Page 1

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be followed during all

phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

• Read and understand the safety and operational information in this manual.

• Apply all the listed safety precautions.

• Verify that the voltage selector at the line power cord input is set to the correct line voltage. Operating the instrument

at an incorrect line voltage will void the warranty.

• Make all connections to the instrument before applying power.

• Do not operate the instrument in ways not specied by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the safety standards of design,

manufacture, and intended use of the instrument. B&K Precision assumes no liability for a customer’s failure to comply

with these requirements.

2

Category rating

The IEC 61010 standard denes safety category ratings that specify the amount of electrical energy available and the

voltage impulses that may occur on electrical conductors associated with these category ratings. The category rating is

a Roman numeral of I, II, III, or IV. This rating is also accompanied by a maximum voltage of the circuit to be tested,

which denes the voltage impulses expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be connected to the

mains supply. The voltages in the environment are typically derived from a limited-energy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be connected to the mains

supply at a standard wall outlet or similar sources. Example measurement environments are portable

tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be connected to the mains

installation of a building. Examples are measurements inside a building’s circuit breaker panel

or the wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be connected to the primary

power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is specied in this manual

for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or higher than the

instrument’s category rating to maintain the instrument’s category rating. Failure to do so will lower the category rating

of the measuring system.

Page 3

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains power should be

115 V RMS or 230 V RMS. Use only the power cord supplied with the instrument and ensure it is appropriate for your

country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical safety ground. This

instrument is grounded through the ground conductor of the supplied, three-conductor AC line power cable. The power

cable must be plugged into an approved three-conductor electrical outlet. The power jack and mating plug of the power

cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible conductive parts

(including control knobs) may provide an electric shock. Failure to use a properly-grounded approved outlet and the

recommended three-conductor AC line power cable may result in injury or death.

3

Unless otherwise stated, a ground connection on the instrument’s front or rear panel is for a reference of potential only

and is not to be used as a safety ground. Do not operate in an explosive or ammable atmosphere.

Do not operate the instrument in the presence of ammable gases or vapors, fumes, or nely-divided particulates.

The instrument is designed to be used in oce-type indoor environments. Do not operate the instrument

• In the presence of noxious, corrosive, or ammable fumes, gases, vapors, chemicals, or nely-divided particulates.

• In relative humidity conditions outside the instrument’s specications.

• In environments where there is a danger of any liquid being spilled on the instrument or where any liquid can condense

on the instrument.

• In air temperatures exceeding the specied operating temperatures.

• In atmospheric pressures outside the specied altitude limits or where the surrounding gas is not air.

• In environments with restricted cooling air ow, even if the air temperatures are within specications.

• In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating temperature range is

0∘C to 40∘C and 20% to 80% relative humidity, with no condensation allowed. Measurements made by this instrument

may be outside specications if the instrument is used in non-oce-type environments. Such environments may include

rapid temperature or humidity changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise,

strong electric elds, or strong magnetic elds.

Page 4

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets on or inside the

instrument, remove the instrument’s power cord, remove the instrument from service, label it as not to be operated,

and return the instrument to B&K Precision for repair. Notify B&K Precision of the nature of any contamination of the

instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants, solvents, acids/bases,

or other such chemicals. Clean the instrument only with a clean dry lint-free cloth or as instructed in this manual. Not

for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component in a life-support

device or system.

4

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and internal adjustments must

be made by qualied service-trained maintenance personnel who are aware of the hazards involved when the instrument’s

covers and shields are removed. Under certain conditions, even with the power cord removed, dangerous voltages may

exist when the covers are removed. To avoid injuries, always disconnect the power cord from the instrument, disconnect

all other connections (for example, test leads, computer interface cables, etc.), discharge all circuits, and verify there

are no hazardous voltages present on any conductors by measurements with a properly-operating voltage-sensing device

before touching any internal parts. Verify the voltage-sensing device is working properly before and after making the

measurements by testing with known-operating voltage sources and test for both DC and AC voltages. Do not attempt

any service or adjustment unless another person capable of rendering rst aid and resuscitation is present.

Do not insert any object into an instrument’s ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault condition in the circuit

exists.

Fuse replacement must be done by qualied service-trained maintenance personnel who are aware of the instrument’s fuse

requirements and safe replacement procedures. Disconnect the instrument from the power line before replacing fuses.

Replace fuses only with new fuses of the fuse types, voltage ratings, and current ratings specied in this manual or on

the back of the instrument. Failure to do so may damage the instrument, lead to a safety hazard, or cause a re. Failure

to use the specied fuses will void the warranty.

Servicing

Page 5

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the instrument to

B&K Precision for service and repair to ensure that safety and performance features are maintained.

For continued safe use of the instrument

• Do not place heavy objects on the instrument.

• Do not obstruct cooling air ow to the instrument.

• Do not place a hot soldering iron on the instrument.

• Do not pull the instrument with the power cord, connected probe, or connected test lead.

• Do not move the instrument when a probe is connected to a circuit being tested.

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and other European

countries with separate collection systems)

This product is subject to Directive 2002/96/EC of the European Parliament

and the Council of the European Union on waste electrical and electronic equipment

(WEEE), and in jurisdictions adopting that Directive, is marked as being put on the

market after August 13, 2005, and should not be disposed of as unsorted municipal

waste. Please utilize your local WEEE collection facilities in the disposition of this

product and otherwise observe all applicable requirements.

5

Page 6

Safety Symbols

Symbol Description

indicates a hazardous situation which, if not avoided, will result in death or serious injury.

indicates a hazardous situation which, if not avoided, could result in death or serious injury

indicates a hazardous situation which, if not avoided, will result in minor or moderate injury

Refer to the text near the symbol.

Electric Shock hazard

Alternating current (AC)

Chassis ground

Earth ground

This is the In position of the power switch when instrument is ON.

This is the Out position of the power switch when instrument is OFF.

is used to address practices not related to physical injury.

6

Page 7

Contents

1 General Information 9

1.1 Organization 9

1.2 Description 10

1.3 Features 10

1.4 Front Panel 11

1.5 Rear Panel 13

1.6 Touch Screen Display 14

2 Installation 17

2.1 Contents 17

2.2 Input Power & Fuse Requirements 17

2.3 Connections 18

2.4 Preliminary Check 18

3 Getting Started 20

3.1 Initialization 20

3.2 Taking Measurements 22

3.2.1 Continuous Mode 22

3.2.2 Pulse Mode 23

3.2.3 Statistical Mode 24

4 Operation 26

4.1 Control Menus 26

4.2 Parameter Date Entry and Selection 26

4.2.1 Numerical Data Entry & Drop Down Menus 26

4.3 Menu Reference 27

4.3.1 Main Menu 27

4.3.2 Measure > 28

4.3.3 Display > 29

4.3.4 Stat. Mode > 29

4.3.5 Channel > 30

4.3.6 Channel Settings 31

4.3.7 Time > 34

4.3.8 Trigger > 34

4.3.9 Pulse Def. > 36

4.3.10 CH# Pulse Def 36

4.3.11 Favorites > 38

4.3.12 System > 38

5 Application Notes 42

5.1 Introduction to Pulse Measurements 42

5.1.1 Measurement Fundamentals 42

5.1.2 Diode Detection 44

5.1.3 Pulse Denitions 46

5.1.4 Standard IEEE Pulse 46

5.1.5 Automatic Measurements 47

5.1.6 Automatic Measurement Criteria 47

5.1.7 Automatic Measurement Terms 48

5.1.8 Automatic Measurement Sequence 49

5.1.9 Average Power Over an Interval 52

5.1.10 Statistical Mode Automatic Measurements 53

5.2 Measurement Accuracy 54

Page 8

6 Maintenance 55

6.1 Safety 55

6.2 Cleaning 55

6.3 Inspection 55

6.4 Lithium Battery 56

6.5 Software Upgrade 56

7 Service Information 57

8 LIMITED THREE-YEAR WARRANTY 58

8

Page 9

General Information

This instruction manual provides you with the information you need to install, operate, and maintain the RFM3000 RF

Power Meter. Section 1 is an introduction to the manual and the instrument.

1.1 Organization

The manual is organized into ve sections and two Appendices, as follows:

Section 1

General Information presents summary descriptions of the instrument and its principal features, acces-

sories, and options.

Section 2

Section 3

Section 4

Section 5

Installation provides instructions for unpacking the instrument, setting it up for operation, connecting

power and signal cables, and initial power-up.

Getting Started describes the controls and indicators and the initialization of operating parameters.

Several practice exercises are provided to familiarize yourself with essential setup and control procedures.

Operation describes the display menus and procedures for operating the instrument locally from the

front panel.

Application Notes provides supplementary information about RFM3000 and sensor operation, advanced features, pulse measurement information, and measurement accuracy.

Page 10

General Information 10

1.2 Description

The RFM3000 provides design engineers and technicians the utility of traditional benchtop instruments, the exibility

and performance of modern USB RF power sensors, and the simplicity of a multi-touch display built with advanced

technology.

As a benchtop meter, the RFM3000 provides a standalone solution for capturing, displaying, and analyzing peak and

average RF power in both the time and statistical domains through an intuitive, touch screen display.

The RFM3000 RF Power Meter utilizes up to four RFP Series Sensors with industry-leading performance and capabilities

either independently or for synchronized multi-channel measurements of CW, modulated, and pulsed signals.

Providing the ultimate exibility, the RFM3000 sensors can be disconnected and independently used as standalone

instruments.

1.3 Features

• Compatible with B&K Precision’s RFP3000 Series USB RF Power Sensors

• Capture/display/analyze peak and average power

• Independent or synchronous multi-channel measurements (up to 4 channels)

• Trigger synchronization

• Supports SCPI-1999.0

• Sensor verication test source

• Display 16 common power measurements

• Ethernet:10/100/1000 BaseT; HiSLIP

• HDMI output for mirror display

• Sensors can be used as standalone instruments

Page 11

General Information 11

1.4 Front Panel

Refer to table 1.1 for a description of each of the illustrated items. The function and operation of all controls, indicators,

and connectors are the same on the standard and optional models.

Figure 1.1 Front Panel

Page 12

General Information 12

Item Description

Four sensor inputs are located on the front and rear panels of the instrument. These are stan-

1 USB Host

dard USB 2.0 Type A receptacles designed to accept only RFP3000 Series Sensors or standard

USB keyboards, mice, and ash drives.

Four sensor trigger inputs are located on the front and rear panels of the instrument. These

are standard SMB receptacles designed to accept only BK Precision power sensor trigger ca-

2 Sync Ports

bles.

Do not attempt to connect anything other than RFP3000

sensors and trigger cables!

The output of the built-in 50 MHz programmable test source is available from a Type-N

3 RF Output

connector located on the front, or optionally on the rear panel of the instrument. This test

source is used to verify basic performance of sensors used with the RFM3000.

4 Display Screen

5

6

7

8

Color touch screen display for the measurement and trigger channels, screen menus, status

messages, text reports, and help screens.

Favorites key. (This function is not fully implemented at this time). Enables the user to setup

a customized menu to allow grouping frequently used menu items into one convenient menu.

Store image key saves a screen image of the meter to local storage. The images can be

copied to an external USB storage device.

Used to assist navigating between items on the display and in the menus. Unless the user is

in digit editing numeric entry mode.

Used for incrementing or decrementing numeric parameters, or scrolling through multi-line or

multi-page displays.

Selects an on-screen item or menu and completes a numeric or picklist entry

Toggles the instrument between “on” (fully powered) and “standby” (o, except for certain

low-power internal circuits) modes. Entering standby mode will perform a save of the current

instrument state before shutdown. Pressing and holding the On/Standby key for several seconds will force standby mode if the instrument has become non-responsive. In this case, no

context save is performed

Table 1.1 Front Panel

Page 13

General Information 13

1.5 Rear Panel

Refer to table 1.2 for a description of each of the illustrated items. The function and operation of all controls, indicators,

and connectors are the same on the standard and optional models.

Figure 1.2 Rear Panel

Page 14

General Information 14

Item Description

Four sensor inputs are located on the front and rear panels of the instrument. These are stan-

1 USB Host

2 Sync Ports

3 RF Output

4 Trig In

dard USB 2.0 Type A receptacles designed to accept only RFP3000 Series Sensors or standard

USB keyboards, mice, and ash drives.

Four sensor trigger inputs are located on the front and rear panels of the instrument. These

are standard SMB receptacles designed to accept only BK Precision power sensor trigger cables.

Do not attempt to connect anything other than RFP3000

sensors and trigger cables!

The output of the built-in 50 MHz programmable test source is available from a Type-N

connector located on the front, or optionally on the rear panel of the instrument. This test

source is used to verify basic performance of sensors used with the RFM3000.

BNC input for connecting an external trigger signal to the power meter. Voltage range is±5

volts, but the input impedance is 1 Megohm to allow use of common 10x oscilloscope probe

for a±50 volt input range.

5 Multi-I/O

6 LAN Ethernet

7 HDMI

8 AC Line Input

9 HDMI Cooling air intake.

10 GPIB

BNC input/output for exible use. May serve as a status or alarm output, signal level monitor, or settable voltage source

LAN connector for remote control and rmware updates. Allows DHCP or xed (IP / Subnet) setting mode. LAN parameters can be congured through the menu.

HDMI receptacle for connecting an external monitor to mirror front panel display. The image

resolution will be 800 x 480 and will be stretched to t the external full display size.

A multi-function power input module is used to house the AC line input, main power switch,

and safety fuse. The module accepts a standard AC line cord, included with the power meter.

The power switch is used to shut o main instrument power. The safety fuse may also be accessed once the line cord is removed. The instrument’s power supply accepts 90 to 264 VAC,

so no line voltage selection switch is necessary.

24-pin GPIB (IEEE-488) connector for connecting the power meter to the remote control

General Purpose Instrument Bus. GPIB parameters can be congured through the menu.

Replace fuse only with specied type and rating:

1.0A-T (time delay type), 250 VAC.

Table 1.2 Rear Panel

1.6 Touch Screen Display

The RFM3000 can be controlled through the touch screen display and by use of the front panel buttons. Table 1.3

describes the dierent areas of the display layout of the RFM3000. Figure 1.3 shows the Graph Display mode of the

instrument using the Pulse Measure mode with a menu exposed. Figure 1.4 shows the same measure mode with the

Page 15

General Information 15

menus hidden. The Text Display mode of the instrument provides a table view of measured parameters. Parameters

depend on the Measure mode selected. See Section Menu Referencefor more information on the display format.

Figure 1.3 Display

Figure 1.4 Display Hidden Menu

Page 16

General Information 16

Item Description

Indicates the measurement acquisition status of the unit. In Pulse mode, the sample rate and

1 Status Bar

number of sweeps per second are also shown. In Statistical mode, it indicates the gating setting in use, run time, and number of points.

Displays a table of measurements for each channel that is enabled on the meter. In Pulse and

2 Parameters

Continuous mode, measurements indicated are for power levels at each marker and the average power between the markers. For Statistical mode, the measurements are Average power,

Maximum power, and Peak-to-Average Ratio or Crest Factor.

This area indicates which channels are ON and their individual scale and vertical center.

3 Channel Status

The base RFM3000 model only permits two sensors to be

active at any one time. With the RFM300-4CH

option, four sensors can be active at any one time.

4 Main Display

5 Menu Bar

This area will show a plot when in Graph Display mode or a table of parameters when in Text

Display mode for the measurement mode selected.

Select to show and to hide the on-screen menus.

6 Menu Parth Used to navigate the menu structure. Shows the menu that will be displayed when selected.

7

Current

Menu/Home

8 Horizontal Scale

9 Measure Mode

Displays the name of the current menu and provides a home shortcut to the top-level Main

menu. When in the Main or top level menu, this eld is not available.

For Pulse and Continuous mode, indicates the time per division for the waveform display. In

Statistical mode, the horizontal scale for the CCDF graph is in dBr (dB relative).

Indicates and allows selection of the current Measurement mode. Modes available are Continuous, Pulse, and Statistical.

10 Display Mode

Indicates and allows selection of the current Display mode in use. Modes available are Graph

and Text.

The Graph Display mode for Continuous Measure mode

will be a at trace. It is best to use Text Display mode

for continuous signal measurements.

Table 1.3 Display

Page 17

Installation

This section contains unpacking and repacking instructions, power requirements, connection descriptions, and preliminary

checkout procedures.

2.1 Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items from the shipping carton,

and check for any obvious signs of physical damage that may have occurred during transportation. Report any damage

to the shipping agent immediately. Save the original packing carton for possible future reshipment. Every power supply

is shipped with the following contents:

• RFM3000 RF Power Meter

• Line Cord

• Information Card (describes where to download the latest manual, software, utilities)

2.2 Input Power & Fuse Requirements

The RFM3000 is equipped with a switching power supply that provides automatic operation from a line voltage input

within: The supply has a universal AC input that accepts line voltage input within:

Voltage: 100 - 240 VAC (+/- 10 %)

Frequency: 43 to 63 Hz

Input Power: 70 VA MAX.

Before connecting the instrument to the power source, make certain that a 1.0-ampere

time delay fuse (type T) is installed in the fuse holder on the rear panel.

Before removing the instrument cover for any reason, position the input module power

switch to o (0 = OFF; 1 = ON) and disconnect the power cord.

Connect the power cord supplied with the instrument to the power receptacle on the rear panel. See gure ??

The included AC power cord is safety certied for this instrument operating in rated range. To change a cable or add

an extension cable, be sure that it can meet the required power ratings for this instrument. Any misuse with wrong

or unsafe cables will void the warranty.

Page 18

Installation 18

2.3 Connections

Sensor(s)

Note:

Trigger

Note:

The Sync cable must be connected to the Sync port corresponding to the USB port for the sensor Channel in use.

Compatible sensors can be connected to any of the USB ports on the front or rear panel. The base

RFM3000 model only permits two sensors to be active at any one time. With the RFM3000-4CH

model, four sensors can be active at any one time. Sensors become active when plugged into a USB

port or immediately if already plugged in when the RFM3000 powers up.

The base RFM3000 model only permits two sensors to be active at any one time.

With the RFM3000-4CH option, four sensors can be active at any one time.

Most triggered applications can use the RF signal applied to the sensors for triggering. For measurements requiring external triggering, connect the external trigger signal to the Trig In BNC connector

on the rear panel and connect a Sync cable from the Sync connector on the meter to the Multi I/O

port on the sensor.

Remote

If the instrument is to be operated remotely using the GPIB (IEEE-488) bus, connect the instrument

to the bus using the rear panel GPIB connector and appropriate cable. For Ethernet control, connect

to the rear panel LAN connector. In most cases, it will be necessary to congure the interface using

the System > I/O > Cong menu.

2.4 Preliminary Check

The preliminary check veries that the instrument is operational and has the correct software installed. It should be

performed before the instrument is placed into service.

To perform the preliminary check, proceed as follows:

1. Press the lower half (marked "O") of the power switch in the center of the power module on the rear panel.

2. Connect the AC (mains) power cord to a suitable AC power source; 90 to 264 VAC, 47 to 63 Hz.

– The power supply will automatically adjust to voltages within this range.

3. Press the upper half (marked "—") of the power switch in the center of the power module on the rear panel, it will

enter standby mode.

4. Press the ON/STBY key on the front panel to turn the instrument on. The cooling fan and display backlight should

turn on.

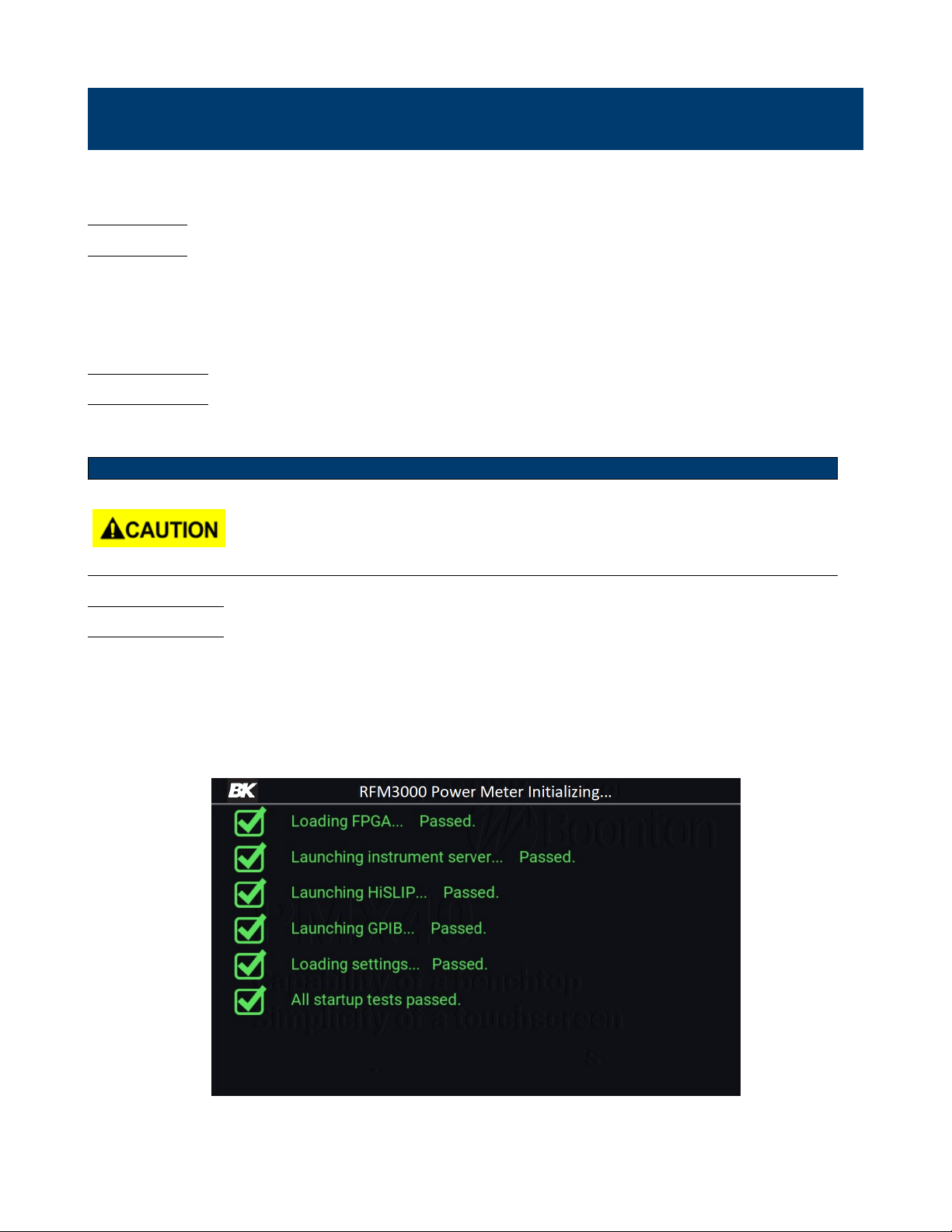

5. A bootup screen should appear that shows the boot status. After a self-check, the instrument will execute the

application program. There will be some temporary dialogs indicating application initialization and channel updating.

After several moments, a screen similar to gure 2.1 should be displayed.

Page 19

Installation 19

Figure 2.1 Power-On Display

6. On the front panel, press the select key to bring up the on-screen menu. From the Main menu, use the touch screen

or the navigation keys on the front panel to browse to System > Reports > Conguration and select Show. A display

similar to gure 2.2 will appear.

Figure 2.2 Conguration Report Display

Page 20

Getting Started

This chapter will introduce the user to the RFM3000 RF Power Meter. The chapter will identify display organization,

list the conguration of the instrument after initializing, and provide practice exercises for front panel operation. For

additional information, see Section 4 Operation.

3.1 Initialization

The steps below initialize the RFM3000 and prepare it for normal operations. Step 3 should only be performed when you

wish to set the meter operations to a known state. This is typically done when you rst power on the instrument or at

the start of a new test.

1. If the main power is o, press the power switch located on the rear panel. See gure 1.2.

2. Press the key to turn on the RFM3000.

3. After a self-check, the instrument will execute the application program.

– There will be some momentary dialogs indicating application initialization and channel updating.

– After the last dialog the main screen will be on the display.

When selecting a sensor for an exercise or a measurement, be sure you know the power range of

the sensor. Operation beyond the specied upper power limit may result in a permanent change

of characteristics or burnout.

4. Connect the sensor USB cable to the Channel 1 input on the front or rear of the instrument.

– When the sensor is connected or disconnected, the instrument will momentarily show a channel update dialog.

Note:

Connecting the Sync cable from the Multi I/O port on the sensor to the corresponding Sync port on the instrument

for the sensor in use is necessary if using an external trigger or when performing measurements across multiple channels

5. Use the nagivation keys to navigate the menus.

– The touch screen can be used to navigate the menus.

6. From the Main menu, select the Measure menu, and navigate to the Meas. Settings option.

7. Select Initialize.

– This will load the default operating parameters listed in table 3.1.

– This table only shows the parameters that are aected by initialization.

Page 21

Getting Started 21

Parameter Default

Measure Mode Select Graph

Parameters Related to the Measure Menu Measurement

Measurement Run

Parameters Related to the Display Menu

View Graph

Parameters Related to the Channel > Channel # > Menus

Channel1 On

Channel2 On

Channel3 On(4 CH option)

Channel4 On(4 CH option)

Vertical Scale 10 dB/Div

Vertical Center -20.00 dBm

Averaging 8

Units dBm

Video BW HIGH

Peak Hold OFF

dB Oset 0 dB

Parameters Related to the Time Menu

Timebase 100 uS/div

Position 5.0 divisions

Trigger Delay 0.0 uS

Parameters Related to the Trigger Menu

Holdo 0 uS

Trigger Mode AUTOPKPK

Trigger Slope Positive

Trigger Source CH1

Parameters Related to the Markers Menu

Marker 1 -300 uS

Marker 2 300 uS

Parameters Related to the Pulse Def. > CH# Pulse Def > Menus

Distal 90%

Mesial 50%

Proximal 10%

Pulse Units Watts

Start Gate 5.00%

End Gate 95%

Parameters Related to the Stat Mode Menu

Cursor Mode Power

Table 3.1 Default

Page 22

Getting Started 22

3.2 Taking Measurements

To perform accurate measurements, the following is a minimum list of things you should know about the signal that you

wish to measure.

Signal Frequency

The center frequency of the carrier must be known to allow sensor frequency response compensation.

Modulation Bandwidth

If the signal is modulated, know the type of modulation and its bandwidth. Note that power sensors respond only to

the amplitude modulation component of the modulation, and constant envelope modulation types such as FM can be

considered a CW carrier for power measurement purposes.

3.2.1 Continuous Mode

Continuous mode is best for measuring repetitive signals. Since this mode performs a continuous measurement, it does

not dierentiate between the times a pulsed or periodic signal is o, and the times it is on. If you wish to make

measurements that are synchronous with a period of a waveform, consider using Pulse mode instead.

Continuous mode is best for the following types of measurement:

• Moderate signal level (above -40 dBm for Peak sensors and -60 dBm for CW sensors).

• Signal that is CW or continuously modulated with a modulation bandwidth that is less than the VBW of the sensor

in use.

• Signal modulation may be periodic, but only non-synchronous measurements are needed (overall average and peak

power).

• Noise-like digitally modulated signals such as CDMA and OFDM when only average measurements are needed.

The measured result is the average power of the signal. Since the graphic display would basically just show a straight

line, measurements in Continuous mode are best viewed using the Text Display mode. Figure 3.1 shows a two-channel

measurement displaying an average, minimum, and maximum power in Continuous mode.

Figure 3.1 Average

Page 23

Getting Started 23

3.2.2 Pulse Mode

For periodic or pulsed signals, it is often necessary to analyze the power for a portion of the waveform, or a certain region

of a pulse or pulse burst. For these applications, the RFM3000 Series has a triggered Pulse mode.

The trigger signal can be either internal, triggered from a rising or falling edge on the measured signal; or external,

triggered from a rear-panel BNC input. The trigger level and polarity are both programmable, as is the trigger delay time

and trigger holdo time. Displays of both pre- and posttrigger data are available, and an auto-trigger mode can be used

to keep the trace running when no trigger edges are detected.

An auto peak-to-peak trigger level setting can be chosen to automatically set the trigger level based on the currently

applied signal. The timebase can be set from 5 ns/div to 50 ms/div. The RFM3000’s graphical display has 10 horizontal

and 8 vertical divisions. Vertical units can be set in dBm, Watts, and dB Volts. Setting vertical resolution does not aect

the sensitivity of the instrument and is provided for ease of viewing.

Programmable markers can be moved to any portion of the trace that is visible on the screen. They can be used to mark

regions of interest for detailed power analysis. The instrument can display power at each marker, as well as average,

minimum, and maximum power in the region between the two markers. This is very useful for examining the power

during a TDMA or GSM burst when only the modulated portion in the center region of a timeslot is of interest.

By adjusting trigger delay and other parameters, it is possible to measure the power of specic timeslots within the burst.

Trigger holdo allows burst synchronization even if there is more than one edge in the burst that may satisfy the trigger

level. Set the holdo time to slightly shorter than the burst’s repetition interval to guarantee that triggering occurs at

the same point in the burst each sweep. Figure 3.2shows marker measurements for pulses on CH1 and CH2.

Figure 3.2 Marker Measurements

Pulse mode is only available when using RFP Series power sensors and is the best choice for most pulse modulated and

periodic signals. Pulse mode requires a repeating signal edge that can be used as a trigger, or an external trigger pulse

that is synchronized with the modulation cycle.

Pulse mode performs measurements that are synchronous with the trigger (that is the measurements are timed or gated)

so that the same portion of the waveform is measured on each successive modulation cycle. Multiple modulation cycles

may be averaged together, and measurement intervals may span both before and after the trigger.

Page 24

Getting Started 24

Pulse mode is best for the following types of measurements:

• Moderate signal level (above about -40 dBm except when modulation is o).

• The signal is periodic.

• A time snapshot of a single event is needed (minimum single-shot time is 200 nanoseconds).

• Typical modulation and signal types: LTE, 5G, RADAR, SatCom, TCAS, Bluetooth, Wireless LAN.

3.2.3 Statistical Mode

Certain modulated signals are completely random and provide no event that can serve as a trigger for measurements.

CDMA or OFDM are common examples. The RFM3000’s Statistical mode was designed to provide measurements for

these types of signals.

Statistical mode is only available when using peak power sensor. It is the best choice for analyzing signals with a high

crest factor, that are noise-like with random or infrequent peaks, or are modulated in a random, non-periodic fashion.

Statistical mode yields information about the probability of occurrence of various power levels without regard for when

those power levels occurred.

In Statistical mode the instrument continuously samples the input signal and processes all of the samples to build power

histograms. Many digitally modulated spread-spectrum formats use bandwidth coding techniques or many individual

modulated carriers to distribute a source’s digital information over a wide bandwidth, and temporally spread the data

for improved robustness against interference. When these techniques are used, it is dicult to predict when peak signal

levels will occur. Analysis of millions of data points gathered during a sustained measurement of several seconds or more

can yield the statistical probabilities of each signal level with a high degree of condence.

Statistical mode is best forthe following types of measurements:

• Moderate signal level (above about -40 dBm except when modulation is o).

• Noise-like digitally modulated signals such as CDMA (and all its extensions) or OFDM when probability information

is helpful in analyzing the signal.

• Any signal with random, infrequent peaks, when you need to know the peak-to-average ratio or Crest Factor and just

how infrequent those peaks are.

Complementary Cumulative Distribution Function (CCDF)

The statistical analysis of the current sample population is displayed using a normalized Complementary Cumulative

Distribution Function (CCDF) presentation shown in gure ??. The CCDF is the probability of occurrence of a range

of peak-to-average power ratios on a log-log scale. CCDF is non-increasing in y-axis and the maximum power sample

lies at 0%. A cursor allows measurement of power or percentage at a user-dened point on the CCDF. As with all other

graphical displays, the trace can be easily scaled and zoomed. The statistical data may be presented as a table in Text

Display mode.

The CCDF is a useful tool for analyzing communication signals that have a Gaussian-like distribution (CDMA, OFDM)

where signal compression can be observed at rarely occurring peaks. It is most often presented graphically using a log-log

format where the x-axis represents the relative oset in dB from the average power level and the log-scaled y-axis is the

percent probability that power will exceed the x-axis value.

Page 25

Getting Started 25

CCDF CCDF with Cursor Menu

Figure 3.3 CCDF

In a non-statistical peak power measurement, the peak-to-average ratio is the parameter that describes the headroom

required in linear ampliers to prevent clipping or compressing the modulated carrier. The meaning of this ratio is easy

to visualize in the case of simple modulation in which there is close correspondence between the modulating waveform

and the carrier envelope. When this correspondence is not present, the peak-to-average ratio alone does not provide

adequate information.

It is necessary to know what fraction of time the power is above (or below) particular levels. For example, some digital

modulation schemes produce narrow and relatively infrequent power peaks that can be compressed with minimal eect.

The peak-to-average ratio alone would not reveal anything about the fractional time occurrence of the peaks, but the

CCDF clearly shows this information. In Figure 3-8, assume a full length run of one hour plus has been made and the

CCDF is analyzed. At 0% is the maximum peak power that occurred during the entire run. At 1% is the power level

that was exceeded only 1% of the time during the entire run.

Note that this analysis does not depend upon any particular test signal, or upon synchronization with the modulating

signal. The analysis can be done using actual communication system signals. Normal operation is not disturbed by

the need to inject special test signals. This type of analysis is particularly suited to the situation in which the bit error

rate (BER) or some other error rate measure is correlated with the percentage of time that the signal is corrupted. If

known short intervals of clipping are tolerable, the CCDF can be used to determine optimum transmitter power output.

The CCDF is also used to evaluate various modulation schemes to determine the demands that will be made on linear

ampliers and transmitters and the sensitivity to non-linear behavior.

Page 26

Operation

This section presents the control menus and procedures for operating the RFM3000 in the manual mode. All the display

menus that control the instrument are illustrated and accompanied by instructions for using each menu item.

4.1 Control Menus

The menus that control the RFM3000 RF are accessed from the top-level MAIN menu. Display the MAIN menu by

selecting the icon on the display. The Menus and parameters may be selected by using the navigation keys or the

touch screen.

Some menus have mode-dependent properties. Typically, one or more menu boxes in a submenu may change as the

measurement mode is changed from Continuous to Pulse to Statistical. Section Menu Reference these menus are

indicated for mode dependency.

Menus with more selections than what ts on the display can be scrolled with the touch screen or front panel buttons.

4.2 Parameter Date Entry and Selection

The RFM3000’s parameters can be changed in various ways depending on the type of parameter being addressed.

4.2.1 Numerical Data Entry & Drop Down Menus

Numerical data can be incremented/decremented by selecting the “+” and “–“ icons with the front panel keys or by

touching them. Selecting the numeric setting brings up an on-screen numeric keypad as shown in gure 4.1.

Some parameters use a drop down menu to select a setting. The Trigger source setting in gure 4.1 is an example of a

drop down menu. Use the arrow up and down icons to cycle through the settings or select the value to view all available

option in the drop down menu.

Numeric Keypad Trig Source Drop Down Menu

Figure 4.1 Numerical Data Entry & Drop Down Menus

Page 27

Operation 27

4.3 Menu Reference

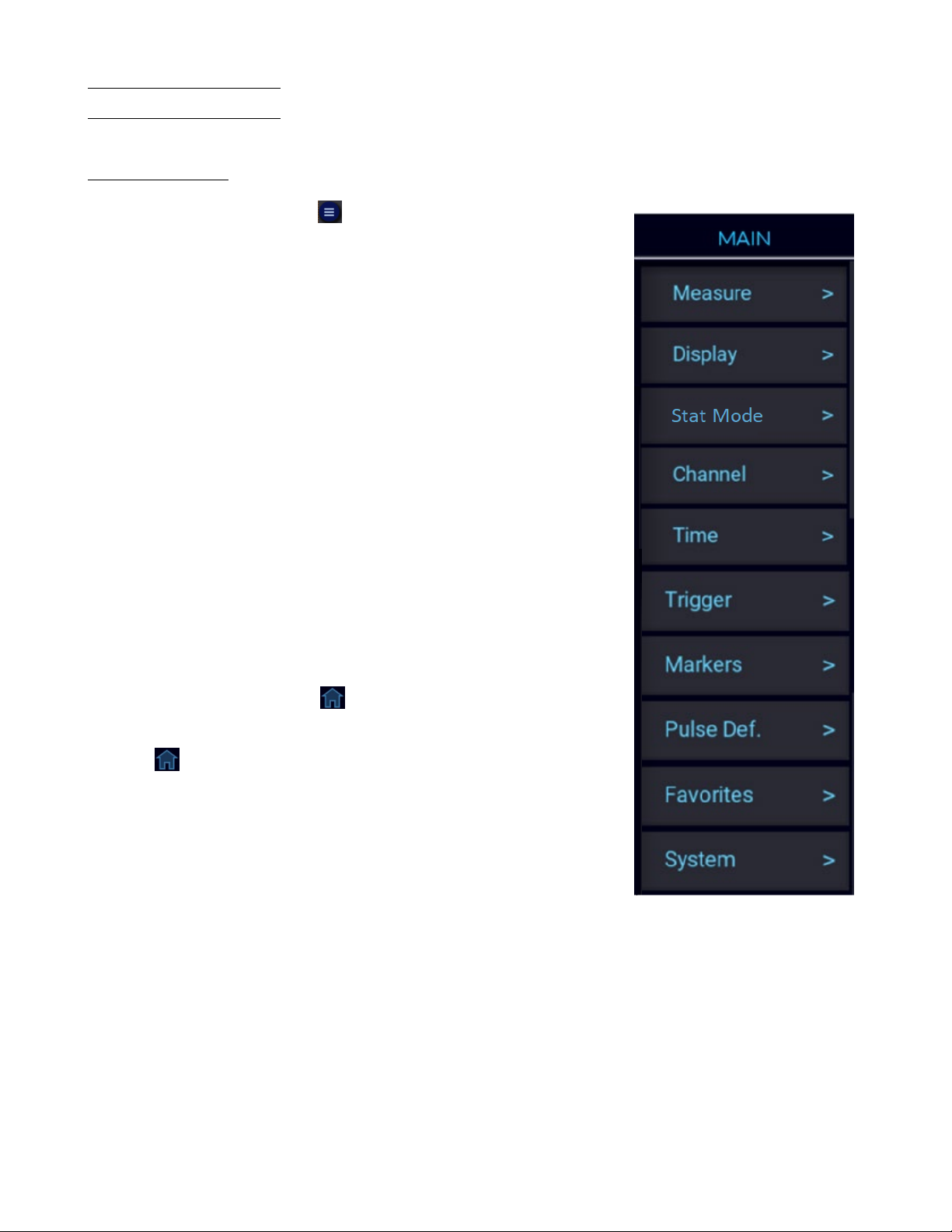

4.3.1 Main Menu

To open the Main menu press the icon.

The Main Menu shown in gure 4.2 is the top most menu level from which

all other menus originate.

Measure >

Display >

Stat. Mode >

Channel >

Time >

Trigger >

Markers >

Pulse Def. >

Favorites >

System >

When navigating any submenu the icon will appear to the right of the

submenu name.

Press the icon to return to the main menu.

Figure 4.2 Main Menu

Page 28

Operation 28

4.3.2 Measure >

To enter the Measure menu:

Press the icon then select the Measure menu.

The available setting vary depending on the mode selected. See gure 4.3 to view the available settings in each menu.

Measurement

Toogle the state of the data acquisition mode for taking measurements. If Measurement is set to Run, the RFM3000

immediately begins taking measurements (Continuous and Statistical modes), or arms its trigger and takes a measurement

each time a trigger occurs (Pulse Mode). If set to Stop, the measurement will begin (or be armed) if Start is selected

under the Single Sweep setting (Pulse Mode Only), and will stop once the measurement criteria (averaging) has been

satised.

Meas. Clear/Stat Capture

Selecting Execute clears display traces, data buers, and clears averaging lters to empty. In Statistical Measure mode,

the menu item is replaced with Stat Capture and selecting Reset clears the acquired sample population.

Single Sweep

Only available in Pulse mode. Select to start a single measurement cycle in Pulse mode when Measurement is set to

Stop. Enough trace sweeps must be triggered to satisfy the channel averaging setting.

Meas. Settings

This will load the default operating parameters listed in table 3.1. Only the settings shown in the table are aected and

all others remain in their current state.

Cont. Mode

Measure Menu

Pulse Mode

Measure Menu

Figure 4.3 Measure Menus

Stat. Mode

Measure Menu

Page 29

Operation 29

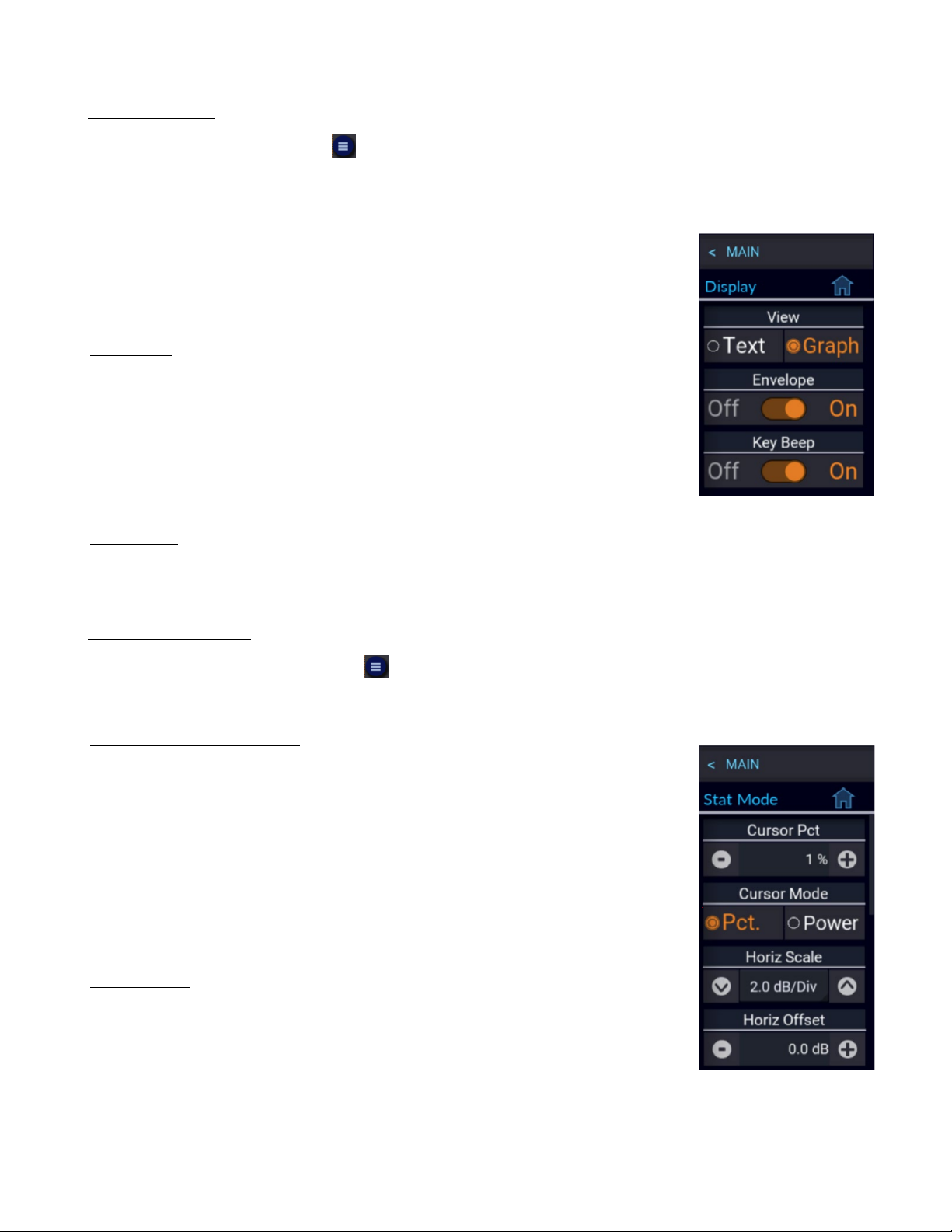

4.3.3 Display >

To enter the Display menu press the icon then select the Display menu.

View

Toogle between Text and Graph view. Text view displays a table of measurements for

the current measurement mode. In Continuous mode, selecting Text displays the enabled

channel power as shown in gure 3.1. Selecting Graph displays the trace graphical view.

Envelope

Enables/disables the Envelope display mode. In Pulse and Modulated modes, the Envelope display is used to highlight the range of signal excursions. When Envelope display

mode is On, the trace is drawn as a wide line. The line is lled in between the minimum

and maximum power readings. A series of vertical pixels, representing the range of signal

excursions or "envelope" of the signal will be illuminated for each horizontal trace pixel.

Envelope display is only available for Peak Power sensors.

Key Beep

Enable/disable the audible key beep.

4.3.4 Stat. Mode >

To enter the Stat. Mode menu press the icon then select the Stat. Mode menu.

Cursor Pct./Cur Pow Ref

Sets the CCDF cursor to the desired probability. When Cursor mode is set to Power, the

menu item changes to Cur Pow Ref and sets the desired power

Cursor Mode

Select the independent variable for the CCDF cursor. If Percent is selected, probability

at the cursor’s intersection with the CCDF curve will be measured. If Power is selected,

relative power at the cursor’s intersection with the CCDF curve will be measured.

Figure 4.4 Display Menu

Horiz Scale

Select the horizontal scale for the statistical graphic display.

Horiz Oset

Select the horizontal oset for statistical graphic display.

Figure 4.5 Stat. Mode

Page 30

Operation 30

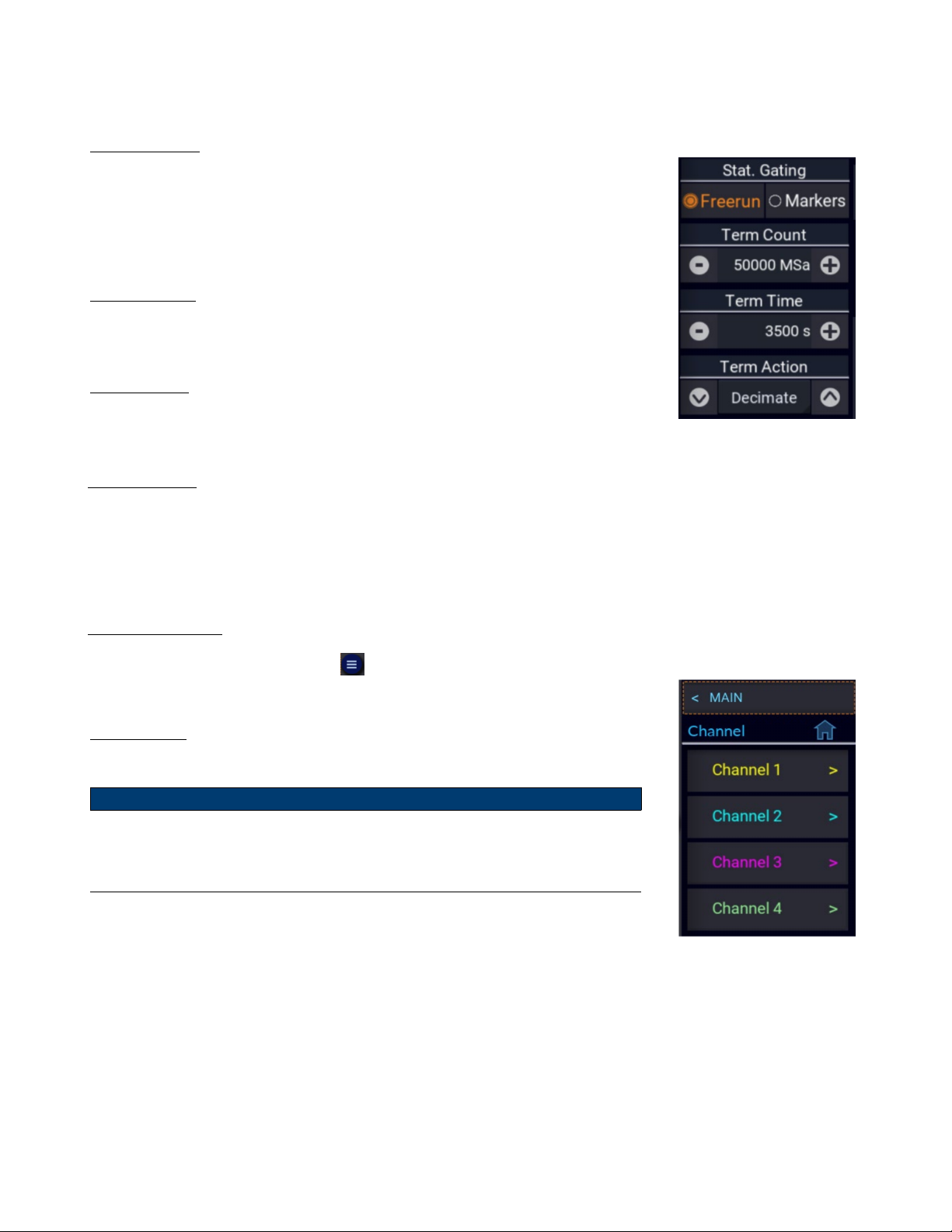

Stat. Gating

Select Freerun or Markers gating for statistical acquisition. If Freerun is selected, all

the samples are acquired without regard of sweep acquisition. If Markers are selected,

then only samples within the time marker interval on the Pulse mode triggered sweep

will be included in the statistical sample population.

Term Count

Sets the terminal sample count for the CCDF acquisition.

Term Time

Sets the terminal running time for the CCDF acquisition.

Figure 4.6 Stat. Mode

Term Action

Select the action to take when either the terminal count is reached or terminal time has elapsed. Selecting Decimate will

divide all sample bins by 2 and continue. The total sample count will be halved each time a decimation occurs. Selecting

Restart clears the statistical sample population and starts a new one. Selecting Stop will stop accumulating samples and

hold the result.

4.3.5 Channel >

To enter the Channel menu press the icon then select the Channel menu.

Channel #

Select the channels settings menu to be congured.

Note:

The base RFM3000 model only permits two sensors to be active at any one time.

With the RFM-4CH option, four sensors can be active at any one time.

Figure 4.7 Channels

Page 31

Operation 31

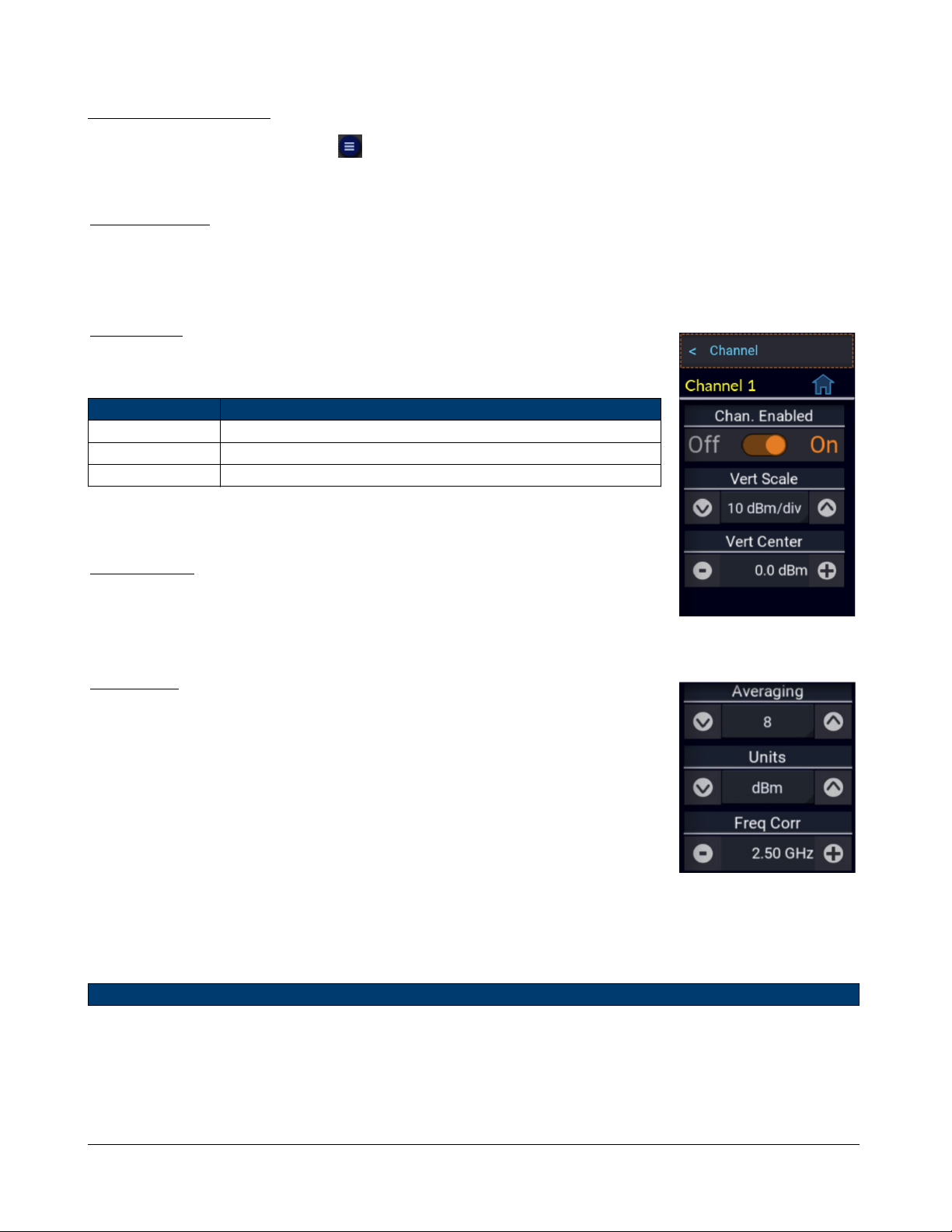

4.3.6 Channel Settings

To enter the Channel menu press the icon then select the Channel > Channel # menu.

Chan Enabled

Toggle the display of the trace and measurements for the selected channel. The channel may still be used as a trigger source when set to O.

Vert Scale

Set the power or voltage vertical axis level for the trace display based on the untis as

shown in table 4.8

Units Scale

dBm 0.1, 0.2, 0.5 1, 2, 5, 10, 20, 50 dB/div

Watts 1 pW to 500 MW/div in a 1-2-5 progression

Volts 1 µV to 100 kV/ div in a 1-2-5 progression

Table 4.1 Vertical Scale Range

Vert Center

Set the power or voltage, horizontal centerline, level of the graph for the specied

channel in the selected channel untis.

Averaging

Only available in Pulse and Statistical modes. Set the number of traces averaged together to form the measurement result on the selected channel. Averaging can be used

to reduce display noise on both the visible trace, marker, and automatic pulse measurements.

Trace averaging is a continuous process in which the measurement points from each

sweep are weighted (multiplied) by an appropriate factor and averaged into the existing

trace data points.

The most recent data will always have the greatest eect on the trace waveform, and

older measurements will be decayed at a rate determined by the averaging setting and

trigger rate. This averaging technique is often referred to as “exponential” averaging

because averaging imposes a rst-order Innite Impulse Response (IIR) exponential

lter with a time constant of "n" where n is the Average (number of averages) setting.

Note:

Figure 4.8

Channel Setttings

Figure 4.9

Channel Setttings

For timebase settings of 200 ns/div and faster, the RFP3000 Series sensors acquire samples using a technique called

equivalent time or random interleaved sampling (RIS). In this mode, not every pixel on the trace gets updated on

each sweep, and the total number of sweeps needed to satisfy the average setting will be increased by the sample interleave ratio of that particular timebase. At all times the average trace is the average of all samples for each pixel,

and the min/max are the lowest and highest of that same block of samples for each pixel.

Page 32

Operation 32

Units

Select the channel units. The trace may be shown in units of dBm, Watts, or Volts. The Units selection determines the

range of the scale values and also aects displayed text and measurement values.

Freq. Corr

Sets the measurement frequency for the RF signal that is applied to the sensor for the current measurement. The

appropriate frequency calibration factor from the sensor’s calibration table will be interpolated and applied automatically.

Application of this calibration factor compensates for the eect of variations in the atness of the sensor’s frequency

response.

Note:

The power sensor has no way to determine the carrier frequency of the applied signal, so the user must always enter

the frequency.

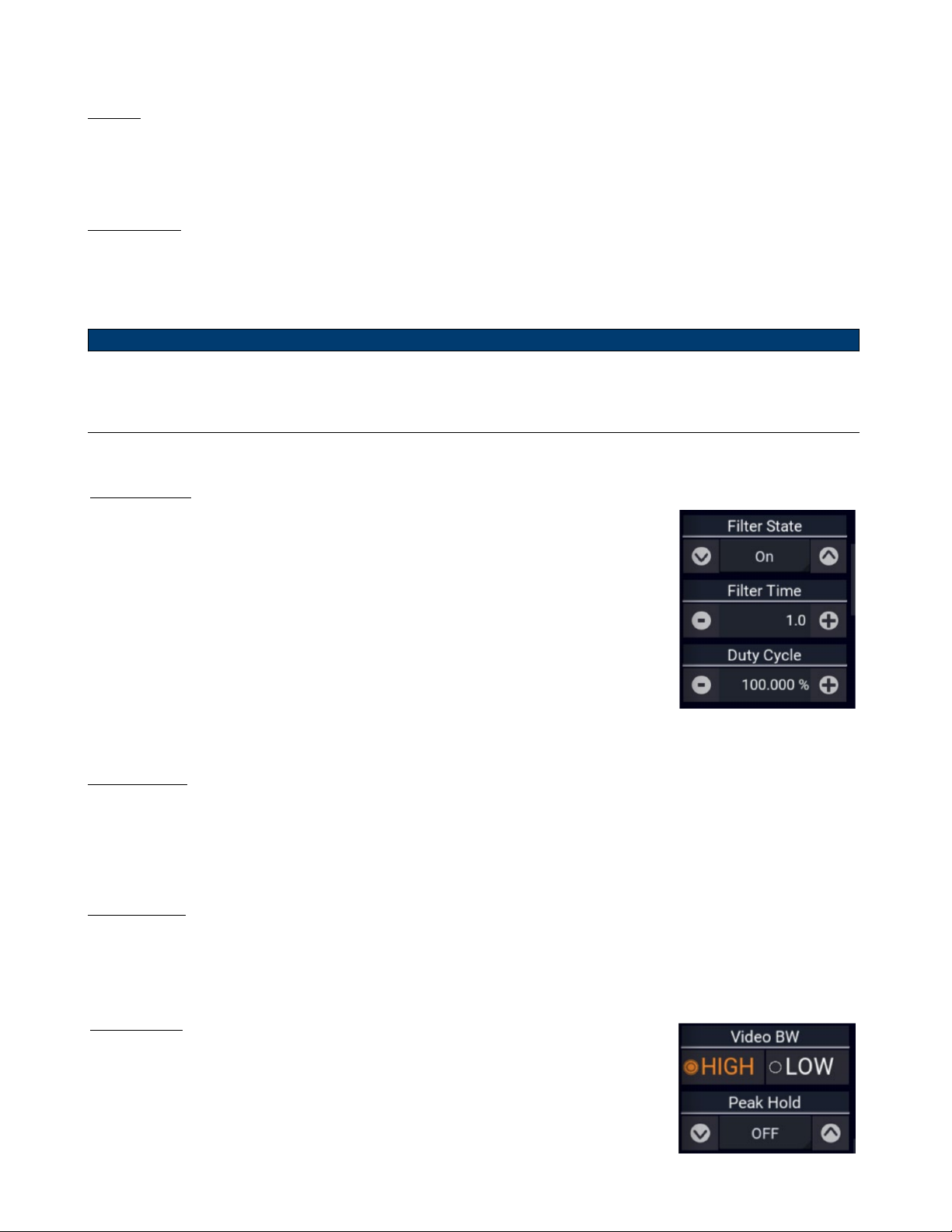

Filter State

Available in Continuous mode only. Sets the current value of the integration lter. The

lter can be set to O, On, or Auto.

O, provides no ltering, and can be used at high signal levels when absolute minimum

settling time is required.

On, allows a user-specied integration time to be entered for use.

Auto, uses a variable amount of ltering, which is set automatically by the power meter based on the current signal level to a value that gives a good compromise between

measurement noise and settling time at most levels.

Figure 4.10

Channel Setttings

Filter Time

Available in Continuous mode only. Sets the length of the integration lter. The lter is a “sliding window” which

averages samples taken within a time window whose duration is set by this eld. All samples within the time window are

equally weighted.

Duty Cycle

Available in Continuous mode only. Sets the duty cycle in percent for calculated CW pulse power measurements. Setting

the duty cycle to 100% is equivalent to a CW measurement.

Video BW

Sets the sensor video bandwidth of the selected channel. HIGH is appropriate for most

measurements. The actual bandwidth depends upon the sensor model.

LOW bandwidth oers additional noise reduction for CW or signals with very low

modulation bandwidth. If LOW bandwidth is used on signals with fast modulation,

measurement errors may result if the sensor cannot track the fast-changing envelope

of the signal.

Figure 4.11

Channel Setttings

Page 33

Operation 33

Peak Hold

Set the operating mode of the selected channel’s peak hold function.

When set to OFF, peak values are not held.

When set to instantaneous (INST) instantaneous peak readings are held until reset by a new acquisition or cleared

manually. This setting is used when it is desirable to hold the highest peak over a long measurement interval without

any decay.

When set to average (AVG) peak readings are held for a short time, and then decayed towards the average power at a rate

proportional to the Averaging setting. This is the best setting for most signals, because the peak will always represent

the peak power of the current signal, and the resulting peak-to-average ratio will be correct shortly after any signal level

changes.

dB Oset

Sets a measurement oset in dB for the selected channel. This is used to compensate for external couplers, attenuators, or ampliers in the RF signal path ahead of the

power sensor.

Zero

Performs a zero oset null adjustment. The sensor does not need to be connected to

any calibrator for zeroing. This action removes the eect of small, residual power osets, and should be performed prior to low-level measurements. The procedure is often

performed in-system. There should be no RF signal applied to the sensor input prior to

zeroing.

Figure 4.12

Channel Setttings

Fixed Cal

Performs a single point sensor gain calibration of the selected channel at 0 dBm and the current frequency setting. This

requires a calibrated 0 dBm (1.00 mW) signal source at the current measurement frequency. This procedure calibrates

the sensor’s gain at a single point. At other levels, that gain setting is combined with stored linearity factors to compute

the actual power.

The built-in test source of the RFM3000 is not a suciently calibrated source for performing

a xed calibration. An external calibration source is required. Note that xed calibration is

NOT REQUIRED for USB power sensors.

Page 34

Operation 34

4.3.7 Time >

To enter the Time menu press the icon then select the Time tab.

Timebase

Controls the timebase, horizontal scale, of the Trace View. The Timebase pulldown

menu permits selection of xed timebase ranges from 5 ns/div to 50 ms/div (sensor

series dependent) in a 1-2-5 progression.

Position

Sets the location of the trigger point on the acquired trace waveform. The Trig Delay

setting is in addition to this setting, and will cause the trigger position to appear in a

dierent location.

Figure 4.13

Time Setttings

Trig Delay

The trigger delay time is set in seconds with respect to the trigger. Positive values means that the trace display shows a

time interval after the trigger event. This positions the trigger event to the left of the trigger point on the display, and

is useful for viewing events during a pulse, or some xed delay time after the rising edge trigger. Negative trigger delay

mean that the trace display shows a time interval before the trigger event, and is useful for looking at events preceding

the trigger edge.

4.3.8 Trigger >

To enter the Trigger menu press the icon then select the Trigger tab.

Trigger Holdo

Set the trigger holdo time. Trigger holdo is used to disable the trigger for a specied amount of time after each trigger event. The holdo time starts immediately

after each valid trigger edge and will not permit any new triggers until the time has

expired. When the holdo time is up, the trigger re-arms, and the next valid trigger event (edge) will cause a new sweep. This feature is used to help synchronize the

power meter with burst waveforms such as a TDMA or GSM frame. The trigger holdo resolution is 0.01 microseconds, and it should be set to a time that is longer than

the burst duration but shorter than the frame repetition interval.

Trigger Level

Sets the threshold level for the trigger signal used in the Auto and Normal trigger

modes. The trigger level can be entered numerically or changed by using arrow keys.

The trigger level range has a range that is sensor model dependent (see the sensor

specications for your specic sensor model).

The trigger range is automatically adjusted to include the dB Oset parameter set for the

source channel. For example, if the trigger level = 10 dBm and the dB Oset is changed

Figure 4.14

Trigger Setttings

Page 35

Operation 35

from 0 to 20 dB, then the oset-adjusted trigger level will be displayed to the user as 30 dBm. Likewise, the maximum

trigger level range will be extended to 40 dBm. The trigger level set point and setting range are both shifted upward by

20 dB.

Trigger Mode

Set the trigger mode for synchronizing data acquisition with pulsed signals.

Normal mode will cause a sweep to be triggered each time the power level crosses the preset trigger level in the direction

specied by the trigger slope setting. If there are no edges that cross this level, no data acquisition will occur.

Auto mode operates in much the same way as Normal mode but will automatically generate a trace if no trigger edges

are detected for a period of time (100 to 500 milliseconds, depending upon timebase). This will keep the trace updating

even if the pulse edges stop.

The Auto PK-PK mode operates the same as Auto mode but will adjust the trigger level to halfway between the highest

and lowest power or voltage levels detected. This aids in maintaining synchronization with a pulse signal of varying level.

The Freerun mode forces unsynchronized traces at a high rate to assist in locating the signal.

Trigger Source

Set the trigger source used for synchronizing data acquisition. The CH # settings use the signal from the associated

sensor. Ext setting uses the signal applied to the rear panel TRIG IN connector.

The trigger source can be any of the resource channels (CH1, CH2, etc.), or the Ext(ernal) trigger input signal. The

Ind(ependent) trigger setting allows each connected sensor to trigger independently from its own RF input.

The external trigger is attached to the Trig In BNC connector on the rear of the RFM3000 Power Meter and requires a

TTL signal level, minimum pulse width of 10 ns, and maximum frequency of 50 MHz.

Note:

Connecting the Sync cable from the Multi I/O port on the sensor to the corresponding Sync port on the instrument

for the sensor in use is necessary if using an external trigger or when performing measurements across multiple channels.

Trigger Slope

Set the trigger slope or polarity. When set to +, trigger events will be generated when a signal’s rising edge crosses the

trigger level threshold. When – is selected, trigger events are generated on the falling edge of the pulse.

Page 36

Operation 36

Markers >

To enter the Markers menu press the icon then select the Markers > tab.

Marker #

Set the time position of marker 1 or 2 relative to the trigger. Note that time markers

must be positioned within the time limits of the trace window in the graph display. If

a time outside of the display limits is entered, the marker will be placed at the rst or

last time position as appropriate.

ΔTime

Displays the result of Marker 2 - 1 in seconds. This item is read only.

Figure 4.15

Marker Setttings

4.3.9 Pulse Def. >

To enter the Pulse Def menu press the icon then select the Pusle Def. > tab.

CH # Pulse Def

Select the channel to be congured.

Figure 4.16

Pulse Def Menu

4.3.10 CH# Pulse Def

To enter the CH# Pulse Def menu press the icon then select the CH# Pusle Def. > tab of the channel to be

congured.

Page 37

Operation 37

Distal

Sets the pulse amplitude percentage that denes the end of a rising edge or beginning

of a falling edge transition. Typically, this is 90% voltage or 81% power relative to the

top level of the pulse. This setting is used when making automatic pulse risetime and

falltime calculations.

Mesial

Sets the pulse amplitude percentage that denes the midpoint of a rising or falling

edge transition. Typically, this is 50% voltage or 25% power relative to the top level

of the pulse. This setting is used when making automatic pulse width and duty cycle

calculations.

Proximal

Sets the pulse amplitude percentage that denes the beginning of a rising edge or end

of a falling edge transition. Typically, this is 10% voltage or 1% power relative to the

top level of the pulse. This setting is used when making automatic pulse risetime and

falltime calculations.

Pulse Unites

Controls whether the distal, mesial, and proximal thresholds are computed as voltage or

power percentages of the top/bottom amplitudes. If Volts is selected, the pulse transition thresholds are computed as voltage percentages. If Watts are selected, they are

computed as power percentages.

units setting.

Many pulse measurements call for 10% to 90% voltage (which equates to 1% to 81% power) for risetime and falltime

measurements, and measure pulse widths from the half-power (–3 dB, 50% power, or 71% voltage) points. The Pulse

Units setting is independent of the channel’s display

Figure 4.17

CH# Pulse Def Menu

Start Gate

Sets the beginning of the pulse measurement region as a percentage of the pulse width. The Start Gate has a continuous

range of 0.0% to 40.0% of the pulse width and may be entered numerically or varied using the up or down arrows.

End Gate

Sets the end of the pulse measurement region as a percentage of the pulse width. The End Gate has a continuous range

of 60.0% to 100.0% of the pulse width and may be entered numerically or varied using the up or down arrows.

The Gate settings dene the measurement interval for the following power related pulse measurements: Pulse Average,

Pulse Peak, Pulse Minimum, and Pulse Droop/Tilt. Pulse timing measurements between mesial crossings such as width

and period are not aected. The purpose of the Pulse Gate setting is to exclude edge transition eects from the pulse

power measurements.

Page 38

Operation 38

4.3.11 Favorites >

To enter the Favorites menu press the icon then select the Favorites > tab.

This function is not fully implemented at this time). Enables the user to setup a customized menu to allow grouping

frequently used menu items into one convenient menu.

4.3.12 System >

To enter the System menu press the icon then select the System > tab.

The System menu displays the available system-level features and functionality.

Seonsr Data >

I/O Cong >

Calibration >

Exit >

Reports >

Update Software

cm

Figure 4.18 System Menu

Sensor Data >

To enter the Sensor Data menu press the icon then select the System > Sensor Data > tab.

Press Show to display information about the selected sensor in a pop-up log.

See gure 4.19.

Figure 4.19 CH1 Information

Figure 4.20 Sensor Data

Page 39

Operation 39

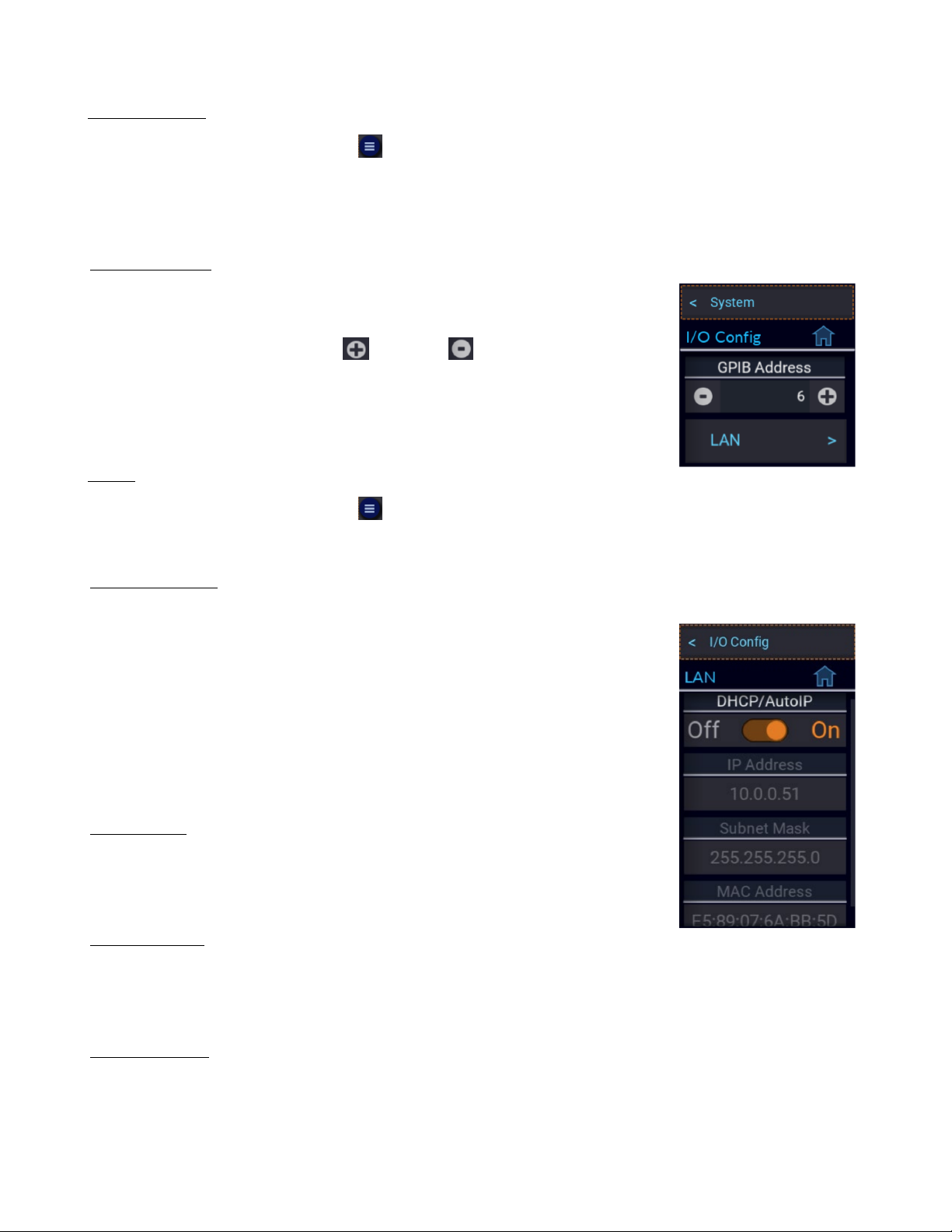

I/O Cong >

To enter the I/O Cong menu press the icon then select the System > I/O Cong > tab.

The RFM3000 supports remote communication over LAN and GPIB (optional).

GPIB Address

Set and View the current GPIB address in use for instruments equipped with GPIB

option.

To increae the GPIB address press the icon or the icon do decrease the address. Pressing the number box located between the increase and decrease icon will

open the numeric keypad. The numeric keypad can be used to instantaneously change

the GPIB address

LAN

Figure 4.21 I/O Cong

To enter the I/O Cong menu press the icon then select the System > I/O Cong > LAN > tab.

DHCP/AutoIP

Set the state of DHCP/AutoIP system for the Ethernet port.

If DHCP/AutoIP is enabled (On), the instrument will attempt to obtain its IP Address

and Subnet Mask, a DHCP (dynamic host conguration protocol) server on the network. If no DHCP server is found, the instrument will select its own IP Address and

Subnet Mask values using the AutoIP protocol.

If DHCP/AutoIP is disabled (O), the instrument will use the IP Address and Subnet

Mask values that have been set by the user.

IP Address

Set the Internet Protocol (IP) address of the Ethernet adapter. If DHCP/AutoIP mode

is enabled, this menu is read-only.

Subnet Mask

Figure 4.22 LAN

Set the subnet mask for the Ethernet adapter. If DHCP/AutoIP mode is enabled, this

menu is read-only.

MAC Address

Displays the MAC address for the Ethernet adapter. This menu item is read-only.

Page 40

Operation 40

Calibration >

To enter the Calibrator menu press the icon then select the System > Calibrator > tab.

Cal Output

Enable/disable the output of the built-in 0 dBm 50 MHz test source.

Note:

The built-in test source of the RFM3000 is not a suciently calibrated source for performing a xed calibration. An external calibration source is required.

Figure 4.23 Calibrator

Exit >

To enter the Exit menu press the icon then select the System > Exit > tab.

Exit to Desktop

Exits the RFM3000 Power Meter Main application to access the OS Desktop.

Shut Down

Shuts down power to the PMX40 putting the meter in standby mode and is the same

as pressing the ON/Standby button on the front panel.

Reports >

To enter the Reports menu press the icon then select the System > Reports > tab.

Conguration

Select Show to display an About dialog with conguration information for the

RFM3000 Power Meter like that shown in gure 2.2.

Figure 4.24 Exit

Figure 4.25 Reports

Page 41

Operation 41

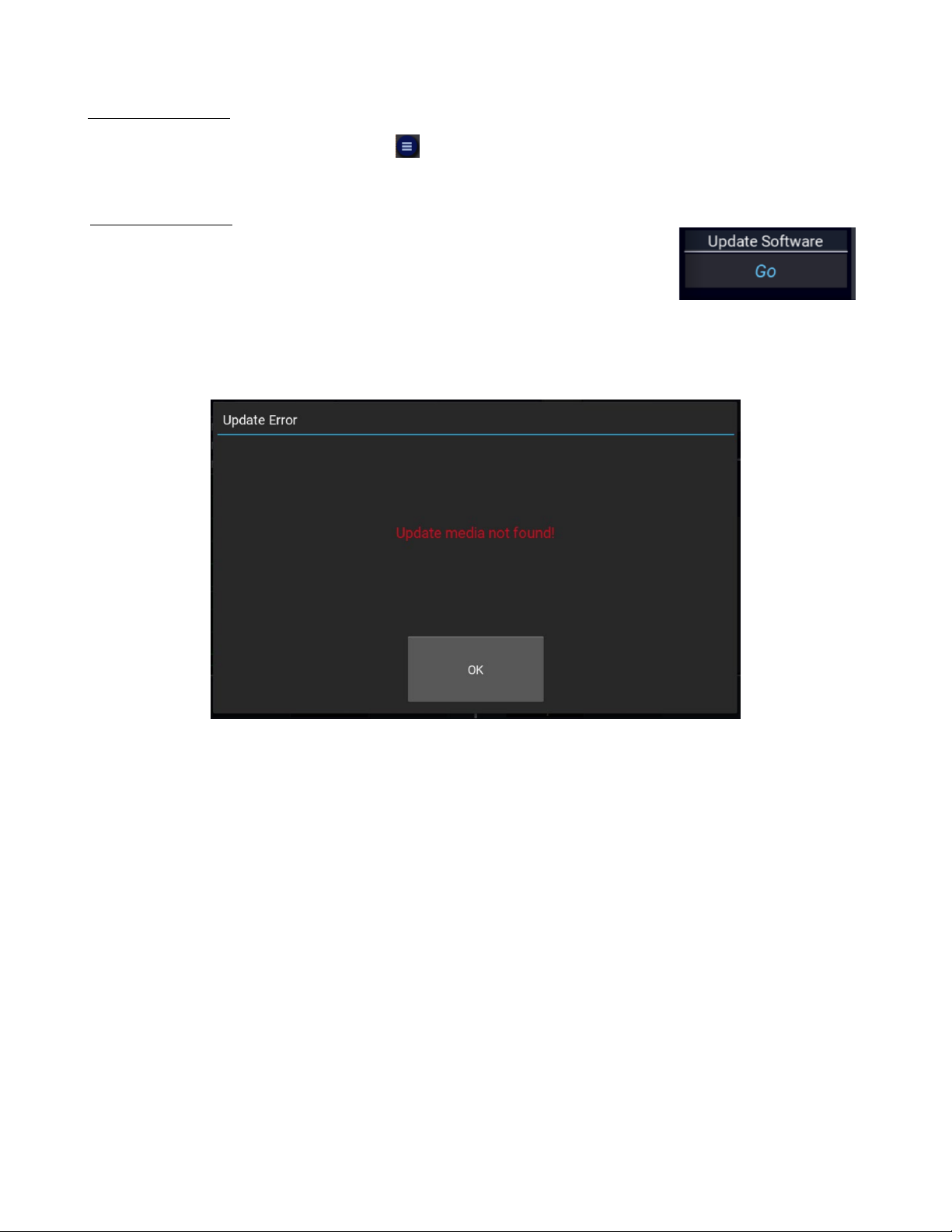

Update Software

To view the Update Sofware option press the icon then select the System > tab.

Update Software

Select Go to search the connected USB drive for the *.tar software update le and update or re-install the version found. If no valid le is found, the dialog in gure 4.27

appears.

Figure 4.26

Update Software

Figure 4.27 Update Error

Page 42

Application Notes

This section provides supplementary material to enhance your knowledge of the RFM3000 operation, advanced features, and measurement accuracy. Topics covered in this section include pulse measurement fundamentals, automatic

measurement principles, and an analysis of measurement accuracy.

5.1 Introduction to Pulse Measurements

5.1.1 Measurement Fundamentals

The following is a brief reaview of the power measurement fundamentals.

Unmodulated Carrier Power

The average power of an unmodulated carrier consisting of a continuous, constant amplitude sinewave signal is also

termed continuous wave (CW) power. For a known value of load impedance R, and applied voltage 𝑉

power is:

2

𝑉

𝑟𝑚𝑠

𝑃 =

𝑅

𝑤𝑎𝑡𝑡𝑠

, the average

𝑟𝑚𝑠

Power meters designed to measure CW power can use thermoelectric-based sensors which respond to the heating eect of

the signal or diode detectors which respond to the voltage of the signal. With careful calibration accurate measurements

can be obtained over a wide range of input power levels.

Modulated Carrier Power

The average power of a modulated carrier which has varying amplitude can be measured accurately by a CW type power

meter with a thermoelectric detector, but the lack of sensitivity will limit the range. Diode detectors can be used at low

power, square-law response levels. At higher power levels the diode responds in a more linear manner and signicant

error results.

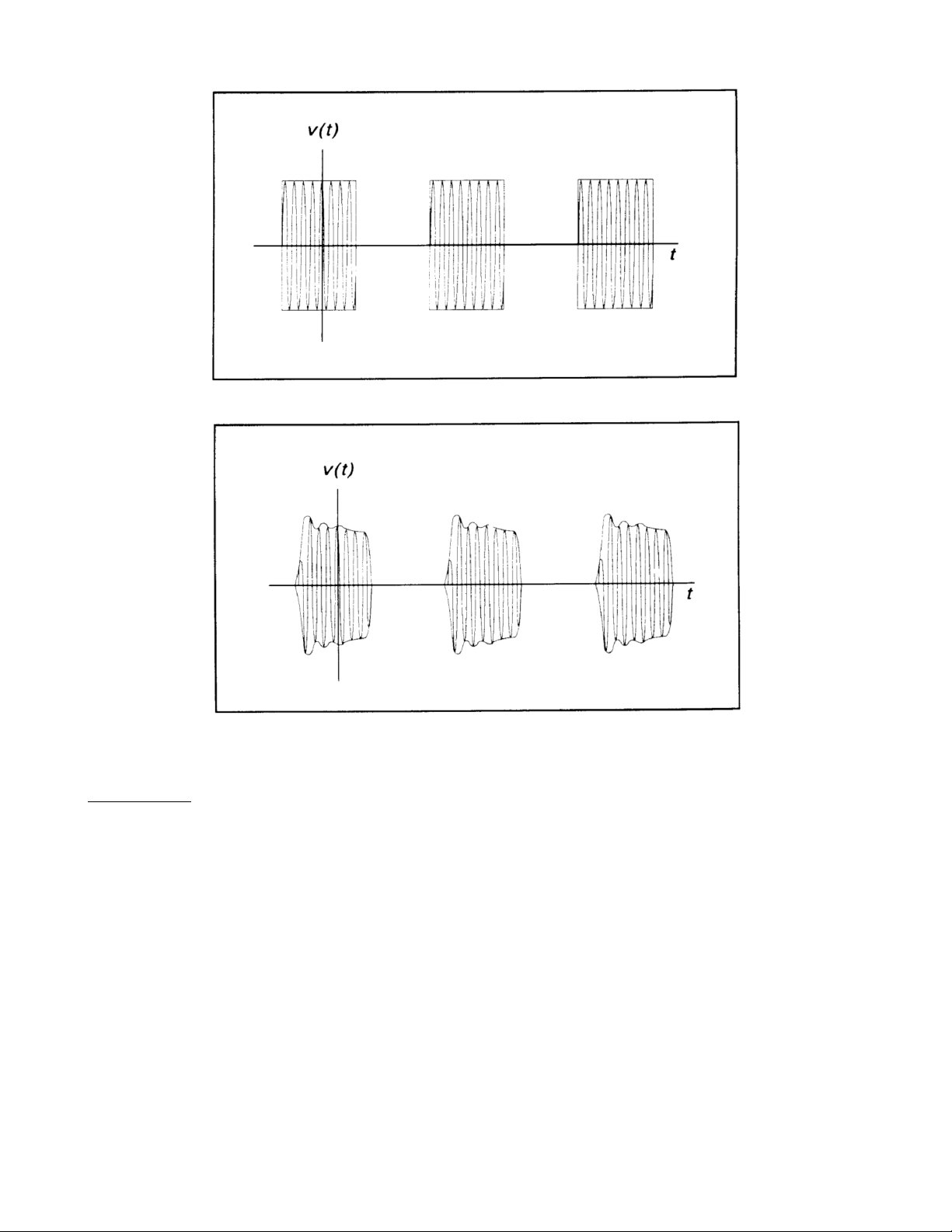

Pulse Power

Pulse power refers to power measured during the on time of pulsed RF signals gure 5.1. Traditionally, these signals

have been measured in two steps: (1) thermoelectric sensors measure the average signal power, (2) the reading is then

divided by the duty cycle to obtain pulse power, 𝑃

𝑃

Where Duty Cycle:

𝐷𝑢𝑡𝑦 𝐶𝑦𝑐𝑙𝑒 =

𝑝𝑢𝑙𝑠𝑒

𝑝𝑢𝑙𝑠𝑒

:

𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑃 𝑜𝑤𝑒𝑟

=

𝐷𝑢𝑡𝑦 𝐶𝑦𝑐𝑙𝑒

𝑃𝑢𝑙𝑠𝑒 𝑊𝑖𝑑𝑡ℎ

𝑃𝑢𝑙𝑠𝑒 𝑃 𝑒𝑟𝑖𝑜𝑑

Pulse power provides useful results when applied to rectangular pulses, but is inaccurate for pulse shapes that include

distortions, such as overshoot or droop (Figure 5.2).

Page 43

Application Notes 43

Figure 5.1 Pulsed RF Signal

Figure 5.2 Distorted Pulsed Signal

Peak Power

The RFM3000 makes power measurements in a manner that overcomes the limitations of the pulse power method and

provides both peak power and average power readings for all types of modulated carriers. The fast-responding diode

sensors detect the RF signal to produce a wideband video signal, which is sampled with a narrow sampling gate. The

video sample levels are accurately converted to power on an individual basis at up to a 100 MSa/sec rate. Since this

power conversion is corrected based upon the sensor’s linearity correction table, these samples can be averaged to yield

average power without restriction to the diode square-law region.

If the signal is repetitive, the signal envelope can be reconstructed using an internal or external trigger. The envelope

can be analyzed to obtain waveshape parameters including, pulse width, duty cycle, overshoot, rise time, fall time, and

droop. In addition to time domain measurements and simple averaging, the RFM3000 has additional capabilities that

allow it to perform statistical analysis on a complete set of continuously sampled data points.

Data can be viewed and characterized using a CCDF presentation format. These analysis tools provide invaluable

information about peak power levels and their frequency of occurrence, and are especially useful for non-repetitive

signals, such as those used in 5G and Wi-Fi applications.

Page 44

Application Notes 44

5.1.2 Diode Detection

Wideband diode detectors are the dominant power sensing device used to measure pulsed RF signals. Several diode

characteristics must be compensated to make meaningful measurements. These include the detector’s nonlinear amplitude response, temperature sensitivity, and frequency response characteristic. Additional potential error sources include

detector mismatch, signal harmonics, and noise.

Detector Response

The response of a single-diode detector to a sinusoidal input is given by the diode equation:

𝑖 = 𝐼𝑠(𝑒𝑎𝑣− 1)

where:

𝑖 = 𝑑𝑖𝑜𝑑𝑒𝑐𝑢𝑟𝑟𝑒𝑛𝑡

𝑣 = 𝑛𝑒𝑡𝑣𝑜𝑙𝑡𝑎𝑔𝑒𝑎𝑐𝑟𝑜𝑠𝑠𝑡ℎ𝑒𝑑𝑖𝑜𝑑𝑒

𝐼𝑠= 𝑠𝑎𝑡𝑢𝑟𝑎𝑡𝑖𝑜𝑛𝑐𝑢𝑟𝑟𝑒𝑛𝑡

𝛼 = 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡

An ideal diode response curve is plotted in gure 5.3

Figure 5.3 Ideal Diode Response

The curve indicates that for low microwave input levels (Region A), the single-diode detector output is proportional to

the square of the input power. For high input signal levels (Region C), the output is linearly proportional to the input.

In between these ranges (Region B), the detector response lies between square-law and linear.

For accurate power measurements over all three regions illustrated in gure 5.3, the detector response is pre-calibrated

over the entire range. The calibration data is stored in the instrument and recalled to adjust each sample of the pulse

power measurement.

Page 45

Application Notes 45

Temperature Eects

The sensitivity of microwave diode detectors (normally Low Barrier Schottky diodes) varies with temperature. However,

ordinary circuit design procedures that compensate for temperature-induced errors adversely aect detector bandwidth.

A more eective approach involves sensing the ambient temperature during calibration and recalibrating the sensor when

the temperature drifts outside the calibrated range.

This process can be made automatic by collecting calibration data over a wide temperature range and saving the data in

a form that can be used by the power meter to correct readings for ambient temperature changes.

Frequency Response

The carrier frequency response of a diode detector is determined mostly by the diode junction capacitance and the device

lead inductances.

The frequency response will vary from detector to detector and cannot be compensated readily. Power measurements

must be corrected by constructing a frequency response calibration table for each detector.

Mismatch

Sensor impedance matching errors can contribute signicantly to measurement uncertainty, depending on the mismatch

between the device under test (DUT) and the sensor input. This error cannot be easily calibrated out, but can be

minimized by employing an optimum matching circuit at the sensor input.

Signal Harmonics

Measurement errors resulting from harmonics of the carrier frequency are leveldependent and cannot be calibrated out.

In the square-law region of the detector response (Region A, Figure 5-3), the signal and second harmonic combine on

a root mean square basis. The eects of harmonics on measurement accuracy in this region are relatively insignicant.

However, in the linear region (Region C, gure 5.3), the detector responds to the vector sum of the signal and harmonics.

Depending on the relative amplitude and phase relationships between the harmonics and the fundamental, measurement

accuracy may be signicantly degraded. Errors caused by even-order harmonics can be reduced by using balanced diode

detectors for the power sensor. This design responds to the peak-to-peak amplitude of the signal, which remains constant

for any phase relationship between fundamental and even-order harmonics. Unfortunately, for odd-order harmonics, the

peak-to-peak signal amplitude is sensitive to phasing, and balanced detectors provide no harmonic error improvement.

Measurement errors resulting from harmonics of the carrier frequency are leveldependent and cannot be calibrated out.

In the square-law region of the detector response (Region A, gure 5.3), the signal and second harmonic combine on

a root mean square basis. The eects of harmonics on measurement accuracy in this region are relatively insignicant.

However, in the linear region (Region C, gure 5.3), the detector responds to the vector sum of the signal and harmonics.

Depending on the relative amplitude and phase relationships between the harmonics and the fundamental, measurement

accuracy may be signicantly degraded. Errors caused by even-order harmonics can be reduced by using balanced diode

detectors for the power sensor. This design responds to the peak-to-peak amplitude of the signal, which remains constant

for any phase relationship between fundamental and even-order harmonics. Unfortunately, for odd-order harmonics, the

peak-to-peak signal amplitude is sensitive to phasing, and balanced detectors provide no harmonic error improvement.

Noise

For low-level signals, detector noise contributes to measurement uncertainty and cannot be calibrated out. Balanced

detector sensors improve the signal-to-noise ratio by 3 dB, because the signal is twice as large.

Page 46

Application Notes 46

5.1.3 Pulse Denitions

IEEE Std 194™-1977 Standard Pulse Terms and Denitions “provides fundamental denitions for general use in time

domain pulse technology.” Several key terms dened in the standard are reproduced in this subsection, which also denes

the terms appearing in the RFM3000 text mode display of automatic measurement results.

5.1.4 Standard IEEE Pulse

The key terms dened by the IEEE standard are abstracted and summarized below. These terms are referenced to the

standard pulse illustrated ingure 5.4

Figure 5.4 Stanard IEEE Pulse

Note:

IEEE Std 194™-1977 Standard Pulse Terms and Denitions has been superseded by IEEE Std 181™-2003. Many of

the terms used below have been deprecated by the IEEE. However, these terms are widely used in the industry. For

this reason, they are retained.

Page 47

Application Notes 47

Term Denition

Base Line

Top Line The portion of a pulse waveform which represents the second nominal state of a pulse.

First Transition

Last Transition

Proximal Line

Distal Line

Mesial Line

The two portions of a pulse waveform which represent the rst nominal state from

which a pulse departs and to which it ultimately returns.

The major transition of a pulse waveform between the base line and the top line (commonly called the rising edge).

The major transition of a pulse waveform between the top of the pulse and the base

line (commonly called the falling edge).

A magnitude reference line located near the base of a pulse at a specied percentage

(normally 10%) of pulse magnitude.