Page 1

ServSensor V4E

Use this intelligent environmental monitoring

device to identify problems before they disrupt

your equipment.

Features an embedded Web server and Linux operating system.

EME134A -R3

Contact

Information

EME134A-R3

Order toll-free in the U.S. or for FREE 24/7 technical support: Call 877-877-BBOX

(outside U.S. call 724-746-5500)

www.blackbox.com • info@blackbox.com

Page 2

Trademarks Used in this Manual

Trademarks Used in this Manual

Black Box and the Double Diamond logo are registered trademarks of BB Technologies, Inc.

Bluetooth is a registered trademark of Bluetooth Sig, Inc.

Unicenter is a registered trademark of Computer Associates Think, Inc.

SiteScope is a registered trademark of Freshwater Software, Inc.

HP and OpenView are registered trademarks of Hewlett-Packard Company.

IBM and Tivoli are registered trademarks of International Business Machines Corporation.

WhatsUp is a registered trademark of Ipswitch, Inc.

Linux is a registered trademark of Linus Torvalds.

MS-DOS is a registered trademark of Microsoft Corporation.

Denika and WebNM are registered trademarks of Plixer International, Inc.

Big Brother is a registered trademark of Quest Software, Inc.

MRTG is a registered trademark of Rand Investments, Inc.

Somix is a registered trademark of Somix Technologies, Inc.

Any other trademarks mentioned in this manual are acknowledged to be the property of the trademark owners.

We‘re here to help! If you have any questions about your application

or our products, contact Black Box Tech Support at 724 -746-5500

or go to blackbox.com and click on “Talk to Black Box.”

You’ll be live with one of our technical experts in less than 60 seconds.

Page 2

877-877-2269 | blackbox.com

EME134A-R3

Page 3

FCC and IC RFI Statements

Federal Communications Commission and Industry Canada Radio Frequency Interference

Statements

This equipment generates, uses, and can radiate radio-frequency energy, and if not installed and used properly, that is, in strict

accordance with the manufacturer’s instructions, may cause inter ference to radio communication. It has been tested and found to

comply with the limits for a Class A computing device in accordance with the specifications in Subpart B of Part 15 of FCC rules,

which are designed to provide reasonable protection against such interference when the equipment is operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct the interference.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to

operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emis sion from digital apparatus set out in the Radio

Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la classe A prescrites dans le Règlement sur le brouillage radioélectrique publié par Industrie Canada.

EME134A-R3

877-877-2269 | blackbox.com

Page 3

Page 4

NOM Statement

Instrucciones de Seguridad

(Normas Oficiales Mexicanas Electrical Safety Statement)

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca de la tina de baño, lavabo, sótano mojado o cerca

de una alberca, etc.

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá a lo descrito en las instrucciones de operación.

Todo otro servicio deberá ser referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no interfiera su uso. La colocación del aparato eléctrico

sobre una cama, sofá, alfombra o superficie similar puede bloquea la ventilación, no se debe colocar en libreros o gabinetes

que impidan el flujo de aire por los orificios de ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor como radiadores, registros de calor, estufas u otros

aparatos (incluyendo amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del tipo descrito en el instructivo de operación, o como

se indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no sean pisados ni pellizcados por objetos colocados

sobre o contra ellos, poniendo particular atención a los contactos y receptáculos donde salen del aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 4

877-877-2269 | blackbox.com

EME134A-R3

Page 5

Table of Contents

Table of Contents

1. Specifications .......................................................................................................................................................................................... 6

2. Overview ............................................................................................................................................................................................ 7

2.1 Introduction .................................................................................................................................................................................... 7

2.2 What‘s Included .............................................................................................................................................................................. 7

2.3 Hardware Description ..................................................................................................................................................................... 8

2.3.1 Front Panel ........................................................................................................................................................................... 8

2.3.2 Back Panel ............................................................................................................................................................................ 9

3. Installation ...........................................................................................................................................................................................10

3.1 Setting the IP Address ....................................................................................................................................................................10

3.2 Testing the New IP Address with the “Ping” Command .................................................................................................................12

3.3 Firmware Upgrade .........................................................................................................................................................................14

3.4 Multiusers and Groups Setup .........................................................................................................................................................19

3.4.1 Group Setup........................................................................................................................................................................19

3.4.2 User Setup ..........................................................................................................................................................................21

3.5 Services and Security .................................................................................................................................................................... 23

3.5.1 Active Services Application (Disabling)................................................................................................................................ 23

3.5.2 Closing or Changing Ports Disabling HTTP and Enabling HTTPS .......................................................................................... 24

3.5.3 The SNMPv3 SSL Security Feature ....................................................................................................................................... 24

3.5.4 Active Security ................................................................................................................................................................... 25

3.5.5 The NAC or Network Access Control Security Feature ........................................................................................................ 26

3.6 Setting Up a Sensor ...................................................................................................................................................................... 26

3.6.1 Notification Thresholds ....................................................................................................................................................... 28

3.6.2 Advanced Sensor Settings .................................................................................................................................................. 30

3.7 Using an Internal Mic as a Sound Detection Sensor ....................................................................................................................... 47

3.8 Expansion Ports ............................................................................................................................................................................ 49

4. Notifications .......................................................................................................................................................................................... 53

4.1 Adding a Notification .................................................................................................................................................................... 53

4.2 SNMP Trap .................................................................................................................................................................................... 54

4.3 E-mail .......................................................................................................................................................................................... 58

4.4 SMS Notification ........................................................................................................................................................................... 63

5. Camera .......................................................................................................................................................................................... 70

5.1 Basic Setup ................................................................................................................................................................................... 70

5.2 Pan/ Tilt Camera Functions ............................................................................................................................................................ 76

5.3 Automating Camera Movements .................................................................................................................................................. 78

5.4 Recording from the Camera .......................................................................................................................................................... 82

5.5 Picture Log ................................................................................................................................................................................... 86

6. Mapping .......................................................................................................................................................................................... 89

6.1 Adding a Map .............................................................................................................................................................................. 89

6.2 Monitoring via the Map Interface .................................................................................................................................................. 93

7. Filters .......................................................................................................................................................................................... 95

7.1 Sensor Filters ................................................................................................................................................................................ 95

7.2 Syslog Filters ................................................................................................................................................................................. 97

8. Making the ServSensor Visible to the Internet ..................................................................................................................................... 100

9. SEC to SEC SNMP Trap Receive ............................................................................................................................................................101

9.1 Introduction .................................................................................................................................................................................101

9.2 SNMP Trap Sender (A) SEC (10.1.1.225) configuration ..................................................................................................................101

9.3 Getting OIDs for the SNMP Traps .................................................................................................................................................107

9.4 SNMP Trap Receiver (B) SEC (10.1.1.137) configuration ................................................................................................................. 112

10. SNMP Trap Receiver Controlling IO-digital8 Relay ................................................................................................................................. 117

11. Frequently Asked Questions (FAQs) ......................................................................................................................................................126

EME134A-R3

877-877-2269 | blackbox.com

Page 5

Page 6

Chapter 1: Specifications

1. Specifications

Certifications: AdRem NetCrunch, Quest Software–Big Brother®, Castle Rock, HP® OpenView®, IBM® Tivoli®, LoriotPro, Logalot,

MRTG®, SiteScope®, Somix®—WebNM® and Denika®, WhatsUp® Gold, Computer Associates Unicenter® TNG

Components: Manufactured using highly integrated, low-power surface-mount technology to ensure long-term reliability;

32-bit Xscals PXA270, 520-MHz processor, 128 MB Flash memory, internal on-board 2 GB SD memory slot drive plus card

Expandable Modules: EME1X8: 8-port intelligent sensors module;

EME1DC16: 16-port dry-contacts modules

Mean Time Between Failures (MTBF): 400,000 hours

Network Interface: (1) 10/100BASE-T Ethernet RJ-45

Connectors: Inputs: (8) RJ-45 for connecting sensors; (2) RJ-45 expansion ports; (4) video input ports V1–4, NTSC/PAL;

(1) USB Version 1.1 Type A; (4) PTZ 2-pin controllers; (1) 2.5" jack for analog audio; (1) RS-485 2-pin terminal box

(used for Modbus);

Output: (1) 2.5" jack for analog audio; (1) 2.5" jack for microphone

Temperature Tolerance: Operating: -31 to 131° F (-35 to +55° C)

Humidity: 20 to 80%, noncondensing

Indicators: (3) LEDs: (1) Power, (1) Network Connectivity, (1) LED for sensor on-line and threshold status

Power: Output: 7.0–9 VDC, 3 amps;

Consumption: 6.46 watts, 0.86 amps

Size: 1.8"H x 8.5"W x 5.4"D (4.6 x 21.6 x 13.7 cm)

Weight: 2.4 lb. (1.1 kg)

Page 6

877-877-2269 | blackbox.com

EME134A-R3

Page 7

Chapter 2: Overview

2. Overview

2.1 Introduction

Used for environmental monitoring, the ServSensor V4E identifies problems before they lead to business disruptions. This highspeed, accurate, intelligent monitoring device features a completely embedded host and Linux® operating system. It includes video

capability, so you can connect your own cameras through the rear-panel connectors.

2.2 What’s Included

Your package should contain the following items. If anything is missing or damaged, contact Black Box Technical Support at

724-746-550 0.

• (1) ServSensor V4E unit

• (1) 5-ft. crossover cable

• (1) 5-ft. straight-pinned cable

• (2) rackmounting brackets

• (1) 7.0–9.0-V, 2.5-A power supply

• (1) temperature/humidity sensor (EME1TH2-005) with RJ-45 to RJ-45 cable

• (4) terminal blocks (installed)

• (1) CD-ROM containing this user’s manual

EME134A-R3

877-877-2269 | blackbox.com

Page 7

Page 8

Chapter 2: Overview

2.3 Hardware Description

Figure 2-1 illustrates the ServSensor’s front panel. Table 2-1 describes its components.

2.3.1 Front Panel

4

5

6 7

1 2

Number Component Description

1 Power LED When the unit is powered on, the power LED will be lit continuously. If the

2 Link LED The Link LED indicates network connectivity. It lights when a network is

3 Activity LED The Activity LED flashes when network traffic is sent to or received by the

4 Mic The mic is a small hole for access to the internal microphone. Use it as a

5 Memory slot Insert SD memory card here.

6 Status/Online LEDs 1–8 The Status/Online LEDs are numbered 1–8. They indicate the connectivity

The LEDs can also indicate the progress of an upgrade. The red LEDs move

3

Figure 2-1. Front panel.

Table 2-1. Front panel components.

power LED is flashing, there is a problem with the CPU. Contact Technical

Support at 724-746-5500 or info@blackbox.com.

connected to the ServSensor V4E.

ServSensor V4E.

sound sensor (or use an external mic).

status of the sensors connected to each port. You can also use these LEDs to

indicate system status during various operations.

from left to right to indicate activity, and all the green LEDs indicate overall

progress of the upgrade. When all the red lights are off and the green are on,

the upgrade/recovery process is complete.

These lights also indicate if the unit is operating in safe mode. This is when

The unit may enter recovery mode if a firmware upgrade is incomplete. In this

7 Expansion ports E1–E2 Use the two expansion ports numbered E1–E2 to connect the 8-port

Page 8

the unit loads the operating system (OS) with a minimal set of drivers. If your

device enters safe mode after rebooting, contact Black Box Technical Support

at 724-746-5500 or info@blackbox.com.

case, the unit displays a continuously lit row of red LEDs. If this happens,

contact Black Box Technical Support at 724-746-5500 or info@blackbox.com.

expansion module (EME1X8) and/or the 16 dry-contact expansion module

(EME1DC16).

877-877-2269 | blackbox.com

EME134A-R3

Page 9

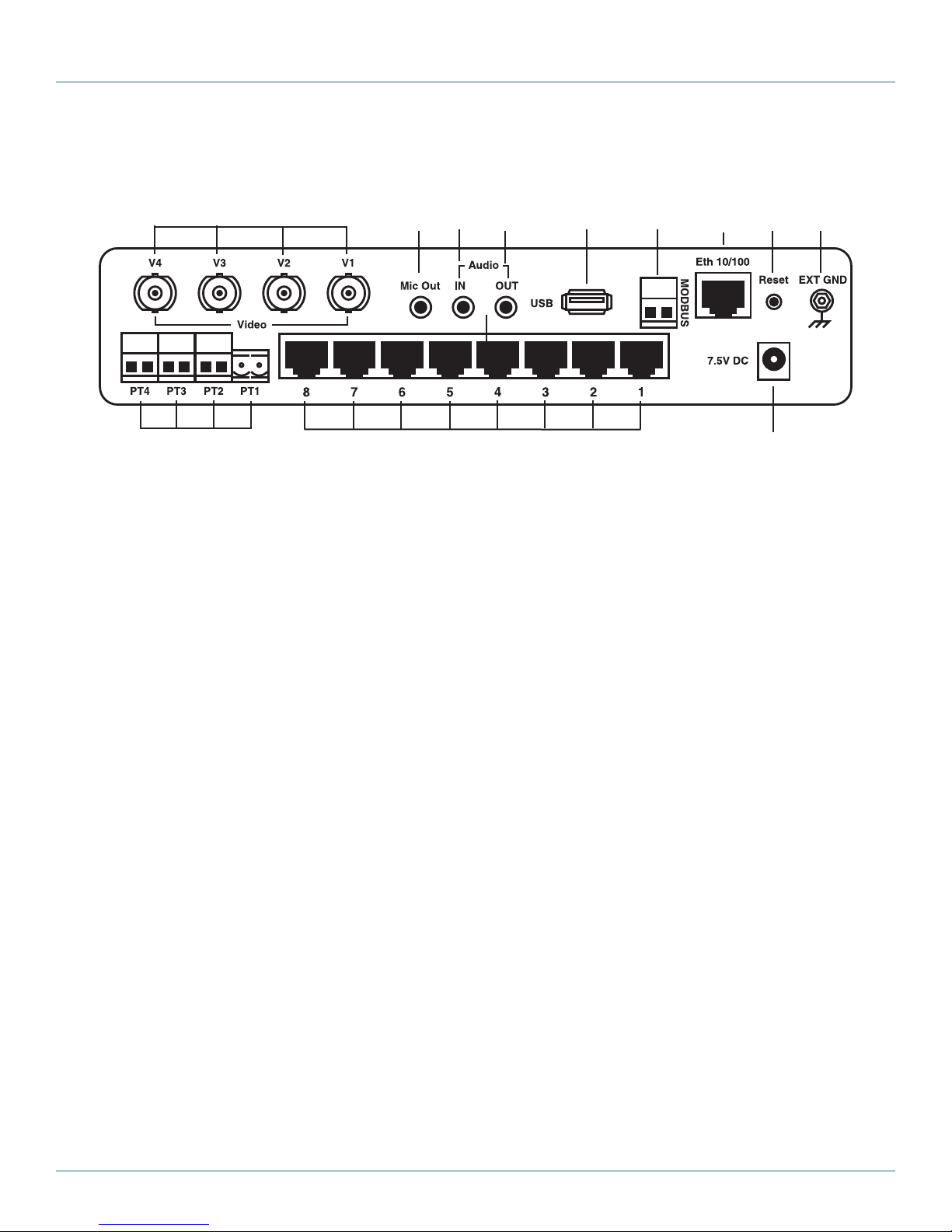

2.3.2 Back Panel

Figure 2-2 shows the ServSensor’s back panel. Table 2-2 describes its components.

11 12 13 14 15 16 17 18 19

8 9 10

Figure 2-2. Back panel.

Chapter 2: Overview

Table 2-2. Back panel components.

Number Component Description

8 (4) terminal blocks (PT1–PT4) Use the four 2-pin terminal blocks labeled PT1–PT4 to connect a PTZ

camera to the ServSensor V4E.

9 (8) RJ-45 connectors Use these ports to connect Intelligent Sensors to the ServSensor V4E.

10 Barrel connector This is a 7.5V DC plug. Connect a 7.0–9.0-V, 2.5-A power supply (included).

11 (4) video connectors (V1–V4) Use the four video inputs (V1–V4) to connect a PAL/NTSC camera via a BNC

jack.

12 Mic out connector Connect an external microphone for voice modem applications.

13 Audio in Connect an external microphone.

14 Audio out Connect the output for external speakers.

15 USB Type A port Use the USB 1.1 port to connect a USB GBarPRS/GSM compatible modem,

a USB Wi-Fi® dongle, or a USB Bluetooth® dongle.

16 2-pin terminal block (RS-485 port) The ServSensor v4E supports Modbus master or slave.

17 RJ-45 10/100 network port Use this RJ-45 port to connect your ServSensor V4E to the network.

18 Safe Mode button NOTE: This button does NOT reset the unit.

Press the button once to announce the IP address of the unit through the

internal speaker. It also broadcasts the IP address to the IPset program.

Hold down the button for 12 seconds to turn off password checking when

Press and hold the button for more than 12 seconds to reboot the unit

19 EXT GND Use the EXT. GND connector to externally ground the unit.

EME134A-R3

accessing the Web based interface.

inoto the firmware upgrade or “SAFE” mode.

877-877-2269 | blackbox.com

Page 9

Page 10

Chapter 3: Installation

3. Installation

3.1 Setting Up the IP Address

The ServSensor V4E is shipped with the default IP address of 192.168.0.100. Follow the steps listed below to change this IP

address to fit your own network configuration.

Before starting, make sure you have these items:

• (1) RJ-45 male CAT5 crossover cable

• (1) PC with Ethernet card

• (1) power socket used to plug in the unit

To set up the IP address:

1. Connect the ServSensor V4E via its Ethernet port to your computer’s Ethernet port with a CAT5 crossover cable.

2. Open a Web browser and type the default IP address (as in Figure 3-1), then press the Enter key.

NOTE: In some cases, your computer might not be able to connect to this default IP address. In this situation, you will need to

change the IP address of your PC. See Chapter 9 for instructions.

3. After you press the Enter key in Step 2, Figure 3-2 appears. The default password for Admin is “public.” Change the password

to make your unit secure.

Page 10

Figure 3-1. Google Web browser screen.

877-877-2269 | blackbox.com

EME134A-R3

Page 11

Chapter 3: Installation

Figure 3-2. User type/password screen.

4. Next, the home page will be displayed. It looks similar to the screen shown in Figure 3-3.

EME134A-R3

Figure 3-3. Settings tab.

877-877-2269 | blackbox.com

Pa ge 11

Page 12

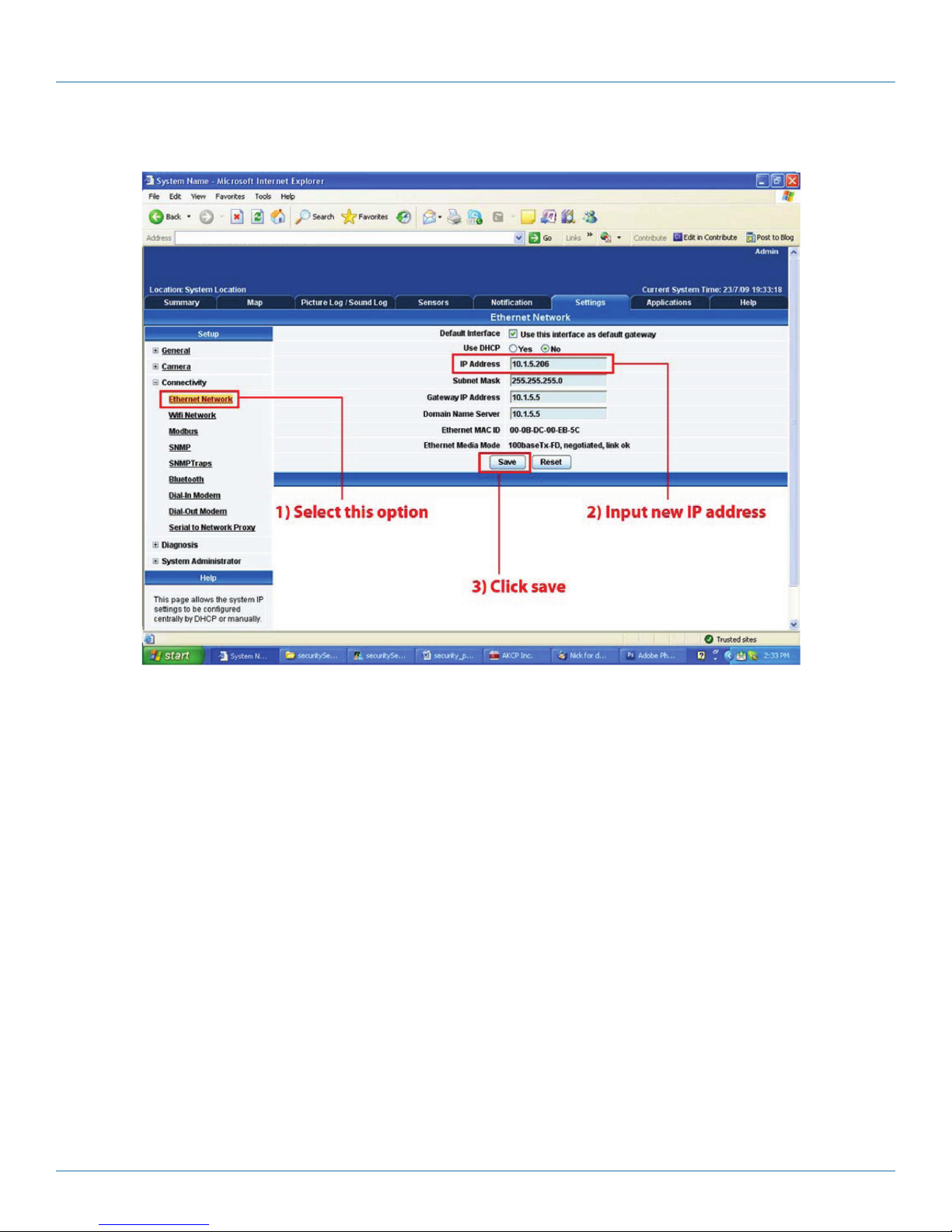

Chapter 3: Installation

5. Click on “Ethernet network” from the list on the left frame of the page. See Figure 3-4.

Figure 3-4. Ethernet network screen.

To change the IP address of the ServSensor V4E:

1. Select Ethernet network.

2. Input the new IP address.

3. Click the “Save” button.

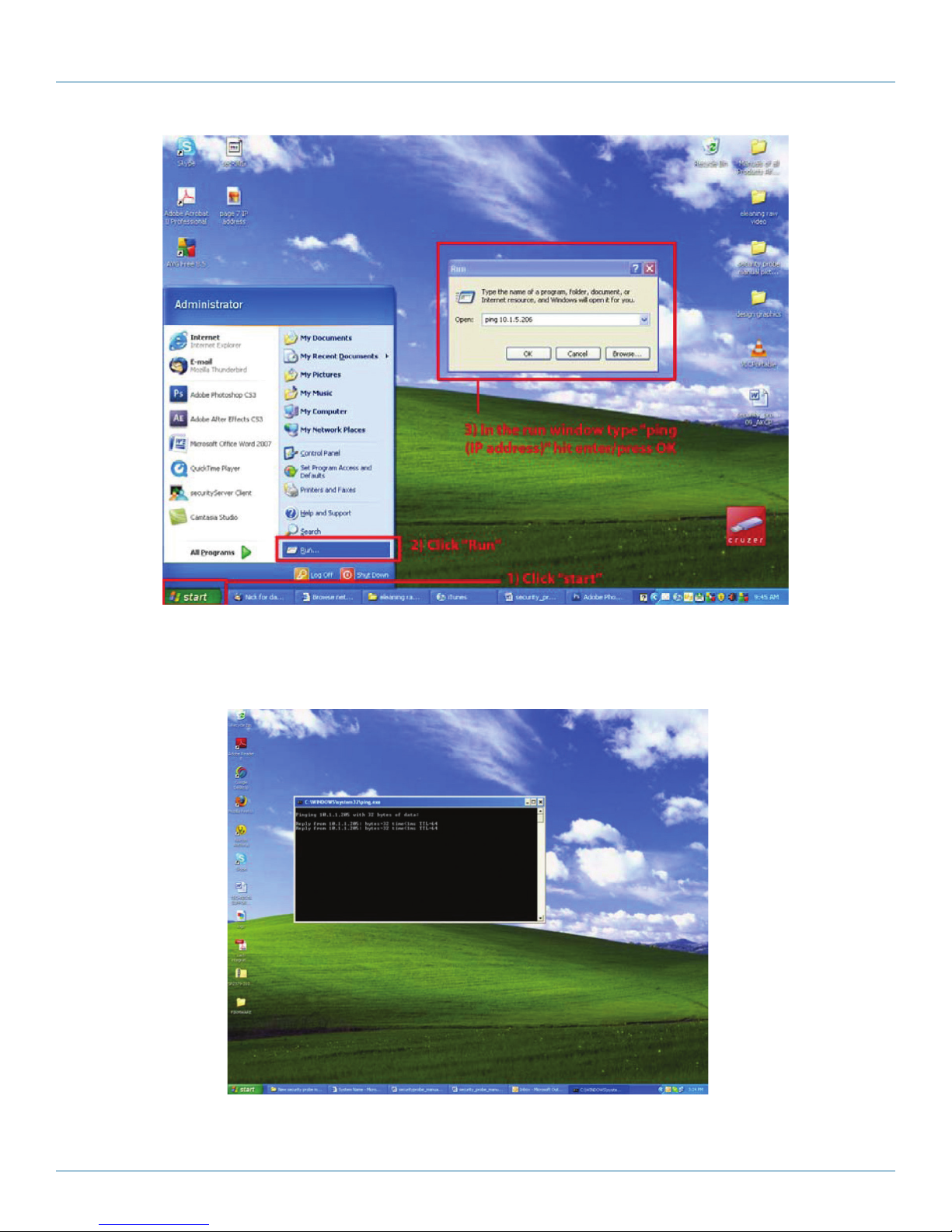

3.2 Testing the New IP Address with the “Ping” Command

Once you assign the new IP address, use the “ping” command to test the ServSensor V4E. You can also use this command as a

diagnostic tool to check whether your unit is connected to the network. See Figure 3-5.

1. Click “Start.”

2. Click “Run.”

3. Type “ping” and the new IP address, and press Enter.

Page 12

877-877-2269 | blackbox.com

EME134A-R3

Page 13

Chapter 3: Installation

Figure 3-5. Ping command screen.

4. After you press the “Enter” key, an MS-DOS® prompt window showing the test results appears (see Figure 3-6). If you get a

message saying “request timed out,” either the IP address is incorrect or a ServSensor V4E is not connected to the network.

EME134A-R3

Figure 3-6. MS-DOS window.

877-877-2269 | blackbox.com

Page 13

Page 14

Chapter 3: Installation

3.3 Firmware Upgrade

Make sure you are running the latest firmware. Contact Black Box Technical Support at 724-746-5500 or info@blackbox.com for

the latest firmware.

NOTE: This manual refers to the Default IP address, 192.168.0.100. Substitute this for your own IP address if you have changed

the default IP address.

This tutorial gives you the information you need to upgrade the firmware.

To get to the tutorial’s starting point:

• Log in as administrator.

• Click the “Settings” tab.

Page 14

Figure 3-7. Settings tab.

877-877-2269 | blackbox.com

EME134A-R3

Page 15

Chapter 3: Installation

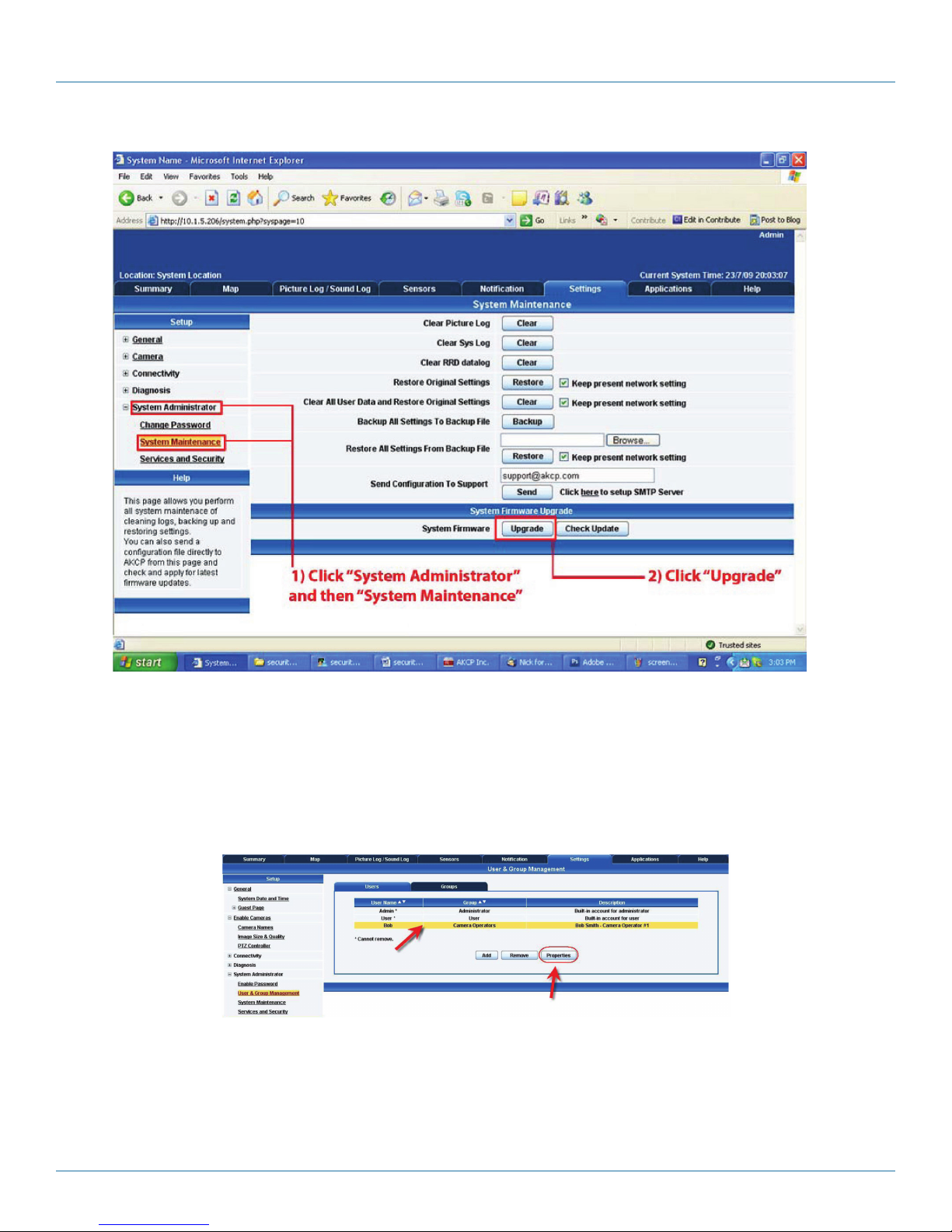

Figure 3-8. System Administrator, System Maintenance screen.

1. Click “System Administrator” and then “System Maintenance.”

2. Click “Upgrade.”

3. The popup screen shown in Figure 3-9 appears.

Figure 3-9. Reboot prompt.

4. Click “OK.” The unit will reboot in Safe Mode. Then you will be redirected to the Safe Mode Web-based interface. This can

take some time, so please be patient. The page will display the message shown in Figure 3-10 when rebooting.

EME134A-R3

877-877-2269 | blackbox.com

Page 15

Page 16

Chapter 3: Installation

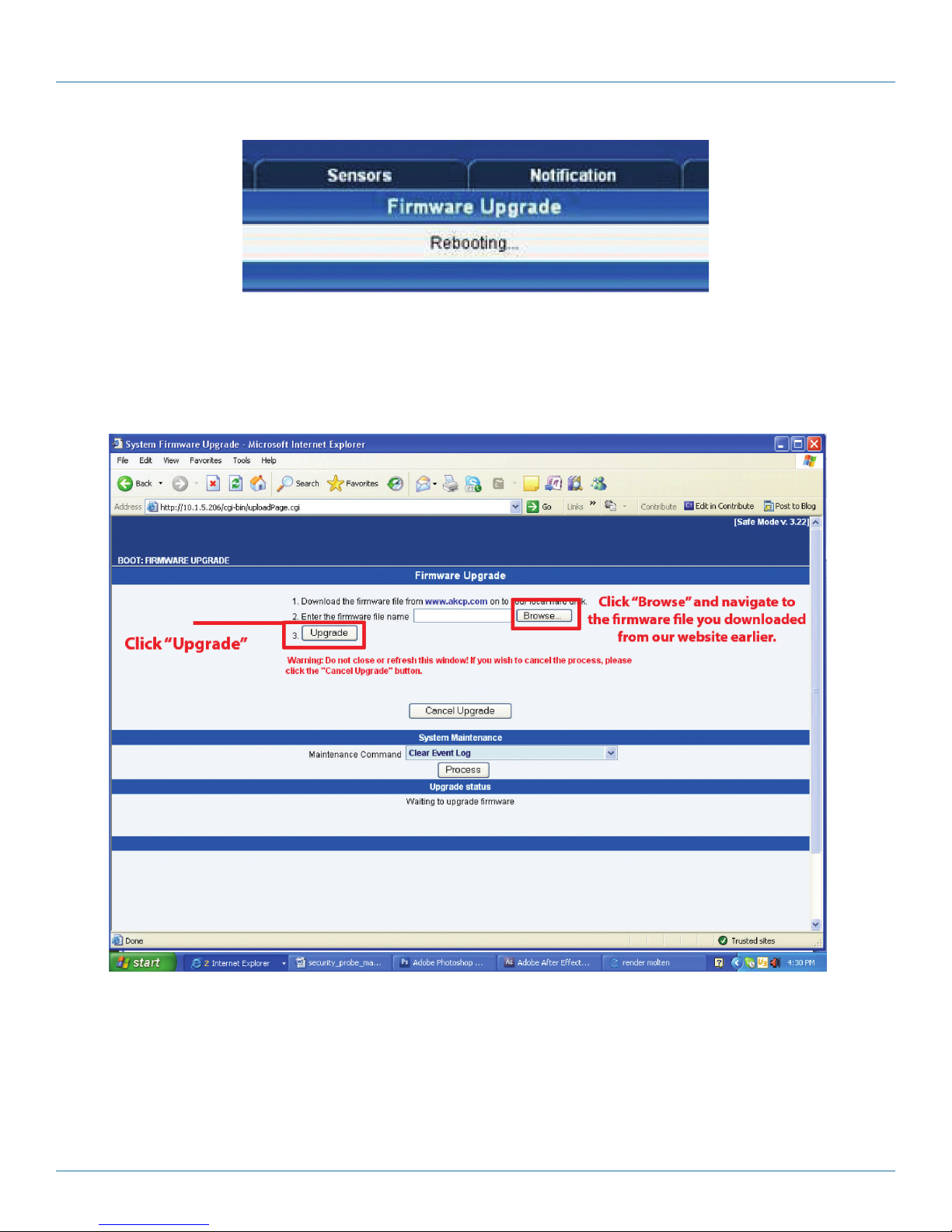

Figure 3-10. Firmware Upgrade Rebooting screen.

5. After the ServSensor reboots, the page shown in Figure 3-11 appears. Click “Browse” and navigate to the firmware file

you downloaded, then click “Upgrade.”

6. During the process, you will see the messages shown in Figure 3-12.

Page 16

Figure 3-11. Upgrade button.

877-877-2269 | blackbox.com

EME134A-R3

Page 17

Chapter 3: Installation

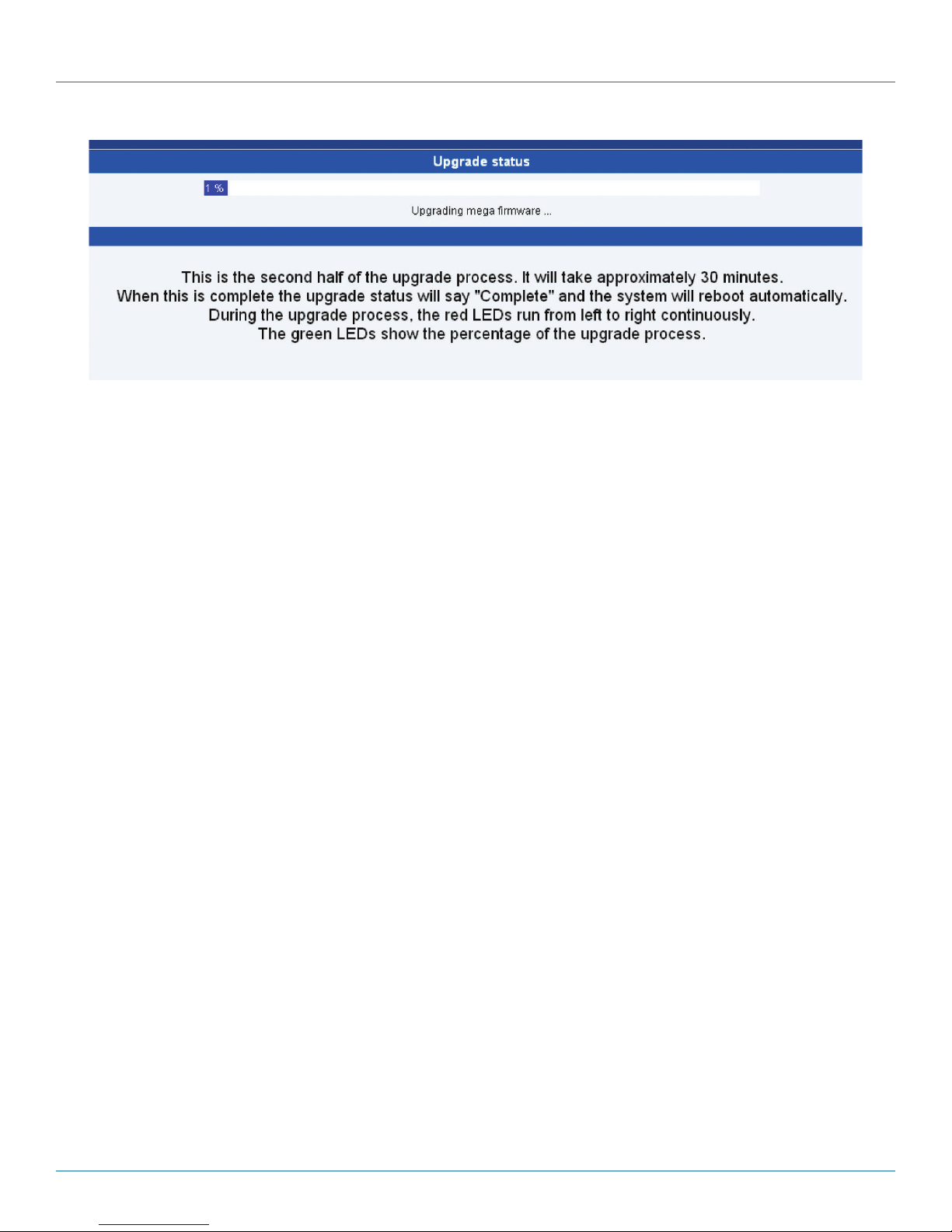

Figure 3-12. Upgrade status screen.

7. The unit will then reboot. The process is complete when the LEDs are back to their “normal” status.

NOTE: If the unit gets disconnected from the AC power or something else occurs during the firmware update that results in the

unit not being rebooted, leave the power on. The unit should boot back to the normal mode.

NOTE: Do NOT push the safe mode button on the back of the unit.

If the unit does not boot back to normal mode or reamins with the LEDs circling in a counter-clockwise rotation after 30 minutes,

the unit is most likely stuck in safe mode.

If this is the case, DO NOT CONTINUE TO PRESS THE SAFE MODE BUTTON ON THE BACK OF THE UNIT. Instead, perform the

following steps:

Firmware Update Mode Using LinuxIPSet

NOTE: We recommend tha you use the Web interface when upgrading the firmware on the units. If you are not able to access

the Web interface, then use the LinuxIPSet.

To set the unit back to normal mode:

1. Power OFF your device.

2. Connect the ServSensor V4E via crossover cable directly to your computer’s network interface card.

3. Reconfigure your network interface card’s TCP/IP settings (IP Address: 192.168.0.2, subnet address: 255.255.255.0, default

gateway and DNS: leave both blank).

4. Make sure that firewall programs are temporarily turned OFF or make an exception for InuxIPSET5.8.1.exe.

5. Run InuxIPSET5.8.1.exe from your product CD, or from the firmware update compressed file.

6. Click on the “Firmware Upgrade” option mode in the LinuxIPSet.

7. Press and hold the reset button, and power ON the unit. Remember not to let go until you see the text in the LinuxIPSet

(received a request of “kernel-pxa.img” from 192.168.0.100).

8. Check the Link LED. It should turn ON. Wait for the green bar to appear in the LinuxIPSet after a minute or two.

9. Click on this bar to access the device’s Web interface and start uploading thenew firmware to the SD card or to the unit.

NOTE: If your Web browser displays “404 not found” or “page cannot be displayed” errors, then try pasting

http://192.168.0.100/index2.html directly to your browser’s address bar.

NOTE: If you still have a problem with the upgrade or the unit, contact Black Box Technical Support at 724-746-5500

or info@blackbox.com.

EME134A-R3

877-877-2269 | blackbox.com

Page 17

Page 18

Chapter 3: Installation

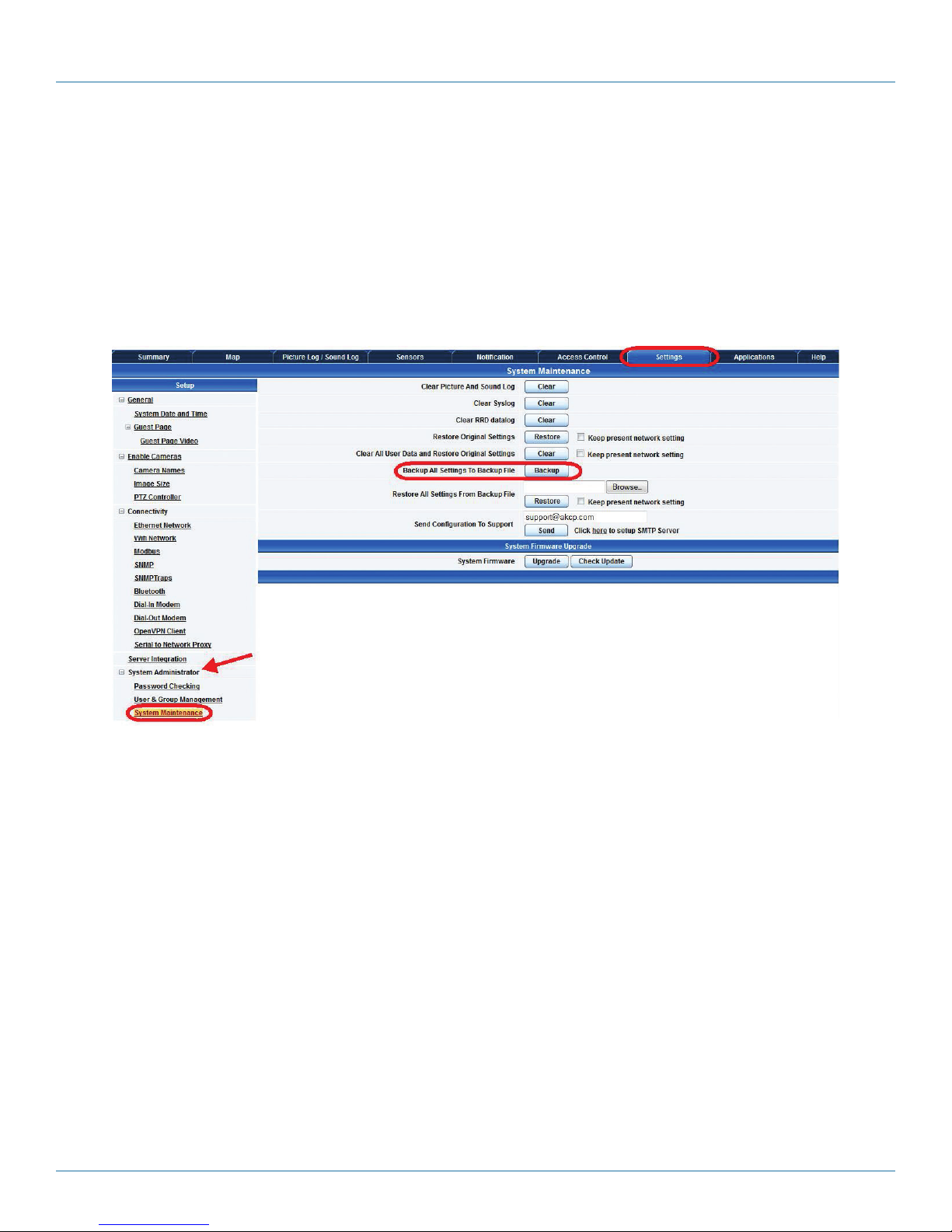

Creating a Backup Configuration File

Keep in mind that after you set up your ServSensor V4E unit and have all the settings and alerts completed, you can create a

backup configuration file. This file will contain the configuration of the unit’s settings and also the sensor settings and notification

alerts.

These backup configuration files can be loaded on other units as long as they are the same basic type. For example, you can load

a backup config file from a ServSensor V4E onto a ServSensor V4ES unit. You can also use the utility to push out the same

configuration file to multiple units on your network simultaneously.

Figure 3-13.

To create your backup config file, you first need to log in to the unit as an Administrator. Then, navigate to the

Settings page > System Administrator >System Maintenance and click on the “Backup” button as shown in the screen shot

above.

You will then browse to where you would like to store the backup file on the PC, choose the Save button, then click on the OK

button.

You can restore this or another backup file using the Restore All Settings From Backup File.

Page 18

877-877-2269 | blackbox.com

EME134A-R3

Page 19

Chapter 3: Installation

3.4 Multi-users and Groups Setup

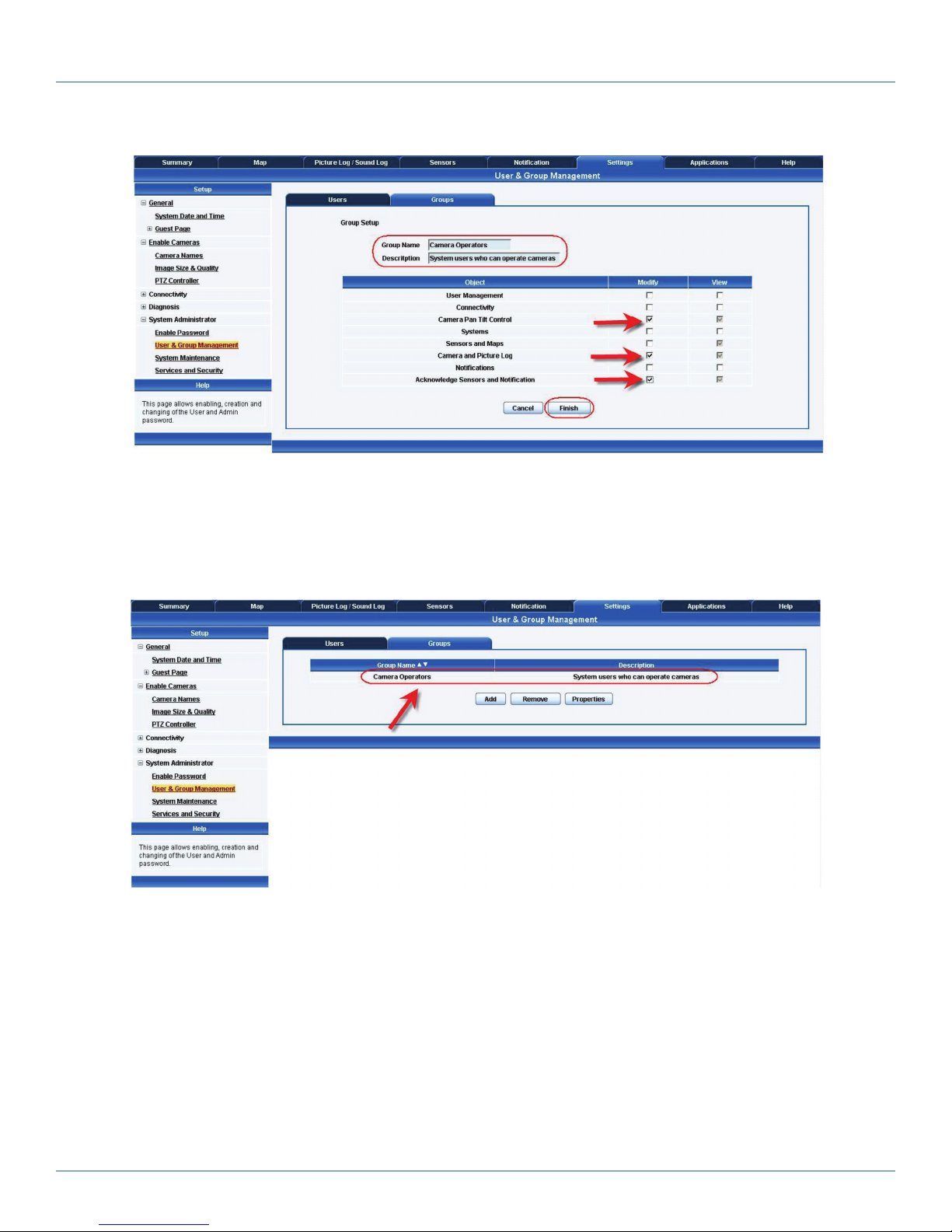

3.4.1 Group Setup

1. Log in to the ServSensor V4E with the Administrator password. The default will be “public” if you have not changed this yet.

2. Click on the Settings page, then System Adminstrator, then User & Group Management as shown in Figure 3-14.

NOTE: The following screen diagrams may appear small and hard to read. Please use the zoom feature in your PDF reader

program to increase the size of the page to better view these screen diagrams.

Figure 3-14. Group setup screen.

3. Click on the “Go to Group Setup” link that will take you to the Groups page shown in Figure 3-15.

Figure 3-15. Add button.

4. Click on the “Add” button to add your groups as shown in Figure 3-15.

EME134A-R3

877-877-2269 | blackbox.com

Page 19

Page 20

Chapter 3: Installation

s

Figure 3-16. User & Group Management screen.

5. Enter your group name. For example, we have added a group called “Camera Operators”and entered our description.

6. Check the objects with the Web interface that this group will be able to Modify and View. Then, click the “Finish” button to

save your group.

Figure 3-17. Camera Operators group added.

7. The new group “Camera Operators” has been added to our group list as shown in Figure 3-17.

Page 20

877-877-2269 | blackbox.com

EME134A-R3

Page 21

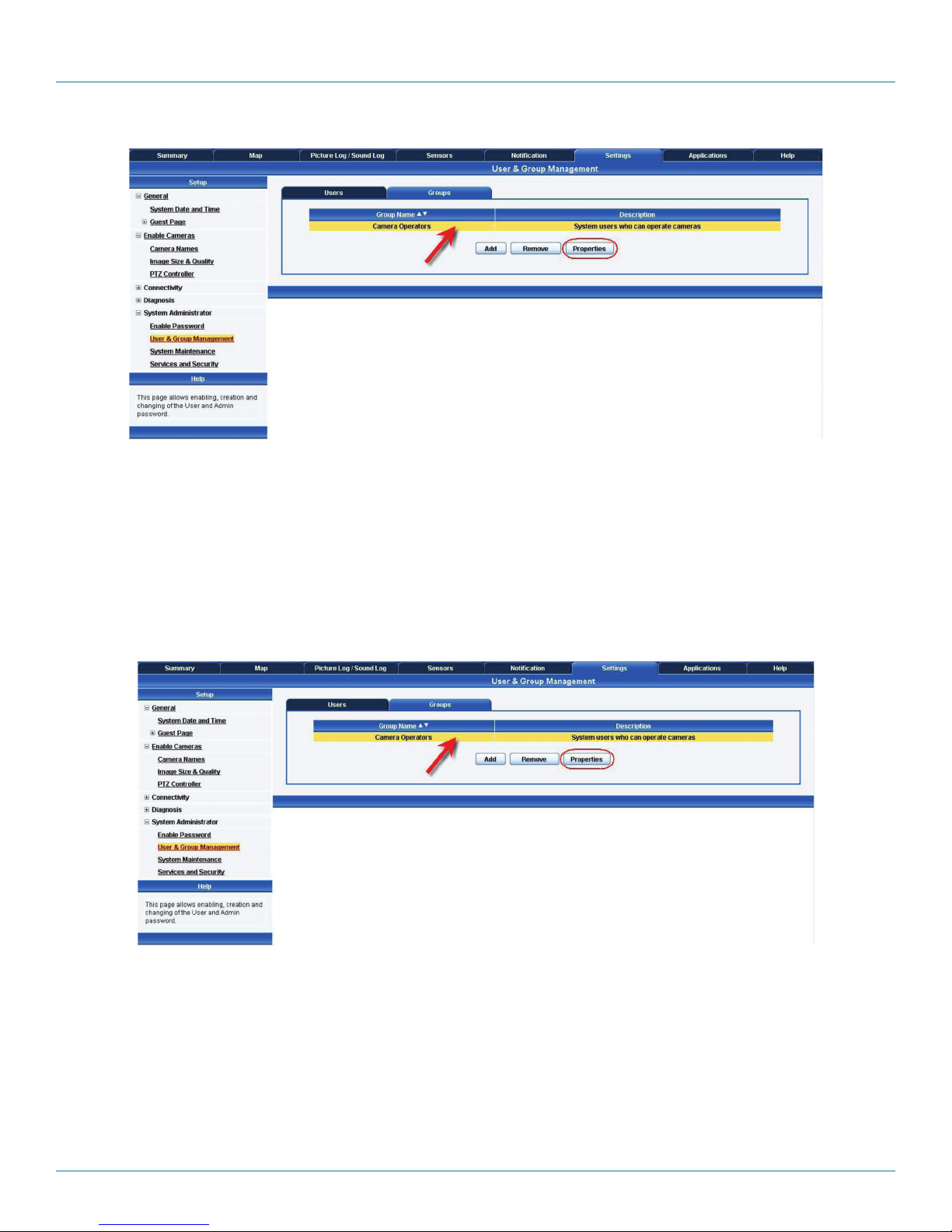

Figure 3-18. User & Group Management screen.

Chapter 3: Installation

8. If you want to modify your group settings, click on the group you want to modify. Then click on the “Properties” button as

shown in Figure 3-18.

3.4.2 User Setup

1. Click on the “Users” tab and then click the “Add” button to add the new users to your groups as shown in Figure 3-19.

Figure 3-19. User setup screen.

EME134A-R3

877-877-2269 | blackbox.com

Page 21

Page 22

Chapter 3: Installation

2. Enter your user details as shown in Figure 3-20. In our example, we have entered Bob Smith as your camera operator #1 into

our “Camera Operators” group. We have also added the option so that this user cannot change his login password. After

adding your users for each group, click the “Finish” button to save each user.

Figure 3-20. Enter user details.

3. The new user has been entered into our list of users.

Figure 3-21. User list.

Page 22

877-877-2269 | blackbox.com

EME134A-R3

Page 23

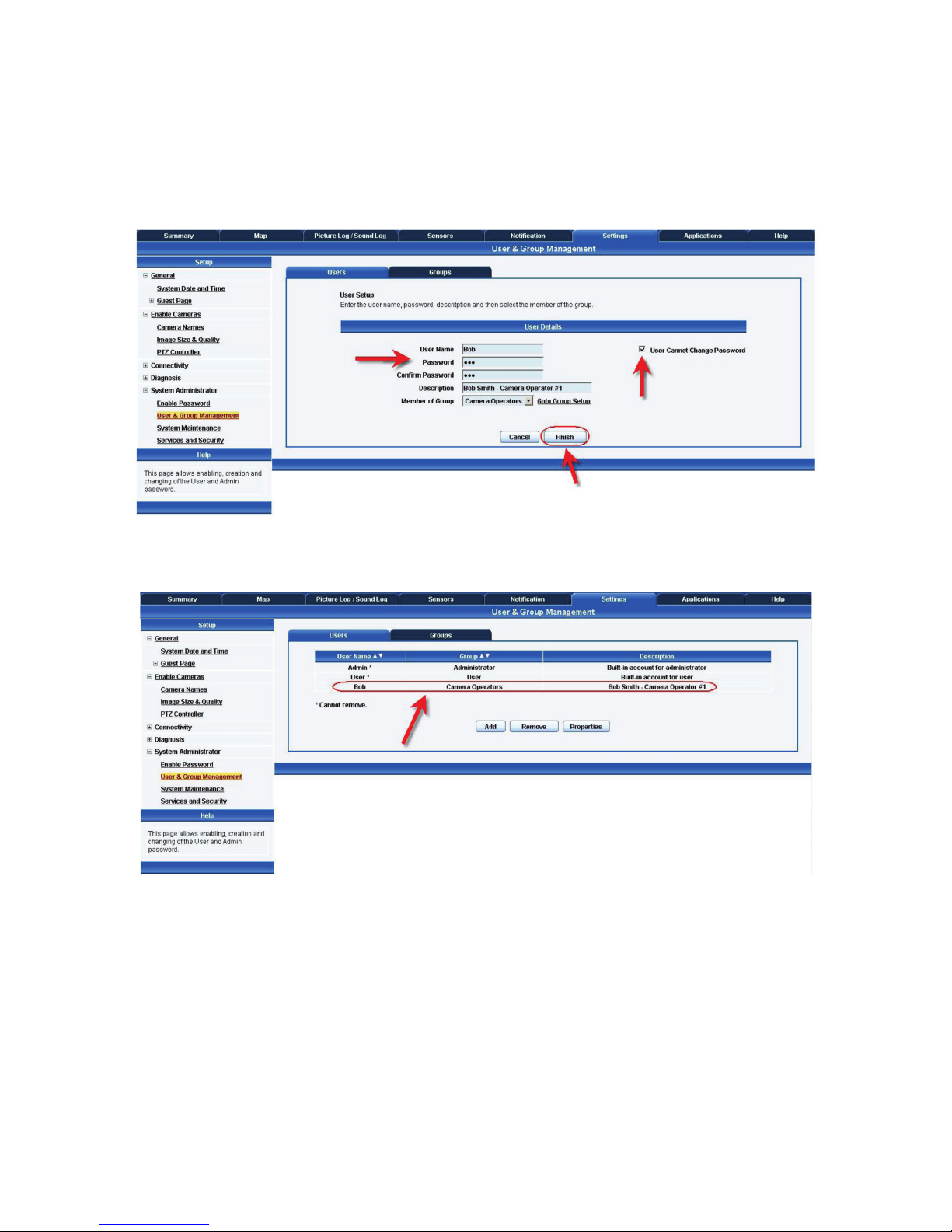

Chapter 3: Installation

4. To modify a user’s setting, click on the user to select it, then click the “Properities” button as shown in Figure 3-22.

FIgure 3-22. Properties button.

3.5 Services and Security

3.5.1 Active Services Application (disabling)

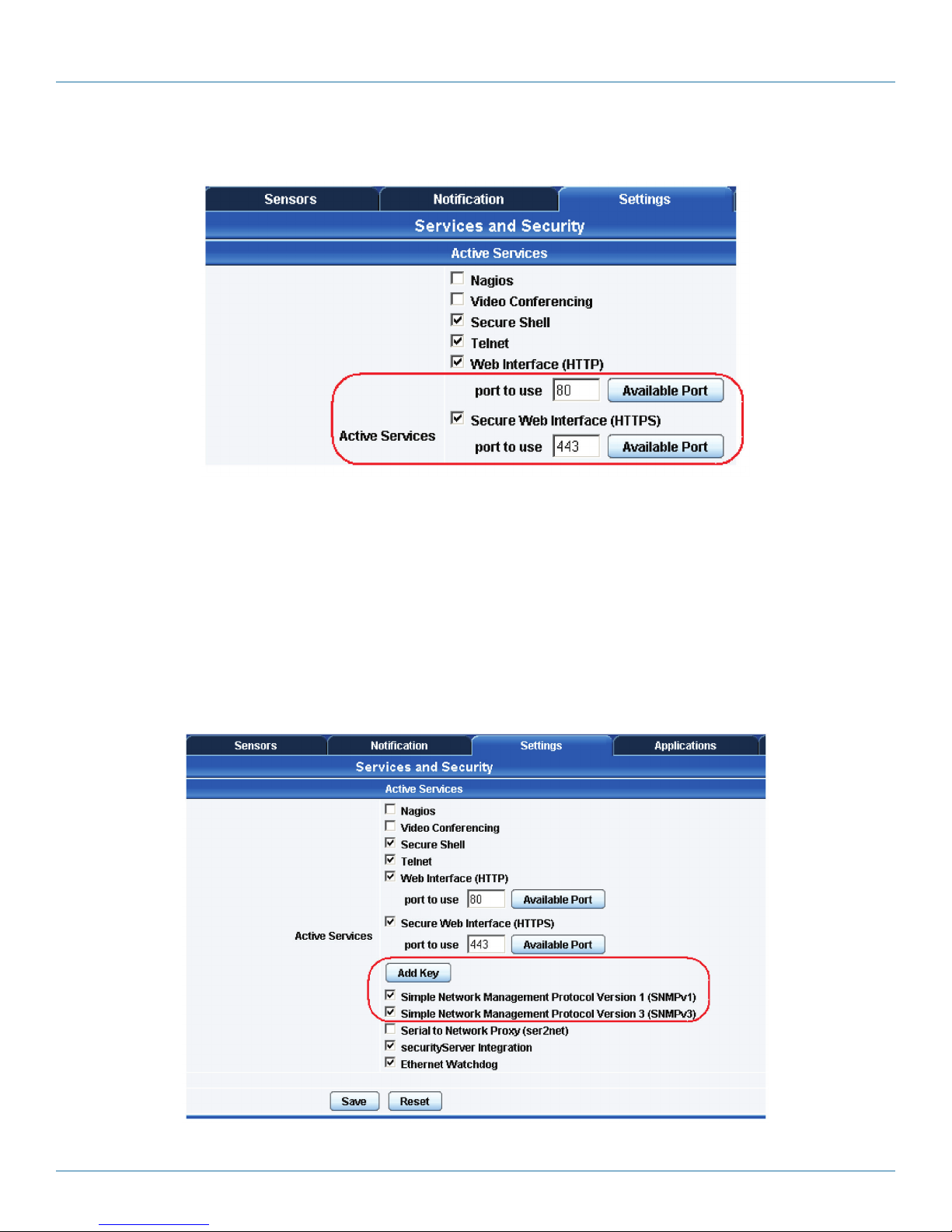

Figure 3-23. Services and Security screen.

You can enable or disable the Nagios, Video Conferencing, Secure Shell, and Telnet applications running on the unit to make it

more secure.

EME134A-R3

877-877-2269 | blackbox.com

Page 23

Page 24

Chapter 3: Installation

3.5.2 Closing or Changing Ports Disabling HTTP and Enabling HTTPS

Figure 3-24. Active services.

You can also close or change the ports used to access the unit’s Web interface, disable HTTP, and enable HTTPS only.

The “s” at the conclusion of HTTPS stands for secure. The SSL/TLS connection type is used primarily for high-value sites or

“pages,” to make it more likely to be unreadable to someone at the end points.

The traffic between client and the ServSensor V4E is not cached along the various units as it moves across the Internet, so it can’t

be accessed by someone after the connection is terminated.

3.5.3 The SNMPv3 SSL Security Feature

Page 24

Figure 3-25. Add Key screen.

877-877-2269 | blackbox.com

EME134A-R3

Page 25

Chapter 3: Installation

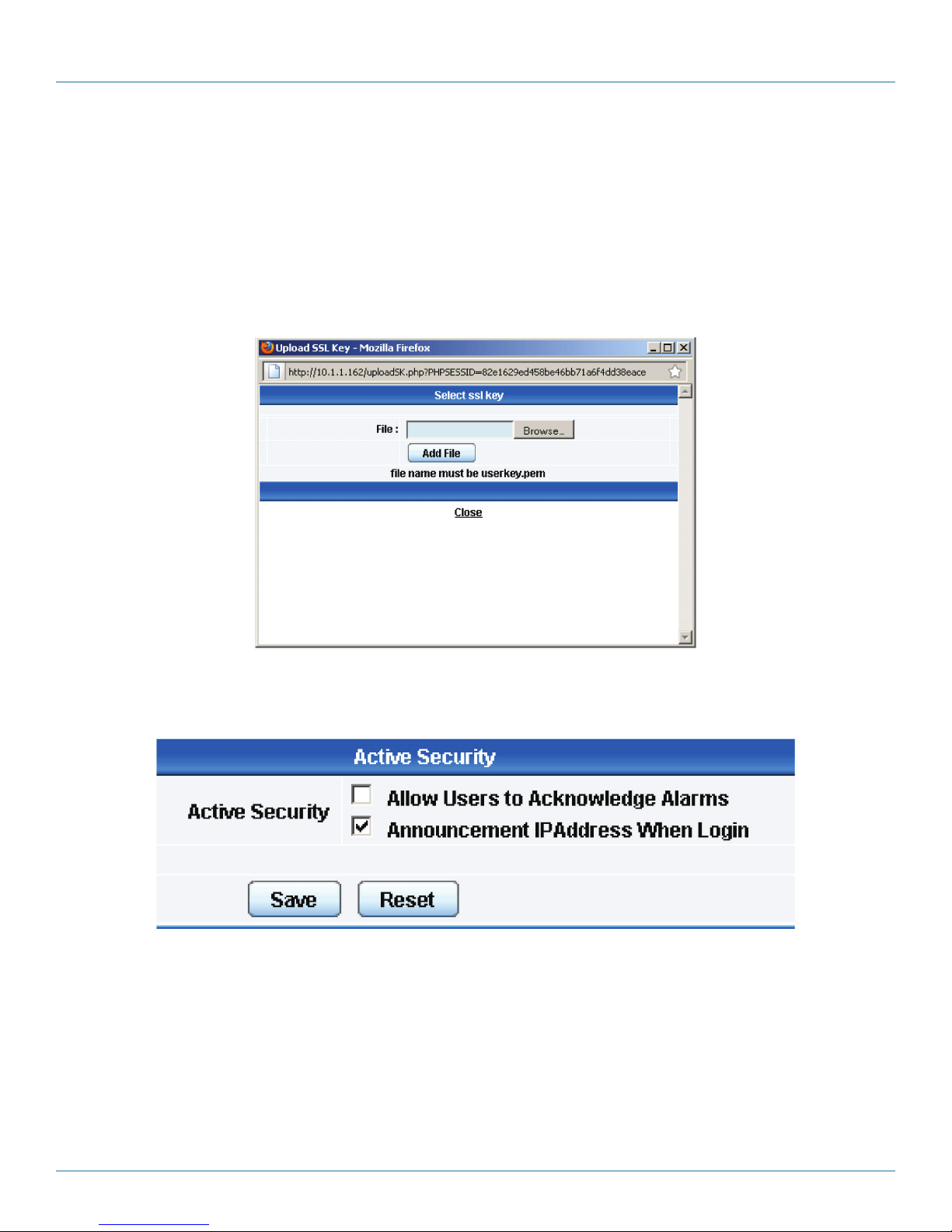

Use the SNMPv3 SSL (Secure Sockets Layer), which is the standard security technology for establishing the encrypted link betwen

the ServSensor and the Web browser. The link ensures that all data passed between the ServSensor and the browser remains

private and integral.

SNMPv3 provides important security features:

• Confidentiality—Encrypts packets to prevent snooping by an unauthorized source.

• Integrity—Message integrity to ensure that a packet has not been tampered with in transmit.

• Authentication—To verify that the message is from a valid source.

Figure 3-26. Select SSL Key screen.

3.5.4 Active Security

Figure 3-27. Network Access Control screen.

In the active security section, you can enable users who are logged into the unit’s Web interface to “Acknowledge” alarms, which

is normally reserved only for the Administrator.

When the unit boots up, it will announce the IP address that it has been configured with. As an added security feature, this

announcement can be disabled so that the IP address remains unknown.

EME134A-R3

877-877-2269 | blackbox.com

Page 25

Page 26

Chapter 3: Installation

3.5.5 The NAC or Network Access Control Security Feature

The NAC or Network Access Control feature enables you to restrict access to the Web interface for only certain IP addresses, or

deny access to the Web interface for only certain IP addresses.

Figure 3-28. NAC security screen.

3.6 Setting Up a Sensor

This section describes the basic setup of a sensor, using a Black Box temperature sensor as an example. If you require information

on specific functions of a particular sensor, then download the manual for that sensor from our Web site, www.blackbox.com.

1. Plug the sensor into one of the RJ-45 “intelligent sensor ports” on the ServSensor’s rear panel. In this example, we will use

Port 1. See Figure 3-29.

Figure 3-29. Intelligent sensor Port 1.

Page 26

877-877-2269 | blackbox.com

EME134A-R3

Page 27

Chapter 3: Installation

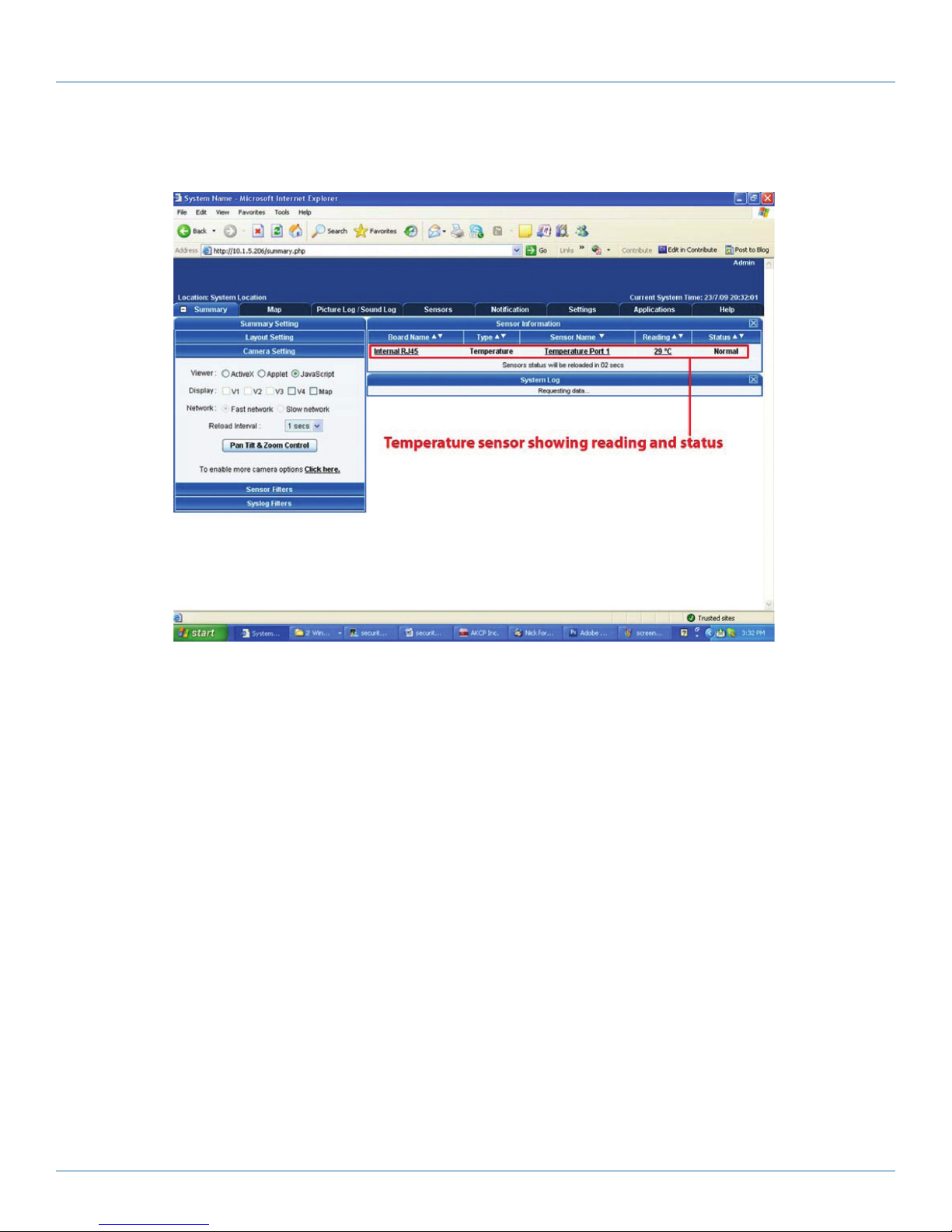

2. Point your browser to the ServSensor’s IP address (the default is 192.168.0.100). Log in as the administrator using your

administrator password (the default is “public”). You will then be taken to the summary page shown in Figure 3-30.

Figure 3-30. Summary page.

The temperature sensor should be listed, along with its current reading and status. If this is not shown, go to Chapter 9.

This summary page enables you to quickly see which sensors are connected and their status, view the system log, and also view

footage from any connected cameras. Next are some of the tools the Web-based interface provides for getting feedback from

the sensors.

EME134A-R3

877-877-2269 | blackbox.com

Page 27

Page 28

Chapter 3: Installation

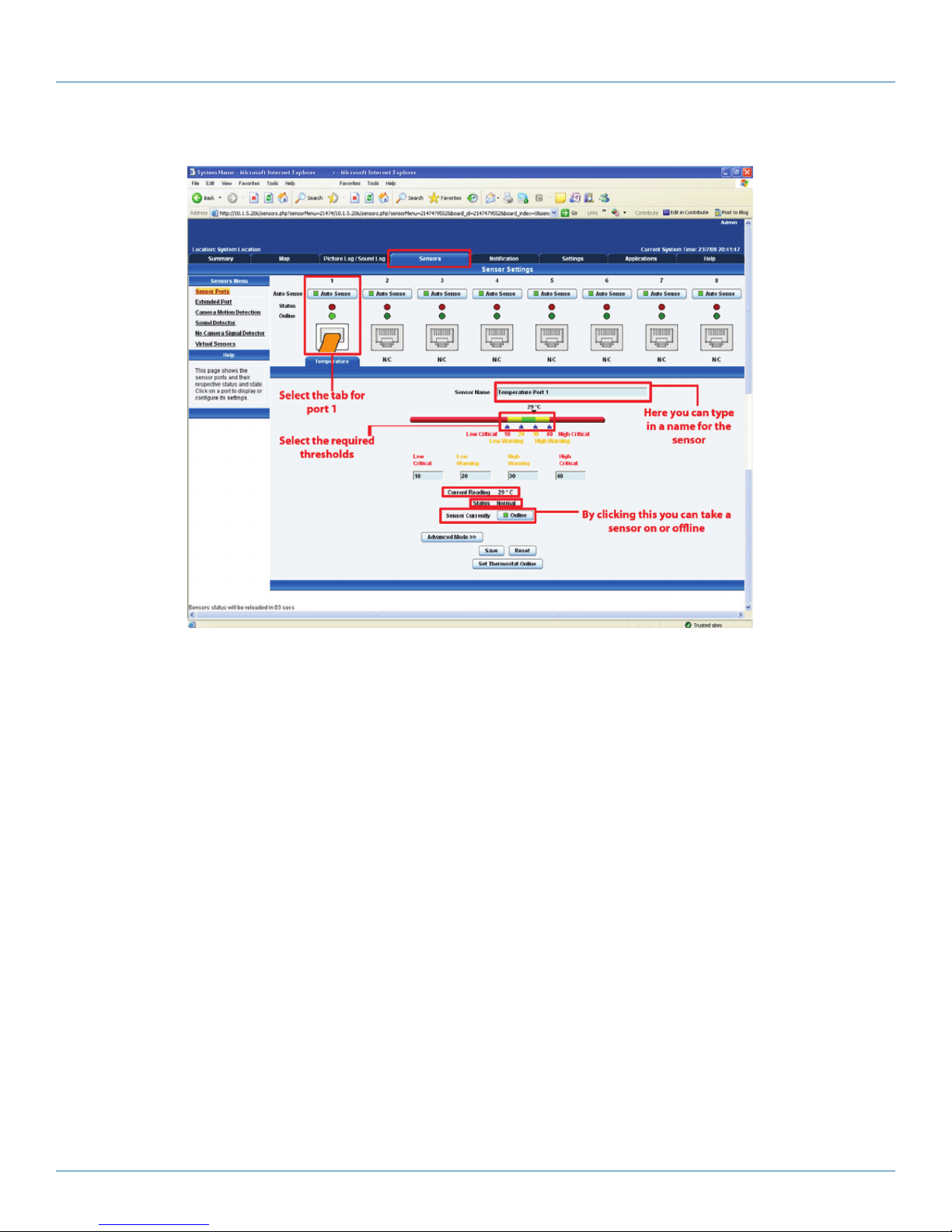

3. Click on the temperature sensor’s name (indicated in Figure 3-29). This will bring you to Figure 3-31, the Sensors page.

Figure 3-31. Sensors page.

NOTE: Another way to access this page is to click on the “Sensors” tab at the top of the page.

3.6.1 Notification Thresholds

From this page, you can carry out various operations as indicated above. You can also view the current status (normal, low critical,

high critical, etc). In Figure 3-30, the sensor indicates a temperature of 29° C and a status of Normal. If you click on the blue

marker arrow next to the “Set the required threshold” label (shown in Figure 3-31), you can drag this marker to re-configure the

thresholds. After dragging the marker, click “Save.” In Figure 3-31, you can see that this marker has been moved to make a new

threshold, and the sensor status has changed along with it.

Page 28

877-877-2269 | blackbox.com

EME134A-R3

Page 29

Chapter 3: Installation

Figure 3-32. High critical status shown.

If the marker is then dragged back above the current temperature reading, the status should return to a normal condition again.

NOTE: If this does not happen right away, press the browser’s refresh button.

Figure 3-33. Normal status indicated.

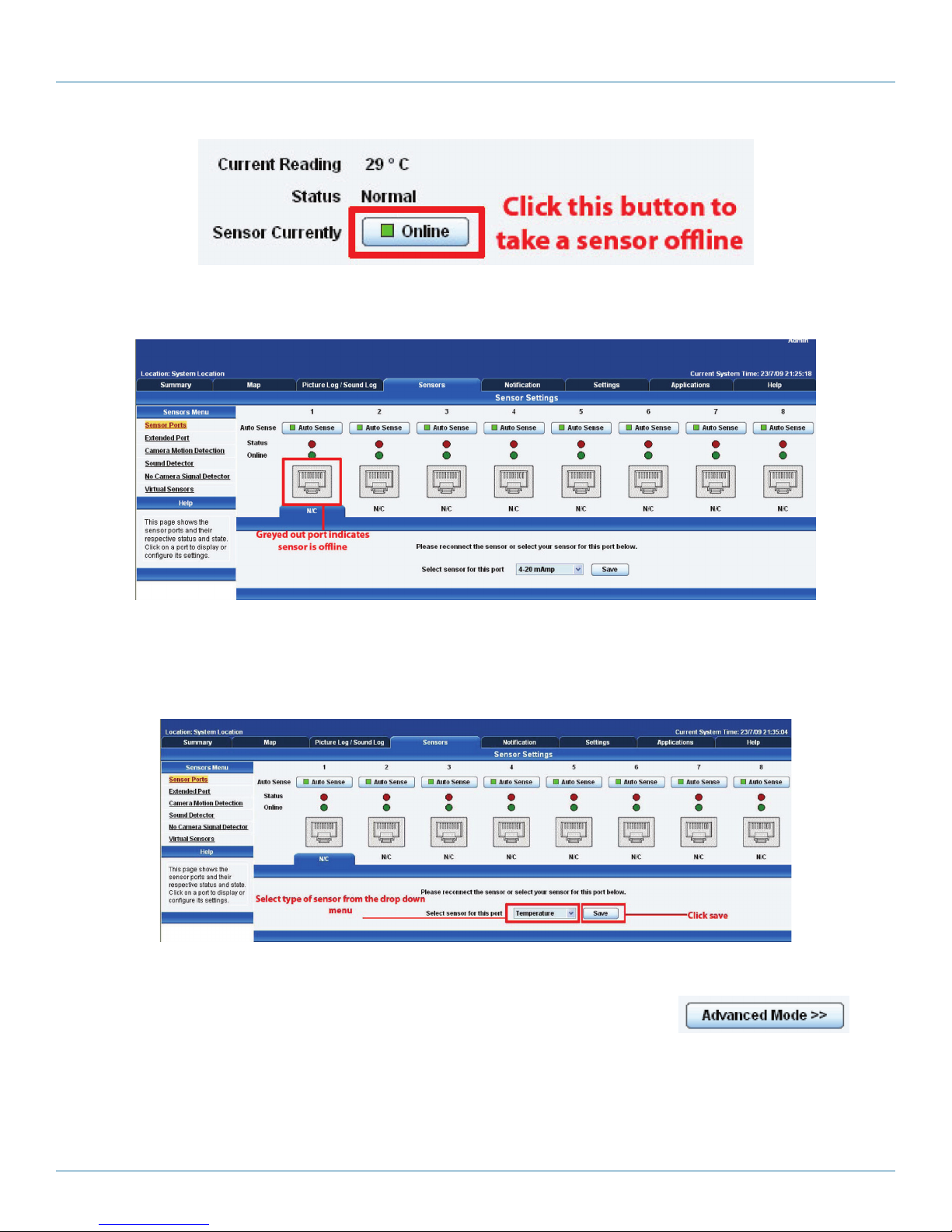

If you want to take a sensor offline, then click on the “sensor currently” button. This will place the sensor offline and you won’t

have to physically unplug it. See Figure 3-33.

EME134A-R3

877-877-2269 | blackbox.com

Page 29

Page 30

Chapter 3: Installation

Figure 3-34. Sensor Online/Offline screen.

Your page will look similar to Figure 3-35 after you take the sensor offline.

Figure 3-35. Sensor Offline screen.

To bring a sensor back online, select the type from the drop-down menu and click “Save.” See Figure 3-36.

Figure 3-36. Select Sensor Type screen.

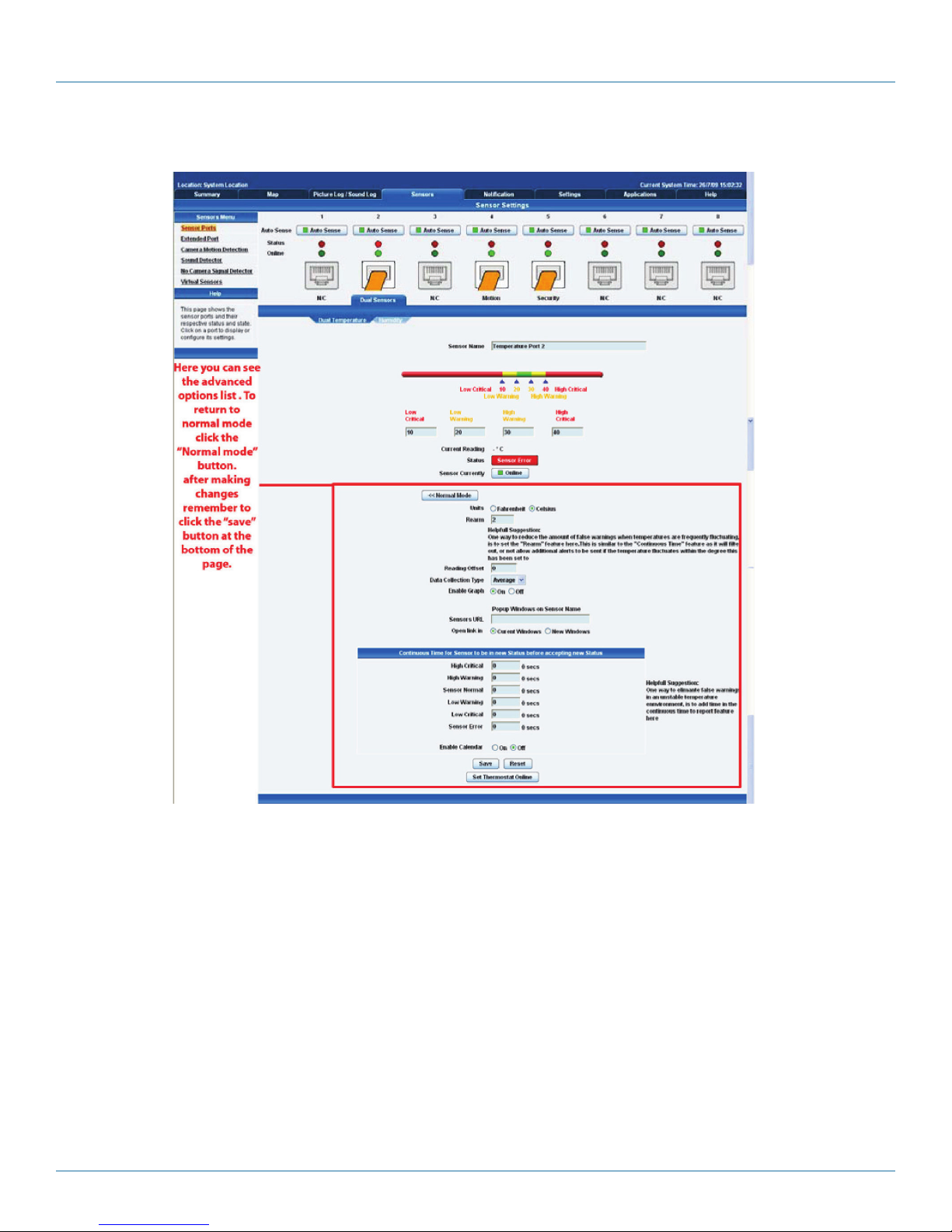

3.6.2 Advanced Sensor Settings

Near the bottom of the sensors page, you will see the Advanced Mode button (shown at right).

Click on this button to get the options shown in Figure 3-37.

Page 30

877-877-2269 | blackbox.com

EME134A-R3

Page 31

Chapter 3: Installation

EME134A-R3

Figure 3-37. Advanced sensor screen.

877-877-2269 | blackbox.com

Page 31

Page 32

Chapter 3: Installation

Advanced Mode Functions:

Figure 3-38.

Units: Changes units from C to F or vice versa

Rearm:

Figure 3-39.

The Rearm parameter is useful for sensors, such as the temperature and humidity sensors, since their values can vary.

This prevents the sensor from flickering between two states. For example, if the Warning High threshold for the temperature

sensor is set to 80 degrees, and the sensor temperature varies between 79 and 80, you might receive a very large number of

e-mails, traps, and events logged. The Rearm parameter prevents this by forcing the temperature to drop by the Rearm value

before changing the state back to normal. In this example, if Rearm is set to 2, then the sensor would have to drop from 80

down to 77 before the status would change from Warning High back to normal.

Page 32

877-877-2269 | blackbox.com

EME134A-R3

Page 33

Reading offset:

Chapter 3: Installation

Figure 3-40.

The Reading Offset is a calibration tool. If you want to calibrate the temperature sensor, for example, you could enter an offset

value of 5. This means that if the sensor reads 20 degrees then it would record as 25 degrees. This figure can also be a minus figure (for example, -5 would show 15 degrees instead of 20).

EME134A-R3

877-877-2269 | blackbox.com

Page 33

Page 34

Chapter 3: Installation

Data Collection Type:

Data Collection Type refers to the data collection from the sensor and how the data is then displayed on the graphs.

There are three options for the collection of data. Average, Highest, and Lowest. The default setting is “Average.”

When the data collection type is set to “Average,” the output graphs for the daily, monthly, and yearly are the same size on the

screen. For the daily graph, each data point on the graph is one data point collected from the sensor. But, for the monthly and

yearly graph, in order to display more data into the same size as the daily graph, some consolidation on the data is needed. One

data point on the monthly and yearly graph is an average of the sensor data in a range.

The maximum and minimum values showing on the monthly and yearly graphs are the value of this consolidated data and not

the raw data over that period of that time.

The When the Data Collection Type is set to the Highest setting, then you will get the graphing output displaying the sensors

highest reading. This is the same for the Lowest setting.

Page 34

Figure 3-41.

877-877-2269 | blackbox.com

EME134A-R3

Page 35

Display Style:

Chapter 3: Installation

Figure 3-42.

You can keep the sensor’s “Display Style” in the Web interface as the basic style (the slide bar style) or you can change it to the

“Gauge Style” type.

Figure 3-43.

When switching to the gauge style type, you will first be prompted with the popup dialog box shown above.

EME134A-R3

877-877-2269 | blackbox.com

Page 35

Page 36

Chapter 3: Installation

Figure 3-44.

You will now see the new display where you can set the sensor’s threshold levels as shown above.

Figure 3-45.

Page 36

877-877-2269 | blackbox.com

EME134A-R3

Page 37

Chapter 3: Installation

After clicking on the “Advanced Settings” tab, you can change the text and colors for each sensor threshold as shown in the

previous screen.

Check rate of change:

Figure 3-46.

When enabling the “check rate of change” feature for this sensor, you can set the rate in a percentage from 1% to 50% over a

period of time from 1 to 20 minutes. You can set the direction to Up, Down, or Both and you can set the Status when the limit is

exceeded to show either High Critical or Low Critical.

Now you can tie this sensor alert to any notification.

EME134A-R3

877-877-2269 | blackbox.com

Page 37

Page 38

Chapter 3: Installation

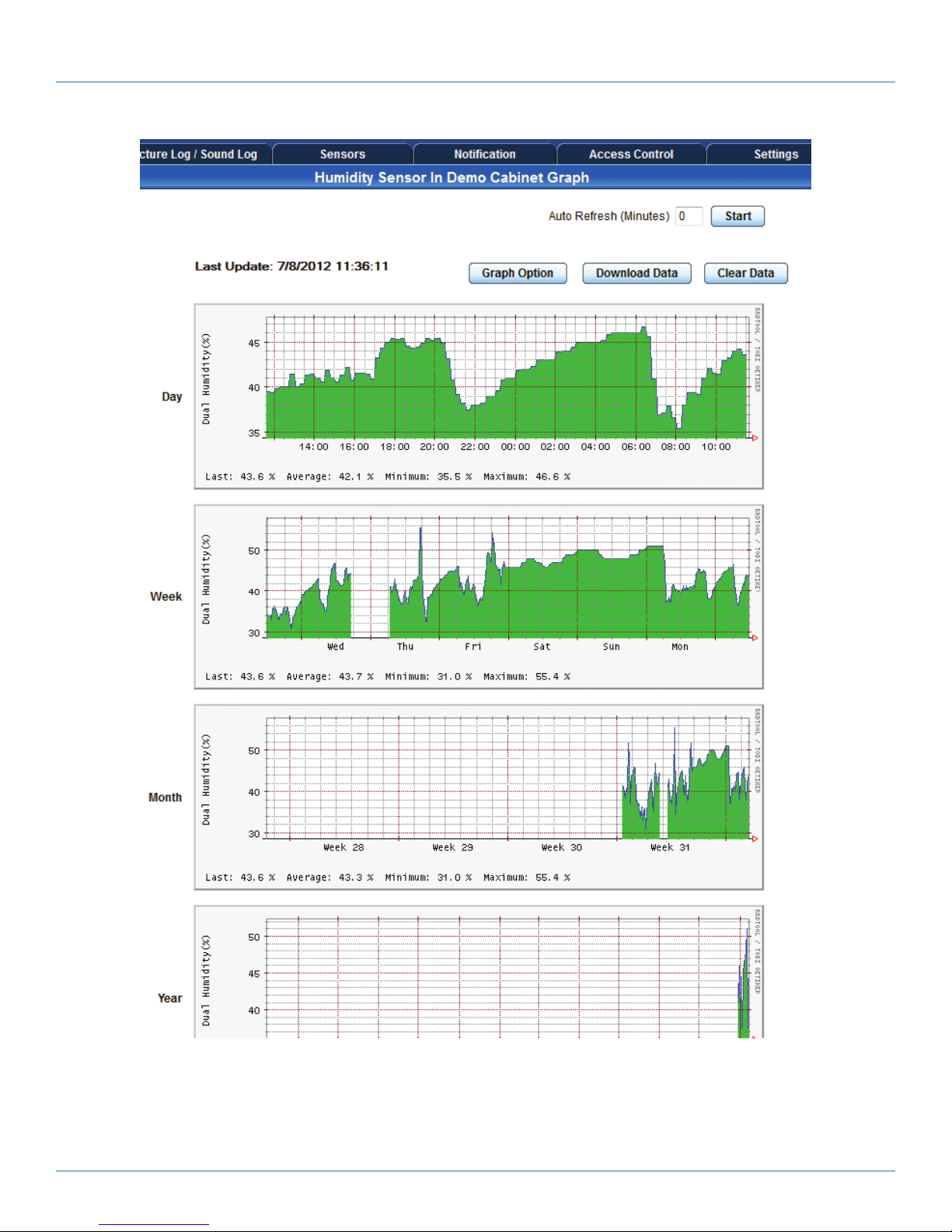

Graphing Sensor Data:

Figure 3-47.

To save the data from the sensors on the ServSensor V4E, you will need to enable the Graphing feature on the unit. You need to

change the Enable Graph to the On position and click on the Save button to enable the graphing.

Page 38

877-877-2269 | blackbox.com

EME134A-R3

Page 39

Chapter 3: Installation

After clicking on the “Click Here to View Graph” link shown in the screen shot on the previous page, you will then see the graphs

for this sensor.

EME134A-R3

Figure 3-48.

877-877-2269 | blackbox.com

Page 39

Page 40

Chapter 3: Installation

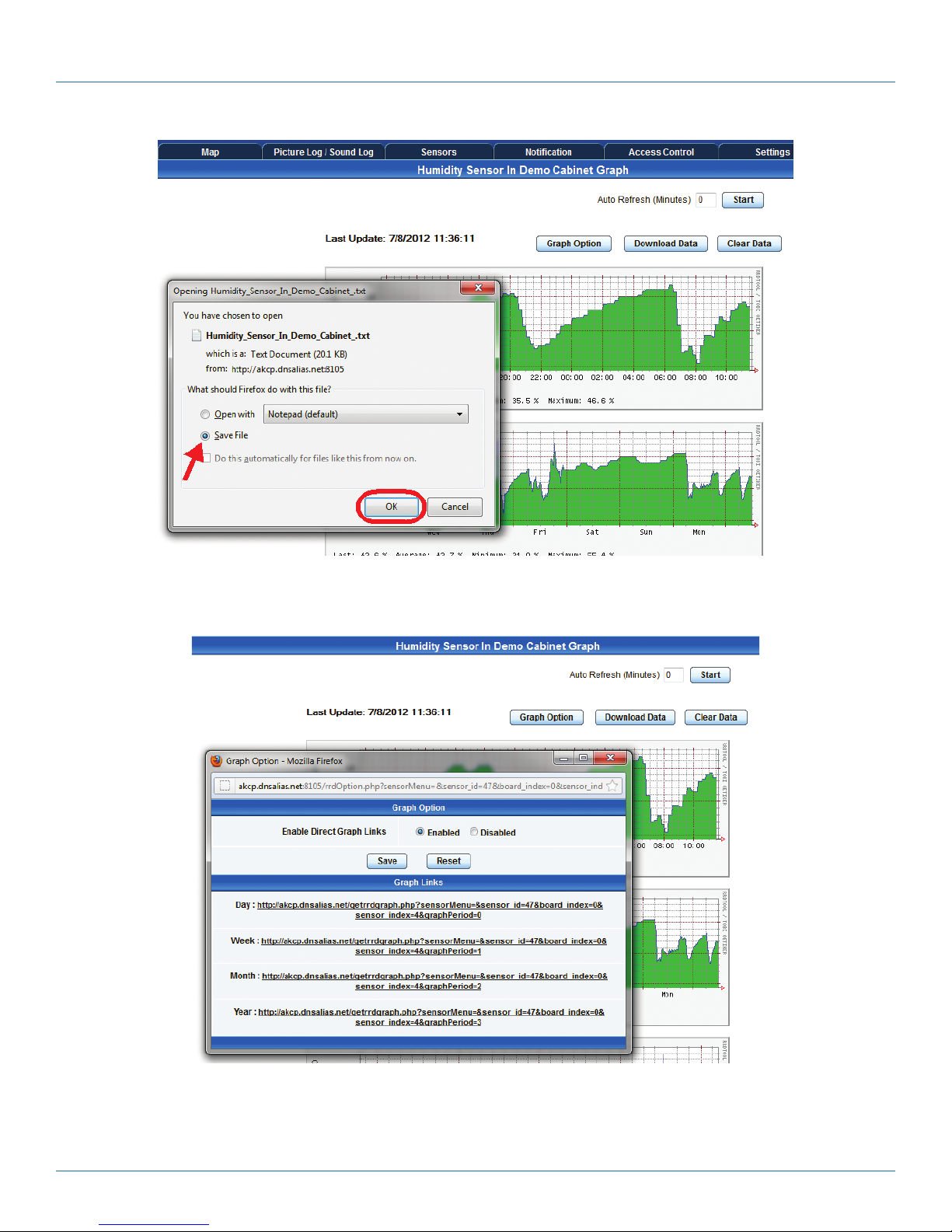

You can download the sensor data to a text file by clicking on hte “Download Data” button shown in the screen above.

Page 40

Figure 3-49.

877-877-2269 | blackbox.com

EME134A-R3

Page 41

Chapter 3: Installation

The popup box will display as shown in the screen above.

Figure 3-50.

You can also set the graph options by clicking on that button , then enabling the graphing page URLs as shown in the screen

above.

EME134A-R3

Figure 3-51.

877-877-2269 | blackbox.com

Page 41

Page 42

Chapter 3: Installation

Figure 3-52.

The Sensors URL feature in the Advanced Settings tab is the optional Hyperlink URL for each sensor.

This feature allows you to add a Hyperlink to a sensor, then this link will be displayed in the ServSensor V4E 5E’s mapping feature

for that sensor (see the screen shot below).

Page 42

Figure 3-53.

877-877-2269 | blackbox.com

EME134A-R3

Page 43

Chapter 3: Installation

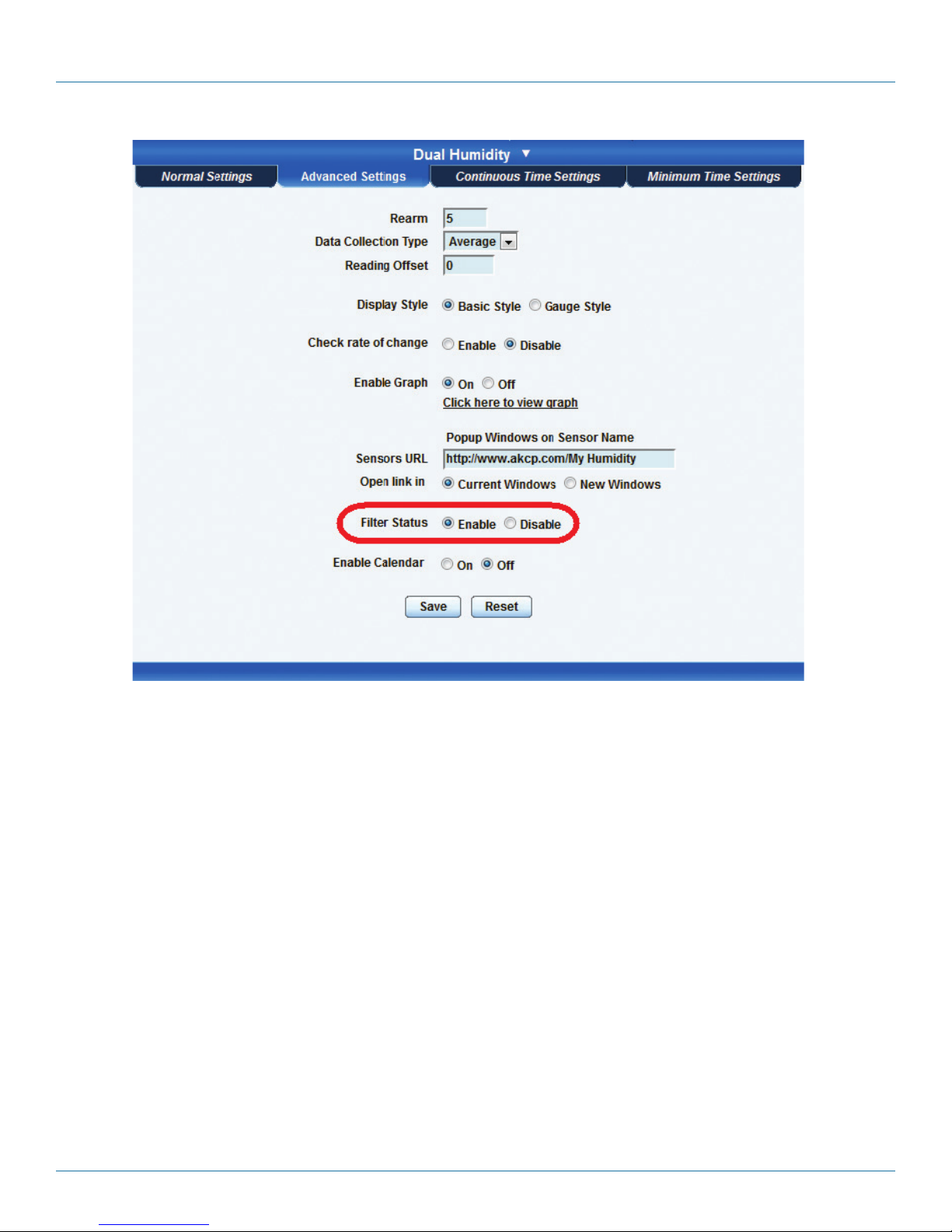

F1

Figure 3-54.

The Sensor Filter Status is a a feature that you can Enable or Disable. If the status of the sensor changes very rapidly, then it will

report how many times the sensor status changed, instead of having 36 separate entries in the syslog entry. This reduces writing

to the flash and improves performance.

EME134A-R3

877-877-2269 | blackbox.com

Page 43

Page 44

Chapter 3: Installation

Enable Calendar: If you select this option then the following will be displayed:

Figure 3-55.

In our example, we monitor an office building between the hours of 7 PM–9 AM, Monday–Friday only. In this picture, we have

selected the “Do Not Report” option for the hours that we do not wish to receive any notifications for or have any events logged.

You change the status of that time frame (Report / Do Not Report) by simply clicking on the square. This will change it from blue

to gray; a second click will return it to blue.

Figure 3-56.

Page 44

877-877-2269 | blackbox.com

EME134A-R3

Page 45

Continuous Time Settings Tab

Chapter 3: Installation

Figure 3-57.

The following advanced functions are for setting the time frame in which the system should delay a notification being triggered

when a sensor gives a reading that exceeds the thresholds (high warning, normal, etc).

Continuous Time to Report High Critical: This helps to eliminate unnecessary messages during minor fluctuations. You can set the

amount of time to delay a notification of a status change from high warning to high critical. Enter the time in seconds and press

the “Save” button. The amount of time that can be entered is between 0 and 65535 seconds, which equals approximately 18

hours

Continuous Time to Report High Warning: As above, but delays notification for “High Warning.”

Continuous Time to Report for Normal: As above, but delays notification for return to “Normal” state.

Continuous Time to Report for Low Warning: As above, but delays notification for “Low Warning” state.

Continuous Time to Report for Low Critical: As above, but delays notification for “Low Critical” state.

Continuous Time to Report for Sensor Error: As above, but delays notification being sent for sensor going into an error state.

Example: An airflow sensor or humidity sensor may have temporary drops in readings that are normal operating characteristics; a

logical time limit is set to show abnormal conditions.

EME134A-R3

877-877-2269 | blackbox.com

Page 45

Page 46

Chapter 3: Installation

Minimum Time Settings Tab

Figure 3-58.

Minimum Time Status prevents the status from fluctuating within the time set. For example, a sensor can only show a high critical

state once within 3 seconds, if the value is set to 3 seconds.

Page 46

877-877-2269 | blackbox.com

EME134A-R3

Page 47

Chapter 3: Installation

3.7 Using an Internal Mic as a Sound Detection Sensor

You can use the internal microphone (or an external microphone plugged into the line-in jack) as a sound detector.

This tutorial provides you the information you need to set up the internal mic as a sound detection sensor.

To get to the starting point of this tutorial:

• Log into the Web based interface.

• Click on the Sensors tab.

Figure 3-59.

• Click “Sound Detector” under the Sensors menu. See Figure 5-39.

• Click “Advanced Mode.”

• After you click on the Advanced Mode button, you’ll see the advanced options available.

EME134A-R3

877-877-2269 | blackbox.com

Page 47

Page 48

Chapter 3: Installation

Recording Source: Here you can choose either internal or external microphone.

Microphone Boost (+20 dB): Boosts the microphone by 20 dB.

Microphone Sensitivity: The level of sensitivity that can be set.

For example, if you set the level to 80, the microphone will detect more sound than if the level were set at 20.

Pulse Length: This defines the minimum duration of a sound to trigger an alert notification.

Rearm: The Rearm parameter prevents the sensor from flickering between two states. For example, if the Warning High thresh-

old for the sound sensor is set to 80 and the sensor temperature varies between 79 and 80, a very large number of e-mails, traps,

and events would be logged. The Rearm parameter prevents this by forcing the signal level to drop by the Rearm value before

changing the state back to normal. In this example, if Rearm is set to 2. then the sensor would have to drop from 80 down to 77

before the status would change from Warning High back to normal.

Data Collection Type: There are three settings for this parameter: lowest, highest, and average. Data will be collected for the

lowest, highest, or average sound reading accordingly.

NOTE: As with all the other sensors, you can now set up the sound detector to be attached to a notification. Then, when your

thresholds are broken, it will trigger a specified type of notification.

Page 48

Figure 3-60.

877-877-2269 | blackbox.com

EME134A-R3

Page 49

Chapter 3: Installation

3.8 Expansion Ports

The ServSensor has two expansion ports that enable you to connect up to four daisychainable expansion modules. The available

expansion modules are an 8-port intelligent sensor board (EME1X8) and an opto-isolated (16) dry-contact expansion module

(EME1DC16). In this section, we will go through the basic setup of the 8-port intelligent sensor board. If you need information on

specific functions of a particular sensor or expansion board, then please refer to the relevant manual for that product.

1. Plug the expansion board into one of the four ports located on the front panel of the unit. These are numbered E1–E2.

Figure 3-61. Plug expansion boards into these ports.

2. From the summary page, navigate to the “Sensors” tab. Then click “Expansion ports” as outlined in Figure 3-62.

EME134A-R3

Figure 3-62. Sensors tab, extended port option.

877-877-2269 | blackbox.com

Page 49

Page 50

Chapter 3: Installation

Figure 3-63.

3. A list of all extended ports will be shown. Each port will display any available extension modules, which will be highlighted in

green. Click on the module to go to the sensor settings page.

Page 50

Figure 3-64. Extended Port1 selection.

877-877-2269 | blackbox.com

EME134A-R3

Page 51

4. This will bring you to the Extended Port Sensors page (see Figure 3-65).

Chapter 3: Installation

Figure 3-65. Extended Port Sensors page.

5. Once you have clicked on the “Dual sensors” tab, you will be directed to the Notification Thresholds page (see Figure 3-66).

From this page, you can carry out various operations as indicated in the sensor settings tutorials.

EME134A-R3

877-877-2269 | blackbox.com

Page 51

Page 52

Chapter 3: Installation

Figure 3-66. Notification thresholds page.

Page 52

877-877-2269 | blackbox.com

EME134A-R3

Page 53

Chapter 4: Notifications

4. Notifications

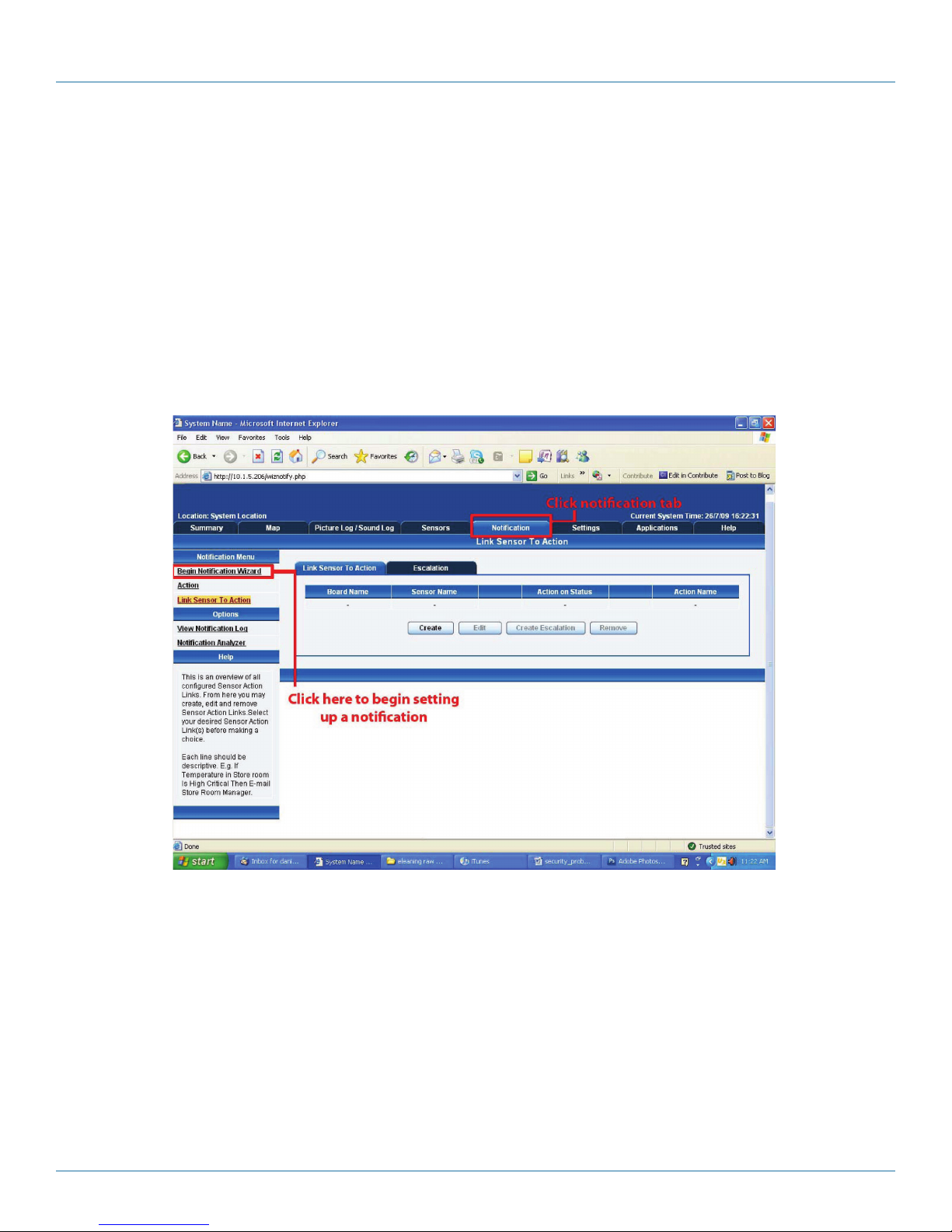

If you set up a notification, you can define the action to take when the sensor gives a reading beyond your set thresholds. This

enables you to determine how you will be notified that a sensor’s reading has reached the specified parameters (high warning,

critical, etc.) described in Chapter 3.

This tutorial provides you with the information you need to set up a notification.

To get to the starting point of this tutorial:

• Login as administrator.

• Click the “Notifications” tab.

4.1 Adding a Notification

1. Click on the “Begin Notification Wizard” tab as shown in Figure 4-1.

EME134A-R3

Figure 4-1. Notification Wizard tab.

877-877-2269 | blackbox.com

Page 53

Page 54

Chapter 4: Notifications

2. The Notification Wizard page will be displayed as shown in Figure 4-2.

Figure 4-2. Notification Wizard page.

Next, you’ll see a few different ways to set up a notification step-by-step.

4.2 SNMP Trap

If you set up a notification via an SNMP trap, when your sensor reaches a certain threshold, it will send a notification to your

SNMP server.

This tutorial provides you the information you need to set up an SNMP trap.

To get to the tutorial’s starting point:

• Log in as administrator.

• Click the “Notifications” tab.

• Choose “Notifications Wizard.”

• Choose “SNMP Trap.”

Page 54

877-877-2269 | blackbox.com

EME134A-R3

Page 55

Chapter 4: Notifications

1. After selecting to add an SNMP trap, you will need to fill in the following information shown in Figure 4-3.

Figure 4-3. Add an SNMP trap.

2. Once this information is correct, click the “Add Trap Destination” button. Input another trap or click on “Next.” Enter the

parameters shown in Figure 4-4.

These parameters set the maximum number of times to send the trap notification and the time interval between each

notification.

EME134A-R3

Figure 4-4. Notification parameters.

877-877-2269 | blackbox.com

Page 55

Page 56

Chapter 4: Notifications

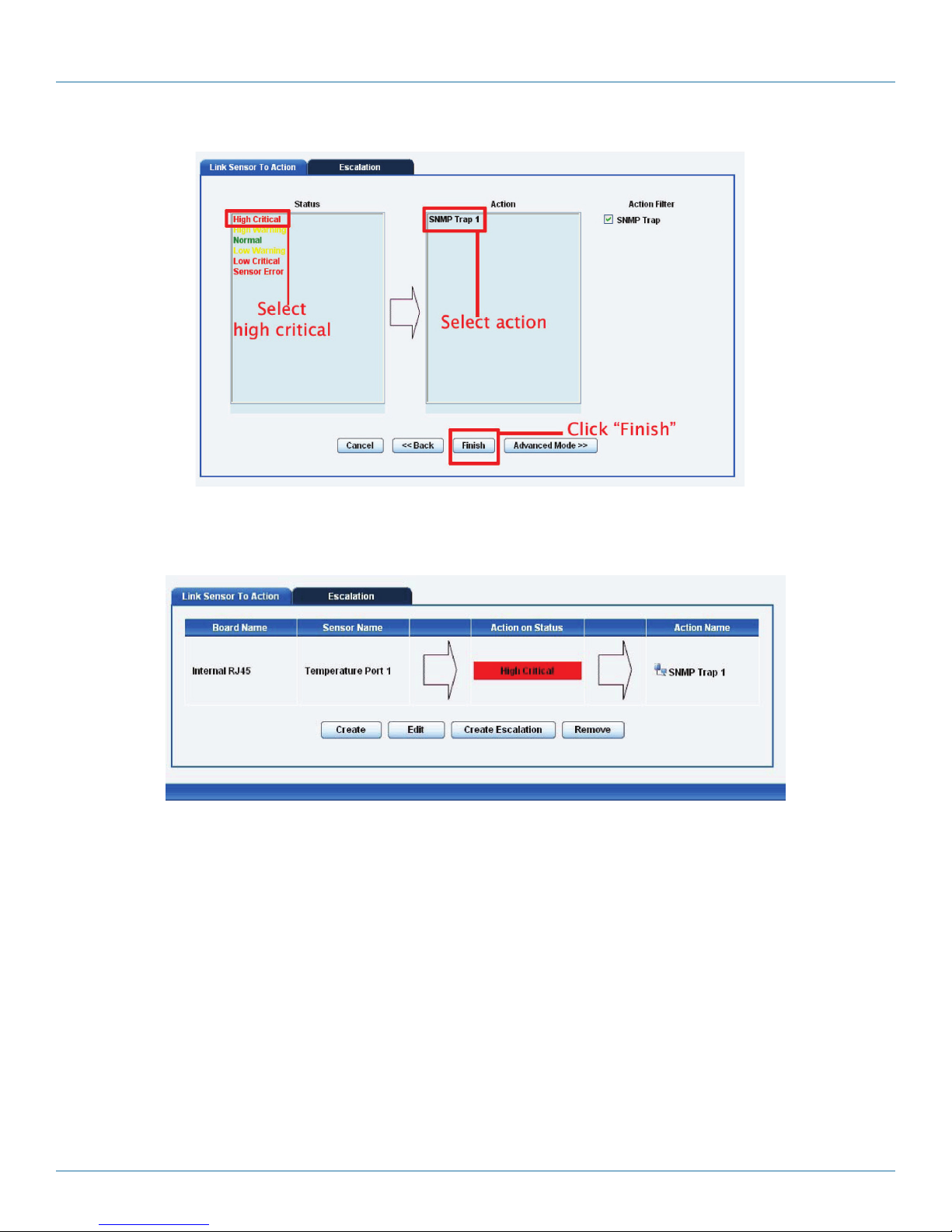

3. After clicking “Next,” you’ll see the screens shown in Figures 4-5 and 4-6.

Figure 4-5. Parameter Selection, screen #1.

Figure 4-6. Parameter Selection, screen #2.

On these screens, you can select the parameters for when to send the SNMP trap notification. In this example, we selected to

bind the SNMP trap to the temperature sensor connected on Port 1. The trap will be sent when the sensor reads a “High Critical”

and we bind this to the SNMP trap we just created and named “SNMP Trap 1.”

Page 56

877-877-2269 | blackbox.com

EME134A-R3

Page 57

Chapter 4: Notifications

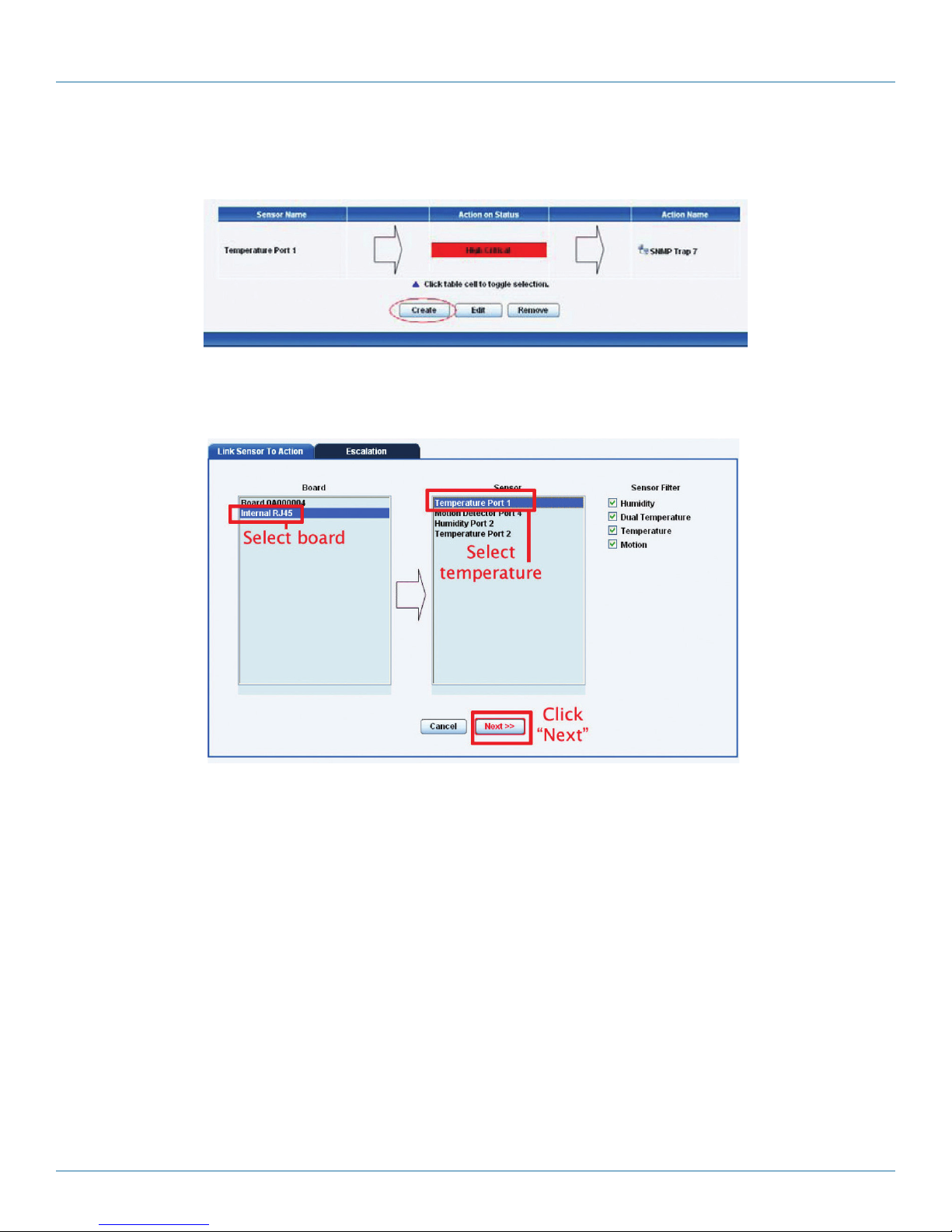

4. Once we have created the parameters for the SNMP trap, we need to make it active. To do this, go back to the “Notifications”

tab. (It should look like the screen shown in Figure 4-7.) Click “Create.”

Figure 4-7. Notifications tab.

5. Select the sensor and SNMP trap parameters (see Figures 4-8 and 4-9). First, click on the board that the sensor is attached to

and then select the sensor and click “Next.”

6. Select the status that you want to issue the notification for, select the action type, then click “Finish.”

EME134A-R3

Figure 4-8. Select the sensor.

877-877-2269 | blackbox.com

Page 57

Page 58

Chapter 4: Notifications

Figure 4-9. Select the SNMP parameters.

7. The SNMP trap has been added to the Notifications page.

Figure 4-10. SNMP trap added.

NOTE: To remove this trap and make it inactive, highlight the notification and click “Remove.”

You can repeat this process to set up multiple SNMP traps for different sensors or for multiple SNMP servers, etc.

4.3 E-mail

This tutorial provides you the information needed to setup an e-mail notification.

To get to the starting point of this tutorial:

• Log in as administrator.

• Select the “Notifications” tab.

• Click “Notification Wizard.”

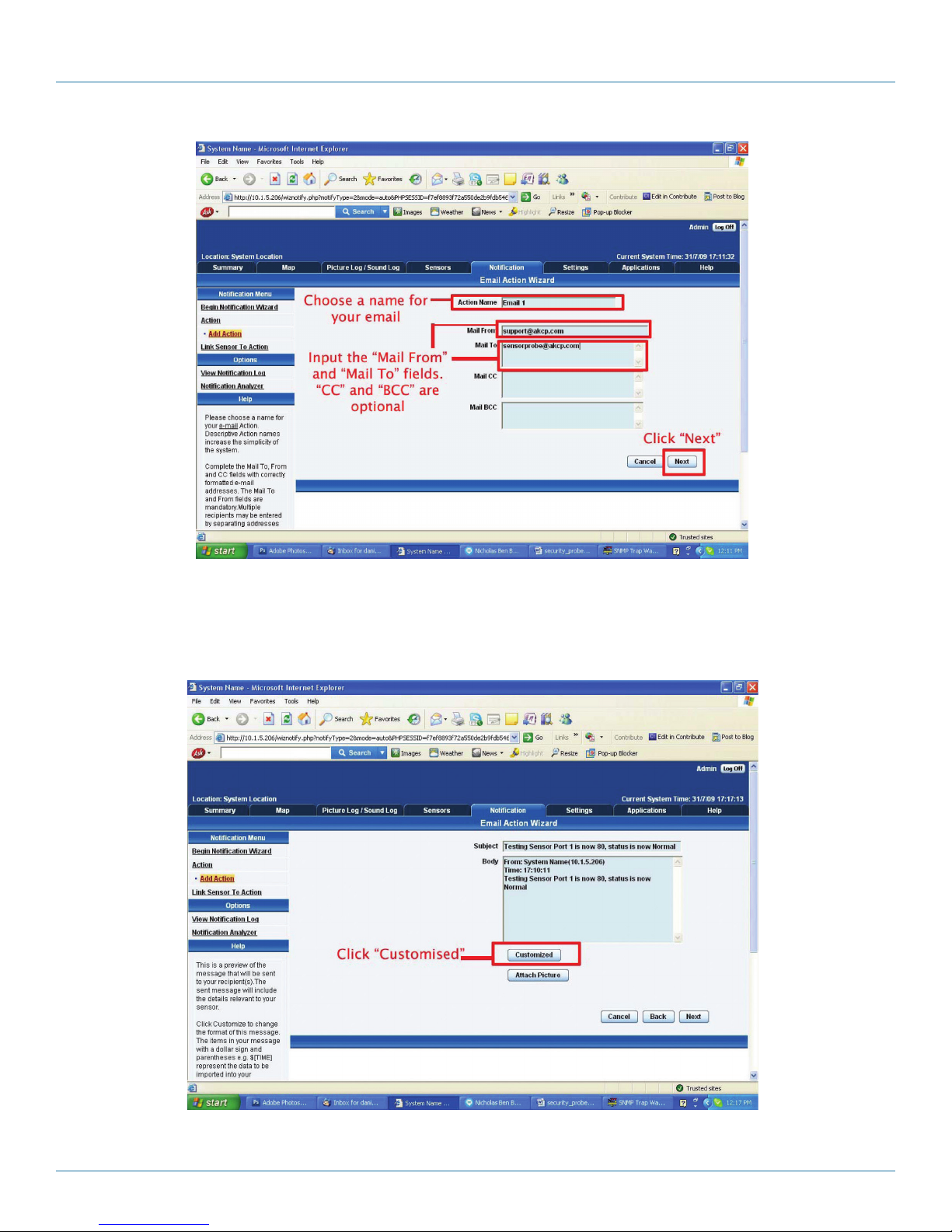

1. If you set up an e-mail notification, Figure 4-11 will appear. Click the “Action Name” field and choose a name for your e-mail.

Click the “Mail From” and “Mail To” fields and enter the appropriate information, then click “Next.”

Page 58

877-877-2269 | blackbox.com

EME134A-R3

Page 59

Chapter 4: Notifications

Figure 4-11. E-mail Action Wizard screen.

2. After clicking “Next,” you will get a page where you can input the e-mail name and message. Click the “Customize” button,

and the fields will re-write in a format that will allow for an automated e-mail that will display the sensor information.

EME134A-R3

Figure 4-12. Input e-mail name and message.

877-877-2269 | blackbox.com

Page 59

Page 60

Chapter 4: Notifications

3. If you have a camera attached, you can click “Attach Picture” to add a .jpg photo to your notification e-mail.

Figure 4-13. Attach picture.

4. Click “Next.”

5. Now you need to input your SMTP server address for your e-mail account.

Figure 4-14. Input SMTP server addresss.

6. Once this is entered, click “Next.”

7. Now, as with the SNMP trap, you can select how many times to attempt to resend the e-mail, and the time elapsed between

each attempt.

Figure 4-15. Select frequency to resend e-mail attempts.

8. Click “Next” after you fill in your parameters.

Page 60

877-877-2269 | blackbox.com

EME134A-R3

Page 61

Chapter 4: Notifications

9. Now link the e-mail you just created to the temperature sensor on Port 1. Select the board the sensor is attached to, then

select the sensor and click “Next.”

Figure 4-16. Select sensor.

10. Select the status you want to issue the alert for and then select the action type.

Figure 4-17. Select status and action type.

EME134A-R3

877-877-2269 | blackbox.com

Page 61

Page 62

Chapter 4: Notifications

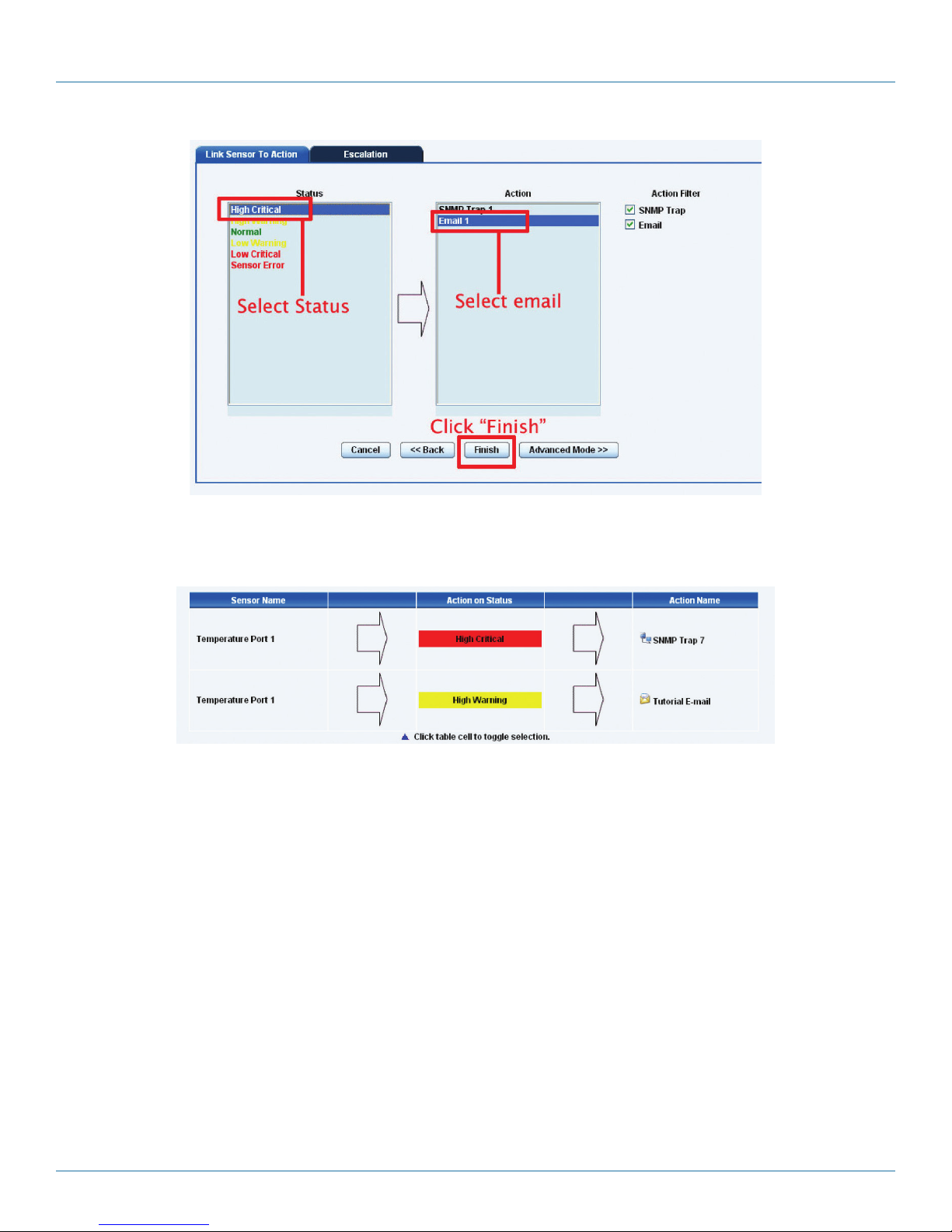

11. Click “Finish.” You will now be taken back to screen shown in Figure 4-18.

12. Click on “Create.”

Figure 4-18. Create button.

13. Create the notification link as before. Then click “Finish.”

Figure 4-19. Create notification link: select board, select temperature.

Page 62

877-877-2269 | blackbox.com

EME134A-R3

Page 63

Chapter 4: Notifications

Figure 4-20. Create notification tab: select status, select e-mail.

14. You will now be back at the main notification page. You should now see listed our two notifications, the SNMP trap and the

e-mail.

Figure 4-21. SNMP Trap and E-mail Notifications screen.

As you can see from this page, an SNMP trap is set up to give us notification of a “High Critical,” and an e-mail notification that

will activate on a “High Warning.”

4.4 SMS Notification

Set up a notification so that you will be sent an SMS message. This message can be sent via a GSM/GPRS mobile phone

connected via a Bluetooth connection or the USB port.

This tutorial provides you with the information you need to set up a SMS notification.

To get to the starting point of this tutorial:

• Log in as administrator.

• Select the “Notifications” tab.

• Click “Notification Wizard.”

1. From the list of notification types, select SMS and click “Next.” You will then be presented with the screen shown in Figure

4-22. Select the “Action Name” field and enter a notification name. Then select the “Phone Number” field and enter the

phone number you want to send the notification to. Click “Next.”

EME134A-R3

877-877-2269 | blackbox.com

Page 63

Page 64

Chapter 4: Notifications

Figure 4-22. SMS Action Wizard, screen #1.

2. You can now either add multiple numbers, delete phone numbers, “Cancel” this action, or click “Next.” In this case, we will

click “Next.”

3. Now we will set up the message that will be sent to the phone. You will see the screen shown in Figure 4-24.

Page 64

Figure 4-23. SMS Action Wizard, screen #2.

877-877-2269 | blackbox.com

EME134A-R3

Page 65

Figure 4-24. Customize macro screen.

Click the “Customized” button to add a macro to your notification.

Chapter 4: Notifications

NOTE: A macro is a script that returns specific data collected by the unit. In our example, the macro will tell the notification to

contain the “description” (sensor name), the value (current sensor reading), and the status (high/low warning, etc.). These

macros are common to all sensor notifications.

4. You will now see that the SMS message has changed its format to include the Macro script. (See Figure 4-25.) Click “Next.”

Figure 4-25. Macro script message.

EME134A-R3

877-877-2269 | blackbox.com

Page 65

Page 66

Chapter 4: Notifications

5. Next, we will set up the type of connection. This will depend on the type of modem you are connecting. For the purpose of

this tutorial, we will assume you are connecting a GSM/GPRS enabled modem to the serial port. Select COM1 from the list.

(See Figure 4-26.)

Choose the connection type you want to use

Figure 4-26. Choose the Connection Type You Want to Use screen.

6. Choose the port that the modem is connected to.

7. You will now be able to select the number of times you want the SMS to be resent and the interval between sending them.

(See Figure 4-27.)

8. Select the number of times you want to resend this notification and the interval (in seconds). Click “Next.”

Figure 4-27. Select number of times to resend and intervals.

9. Select the sensor that you want to bind this notification to.

Page 66

877-877-2269 | blackbox.com

EME134A-R3

Page 67

10. Choose the board and sensor, then click “Next.”

Chapter 4: Notifications

Figure 4-28. Choose board and sensor.

11. This time we will use this notification for a low warning. Then select the notification name we assigned, in this case we chose

“SMS 1.” Click “Finish” to finalize this. (See Figure 4-29.)

12. Now we will add the SMS notification to our active list. This is the same process as for the others—simply click on “Create”

and then select the appropriate parameters. Follow Steps A–F below and on the next page.

EME134A-R3

Figure 4-29. Link sensor to action screen.

877-877-2269 | blackbox.com

Page 67

Page 68

Chapter 4: Notifications

A. Select the board the sensor is connected to.

B. Select the sensor.

C. Click “Next.”

Figure 4-30. Steps A–C.

D. Select the status you want to issue the alert for.

E. Select the action type.

F. Click “Finish.”

Page 68

Figure 4-31. Steps D–F.

877-877-2269 | blackbox.com

EME134A-R3

Page 69

Chapter 4: Notifications

13. You will now be back at the main notification page. The page should display three types of notifications: the SNMP trap,

e-mail, and SMS.

Figure 4-32. Main Notification page.

For the purposes of this tutorial, we will not cover the setup of every type of notification. However, with this information, you

should be able to follow the procedure for the other types of notifications easily, as they all follow a similar format. If you have

questions, contact Black Box Technical Support at 724-746-5500 or info@blackbox.com.

EME134A-R3

877-877-2269 | blackbox.com

Page 69

Page 70

Chapter 5: Camera

5. Camera

5.1 Basic Setup

Connect up to four cameras to the ServSensor through the video inputs (V1 –V4).

The following tutorial provides you with the information needed to set up the camera functions.

In this tutorial, we are going to assume you are connecting a Black Box pan/tilt camera, and we are connecting it to port number

V4.

To get to the starting point of this tutorial:

• Connect camera to a video (“V”) port.

• Log into the Web-based interface as administrator.

1. Once you are logged in, you will be taken to the default summary page.

2. You may or may not see the live image from the camera already. If not, click on “Camera Setting” and follow the instructions

on the following screens.

Page 70

Figure 5-1. Default Summary page.

877-877-2269 | blackbox.com

EME134A-R3

Page 71

Chapter 5: Camera

Figure 5-2. Summary page options.

NOTE: At this stage, you will begin opening up multiple windows that may obscure valuable information displayed on the

summary page. To prevent this from happening, drag each window to a new position to accommodate your preferred

layout. To achieve this, follow the directions below.

EME134A-R3

Figure 5-3. Opening multiple windows.

877-877-2269 | blackbox.com

Page 71

Page 72

Chapter 5: Camera

Figure 5-4.

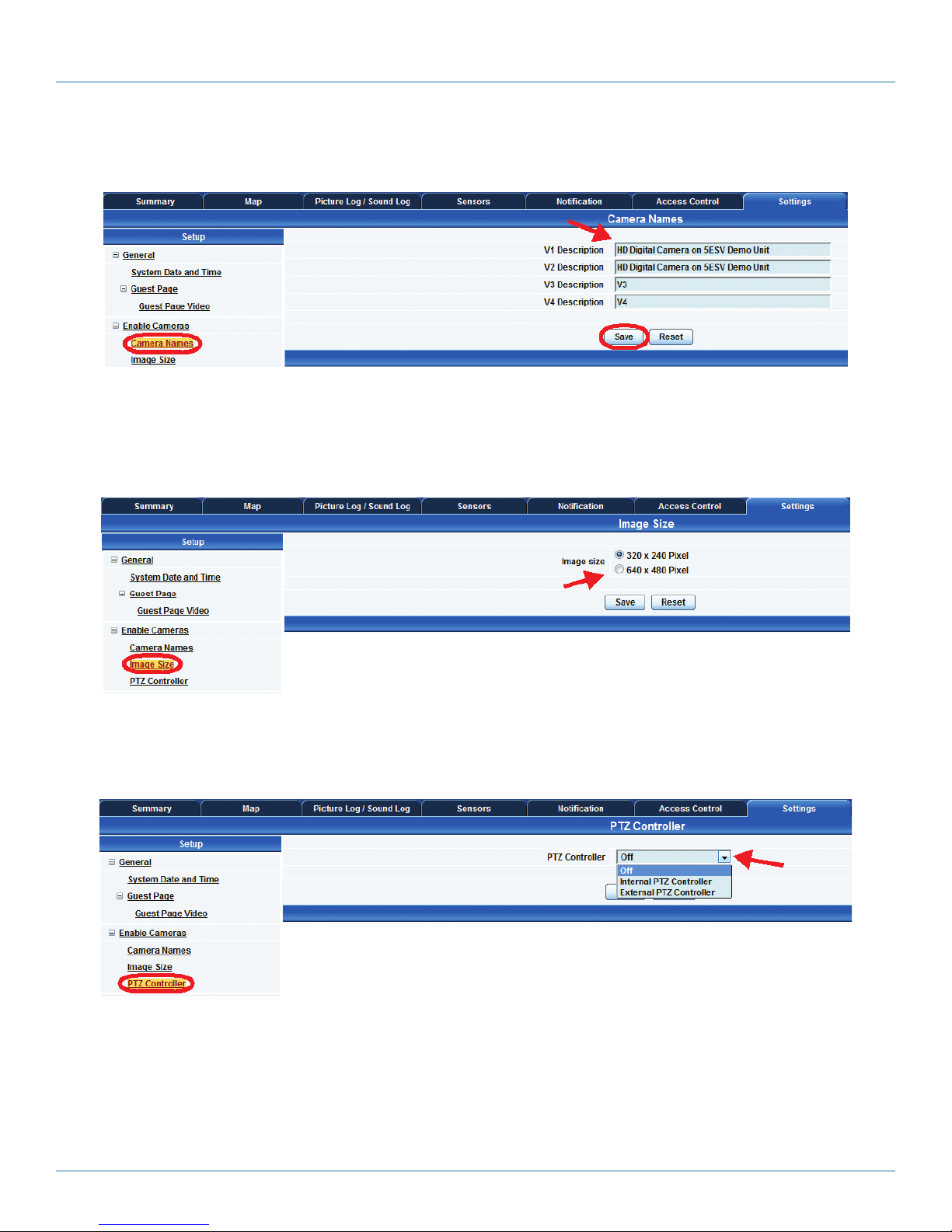

To check the cameras settings in the Web interface, you first need to go to the Settings page, then the Enable Cameras page.

Press the Check Video Signal button to scan the camera ports on the unit for connected cameras.

After the camera or cameras are detected, you will then see this pop-up message shown in the screen shot above. Click on the

OK button.

Page 72

Figure 5-5.

877-877-2269 | blackbox.com

EME134A-R3

Page 73

Chapter 5: Camera

Figure 5-6.

The cameras connected to the ServSensor V4E 5E base unit will now be checked in the Enabled box as shown in the screen shot

above.

EME134A-R3

Figure 5-7.

877-877-2269 | blackbox.com

Page 73

Page 74

Chapter 5: Camera

You can then check to make sure the video stream is working by clicking on the “Preview” button. If the image appears upside

down, you can enable the “Rotate 180” setting to correct the image depending on how the camera is mounted.

Figure 5-8.

After your cameras are enabled, you can then name then as you require by first selecting the “Camera Names” link from the

Setup column, then renaming the test in each of the V1–V4 description fields as shown in the screen shot above.

Figure 5-9.

By clicking on the “Image Size” link in the Setup column, you can then change the Image Size of the streaming video from your

cameras to either 320 x 240 or 640 x 480.

Figure 5-10.

If you are using pan tilt cameras or other third party Pelco-D cameras, then you will need to enable the PTZ Controller from the

PTZ Controller page as shown above. You will always normally choose the “Internal PTZ Controller.”

Note: The External PTZ Controller refers to an obsolete option where an external controller could be connected to the unit.

Page 74

877-877-2269 | blackbox.com

EME134A-R3

Page 75

Chapter 5: Camera

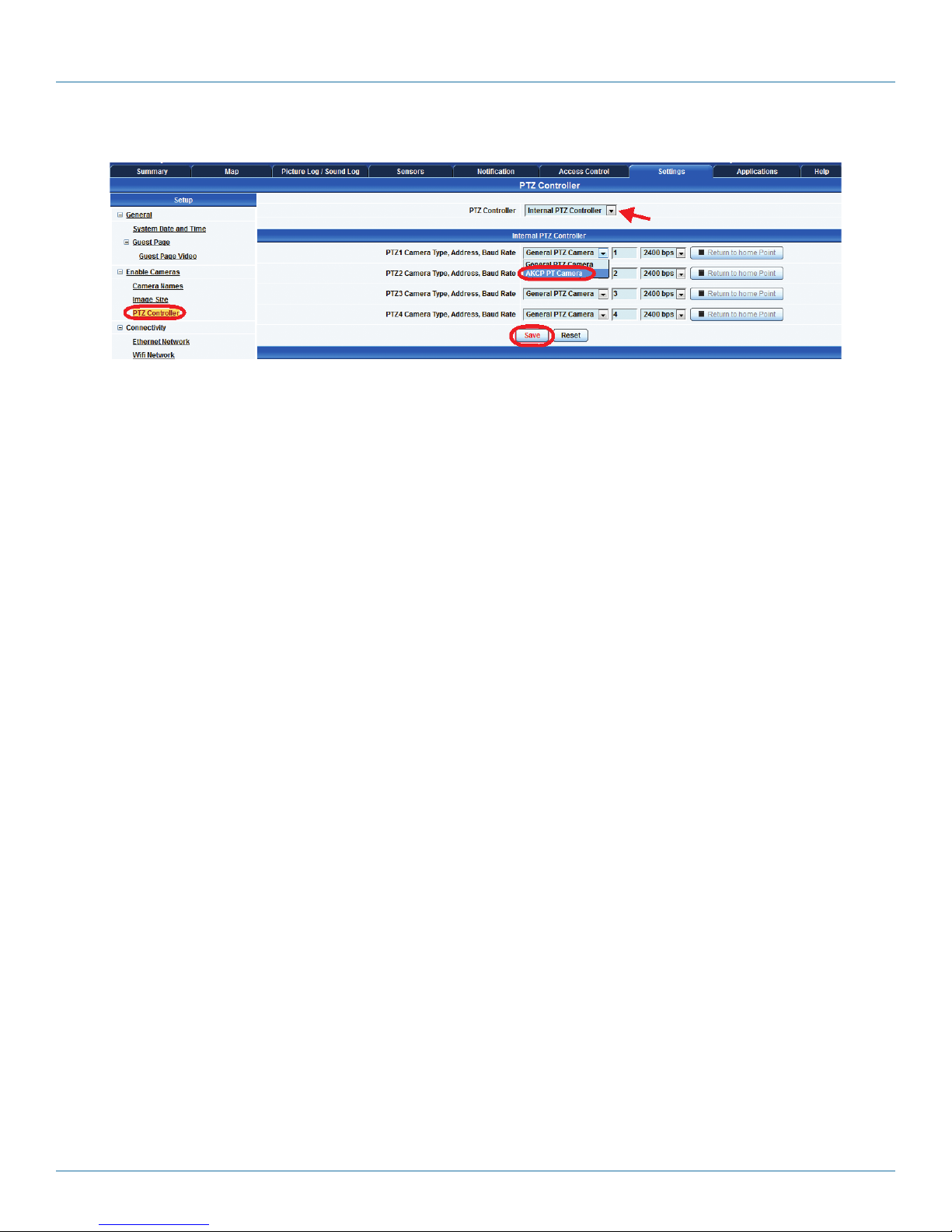

Figure 5-11.

Now that the Internal PTZ controller is set, you need to select “General PTZ Camera” from the drop-down list as shown in the

screen shot above.

Note: For more information on the cameras, cable run lengths etc., please refer to the FAQ section at the end of this manual.

EME134A-R3

877-877-2269 | blackbox.com

Page 75

Page 76

Chapter 5: Camera

5.2 Pan/Tilt Camera Functions

This tutorial provides you with the information needed to set up an MMS notification.

To get to the starting point of this tutorial:

• Log in as administrator.

• From the summary page, select options.

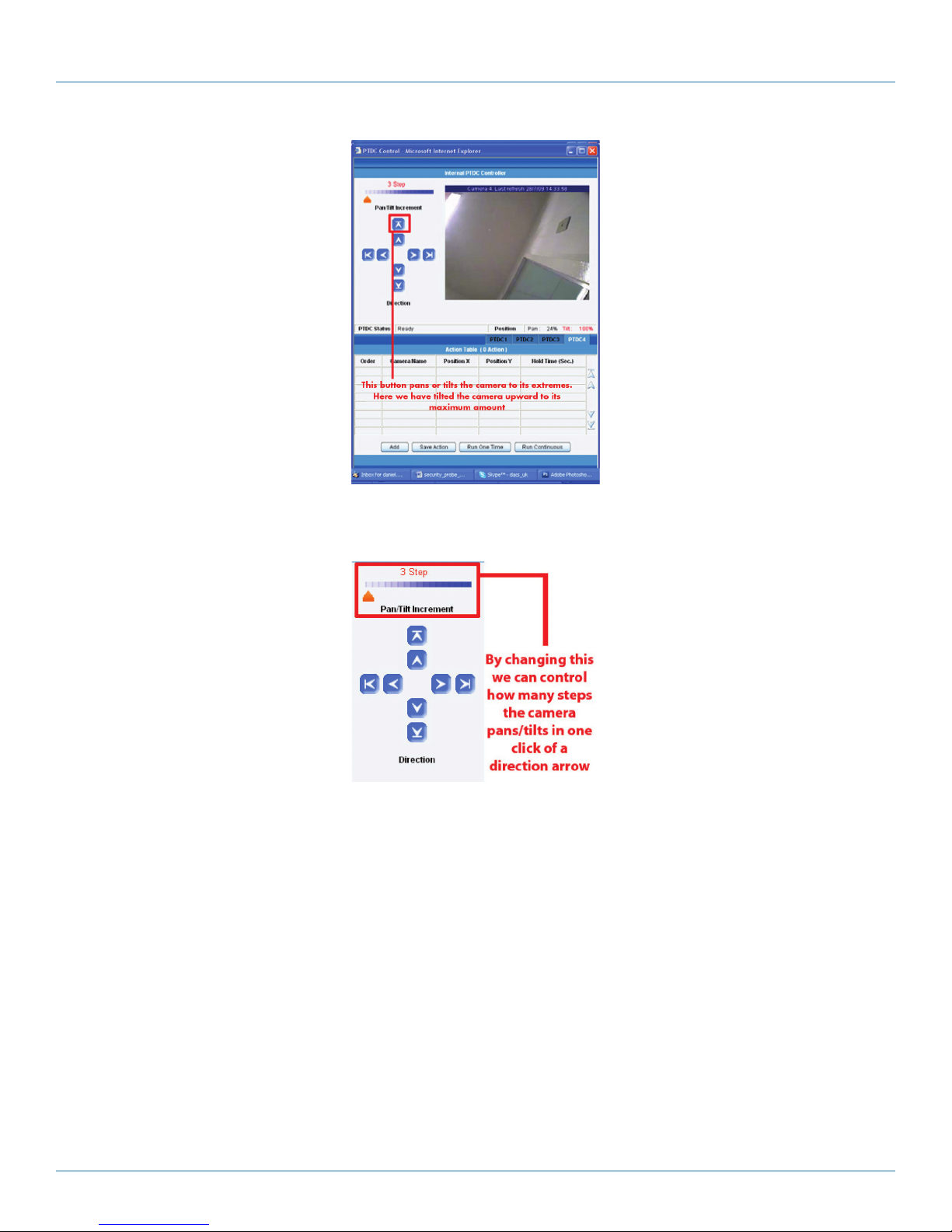

1. First, click on the “Pan Tilt & Zoom Control” button.

Page 76

Figure 5-12. PTZ control screen.

877-877-2269 | blackbox.com

EME134A-R3

Page 77

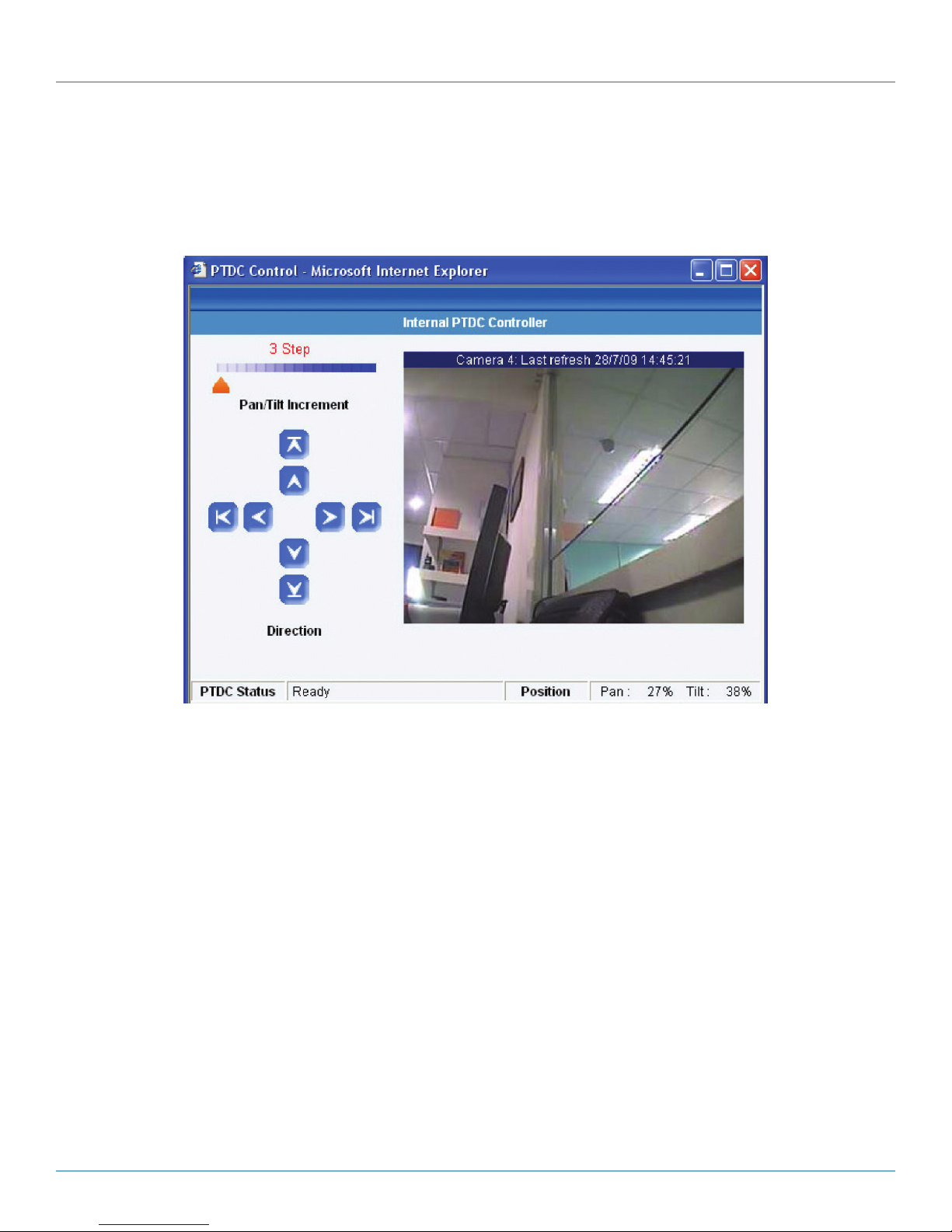

2. Pan and tilt the camera via the pan/tilt arrows. See Figures 5-13 through 5-16.

Chapter 5: Camera

Figure 5-13. Pan/Tilt, screen 1.

Figure 5-14. Pan/Tilt, screen 2.

EME134A-R3

877-877-2269 | blackbox.com

Page 77

Page 78

Chapter 5: Camera

Figure 5-15. Pan/Tilt, screen 3.

Figure 5-16. Pan/Tilt, screen 4.

NOTE: You can also pan and tilt the camera by placing your mouse on the video image and clicking the position that you want

the camera to face. This is useful when you want to enter the values for automated camera movements.

5.3 Automating Camera Movements

This tutorial provides you with the information needed to set up automated camera movements.

To get to the starting point of this tutorial:

• Log in as administrator.

Page 78

877-877-2269 | blackbox.com

EME134A-R3

Page 79

Chapter 5: Camera

• Select options from the summary page.

• Click “Pan Tilt & Zoom Control.” (See Figure 5-12.)

We will now look at creating automated camera movement. This will make the camera automatically pan or tilt at preset intervals.

(See Figure 5-17.)

Figure 5-17. Top of the internal PTDC controller screen.

1. Click on the add button, the following pages will appear.

EME134A-R3

877-877-2269 | blackbox.com

Page 79

Page 80

Chapter 5: Camera

Figure 5-18. Bottom of the internal PTDC controller screen.

Figure 5-19. Setting position of X (pan) and Y (tilt).

Page 80

877-877-2269 | blackbox.com

EME134A-R3

Page 81

Chapter 5: Camera

Figure 5-20. Action table.

Click “Add” in Figure 5-20 to move the camera to a new position shown in Figure 5-13.

EME134A-R3

Figure 5-21. New coordinates set for pan/tilt.

877-877-2269 | blackbox.com

Page 81

Page 82

Chapter 5: Camera

2. Repeat this process as many times as you want to automate the camera’s movement so that it covers the area you need to

monitor. In this example, we have added three different positions.

Figure 5-22. Action table.

3. After clicking “Save Action,” click on “Run Continuous.” This will start the script running. You should then see instant feedback

from the live stream in the camera window as the camera pans through these positions.

5.4 Recording from the Camera

To record from the camera, you first need to have ActiveX controls installed on your PC. The Web interface will direct you on how

to do this. For this tutorial, we will assume this is done.

This tutorial provides you with the information you need to set up the recording from the camera.

To get to the starting point of this tutorial:

• Log in as administrator.

• From summary page, select options.

1. Select ActiveX as the mode of display. (Some users may need to install it. If so, follow the on-screen instructions.) Your camera

window will change, giving you setup and record options.

Page 82

877-877-2269 | blackbox.com

EME134A-R3

Page 83

Chapter 5: Camera

Figure 5-23. Select ActiveX.

2. Click “Record” and the camera record window will now open.

EME134A-R3

877-877-2269 | blackbox.com

Page 83

Page 84

Chapter 5: Camera

Figure 5-24. Camera record window.

3. Now we need to set up the capture parameters. Click on “Setup Record Test.”

Page 84

877-877-2269 | blackbox.com

EME134A-R3

Page 85

Chapter 5: Camera

Figure 5-25. Setup record test.

Figure 5-26. Select video save parameters.

EME134A-R3

877-877-2269 | blackbox.com

Page 85

Page 86

Chapter 5: Camera

4. To begin capture, simply click on “Record.”

NOTE: If you want to record and run the automated camera movements at the same time, start the automated camera

movements from the “PTZ Control.”

5.5 Picture Log

The camera can be used to automatically log a photo and send it as part of a notification. Continuing our example of setting up

the temperature sensor in this part of the tutorial, we are going to use the camera to capture an image from 2 seconds and 1

second before and 2 seconds after the event. The event will be when the temperature sensor reading is at “High Critical.”

This tutorial provides you with the information needed to set up an MMS notification.

To get to the starting point of this tutorial:

• Log in as administrator.

• Select the “Notifications” tab.

Page 86

Figure 5-27. Record button.

877-877-2269 | blackbox.com

EME134A-R3

Page 87

Chapter 5: Camera

• Select “Notification Wizard.”

• Choose “Picture Log” as the notification type (follow previous “Notifications Wizard” instructions). See Section 4.2.

1. Once this is done, you can add it to the active notifications so your page should now look like the screen in Figure 5-28.

Figure 5-28. Add Picture Log screen.

NOTE: As you can see from the screen shot above, we have set the picture log to be created when the temperature sensor is at a

“High Critical” state.

2. Adjust the notification thresholds to trigger a response. This has triggered the picture log notification.

3. Click the “Picture Log/Sound Log” tab. See Figure 5-29.

EME134A-R3

877-877-2269 | blackbox.com

Page 87

Page 88

Chapter 5: Camera

4. Click “View.”

Figure 5-29. Picture and Sound Log tab.

From here you can see there is a series of images. These have been taken at the preset time intervals, before and after the event.

These parameters were set up in the notification wizard previously.

Page 88

Figure 5-30. Images.

877-877-2269 | blackbox.com

EME134A-R3

Page 89

Chapter 6: Mapping

6. Mapping

The mapping feature allows instant visual feedback about a sensor’s position and status. It is a useful monitoring tool for a setup

with several sensors in different positions.

This tutorial provides you with the information needed to set up the mapping feature.

To get to the starting point of this tutorial:

• Log in as administrator.

• Click the “Map” tab.

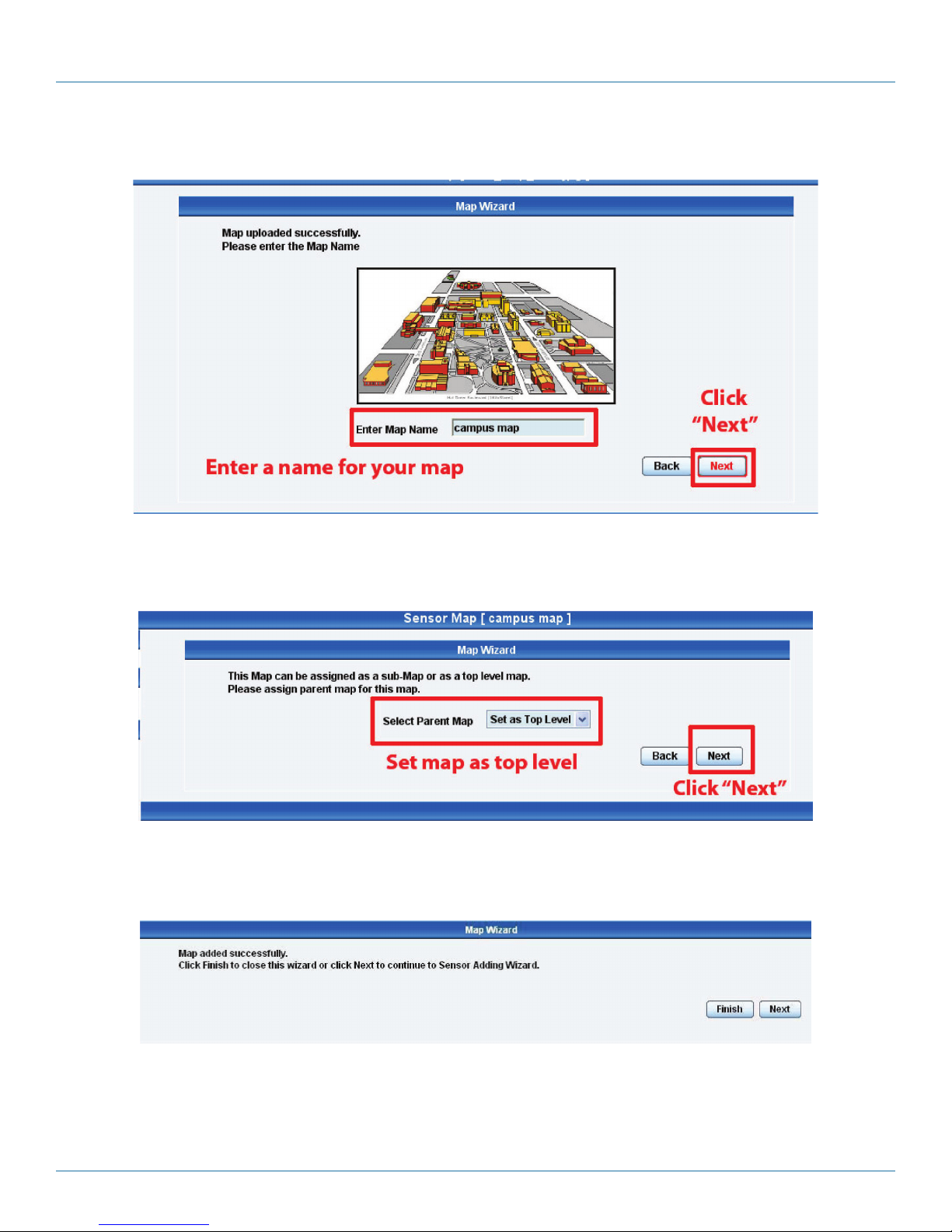

6.1 Adding a Map

1. First, we need to add a picture file to be used as the map. This can be a blueprint of your office, a 3D picture of your office/site

being monitored, or a photo of the wiring closet you are monitoring.

NOTE: The maximum map file size is 512 KB.

2. Browse to the file on your hard drive that you want to use.

EME134A-R3

Figure 6-1. Click on the “Map” tab.

Figure 6-2. Browse to selected file.

877-877-2269 | blackbox.com

Page 89

Page 90

Chapter 6: Mapping

3. In this tutorial, we are going to use a 3D map of a campus site we are monitoring.

Figure 6-3. Enter map name.

4. Choose to have the map as a top-level map.

Figure 6-4. Enter map level.

5. You will now have the option to finish or to add sensors to your map. For this tutorial, click “Next.”

Page 90

Figure 6-5. “Finish” or “Next.”

877-877-2269 | blackbox.com

EME134A-R3

Page 91

Chapter 6: Mapping

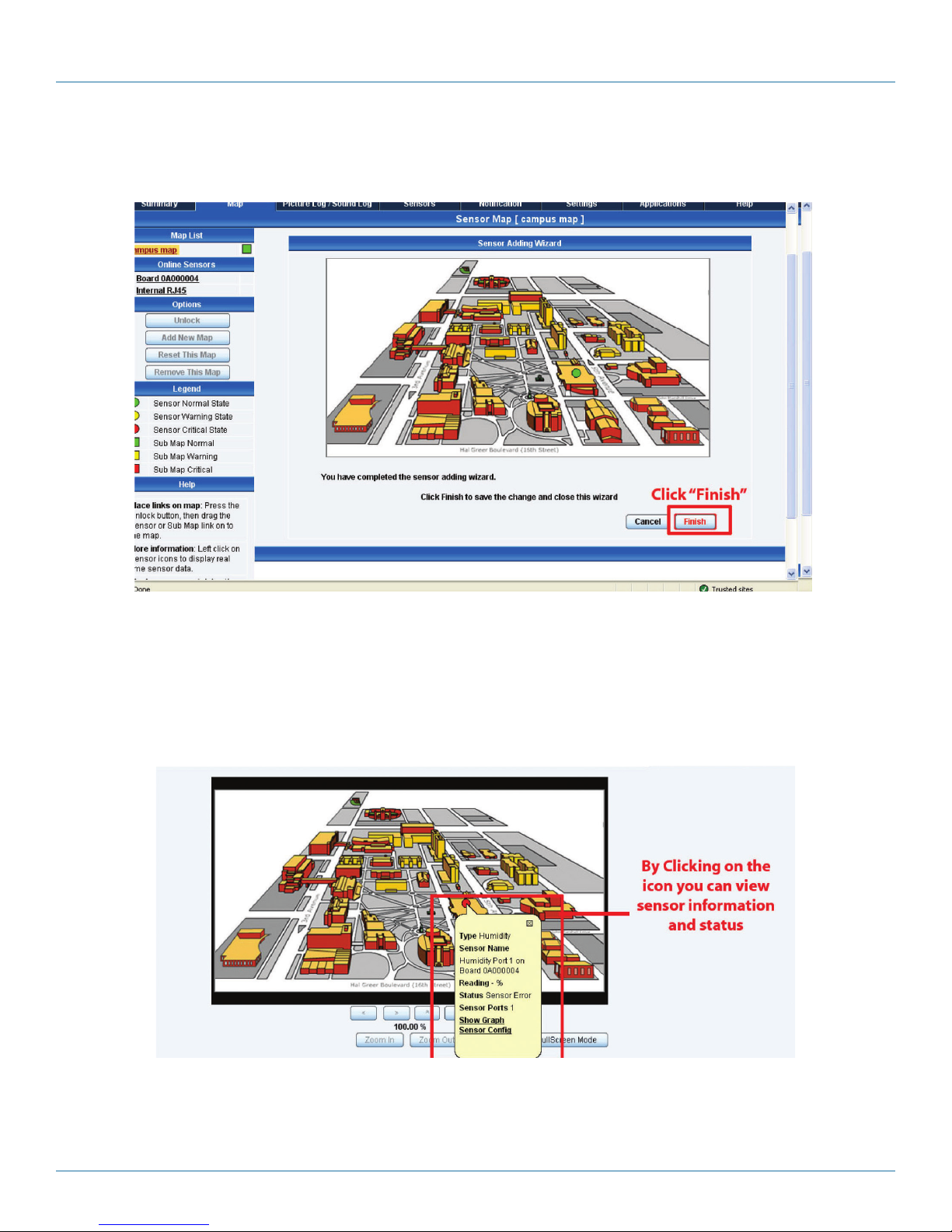

6. You will now be taken to the map page where it will display your map. To add sensors, click “Next.”

Figure 6-6. Sensor map.

7. After clicking “Next,” click the “Unlock” button. This enables you to add sensors to the map.

EME134A-R3

Figure 6-7. Add sensors to map.

877-877-2269 | blackbox.com

Page 91

Page 92

Chapter 6: Mapping

8. You can now drag sensor icons and position them on the map.

Figure 6-8. Position sensor icons on map.

9. After you have positioned the sensors in the correct location of your map, click “Unlock.”

Page 92

877-877-2269 | blackbox.com

EME134A-R3

Page 93

Figure 6-9. Click “Unlock.”

10. Finally you click on the “Finish” button to save your changes.

Chapter 6: Mapping

Figure 6-10. Save changes.

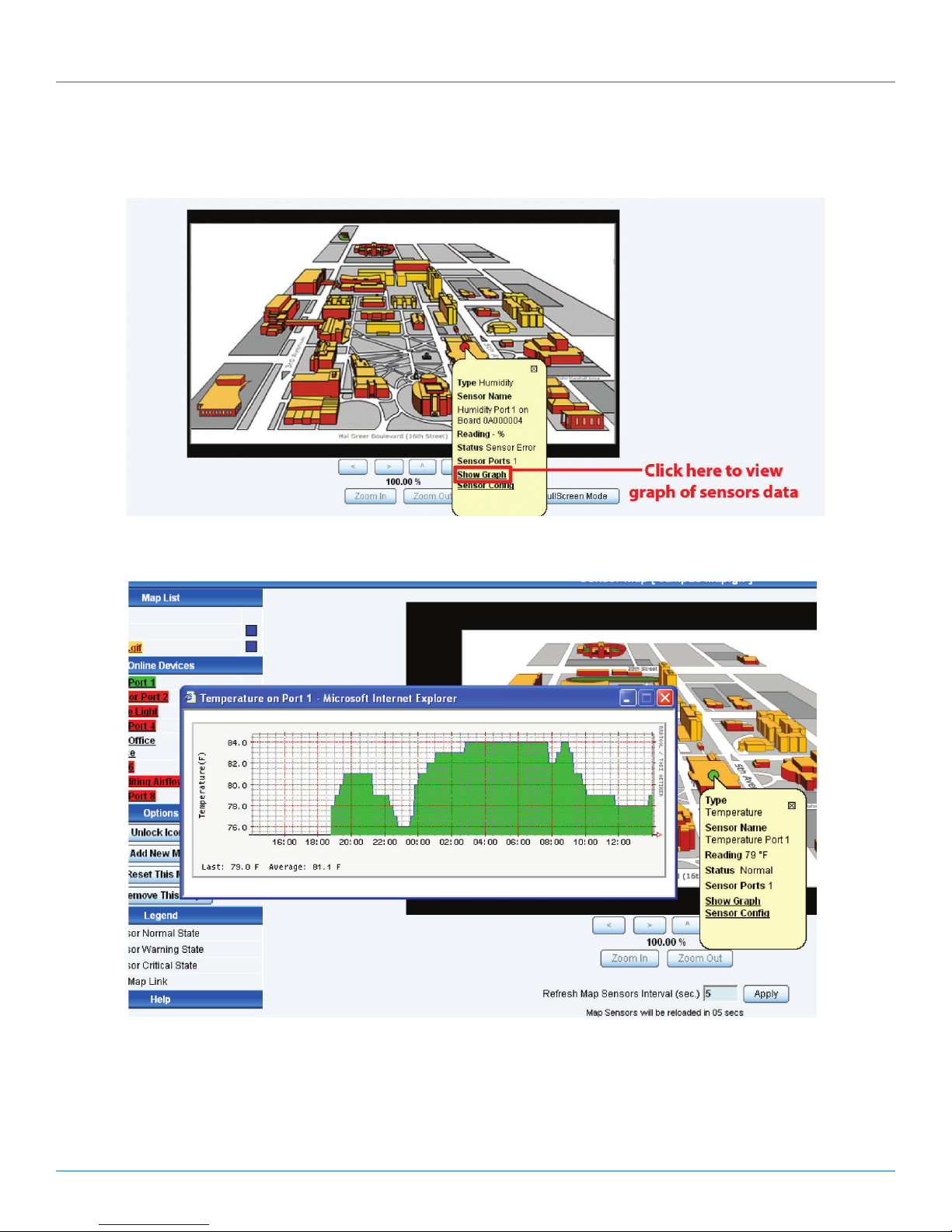

6.2 Monitoring via the Map Interface

Now we are going to look at how to monitor the sensor status and use the map interface.

1. To see further information about a sensor, you can click on its icon. First, you must click on the “Lock Icons” button.

If you connect other sensors, these too can be dragged and positioned on the map.

EME134A-R3

Figure 6-11. Using the map interface.

877-877-2269 | blackbox.com

Page 93

Page 94

Chapter 6: Mapping

2. If you click on “Show Graph” you can view a graph of the sensor’s collected data. See Figures 6-12 and 6-13.

Figure 6-12. View graph of sensors data.

Page 94

Figure 6-13. Graph of sensors data screen.

877-877-2269 | blackbox.com

EME134A-R3

Page 95

Chapter 7: Filters

7. Filter s

7.1 Sensor Filters