Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

CUSTOMER

SUPPORT

INFORMATION

JANUARY 1997

IC716A

IC716A-RJ

IC716C

RM110A

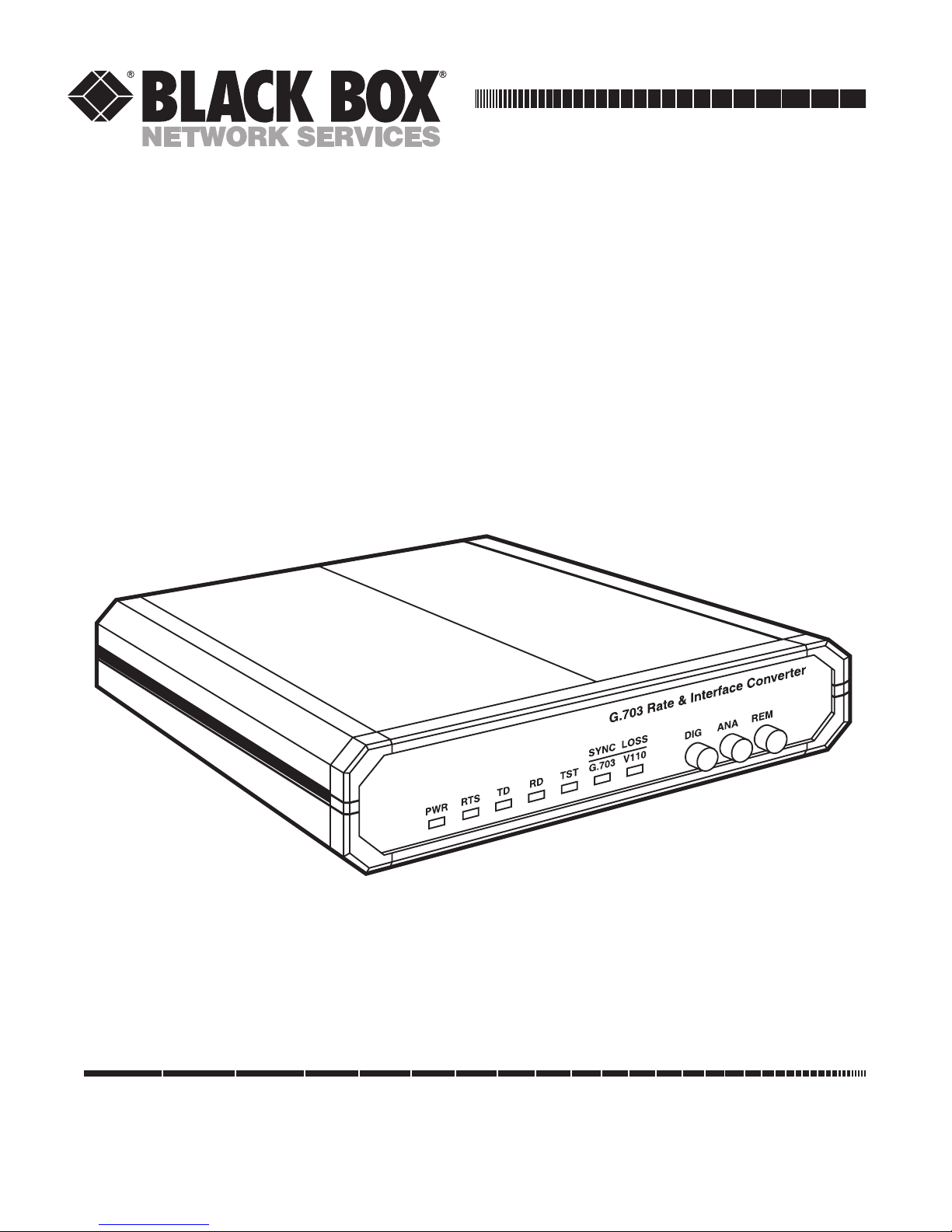

G.703 Rate and Interface Converters

FCC STATEMENT

1

FEDERAL COMMUNICATIONS COMMISSION

AND

INDUSTRY CANADA

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio-frequency energy, and if not installed and used

properly, that is, in strict accordance with the manufacturer’s instructions, may cause interference to radio

communication. It has been tested and found to comply with the limits for a Class A computing device in

accordance with the specifications in Subpart B of Part 15 of FCC rules, which are designed to provide

reasonable protection against such interference when the equipment is operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference, in which

case the user at his own expense will be required to take whatever measures may be necessary to correct

the interference.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital apparatus set out in the Radio

Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques

de la classe A prescrites dans le Règlement sur le brouillage radioélectrique publié par Industrie Canada.

G.703 RATE AND INTERFACE CONVERTERS

2

INSTRUCCIONES DE SEGURIDAD (Normas Oficiales Mexicanas Electrical Safety Statement)

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca de la tina de baño, lavabo, sótano

mojado o cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá a lo descrito en las instrucciones de

operación. Todo otro servicio deberá ser referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no interfiera su uso. La colocación del aparato

eléctrico sobre una cama, sofá, alfombra o superficie similar puede bloquea la ventilación, no se debe colocar en

libreros o gabinetes que impidan el flujo de aire por los orificios de ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor como radiadores, registros de calor, estufas

u otros aparatos (incluyendo amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del tipo descrito en el instructivo de

operación, o como se indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no sean pisados ni pellizcados por objetos

colocados sobre o contra ellos, poniendo particular atención a los contactos y receptáculos donde salen del aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean derramados sobre la cubierta u orificios de

ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

TRADEMARK

3

TRADEMARKS USED IN THIS MANUAL

Any trademarks mentioned in this manual are acknowledged to be the property of the trademark owners.

WARNING!

Always observe standard safety precautions during installation, operation, and

maintenance of this product. To avoid the possibility of electrical shock, disconnect the

power cord from the power source before you open up the unit or perform any repairs.

G.703 RATE AND INTERFACE CONVERTERS

4

Contents

Chapter Page

1. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2.1 G.703 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2.2 Rate Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.3 Async/Sync Converter and V.54 Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.4 Transmit FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.5 RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Mechanical Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.1 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2 Rear-Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.3 Strap Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3.4 Installing the Internal Jumpers and Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.1 Buttons and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2.1 Powering On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2.2 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Reconfiguring the G.703 Rate and Interface Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5. Tests and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.1 Loop Tests (DIG, ANA, and REM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.2 Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.3 Local Test—Local Loopback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.4 Communication Link Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.4.1 Remote Digital Loopback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.4.2 Local Digital Loopback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Appendix A. The RM110A Rack and the G.703 Rate and Interface Converter Card . . . . . . . . . . . . . . . .20

A.1 Rack Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

A.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

A.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

A.4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Appendix B. V.24/RS-232 Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Appendix C. Rack Adapter Installation Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

C.1 Rack Adapter Kit—Single-Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

C.2 Rack Adapter Kit—Dual-Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

CHAPTER 1: Specifications

5

1. Specifications

Interface — Codirectional, 64 Kbps; connects to an EIA RS-232/CCITT V.24

terminal interface

Line — 4-wire

Maximum Range — Up to 0.5 miles (800 m) over 24 gauge

Data Rates — 600, 1200, 2400, 4800, 7200, 9600, 14,400, 19,200 bps

Character Length in Async Mode — Selectable 8, 9, 10, 11 (includes Start+Stop+Parity+Character

Bits)

Control Signals — RTS, DTR, DCD, DSR, CTS are passed through according to

CCITT I.463; DSR may be set to constantly ON (strapselectable)

Impedance — 120Ω balanced

Protocol — Sync or async, full duplex

Connectors — IC716A: (1) 5-screw terminal block; IC716A-RJ: (1) RJ-45

female; Both: (1) DB25 female

Diagnostics — Front-panel pushbuttons DIG (Local Digital Loopback), ANA

(Local Analog Loopback), REM (Remote Digital Loopback),

or (V.54) activated from RS-232/V.24 DTE; DIG is activated by

a manual switch; REM is activated by a manual switch or by the

DTE interface signal (Pin 21); ANA is activated by a manual

switch or by the DTE interface signal (Pin 18)

Indicators — (7) LEDs: PWR, RTS, TD, RD, TEST, G.703 SYNC LOSS,

V.110 SYNC LOSS

Balance — Better than 45 dB (up to 256 KHz)

Timing Elements — Transmit clock (derived from 3 alternative sources: Internal

oscillator, external from the DTE [Pin 24] low-speed clock,

and loop clock derived from the receive signal, looped back

as a transmit clock) and low-speed clock (the DCE low-speed

timing signal [pins 15 and 17] is derived from the 64-KHz

clock)

Return Loss — Better than 20 dB (up to 256 KHz); Better than 14 dB

(up to 384 KHz)

Clock Frequency — 64 KHz

Frequency Tracking — ±500 ppm

“Pulse” Amplitude — 1.0V nominal

“Zero” Amplitude — 0V±0.1V maximum

Operating Temperature — 32 to 122°F (0 to 50°C)

G.703 RATE AND INTERFACE CONVERTERS

6

Relative Humidity Tolerance — 10 to 90%, noncondensing

Power — 115 VAC (230-VAC version available)±10%, 47 to 63 Hz, 3 watts;

0.1 A slow-blow fuse; AC/DC overvoltage protection, connected

via transformers to transmit or receive telephone lines (or

coaxial cable)

Size — IC716A, IC716A-RJ: 1.8"H x 7.6"W x 9.5"D (4.6 x 19.3 x

24.1 cm); IC716C: 9"H x 6.2"W x 1"D (22.9 x 15.8 x 2.5 cm)

Weight — IC716A, IC716A-RJ: 3.1 lb. (1.4 kg); IC716C: 0.6 lb. (0.3 kg)

CHAPTER 2: Introduction

7

2. Introduction

2.1 General Description

The G.703 Rate and Interface Converter allows low-speed V.24 equipment to be connected to a G.703

codirectional (64 Kbps) interface. This conversion enables connection of low-speed data channels to the

PCM network. The rate conversion is performed according to CCITT I.463 (V.110) and I.460 standards.

This rate conversion also enables access to ISDN terminal adapters through the telecommunication

network.

The Converter operates synchronously or asynchronously, converting V.24 rates up to 19,200 bps. For

async rates of 600 bps and higher, the async-to-sync conversion is compatible with CCITT V.14. For async

rates lower than 600 bps, the Converter operates in synchronous mode at 19,200 bps and multi-samples

the data.

Operating full duplex at a transmission rate of 64 Kbps, the Converter has a range of up to a half mile

(800 m) from the G.703 equipment. The high-speed transmit timing source is strap-selectable for either

recovered clock from the G.703 interface, external timing from the V.24 interface, or internal timing.

The Converter features V.54 diagnostic capabilities for performing local loopback and remote digital

loopback. When in the digital loopback mode, the operator at either end of the line may test both units

and the line. The loopback is controlled either by front-panel buttons or by Pins 18 and 21 of the

V.24/RS-232 interface.

All V.24 configuration parameters—such as bit rate, bit length, and sync/async—can be selected at each

Interface Converter. Alternatively, parameters can be selected at a “master” Interface Converter, and

downline-loaded from the “master” to a “slave” Interface Converter.

The control signals RTS and DTR are passed through end-to-end to DCD and DSR, respectively, in

compliance with CCITT I.463 (V.110). DSR can be optionally set separately to be continuously ON.

The Converter is coupled to the G.703 4-wire interface line through isolation transformers which, in

conjunction with other circuitry, protect against AC or DC overvoltages. The protection circuitry enables

operation even when DC is connected to the line.

The Interface Converter is available as a desktop unit (with either terminal blocks or RJ-45 connectors)

or as a rackmount card for a 19-inch rack. The RM110A rack (power supply 100 VA) can carry up to

fourteen cards. Special hardware for mounting standalone units in a 19-inch rack can be ordered

separately. The special hardware enables installation of either one or two units side by side. The unit

height is only 1U (1.75"), requiring minimal rack space.

G.703 RATE AND INTERFACE CONVERTERS

8

2.2 Functional Description

When reading this section refer to the diagram below.

Figure 2-1. G.703 Rate and Interface Converter Block Diagram.

2.2.1 G.703 I

NTERFACE

The G.703 interface on the transmit side converts the analog transmit signal to a three-level signal, and

inserts a bipolar violation every block of eight bits (according to the G.703 standard). On the receive

side, the interface provides the digital signal (from the received analog signal) synchronized with the

violation signal. If no violation signal is received, the G.703 SYNC LOSS indicator lights.

The G.703 interface also provides one of three rate-adapter timing sources:

• Internal (a free-running crystal oscillator)

• Receive (synchronized with the received G.703 signal)

• External (synchronized with the low-speed clock provided by the DTE on Pin 24)

NOTE

The system needs one master clock. If one unit is set to Internal/External clock, the

other unit must be set to Receive clock (or RCVB if needed). RCVB is a special option

provided for cases in which the timing source is the Receive clock, but the incoming

low-speed data is synchronized according to the External clock. In such cases, external

synchronization between the G.703 network and the local DTE must be provided (refer

to Figure 2-2).

RS-232

INTERFACE

TD

E.CK

TRANSMIT

FIFO

RD (LOW SPEED)

TC & RC

ASYNC/SYNC

CONVERTER

AND

V.54

CIRCUITS

RATE

ADAPTOR

G.703

INTERFACE

TD

LOW-SPEED

CLOCK

RD

TXC 64 KHz

RXD

TXC

RXD

RXC

RECEIVE

FIFO

EXTERNAL

RECEIVE

INTERNAL

G.703

SYNC LOSS

V.1 10

SYNC LOSS

TEST

INT

TD

EXTERNAL/RECEIVE CLOCK WITH

EXTERNAL BUFFER

HIGH

SPEED

CHAPTER 2: Introduction

9

Figure 2-2. G.703 Rate and Interface Converter Synchronization Options.

2.2.2 RATE ADAPTER

The rate adapter implements the V.110 (I.463) standard. RTS, DTR, and incoming low-speed data are

transmitted to the line (on 64 KHz) in frames. The receive side of the block checks the incoming frames

and sends the relevant data to the low-speed channel. If the unit loses synchronization on the received

frames, the V.110 SYNC LOSS indicator lights. The RTS and DTR signals are passed through as DCD and

DSR.

The rate adapter also provides the low-speed transmit and receive clock.

2.2.3 A

SYNC/SYNC CONVERTER AND V.54 CIRCUITS

If the DTE is an async type, an async/sync conversion is provided (as described in the V.22 standard).

The V.54 circuits send and receive the pattern in order to provide the remote digital loop in the remote

unit as well as the remote digital loop in the local unit.

2.2.4 T

RANSMIT FIFO

The transmit FIFO compensates for phase differences if the unit is synchronized to the external lowspeed clock provided on Pin 24 (DTE timing). It is also used when the Interface Converter is

synchronized with the received G.703 signal, and the DTE provides the clock (Transmit Clock set to

RCVB—refer to Table 3-1). In this case the DTE and digital transmission system must be externally

synchronized.

2.2.5 RS-232 I

NTERFACE

The RS-232 interface provides a standard voltage conversion to V.24/RS-232 levels.

NOTE

1. In order to enable the DCD and RD on the remote unit, the local RTS must be in the ON

state.

2. If the unit is not synchronized according to V.110 (I.463), the CTS, DSR, and DCD pins

are in the OFF state.

G.703 Rate and

Interface Converter

G.703

NETWORK

G.703 Rate and

Interface Converter

V.24

MUX

EXTERNAL CLOCK SYNCHRONIZATION

G.703G.703

RCV RCVB

V.24

EXTERNAL

CLOCK

G.703 RATE AND INTERFACE CONVERTERS

10

Figure 2-3. Clock Diagram.

Figure 2-4. Clock Configuration.

TX

Digital Transmission

Media

Low Speed

TC & RC

TX

64 Kbps

RXRX FIFOFIFO

TX

Low Speed

TC & RC

TX

RXRX FIFOFIFO

INT RCV

TC & RC

EXT CLK

FIFO

TC & RC

Ext. sync.

provided by

DTE

FIFO

External

Clock

EXT RCVB

XMT

FIFO

TX

Internal

RCV

FIFO

RX

External

EXT or RCVB

TD

RC

TC

EXT CLK

CLOCK AND

DATA

High

Speed

Receive

CLOCK AND

DATA

RD

Low Speed

LOW

SPEED

SIDE

G.703

SIDE

64 Kbps

Low

Speed

Internal, Receive

CHAPTER 3: Installation

11

3. Installation

This chapter provides instructions for the mechanical and electrical installation of the G.703 Rate

and Interface Converter standalone models. If you need to install the Card, go to Appendix A.

Once you’ve completed the installation, refer to Chapter 4 for operating information and system

checkout to assure normal operation.

3.1 Site Preparation

Install the Interface Converter within 5 feet (1.5 m) of an easily accessible grounded AC outlet. The

outlet should be capable of furnishing 115 VAC or 230 VAC, depending on the rated voltage of the unit.

Allow at least 36 inches (90 cm) of frontal clearance for operating and maintenance accessibility.

Allow at least 4 inches (10 cm) clearance at the rear of the unit for signal lines and interface cables.

3.2 Mechanical Assembly

The Interface Converter standalone is designed for tabletop or bench installation, and is delivered

completely assembled. No provisions are made for bolting the Converter to the tabletop.

The IC716C is the card version of the G.703 Rate and Interface Converter. It’s installed in the

RM110A rack.

3.3 Electrical Installation

3.3.1 POWER CONNECTION

AC power is supplied to the Converter through a standard 3-prong plug.

CAUTION!

This unit should always be grounded through the protective earth lead of the power

cable.

When connecting AC power to this unit, the mains plug should only be inserted in an

outlet provided with a protective earth contact. The protective action must not be

negated by use of an extension cord (power cable) without a protective conductor

(grounding). Interrupting the protective (grounding) conductor (inside or outside the

unit) or disconnecting the protective earth terminal can make this unit dangerous.

The line fuse is located in an integral fuse holder on the rear panel. Make sure that only

fuses of the required rating, as marked on the Interface Converter’s rear panel, are used

for replacement. Do not use repaired fuses or short-circuit the fuse holder. Always

disconnect the mains cable before removing or replacing the fuse.

Whenever it is likely that the fuse protection has been damaged, make the unit in

operative and secure it against unintended operation.

G.703 RATE AND INTERFACE CONVERTERS

12

3.3.2 REAR-P

ANEL CONNECTORS

The digital V.24/RS-232 interface on the rear panel of the Converter is a 25-pin connector. The line

connector may be either an RJ-45 female or a 5-screw terminal block.

G.703 Side

RJ-45 Female Connector

The pin assignments for the RJ-45 connector are listed below.

Pin Function

3 Receive

6 Receive

4 Transmit

5 Transmit

2 Shield (chassis ground)

Terminal Block

The 5-screw terminal block provides four screws for connecting the transmit and receive twisted-pair

lines. The transmit and receive pairs are polarity-insensitive. The transmit pair is connected to the

terminals marked XMT (data out), and the receive pair is connected to the terminals marked RCV (data

in). The screw marked GND is connected to the AC power ground wire.

DTE Side

V

.24/RS-232 Interface Connector

For the pinout, refer to Appendix B.

3.3.3 S

TRAP S

ELECTION

When the electrical installation has been completed and checked, determine the required configuration

of the Converter and position the straps accordingly. The PCB strap locations in Figure 3-1 correspond

to the numbers listed under “Strap Identity” in Table 3-1.

CAUTION

To avoid accidental electric shock, disconnect the G.703 Rate and Interface Converter’s

power cord before opening the unit.

3.3.4 I

NSTALLING THE INTERNAL JUMPERS AND SWITCHES

a) Disconnect the power cord from the AC outlet.

b) Using a flat-bladed screwdriver, loosen the two screws at the rear panel.

c) Use the screws as levers to pull out the interior like a drawer.

d) Adjust the jumpers and switches as required, according to Table 3-1.

e) Push the interior section back inside the unit and tighten the retaining screws.

CHAPTER 3: Installation

13

Table 3-1. Strap Selection

(Strap identity numbers correspond to PCB Strap Locations of Figure 3-1)

Strap Identity Function Possible Settings Factory Setting

1

Selects the low-speed data rate. 0 — 0.6

Baud Rates 1 — 1.2

(Kbps) 2 — 2.4

3 — 4.8 3

4 — 7.2

5 — 9.6

6 — 14.4

7 — 19.2

2 Selects the transmit clock (64 KHz) from either: INT

TC G.703 internal clock (INT), receive clock (RCV), external clock EXT

(EXT), or receive clock plus FIFO active for transmit data RCV RCV

with DTE timing provided (RCVB). RCVB

3 S1—Selects if the unit works according to its own (“Master”) Master ↑ Master

DIP Switches configuration for baud rate, sync/async and bit lengths or Slave ↓

according to the remote unit (“Slave”).

S2—Provides an async/sync conversion. ASYNC ↑ ASYNC

SYNC ↓

S3/S4—Character length (includes start bits+stop bits+data 8↑↑

bits+parity) 9↓↑

10↑↓

11↓↓ 11

4 Enables Remote loopback from the DTE. EN

Pin 21* DIS DIS

5 Enables Local loopback from the DTE. EN

Pin 18* DIS DIS

6 Enables the activation of front-panel pushbutton. EN EN

Switch DIS

7 Sets DSR constantly ON (space) independently of the ON ON

DSR remote DTR or reflects the remote DTR. REM

8 The CONNECT setting connects Signal Ground to Chassis CON

C.GND Ground. The DIS disconnects them. DIS DIS

*Note: If the DTE does not provide the test pins for analog and remote loopback, the “DTE command” jumper

for Pin 18 and Pin 21 must be always set to DIS.

G.703 RATE AND INTERFACE CONVERTERS

14

Figure 3-1. Layout of the G.703 Rate and Interface Converter Board.

(Refer to Table 3-1 for strap selection.)

BAUD RATE (kbps)

0-0.6

1-1.2

2-2.4

3-4.8

4-7.1

5-9.6

6-14.4

7-19.2

0

1

2

3

4

5

6

7

8

9

S1

1

2

3

4

DIS

EN

SWITCH

DIS

EN

PIN 21 PIN 18

DIS

CON

C.GND

DSR

ON

REM

INT

EXT

RCV

RCVB

TC G703

BITS

S2 S3

M

S

ASYNC

SYNC

8

9

10

11

8

4

5

7

2

3

6

1

CHAPTER 4: Operation

15

4. Operation

IMPORTANT!

Make sure you’ve gone through all the installation procedures in Chapter 3 before

attempting to operate the G.703 Rate and Interface Converter.

4.1 Buttons and Indicators

The test buttons and LED indicators are located on the Converter’s front panel. Press the button to

activate (turn ON) the corresponding test. Press the button again to deactivate (turn OFF) the test. The

functions of each button and indicator are described in Tables 4-1 and 4-2.

Table 4-1. Pushbutton Tests

Control Function

DIG The Digital loopback switch causes the local Converter to loop (loop 2) received data to its

transmitter. Data Set Ready goes low (see Figure 5-4).

ANA The Local loopback (V.54 loop 3) switch causes the local Converter to loop its transmitter output

back to its receiver (see Figure 5-2). The transmitter continues to send to the line. This loopback

may also be activated from the DTE when “Pin 18” is set to EN.

REM The Remote Digital Loopback (V.54 Loop 2) switch causes the remote Converter to loop received

data to its transmitter (see Figure 5-3). Data Set Ready goes low. This loopback may also be

activated from the terminal when “Pin 21” is set to EN.

Table 4-2. LED Indicators

Indicator Function

PWR (green) On when power is on.

RTS (yellow) ON when terminal activates Request to Send.

TD (yellow) On when steady SPACE is being transmitted. Flickers when data is transmitted.

RD (yellow) ON when steady SPACE is being received. Flickers when data is received.

TEST (red) ON when the Converter is in any of the three loopback modes.

SYNC LOSS

G.703 OFF for normal operation. ON if violations are not present on receive signal.

V.110 OFF for normal operation. ON if synchronization is lost on more than three consecutive

frames on the incoming G.703 signal.

G.703 RATE AND INTERFACE CONVERTERS

16

4.2 Operating Procedure

The G.703 Rate and Interface Converter requires no operator attention once it is installed (refer to

Chapter 3), except for occasional monitoring of the front-panel indicators. Intervention is only

required when:

• The Converter has to be adapted to new operational requirements, or

• Diagnostic loops are required.

4.2.1 P

OWERING ON

The Converter is turned on as soon as its AC power cord is connected to the AC power mains outlet.

The PWR indicator lights, indicating that the Converter is on. Verify that the local and remote

Converters are in operation by checking that the front-panel LEDs on the local and remote units

match the following indicator conditions:

• PWR: On

• RTS: On

• TD: Flashing or Off

• RD: Flashing or Off

• TEST: Off

• SYNC LOSS:

V.110 — Off

G.703 — Off

NOTE: If the LEDs do not match the indicator conditions listed above, verify that none of the front-panel

test buttons are pressed in.

To turn off the AC power to the Converter, remove the AC power cord from the AC source.

4.2.2 T

ESTING

In order to verify that the Converter is operating correctly, use the loopback tests as described in

Chapter 5.

4.3 Reconfiguring the G.703 Rate and Interface Converter

If it becomes necessary to reconfigure the Converter for a different type of operation, field straps must

be changed to correspond to the new operating mode.

For guidance in repositioning the straps and switches, refer to Section 3.3.4. Field straps should be

changed by an experienced technician.

CAUTION

To avoid accidental electric shock, disconnect the Converter power cord before

opening the unit.

CHAPTER 5: Tests and Diagnostics

17

5. Tests and Diagnostics

This chapter contains procedures for performing system diagnostic tests and fault isolation.

5.1 Loop Tests (DIG, ANA, and REM)

The loop test buttons (DIG, ANA, and REM) and the LED indicators built into the Converter allow rapid

checking of the data terminals, the Converter, and the lines. Use the test procedures provided in this

chapter to verify normal system operation and to isolate faulty equipment in the event of failure.

Before testing the operation of the data-system equipment and their line circuits, make sure that all units

are turned on and are configured correctly.

5.2 Self-Test

To verify that the Converter is operating correctly, initiate the self-test by pressing the ANA button (see

Figure 5-1).

Press the ANA (Local Loopback) button. The TEST indicator lights. Both V.100 and G.703 SYNC LOSS

indicators should not light. If one of the SYNC LOSS indicators lights up or blinks, then the Converter is

faulty and should be replaced. If the test executes correctly, restore all the buttons and jumpers to the

required position.

Figure 5-1. Self-Test.

5.3 Local Test—Local Loopback

This test is activated by pressing the ANA button. This test checks the performance of the local Interface

Converter, the local data terminal, and the connections between them. It is performed separately at the

local and the remote sites (refer to Figure 5-2).

TRANSMITTER

RECEIVER

V.11 0

SYNC LOSS

G.703

ANA

DEPRESSED

XMTR

RCVR

G.703 Rate and Interface Converter

G.703 RATE AND INTERFACE CONVERTERS

18

Figure 5-2. Local Interface Converter in Local Loopback.

a) Press the ANA (Local Loopback) button. The TEST indicator should light. The Converter’s

transmit output is not connected to its own receiver. (This test can also be activated via the

appropriate pin on the DTE interface.) The Interface Converter continues to send data to

the line side. The V.110 and G.703 SYNC LOSS indicators should not light.

b) Verify that the data terminal equipment is operating properly and can be used for a test.

If a fault is indicated, call a technician or replace the unit.

c) Execute the test using one of these methods: Use the DTE and check the echoed data stream,

or use an “external” Bit Error Rate Tester (BERT).

d) Perform Step (c) at both ends. If the BERT test indicates correct operation, but the data terminal

indicates a fault, follow the manufacturer’s test procedures for the data terminal and verify the

cable connecting the terminal and the Converter. After completing the test (or when the fault

has been corrected), restore the ANA button to the OFF position. Proceed to the Communication

Link Test (see the next section).

5.4 Communication Link Tests

5.4.1 REMOTE DIGITAL LOOPBACK

Activate this test by pressing the REM button. The test determines the performance of both the local

and the remote Converters, as well as their interconnecting lines. The Remote Digital Loopback test

consists of providing a loopback at the remote unit, as shown in Figure 5-3.

a) Press the REM (Remote Loopback) button to provide a loopback at the remote Converter. The

TEST indicator should light at both the local and remote units. (This test can also be activated

via the appropriate pin on the DTE interface.) The SYNC LOSS indicators on both units should

not light.

b) Perform the BERT test as explained in Section 5.3, Step (c).

c) If Step (b) indicates a fault, and if the self-test described in Section 5.2 was successful

for both the local and remote units, then the line circuits are not operating properly.

ANA

DEPRESSED

DATA

TERMINAL

XMTR

RCVR

LINE

DATA

CLK

CLK

DATA

G.703 Rate and Interface Converter

CHAPTER 5: Tests and Diagnostics

19

Figure 5-3. Remote Interface Converter in Digital Loopback.

5.4.2 LOCAL DIGITAL LOOPBACK

This test is activated by pressing the DIG button. The test consists of looping the received data back to

the remote Interface Converter, as shown in Figure 5-4. Using this test, the operator at the remote end

can determine the performance of the local and remote Converters, and of the lines interconnecting

them. (The Local Digital Loopback test is equivalent to activating the remote loopback from the remote

Converter.)

Figure 5-4. Local Interface Converter in Digital Loopback.

DIG

DEPRESSED

DATA

CLK

RCVR

DATA

CLK

XMTR

XMTR

RCVR

REMOTE

DATA

TERMINAL

LOCAL

DATA

TERMINAL

Local Converter Remote Converter

REM

DEPRESSED

DATA

CLK

RCVR

CLK

DATA

XMTR

XMTR

RCVR

REMOTE

DATA

TERMINAL

LOCAL

DATA

TERMINAL

Local Converter Remote Converter

G.703 RATE AND INTERFACE CONVERTERS

20

Appendix A. The RM110A Rack and the

G.703 Rate & Interface Converter Card

A.1 Rack Description

The RM110A rack consists of a power supply and up to fourteen plug-in G.703 Rate and Interface

Converter Cards. The rear panel consists of fourteen terminal blocks and fourteen connectors. Each

terminal block provides five screw connections for connecting the transmit and receive lines. The

transmit pair connects to the terminals marked XMT; the receive pair connects to the terminals marked

RCV. A nut for optional ground connection is supplied at the left side of the rear panel. The interface

connector is a DB25 female connector, which provides all digital interface signals.

Figure A-1. RM110A Rack.

Control/Indicator/Connector Location Function

Card Slots 1 through 14 Front panel Card slots. Slot 1 is on the left-hand side. Unused

slots are closed with blank panels.

Power-Supply Module Front panel, right side Provides power to enclosure models.

POWER Indicator On the power-supply module Indicates when power is ON.

Power Connector Rear panel, left side Line power connector (3-prong) with integral fuse.

Main Channel Connectors Rear panel, bottom row DB25 female connectors for V.24 connection.

4-wire Terminal Blocks Rear panel, top row For connection of G.703 (balanced) 4-wire lines.

Each card has a separate terminal-block connector.

APPENDIX A: The RM110A Rack and the G.703 Rate and Interface Converter Card

21

A.2 Power Supply

The power supply can accept either 115 or 230 VAC, depending upon the rated voltage of the unit.

Essentially, it consists of a power-line transformer, a fuse, and an operating switch. All power-regulating

circuitry is located on the Converter cards themselves. Each Converter card has 5- and 12-VDC fuses

which protect the system and power supply against a short circuit in the card. Primary power needed

is 115/230 VAC±10%, 47 to 63 Hz, at 24 VA maximum.

AC power should be supplied through a 5-foot (1.5-m) standard power cord between the AC mains

socket at the rear of the power-supply module and a standard, grounded, easily accessible AC outlet.

An integral fuse is located in the AC mains socket of the power supply.

CAUTION!

This unit should always be grounded through the protective earth lead of the power

cable.

When connecting AC power to this unit, the mains plug should only be inserted in an

outlet provided with a protective earth contact. The protective action must not be

negated by use of an extension cord (power cable) without a protective conductor

(grounding). Interrupting the protective (grounding) conductor (inside or outside the

unit) or disconnecting the protective earth terminal can make this unit dangerous.

The line fuse is located in an integral fuse holder on the rear panel. Make sure that only

fuses of the required rating, as marked on the RM110A rear panel, are used for

replacement. Do not use repaired fuses or short-circuit the fuse holder. Always

disconnect the mains cable before removing or replacing the fuse.

Whenever it is likely that the fuse protection has been damaged, make the unit

inoperative and secure it against unintended operation.

A.3 Installation

After installing the RM110A in the 19-inch rack:

a) Insert the G.703 Rate and Interface Converter cards. Do not use excessive force. If the card

does not go in easily, remove the card, realign it with the enclosure guides, and reinsert it.

b) Push the bottom of the cards further into the rack to ensure they are fully inserted into

the edge connectors.

c) Tighten the screw on the top of each card.

A.4 Operation

The supply of power to all cards is provided by the power module on the right hand side of

the RM110A rack. There is no ON/OFF switch. Once you plug the rack in, the power is ON

(as noted by the lit POWER LED).

When the power supply is ON, exposure is limited to 30V on any card or accessible area of the rack.

G.703 RATE AND INTERFACE CONVERTERS

22

Appendix B. V.24/RS-232

Interconnection

Table B-1. DTE Interface Signal Assignments

V.24 RS-232C DTE Pin Signal Name Description

101 AA 1 Protective Ground Chassis ground. May be isolated from Signal Ground (refer

to GND Strap in Table 3-1).

102 AB 7 Signal Ground Common signal and DC power supply ground.

N/A N/A 9 +5 volts Output +5VDC.

10 — —

103 BA 2 Transmitted Data Serial digital data from a terminal or other source. If

accompanied by an external data-rate clock, data transitions

must occur on positive-going transitions of the external

transmit output clock.

104 BB 3 Received Data Serial Digital data at the output of the unit receiver. The data

transitions occur on the rising edge of the clock.

105 CA 4 Request to Send A positive level to the Converter when data transmission is

desired.

106 CB 5 Clear to Send A positive level from the Converter, after receipt of Request

to Send and when the Converter is ready to transmit.

107 CC 6 Data Set Ready A positive level from the Converter when the power is on

and the Converter is not in the DIGITAL LOOP mode or has

not received a REMOTE LOOPBACK signal from the

remote unit; otherwise, Data Set Ready follows the remote

DTR.

109 CF 8 Receive Line A positive level from the Converter, except when a loss of

Signal Detector the received input signal is detected or when remote RTS is

(Carrier Detect) negative.

113 DA 24 External Trans. A serial data-rate clock input from the data source. Positive

Serial Clock clock transitions correspond to data transitions.

114 DB 15 Transmitter Signal A transmit data-rate clock for use by external data source.

Element Timing Positive clock transitions correspond to data transitions.

APPENDIX B: V.24/RS-232 Interconnection

23

Table B-1 (continued). DTE Interface Signal Assignments

V.24 RS-232C DTE Pin Signal Name Description

115 DD 17 Receiver Signal A receive data-rate clock output for use by external data

sink. Positive clock transitions correspond to data

transitions.

142 — 25 Test Indicator A control-signal output from the Converter. Positive during

any test mode.

141 — 18 Loop 3 A control-signal input; when on, commands the Converter

Test Command into Local Analog Loopback (V.54 Loop 3).

140 — 21 Loop 2 A control-signal input; when on, commands the Converter to

Test Command send a remote Loopback Command (V.54 Loop 2) to the

remote Converter.

108 — 20 Data Terminal This input signal is passed through to the remote Converter

Ready as DSR.

G.703 RATE AND INTERFACE CONVERTERS

24

Appendix C. Rack Adapter

Installation Kits

The G.703 Rate and Interface Converter’s exterior casing was designed to simplify access to the interior

strap settings and to simplify installation in 19-inch racks.

You can access the Converter’s interior by releasing two rear-panel screws and then using them as levers

to pull out the interior like a drawer.

Unit height for installation in 19-inch racks corresponds to 1U (1.75"), with the width slightly less than

half the available mounting width. A rack adapter kit (part number RM523) is available for installation

of either a single unit or two units side by side.

IMPORTANT!

Before you open the Converter, disconnect the unit from AC power.

C.1 Rack Adapter Kit—Single-Unit Installation

The rack adapter components for single-unit installation include one short bracket and one long

bracket. The brackets are fastened by means of screws to the side walls of the case, as shown in the

illustration below. The short bracket attaches to the left side of the unit, and the long bracket to the

right side of the unit.

To prepare the unit for rack installation, attach the two brackets to the side walls of the unit. Each

bracket is fastened by means of two screws (with flatwashers), which are inserted into the two front holes

on the side wall (nuts are already in place, on the inner side of the wall.

APPENDIX C: Rack Adapter Installation Kits

25

After attaching the brackets, the unit is ready for installation in the 19-inch rack. Fasten the brackets to

the side rails of the 19-inch rack by means of four screws (not included in the kit).

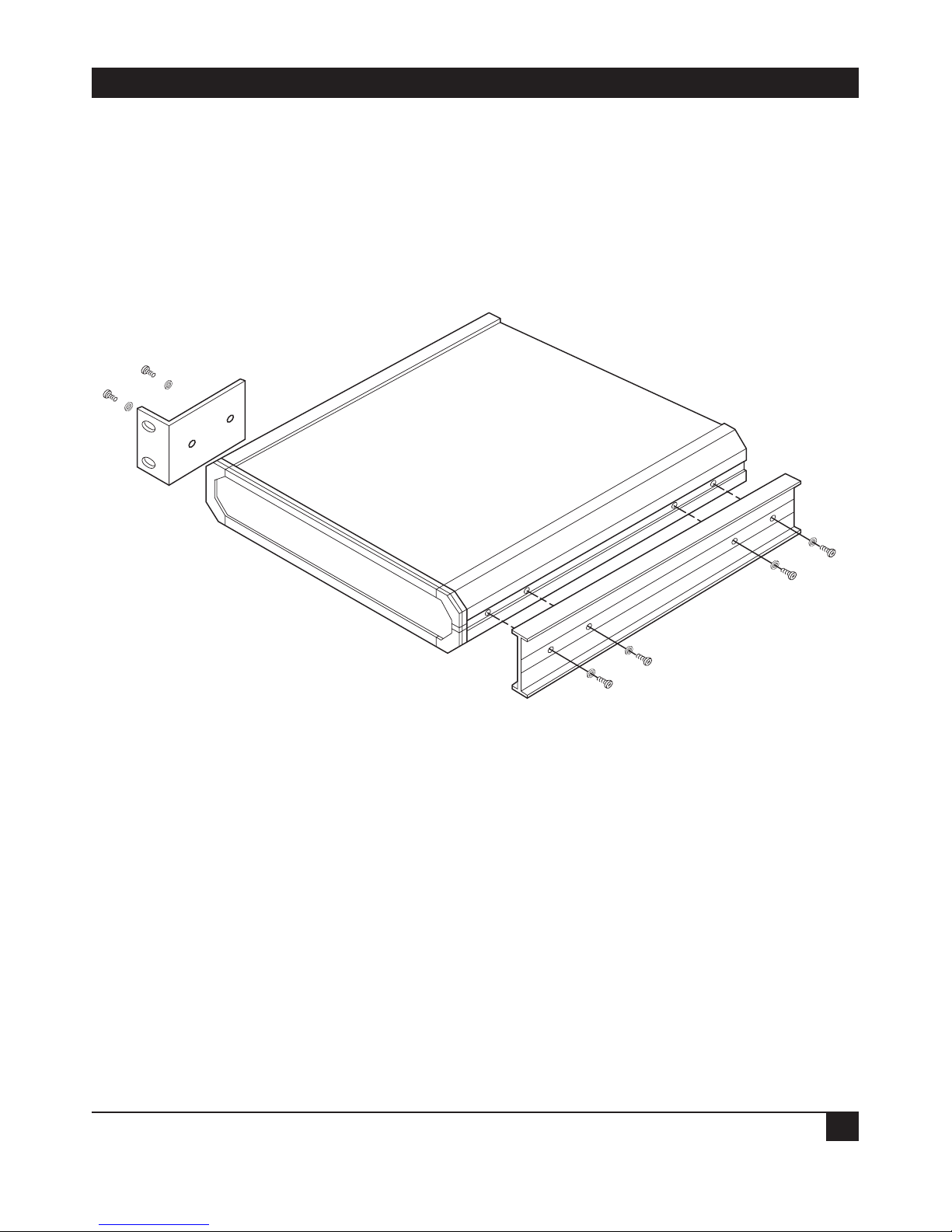

C.2 Rack Adapter Kit—Dual-Unit Installation

The rack adapter components for two units include two long side rails (one for each unit) which slide

one within the other to fasten the two units together, and two short side brackets which fasten the two

units to the 19-inch rack. (See the illustration below.)

To install two units:

1) Attach a long side rail to each unit (right side for one unit, left side for the other unit) using the

four screws and flat washers supplied. The long side rails must be attached in opposing fashion,

the narrow flange of the first rail opposite the wide flange of the second rail.

2) Attach a short bracket to the other side of each unit using the four screws and flat washers

supplied.

3) Slide one unit side rail within the other, so as to fasten the two units together (see the illustration

on the next page).

4) Secure the plastic caps supplied to the ends of the joined rails, to prevent sliding of the units and

to protect the rail ends.

The assembled units can now be fastened to the side rails of the 19-inch rack, by means of four screws

(not included in the kit), to each side.

G.703 RATE AND INTERFACE CONVERTERS

26

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 1997. Black Box Corporation. All rights reserved.

Loading...

Loading...