Page 1

CB-CP100 CB-ACC-232DTE-30 CB-PS -12V

CB-CP200 CB-ACC-232DCE-30 CB-PS-24V

CB-ACC-IR-UNI CB-APP-LIC CB-CP-RMK

ControlBridge Processor

User Manual

Control and Manage Critical Systems using the ControlBridge Processor.

Contact

Information

Order toll-free in the U.S. or for FREE technical support: Call 877-877-BBOX

(outside U.S. call 724-746-5500)

www.blackbox.com • info@blackbox.com

Page 2

Trademarks Used in this Manual

Trademarks Used in this Manual

Black Box and the Double Diamond logo are registered trademarks of BB Technologies, Inc.

Any other trademarks mentioned in this manual are acknowledged to be the property of the trademark owners.

We‘re here to help! If you have any questions about your application

or our products, contact Black Box Tech Support at 877-877-2269

or go to blackbox.com and click on “Talk to Black Box.”

You’ll be live with one of our technical experts in less than 60 seconds.

Page 2

877-877-2269 | blackbox.com

Page 3

FCC and IC RFI Statements

Federal Communications Commission and Industry Canada Radio Frequency Interference

Statements

This equipment generates, uses, and can radiate radio-frequency energy, and if not installed and used properly, that is, in strict

accordance with the manufacturer’s instructions, may cause inter ference to radio communication. It has been tested and found to

comply with the limits for a Class A computing device in accordance with the specifications in Subpart B of Part 15 of FCC rules,

which are designed to provide reasonable protection against such interference when the equipment is operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct the interference.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to

operate the equipment.

This digital apparatus does not exceed the Class A limits for radio noise emis sion from digital apparatus set out in the Radio

Interference Regulation of Industry Canada.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques

de la classe A prescrites dans le Règlement sur le brouillage radioélectrique publié par Industrie Canada.

Disclaimer:

Black Box Network Services shall not be liable for damages of any kind, including, but not limited to, punitive, consequential or cost of cover damages, resulting

from any errors in the product information or specifications set forth in this document and Black Box Network Services may revise this document at any time

without notice.

877-877-2269 | blackbox.com

Page 3

Page 4

NOM Statement

Instrucciones de Seguridad

(Normas Oficiales Mexicanas Electrical Safety Statement)

1. Todas las instrucciones de seguridad y operación deberán ser leídas antes de que el aparato eléctrico sea operado.

2. Las instrucciones de seguridad y operación deberán ser guardadas para referencia futura.

3. Todas las advertencias en el aparato eléctrico y en sus instrucciones de operación deben ser respetadas.

4. Todas las instrucciones de operación y uso deben ser seguidas.

5. El aparato eléctrico no deberá ser usado cerca del agua—por ejemplo, cerca de la tina de baño, lavabo, sótano mojado o cerca

de una alberca, etc.

6. El aparato eléctrico debe ser usado únicamente con carritos o pedestales que sean recomendados por el fabricante.

7. El aparato eléctrico debe ser montado a la pared o al techo sólo como sea recomendado por el fabricante.

8. Servicio—El usuario no debe intentar dar servicio al equipo eléctrico más allá a lo descrito en las instrucciones de operación.

Todo otro servicio deberá ser referido a personal de servicio calificado.

9. El aparato eléctrico debe ser situado de tal manera que su posición no interfiera su uso. La colocación del aparato eléctrico

sobre una cama, sofá, alfombra o superficie similar puede bloquea la ventilación, no se debe colocar en libreros o gabinetes

que impidan el flujo de aire por los orificios de ventilación.

10. El equipo eléctrico deber ser situado fuera del alcance de fuentes de calor como radiadores, registros de calor, estufas u otros

aparatos (incluyendo amplificadores) que producen calor.

11. El aparato eléctrico deberá ser connectado a una fuente de poder sólo del tipo descrito en el instructivo de operación, o como

se indique en el aparato.

12. Precaución debe ser tomada de tal manera que la tierra fisica y la polarización del equipo no sea eliminada.

13. Los cables de la fuente de poder deben ser guiados de tal manera que no sean pisados ni pellizcados por objetos colocados

sobre o contra ellos, poniendo particular atención a los contactos y receptáculos donde salen del aparato.

14. El equipo eléctrico debe ser limpiado únicamente de acuerdo a las recomendaciones del fabricante.

15. En caso de existir, una antena externa deberá ser localizada lejos de las lineas de energia.

16. El cable de corriente deberá ser desconectado del cuando el equipo no sea usado por un largo periodo de tiempo.

17. Cuidado debe ser tomado de tal manera que objectos liquidos no sean derramados sobre la cubierta u orificios de ventilación.

18. Servicio por personal calificado deberá ser provisto cuando:

A: El cable de poder o el contacto ha sido dañado; u

B: Objectos han caído o líquido ha sido derramado dentro del aparato; o

C: El aparato ha sido expuesto a la lluvia; o

D: El aparato parece no operar normalmente o muestra un cambio en su desempeño; o

E: El aparato ha sido tirado o su cubierta ha sido dañada.

Page 4

877-877-2269 | blackbox.com

Page 5

Table of Contents

Table of Contents

1. Specifications ......................................................................................................................................................................... 6

2. Overview ...............................................................................................................................................................................7

2.1 Description .................................................................................................................................................................... 7

2.2 Features ......................................................................................................................................................................... 7

2.3 What’s Included ............................................................................................................................................................ 8

2.4 Hardware Description .................................................................................................................................................... 9

2.4.1 ControlBridge Processor 100 (CB-CP100) ............................................................................................................. 9

2.4.2 ControlBridge Processor 200 (CB-CP200) .......................................................................................................... 10

2.4.3 Accessories ......................................................................................................................................................... 11

3. Installation ........................................................................................................................................................................... 13

3.1 Shelf Placement or Stacking ........................................................................................................................................ 13

3.2 Rackmounting ............................................................................................................................................................. 14

4. Operation ............................................................................................................................................................................ 15

4.1 Factory and System Default Settings ........................................................................................................................... 15

4.2 Indicators ..................................................................................................................................................................... 16

4.3 IR Sensor ..................................................................................................................................................................... 17

4.3.1 Capturing IR Codes.............................................................................................................................................18

4.3.2 IR Control Panels Receiver ..................................................................................................................................19

5. Connecting .......................................................................................................................................................................... 20

5.1 Power In ...................................................................................................................................................................... 20

5.2 Power over Ethernet .................................................................................................................................................... 21

5.3 ControlBridge Network ............................................................................................................................................... 21

5.4 Serial ............................................................................................................................................................................ 25

5.5 Versatile I/O Ports ........................................................................................................................................................ 27

5.6 General I/O .................................................................................................................................................................. 35

5.7 Relay ............................................................................................................................................................................ 36

5.8 Audio Line ................................................................................................................................................................... 36

6. Upload User Application ......................................................................................................................................................38

6.1 Using ControlBridge Builder ........................................................................................................................................38

6.2 Using Admin Control Panel .........................................................................................................................................39

7. Admin Control Panel ...........................................................................................................................................................40

7.1 Access Admin Control Panel ........................................................................................................................................ 40

7. 2 Lo gin ...........................................................................................................................................................................40

7.3 Configuration ..............................................................................................................................................................40

7.4 Date and Time .............................................................................................................................................................42

7.5 Applications .................................................................................................................................................................43

7.6 File Storage ..................................................................................................................................................................44

7.7 E- m ail ..........................................................................................................................................................................45

7. 8 Sy s te m ......................................................................................................................................................................... 45

7.9 Pa s s w or d .....................................................................................................................................................................46

7.10 Backup ........................................................................................................................................................................47

7.11 R e s e t ...........................................................................................................................................................................48

7.12 Logout ......................................................................................................................................................................... 49

7.13 Li cen s e ......................................................................................................................................................................... 49

877-877-2269 | blackbox.com

Page 5

Page 6

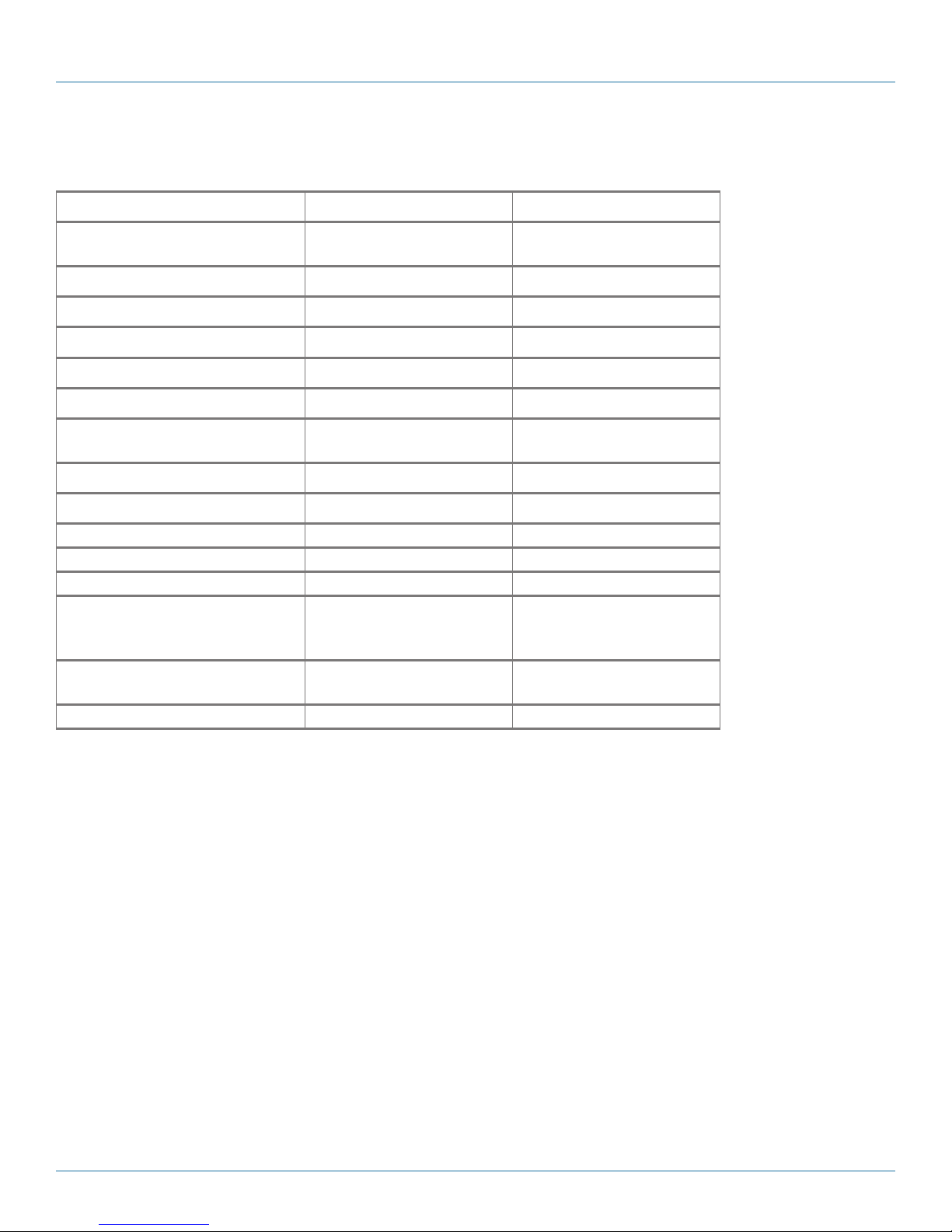

Chapter 1: Specifications

1. Specifications

Specification CB-CP100 CB-CP200

Approvals Power Supply: IEEE 802.3af

CE, FCC, RoHS

Audio — Line in, LIne out

Bidirectional Serial RS-232/485 3 —

Bidirectional Serial RS-232/422/485 — 2

Enclosure Aluminum Aluminum

General I/O (Analog In/Digital Out) — 4

IR Receivers For capture: 1 For capture: 1;

IR/Serial Output — 4

Low-Voltage Relay, 24 V / 0.5 A — 2

RAM / Non-volatile flash 64 MB / 256 MB 512 MB / 4 GB minimum

Versatile I/O Ports 8 —

Wired 10/100BASE-T Ethernet 1 1

Power 24 VDC power supply,

maximum 4 W, PoE,

IEEE 802.3af Class 0

Dimensions 1.7"H x 4.1"W x 3.6"D

(4.4 x 10.5 x 9.2 cm)

Weight 0.7 lb. (0.3 kg) 1.1 lb. (0.5 kg)

CE, FCC, RoHS

For wireless control panels: 1

24 VDC power supply,

maximum 4 W, PoE,

IEEE 802.3af Class 0

1.7"H x 8.3"W x 3.6"D

(4.4 x 21.0 x 9.2 cm)

Page 6

877-877-2269 | blackbox.com

Page 7

Chapter 2: Overview

2. Overview

2.1 Description

The ControlBridge units are Ethernet IP enabled controllers equipped with various types of control ports. Control ports include

bi-directional serial channels RS-232/422/485, serial outputs, versatile I/O ports, infrared outputs, general I/Os, 24 volts relay

outputs, DALI, KNX, DMX512, and EnOcean ports. The Ethernet port allows for bi-directional IP control of any manufacturer

IP enabled products. All models are fully compatible with ControlBridge button panels.

An Internal IR sensor allows users to capture IR codes and, for some models, receive IR codes from hand-held remotes.

Convenient for testing and troubleshooting, the ControlBridge Unit also has front panel indicator LEDs to indicate the status

of all the control ports.

The controller keeps date and time with its on-board real time clock (RTC), allowing for a wide variety of distributed

intelligence scheduling applications.

A single cable Ethernet connection provides easy network integration. The controllers are equipped with Power over Ethernet

(PoE) technology, enabling an Ethernet network cable to deliver both data and power.

This controller comes complete with a web server and allows setup through a standard web browser. Unit programming is

based on the Black Box standard programming tool ControlBridge Builder.

Both models include a web server and allow for setup through a standard web browser.

The aluminium enclosure can be installed on a tabletop or a 19-inch rack using the ControlBridge Control Processor 19-inch

Mounting Kit (CB-CP-RMK).

2.2 Features

• Ethernet IP enabled controllers

®

• Modern ARM

• On-board real time clock

• Wired 10/100BASE-T LAN

• Bi-directional control of any IP enabled products through the Ethernet port

• Various types of control ports

• Bi-directional serial RS-232/422/485

• IR /serial outputs (IR up to 1.2 MHz)

• General I/Os

• Relays NO-C-NC 24 V

• Real time clock (RTC) for scheduling application

processor platform

• Web server and Admin Web for setup through a standard web browser

• Aluminium enclosure design for desktop and 19-inch kit enables rackmounting

• Various accessories available

877-877-2269 | blackbox.com

Page 7

Page 8

Chapter 2: Overview

2.3 What's Included

Your package should include the following items. If anything is missing or damaged, contact Black Box Technical Support at

877-877-BBOX (2267) or info@blackbox.com.

CB-CP100:

• (1) ControlBridge 100

• (1) 24-VDC power supply

• (1) straight-through Ethernet cable

• (2) IR adapters

• (1) connector set

CB-CP200:

• (1) ControlBridge 200

• (1) 24-VDC power supply

• (1) straight-through Ethernet cable

• (4) IR adapters

• (1) connector set

Page 8

877-877-2269 | blackbox.com

Page 9

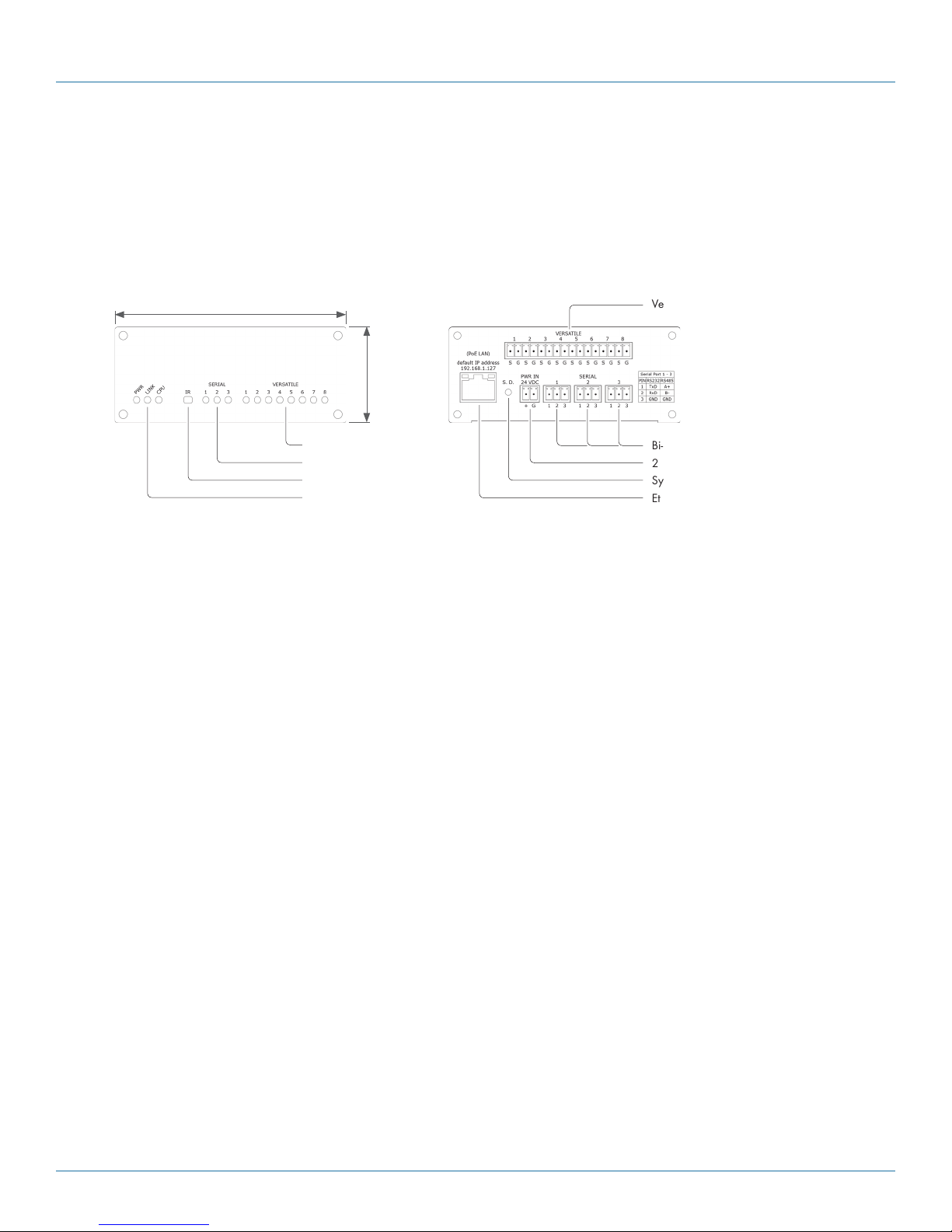

2.4 Hardware Description

2.4.1 ControlBridge Processor 100 (CB-CP100)

Figure 2-1 shows the ControlBridge Processor 100 (CB-CP100). Table 2-1 describes its components.

Chapter 2: Overview

105 mm

43.5 mm

Versatile port indicators

Serial port indicators

IR capture sensor

Power, link, and CPU indicators

Figure 2-1. ControlBridge Processor 100.

Versatile ports

Bi-directional serial ports

24-VDC power supply

System Default button

Ethernet with PoE

877-877-2269 | blackbox.com

Page 9

Page 10

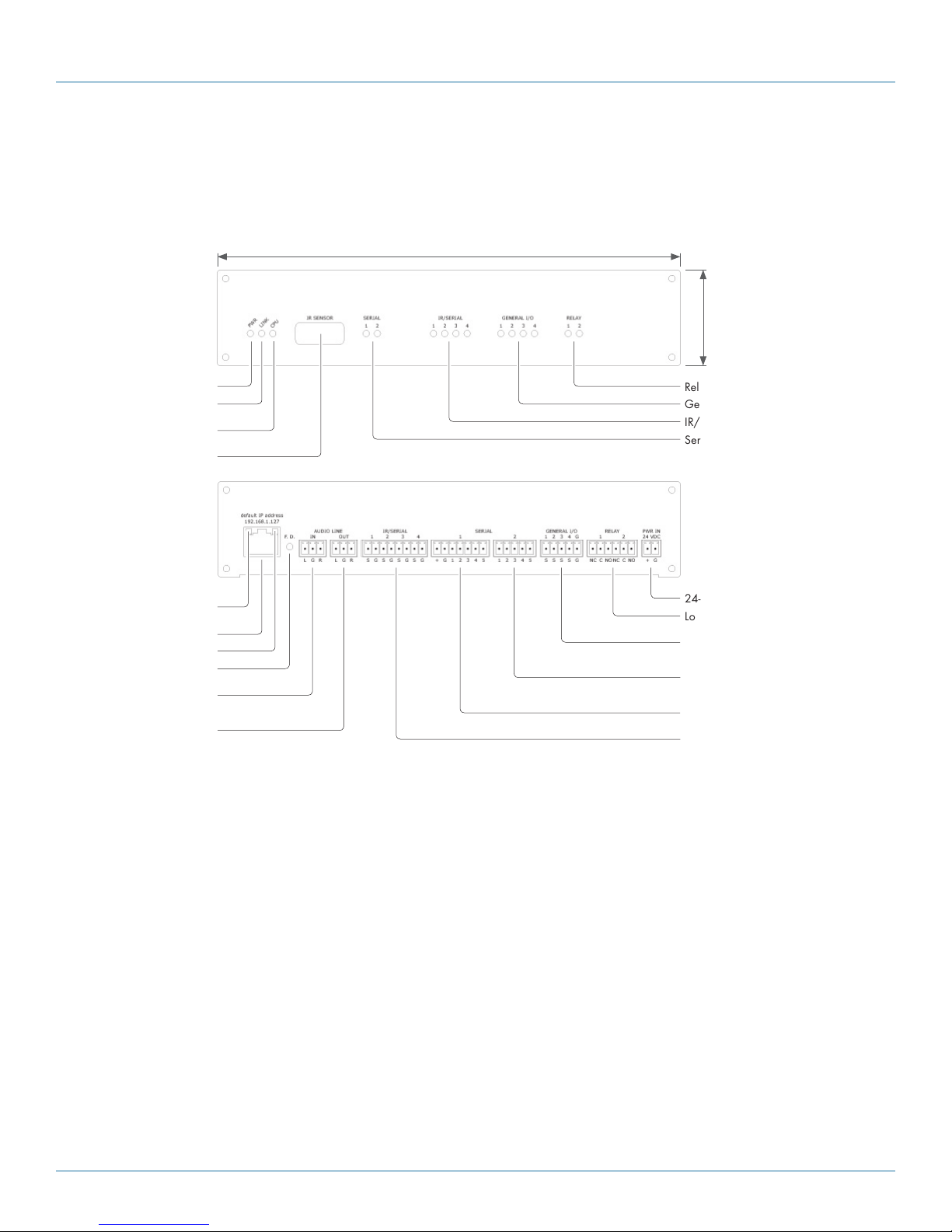

Chapter 2: Overview

2.4.2 ControlBridge Processor 200 (CB-CP200)

Figure 2-2 shows the ControlBridge Processor 200 (CB-CP200). Table 2-2 describes its components.

210 mm

43.5 mm

Power indicator (blue)

CPU indicator (yellow)

Ethernet indicator (green)

(Link and Activity)

IR sensors

Ethernet activity

indicator (yellow)

Ethernet

Ethernet link indicator (green)

Button Factory Default

Unbalanced audio

line input

Unbalanced audio

line output

Relay 1 - 2 indicators (red)

General I/O 1 - 4 indicators (green)

IR/Serial 1 - 4 indicators (yellow)

Serial 1 - 2 indicators (green / red)

24-VDC power supply

Low voltage relay 1 - 2

General I/O 1 - 4

with common ground

Bi-directional serial port 2

RS-232/422/485

Bi-directional serial port 1

RS-232/422/485 with power 24 VDC

IR/Serial output 1 - 4

Figure 2-2. ControlBridge Processor 200.

Page 10

877-877-2269 | blackbox.com

Page 11

Chapter 2: Overview

2.4.3 Accessories

IR Adapter

The IR Adapter (CB-ACC-IR-UNI) is an infrared emitter that is compatible with IR/serial output and versatile I/O ports. The adapter

mounts on the receiver window using double-sided adhesive tape.

2-pin, 3.5-mm

connector

Figure 2-3. IR adapter.

Serial IO Cable DTE

The Serial IO Cable DTE (CB-ACC-232DTE-30) is 3.0-m long and supports bi-directional communication between the serial device

and the ControlBridge.

DB9 M connector

(controlled device)

Figure 2-4. Serial IO Cable DTE (CB-ACC-232DTE-30).

IR emitter

5-pin, 3.5-mm

connector

877-877-2269 | blackbox.com

Pa g e 11

Page 12

Chapter 2: Overview

Serial IO Cable DCE

The Serial IO Cable DTE (CB-ACC-232DCE-30) is 3.0-m long and supports bi-directional communication between the serial device

and the ControlBridge.

DB9 F connector

(controlled device)

Figure 2-5. Serial IO Cable DCE (CB-ACC-232DTE-30).

ControlBridge Control Processor 19-inch Mounting Kit (CB-CP-RMK)

The ControlBridge Control Processor 19-inch Mounting Kit (CB-CP-RMK) is a shelf that supports your ControlBridge Processor 100

or 200 in a 19-inch rack. It's made of stainless steel and measures 1 U high (1.75") and 19" wide. The shelf weighs 1.3 kg and

includes mounting hardware.

5-pin, 3.5-mm

connector

Figure 2-6. ControlBridge Processor rackmounting shelf.

Page 12

877-877-2269 | blackbox.com

Page 13

Chapter 3: Installation

3. Installation

3.1 Shelf Placement or Stacking

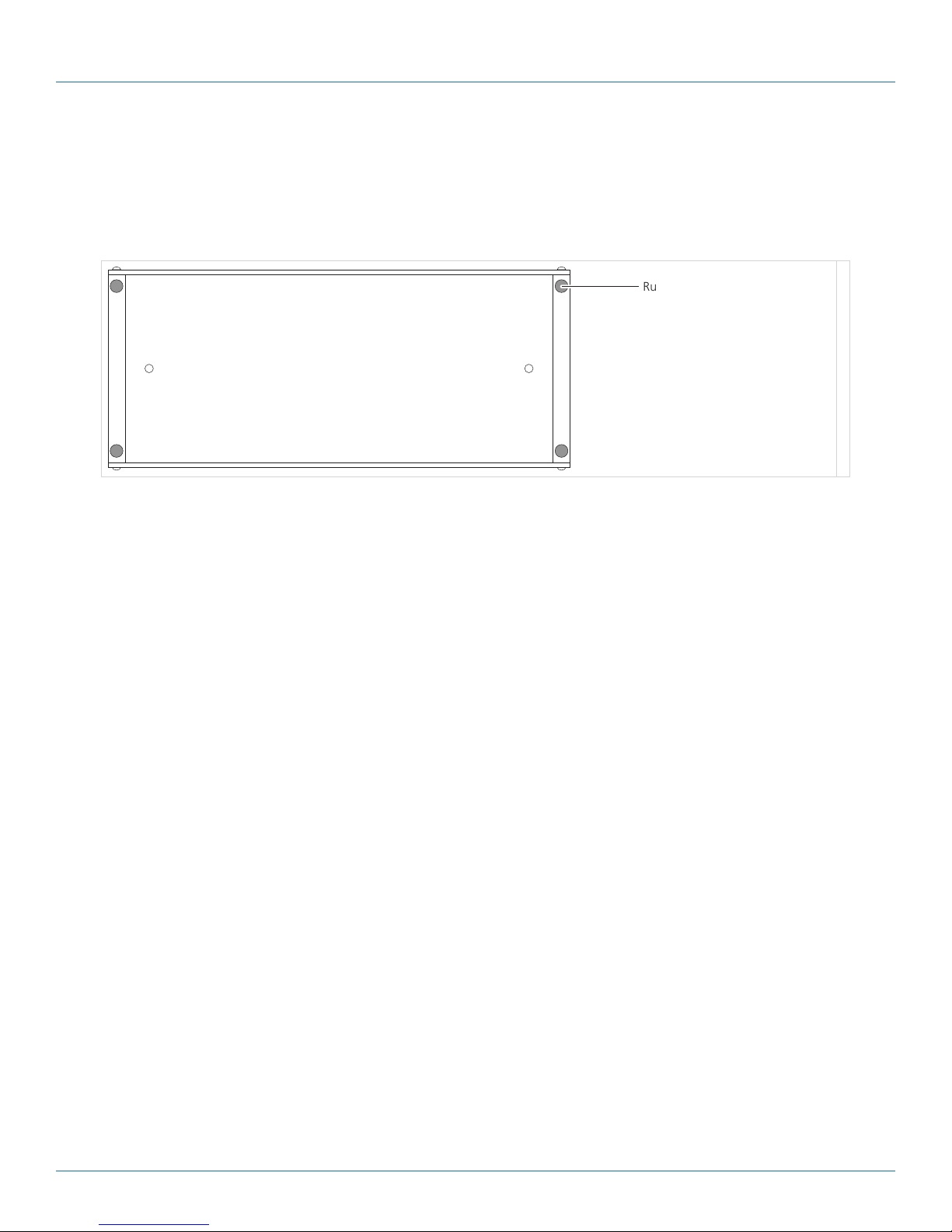

Four rubber feet are provided for shelf placement or stacking. Stick the rubber feet near the corner edges on the bottom side

of the controllers - see picture below.

Rubber feet

Figure 3-1. Installing rubber feet on the ControlBridge Processor.

877-877-2269 | blackbox.com

Page 13

Page 14

Chapter 3: Installation

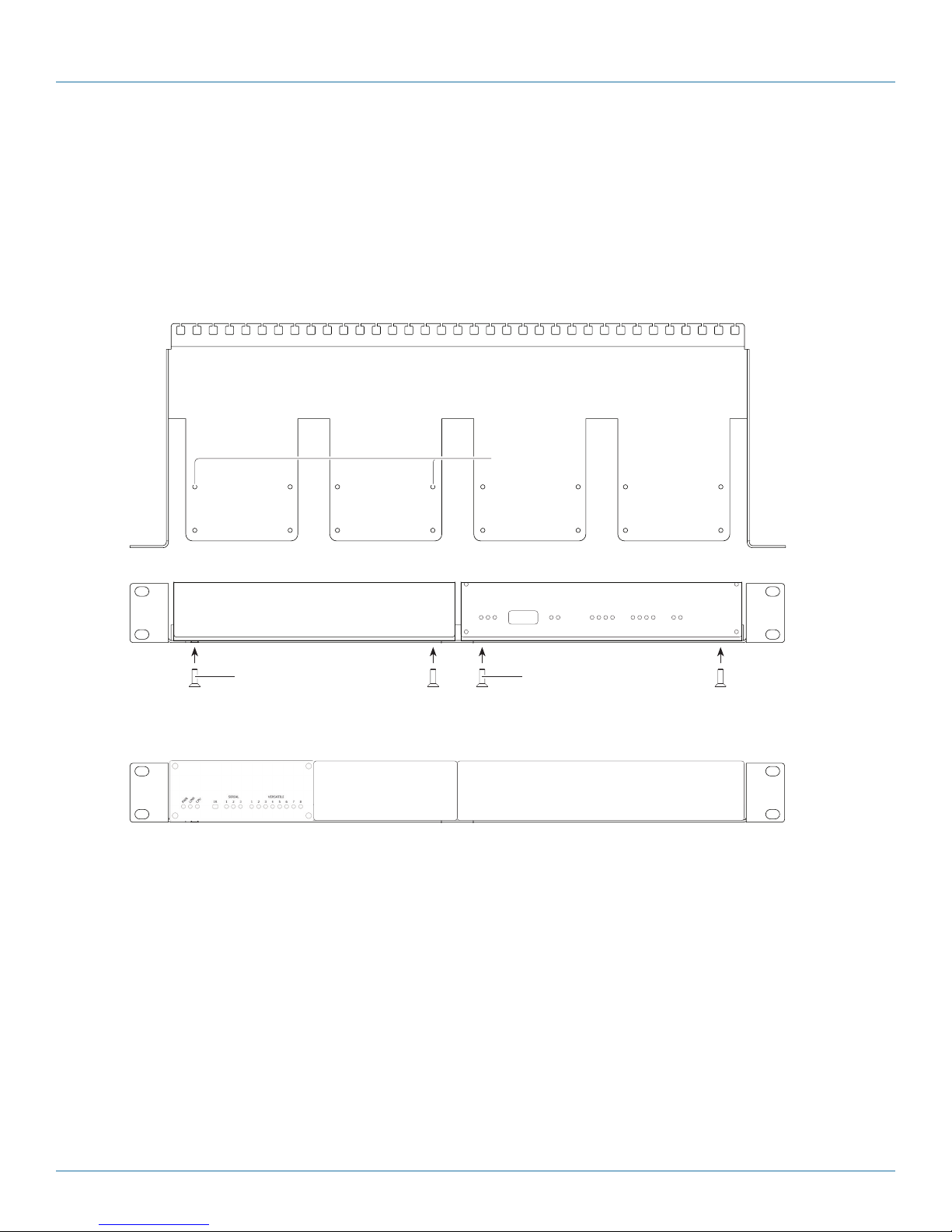

3.2 Rackmounting

The Rackmounting Shelf (CB-CP-RMK) provides a simple solution for installing controllers in a 19-inch rack. It allows you to

install up to two half-rack sized controllers in a single 19-inch unit rack space. All necessary accessories are supplied with the

shelf.

Attach the controller to the Rackmounting Shelf using two M3 x 6 screws to the female threads on the bottom side of the

controller - see picture below. The M3 x 6 screws are included with the Rackmounting Shelf. Don’t use longer screws; this

might damage PCBs inside the unit. If you install only one controller, use the cover panel delivered with the shelf.

Screw holes

SERIAL IR/SERIAL GENERAL I/O RELAYIR SENSOR

PWR

LINK

CPU

12 123 41 2123 4

PWR

LINK

CPU

SERIAL IR/SERIALG ENERAL I/O RELAYIR SENSOR

12 1234 12123 4

Screws M3 x 6 Screws M3 x 6

NOTE: If you install less controllers, use the cover panels delivered with the shelf to cover empty positions.

Cover panel 1/4

Cover panel 1/2

Figure 3-2. Rackmounting the ControlBridge Processor(s).

Page 14

877-877-2269 | blackbox.com

Page 15

Chapter 4: Operation

4. Operation

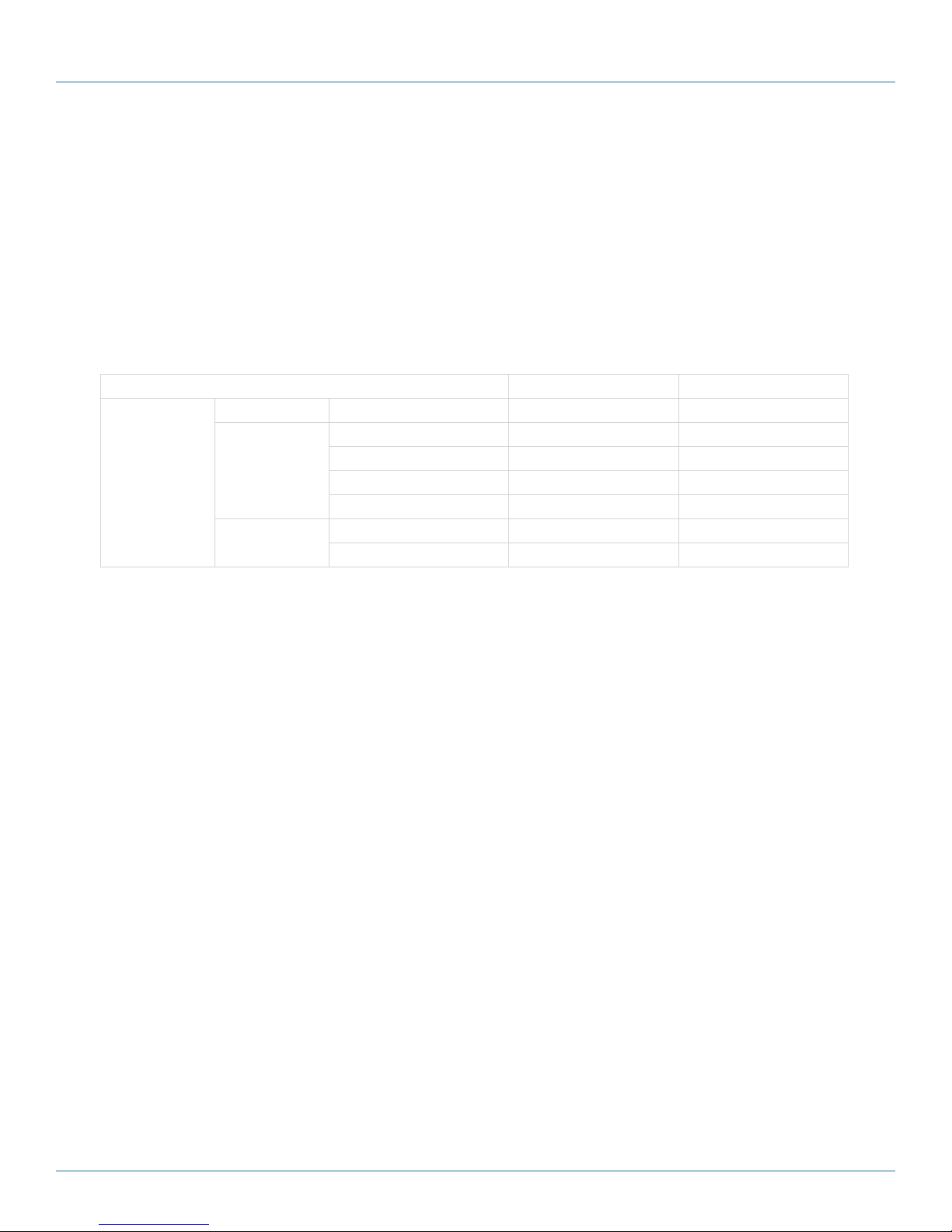

4.1 Factory and System Default Settings

Every device shipped from the factory is set according to table bellow, Factory Default column.

To restore the System Default settings, press the System Default (S.D.) button. This button enables you to connect if you lost

the password or if you do not know the IP settings. Press the S.D. button until the CPU LED indicator flashes to confirm the

system defaults settings are restored according to table below, System Default column. Use a thin screwdriver to press the

S.D. button.

Table 4-1. Factory and System Default settings.

Factory Default System Default

Configuration Identification Name Empty Not changed

IP settings Host name Empty Not changed

IP address 192.168.1.127 192.168.1.127

Subnet mask 255.255.255.0 255.255.255.0

Default gateway 192.168.1.1 192.168.1.1

DNS Primary DNS server Empty Not changed

Secondary DNS server Empty Not changed

877-877-2269 | blackbox.com

Page 15

Page 16

Chapter 4: Operation

Date and time Date and Time Day, month, year Real Not changed

Internet clock Use Internet clock Not Not changed

Applications Empty Not changed

File storage Empty Not changed

System Firmware Current version Not changed

Password Empty Empty

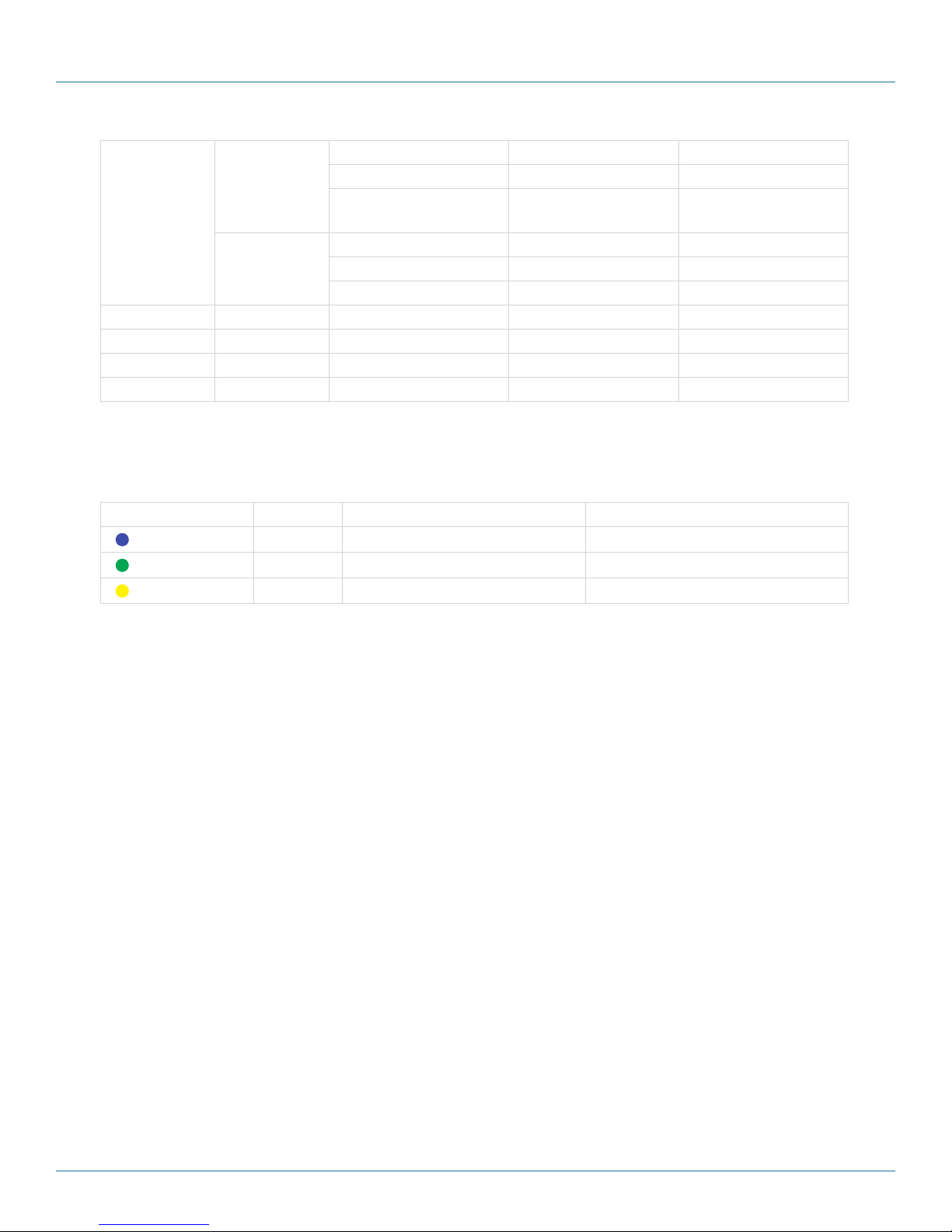

4.2 Indicators

Indicator Color Off On / Flashing

POWER Blue No power presented. Power is ON. The unit is ready.

LINK Green Network is not detected. Network link / activity

CPU Yellow No activity. System default indication.

Hour, minute, second Real Not changed

Time zone (UTC) Coordinated

Universal Time

Primary NTP server Empty Not changed

Secondary NTP server Empty Not changed

Table 4-2. General Indicators.

Not changed

Page 16

877-877-2269 | blackbox.com

Page 17

Chapter 4: Operation

Table 4-3. Control Port Indicators.

Indicator Color Off On / Flashing

ANALOG Yellow Analog output is set to 0 V. Analog output is set to 10 V.

DALI

DIGITAL I/O Green Output is switched OFF. Output is switched ON.

DMX512

EnOcean

GENERAL I/O Green Output is switched OFF. Output is switched ON.

IR/SERIAL Yellow No data or IR code transmitted. Data or IR code is being transmitted.

KNX

RELAY Red Relay is switched OFF. Relay is switched ON.

SERIAL

VERSATILE

Green

Red

Green

Red

Green

Red

Green

Red

Green

Red

Green

Yellow

No data activity. Data activity.

No data activity. Data activity.

No data activity. Data activity.

No data activity. Data activity.

No data transmitted or received.

Output is switched OFF.

No data or IR code transmitted.

Data is being transmitted.

Data is being received.

Output is switched ON.

Data or IR code is being transmitted.

4.3 IR Sensor

The following table explains how the IR sensor works for each controller model.

Table 4-4. IR sensor functions.

Controller IR codes capture

ControlBridge 100

ControlBridge 200

ü

ü ü

IR control panels

receiver

Not applicable

877-877-2269 | blackbox.com

Page 17

Page 18

Chapter 4: Operation

4.3.1 Capturing IR Codes

All controllers are equipped with an IR capture sensor and are able to capture IR codes. Captured IR codes can be used in both

controller models.

The capture procedure consists of the following steps:

1. Connect the capture unit and the PC with ControlBridge Builder to the same Network.

2. Arrange the IR remote and the capture unit as described below.

PWR

LINK

CPU

SERIAL IR/SERIAL GENERAL I/O RELAYIR SENSOR

1 2 1 2 3 4 1 21 2 3 4

IR remoter

Figure 4-1. IR remote configuration.

• Be sure to set the proper distance between the capturing unit and the remote unit to accommdate the the capturing unit’s

requirements.

• Start ControlBridge Builder and go to the appropriate driver and command

• Set the IP address of the unit used for capture.

• Push the Start Capture button in ControlBridge Builder and then press the appropriate button on the IR remote.

Page 18

Button Start Capture

Figure 4-2. Start Capture button.

877-877-2269 | blackbox.com

Page 19

Chapter 4: Operation

4.3.2 IR Control Panels Receiver

The built-in IR sensor functions the same as other IR receivers. This means that ControlBridge can receive an IR signal from

wireless IR control panels without using an external IR receiver.

e

The IR Adapter connects to the rest of the control system via

IR communication.

17 654328

ON

As the IR receiver you can use

The remote control unit

IR receiver built into ControlBridge controllers

IR receiver built into 8-Button Laminated Keypad

and 8-Button Engraved Keypad keypads.

Controller

1

2

4

3

5

7

6

8

Fn

9

0

Channel

Enter

Menu

Volume

Exit

Rec

Pause

Figure 4-3. IR control panel receiver.

877-877-2269 | blackbox.com

Page 19

Page 20

Chapter 5: Connecting

5. Connecting

The following table describes connections for both controllers.

Table 5-1. ControlBridge connections.

Unit Connection

Power supply 24 VDC

Power over Ethernet

Ethernet

Serial RS-232/485

Serial RS-232/422/485

IR/Serial output

Versatile

General I/O

Low-voltage relay

DALI

KNX

DMX512

EnOcean

ControlBridge 100 1 1 1 3 8

ControlBridge 200 1 1 1 2 4 4 2

5.1 Power In

The unit requires power 24 VDC from an external power supply. Use any unit ONLY with the power adapter supplied in the

product package. Using another power supply may damage the unit.

Power consumption

▪ ControlBridge 100 max. 4 W

▪ ControlBridge 200 max. 4 W

Table 5-2. Connector Pin Out.

PWR IN

2-pin 3.5 mm Pin Description

+ Power +24 VDC

+ G

G Ground

Power Adapter

A standard power adapter is delivered with the ContrBridge. Attach the 2-pin connector of the power supply unit to the PWR

IN connector located on the rear panel and attach the power cable to a power outlet.

ControlBridge

Network

default IP address

192.168.1.127

IN OUT 1 2 3 4 1 2 1 2 3 4 G 1 2 24 VDCF. D .

L G R L G R S G S G S G S G + G 1 2 3 4 5 1 2 3 4 5 S S S S G NC C NONC C NO + G

PWR INRELAYGENERAL I/OSERIALIR/SERIALAUDIO LINE

Figure 5-1. Power adapter.

Page 20

877-877-2269 | blackbox.com

Page 21

Chapter 5: Connecting

5.2 Power over Ethernet (PoE)

The ControlBridge units are equipped with PoE and are compatible with standard IEEE 802.3af / Class 0 Ethernet with PoE

Infrastructure.

Ethernet

with PoE

Ethernet cable

Figure 5-2. Ethernet connection with PoE infrastructure.

5.3 ControlBridge Network

The ControlBridge links to a 10/100 BASE-T LAN via its RJ-45 connector.

The length of the Ethernet cable connecting controller to the network must not exceed 100 meters.

Table 5-3. Connector pinout.

RJ-45 Pin Signal CAT5 Cable Color

1 TX_D1+ and PoE White / Orange

2 TX_D1- and PoE Orange

3 RX_D2+ and PoE White / Green

4 Blue

5 White / Blue

6 RX-D2- and PoE Green

7 White / Brown

8 Brown

877-877-2269 | blackbox.com

Page 21

Page 22

Chapter 5: Connecting

Direct PC Connection

Attach one end of an RJ-45 Ethernet cable to the ControlBridge Network port and attach the other end of the RJ-45 Ethernet

cable to your computer. Use straight-through cable if your PC supports autosensing or cross-over cable if your PC doesn’t

support autosensing.

ControlBridge

Network

default IP address

192.168.1.127

IN OUT 1 2 3 4 1 2 1 2 3 4 G 1 2 24 VDCF. D .

L G R L G R S G S G S G S G + G 1 2 3 4 5 1 2 3 4 5 S S S S G NC C NONC C NO + G

Ethernet cable

straight-through or crossed-over

Figure 5-3. Direct PC connection.

LAN Network Connection

PWR INRELAYGENERAL I/OSERIALIR/SERIALAUDIO LINE

Attach one end of an RJ-45 Ethernet straight-through cable to the ControlBridge Network port and attach the other end of

the RJ-45 Ethernet cable to your computer.

ControlBridge

Network

default IP address

192.168.1.127

IN OUT 1 2 3 4 1 2 1 2 3 4 G 1 2 24 VDCF. D .

L G R L G R S G S G S G S G + G 1 2 3 4 5 1 2 3 4 5 S S S S G NC C NONC C NO + G

PWR INRELAYGENERAL I/OSERIALIR/SERIALAUDIO LINE

Network

Ethernet cable straight-through

Figure 5-4. LAN network connection.

Page 22

877-877-2269 | blackbox.com

Page 23

Windows Local Network Settings

Follow these steps for Windows 7:

1. Start Windows 7.

2. Click Start.

3. Enter ncpa.cpl into the Search Box and press Enter. The following window is displayed.

Chapter 5: Connecting

Figure 5-5. Windows 7 screen 1.

3. Right-click on network adapter used for connection with controller and then right-click and select Properties.

4. Select Internet Protocol (TCP/IP) and click Properties button.

Figure 5-6. Windows 7 screen 2.

877-877-2269 | blackbox.com

Page 23

Page 24

Chapter 5: Connecting

Follow these steps for Windows XP:

1. Start Windows XP.

2. Click Start, then click Control Panel and choose the option to switch to Classic View.

3. Double-click Network Connections.

Figure 5-7. Windows XP screen 1.

1. Select Use the following IP address option. Set IP address to 192.168.1.1 (or other address different from 192.168.1.127

and from 192.168.1.128) and Subnet mask to 255.255.255.0. Leave other options unchanged and click OK.

Page 24

Figure 5-8. Windows XP screen 2.

877-877-2269 | blackbox.com

Page 25

5.4 Serial

Chapter 5: Connecting

Table 5-4. Serial ports on the ControlBridge units.

Unit Serial port

Serial RS-232/485

ControlBridge 100 3

ControlBridge 200 1 1

Bi-directional Serial RS-232/485

These bi-directional serial channels are used for RS-232 and RS-485 communication. Maximum speed is 115,200 bps. The

default mode for all channels is RS-232; you must set other modes in the programming application. For more details, see your

programming manuals.

RS-232 Mode

Output signal levels for RS-232 are in the -10 V to +10 V range. This is the default mode for all channels.

Table 5-5. RS-232 pinout.

SERIAL RS-232

3-pin 3.5 mm Pin Signal Description Direction

1 TxD RS-232 Transmitted Data

1 2 3

2 RxD RS-232 Received Data

3 GND Ground —

Serial RS-232/422/485

Serial RS-232/422/485

with power 24 VDC

From controller

To controller

RS-485 Mode

You must set this mode in the programming application.

3-pin 3.5 mm Pin Signal Description

1 A+ RS-485 Data +

1 2 3

2 B- RS-485 Data -

3 GND Ground

Table 5-6. RS-485 pinout.

SERIAL RS-485

877-877-2269 | blackbox.com

Page 25

Page 26

Chapter 5: Connecting

Bi-directional Serial RS-232/422/485

These bi-directional serial channels are used for RS-232, RS-422, and RS-485 communication. The maximum speed is 115,200

bps. The default mode for all channels is RS-232; you must set other modes in the programming application. For more details,

see the programming manuals.

RS-232 Mode

Output signal levels for RS-232 are in the -10 V to +10 V range. This is the default mode for all channels.

Table 5-7. RS-232 pinout.

SERIAL RS-232

5-pin 3.5 mm Pin Signal Description Direction

From controller

From controller

To controller

To controller

1 2 3 4 5

1 TxD RS-232 Transmitted Data

2 RTS RS-232 Request to Send

3 GND Ground —

4 RxD RS-232 Received Data

5 CTS RS-232 Clear to Send

RS-422 Mode

You must set this mode in the programming application.

Table 5-8. RS-422 pinout.

5-pin 3.5 mm Pin Signal Description Direction

1 Tx A+ RS-422 Transmit Data (Idles High)

2 Tx B- RS-422 Transmit Data (Idles Low)

3 GND Ground —

1 2 3 4 5

4 Rx A+ RS-422 Receive Data (Idles High)

5 Rx B- RS-422 Receive Data (Idles Low)

RS-485 Mode

You must set this mode in the programming application.

Table 5-9. RS-485 pinout.

5-pin 3.5 mm Pin Signal Description

1 A+ RS-485 Data +

2 B- RS-485 Data -

3 GND Ground

1 2 3 4 5

4 N.C. Not Connected

5 N.C. Not Connected

SERIAL RS-422

From controller

From controller

To controller

To controller

SERIAL RS-485

Page 26

877-877-2269 | blackbox.com

Page 27

Chapter 5: Connecting

5.5 Versatile I/O Ports

Depending on the application, the versatile I/O ports can be used in multiple ways as described in the following table.

Table 5-10. Versatile port functions.

Input modes

Digital input Adjustable threshold

• High sensitivity - binary 0 < 1.45 V, binary 1 > 2.05 V

• Low sensitivity - binary 0 < 5.8 V, binary 1 > 8.2 V

Input impedance >100 kΩ

Adjustable digital filter

Pulse counter Adjustable threshold as above

Input impedance as above

Pulse length min. 1 ms, max. frequency 500 Hz

Max. number of pulses 2 147 483 647 (Long)

Adjustable digital filter

Voltage input Range 0 to 2.5 VDC, 0 to 10 VDC, auto

Input impedance >100 k-ohms

Resolution 12-bit

Adjustable digital filter

Accuracy ±0.1 % of reading, ±0.1 % of range

(0.1 to 10 V, digital filter applied)

Resistance input Range 2 kohms, 20 kohms, 200 kohms, auto¸

Resolution 12-bit

Adjustable digital filter

Accuracy (digital filter applied)

• 100 ohms to 800 ohms: ±3 % of reading, ±0.1 % of range

• 800 ohms to 20 kohms: ±0.3 % of reading, ±0.1 % of range

• 20 kohms to 200 kohms: ±1 % of reading, ±0.1 % of range

Output modes

Digital output Max. sink current 200 mA / max. 30 VDC

Catch diodes for use with real load

Current pullup Current-source pull-up 12 V / 10 mA

Current pulldown Current-source pull-down -12 V / 10 mA

IR output Maximum IR carrier frequency 500 kHz

Up to 3 original IR Adapter in parallel

Serial output RS-232

Serial data baud rate 300 bps ÷ 115,200 bps

Warnings

• The port is protected to 30 VDC maximum. Exceeding this voltage may damage the port.

• Incorrect wiring may damage the versatile port or the connected device.

• All versatile ports in the unit have common ground, which connects to the grounds of other control ports.

That means versatile ports are not isolated from other control ports.

Table 5-11. Connector pinout.

877-877-2269 | blackbox.com

Page 27

Page 28

Chapter 5: Connecting

2-pin 3.5 mm Pin Signal Description

S Signal Versatile port signal (input/output)

S G

G GND Ground

Digital Input

Every versatile port can be used as a digital input for contacts, buttons, sensors, etc. For digital input usage, the output must

be in an open state and current pull-up and current pull-down can be used.

Parameters of pulse counter input are as follows:

• Adjustable threshold

• High sensitivity - binary 0 < 1.45 V, binary 1 > 2.05 V

• Low sensitivity - binary 0 < 5.8 V, binary 1 > 8.2 V

• Input impedance >100 kohms

• Adjustable digital filter

The port offers adjustable threshold as described in the following picture.

Input [V]

High sensitivity

binary 0 < 1.45 V, binary 1 > 2.05 V

10

5

binary 0 < 5.8 V, binary 1 > 8.2 V

Input [V]

10

5

Low sensitivity

8.2

5.8

2.05

1.45

binary 0 binary 1 binar y 0

Figure 5-9. Adjustable threshold.

The following table describes how to use digital input.

Table 5-12. Digital input.

Detecting a pushbutton or contact

Any button or contact closure can be connected.

S G

binary 0 binary 1 binar y 0

Page 28

877-877-2269 | blackbox.com

Page 29

Pulse Counter

Pulse counter input parameters are as follows:

• Adjustable threshold as above

• Input impedance as above

• Pulse length min. 1 ms, max. frequency: 500 Hz

• Max. number of pulses: 2 147 483 647 (Long)

• Adjustable digital filter

The following table describes how to use pulse counter input.

Table 5-13. Pulse countter input.

Energy meters S0 interface pulse counter

Many meters have pulse outputs, including electric meters (single phase,

3-phase), gas meters, water flow meters, etc. For an electric meter, a pulse

output corresponds to a certain amount of energy passing through the

Energy meter

S0+

S0-

I

= 20 mA

max

meter (kWhr/Whr). For single-phase domestic electric meters, each pulse

usually corresponds to 1 Whr (1000 pulses per kWhr). For higher power

meters (often three-phase), each pulse corresponds to a greater amount of

energy eg. 2 Whr per pulse or even 10 Whr per pulse.

Chapter 5: Connecting

S G

simple galvanically isolated open-collector output channel.

Voltage Input

Voltage input parameters are as follows:

• Range 0 to 2.5 VDC, 0 to 10 VDC, auto

• Input impedance >100 kohms

• Resolution 12-bit

• Adjustable digital filter

• Accuracy ±0.1 % of reading, ±0.1 % of range (0.1 to 10 V, digital filter applied).

For pulse outputs from third-party energy meters, S0 interface defines a

877-877-2269 | blackbox.com

Page 29

Page 30

Chapter 5: Connecting

The following table describes how to use voltage input.

Table 5-14. Voltage input.

Detecting a voltage

+

-

S G

Reading voltage

S G

Max.

10 VDC

+

-

Sensors with voltage output 0 - 10 VDC

Potentiometer with external power supply

Max.

10 VDC

Page 30

877-877-2269 | blackbox.com

Page 31

Resistance Input

Parameters of resistance input are as follows:

• Range 2 kohms, 20 kohms, 200 kohms, auto

• Resolution 12-bit

• Adjustable digital filter

• Accuracy (digital filter applied)

• 100 ohms to 800 ohms: ±3 % of reading, ±0.1 % of range

• 800 ohms to 20 kohms: ±0.3 % of reading, ±0.1 % of range

• 20 kohms to 200 kohms: ±1 % of reading, ±0.1 % of range

The following table describes how to use resistance input.

Table 5-15. Resistance input.

Reading resistance

Chapter 5: Connecting

100 to 200 kohms

S G

Temperature sensors

100 to 200 kohms

S G

Potentiometer for light, temperature and volume control.

Thermistors and temperature sensors can be connected.

877-877-2269 | blackbox.com

Page 31

Page 32

Chapter 5: Connecting

Digital Output

For digital output the open collector switch is used. Parameters of digital output are as follows:

• Max. sink current 200 mA / max. 30 VDC

• Catch diodes for use with real load

The following table describes how to use digital output.

Table 5-16. Digital output.

Driving a relay coil

Max.

30 VDC

Driving LED indicator

Driving LED strip

Max.

30 VDC

+

-

+

-

S G

Max.

250 mA

Driving relays with low-voltage coil

Max.

250 mA

S G

Driving LEDs for custom indicators on keyboards, control panels,

etc.

Driving LED strips with max. voltage 30 VDC and max. current

200 mA.

S G

Page 32

877-877-2269 | blackbox.com

Page 33

Chapter 5: Connecting

IR Output

This mode of versatile port provides output for infra-red emitters (IR Adapters). Parameters of IR output are as follows:

• The maximum IR carrier frequency is 500 kHz.

• Up to three original infra-red emitters (IR Adapters) can be connected to each output in parallel. All emitters send the same

IR codes. This configuration can be used for different types of devices.

WARNING: We do not recommend connecting more infra-red emitters from various manufacturers in parallel

because the output can be either overloaded or damaged.

Connecting

S G

Controlled Device 1 Controlled Device 2 Controlled Device 3

IR AdapterIR Adapter IR Adapter

FIgure 5-10. IR output.

Serial Output

This mode provides one-way RS-232 output channel.

Serial output parameters are as follows:

• RS-232 mode only

• Serial data baud rate 300 bps to 115,200 bps

WARNING: If there are more ports in the unit, all pins labelled G are connected together.

Connecting

Controlled

Device

RxD

G

S G

Figure 5-11. Serial output.

877-877-2269 | blackbox.com

Page 33

Page 34

Chapter 5: Connecting

IR/SERIAL

This type of port provides:

• Output for infra-red emitters (IR Adapters); the maximum IR output rate is 1.2 MHz.

• For RS-232 serial output (one way), the maximum serial data rate is 115 200 Bd (bps), and output signal levels

for RS-232 are in the -12 V to +12 V range.

The IR outputs and RS-232 outputs can be combined on independent outputs (for example, three outputs can be used as IR,

and five outputs can be used as RS-232).

Table 5-17. IR/Serial.

IR/SERIAL

2-pin 3.5 mm Pin Signal Description

S Signal IR/Serial Signal (Output)

S G

NOTES:

• All pins labelled G are connected together.

• Up to three original infra-red emitters (IR Adapters) can be connected to each output in parallel

• We do not recommend connecting more infra-red emitters from various manufacturers in parallel, because the output can

be either overloaded or damaged.

G GND Ground

Page 34

877-877-2269 | blackbox.com

Page 35

Chapter 5: Connecting

5.6 General I/O

General I/O provides analog input as well as digital output. Each General I/O port can be used either as input or as output.

A 680-ohms pull-up resistor connects to +5 VDC and can be switched on and off for each I/O independently. I/O voltage with

pull-up on is approx. +4.3 VDC, because the protection diode is connected in series (0.7 V dropdown).

Analog input is rated 0 – 5 VDC. Analog to digital (A/D) converter has 10-bits precision (i.e. 1024 levels).

Digital output can switch max. 24 VDC / 80 mA. Output voltage for output switch on is approx. 0.6 V.

I/O schematic diagram

+5 VDC

ON OFF

PULLUP

value ON / OFF

680 Ohm

Input / Output Signal

Ground

Figure 5-12. I/O schematic diagram.

Connector pinout

Table 5-18. Connector pinout.

GENERAL I/O

5-pin 3.5 mm Pin Signal Description

1 2 3 4

S S GS S

S Signal Input / Output Signal 1 - 4

G GND Common ground for all I/Os

A

INPUT

D

10 bit

OUTPUT

value CLOSE / OPEN

877-877-2269 | blackbox.com

Page 35

Page 36

Chapter 5: Connecting

5.7 Relay

This port provides one isolated low voltage relay. Each relay contact closure is rated 24 V / 0.5 A.

Normally Closed (NC) and Normally Open (NO) contacts as well as Common (C) contact of each relay can be used. The

Normally Closed (NC) position is the state of the relay when it is not turned on (energized).

Relay open Relay closed

NC

NC

Connector pin out

3-pin 3.5 mm Pin Description

NC Relay Contact Normally Closed

C Relay Contact Common

C NO

NC

NO Relay Contact Normally Open

5.8 Audio Line

IN

C

NO

C

NO

Figure 5-13. Relay.

Table 5-19. Relay connnector pinout.

RELAY

This connector provides unbalanced line level audio.

Connector pinout

3-pin 3.5 mm Pin Signal Description

L Left Left channel input

G GND Ground

L G R

R Right Right channel input

Page 36

Table 5-20. Audio line in connector pinout.

AUDIO LINE IN

877-877-2269 | blackbox.com

Page 37

Chapter 5: Connecting

OUT

This connector provides un-amplified unbalanced line level audio. Connect audio devices, such as an audio amplifier or

powered speakers to this connector.

Connector pin out

Table 5-21. Audio line out connector pinout.

AUDIO LINE OUT

3-pin 3.5 mm Pin Signal Description

L Left Left channel output

L G R

G GND Ground

R Right Right channel output

877-877-2269 | blackbox.com

Page 37

Page 38

Chapter 6: Upload User Application

6. Upload User Application

The user application is dedicated to control and it is programmed by ControlBridge Builder programming tools.

6.1 Using ControlBridge Builder

Follow these steps:

1. Connect the controller to your computer as described in the Connecting / ControlBridge Network chapter.

2. Run ControlBridge Builder on your PC.

3. Open a project in ControlBridge Builder. You must have the appropriate controller properly inserted and configured.

4. Use the tool bar Final button to open the Upload and Export Application dialog box.

5. Be sure your controller is checked.

Final Button

Upload Button

Figure 6-1. ControlBridge Builder screen.

6. Use the Upload button to start application upload.

7. If controller firmware isn’t updated, it will be uploaded automatically first and then the application upload will be finished.

Page 38

877-877-2269 | blackbox.com

Page 39

Chapter 6: Upload User Application

6.2 Using Admin Control Panel

Follow these steps:

1. Run ControlBridge Builder on your PC.

2. Open a project in ControlBridge Builder. It’s necessary to have the appropriate controller properly inserted and configured.

3. Use the tool bar Final button to open the Upload and Export Application dialog box.

Final Button

Export As Application Files ...

Figure 6-2. Admin Web screen.

4. Be sure your controller is checked.

5. Use the Export As... button and select Application Files ...to export an application and store it in file named *.cvca.

6. Connect the controller to your computer as described in the Connecting / ControlBridge Network chapter.

7. Run the Internet browser on your PC and type in the same controller IP address that you see in the ControlBridge Builder

project, Properties / IP address window.

8. Admin Control Panel is shown.

9. Go to the System page and check the current firmware version. In case there is no actual controller firmware version,

upload the firmware version that corresponds to the firmware version in the ControlBridge Builder project.

10. Go to the Applications page and upload the application file *.cvca.

11. Start the uploaded application by pressing the Start button.

877-877-2269 | blackbox.com

Page 39

Page 40

Chapter 7: Admin Control Panel

7. Admin Control Panel

7.1 Access Admin Control Panel

Run the Internet browser on your PC and type in the controller IP address. The factory default IP address is 192.168.1.127.

7.2 Login

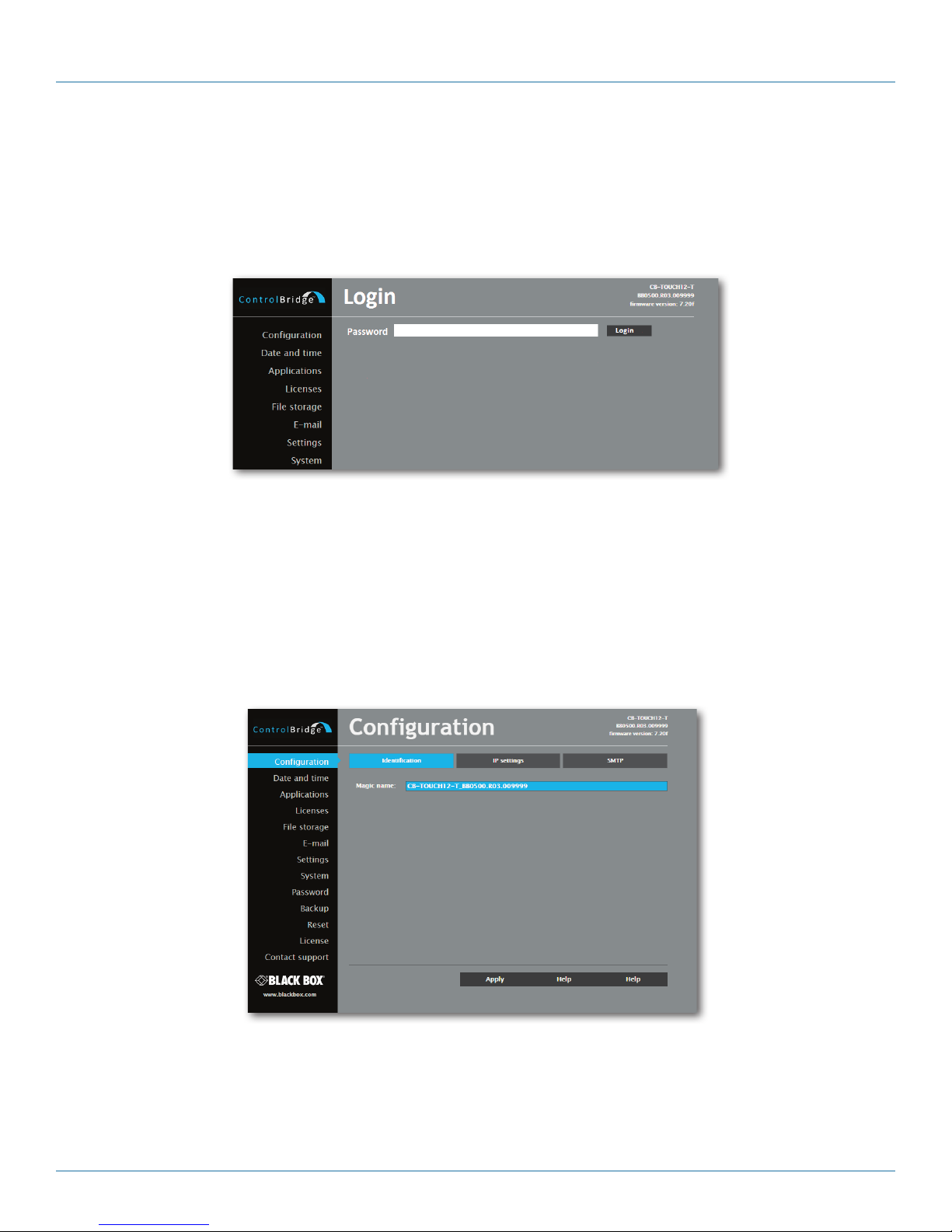

Figure 7-1. Login screen.

This screen isn’t displayed if password is empty (factory default status).

If password isn’t empty, you have to login first in order to access the configuration web pages.

Enter your password into the Password box and click the Login button to enter the ControlBridge Unit web pages.

Remember that the password is case sensitive. To change your password, use the Password menu after you are logged in.

7.3 Configuration

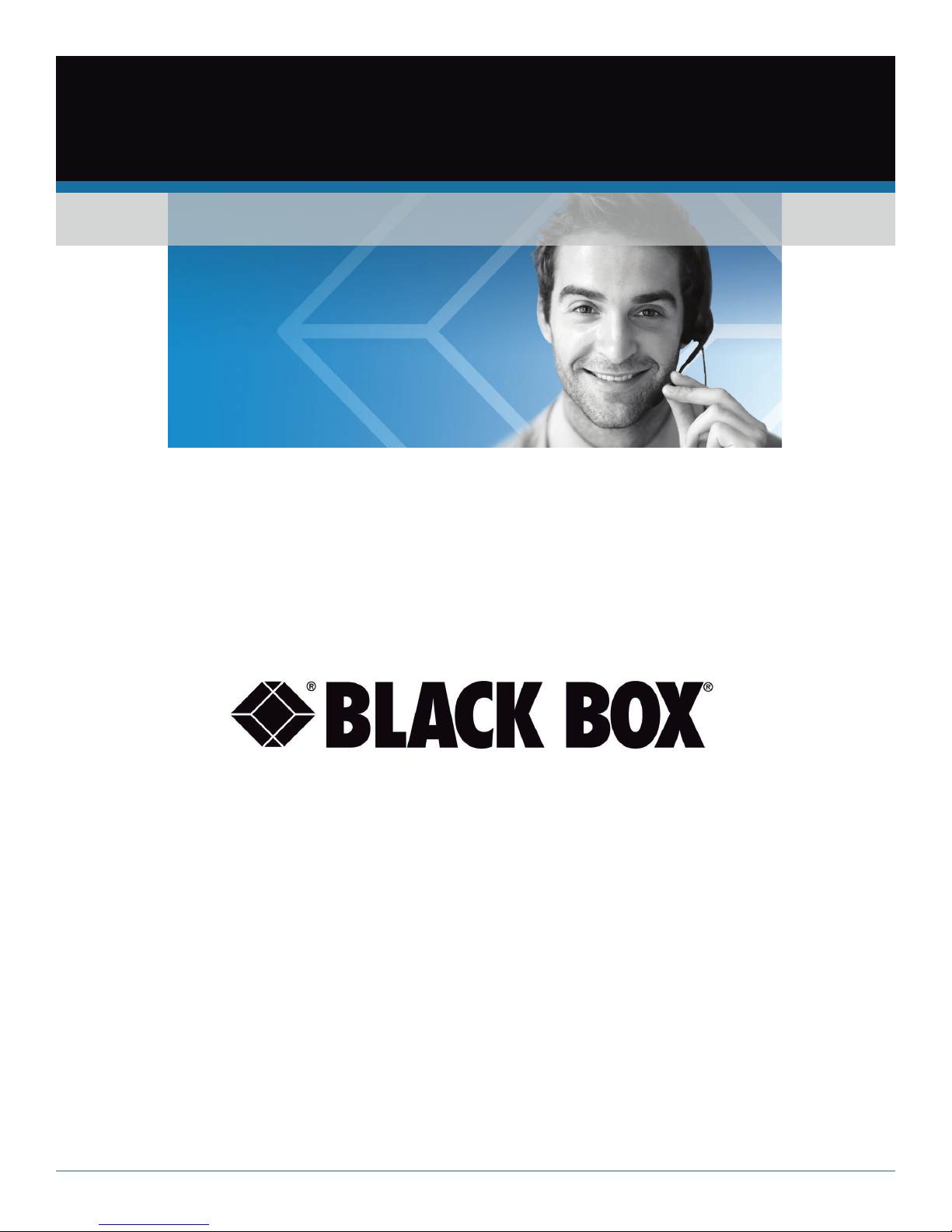

Identification

Figure 7-2. Configuration screen, Identification tab.

Each ControlBridge Unit can be identified by a unique identification name. Unique names are most useful in applications

requiring more than one ControlBridge Unit. This enables programmers and installers to reference ControlBridge Units with

logical, user friendly names, like “boardroom,” “lobby,” etc. To set the ControlBridge Unit identity, enter the unique name

you wish to use in the Name box. Click the Apply button for any changes to become effective.

Page 40

877-877-2269 | blackbox.com

Page 41

Chapter 7: Admin Control Panel

IP Settings

Figure 7-3. IP Settings tab.

This page is used for setting the communication parameters for your ControlBridge Unit.

The ControlBridge Unit uses standard internet protocol (IP) communication parameters. Certain parameters can be reset by the user.

On start up, this page will display the ControlBridge Unit’s given Physical address (MAC), and Current IP Address. Carefully note this

addressing information (and any changes you elect to make to the IP address, subnet mask, or default gateway). You must enter this

information into the ControlBridge Builder program written for your specific application. For control systems with more than one

ControlBridge Units, you must give a unique IP address to each ControlBridge Unit.

Some control systems are “standalone” and not part of a larger network. For such “standalone” systems, the Host name

is optional. However, for control systems that are connected to a larger network, obtain the Host name from the network

administrator, and enter it into the corresponding box. DHCP is not supported in this release.

Be sure to click the Apply button for any changes to become effective!

SMTP

This page is used to set SMTP server parameters. Set a name or an address and the port of your SMTP server.

The SMTP server and port are used by the XPL2 commands EmailSend and PresetEmailSend.

Figure 7-4. SMTP tab.

877-877-2269 | blackbox.com

Page 41

Page 42

Chapter 7: Admin Control Panel

Be sure to click the Apply button for any changes to become effective!

7.4 Date and Time

Current Date and Time

Figure 7-5. Current Date and Time screen.

Use this page to set the time clock on your ControlBridge Unit. The current date, time, and time zone are shown on the

Current time line.

The applicable boxes can be selected to enter changes to the

• date: day/month/year,

• time: hour/minute/second.

Be sure to click the Apply button for any changes to become effective!

Time Zone

Page 42

Figure 7-6. Time Zone.

877-877-2269 | blackbox.com

Page 43

Chapter 7: Admin Control Panel

Use this page to set the time zone on your ControlBridge Unit. The current date, time, and time zone are shown on the

Current time line. Select the time zone box to enter changes to the Time zone.

Be sure to click the Apply button for any changes to become effective!

Internet Clock

Figure 7-7. Internet Clock screen.

Use this page to synchronize the ControlBridge Unit’s date and time with an internet clock. Begin by selecting the check box

for Use Internet clock. Next, enter the IP addresses (or complete address name) of the primary and secondary NTP servers in

the Primary NTP server and Secondary NTP server boxes.

Be sure to click the Apply button for any changes to the internet clock to become effective.

7.5 Applications

Figure 7-8. Applications.

877-877-2269 | blackbox.com

Page 43

Page 44

Chapter 7: Admin Control Panel

Use this page to upload compiled ControlBridge Builder programs to your ControlBridge Unit.

All uploaded applications are listed on this page, along with their file properties: file name/file size/date. The ControlBridge

Unit has a generous memory pool; unused free space is shown at the bottom of this page. The ControlBridge Unit also permits

other service functions, including deleting files, downloading programs back to a personal computer, and starting/stopping

specific applications.

A “running flag” denotes the active application. To stop the running application, press the Start/Stop button. To restart a

stopped application, press the Start/Stop button again.

Files are uploaded from a personal computer to the ControlBridge Unit by selecting the desired application program, and

clicking the Upload button. Files are downloaded from the ControlBridge Unit to a personal computer by clicking the File

name. Files are easily deleted with the Delete button. The Total stop button stops a running application. This application will

not automatically start after reset.

7.6 File Storage

You can use the ControlBridge Unit’s generous memory pool for an auxiliary file storage. This is helpful for storing presets,

in archiving electronic manuals, pdf files, and other support documentation. You can manage file storage via the file storage

page.

A list of existing files, folders, and their properties is shown. To delete a file or a folder, click the Delete button on the

corresponding line. To delete all files and folders from the current folder, click the Delete All button.

To create a new folder, enter a name for the new folder, and click the Create button. To upload a file, select the desired file,

and click the Upload button.

NOTE: Files are automatically compressed for the ControlBridge Unit’s internal file system. Accordingly, the size of your

uncompressed file before storing may not match the decrease of free space shown on the ControlBridge Unit.

Page 44

Figure 7-9. File storage screen.

877-877-2269 | blackbox.com

Page 45

7.7 E -m ail

Chapter 7: Admin Control Panel

Figure 7-10. E-mail screen.

Use this page to set e-mail parameters and recipients’ addresses.

You must set the SMTP server. See the Configuration/SMTP setting.

The sender Name and E-mail are the addresses of your ControlBridge Unit. The sender Name and E-mail are used by the XPL2

commands EmailSend and PresetEmailSend.

The recipient Names and E-mails are addresses of recipients where e-mails will be sent using the XPL2 command

PresetEmailSend.

7.8 Sy stem

Firmware

Use this page to update the ControlBridge Unit firmware. The Current version of firmware is shown. To upload new firmware,

select the desired version, and click the Upload button.

Figure 7-11. Firmware screen.

877-877-2269 | blackbox.com

Page 45

Page 46

Chapter 7: Admin Control Panel

Information

The Information page shows basic information about your ControlBridge Unit’s firmware and version.

Format Data Area

Figure 7-12. Format Data Area tab.

To completely clear all data and restore the factory default settings, click the Format data area button.

This will remove all data, including Applications and File storage files. Configuration will be cleared, including IP address and

password. IP address will be restored to the default 192.168.1.127.

7.9 Pas s wo rd

Page 46

Figure 7-13. Password screen.

877-877-2269 | blackbox.com

Page 47

Chapter 7: Admin Control Panel

You need a case-sensitive password to login to the admin web pages. Set a new password via the New password box. You

must reenter the password in the Confirm new password box. An error message will appear if the confirmation does not

match, in which case you should reenter your password again in both boxes.

Finally, click the Apply button to implement the new password.

7.10 B ac kup

Figure 7-14. Backup screen.

Use this page for backup applications, files, folders and ControlBridge Unit’s configuration. The Backup copies all Applications,

Application data, File storage, and ControlBridge Unit’s settings to the one archive. This archive is saved to the PC. To start the

backup process, click the Backup button.

NOTE: To see the backed-up/restored applications, click the Applications menu. To see backed-up/restored files and folders,

click the File Storage menu. Use this page to backup of all applications, files, and folders.

Restore

Figure 7-15. Restore screen.

877-877-2269 | blackbox.com

Page 47

Page 48

Chapter 7: Admin Control Panel

READ ALL IMPORTANT NOTES THAT FOLLOW BEFORE USING THIS OPERATION!

Use this page to restore all applications, files, and folders. Restore copies of all applications, files, and folders from a backup

archive on the PC to their corresponding locations on the ControlBridge Unit.

To start the restore process, select the desired backup archive, then click the Restore button. The restore process can take up

to 10 minutes, depending on the size of the files being restored.

ControlBridge Unit’s settings can also be restored too: check the “Restore configuration” box. The ControlBridge Unit’s

settings are accessible via the Configuration, Date and time, and Password menus.

Important note: Actual password and IP settings will be restored too.

Important note: When restoring files, the running application will stop and all applications, files, and folders

currently stored in the ControlBridge Unit will be deleted! If you want to retain them, use the

Backup command before the Restore command.

NOTE: To see the backed-up/restored applications, click the Applications menu. To see backed-up/restored files and folders,

click the File Storage menu.

7.11 R es et

To restart your ControlBridge Unit, click the Reset button.

Page 48

Figure 7-16. Reset screen.

877-877-2269 | blackbox.com

Page 49

7.12 Lo go ut

Figure 7-17. Logout screen.

This screen isn’t displayed if the password is empty (factory default status).

Chapter 7: Admin Control Panel

7.13 License

This page describes the software license.

Figure 7-18. License screen.

877-877-2269 | blackbox.com

Page 49

Page 50

NOTES

Page 50

877-877-2269 | blackbox.com

Page 51

NOTES

877-877-2269 | blackbox.com

Pag e 51

Page 52

Black Box Tech Support: FREE! Live. 24/7.

Tech support the

way it should be.

Great tech support is just 60 seconds away at 877-877-2269 or blackbox.com.

About Black Box

Black Box provides an extensive range of networking and infrastructure products. You’ll find everything from cabinets and racks

and power and surge protection products to media converters and Ethernet switches all supported by free, live 24/7 Tech support

available in 60 seconds or less.

© Copyright 2016. Black Box Corporation. All rights reserved. Black Box® and the Double Diamond logo are registered trademarks of BB Technologies, Inc.

Any third-party trademarks appearing in this manual are acknowledged to be the property of their respective owners.

CB-CP100, version 1

877-877-2269 | blackbox.com

Loading...

Loading...