Page 1

1000 Park Drive • Lawrence, PA 15055-1018 • 724-746-5500 • Fax 724-746-0746

© Copyright 2000. Black Box Corporation. All rights reserved.

Page 2

CUSTOMER

SUPPORT

INFORMATION

Order toll-free in the U.S. 24 hours, 7 A.M. Monday to midnight Friday: 877-877-BBOX

FREE technical support, 24 hours a day, 7 days a week: Call 724-746-5500 or fax 724-746-0746

Mail order: Black Box Corporation, 1000 Park Drive, Lawrence, PA 15055-1018

Web site: www.blackbox.com • E-mail: info@blackbox.com

APRIL 2000

EFN06-24

EFN06-36

EFN12-24

EFN12-36

6-Fiber Buffer Tube Fanout Kit

12-Fiber Buffer Tube Fanout Kit

Page 3

Page 4

1

CONTENTS

Contents

1. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 What the Package Includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 What You Need to Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Preparing the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Preparing the Buffer Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Threading the Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Marking the Buffer Tube Fanout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Fiber Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Installing the Buffer Tube Fanout into Hardware. . . . . . . . . . . . . . . 16

TRADEMARKS USED IN THIS MANUAL

Any trademarks mentioned in this manual are acknowledged to be the

property of the trademark owners.

Page 5

2

6- OR 12-BUFFER TUBE FANOUT KIT

1. Specifications

Buffer Tube Diameter—6-Fiber Buffer Tube Fanout: 2.4-mm buffer tubes;

12-Fiber Buffer Tube Fanout: 3.0-mm buffer tubes

Protective Tube Diameter—900 µm

Temperature—32 to 158°F (0 to 70°C)

Page 6

3

CHAPTER 2: Introduction

2. Introduction

2.1 Description

Because individual fiber optic cable strands have an extremely small diameter, to

terminate the cable you must first enclose each strand in protective tubing. Once

the cable is enclosed, you can then add fiber optic connectors, such as SC, to each

enclosed cable.

The Buffer Tube Fanout Kits are specifically designed to terminate 6- and 12fiber buffer tubes. Perfect for users who want to field-install connectors, the kits

provide a compact, easy-to-install fanout solution. No additional hardware or space

other than that required for terminating tight-buffered cables is required. With

these kits, you don’t even need epoxy!

The Kits feature a 900-µm fanout assembly that is color-coded to match the fiber

color scheme. The fanout assembly is available with 6- or 12-fiber units in lengths

of 25 or 36 inches (63.5 or 91.4 cm). These different lengths give you the flexibility

you need for a variety of hardware options.

You can install the 6-Fiber Buffer Tube Fanout on 2.4-mm buffer tubes or the

12-Fiber Buffer Tube Fanout on 3.0-mm buffer tubes for indoor applications. The

Buffer Tube Fanouts branch the fibers from a buffer tube into individual fibers

protected by 900-µm PVDF protective tubing. You can then install connectors on

the fiber according to your hardware interface requirements.

One Buffer Tube Fanout is required for each 6- or 12-Fiber Buffer Tube. Please

read the installation instructions in Chapter 3 before assembling the Buffer Tube

Fanout.

Page 7

4

6- OR 12-BUFFER TUBE FANOUT KIT

2.2 Precautions

WARNING

Wear safety gloves to protect your hands from chemicals and accidental

injury when handling sharp-bladed tools.

Wear safety glasses to protect your eyes from accidental injury when

handling chemicals and cutting fiber. Pieces of glass fiber are very

sharp and can damage the cornea of the eye.

CHEMICAL PRECAUTIONS: Contains hydrocarbons. If ingested, DO

NOT INDUCE VOMITING. Call a physician immediately. KEEP OUT OF

THE REACH OF CHILDREN.

CAUTION

Fiber optic cable is sensitive to excessive pulling, bending, and

crushing forces. Consult the cable specification sheet for the cable you

are installing. Do not bend cable or buffer tubes more sharply than their

minimum recommended bend radius. Do not apply more pulling force to

the cable than specified. Do not crush the cable or buffer tubes or allow

them to kink. Doing so may cause damage that can alter the

transmission characteristics of the cable—the cable may have to be

replaced.

2.3 What the Package Includes

Check to make sure your package includes the following items (refer to

Figure 2-1). If anything is missing or damaged, please contact Black Box at

724-746-5500.

Buffer Tube Fanout top

Buffer Tube Fanout bottom

6-ft. (1.8-m)or 12-ft. (3.6-m) 900-µm color-coded assembly, 25 in. (63.5 cm)

or 36 in. (91.4 cm) long

➂

➁

①

Page 8

5

CHAPTER 2: Introduction

Figure 2-1. Package Contents.

2.4 What You Need to Supply

You’ll need the following items:

• Electrical tape

• Lint-free tissues

• Clean rags

• Permanent marker

• Wire markers

• Buffer tube stripper

• Buffer tube clamps

• d’Gel cable cleaner (liquid or wipes)

• Pliers

①

➁

➂

Page 9

6

6- OR 12-BUFFER TUBE FANOUT KIT

3. Installation

3.1 Preparing the Cable

CAUTION

Read the cable manufacturer’s sheath-removal instructions. Some

cable-stripping procedures may call for a slightly longer length at the

end of the cable to allow for cable core (buffer tube) damage caused

when accessing rip cords, etc. Be sure to add such length (typically 6 to

10 inches) to the strip length in Step 2, below.

You can assemble a Buffer Tube Fanout any time after you’ve removed the cable

sheath and cleaned the buffer tubes.

Installation factors such as the length of cable slack available, the location of

terminating hardware, and the question of storing buffer tube slack as opposed to

cable slack, can dictate when and where you choose to mount the cable end and

assemble the Buffer Tube Fanout.

Figures 3-1 and 3-2 illustrate two typical installation options.

Option 1 (Refer to Figure 3-1)

1. Prepare the cable end.

2. Route the cable end to a work surface.

3. Assemble the Buffer Tube Fanout.

4. Mount the cable on the hardware, and route the Buffer Tube Fanout and

tubes inside the hardware.

5. Install the Buffer Tube Fanout in the hardware.

Page 10

7

CHAPTER 3: Installation

Figure 3-1. Option 1.

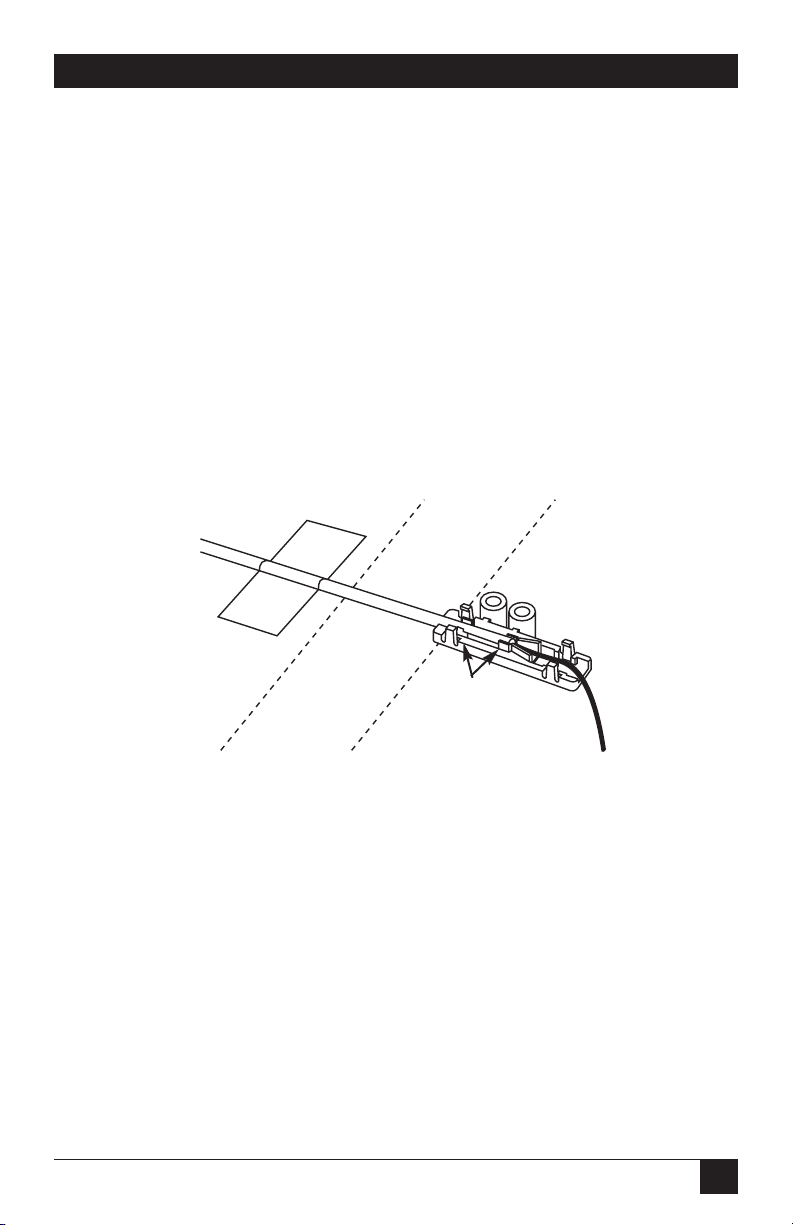

Option 2

1. Prepare the cable end.

2. Mount the cable on the hardware.

3. Route the buffer tubes to a work surface.

4. Assemble the Buffer Tube Fanout.

5. Route Buffer Tube Fanout and tubes inside the hardware.

6. Install the Buffer Tube Fanout in the hardware.

Figure 3-2. Option 2.

Buffer Tube Fanout

taped to work surface

Rack

Buffer Tube Fanout

taped to work surface

Buffer

tubes

Cable mounting point

Permanent routing

Permanent routing

Temporary cable routing

to work surface

Page 11

8

6- OR 12-BUFFER TUBE FANOUT KIT

Determine the total strip length requirement for your installation. This length

will be:

• The buffer tube length(s) required to route the tubes from the cable sheath

attachment point to the planned location of the Buffer Tube Fanout body.

plus

• either 35 inches (for the 25-inch fiber assembly) or 46 inches (for the 36-inch

fiber assembly)

plus

• (optional) any additional length called for in the cable stripping procedure as

a safety factor

plus

• (optional) the distance from the cable mounting point to a work surface if

you are performing an Option 2 installation.

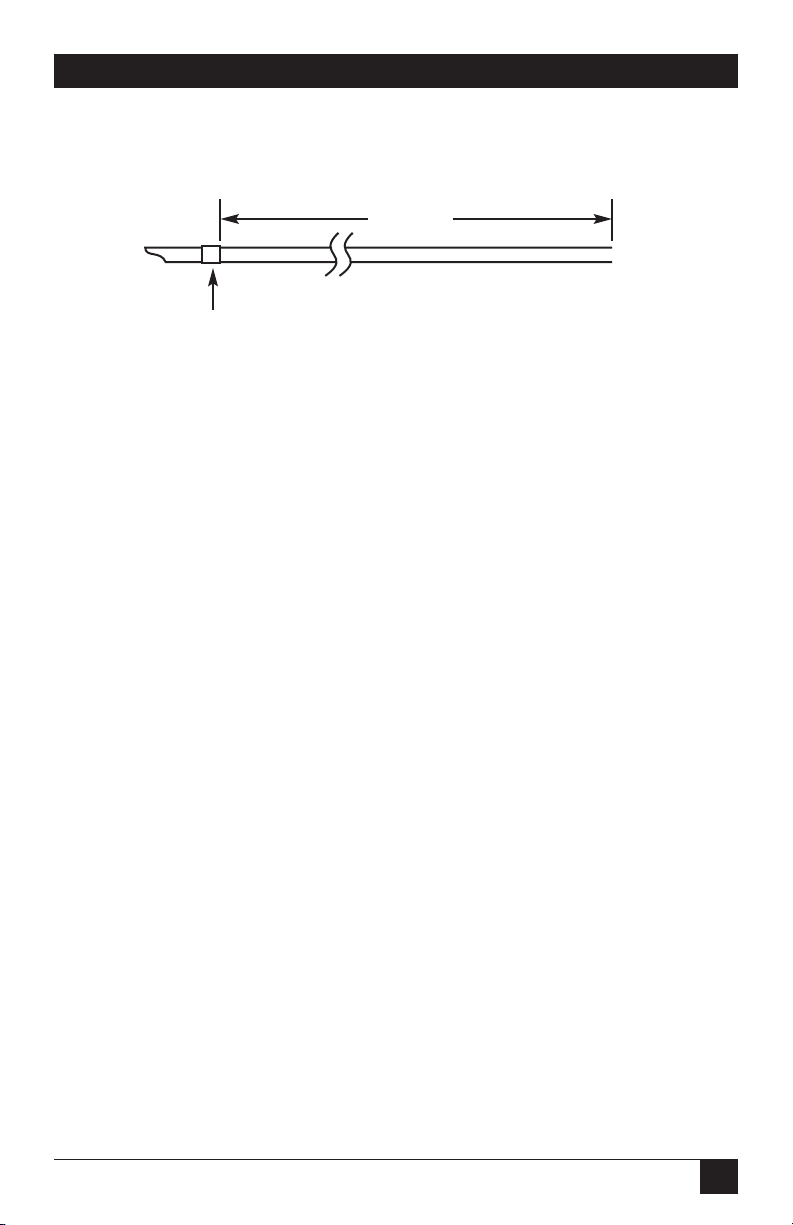

Mark this strip length from the end of the cable by wrapping the spot with a

piece of tape (see Figure 3-3).

Page 12

9

CHAPTER 3: Installation

Figure 3-3. Cable Strip Length.

Strip the cable according to the cable manufacturer’s instructions for removing

the sheath. Determine the cable central member and strength member yarn

lengths needed to secure the cable from the instructions provided with the

hardware.

If you are working with a grease or gel-filled water-blocked cable, use a d’Gel

wipe (or a tissue soaked with d’Gel liquid) to remove any flooding compound from

the buffer tubes.

Depending on the kit you’re using, measure 35 inches (88.9 cm) or 46 inches

(116.8 cm) of buffer tube from the end of the tubes. Use a permanent marker to

mark each tube at that spot.

CAUTION

To minimize the chance of breaking a fiber, follow the remaining steps

in this procedure one buffer tube at a time.

Tape

Strip length

Page 13

10

6- OR 12-BUFFER TUBE FANOUT KIT

3.2 Preparing the Buffer Tube

1. Tape the cable end to a work surface so that the marks on the buffer tubes

can reach the work surface edge (see Figure 3-4).

2. Select the first buffer tube. Use a buffer stripping tool to remove the buffer

tube back to the mark made in permanent marker.

3. Tape down the buffer tube that will receive the Buffer Tube Fanout. Make

sure 1 to 2 inches of tube overhang the work surface edge (see Figure 3-4).

Figure 3-4. Taping the Buffer Tube Fanout.

4. Wipe the filling compound from the exposed fibers with a d’Gel wipe (see

Figure 3-5). Use a clean, lint-free tissue to thoroughly dry each fiber.

Figure 3-5. Cleaning the Filling Compound from the Exposed Fibers.

5. Run a dry finger along each fiber to check for any filling compound residue.

If residue is present on the fiber, repeat step 4.

Buffer

tube

Tape

Tape

Page 14

11

CHAPTER 3: Installation

IMPORTANT

Make sure that the fibers are clean and dry. Any residue left on the fiber

will obstruct threading operations into the 900-µm assembly pieces.

6. Place the crimp tabs of the bottom piece of the Buffer Tube Fanout on the

end of the buffer tube. Press the tab with pliers to secure the Buffer Tube

Fanout bottom to the end of the tube (see Figure 3-6).

CAUTION

Be careful not to crush the tube. Crimp only until the tube begins to

deform. Spaces between the ends of the crimp tabs are normal for most

applications.

Check the crimp for effectiveness by pulling on and twisting the tube. The

tube should not move when pulling gently on it.

Figure 3-6. Securing the Buffer Tube Fanout Bottom to the End of the

Tube.

3.3 Threading the Fibers

1. Approximately 2 inches (5 cm) off to either side of the tube and Buffer Tube

Fanout bottom, use strapping tape to secure the plastic section of the 900-µm

assembly to the table’s edge as shown in Figure 3-7.

NOTE

The plastic section 900-µm assembly has color-coded legs and

corresponding numbers on its plastic housing. The number 1, or blue

tube should be on the front bottom right corner of the assembly.

2. Separate and untangle the number 1 (blue) fiber back to the point where it

exits the buffer tube.

Tabs

Page 15

12

6- OR 12-BUFFER TUBE FANOUT KIT

3. Carefully thread about three inches of the first fiber into the #1 slot of the

900-µm tube (see Figure 3-7).

Figure 3-7. Threading the Fiber.

4. Repeat steps 2 and 3 for the remaining fibers in sequential fiber order

(orange, green, brown, etc.). Work the threading process across the 900-µm

tube assembly in the proper order.

NOTE

Do not let any of the fibers cross each other during this threading

operation.

5. After all of the fibers have been inserted into the 900-µm tubes, gently push

the fibers into the tubes as a group until the fiber ends protrude from the

ends of the tubes.

1) Blue

2) Orange

3) Green

4) Brown

5) Slate

6) White

7) Red

8) Black

9) Yellow

10) Violet

11) Rose

12) Aqua

Top view

#1 fiber

Page 16

13

CHAPTER 3: Installation

6. Carefully pull the fibers out of the tube ends to take up most of the excess

length between the Buffer Tube Fanout body and the 900-µm assembly.

NOTE

Leave a small fiber loop between the Buffer Tube Fanout body and the

900-µm assembly to prevent fiber breakage during later steps in this

procedure (see Figure 3-8).

Figure 3-8. Leaving a Loop to Prevent Fiber Breakage.

7. Untape the 900-µm assembly from the table edge. Carefully slide the assembly

while gently pulling the bare fibers protruding from the 900-µm tube ends

until the assembly is above the fanout body (see Figure 3-9).

Figure 3-9. Pulling the Assembly.

At times the fibers will twist as a group when sliding the 900-µm assembly

toward the buffer tube. Rotate the 900-µm assembly opposite the direction of

twist until the fibers straighten out. Severe twists left in the fibers could

exhibit long term micro-bending effects on the fiber performance and add

loss.

Page 17

14

6- OR 12-BUFFER TUBE FANOUT KIT

NOTE

Because buffer tubes are semi-rigid, they require careful handling to

compensate for their “memory” and “springy” nature. Buffer tubes will

tend to quickly return to their original position after handling. Whenever

you use tape to anchor the tubes down, use care to control the tubes

when removing the tape.

8. Lower the insert section into the Buffer Tube Fanout body and press it into

place (see Figure 3-10).

Figure 3-10. Pressing the Insert Section into Place.

9. Align the top of the Buffer Tube Fanout body with the bottom and press

them together until the top snaps into place (see Figure 3-11).

Figure 3-11. Pressing the Bottom and Top Together.

10. Remove the tape from the buffer tube.

11. Separate another buffer tube and assemble the next Buffer Tube Fanout by

repeating steps 2 through 10.

Page 18

15

CHAPTER 3: Installation

NOTE

We recommend working with the tubes in sequential order to maintain

installation organization.

3.4 Marking the Buffer Tube Fanout

To aid in the identification and maintenance of the fanout assemblies, use

numbered wire markers. These markers can individually identify each Buffer Tube

Fanout with respect to its buffer tube number if the buffer tubes are not easily

distinguished (see Figure 3-12).

Figure 3-12. Marking the Buffer Tube Fanout.

3.5 Fiber Termination

1. Trim the excess fiber lengths to a length of 2 inches (5.1 cm) from the end of

the 900-µm tubing.

2. Terminate each fiber, working one Buffer Tube Fanout assembly at a time,

following the instructions provided with the connectors.

3. Test the connectors in accordance with standard test procedures or any

recommended test procedures supplied by the connector vendor.

Color-coded

900-µm tubes

Buffer tube

number

Page 19

16

6- OR 12-BUFFER TUBE FANOUT KIT

3.6 Installing the Buffer Tube Fanout into Hardware

1. You can either bolt or tape the Buffer Tube Fanout into pieces of hardware.

Refer to the instructions provided with the hardware you’re using to

determine the best method.

2. To route the Buffer Tube Fanout assembly into the hardware:

a. Hold the Buffer Tube Fanout body while grasping the buffer tube just outside

the assembly.

b. Carefully guide the Buffer Tube Fanout assembly into place, taking care to

prevent the buffer tube from kinking at the entrance to the Buffer Tube

Fanout body.

Loading...

Loading...