Page 1

MDL Series

Programmable DC Electronic Load

Models: MDL001, MDL002, MDL200, MDL252,

MDL305, MDL400, MDL505, MDL600

USER MANUAL

Page 2

Safety Summary

The following general safety precautions must be observed during all phases of operation of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the instrument. We

assume no liability for the Customer’s failure to comply with these requirements.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use, pollution degree 2 environments. It is designed to

operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the

specifications tables for the AC mains voltage requirements and ambient operating temperature

range.

BEFORE APPLYING POWER

Verify that all safety precautions are taken. Note the instrument's external markings described

under "Safety Symbols".

GROUND THE INSTRUMENT

This product is a Safety Class 1 instrument (provided with a protective earth terminal). To minimize

shock hazard, the instrument chassis and cover must be connected to an electrical ground. The

instrument must be connected to the AC mains power through a grounded power cable, with the

ground wire firmly connected to an electrical ground (safety ground) at the power outlet. Note:

Any interruption of the protective (grounding) conductor or disconnection of the protective earth

terminal will cause a potential shock hazard that could result in personal injury.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of fumes or flammable gases.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers except as instructed in this guide for

installing or removing electronic load modules. Component replacement and internal adjustments

must be made only by qualified service personnel. Do not replace components with power cable

connected. Under certain conditions dangerous voltages may exist even with the power cable

removed. To avoid injuries, always disconnect power, discharge circuits, and remove external

voltage sources before touching components.

2

Page 3

DO NOT SERVICE OR ADJUST ALONE

Direct current

Alternating current

Both direct and alternating current

Protective earth (ground) terminal

Attention (refer to accompanying documents)

WARNING

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which,

if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a

WARNING sign until the indicated conditions are fully understood and met.

CAUTION

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which,

if not correctly performed or adhered to, could result in damage to or destruction of part or all of

the product. Do not proceed beyond a CAUTION sign until the indicated conditions are fully

understood and met.

Do not try to do some internal service or adjustment unless another person capable of rendering

first aid resuscitation is present.

Safety Symbols

3

Page 4

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and other

European countries with separate collection systems)

This product is subject to Directive 2002/96/EC of the European Parliament and the Council of the

European Union on waste electrical and electronic equipment (WEEE), and in jurisdictions adopting

that Directive, is marked as being put on the market after August 13, 2005, and should not be

disposed of as unsorted municipal waste. Please utilize your local WEEE collection facilities in the

disposition of this product and otherwise observe all applicable requirements.

CE Declaration of Conformity

The DC electronic load meets the requirements of Low Voltage Directive 73/23/EEC and

Electromagnetic Compatibility Directive 89/336/EEC amended by 93/68/EEC.

Low Voltage Directive

- EN61010-1: 2001

EMC Directive

- EN50081-1

- EN50082-1

4

Page 5

Table of Contents

Safety Summary ........................................................................................2

Compliance Statements.............................................................................4

Product Overview .....................................................................................8

Description .................................................................................................................................. 8

Features ...................................................................................................................................... 9

Front Panel ................................................................................................................................ 10

Rear Panel ................................................................................................................................. 11

Protection Functions .................................................................................................................. 12

Overvoltage Protection (OVP) ................................................................................................ 12

Overcurrent Protection (OCP) ................................................................................................. 12

Overpower Protection (OPP) .................................................................................................. 14

Overtemperature Protection (OTP) ......................................................................................... 15

Reverse Voltage Protection (LRV/RRV) ................................................................................... 15

Menu List .................................................................................................................................. 16

Setup Menu ........................................................................................................................... 16

Configuration Menu ............................................................................................................... 19

Automatic Test Menu ............................................................................................................. 20

Installation .............................................................................................. 21

Inspection ................................................................................................................................. 21

Cleaning .................................................................................................................................... 21

Installing Modules ..................................................................................................................... 22

Channel Number ....................................................................................................................... 24

Location .................................................................................................................................... 25

Input Voltage Selection .............................................................................................................. 27

Turn-On Checkout ..................................................................................................................... 28

If the Electronic Load Does Not Turn On ..................................................................................... 29

Load Connection ..................................................................................... 30

Remote Sense Connection ......................................................................................................... 31

Parallel Connection .................................................................................................................... 32

Mainframe 8-pin Control Connector........................................................................................... 33

External Trigger Connections ..................................................................................................... 34

5

Page 6

External ON/OFF Control Connection ......................................................................................... 35

Mainframe Extension Connections ............................................................................................. 35

PC Control Connection ............................................................................................................... 36

Operation ............................................................................................... 37

Operating Modes ....................................................................................................................... 37

Constant Current (CC) mode ................................................................................................... 37

Constant Voltage (CV) Mode .................................................................................................. 39

Constant Resistance (CR) Mode .............................................................................................. 40

Constant Power (CW) Mode ................................................................................................... 41

Constant Impedance (CZ) Mode .............................................................................................. 41

Setting CV, CC, CR, CW, CZ Mode ............................................................................................ 43

Local Operation ......................................................................................................................... 44

Mainframe ............................................................................................................................. 44

Module .................................................................................................................................. 47

Module Panel Lock ................................................................................................................. 48

Switching Channels ................................................................................................................ 48

Channel Synchronization ........................................................................................................ 48

VFD Indicator Function Description ........................................................................................ 49

Transient Operation .................................................................................................................. 50

Continuous............................................................................................................................. 50

Pulse ...................................................................................................................................... 51

Toggle .................................................................................................................................... 52

Setting Up A/B Transient Operation ....................................................................................... 52

List Operation ............................................................................................................................ 55

Setting Up List Operation Mode.............................................................................................. 55

Triggered Operation .................................................................................................................. 59

Trigger Function ..................................................................................................................... 59

Trigger Source ........................................................................................................................ 59

Short Operation ......................................................................................................................... 59

Input On/Off Operation ............................................................................................................. 60

Von Operation ........................................................................................................................... 60

6

Page 7

Setting Up Von Function ......................................................................................................... 61

Save and Recall Operation ......................................................................................................... 62

Module Controlling Link ............................................................................................................. 63

Voltage Failure Indication ....................................................................................................... 64

Current Monitoring ................................................................................................................ 64

Digital I/O .............................................................................................................................. 64

Remote Sense Function .......................................................................................................... 65

External Analog Control .......................................................................................................... 65

Automatic Test .......................................................................................................................... 65

Setting Up Test Files ............................................................................................................... 65

Recall Test Files ...................................................................................................................... 70

Remote Operation ..................................................................................................................... 70

USB Interface ......................................................................................................................... 71

Ethernet Interface .................................................................................................................. 71

GPIB Interface ........................................................................................................................ 71

RS-232 Interface ..................................................................................................................... 72

RS-232 Data Format ...................................................................................................................... 72

Baud Rate ...................................................................................................................................... 72

Parity ............................................................................................................................................. 72

RS-232 Flow Control ...................................................................................................................... 73

RS-232 Connections ...................................................................................................................... 73

RS-232 Troubleshooting ................................................................................................................ 74

Communication Setting .......................................................................................................... 74

Specifications .......................................................................................... 75

Supplementary Characteristics................................................................................................... 77

SERVICE INFORMATION ........................................................................... 78

LIMITED THREE-YEAR WARRANTY ........................................................... 79

7

Page 8

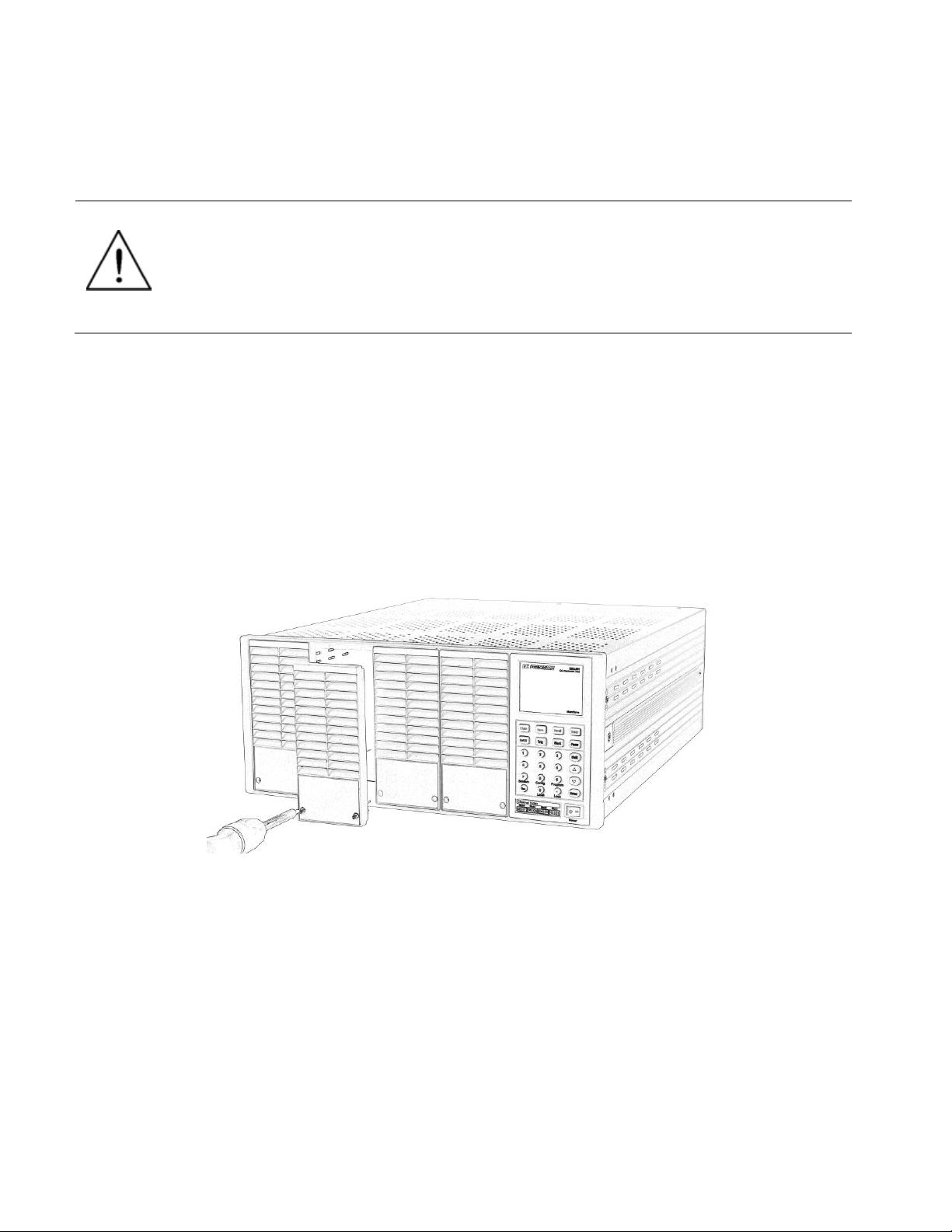

Product Overview

This section describes the main features and menus of the MDL Series DC Electronic Load. The MDL

Series is comprised of two parts, mainframes and modules. The mainframes mentioned are the

MDL001 mainframe and the MDL002 mainframe extension. Modules in this series include the

MDL200, MDL252, MDL305, MDL400, MDL505, and MDL600. Unless otherwise noted, this

document will refer to all of these instruments as “electronic load”. The range of each module’s

specific voltage, current, and power is listed in the Specifications section.

Description

The MDL Series is a multi-channel programmable DC electronic load system. With programming

and remote control capabilities, the MDL Series DC electronic load can provide multiple solutions

according to the requirements of your design and is suitable for testing a wide range of power

sources from multi-output DC power supplies to batteries, fuel cells, and photovoltaic arrays.

Up to four modules can be installed into the MDL001 mainframe to support up to a total of 8

channels. Adding the MDL002 mainframe extension will enable the system to support four

additional module slots for a maximum of 16 channels. The electronic load is configured by

installing user-selectable modules into the mainframe and operated using the front panel keypad

and rotary knob. It can also be controlled remotely via USB, RS-232C, LAN, or GPIB interface. The

electronic load modules all have similar functions, but may differ in range of input voltage, current,

and power. The high resolution voltage and current measurement system provides both accuracy

and convenience.

The electronic load can be used in one of five different operation modes: constant voltage (CV),

constant current (CC), constant resistance (CR), constant power (CW), or constant impedance (CZ).

All panel operation and programming functions are carried out on the MDL001 mainframe panel. A

wide range of dynamic loading applications can be simulated through user-programmable slew

rates, load levels, duration, and conducting voltage.

8

Page 9

Features

CC/CV/CR/CW/CZ operating modes

Removable modules for easy system flexibility

Bright VFD display for both mainframe and modules

Power range up to 2400 W (4800 W with mainframe extension)

Supports up to 16 channels with mainframe extension

Operate identical modules in parallel mode for high current applications

Synchronous load on/off function

16-bit voltage and current metering providing high resolution of 0.1 mV and 0.01 mA

Transient mode up to 25 kHz

List mode (sequence mode) – minimum 20 us step width with 84 user programmable steps

Adjustable slew rate in CC mode

Automatic test function

101 memory areas to save/recall setting parameters

Analog current control and monitoring

Remote sensing

Standard LAN, GPIB, USBTMC compliant USB, and RS-232 interfaces with SCPI protocol

support

OVP/OCP/OPP/OTP and reverse voltage protection

9

Page 10

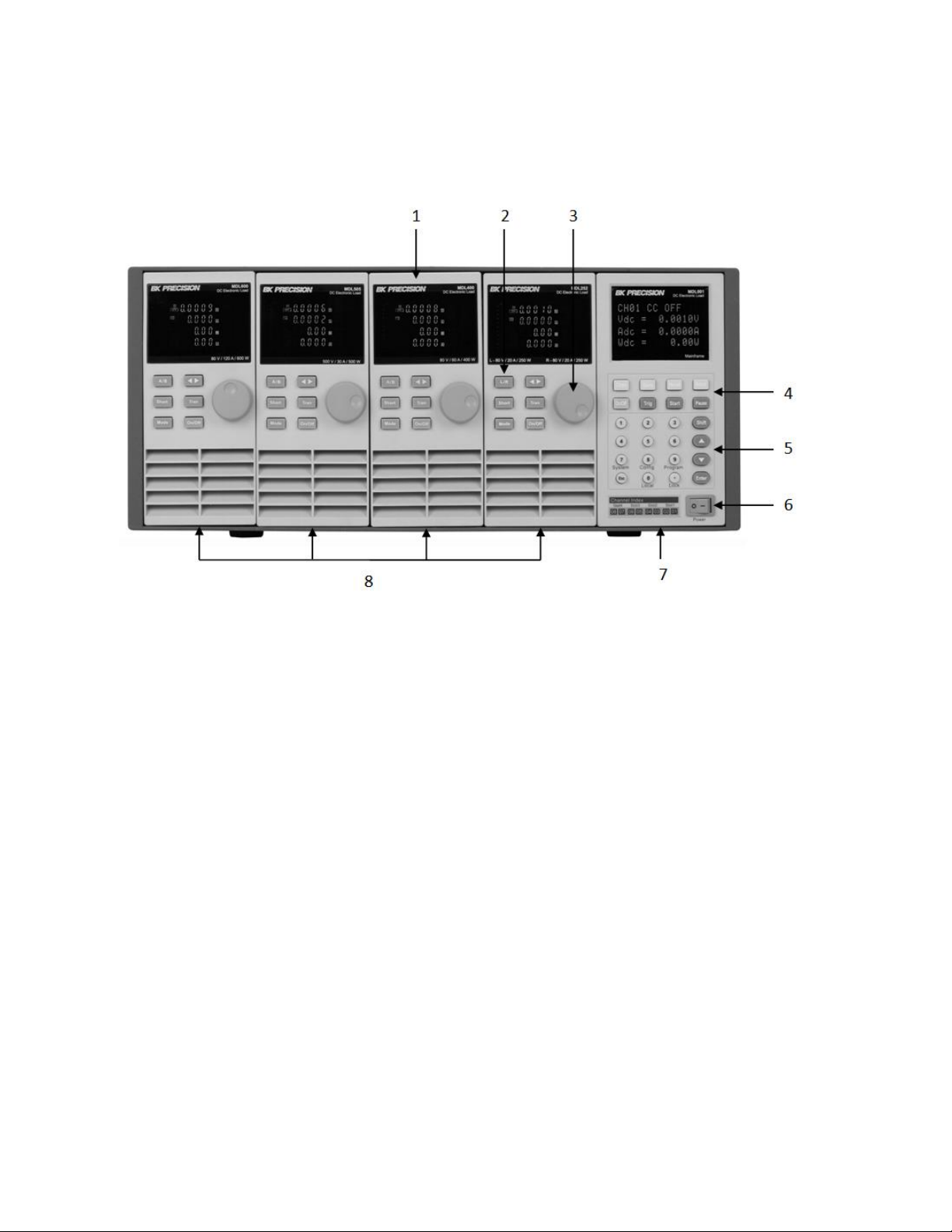

Front Panel

Figure 1 - MDL Series Front Panel

1) VFD DISPLAY

Displays electronic load information.

2) MODULE PANEL KEYS

Controls module functions. Refer to Module section for more details on the use of these

keys.

3) ADJUSTMENT KNOB

Used to change parameters.

4) MAINFRAME FUNCTION KEYS

Controls each channel’s operating status. Refer to Mainframe section for more details on

the use of these keys.

5) MAINFRAME NUMERIC ENTRY AND SHIFT KEYS

Refer to Mainframe section for more details on the use of these keys.

6) POWER SWITCH

Turns the system on or off.

7) MAINFRAME

8) MODULES

10

Page 11

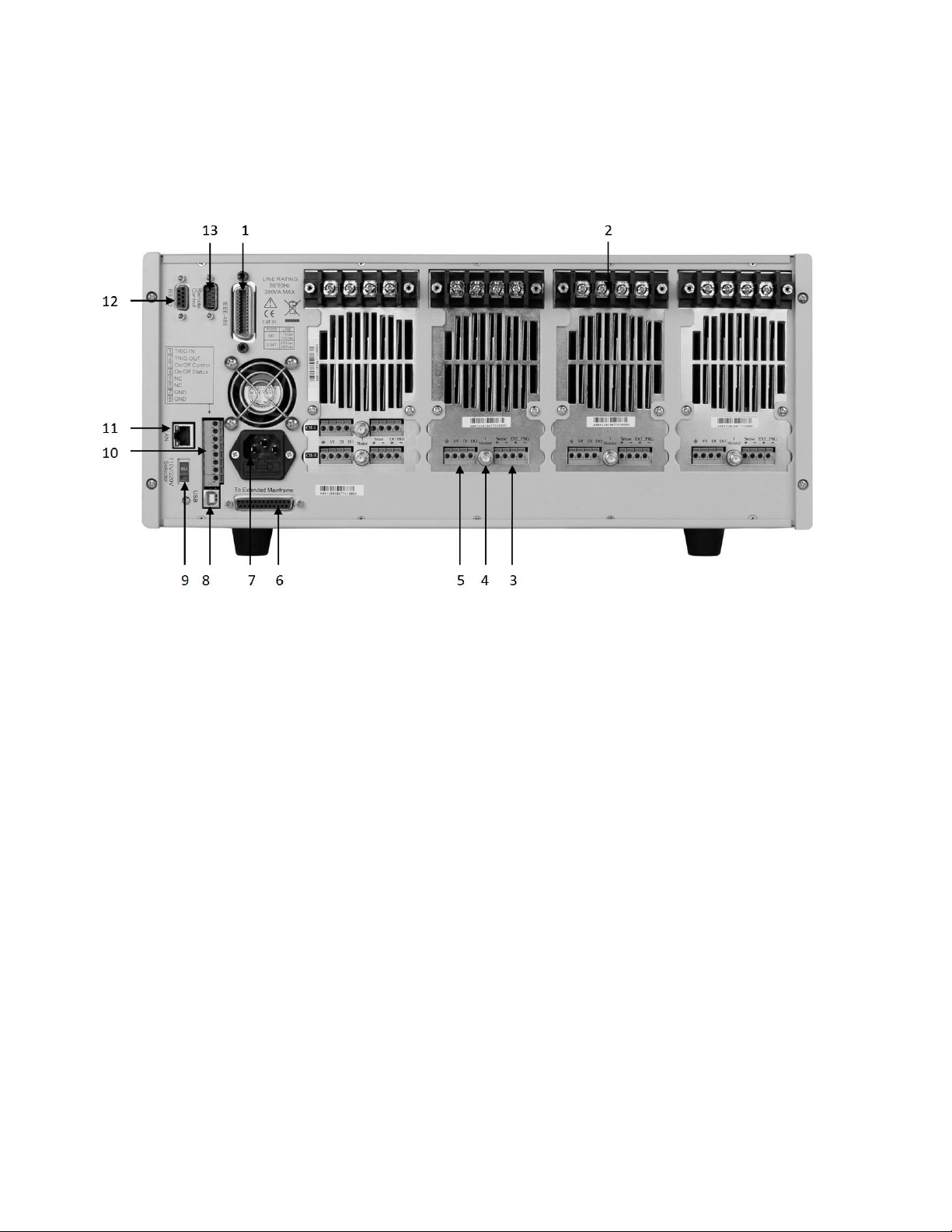

Rear Panel

Figure 2 - MDL Series Rear Panel

1) GPIB interface

2) Input terminal of module

3) Remote measurement and external input control terminal

4) Current monitoring output

5) Digital I/O and VF output terminal

6) Extended module interface

7) AC Power input socket

8) USB interface

9) Line voltage selection switch (110V/220V)

10) Trigger I/O and load on/off terminals

11) LAN interface

12) RS-232 interface

13) Not used – for factory use only

11

Page 12

Protection Functions

The electronic load has the following protection functions: Overvoltage protection (OVP),

overcurrent protection (OCP), overpower protection (OPP), overtemperature protection (OTP), and

local and remote reverse voltage protection (LRV/RRV).

The mainframe will act appropriately once any of the above protections are active. You can press

any button on the front panel to restore the protection function. For example, if the electronic

load triggers the overtemperature protection, the buzzer will alarm, the input will automatically

turn off, and the mainframe VFD will display OTP.

Overvoltage Protection (OVP)

If the OVP circuit has triggered, input will turn off, buzzer alarm will go off, and the status register’s

OV and VF bit will be set. The mainframe will display OVP and the condition will remain until they

are reset. Once overvoltage protection occurs, the 8-pin connector’s VF pin on the rear panel will

output TTL high voltage level. You can control the output state of the power supply under test via

this pin (see Figure 31).

Operations to Clear the OVP State

Check whether the input voltage is within the electronic load’s rated voltage or the programmed

protection voltage ranges. If it is outside the range, please disconnect the device under test. Then

press any key on the front panel or remotely send SCPI command PROTection:CLEar. The OVP

displayed on the front panel will turn off and the electronic load exits OVP protection state.

Overcurrent Protection (OCP)

The electronic load includes both hardware and software overcurrent protection features.

Hardware OCP - The electronic load’s maximum input current will be limited to approximately

110% of the current range. Once the hardware OCP is triggered, the status register’s OC bit will be

set. When the hardware OCP is removed, the status register’s OC bit will be reset. Hardware

overcurrent protection will not affect the electronic load’s on/off state.

Software OCP - Users can set the electronic load’s software OCP value with the following steps.

12

Page 13

Panel Operations

VFD Display

1. Power on the electronic load.

Self-test

2. Press Shift + ⑧ to enter Configuration menu.

Sync On Set

Von

Meter

Protect

List

Ext. Ctrl Set

About

Exit

3. Press key to select <Protect> and press Enter to go into protection

menu.

Max Power Set

Alimit State

Alimit Point

Alimit Delay

Plimit Point

Plimit Delay

OnTimer State

OnTimer Set

Exit

4. Press key to select <Alimit State> and press Enter. Select <On>

and press Enter to confirm.

On

Off (Default)

5. Press key to select <Alimit Point> and press Enter. Input OCP

current value and press Enter to confirm.

Current Limit

Set= 40.000A

6. Press key to select <Alimit Delay> and press Enter. Input delay

time before alarm and press Enter to confirm.

Current Limit

Delay= 3S

7. Press Esc key to exit menus.

If the electronic load’s current value is above the set overcurrent protection value, the electronic

load will automatically turn off and the VFD will display OCP. At the same time, the OC and PS bits

in the status register will be set and remain until they are reset.

Operations to Clear the OCP State

Check whether the input current is within the electronic load’s rated current or the programmed

protection current ranges. If it is outside the range, disconnect the device under test. Then press

any key on the front panel or remotely send SCPI command PROTection:CLEar. The OCP displayed

on the front panel will turn off and the load exits OCP protection state.

13

Page 14

Overpower Protection (OPP)

Panel Operations

VFD Display

1. Power on the electronic load.

Self-test

2. Press Shift + ⑧ to enter Configuration menu.

Sync On Set

Von

Meter

Protect

List

Ext. Ctrl Set

About

Exit

3. Press key to select <Protect> and press Enter to go into

protection menu.

Max Power Set

Alimit State

Alimit Point

Alimit Delay

Plimit Point

Plimit Delay

OnTimer State

OnTimer Set

Exit

4. Press key to select <Plimit Point> and press Enter. Input OPP

power value and press Enter to confirm.

Power Limit

Set= 210.00W

5. Press key to select <Plimit Delay> and press Enter. Input delay

time before alarm and press Enter to confirm.

Power Limit

Delay= 3S

6. Press Esc key to exit menus.

The electronic load includes both hardware and software OPP features.

Hardware OPP – In the event that the electronic load’s input power exceeds the set power

protection limit, the hardware OPP will limit the power. Once the hardware OPP is triggered, the

status register’s OP bit will be set. When the hardware OPP is removed, the status register’s OP bit

will be reset. Hardware overpower protection will not turn the electronic load’s input off.

Software OPP - Users can set the electronic load’s software OPP value with the following steps.

If the electronic load’s power value is above the set overpower protection value, the electronic

load will automatically turn off and the VFD will display OPP. At the same time, the OP and PS bits

in the status register will be set and remain until they are reset.

14

Page 15

Operations to Clear the OPP State

Check whether the input power is within the rated power range or the programmed protection

ranges. If it is outside the range, disconnect the device under test. Then press any key on the front

panel or remotely send command PROTection:CLEar. The OPP displayed on the front panel will

turn off and the electronic load exits OPP protection state.

Overtemperature Protection (OTP)

Each module has an overtemperature protection circuit, which will turn off the input if the internal

temperature exceeds safe limits. When the electronic load’s internal circuit temperature is over

85C, the load will enable OTP. Input will automatically be turned off and the VFD will display OTP.

At the same time the OT and PS bits in the status register will be set and remain until they are

reset.

Operations to Clear the OTP State

When the electronic load temperature has dropped below the protection point, press any key on

the front panel or remotely send command PROTection:CLEar. The OTP displayed on the front

panel will turn off and the electronic load exits OTP protection state.

Reverse Voltage Protection (LRV/RRV)

This function protects the electronic load in case the input DC voltage lines are connected with the

wrong polarity. When a reverse voltage (LRV – local reverse voltage, RRV – remote reverse voltage)

connection condition is detected, the input will immediately turn off, the buzzer will alarm the

user, and the status register’s reverse voltage (LRV/RRV) and VF bits will be set. The mainframe will

display LRV/RRV until they are reset.

In this condition, the 8-pin connector’s VF pin will output a high level. You can disconnect the

power supply via this signal (see Figure 31).

Operations to Clear the Reverse Voltage State

Check whether the connection is reversed. If so, disconnect the device to be measured and the

reverse voltage state will be cleared.

15

Page 16

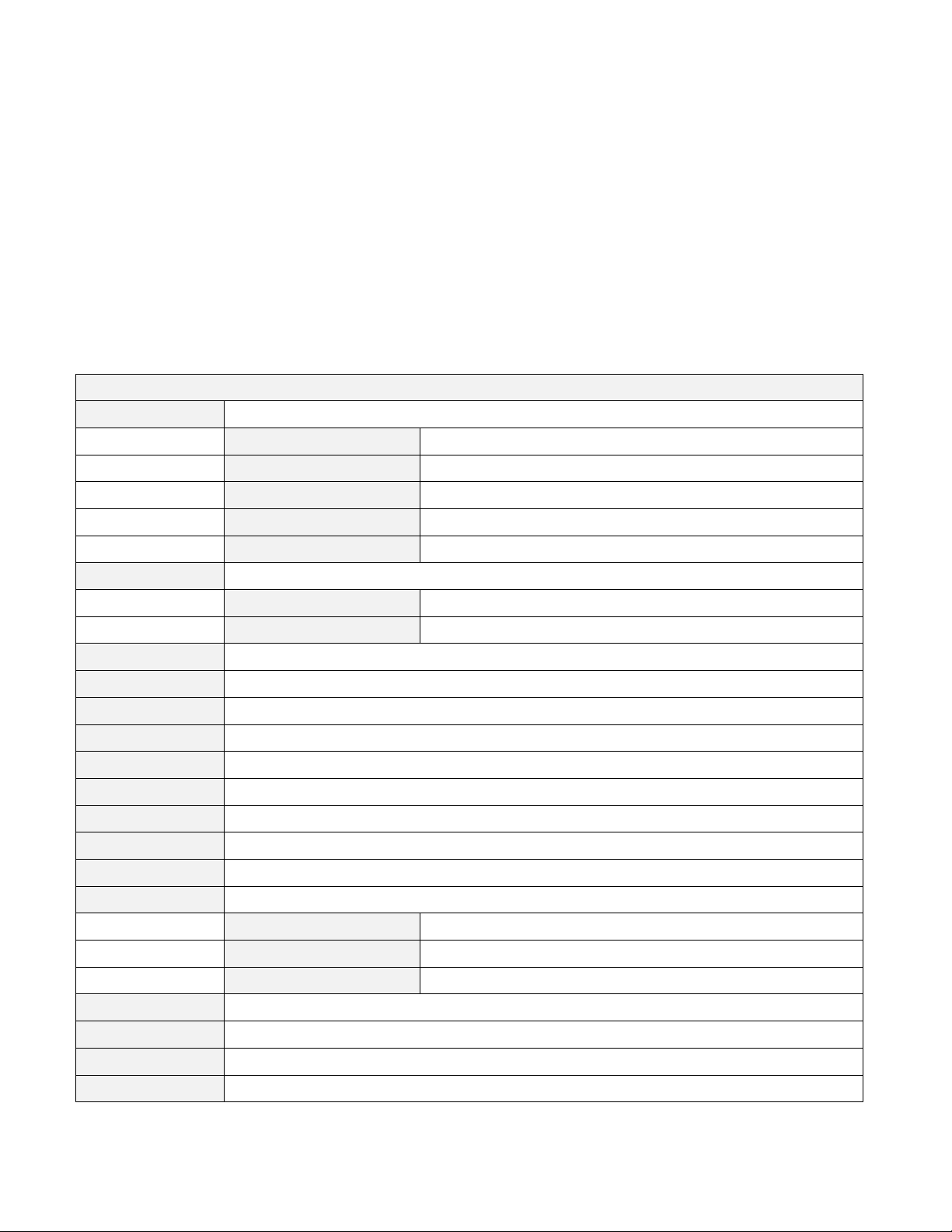

Menu List

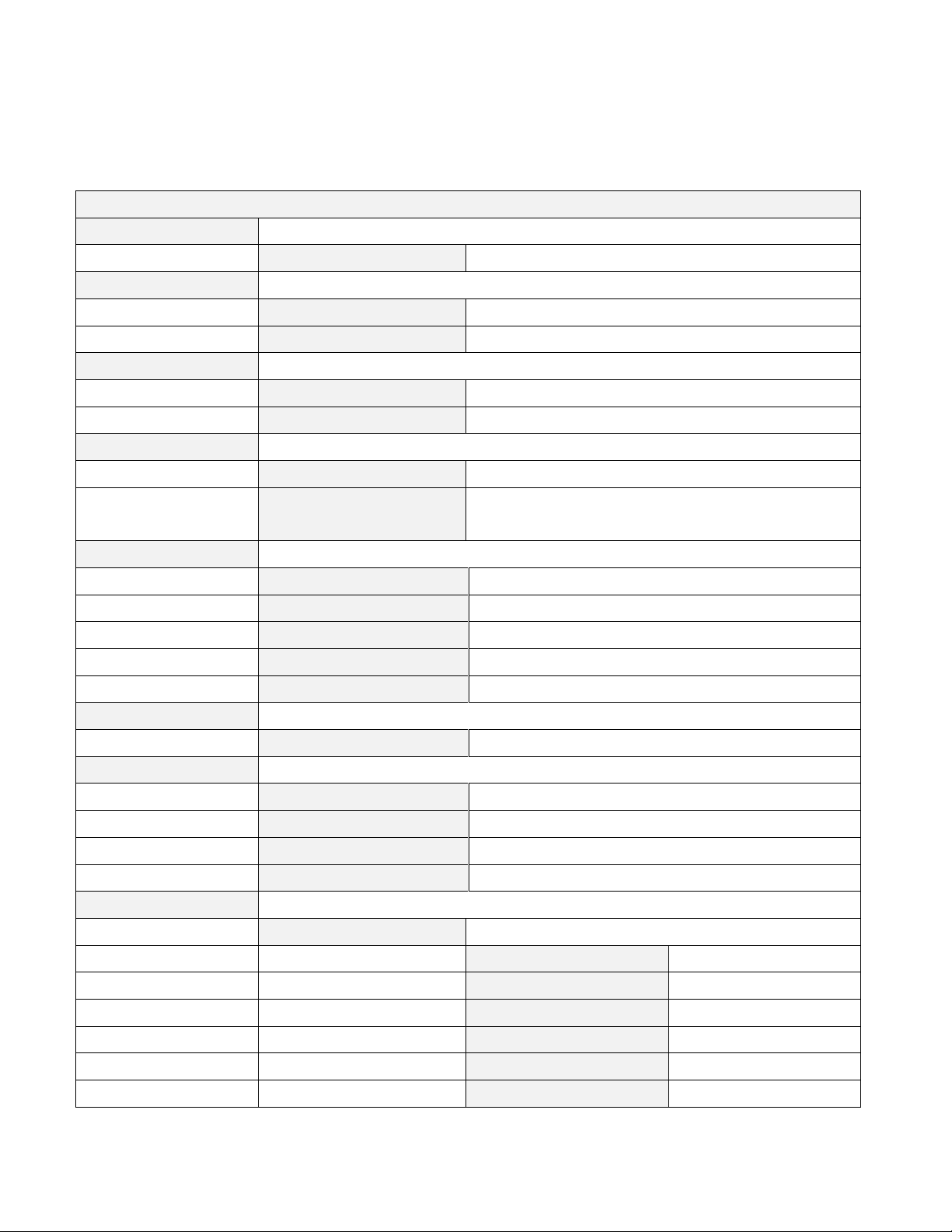

SETUP

MODE

Select working mode

CONST CURRENT

Load works in CC mode

CONST VOLTAGE

Load works in CV mode

CONST RESISTANCE

Load works in CR mode

CONST POWER

Load works in CW mode

CONST IMPEDANCE

Load works in CZ mode

CC/CV RANGE

Switch the range

HIGH RANGE

Set high range

LOW RANGE

Set low range

I / V / R / W SET

Set the working current/voltage/resistance/power value

Vmax/Amax

Set up the maximum voltage value/maximum current value

Vmin/Amin

Set up the minimum voltage value/minimum current value

∫=2.500A/us

Set the rising slew rate (only in CC mode)

∫=2.500A/us

Set the falling slew rate (only in CC mode)

TRAN A=0.00A

Set up level A value

Ta=0.0005S

Set up level A width

TRAN B=0.00A

Set up level B value

Tb=0.0005S

Set up level B width

T MODE

Set up the transient mode

CONTINUOUS

Continuous mode

PULSE

Pulse mode

TOGGLE

Toggle mode

RLC R=7500.0Ω

Set up the resistance value

RLC L=0uH

Set up the inductance value

RLC C=10uF

Set up the capacitance value

EXIT

Exit the setup menu

The following menus can be viewed on the VFD display. Use keys to scroll through the menu

list and press Enter key to enter the selected menu function. Use keys to scroll through the

VFD screen and press Enter key to enter its submenu. Press Esc to go back to the previous menu

selection. Pressing number keys can directly select a channel.

Setup Menu

Press Setup key to enter the setup menu.

16

Page 17

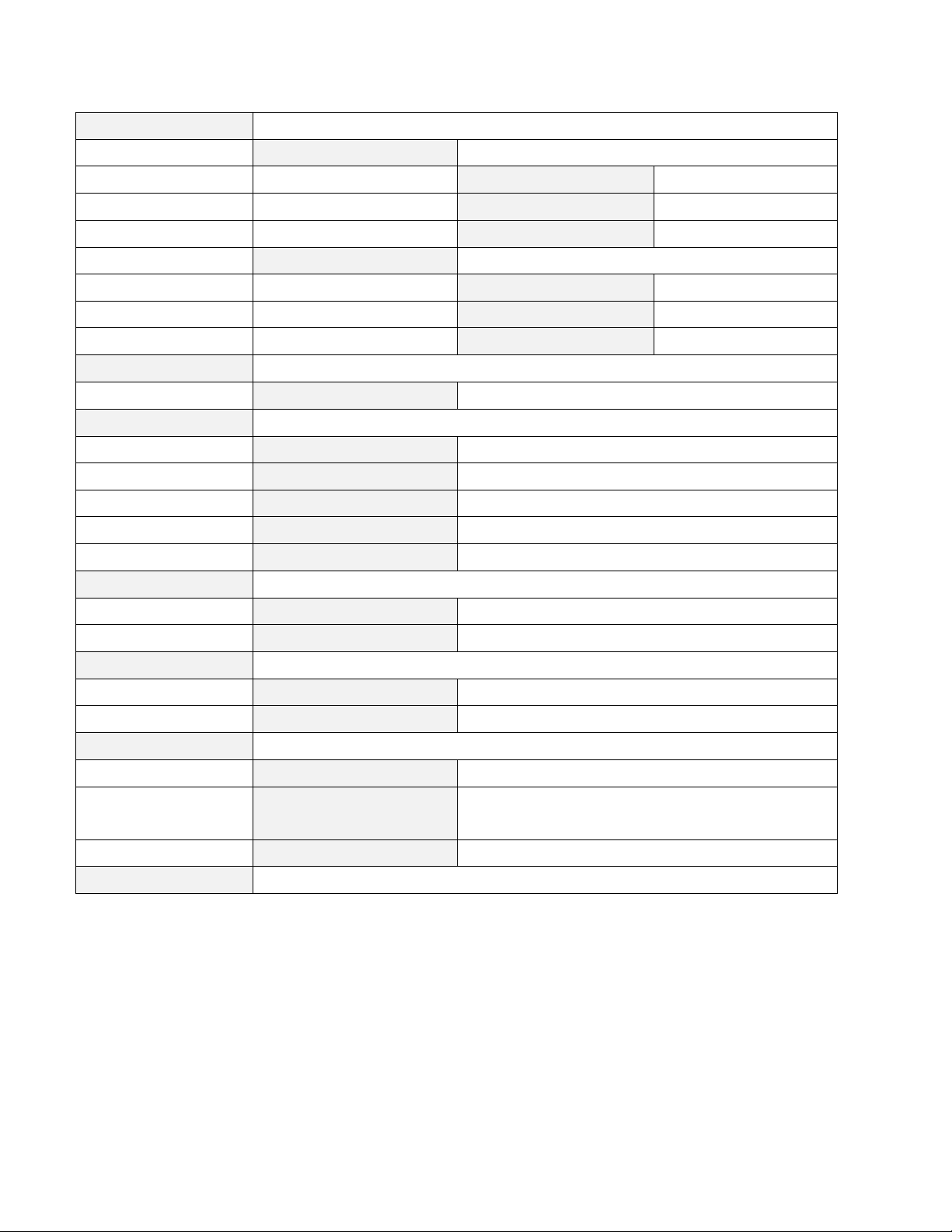

System Menu

MENU

INITIALIZE

INITIALIZE DEFAULT SET

Resume all configuration to default settings

POWER ON SET

RST (DEFAULT)

Set the load’s input state to default at power on

SAV0

Set the load’s input state to SAV0 at power on

BUZZER SET

Set up the buzzer state

ON

Enable the function

OFF (DEFAULT)

Disable the function

LOAD ON KNOB

Module knob mode setting

UPDATE (DEF)

Real-time update

OLD

No update (when turning load ON/OFF, original

value before use of rotary knob will be set)

TRIGGER SOUR.

Set up the trigger mode

MANUAL (DEF)

Manual trigger

EXTERNAL

External signal trigger mode

HOLD

Hold trigger mode

BUS

Bus trigger mode

TIMER

Timer trigger

TRIGGER TIMER

Trigger timer setting

TRIGGER TIMER SET

Set the time of the trigger timer

COMMUNICATION

Select the interface for remote communication

RS232 (DEF)

USBTMC-USB488

GPIB

ETHERNET

RS232 SET

BAUDRATE SET

Set up the communication baud rate

4800 (DEFAULT)

9600

19200

38400

57600

115200

Press Shift + ⑦ key to enter the System menu.

17

Page 18

RS232 SET

PARITY SET

Set up the communication parity

NONE (DEFAULT)

ODD

EVEN

HANDSHAKE SET

Select the handshake protocol

NONE (DEFAULT)

CTS/RTS

XON/XOFF

GPIB ADDRESS

GPIB address setting

GPIB ADDRESS SET

Set up communication address

ETHERNET SET

Ethernet settings

GATEWAY SET

Gateway setting

IP SET

IP setting

MASK SET

Mask setting

PORT SET

Port setting

EXIT

EXPAND MODULE

Module expansion

ON

Enable the function

OFF (DEFAULT)

Disable the function

LANGUAGE SET

Communication protocol

SCPI (DEFAULT)

SCPI protocol

EXTEND TABLE

Expand SCPI protocol, compatible with others

ABOUT

Mainframe production information

MDL###

Mainframe production model number

SN:

##################

Mainframe production serial number

VER: 1.43

Mainframe software version

EXIT

18

Page 19

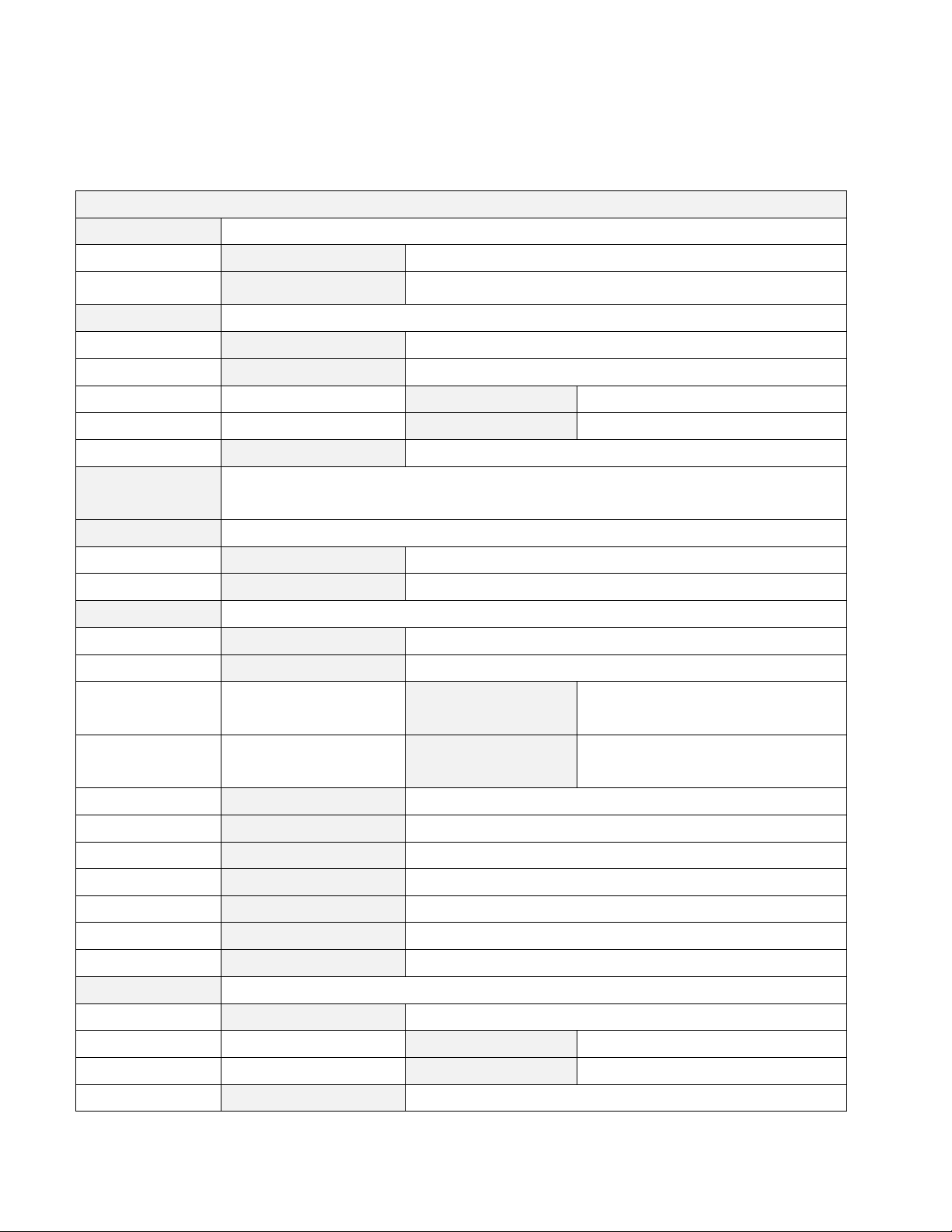

Configuration Menu

MENU

SYNC ON SET

Setup Synchronization ON / OFF function

ON (DEFAULT)

Turn on synchronization function

OFF

Turn off synchronization function

VON

VON POINT

Set the load’s Von point

VON LATCH

Von latch state

ON (DEFAULT)

Turn on Von latch

OFF

Turn off Von latch

EXIT

Exit the menu

AVERAGE

COUNT

Average count setting 2^X (adjustable from 2^2 to 2^16)

V AUTORANGE

Auto switching voltage range

ON (DEFAULT)

Enable this function

OFF

Disable this function

PROTECT

Load protecting function

MAX POWER SET

Set up hardware power protection state

ALIMIT STATE

Set up software current protection state

ON

Turn on software current

protection state

OFF (DEFAULT)

Turn off software current

protection state

ALIMIT POINT

Set up software current protection value

ALIMIT DELAY

Set up software current protection delay

PLIMIT POINT

Set up software power protection value

PLIMIT DELAY

Set up software power protection delay

ON TIMER STATE

Set up LOAD ON timer state

ON TIMER SET

Set up LOAD ON timer time

EXIT

Exit the menu

LIST

FUNCTION MODE

Select mode

FIXED

Choose fixed operation mode

LIST

Choose list operation mode

RECALL LIST

Recall list operation file

Press Shift + ⑧ key to enter the channel Configuration menu.

19

Page 20

EDIT LIST

Edit list operation file

HIGH RANGE

Edit high range of list operation

LOW RANGE

Edit low range of list operation

EXT. CTRL SET

External analog control function

ON

Turn on external analog control function

OFF (DEFAULT)

Turn off external analog control function

REM SENSE SET

Remote sense function

ON

Enable remote sense function

OFF (DEFAULT)

Disable remote sense function

ABOUT

Module production information

MDL###

Channel production model

SN:

##################

Channel production serial number

VER: 1.35

Channel software version

EXIT

Exit the menu

PROGRAM

RUN PROGRAM

Run the testing file

RECALL PROG

Recall the testing file

EDIT PROGRAM

Edit the testing file

EXIT

Automatic Test Menu

Press Shift + ⑨ key to enter the program menu.

20

Page 21

Installation

WARNING : To prevent electric shock, please unplug the power cord connected to the

unit before cleaning.

Inspection

This instrument was carefully inspected before shipment. Upon receipt, inspect the instrument for

damage that might have occurred during transit. If any sign of damage is found, please notify your

B&K Precision distributor.

The following standard and optional accessories are provided with each mainframe or module.

Mainframes include:

Power cord

User manual

Mainframe extension cable accessory (MDL002 only)

Modules include:

Certificate of calibration and test report

Optional accessories:

Rack mount kit IT-E153A (available for mainframes MDL001 and MDL002)

Cleaning

Use a dry cloth or one slightly dampened with water to clean the external case parts. Do not

attempt to clean internally.

21

Page 22

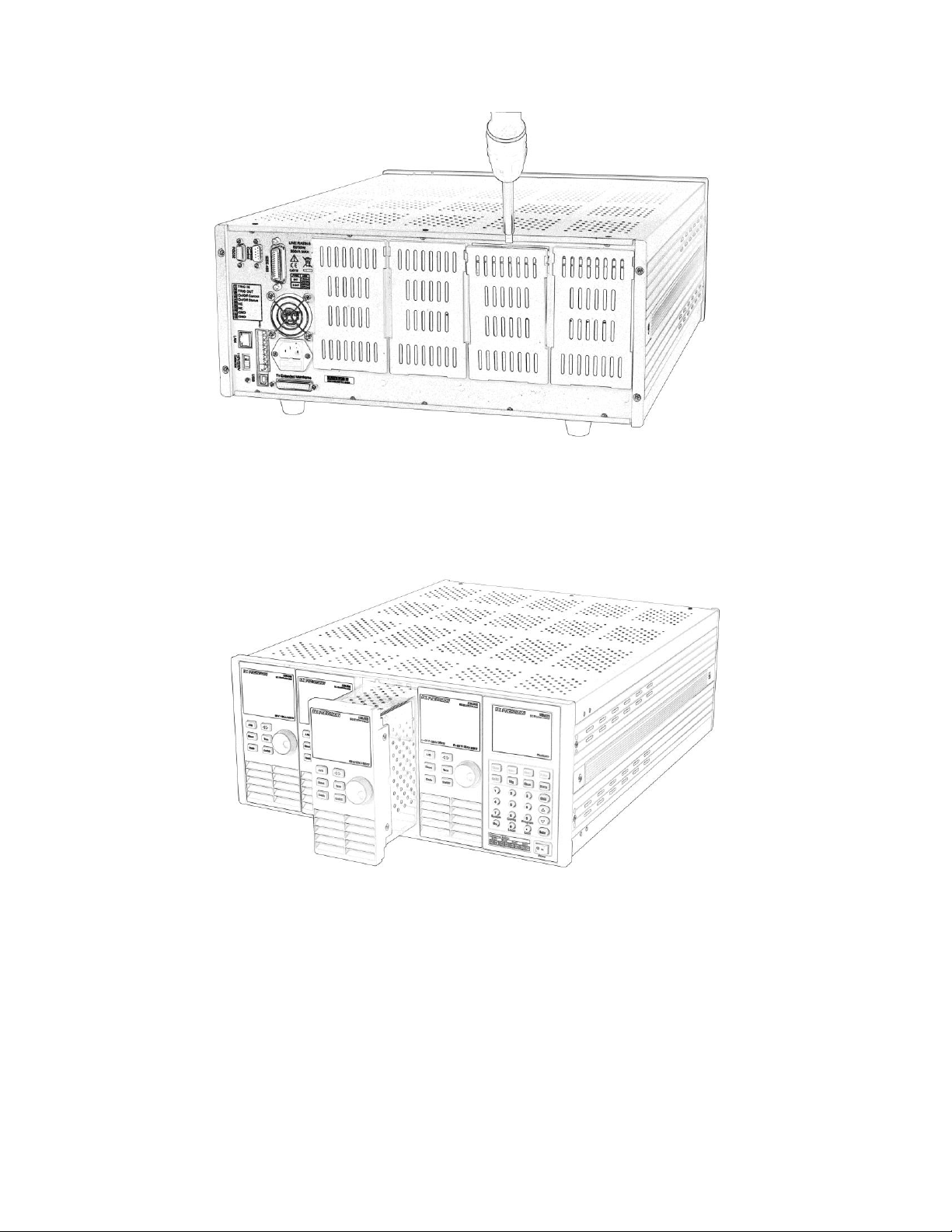

Installing Modules

CAUTION : Static electricity may damage load modules. Please install modules

according to standard electrostatic prevention. Avoid touching joints and circuit

boards.

One can install any combination of modules up to 2400 W total in the MDL001 mainframe in any

order. This also applies to the MDL002 mainframe extension, allowing a maximum of 4800 W total

when connecting the MDL001 and MDL002 together. The procedure of installing modules to the

mainframe extension is the same as that of the MDL001 mainframe.

Installation Procedure

1. Turn the mainframe off and disconnect the power cord.

2. Loosen screws on front panel plastic cover and remove from mainframe.

Figure 3a - Module Installation

3. Remove plastic cover on rear with flat-blade screwdriver.

22

Page 23

Figure 3b - Module Installation

4. Insert and slide the selected modules into the slot.

Figure 3c - Module Installation

5. Insert and tighten module screws on rear panel.

23

Page 24

Figure 3d - Module Installation

6. Install more modules in other slots following the same process (steps 2 through 5).

7. Reconnect the power cord.

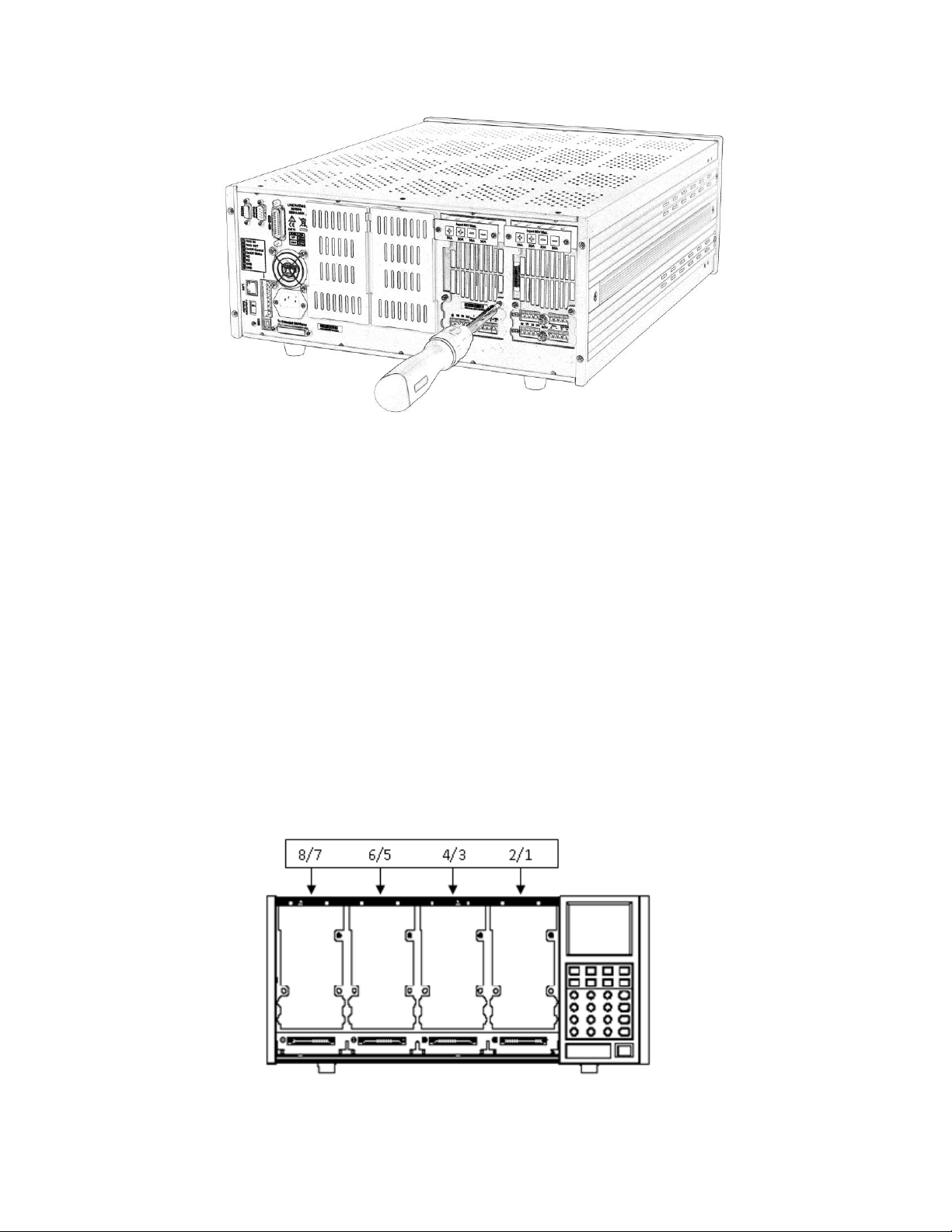

Channel Number

The channel number for all modules is determined by the location of the modules in relation to the

mainframe and ordered from right to left. With the MDL001 mainframe, the total number of

channels is 8. Channels 1 and 2 are next to the mainframe front panel, while channels 7 and 8 are

located on the left side. Load channel number is fixed even if the location is unoccupied. Dualchannel modules such as the MDL252 have two channels. If it is a single-channel module, the

channel number is automatically assigned the first number of the slot. Figure 4 shows the default

channel number order.

Figure 4 - Channel Number Distribution

24

Page 25

The following figures show examples of how channels are assigned when single-channel and dualchannel modules are installed.

Figure 5 - Channel Number Order When Installing Four Single-Channel Modules

Figure 6 – Channel Number Order When Installing Two Single-Channel Modules and Two Dual-Channel Modules

Note : Mainframe extension module channels are numbered 11-18.

Location

The operating temperature of the MDL Series DC Electronic Load is 0 to 40 ℃. A fan cools the

electronic load by drawing air through both the top and front, and then exhausting it out the back.

Therefore, the electronic load must be installed in a location that allows sufficient space on the

front and back of the unit for adequate air circulation. Minimum clearances for bench operation

are 2 inches from the top and 3 inches from the front and back. If there are radiator fans in your

25

Page 26

cabinet, please avoid installing the load near the fan, since it may limit air circulation of the load. If

CAUTION : Do not block the fan exhaust at the rear of the load. When the load is used

on a bench, make sure there is enough space on the front and rear of the equipment

for air circulation.

you are installing equipment on top of your electronic load in the cabinet, use a filler panel above

the unit to ensure adequate air circulation.

The MDL Series can be placed in a standard 19-inch rackmount shelf. Rack mount kit IT-E153A is

available for use with mainframe (MDL001) and mainframe extension (MDL002). When mounted,

there is no need to remove the bottom studs.

Figure 7 - MDL001 and MDL002 Outline Diagram

The MDL002 mainframe extension has the same dimensions as the MDL001 mainframe.

26

Page 27

CAUTION : Check to make sure correct fuse is installed when line voltage is switched.

Figure 8 - Module Outline Diagram

Note : Dimensions are in millimeters (mm).

Input Voltage Selection

The electronic load can work under 110/220V±10% AC input, identified by an input line voltage

switch on the rear (refer to Figure 9). If the indicated line voltage does not match your region,

please use the switch in the back of the unit to choose your input line voltage, install appropriate

fuse (refer to Table 1 - Fuse Table below), and then insert power cord.

27

Page 28

Figure 9 – Input Voltage Selection

Mainframe VFD Display

Description

BOIS Ver 1.20

VFD displays software version

SYSTEM SELF TEST

System self-check

CH1/2/3/4/5/6/7/8

SCAN…

□7□5□3□1

Detecting all installed modules

e.g.:CH01 CV OFF

Vdc=0.0000V Adc=0.0000A

Wdc= 0.00W

Displays information of channel 1 or the leftmost channel.

Use up and down key to select other channels.

WARNING: Your electronic load is equipped with a 3-wire grounding type power cord;

the third conductor being ground. The electronic load is grounded only when the

power-line cord is plugged into an appropriate receptacle. Do not operate your power

supply without adequate cabinet ground connection.

Turn-On Checkout

When you turn on the electronic load, the front-panel display will light up briefly while the

electronic load performs its power-on self-test. The following table shows the procedure of the

self-test.

28

Page 29

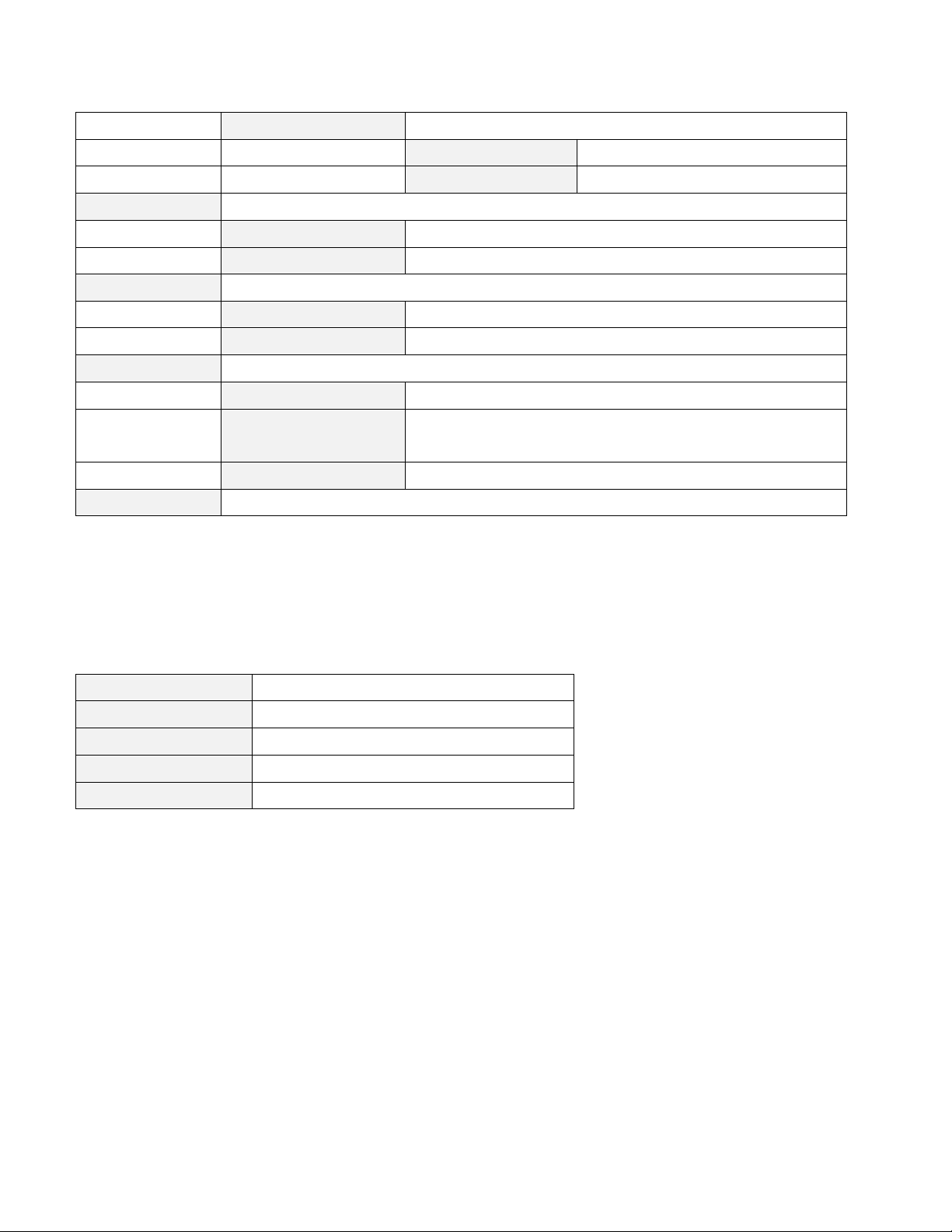

If the Electronic Load Does Not Turn On

Product

Fuse specification (110VAC)

Fuse specification (220VAC)

MDL001

T5A, 250V

T2.5A, 250V

MDL002

T5A, 250V

T2.5A, 250V

Use the following troubleshooting steps to help solve problems you might encounter when turning

on the instrument:

1) Verify that there is AC power to the electronic load.

First, verify that the power cord is firmly plugged into the power receptacle on the rear

panel of the electronic load. You should also make sure the power source you plugged the

electronic load into is energized. Then check to see that the electronic load is turned on.

2) Verify the power line voltage setting.

The line voltage is set to the proper value for your country (110VAC or 220VAC) when the

electronic load is shipped from factory. Change the line voltage setting if it is not correct.

3) Verify that the correct power line fuse is installed.

If fuse is blown, please replace it according to the following specification.

Table 1 - Fuse Table

4) Replace fuse.

Use a flat-bladed screwdriver to open the small plastic cover under the AC input connector

on the rear panel of the load and then replace with matching fuse.

Figure 10 - Fuse Location

29

Page 30

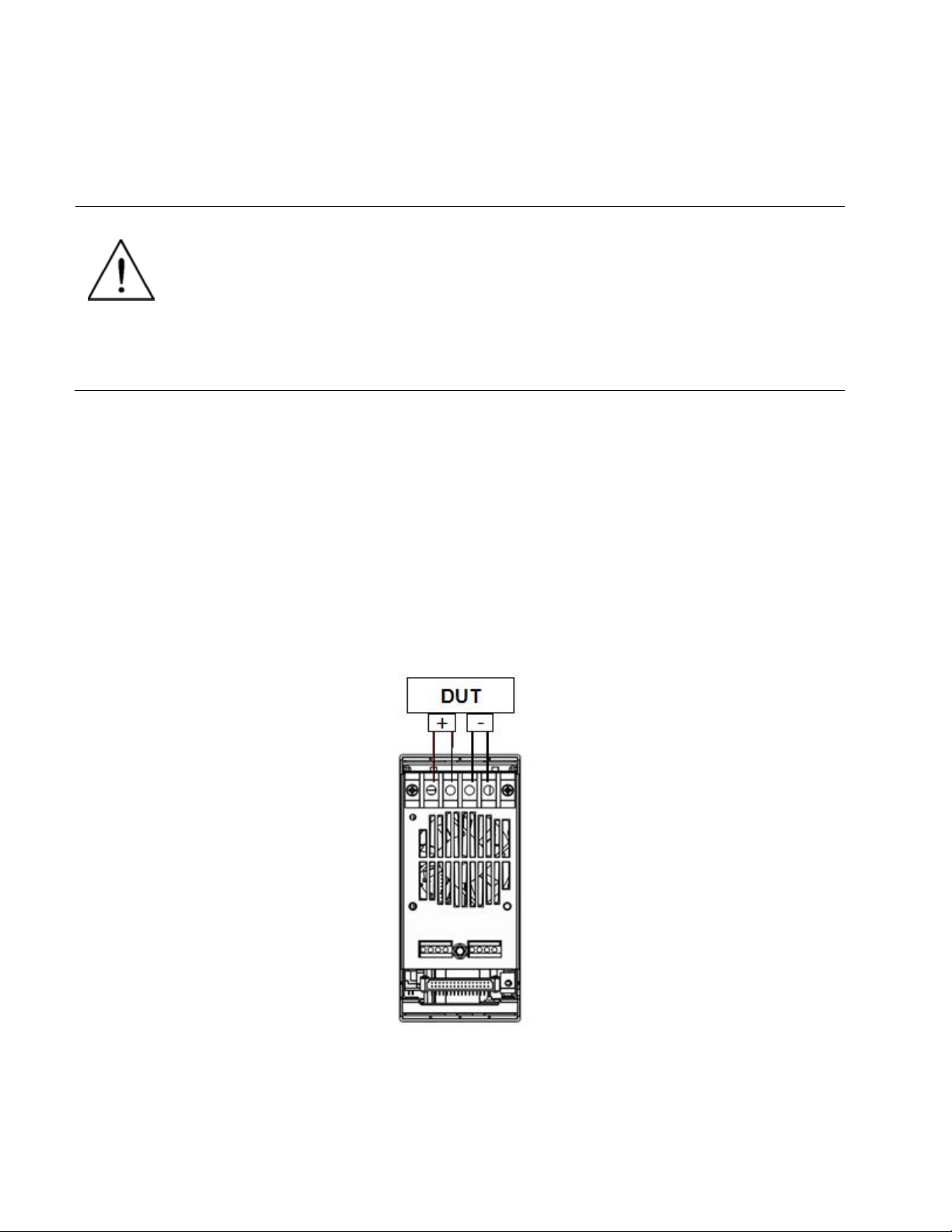

Load Connection

WARNING : To satisfy safety requirements, load wires between the electronic load

and the device under test (DUT) should have a current rating high enough not to

overheat while carrying the short-circuit output current. Never make connections

between the electronic load and a DUT while the electronic load inputs are turned ON

and/or the DUT has live power at its output.

Before connecting the device to be measured to the electronic load, please remove the cover on

the output terminals of the load and cover it after completing the connection. Please pay attention

to the type, length, and polarity when wiring. Avoid using wires of minimum specification of

heating, which are unable to supply good load regulation. Generally speaking, if the wires are short

enough, they can control a voltage drop of less than 0.5 V. In addition, bonding them together can

reduce induction and noise. Connect wire from positive terminal of module to positive terminal of

device. Similarly, connect the corresponding negative terminal. Figure 11 illustrates a typical

connection of the module with the device to be measured.

Figure 11 - Connection of Load and Device Under Test (DUT)

30

Page 31

There are two positive terminals and two negative terminals on the rear panel of every module.

WARNING : Each terminal can carry up to 30 A current. Double-terminal connection is

needed when the input current is more than 30 A. Refer to Figure 11 - Connection of

Load and Device Under Test (DUT) for double-terminal connection.

Single terminal connection is adequate when the input current is less than 30 A.

Remote Sense Connection

If the lead length is relatively long, there will be a voltage drop in the leads connected between

load and measured object. Remote sensing can compensate for this condition and provide better

accuracy in your measurement. Figure 12 illustrates a typical connection between module and

device for remote sense operation.

Figure 12 - Remote Sense Connection

31

Page 32

There are two input connectors. One is the electronic load’s input measurement terminal and the

CAUTION : The electric potential on the positive terminal of Vsense connector must

be higher than the negative terminal.

other is the Vsense measurement terminal. When Vsense is connected to device to be measured,

the electronic load will switch to Vsense mode automatically. There is no need to change a setting

in the menu and the front panel of the module will show “sense”.

Parallel Connection

Parallel connection can be applied between modules of the same model to increase current and

power dissipation, but it cannot be applied between different modules. Modules can be paralleled

in CC, CR, or CW mode, but cannot be paralleled in CV or CZ mode. Each module will dissipate the

power it has been programmed at. For example, after being paralleled, two single-channel

modules rated at 80V/40A/300W can dissipate up to 80V/80A/600W. Figure 13 illustrates the

paralleled connection for increased power dissipation.

Figure 13 - Parallel Module Connection

32

Page 33

Mainframe 8-pin Control Connector

Pin

Signal

Description

1

Trigger IN

Trigger Signal Input

2

Trigger OUT

Trigger Signal Output

3

ON/OFF IN

Synchronization ON/OFF Control Signal Input

4

ON/OFF OUT

Synchronization ON/OFF Signal Output

5

NC

No Connection

6

NC

No Connection

7

GND

Ground

8

GND

Ground

The mainframe’s 8-pin control terminal on the rear panel is shown below. This is used for external

trigger and ON/OFF control connections.

Figure 14 – Mainframe Rear Panel 8-pin Control Connector

Table 2 - Control Connector Pinout

33

Page 34

External Trigger Connections

There are five kinds of trigger modes:

1) Front panel TRIG trigger mode

2) Rear panel trigger mode

3) BUS trigger mode

4) Timer trigger mode

5) Hold trigger mode

Setting these modes is done through the System menu (Shift + ⑦) under <Trigger Source>. Press

Enter to confirm setting and Esc to exit menu.

Trigger Modes

1) To use front panel trigger mode, first set the trigger source as MANUAL. Press Trig to start

panel trigger mode.

2) To use rear panel trigger mode, first set the trigger source as EXTERNAL. Inputting a TTL

level pulse (>10 us) to the trigger signal input (pin 1) of mainframe’s Mainframe 8-pin

Control Connector on the rear panel will enable a trigger operation. The following figure

shows one way to produce a trigger signal.

When making contact with a TTL pulse source, it produces a trigger to change the setting

value (voltage, current, resistance, etc.), e.g. switch in transient mode, or create a pulse in

dynamic pulse mode. At the same time, it will output a trigger signal on pin 2.

3) To use BUS trigger mode, first set the trigger source as BUS. Connect the electronic load by

GPIB, USB, or Ethernet communication interface. When the TRIG command is received, the

load will produce a trigger signal.

4) To use timer trigger mode, first set the trigger source as TIMER. Set the TRIGGER TIMER's

time, and the electronic load will trigger at specified trigger timer setting and also produce

a trigger signal on rear Trigger Out pin.

5) To use hold trigger mode, first set trigger source as HOLD. Then send the TRIG:IMM

command to trigger the electronic load. Pin 2 of 8-pin Control Connector on the rear will

also output a corresponding trigger signal when the electronic load receives the TRIG:IMM

command.

34

Page 35

External ON/OFF Control Connection

ON/OFF IN (pin 3 of rear 8-pin Control Connector) is used to toggle the multi-channel electronic

load inputs ON or OFF. When ON/OFF IN pin receives a TTL level pulse (>10us), the ON/OFF state

of the load will toggle. SYNC ON SET function can be set to ON for multiple channels to toggle more

than one channel at a time.

ON/OFF OUT (pin 4 of rear 8-pin Control Connector) indicates ON/OFF state of the multi-channel

electronic load. If SYNC ON SET function of any specific channel is set to ON and the channel’s

input state is ON, pin 4 outputs a low TTL level signal. If the input state is off, pin 4 outputs a high

TTL level signal.

Mainframe Extension Connection

Figure 15 – Mainframe Extension Connection

This interface is used to connect the mainframe extension to expand the number of channels. Up

to 16 total channels can be supported when mainframe is connected to the mainframe extension.

Procedure:

1. Use expansion cable to connect the mainframe extension interface between the mainframe

and mainframe extension.

2. Press Shift + ⑦ to enter System menu. Use keys to navigate through menu.

3. Select <Expand module> and choose ON to enable expand function.

4. Press Enter to confirm.

35

Page 36

PC Control Connection

The MDL Series DC Electronic Load can achieve remote control via USB, RS-232, LAN, or GPIB

interface, but only one interface can be used at a time. Choose the interface via the System menu

(Shift + ⑦). Connect communication cable before powering on. Do not hot plug, as it may

damage the communication interface of the electronic load. The following procedure shows how

to connect the RS-232 cable between the electronic load and PC.

Procedure:

1. Connect RS-232 cable.

2. Power on the electronic load.

3. Select channel number via keys.

4. Enter System menu by pressing Shift + ⑦. Use keys to navigate through menus.

5. Select <Communication> and select <RS-232>. Press Enter to confirm.

6.

Now the display will return to main menu. Select

menu, you can set the values for baud rate, parity, and handshake using keys and

Enter key.

See Menu List for full listing of menus and submenus applicable to all other remote interfaces.

<RS-232 Set> and press Enter. In this

36

Page 37

Operation

Operating Modes

The electronic load can work in the following modes:

1) Constant current (CC) operation mode

2) Constant voltage (CV) operation mode

3) Constant resistance (CR) operation mode

4) Constant power (CW) operation mode

5) Constant impedance (CZ) operation mode

Constant Current (CC) mode

In this mode, the electronic load will sink a current in accordance with the programmed value

regardless of the input voltage.

Figure 16 - Constant Current Mode

Ranges

When working in CC mode, you can press the Setup key to enter the RANGE menu. Two

overlapping ranges can be selected: LOW RANGE or HIGH RANGE. Current can be edited in either

of the two ranges. Low range will supply higher accuracy and better resolution when you set lower

current. If any value you set is outside the maximum value of the LOW RANGE, you should select

HIGH RANGE. If the electronic load is in remote control mode, you can use the CURR:RANG

command to switch current range.

37

Page 38

Immediate Current Value

Set the current level via front panel or by sending SCPI command CURR <n>. If the load is in CC

mode, the new current level setting immediately changes the input at a rate determined by the

slew rate. If the load is not in CC mode, the current level setting will be saved for use until mode is

switched to CC mode.

Transient Current Level

A/B transient current level can be set on the front panel or by remote operation. The load can

continuously toggle between the two levels when transient operation is turned on.

Set Slew Rate

The current slew rate determines the rate at which the input current to a module changes to a new

programmed value. You can set the current level’s rise/fall slew rate on the front panel or by

remote operation. The programmed slew rate is immediately in effect to the triggered and

transient current level changes.

Slew Rate Measurement and Actual Transition time

Current slew rate is defined as the change in current over time. A programmable slew rate allows a

controlled transition from one load setting to another. The actual transition time is defined as the

time for the input to change from 10% to 90%, or 90% to 10% of the programmed current values.

The graph below illustrates slew rate measurements.

Figure 17 - Slew Rate Measurement

38

Page 39

Between the 10% and 90% region, the slew rate can be measured by observing the steepest slope

portion. In case of very large load changes, e.g. from no load to full load, the actual transition time

will be larger than the expected (measured) time. For this reason, the firmware allows the user to

program slew rate values outside of the specified slew rate ranges. The minimum transition time

for all programmable slew rates is also limited in cases where the transition from one setting to

another is very small, due to bandwidth limitations of the load.

Constant Voltage (CV) Mode

In this mode, the electronic load will attempt to sink enough current to control the source voltage

to the programmed value.

Figure 18 - Constant Voltage Mode

Ranges

When working in CV mode, you can press the Setup key to enter the RANGE menu. Two

overlapping ranges can be selected: LOW RANGE or HIGH RANGE. Voltage can be edited in either

of the two ranges. Low range will supply higher accuracy and better resolution when you set lower

current. If any value you set is outside the maximum value of the LOW RANGE, you should select

HIGH RANGE. If the electronic load is in remote control mode, you can use the VOLT:RANG

command to switch voltage range.

Voltage Level

Set the voltage level on front panel or by sending SCPI command VOLT <n>. If the load is in CV

mode, the new setting immediately changes the input. If the electronic load is not in CV mode, the

set voltage level will be saved in the instrument for use until the mode is switched to CV mode.

39

Page 40

Transient Voltage Level

A/B transient voltage level can be set on front panel or by remote operation. The electronic load

can continuously toggle between the two levels when transient operation is turned on.

Constant Resistance (CR) Mode

In this mode, the electronic load is equivalent to a constant resistance, as shown below. The

electronic load will linearly change the current, according to the input voltage.

Figure 19 - Constant Resistance Mode

Ranges

When working in CR mode, you can press the Setup key to enter the RANGE menu. Two

overlapping ranges can be selected: LOW RANGE or HIGH RANGE. Resistance can be edited in

either of the two ranges. Low range will supply higher accuracy and better resolution when you set

lower resistance. If any value you set is outside the maximum value of the LOW RANGE, you should

select HIGH RANGE. If the electronic load is in remote control mode, you can use the RES:RANG

command to switch resistance range.

Immediate Resistance Level

Set the resistance level via front panel or by sending SCPI command RES <n>. If the load is in CR

mode, the new resistance level setting immediately changes the input. If the load is not in CR

mode, the resistance level setting will be saved for use until mode is switched to CR mode.

Transient Resistance Level

A/B transient resistance level can be set on front panel or by remote operation. The load can

continuously toggle between the two levels when transient operation is turned on.

40

Page 41

Constant Power (CW) Mode

In this mode, the electronic load will consume a constant power. When input voltage increases,

the input current will decrease, while power (P = V*I) will remain the same.

Figure 20 - Constant Power Mode

Ranges

When working in CW mode, you can press the Setup key to enter the RANGE menu. Two

overlapping ranges can be selected: LOW RANGE or HIGH RANGE. Power can be edited in either of

the two ranges. Low range will supply higher accuracy and better resolution when you set lower

power. If any value you set is outside the maximum value of the LOW RANGE, you should select

HIGH RANGE. If the electronic load is in remote control mode, you can use the POW:RANG

command to switch power range.

Immediate power level

Set the power level via the front panel. If the load is in CW mode, the new power level setting

immediately changes the input. If the load is not in CW mode, the power level setting will be saved

for use until mode is switched to CW mode.

Transient power level

A/B transient power level can be set via the front panel or by remote operation. The electronic

load can continuously toggle between the two levels when transient operation is turned on.

Constant Impedance (CZ) Mode

In this mode, the electronic load uses an A/D converter to sample and a built-in DSP calculation to

simulate the transient current wave of the tested components.

Circuit principle is as follows:

41

Page 42

V

S

Ls Rs

R

L

C

L

+

-

Is

Figure 21 - Constant Impedance Mode

Ranges

When working in CZ mode, you can press the Setup key to enter the RANGE menu. Two

overlapping ranges can be selected: LOW RANGE or HIGH RANGE. Impedance can be edited in

either of the two ranges. Low range will supply higher accuracy and better resolution when you set

lower impedance. If any value you set is outside the maximum value of the LOW RANGE, you

should select HIGH RANGE. If the electronic load is in remote control mode, you can use the

IMP:RANG command to switch impedance range.

Immediate Impedance level

Set the impedance level via the front panel. If the load is in CZ mode, the new impedance level

setting immediately changes the input. If the load is not in CZ mode, the impedance level setting

will be saved for use until mode is switched to CZ mode. You should select the channel to be edited

before setting impedance parameters. Press the SETUP button to enter CZ mode. After choosing

the high-low range, the front panel will display the following:

Rset: set the impedance value (RL)

Vmax: set the maximum voltage

Vmin: set the minimum voltage

RLC R: set the series resistance value (Rs)

RLC L: set the series inductance value (Ls)

RLC C: set the parallel capacitance value (CL)

42

Page 43

Setting CV, CC, CR, CW, CZ Mode

Panel Operations

VFD Display

1. Power on the electronic load.

Self-test

2. Press keys to select the channel to be edited, such as channel 1.

CH01 CC OFF

Vdc=0.0000V

Adc=0.0000A

Wdc=0.00W

3.

Press Setup key to enter the channel setup menu, press Enter key to

enter the <Mode> selection menu and press key to select CV, CC, CR,

CW, or CZ mode. Press Enter key to confirm.

CH01

Mode=CC

RANGE=HIGH

Iset=9.000A

4. Press key to select <Range> selection menu. Press Enter key to enter

the <Range> selection menu and press key to choose <Low Range> or

<High Range>. Press Enter key to confirm.

CH01

HIGH RANGE

LOW RANGE

5. Press key to select the voltage setting <Vset>, current setting <Iset>,

resistance setting <Rset>, power setting, or impedance setting and press

Enter key to confirm.

CH01

Const Current

Set= 1.25A

6. Press key to select the rise slope setting <∫>. Input value and press

Enter key to confirm. (CC mode only)

CH01

Rise Speed Set

= 1.00A/Us

7. Press key to select the fall slope setting <∫>. Input value and press

Enter key to confirm. (CC mode only)

CH01

Fall Speed Set

= 2.00A/Us

8. Press Esc key to exit.

9. Press On/Off key to turn on the load’s input.

CH1 CC ON

Vdc=0.0000V

Adc=0.0000A

Wdc=0.00W

The following procedure will show you a basic example of how to set up your operation mode from

the front panel.

43

Page 44

Local Operation

Mainframe Panel

The front panel keys are effective only in the local mode. When the load is powered on, it works in

local mode automatically (unless any of the remote interfaces are connected to a device

controlling it) and then you can select channel number and set parameters such as voltage or

current via the front panel keys. When the load is repowered on, the mainframe will scan all the

installed modules once again, and can recall the parameters from the last time it was powered off.

Figure 22 - MDL001 Mainframe Front Panel

1. VFD DISPLAY

When powering on, the VFD screen will light up and show the instrument’s firmware version.

Then the system will begin power-on self-test, check all the installed modules of the load,

and display every channel’s number, voltage, and current measurements.

44

Page 45

2. FUNCTION KEYS

Key

Description

Chan

This key is used to switch channels. Every module has its own channel number and can be

selected from the mainframe panel.

Save

This key is used to save parameters. After selecting a channel and editing its parameters,

press the Save key to save your settings into non-volatile memory. Up to 101 groups of

parameters can be saved.

Recall

This key can be used to quickly recall a saved group of parameters from memory.

Setup

This key is used to enter the specific channel’s menu. For example, pressing this key allows

you to set up A/B transient mode and CC/CV/CR/CW/CZ mode. For more details, view the

Menu List section.

On/Off

This key is used to turn the module’s input state on or off. When the synchronization function

in the channel menu is enabled, pressing this key can control the on/off state of all channels.

Trig

This key is used to trigger the electronic load. Select the Manual Trigger mode to use front

panel triggering.

Start

This key is used to start an automatic test.

Pause

This key is used to pause an automatic test. The VFD will display pausing at each step. Press

the key again to test the file continuously.

45

Page 46

3. ENTRY/SHIFT KEYS

Key

Description

⓪ ①

② ③

④ ⑤

⑥ ⑦

⑧ ⑨

These are number input keys.

Esc

This key can be used to exit any working state.

This key is used for decimal.

These keys are used to move up and down the menu selection.

Enter

This key is used to confirm selection.

Shift

This key is used to enter other menus and functions.

Shift + ⑦

(System)

Press this key combination to enter the System menu.

Shift + ⑧

(Config)

Press this key combination to enter the Configuration menu.

Shift + ⑨

(Program)

Press this key combination to enter the Program menu.

Shift + ⓪

(Local)

Press this key to switch the electronic load to local mode when in remote sense mode.

Shift +

(Lock)

Press this key to lock the module’s panel keys and knob. Repress the button to unlock.

4. POWER SWITCH

This switch turns the electronic load on or off.

46

Page 47

Module Panel

Key

Description

A/B

(single channel modules)

Switch A/B transient preset value.

L/R

(dual-channel modules)

Switch the left/right channels. Press this key + rotary knob to control

the two channels.

Short

Used for short testing. This allows the load to simulate a short circuit

at the input.

Mode

Switches the operating mode (CC, CR, CV, CW, CZ).

Move the cursor position. Press key to move the cursor to the position

you want to edit, and then use the rotary knob to adjust value.

Figure 23 - Module Front Panel

1. VFD DISPLAY

Bright VFD display shows module‘s operating mode.

2. ROTARY KNOB

Used to change parameter values.

3. PANEL KEYS

47

Page 48

Tran

Selects the transient mode. Press this key first to enable transient

mode before running A/B transient operation and then send the

triggering signal to run a program.

On/Off

Control module’s input on/off state

WARNING : Do not place any objects that may block or cover air inlet.

4. AIR INLET

Module’s air inlet for cooling purposes.

Module Panel Lock

Press Shift + key to lock current channel’s keys and knob operation. To unlock, press Shift +

key again.

Switching Channels

There are three ways to switch channels:

1) Press Chan + number key

2) Press Chan + key

3) Press the number key of the channel in SETUP menu

Channel Synchronization

If you want to change the synchronization of the channels, you can set this in the Configuration

menu. Switch to the channel on the mainframe and then press Shift + ⑧ key to enter the

Configuration menu. Select and enter the <SYNC ON SET> submenu. Select <ON> or <OFF> and

press Enter. When you turn on this function, the On/Off key can control the input state of the

corresponding module synchronously. In the same method, you can set up synchronization with

other channels. When in remote control mode, you can send SCPI command INPut:ALL ON to

synchronously load all channels.

48

Page 49

VFD Indicator Function Description

The detailed illustration of the VFD and all indicator functions are as follows:

Figure 24 - Load Module VFD Panel

L/R is the indicator of the dual-channel module’s left/right channel. If you want to edit left/right

channel parameters, first select the channel using the L/R key. Single-channel module will always

display R.

OFF indicates that the module input is off. When module input is enabled, OFF indicator will turn

off.

CC/CV/CR/CW/CZ indicates the module’s operating mode.

VFD display screen shows four lines of numbers. The first line shows the measured voltage value.

The second line shows the measured current value. The third line shows the measured circuit’s

power value. The fourth line shows the setup value, and users can set A/V/Ω value here.

Short is displayed when short circuit function is enabled on the module.

Tran is displayed when TRANSIENT mode is enabled on the module.

List is displayed when selecting LIST mode in the Configuration menu.

Sense is enabled in remote sense function. There is no need to set this in the menu, as you only

need to link the circuit to remote sense terminals and ‘Sense’ will be displayed.

49

Page 50

Transient Operation

Continuous

Generates a respective pulse stream that toggles between two load levels.

Pulse

Generates a load change that returns to its original state after some time period.

Toggle

Generates a repetitive pulse stream that toggles between two load levels.

It is similar to continuous mode except that the transient points are controlled by

explicit triggers instead of an internal transient generator.

Transient operation enables the module to periodically switch between two load levels, as might

be required for testing power supplies. Transient operation can be turned on and off from the

front panel (Tran and Trig keys). Before you turn on the operation, you should set the parameters

associated with the transient operation. The parameters include: A level, A width, B level, B width,

and transient testing modes. There are three different transient testing modes: continuous, pulse,

and toggle.

Continuous

In this mode, the electronic load generates a repetitive pulse stream that toggles between two

load levels. Load could switch the state between two value settings, value A and value B.

In CC mode, transient testing can be used to check the stability of the source voltage. Transient

functions have two current levels (A level, B level), which should be in the same range (high range

or low range). You can set the A/B level delay time and the rise/fall slew rate via the mainframe

keypad.

The slew rate determines the rate at which the level changes. Press Trig key, and the load will

continuously switch between the A/B levels preset. Transient loads are usually used to test the

power supply’s performance under continuous changing load conditions. Figure 25 shows the

current waveform of continuous transient operation mode.

50

Page 51

Figure 25 - Continuous Transient Operation Current Waveform

Pulse

In this mode, the electronic load generates a transient pulse of programmable width when pulse

transient operation is in effect.

In pulse mode, you can set A/B level, A/B width, and A/B slew rate via the mainframe keypad. The

electronic load will automatically switch to A level after maintaining A width time. Then it will

switch to B level. The electronic load will not switch to A level again until the instrument receives

the pulse signal. The following figure shows the current waveform in pulse transient operation.

Figure 26 - Pulse Transient Operation

51

Page 52

Toggle

In toggle mode, the electronic load will switch between A level and B level when receiving a trigger

signal after the transient operation is enabled. The following picture shows the current waveform

in toggle transient operation.

Figure 27 - Toggle Transient Operation

Setting Up A/B Transient Operation

The following is a short tutorial of how to set up A/B transient operation for your electronic load.

In this example, we will set up rise speed at 1 A/us and fall speed at 2 A/us. The electronic load will

be in continuous transient mode and switch between 10 A and 2 A in durations of 0.002 s and

0.003 s respectively.

Note : When setting up steps, make sure all transient level, slew, and width parameters are

within the modules’ specified limits.

52

Page 53

A/B Transient Operation Tutorial

Panel Operations

VFD Display

1. Power on the electronic load.

Self-test

2. Press keys to select the channel to be edited. In this example, we

select channel 1.

CH01 CC OFF

Vdc = 0.0000V

Adc = 0.0000A

Wdc = 0.00W

3. Press Setup to enter the channel setup menu. Select <Mode> and

press Enter to change the operating mode to CC mode. Press Enter to

confirm.

CH01

Mode=CC

RANGE=HIGH

Iset=9.000A

4. Press key to select <Range> setting and press Enter. Then press

key to select LOW RANGE and press Enter to confirm.

CH01

HIGH RANGE

LOW RANGE

5. Press key to select the rise slope setting <∫> and press Enter. For

1A/us, input 1 and press Enter to confirm.

CH01

Rise Speed Set

= 1.00A/Us

6. Press key to select the fall slope setting <∫> and press Enter. For

2A/us, input 2 and press Enter to confirm.

CH01

Fall Speed Set

= 2.00A/Us

7. Press key to select A level setting <TRANa> and press Enter. For

10A, input 10 and press Enter to confirm.

CH01

Transition A

Level = 10.00A

8. Press key to select A width setting <Ta> and press Enter. For 0.002s,

input .002 and press Enter to confirm.

CH01

Tran. A Width =

0.002S

9. Press key to select B level setting <TRANb> and press Enter. For 2A,

input 2 and press Enter to confirm.

CH01

Transition B

Level = 2.00A

10. Press key to select B width setting <Tb> and press Enter. For 0.003s,

input .003 and press Enter to confirm.

CH01

Tran. B Width =

0.003S

11. Press key to select transient operation mode <Tmode> and press

Enter. Select Continuous and press Enter key to confirm.

CH01

Continuous

Pulse

Toggle

53

Page 54

12. Press Esc key to exit.

CH01 CC OFF

Vdc = 0.0000V

Adc = 0.0000A

Wdc = 0.00W

13. Press Shift + ⑦ to enter System menu. Press key to select <Trigger

source> and press Enter. Select <Manual> and press Enter to confirm.

MANUAL

EXTERNAL

HOLD

BUS

TIMER

14. Press Esc key to exit.

CH01 CC OFF

Vdc = 0.0000V

Adc = 0.0000A

Wdc = 0.00W

15. Press On/Off key to turn on the electronic load’s input.

CH01 CC ON

Vdc = 0.0000V

Adc = 0.0000A

Wdc = 0.00W

16. Press Tran key on channel 1 module to enable transient operation.

17. Press Trig key on mainframe panel to trigger transient operation.

Transient Operation Programming Example

If in remote control mode, you can use the following example commands for transient operation

(refer to MDL Series Programming Guide for more information).

CURRent:TRANsient:MODE CONTinous

CURRent:TRANsient:ALEVel 10

CURRent:TRANsient:AWIDth 0.2ms

CURRent:TRANsent:BLEVel 2

CURRent:TRANsient:BWIDth 0.3ms

TRANsient ON

TRIGger:IMMediate

54

Page 55

List Operation

Panel Operations

VFD Display

1. Power on the electronic load.

Self-test

List mode lets you generate complex sequences of input changes on a single channel with rapid,

precise timing, which may be synchronized with internal or external signals. This is useful when

running test sequences with a minimum amount of overhead.

The parameters of List operation include the name, number of steps (2-84), step width time (20us3600s), and every steps’ set value and slew rate. The list file can be saved in non-volatile memory

where it can be quickly recalled. Users can edit up to 7 groups of List files in CC mode only.

In List operation mode, the electronic load begins to enable the List operation when it receives the

trigger signal and will continue until the List operation is completed or the instrument receives

another trigger signal.

List Sequence

Figure 28 - List Mode Current Waveform

Setting Up List Operation Mode

The following is a quick tutorial of how to set up List Mode for your electronic load.

55

Page 56

2. Press keys to select the channel to be edited.

CH01 CC ON

Vdc=0.0000V

Adc=0.0000A

Wdc=0.00W

3. Press Shift + ⑦ to enter System menu. Press key to select <Trigger

source> and press Enter. Select <Manual> and press Enter to confirm.

MANUAL

EXTERNAL

HOLD

BUS

TIMER

4. If electronic load is on, press On/Off key to turn off the electronic

load’s input.

CH01 CC OFF

Vdc=0.0000V

Adc=0.0000A

Wdc=0.00W

5. Press Shift + ⑧ to enter Configuration menu. Press key to select

<List> and press Enter. Press key to select <Edit List> and press

Enter.

FUNCTION MODE

RECALL LIST

EDIT LIST

EXIT

6. Press key to select high range or low range and press Enter to

confirm.

High Range

Low Range

7. Input number of steps in List. Input value and press Enter to confirm.

List file step

= 5

8. Set first step’s current level. Input value and press Enter key to

confirm.

Step 001 level

= 1A

9. Set first step’s slew rate. Input value and press Enter key to confirm.

Step 001 rate

= 0.5A/us

10. Set first step’s width time. Input value and press Enter key to confirm.

Step 001 width

= 6S

11. Set second step’s current level. Input value and press Enter key to

confirm.

Step 002 level

= 2A

12. Set second step’s slew rate. Input value and press Enter key to

confirm.

Step 002 rate

= 0.1A/us

56

Page 57

13. Set second step’s width time. Input value and press Enter key to

confirm.

Step 002 width

= 5S

14. Set parameters for steps 3 through 5 in the same manner described

above.

15. Set number of run cycles. Input value and press Enter to confirm.

Repeat Count

= 1