Page 1

Model: XLN3640, XLN6024, XLN8018, XLN10014

High Power Programmable

DC Power Supply

Click for models XLN15010, XLN30052 & XLN60026

USER MANUAL

www. .com

information@itm.com1.800.561.8187

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel

and must be observed during all phases of operation, service, and repair of this

instrument. Before applying power, follow the installation instructions and become

familiar with the operating instructions for this instrument.

Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the

instrument. B &K Precision assumes no liability for a customer’s failure to comply

with these requirements. This is a Safety Class I instrument.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be

connected to an electrical ground. This instrument is grounded through the

ground conductor of the supplied, three-conductor ac power cable. The

power cable must be plugged into an approved three-conductor electrical

outlet. Do not alter the ground connection. Without the protective ground

connection, all accessible conductive parts (including control knobs) can

render an electric shock. The power jack and mating plug of the power cable

meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component

replacement and internal adjustments must be made by qualified maintenance

personnel. Disconnect the power cord before removing the instrument

covers and replacing components. Under certain conditions, even with the

power cable removed, dangerous voltages may exist. To avoid injuries,

always disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service or adjustment unless another person,

capable of rendering first aid and resuscitation, is present.

www. .com

information@itm.com1.800.561.8187

Page 3

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any unauthorized modifications to

this instrument. Return the instrument to B&K Precision for service and

repair to ensure that safety features are maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the following examples,

denote a hazard and appear throughout this manual. Follow all instructions

contained in these statements.

A WARNING statement calls attention to an operating procedure, practice, or

condition, which, if not followed correctly, could result in injury or death to

personnel.

A CAUTION statement calls attention to an operating procedure, practice, or

condition, which, if not followed correctly, could result in damage to or

destruction of part or all of the product.

WARNING:

Do not alter the ground connection. Without the protec

tive ground

connection, all accessible conductive parts (including control knobs)

can render an electric shock. The power jack and mating plug of the

power cable meet IEC safety standards.

WARNING:

To avoid electrical shock hazard, disconnect power cord

before

removing covers. Refer servicing to qualified personnel.

CAUTION:

Before connecting the line cord to the AC mains, check the rear panel

AC line voltage indicator. Applying a line voltage other than the

indicated voltage can destroy the AC line

fuses. For continued fire

protection, replace fuses only with those of the specified voltage and

current ratings.

CAUTION:

This product uses components which can be damaged by

electro-

static discharge (ESD). To avoid damage, be sure to follow

proper pr

ocedures for handling, storing and transporting parts and

subassemblies which contain ESD-sensitive components.

www. .com

information@itm.com1.800.561.8187

Page 4

1

Store/Move/Maintain

Storage

When this device i s n ot i n u se, p roperly p ackage i t and store i t in an

environment suitable for storage (if present in a good preserving environment,

the packaging process can be waived).

Freight

While m oving t his pr oduct, m ove i t by us ing t he o riginal packaging to pa ck

this pr oduct i n a dvance. I f t he packaging material i s l ost, u se an eq uivalent

buffer material to replace i t i n p ackaging; an d with external m arks i ndicating

“fragile & water-prevention”.

Maintenance

Please r eturn the pow er s upply to fa ctory fo r any repair, s ervice, o r

maintenance.

Disposal

When the device is in an u nusable condition a nd can’t b e r epaired, p lease

discard it a ccording t o y our c ompany’s disposal p rocedures or local l egal

procedures. Don’t discard arbitrarily to avoid polluting the environment.

www. .com

information@itm.com1.800.561.8187

Page 5

2

Table of Contents

1. Preface ...................................................................................................... 1

1.1 Products Outline ................................................................................ 1

1.2 Features ............................................................................................. 2

1.3 Specifications .................................................................................... 4

2. Cautions Before Using ............................................................................ 9

2.1 Check and Confirm Accessories before Using .................................. 9

2.2 Operation Instructions ....................................................................... 9

2.3 Ambient Environment ....................................................................... 9

2.4 Storage ............................................................................................. 10

2.5 Power-line voltage ........................................................................... 10

2.6 Fuses ................................................................................................ 10

2.7 Warm-up Time ................................................................................. 11

2.8 Power-off procedure ........................................................................ 11

2.9 Cautions in Operation ...................................................................... 11

3. Front Panel Operation .......................................................................... 12

3.1 XLN3640/XLN6024/XLN8018/XLN10014 Panel ......................... 12

3.1.1 Front Panel ................................................................................. 12

3.1.2 Rear Panel .................................................................................. 30

4. Operation Instructions ......................................................................... 34

4.1 Voltage Setting................................................................................. 34

4.2 Current Setting ................................................................................ 34

4.3 Over-voltage Protection OVP .......................................................... 34

4.4 Over-current Protection OCP .......................................................... 34

4.5 Voltage Output ................................................................................. 35

www. .com

information@itm.com1.800.561.8187

Page 6

3

4.6 Control Voltage Output with Rotary knob ....................................... 35

4.7 Timer Function ................................................................................ 35

4.8 Series (cascade) / Parallel Mode Setting ......................................... 36

4.8.1 Parallel Connection Setting ........................................................ 36

4.8.2 Series Mode Setting ................................................................... 38

4.8.3 Error Message of Series/Parallel Connection ............................ 41

4.9 External Tuning Setting ................................................................... 42

4.10 Timer of Current Flow ..................................................................... 43

4.11 Programmable Capability (SCPI Command Only) ......................... 44

4.12 Multi-unit Connection mode (RS485) ............................................. 50

5. Protection and Error Messages............................................................ 54

5.1 Over-voltage Protection (OVP) ....................................................... 54

5.2 Over-current Protection (OCP) ........................................................ 54

5.3 Overpower Protection (OPP) ........................................................... 54

5.4 Constant Voltage Protection (CV TO CC) ....................................... 55

5.5 Constant Current Protection (CC TO CV)....................................... 55

5.6 Over-temperature Protection (OTP) ................................................ 55

5.7 Low Voltage Protection (ACD) ....................................................... 56

5.8 Error Input Message ........................................................................ 56

6. Remote Interface communication protocol ........................................ 57

6.1 Prefaces ........................................................................................... 57

6.2 Parameters Definition ...................................................................... 57

6.3 The Error/Event List ........................................................................ 58

6.4 Remote Communication Protocol ................................................... 59

6.5 SCPI Conformity Information ......................................................... 62

6.5.1 Common SCPI commands ......................................................... 62

6.5.2 SCPI Command subsystem ........................................................ 63

www. .com

information@itm.com1.800.561.8187

Page 7

4

6.6 State Bit Definition .......................................................................... 74

6.7 LAN Communication (-GL versions) .............................................. 75

Using Web Server........................................................................................... 75

Main Page (Home) .................................................................................. 75

Using Telnet ............................................................................................ 78

Using Sockets .......................................................................................... 78

7. Assemble Accessories ............................................................................ 79

7.1 Assemble Rack Mount Brackets ..................................................... 79

7.2 Assembly of Output Protective Cover

(XLN6024/XLN8018/XLN10014) .................................................. 80

7.3 Assembly of Remote Sense Protective Cover

(XLN6024/XLN8018/XLN10014) .................................................. 81

8. Accessories ............................................................................................. 82

9. Service Information .............................................................................. 84

10. Limited Three-year Warranty ............................................................. 85

www. .com

information@itm.com1.800.561.8187

Page 8

1

1. Preface

1.1 Products Outline

B&K P recision models XLN3640/XLN6024/XLN8018/XLN10014 are

programmable D C pow er supplies with s ingle ou tputs that of fer t he

maximum power output up to 1440 watts (0 -- 36 V/40 A or 0 -- 60 V/24 A

or 0 -- 80 V/18 A or 0 -- 100 V/14.4 A). With a 16-bit D/A, A/D converter

embedded, the pow er supplies come w ith the resolution of 1mV i n voltage

setting and 1mA in current setting. By connecting up to 4 power supplies in

parallel o r se ries, a maximum power out put up t o 5760 watts can be

generated. With four XLN10014 connected in s eries, the maximum output

voltage can reach 400 V. W ith four XLN3640 connected in parallel, t he

output current can reach up to 160 A.

The XLN series provides a rotary control knob and numerical and function

keys to m ake t he instrument c onvenient a nd e asy t o use. Additionally, th e

power supplies provide a memory space for storage of 10 instrument settings

that can be recalled directly. This feature offers a n easy w ay t o r estore t he

application settings. In addition, users can program to control when to cut off

the output. This feature provides extra safety f or burn-in a nd e lectroplating

applications. The supplies also pr ovide over voltage protection (OVP), over

current protection (OCP), and over power protection (OPP) features used to

keep t he out put v oltage a nd c urrent w ithin s afety le vel and preventing

damage to the UUT (Unit Under Test) due to excessive current. The key lock

feature is added to avoid accidental setting changes to the XLN series. When

the i nput pow er a nd the l oad c hange, t he power supplies maintain a stable

output due to load and line regulation of less than 0.05%; the transient time

less than 1 m s. In remote mode, the s upplies can output a n ew

voltage/current setting 50 ms after receiving a command, which can increase

the throughput on production lines.

www. .com

information@itm.com1.800.561.8187

Page 9

2

1.2 Features

1) Output Voltage & Current

Voltage output range: 0 -- 36V (XLN3640) / 0 -- 60V (XLN6024)

0 -- 80V (XLN8018) / 0 -- 100V

(XLN10014)

Current output range: 0 -- 40A (XLN3640) / 0 -- 24A (XLN6024)

0 -- 18A (XLN8018) / 0 -- 14.4A

(XLN10014)

Power output range: 0 -- 1440W

2) Rotary knob, numerical keys and functions keys

The rotary knob can be used t o rapidly ch ange the o utput voltage s etting

and si mulate t he surge of the voltage output. It offers a good s olution for

testing triggering c ircuits. Numerical k eys allow f or direct e ntry o f

parameters. U sing function k eys t o s witch modes m akes t he overall

operation more convenient.

3) Precise voltage and current measurement

Besides t he pr ecise out put, the X LN s eries also of fers the cap ability to

measure voltage & cu rrent accurately (read b ack), saving users the extra

expense and space for extra measuring instruments.

4) Internal memory and timer function

The XLN series provides a memory s pace for storage an d r etrieval of 10

instrument settings. The instruments provide one (1) ti mer w ith the

resolution o f 1 s econd. The t imers a re used to time the outputs. When the

timer c ounts down t o z ero t he power s upply will a utomatically turn th e

output off. This feature is useful when the supply is providing power to the

test o bject in a burn-in r oom where o perators can precisely set t he t ime

when the equipment is to shut off.

5) OVP (over voltage protection), OCP (over current protection) and OPP

(over power protection) and key lock functions

The over voltage protection (OVP), over current protection (OCP) and over

power protection (OPP) features limit t he m aximum output c urrent and

voltage t o av oid d amages t o the unit unde r test (UUT). The ke y l ock

feature d isables a ll k eys e xcept the C LR k ey. It p revents damaging the

www. .com

information@itm.com1.800.561.8187

Page 10

3

UUT by accidentally entering the wrong settings.

6) Series & parallel connection mode

The series-parallel connection mode of two or more units (maximum to 4

units) significantly increases the combined output power to a maximum of

5760 W. In parallel connection mode of four XLN3640 the maximum

output is 36 V/160 A; and in series connection mode of four XLN10014,

the maximum output is 400 V/14.4 A.

7) Multi-unit connection mode

The RS 485 interface can be used to connect multiple power supplies in

series, up to maximum of 30 units. They can be controlled via USB

interface with a computer.

www. .com

information@itm.com1.800.561.8187

Page 11

4

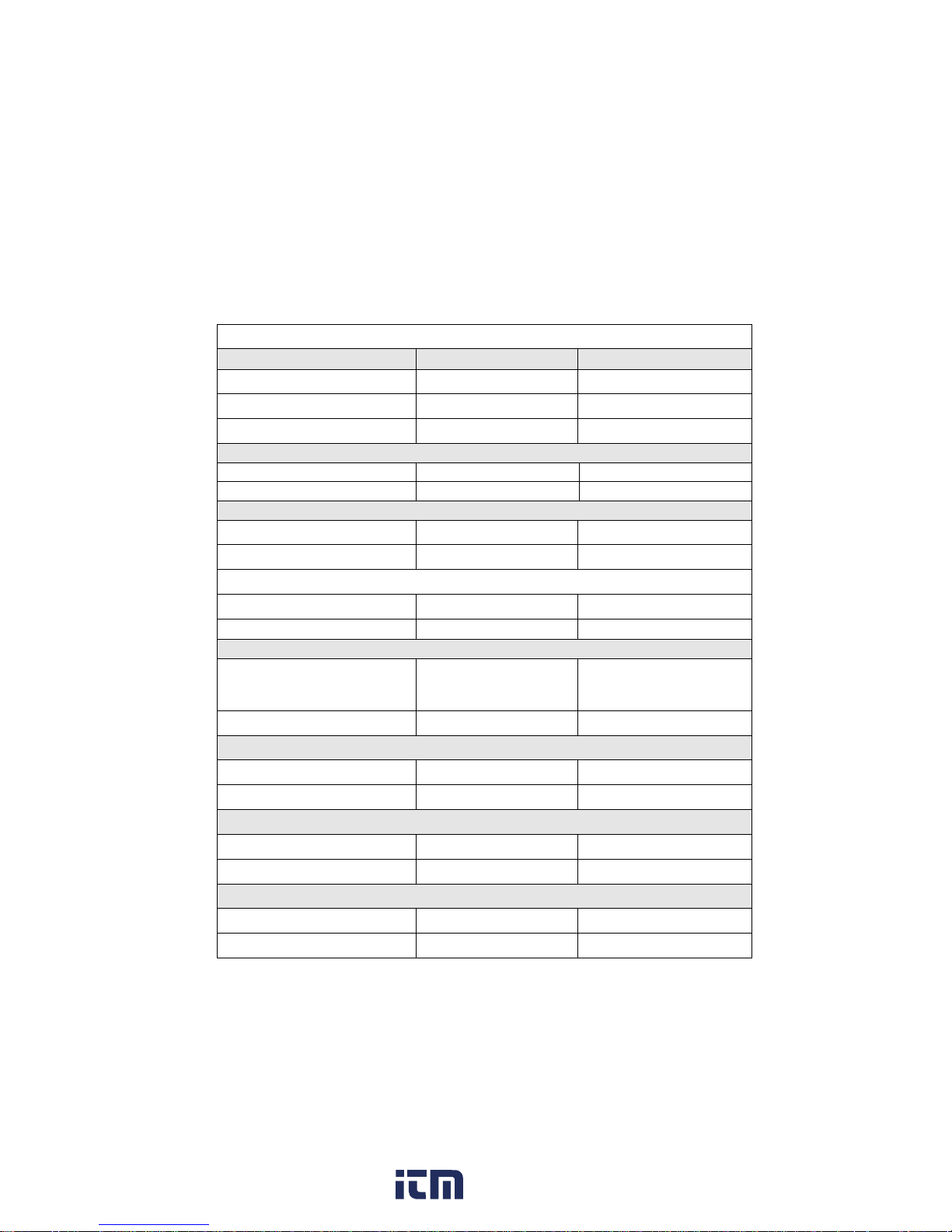

1.3 Specifications

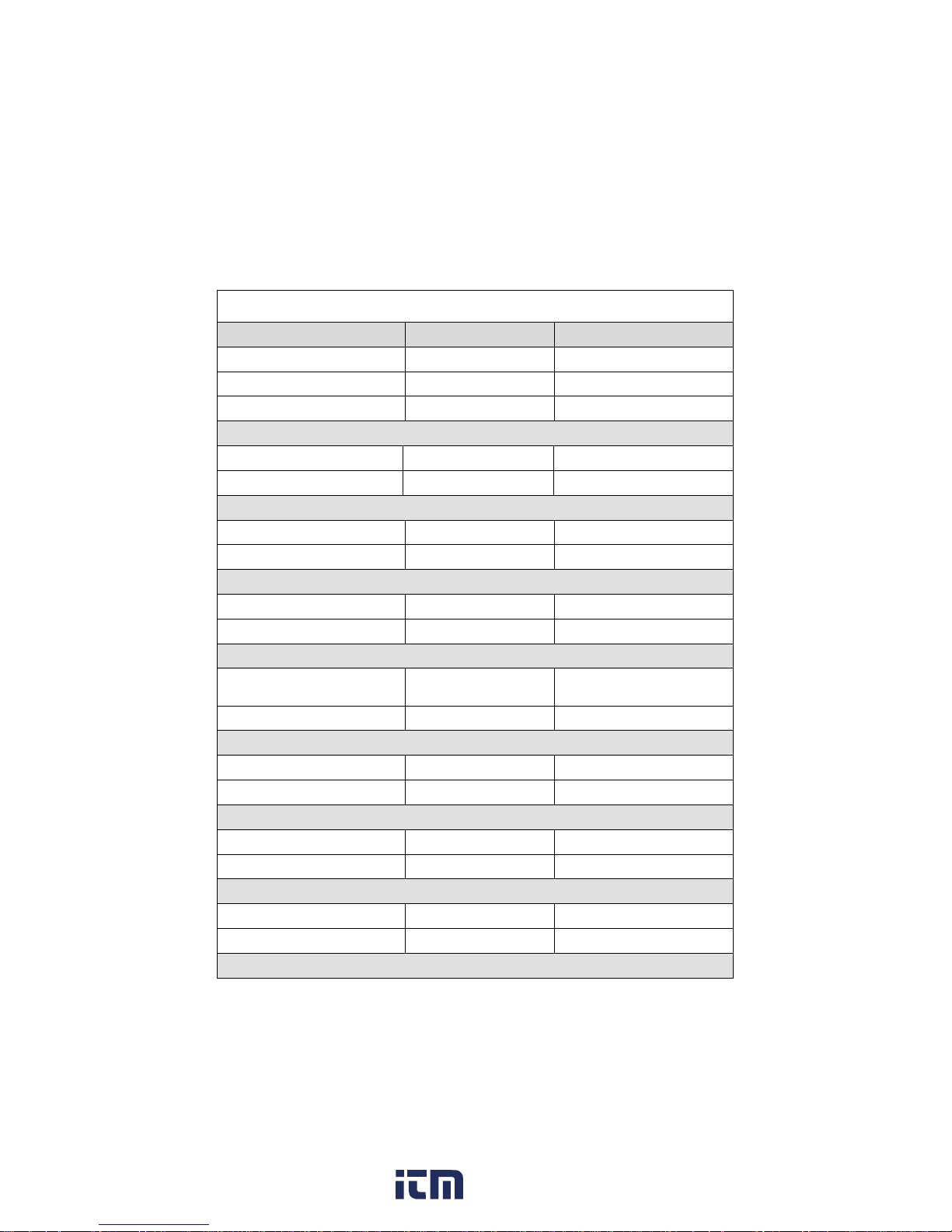

XLN3640/XLN6024 Specifications

Output Rating

XLN3640 XLN6024

Output Voltage 0--36 V 0--60 V

Output Current 0--40 A 0--24 A

Output Power 1440 W 1440 W

Output Protection

OVP Adjustment Range

2--38 V

3--64 V

OVP Accuracy

200 mV

300 mV

Line Regulation

Voltage ≤ 4 mV ≤ 6 mV

Current ≤ 4 mA ≤ 4 mA

Load Regulation

Voltage ≤ 8 mV ≤ 8 mV

Current

≤ 8 mA

≤ 7 mA

Ripple/Noise (20Hz-20MHz)

Normal Mode Voltage

( ≥ 0.5 % of max. power)

≤ 5 mVrms/≤ 60 mVpp ≤ 6 mVrms/≤ 70 mVpp

Normal Mode Current ≤ 90 mA ≤ 70 mA

Programming Resolution

Programming 1 mV/1 mA 1.5 mV/1 mA

Readback 1 mV/1 mA 1.5 mV/1 mA

Programming Accuracy ±(% output+offset)

Voltage 0.05 %+10 mV 0.05 %+15 mV

Current 0.05 %+10 mA 0.05 %+18 mA

Readback Accuracy ±(% output+offset)

Voltage 0.05 %+10 mV 0.05 %+15 mV

Current 0.05 %+10 mA 0.05 %+18 mA

www. .com

information@itm.com1.800.561.8187

Page 12

5

General

Average Command Response

Time

<50 ms <50 ms

Power Factor Correction

0.99

(Full load)

0.99

(Full load)

Remote Sense Compensation 2V 2V

Rising Time at Full Load ≤ 15 ms ≤ 20 ms

Rising Time at No Load ≤ 15 ms ≤ 20 ms

Falling Time at Full Load ≤ 15 ms ≤ 20 ms

Falling Time at No Load ≤ 1000 ms ≤ 1000 ms

Standard Interface USB

Transient Response Time ≤ 1 ms

Efficiency 80 %

AC Line Rated Input Voltage

100--240 VAC

(Full load)

Tolerance/Variation in

Voltage

-15% -- +10%

(10% power de-rating mode

when voltage under 95 VAC)

Rated Frequency 47 Hz--63 Hz

Maximum Rated Input Power 1700 VA

Temperature Ratings(O) Operation (0 °C -- 40 °C)

Temperature Ratings(S) Storage (-10 °C -- 70 °C)

Dimensions(W*H*D) 16.5 x 1.7 x 17 inch(420 x 43.6 x 432 mm)

Weight 19.8 lbs. (9 kg)

Standard Accessories

Power Cord, Terminal Blocks for Rapid Plug

Connector, Rackmount Kit, Manual

Standard Interface USB

Optional Interface LAN & GPIB

www. .com

information@itm.com1.800.561.8187

Page 13

6

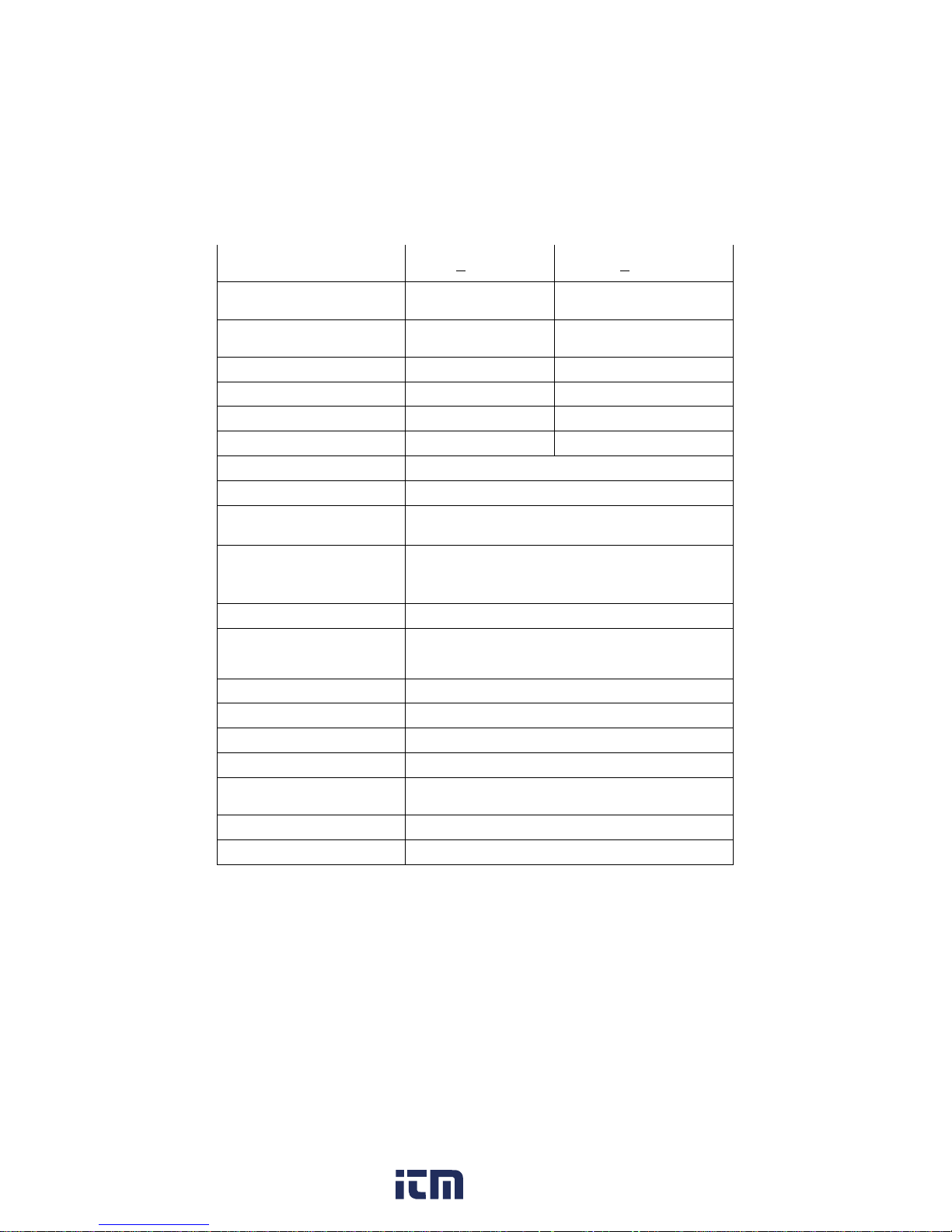

XLN8018/XLN10014 Specifications

Output Rate

XLN8018 XLN10014

Output Voltage

0~80 V 0~100 V

Output Current

0~18 A 0~14.4 A

Output Power 1440 W 1440 W

Output Protection

OVP Adjustment Range

4~85 V 5~105 V

OVP Accuracy 400 mV 500 mV

Line Regulation

Voltage ≤ 8 mV ≤ 10 mV

Current ≤ 4 mA ≤ 4 mA

Load Regulation

Voltage ≤ 10 mV ≤ 12 mV

Current ≤ 6.5 mA ≤ 6 mA

Ripple/Noise (20Hz-20MHz)

Normal Mode Voltage

( ≥ 0.5 % of max. power)

≤ 7 mVrms/≤ 80

mVpp

≤ 8 mVrms/≤ 80 mVpp

Normal Mode Current ≤ 50 mA ≤ 40 mA

Programming Resolution

Programming 2 mV/1 mA 2.5 mV/1 mA

Readback 2 mV/1 mA 2.5 mV/1 mA

Programming Accuracy ±(% output+offset)

Voltage 0.05 %+20 mV 0.05 %+25 mV

Current 0.05 %+7 mA 0.05 %+6 mA

Readback Accuracy ±(% output+offset)

Voltage 0.05 %+20 mV 0.05 %+25 mV

Current 0.05 %+7 mA 0.05 %+6 mA

General

www. .com

information@itm.com1.800.561.8187

Page 14

7

Average Command

Response Time

<50 ms <50 ms

Power Factor Correction

≥ 0.99

(Full load)

≥ 0.99

(Full load)

Remote Sense

Compensation

2 V 2 V

Rising Time at Full Load ≤ 25 ms ≤ 30 ms

Rising Time at No Load ≤ 25 ms ≤ 30 ms

Falling Time at Full Load ≤ 25 ms ≤ 30 ms

Falling Time at No Load ≤ 1000 ms ≤ 1000 ms

Transient Response Time ≤ 1 ms

Efficiency ≥ 80 %

AC Line Rated Input

Vo l t a g e

100~240 VAC

( Full load )

Tolerance/Variation in

Voltage

-15 %~+10 %

( 10 % power de-rating mode

when voltage under 95 VAC )

Rated Frequency

47 Hz~63 Hz

Maximum Rated Input

Power

1700 VA

Temperature Ratings(O) Operation (0 °C -- 40 °C)

Temperature Ratings(S) Storage (-10 °C -- 70 °C)

Dimensions(W*H*D) 16.5 x 1.7 x 17 inch (420 x 43.6 x 432 mm)

Weight 19.8 lbs. (9 kg)

Standard Accessories

Power Cord, Terminal Blocks for Rapid Plug

Connector, Rackmount Kit, Manual

Standard Interface USB

Option Interface LAN & GPIB

Specifications and information is subject to change without notice

www. .com

information@itm.com1.800.561.8187

Page 15

8

Features of models XLN3640/XLN6024/XLN8018/XLN10014:

Graphical, easy to read LCD display

Compact, high efficiency and power density

40 A output connector for quick connectivity

Convenient numerical & function keys

Store and recall 10 instrument settings

Timer (1 sec -- 100 hours)

Programmable (SCPI command only)

List mode supports up to 10 s ets o f pr ogram and m aximum 150 s teps in

total

Auxiliary 5 V/1 A output

Built-in precise voltage and current measurement

OVP, OCP, OPP and key-lock function

Series & parallel connection setup (up to 4)

Multi-unit connection mode via RS485 interface allows c onnection o f up

to 30 power supplies.

Average measuring time per measurement is 50 ms

Standard USB interface

Optional i nterfaces: GPIB, L AN (order m odels X LN3640-GL,

XLN6024-GL, XLN8018-GL, XLN10014-GL)

www. .com

information@itm.com1.800.561.8187

Page 16

9

2. Cautions Before Using

2.1 Check and Confirm Accessories before Using

After r eceiving t his product, please verify the items received i n acco rdance

with the ones listed below:

1. The appearance of the products is without scratch or other damages.

2. Standard parts as shown in parts list of section 8.

2.2 Operation Instructions

In order t o avoid damaging the i nstrument due t o improper ope ration, b e

sure to r ead t his user manual. To maintain the s pecified accuracy, f actory

calibration should be performed annually.

2.3 Ambient Environment

1. Do not l ocate or op erate this p roduct i n an e nvironment w ith dus t,

vibration, or corrosive gas and do not expose this product directly to

the sunlight. O perate it in an e nvironment with temperature 0--40

o

C

& r elative h umidity 2 0%--80%. P ause t he ope ration when a mbient

temperature is over 40

o

C; undo t he operation onl y a fter the ambient

temperatures d rops t o t he accep table t emperature r ange. O perating

temperature over the above range would damage the instrument.

2. This product is equipped with one blow-out t ype c ooling fan on the

back board and three in-take cooling fans on inner side of front board.

Provide room for good ventilation near the cooling fans and keep the

boards w ith a space above 10cm away from w all. To maintain good

accuracy, do not block the ventilation holes in the front and the rear

parts of the unit.

3. Although the product is designed with filters to minimize noise from

AC power so urce, it i s r ecommended t hat it be operated in a low

power no ise e nvironment with p roper e arth g round. If t he pow er

noise is unavoidable, please install a power filter.

www. .com

information@itm.com1.800.561.8187

Page 17

10

2.4 Storage

The storage temperature r ange of this pr oduct i s w ithin -10ºC - 70ºC and

R.H. s hould be w ithin 80 % without moisture condensing. I f not op erating

this pr oduct f or a l ong t ime i nterval, p ack i t w ith original pa ckaging or

similar one and put it in a dry place without exposure to direct sunlight.

2.5 Power-line voltage

Rated AC power s ource c onnected to t his p roduct is w ithin 1 00 V-240 V

(refer to the Product Specification for details). Before connecting to external

power so urce, be sure t hat t he p ower sw itch is in OFF state and verify the

suitability of pow er c able ( including t he e xtension l ine). It should be

compatible with the rated voltage/current and should be firmly connected.

Warning :

The power cable attached with this product is certified

for safety. To change a cable or add an extension cable,

be sure that it can meet the required power ratings of

this product. Any misuse with an additional cable

would void the warranty of this product.

2.6 Fuses

This product is a switching mode power supply. The fuse installed inside is a

multi-barrier protection hardware design. It should not br eak unde r no rmal

operation. I n c ase the fuse does melt, it indicates another m alfunction that

causes t he f use t o break. In this case, it is suggested to send t his pr oduct

back to service.

Warning :

Any disassembling of the casing or changing the fuse not

performed by an authorized service technician will void

the warranty of the instrument.

www. .com

information@itm.com1.800.561.8187

Page 18

11

2.7 Warm-up Time

The XLN series is fully operable upon switching the power on. However, to

reach the specified equipment accuracy, please allow the supply to warm up

for at least 30 minutes.

2.8 Power-off procedure

When the supply is not in use, be sure to turn the power switch on the panel

to the OFF position to turn off the power. After the power switch is turned to

the OFF p osition, the inner f ans w ill s till r un f or approximately 10 -15

seconds to carry on the inside electric capacitor discharge process per safety

code requirement. Once the discharge p rocess is complete, this product will

carry out the automatic shut-down process

2.9 Cautions in Operation

A. While connected i n series, eac h power s upplies should be in pow er-on

state and output should be "ON". In case t here is any one supply t hat is

in power-off state or o utput is "OFF", the associated output current will

flow over the output bypass diode of the power-off unit and burn it out.

B. While in parallel c onnection m ode, t he out put v oltage of e ach power

supplies should be set to equal values. If the setting value of each unit is

not the same, the higher output voltage will feed back to the smaller unit

and destroy its inner parts.

C.

When the AC input voltage is lower than the full-load voltage which is

100 VAC, the supplies will activate an inner over temperature protector

and c ut of f the output i n r esponse to t he condition. To e nsure that t he

entire test process can be complete smoothly, confirm that the input AC

voltage is within the specified range.

www. .com

information@itm.com1.800.561.8187

Page 19

12

3. Front Panel Operation

3.1 XLN3640/XLN6024/XLN8018/XLN10014 Panel

3.1.1 Front Panel

(1) Power switch:

Please consult the “Cautions before use” section before turning on power

switch.

(2) Display:

192x32 Graphic LCD Module

(3) Current setting

:

Press

to set up the current limit.

(4) Voltage setting

:

Press

to set up the output voltage.

(5) Dot/Local :

This bu tton i s a pplied a s a decimal po int. Or p ush t his but ton a fter

entering R EMOTE onl ine s tate t o revert b ack t o LOCAL m ode

(unit-operation mode). Or press this button to release after entering

LOCK mode.

1 2 3 4 5 6 7

8

9

10

11

12 13 14

15

www. .com

information@itm.com1.800.561.8187

Page 20

13

(6) ESC/CLR :

Press this bu tton to c lean up num erical s etting o r jump t o t he previous

screen.

(7) Numerical keys

- :

They are used to directly input the voltage or current value or choose the

setting option in Menu screen.

(8) Down/Right/Store

:

This key is a multi-function key for the following three functions:

Down:

In “Menu Setting” status, use this “Down” key to move cursor

to the next item.

Right: Under “Output” status, use this key to move cursor right.

Store:

Under Memory S etting st atus, u se this k ey t o store s etting to

the selected memory set.

(9) Up/Left/Recall :

This key is a multi-function key for the following three functions:

Up:

In “Menu

Setting” status, use this “Down” key to move cursor

to the up item.

Left: Under “Output” status, use this key to move cursor left.

Recall:

Under Memory S etting st atus, u se t his k ey t o r ecall se tting

from the selected memory set.

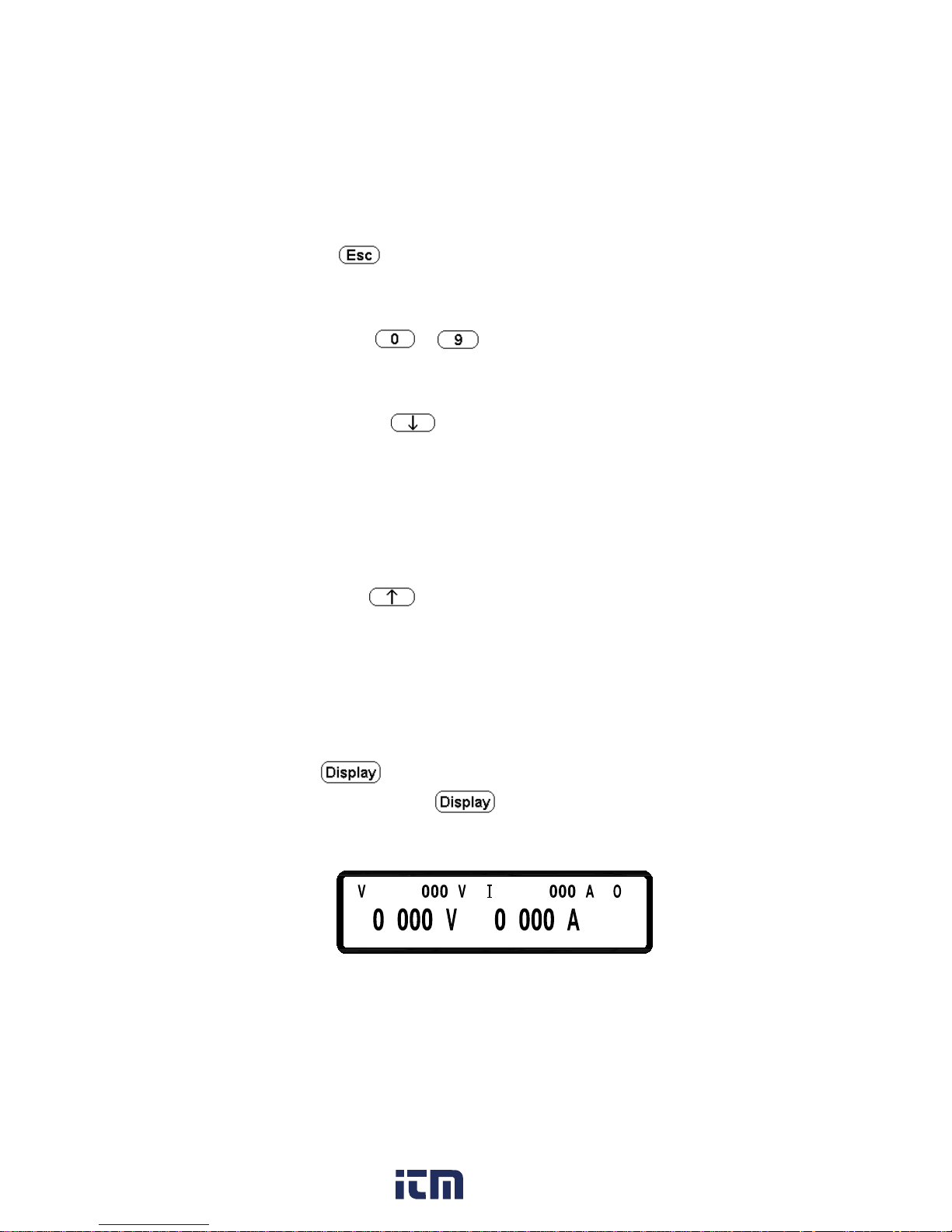

(10) Display :

In “ Menu S etting”, p ress

to return t o m ain screen or toggle

the display to show voltage an d current or power a nd load resistance as

shown below:

=36. FF

5

1

.

=

.

.

www. .com

information@itm.com1.800.561.8187

Page 21

14

.

1= .

5

FF

.

3=6

.

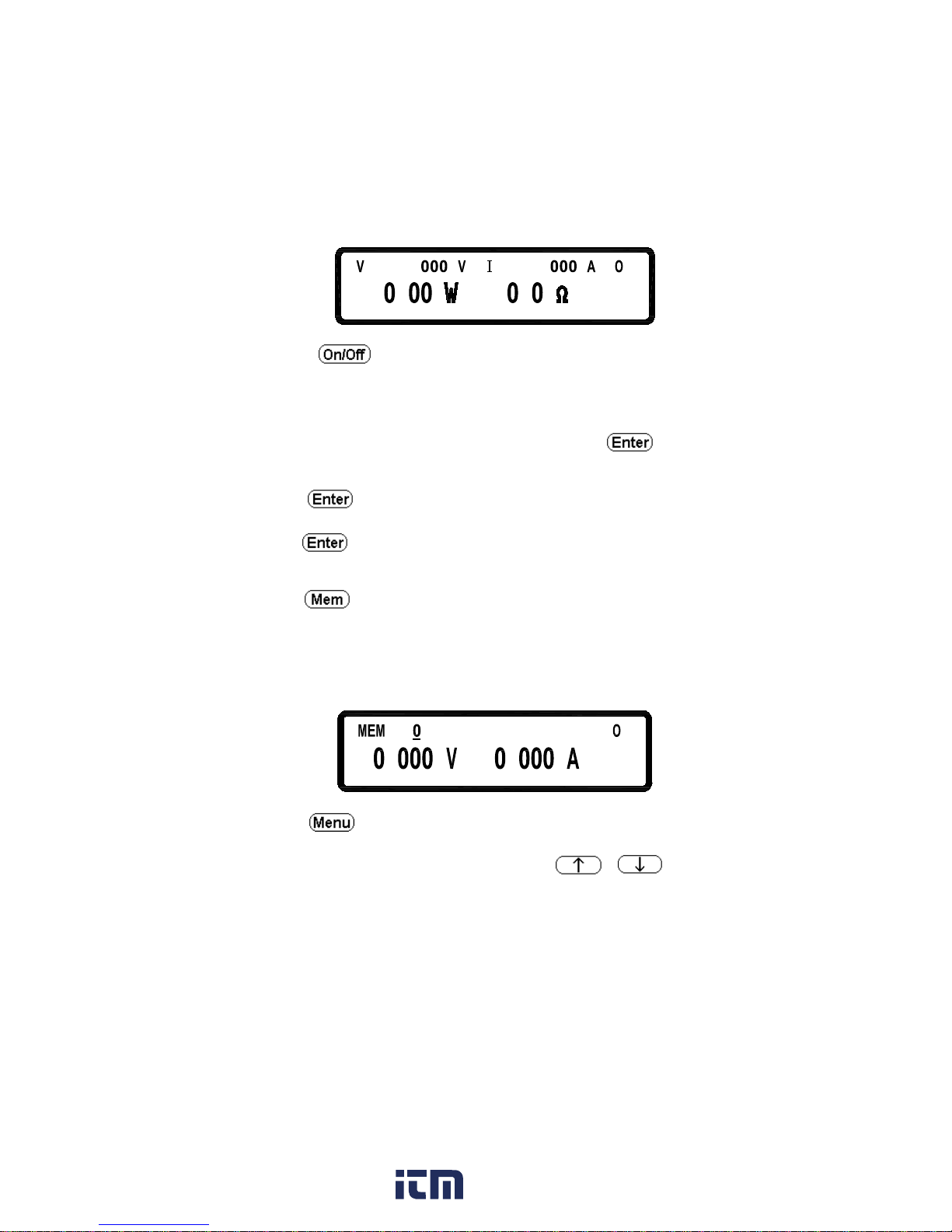

(11) Output :

Control the On/Off of the output power.

(12) The rotary knob:

Use t his knob to ad just v oltage o r cu rrent ( press

first t o le t

cursor display first). This is adjustable when output is ON.

(13) Enter

:

This ke y is the c onfirmation key o f c urrent or vo ltage s etting va lue; o r

press

under ou tput s tatus t o dy namically a djust v oltage ( at C V

mode) or current (at CC mode).

(14) Mem

:

Press this key to enter access the storage memory. Users can then use the

numerical key or knob to select the target m emory set to s ave o r recall

the configuration by pressing t he STORE or RECALL k ey. Ten sets are

available in selection.

=

FF

.

.

(15) Menu :

Use this key to enter system parameter settings. There are eight (8) major

items unde r ope ration. Users m ay press

,

to scr oll

through t he m enu list or the num erical k eys to enter the corresponding

item number in the menu list.

www. .com

information@itm.com1.800.561.8187

Page 22

15

.

4

5

6

.

.

F

LL L

T

L T T F

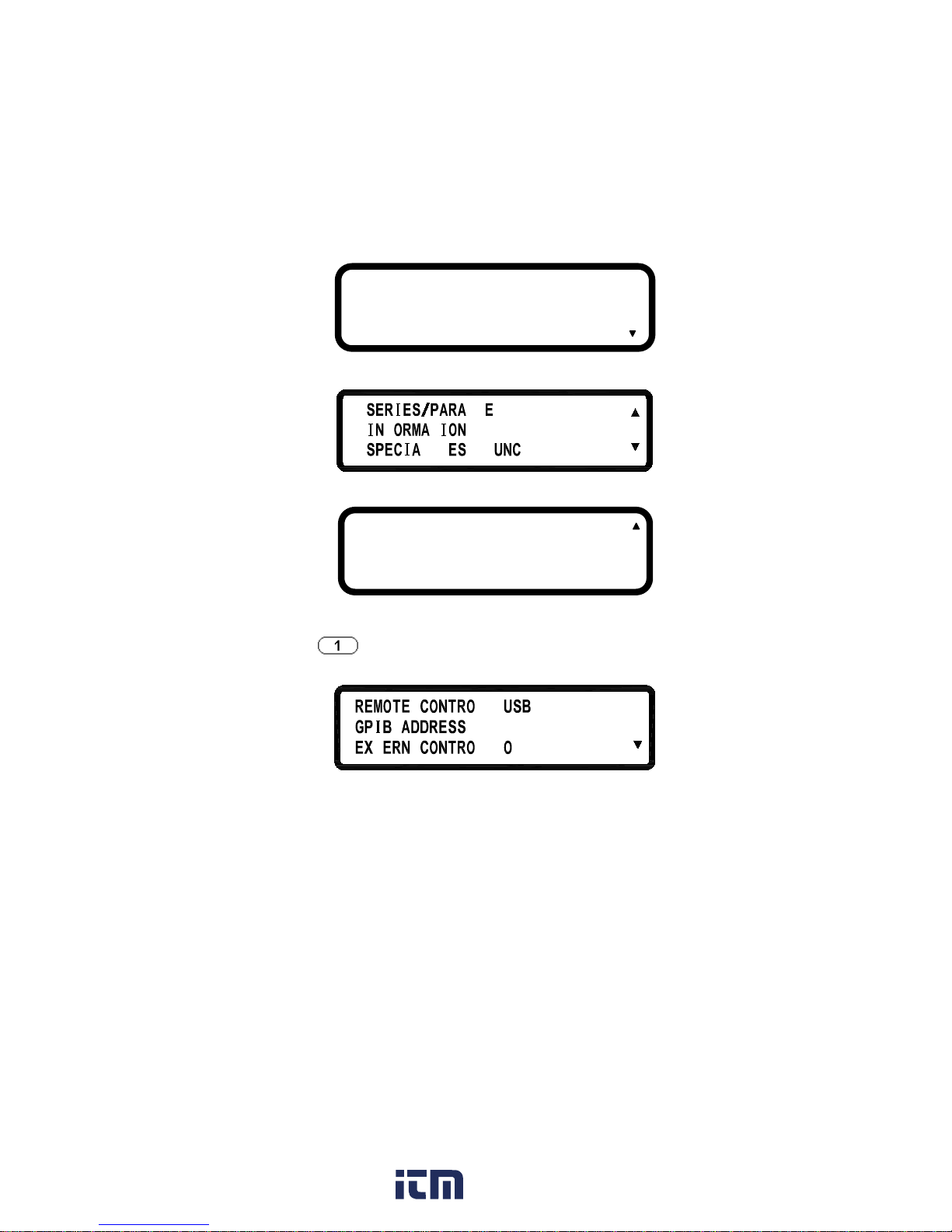

1. SYSTEM SETTING:

Pressing

key i n t he f irst pa ge of Menu S etting will e nter the

following “SYSTEM SETTING” menu.

L=

= 1

T

=L

FF

REMOTE CONTROL:

Choose the remote interface

(USB/GPIB/ETHERNET)

*GPIB and ETHERNET available only

with on models with “-GL” suffix

*USB control requires installing USB

drivers first. Download USB driver

*US

B interface is a virtual COM port. T he settings are:

Baudrate : 57600 bps

1 . SYSTEM SETTING

2 . OUTPUT SETTING

3 . PROTECTION

7 . TIMER CONTROL

8 . CALIBRATION

9 . CHAIN SETTING

www. .com

information@itm.com1.800.561.8187

Page 23

16

Data bit : 8

Parity check : none

Stop bit : 1

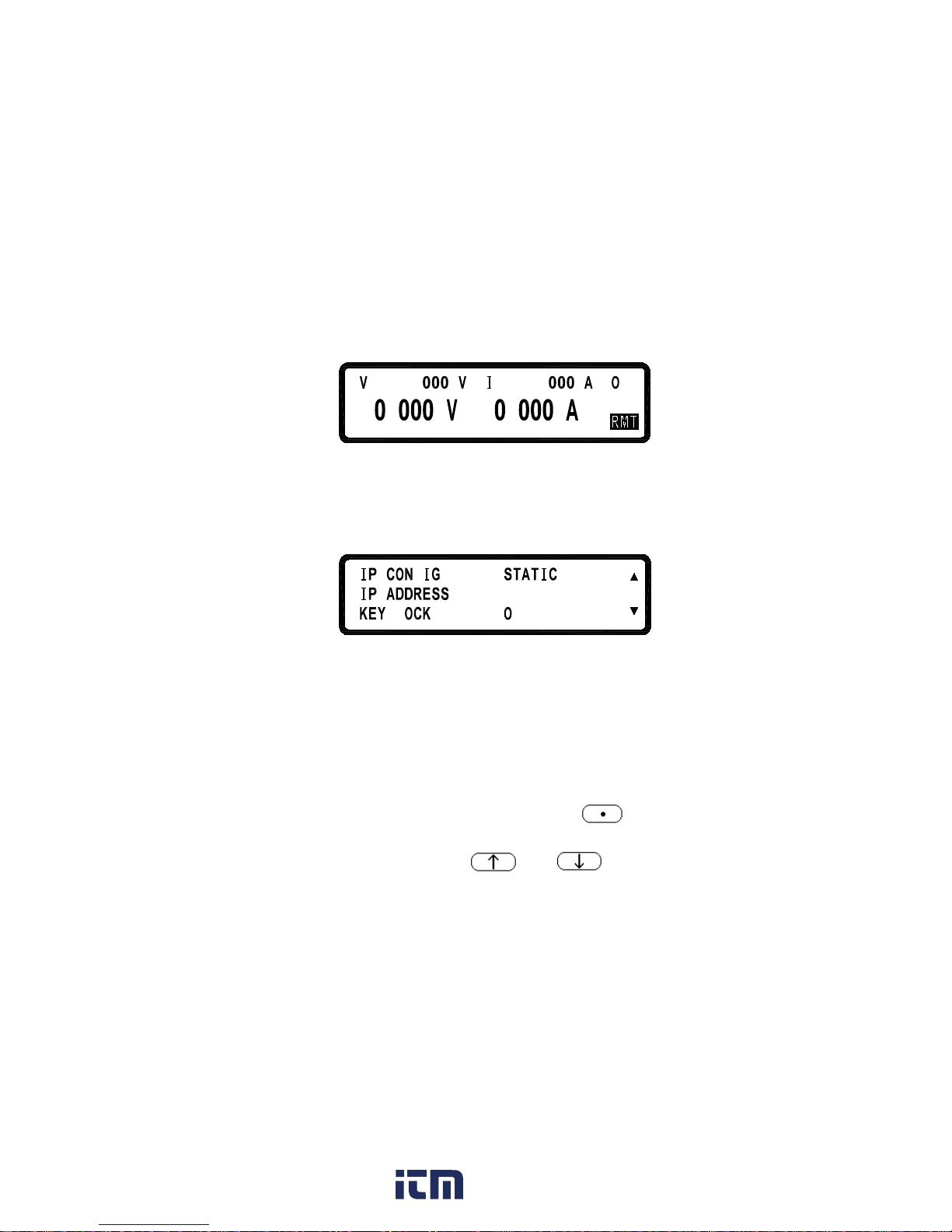

*When entering t he Remote mode, screen will present R MT indicator as

shown in the following picture.

1

.

= .

5

F

F

3

.

= .

6

GPIB ADDRESS:

Set up GPIB ADDRESS (1-30)

EXTERN CONTROL:

Set up t he external

control to voltage

control (VOLT 0-10 V or 0-5 V), res

istance

control (RES 0-5K) or off (OFF).

=

5

F

52=

= F

552. 552. 552

.

F

L

IP CONFIG:

STATIC : User can input IP address

IP ADDRESS:

If IP C ONFIG is set to S TATIC, us ers can enter

a

static IP address here.

Note:

If you are not sure of the IP settings, consult

your network administrator.

KEY LOCK:

While e xiting the s etting screen after en

able K EY

LOCK, all keys except the key

are l ocked.

Only this key can disable KEY LOCK.

*Simultaneously pressing both and keys in th e main

screen can also lock keys.

*While e ntering K EY LOCK state, sc reen w ill present LCK indicator in

the bottom right corner.

www. .com

information@itm.com1.800.561.8187

Page 24

17

L

=

F

L

L

=

=

L

L

L

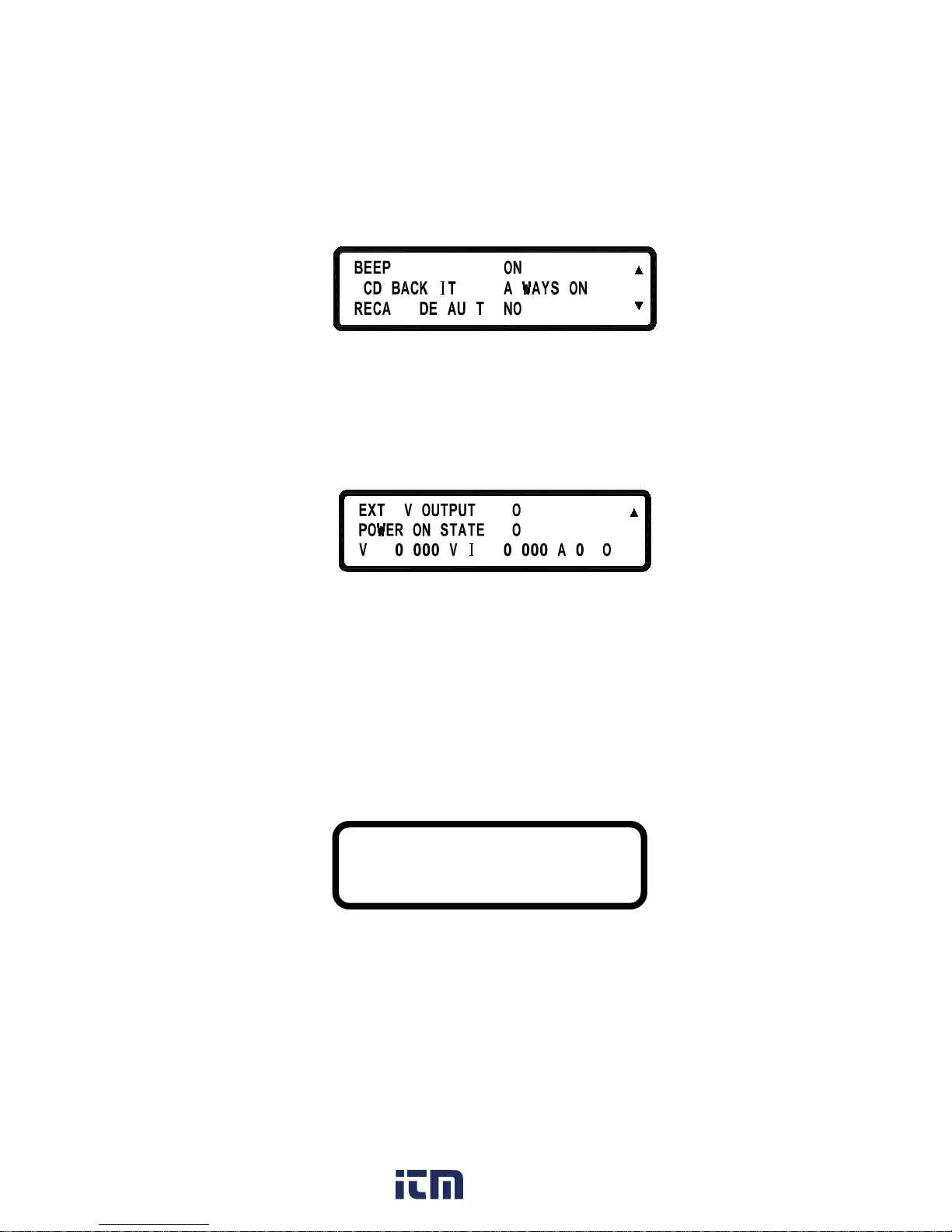

BEEP:

Turns the Buzzer ON/OFF

LCD BACKLIT:

Set the backlight of the LCD to Always

ON or OFF after 1/5/10/30 minutes

RECALL DEFAULT:

Restores the manufacturer

default

settings

.

FF=

F

=

,

=.F

=,FF

5

=

Ext 5V OUTPUT:

Turns the extra 5V power output

(on the rear

panel) ON/OFF.

POWER ON STATE:

Users can set t he ou tput state

of t he supply

when powered on. When OFF is selected, the

XLN series will do nothing after power on.

If

LAST is sel ected, then a t power on

the

supply w ill

use t he last set ting b efore it

turned off previously. If USER (user defined)

is sel ected,

a p rompt w ill a sk f or setting

output voltage, current, a nd output s tate.

Once set, these values are then used the next

time the supply is powered on.

HOT KEY:

Set the HOT KEY function ON/OFF. I

f the

HOT KEY function is ON, user can use 0 –

9

number keys to recall the voltage and current

HOT KEY = OFF

www. .com

information@itm.com1.800.561.8187

Page 25

18

setting values stored inside internal memory.

*If e ntering t he HOT K EY mode, sc reen w ill indicate HOT s ymbol a s

shown in the following illustration.

6

.

=

3

.

4

.

=

.

F

F

2. OUTPUT SETTING:

Press

in the first p age o f Menu S etting t o enter OUTPUT

SETTING menu.

VOLT LIMIT:

Upper limit of the output voltage setting

CURR LIMIT:

Upper limit of the output current setting

VOLT SLEW RATE:

Voltage ascending/descending slope

(XLN3640: 0.01 - 2.4V/ms)

(XLN 6024:0.01 - 3V/ms)

(XLN 8018:0.01 - 3.2V/ms

(XLN 10014:0.01 - 3.3V/ms)

VOLT LIMIT MAX = 60.500 V

CURR LIMIT MAX = 24.500 A

VOLT LIMIT MIN = 0.000 V

CURR LIMIT MIN = 0.010 A

VOLT SLEW RA TE = 3.0000 V/mS

CURR SLEW RA TE = 1.2000 A/mS

CONNECTOR DROP = DISABLE

EXT FULL VOLT = 10 V

www. .com

information@itm.com1.800.561.8187

Page 26

19

CURR SLEW RATE:

Current ascending/descending slope

(XLN 3640:0.01 - 2.5A/ms)

(XLN 6024:0.01 - 1.2A/ms)

(XLN 8018:0.01 - 0.72A/ms

(XLN 10014:0.01 - 0.48A/ms)

CONNECTOR DROP:

Turns on/off the connector drop calibration

function

EXT FULL VOLT:

External voltage control full-scale setting.

Select between 10 V or 5 V for full-scale

control.

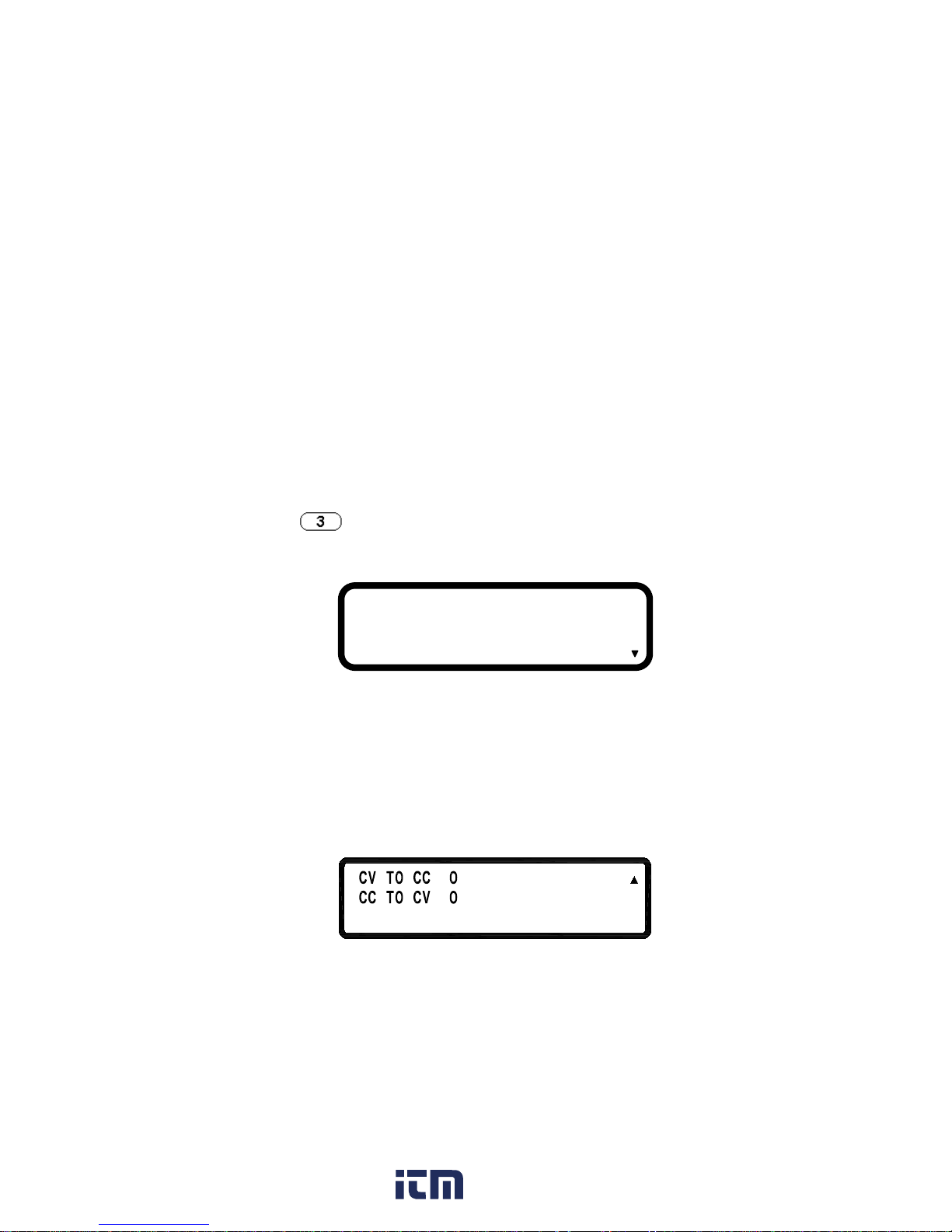

3. PROTECTION SETTING (PROTECTION)

Press

key in th e first screen of “Menu S etting” to e nter

PROTECTION menu.

OVP:turns on/off the

overvoltage protection

SET: set up the overvoltage protecting

point.

OCP:turns on/off the

overcurrent protection

SET:

set up the overcurrent protecting

point.

OPP:turns on/off the overpower

protection

SET: set up the overpower protecting

point.

FF

FF

=

=

CV TO CC:

Enable/disable the protection of t he change

OVP = OFF SET = 38.000 V

OCP = OFF SET = 42.000 A

OPP = OFF SET = 1440.000 W

www. .com

information@itm.com1.800.561.8187

Page 27

20

from CV to CC mode

CC TO CV:

Enable/disable the protection of th e change

from CC to CV mode

4. SERIES/PARALLEL SETTING

Press

in t he second screen of Menu S etting t o e nter

SERIES/PARALLEL menu.

L

T

L

T

FF

=

=

T

SELECT MODE: Choose

series or parallel operation

mode.

MASTER/SLAVE:

Refer to “ Series/Parallel S etting”

section

for t he d etailed setting

procedure of MASTER/SLAVE mode.

5. INFORMATION

Press

in the second screen of “Menu Setting” to enter

INFORMATION screen.

F

463L

L

:

1

31

.

L

6. SPECIAL TEST FUNCTION

Press

in the second screen of “Menu Setting” to enter SPECIAL

TEST FUNCTION menu.

1. CURRENT COUNT ER TEST

2. PROGRAM MODE

3. MEASURE AVERAGE

www. .com

information@itm.com1.800.561.8187

Page 28

21

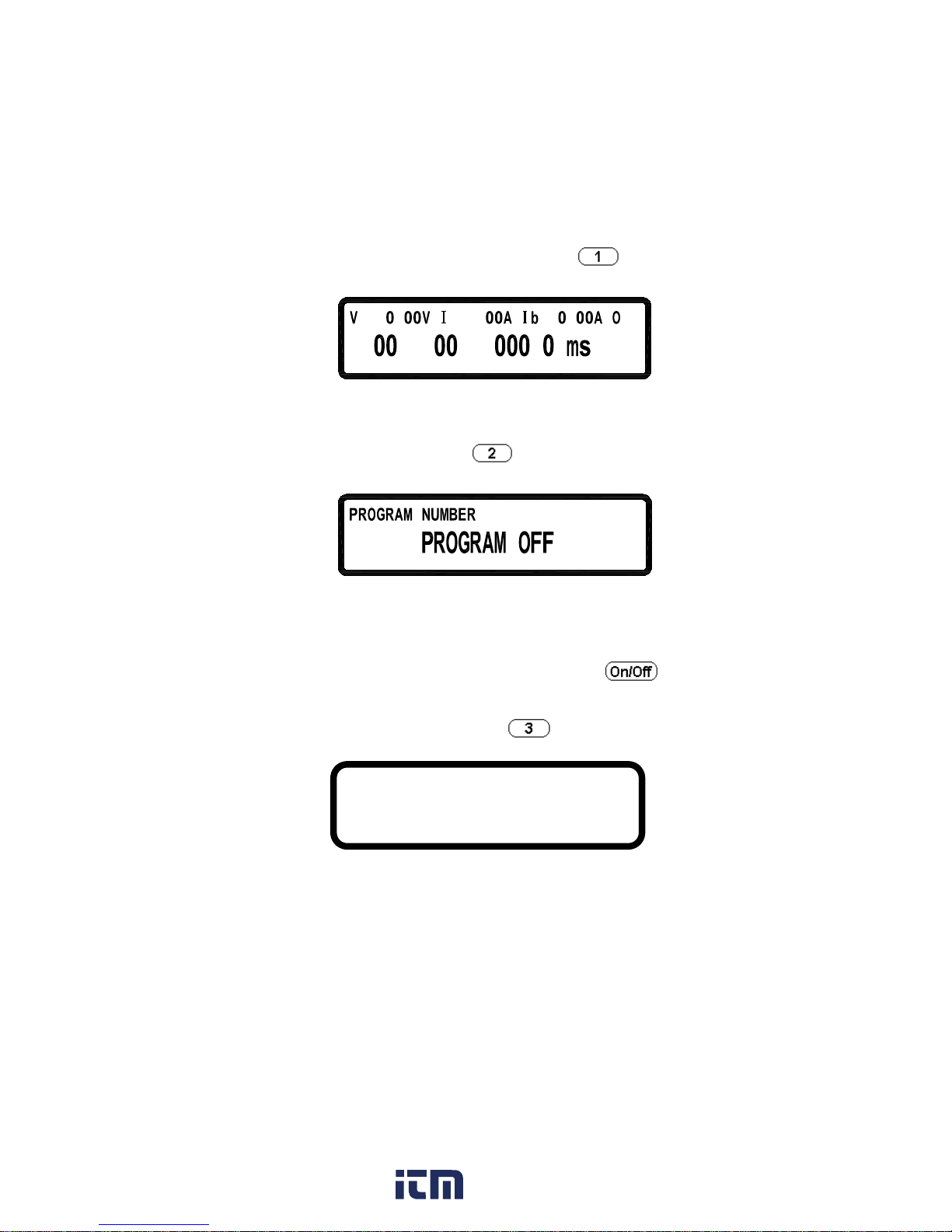

6.1 CURRENT C OUNTER T EST: Press to e nter t he

CURRENT COUNTER TEST screen.

= 1 . = .

:

.

FF

= 1 .

:

Refer to “Current Counting” section for the detailed setting procedure.

6.2 PROGRAM MODE: Press

to enter the PROGRAM MODE

menu.

1=

Before r unning t he pr ogram, us er needs t o input the p rogrammed

values through the USB or G PIB i nterface into the power su pplies.

Users may save up to 10 programs ( program number 1 t hrough 10)

inside the memory and r ecall them in this Program Mode screen by

selecting the program number and then pressing

to execute

the program.

6.3 MEASURE A VERAGE: Press

to enter th e MEASURE

AVERAGE page.

AVERAGE TIME:

Set the average measure time.

7. TIMER CONTROL

AVERAGE TIME = 2

www. .com

information@itm.com1.800.561.8187

Page 29

22

Press

in t he t hird pa ge of Menu S etting t o e nter T IMER

CONTROL screen.

=

=

FF

r

ni ec

TIMER:

Turn on/off TIMER function.

TIME:

Set up OUTPUT ON time (Max:999Hr 59Min

59Sec)

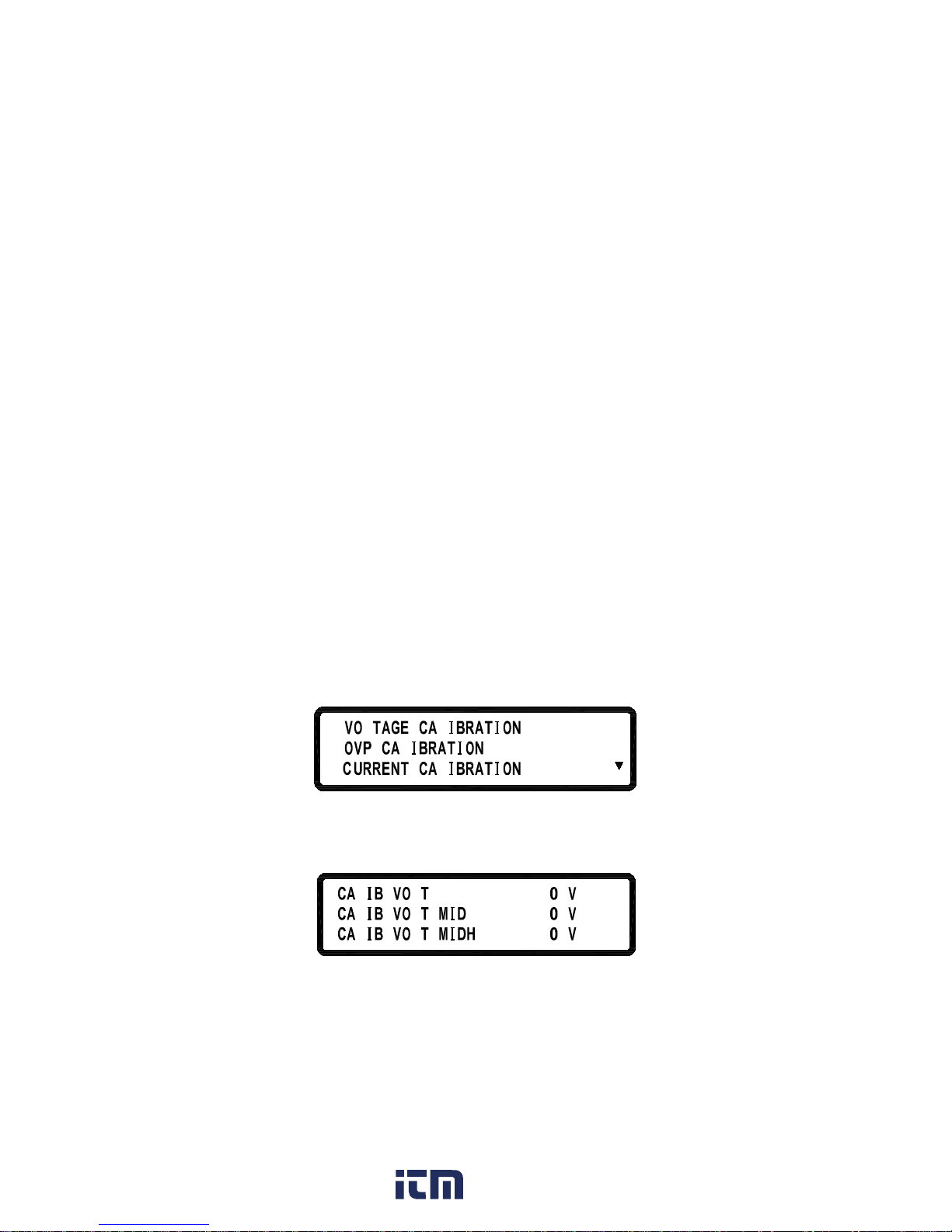

8. CALIBRATION

Press

in the t hird page of “Menu Setting” to enter

CALIBRATION menu. Users must enter t he p assword to access

calibration mode.

:

L

8.1 Equipment Requirements

1. 5 ½ Digital Volt meter.

2. Shunt for current calibration (100 A/ 10 m Ω)

8.2 Calibration Procedure

A. Connect power s upply output t erminal to D VM (as s hown i n

Figure 1 below). Turn on the s upply. O nce the u nit enters t he

main p age, p ress MENU and se lect “8. Calibration” and ke y i n

VOLTAGE CALIBRATION

www. .com

information@itm.com1.800.561.8187

Page 30

23

password “13579” to enter the following calibration menu screen:

Figure 1

L

1

.

3

2

.

.

L

L

L

B. Press “1” to access Voltage Calibration Procedure.

C.

L

o

468.1=L

5

2

1=L

=

2 4

455

.

11L

L

L

L

L

www. .com

information@itm.com1.800.561.8187

Page 31

24

LL

i

87.53=

D. According to voltage value displayed on DVM, fill in the values

for their corresponding functions and press ENTER. If any DVM

read-back value at each voltage function does not fit with the

following table below, please inspect the hardware.

XLN3640

Function

Setting

Val ue

Range of Read-Back Value

Lo 1.8V 1.5 - 2.0 V

MIDL 12V 10 - 13 V

MIDH 24V 21 - 25 V

Hi 32.4V 31 - 34 V

XLN6024

Function

Setting

Val ue

Range of Read-Back Value

Lo

3V

2.4 - 3.6 V

MIDL

20V

18 - 22 V

MIDH

40V

36 - 44 V

Hi

57V

53 - 61 V

XLN8018

Function

Setting

Val ue

Range of Read-Back Value

Lo

4V

3.6 - 4.4 V

MIDL

26V

23.5 - 28.5 V

www. .com

information@itm.com1.800.561.8187

Page 32

25

MIDH

53V

48 - 58 V

Hi

76V

69 - 83 V

XLN10014

Function

Setting

Val ue

Range of Read-Back Value

Lo

5V

4.5 - 5.5 V

MIDL

33V

29.7 - 36.3 V

MIDH

66V

59 - 72 V

Hi

95V

85 - 104 V

E. When pressing ENTER at Hi function, and the calibration data

values will be stored in FLASH and unit will return to calibration

main screen.

A. Press 2 in the calibration main page to enter OVP calibration

page.

OVP CALIBRATION

L

L

a=

o

L

=

i

B. Press ENTER to access OVP calibration procedure at Low function.

www. .com

information@itm.com1.800.561.8187

Page 33

26

L

L

n

i

abilaLo=

=

i

...

C. Jump to Hi function when completed.

L

L

Lo=

=

i

a

D. Press ENTER to access OVP calibration procedure at High function.

E.

L

L

Lo=

a=

i

lib

ain

. . .

F. After completing the above steps, calibration value will be stored in

FLASH and unit will return to the calibration main screen.

G. If calibration is not completed in 10 seconds after starting, please

inspect OVP circuit.

A. Connect two output terminals of the power supply to two ends of the

current shunt, and connect DVM to the sensor of current shunt to

measure DC voltage as shown Figure 2. Press 3 to enter current

calibration screen.

CURRENT CALIBRATION

B. First, input parameter (resistance of current shunt, mΩ) of current

www. .com

information@itm.com1.800.561.8187

Page 34

27

measurement fixture. According to voltage value shown on DVM,

fill in that value that corresponds to the function and press ENTER

key.

Figure 2

.

F

L

L

.

1

=

3

o

L

=

=L 1

.

1

.

www. .com

information@itm.com1.800.561.8187

Page 35

28

C. Please inspect the hardware if the current value is inconsistent with

the value in the tolerance error table below after the calibration

values of each function is changed to actual current value.

XLN3640

Function Setting Range of Transformation Value

Lo

0.1A

0 - 0.5 A

MIDL

13A

11 - 14 A

MIDH

26A

23 - 27 A

Hi

38A

34 - 39 A

XLN6024

Function Setting Range of Transformation Value

Lo

0.06A

0 - 0.5 A

MIDL

7.8A

6.6 - 9 A

MIDH

15.6A

14 - 17.2 A

Hi

22.8A

21 - 24.6 A

XLN8018

Function Setting Range of Transformation Value

Lo 0.045A 0 - 0.1 A

MIDL 5.9A 5.3 - 6.5 A

MIDH 12A 10.8 - 13.2 A

Hi 17A 15.3 - 18.7 A

CALIB CURR MIDH = 258.246 mV

CALIB CURR Hi = 377.559 mV

www. .com

information@itm.com1.800.561.8187

Page 36

29

XLN10014

Function Setting Range of Transformation Value

Lo

0.03625A

0 - 0.1 A

MIDL 4.7A 4.2 - 5.2 A

MIDH 9.5A 8.55 - 10.45 A

Hi 13.7A 12.33 - 15.07 A

D. The calibration value will be stored in FLASH after pressing

ENTER at Hi function.

9. Series Connection Control Setting (CHAIN)

Press

in Menu setting page to enter CHAIN SETTING

page.

FF=FF

1=

CHAIN ON/OFF : On/Off Series Connection Mode

CHAIN ADDRESS : Setting Address (1 – 30)

For the detailed setting information, please refer to “SERIES

CONNECTION FUNCTION” section.

www. .com

information@itm.com1.800.561.8187

Page 37

30

3.1.2 Rear Panel

Cooling fans:

The supply automatically adjusts fan’s rpm according to the load condition.

(16) Cooling fan:

The rear cooling fan speed is temperature control.

(17) Power output terminal:

Please pay attention to the correct polarities when making connection.

(18) RMT/LCL Sense:

When Remote s ense is sel ected, the w ire connection can be setup as

follows (shown i n t he f igure below): positive s ense (+S) and positive

lead ( +) of the D C output a re c onnected to t he positive end (+) of the

device, whereas negative sense (-S) and negative lead ( -) of the D C

output are connected to the negative end (-) of the device under test. This

connection w ill c ompensate the v oltage dr opped du e t o c urrent f low

through long power wires (the maximum compensation voltage is 2 V).

16

17

18

19

20

21

22

23

24

25

26

www. .com

information@itm.com1.800.561.8187

Page 38

31

When L ocal sense is se lected, the w ire connection can be setup as

follows (shown i n t he figure a bove):positive sen se (+S) is connected t o

the positive lead (+) and negative sense (-S) is connected to the negative

lead ( -), w hereas the p ositive l ead (+) of the D C output is connected t o

the p ositive e nd (+) of the de vice a nd the negative lead ( -) of the D C

output is connected to the negative end (-) of the device under test. When

this sensing mode is selected, the power wires from the DC output leads

to the device under test should be as short as possible.

(19) LAN (optional):

The ETHERNET interface connector

(20) GPIB (optional):

The GPIB interface connector

(21) AC power input:

The power receptacle is for a power source within 100 VAC - 240 VAC.

(22) Earth connection:

Used for earth ground connection.

www. .com

information@itm.com1.800.561.8187

Page 39

32

(23) 5V/1A Output:

XLN series offers an extra output with a constant ou tput voltage of 5 V

and the maximum output current of 1 A. This extra power supply can be

switched on or off under the “System Setting” menu.

(24) USB :

USB interface connector.

(25) EXT CTL:

Models XLN3640/XLN6024/XLN8018/XLN10014 offer t he capability

of setting t he out put v oltage/current by adjusting an external input

voltage/resistance. The range of the external input voltage is 0 - 10 VDC

or 0 - 5 VDC, which c orresponds to t he o utput voltage of 0 - 36 V for

XLN3640, 0 - 60 V for XLN6024, 0 - 80 V for XLN8018, and 0 - 100 V

for XLN10014 and corresponding to the output current of 0 - 40 A for

XLN3640, 0 - 24 A for XLN6024, 0 - 18 A for XLN8018, and 0 - 14.4 A

for XLN10014. The r ange of the external resistance i s 0 - 5 K ohm

which corresponds to the output v oltage of 0 - 36 V for XLN3640, 0 60V for XLN6024, 0 - 80 V for XLN8018, and 0 - 100 V for XLN10014

and corresponding to the output current of 0 - 40 A for XLN3640, 0 - 24

A for XLN6024, 0 - 18 A for XLN8018, and 0 - 14.4 A for XLN10014.

(26) RS485:

While in series or parallel c onnection or mu lti-unit series connection

(CHAIN), RS485 interface can be used f or communication and

synchronization between master and slave.

(27) Protection cover of the RMT/LCL Sense connector

(XLN6024/XLN8018/XLN10014):

WARNING:

When the RMT/LCL Sense is not activated and/or not

used, the protection cover must be covered

. T o prevent

electric shock, do not dissemble this protective cover.

(28) Protection cover of the output leads

(XLN6024/XLN8018/XLN10014):

www. .com

information@itm.com1.800.561.8187

Page 40

33

WARNING:

This PRODUCT is designed meeting safety code and has

passed the related qualification test. In case no output

cable is connected, close the protection cover and fasten

the screws in so as to protect user from electric shock or

other hazards.

www. .com

information@itm.com1.800.561.8187

Page 41

34

4. Operation Instructions

4.1 Voltage Setting

Press

and set the output voltage by pressing the numerical keys directly,

and then press

to confirm the setting.

=

.

.

=

1

5

.

FF

4.2 Current Setting

Press

and set the output current by pressing the numerical keys directly

and then press

to confirm the setting.

=

.

FF.

63

=

.

4.3 Over-voltage Protection OVP

Press

to e nter the C onfiguration menu and p ress to enter the

PROTECTION setting menu. Then, using the knob set OVP t o ON and press

to c onfirm i t. N ow t he c ursor w ill m ove t o t he value setting for t he

OVP on t he right hand side. Enter the OVP value h ere by pressing the

numerical keys.

F

F

S

=

3

.

8

S

S

=

=

204

41 4

.

.

F

F

=

=

=

4.4 Over-current Protection OCP

Press

to enter the “Configuration” menu and press to enter the

PROTECTION setting screen. Then, use the knob to set OCP to ON and press

www. .com

information@itm.com1.800.561.8187

Page 42

35

to confirm i t. N ow t he c ursor w ill m ove t o the value setting for t he

OCP on the right hand side. Enter th e O CP v alue by pr essing the n umerical

keys.

F

=

=

=

F

8

.

3

=

S

S

S

=

=

02441 4

.

.

4.5 Voltage Output

After the voltage, current and protection settings are entered, press

to

output voltage. User will be able to recognize the setting values and the actual

output values from the LCD.

.

=

1

5

.

.

63

=

.

4.6 Control Voltage Output with Rotary knob

When the output is ON, user may still increase or decrease the out put voltage

by turning the rotary knob. The p rocedure i s: press

and c ursor

appears i n r esponse; p ress

or

to m ove the cursor to th e d igit

you want to change and turn the knob to increase or decrease the output voltage

value a t the c ursor. The changes o f t he v oltage setting a nd t he output voltage

can be observed.

.

= 1

5

.

.

63

=

.

4.7 Timer Function

When the “Timer S etting” f unction i s O N, i t w ill activate th e t imer. After

timer setting i s m ade, r eturn t o t he m ain screen. A fter s etting up the ou tput

current & v oltage and press to ou tput, the screen will s how t he

www. .com

information@itm.com1.800.561.8187

Page 43

36

countdown of the timer. Once it reaches down to zero, the supply will turn off

the output automatically.

=

.

ce55

:

:

.

4.8 Series (cascade) / Parallel Mode Setting

The XLN3640/XLN6024/XLN8018/XLN10014 uses t he se ries/parallel m ode

(4 supplies maximum) to increase the output power capability. By connecting 4

instruments in parallel, the combined unit can offer 36 V/160 A pow er output.

By c onnecting 4 XLN10014 units in se ries, t he combined supply can output

400 V/14.4 A. Note that you c annot pe rform bot h pa rallel and series mode at

the s ame time. Series c onnection will be off o nce series (cascade) / p arallel

connection function is turned on.

4.8.1 Parallel Connection Setting

While c onnecting f our s ets of XLN3640/XLN6024/XLN8018/XLN10014 in

parallel, the wiring should be setup like the following:

After w iring i s complete, configure one XLN3640 / XLN6024 / XLN8018 /

XLN10014 as the Master and the other three are Slave A, B and C. After one of

the supplies is configured to be the Master, it will start searching for all Slaves

www. .com

information@itm.com1.800.561.8187

Page 44

37

that are connected to the Master. Therefore, in order to correctly configure the

correctly, user must set up the Slaves

before

To set a XLN3640/XLN6024/XLN8018/XLN10014 to slave mode, p ress

the Master is set.

,

, and

in t he m ain screen to en ter the se ries/parallel

setting op tion. And t hen select the p arallel m ode by turning the k nob (SCPI

command is “PS:MODE PARALLEL”) and then press

to c onfirm. It

will continue to the next line f or the MASTER/SLAVE selection. Turning the

knob t o select SLAVE A (SCPI c ommand i s “ PS:TYPE SLA VEA”) for the

supply and pr ess

to c onfirm t he s etting. Using the sam e p rocedure,

setup SLAVE B and C for another two (2) supplies as shown below.

L

LL

=

=

L

L

L

To s et the master unit, pr ess

,

, and

in t he main screen

to en ter the series/parallel setting option. And then use t he k nob t o select the

parallel mode (SCPI command is “PS:MODE PARALLEL”) and press

to confirm. It will continue to the next line for the MASTER/SLAVE selection.

Use knob again to select MASTER (SCPI command is “PS:TYPE MASTER”)

and t hen press

to confirm. A fter i t is co nfirmed as t he Ma ster the

XLN3640/XLN6024/XLN8018/XLN10014 will start sea rching f or al l S laves,

as shown below:

= LL L

=

F L

...

L

L

If wiring is correct, screen will appear as:

L

= LL L

=

:

L

L

F

www. .com

information@itm.com1.800.561.8187

Page 45

38

After receiving the control command from the Master, all Slaves will be locked

on to the SLAVE screen. At t his poi nt all k eys e xcept

are locked so

that slaves cannot be operated by front keys except controlled by the Master as

shown below:

:

:

LLL

Once the Master and Slave settings are done, users can then operate the Master

only to set up the combined output voltage and current of the complete system.

To release from this operation mode (parallel operation mode in this example),

press

(LCL) t o access to the series/parallel setting screen and turn the

knob to select O FF for series/parallel selection to disable the series or parallel

operation m ode a nd return to the l ocal o peration mode so that th e

XLN3640/XLN6024/XLN8018/XLN10014 can be controlled by press the front

keys again. Do not change t he o peration m ode w hile

XLN3640/XLN6024/XLN8018/XLN10014 is in t heir output states or there w ill

be a Master’s co mmunication failure an d an error message w ill b e d isplayed.

After power-off, if you want to keep the previous series/parallel setting, please

turn on the Slave first. Then turn on the Master.

4.8.2 Series Mode Setting

While c onnecting f our s ets o f XLN3640/XLN6024/XLN8018/XLN10014 in

series, the wiring setup should be configured as shown:

www. .com

information@itm.com1.800.561.8187

Page 46

39

After w iring i s c omplete, configure one supply as t he Master an d the o ther

three as the Slave A, B, and C. After the power supply is configured as Master,

it will start searching for all Slaves that are connected to the Master. Therefore,

in order to setup correctly, user must set up the Slaves

before

To s et a XLN3640/XLN6024/XLN8018/XLN10014 to th e slave mode, p ress

the Master is set.

,

, and

in t he m ain screen to en ter the se ries/parallel

setting o ption. Then select the SERIES mode by turning the k nob (SCPI

command is “P S:MODE SERIES”) and t hen press

to c onfirm. It will

continue to the next line for the MASTER/SLAVE selection. Turn the knob to

select S LAVE A ( SCPI command i s “P S:TYPE SLAVEA”) for the instrument

and pr ess

to c onfirm t he setting. Using the same p rocedure to se t u p

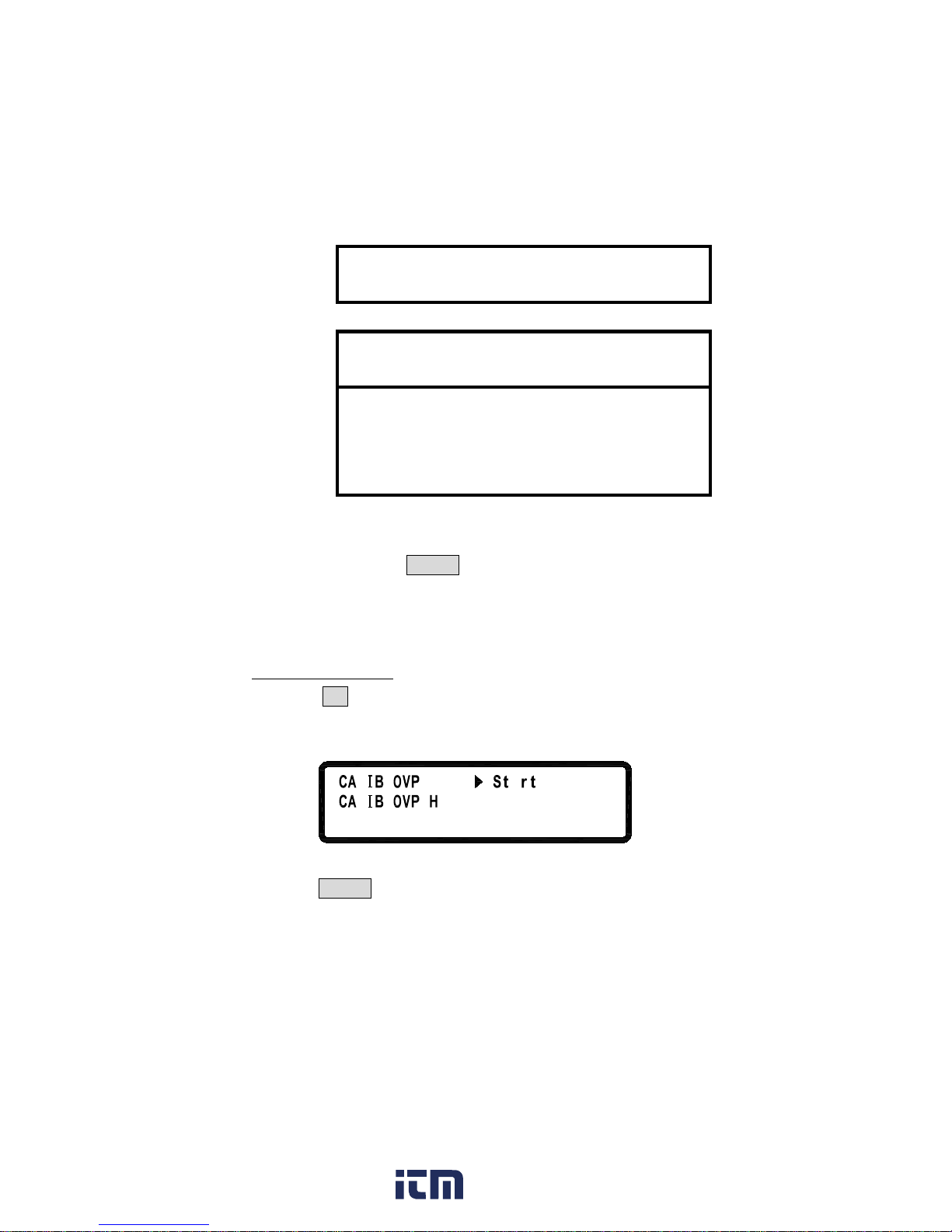

SLAVE B and C for the other two supplies.

L

L

=

=

L

To s et the master unit, press

,

,

and

in the main screen to

enter the ser ies/parallel set ting option. Then use the k nob to select the series

mode (SCPI command is “PS:MODE SERIES”) and press

to confirm.

It w ill c ontinue to the next l ine for the MASTER/ S L AV E selection. Use knob

again t o select MASTER (SCPI co mmand i s “PS:TYPE MASTER”) and then

press

to c onfirm. A fter c onfirming t he s upply as the Ma ster, it will

www. .com

information@itm.com1.800.561.8187

Page 47

40

start searching for all Slaves, as shown below.

=

=

F

L

.. .

L

L

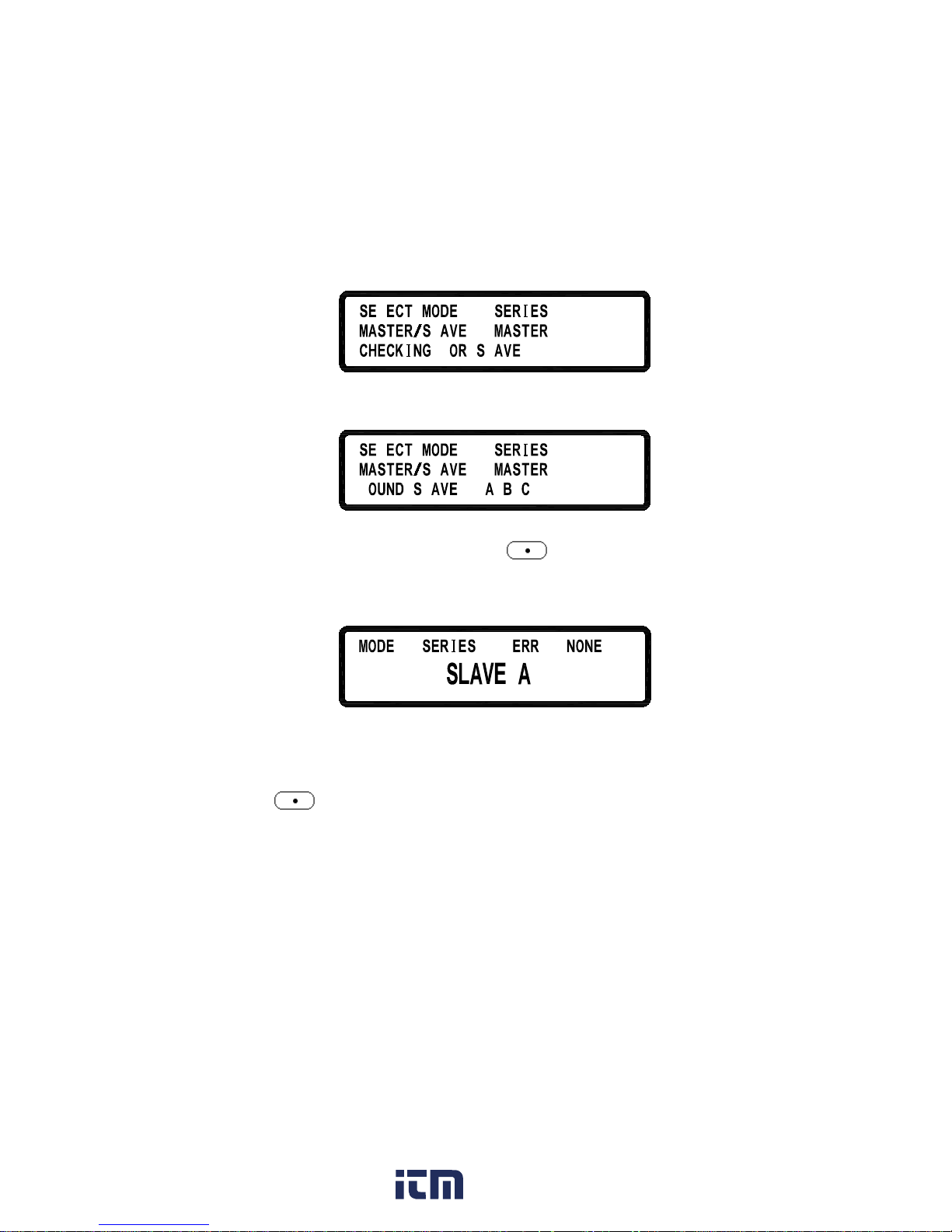

If wiring is correct, this screen will appear:

L

=

=

:

L

L

F

After receiving the control command from the Master, all Slaves will be locked

on t he SLAVE screen and all k eys ex cept

are disabled so t hat s laves

cannot be operated by pressing front keys. This ensures the Master supply be

in control.

::

Once the Master and Slave settings are done, users can then operate the Master

only to set up the output voltage and current.

To release from this operation mode (series operation mode in this example),

press

(LCL) to access to the series/parallel setting screen and turn

the knob to select OFF for series/parallel selection to leave the series or

parallel operation mode and return to the local operation mode so that the

power supply can be controlled by pressing the front keys again. Do not

change the operation mode while the instruments are in their output state or

they will cause the Master’s communication to fail and display an error

message. After power-off, if you want to keep the previous series/parallel

setting, please turn on the Slave first. Then turn on the Master.

www. .com

information@itm.com1.800.561.8187

Page 48

41

4.8.3 Error Message of Series/Parallel Connection

If the RS485 w iring i s wrong or th e s ignal is not correct, the Master w ill

display the following message in the screen for searching Slaves:

L

L

LL

=

=

:

L

L

F

If more than one Master is being set in the series/parallel operation mode, the

following message will be displayed.

L

L

L

=

LL

L

=

,

L

If one of the pow er supplies is set to different series/ parallel operation mode,

the following message will appear on-screen:

L

L

L

LL

=

=

,

L

After f inishing se tting p rocedure, if t he Master cannot ha ve a communication

with one o f t he t hree Slaves, the Master w ill p resent t he f ollowing e rror

message (Slave A in this example).

L

!!!

After finishing the setting p rocedure, i f a Slave receives only the ou tput

command sent by the Master but does not receive the synchronization signal, it

will p resent the following error m essages. The e rror m essage “SYNC ON” is

shown when the slave is not receiving t he synchronous output ON signal. The

www. .com

information@itm.com1.800.561.8187

Page 49

42

error m essage “SYNC OF F” is s hown w hen the s lave is no t receiving th e

synchronous output OFF signal.

LL L

::

4.9 External Tuning Setting

Models XLN3640/XLN6024/XLN8018/XLN10014 provides the c apability to

control the ou tput v oltages by an external voltage/resistance. The range of the

external voltage is in 0 - 10 VDC or 0 - 5 VDC and the range of t he external

variable resistance is between 0 - 5 kΩ to control the output v oltage (0 - 36 V

for XLN3640, 0 - 60 V for XLN6024, 0 - 80 V for XLN8018, and 0 - 100 V for

XLN10014) and the o utput current (0 - 40 A for XLN3640, 0 - 24 A f or

XLN6024, 0 - 18 A for XLN8018, and 0 - 14.4 A for XLN10014). The wirings

of the external control are shown in the following figure.

The external v oltage c ontrol o r e xternal r esistance c ontrol can b e se t in the

“system set ting” screen. Since th e e xternal control circuit uses a 12bit D /A

converter for 0 - 36 V for XLN3640 (or 0 - 60 V for XLN6024 or 0 - 80 V for

XLN8018 o r 0 - 100 V fo r XLN10014) output v oltage a nd 0 - 40A for

www. .com

information@itm.com1.800.561.8187

Page 50

43

XLN3640 (or 0 - 24 A for XLN6024 or 0 - 18 A for XLN8018 or 0 - 14.4 A for

XLN10014) output c urrent, the resolution o f v oltage a nd c urrent w ill b e

different in response. The screen will show similar to the following (accuracy is

10mV):

4.10 Timer of Current Flow

This function of fers testing of the c utoff time o f a breaker o r a fuse. First,

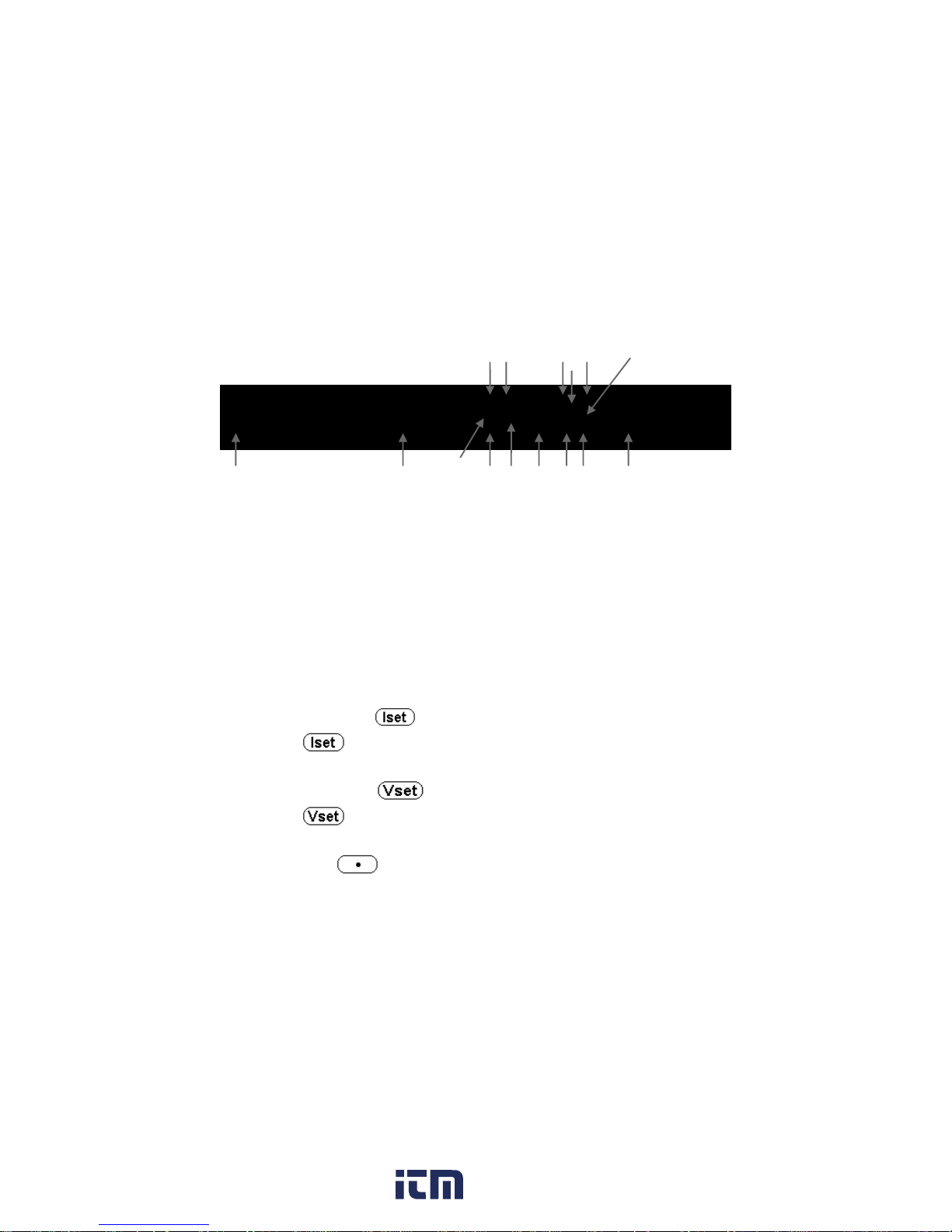

connect the test object to output terminal as shown below.

Press

,

,

and then

in the main screen to enter the current

flow counter screen.

= 1. = .

:

.

FF= 1 .

:

Press VSET to set the voltage. Then press ISET to set the current (I), which is

the m aximum cu rrent y ou w ant t o t est. P ress ISET t wice t o set the

breaker/fuse cu rrent ( Ib). A fter s etting up the output voltage/current and

pressing

to turn on t he output, the system w ill st art co unting down

the timer until the breaker or fuse is open. The count starts from when output

has reached the Ib current. The resolution of the timer is 100us (0.1 ms) and

the maximum c ounting period is on e hou r. I f the counter d oesn’t w ork a fter

V = 36.00 V

I = 40.00 A OFF

0.00 V 0.00 A

www. .com

information@itm.com1.800.561.8187

Page 51

44

pressing , e rror oc curs h erein a nd the screen will d isplay an error

message after two seconds. One of the following three scenarios may happen:

A. Connector not ready

If a f use is not properly connected to the ou tput c onnector or a breaker under

test has no t be en s witched t o O N po sition, t he screen w ill show a n e rror

message as shown below.

LF !:!

:

.

!

B. Current setting too large

The output current is set too big that a breaker is open or a fuse is burnt to open

before out put current i s reaching t he s etting v alue. The screen w ill sh ow a n

error message as shown below.

!F L:! L

:

.

!

C. Voltage setting too small

The voltage is set too small, therefore the output current is unable to reach the

setting value. The screen will show an error message as shown below.

LF !:!

:

.

LL !

4.11 Programmable Capability (SCPI Command Only)

Models XLN3640/XLN6024/XLN8018/XLN10014 provides the c apability to

support list mode, which allows users to download a small program to internal

memory a nd execute a program from t here. There are memory spaces to store

www. .com

information@itm.com1.800.561.8187

Page 52

45

10 programs that can have 150 steps in total for setting purpose. This can only

be pr ogrammed r emotely via U SB, G PIB, or L AN with S CPI c ommands o r

with the included software. Each program doe s not restrict the step quantity,

however, the sum of 10 programs are restricted to 150 steps. For each program

users can se t u p h ow m any t imes t o repeat the pr ogram. For each st ep u sers

may be able t o set up t he output voltage, current, and pe riod of time ( 50 ms

minimum) t o st ay o n t he st ep. Please refer t o “SCPI co mmand su bsystem”

section for detail SCPI commands.

Below are some examples of commands used to setup a custom program in list

mode.

Example 1:

To ou tput t he w ave f orm shown above, users m ay ed it the program as the

following orders:

PROG 1

Choose program number

PROG:CLE

Clear program 1 data

PROG:REP 0

No repeat (repeat one time for “1”)

PROG:TOTA 8 Set program 1 to have 8 steps in total

PROG:STEP 1

Following 3 settings are for step 1

PROG:STEP:CURR 1

Set output current to 1 ampere

PROG:STEP:VOLT 5

Output voltage is set to 5 volts

PROG:STEP:ONT 0.1 Output ON time is set to 0.1 sec

PROG:STEP 2 Following 3 settings are for step 2

PROG:STEP:CURR 1

PROG:STEP:VOLT 10

www. .com

information@itm.com1.800.561.8187

Page 53

46

PROG:STEP:ONT 0.1

PROG:STEP 3 Choose step 3

PROG:STEP:CURR 1

PROG:STEP:VOLT 15

PROG:STEP:ONT 0.1

PROG:STEP 4 Choose step 4

PROG:STEP:CURR 1

PROG:STEP:VOLT 20

PROG:STEP:ONT 0.1

PROG:STEP 5

Choose step 5

PROG:STEP:CURR 1

PROG:STEP:VOLT 15

PROG:STEP:ONT 0.1

PROG:STEP 6

Choose step 6

PROG:STEP:CURR 1

PROG:STEP:VOLT 10

PROG:STEP:ONT 0.1

PROG:STEP 7

Choose step 7

PROG:STEP:CURR 1

PROG:STEP:VOLT 5

PROG:STEP:ONT 0.1

PROG:STEP 8 Choose step 8

PROG:STEP:CURR 1

PROG:STEP:VOLT 0

PROG:STEP:ONT 0.1

PROG:NEXT 0

Select next program to r un a fter

program 1 is complete, 0 means stop

PROG:SAV

After edit, use Save command to store

program 1 in the hardware

PROG 1

PROG:RUN ON

To run the pr ogram s tored in t he

hardware, select program

number a nd

then us e RUN ON c ommand t o

execute the program.

www. .com

information@itm.com1.800.561.8187

Page 54

47

Example 2:

To out put t he w ave f orm s hown a bove, the f ollowing example program can

be used.

PROG 2

Choose program number

PROG:CLE

Clear program 2 data

PROG:REP 0

No repeat after running this program

PROG:TOTA 8

Set program 2 to have 8 steps in total

PROG:STEP 1

Settings for step 1

PROG:STEP:CURR 2

Set output current to 2 amperes

PROG:STEP:VOLT 20

Set output voltage to 20 volts

PROG:STEP:ONT 0.5

Set output ON time to 0.5 sec

PROG:STEP 2

Choose step 2

PROG:STEP:CURR 2

PROG:STEP:VOLT 15

PROG:STEP:ONT 0.5

PROG:STEP 3

Settings for step 3

PROG:STEP:CURR 2

PROG:STEP:VOLT 20

PROG:STEP:ONT 0.5

PROG:STEP 4

Choose step 4

PROG:STEP:CURR 2

PROG:STEP:VOLT 10

PROG:STEP:ONT 0.5

PROG:STEP 5

Choose step 5

PROG:STEP:CURR 1

PROG:STEP:VOLT 20

PROG:STEP:ONT 0.5

PROG:STEP 6

Choose step 6

www. .com

information@itm.com1.800.561.8187

Page 55

48

PROG:STEP:CURR 2

PROG:STEP:VOLT 5

PROG:STEP:ONT 0.5

PROG:STEP 7

Choose step 7

PROG:STEP:CURR 2

PROG:STEP:VOLT 20

PROG:STEP:ONT 0.5

PROG:STEP 8

Choose step 8

PROG:STEP:CURR 2

PROG:STEP:VOLT 0

PROG:STEP:ONT 0.5

PROG:NEXT 0

Select next program to run after

program 2 is complete, 0 means stop

PROG:SAV

After edit, use Save command to store

program 2 in the hardware

PROG 2

PROG:RUN ON

To run the program stored in the

hardware, select program number and

then use RUN ON command to

execute the program.

www. .com

information@itm.com1.800.561.8187

Page 56

49

Example 3:

If i t n eeds t o execute P rogram 2 r ight af ter P rogram 1 i s ex ecuted then

program 1 s hall be modified to have NEXT 2 command. The following steps

can be taken for the modification and execute the programs.

PROG 1 Select program 1

PROG:NEXT 2 Change the NEXT command from

NEXT 0 to NEXT 2

PROG:S AV After edit is complete use Save

command to store changes in the

hardware

PROG 1

PROG:RUN ON

To run the program, select the

program

number first and then use RUN ON

command to execute it.

www. .com

information@itm.com1.800.561.8187

Page 57

50

4.12 Multi-unit Connection mode (RS485)

XLN3640 / XLN6024 / XLN8018 / XLN10014 c an us e R S485 to p rovide

multi-units series connection function for up to 30 units (If more than 10 units,

please ad d a 120Ω resistor t erminator in t he l ast un it a s s hown i n t he be low

figure. Turn on the system after series connection i s completed. Press

on t he main page and s et CHAIN ON/OFF t o ON ( Series/Parallel

connection will be cancelled) and set each unit with a different Address (1 - 30).

Then by using USB connected to PC, multiple units can be controlled by using

the commands in “SERIES CONNECTION COMMAND LIST” section below.

SERIES CONNECTION COMMAND LIST

The series connection command used by all XLN series power supplies

use a ca rriage r eturn ( CR) ch aracter f or t ermination o f al l A SCII st rings.

For example, the system w ill respond with the corresponding value or string

when delivering the inquire command, or respond “OK” when delivering the

setting command. In case any errors happen, the system will respond with an

error message. (Please refer to ERROR RESPONSE LIST section).

www. .com

information@itm.com1.800.561.8187

Page 58

51

SYSTEM CONTROL COMMAND:

Command Description

==================================================

CADR followed by address, which can be 1 to 30 and

is used to access the power supply

CCLS Clear status

CRST Reset command. Brings the power supply to a

known state

CIDN? Returns the power supply model identification

CREV? Returns the firmware version

CSN? Returns the serial number

CST? Returns the device status

CCLR? Clear protect

==================================================

OUTPUT CONTROL COMMAND:

Command Description

==================================================

CPV Sets the output voltage value in Volts

CPV? Reads the output voltage setting

CMV? Reads the actual output voltage

CPC Sets the output current value in Amperes

CPC? Reads the output current setting

CMC Reads the actual output current

CDVC? Display voltage and current data

COUT Turns the output to ON or OFF

COUT? Returns the output On/Off status

COV Sets the OVP level

COV? Returns the OVP setting level

COVP Sets the OVP on/off

COVP? Returns the OVP on/off

COC Sets the OCP level

www. .com

information@itm.com1.800.561.8187

Page 59

52

COC? Returns the OCP setting level

COCP Sets the OCP on/off

COCP? Returns the OCP on/off

COP Sets the OPP level

COP? Returns the OPP setting level

COPP Sets the OPP on/off

COPP? Returns the OPP on/off

CMODE? Returns the power supply operation mode

==================================================

SYNCHRONOUS CONTROL COMMAND:

Command Description

==================================================

GRST Reset command. Brings the power supply to a

known state

GCLS Clear status

GCLR Clear protect

GPV Sets the output voltage value in Volts

GPC Sets the output current value in Amperes

GOUT Turns the output to ON or OFF

GOV Sets the OVP level

GOVP Sets the OVP on/off

GOC Sets the OCP level

GOCP Sets the OCP on/off

GOP Sets the OPP level

GOPP Sets the OPP on/off

==================================================

EXAMPLES:

Q1. How to read back ID for Address 5 on the system?

CADR 5 OK

CIDN? B&K Precision. XLN 3640,A1234567,1.15,0

Q2. How to set up Voltage for Address 7 on the system?

www. .com

information@itm.com1.800.561.8187

Page 60

53

CADR 7 OK

CPV 20 OK

Q3. How to set up Output for Address 7 on the system?

CADR 3 OK

COUT 1 OK

Q4. How to read back Voltage value for Address 1 on the system?

CADR 1 OK

CMV? 10.001

Q5. How to set up Current for all the systems?

GPC 5 No response

Q6. How to set up Output for all the systems?

GOUT 1 No response

ERROR RESPONSE LIST

If PC delivers an error command or connection fails, a return string will be sent

and is described below:

String Description

===============================================

OK No error

Time out Wait response time out

Range error Input value is out of range

Multi master There are more than one controller in the whole system

www. .com

information@itm.com1.800.561.8187

Page 61

54

5. Protection and Error Messages

5.1 Over-voltage Protection (OVP)

When t he OVP is activated and voltage measured exceeds the setting point of

protected v oltage, the system will e nter the “Over Voltage P rotect” mode that

will shut o ff t he output and show O VP on t he display. P ress to reset

the protection mode and deactivate the buzzer.

=36.

.

=

.

4

0

.

FF

5.2 Over-current Protection (OCP)

When t he OCP i s activated an d cu rrent measured exceeds the setting point of

protected current, system will enter the “Over Current Protect” m ode that will

shut of f t he out put and show O CP on t he display. P ress

to reset the

protection mode and deactivate buzzer.

.

63

=

.

1

0

.=

.

FF

5.3 Overpower Protection (OPP)

When the O PP i s a ctivated a nd pow er measured exceeds the se tting point of

protected p ower, sy stem w ill en ter t he “O ver P ower Protect” m ode that w ill

shut of f the output and display OPP on the screen. P ress to reset th e

protection mode and deactivate buzzer.

.

63

=

.

1

0

.=

.

FF

www. .com

information@itm.com1.800.561.8187

Page 62

55

5.4 Constant Voltage Protection (CV TO CC)

When this function is activated, the power supply will stay in CV mode. If load

changes force the system to transition from CV to CC (constant current) mode,

the system will enter the “CV TO CC Protect” state that will shut off the output

and d isplay t he C VC m essage o n the screen. P ress

to r eset th e

protection and deactivate the buzzer.

5.5 Constant Current Protection (CC TO CV)

When this function is activated the power supply will stay in CC mode. If load

changes forces t he transition from CC to CV (constant v oltage) m ode, the

system will en ter t he “CC TO C V P rotect” state that w ill shut off output a nd

display CCV message on the sc reen. Press

to reset the protection and

deactivate buzzer.

=36.

.

=

.

0

1

.

FF

5.6 Over-temperature Protection (OTP)

When the in strument detects abnormally hi gh t emperature, the system w ill

enter t he “O ver T emperature Protect” mode that w ill shut off the output and

display t he error message as shown i n t he following figure. P ress to

reset the protection and deactivate buzzer.

L

!!!!

.

V = 36.00 V

I = 40.00 A OFF

0.000 V 0.000 A

CVC

www. .com

information@itm.com1.800.561.8187

Page 63

56

5.7 Low Voltage Protection (ACD)

When the machine h as d etected abnormally l ow A C power input, system will

enter the “ AC Detect Low Protect” mode that will shut off output and display