Page 1

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 2007. Black Box Corporation. All rights reserved.

Page 2

Order toll-free in the U.S.: Call 877-877-BBOX (outside U.S. call 724-746-5500)

FREE technical support 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mailing address: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

CUSTOMER

SUPPORT

INFORMATION

FEBRUARY 2007

IC027A-R3

488 Controller

Page 3

FCC/IC RFI STATEMENTS

1

FEDERAL COMMUNICATIONS COMMISSION

AND

INDUSTRY CANADA

RADIO FREQUENCY INTERFERENCE STATEMENTS

This equipment generates, uses, and can radiate radio-frequency energy, and if not installed and used

properly, that is, in strict accordance with the manufacturer’s instructions, may cause interference to radio

communication. It has been tested and found to comply with the limits for a Class A computing device in

accordance with the specifications in Subpart B of Part 15 of FCC rules, which are designed to provide reasonable

protection against such interference when the equipment is operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference, in which

case the user at his own expense will be required to take whatever measures may be necessary to correct

the interference.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emission from digital apparatus set out in the Radio

Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la classe A prescrites dans le Règlement sur le brouillage radioélectrique publié par Industrie Canada.

Page 4

488 CONTROLLER

2

INSTRUCCIONES DE SEGURIDAD (Normas Oficiales Mexicanas Electrical Safety Statement)

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca de la tina de baño, lavabo, sótano mojado o

cerca de una alberca, etc..

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá a lo descrito en las instrucciones de

operación. Todo otro servicio deberá ser referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no interfiera su uso. La colocación del aparato

eléctrico sobre una cama, sofá, alfombra o superficie similar puede bloquea la ventilación, no se debe colocar en libreros

o gabinetes que impidan el flujo de aire por los orificios de ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor como radiadores, registros de calor, estufas u

otros aparatos (incluyendo amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del tipo descrito en el instructivo de operación, o

como se indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no sean pisados ni pellizcados por objetos

colocados sobre o contra ellos, poniendo particular atención a los contactos y receptáculos donde salen del aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean derramados sobre la cubierta u orificios de

ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 5

3

EUROPEAN UNION DECLARATION OF CONFORMITY

EUROPEAN UNION DECLARATION OF CONFORMITY

To maintain safety, emission, and immunity standards of this declaration, the following conditions must

be met.

• Serial and IEEE cables must have a braided shield connected circumferentially to their connectors’

metal shells.

• All cable screw locks must be tightened at both ends of the cable.

• The host computer must be properly grounded.

• Some inaccuracy is to be expected when I/O leads are exposed to RF fields or transients.

• The operator must observe all safety cautions and operating conditions specified in the documentation

for all hardware used.

• The host computer, peripheral equipment, power sources, and expansion hardware must be CE

compliant.

• All power must be off to the device and externally connected equipment before internal access to the

device is permitted.

• An external power supply is provided with this product. Its input is 100–240 VAC, 50–60 Hz, 0.5 A

maximum power draw. Its 9-VDC, 15 W maximum, 1.7 A output connects to the power input of the unit.

• The RS-232/422 terminal is meant to be connected only to devices with serial-communications-level

signals. The IEEE 488 terminal is meant to be used only with non-isolated IEEE 488 systems. The

common mode voltage (cable shell to earth) must be zero.

• Terminal Installation Category for CE Compliance is Category 1.

• Operating environment for CE compliance is: Indoor use at altitudes below 2000 m, 0 to 40°C, 80%

maximum RH up to 31°C decreasing linearly 4%RH/°C to 40°C.

WARNING!

Noted conditions pertain to potential safety hazards. When you see the WARNING!,

IMPORTANT!, or CAUTION! notes, carefully read the information and be alert to the

possibility of personal injury.

Failure to follow these directives voids emissions and immunity compliance.

Page 6

488 CONTROLLER

4

TRADEMARKS USED IN THIS MANUAL

Macintosh is a registered trademark of Apple Computer, Inc.

BLACK BOX and the Double Diamond logo are registered trademarks of BB Technologies, Inc.

Hewlett-Packard and HP are registered trademarks of Hewlett-Packard.

AT and IBM are registered trademarks of IBM Corporation.

Any other trademarks mentioned in this manual are acknowledged to be the property of the trademark owners.

Page 7

CONTENTS

5

Chapter Page

1. Specifications....................................................................................................................................................8

2. Introduction ...................................................................................................................................................10

2.1 Description............................................................................................................................................10

2.2 What’s Included....................................................................................................................................10

2.3 Abbreviations ........................................................................................................................................11

3. Getting Started ...............................................................................................................................................12

3.1 Configuration .......................................................................................................................................12

3.2 Serial-Port Settings................................................................................................................................14

3.2.1 Serial Baud Rate .......................................................................................................................14

3.2.2 Serial Word Length (Data Bits)...............................................................................................15

3.2.3 Serial Stop Bits .........................................................................................................................16

3.2.4 Serial Parity...............................................................................................................................16

3.2.5 Serial Echo................................................................................................................................17

3.2.6 Serial Handshake .....................................................................................................................17

3.3 Selecting Terminator Substitution.......................................................................................................18

3.3.1 Serial Terminator .....................................................................................................................18

3.3.2 IEEE Bus Terminator...............................................................................................................19

3.4 Selecting the Mode...............................................................................................................................19

3.5 Selecting the IEEE Address..................................................................................................................20

3.6 Feature Selections.................................................................................................................................21

3.6.1 Controller Pass-Thru Features ................................................................................................21

3.6.2 Peripheral Pass-Thru Features ................................................................................................22

3.7 Serial Interface .....................................................................................................................................22

3.7.1 RS-232/RS-422 Signal Level Selection....................................................................................22

3.7.2 Serial Signal Descriptions ........................................................................................................23

3.7.3 Serial-Cable Wiring Diagrams .................................................................................................24

3.8 General Operation ...............................................................................................................................26

3.9 Is Anyone Out There? ..........................................................................................................................27

4. IEEE Operating Modes..................................................................................................................................28

4.1 Introduction..........................................................................................................................................28

4.2 Operating Mode Transitions................................................................................................................28

4.3 System Controller Mode ......................................................................................................................30

4.4 System Controller, Not Active Controller Mode.................................................................................31

4.5 Not System Controller Mode ...............................................................................................................33

4.6 Active Controller, Not System Controller Mode.................................................................................34

4.7 Controller Pass-Thru Mode..................................................................................................................34

4.8 Peripheral Pass-Thru Mode .................................................................................................................34

5. Command Descriptions .................................................................................................................................35

5.1 Introduction..........................................................................................................................................35

5.2 Command-Description Format............................................................................................................36

5.2.1 Syntax........................................................................................................................................36

5.2.2 Response...................................................................................................................................38

5.2.3 Mode .........................................................................................................................................38

5.2.4 Bus States ..................................................................................................................................39

5.3 Memory Use ..........................................................................................................................................40

5.4 The Commands ....................................................................................................................................40

Contents

Page 8

488 CONTROLLER

6

Contents (continued)

Chapter Page

6. Controller Pass-Thru Operation ...................................................................................................................74

6.1 Introduction..........................................................................................................................................74

6.2 Serial and IEEE Terminator Substitution ...........................................................................................74

6.3 IEEE Address Selection ........................................................................................................................75

6.4 Talk Back On Terminator.....................................................................................................................75

6.5 Plotter Applications..............................................................................................................................76

6.6 Printer Applications .............................................................................................................................78

7. Peripheral Pass-Thru Operation ...................................................................................................................79

7.1 Introduction..........................................................................................................................................79

7.2 Serial and IEEE Input Buffers .............................................................................................................79

7.3 IEEE Data Transfers..............................................................................................................................80

7.3.1 Blind Bus Data Transfers .........................................................................................................80

7.3.2 Controlled Bus Data Transfers................................................................................................81

7.4 Serial Poll Status Byte Register ............................................................................................................82

7.5 Use of Serial and Bus Terminators ......................................................................................................83

7.6 IEEE 488 Bus Implementation ............................................................................................................83

7.6.1 My Talk Address (MTA)...........................................................................................................83

7.6.2 My Listen Address (MLA) .......................................................................................................83

7.6.3 Device Clear (DCL and SDC) .................................................................................................84

7.6.4 Interface Clear (IFC)...............................................................................................................84

7.6.5 Serial Poll Enable (SPE) ..........................................................................................................84

7.6.6 Serial Poll Disable (SPD) .........................................................................................................84

7.6.7 Unlisten (UNL)........................................................................................................................84

7.6.8 Untalk (UNT) ..........................................................................................................................84

7.7 IEEE Address Selection ........................................................................................................................84

8. IEEE 488 Primer.............................................................................................................................................85

8.1 History ...................................................................................................................................................85

8.2 General Structure .................................................................................................................................85

8.3 Send It To My Address..........................................................................................................................87

8.4 Bus Management Lines ........................................................................................................................87

8.4.1 Attention (ATN) ......................................................................................................................87

8.4.2 Interface Clear (IFC)...............................................................................................................87

8.4.3 Remote Enable (REN).............................................................................................................87

8.4.4 End or Identify (EOI)..............................................................................................................87

8.4.5 Service Request (SRQ) ............................................................................................................87

8.5 Handshake Lines ..................................................................................................................................88

8.5.1 Data Valid (DAV) .....................................................................................................................88

8.5.2 Not Ready For Data (NRFD) ...................................................................................................88

8.5.3 Not Data Accepted (NDAC)....................................................................................................88

8.6 Data Lines .............................................................................................................................................89

8.7 Multiline Commands............................................................................................................................89

8.7.1 Go To Local (GTL)..................................................................................................................89

8.7.2 Listen Address Group (LAG) ..................................................................................................89

8.7.3 Unlisten (UNL)........................................................................................................................89

8.7.4 Talk Address Group (TAG) .....................................................................................................89

8.7.5 Untalk (UNT) ..........................................................................................................................89

8.7.6 Local Lockout (LLO) ..............................................................................................................89

8.7.7 Device Clear (DCL) .................................................................................................................89

Page 9

CONTENTS

7

Chapter Page

8.7.8 Selected Device Clear (SDC)...................................................................................................89

8.7.9 Serial Poll Disable (SPD) .........................................................................................................89

8.7.10 Serial Poll Enable (SPE) ..........................................................................................................89

8.7.11 Group Execute Trigger (GET)................................................................................................89

8.7.12 Take Control (TCT).................................................................................................................89

8.7.13 Secondary Command Group (SCG).......................................................................................90

8.7.14 Parallel Poll Configure (PPC) .................................................................................................90

8.7.15 Parallel Poll Unconfigure (PPU) ............................................................................................90

8.8 More On Service Requests ...................................................................................................................90

8.8.1 Serial Poll..................................................................................................................................90

8.8.2 Parallel Poll...............................................................................................................................90

9. Theory of Operation & Board Layout ..........................................................................................................91

9.1 Theory of Operation ............................................................................................................................91

9.2 Board Layout.........................................................................................................................................92

Appendix A: 488 Controller Command Summary.............................................................................................94

Appendix B: 488 Controller Error Messages......................................................................................................97

Appendix C: Character Codes and IEEE Multiline Messages ...........................................................................99

Appendix D: Sample Programs .........................................................................................................................101

Page 10

488 CONTROLLER

8

488 Controller

IEEE 488-1978 Implementation: C1, C2, C3, C4, and C28 controller subsets; SH1, AH1, T6,

TE0, L4, LE0, SR1, RL0, PP0, DC1, DT1, E1

Terminators: Selectable CR, LF, LF-CR, and CR-LF with EOI

Connector: Standard IEEE 488 connector with metric studs

Serial Interface

EIA RS-232C: AB, BA, BB, CA, CB

EIA RS-422A: Balanced voltage on TxD and RxD

Character Set: Asynchronous bit serial

Output Voltage: ±5 volts minimum (RS-232C); 3.5 volts typical (RS-422A)

Input Voltage: ±3 volts minimum; ±15 volts maximum

Baud Rate: Selectable 110, 300, 600, 1200, 1800, 2400, 3600, 4800, 7200,

9600, 19,200, and 57,600

Data Format: Selectable 7 or 8 data bits; 1 or 2 stop bits; odd, even, mark,

space and no parity on transmit

Duplex: Full with Echo/No Echo

Serial Control: Selectable CTS/RTS or X-ON/X-OFF

Terminators: Selectable CR, LF, LF-CR, and CR-LF

Connector: DB25; RS-232C DCE configured

1. Specifications

Page 11

9

CHAPTER 1: Specifications

General

Data Buffer: 32,000 characters total, dynamically allocated

Environment: 0 to 50°C; 0 to 70% R.H. to 35°C; Linearly derate

3% R.H./°C from 35 to 50°C

Controls: Power switch (external), IEEE and serial parameter switches

(internal); jumper selection of RS-232 or RS-422 operation

(internal)

Certification: FCC, CE

Indicators: (4) LEDs: Talk, Listen, SRQ, Error, and Power

Power: Input: 100–240 VAC, autosensing, 50–60 Hz,

0.5 A maximum;

Output: 9 V, 15 W maximum, 1.7 A

Size: 2.7"H x 5.5"W x 7.4"D (6.9 x 14 x 18.8 cm)

Weight: 3.6 lb. (1.6 kg)

WARNING!

Do not use this interface outdoors. The interface is intended for indoor use only. Using this

equipment outdoors could result in equipment failure, bodily injury, or death.

CAUTION

Do not connect AC line power directly to the 488 Controller. Direct AC connection will

damage equipment.

Page 12

488 CONTROLLER

10

2.1 Description

The 488 Controller converts a host RS-232 or RS-422 computer into an IEEE 488 bus talker, listener, and

controller. The 488 Controller provides full IEEE 488-1978 bus implementation including advance

capabilities such as PASS CONTROL, RECEIVE CONTROL, PARALLEL POLL, SERIAL POLL, and

SECONDARY ADDRESSING. The device may be located several hundred feet from the host and may

control as many as fourteen 488 bus instruments. In the noncontroller mode the 488 Controller converts

the host into a bus peripheral for data processing and mass storage.

The 488 Controller interprets simple high-level commands sent from the computer’s serial port and

performs the necessary, and usually complex, bus control and handshaking. The commands and protocol

are similar to those used by the Hewlett-Packard

®

HP-85 computer.

Additional features provide a transparent IEEE to serial converter and a serial to IEEE pass-thru controller.

As a serial-to-IEEE-488 converter, the 488 Controller receives data from a serial host, then automatically

performs the bus sequences necessary to send this data to the IEEE 488 device. If desired, data can be

requested from the IEEE 488 device and returned to the host.

As an IEEE-488-to-serial converter, the 488 Controller is a peripheral to an IEEE 488 controller. Data

received from the controller is sent to the serial device and data received from the serial device is buffered

for transmission to the IEEE 488 controller. The 488 Controller can inform the host, by the serial poll-status

byte, that it has received data from the serial device.

2.2 What’s Included

Your package should include the IEEE 488 controller, an AC power cable, and this user’s manual.

2. Introduction

Page 13

11

CHAPTER 2: Introduction

2.3 Abbreviations

The following IEEE 488 abbreviations are used throughout this manual.

addr n IEEE bus address “n”

ATN Attention line

CA Controller Active

CO Controller

CR Carriage Return

data Data String

DCL Device Clear

GET Group Execute Trigger

GTL Go To Local

LA Listener Active

LAG Listen Address Group

LF Line Feed

LLO Local Lock Out

MLA My Listen Address

MTA My Talk Address

PE Peripheral

PPC Parallel Poll Configure

PPU Parallel Poll Unconfigure

REN Remote Enable

SC System Controller

SDC Selected Device Clear

SPD Serial Poll Disable

SPE Serial Poll Enable

SRQ Service Request

TA Talker Active

TAD Talker Address

TCT Take Control

term Terminator

UNL Unlisten

UNT Untalk

* Unasserted

Page 14

488 CONTROLLER

12

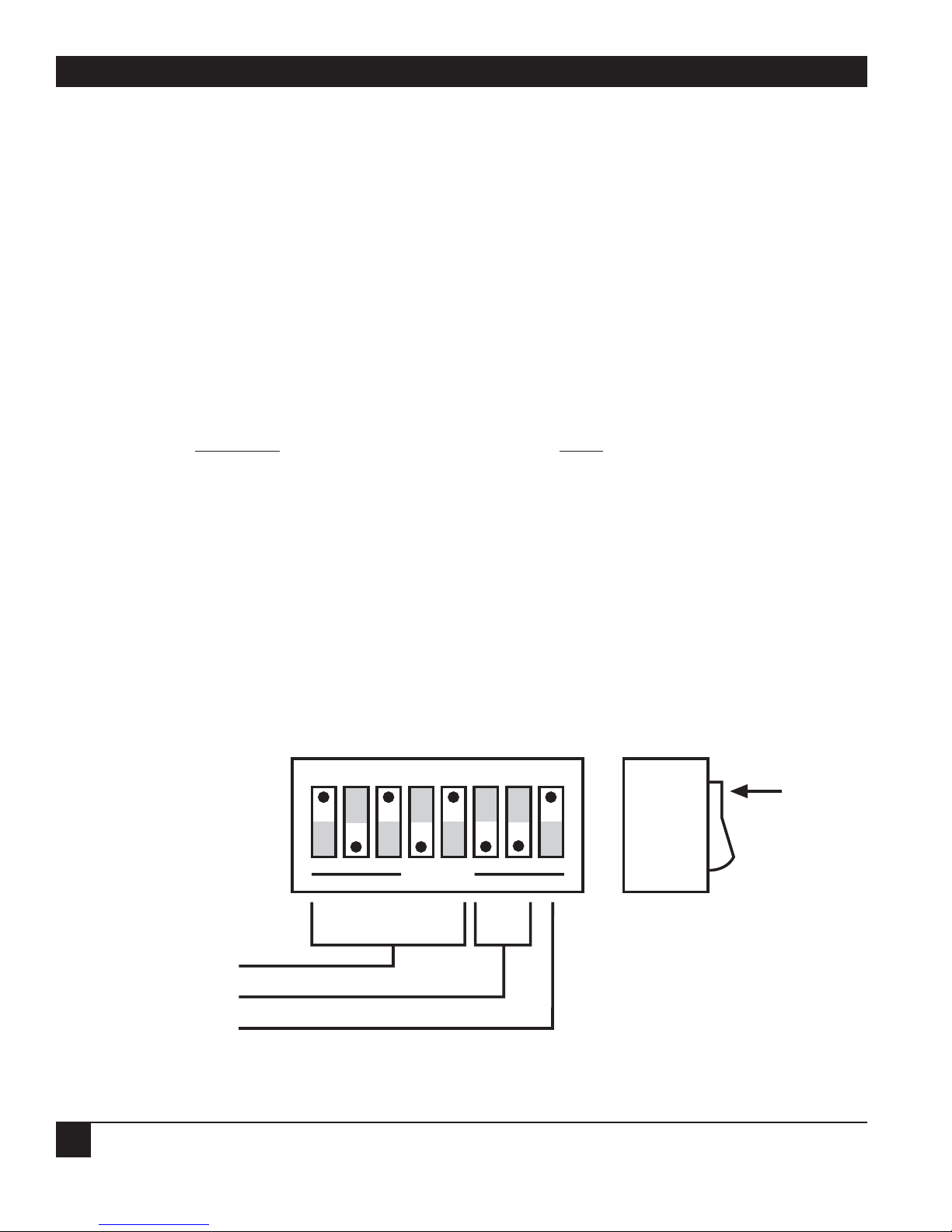

3.1 Configuration

Three internal DIP switches set the interface’s configuration.

NOTE

Selectable functions are read only at power-on and should only be set prior to applying

power to the interface.

The figures below and on the next page illustrate the factory-default conditions, which are:

Serial Por

t: IEEE:

9600 Baud Mode = System Controller

8 Data Bits Address = 10

2 Stop Bits Bus Terminator = CR-LF; EOI Disabled

No Parity Talk-Back Enabled

Serial Terminator = CR-LF

Echo Disabled

RTS/CTS Handshake

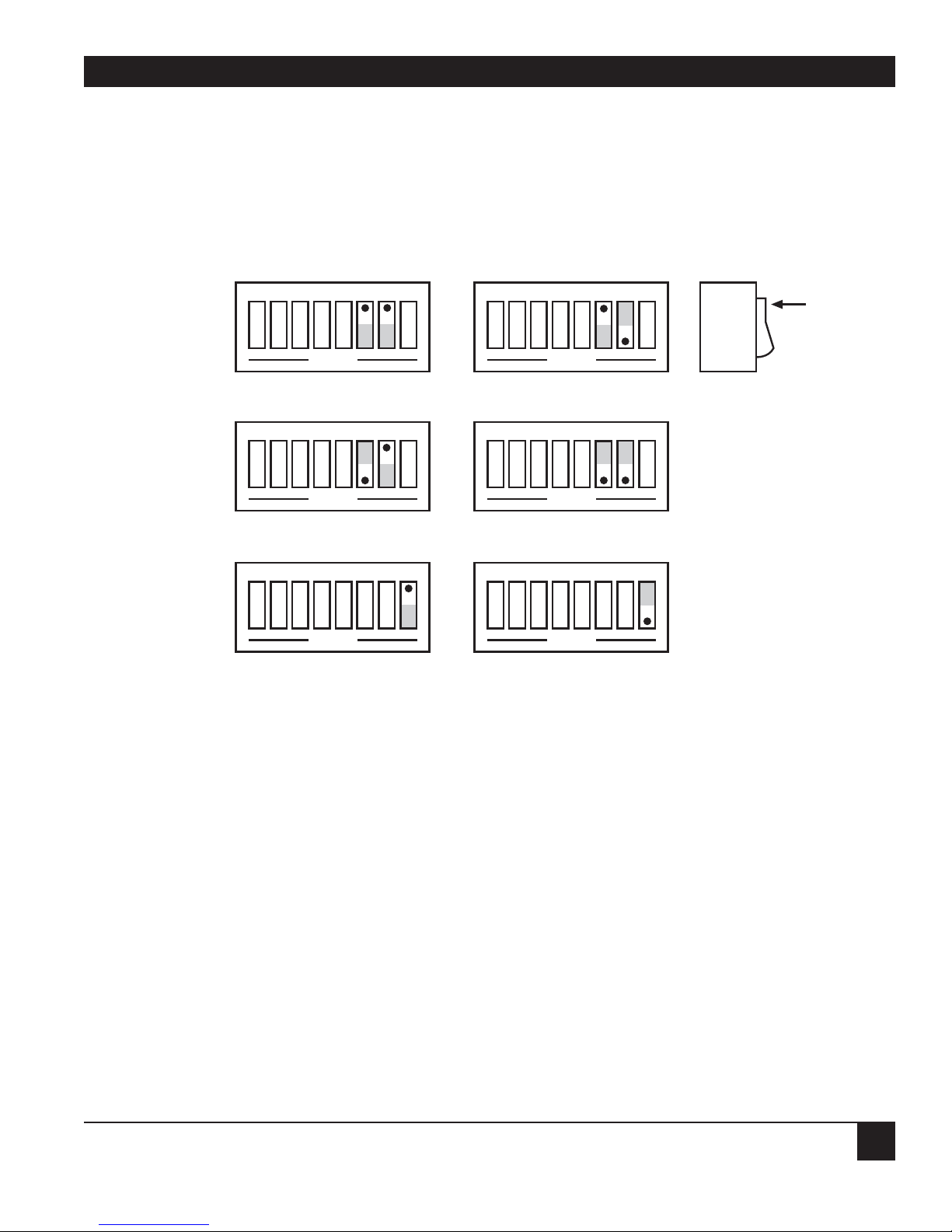

Figure 3-1. SW3 factory-default settings.

1 2 3 4 5

6

7 8

OPEN

SW3

IEEE Addr

IEEE Term

EOI

10

CR-LF

Disabled

Switch

Side

View

DOT

3. Getting Started

Page 15

13

CHAPTER 3: Getting Started

Figure 3-2. SW2 factory-default settings.

Figure 3-3. SW1 factory-default settings.

1 2 3 4 5 6 7 8

OPEN

SW1

Baud Rate

Handshake

Word Length

9600

RTS/CTS

8 Data Bits

Switch

Side

View

DOT

Pass-Thru Feature

Enabled

Stop Bits

2 Stop Bits

1 2 3 4 5 6 7 8

OPEN

SW2

Mode

Serial Term

Echo

SC

CR-LF

Switch

Side

View

DOT

Parity

No Echo

No Parity

Page 16

488 CONTROLLER

14

The 488 Controller is configured as an IEEE controller. In this mode, the 488 Controller allows an RS-232

host computer to control up to 14 IEEE 488 devices. This mode of operation is described in detail, along

with its command descriptions, in Chapters 4 and 5. These sections also cover the Peripheral mode of

operation.

The 488 Controller can be configured to transparently communicate with a single IEEE peripheral, such

as a plotter. This Controller Pass-Thru mode is described in detail in Chapter 6.

The 488 Controller may also be configured as a transparent IEEE Pass-Thru Peripheral. As a Pass-Thru

Peripheral, it allows an IEEE controller to communicate with an RS-232 device. The Peripheral Pass-Thru

operation mode is described in detail in Chapter 7.

To modify any of these defaults, follow this simple procedure:

1) Disconnect the power supply from the AC line and from the 488 Controller. Also disconnect any IEEE

or serial cables prior to disassembly.

WARNING

Never open the 488 Controller’s case while it is connected to the AC line. Failure to

observe this warning may result in equipment failure, personal injury, or death.

2) Place the 488 Controller upside down on a flat surface. Remove the four screws located near the rubber

feet.

3) Return the interface to the upright position and carefully remove the top cover.

4) Change whichever DIP-switch settings you need to change.

5) When you have made all of your changes, reverse this procedure to reassemble the 488 Controller.

3.2 Serial-Port Settings

The first parameters to configure are those that correspond to the RS-232 port. These include baud rate,

word length, number of stop bits, parity selection, and type of RS-232 handshake. Each of these is described

in Sections 3.2.1 through 3.2.6.

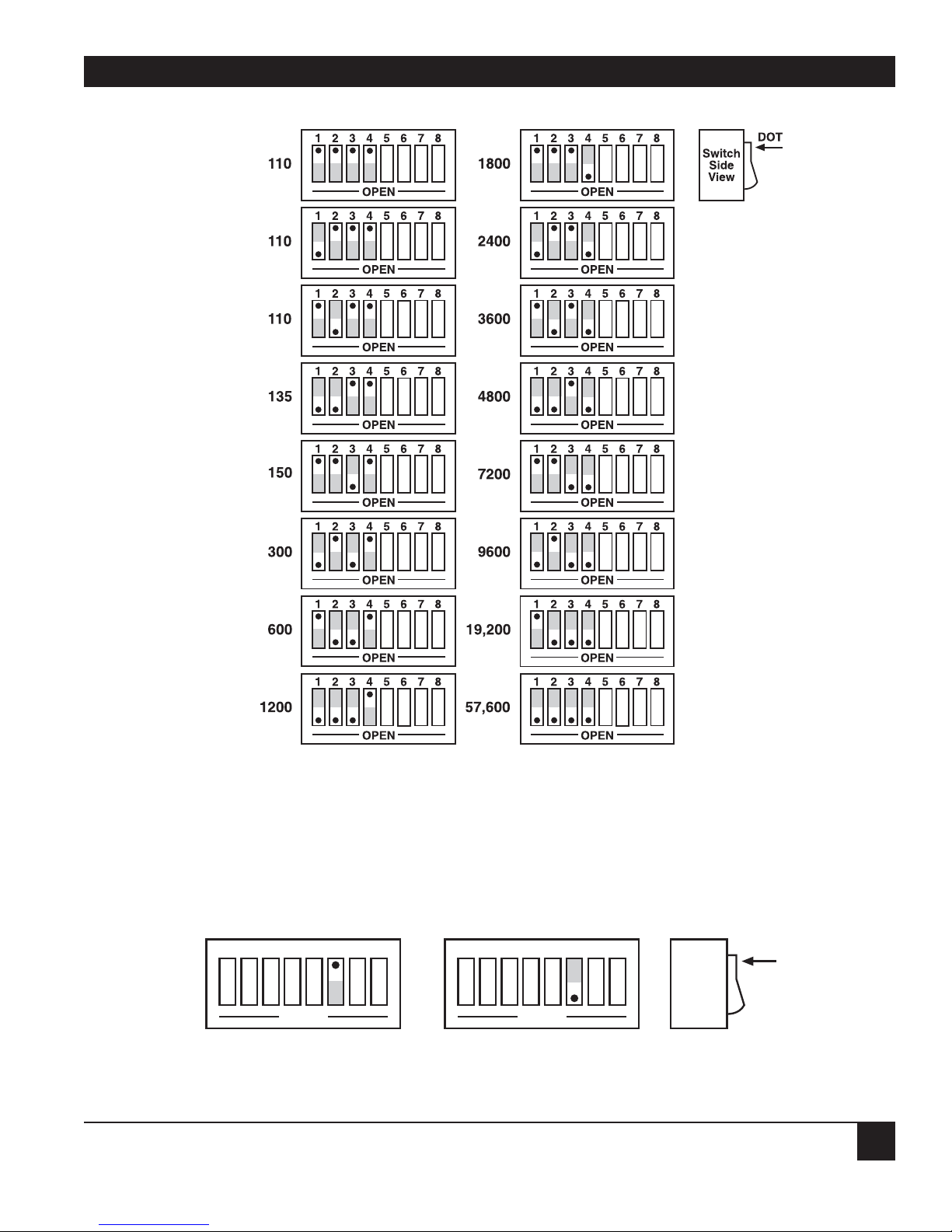

3.2.1 S

ERIAL

BAUD RATE

The “baud rate” is the number of serial bits per second transferred into and out of the serial interface.

SW1-1 through SW1-4 determine the serial baud rate. The factory-default baud rate is 9600 baud. Baud rates

may be selected from 110 to 57,600 baud. Refer to the following diagram for specific baud rates.

Page 17

15

CHAPTER 3: Getting Started

Figure 3-4. Switch SW1: Selecting the serial baud rate.

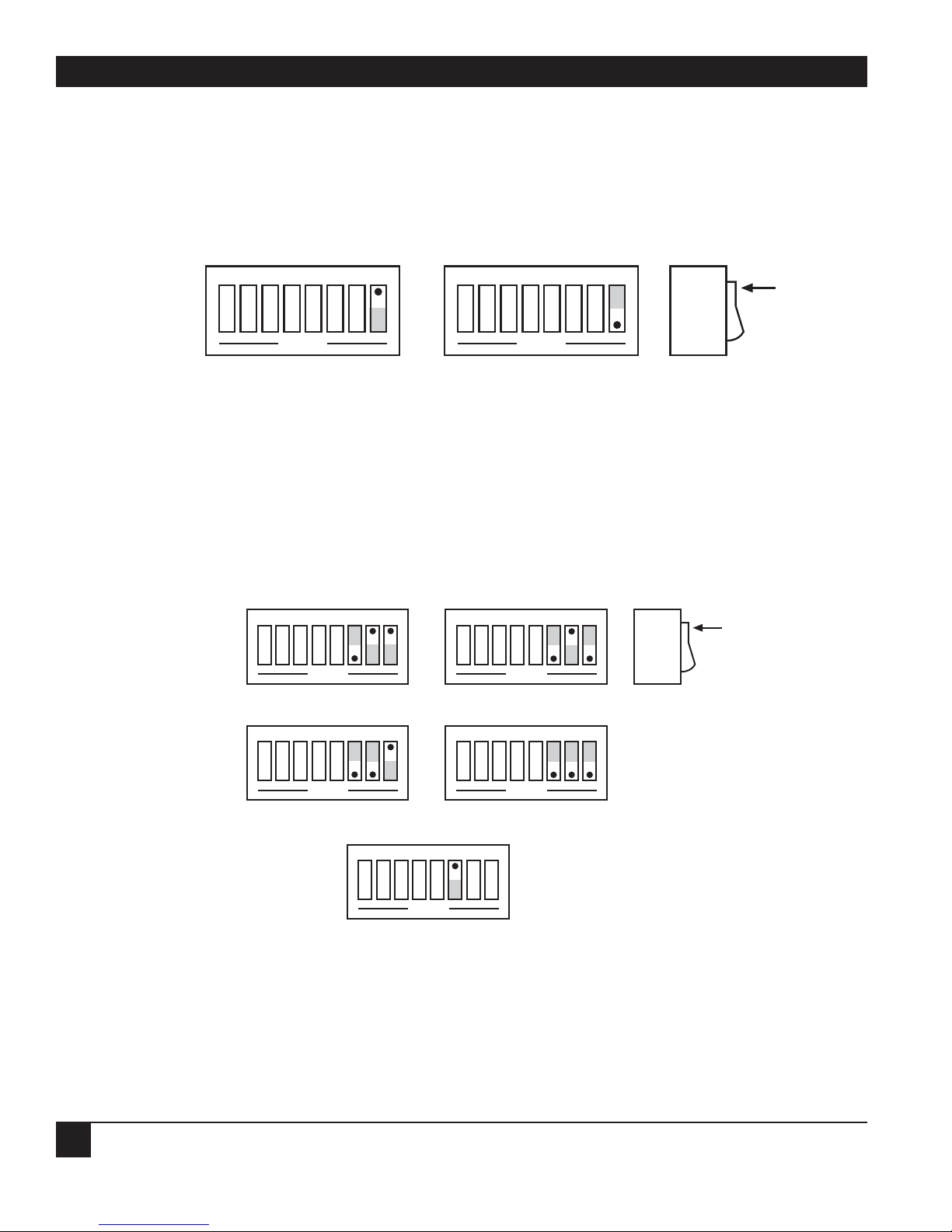

3.2.2 SERIAL WORD LENGTH (DATA BITS)

SW1-6 determines the number of data bits, often referred to as word length, for each serial character

transmitted or received. The factory default is 8 data bits.

Figure 3-5. Switch SW1: Selecting the serial word length (data bits).

1 2 3 4 5

6

7 8

OPEN

8 Data Bits

1 2 3 4 5

6

7 8

OPEN

7 Data Bits

Switch

Side

View

DOT

Page 18

488 CONTROLLER

16

3.2.3 SERIAL S

TOP BITS

Switch SW1-8 determines the number of stop bits contained in each serial character transmitted

and received. The factory default is 2 stop bits.

Figure 3-6. Switch SW1: Selecting the serial stop bits.

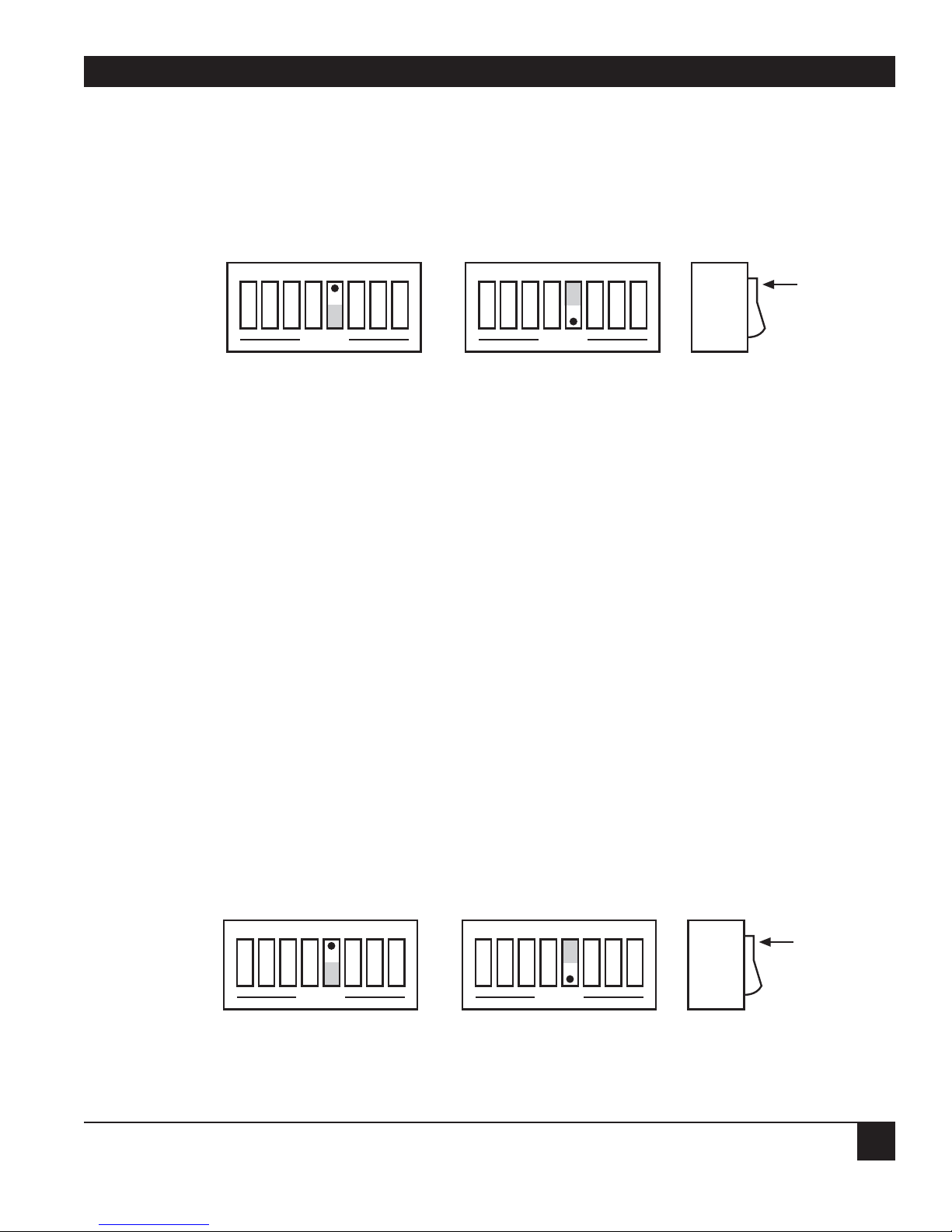

3.2.4 S

ERIAL P

ARITY

Serial parity is selected with S2-6 through S2-8. The 488 Controller generates the selected parity during serial

transmissions but it does not check parity on data that is received. The factory default is parity disabled.

Figure 3-7. Switch SW2: Selecting the serial parity.

Switch

Side

View

DOT

1 2 3 4 567 8

OPEN

Mark Parity

1 2 3 4 567 8

OPEN

Odd Parity

1 2 3 4 567 8

OPEN

Space Parity

1 2 3 4 567 8

OPEN

Even Parity

1 2 3 4 567 8

OPEN

Parity Disabled

Switch

Side

View

DOT

1 2 3 4 5

6

7 8

OPEN

2 Stop Bits

1 2 3 4 5

6

7 8

OPEN

1 Stop Bit

Page 19

17

CHAPTER 3: Getting Started

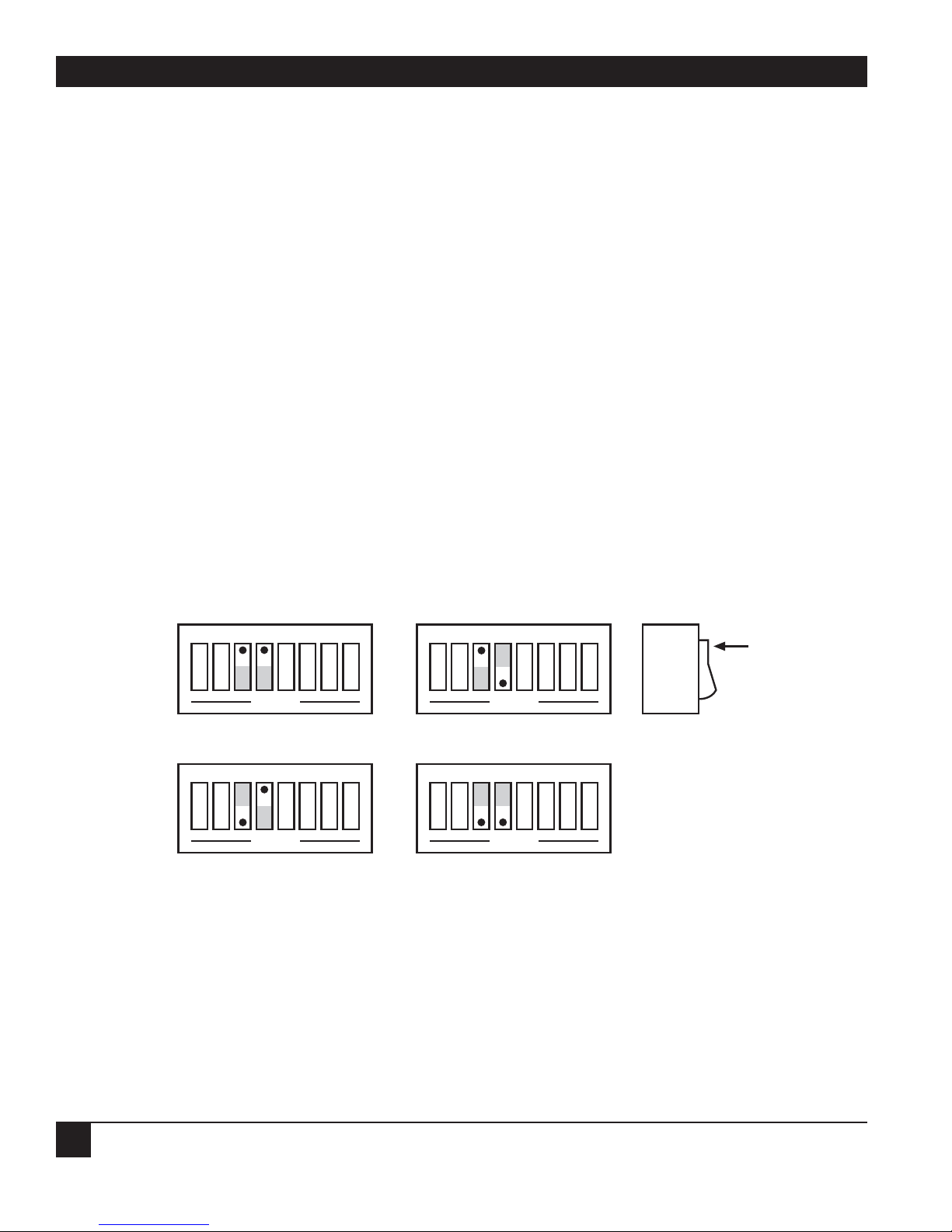

3.2.5 SERIAL E

CHO

Serial data sent to the 488 Controller will be echoed back to the serial host if SW2-5 is set to the open

position. The factory default is Echo Disabled.

Figure 3-8. Switch SW2: Enabling or disabling echo.

3.2.6 S

ERIAL HANDSHAKE

Switch SW1-5 is used to select hardware (RTS/CTS) or software (X-ON/X-OFF) serial handshake control.

With X-ON/X-OFF, the 488 Controller issues an X-OFF character (ASCII value of &H13) when its buffer

memory is near full. When the X-OFF character is sent, there are still more than 1000 character locations

remaining to protect against buffer overrun. When it is able to accept more information, the 488 Controller

issues an X-ON character (ASCII value of &H11). The 488 Controller also accepts X-ON/X-OFF on transmit

from the serial host it is communicating with. RTS/CTS serial control becomes inactive when X-ON/X-OFF

is enabled. The RTS output is, however, set to an active high state. The CTS input is not used for this

handshake and may be left floating (unconnected).

With RTS/CTS, the 488 Controller unasserts RTS (sets RTS low) when its buffer memory is near full. When

RTS is unasserted, there are still more than 1000 character locations remaining to protect against buffer

overrun. When it is able to accept more information, the 488 Controller asserts RTS (sets RTS high). The

488 Controller will not transmit data to the serial host if it detects the CTS input unasserted (low) when

configured for this hardware handshake.

The factory-default serial control is hardware, RTS/CTS.

Figure 3-9. Switch SW1: Selecting the serial handshake.

Switch

Side

View

DOT

1 2 3 4 5

6

7 8

OPEN

RTS/CTS

1 2 3 4 5

6

7 8

OPEN

X-ON/X-OFF

1 2 3 4 5

6

7 8

OPEN

Echo Disabled

1 2 3 4 5

6

7 8

OPEN

Echo Enabled

Switch

Side

View

DOT

Page 20

488 CONTROLLER

18

3.3 Selecting Terminator Substitution

In the Controller and Peripheral Modes, the 488 Controller is not sensitive as to whether CR or LF is used

as a serial input terminator to a command. In general, it requires only one of either to cause command

execution. The IEEE input terminator is fixed to LF. The switches that allow terminator selection, shown in

the following diagrams, set only the serial output and IEEE output terminators for these operation modes.

In the transparent Pass-Thru modes, the 488 Controller can be configured to provide RS-232-to-IEEE 488

and IEEE-488-to-RS-232 terminator substitution. This is useful when interfacing an RS-232 device which only

issues carriage return (CR) as an output terminator to an IEEE controller which expects a carriage return

followed by a line feed (CR-LF).

In the above case, the serial terminator should be selected for CR Only while the IEEE terminator is set to

CR-LF. When a serial CR character is received, it is discarded, and an IEEE CR-LF is substituted for it. In the

IEEE-to-RS-232 direction, the IEEE CR is unconditionally discarded. When it receives the IEEE LF, a serial

CR is substituted.

To make the 488 Controller totally data transparent in the Pass-Thru modes, set both the serial and IEEE

terminators to be CR Only or LF Only.

3.3.1 S

ERIAL TERMINATOR

SW2-3 and SW2-4 select the serial terminators for the serial input (Pass-Thru Modes Only) and output.

The factory default is CR-LF.

Figure 3-10. Switch SW2: Selecting the serial terminator.

Switch

Side

View

DOT

CR Only

1 2 3 4 5

6

7 8

OPEN

LF-CR

1 2 3 4 5

6

7 8

OPEN

1 2 3 4 5

6

7 8

OPEN

LF Only

1 2 3 4 5

6

7 8

OPEN

CR-LF

Page 21

19

CHAPTER 3: Getting Started

3.3.2 IEEE BUS T

ERMINATOR

SW3-6 through SW3-8 set the IEEE bus terminators used for data sent or received (Pass-Thru modes only)

by the 488 Controller. EOI, a line used to signal the end of a multiple character bus transfer, may also be

enabled. If enabled, EOI is asserted when the last selected bus terminator is sent. Factory default is CR-LF

with EOI disabled.

Figure 3-11. Switch SW3: Selecting the IEEE bus terminator.

3.4 Selecting the Mode

SW2-1 and SW2-2 set the major operating mode of the 488 Controller. There are four distinct modes

of operation.

1. System Controller

2. Peripheral

3. Controller Pass-Thru

4. Peripheral Pass-Thru

Switch

Side

View

DOT

1 2 3 4 5

6

7 8

OPEN

LF Only

1 2 3 4 5

6

7 8

OPEN

CR-LF

1 2 3 4 5

6

7 8

OPEN

CR Only

1 2 3 4 5

6

7 8

OPEN

LF-CR

1 2 3 4 5

6

7 8

OPEN

EOI Disabled

1 2 3 4 5

6

7 8

OPEN

EOI Enabled

Page 22

488 CONTROLLER

20

As a System Controller, the 488 Controller accepts simple high-level ASCII commands from a serial host. It

interprets these commands and performs the required bus action to bidirectionally communicate with up to

14 IEEE devices. As a Peripheral, the 488 Controller becomes a bus device. It accepts simple high-level ASCII

commands from a serial host and interprets these commands and status to communicate with another IEEE

controller. Applications include computer-controlled automatic test systems. These operation modes are

discussed in Chapters 4 and 5.

The IEEE Controller Pass-Thru (RS-232 to IEEE Converter) mode allows a serial host device to send data to

a single IEEE bus peripheral. Applications include interfacing a listen-only or addressable IEEE

printer/plotter to a serial printer port. Refer to Chapter 6 for more detailed information on the Controller

Pass-Thru operation mode.

The Peripheral Pass-Thru mode is used when interfacing a serial device to an IEEE controller. Data which

is sent by the IEEE controller to the 488 Controller is transmitted out its serial port. Data received from the

serial device is buffered by the 488 Controller until it is read by the IEEE controller. Refer to Chapter 7 for

more detailed information on the Peripheral Pass-Thru operation mode.

The factory default is the System Controller mode.

Figure 3-12. Switch SW2: Selecting the mode.

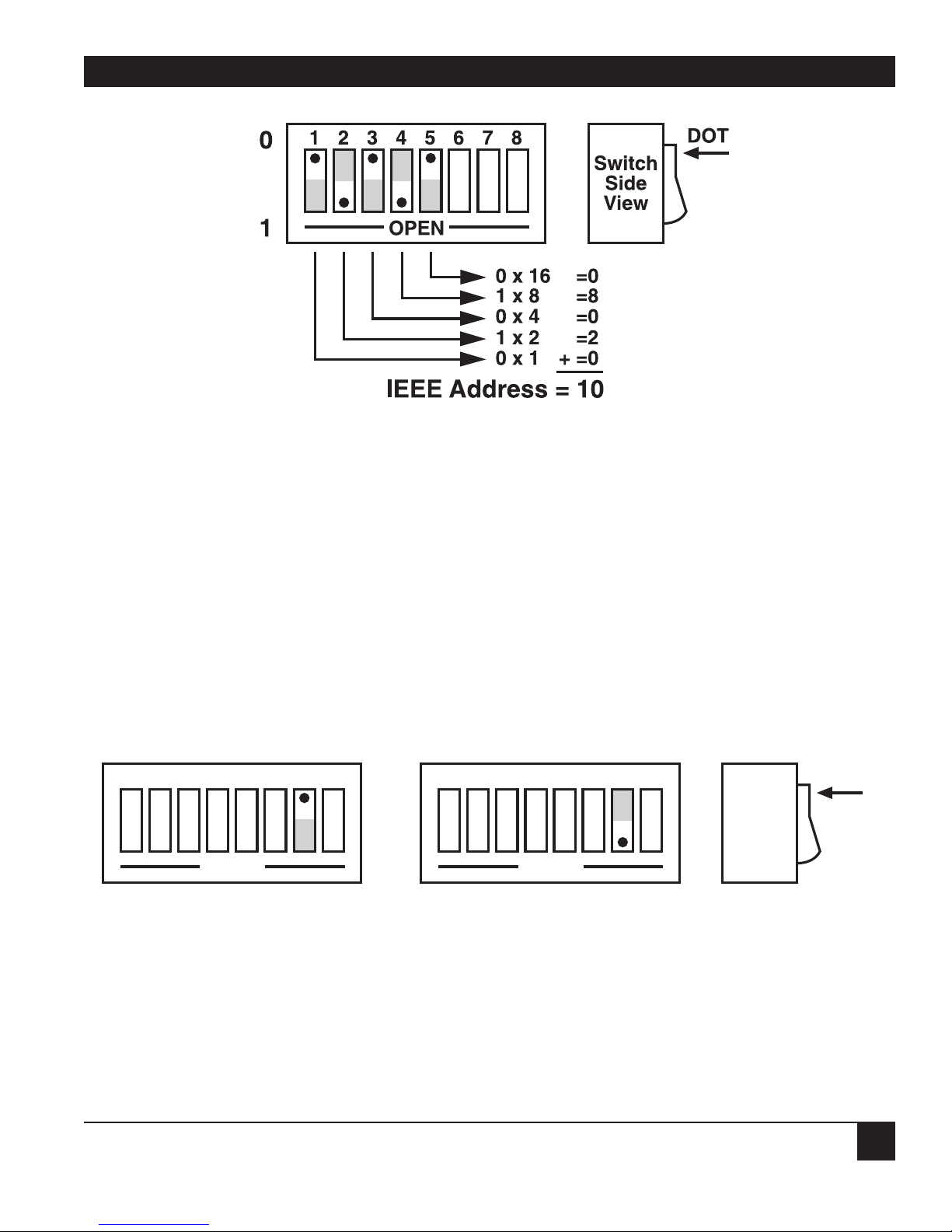

3.5 Selecting the IEEE Address

SW3-1 through SW3-5 select the IEEE bus address of the 488 Controller when in the System Controller,

Peripheral and Peripheral Pass-Thru modes. These same switches are used in the Controller Pass-Thru mode

to select the address of the device that will be controlled. (Refer to Chapter 7 for additional information.)

The address is selected by simple binary weighting, with SW3-1 being the least significant bit and SW3-5 the

most significant. The factory default is address 10.

Listen Only is a special type of Peripheral Pass-Thru operation. In the Listen Only mode the 488 Controller

accepts all data transmitted on the bus, ignoring any bus addressing, and transfers it out its serial port. The

488 Controller is set to Listen Only mode by setting its address to 31. If the IEEE address is set to 31 in the

System Controller, Peripheral, or Peripheral Pass-Thru mode, it is adjusted to address 30.

Switch

Side

View

DOT

1 2 3 4 5

6

7 8

OPEN

Controller Pass-Thru

1 2 3 4 5

6

7 8

OPEN

Peripheral Pass-Thru

1 2 3 4 5

6

7 8

OPEN

Peripheral

System Controller

1 2 3 4 5

6

7 8

OPEN

Page 23

21

CHAPTER 3: Getting Started

Figure 3-13. Switch SW3: Selecting the IEEE address.

3.6 Feature Selections

The functions of the remaining switches are dependent on the mode selected. A brief description of each

of these features follows. Refer to the listed sections for additional information.

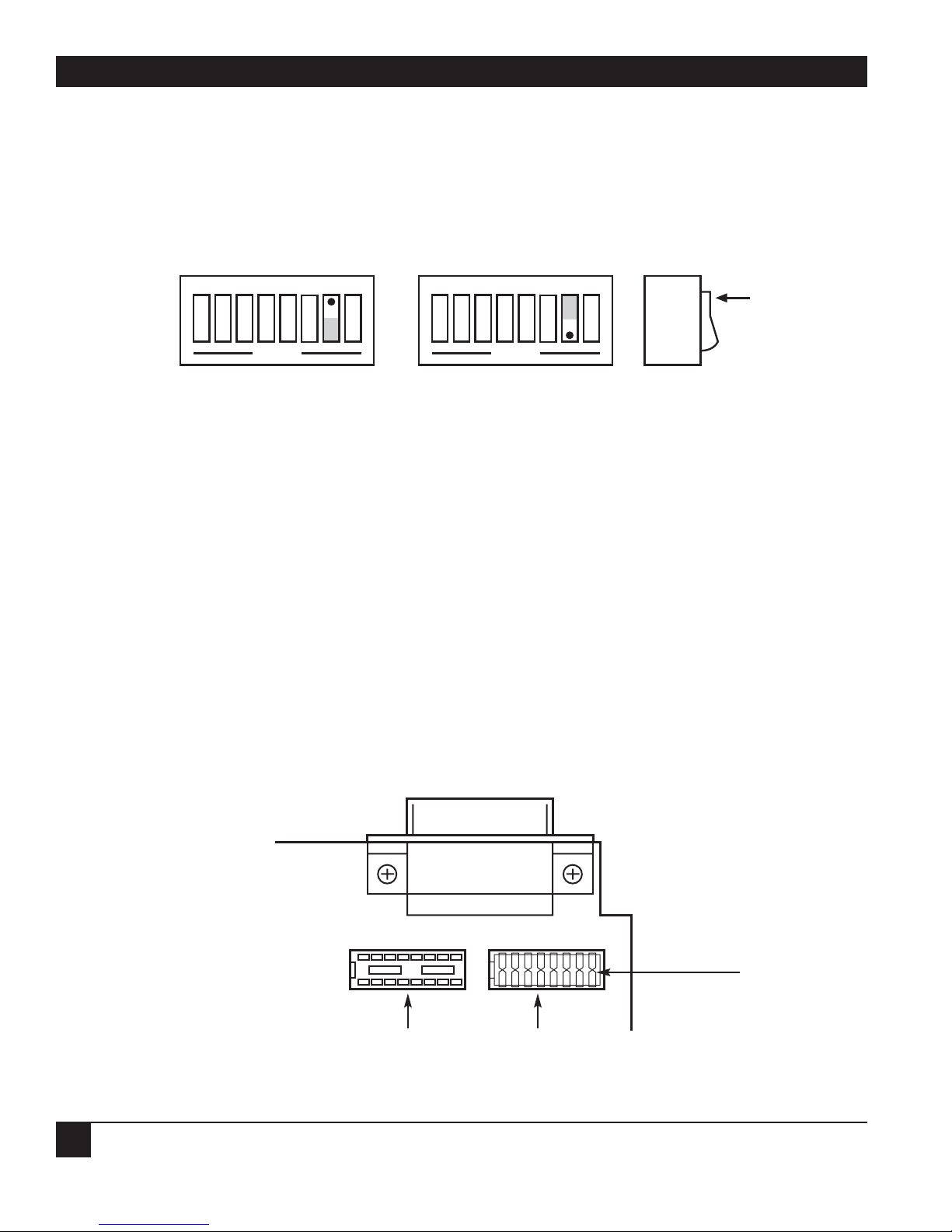

3.6.1 CONTROLLER PASS-THRU FEATURES

In the IEEE Controller (RS-232-to-IEEE-488 converter) mode, SW1-7 determines whether the interface

should, after sending the IEEE bus terminators, address the attached bus device to talk. The factory default

is Talk-back On Terminator enabled.

Refer to Chapter 6 for complete details on these features.

Figure 3-14. Switch SW1: Enabling or disabling “Talk Back on Terminator” in Controller mode.

Switch

Side

View

DOT

1 2 3 4 5

6

7 8

OPEN

Talk-Back on

Terminator Disabled

1 2 3 4 5

6

7 8

OPEN

Talk-Back on

Terminator Enabled

Page 24

488 CONTROLLER

22

3.6.2 PERIPHERAL P

ASS-THRU FEATURES

In the Peripheral Pass-Thru (IEEE-488-to-RS-232 converter) mode, SW1-7 enables the interface to assert

the SRQ IEEE bus interface line to indicate that it has received the last-switch-selected serial terminator

character from the serial device.

Figure 3-15. Switch SW1: Enabling or disabling SRQ on last serial terminator in Peripheral mode.

3.7 Serial Interface

The 488 Controller has the ability to output signal levels that are compatible with either RS-232 or RS-422.

An internal DIP shorting plug determines which electrical specification is chosen. If the interface is to be

connected to an IBM

®

PC or compatible, select the RS-232 level. If it will be connected to a Macintosh®, use

the RS-422 level. For connection to other computers, refer to the manufacturer’s manual to determine

which levels are supported.

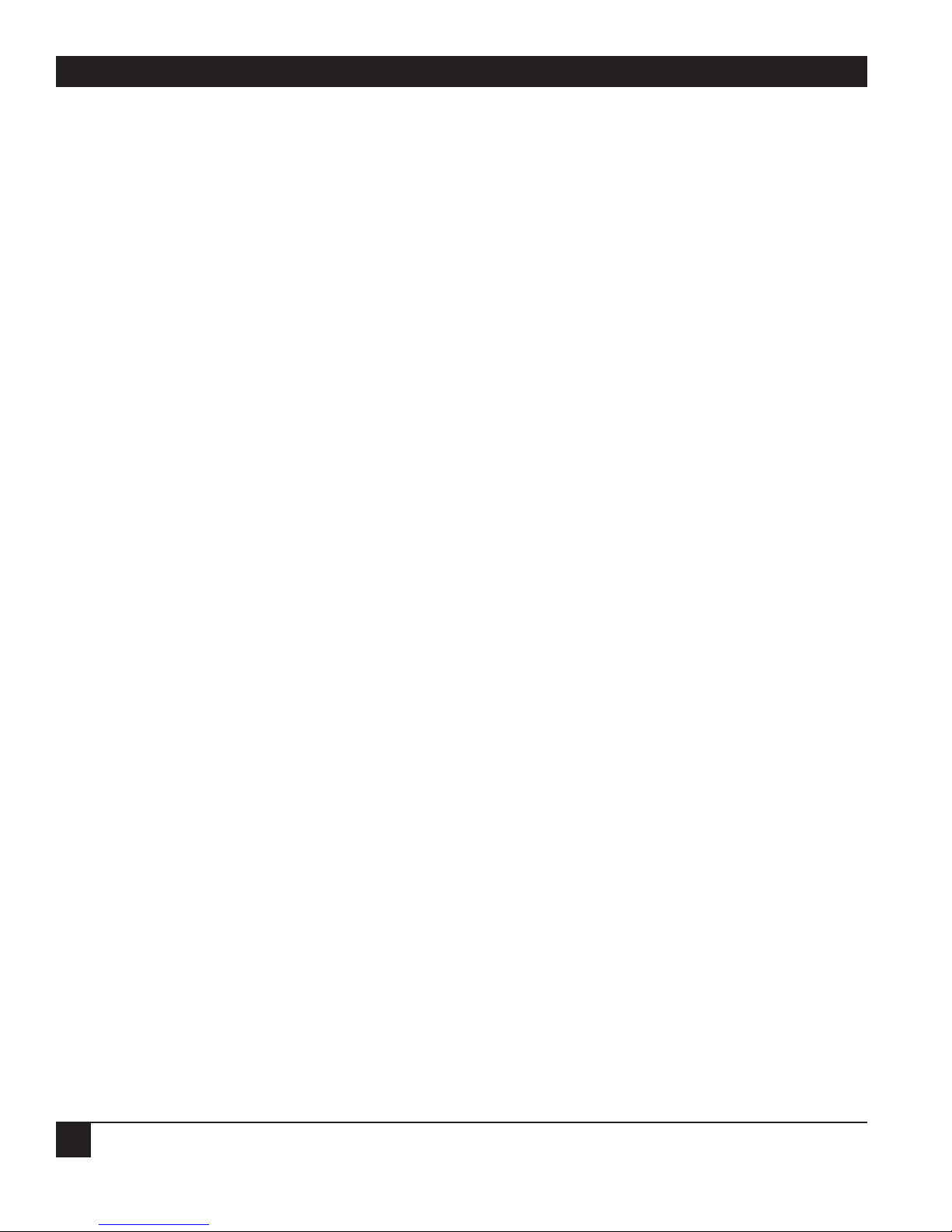

3.7.1 RS-232/RS-422 S

IGNAL LEVEL SELECTION

The 488 Controller’s factory default signal levels are compatible with RS-232. To select RS-422 levels,

carefully remove the 8-position shorting plug with a small flat-blade screwdriver from J106. Install the

DIP jumper into J205, making certain that all shorting plug pins are inserted correctly.

Figure 3-16. Selecting RS-232 or RS-422 signal levels.

Switch

Side

View

DOT

1 2 3 4 5

6

7 8

OPEN

SRQ on Last

Terminator Disabled

1 2 3 4 5

6

7 8

OPEN

SRQ on Last

Terminator Enabled

Shorting Plug

RS-232

RS-422

Page 25

23

CHAPTER 3: Getting Started

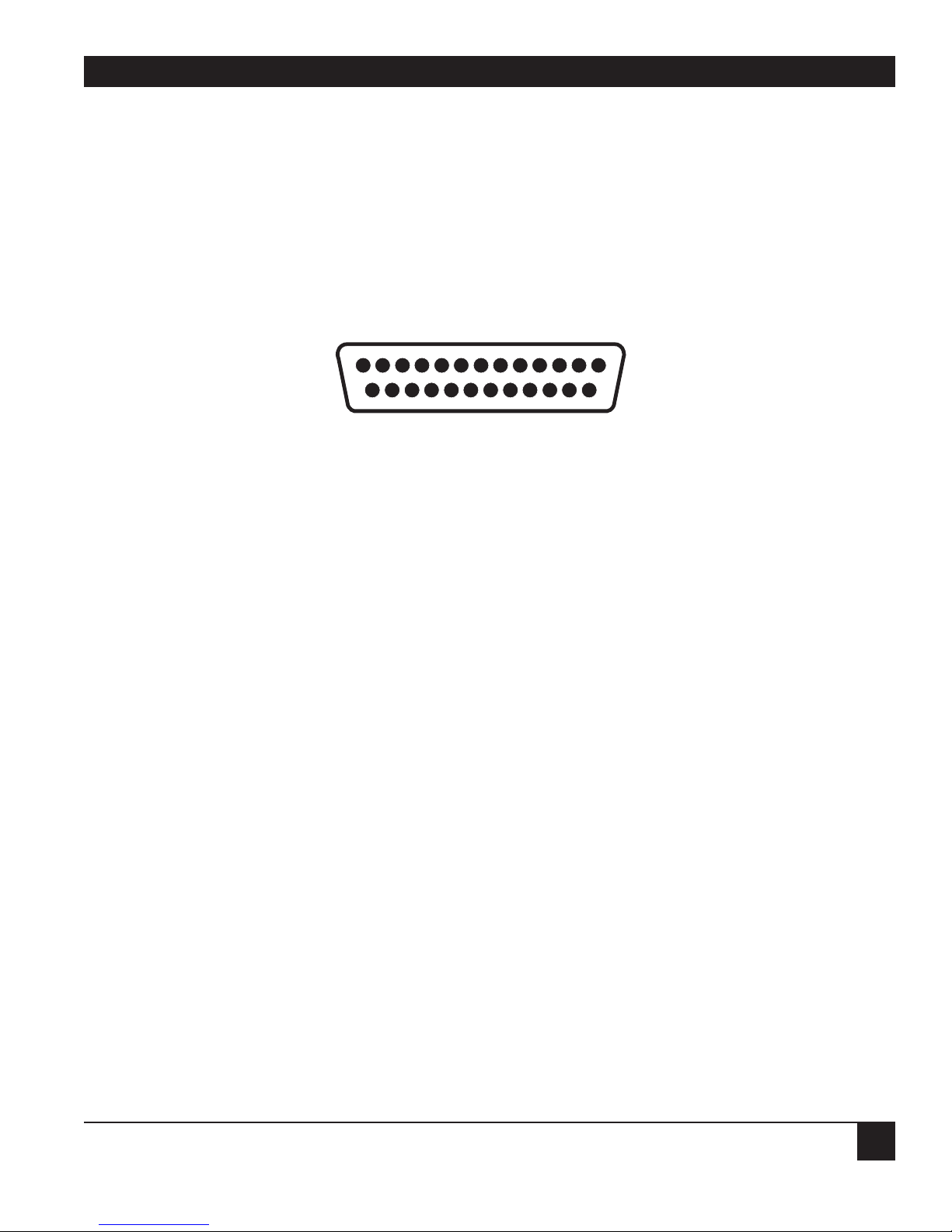

3.7.2 SERIAL S

IGNAL DESCRIPTIONS

The 488 Controller is equipped with a standard DB25 female connector on its rear panel and requires

a standard DB25 male mating connector. The 488 Controller’s connector is configured as DCE type

equipment for RS-232 communications, which means the 488 Controller always transmits data on Pin 3

and receives data on Pin 2. The following lists and describes the RS-232 and RS-422 signals provided on

the 488 Controller.

Figure 3-17. Rear view of the 488 Controller’s serial connector.

-RxD Receive Data—Input—Pin 2

This pin accepts serial data sent by the RS-232 or RS-422 host. The serial data is expected

with the word length, baud rate, stop bits, and parity selected by the internal switches. The

signal level is low true.

-TxD Transmit Data—Output—Pin 3

This pin transmits serial data to the RS-232 or RS-422 host. The serial data is sent with the

word length, baud rate, stop bits, and parity selected by the internal switches. The signal

level is low true.

CTS Clear To Send—Input—Pin 4

The CTS input is used as a hardware-handshake line to prevent the 488 Controller from

transmitting serial data when the RS-232 host is not ready to accept it. When RTS/CTS

handshake is selected on the internal switches, the 488 Controller will not transmit data

out -TxD while this line is unasserted (lowered). If the RS-232 host is not capable of driving

this line it can be connected to the Vtest output (Pin 6) of the 488 Controller. If X-ON/X-OFF

handshake is selected, the CTS line is not tested to determine if it can transmit data.

RTS Request To Send—Output—Pin 5

The RTS output is used as a hardware handshake line to prevent the RS-232/RS-422 host

from transmitting serial data if the 488 Controller is not ready to accept it. When RTS/CTS

handshake is selected on the internal switches, the 488 Controller will drive the RTS output

high when there are more than 1000 character locations available in its internal buffer. If

the number of available locations drops to less than 1000, the 488 Controller will unassert

(lower) this output. If X-ON/X-OFF handshake is selected, the RTS line will be permanently

driven active high.

13 1

25 14

-RXD

-TXD

CTS

RTS

+VTEST

GND

+VTEST

+RXD

+TXD

Page 26

488 CONTROLLER

24

+Vtest Test Voltage—Output—Pin 6

This pin is connected to +5 volts through a 1K resistor. It is also common to Vtest on pin 9.

Gnd Ground—Pin 7

This pin sets the ground reference point for the other RS-232 inputs and outputs.

+Vtest Test Voltage—Output—Pin 9

This pin is connected to 5 volts through a 1K resistor. It is also common to Vtest on pin 6.

+RxD Receive Data Plus—Input—Pin 14

This pin accepts serial data sent by the RS-422 host. The serial data is expected with the word

length, baud rate, stop bits, and parity selected by the internal switches. The signal level is

high true and only connected to this pin when RS-422 operation is selected. It is 180 degrees

out of phase with -RxD.

+TxD Transmit Data Plus—Output—Pin 16

This pin transmits serial data to the RS-422 host. The serial data is sent with the word length,

baud rate, stop bits, and parity selected by the internal switches. The signal level is high true

and only connected to this pin when RS-422 operation is selected. It is 180 degrees out of

phase with -TxD.

3.7.3 S

ERIAL-CABLE WIRING DIAGRAMS

If a cable was not purchased with the 488 Controller, the following diagrams will help you make your own

cable. Simple soldering skills and attention to detail will ensure successful construction.

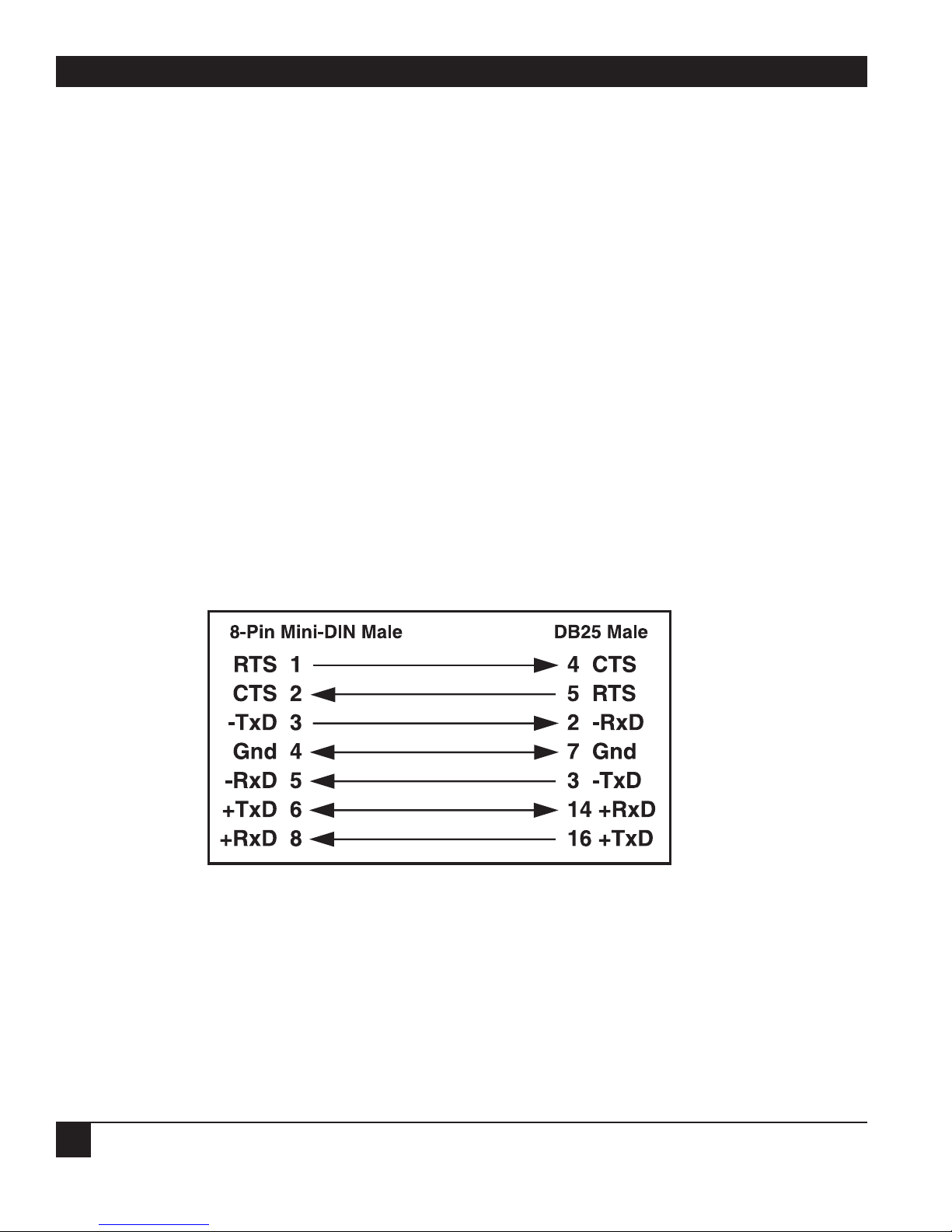

Figure 3-18. Wiring diagram: Macintosh to 488 Controller.

Page 27

25

CHAPTER 3: Getting Started

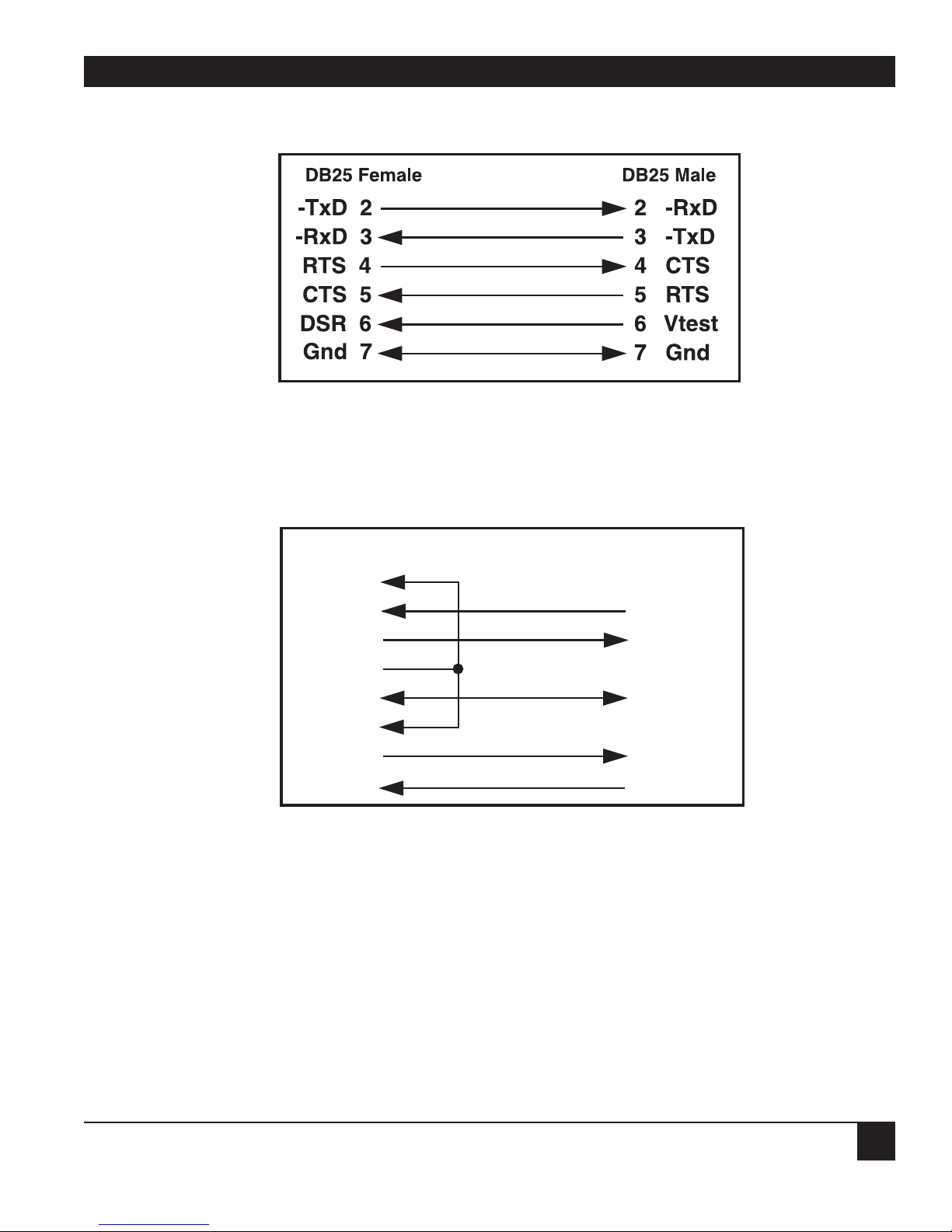

Figure 3-19. Wiring diagram: IBM PC or compatible with DB25

serial connector to 488 Controller (RS-232).

Figure 3-20. Wiring diagram: IBM AT

®

or compatible with DB9

serial connector to 488 Controller (RS-232).

NOTE

Standard AT 9-pin-to-25-pin adapter cables are not wired as shown above and will not work

with the 488 Controller.

DCD 1

-RxD 2 3 -TxD

-TxD 3 2 -RxD

DTR 4

Gnd 5 7 Gnd

DSR 6

RTS 7 4 CTS

DB9 Female DB25 Male

CTS 8 5 RTS

Page 28

488 CONTROLLER

26

3.8 General Operation

Refer to the following sections for specific operational modes. This section gives a general test of functionality. After setting the power-on defaults and reassembling the 488 Controller, plug the power-supply

connector into the rear jack on the interface.

CAUTION

Never plug the power supply into the 488 Controller while it is connected to AC line power.

If you do, you could damage the 488 Controller.

WARNING

The power supply provided with the interface is intended for indoor use only. Using it

outdoors could result in equipment failure, personal injury, or death.

After plugging the power supply connector into the 488 Controller, plug the power supply into AC line

power. Turn the rear-panel power switch ON (the “1” position). All the front-panel indicators should light

momentarily while the 488 Controller performs an internal ROM and RAM self-check. At the end of this

self-check, all indicators except POWER should turn off.

If there is an error in the ROM checksum, all of the LEDs will remain on. Flashing LEDs indicate a RAM

failure. Should such an error occur, turn the rear-panel switch to the OFF (0) position and retry the above

procedure.

If the front-panel indicators do not flash and the POWER indicator does not remain lit, there may not be

any power supplied to the interface. If this happens, check the AC line and the power supply’s rear-panel

connection.

If the controller operates properly, connect an interface cable to the 488 Controller’s rear (DB25)

connector. Connect the other end to the host’s serial port. Except for connecting IEEE bus instruments, the

488 Controller is installed and ready to use.

WARNING

The 488 Controller makes its earth ground connection through the serial interface cable. It

should only be connected to IEEE bus devices after being first connected to the host.

Failure to do so may allow the 488 Controller to float to a bus device test voltage. This

could result in damage to the 488 Controller, personal injury, or death.

Page 29

27

CHAPTER 3: Getting Started

3.9 Is Anyone Out There?

Before connecting any IEEE bus devices to the 488 Controller, try this simple operational check. The 488

Controller must be configured for either System Controller or Peripheral mode operation. This test will

not work in either of the Pass-Thru modes.

Running BASIC on the host, or any programming language which supports the serial ports, type the

following (or its equivalent).

OPEN "COM1:9600, N, 8, 2, cd, ds" AS 1 [Return]

PRINT #1,"HELLO" [Return]

LINE INPUT #1,A$ [Return]

PRINT A$ [Return]

The 488 Controller will respond with (and the host will display):

488 Controller Revision N.N Copyright (C) 1988

where N.N is the release and revision number of the firmware.

If you obtain the response above, then your 488 Controller is fine and ready to connect your host to the

powerful IEEE-488 General Purpose Interface Bus. If you did not receive the message above, check that the

interface cable is properly connected and fits. If the 488 Controller is not installed correctly, call Black Box

Technical Support.

Page 30

488 CONTROLLER

28

4.1 Introduction

There are four types of IEEE bus devices: Active Controllers, Peripherals, Talk-Only devices, and ListenAlways devices. Talk-Only and Listen-Always devices are usually used together, in simple systems, such as

a Talk-Only digitizer sending results to a Listen-Always plotter. In these simple systems, no controller is

needed, because the talker assumes that it is the only talker on the bus, and the listener(s) assume that

they are all supposed to receive all the data sent over the bus. This is a simple and effective method of

transferring data from one device to another, but is not adequate for more complex systems where, for

example, one computer is controlling many different bus devices.

In more complex systems, the Active Controller sends commands to the various bus Peripherals telling them

what to do. Commands such as Unlisten, Listen Address Group, Untalk, and Talk Address Group are sent by

the controller to specify which device is to send data, and which devices are to receive it. For more details

about the IEEE bus protocols, see Chapter 8.

When an IEEE bus system is first turned on, some device must be the Active Controller. This device is the

System Controller and always keeps some control of the bus. In particular, the System Controller controls

the Interface Clear (IFC) and Remote Enable (REN) bus management lines. By asserting Interface Clear,

the System Controller forces all the other bus devices to stop their bus operations, and regains control as

the Active Controller.

4.2 Operating Mode Transitions

The System Controller is initially the Active Controller. It can, if desired, pass control to another device

and thereby make that device the Active Controller. The System Controller remains the System Controller.

The device to which control is passed must be able to take on the Active Controller role. It would make no

sense to try to pass control to a printer. Control should only be passed to other computers that are capable,

and ready, to become the Active Controller. There must be exactly one System Controller on the IEEE bus.

All other potential controllers must be configured as Peripherals when they power on.

The state diagram on the next page shows the relationships between the various operating modes. The top

half of the state diagram shows the System Controller’s two operating states. At power-on, it is the active

controller. It directs the bus transfers by sending the bus commands mentioned previously. It also has

control of the Interface Clear and Remote Enable bus lines. The System Controller can pulse Interface

Clear to reset all other bus devices.

As shown in the diagram, the System Controller can pass control to some other bus device and thereby

become a Peripheral to the new Active Controller. If the System Controller receives control from the new

Active Controller, then it will once again become the Active Controller. The System Controller can also

force the Active Controller to relinquish control by asserting the Interface Clear signal.

The bottom half of the state diagram shows the two operating states of a Not System Controller device. At

power on, it is a Peripheral to the System Controller, which is the Active Controller. If it receives control

from the Active Controller, it becomes the new Active Controller. Even though it is the Active Controller, it

is still not the System Controller. The System Controller can force the Active Controller to give up control

by asserting Interface Clear. The Active Controller can also give up control by passing control to another

device, which may or may not be the System Controller.

4. IEEE Operating Modes

Page 31

29

CHAPTER 4: IEEE Operating Modes

Figure 4-1. IEEE bus operating modes state diagram.

In summary, a bus device is set in hardware as either the sole System Controller in the system, or as a nonSystem Controller. At power on, the System Controller is the Active Controller, and the other devices are

Peripherals. The System Controller can give up control by Passing Control, and can regain control by

asserting Interface Clear, or by receiving control. A Peripheral can become the Active Controller by

receiving control, and can give up control by Passing Control, or upon detecting Interface Clear.

Active

System

Controller

SC-CA

Active

Controller,

Not System

Controller

*SC-CA

System

Controller,

Not Active

SC-*CA

Peripheral,

Not System

Controller

*SC-*CA

Power On

Power On

Controller Active (CA) Peripheral (*CA)

Not System Controller (*SC)

Passes Control

Receives Control or

Asserts Interface Clear

Receives Control

Passes Control or

Detects Interface Clear

System Controller (SC)

Page 32

488 CONTROLLER

30

4.3 System Controller Mode

The most common 488 Controller configuration is as the System Controller, controlling several IEEE-bus

instruments. In this mode, the 488 Controller can perform all of the various IEEE-bus protocols necessary to

control and communicate with any IEEE-488-bus devices. As the System Controller in the Active Controller

mode, the 488 Controller can use all commands that are available for the Active Controller state, plus

control the Interface Clear and Remote Enable lines. The allowed bus commands and their actions are as

follows:

ABORT Pulse Interface Clear.

LOCAL Unassert Remote Enable, or send Go To Local to selected devices.

REMOTE Assert Remote Enable, optionally setting devices to Remote.

LOCAL LOCKOUT Prevent local (front-panel) control of bus devices.

CLEAR Clear all or selected devices.

TRIGGER Trigger selected devices.

ENTER Receive data from a bus device.

OUTPUT Send data to bus devices.

PASS CONTROL Give up control to another device which becomes the Active

Controller.

SPOLL Serial Poll a bus device, or check the Service Request state.

PPOLL Parallel Poll the bus.

PPOLL CONFIG Configure Parallel Poll responses.

PPOLL DISABLE Disable selected bus devices’ Parallel Poll response.

PPOLL UNCONFIG Disable all bus devices’ Parallel Poll response.

SEND Send low-level bus sequences.

RESUME Unassert Attention. Used to allow Peripheral-to-Peripheral transfers.

Page 33

31

CHAPTER 4: IEEE Operating Modes

4.4 System Controller, Not Active Controller Mode

After Passing Control to another device, the System Controller is no longer the Active Controller. It acts

as a Peripheral to the new Active Controller, and the allowed bus commands and their actions are modified

accordingly. However, it still maintains control of the Interface Clear and Remote Enable lines. The available

bus commands and their actions are:

ABORT Pulse Interface Clear.

LOCAL Unassert Remote Enable.

REMOTE Assert Remote Enable.

ENTER Receive data from a bus device as directed by the Active Controller.

OUTPUT Send data to bus devices as directed by the Active Controller.

REQUEST Set own Serial Poll request (including Service Request) status.

SPOLL Get own Serial Poll request status.

As a bus Peripheral, the 488 Controller must respond to the commands issued by the Active Controller. The

controller can, for example, address the 488 Controller to listen in preparation for sending data. There are

two ways to detect our being addressed to listen: through the STATUS command, or by detecting an event

with the ARM or ON DOMACRO commands.

The STATUS 1 command can be used to watch for commands from the Active Controller. The Operating

Mode, which is a “P” while the 488 Controller is a Peripheral, will change to a “C” if the Active Controller

Passes Control to the 488 Controller. The Addressed State will go from Idle (I) to Listener (L) or Talker (T)

if the 488 Controller is addressed to listen or to talk, and will go back to Idle (I) when the Active Controller

issues Unlisten (UNL), Untalk (UNT), or specifies another talker (TAG). The Triggered (T1) and Cleared

(C1) indicators will be set when the 488 Controller is triggered or cleared, and reset when STATUS 1 is read.

The Address Change indicator will be set (G1) when the address state changes. These indicators allow the

program to sense the commands issued to the 488 Controller by the Active Controller. The following BASIC

program fragment illustrates how to use the Address Change and Addressed State indicators to

communicate with the Active Controller.

Page 34

488 CONTROLLER

32

First, we check STATUS until it indicates that there has been an address change:

200 PRINT#1,"STATUS1"

210 INPUT#2 ST$

220 'Has there been no Address Change?

230 IF MID$(ST$,7,1)="0" THEN 200

240 'Are we still in the idle state?*

250 STATE$=MID$(ST$,9,1)

260 IF STATE$="I" THEN 200

270 'Are we addressed to listen?

280 IF STATE$="L" THEN 400

290 'Are we addressed to talk?

300 IF STATE$="T" THEN 500

310 PRINT "BAD ADDRESSED STATE VALUE: ";ST$: STOP

*This means “are we still in a state where there is no communication.”

If we are addressed to listen, then we ENTER a line from the controller and print it out.

400 'Listen state

410 PRINT#1,"ENTER"

420 LINE INPUT#1,A$

430 PRINT A$

440 GOTO 200

If we are addressed to talk, then we INPUT a line from the keyboard and OUTPUT it to the controller.

500 'Talk state

510 LINE INPUT A$

520 PRINT#1,"OUTPUT;";A$

530 GOTO 200

Page 35

33

CHAPTER 4: IEEE Operating Modes

You can also detect these conditions with the ARM or ON DOMACRO commands and handle them in an

exception as described in Chapter 5. The various arm conditions and their meanings are as follows:

SRQ The internal Service Request state is set. See the SPOLL command in

Chapter 5.

PERIPHERAL The 488 Controller is in the Peripheral (*CA) operating mode.

CONTROLLER The 488 Controller is the Active Controller (CA).

TRIGGER The 488 Controller, as a Peripheral, has received a Trigger bus command.

CLEAR The 488 Controller, as a Peripheral, has received a Clear bus command.

TALK The 488 Controller is in the Talk state and can OUTPUT to the bus.

LISTEN The 488 Controller is in the Listen state and can ENTER from the bus.

IDLE The 488 Controller is in neither the Talk nor Listen state.

CHANGE An Address Change has occurred, i.e. a change between Peripheral and

Controller, or among Talk, Listen, and Idle has occurred.

ERROR An error, either command or bus, has been detected by the 488 Controller.

4.5 Not System Controller Mode

If the 488 Controller is configured as not the System Controller then, at power on, it will be a bus

Peripheral. It might use a program like the one described previously to communicate with the Active

Controller. The bus commands available to the 488 Controller when it is not the System Controller and

not the Active Controller (*SC*CA) are:

ENTER Receive data from a bus device as directed by the Active Controller.

OUTPUT Send data to bus devices as directed by the Active Controller.

REQUEST Set own Serial Poll request (including Service Request) status.

SPOLL Get own Serial Poll request status.

Page 36

488 CONTROLLER

34

4.6 Active Controller, Not System Controller Mode

If the Active Controller passes control to the the 488 Controller, then the 488 Controller will become the

new Active Controller. This can be detected by the STATUS command or as an ARMed event. As an Active

Controller, but not the System Controller, the following bus commands are available:

ABORT Assert Attention and send My Talk Address to stop any bus transfers.

LOCAL Send Go To Local to selected devices.

LOCAL LOCKOUT Prevent local (front-panel) control of bus devices.

CLEAR Clear all or selected devices.

TRIGGER Trigger selected devices.

ENTER Receive data from a bus device.

OUTPUT Send data to bus devices.

PASS CONTROL Give up control to another device, which becomes the Active Controller.

SPOLL Serial Poll a bus device, or check the Service Request state.

PPOLL Parallel Poll the bus.

PPOLL CONFIG Configure Parallel Poll responses.

PPOLL DISABLE Disable the selected bus devices’ Parallel Poll response.

PPOLL UNCONFIG Disable all bus devices’ Parallel Poll response.

SEND Send low-level bus sequences.

RESUME Unassert Attention. Used to allow Peripheral-to-Peripheral transfers.

4.7 Controller Pass-Thru Mode

This mode is intended to provide bidirectional data-transparent conversion between an RS-232/RS-422 host

computer and an IEEE 488 peripheral, such as a printer or an HP

®

-IB plotter. This mode’s operation is

covered in Chapter 6 of this manual.

4.8 Peripheral Pass-Thru Mode

This mode provides bidirectional data transparent conversion between an IEEE 488 controller and a serial

device. This Peripheral Pass-Thru mode does not require the serial device to control data to it. There is no

command line, so this mode requires no serial commands. This operation mode is described in Chapter 7.

Page 37

35

CHAPTER 5: Command Descriptions

5.1 Introduction

This section contains a detailed description of each of the high-level commands available for the 488

Controller. There are two types of commands: bus commands and system commands. Bus commands

communicate with the IEEE 488 bus. System commands configure or request information from the

488 Controller.

Bus Commands:

ABORT PPOLL CONFIG

CLEAR PPOLL DISABLE

ENTER PPOLL UNCONFIG

LOCAL REMOTE

LOCAL LOCKOUT REQUEST

OUTPUT RESUME

PASS CONTROL SEND

PPOLL SPOLL

TRIGGER

System Commands:

ARM MACROENDM

COMMENT MASK

COUNT MEMORY

DELAY ON <event> DOMACRO

DISARM READ

DOMACRO RESET

ERASE STATUS

ERROR STERM

HELLO TERM

ID TIME OUT

TRACE

5. Command Descriptions

Page 38

488 CONTROLLER

36

5.2 Command-Description Format

Each command description is divided into several areas.

5.2.1 S

YNTAX

The command description’s syntax section describes the proper command syntax which must be sent to the

488 Controller using the IBM BASIC PRINT# command, or its equivalent in other languages, to the COM

port. The following conventions are used in the syntax descriptions:

No command, along with its options, may be more than 127 characters long. The OUTPUT command’s data

part is not constrained by this length. It is, however, limited to the available USER MEMORY. The OUTPUT

#count;data may be as long as necessary. Refer to the OUTPUT command for more information.

Enter items in capital letters, such as ENTER or OUTPUT, exactly as stated, except use abbreviations with

some commands to reduce serial transmission traffic.

Items in lower case, such as addr or count, represent parameters which must be substituted with an

appropriate value.

Blank spaces in commands are generally ignored. Thus, LOCAL LOCK OUT is the same as

LOCALLOCKOUT. Spaces are not ignored in four places: the OUTPUT command’s data part, within

quoted strings in a SEND command, after an apostrophe (') in a terminator specification (term), and after

the semicolon following the ID command.

The number sign (#) and the semicolon (;) must be present exactly as shown. A comma (,) represents an

address separator. You can use the slash (/) or period (.) in its place as the address separator.

Use optional semicolons ([;]) if desired.

Items enclosed in square brackets ([item]) are optional. Multiple items enclosed in square brackets

separated by vertical lines ([item1|item2|item3]) are optional; any one or none may be chosen. No more

than one item may be selected.

Ellipses (...) within square brackets mean that the items in the brackets may be repeated as many times as

desired.

Braces, or curly brackets ({item1|item2}), mean that exactly one of the enclosed items is required.

Bracket combinations are possible. For example, {term[term] [EOI] |EOI} allows the choice of “term,” “term

EOI,” “term term,” “term term EOI,” or just “EOI,” but does not allow the choice of “nothing.”

Numeric parameters (those that are given as numbers) are decimal unless preceded by &H, in which case

they are considered to be hexadecimal. Thus 100 is decimal 100, &H64 is hexadecimal 64 which equals

decimal 100, &HFF is decimal 255, and 0FF is invalid because F is not a valid decimal digit. The only

exception to this rule is that bus addresses, both primary and secondary, must be specified as two-digit

decimal numbers. Hexadecimal bus addresses are not allowed.

Several commands require additional or optional parameters. These are further described with each

command, but the more common ones are discussed next.

Page 39

37

CHAPTER 5: Command Descriptions

Bus Addressing

pri-addr A two-digit primary device address in the range of 00 to 30.

sec-addr An optional two-digit secondary device address in the range of 00 to 31.

addr An IEEE bus address. A numeric primary address optionally followed by a secondary

address. Thus addr is of the form...

{pri-addr [sec-addr]}

where pri-addr is a two-digit primary address in the range from 00 through 30 and

sec-addr is a two-digit secondary address from 00 through 31. Numeric addresses

must be given as two-digit numbers: for example, 05 for address 5, and 1601 for

primary address 16, secondary address 1.

[,addr] An optional bus addresses list, each address preceded by an address separator: either

a comma (,), a slash (/) or a period (.).

No more than 15 bus addresses are allowed in any single command.

Character Count

#count The number of characters to be transferred. A pound sign (#) followed by an integer

in the range of 1 to 65535 (2

16

-1). May be specified in hexadecimal by preceding it

with &H. The hexadecimal range is &H1 to &HFFFF. A zero character count is

invalid.

ASCII Characters

$char A single character whose ASCII value is the number char, a decimal number in the

range from 0 to 255, or a hexadecimal number in the range from &H0 to &HFF. For

example, $65 is the letter “A,” as is $&H41.

CR The carriage return character ($13, $&H0D).

LF The line feed character ($10, $&H0A).

'X Any printable character. The apostrophe is immediately followed, without any

intervening spaces, by a single character which is taken to be the character specified.

ASCII Character Strings

data An arbitrary characters string. No special forms given above ($char, CR, LF, or 'X)

are used. For example, CRLF as data is taken as the letters “C,” “R,” “L,” and “F,” not

as carriage return and line feed.

'data' An arbitrary characters string enclosed in apostrophes (') or quotes (").

Page 40

488 CONTROLLER

38

Terminators

term Any single character, specified as CR, LF, 'X, or $char as described previously. Part

of terminator sequence used to mark data and commands’ lines’ ends.

[term] An optional term character. term[term], means that one or two terminators may

be specified.

EOI The IEEE bus End-Or-Identify signal. When asserted during the transfer of a

character, EOI signals that that character is the last in the transfer. On input, EOI,

if specified, causes the input to stop. On output, EOI causes the bus EOI signal to

be asserted during transmission of the last character.

NONE The no-end-of-line-character indicator. When STERM NONE is specified, the 488

Controller does not append any serial output terminator(s) to serially transmitted

data.

5.2.2 R

ESPONSE

The command description’s response section describes the response that the user’s program should read

from the serial host’s COM port after sending the command. If a response is provided, it must be read to

maintain proper program sequence.

5.2.3 MODE

This command description section specifies the operating modes in which the command is valid.

The 488 Controller may be configured as the System Controller, in which case it will initially be the Active

Controller, or as a Not System Controller, in which case it will initially be in the Peripheral state. The 488

Controller configuration as System Controller or Not System Controller is fixed by a hardware switch setting

and cannot be changed by software, but the 488 Controller can change between Active Controller and

Peripheral as required (see Chapter 4).

The modes are referred to by their names and states, as given in the table below:

Description

State

System Controller SC

Not System Controller *SC

Active Controller CA

Peripheral (Not Active Controller) *CA

Active System Controller SCCA

System Controller, Not Active Controller SC*CA

Not System Controller, Not Active Controller *SC*CA

Not System Controller, Active Controller *SCCA

Page 41

39

CHAPTER 5: Command Descriptions

5.2.4 BUS STATES

This section describes the bus command and data transfers using IEEE bus mnemonics, abbreviated

as follows:

DIO lines

8 7654321

ATN Attention

data Data String

DCL Device Clear x 0 0 1 0 1 0 0

GET Group Execute Trigger x 0 0 0 1 0 0 0

GTL Go To Local x 0 0 0 0 0 0 1

IFC Interface Clear

LAG Listen Address Group x 0 1 a d d r n

LLO Local Lock Out x 0 0 1 0 0 0 1

MLA My Listen Address x 0 1 a d d r n

MTA My Talk Address x 1 0 a d d r n

PPC Parallel Poll Configure x 0 0 0 0 1 0 1

PPD Parallel Poll Disable x 1 1 1 0 0 0 0

PPE Parallel Poll Enable x 1 1 0 S P3 P2 P1

PPU Parallel Poll Unconfigure x 0 0 1 0 1 0 1

REN Remote Enable

SDC Selected Device Clear x 0 0 0 0 1 0 0

SPD Serial Poll Disable x 0 0 1 1 0 0 1

SPE Serial Poll Enable x 0 0 1 1 0 0 0

SRQ Service Request

TAG Talker Address Group x 1 0 a d d r n

TCT Take Control x 0 0 0 1 0 0 1

UNL Unlisten x 0 1 1 1 1 1 1

UNT Untalk x 1 0 1 1 1 1 1

(x = “don’t care”)

If a command is preceded by an asterisk, then that command is unasserted. For example, *REN states that

the remote enable line is unasserted. Conversely, REN without the asterisk states that the line becomes

asserted.

Page 42

488 CONTROLLER

40

5.3 Memory Use

Memory in the 488 Controller is dynamically allocated for the serial input, serial output, and macro buffers.

This allows for the most efficient partitioning of memory for any given application. This memory is kept in

the user “heap” (a vernacular for heap of memory) until required by the system.

At power on, each serial buffer is allocated a 127-byte minibuffer or queue. When the serial input (or

output) requires more buffer space, additional queues are allocated. When a queue is empty, it is released

from the input buffers so that it may be re-allocated when, and where, required. Macro queues are not

allocated unless a macro is defined.

There are approximately 240 available queues for a total of 29,000 bytes of buffer (character) space. Queues

are continually allocated and released as required. Of the 240 available queues, 230 are issued without

regard to controlling the receipt of additional serial input data.

When the serial input buffer requests one of the last 10 queues (1270 character locations left), it signals

the serial host that it should stop sending data. This is accomplished by either unasserting RTS or issuing

“X-OFF,” depending on which serial handshake control has been switch selected. When more than 10

queues become available, it asserts RTS or issues X-ON.

5.4. The Commands

The commands provided in the 488 Controller, in alphabetical order, are described on the following pages.

@ Command

The system command @, followed by a CR and/or LF, is used to unlock the 488 Controller from an

inappropriate command. An example of such a command would be requesting data from a nonexistent