Page 1

Data Sheet and User Guide

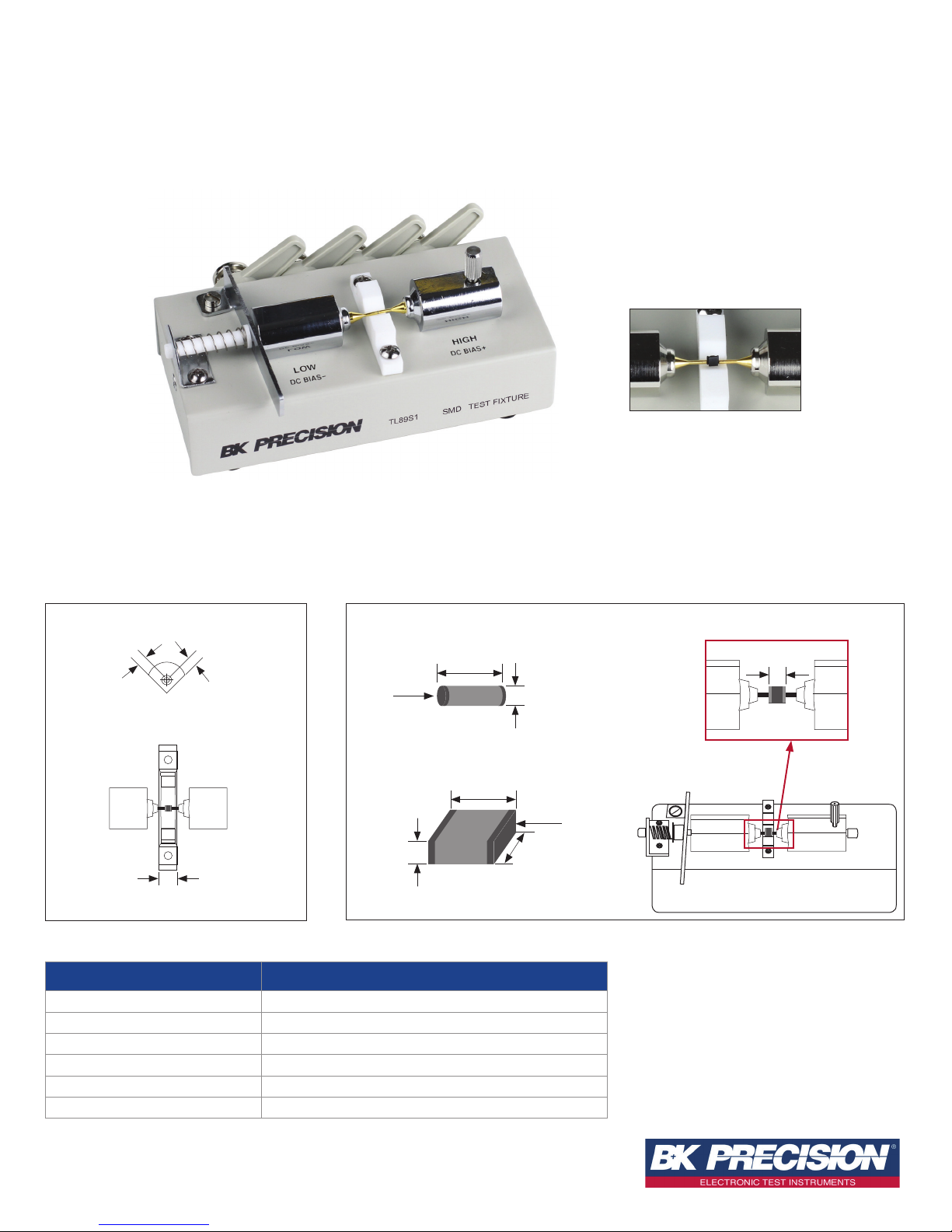

SMD Test Fixture

TL89S1

Component insertion site (closeup)

Test fixture for measuring small surface-mount devices (SMD)

The TL89S1 fixture is designed to probe SMD components with repeatable and accurate impedance measurements. The contactors are easily adjusted to

accommodate different sized components while applying the appropriate contact pressure. This test fixture is attached directly to the front panel of LCR models

889B, 891, 894, and 895.

Contactor pin

0.77 mm

0.77 mm

side view

7.0 mm

Component insertion site

Note: All mechanical measurements are typical

Specification TL89S1

Frequency DC to 10 MHz

DC Bias ±40 V peak max (AC+DC)

Operating Temperature 0 ºC to 40 ºC

Terminal Connection BNC, 4 terminal-pair

Dimensions (W x H x D) 5.125 x 2.37 x 3.31 inches (130 x 60.3 x 84 mm)

Weight: 0.67 lbs (0.305 kg)

Electrode

3.0 mm

8.1 mm

Cylindrical type

8.1 mm

Rectangular type

Component sizes

3.0 mm

Electrode

9.5 mm

0.2 mm ~ 8.1 mm

HIGHLOW

Technical data subject to change

© B&K Precision Corp. 2017

www.bkprecision.com

Page 2

SMD Test Fixture

TL89S1

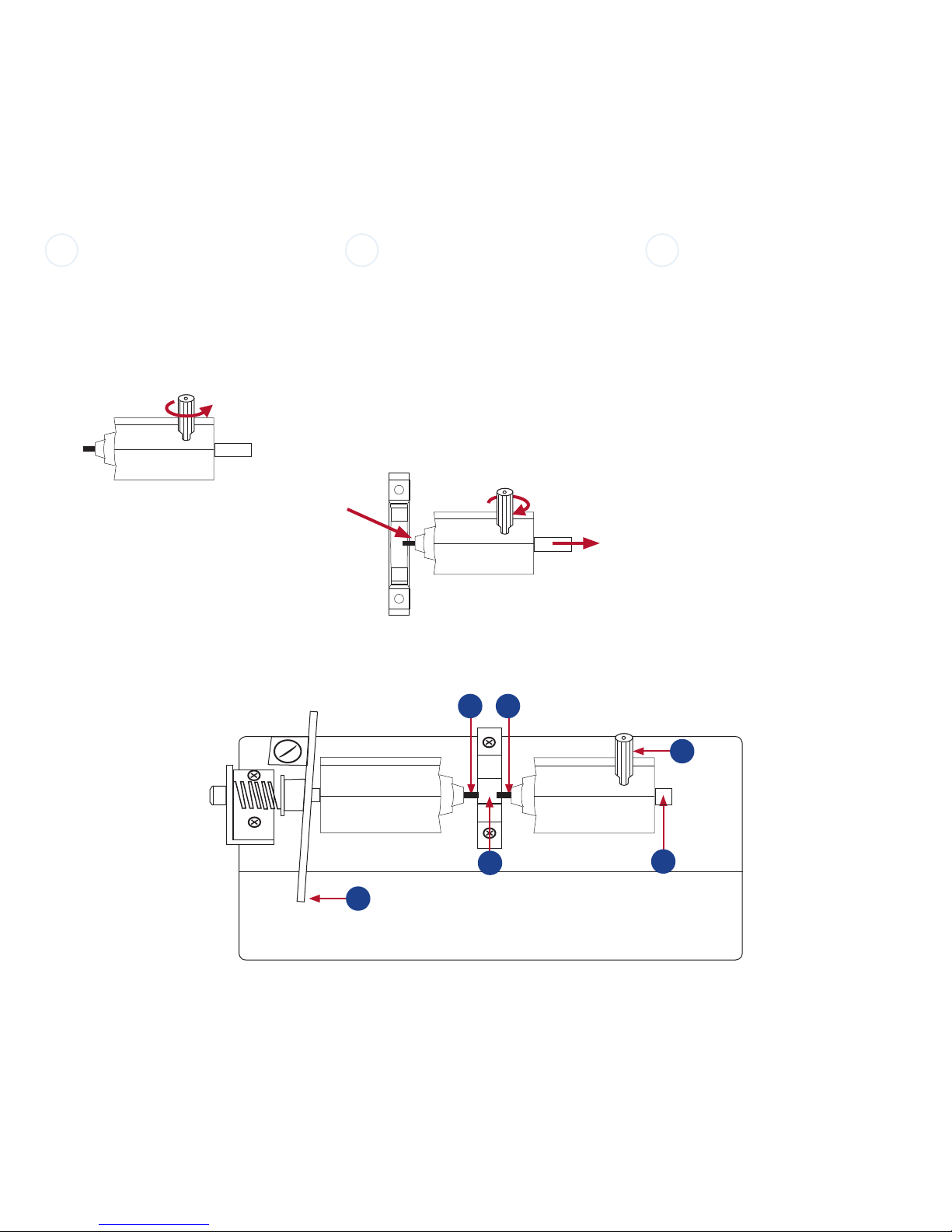

Adjusting the contactor pins

I

Loosen the lock screw (1) by turning the screw

counter clockwise 2 full turns.

Counter clockwise

(loosen)

HIGH

II III

Press the High contactor (2) to start the

extraction, grip the Contactor rod (4) on the

opposite side and pull the contactor open to

create a gap large enough to loosely fit the new

component. If more space is required, push the

Insertion lever (6) to the left until the component

fits into the Component insertion site (5).

clockwise (tighten)

HIGH

Gently press in on contactor rod (4) until the new

component is centered in component insertion

site (5).

Continue to apply pressure to the contactor rod

(4) while tightening the lock screw by turning it

clockwise. Do not over tighten the lock screw.

This completes the adjustment process and

components of the same size can now be easily

changed.

Press the Insertion lever (6) to retract the Low

contactor pin. While holding the lever open,

remove the previous component and place the

next component in the insertion site (5). Slowly

release the lever to contact the new component

and begin the next measurement.

Note: The contactor pins should be cleaned

periodically to remove contamination.

1. Lock screw

2. High contactor pin

3. Low contactor pin

4. Contactor rod

5. Component insertion site

6. Insertion lever

23

1

LOW

5

HIGH

4

6

Test fixture illustration

2

v082917

www.bkprecision.com

Loading...

Loading...