Page 1

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be followed during all

phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

• Read and understand the safety and operational information in this manual.

• Apply all the listed safety precautions.

• Verify that the voltage selector at the line power cord input is set to the correct line voltage. Operating the instrument

at an incorrect line voltage will void the warranty.

• Make all connections to the instrument before applying power.

• Do not operate the instrument in ways not specied by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the safety standards of design,

manufacture, and intended use of the instrument. B&K Precision assumes no liability for a customer’s failure to comply

with these requirements.

2

Category rating

The IEC 61010 standard denes safety category ratings that specify the amount of electrical energy available and the

voltage impulses that may occur on electrical conductors associated with these category ratings. The category rating is

a Roman numeral of I, II, III, or IV. This rating is also accompanied by a maximum voltage of the circuit to be tested,

which denes the voltage impulses expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be connected to the

mains supply. The voltages in the environment are typically derived from a limited-energy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be connected to the mains

supply at a standard wall outlet or similar sources. Example measurement environments are portable

tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be connected to the mains

installation of a building. Examples are measurements inside a building’s circuit breaker panel

or the wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be connected to the primary

power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is specied in this manual

for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or higher than the

instrument’s category rating to maintain the instrument’s category rating. Failure to do so will lower the category rating

of the measuring system.

Page 3

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains power should be

115 V RMS or 230 V RMS. Use only the power cord supplied with the instrument and ensure it is appropriate for your

country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical safety ground. This

instrument is grounded through the ground conductor of the supplied, three-conductor AC line power cable. The power

cable must be plugged into an approved three-conductor electrical outlet. The power jack and mating plug of the power

cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible conductive parts

(including control knobs) may provide an electric shock. Failure to use a properly-grounded approved outlet and the

recommended three-conductor AC line power cable may result in injury or death.

3

Unless otherwise stated, a ground connection on the instrument’s front or rear panel is for a reference of potential only

and is not to be used as a safety ground. Do not operate in an explosive or ammable atmosphere.

Do not operate the instrument in the presence of ammable gases or vapors, fumes, or nely-divided particulates.

The instrument is designed to be used in oce-type indoor environments. Do not operate the instrument

• In the presence of noxious, corrosive, or ammable fumes, gases, vapors, chemicals, or nely-divided particulates.

• In relative humidity conditions outside the instrument’s specications.

• In environments where there is a danger of any liquid being spilled on the instrument or where any liquid can condense

on the instrument.

• In air temperatures exceeding the specied operating temperatures.

• In atmospheric pressures outside the specied altitude limits or where the surrounding gas is not air.

• In environments with restricted cooling air ow, even if the air temperatures are within specications.

• In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating temperature range is

0∘C to 40∘C and 20% to 80% relative humidity, with no condensation allowed. Measurements made by this instrument

may be outside specications if the instrument is used in non-oce-type environments. Such environments may include

rapid temperature or humidity changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise,

strong electric elds, or strong magnetic elds.

Page 4

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets on or inside the

instrument, remove the instrument’s power cord, remove the instrument from service, label it as not to be operated,

and return the instrument to B&K Precision for repair. Notify B&K Precision of the nature of any contamination of the

instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants, solvents, acids/bases,

or other such chemicals. Clean the instrument only with a clean dry lint-free cloth or as instructed in this manual. Not

for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component in a life-support

device or system.

4

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and internal adjustments must

be made by qualied service-trained maintenance personnel who are aware of the hazards involved when the instrument’s

covers and shields are removed. Under certain conditions, even with the power cord removed, dangerous voltages may

exist when the covers are removed. To avoid injuries, always disconnect the power cord from the instrument, disconnect

all other connections (for example, test leads, computer interface cables, etc.), discharge all circuits, and verify there

are no hazardous voltages present on any conductors by measurements with a properly-operating voltage-sensing device

before touching any internal parts. Verify the voltage-sensing device is working properly before and after making the

measurements by testing with known-operating voltage sources and test for both DC and AC voltages. Do not attempt

any service or adjustment unless another person capable of rendering rst aid and resuscitation is present.

Do not insert any object into an instrument’s ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault condition in the circuit

exists.

Fuse replacement must be done by qualied service-trained maintenance personnel who are aware of the instrument’s fuse

requirements and safe replacement procedures. Disconnect the instrument from the power line before replacing fuses.

Replace fuses only with new fuses of the fuse types, voltage ratings, and current ratings specied in this manual or on

the back of the instrument. Failure to do so may damage the instrument, lead to a safety hazard, or cause a re. Failure

to use the specied fuses will void the warranty.

Page 5

Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the instrument to

B&K Precision for service and repair to ensure that safety and performance features are maintained.

For continued safe use of the instrument

• Do not place heavy objects on the instrument.

• Do not obstruct cooling air ow to the instrument.

• Do not place a hot soldering iron on the instrument.

• Do not pull the instrument with the power cord, connected probe, or connected test lead.

• Do not move the instrument when a probe is connected to a circuit being tested.

Compliance Statements

5

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and other European

countries with separate collection systems)

This product is subject to Directive 2002/96/EC of the European Parliament

and the Council of the European Union on waste electrical and electronic equipment

(WEEE), and in jurisdictions adopting that Directive, is marked as being put on the

market after August 13, 2005, and should not be disposed of as unsorted municipal

waste. Please utilize your local WEEE collection facilities in the disposition of this

product and otherwise observe all applicable requirements.

Page 6

Safety Symbols

Symbol Description

indicates a hazardous situation which, if not avoided, will result in death or serious injury.

indicates a hazardous situation which, if not avoided, could result in death or serious injury

indicates a hazardous situation which, if not avoided, will result in minor or moderate injury

Refer to the text near the symbol.

Electric Shock hazard

Alternating current (AC)

Chassis ground

Earth ground

This is the In position of the power switch when instrument is ON.

This is the Out position of the power switch when instrument is OFF.

is used to address practices not related to physical injury.

6

Page 7

Contents

1 General Information 9

1.1 Organization 9

1.2 Product Overview 10

1.3 Architecture 11

1.4 Features 11

1.5 Contents 12

1.6 Dimensions (H x W x L) 12

2 Hardware Overview 13

2.1 Sensor Connections 13

2.2 Status LED Codes 14

2.3 Power Requirements 14

3 Getting Started 15

3.1 Installing the Power Analyzer Software 15

3.2 Connecting the RFP Series RF Power Sensor 16

3.3 Introduction to the Power Analyzer Software 16

3.3.1 Docking Windows 18

3.3.2 Main Application 19

3.3.3 Available Resources Window 19

3.3.4 The Main Toolbox 19

3.3.5 Trace View Window 20

3.3.6 Channel Control Window 22

3.3.7 Time/Trigger Settings Window 23

3.3.8 Marker Settings Window 24

3.3.9 Pulse Denitions Windows 24

3.3.10 Automatic Measurements Windows 25

3.3.11 Display Settings Windows 27

3.3.12 CCDF View Window 28

3.3.13 Statistical Measurements Window 28

4 Operation 29

4.1 Power Analyzer Software 29

4.1.1 Initializing the Software 29

4.1.2 Connecting the RFP Series Sensor 30

4.1.3 Trace View Display 31

4.1.4 Formatting Trace View Display 33

4.1.5 Main Toolbar 34

4.1.6 Time/Trigger Control Window 37

4.1.7 Channel Control Window 41

4.1.8 Automatic Measurements Display 44

4.1.9 Pulse Denition Window 45

4.1.10 Marker Settings Windows 46

4.1.11 Statistical CCDF Graph Display 48

4.1.12 Statistical Mode Control Window 49

4.1.13 Meter View 51

4.1.14 Acquisition Status Bar 53

4.1.15 Archiving Measurement Setups 53

4.2 Multichannel Operation 54

4.2.1 Multichannel Measurement 54

4.2.2 Multichannel Triggering 56

4.2.3 Multichannel Individual Sensor Tabs 58

4.3 Measurement Buer Mode(API remote programming only) 59

Page 8

4.3.1 Buer Overview 59

4.3.2 Measurement Buer Mode Operation 61

4.3.3 Measurement Buer Mode User Settings 65

5 Remote Programming 67

5.1 Communication Overview 67

6 Denitions & Measurements 68

6.1 Pulse Measurements 68

6.1.1 Pulse Denitions 68

6.1.2 Standard IEEE Pulse 68

6.1.3 Automatic Pulse Measurements 70

6.1.4 Automatic Pulse Measurement Criteria 71

6.1.5 Automatic Pulse Measurement Sequence 71

6.2 Marker Measurements 74

6.2.1 Average Power Over a Time Interval 75

6.3 Automatic Statistical Measurements 76

7 Maintenance 77

7.1 Safety Recommendation 77

7.2 Cleaning 77

7.3 Inspection and Performance Verication 77

7.4 Connector Care 77

7.5 Software and Firmware Updates 79

7.5.1 Firmware Update Procedure 79

7.5.2 Power Analyzer Software Update Procedure 82

7.5.3 Checking for New Firmwarr After the Initial Installation 84

8

8 Specications 87

9 Service Information 89

10 LIMITED THREE-YEAR WARRANTY 90

Page 9

General Information

The user manual provides the information needed to install, operate and maintain the RFP3000 Sensor Series.

Chapter 1 is an introduction to the manual and the instrument.

1.1 Organization

The manual is organized into seven chapters:

Chapter 1 - General Information presents a summary descriptions of the instrument and its principal features, accessories

and options. Also included are specications for the instrument.

Chapter 2 – Hardware Installation provides instructions for unpacking the instrument, setting it up for operation, connecting power and signal cables, and initial power-up.

Chapter 3 - Getting Started describes the basic operation of the RFP Series Real-Time Power Sensors and the Power

Analyzer Software.

Chapter 4 - Operation describes, in detail, the Graphical User Interface (GUI) of the Power Analyzer Software and the

RFP Series Real-Time Power Sensors.

Chapter 5 - Remote Programming explains the command set and procedures for operating the instrument remotely.

Chapter 6 – Making Measurements provides denitions for key terms used in this manual and on the GUI displays as well

as methodologies used to calculate automated pulse, marker and statistical measurements.

Chapter 7 - Maintenance includes procedures for installing software and verifying fault-free operation.

Page 10

General Information 10

1.2 Product Overview

The new RF power measurement line includes 6, 18 and 40 GHz models, and is designed for measurement of wideband

modulated signals.

The RFP RF Power Sensors are the latest series of products from BK Electronics that turn your PC or laptop using a

standard USB 2.0 port into a state-of-the-art peak power analyzer without the need for any other instrument. Power

measurements from the RFP Series RF Power Sensors can be displayed on your computer or can be integrated into a

test system with a set of user-dened software functions.

The RFP3000 Power Sensors include the models RFP3006, RFP3008, RFP3018, RFP3118, RFP3040, and RFP3140.

Collectively they cover a frequency range of 50 MHz to 40 GHz. Oering broadband measurements with rise times up

to 3 ns, time resolution of 100 ps, and video bandwidths up to 195 MHz.

The RFP300 Power Sensors enable rapid pulse integrity determinations. Eective sampling rate is up to one hundred

times faster than conventional power meters so ner waveform details are visible. They perform automatic capture of

pulse power, overshoot, droop, edge delay and skew timing, and edge transition times.

The RFP3000 Real-Time Power Sensors have exceptional trigger stability of less than 100 ps trigger jitter regardless of

the trigger source which yields much greater waveform detail because a stable trigger point yields a stable waveform.

Using dedicated trigger circuitry rather than software-based triggering provides precise timestamping of relative triggerto-sample delay. This precision permits the use of random interleaved sampling (RIS) for repetitive waveforms with

resulting eective sampling rate of 10 GS/s which permits accurate, direct measurement of fast timing events without

requiring interpolation between samples.

Real Time Power Processing oers new possibilities for power integrity measurements because every pulse is analyzed

and none are discarded. Trace acquisition, averaging and envelope times are drastically reduced resulting in simultaneous

analysis of average, peak and minimum Power.

The RFP Series Real-Time Power Sensors are supported by the Power Analyzer Software, a Windows based software

package that provides control and readout of the sensors. It is an easy to use program that provides both time and

statistical domain views of power waveforms with variable peak hold and persistence views. Power measurements are

supported using automated pulse and statistical measurements, power level and timing markers. The GUI application

is easily congured with dockable or oating windows and measurement tables that can be edited to show only the

measurements of interest.

The RFP Series Power Sensor Programming Reference provides basic information on using the RFP Series Real-Time

Power Sensor Application Programming Interface (API) in an end-user application. The API consists of a Dynamic Link

Library, which is required for use of the Power Analyzer Software. The API includes a programming reference, as well

as code examples for C++, C# and Visual Basic.

The RFP Series Real-Time Power Sensors are ideal for manufacturing, design, research, and service in commercial and

military applications such as telecommunications, avionics, RADAR, and medical systems. They are the instrument of

choice for fast, accurate and highly reliable RF power measurements, equally suitable for product development, compliance

testing, and site monitoring applications.

Page 11

General Information 11

1.3 Architecture

The Sensor functions as an ultra-fast, calibrated power measurement tool, which acquires and computes the instantaneous,

average and peak RF power of a wideband modulated RF signal. The internal A/D converter samples the detected RF

signal at up to 100 M samples/second, and a digital signal processor carries out the work required to form the digital

samples into a correctly scaled and calibrated trace on the display. Figure 1.1 shows a block diagram of the peak power

sensor.

Figure 1.1 Real-Time Power Sensors Block Diagram

The rst and most critical stage of a peak power sensor is the detector, which removes the RF carrier signal and outputs

the amplitude of the modulating signal. The width of the detector’s video bandwidth dictates the sensor’s ability to track

the power envelope of the RF signal. The picture on the left in Figure 1.2 below shows how a detector with insucient

bandwidth is unable to faithfully track the signal’s envelope, therefore aecting the accuracy of the power measurement.

The detector on the right has sucient video bandwidth in order to track the envelope accurately. The fast detectors

used in peak power sensors are by their nature non-linear, so shaping procedures within the digital processor must be

used in order to linearize their response. When measuring instantaneous peak power, a high sample rate is important in

order to ensure that no information is lost. The RFP Series Real-Time Power Sensors have a sample rate of 100 MHz

(RFP3000), enabling capture and analysis of power versus time waveforms at very high resolution.

Figure 1.2 Detector Envelope Tracking Response

1.4 Features

• Real-Time Power Processing™

• 16 automated pulse measurements

• Crest Factor and statistical measurements (e.g., CCDF)

• Synchronized multi-channel measurements (up to 8 channels with GUI, >8 with remote control)

• Power Analyzer: advanced measurement and analysis software

Page 12

General Information 12

1.5 Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items from the shipping carton,

and check for any obvious signs of physical damage that may have occurred during transportation.

Report any damage to the shipping agent immediately. Save the original packing carton for possible future reshipment.

Every unit is shipped with the following contents:

• RFP 3000 Series Sensor

• Factory test and calibration certicate

• USB Type-A Cable (6 ft)

• External Trigger Multi-I/O Cable (SMB to BNC)

• Trigger Sync Cable (SMB to SMB) for triggering multiple sensors

• RFP Series Welcome Card containing URL to downloadable Power Analyzer Software, drivers and documentation on

BK website

Note:

Ensure the presence of all the items above. Contact the distributor or B&K Precision if anything is missing.

Save the packing material and container to return the instrument, if necessary. If the original materials (or suitable

substitute) are not available, contact the distributor to purchase replacements. Store materials in a cool, dry environment.

1.6 Dimensions (H x W x L)

The RFP 3000 Sereies Sensors dimensions are approximately:

1.7” x 1.7” x 5.7” (4.3 cm x 4.3 cm x 14.5 cm)

H x W L

Figure 1.3 Dimensions

Page 13

Hardware Overview

This section contains power requirements, connection descriptions and preliminary checkout procedures.

2.1 Sensor Connections

The end panel of the RFP Series RF Power Sensor shown in Figure 2.1, has two connectors and the Status LED. The

center connector is a USB Type B receptacle used to connect the power sensor to the host computer.

The connector labeled Multi I/O is an SMB plug and can serve as a trigger input, status output, or as a trigger

synchronization interconnect when multiple power sensors are used.

Figure 2.1 USB

Connector and Status LED

Connect the power sensor to your PC through the supplied USB cable. Note that the cable should be secured to the

sensor using the captive screw on the USB plug. The power sensor is USB 2.0 compatible. It is recommended that you

use the USB cable supplied with your sensor.

Connect the power sensor to RF Source. All RFP Series Sensors models are equipped with a precision Type-N male RF

connector. Connect the power sensor to the RF signal to be measured.

Caution:

• Do not rotate the body of the sensor when connecting the sensor to a unit under test (UUT).

To avoid internal sensor damage, connect and disconnect the sensor by turning the metal nut only.

• Ensure that you do not apply any excessive force on the sensor once it has been connected.

• Do not apply RF power levels greater than +20 dBm to the RF input of the sensor.

Page 14

Hardware Overview 14

2.2 Status LED Codes

The information labels shown in gure 2.2 on the RF Power Sensor contain information on the maximum power levels

the device can handle.

The end panel, shown in gure 2.3, includes a Status LED. The color and ash pattern indicate the sensors status as

indicated on the label on the side panel shown.

Top View

Figure 2.2 Top View

Bottom View

Figure 2.3 Bottom View

2.3 Power Requirements

The RFP3000 Sensors require 2.5 Watts at 5 Volts, this is supplied via a USB port. The power sensor MUST be

connected to a USB 2.0 port that is able to supply the full 500 mA.

Note:

Usually a USB 2.0 port is capable of supplying 500 mA current through its port. When an unpowered

USB hub is used (sometimes the hub is internal), available current may need to be shared between

connected devices.

Page 15

Getting Started

This chapter will introduce the RFP Series RF Power Sensors, and will discuss basic connection and operation. For

additional information please see Chapter 4 "Operation".

3.1 Installing the Power Analyzer Software

This section describes the installation and use of the Power Analyzer Software for RFP Series RF Power Sensors. Before

you start, check your PC for software compatibility.

Note:

Do not connect the power sensor to your PC until you have installed the Power Analyzer Software.

The Power Analyzer Software requires the following minimum computer characteristics:

Processor

RAM

Operating System

Hard-Disk Free Space

Display Resolution

Interface

1.3 GHz or higher recommended

512 MB (1 GB or more recommended)

Microsoft® Windows® 10 (64-bit)

Min 1.0 GB free space to install or run

800x600 (1280x1024 or higher recommended)

USB 2.0 high speed

Procedure

To install the Power Analyzer Software, follow these steps:

1. Download the installation package from the Docs & Software tab of the product page on the BK Precision website.

2. The installation process is initiated by running “BPAInstaller.exe” with admin permissions.

• When you select install for the rst time, read the license agreement, accept it and then click on "Install" in order

to proceed with the installation process.

3. By default, the main software application will be installed in the following folder: C:\Program Files

(x86)\BKPrecision\Power Analyzer\.

– Once the installation has successfully completed, click the ”Close” button to exit the wizard.

4. Double click the Power Analyzer icon on the desktop to launch the application.

Page 16

Getting Started 16

3.2 Connecting the RFP Series RF Power Sensor

After unpacking and following the software installation discussed in chapter "Hardware Overview" and section Installing

the Power Analyzer Software, a sensor device can be connected to the USB port of the PC.

When the sensor device is rst connected to the USB port, there will be a one-time driver le installation. Wait until

Windows OS installs the driver le. An automatic device detection message will appear.

Note:

Older or newer operating system may behave dierently. Contact BK Precision if you have a problem.

The Windows pop-up shown in gure 3.1 noties that the USB driver for RFP3006 Sensor has been installed.

Figure 3.1 USB Driver Installed Notication

3.3 Introduction to the Power Analyzer Software

Upon installing the software, congured the USB drivers and connected the power sensor to the PC. The Power Analyzer

Software will be ready to take measurements.

Open the Power Analyzer Software from the BK Precision group in the Windows Start Menu or by double clicking

on the desktop icon .

A splash screen will welcome you to the application.

Figure 3.2 Power Analyzer Software Splash Screen

Page 17

Getting Started 17

Under the "Available Resources Window", a pop up box will appear as below with the list of connected devices name

and hardware information. The initial view of the Power Analyzer Software is shown in gure 3.3. The display colors

may be dierent.

Figure 3.3 Available Resources

In the Available Resources window, check the “Select” box for one or more connected sensors, then click "New Virtual

Pwr Analyzer". This will launch a new Virtual Power Analyzer instance containing trace and control windows. If an RF

signal is connected to the USB sensor, the measured waveform will appear in the trace window.

A “Virtual Power Analyzer” is analogous to a benchtop RF Power Analyzer with one or more sensors connected. Time

and trigger controls are typically common to all sensors within a Virtual Power Analyzer, while channel-specic controls

are available for most other settings. This oers users the familiar, multi-channel approach common to power meters

and oscilloscopes.

When independent control of time base-related settings is desired, it is possible to open multiple Virtual Power Analyzers,

each with their own full set of controls.

Page 18

Getting Started 18

3.3.1 Docking Windows

The Power Analyzer Software uses dockable windows to allow the user to arrange the various windows in the cong-

uration of their choice. You can drag a docked window by clicking its title bar. This action enables you to move the

window to a dierent docked position or undock it.

To dock tool windows

• Click the tool window to dock.

• Drag the window toward the middle of the software main window.

• A guide diamond will appear with four arrows pointing toward the four sides of the main window.

• When the tool window being dragged reaches the location to dock it, move the pointer over the corresponding portion

of the guide diamond. The designated area is shaded blue.

• To dock the window in the position indicated, release the mouse button. Note that docked windows can be overlapped.

By selecting individual tab, it is possible to resize each tool windows and can be repositioned as below picture.

• A tool window can be docked to a portion of one of the side walls of the software by dragging it to the side until you

see a secondary guide diamond. Click one of the four arrows to dock the tool window to that portion of the side wall.

The following diagram shows the guide diamonds with arrows that appear when you drag a tool window toward the

center of the BK Precision software main window. The diamond on the right edge only appears when a tool window is

being dragged towards the edge of the main application window.

Figure 3.4 Docking a Sidebar

Note:

Each of the tool windows is highlighted as a rectangular box to be positioned by dragging in any direction within the

main window. Figure 3.4 is one example, but all the tool windows can be rearranged within the main software window.

Page 19

Getting Started 19

3.3.2 Main Application

The main application window is divided into several major sections and dockable windows depending on the type of

measurement selection. These windows can be arranged easily by docking and undocking within the main application

display area.

3.3.3 Available Resources Window

Sensors can be selected from the "Available Resources" window. A description for each connected resource will indicate

the hardware version, model and channel information including alias. User can select up to eight resources per Virtual

Power Analyzer. Following resource selection, click on "New Virtual Pwr Analyzer" and a new Virtual Power Analyzer

instance will open with a default conguration suitable for pulse measurements.

3.3.4 The Main Toolbox

Figure 3.5 Selecting a Sensor

Figure 3.6 Main Toolbar Controls

Page 20

Getting Started 20

3.3.5 Trace View Window

In order to display a pulse measurement, users must select the icon from the Main Toolbar.

The settings and settings related to pulse measurement can be selected from Main Toolbar and can

be applied to the measurement.

The Trace button on the Main Toolbar is used to setup and display a pulse measurement.

Figure 3.7 Main Toolbar

A measurement window conguration suitable for pulse measurements is shown in gure 3.8. This shows a large trace

window, automatic measurements, and a tabbed control box for time and channel settings.

Figure 3.8 Main Application Window

The Power Analyzer Software allows the user to directly enter numeric values for most settings in the Channel Control

and Time/Trigger windows. For many of the controls, additional methods such as increment/decrement or preset buttons

are available.

Page 21

Getting Started 21

Trace Pan and Zoom

The mouse can be used to select a zoom area to view detail in an area of interest on the displayed waveform. The

highlighted dragged rectangular area indicates the minimum area that will be shown when the zoom operation completes.

Horizontal pan or zoom adjusts the time base (within preset values) and the trigger delay to highlight an area of interest

without vertical rescaling.

Direct pan or zoom to waveform areas of interest is available by selecting any option from the lower toolbar of the trace

window. Available options for zoom/pan control are: Horizontal & Vertical, Horizontal, Pan and None with Undo and

Redo selections.

Figure 3.9 Zoom and Pan

Clicking on the Trace View display and dragging will open a zoom box, releasing the mouse button will result in the trace

being expanded to show the area contained in the zoom box

Auto Set

The button below the trace window attempts to congure level scaling, trigger level and timing for a “best t”

display based upon amplitude and timing of the applied signal. All other parameters are set back to defaults. If the Auto

Set process fails, all settings are left untouched.

Trace Data Export

Any trace window can be exported and saved or printed as a PDF or CSV document by selecting the button

from the lower toolbar of the trace window. An exported trace le can easily be imported into a spreadsheet or other

report le or documentation.

Page 22

Getting Started 22

3.3.6 Channel Control Window

Select the icon and a dockable sidebar will appear on the righthand

side of the main application window by default. This allows you to change all

related settings to control one or more sensor channels. Channel control setting

is dened by several parameters as listed below.

Channel: Select one or all channels (for multi-channels) via the dropdown list.

Selecting the "All" permits simultaneous update on all measurement channels

(up to 8) for most settings.

Units: Selects dBm, Watts or Volts measurement units. Selection aects

displayed text, measurements, and trace.

Vert Scale / Center: Sets vertical amplitude scaling and centering of the

displayed waveform. These settings aect only the trace display.

Sensor Enabled: Enable or disable individual connected sensors.

Trace Avg: Sets number of acquired sweeps averaged together for displayed

trace in pulse/triggered modes. Useful for noisy signals.

Mod Filter/Filter Mode: Sets manual or automatic lter integration time

window for measurements in modulated (non-triggered) acquisition modes.

Peak Hold Mode/Decay Count: Sets peak hold duration (# of sweeps).

Tracks Trace Avg setting or may be independent.

Video BW: Selects sensor video bandwidth, high or low.

Frequency: Sets measurement frequency for the applied RF signal.

Cal & Corrections: Oset compensates reading for external gain/loss.

Zeroing and Fixed Cal: Sensor zeroing and xed calibration can be performed

by selecting each specic button.

Figure 3.10 Channel Control Menu

Page 23

Getting Started 23

3.3.7 Time/Trigger Settings Window

Select the icon to customize all related settings for both time base and trigger of a pulse signal.

Time base: Acquisition time in seconds per division. The power sensors use a

xed grid of 10 divisions for the sweep extents. Settings are in a 1- 2-5

sequence. Consult series specications for time base range.

Trigger Delay: Trigger delay can be adjusted by manually entering a numerical

value into the eld or using the up-down arrow keys. Click the “0” icon to reset

the trigger delay to zero seconds (RTP5000 only).

Trigger Position: Trigger position can be changed by entering numerical values

into the “Divisions” eld, clicking the scroll arrows, dragging the slide control, or

by clicking the L/M/R (Left/Middle/Right) indicators.

Trigger Source: Several trigger modes are available for each trigger source

under "Trigger Control" section. Multiple trigger sources are available under the

drop-down list including both "Internal" and "External" selection.

Trigger Mode: Select Normal, Auto, Auto Level or Free run. Trigger Level:

Sets trigger level when trigger source is INT and trigger mode is Auto or

Normal.

Slope: Select rising or falling edge triggering.

Holdo: Sets trigger holdo time and selects between Normal or Gap holdo

mode.

Trigger Skew Adjustment: This feature allows the user to adjust the skew for

internal trigger with master trigger output, and also external and slave triggers.

Skew adjustments allow to calibrate out trigger delay between sensors so the

user can measure propagation delay of the DUT from input to output. Manual

skew adjustments can be made by entering the skew value in the numeric entry

eld. The button to the right of each skew adjustment is the Auto-Skew button

which is described in detail in section "Time/Trigger Control Window". This

feature allows automatic adjustment of the skew.

Figure 3.11 Time/Trigger Menu

Page 24

Getting Started 24

3.3.8 Marker Settings Window

Programmable markers can be moved to any portion of the trace

that is visible on the screen. They can be used to mark regions of

interest for detailed power analysis. The instrument can display

power at each marker, as well as average, minimum, and maximum

power in the region between the two markers.

Click the icon to control the settings for time markers and

amplitude reference lines of a pulse signal.

Markers: Time Marker position settings will allow you to change

both marker 1 and marker 2 time positions by using either arrow

keys or entering numerical values into the eld. It will also display

the time delta value between the two markers.

Reference Lines: Also known as Horizontal Markers, can be

enabled by selecting On/O button for each individual channel.

Once enabled, users may select several options for automatic

amplitude tracking from the Tracking drop down list: O,

Markers, TopBottom, DistalMesial and DistalProximal. Two

reference lines can be set by using up/down arrow keys. Horizontal

markers are useful to determine the dierence with regard to loss.

3.3.9 Pulse Denitions Windows

Click the icon to control the settings of the pulse

thresholds and the pulse gate.

Pulse Thresholds: Pulse denition setting allows user to dene

distal, mesial and proximal values for pulse thresholds. It is also

possible to change pulse unit from watts to volts.

Pulse Gate: Pulse start and end gate can be changed both

numerically and by changing up/down arrow keys.

Chapter 6 contains a detailed description of each pulse threshold

level and the pulse measurement process.

Figure 3.12 Marker Settings Menu

Figure 3.13 Pulse Denition Menu

Page 25

Getting Started 25

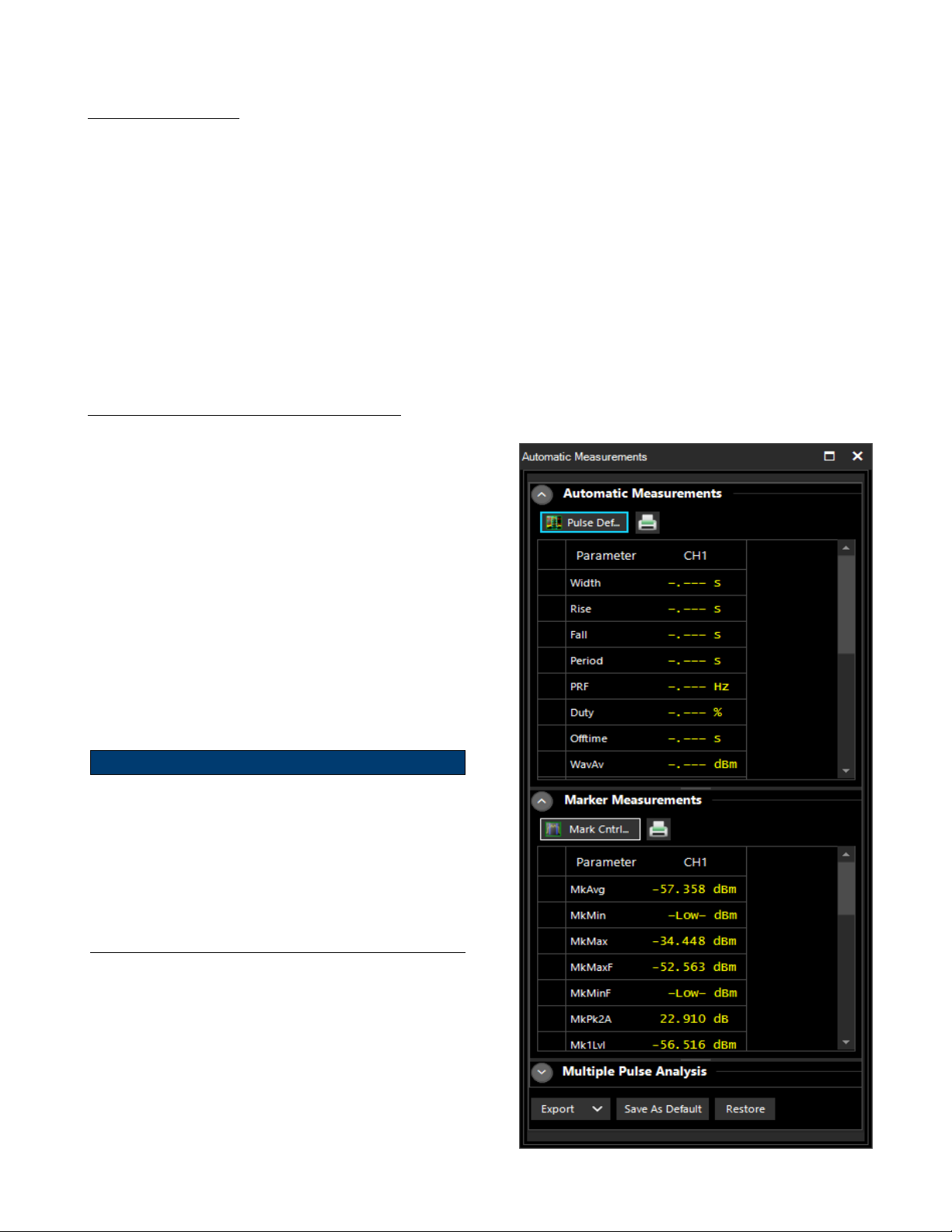

3.3.10 Automatic Measurements Windows

Select the icon to display a tabulated eld with a list of parameters for RF pulse measurements including marker

measurements. Below is an example screenshot for automatic parameters displayed for a typical pulse measurement.

Note:

All eld parameters are customizable, and can be edited or deleted from the list. The whole table can be copied and

pasted into a spreadsheet in order to make any custom report le along with captured screenshots by selecting export

button as provided by the software.

Automatic Pulse Measurements Automatic Marker Measurements Multiple Pulse Analysis

Figure 3.14 Auto Measurement

Page 26

Getting Started 26

Customize Field Parameters

All eld parameters under automatic measurement are

customizable, and can be edited or deleted from the list

by selecting individual parameter elds and then by using

right click button of the mouse.

Export or Copy Field Parameters

The whole automatic table or individual parameter eld can be

copied and then pasted into a simple spreadsheet or document

in order to make a custom report le along with captured

screenshots provided by the application.

To select multiple parameters right click using the mouse while

holding the Ctrl key.

Figure 3.15 Pulse Measurements Customize

Figure 3.16 Select Multiple parameters

Page 27

Getting Started 27

3.3.11 Display Settings Windows

The display settings allow for customization of data and trace colors for each measurement channel, and enable or disable

trace display features such as Average, Envelope, Maximum, Minimum and Persistence. It is also possible to adjust

marker color, background, grid colors and more under "Graph Colors" section of the display settings.

To open the Display Settings Windows left click on the Graph Settings icon located in the View tab.

Figure 3.17 Graph Settings

Figure 3.18 Display Settings

Page 28

Getting Started 28

3.3.12 CCDF View Window

For statistical measurements, select the icon from menu bar to view a CCDF graph. The sidebar on the CCDF

screen allows adjustment of horizontal scale, horizontal oset, cursor type, cursor position and dB oset. The user can

also enable/disable capture or reset the statistical data acquisition.

Figure 3.19 Complementary Cumulative Distribution Function Graph

3.3.13 Statistical Measurements Window

Select the icon, to tabulate a list of statistical measurements .

An example can be seen in gure 3.20

Figure 3.20

Statistical Measurements Window

Page 29

Operation

This section presents the procedures for operating the RFP Sensors using the Power Analyzer Software. All the display

windows that control the sensor are illustrated and accompanied by instructions for using each in the window.

4.1 Power Analyzer Software

The Power Analyzer Software is a Windows-based software program that provides immediate RF power measurements

from RFP Sensors without the need for programming on your Windows OS based computer. The measurements parameters from the power sensor can be displayed on your computer or can be integrated into a test system using an

Application Program Interface (API).

Note:

This section of the manual assumes that the Power Analyzer Software has been installed on a computer using the in-

structions provided in the "Getting Started" chapter of this manual.

4.1.1 Initializing the Software

Use a mouse or other pointing device to click on the View tab on the top of the window.

Click on Load Defaults – this will load the default Windows Theme ‘Visual Studio 2012 Dark’ and will reset all application

measurement settings to default values provide a known initial state.

Click on the down arrow adjacent to the theme to view the pull-down menu showing the available themes. The themes

establish the look of the Windows environment setting colors, fonts, and backgrounds.

The balance of this chapter will use the ‘Default” theme.

Click on any of the available themes to see what they look like. Select the theme you wish to use.

Figure 4.1 Selecting Theme

Page 30

Operation 30

4.1.2 Connecting the RFP Series Sensor

Connect the RFP Sensor to one of the USB ports of a computer using the supplied USB cable.

Connect power sensor to RF Source using the standard Type N connection port on the sensor.

Note:

• Do not turn the body of the sensor when connecting the sensor to a unit under test (UUT).

To avoid internal sensor damage, connect and disconnect the sensor by turning the metal

nut of the N connector only until it is ‘hand tight’.

• Ensure that you do not apply any excessive force on the sensor once it has been connected.

• Do not exceed the specied RF power at the RF input of the sensor.

Once the power sensor is connected, a pop up box will appear in the Power Analyzer Software as in gure 4.2 with

the list of connected devices name and hardware information.

Figure 4.2 Available Resources Window

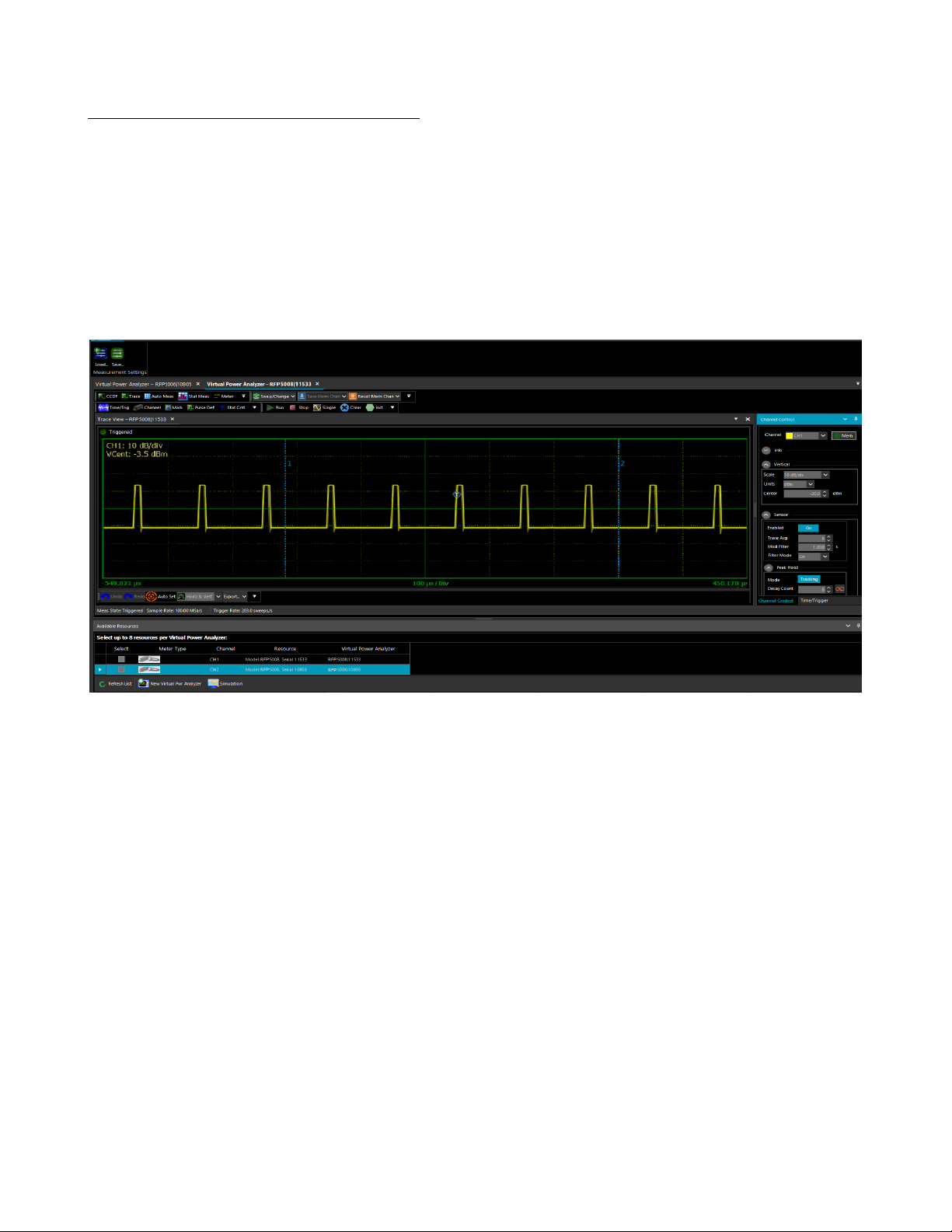

Up to eight sensors can be connected to the software. Click on the “Select” box of one of the sensors, click the "New

Virtual Pwr Analyzer" button at the bottom, a new Virtual Power Analyzer window will show up. If you have an

RF signal connected already to the power sensor, the measured signal should display in the Trace View window which

appears along with the Channel Control tool window as shown in gure 4.3.

Figure 4.3 Trace View

Page 31

Operation 31

4.1.3 Trace View Display

The Trace View window in gure 4.3 displays a trace of power versus time. The readout in the upper left corner shows

the channel number of the trace, the vertical scale factor and the vertical center. In gure 4.3 Channel 1 is displayed

with a vertical scale of 10 dB/div(ision) and a vertical center of -3.5 dBm.

The horizontal scale of the trace in the Trace View window is shown at the bottom of the grid. At the center of the

horizontal axis is the horizontal scale factor. Numbers at the right and left ends of the horizontal axis show the trace

start and end times relative to the trigger.

The two vertical blue lines labeled 1 and 2 are markers used for measurements of the displayed signals. These will be

discussed later in the manual.

Trace View Toolbox

The bar at the bottom of the Trace View window provides a number of useful tools that can be used to optimize the

trace display and archive the trace(s):

• The Export menu box is used to export any trace window as a PDF or CSV document. These exported trace les

can be used for a report or document.

• The Undo and Redo buttons work in conjunction with the display expansion (zoom) function to

remove (Undo) and restore (Redo) changes in display scaling.

• Auto Set provides an automatic setup of the trace display scaling which optimizes the trace view in the Trace View

window.

• The Cursor Mode menu box is used to select the zoom mode.

– Horiz(zontal) & Vert(ical) lets the graphical drag and drop zoom control both horizontal and vertical expansion.

– Horizontal limits the zoom controls to aecting the horizontal scaling only

– Pan allows the user to click and drag the trace either horizontally or vertically.

– None turns o both zoom and panning.

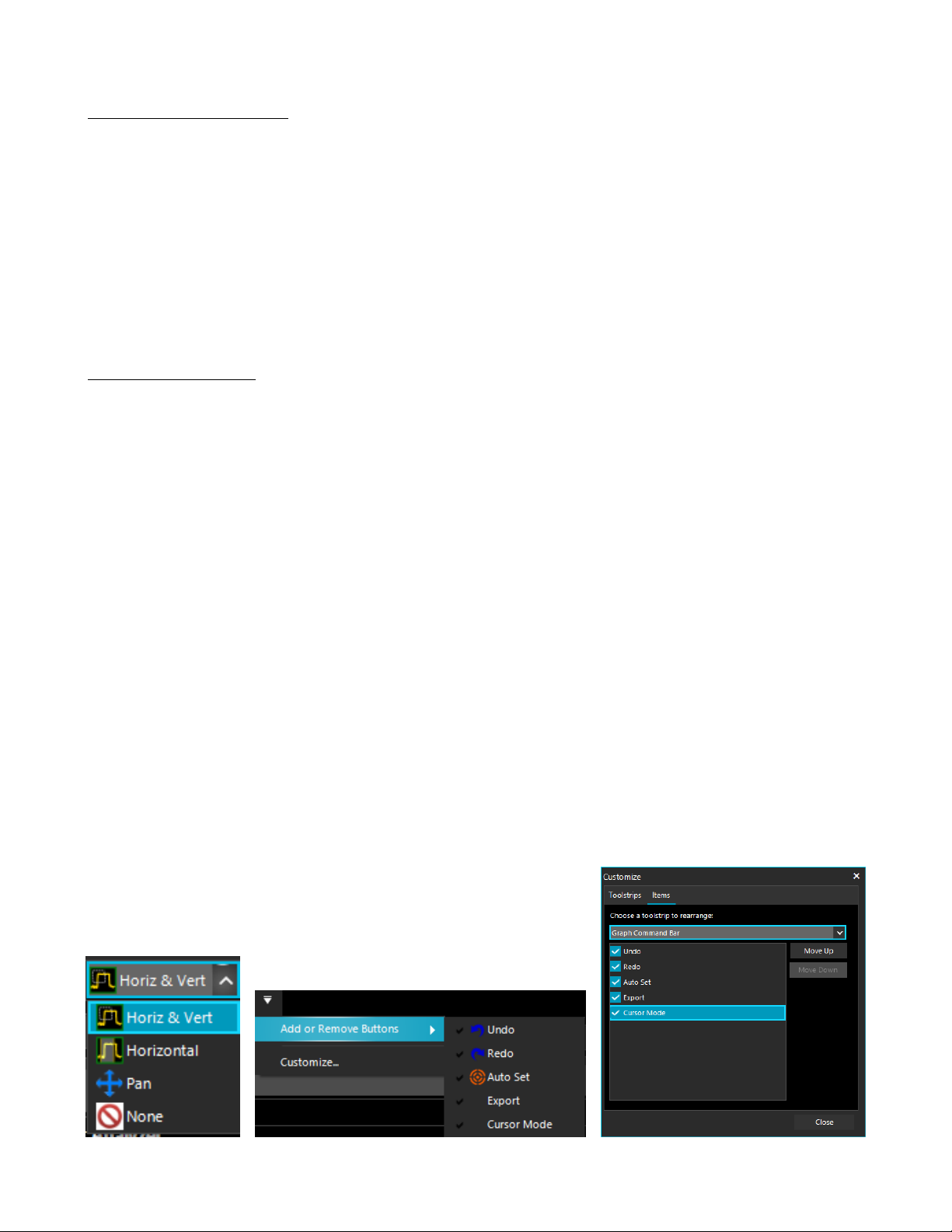

• The pull-down menu box is used to customize the Trace View toolbox.

– Add or Remove Buttons sets the tools to be displayed in the toolbox.

– Customize sets the order of the tools displayed in the toolbox.

Cursor Mode Add or Remove Buttons Customize

Figure 4.4 Trace View Toolbox Pull Down Menus

Page 32

Operation 32

Trace Pan and Zoom

The application has a trace zoom feature which lets a user to drag a rectangular box (like the one shown in gure 4.5)

around the trace in order to zoom onto a special area of the displayed waveform.

The highlighted dragged rectangular area indicates the minimum area that will be shown when the zoom operation

completes. The zoom area is constrained to the preset Time base settings and trigger Vernier limits.

Note that in gure 4.5 that the zoom horizontal scale changes from 10 µs/div to 50 ns/div the nearest available xed

Time base setting. Vertical scaling is similarly constrained.

Figure 4.5 Horizontal and Vertical Display Expansion

Note:

Horizontal or horizontal and vertical display expansion (zoom) is accomplished by clicking on the trace view and dragging

the mouse diagonally while holding the mouse button down. A box will outline the area to be expanded. Releasing the

mouse button will rescale the trace.

Page 33

Operation 33

4.1.4 Formatting Trace View Display

To open the Display Settings Windows left click on the Graph Settings icon lovated in the View tab.

Figure 4.6 Display Settings

The Display Settings pop-up is used to congure the Graph View. The elements to be displayed can be chosen and their

colors may be selected along with the background color.

The upper section of the Display Settings labeled Trace controls the conguration of the selected trace. There can be

a maximum of eight traces. The conguration of each trace includes the trace color, the choice of ve viewable trace

attributes, and the trace refresh time. Trace attributes include graphical view of the average value, envelope, maxima,

minima, and persistence (trace history). The defaults are to Show Avg and Show Envelope. Each of the selected elements

is overlaid on the trace.

Note:

The sensor acquires all three "traces" (average, min and max) when required . These are used for several of the marker

measurements such as interval peak-to-average, and others.

For the marker intervals, Min and Max (highest maximum trace and lowest minimum trace points) as well as MinF and

MaxF (min and max ltered) which are the highest and lowest points on the average trace.

The former measurements are useful for looking at modulation, while the latter are most useful for seeing systematic

peaks and dips (for example, ringing) of a repetitive waveform with the noise reduced.

A check box for Disable HW Acceleration can be checked if the computer does not have a monitor or graphics card or

if it is being operated remotely using remote desktop. Note: This change will not take eect until the next time a trace

window is opened.

The lower section of the Display Settings pop-up provides controls for color choices for trace grid, border, and background.

Markers, axis label, crosshair color selections are also included. Color choices are made by clicking on the ellipsis symbol

(…) adjacent to each element. This will bring up the Color Dialog palette used to set the desired color for the element.

Page 34

Operation 34

4.1.5 Main Toolbar

The Power Analyzer Software always displays the Main Toolbar that is located at the top of the main program window

and contains shortcuts to commonly used functions and measurements.

The Main Toolbar can be customized as discussed below. Figure 4.7 shows the Main Toolbar:

Figure 4.7 Main Toolbar

The Main Toolbar contains three sections called Toolstrips. The group of shortcuts on the left, including CCDF, Trace,

Auto Meas(urement) and Stat(istical) Meas(urement) are the Measurement Windows Toolstrip and will bring up

trace display or measurement windows. The middle group with Time/Trig, Channel, Mark, Pulse Def(initions) and

Stat(istical) Cntl(Control) are the Control Windows Toolstrip, and will cause setup and control windows to be displayed.

The nal group including Run, Stop, Single, Clear and Init(ialize) are the Acquisition Control Toolstrip and aect the

state of the acquisition.

Any of the toolstrips may be separated from the Main Toolbar and re-positioned by clicking on the ellipsis symbol at the

left end of any of the groups and dragging the toolstrip.

The drop-down menu bar on the right of each section allows the user to edit the tools bar by adding or removing any of

the items under the Items tab. The Toolstrips tab allows the user to show or hide the tools strips.

Acquisition Control Toolstrip

Figure 4.8 Acquisition Control Toolstrip

The buttons on this toolstrip control the state of the acquisition:

• Run – Starts the measurement acquisition and allows it to run continuously until stopped.

• Stop – Stops the measurement acquisition.

• Single – Starts a single measurement acquisition and then stops.

• Clear – Erases the acquired data trace. Useful in clearing a single or averaged acquisition.

• Init – Initializes or resets all settings for the active Virtual Power Meter to default values.

Page 35

Operation 35

Measurement Control Toolstrip

Figure 4.9 Measurement Control Toolstrip

The buttons on this toolstrip create Trace View and CCDF Graph displays as well as the automated power measurement

and statistical Measurement tabular display windows:

• CCDF – This button turns on the complementary cumulative distribution function (CCDF) display. If the CCDF

display is already opened but hidden behind the Trace View display this button will bring the CCDF trace to the

foreground.

• Trace - This button turns on the Trace View trace that displays power versus time.

• Auto Meas – This button opens Automatic Measurement windows showing the automatic Pulse and Marker Measurements tables.

• Stat Meas – This button opens the Statistical Measurements window displaying the measurements associated with

the CCDF Graph.

Control Windows Toolstrip

Figure 4.10 Control Windows Toolstrip

The buttons on this toolstrip control the setup windows for the acquisition, and measurement functions.

• Time/Trig – This button displays the Trigger and Time base control windows.

• Channel – This button brings up the Channel Control Window allowing control of the vertical range and oset as

well as sensor related settings

• Mark – This button causes the Marker Settings window to be displayed. Marker and reference lines can be controlled

from here.

• Pulse Def – This button displays the Pulse Denitions window controlling the pulse measurement thresholds, units,

and gating.

• Stat Cntl – This button brings up the Stat(istics) Mode Control window with scaling and population control for the

CCDF display.

Page 36

Operation 36

Memory Channel Toolstrip

Figure 4.11 Memory Channel Toolstrip

The Memory Channel toolstrip contains Swap/Change, Save Mem(ory) Chan(nel), and Upload Mem(ory) Chan(nel), and

controls the sensor connection source and saving and recalling Mem(ory) traces. The Memory Channel is a reference

trace that appears on the Trace View when Mem+ is enabled.

• Swap/Change - Swap/change allows you to change sensors for a particular session if more than one is connected.

• Save Mem(ory) Chan(nel) – Saves the current Memory channel to a user selected folder on the computer.

• Upload Mem(ory) Chan(nel) – recalls a stored Memory Channel to the Memory Channel Trace on the Trace View.

Page 37

Operation 37

4.1.6 Time/Trigger Control Window

Pressing the Time/Trig button icon the Control Windows toolstrip will bring

up the Time base / Trigger Control window shown in gure 4.12

This window has four sections Time(base), Trigger Position, Trigger Con-

trol, and Trigger Skew Adj(ust). Any of these sections can be opened or

collapsed by clicking on the up/down arrow buttons to the left of the section

titles.

Time and Trigger Position Controls

Settings in the Time and Trigger Position Control groups aect horizontal

scaling and position of the acquired waveform.

Time base controls the Time base or horizontal scale of the acquisition and

is noted on the horizontal axis label of the Trace View. The Time base pulldown menu permits selection of xed Time base ranges from 5 ns/div to 50

ms/div (sensor series dependent) in a 1-2-5 progression.

Trig(ger) Delay can be adjusted either manually entering a numerical value

into the eld or using the up-down arrow keys.

The trigger delay time is set in seconds with respect to the trigger. Positive values mean that the trace display shows a time interval after the trigger

event. This positions the trigger event to the left of the trigger point on the

display, and is useful for viewing events during a pulse, or some xed delay

time after the rising edge trigger. Negative trigger delay mean that the trace

display shows a time interval before the trigger event, and is useful for looking at events preceding the trigger edge.

Pressing the ‘0’ button to the right of the trigger delay entry eld resets the

trigger delay to zero.

The range of trigger delay times is dependent on the Time base setting and

is summarized in table 4.1. Note the range will also depend upon the trigger

position.

Time base Setting Trigger Delay Range

5 ns/div to 10 us/div -1.26 ms to 100 ms

20 us/div -1.26 ms to 200 ms

50 us/ div -5.04 ms to 200 ms

100 us/ div -6.3 ms to 500 ms

200 us/div -12.6 ms to 1

500 us/div -31.5 ms to 1 s

1 ms/div -63 ms to 1 s

2 ms/div to 10 ms/div -126 ms to 1 s

20 ms/div -252 ms to 1 s

50 ms/div -628 ms to 1 s

Figure 4.12

Time/Trig Control Window

Table 4.1 Trigger Delay Range

Page 38

Operation 38

Note:

Trigger delay ranges in table 4.1 are for the trigger position set to 0 divisions (Left). If trigger delay and position settings result in a pre-trigger capture interval greater than 1.26 ms, the sensor will automatically reduce the sample rate to

avoid overowing its pre-trigger memory.

Trigger Position controls are used to set the location of the trigger point on the acquired trace waveform. It can be

changed by entering numerical values into the Divisions eld from -30 to +30 divisions, by positioning the horizontal

slider bar, or by clicking on the L, M or R indicators to select one of three default positions: Left (zero divisions), Middle

(ve divisions) or Right (ten divisions).

Trigger Controls

Settings in the Trigger Control group provides control to aect the trigger source, mode, trigger level, slope, and trigger

holdo.

Trigger Source

The trigger source can be any of the resource channels (CH1, CH2, etc.), or the Ext(ernal) trigger input signal. The

Ind(ependent) trigger setting allows each connected sensor to trigger independently from its own RF input.

The external trigger is attached to the RTP Series Real-Time Power Sensors via the Multi-I/O connector adjacent to the

USB port on the RTP Series Real-Time Power Sensors. The connector is an SMB type. The external trigger requires a

TTL signal level, minimum pulse width of 10 ns, and maximum frequency of 50 MHz.

In a multichannel set-up, the sensors can be triggered independently as described above or in a master/slave conguration.

In master/slave conguration, one channel (CH1, CH2, etc.) is selected as the source (master) and the remaining sensors

automatically operate in slave mode. See Multichannel Operation for additional information.

Trigger Mode

There are four available trigger modes: Normal, Auto, Autolevel, and Freerun.

• Normal – The unit triggers when the amplitude of selected trigger source transitions above the preset trigger level

when positive trigger slope is selected or if it transitions below the preset trigger level when negative trigger slope is

selected. No automatic trigger actions takes place.

• Auto- Auto trigger mode operates in much the same way as Normal trigger mode, but will automatically generate

a trace if no trigger edges are detected for a period of time. If a triggerable signal edge occurs during auto-trigger

operation, the trigger system will resynchronize with the signal. For trigger rates below approximately 10 Hz, the

Auto trigger time delay may interfere with resynchronization. Use Normal mode if this occurs.

• AutoLevel - performs the same function as Auto and, in addition, automatically sets the trigger level based on the

peak-to-peak amplitude of the signal. For many signals this will provide a fully automatic trigger system. For slow

rate signals and complex level patterns, it may not produce the desired display. Use Normal mode if this occurs.

• Freerun - Free Run generates horizontal sweeps asynchronously, without regard to trigger conditions. This mode is

useful for locating low duty-cycle events visually.

Trigger Level

Sets the threshold level for the trigger signal in the Auto and Normal trigger modes. The trigger level can be entered

numerically or changed by using arrow keys. The trigger level range has a maximum value of 20 dBm and a minimum

range that is sensor model dependent (see the sensor specications for your specic sensor model)

Page 39

Operation 39

The trigger range is automatically adjusted to include the dB Oset parameter selected in the Cal & Corrections section

of the Channel Control window. For example, if the trigger level = 10 dBm and the dB Oset is changed from 0 to 20

dB, then the oset-adjusted trigger level will be displayed to the user as 30 dBm. Likewise, the maximum trigger level

range will be extended to 40 dBm. The trigger level set point and setting range are both shifted upward by 20 dB.

Trigger Slope

Sets the trigger slope or polarity. When set to Pos(itive), trigger events will be generated when a signal’s rising edge

crosses the trigger level threshold. When Neg(ative) is selected, trigger events are generated when the falling edge of the

pulse crosses the threshold. Trigger slope can be selected by using Pos and Neg button boxes under slope.

Holdo (Time)

The holdo time can be entered and adjusted numerically to 0.01 µs resolution, or using the up and down arrow keys in

1 µs increments. The eect of Holdo time depends on the Holdo Mode. Set the trigger holdo time in microseconds.

Holdo Mode

There are two trigger holdo modes: Normal and Gap.

Normal Holdo

Normal trigger holdo is used to disable the trigger for a specied amount of time after each trigger event.

The holdo time starts immediately after each valid trigger edge, and will not permit any new triggers until

the time has expired. When the holdo time is up, the trigger re-arms, and the next valid trigger event

(edge) will cause a new sweep. This feature is used to help synchronize the RTP Series Real-Time Power

Sensors with burst waveforms such as a TDMA or GSM frame. For periodic burst signals, the trigger

holdo time should be set slightly shorter than the burst or frame repetition interval.

Gap Holdo

Gap or frame holdo is very useful for packet-based communication signals where the transmission burst

contains deep modulation which may fall briey below the trigger threshold, or when bursts or pulses are

of varying length and spacing, making normal holdo ineective. In most cases, the "o" time between

transmission bursts, or frames, is considerably longer than the instantaneous modulation dips.

In gap holdo the trigger is not armed until the trigger source remains inactive (below the trigger threshold

for positive trigger slope, or vice versa for negative slope) for at least the set duration. If trigger polarity

is positive, and gap holdo is set for 1 us, then the signal must stay below the trigger level for at least 1 us

before the trigger is armed. Then, the next rising edge following a gap of 1 us or longer will trigger the

acquisition.

Page 40

Operation 40

Trigger Skew Adj(ust)

Trigger Skew aligns the edge crossing with the trigger point for each of the trigger sources. This is done internally by

adding a trim value to the trigger delay setting. Since the dierent trigger sources (internal, external, and slave) have

dierent delays, the system stores a value for each.

Trigger Skew requires a fast RF pulse (Trise < 10 ns) to adjust ’Int’ skew. To auto-adjust ’Ext’ requires a fast RF pulse

aligned with a fast external trigger pulse applied to the sensor’s MIO input. Adjusting the ’Slave’ source requires two

sensors connected to a common, fast RF pulse (Trise < 10 ns) and interconnected for cross-trigger via their MIO inputs.

You can de-skew one setting at a time until all three sources are calibrated.

Deskewing can be done automatically by clicking on the double slope icon on the left of “ns”, shown in gure ??

Automatic deskewing requires a fast edge, repetitive signal.

Figure 4.13 Trigger Skew Adj

Page 41

Operation 41

4.1.7 Channel Control Window

The Channel Control window allows you to change all related settings to

control sensor channels. The Power Analyzer Software has the capabil-

ity of handling multiple control channels by selecting each individually from

the drop-down list. Channel control setting is dened by several parameters

as listed below:

Channel

You can select an individual channel or all measurement channels (for

multichannel operation) by using the drop-down list. The channel labeled

MEM1 is a memory channel which is a reference trace that can be stored

or recalled as need.

The button causes the current trace to be stored in the Memory

Channel. The current memory channel can be stored to the computer hard

drive using the Save Mem Chan button in the Memory channel toolstrip.

Likewise, a previously stored memory trace can be recalled using the

Upload Mem Chan button.

To turn o the Memory Channel, select MEM1 or MEM2 from the Channel

drop down menu, then click on the “On” button next to "Enabled" in the

Sensor menu (see below) to select “O”.

Info

The Info group shows the pertinent information for the selected sensor.

Sensor model number,serial number, and rmware and FPGA versions for

the selected channel are displayed in this group.

Pressing the Advanced button will result in a Sensor Info pop-up with

three tabs: Sensor Data, Cal Factors, and Hardware Info.

Sensor Data contains identication and calibration information

for the sensor.

Cal Factors contain the frequency response calibrations factors

for both high and low bandwidth calibration.

Hardware Info contains information on the current state of the

sensor hardware including the detector temperature and key power

source voltage readings.

Figure 4.14 Channel Control Window

Page 42

Operation 42

Vertical

The Vertical group contains controls that aect vertical settings for the selected power sensor.

Scale - Vertical scale sets the scaling of the level axis of the Trace View based on the selection of units as shown in table

4.2

Units Scale

dBm 0.1, 0.2, 0.5 1, 2, 5, 10, 20, 50 dB/div

Watts 1 pW to 500 MW/div in a 1-2-5 progression

Volts 1 µV to 100 kV/ div in a 1-2-5 progression

Table 4.2 Vertical Scale Range

Units - The trace presentation may be shown in units of dBm, Watts or Volts. The Units selection determines the range

of the scale values. Note that the Units setting also aects text measurement values in the Measurement windows.

Center - Set the power or voltage level of the horizontal centerline of the graph for the specied channel in the selected

channel units. The center position can be entered numerically or adjusted by using up and down arrow keys.

Sensor

The Sensor group controls acquisition parameters for the selected power sensor.

Enabled - Individual sensors or all the selected sensors can be enabled or disabled by using the alternate action On/O

button. This functionality also enables or disables the MEM channels.

Trace Avg – Trace averaging can be used to reduce display noise on both the visible trace, and on automatic marker

and pulse measurements. Trace averaging is a continuous process in which the measurement points from each sweep are

weighted (multiplied) by an appropriate factor and averaged into the existing trace data points. In this way, the most

recent data will always have the greatest eect upon the trace waveform, and older measurements will be decayed at a

rate determined by the averaging setting and trigger rate. This averaging technique is often referred to as ‘exponential’

averaging because averaging imposes a rst-order Innite Impulse Response (IIR) exponential lter with a time constant

of "n" where n is the Trace Avg (number of averages) setting.

Sensor averaging can be set by selecting a number of averages from 1 (no averaging) to 16384 in binary steps using the

up and down arrow buttons in the Trace Avg eld.

Note:

For Time base settings of 200 ns/div and faster, the sensor acquires samples using a technique called equivalent time or

random interleaved sampling (RIS). In this mode, not every pixel on the trace gets updated on each sweep, and the total

number of sweeps needed to satisfy the average setting will be increased by the sample interleave ratio of that particular

Time base. At all times the average trace is the average of all samples for each pixel, and the min/max are the lowest

and highest of that same block of samples for each pixel.

Page 43

Operation 43

Mod Filter sets the modulation lter integration time. It is used in modulated mode measurements and does not aect

the pulse mode (triggered) measurements shown in the trace view. The modulation lter is a “sliding window” lter

which averages samples taken within a time window whose duration is set by this eld. All samples within the time

window are equally weighted.

Filter Mode controls the modulation lter. The lter can be set to On (manual lter time setting), None (integration

time is set to the minimum 1 ms value), or Auto (integration time automatically selected based upon input level).

Peak Hold settings control the operating mode of the selected channel’s peak hold function. Peak Hold aects the

envelope trace (if displayed) as well as peak or dynamic range marker and pulse measurements.

In Tracking mode, the maxima and minima traces "decay" towards the average with a time constant that is

the same as the averaging setting. If averaging is set fast (Trace Avg is set to a low value), then the maxima

and minima decay quickly (are not held very long) while long averaging (Trace Avg is set to a high value) settings yields a ‘atter’ trace and maxima and minima peaks decay slowly back to the average power level.

In Manual mode the averaging and peak time constants are independent (do not track each other). Rather,

peaks are held for a time proportional to the Decay Count setting. Decay Count can be set from 1 to 16384

and increments in binary steps.

Manual mode can be useful if you want to set averaging short to see short-term signal uctuations from one

trace to the next, yet want the peaks held for a long time to get a better feel of longer-term peak stress on

your system.

The Innite Hold button sets the Decay Count to innity. Signal peaks and dips are held indenitely and

never decayed. This is useful for long-term monitoring for glitches, spikes, dropouts, or other intermittent signal events.

Note:

The eects of the peak hold, i.e. min/max decay, are only visible when the "envelope" or "min/max" display is

enabled in the view options (See section 3.3.11 and the associated gure 3.18. The marker min/max values

are always aected.

Video BW sets the sensor video bandwidth for the selected sensor. High is appropriate for most measurements, and the

actual bandwidth depends upon the sensor model. Low bandwidth oers additional noise reduction for CW or signals

with very low modulation bandwidth. If Low bandwidth is used on signals with fast modulation, measurement errors may

result if the sensor cannot track the fast-changing envelope of the signal.

Frequency should be set to the RF frequency that is applied to the sensor for the current measurement. The appropriate

frequency calibration factor from the sensor’s calibration table will be interpolated and applied automatically. Application

of this calibration factor compensates for the eect of variations in the atness of the sensor’s frequency response.

The power sensor has no way to determine the carrier frequency of the applied signal, so the user must always enter the

frequency.

Page 44

Operation 44

Cal & Corrections

The Calibration and Corrections group controls coarse and ne corrections to the measurements.

Oset - Sets a measurement oset in dB for the selected sensor. This is used to compensate for external

couplers, attenuators or ampliers in the RF signal path ahead of the power sensor.

Zero - Performs a zero oset null adjustment. The sensor does not need to be connected to any calibrator

for zeroing. This action removes the eect of small, residual power osets, and should be performed prior to

low-level measurements. Note that there should be no RF signal applied to the sensor input prior to zeroing.

Fixed Cal - Performs a calibration at 0 dBm at the currently set frequency. This requires a calibrated 0 dBm

(1.00 mW) signal source at the current measurement frequency.

4.1.8 Automatic Measurements Display

Clicking on the AutoMeas icon in the Measurement

Control Toolstrip will bring up the Automatic Measurements window to the left of the Trace View as shown

in gure 4.15. This window includes two related subwindows, Pulse Measurements and Marker Measurements. The Pulse Measurements window shows the

sixteen default eld pulse parameters. The eld pulse

parameter measurements are computed with methods

described in IEEE Std 181™-2011 and detailed in Section 6 on pulse terms and denitions.

The Marker Measurements window shows twenty-one

marker measurements.

Note:

All eld parameters are customizable, can be edited or

deleted from the list by selecting individual parameter

elds and then by using right click button of the mouse.

The whole table can be copied and pasted into a spreadsheet in order to make any custom report le along with

captured screenshots by selecting export button as provided by the software.

Figure 4.15 Automatic Measurements Window

Page 45

Operation 45

Any individual parameter or group of parameters on pulse or marker measurements can be highlighted by left clicking

with the mouse and using the up and down arrow keys a group of them can be selected. Selected cells can be copied

by right clicking on the parameter(s) and selecting copy. The copied cells can be pasted into a spreadsheet or document.

Clicking on the printer icon next to either table will open a Print Preview window allowing the user to print the table.

Clicking on the Export button will open a viewer showing the whole table. The contents of the viewer can be saved or

printed as PDF or CSV les, if desired.

4.1.9 Pulse Denition Window

Clicking on the Pulse Def button in the Pulse Measurement title bar or on

the Pulse Meas button on the Measurement Control Toolstrip will open

the Pulse Denitions window shown in Figure 4.11. This window contains

the pulse thresholds, pulse analysis units and gate settings for the selected

sensor.

Pulse Thresholds

Pulse denition settings allows user to dene distal, mesial, and proximal

values for pulse thresholds, and the pulse units.

Distal - Sets the pulse amplitude percentage that denes the end

of a rising edge or beginning of a falling edge transition. Typically,

this is 90% voltage or 81% power relative to the top level of the

pulse. This setting is used when making automatic pulse risetime

and falltime calculations.

Mesial – Sets the pulse amplitude percentage that denes the

midpoint of a rising or falling edge transition. Typically, this is 50%

voltage or 25% power relative to the top level of the pulse. This

setting is used when making automatic pulse width and duty cycle

calculations.

Proximal – Sets the pulse amplitude percentage that denes the

beginning of a rising edge or end of a falling edge transition.

Typically, this is 10% voltage or 1% power relative to the top level

of the pulse. This setting is used when making automatic pulse

risetime and falltime calculations.

Pulse Units – Controls whether the distal, mesial, and proximal thresholds are computed as voltage or power

percentages of the top/bottom amplitudes. If Volts is selected, the pulse transition thresholds are computed as

voltage percentages, and if Watts, they are computed as power percentages.

Figure 4.16 Pulse Denition Window

Many pulse measurements call for 10% to 90% voltage (which equates to 1% to 81% power) for risetime and

falltime measurements, and measure pulse widths from the half-power (–3 dB, 50% power, or 71% voltage)

points. The Pulse Units setting is independent of the channel’s display units setting.

Page 46

Operation 46

Pulse Gate

The Pulse Gate settings dene the measurement interval for the following power related pulse measurements: Pulse

Average, Pulse Peak, Pulse Minimum and Pulse Droop/Tilt. Pulse timing measurements between mesial crossings such

as width and period are not aected. The purpose of the Pulse Gate setting is to exclude edge transition eects from

the pulse power measurements. Automatic pulse measurements are then performed between Start Gate and End Gate

points.

Start Gate - Sets the beginning of the pulse measurement region as a percentage of the pulse width. The Start Gate

has a continuous range of 0.0 % to 40.0 % of the pulse width and may be entered numerically or varied using the up or

down arrows.

End Gate - Sets the end of the pulse measurement region as a percentage of the pulse width. The End Gate has a

continuous range of 60.0 % to 100.0 % of the pulse width and may be entered numerically or varied using the up or

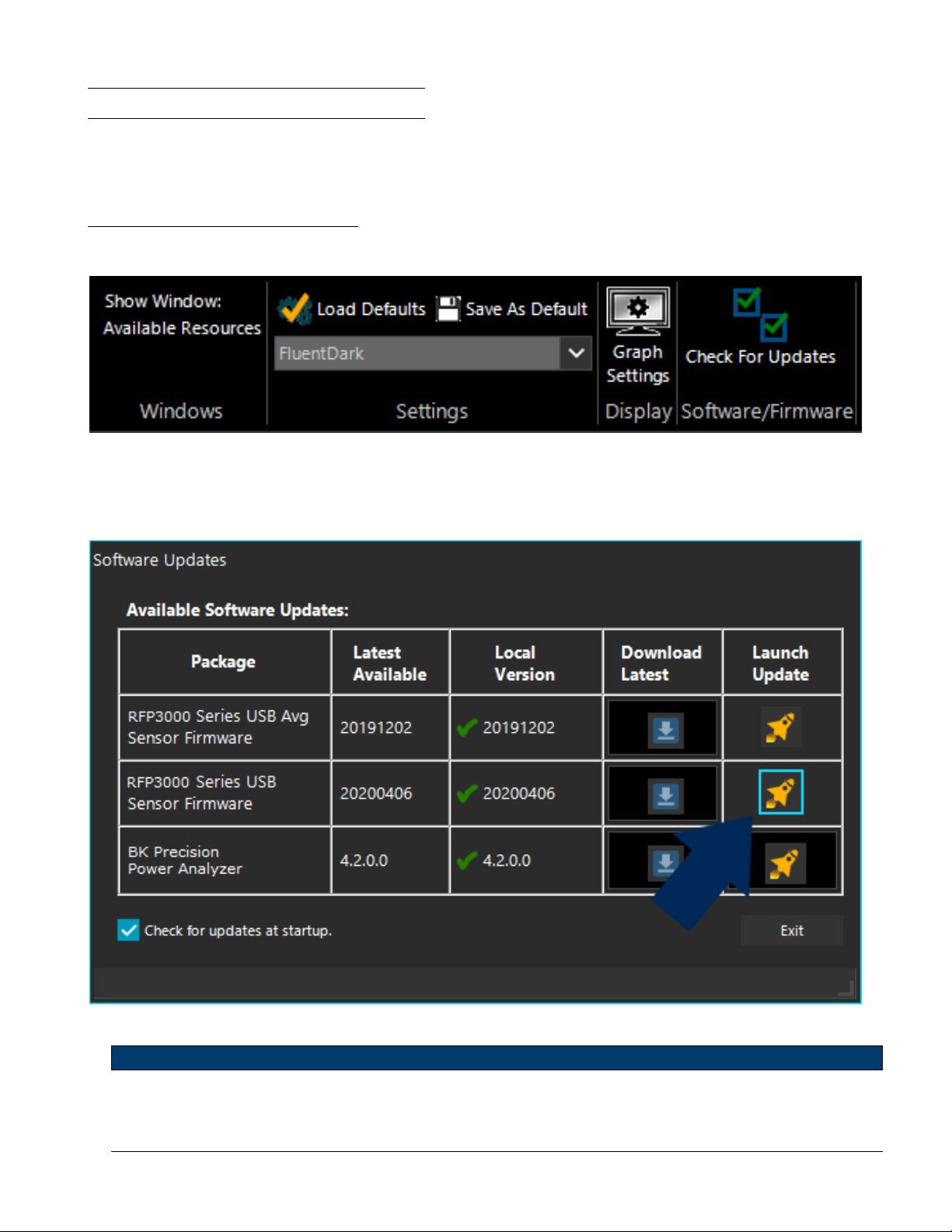

down arrows.