active ON Green

FX LinkLoss is valid/Flash on Activity ON Green

Software Disabled fiber port

On Yellow

(via iView²)

Page 16 724-746-5500 | blackbox.com LMC5022C-R3

Page 17

Chapter 6: Troubleshooting

6. Troubleshooting

• During install ation, first test the fiber and twisted pair connections with all

troubleshooting features disabled, then enable these features, if desired,

just before final installation. This will reduce the features’ interference with

testing.

• When worki ng with units where the features cannot be disabled, establish

both the twisted pair and fiber connections before the link LEDs will light.

• To test a L2 by itself, first, have an appropriate fiber patch cable, then

follow these steps:

1. Connect the L2 to the twisted pair device with a twisted pair cable.

2. Loop a single strand of fiber from the transmit port to the receive port of

the L2.

3. Verify that both the twisted pair and the fiber link are lit (see LEDs,

below) on the L2.

• Use the appropriate twisted pair cable, and have the crossover/pass-

through switch set correctly.

• Whenever possible, set the devices connected to the L2 (hub, switch, NIC

card) to the desired speed and Duplex setting, and turn Auto Negotiation

OFF. Refer to Auto Negotiation on L2, also configure the devices on the

opposite sides of the L2 to operate at the same speed and Duplex setting.

NOTE

Some 10/100 devices can not be set by the end user, and must Auto Negotiate to

receive a signal.

LMC5022C-R3 724-746-5500 | blackbox.com Page 17

Page 18

Chapter 7: Contacting Black Box

7. Contacting Black Box

Black Box Customer Service

Order toll-free in the U.S.: Call 877-877-BBOX

(outside U.S. call 724-746-5500)

Free technical support, 24 hours a day, 7 days a week.

Call: 724-746-5500 or Fax: 724-746-0746

Mail order: Black Box Corporation

1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com

E-mail: info@blackbox.com

WARNING

Disconnect all power supplies before servicing.

Page 18 724-746-5500 | blackbox.com LMC5022C-R3

Page 19

Chapter 8: Fiber Optic Cleaning & ESD Precautions

8. Fiber Optic Cleaning Guidelines

Fiber Optic transmitters and receivers are extremely susceptible to

contamination by particles of dirt or dust, which can obstruct the optic path and

cause performance degradation. Good system performance requires clean

optics and connector ferrules.

1. Use fiber patch cords (or connectors, if you terminate your own fiber) only from a

reputable supplier; low-quality components can cause many hard-to-diagnose

problems in an installation.

2. Dust caps are installed at Black Box to ensure factory-clean optical devices.

These protective caps should not be removed until the moment of connecting the

fiber cable to the device. If you need to disconnect the fiber device, reinstall the

protective dust caps.

3. Store spare caps in a dust-free environment such as a sealed plastic bag or box

so that when reinstalled they do not introduce any contamination to the optics.

4. If you suspect that the optics have been contaminated, alternate between

blasting with clean, dry, compressed air and flushing with methanol to remove

particles of dirt.

Electrostatic Discharge Precautions

Electrostatic discharge (ESD) can cause damage to any product, add-in

modules or stand alone units, containing electronic components. Always

observe the following precautions when installing or handling these kinds of

products.

1. Do not remove unit from its protective packaging until ready to install.

2. Wear an ESD wrist grounding strap before handling any module or component.

If the wrist strap is not available, maintain grounded contact with the system unit

throughout any procedure requiring ESD protection.

3. Hold the units by the edges; do not touch the electronic components or gold

connectors.

4. After removal, always place the boards on a grounded, static-free surface, ESD

pad or in a proper ESD bag. Do not slide the modules or stand alone units over

any surface.

WARNING! Integrated circuits and fiber optic components

are extremely susceptible to electrostatic discharge damage.

Do not handle these components directly unless you are a

qualified service technician and use tools and techniques that

conform to accepted industry practices.

LMC5022C-R3 724-746-5500 | blackbox.com Page 19

Page 20

LMC5022C-R3, Rev. 1 50-80921BB-01 Rev A0

Loading...

Loading...