Page 1

How To Use

Data Communications

with the Watlow

Series 945

User's Manual

Watlow Controls, 1241 Bundy Blvd., P.O.Box 5580, Winona, MN 55987-5580, Phone: 507/454-5300, Fax: 507/452-4507

W945-SA50-9210

March, 1992

Supersedes:

W945-SA40-9119

How to Use Data Communications

Made in the U.S.A.

$5.00

Printed on Recycled Paper

WATLOW Series 945

1

Page 2

Contents

Page Item

3 Data Communications and the Series 945

3 Hardware Interfaces Protocols

3 Communications Wiring

4 RS-422A Interface Pinouts

5 RS-423A Interface Pinouts

(RS-232C Compatible)

6 EIA-485 Interface Pinouts

6 Connecting the Control and Computer

7 Setting Hardware Protocol Switches

7 Network Connections

7 Series 945 Communication Parameters

8 Communications Setup Parameters

10 ASCII and Series 945 Information

11 Series 945 General Message Syntax

11 Message Syntax

11 Data Rules

12 Command List

12 Example Format

13 XON/XOFF Protocol for RS-423A

13 Start and Stop Communicating with the

Series 945 and XON/XOFF

14 XON/XOFF "=" Command Example

15 XON/XOFF "?" Command Example

16 ANSI X3.28 Protocol for RS-422 & EIA-485

16 Device Address

16 Starting Communications in ANSI X3.28

17 Stopping Communications in ANSI X3.28

17 ANSI X3.28 "=" Command Example

18 ANSI X3.28 "?" Command Example

19 "?" Command

20 "=" Command

22 Data Logging

23 Table Printout

23 Statistical Process Control - SPC

24 The Difference Between Control and

Specification Limits

25 Chart and SPC Printout

26 NAKs and Error Codes

26 User Responsibility

27 Index

Figures Item

1 RS-422 Interface Wiring

2 RS-423 Interface Wiring

3 EIA-485 Interface Wiring

4 RS-422/RS-423 Switch Selection

5 General Message Syntax Example

6 XON/XOFF "=" Command Example

7 XON/XOFF "?" Command Example

8 ANSI X3.28 "=" Command Example

9 ANSI X3.28 "?" Command Example

10 Data Logging Interface Wiring

11 Table Printout Example

12 Chart & SPC Printout Example

Tables Item

1 Setup Menu Prompts and Descriptions

2 ASCII Character Set

3 ASCII Control Characters (Partial Set)

4 Address to ASCII Conversion

5 "?" Command Data and Responses,

Partial Set

6 "=" Command and "?" Command Data

7 Printer Troubleshooting

2

WATLOW Series 945

How to Use Data Communications

Page 3

How to Use Data Communications

with the Watlow Series 945

This manual is a supplement to the Series 945 User's Manual. It is for users with

the data communications option. Use in conjunction with the Series 945 User's

Manual.

This is expert user-level material and requires previous experience with data

communications.

Two Serial Hardware Interfaces and

Two Software Protocols

Depending on your units model number, you may have one of two hardware

interfaces:

1)RS-422A for a "multidrop" or (multiple device) network, up to ten devices total;

with 4000 ft. network length limit, or RS-423A (RS-232C compatible) for one on

one communication with a 50 ft. network length limit with a 945 and a host

computer (945A-XXXX--B000). Selecting RS-422A or RS-423A is user selectable via internal switches. See Page 7.

Data Comm

2)EIA-485 (945A-XXXX-D000) also for a multidrop network, up to 32

addresses total, and with a 4000 ft. network length limit.

There are two protocols available to you. Depending on the type of network you

need, you must use the correct combination of interface and protocol.

We use ANSI X3.28 Protocol, based on ANSI X3.28 - 1976 Subcategories 2.2,

and A3, with the RS-422A and EIA-485 interface to run a multiple device network.

We also use XON/XOFF Protocol, a simpler protocol, to run a two device network

with an RS-423A interface. XON/XOFF will also work with the RS-422A and EIA485 interface, but the network is limited to two devices (one computer or printer

and a Series 945). XON/XOFF Protocol requires no responses to messages like

the ANSI X3.28 Protocol does. Likewise, ANSI X3.28 Protocol, which provides a

response to every message, will work with the RS-423 interface. But again you are

limited to one Series 945 and a host computer or printer.

To select which protocol you are going to use, go into the SETUP menu and use

the MODE key to advance to the Prot parameter. Select either FULL, for ANSI

X3.28 2.2 - A.3, or On for XON - XOFF.

If you are using ANSI X3.28 Protocol, choose an address number for the control

under the Addr parameter following the Prot parameter. This parameter will only

appear if Prot = FULL.

Communications Wiring

To connect your Series 945 to a computer or printer, use the next three pages as a

reference. Your computer or printer hardware manual will provide more detailed

serial port pin information. Also refer to the noise prevention section in Appendix 1

of the Series 945 User's Manual. In the often noisy environments of industrial

locations, it is important not to take noise isolation lightly.

How to Use Data Communications

WATLOW Series 945

3

Page 4

1

0

RS-422A

Figure 1 RS-422A Interface,

Pin Designations.

Series 945 #

RS-422A Interface Pinouts

945A-XXXX-B000

The RS-422A communications uses a four wire (full duplex) system. There are

two separate lines for transmitting, and two lines for receiving data between the

computer and the Series 945. With RS-422A you can have from one to ten Series

945 controls connected to a single computer.

This diagram is a typical wiring example. The connections on the host computer

may vary depending on models. Refer to your computer user's manual for more

information.

Twisted Pair Wire

T +

19

T -

20

R +

21

R -

22

Signal Common

23

(Optional)

Host Computer

(rear view)

Series 945 #1

NOTE:

The Electronic

Industry Association

(EIA) RS-422A

standard recommends a maximum

4000 ft. total network

distance.

19

20

21

22

23

T +

T R +

R -

Signal Common

(Optional)

Twisted Pair Wire

DB-9 female

connector

(viewed from wire side)

R +

R -

Com

1

6

2

7

3

8

T -

4

9

T +

5

4

WATLOW Series 945

How to Use Data Communications

Page 5

RS-423A Interface Pinouts (RS-232C Compatible)

1

945A-XXXX-B000

The RS-423A communications uses a three wire (full duplex) system. There is a

separate line for transmitting, a line for receiving data, and a line for signal common

between the computer and the Series 945. With RS-423A you can have only one

Series 945 control connected to a single computer or printer.

This diagram is a typical wiring example. The connections on the host computer

may vary depending on models. Refer to your computer user's manual for more

information.

Host Computer

(rear view)

RS-423A

Figure 2 RS-423A Interface,

Pin Designations.

R, and RLSD together.

and CTS together.

puter's user manual.

T

20

Jumper to Signal Common

21

R

22

Signal Common

945 #

23

DB-25 female

connector

(viewed from wire side)

DTR (Data Terminal Ready)

1

14

15

16

17

18

19

2 0

21

22

23

24

25

T

2

R

3

3

4

RTS (Request To Send)

4

5

CTS (Clear To Send)

6

DSR (Data Set Ready)

Com

7

RLSD (Received Line Signal Detector)

8

9

10

11

12

13

NOTE:

The Electronic

Industry Association

(EIA) RS-423A

standard recommends a maximum

50 foot total pointto-point distance.

How to Use Data Communications

WATLOW Series 945

5

Page 6

EIA-485

1

EIA-485 Interface Pinouts

945A-XXXX-D000

The EIA-485 communications uses a two wire (half duplex) system. There are only

two lines, both lines used for transmitting and receiving. Only one device, the

computer or the control, can be speaking at a time. There is a 1 millisecond delay

requried for the Series 945 to go between transmission and receipt of data. With

EIA-485 you can have from one to thirty-two Series 945 controls connected to a

computer.

Figure 3 EIA-485 Interface, Pin

Designations.

Series 945 #

Series 945 #31

This diagram is a typical wiring example. The connections on the host computer

may vary depending on models. Refer to your computer user's manual for more

information.

Twisted Pair Wire

T+/R+

19

T-/R-

20

Signal Common

23

(Optional)

Host Computer

(rear view)

Twisted Pair Wire

T+/R+

19

T-/R-

20

Signal Common

23

#32

(Optional)

DB-9 female

connector

(viewed from wire side)

1

6

2

7

3

8

4

9

5

Com

T-/R-

T+/R+

T+/R+

T-/R-

NOTE:

The Electronic

Industry Association

EIA-485 standard

recommends a

maximum 4000 ft.

total network distance.

6

WATLOW Series 945

Connecting the Control and the Computer

Remove power from both the Series 945 and your computer or printer before

connecting them together. This prevents noise or static interference from entering

the data communication lines. Assemble a cable and the appropriate wiring at your

computer or printer. Refer to the wiring on Page 4 through 6. As soon as you

connect the data communications line(s), you're ready to apply power to your

system.

How to Use Data Communications

Page 7

A

A

(Up) RS-423A

(Up) RS-423

(Down) RS-422

(Down) RS-422A

A007-1830

How to Set the Hardware Protocol Switches

for 945A-XXXX-B000 Units Only

The RS-422/RS-423 switches are on the Communication Module Board (A007-

1830). Figure 4 shows the location of this board. You can select C1 for RS-423 or

C2 for RS-422 operation. Both switches must be set the same for the desired

protocol.

To change the position of a switch, remove the power from the Series 945 and turn

the front panel locking screw 90° counterclockwise. To remove the control chas-

Control Chassis - Top View

sis, grip the front panel bezel and pull it straight out from the control case. Set the

switches, C1 (towards you for RS-423) or C2 (away from you for RS-422) then

return the control chassis to the case. Be sure it is oriented correctly. Press firmly,

but gently, to seat the chassis. Secure the front panel locking screw and reapply

power.

Configuration

Figure 4 RS-422A/RS-423A

Switch Selection.

NOTE:

The Series 945

leaves the factory in

RS-423A operation (C1).

Network Connections

You can connect a data communication equipped Series 945 to any computer with

an RS-422A or RS-423A (RS-232C compatible) or EIA-485 serial interface. The

serial interface is the key. The IBM™PC® with an RS-232C serial output card,

for instance, will talk to a single RS-423A equipped Series 945. For a multiple 945

network with the same PC, you'll need an RS-232 to RS-422 converter to act as a

"bus," or multiple connection point.

Watlow recommends the Burr-Brown LDM 422 for that purpose. The address is:

Burr-Brown, Inc., 1141 West Grant Rd,. Suite 131, Tucson, AZ 85705, Phone:

(602) 624-2434, Fax: (602) 623-8965.

For EIA-485, we recommend the Black Box LD485A. Their address is: Black Box

Corporation, Mayview Road at Park Drive, Box 12800, Pittsburgh, PA 152421,

Phone: (412) 746-5530.

Series 945 Comunication Parameters

To communicate with the Series 945, match the serial port settings of your computer with the available settings in the 945:

bAUd Rate = 300, 600, 1200, 2400, 4800, 9600 (choose one)

dAtA = 7o = 7 data bits and odd parity

7E = 7 data bits and even parity (choose one)

8n = 8 data bits and no parity

Start Bit = 1

Stop Bits = 1

How to Use Data Communications

WATLOW Series 945

7

Page 8

Parameters

Setup Menu - Communications Parameters

Enter the Setup menu by pressing the UP/DOWN keys simultaneously for 3

seconds. The lower display shows the LOC parameter, and the upper display

shows its current level. All keys are inactive until you release both keys. You can

reach the LOC parameter from anywhere. This is only a listing and brief explanation of the parameters, refer to Pages 22 through 26 for a thorough explanation of

Statistical Process Control (SPC).

bAUd

dAtA

Prot

Addr

Log

LSL

USL

Baud: Represents the current baud rate for serial communications.

Range: 300, 600, 1200, 2400, 4800, 9600 Default: 1200

Data: Allows the user to select the data bits and parity for communication.

Range: 7 o = 7 data bits and odd parity 7E = 7 data bits and even parity

8 n = 8 data bits and no parity Default: 7 o

Protocol: Selects the communication protocol. Must be On for data logging to

occur. FULL = ANSI X3.28 2.2 - A.3 On = XON - XOFF

Range: FULL or On Default: FULL

Address: Selects the address device if Prot = FULL. Range: 0 to 31 Default: 0

Log: Selects the data logging function for a printout of the data. Appears if Prot =

On. For further expon on SPC, the parameters and printouts, see Page 22 - 26.

Range: OFF, tAbL, CHrt, SPCA, SPCd, SPCn Default: OFF

Lower Specification Limit: This value is the specified deviation below set point,

which statistically the process should not exceed. Appears if Prot = On and Log =

SPCA or SPCd. SPCA Range: rL to Lower USL -2°F/-1°C Default: rL

SPCd Range: 1 to 99 Default: 10

Upper Specification Limit: This value is the specified deviation above set point,

which statistically the process should not exceed. Appears if Prot = On and Log =

SPCA or SPCd.SPCA Range: rH to upper LSL +2°F/1°C Default: rL

SPCd Range: 1 to 99 Default: 10

tbS

Time Base: Selects the time in minutes over which 30 random samples are taken

for computing SPC values. Appears if Prot = On and Log = SPCA or SPCd.

Range: 1 to 60 Default: 5

LinE

Line: Selects the number of lines per page of data logged output. Match this

parameter to the number of lines per page your printer prints. After you select the

number of lines to print, a form feed character is sent to the printer, resetting the

top of the page. Range: 10 to 127 Default: 65

YEAr

Year: Select the current year for the data logging header. Appears if Prot = On

and Log = tAbL, CHrt or SPCA, SPCd, SPCn. Parameter resets to default after a

power interruption. Default: 92

Mon

Month: Select the current month for the data logging header. Appears if Prot =

On and Log = tAbL, CHrt or SPCA, SPCd, SPCn. Parameter resets to default after

a power interruption. Default: 01

dAY

Day: Select the current day for the data logging header. Appears if Prot = On and

Log = tAbL, CHrt or SPCA, SPCd, SPCn. Parameter resets to default after a

power interruption. Default: 01

HOUr

Hour: Represents the 24 hour time-of-day clock setting for minutes. Appears if

Prot = On and Log = tAbL, CHrt or SPCA, SPCd, SPCn. Parameter resets to

default after a power interruption. Range: 0 to 23 Default: 0

8

WATLOW Series 945

How to Use Data Communications

Page 9

Minutes: Represents the 24 hour time-of-day clock setting for minutes. Appears

if Prot = On and Log = tAbL, CHrt or SPCA, SPCd, SPCn. Parameter resets to

default after a power interruption. Range: 0 to 59 Default: 0

Interval: Selects the time interval for the logging function. The logging interval is in

tenth of a minute increments. Appears if Prot = On and Log = tAbL, CHrt or

SPCA, SPCd, SPCn. Range: 0.0 to 60.0 minutes Default: 0.0

Setup

Min

Int

Tag: Selects what variables are to be transmitted out during the data logging

tag

function. Any combination of process, set point and alarms may be "tagged" for

logging. Appears if Prot = On and Log = tAbL.

P = Process S = Set Point A = Alarm Set Points

Range: PSA, PS -, P-A, P- -, -SA, -S-, --A, --- Default: ---

Setup Menu

Use this page as a master copy for your Series 945 data communications Setup

parameters. Do not enter any values here; make photocopies instead.

Table 1 Setup Menu

Prompts and

Descriptions.

Parameter Value Range Factory Default Appears If:

bAUd 300, 600, 2100, 2400, 4800, 9600 1200

dAtA 7 o = 7 data bits and odd parity

7E = 7 data bits and even parity

8 n = 8 data bits and no parity 7 o

Prot FULL = ANSI X3.28 2.2 - A.3 FULL

On = XON - XOFF

Addr 0 to 31 0 Prot = FULL

Log OFF, tAbL, CHrt, SPC OFF Prot = On

LSL SPCA = rL to Lower USL -2°F/-1°C rL Prot = On &

SPCd = 1 to 99 10 Log = SPCA, SPCd

USL SPCA = rH to Upper LSL +2°F/1°C rL Prot = On &

SPCd = 1 to 99 10 Log = SPCA, SPCd

tbS 1 to 60 5 Prot = On &

Log = SPCA, d, n

LinE 10 to 127 65 Prot = On & Log = tAbL

CHrt or SPCA, d, n

YEAr -- 92 Prot = On & Log = tAbL

CHrt or SPCA, d, n

Mon -- 01 Prot = On & Log = tAbL

CHrt or SPCA, d, n

dAY -- 01 Prot = On & Log = tAbL

CHrt or SPCA, d, n

HOUr 0 to 23 0 Prot = On & Log = tAbL

CHrt or SPCA, d, n

Min 0 to 59 0 Prot = On & Log = tAbL

CHrt or SPCA, d, n

Int 0.0 to 60.0 minutes 0.0 Prot = On & Log = tAbL

CHrt or SPCA, d, n

tag PSA, PS-, P-A, P--, -SA, -S-, --A, --- --- Prot = On & Log = tAbL

P = Process S = Set Point

A = Alarm Set Points

Operation Menu

This parameter follows the Aut parameter in the Operation menu. See Page 25 for

more information.

Control Limit Update: When YES is selected, it calculates and prints out control

limits according to the time base. If no is selected, the current control limit is

printed and no subsequent limits are printed. Range: YES or no Default: YES

How to Use Data Communications

CLUP

WATLOW Series 945

9

Page 10

ASCII Char.

Table 2 ASCII Character

Set

ASCII Character Set

Dec Hex Char Dec Hex Char Dec Hex Char Dec Hex Char

00 00 NUL 16 10 DLE 32 20 SP 48 30 0

01 01 SOH 17 11 DC1 33 21 ! 49 31 1

02 02 STX 18 12 DC2 34 22 " 50 32 2

03 03 ETX 19 13 DC3 35 23 # 51 33 3

04 04 EOT 20 14 DC4 36 24 $ 52 34 4

05 05 ENQ 21 15 NAK 37 25 % 53 35 5

06 06 ACK 22 16 SYN 38 26 & 54 36 6

07 07 BEL 23 17 ETB 39 27 ' 55 37 7

08 08 BS 24 18 CAN 40 28 ( 56 38 8

09 09 HT 25 19 EM 41 29 ) 57 39 9

10 0A LF 26 1A SUB 42 2A * 58 3A :

11 0B VT 27 1B ESC 43 2B + 59 3B ;

12 0C FF 28 1C FS 44 2C , 60 3C <

13 0D CR 29 1D GS 45 2D - 61 3D =

14 0E SO 30 1E RS 46 2E . 62 3E >

15 0F SI 31 1F US 47 2F / 63 3F ?

Dec Hex Char Dec Hex Char Dec Hex Char Dec Hex Char

64 40 @ 80 50 P 96 60 ` 112 70 p

65 41 A 81 51 Q 97 61 a 113 71 q

66 42 B 82 52 R 98 62 b 114 72 r

67 43 C 83 53 S 99 63 c 115 73 s

68 44 D 84 54 T 100 64 d 116 74 t

69 45 E 85 55 U 101 65 e 117 75 u

70 46 F 86 56 V 102 66 f 118 76 v

71 47 G 87 57 W 103 67 g 119 77 w

72 48 H 88 58 X 104 68 h 120 78 x

73 49 I 89 59 Y 105 69 i 121 79 y

74 4A J 90 5A Z 106 6A j 122 7A z

75 4B K 91 5B [ 107 6B k 123 7B {

76 4C L 92 5C \ 108 6C l 124 7C |

77 4D M 93 5D ] 109 6D m 125 7D }

78 4E N 94 5E ^ 110 6E n 126 7E ~

79 4F O 95 5F _ 111 6F o 127 7F DEL

Table 3 ASCII Control

Characters

(Partial Set)

10

WATLOW Series 945

ASCII Control Characters (Partial Set)

ASCII Ctrl Key Definition Dec. Hex.

Char. Equiv. Equiv. Equiv.

ENQ Ctrl E Enquiry 5 05

ACK Ctrl F Acknowledge 6 06

NAK Ctrl U Neg. Acknowledge 21 15

STX Ctrl B Start of Text 2 02

ETX Ctrl C End of Text 3 03

EOT Ctrl D End of Transmission 4 04

DLE Ctrl P Data Link Escape 16 10

CR Ctrl M Carriage Return 13 0D

DC1 Ctrl Q XON 17 11

DC3 Ctrl S XOFF 19 13

How to Use Data Communications

Page 11

Series 945 General Message Syntax

As soon as you link the devices, you'll be able to talk to the Series 945 using ASCII

characters.

The Series 945 will respond to any Operating or Setup parameter, plus some

others. The control will respond to either upper or lower case ASCII characters

from your computer.

Both protocol/interface combinations will respond to the general syntax, providing

the commands or queries are correctly transmitted. However, the ANSI X3.28

Protocol requires beginning and ending characters, and the XON/XOFF Protocol

requires ending characters. We'll look at those shortly.

Message Syntax

Messages from your computer to the Series 945 must take this general form. All

commands do not require the full number of data fields.

Command <Space> Data.1 <Space> Data.2 <Space> Data.3... Data.N

Syntax

"Command" is a character set to which the Series 945 will respond. The brackets

"< >" enclose a non-literal description. "Space" is simply a delimiter, an ASCII

space character (Hex 20). "Data Fields" are parameters and values specific to a

command; the number of possible data fields depends on the particular command

you use. Data 1 is here abbreviated, "Data.1", Data 2 is "Data.2" and so on.

In the syntax explanations ahead, we'll show you the specific arguments for each

command. It will speed the process, if you remember this general syntax.

Data Rules

Data fields are parameters and values specific to particular commands. These rules

govern their use. Specific data for each command is listed later in this chapter.

• Data will be ASCII 0 through 9, unless otherwise noted.

• Data can go up to seven total characters, including a minus sign. A + or - sign, if

used, must be first, and it must have a decimal point if applicable.

• Data can use leading zeros. (Up to 7 digits.)

• Data does use decimal points.

• Data.1 portion of message can be up to four total characters.

Command List

These commands, represented by their respective ASCII characters, will enable

you to program the Series 945 from your computer. More detailed descriptions of

the commands are on the pages noted.

? Finds the value of a specific parameter. p. 19

= Sets a specific parameter to a specific value. p. 20

How to Use Data Communications

WATLOW Series 945

11

Page 12

ASCII

Figure 5 Series 945

General Message

Syntax Example.

Example Format

For your benefit, we're presenting message/response examples with syntax required for Series 945 communication. Information bracketed by < > indicates a

description, rather than literal characters. We show each ASCII character that you

must transmit to the Series 945, including space between the characters. (A

"space" is itself an ASCII character, hex 20). For clarity, we also represent each

ASCII character as a hexadecimal pair. The pairs are spread apart on the page for

easy reading. However, electronic devices "see" the hex pairs all together in

"strings," with no spaces in between.

For instance, from the example just below, you want to set the Alarm 1 Low

(A1LO) parameter to 500°. Notice the syntax just below which uses the "=" com-

mand. = <Space> A1LO <Space> 500

=

<Space>

A

ASCII

Characters

HEX

Value

3D 20

1

L

O

Space

5

0

0

41 4C31 20 35 30 30

4F

<CR>

0D

To send this message, key the ASCII characters into your computer, or write them

into your program. The computer, in turn, will send a string similar to the one at the

bottom of the example, 3D2041314C4F20353030.

Notice that we haven't mentioned protocol here, or any characters added to this

syntax by a protocol. With XON/XOFF, the message above can be transmitted

with only an additional Carriage Return <CR> (hex 0D) character at the end.

However, the ANSI X3.28 Protocol requires an envelope of Start of Text <STX>

(hex 02) and End of Text <ETX> (hex 03) characters around the information you

see above. You'll learn how to do that in the pages ahead.

XON/XOFF Protocol for RS-423A

XON/XOFF (flow control) Protocol allows a communicating device (either a 945 or

the host) to suspend transmission of all messages from the other device, and then

to continue transmission when it's again ready.

The device that needs to suspend transmission sends the XOFF character

(hex 13) to stop the other device's transmitter, and XON (hex 11) to restart it. Note

that technically any character will restart the transmitter, but only the XON character

is not a part of any regular message that may be transferring.

Messages transmit according to the syntax described in the XON/XOFF formats

which follow for each command.

12

WATLOW Series 945

The XON/XOFF Protocol requires a Carriage Return character

(hex 0D) at the end of every message.

How to Use Data Communications

Page 13

XON/XOFF "="

How To Start and Stop Communicating

with the Series 945 and XON/XOFF

Starting communications with XON/XOFF Protocol is simple. You just configure

your computer to agree with the Series 945 communication parameters and open its

serial communication port in software. Then begin to "talk" by transmitting a message to the Series 945. You stop communicating with XON/XOFF Protocol simply by

ceasing to send messages.

XON/XOFF "=" Command Example

The general command syntax is the one you've already seen. Each command uses a

slightly different variation of it, depending on the number of arguments required for a

message.

• You want to change the Alarm 1 Low (A1LO) value to 500°. The "=" command will

do the job.

The syntax with XON/XOFF Protocol requires an ending Carriage Return <CR>.

"=" Command Syntax with XON/XOFF Protocol:

= <space> Data.1 <space> Data.2 <CR>

With the "=" Command, Data.1 is the Series 945 parameter, in this case Alarm 1 Low,

A1LO. Data.2 is the value you want to set for that parameter, in this example, 500.

Enter in ASCII:

= <space> A1LO <space> 500 <CR>

The hex string will be:

3D2041314C4F203530300D

=

<Space>

A

ASCII

Characters

HEX

Value

3D 20

1

L

O

Space

5

0

0

41 4C31 20 35 30 30

4F

<CR>

0D

Response from the Series 945:

It sends an "XOFF" when a carriage return is received and then an "XON" when the unit

is done processing the command.

Figure 6 XON/XOFF "="

Command Example.

<XOFF>

<XON>

13 11

• The complete list of "=" Command data (parameters and value limits) is in

Table 6, Pages 20 - 21.

How to Use Data Communications

WATLOW Series 945

13

Page 14

XON/XOFF "?"

Figure 7 XON/XOFF "?"

Command Example.

XON/XOFF "?" Command Example

You want to know the Alarm 1 Low (A1LO) value. The "?" uses a variation of the

message syntax shown just below. This protocol requires an ending carriage

return character.

"?" Command syntax with XON/XOFF Protocol:

? <space> Data.1 <CR>

Enter in ASCII:

? <space> A1LO <CR>

The hex string will be:

3F2041314C4F0D

?

Space

A

ASCII

Characters

1

L

O

CR

HEX

Value

3F 20

41 4C31

4F

0D

The value of A1LO will be between rL (Range Low) and rH (Range High), say, 500.

Response from the Series 945:

<XOFF> <XON> <current value of A1LO> <CR>

The hex response string is:

13113530300D

<XOFF>

<XON>

ASCII

Characters

HEX

Value

13

5

35 30CR0D

11

0

0

30

14

WATLOW Series 945

How to Use Data Communications

Page 15

ANSI X3.28 Protocol for RS-422A and EIA-485

The ANSI X3.28 Protocol provides high quality communications by requiring a

response to every message. With a multiple device or "multidrop" network, this

protocol prevents confusion among the separate devices. Furthermore, if noise

occurs somewhere in the system, no parameter will change because noise can't

comply with the protocol.

By placing messages inside a protocol envelope, the messages are protected. In

the examples to come you'll see how this works.

The ANSI X3.28 Protocol requires STX characters at the beginning of a

message and ETX characters at the end.

Device Address

If you are using the ANSI X3.28 Protocol, you must have a device address (identification) number. A Watlow RS-422A multidrop network can handle up to 10 devices with this protocol. EIA-485 can handle up to 32 devices. Set the address

number with the Series 945 in the Addr parameter under the Setup menu.

ANSI X3.28

Address ASCII Equivalent

0 - 9 0 - 9

10 - 31 A - V

Starting Communications in ANSI X3.28 Protocol

Here's the syntax for starting communications with ANSI X3.28 Protocol. The

master device, your computer, must initiate the data link. The example below

uses the ASCII number 4 as a Series 945 device address.

Enter in ASCII, using this syntax: <Address # 4><ENQ>

4ASCII

Characters

HEX Value

Response from the 945:

<Address # 4><Acknowledge (ACK)>

<ENQ>

34 05

Table 4 Address to ASCII

Conversion.

ASCII

Characters

HEX Value

How to Use Data Communications

4

<ACK>

34 06

WATLOW Series 945

15

Page 16

ANSI X3.28 "="

Stopping Communications in ANSI X3.28 Protocol

The master device, your computer, must end communications with Device #4 by

using Data Link Escape (DLE) and End of Transmission (EOT) characters.

Enter in ASCII: <DLE><EOT>

ASCII

Characters

HEX Value

<DLE>

10 04

<EOT>

Response from the 945:

None

ANSI X3.28 "=" Command Example

The "=" Command sets a specific 945 parameter to a specific value. The general

command syntax applies to all commands. The definition and number of arguments depends on the command itself. See Table 6, Pages 20 - 21.

In this example, you want to change the Alarm 1 Low value to 500°. Here, the "="

command will do the job.

'"=" command Syntax with ANSI X3.28 Protocol:

<STX> = <space> Data.1 <space> Data.2 <ETX>

With the "=" command, Data.1 is the Series 945 parameter, in this case Alarm 1

Low , A1LO. Data.2 is the value you want to set for that parameter, in this example, 500.

Figure 8 ANSI X3.28 "="

Command Example.

16

WATLOW Series 945

Enter in ASCII:

<STX> = <space> A1LO <space> 500 <optional carriage return> <ETX>

The hex string is:

023D2041314C4F2035303003

<STX>

=

ASCII

Character

HEX

Value

<Space>

02 03

3D 20

A

1

L

O

Space

5

0

0

41 4C31 20 35 30 30

4F

Optional

Carriage

Return

How to Use Data Communications

<ETX>

Page 17

Response from the Series 945:

0

<

<ACK>

The hex response string is:

06

• You'll find the the complete list of "=" command arguments (parameters and

value limits) in Table 6, Pages 20 - 21.

ANSI X3.28 "?" Command Example

You need to know the Alarm 1 Low value (A1LO). The "?" uses a variation of the

message syntax shown just below. This syntax requires the protocol start of

text and end of text characters.

"?" command syntax with ANSI X3.28 Protocol:

<STX> ?<space> <Data.1> <ETX>

Enter in ASCII:

<STX> ? <space> <A1LO> <optional carriage return> <ETX>

The hex string will be:

023F2041314C4F03

Optional

Carriage

Return

ASCII

Characters

<STX>

?

Space

A

1

L

O

<ETX>

ANSI X3.28 "?"

Figure 9 ANSI X3.28 "?"

Command Example.

HEX

Value

3F 20

02 03

41 4C31

4F

First response from the Series 945:

<ACK>

The <ACK> hex response string is:

06

Your computer's confirming response:

<EOT>

The <EOT> response hex string is:

04

Second response from the Series 945:

<STX> <current A1LO value> <carriage return> <ETX>

The hex string is:

023530302003

<STX>

ASCII

Characters

HEX

5

<CR>

20

0

Your computer's next response:

<ACK> or < NAK> (if the message needs to be repeated).

The hex string is:

06 or 15

Final response from the Series 945:

<EOT>

The hex string is:

04

How to Use Data Communications

WATLOW Series 945

17

Page 18

Commands

Data.1 Respns Information Comments

C1 ACTUAL Actual process value Between R1L and R1H

Table 5 "?" Commands

and Responses.

These commands

are READ ONLY.

IN 0 J T/C

1 K T/C

2 T T/C

3 N T/C

4 PT2 T/C

5 C T/C

6 Not Used

7 R T/C

8 S T/C

9 B T/C

10 RTD whole

11 RTD tenths

12 0-5V

13 4-20mA

MODE 1 Auto mode Multiple modes are possible.

2 Manual mode

4 Configuration mode

8 Calibration mode

16 Alarm silence active

ERR 0 No error Multiple errors are possible.

1 Open sensor

2 Reversed sensor

4 Ambient sensor

8 Configuration

16 EE Checksum

32 A/D underflow

64 A/D overflow

128 Not used

ER2 0 No error Cleared when ER2 is read.

1 Transmit buffer overflow Only 1 ER2 response is valid.

2 Receive buffer overflow

3 Framing error

4 Overrun error

5 Parity error

6 Talking out of turn

7 Invalid reply error

8 Noise error

16 Process input active

17 Local/remote is local

18 Local/remote is remote

19 Remote not enabled

20 Command not found

21 Parameter not found

22 Incomplete command line

23 Invalid character

24 Number of chars. overflow

25 Input out of limit

26 Read only command

27 Write allowed only

BTYP 0 T/C Only

1 T/C, RTD whole, process

2 T/C, RTD tenths, process

3 R, S, B T/C

MDL Displays 945 X

X = software revision

RSP1 Remote SP Remote set point setting

18

WATLOW Series 945

"?" Command

The "?" Command reads a specific value of the Series 945 parameter (Data.1).

Tables 5 and 6 provide the complete list of parameters you may use, plus responses.

How to Use Data Communications

Page 19

"=" Command

"The "=" Command sets a specific Series 945 parameter (Data.1) to a specific

value (Data.2) when the unit is in the HOLD mode. Use Tables 5 and 6 to select

parameters (Data.1) in the lefthand column. In Table 6 the low and high limit or

code values (Data.2) are in the three center columns.

Data.1 Data.2

Low Limit High Limit Code Function

AXHI Process RL value RH value Alarm High X value

±555/Deviation ±999

A

XLO Process RL value RH value Alarm Low X value

±555/Deviation ±999

ALM 0 No alarms occurring Writing a 0 will clear all

1 A1H occurring alarms if the alarm

2 A1L occurring condition no longer

4 A2H occurring exists.

8 A2L occurring

AL1 0 2 0 Alarm 1 = deviation

1 Alarm 1 = process

2 No Alarm 1

AL2 0 2 0 Alarm 2 = deviation

1 Alarm 2 = process

2 No Alarm 2

ATMN 1 1 1 Auto/Manual toggle must

be sent twice within 5 sec.

AUT 0 3 0 No auto-tuning

1 Slow response tuning

2 Medium response tuning

3 Fast response tuning

CAL* -180°F 180°F Calibration offset

-100°C 100°C

-180 Units 180 Units

CF 0 1 0 Display °C

1 Display °F

CLUP Yes No SPC control limits update

CT

X 1 60 Output X cycle time

DAY 1 31 Day of the month/data log

DB 099°F Dead band

055°C

0 Units 99 Units

DEC 0 2 0 No decimal point

1 0.0

2 0.00

DE

X 0.00 9.99 Output X derivative

DFL 0 1 0 US prompts

1 SI prompts

HOUR 0 23 Hour for data logging

HYS

X 1°F99°F Output X switching hys.

1°C55°C

1 Unit 99 Units

INDC 1 1 1 UP/DOWN key action

INT 0.0 60.0 Time interval in minutes

for logging

0.0 = logging OFF

IT

X 0.00 9.99 Output X integral

Commands

NOTE:

An X means it

applies to either

Output 1 or

Output 2.

Table 6 "=" and "?" Commands. These are

READ or WRITE

commands. See

Table 4 for more "?"

Commands.

* When the 945 RTD

input is 0.1

parameters will have

a decimal point to

the left of the least

significant digit.

°, these

How to Use Data Communications

WATLOW Series 945

19

Page 20

Commands

NOTE:

An X means it

applies to either

Output 1 or

Output 2.

Table 6 Continued

NOTE:

P = Process

S = Set Point

A = Alarm Set Point

- - - = no logging

Data.1 Data.2

Low Limit High Limit Code Function

LAT

X 0 1 0 Latched alarms

1 Non-latched alarms

LINE 10 127 Lines per page for data logging

LOC 0 3 Lock front panel

LOG 0 3 0 Logging OFF See Page 22.

1 Table

2 Chart

3 SPCA

4 SPCd

5 SPCn

L-R 0 1 0 Local set point

1 Remote set point

LSL rL USL Lower -2°F/-1°C SPC lower spec limit

MAN -100 100 Manual % output

MIN 0 59 Minute for data logging

MON 1 12 Month for data logging

OT

X 0 1 or 2* 0 Heat

1 Cool

2* No action

*only applies to Ot2

OT4 0 2 0 Output 4 = Process Retransmit

1 Output 4 = Set Point Retransmit

2 No action

PB

X 0 999°F Proportional Band

555°C dFL = US

999 Units

PB

X% 0.0 999.9 Output X proportional

band DFL = SI

RA

X 0.00 9.99 Rate

RE

X 0.00 9.99 Reset

RH Min. IN range Max. IN range Range High

RL Min. IN range Max. IN range Range Low

RSP 0 2 0 OFF

1 0-5

2 420

RTD 0 1 0 DIN

1 JIS

SIL 0 1 0 Alarm silence OFF

1 Alarm silence ON

SP

X rL rH Set point

TAG 0 7 0 - - - = no logging

1 - - A

2 - S 3 - SA

4 P - 5 P - A

6 PS 7 PSA

tbS 1 60 SPC time interval in minutes

USL LSL Upper 2°F/1°C rH SPC upper spec limit

YEAR 0 99 Year for data logging

l

20

WATLOW Series 945

How to Use Data Communications

Page 21

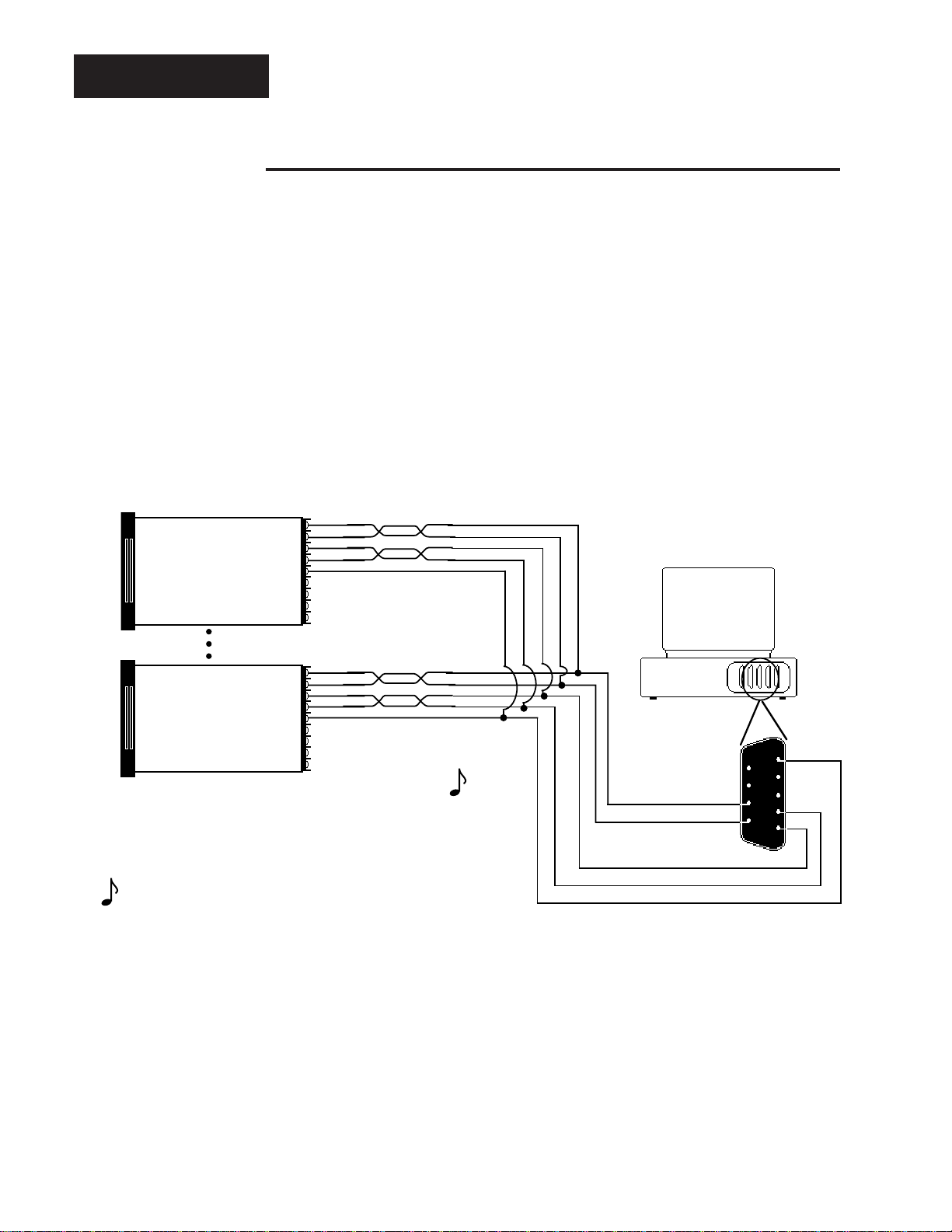

Data Logging

1

4

R

T

The data logging feature is a convenient replacement for chart recorders. Information is sent directly from the Series 945 to a serial printer, or to a computer disk file.

No computer is needed, although the 945 can be connected to a computer with a

serial port and terminal emulation software.

Data logging provides a handy reference to review process performance. The time

intervals between each entry and data printed are user selectable, with the time

display resetting every 24 hours. If there is a power interruption, the time is reset to

0.0. There are several options for the printer output. Choose from table, chart or

SPC (Statistical Process Control). See the following pages for more information on

printer outputs.

Jumper DTR, DSR, and RLSD together.

Also, jumper RTS and CTS together.

Refer to your printer's user manual.

20

Jumper to Signal Common

21

22

Signal Common

Series 945 #

23

Data Logging

Printer

Host Computer

(rear view)

2

15

3

DB-25 female connector

(located on back of printer

viewed from wire side)

DTR (Data Terminal Ready)

T

R

16

4

RTS (Request To Send)

17

5

CTS (Clear To Send)

18

6

DSR (Data Set Ready)

19

Com

7

2 0

RLSD (Received Line Signal Detector)

21

8

9

22

10

23

11

24

12

25

13

Figure 10 Data Logging

Interface Wiring

Example.

Connect the 945 to the printer as in Figure 10; this is a typical wiring example. The

connections on the printer may vary depending on the model, refer to the printer's

user manual. Enter the Setup menu by pressing the UP/DOWN keys simultaneously for three seconds. Mode through the parameters until you reach bAUd

and follow the parameter listing on Page 8. Select the appropriate data for each

prompt and enter your values in the table on Page 9. Data logging begins once

you return to the control set point.

After each line the 945 emits a carriage return. Your printer can be set up to

handle line feeds. The printer must supply a line feed (LF) following a carriage

return (CR). Refer to your printer user's manual for more information.

A data header is printed once the logging function begins. When you change the

time interval (Int) or any selected data (tag), or power is cycled, the header is

printed again. The header always remains the same, regardless of the control

configuration. The time display wraps around to 0.0 every 24 hours. If there is a

power interruption, the control will restart at 0.0 when power is restored.

How to Use Data Communications

WATLOW Series 945

21

Page 22

Data Logging

Figure 11 Table Printout

Example.

Data fields emitted are determined by the tag parameters and control configuration.

As in the following example, tag is set for PSA (Process, Set Points, and Alarm Set

Points). SET-2 is only transmitted when there is a secondary control output, and is

configured the same as the primary output. In the example below, notice A1LO was

changed to 125 resulting in an alarm condition shown as an * (asterisk) in the

PROCESS and LOW-1 columns. After a latching or non-latching alarm is cleared,

the * is removed. The ATUNE column reports the auto-tune status. START denotes the beginning of the sequence, RSTRT signifies auto-tune has been restarted, and END is displayed when complete.

Table Printout

Example: Log = On, Int = 0.5, tag = PSA

P = Process S = Set Points A = Alarm Set Points

Parameters represented:

(C1) (SP1) (SP2) (A1LO) (A1HI) (A2LO) (A2HI) (AUt)

DATE: 01-01-92

TIME PROCESS SET-1 SET-2 LOW-1 HIGH-1 LOW-2 HIGH-2 ATUNE

10:03:47 144 * 200 150 * 240 190 * 210

10:03:58 157 * 200 150 240 190 * 210 START

10:04:34 185 * 200 150 240 190 * 210

10:05:10 177 * 200 150 240 190 * 210

10:05:46 182 * 200 150 240 190 * 210

10:06:02 179 * 200 150 240 190 * 210 END

10:06:38 196 200 150 240 190 210

10:07:14 198 200 150 240 190 210

10:07:50 199 200 150 240 190 210

10:08:26 199 200 150 240 190 210

10:09:02 200 200 150 240 190 210

22

WATLOW Series 945

SPC - Statistical Process Control

SPC tracks variability to help you distinguish between natural variability (common

causes) from unnatural variability (special causes). Based upon measurements,

SPC gives you a picture of how the process is performing. By showing when

special causes are occurring, the SPC printout gives you written changes in the

process. An SPC printout is a picture of the operation. Typically, past data gives

information about what the average measurements and limits should be. These

are traditionally shown by upper and lower control limits. It also gives us a picture

of what is happening now. By comparing the process we can determine when

special, or assignable causes occur. This is advanced user-level material and

requires previous experience with Statistical Process Control (SPC).

For more information we recommend:

Juran's Quality Control Handbook

by J.M. Juran, Editor in Chief & Frank M. Gryna, Associate Editor

Hardcover, 1988 ISBN: 0-7-033176-6

Available from: McGraw Hill

1221 Avenue of the Americas

New York, NY 10020

1-800-2-MCGRAW

How to Use Data Communications

Page 23

The Difference Between Control & Specification Limits

Control limits are established on the control chart at ± 3 standard deviations (3 sigma).

They are based upon the distribution of sample averages and are calculated from the

actual performance of the process. They are typically narrower than specification limits.

Specifications are limits for individual measurements, not averages. They are based upon

engineering or customer requirements, rather than process capability. Process capability

predicts the process performance to predetermined specification limits.

When the LCL (Lower Control Limit) and UCL (Upper Control Limit) values have been

determined, the values for CPKL, CPKU, and CP are calculated and printed once on the

chart. The smaller of these two numbers will be your actual process capability or CPK.

SPC

CPKL =

If the system is too stable "variation insignificant" is printed. Your process is so stable that

even a severe shift or variation greater than ±6 sigma will still maintain a larger CPK

value. If both LSL and USL are left at their default value, they are set to the 4σ values

below and above the process mean value. Once the mean value has been calculated,

these values are used to calculate CPKL and CPKU values.

Average: The mean, or the arithmetic average, ( x ).

Control Limits: Limits on a control chart, based on actual process data, which are used

as criteria for signalling the need for action, or for judging whether a set of data does or

does not indicate a "state of statistical control."

Lower Control Limit (LCL): Control limit derived by the average minus 3 standard

deviation ( x - 3σ ).

Mean: The arithmetic average, obtained by adding all the values together and dividing by

the number of values ( x ).

Process Capability (CPKL and CPKU): A comparison of process performance with

product specifications over a period of time and while the process is in statistical control.

CPK < 0 Average value is outside the specification limits

CPK between 0 and 1 Variation is greater than the limits.

CPK = 1 Variation and the specification limits are the same

CPK between 1 and 1.33 Acceptable process control

CPK between 1.33 and 2 Good process control

CPK > 2 Excellent process control

Mean - LSL

3σ

CPKU =

USL - Mean

3σ

Sigma: The unit of standard deviation. Sigma is the greek letter "s" written σ.

SPCA (Specification limits Absolute): Represents SPC with fixed values that do not

track the set point. When SPCA is chosen, the USL range is the LSL parameter + 2 (LSL

+ 2) to the sensor's range high. Default is the sensor's default range high. The LSL range

is from the sensor's default range low to the sensor's default range high. Default is the

sensor's default range low.

SPCd (Specification limits Deviation): Represents SPC with deviation values that

follow changes to the set point. When SPCd is chosen the range for USL it will be numeric values from 1 to 99. Default is 10. The LSL range is from -1 to -99. Default is -10.

SPCn : There are no user defined values. The USL and LSL parameters are masked.

How to Use Data Communications

WATLOW Series 945

23

Page 24

Chart & SPC

e

e

Chart and SPC Printout

Example: Log = SPCA, Int = 0.1

P = Process S = Set Points

NOTE:

The time is printed

every 5th interval

(Int). The temperature variable (*) is

printed every 10th

interval.

One Int = 6 seconds.

Figure 12 Chart and SPC

Printout Example

Temperatur

*

01:00:01

01:00:31

01:01:01

01:01:31

01:02:01

01:02:31

01:03:01

01:03:31

Tim

Set Point

100°F

*

*

s

s

s

s

s

*

s

s

s

*

s

*

s

s

s

s

*

s

*

s

s

*

s

s

s

s

*

s

s

*

s

s

s

s

*

s

CP = 1.34

*

*

s

s

s

s

s

s

s

s

s

s

s

s

*

s

*

s

s

s

*

s

s

s

*

*

101

*

*

*

*

100

*

*

99

*

*

*

101

*

*

*

*

*

*

Temperature Variable

Lower Control Limit

(SPCA & SPCd only) Upper Control Limit

CPKL = 1.36 CPKU = 1.32

(SPCA & SPCd only) (SPCA & SPCd only)

90

92

Maximum Excursion Maximum Excursion

*

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

(Any messages concerning changes

(Any messages concerning tchanges

in he system are printed here)

in the system are printed here)

PROCESSDATE: 01-01-90

Set Point Variable

Temperature Variable

(SPCA & SPCd only)

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

110

110

12575

The Chart and SPC (Statistical Process Control) format are very similar. The only

difference is the SPC output displays the lower (L) and upper (U) control limit.

They are calculated based upon the mean value of the process variable, and are

derived from 30 random samples taken over the selected time base (tbS), the

mean value used is from the previous timebase samples (ex. the mean from the

first 30 samples is used to compute the control limits for the second 30 samples

and so on for every sample period. If SPCA (Specification limits Absolute or SPCd

(spec. limits Deviation) is selected then the CPKL, CP, or CPKu values will also be

printed. If the variation in the process value is too small to calculate the control

limits, L and U and the message "Variation Insignificant" are printed. If at any time

the process value exceeds the control limits during a print interval, the maximum

process excursion value will be printed (if both L and U are exceeded, both maximum values will be printed) on the next line printed. At any time the control limits

can be locked in by setting CLUP to "no" . If CLUP = no, new control limits can be

set by CLUP = YEs.

24

WATLOW Series 945

How to Use Data Communications

Page 25

Problem Cause Action

Printing all on The line feed Set the printer for a carriage

the same line. is missing. return and line feed.

The printing is Data formats are Match the Series 945 data

garbled. not compatible. format to the printers data

format using the "Data" prompt.

The printer will The printer is off line. Bring the printer on line.

not print.

The transmit and Make sure Terminal #20 and

receive lines are #22 go to the printers appropriate

reversed. receive and transmit terminals.

Error Codes

Table 7 Printer

Troubleshooting.

NAKs and Error Codes

When your message is "not acknowledged" (NAK) in RS-422A or EIA-485 with

ANSI X3.28 Protocol, you may clear ER2 code by reading it. That is, use "?"

Then try the message again; you may have made a syntax error. See the error

code listing in Table 5, Page 19.

With XON/XOFF protocol and the RS-423A interface, the 945 sends no

feedback on commands. Therefore, you may want to query the status of ER 2

after each command you send.

All communications-related error codes are ER2 error codes, that is they are

not considered cause for a shutdown of the 945 unit itself. There is always a

communications error code generated when a <NAK> character is sent under

the ANSI X3.28. With XON/XOFF flow control error codes may be generated,

but there will be no standard indication of this fact.

User Responsibility

All of the previous commands are available on all models of the Series 945 that

have communications capability. It is the responsibility of the user to refrain

from altering parameters which may not appear on the unit. (Example: AXLO

should not be set to 1 or 2 if the unit is not equipped with alarm outputs.)

How to Use Data Communications

WATLOW Series 945

25

Page 26

Index

A

ALM, 20

ANSI X3.28 "=" Command, Fig. 8, 17

ANSI X3.28 "?" Command, Fig. 9, 18

ANSI X3.28 Protocol for RS-422A & EIA-485, 3, 16

ASCII Character Set, Table 1, 10

ASCII Control Characters (Partial Set), Table 2, 10

AXHI, 20

AXLO, 20

ATMN, 20

AUT, 20

B

Baud Rate, 8

BTYP, 19

C

C1, 19

CAL, 20

Carriage Return, 13

CF, 20

Chart Printout, 25

CLUP, 9, 20

Command, "?", 19

Command, "=", 20

Command Data & Responses, Partial Set for "?", 19

Command Data "=" and "?", Table 6, 20

Command List, 12

Communications

Parameters, 8

Switch Selection, 7

Wiring, 3

Connecting the Control and the Computer, 7

CTX, 20

D

Data Parameters, 8

Data Link Escape (DLE), 17

Data Logging, 22

Data Rules, 11

DB, 20

DEC, 20

Device Address, 16

E

EIA-485, 3, 6

End of Text (ETX), 13

End of Transmission (EOT), 17

ERR, 19

ER2, 19

Example Format, 12

F

Flow Control, 13

G

General Message Syntax, 11

H

How to Use Data Comms. with the Series 945, 3

HYSX, 20

26

WATLOW Series 945

I

Identification Number, 16

IN, 19

INDC, 20

INT, 20

Interface Wiring,

RS-422A, Fig. 1, 4

RS-423A, Fig. 2, 5

EIA-485, Fig. 3, 6

L

LATX, 21

LOC, 21

LOG, 8, 21, 22

L-R, 21

LSL, 21

M

MAN, 21

MDL, 19

Message Syntax, 11

MODE, 19

Multidrop, 3

N

NAKs and Error Codes, 26

Network connections, 7

O

OT

X, 21

P

X, 21

PB

Protocol,

XON-XOFF, 13

ANSI X3.28, 16

R

RA

X, 21

REX, 21

RS-422A, 3, 4

RS-423A, 3, 5

RSP, 19, 21

RH, 21

RL, 21

S

Setup Menu, 8

SPC, 23

SP

X, 21

Space, 12

Starting Communications in ANSI X3.28 Protocol, 16

Start of Text (STX), 13

Stopping Communications in ANSI X3.28 Protocol, 17

T

Table Printout, 23

TAG, 21

tbS, 20

Two Hardware Interfaces & Protocols, 3

U

USL, 21

W

Wiring Data Communications, 4 - 6

X

XON/XOFF

"=" Command Example, Fig. 6, 14

"?" Command Example, Fig. 7, 15

How to Use Data Communications

Page 27

Notes

How to Use Data Communications

WATLOW Series 945

27

Page 28

28

Series 945 Data Communications User's Manual

Watlow Controls, 1241 Bundy Blvd., Winona, MN 55987, Phone: 507/454-5300, Fax: 507/452-4507

WATLOW Series 945

How to Use Data Communications

Loading...

Loading...