Page 1

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be followed during all

phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

• Read and understand the safety and operational information in this manual.

• Apply all the listed safety precautions.

• Verify that the voltage selector at the line power cord input is set to the correct line voltage. Operating the instrument

at an incorrect line voltage will void the warranty.

• Make all connections to the instrument before applying power.

• Do not operate the instrument in ways not specied by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the safety standards of design,

manufacture, and intended use of the instrument. B&K Precision assumes no liability for a customer’s failure to comply

with these requirements.

Category rating

The IEC 61010 standard denes safety category ratings that specify the amount of electrical energy available and the

voltage impulses that may occur on electrical conductors associated with these category ratings. The category rating is

a Roman numeral of I, II, III, or IV. This rating is also accompanied by a maximum voltage of the circuit to be tested,

which denes the voltage impulses expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be connected

to the mains supply. The voltages in the environment are typically derived from a limitedenergy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be connected to

the mains supply at a standard wall outlet or similar sources. Example measurement

environments are portable tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be connected to

the mains installation of a building. Examples are measurements inside a building’s circuit breaker panel or the wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be connected to

the primary power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is specied in this manual

for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or higher than the

instrument’s category rating to maintain the instrument’s category rating. Failure to do so will lower the category rating

of the measuring system.

1

Page 3

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains power should be

115 V RMS or 230 V RMS. Use only the power cord supplied with the instrument and ensure it is appropriate for your

country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical safety ground. This

instrument is grounded through the ground conductor of the supplied, three-conductor AC line power cable. The power

cable must be plugged into an approved three-conductor electrical outlet. The power jack and mating plug of the power

cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible conductive parts

(including control knobs) may provide an electric shock. Failure to use a properly-grounded approved outlet and the

recommended three-conductor AC line power cable may result in injury or death.

Unless otherwise stated, a ground connection on the instrument’s front or rear panel is for a reference of potential only

and is not to be used as a safety ground. Do not operate in an explosive or ammable atmosphere.

Do not operate the instrument in the presence of ammable gases or vapors, fumes, or nely-divided particulates.

The instrument is designed to be used in oce-type indoor environments. Do not operate the instrument

• In the presence of noxious, corrosive, or ammable fumes, gases, vapors, chemicals, or nely-divided particulates.

• In relative humidity conditions outside the instrument’s specications.

• In environments where there is a danger of any liquid being spilled on the instrument or where any liquid can condense

on the instrument.

• In air temperatures exceeding the specied operating temperatures.

• In atmospheric pressures outside the specied altitude limits or where the surrounding gas is not air.

• In environments with restricted cooling air ow, even if the air temperatures are within specications.

• In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating temperature range is

0∘C to 40∘C and 20% to 80% relative humidity, with no condensation allowed. Measurements made by this instrument

may be outside specications if the instrument is used in non-oce-type environments. Such environments may include

rapid temperature or humidity changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise,

strong electric elds, or strong magnetic elds.

2

Page 4

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets on or inside the

instrument, remove the instrument’s power cord, remove the instrument from service, label it as not to be operated,

and return the instrument to B&K Precision for repair. Notify B&K Precision of the nature of any contamination of the

instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants, solvents, acids/bases,

or other such chemicals. Clean the instrument only with a clean dry lint-free cloth or as instructed in this manual. Not

for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component in a life-support

device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and internal adjustments must

be made by qualied service-trained maintenance personnel who are aware of the hazards involved when the instrument’s

covers and shields are removed. Under certain conditions, even with the power cord removed, dangerous voltages may

exist when the covers are removed. To avoid injuries, always disconnect the power cord from the instrument, disconnect

all other connections (for example, test leads, computer interface cables, etc.), discharge all circuits, and verify there

are no hazardous voltages present on any conductors by measurements with a properly-operating voltage-sensing device

before touching any internal parts. Verify the voltage-sensing device is working properly before and after making the

measurements by testing with known-operating voltage sources and test for both DC and AC voltages. Do not attempt

any service or adjustment unless another person capable of rendering rst aid and resuscitation is present.

Do not insert any object into an instrument’s ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault condition in the circuit

exists.

Fuse replacement must be done by qualied service-trained maintenance personnel who are aware of the instrument’s fuse

requirements and safe replacement procedures. Disconnect the instrument from the power line before replacing fuses.

Replace fuses only with new fuses of the fuse types, voltage ratings, and current ratings specied in this manual or on

the back of the instrument. Failure to do so may damage the instrument, lead to a safety hazard, or cause a re. Failure

to use the specied fuses will void the warranty.

Servicing

3

Page 5

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the instrument to

B&K Precision for service and repair to ensure that safety and performance features are maintained.

For continued safe use of the instrument

• Do not place heavy objects on the instrument.

• Do not obstruct cooling air ow to the instrument.

• Do not place a hot soldering iron on the instrument.

• Do not pull the instrument with the power cord, connected probe, or connected test lead.

• Do not move the instrument when a probe is connected to a circuit being tested.

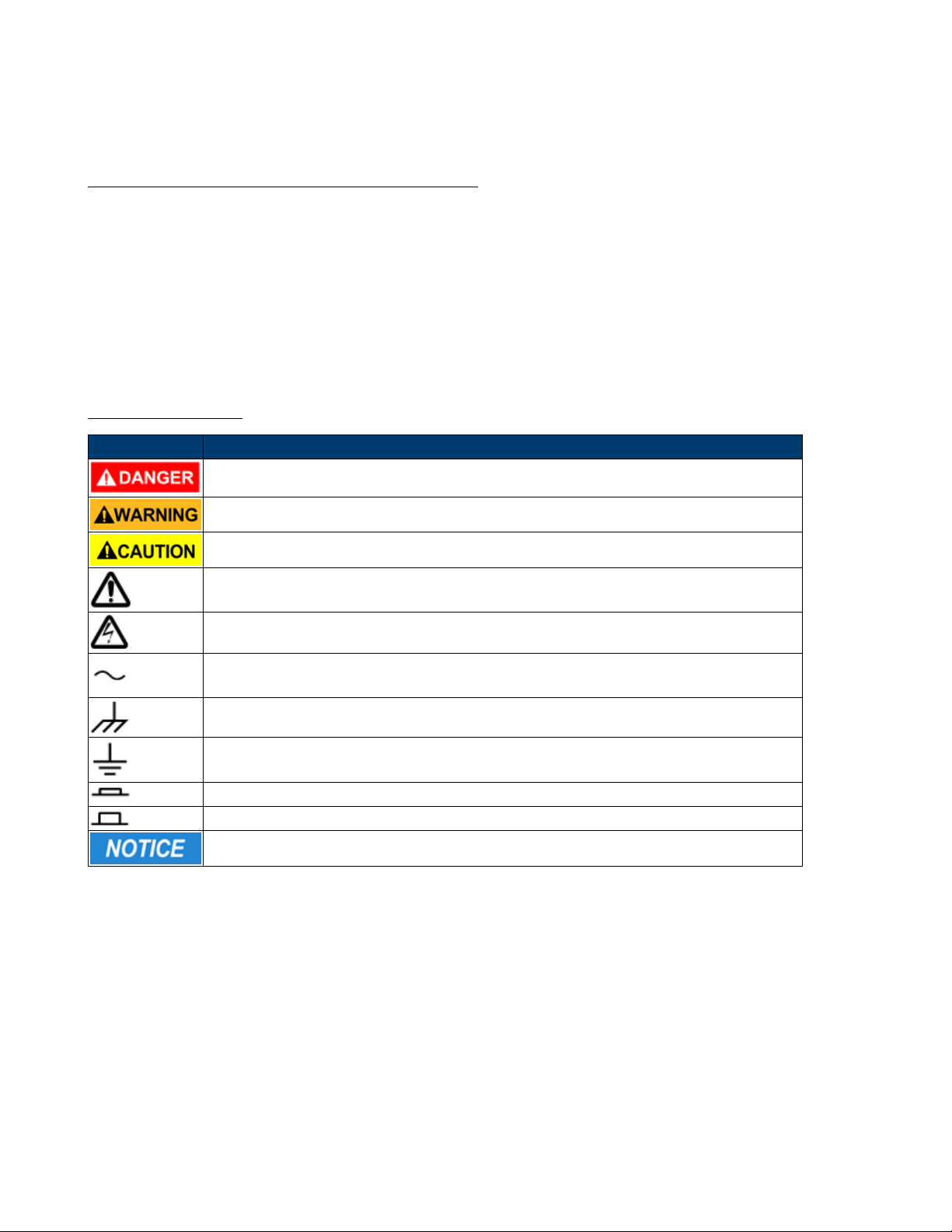

Safety Symbols

Symbol Description

indicates a hazardous situation which, if not avoided, will result in death or serious injury.

indicates a hazardous situation which, if not avoided, could result in death or serious injury

indicates a hazardous situation which, if not avoided, will result in minor or moderate injury

Refer to the text near the symbol.

Electric Shock hazard

Alternating current (AC)

Chassis ground

Earth ground

This is the In position of the power switch when instrument is ON.

This is the Out position of the power switch when instrument is OFF.

is used to address practices not related to physical injury.

2

Page 6

Contents

1 Introduction 6

1.1 Electrical Connections 6

1.2 DAS240-BAT Extension Module 6

1.3 Home screen 8

1.4 Recording Period 8

1.4.1 Example: Recording 9 Channels 9

1.4.2 Example: Power-Line, engine noise, or other electrical noise. 9

2 Setup 10

2.1 Switching On 10

2.1.1 Switching Off 10

2.1.2 In Case of Error 11

2.2 Extension Modules (DAS240-BAT only) 11

2.3 External Power 12

2.4 Battery 12

2.4.1 To Ensure Long Battery Life 12

2.4.2 To Charge the Battery 13

2.5 Calibration 13

2.5.1 Factory Default Calibration 13

2.6 Keypad Lock 14

2.7 System Setup 14

2.8 Language 14

2.9 Screen Shut Off (Dimming) 15

2.10 VNC 15

2.11 Additional Options 15

2.12 Firmware Update 15

2.13 Instrument Conguration Loading and Saving 15

2.14 Network 15

2.15 Alarms 16

3 Channel Setup 17

3.1 All Channels Screen 17

3.2 Individual Channel Screen 17

3.3 Extension Modules (DAS240-BAT only) 17

3.4 Measurement Connections 18

3.4.1 Voltage Measurement 18

3.4.2 Temperature Measurement With a Thermocouple 19

3.4.3 Temperature Measurement With Pt100/Pt1000 and RTD 19

3.4.4 Resistance Measurement 19

3.4.5 Current Measurement 20

4 F(t) Plot 22

4.1 Screen Setup 22

4.1.1 Custom Pages 23

4.2 Freeze Screen and Cursor Measurements 23

4.3 Time Base 24

4.4 Math 24

4.4.1 Math Functions 25

5 XY Plot 28

6 Numeric Display 30

3

Page 7

7 Recording 31

7.1 Create a Recording 31

7.2 View Recording 31

7.2.1 Loading a Recording 31

8 Triggering Recordings 34

8.1 Waiting Start Condition 34

8.2 Recordings 34

8.3 Triggering 35

8.3.1 Single Analog Channel Trigger 35

8.3.2 Single Threshold 36

8.3.3 Multiple Thresholds 37

8.3.4 Trigger Examples 38

8.4 Trigger on Logic Channels 38

9 Alarms 39

9.1 Alarm Status 39

9.2 Analog/Math/Timing Signal Alarm 40

9.3 Analog Signal Combination Alarm 40

9.4 Logic (Digital) Signal Alarm Trigger 41

9.5 Alarm on Recording Start (Trigger Acquisition) 42

10 Logic Channels 43

10.1 Logic Input Connector 43

10.2 Logic Channel Setup 43

10.3 Timing 44

10.4 Alarm Outputs 44

11 File Management 46

11.1 Note: 46

11.1 Setup Files 46

11.1.1 Default 47

11.1.2 Save Setup Files 47

11.1.3 Load Setup Files 47

11.2 Recordings Files 47

12 Remote Interfaces 48

12.1 LAN Interface 48

12.1.1 LAN Setup 48

12.2 VNC 48

12.2.1 Changing the Password 48

12.3 Network File Transfer 48

12.4 Viewing with SeframViewer 49

12.4.1 Example 50

12.5 Device Control with DASLab 50

12.6 Modbus (slave) 51

12.6.1 Setup Modbus Slave 51

12.6.2 Mapping Modbus TCP 52

12.6.2.1 Analog Data 52

12.6.2.2 Logical Data 52

13 Maintenance 53

13.1 Updating the Internal Software 53

14 Specications 54

4

Page 8

15 Thermocouple Measurement Accuracy 55

15.1 J Type Thermocouple Example 55

15.2 Measurement Accuracy: Pm 55

15.3 Voltage of Thermocouple (mV) 55

15.3.1 Example of Accuracy Calculation 56

15.4 Accuracy Class - Class Index 56

15.5 Grounding 57

16 LIMITED TWO-YEAR WARRANTY 58

17 Service Information 59

5

Page 9

Introduction

DAS240-BAT DAS220-BAT

Figure 1.1 Front View

The DAS240-BAT and DAS220-BAT programmable recorders can measure measure voltage, current, temperature (thermocouple, Pt100, Pt1000), resistances, and logic channels. Highlights include:

• An intuitive interface on a wide capacitive and color 10” touchscreen

• 32GB internal memory for storing recordings

• Composed of a main base frame and extension modules of 20 channels each

• Programmable via Ethernet using NTP, FTP and VNC protocols

• Built-in battery with capacity to run the recorder for hours

Model Channels

DAS240-BAT 20-200 using expansion blocks

DAS220-BAT 10

Table 1.1 Channel Options

1.1 Electrical Connections

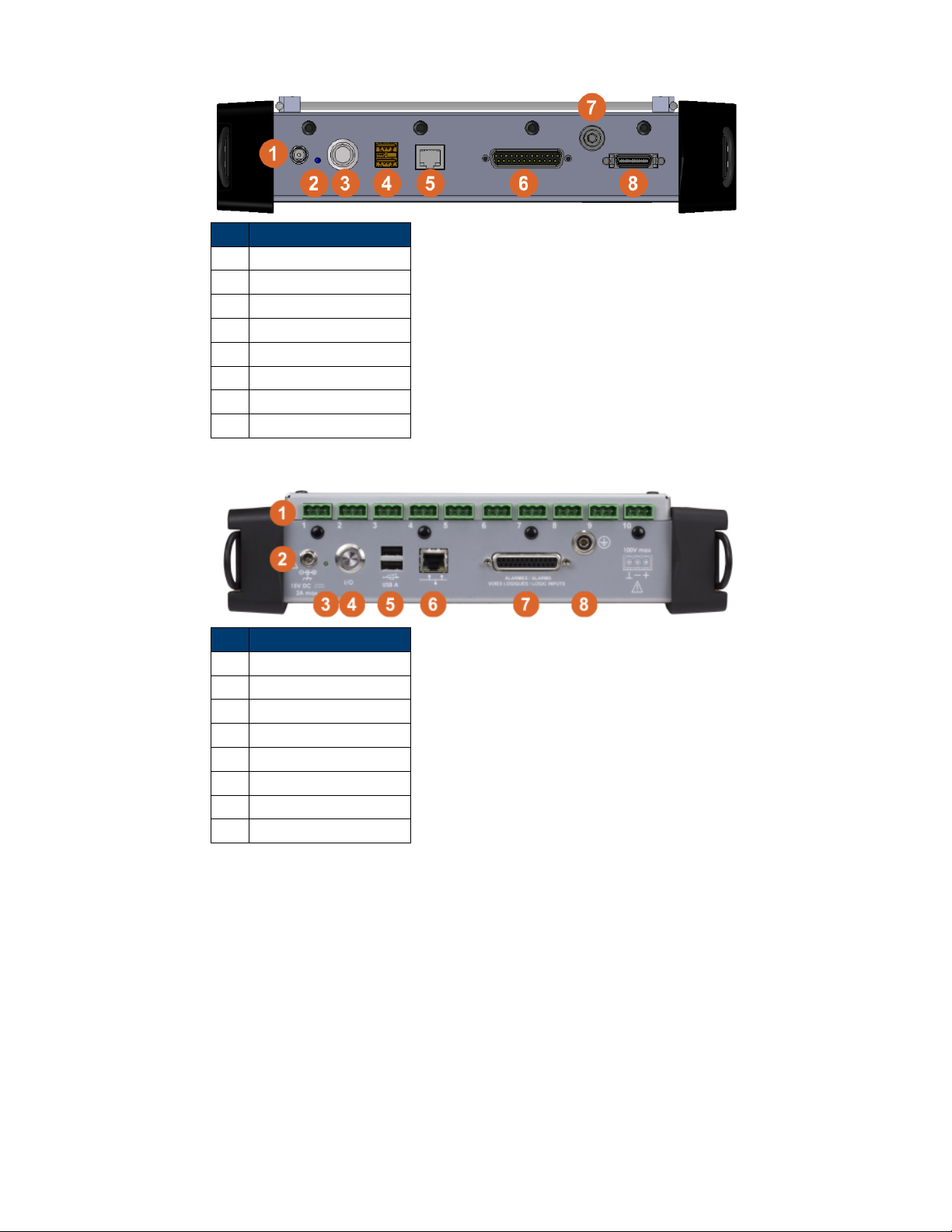

Connection to the recorders uses modular connectors shown in Figure 1.2 and Figure 1.3.

1.2 DAS240-BAT Extension Module

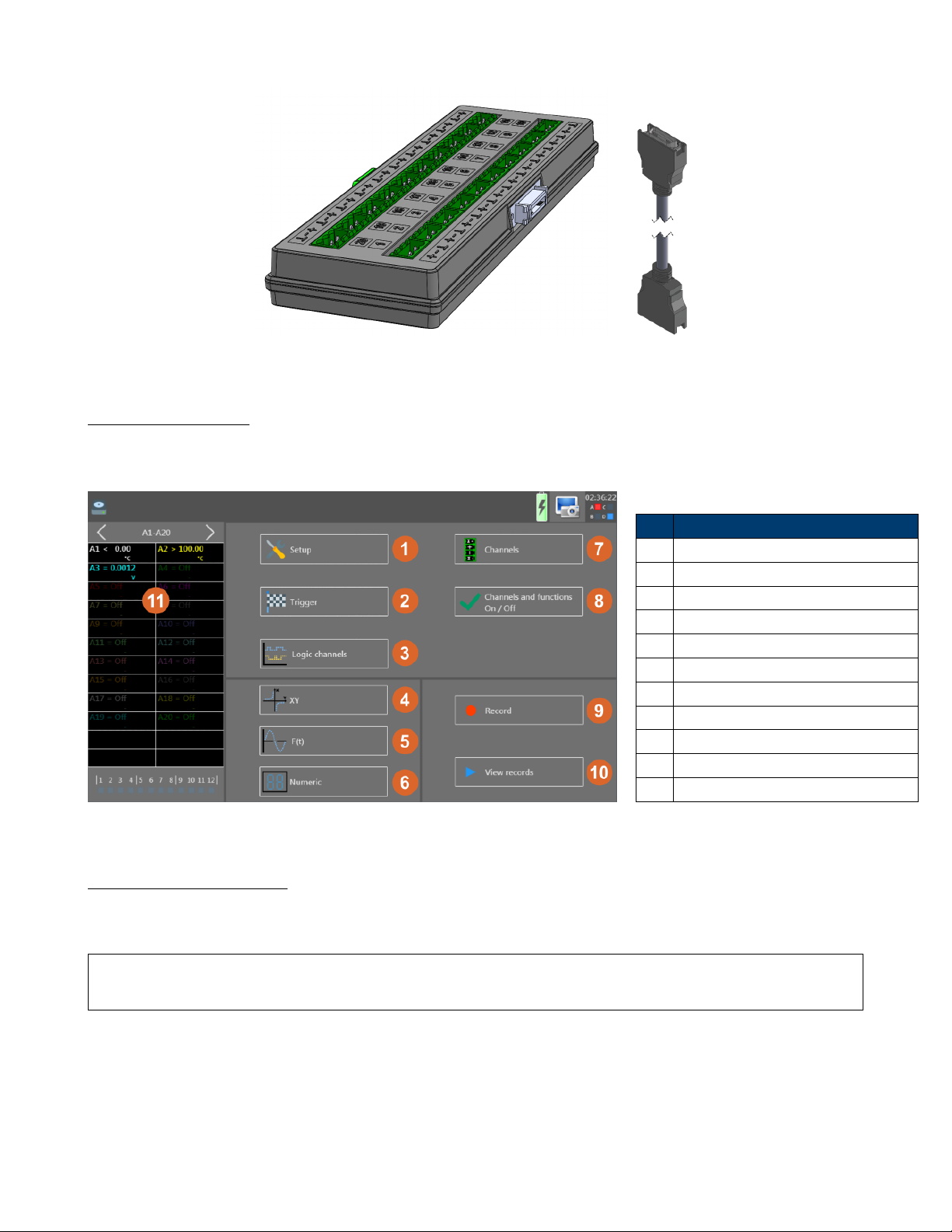

Signals are connected to the unit via terminal blocks, see Figure 1.4. These blocks accommodate 20 connections each

and may be chained together to provide more channels.

6

Page 10

Item Description

1 Power Connector

2 Charging LED

3 ON/OFF Switch

4 USB Connectors

5 LAN Interface

6 Logic and Alarm Signals

7 Ground

8 Expansion Module

Figure 1.2 DAS240-BAT Electrical Connections

Item Description

1 Channel Inputs

2 Power Connector

3 Charging LED

4 ON/OFF Switch

5 USB Connectors

6 LAN Interface

7 Logic and Alarm Signals

8 Ground

Figure 1.3 DAS220-BAT Electrical Connections

7

Page 11

Figure 1.4 Terminal Block and Cable

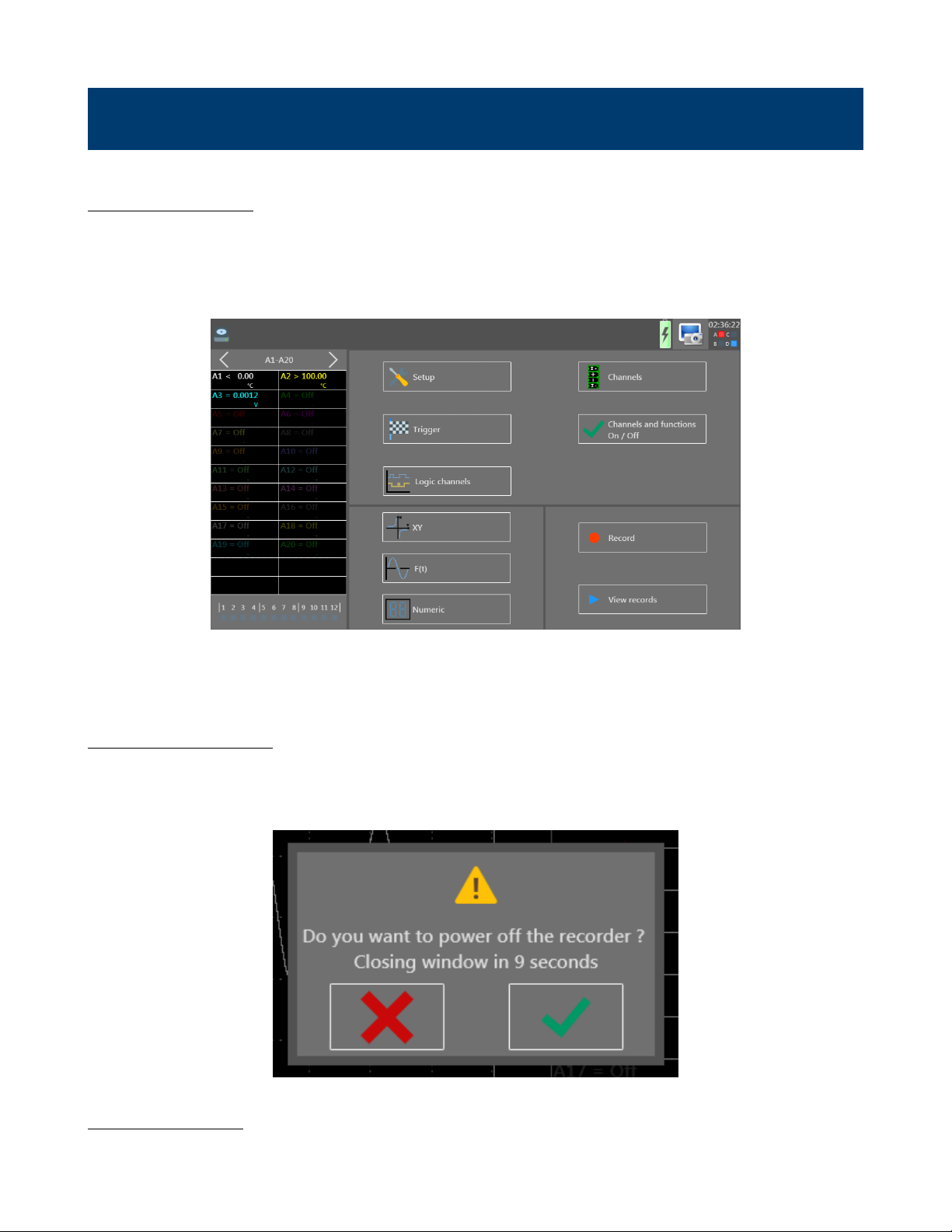

1.3 Home screen

The home screen provides access to the various functions and settings of the unit. Access this menu via the “Home”

button in the top right corner of the screen.

Item Description

1 Setup Menu

2 Trigger Menu

3 Logic Channel Cong Menu

4 XY Display

5 F(t) Display

6 Numeric Display

7 Channel Setup Menu

8 Channel and Function Display Cong

9 Recording Display

10 Recording Replay Screen

11 Channel Conguration Screen

Figure 1.5 Home Screen

1.4 Recording Period

The acquisition sample rate is congurable. The unit samples one channel at a time. The sample period denes the time

a sample consumes.

Note: Each channel is sampled in sequence. The effect is that the rate at which a channel is sampled depends on

the number of channels and the sample period of each channel. See Section 1.4.1

The sample period is set to one of the following settings: 1, 2, 5, 10, 20, 50 and 100ms. When 3-wire thermocouple

measurements (Pt100 and Pt1000) are made, the time periods are doubled. The doubled time periods are highlighted

in the channel setup dialog with a “(x2)” beside the period. Also, by using a congurable low-pass lter per channel,

measurements can be made ltering out higher frequency components.

8

Page 12

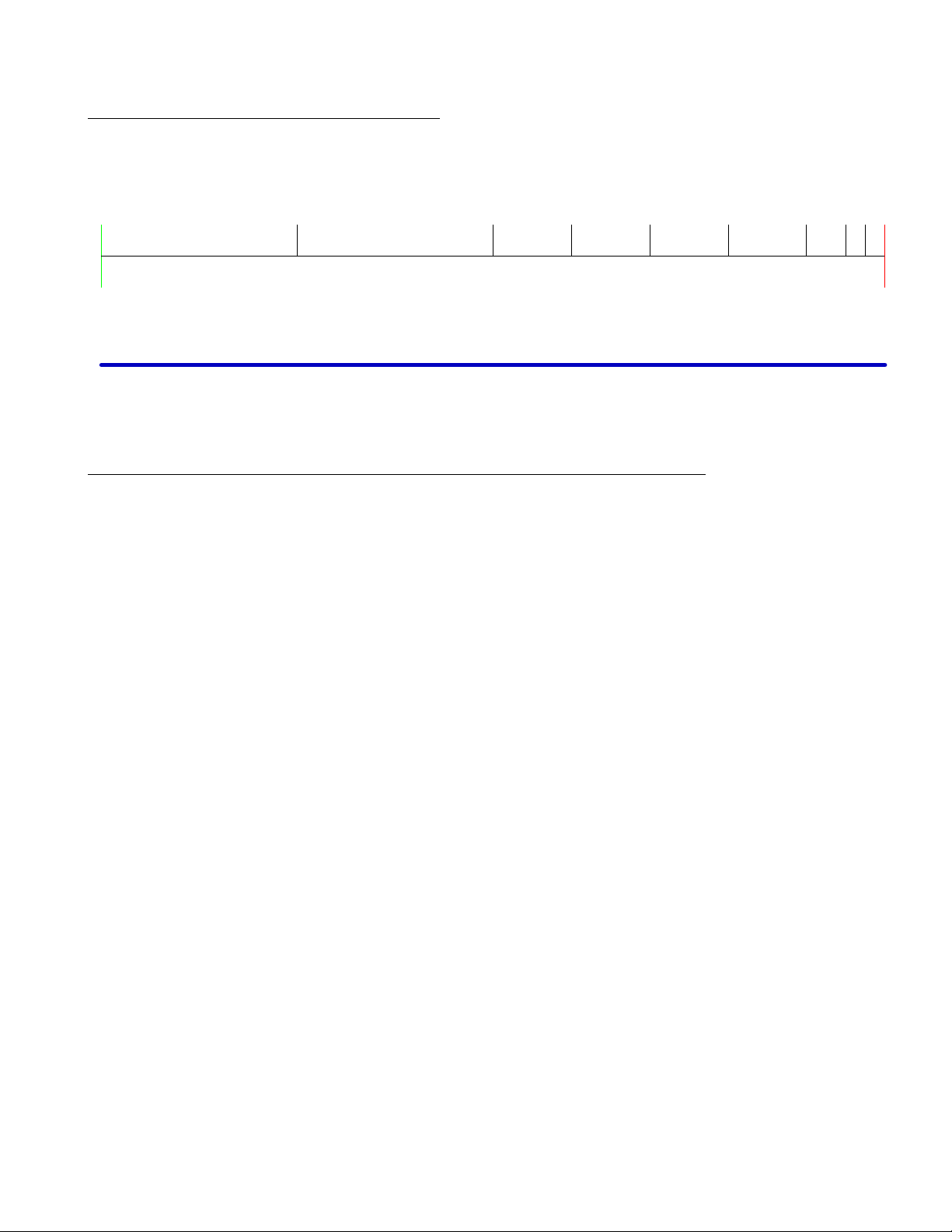

1.4.1 Example: Recording 9 Channels

For example, if 9 channels are sampled, and the settings for each channel sample period are [50, 50, 20, 20, 20, 20,

10, 10, 5] ms each, the total time for an acquisition is 200 ms. Consequently, the minimum recording period, the time

between samples of an individual channel, is 200 ms. See Figure 1.6.

50ms

Start

CH1

50ms

CH2

Total Time = 200 ms

Figure 1.6 9ch Ex.

20ms

CH3

20ms

CH4

20ms

CH5

20ms

Ch6

1.4.2 Example: Power-Line, engine noise, or other electrical noise.

For white noise or noise with lower frequency (lower than recording frequency), you can choose a software lter.

10ms

CH7

5ms

10ms

CH8

CH9

End

9

Page 13

Setup

2.1 Switching On

Prior to powering ON the unit, connect the extension modules1(DAS240-BAT).

Turn on the recorder by pressing the button at the top. When the recorder is on, the ON/OFF button will illuminate,

and displays a startup screen showing the hardware version. It then switches automatically to “F(t)” mode. This display

is accessible from the “Home” menu, Figure 2.1, by pressing the “F(t)” key.

Figure 2.1 Home Screen

On power-up, the unit recalls the last settings and congurations used.

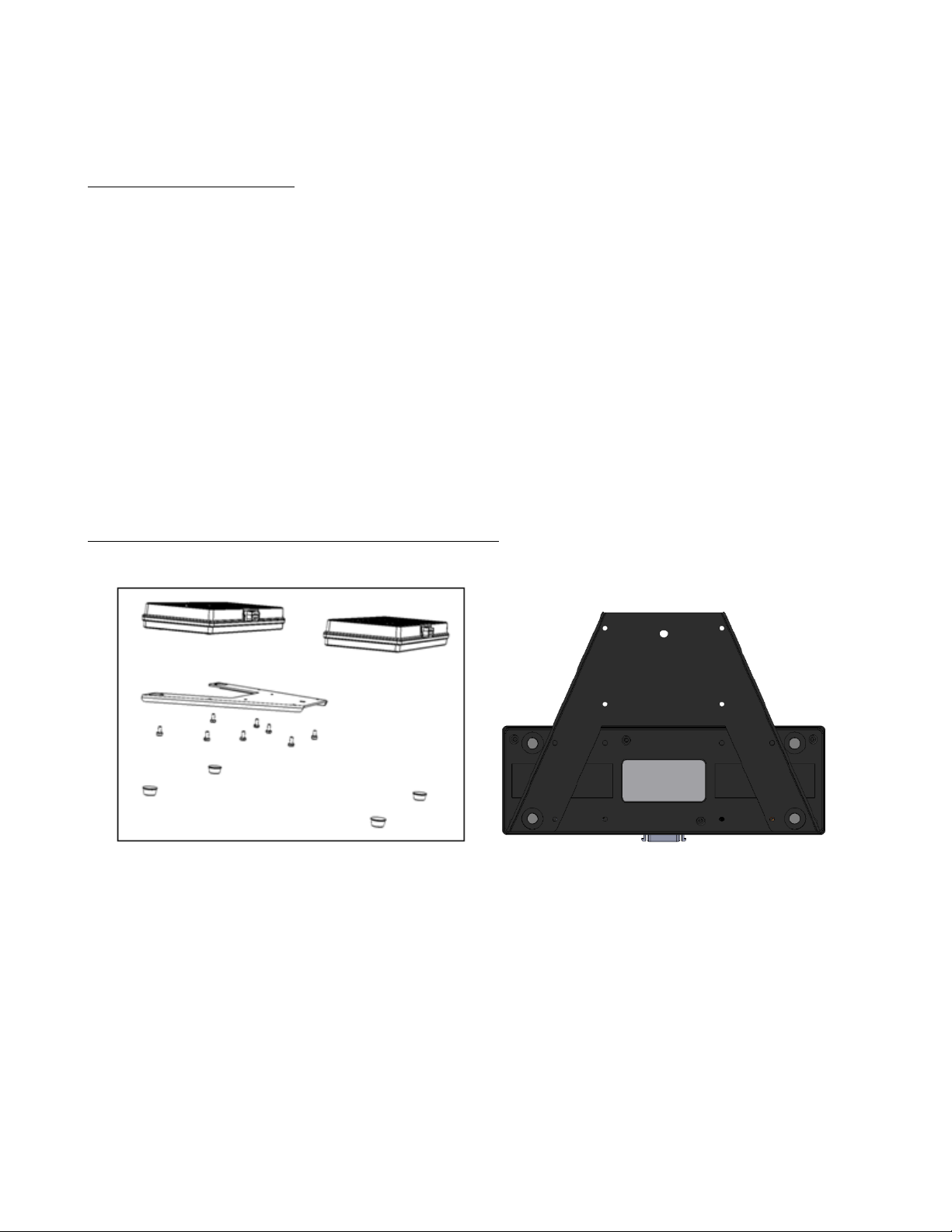

2.1.1 Switching Off

To switch off the recorder, press the ON/OFF button. A dialog box appears prompting the user to conrm powering

off the unit. Select the green check mark to proceed. The dialog disappears if either the red “X” is pressed or the 10 s

countdown expires. Before the unit turns off, the setup will be saved and the current le will be closed.

Figure 2.2 On Off Dialog

1

If there are no modules connected or detected, the will display “Error:Ti” in the lower right-hand corner of the startup screen

10

Page 14

If the recorder does not switch off correctly, then press the ON/OFF button for 5 seconds. Congurations and setup

values may not be saved in this case. This is also true if the unit loses power.

2.1.2 In Case of Error

• If the unit still starts normally: reinitialize to default settings. From the main menu open the “Setup” menu, then

click on “Default setup” key. See Section 2.7.

• Alternatively, the unit can be reset to factory defaults.

− With the unit power off, press the power button to turn the unit on.

− While the unit is booting up, quickly and repeatedly press power button until the display shows a white startup

screen. A setup_error.cnf le will be created in the root folder of the internal memory.

− The unit resets to defaults and reverts to French.

− To change the language back to English, press “Menu Principal”, then “Conguration”, then press the French

ag and select the British ag for English.

Note: If errors persist, please contact B&K Precision for further assistance.

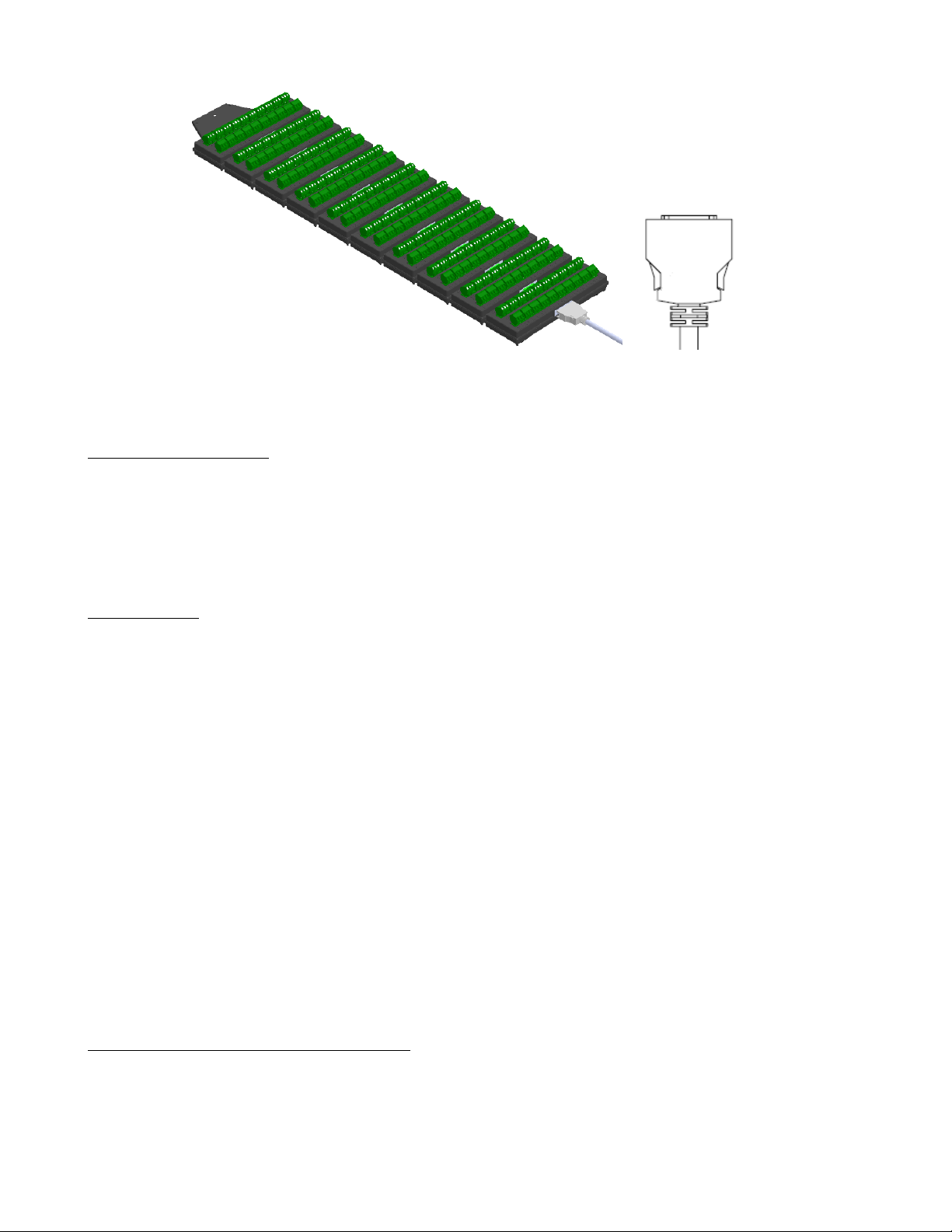

2.2 Extension Modules (DAS240-BAT only)

Up to 10 extension modules may be connected at a time.

Figure 2.3 Extension Modules

To assemble multiple terminal block modules:

• Screw the electrical connectors’ plate to each additional extension

• Assemble the extension modules together

• Screw the plates with the adjacent modules

• Stick the additional adhesive buttress

• Connect the cable using unlocking levers

• Connect the cable on the DAS240-BAT (must be powered off rst)

• Switch on the unit.

11

Page 15

Figure 2.4 Breakout Cable and Module

Note: The unit is delivered with a 70 cm cable.

2.3 External Power

The DAS240-BAT and DAS220-BAT recorders are powered and charged using a 15V DC, 5A power supply.

Warning: To minimize the risk of shock, the instrument chassis and cabinet must be connected to an electrical safety

ground. This instrument is grounded through the ground conductor of the supplied, three-conductor AC line power cable.

The power cable must be plugged into a three-conductor electrical outlet.

Warning: When the charger is connected to the unit, the chassis is connected to the power supply earth ground.

2.4 Battery

The unit is equipped with a lithium-ion battery. If the unit has remained unused for more than one month, check its

charge status and recharge it if necessary.

For continued safe use:

• Never heat up or expose the battery pack to re

• Never short the battery: there is a risk of explosion!

• Do not puncture the battery.

• Do not dismantle the battery pack.

• Do not reverse the polarities of the battery.

• This battery pack includes protection that should not be damaged or removed.

• Do not store the pack in a place exposed to excessive heat.

• Do not damage the protective sheath of the pack.

• Do not store inside a vehicle exposed to the sun.

The battery should last at least 200 full charge-discharge cycles or 2 years.

2.4.1 To Ensure Long Battery Life

• Do not store for a long time without use.

• Store the battery at around 40% charge.

• Do not fully charge or discharge the battery before storage.

12

Page 16

When the battery is nearly discharged, the unit closes all open les, stops the software, and will shut off automatically.

2.4.2 To Charge the Battery

• Connect the provided external AC adapter to the power input of the unit.

• Connect the AC adapter to a electrical outlet.

• The green LED will light when the battery is charging and will turn off when charging is complete.

• Charging can be done with the unit turned on or off.

Note: Battery replacement and service should be performed by B&K Precision. Contact us for details.

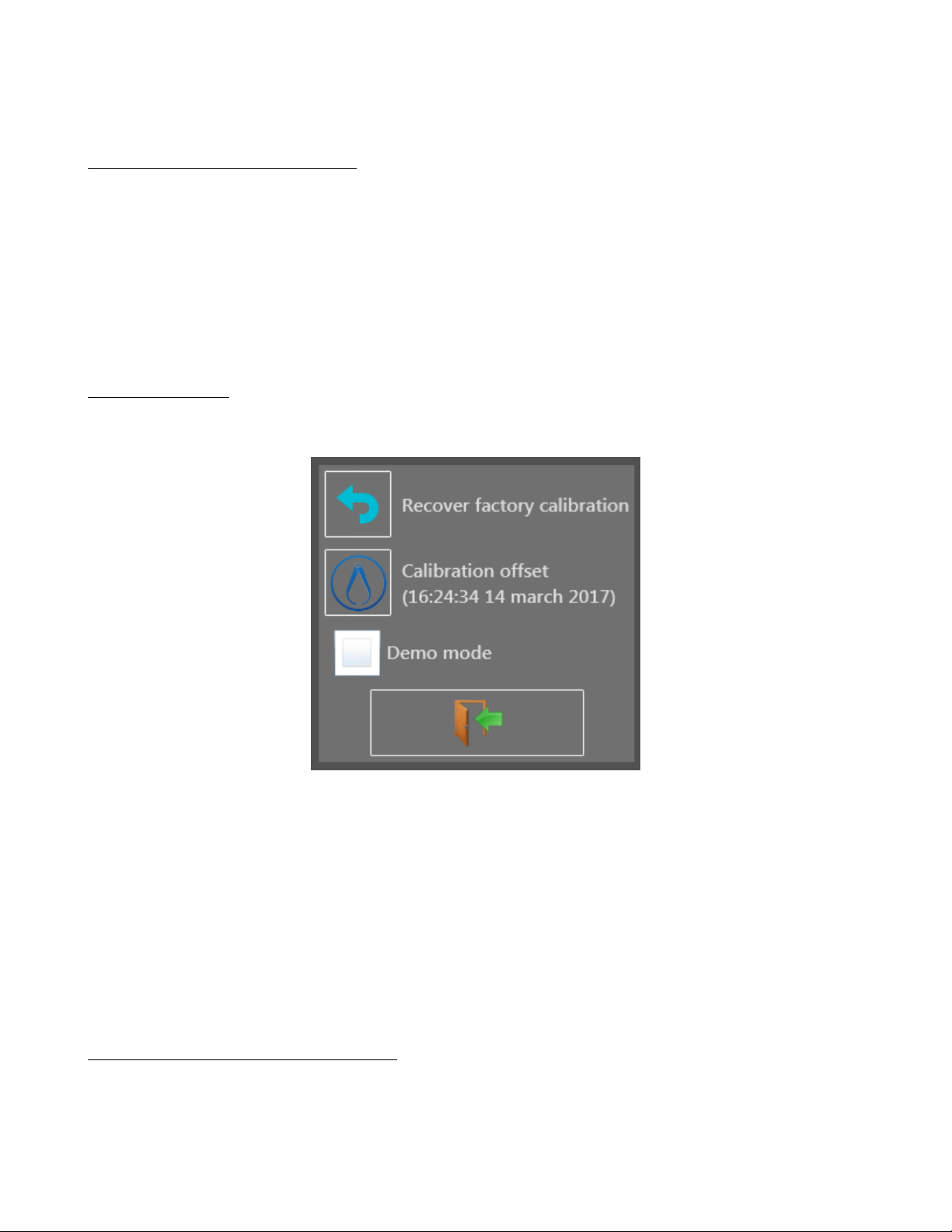

2.5 Calibration

The recorder inputs for the voltage and thermocouple offsets can be calibrated. This will remove any offset present on

different channels.

Figure 2.5 Offset Calibration Screen

1. Let the unit warm up for 20 minutes at ambient temperature 68-77F (20-25C).

2. Enter the recorder main page and then press the “Setup” key.

3. Select the “Additional Option” menu.

4. Select the “Electric Calibration” menu.

5. Press the “Calibration offset” to start calibration. This takes approximately 5 minutes.

6. Power cycle the unit.

2.5.1 Factory Default Calibration

The default factory calibration can be restored to correct any possible mistake in the calibration coecients. This restores

calibration values congured at the factory. This is performed as follows:

13

Page 17

1. Let the unit warm up for 20 minutes at ambient temperature 68-77F (20-25C).

2. Enter the recorder main page and then press the “Setup” key.

3. Select the “Additional Option” menu.

4. Select the “Electric Calibration” menu.

5. Press the “Recover factory calibration”.

6. Power cycle the unit.

2.6 Keypad Lock

To lock all keys:

• Press the “Setup” key.

• Press the “Additional Option” key.

• Press the “Locking the recorder” key.

• Press the green check mark to conrm and lock the unit.

The keypad lock will occur 10 seconds after conrmation.

A yellow padlock appears in the upper right corner of the display when locked. To unlock the recorder, press the lock

icon in the upper right corner repeatedly.

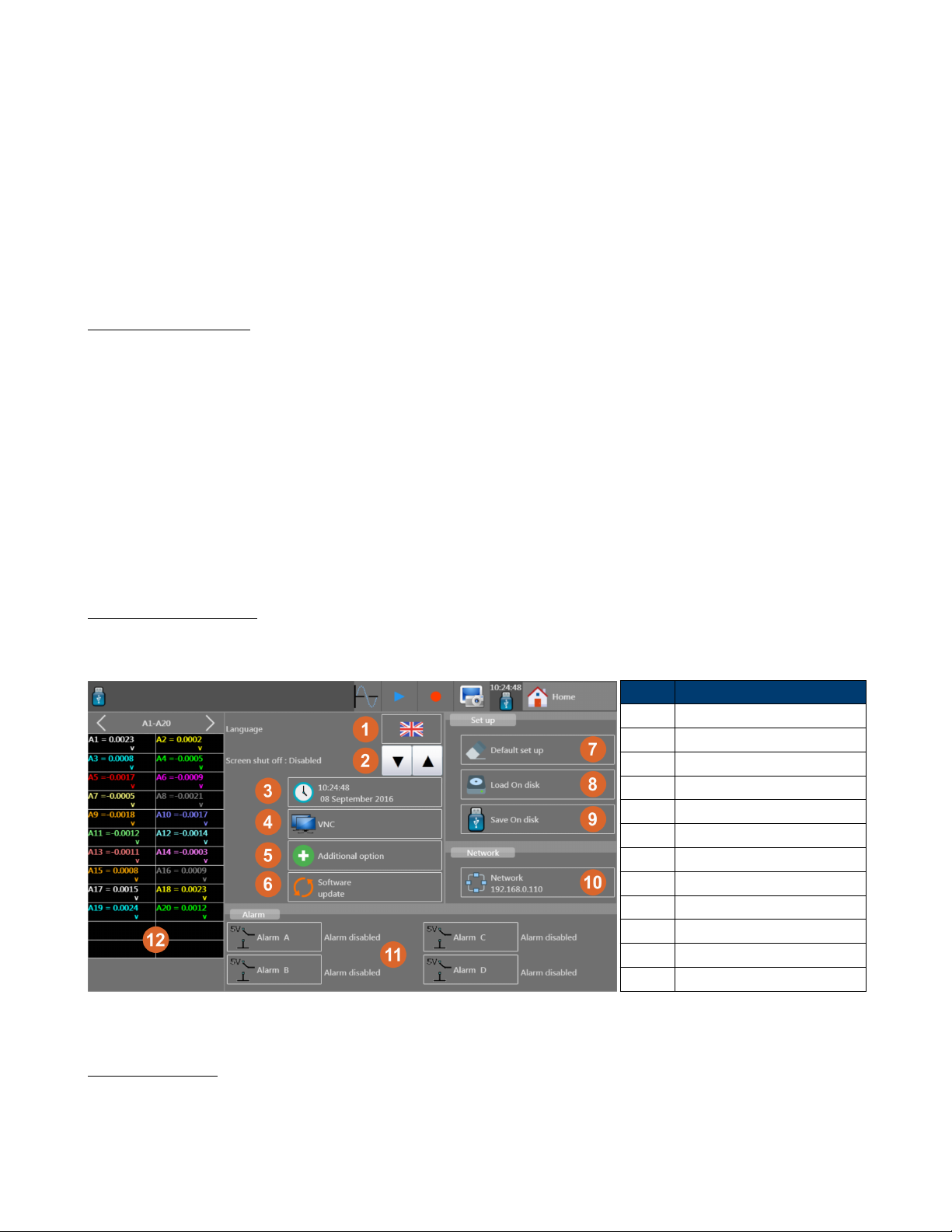

2.7 System Setup

The Setup Menu provides access to general setup of the instrument, monitoring of the alarm outputs, network address

TCP/IP, calibration of the channels, and software (rmware) updating. The setup menu is shown in Figure 2.6.

Button Description

1 Language

2 Screen dimming time

3 Date and time setup

4 VNC setup

5 Additional settings

6 Update

7 Load default settings

8 Load conguration from disk

9 Save conguration to disk

10 Network status and setup

11 Alarms

12 Channels

Figure 2.6 Setup Menu

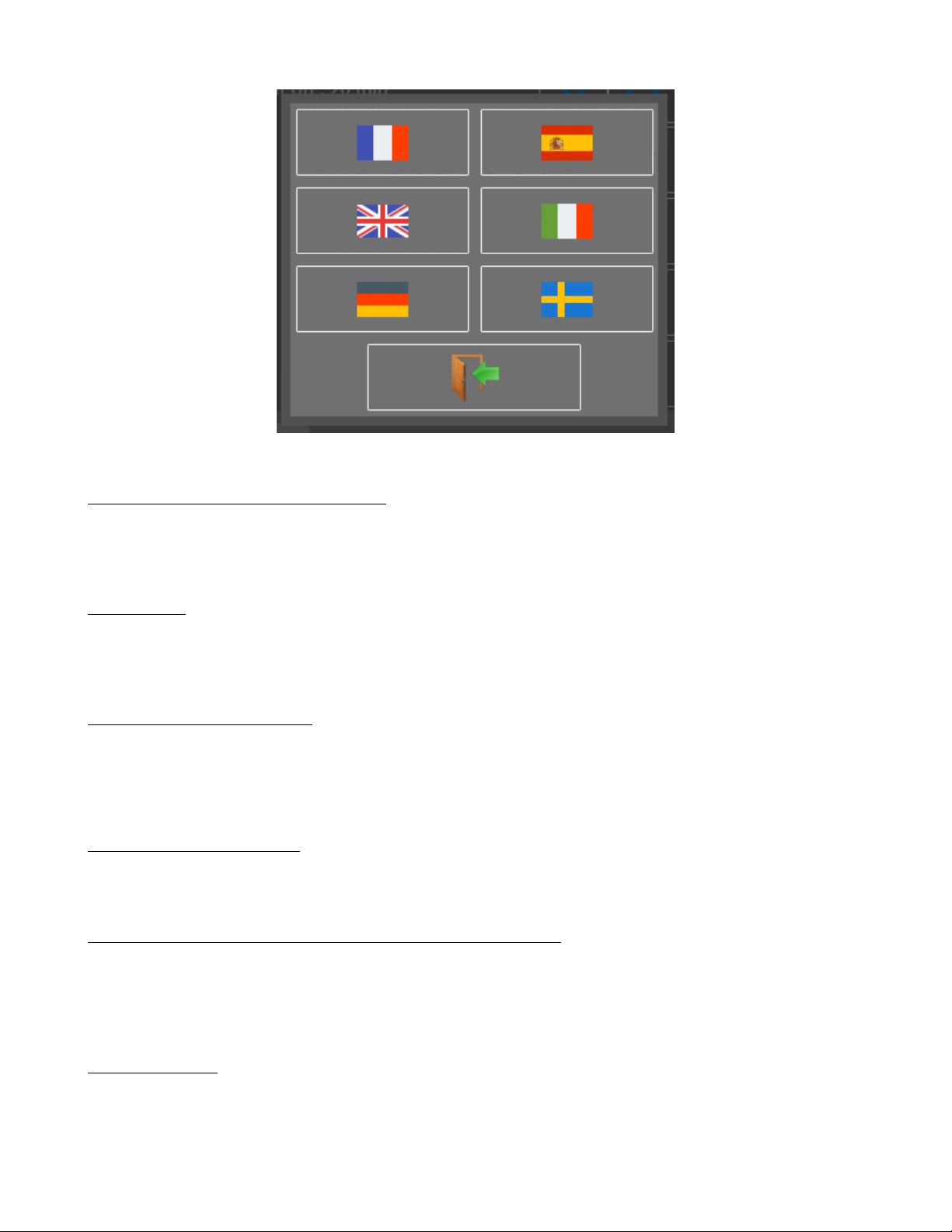

2.8 Language

The system language can be set to one of the following: French, Spanish, English, Italian, German, and Swedish. Open

the language dialog by pressing the ag icon on the setup screen (Home>Setup). Then select the ag icon that correlates

to the language, Figure 2.7.

14

Page 18

Figure 2.7 System Languages

2.9 Screen Shut Off (Dimming)

The amount of time the screen back-light stays at full brightness may be set from 1-30 mins or (disabled). Use the arrow

keys to change the screen shut off timeout.

2.10 VNC

VNC (Virtual Network Computing) allows the user to mirror the front panel using a viewer on a networked computer.

This button is for setting the password. See Section 12.2 for more details.

2.11 Additional Options

Setting the screen brightness, locking the screen, calibrating the machine, setting the start-up screen image and settings

for the Modbus server are available in this menu. See Section 2.5 for calibration information, and see Section 2.6 for

screen lock information.

2.12 Firmware Update

See Chapter 13 for details about updating the rmware.

2.13 Instrument Conguration Loading and Saving

Settings like the F(t) time/division and channels to display may be saved and recalled by the instrument. Also, a default

set of settings may also be loaded. These can be congured with the 3 buttons in the “Setup” box of the setup display

window (home>setup).

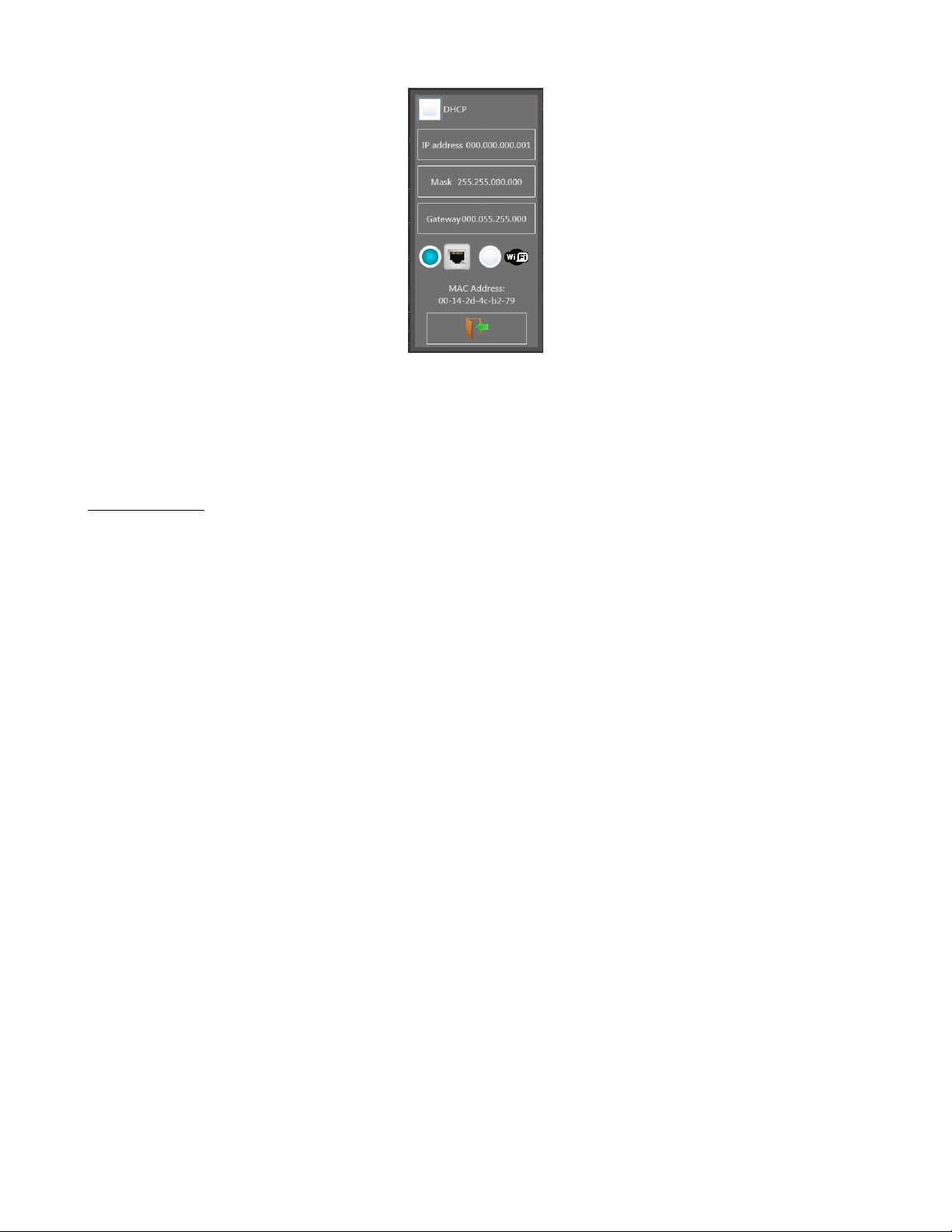

2.14 Network

The current IP addresses of the network is shown within the network button. If there is no network connection, 0.0.0.0

is shown.

15

Page 19

Figure 2.8 Network

Conguration Dialog

Pressing the button opens the network conguration dialog. Available options are shown in this window depending on

the hardware connected. DHCP, IP Address, Subnet Mask, and Gateway IP can be congured here.

2.15 Alarms

See Chapter 9 for details.

16

Page 20

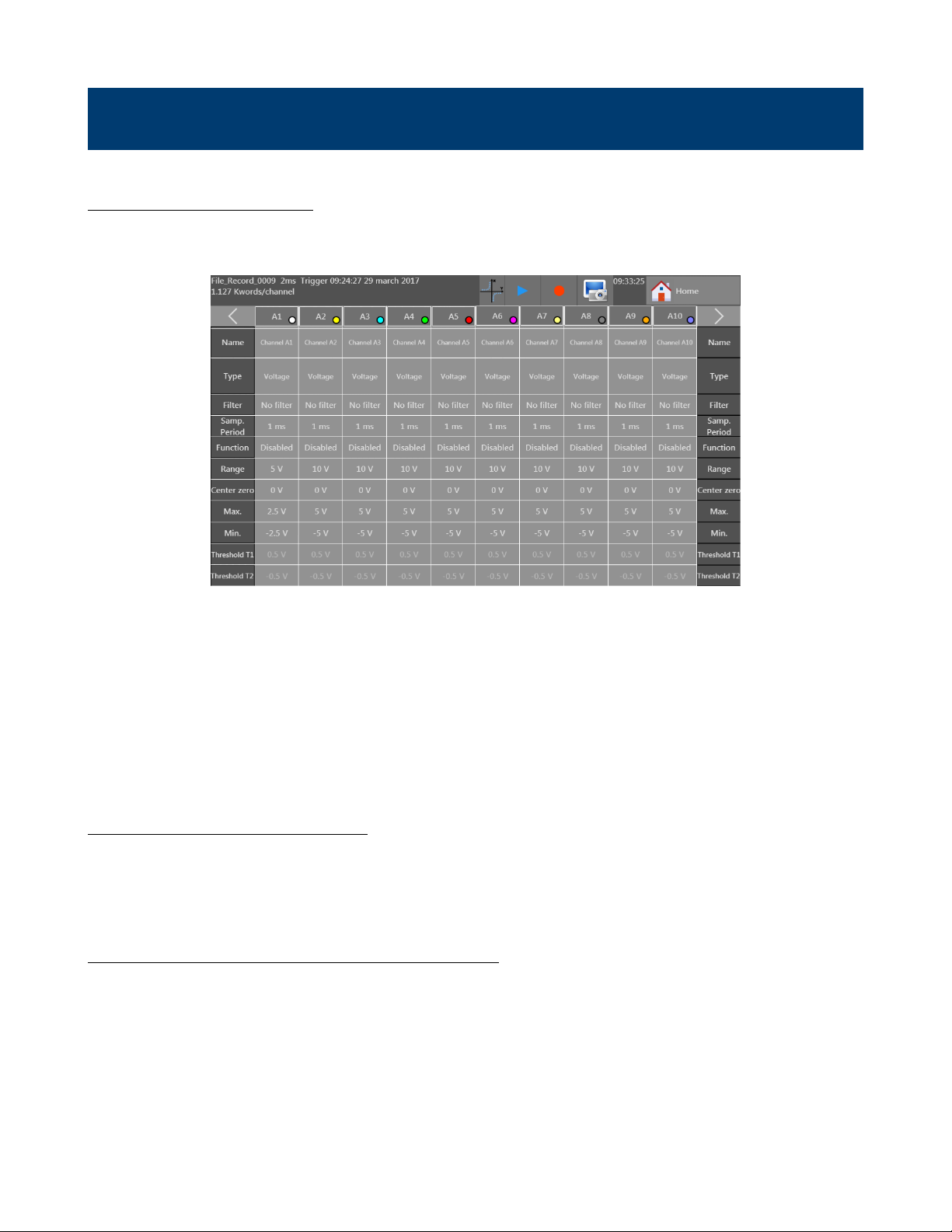

Channel Setup

3.1 All Channels Screen

Access the channel setup menu from the Home screen and press the “Channels” button. The screen shown in Figure 3.1

appears.

Figure 3.1 Channels Menu

The channel conguration screen provides quick access to individual channel settings. Each column lists a set of values

for each channel. The parameter available is listed in the left and right most columns. Pressing the box corresponding to

the channel and parameter opens a dialog box with options for conguring that parameter. The contents of the dialog

change depending on the selected parameter value. For example, when the channel type parameter is opened, selecting

the Thermocouple value modies the box to give further options for thermocouples (type, temperature units, etc…).

Back on the main channel table, the value in the box shows a summary version of the parameter’s congured value.

In the upper right and left corners of the table are navigation arrows for showing more sets of channels. 10 channels may

be shown on screen at a time.

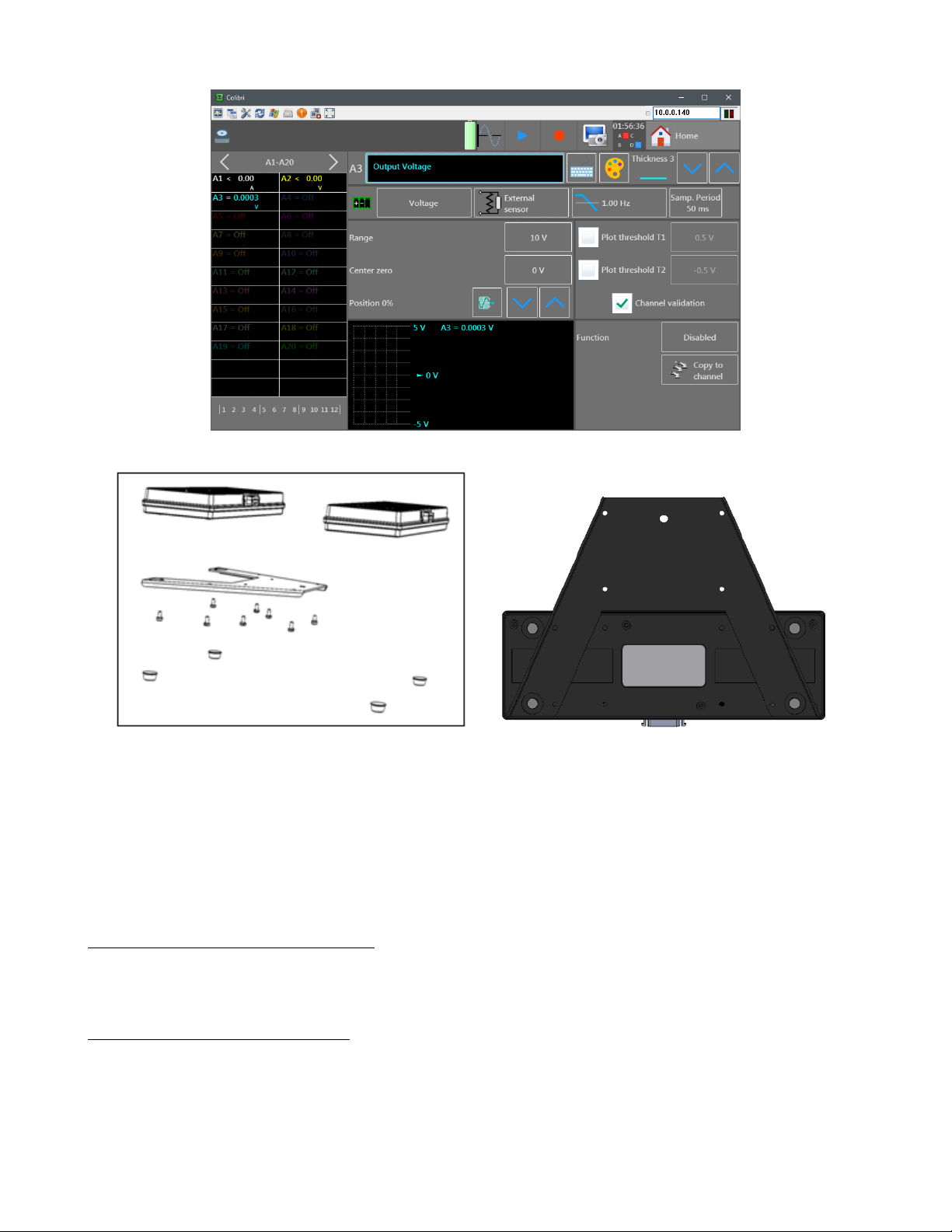

3.2 Individual Channel Screen

The complete set of parameters, values and options are also viewable for a single channel on a single screen. To open this

screen, press the box displaying the Channel ID (A1 for example). This opens a window for setting a greater number of

values than available from the channels table. For example, the plot color and thickness can be set here. See Figure 3.2.

3.3 Extension Modules (DAS240-BAT only)

Up to 10 extension modules may be connected at a time.

To assemble multiple terminal block modules:

• Screw the electrical connectors’ plate to each additional extension

• Assemble the extension modules together

• Screw the plates with the adjacent modules

• Stick the additional adhesive buttress

17

Page 21

Figure 3.2 Channel Conguration Screen

Figure 3.3 Extension Modules

• Connect the cable using unlocking levers

• Connect the cable on the DAS240-BAT (must be powered off rst)

• Switch on the unit.

Note: The unit is delivered with a 70 cm cable.

3.4 Measurement Connections

Using the terminal blocks provided with the unit. Figure 3.5. (Phoenix Contacts: SMSTB 2,5/3-ST5,08 - 1826296)

3.4.1 Voltage Measurement

Voltage measurement is performed between the + and - terminals of the inputs. The “GND” terminal is not used.

18

Page 22

Figure 3.4 Breakout Cable and Module

Figure 3.5 Terminal Blocks

3.4.2 Temperature Measurement With a Thermocouple

The voltage resulting from thermocouple is measured between the + and - terminals of the relevant input. The “GND”

terminal is not used. Errors in reading temperature can be caused by reverse connection of the thermocouple wires.

3.4.3 Temperature Measurement With Pt100/Pt1000 and RTD

The Pt100/Pt1000 probe must be connected to the + and - terminals. The current injects into the “GND” terminal.

For a 4 wire Pt100/Pt1000, only 3 wires are used.

Note: the “gnd” current injection is shared by all channels.

Figure 3.6 shows 2 ways to wire the temperature sensors. Using the 2-wire method, the “-” and “GND” terminals are

connected together at the terminal block. For 3-wire, the ground connects at the measurement point.

2 Wire 3 Wire

Figure 3.6 Terminal

Block Wiring

3.4.4 Resistance Measurement

Connect the resistance to measure between the “+” and “-” terminals and connect the “-” and “GND” terminals together.

For best resolution and accuracy, congure the resistance display range appropriately for the expected value. For example,

19

Page 23

set the on screen range close to the expected measurement value. Based on the range chosen, the unit determines the

sense current and voltage range to use for measurement.

3.4.5 Current Measurement

The recorder includes the option to convert sensed voltage across a shunt or sense resistor into a current reading. From

the “Home” screen, open the “Channels” menu. The “Type” row shows the current function per channel. Press the

square in the “channel” column and “Type” row to open the conguration dialog for the function type. See gure 3.7.

Select the “Current” menu option. The window will change to show a button listing the current shunt value. To change

the value, press the button and a dialog for setting the shunt value will open. See Figure 3.8. Set the value and unit

and press the green check mark to conrm the setting and the screen will return to the previous menu.

To wire the circuit for current measurement, connect the “+” and “-” terminals to the current shunt. Also, set the

current range in the “Channels” window appropriately. Use either an external resistance or a shunt (ref 902406500: 50Ω

Figure 3.9).

Figure 3.7 Channel Function Type

20

Page 24

Figure 3.8 Current Shunt Value Setup

Figure 3.9 50Ω Shunt Module

21

Page 25

F(t) Plot

This mode displays the channel signals versus time, much like an oscilloscope. The time per division is called the

“Timebase” on this unit. The display is normally in a scrolling mode displaying real time data. This changes when

recording data. In that case, the display shows the full record. See Chapter 7 for more information about recording

data.

Item Description

1 Screen Setup, Section 4.1.

2 Congure custom pages,

Section 4.1.1

3 Freeze Screen, Section 4.2

4 Full Screen - change the view to

full screen, touch the screen

anywhere to exit.

5 Timebase, Section 4.3

6 Numerical display - display the

current signal value and control

which channel page is displayed.

7 F(t) plot

Figure 4.1 F(t) Screen

4.1 Screen Setup

Figure 4.2 Screen Setup Dialog

From this dialog, the type of plot, numerical values, math, grid scales, number of plots, and colors are set here. The

number of plots is available when in F(t) mode, and is limited to the number of signals measured. The maximum number

is 10. When in XY mode, the number of plots is replaced by the option to enable a custom grid (background image).

When a custom grid is enabled, the options of directory and le are added to the dialog as in Section 4.3. Lastly, the

choice of displaying points as dots or vectors is available for the XY display mode.

22

Page 26

Figure 4.3 Screen Setup Dialog - XY mode

4.1.1 Custom Pages

Using this menu, set the channels to see on screen from the available channels set using the “Channels and Functions

On/Off” menu. The channels are divided into banks and the shown bank is set here. For example, this allows channels

1 and 10 to be shown on the screen and turn off other channels.

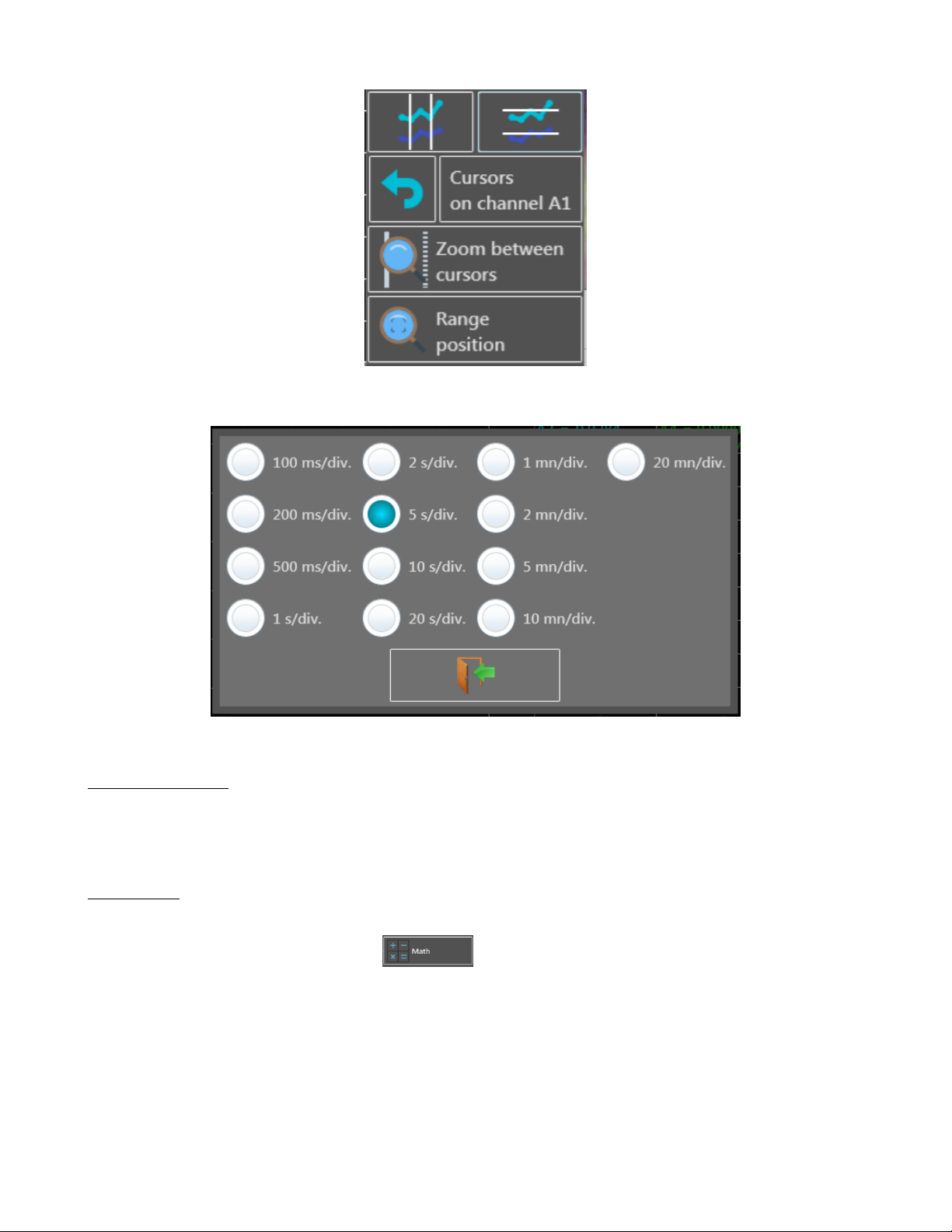

4.2 Freeze Screen and Cursor Measurements

Freezes the graph at the screen to perform measurements through cursors, calculations, save or print the measurements

at screen, in the F(t) mode.

When frozen, horizontal and vertical cursor icons are added to the right-hand panel. Selecting the vertical cursor icon

enables time based cursors. Move the individual cursors by the touchscreen or other mouse interface to set the

cursor positions. selecting the horizontal cursor icon changes the available buttons in the right hand panel, See

Figure 4.4.

Icon Description

Undo the last cursor action completed.

Opens a dialog box for setting the signal to measure with the cursors.

Zoom the selected channel to t within the current cursor settings.

Set the vertical axis parameters for the selected channel.

The range is the vertical span of the channel.

The center value denes what value is the middle of the axis.

The “Position” denes the vertical location of the horizontal axis (time) in percentage.

The range is from -100 to 100 %.

For example, -50 will place the horizontal axis at 2.5 divisions above the bottom of the display.

All together, the range sets how many volts tall the vertical axis is, center sets the

23

Page 27

Figure 4.4 Horizontal

Cursor Options

Figure 4.5 Time Base Setting (Time/Division)

4.3 Time Base

The trace time scale may be set to a number of values. Pressing the Timebase button on the right of the F(t) plot screen

brings up the dialog as shown in Figure 4.5.

4.4 Math

Math functions may be applied to multiple channels. To enable math functions, enable the check-box for “Math” in the

“Screen Setup” window. When enabled, the icon is added to the right hand button panel. Pressing the

button brings up the conguration dialog shown in Figure 4.6. Use the arrow buttons at the top to increase of decrease

the number of math functions. Use the arrows at the bottom to change the channel on which the math is done, or press

the channel named for each row to set the desired channel. See Figure 4.7 for the set of functions available.

The values calculated for each function congured are shown on the main plot screen, colored the same as the channel

they do math on. See Section 4.4.1

Calculated values are displayed in the plot window showing the following:

24

Page 28

• channel number (with its color)

• function name

• value

Figure 4.6 F(t) Channel

Math Settings Dialog

Figure 4.7 F(t) Channel Math Functions Dialog

4.4.1 Math Functions

Math function values may be moved around on the screen. To move the math values, click and drag them to a desired

position on screen.

Minimum

Maximum

Peak to Peak

25

Page 29

Figure 4.8 Math Dialog Box

Low The most frequent value below the median

High The most frequent value above the median

Amplitude

On positive oscillation

On negative oscillation

Average frequency

Cycle average

Rising edge T1 = 10% Amplitude T2 = 90% Amplitude Trise = T2 - T1

𝑀𝑎𝑥−𝐻 𝑖𝑔ℎ

𝐴𝑚𝑝𝑙𝑖𝑡𝑢𝑑𝑒

𝐿𝑜𝑤−𝑀𝑖𝑛

𝐴𝑚𝑝𝑙𝑖𝑡𝑢𝑑𝑒

1

𝑃 𝑒𝑟𝑖𝑜𝑑

Duration of N complete periods

∗100

∗100

𝑁

culated on as many periods as possible

Average duration of a complete cycle cal-

26

Page 30

Falling edge T1 = 90% Amplitude T2 = 10% Amplitude Tfall = T2 - T1

Positive pulse width Measurement of the time of 1st positive pulse. It is measured at 50% of am-

plitude

Negative pulse width Measurement of the time of 1st negative pulse. It is measured at 50% of

amplitude

Positive duty cycle

Negative duty cycle

N : total number of dots

RMS

Standard Deviation

positive pulse duration

𝑝𝑒𝑟𝑖𝑜𝑑

negative pulse duration

𝑝𝑒𝑟𝑖𝑜𝑑

𝑁

1

∑

𝑉

- Note

𝑖

𝑁

𝑖=1

𝑁

√

√

1

𝑁

1

𝑁

∑

(𝑉𝑖)

𝑖=1

𝑁

∑

(𝑉𝑖−𝑉)

𝑖=1

2

- Note

2

2

2

- Note

2

2

Calculated using the whole graphic range

27

Page 31

XY Plot

The XY mode is accessible via the main menu by pressing the XY key. In this mode, one of the channel represents the

horizontal axis (X), and the other channel the vertical axis (Y). For example, if the channel for the horizontal axis is 1V

and the channel for the vertical axis is at 95F, the recorder plots a point at (1,95).

A custom background/grid may also be shown on the display. From the “Screen Setup” menu accessed by pressing the

button on the XY plot screen, select the “custom grid” check-box, select the folder containing the bitmap to be used

(middle button), and select the bitmap using the right most button on the line. Along with the XY plot, a numeric

representation of the current signal values is shown.

Item Description

1 Screen conguration - Open the

measurement display

2 Trace - Allows to start or stop

the trace

3 Delete Allows to delete the

screen

4 X channel Selects the channel

for the horizontal axis

5 Full screen Allows to view on the

full screen, press on the reticule

to come back to the normal

mode

6

Figure 5.1 XY Display Screen

Arrow key shows or hides

the numerical window

Item Description

1 Plot type - F(t) or XY

2 Point display - Dots or vectors

3 Display Numerical Values -

shows the numerical values in a

table

4 Display Boundaries - shows or

hides the axes

5 Custom Grid - congures the

grid and background image

6 Colors - sets the color of the

background, grid and cursor

using a color picker

Figure 5.2 XY Setup Window

28

Page 32

Figure 5.3 Numerical Window

1. The or keys : selects the group to view.

2. By pressing a specic channel:

− The graph terminals are bound to this channel.

− In real time acquisition, the instant value will show up.

− By visualizing the cursors; then the difference value between cursors as well as T1 and T2 values corresponding

to cursors T1 and T2 will be displayed.

3. Press right to hide this window, and when hidden, the icon points left.

29

Page 33

Numeric Display

The numerical window allows to visualize in real time the values of each channel. See Figure 6.1. The number of

channels shown per screen depends on the number of channels selected. Each display page is accessed by pressing the

right and left arrows.

Item Description

1 Cycle display screens (channels, custom sets, logic functions, etc…)

2 Digital channel state (shown when “Logic Channels” option is set in the “Channels and Functions” menu.

3 Reset minimum and maximum recorded values

4 Individual channels, click within each channel to open the conguration menu for that channel

Figure 6.1 Numeric Display Screen

30

Page 34

Recording

The DAS240-BAT and DAS220-BAT can save data to internal storage. The user can then retrieve the data and review

it on the unit, save it to a USB drive, or retrieve it via the Ethernet interface.

7.1 Create a Recording

To create recordings, press the “record” button on either the “setup” screen or from the top ribbon when in any of the

3 data display modes (F(t), XY, or Numeric) to start a recording. See Figure 7.1. Recording starts when the trigger

condition is met. If the trigger function is not running, stop is selected on the trigger setup page, then recording starts

immediately. Figure 7.2 is waiting for a trigger, and Figure 7.3 has started recording.

Figure 7.1 Record Keys

Figure 7.2 Record screen

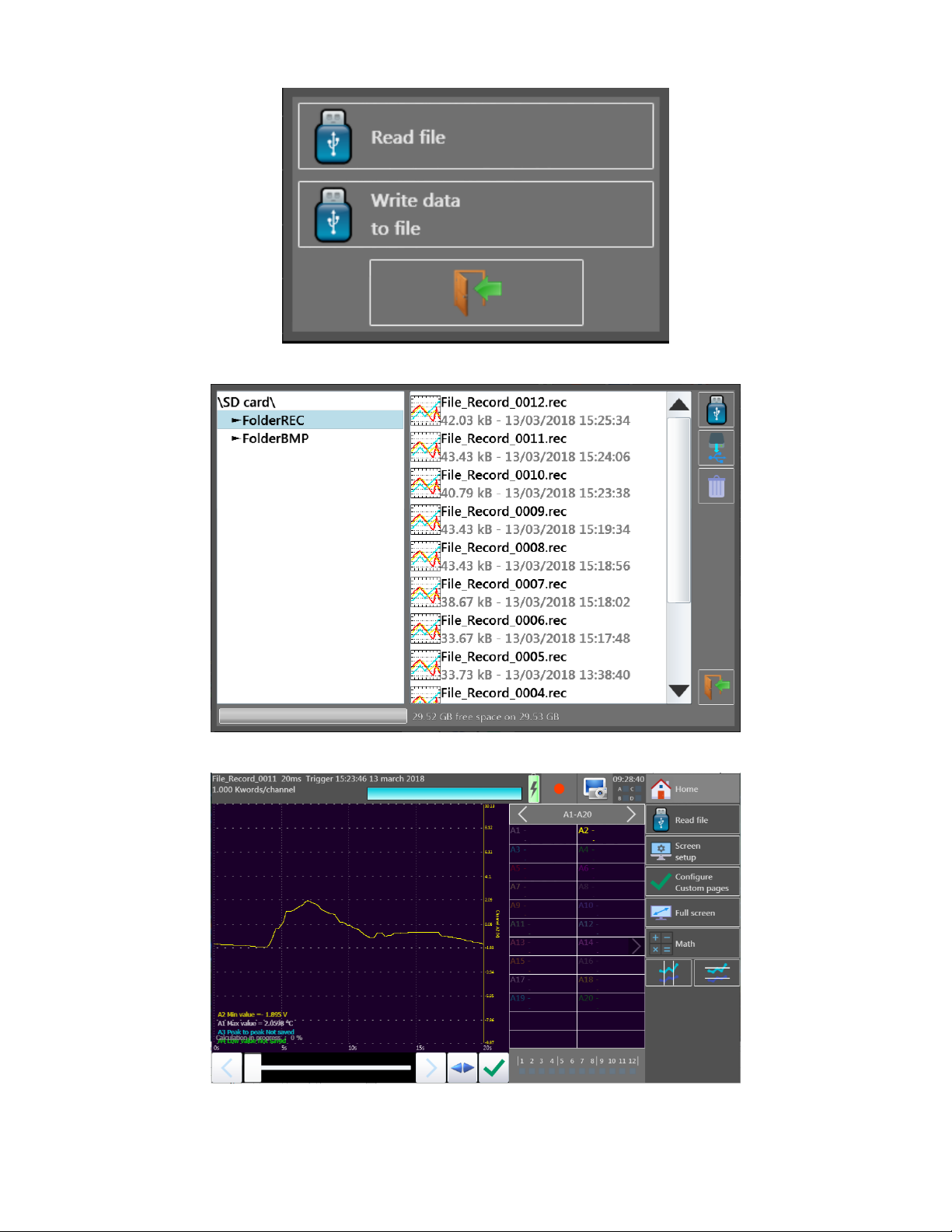

7.2 View Recording

Stored recordings may be recalled and analyzed. With a recording loaded, zooming into portions of the recording and

making cursor measurements can be done. To open a saved recording, navigate to the “Home” screen and press the

button. Alternatively, when in either XY or F(t) screens, the blue triangle (Figure 7.4) in the top

ribbon opens the recording playback mode.

7.2.1 Loading a Recording

31

Page 35

Figure 7.3 Recording started

Figure 7.4 Recording playback

1. Press the button. This will open Figure 7.5.

2. Press the “Read File” button within the new dialog.

3. Navigate and select the recording to view.

4. When a le is selected, a new button appears . Press this button to load the selected recording.

32

Page 36

Figure 7.5 Load Saved Recording File Dialog

Figure 7.6 File Browser

Figure 7.7 Saved Recording Loaded

33

Page 37

Triggering Recordings

Item Description

1 Record le path

2 Recording size

3 Reading storage rate (reading

period)

4 Start condition

5 Stop condition

6 Trigger arm state

Figure 8.1 Trigger Menu

The start and stop functions control the conditions that initiate data recording. Opening the “Start”, or “Stop” trigger

menus open the start condition dialogs with the following recording start options:

Manual pressing a key

Trigger Based on Analog, or Digital signal conditions. See Section 8 for details

Waiting After a delay or at a specied date and hour. See Section 8.1 for details

Automatic Occurs immediately, and automatically stops when the le is full

Pre-Trigger Quantity of samples to record preceeding the trigger

8.1 Waiting Start Condition

Starting a recording at a prescribed later time or date. Figure 8.2 shows the 2 dialogs for conguring each condition.

Waiting on a delay, will wait for the prescribed time and proceed with a recording. Waiting for date delays recording until

a specic time and date. For each, congure the time in hours, mins and seconds, and for the date, the day, month and

year is also set.

8.2 Recordings

• Recording setup:

− Selection the folder

− Selection the le name (beginning of the le name, the end is an incremented numerically)

− Length of the le (maximum or selection of the number of samples per channel)

− Measurement data prior to a trigger event may be included in the data recording. The amount of data is dened

as the “Pre-trigger” samples. The amount of data is set and determines the amount of time before the trigger

event to include in the recording.

• Speed: The maximum speed is determined by the number of channels for acquisition.

34

Page 38

Wait for a Time

Wait for a Date

Figure 8.2 “Waiting” Start Conditions

• Start: Start condition of the data acquisition

• Stop: Stop condition of the data acquisition

− Automatic: when the le is full

− Trigger: on a channel or a combination of analog or logic channels

• After acquisition: action after the end of the data acquisition (only available if the Start and Stop triggers are not

set to Manual)

− Stop: no action

− Rearm: a new le is launched waiting for the Start trigger

• View of the active channels, of the recording time, of the pre-launch

Note: A message “Impossible” shows up when the saving possibilities are exceeded. Fix this by reducing the sampling

speed or the number of channels.

Various conditions are available for starting and stopping acquisition recording. Analog signals, time delays, and logic

inputs are trigger sources. Also, the amount of data prior to a trigger event is congurable. Access the trigger menu

from the “Home” screen and the “Trigger” button. Figure 8.1 is representative of the trigger conguration window.

8.3 Triggering

Triggering is based either on a single channel edges and thresholds, combinations of analog channels, or set digital signal

states.

8.3.1 Single Analog Channel Trigger

To use a single analog channel as a trigger source, the general procedure is as follows:

35

Page 39

Figure 8.3 Start Condition Dialog

1. Select trigger, and “Analog Channel” from the trigger dialog.

2. Set the amount of Pre-trigger samples to record.

3. Choose the trigger source channel.

4. Select the trigger condition (Threshold, level (higher/lower), or edge)

5. Set the trigger analog signal level.

8.3.2 Single Threshold

Figure 8.4 Trigger Threshold Setup

Channel: Selection of the channel, on which the trigger threshold is applied

Threshold 1 / Threshold 2: Selection of the threshold to settle; each channel is tested with reference with 2 thresh-

olds, i.e. you can program a start condition on the channel A1 and the threshold 1, and

a stop condition on this same channel A1 and the threshold 2

Higher / Lower: Trigger when the channel value is more or less than the set threshold

Threshold value: Threshold value selected in real value (taking the current unit and scale of the cong-

uration of the selected channel into account)

Edge: Selection of the active edge of the channel in reference to the threshold

36

Page 40

Pre-triggering (only for start): Gives the acquisition time before the trigger appears.

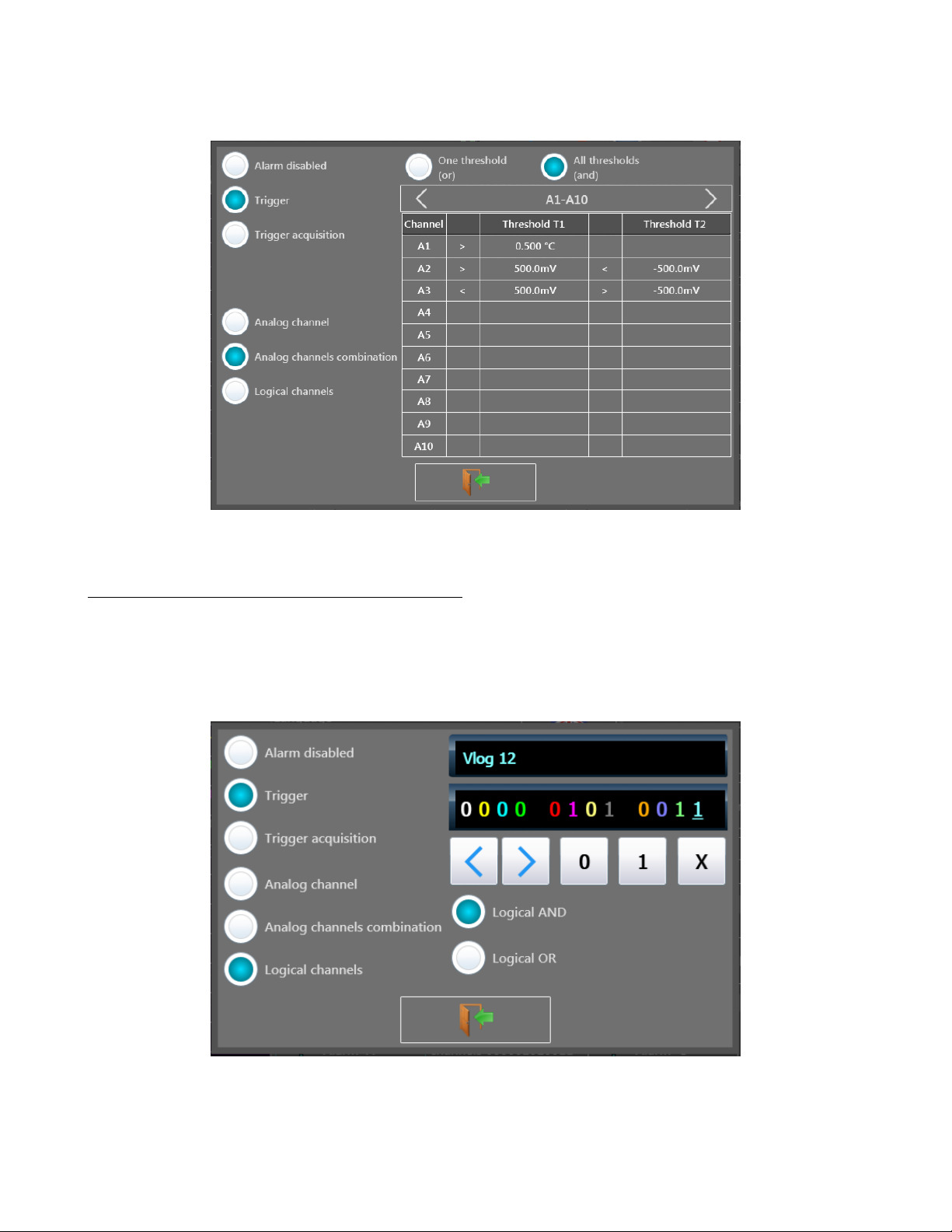

8.3.3 Multiple Thresholds

After selection of a trigger on a set of logic channels, the window allows you to set the trigger under several conditions.

Then, by pressing the various thresholds in front of their respective channels, you open the threshold parameter window.

Figure 8.5 Multiple Threshold Trigger Screen

• One of the thresholds, or the rst achieved condition activates the trigger

• All thresholds, and all conditions must be simultaneously achieved to validate the trigger

• A table makes it possible to select all channels and the validity of the channels

Selecting the channel allows the selection of the thresholds:

• S1 and S2

• Value of the thresholds

• Rising / Falling edge, or Low / High value

Figure 8.6 Trigger

Type Setup Screen

37

Page 41

8.3.4 Trigger Examples

• Edge trigger: you need a change of status

Example: Channel A1, rising edge, threshold = 0V: triggers only if the signal status changes from negative to positive

• Level trigger: no need to pass the threshold

Example: Channel A1, high level, threshold = 0V: triggers only if the signal is positive

• Alarms only have level triggers

8.4 Trigger on Logic Channels

Selecting “Logic Channels” as the trigger source changes the window to show conditions for logic channel triggering.

Each of the logic channels is congured as a 1, 0 or X (don’t care). Use the arrow keys to move through the logic input

bits. Triggering may be congured as either an AND condition or an OR condition. This is applied to each channel.

Lastly, the trigger event is generated on either a Level or Edge condition.

Logic 1 Greater than 4.0 Volts

Logic 0 Less than 1.6 Volts

Figure 8.7 Logic Trigger Setup Screen

38

Page 42

Alarms

4 congurable alarm signals allow signaling from the recorder through the digital port. The alarm signals are high (5V)

when the alarm condition is detected. The main display’s alarm status section indicates the status of the alarms. The

main display alarm status is “sticky” in that when alarm triggers, the eld is set to active (red). See Figure 9.3. The

condition may clear, and the alarm status will continue to show an alarm happened. The digital port clears the alarm

when the programmed condition is not met any longer and returns to 0V.

To congure the alarms, open the “setup” menu from the “home” screen. See Figure 9.1. At the bottom of the screen

are the 4 alarms. Each button opens the conguration dialog for that alarm. See Figure 9.2

9.1 Alarm Status

Figure 9.1 Alarms on Setup Screen

Figure 9.2 Alarm Dialog

Figure 9.3 Alarm Status

39

Page 43

The status of all 4 alarms is always visible in the top ribbon, each with its own small square. The status of each alarm

is indicated 3 colors:

Transparent Alarm disabled

Blue Alarm enabled, not triggered

Red Alarm enabled and triggered

To clear an alarm, press the on screen box containing the alarm statuses.

9.2 Analog/Math/Timing Signal Alarm

An alarm based on analog signal levels, a math function, or a “logical function” is set by selecting the “trigger” function

on the Alarm dialog (Figure 9.2). Signals available for Alarms must be active signals congured in the “Channels”

menus on the “Home” screen.

When selected, the dialog changes contents to show something similar to Figure 9.4.

Select the desired signal by pressing the button listing a channel at the center of the dialog box. Depending on the signal

type, 1 thresholds may be set. The selected threshold is show at the top of the dialog. To set the trigger as a window,

the “channels combination” conguration must be used. See Section 9.3.

Figure 9.4 Analog Alarm Trigger

Figure 9.5 Alarm

Analog Thresholds

9.3 Analog Signal Combination Alarm

More complex triggering based on windows, and combinations of signals is available. The signals are limited to the analog

channels and do not include math and timing as in the single channel alarm. The signals may have 2 thresholds.

40

Page 44

The set of signals congured will trigger the alarm if 1 threshold is true, or all thresholds are true. This is set by the

AND/OR condition at the top of the dialog.

Figure 9.6 Analog Combination Trigger

9.4 Logic (Digital) Signal Alarm Trigger

An alarm based on the logic state of the digital input is congured by selecting the “Logical Channels” option. Following

the typical convention of a 1, 0 and X to denote true, false and “dont’t care” respectively, is used to set the digital patter

to trigger on. Also, using the “AND” or “OR” conditions select when the trigger occurs. With the “AND” condition, all

signals dened must be true for the Alarm to trigger. In the “OR” case, any valid signal, excluding the “X” signals will

trigger an alarm.

Figure 9.7 Digital Trigger

41

Page 45

9.5 Alarm on Recording Start (Trigger Acquisition)

An alarm is also available for signaling the start of a recording. Select the “Trigger Acquisition” option to enable this

type of alarm.

Figure 9.8 Trigger on Alarm

42

Page 46

Logic Channels

Up to 12 logic channels can be recorded simultaneously with the analog channels. In addition, 4 timing channels are also

available for measuring duty cycle, RPM, and pulse count.

10.1 Logic Input Connector

This is a DB-25 connector located on the top of the unit.

Pin Signal Pin Signal

13 Logic Ch 1 19 Function K2

25 Logic Ch 2 6 Function K3

12 Logic Ch 3 18 Function K4

24 Logic Ch 4 5 Ground

11 Logic Ch 5 17 Ground

23 Logic Ch 6 4 Ground

10 Logic Ch 7 16 9-15V 0.2A

22 Logic Ch 8 3 Ground

9 Logic Ch 9 15 Alarm C

21 Logic Ch 10 2 Alarm D

8 Logic Ch 11 14 Alarm A

20 Logic Ch 12 1 Alarm B

7 Function K1

Figure 10.1 Logic Connector

10.2 Logic Channel Setup

To set the logic channels, press the “logic channels” button on the “Home” screen, or from the “F(t)” screen, click within

the logic signal portion of the screen when present, See Figure 10.2. The conguration screen will open and resemble

Figure 10.3.

The set of channels depends on the number of channels chosen. For a given number of channels, the signals enabled on

the connector is xed. For example, if 4 channels are enabled by the up/down arrows beside the text listing the number

of channels, then pins 13, 25, 12, and 24, will be active. They become channels 1-4 respectively.

Figure 10.2 Logic

Channels on the F(t) screen

43

Page 47

Item Description

1 Channel number, color and arrows to

change channel

2 Channel count

3 Enable logic channels

4 Connector (red - selected channel)

5 Additional pin information

6 Channel #, pin, and state (dim -

disabled)

Figure 10.3 Logic Channel Conguration Screen

10.3 Timing

Function channels K1-4 are used for measuring the PWM duty cycle, count, or frequency of up to 4 digital signals. They

are also 3.3V level signals and tolerant of 24V.

Access the setup for these functions from the “Home” screen and pressing the . Then navigate to the

channels K1-4. See Figure 10.4. To congure each channel, either change the parameters on this screen by opening the

menus per eld in the table, or open the conguration screen for a single channel by pressing the channel ID (i.e. K1).

Conguration of a single channel is done via screens similar to Figure 10.5.

Figure 10.4 Timing Function Channels

10.4 Alarm Outputs

Finally, the “Alarm” signals are also present on the Logic connector (A, B, C and D. Pins 14, 1, 15 and 2 respectively).

Their setup and use is described in Section 9. All outputs are TTL 5V. When the unit is powered off, outputs have a

5kΩresistance.

44

Page 48

Figure 10.5 Single Timing Function Setup Screen

45

Page 49

File Management

The recorder is capable of creating recordings, screenshots, and saving device setup congurations. All of these are

stored as les, “*.rec” for recordings, “*.bmp” for screenshots, and “*.cfg” les for congurations. The le view dialog

Figure 11.1 is accessible from the “Home>Setup”, “(Waveform)>Screen Setup>Background”, “Home>View Records”,

“Home>Setup>Load/Save on Disk” screens for example. Each instance of the le dialog allow interaction between

internal and external (USB) storage. Finally, folder navigation and creation is also available.

1 Note:

It is highly advisable to work in a folder and not at the root of the ash disk. When erasing a folder, all les in this

directory will be erased too.

Figure 11.1 File View Screen

1. Read/write to internal ash disk or USB stick (if it was connected during unit startup)

2. Copy the selected le or folder to a USB drive

3. Create and name a new le

4. Create a new folder

5. Delete the selected folder or le

6. Close the window

7. Folder navigation and location window

8. File view and selection window

11.1 Setup Files

Setup congurations are loaded and saved from the “Home>Setup” menu. The conguration may be changed via the 3

buttons in the upper righthand corner of the screen:

46

Page 50

Default Sets up the appliance in standard conguration

Load from disk Loads a conguration from a le in the internal ash disk or an USB stick

Save to disk Saves a conguration into a le in the internal ash disk or an USB stick

These commands are only available when the data recording is stopped.

11.1.1 Default

This action loads the system defaults as programmed into the unit during manufacturing.

11.1.2 Save Setup Files

To save a conguration, press the . The name of the le with the alphanumerical keyboard

displayed on screen, or, if attached, a USB keyboard.

11.1.3 Load Setup Files

To load a conguration, press the . Select the directory and then the le to load, and click “Load”.

11.2 Recordings Files

Saved recordings are transferable between internal storage and USB. Recordings are saved to internal storage. See

Chapter 7 for details.

47

Page 51

Remote Interfaces

12.1 LAN Interface

The LAN connection to the DAS240-BAT supports ModBus, VNC, Sefram Viewer and DAS Lab. Sefram Viewer and

DAS Lab are tools provided by B&K/Sefram, and are available as a single download from http://www.bkprecision

.com. The LAN connection supports 10mBit and 100mBit networks. In the case where a network is not available, using

a crossover cable is also possible.

12.1.1 LAN Setup

Setup of the LAN interface is available by clicking the “Network” button on the “Home” screen. (See Figure 12.1).

Clicking the “Network” button opens the network setup dialog (See Figure 12.2). The LAN interface supports static

and dynamic (DHCP) conguration. For DHCP, the DHCP checkbox is marked, and the network address will be shown

on the “Network” button shown on the “Home” screen. For static IP conguration, using parameters dened for the

network (see your local network administrator for details) are set in the dialog.

Figure 12.1 LAN Conguration Button

12.2 VNC

Use of the unit from another computer is available using VNC (Virtual Network Computing). This presents an interactive

view of the front panel allowing nearly all functions to be used remotely. Numerous software tools are available for using

VNC (ex. UltraVNC).

To open a connection, the IP address of the unit is required. This is found on the “Network” button on the “Setup”

screen.

12.2.1 Changing the Password

Open the “Setup” screen and press the “VNC” button. The resulting dialog box shows the current password. Press the

keyboard icon in order to change the password.

12.3 Network File Transfer

Transfer your les to your computer to save them or view them with the SeframViewer software.

• Using of the Windows le explorer

• Filezilla: freeware (https://lezilla-project.org/)

• Using an external browser (Firefox, Chrome, Edge, etc…)

48

Page 52

DHCP Static

Figure 12.2 LAN Setup

12.4 Viewing with SeframViewer

You can transfer the data acquisition les to a PC computer for viewing.

The SeframViewer software is provided on a CD-ROM with the appliance. You can use it to view the recorded les or

convert it into xls or txt les.

It works under WINDOWS with Framework 2.0.

Transfer of the les from the appliance to the PC computer:

• USB peripheral device

• with the FTP protocol

Launch the SeframViewer software (or double-click on a le)

Open a data acquisition le (sux .rec)

You can select:

• the channels to display

• the display mode f(t) or xy

• the self-calibration of the channels.

Your data acquisition le shows up on screen. The functions of SeframViewer are available.

Refer to the instruction manual included in the software to discover all available functions in SeframViewer by clicking

on the last icon < Help >.

You can also directly create a le (.txt or .xls) by launching the command mode of Windows with the following line (see

the Options sub-menu of the help):

49

Page 53

Figure 12.3 Sefram Viewer

12.4.1 Example

C:\Program Files (x86)\SeframViewer\seframviewer.exe myle.rec /x

will create a .xls le

C:\Program Files (x86)\SeframViewer\seframviewer.exe myle.rec /t

will create a .txt le

Excel@export will directly launch Excel in the browser.

Figure 12.4 Excel Export

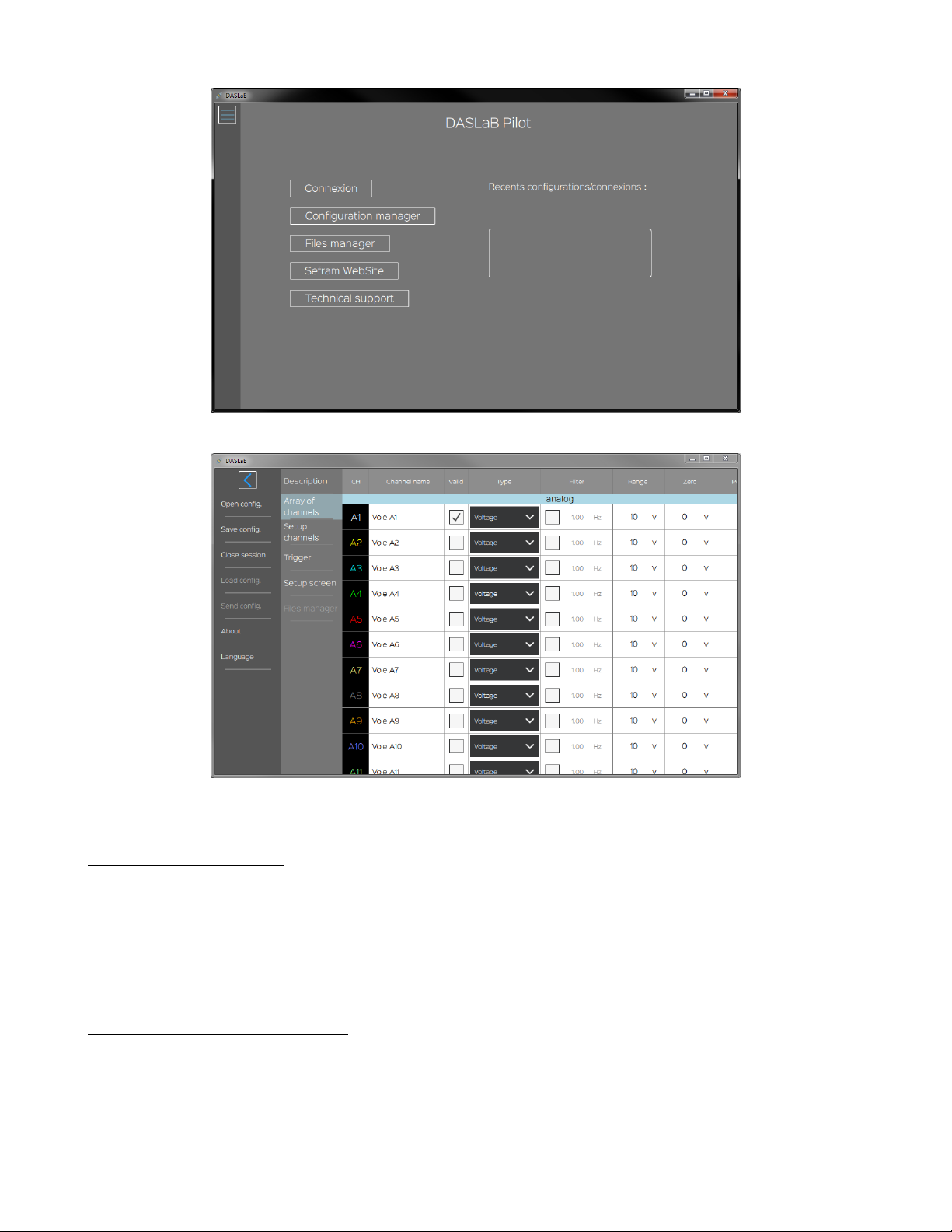

12.5 Device Control with DASLab

The DASLaB software manages congurations of your DAS240-BAT device.

• Open, modify and save your congurations

• Manage congurations remotly using network via Ethernet or WiFi

• Download your record les using network via Ethernet or WiFi

According to your needs, click on the right button. If you want manage your DAS240-BAT or DAS220-BAT using

network, enter the IP address to establish the connection.

For every action, including opening, saving, sending or refreshing congurations, the left sliding menu makes you able to

apply it.

50

Page 54

12.6 Modbus (slave)

Figure 12.5 DASLab

Figure 12.6 DASLab

Modbus is a non-proprietary communication protocol. All Modbus frames are encapsulated into Ethernet frames: it is

called Modbus over TCP/IP.

That protocol is dialog based (question-answer) : the client (master) send a command, and then the server (slave), send

back wanted data.

The DAS240-BAT/DAS220-BAT includes a Modbus TCP Slave service.

12.6.1 Setup Modbus Slave

The Modbus protocol uses ethernet network. So you have to choose the port used for that feature, and then enable the

Modbus TCP server.

Default port for Modbus TCP is 502.

It is possible to use Wi provided a USB Wi adapter is installed and working: for performance reasons however, the

wired USB interface should be used when using Modbus.

51

Page 55

In the Setup page of your instrument, then Additional option, select the “Modbus TCP Server” button.

You could enable or disable the server: click on the radio button < Modbus server state >.

According to your preferences, you are able to change the network port dedicated to the Modbus server. To carry out

that change to a successful conclusion, you must disable the Modbus server, change the port (502 by default), and then

restart the Modbus server.

12.6.2 Mapping Modbus TCP

The instrument shares acquisition data at input registers (0x04) and discrete input (0x02).

12.6.2.1 Analog Data

Acquisition data for the 200 analogs channels, and 4 logicial functions channels (K1 to K4) are located in inputs registers

from the following address : 0x08.

Register Register Description

0x08 A1 High word

0x09 A1 Low word

0x0A A2 High word

0x0B A2 Low word

… …

0x19F K4 High word (channel n* 204)

0x1A0 K4 Low word

Table 12.1 Modbus register map

An input register contains 16 bits, and each channel value is represented as a oat (32 bits).

So, to read one channel, you should read two input registers.

Example : Input A1 from address 0x08 to 0x09

At address 0x08 : -16460 (16 bits)

At address 0x09 : 28160 (16 bits)

Value in oat : -1.40961 (32 bits)

12.6.2.2 Logical Data

Logical values about the 12 logical channels are located in the discrete inputs from the address 0x08.

Register Register Data

0x08 DI1

… …

0x14 DI12

Table 12.2 Register Mapping

52

Page 56

Maintenance

Unplug the unit before any cleaning or maintenance.

Periodically clean the recorder while unplugged, in the following ways:

• Use water and soap to clean the front and rear surfaces.

• Never use any product that contains petroleum by-products, benzene or alcohol: damage the screen printings may

occur

• Wipe with a soft lint-free cloth.

• Use an antistatic product to clean the screen.

13.1 Updating the Internal Software

The internal software is updated regularly with the latest evolutions. These updates are available on our website.

http://www.sefram.com/en/software-updates.html

• To update the software, copy the le that will be provided on an USB stick. Place it on the USB connector on the

rear side of the unit.

• Press the “Setup” key.

• Then press the “Software update” key to enter the update.

• Finally, to run the update, press the “Sofware update” key.

• Then, the internal software automatically copies the necessary les to the new version.

• Turn the unit off and on after the end of the updating process.

53

Page 57

Specications

Note: All specications apply to the unit after:

1. A temperature stabilization time of 15 minutes over an ambient temperature range of 23

2. Short correction operation performed before making measurement.

Specications are subject to change without notice.

∘

C ± 5

∘

C.

54

Page 58

Portable 10-channel data recorder

Model DAS220-BAT

5

www.bkprecision.com

v041519

Specifications

Analog Channels

Analog Input Channels 10 integrated channels

DC Voltage

Ranges

± (0.5, 1, 2.5, 5, 10, 25, 50, 100) mV

± (0.5, 1, 2.5, 5, 10, 25, 50, 100) V

Maximum input Voltage 100 V DC

Accuracy 0.1% of the full scale ±10 µV

Temperature with Thermocouples

Sensors Range by

Type (Cold junction

compensation: ±0.5 °C)

J -210 °C to 1200 °C

K -250 °C to 1370 °C

T -200 °C to 400 °C

S -50 °C to 1760 °C

B 200 °C to 1820 °C

E -250 °C to 1000 °C

N -250 °C to 1300 °C

C 0 °C to 2320 °C

L -200 °C to 900 °C

Temperature with Pt100 and Pt1000

Current 1 mA (Pt100), 100 µA (Pt1000)

Range -200 °C to 850 °C

Measurements 2 and 3 wires

Accuracy (at 20 °C) 0.3 °C ±0.1% of reading

Compensated Resistance

2 wires 30 Ω max.

3 wires 50 Ω max.

Resistance

Ranges 1 kΩ and 10 kΩ

Accuracy 1 Ω (range 1 kΩ) and 10 Ω (range 10 kΩ)

Acquisition System

Resolution 16 bit

Acquisition System Scan, one sample per channel

Sampling Interval

V >50 mV 1 ms to 20 min

V ≤50 mV,

thermocouples and

Pt100 / Pt1000

2 ms to 20 min

Trigger

Date, delay, threshold, combination of

thresholds (and/or), word on logic

channels (and, or, slope, level)

Pre-trigger Variable from 0 to 100k samples

General

Internal Flash Drive Size 32 GB

Maximum File Size 2 GB

Operating Temperature 0 °C to 40 °C, 80% RH (no condensation)

Storage Temperature -20 °C to 60 °C

Display

10” TFT touchscreen LCD,

backlit, 1024 x 600 dots

Power Supply

15 V / 4 A max with main adapter

(100 / 240 VAC)

Interfaces

2 x USB host,

LAN (10/100 base-T with RJ45 socket)

Battery Non removable, Lithium-ion

Typical Battery Life

15 hours with standby mode, 10 hours without

stand-by mode

Safety Cat I 100 V, according to IEC61010-1

Weight 3.3 lbs (1.5 kg)

Dimensions (W x H x D) 2.6” x 11.7” x 6.9” (66 x 298 x 176 mm)

Warranty Two Years

Supplied Accessories

Main adapter 100 / 240 V, manual (CD-ROM),

25 pin male connector

(1)

and backshell, 10 input

connectors, shoulder strap, stylus, soft wipe,

and screwdriver

Order Information for Optional Accessories

902401050 Analog input terminal blocks 20 pack

902408000 Rugged carrying case

902407000 Logic channels patch cord

902406500 4 to 20 mA / 50 Ω shunt

902409000 19” rack-mount kit

Logic Channels

Logic Input/Output

Number of Channels 12

Maximum Permitted Voltage 24 V Cat I

Input Impedance 4.7 kΩ

Sampling Rate 1 ms max.

Timing Input

Number of Channels 4 (K1 to K4)

Maximum Permitted Voltage 24 V Cat I

Input impedance 4.7 kΩ

Sampling Rate 1 ms max.

Pulse Counter 0 to 10 Million, accuracy 1 ppm

Frequency Measurement 1 Hz to 10 kHz, accuracy 0.1%

PWM Measurement 100 Hz to 2 kHz, accuracy 0.1%

Alarm Output

Number of Channels 4 Alarms (A, B, C, D)

Output Level 0 to 5 V

Note: All specifications apply to the unit after a temperature stabilization time of 30 minutes

over an ambient temperature range of 23 °C ± 5 °C.

(1) User configurable with solder cups.

Page 59

Multi-channel recorder

Model DAS240-BAT

5

www.bkprecision.com

v032318

Specifications

Analog Channels

Number of Analog Input Channels

20 channels standard, expandable to 200 with optional 20-channel modules

DC Voltage

Ranges

± (0.5, 1, 2.5, 5, 10, 25, 50, 100) mV

± (0.5, 1, 2.5, 5, 10, 25, 50, 100) V

Maximum input Voltage 100 V DC

Accuracy 0.1% of the full scale ±10 µV

Temperature with Thermocouples

Sensors Range by

Type (Cold junction

compensation: ±0.5 °C)

J -210 °C to 1200 °C

K -250 °C to 1370 °C

T -200 °C to 400 °C

S -50 °C to 1760 °C

B 200 °C to 1820 °C

E -250 °C to 1000 °C

N -250 °C to 1300 °C

C 0 °C to 2320 °C

L -200 °C to 900 °C

Temperature with Pt100 and Pt1000

Current 1 mA (Pt100), 100 µA (Pt1000)

Range -200 °C to 850 °C

Measurements 2 and 3 wires

Accuracy (at 20 °C) 0.3 °C ±0.1% of reading

Compensated Resistance

2 wires 30 Ω max.

3 wires 50 Ω max.

Resistance

Ranges 1 kΩ and 10 kΩ

Accuracy 1 Ω (range 1 kΩ) and 10 Ω (range 10 kΩ)

General

Acquisition System

Resolution 16 bit

Acquisition System Scan, one sample per channel

Sampling Rate

V >50 mV 1 ms to 20 min

V ≤50 mV,

thermocouples and

Pt100 / Pt1000

2 ms

Trigger

Date, delay, threshold, combination of

thresholds (and/or), word on logic

channels (and, or, slope, level)

Pre-trigger Variable from 0 to 100k samples

Internal Storage

Internal Flash Drive Size 32 GB

Maximum File Size 2 GB

Environmental

Operating Temperature 0 °C to 40 °C, 80% RH (no condensation)

Storage Temperature -20 °C to 60 °C

Auxiliary

Display

10” TFT touchscreen LCD,

backlit, 1024 x 600 dots

Power Supply

15 V / 4 A max with main adapter

(100 / 240 VAC)

Interfaces

2 x USB host,

LAN (10/100 base-T with RJ45 socket)

Battery Non removable, Lithium-ion

Typical Battery Life

15 hours with standby mode, 10 hours without

stand-by mode

Safety Cat I 100 V, according to IEC61010-1

Weight 3.3 lbs (1.5 kg)

Dimensions (W x H x D) 2.6” x 11.7” x 6.9” (66 x 298 x 176 mm)

Warranty Two Years

Supplied Accessories

Main adapter 100 / 240 V, manual (CD-ROM),

1 male connector with 25 pins male and cover,

1 cable (70 cm) for measurement module

connection, 1 measurement module (20

channels) with input terminals, a stylus,

a soft wipe, a screwdriver

Order Information for Optional Accessories

902401000 20-channel module

902401050 Input terminal blocks 20 pack

902408000 Rugged carrying case

902407000 Logic channels patch cord

902406500 4 to 20 mA / 50 Ω shunt

902409000 19” rack-mount kit

Logic Channels

Logic Input/Output

Number of Channels 12

Maximum Permitted Voltage 24 V Cat I

Input Impedance 4.7 kΩ

Sampling Rate 1 ms max.

Timing Input

Number of Channels 4 (K1 to K4)

Maximum Permitted Voltage 24 V Cat I

Input impedance 4.7 kΩ

Sampling Rate 1 ms max.

Pulse Counter 0 to 10000000, accuracy 0.1%

Frequency Measurement 1 Hz to 10 kHz, accuracy 0.1%

PWM Measurement 100 Hz to 2 kHz, accuracy 0.1%

Alarm Output

Number of Channels 4 Alarms (A, B, C, D)

Output Level 0 to 5 V

Page 60

Thermocouple Measurement Accuracy

The thermocouple measurements are treated as voltage measurements.

For a given range of temperature measurement, the software calculates the voltage caliber the following way:

• Let < T > the absolute value of the max. measurable value, in

• Add 40

• Search the corresponding voltage value U in the table of thermocouples

• Program the caliber with U included in the range.

∘

C to take the max. cold welding temperature into account

∘

C

15.1 J Type Thermocouple Example

You want to program a measurement range between -50 and + 50∘C with a J thermocouple:

• Max. absolute value T = 50

• Add 40

• Corresponding U voltage according to the tables ThJ U = 4.726 mV

• Programmed caliber: 10 mV (measurement range: -5mV to +5mV)

The measurement inaccuracies below are max. values: the typical values are half to thrice as much.

The temperature measurement accuracy is the sum of several possible uncertainty causes:

• Pl: linearization accuracy

∘

C T + 40 = 90∘C

∘

C

• Ps: weld welding accuracy

• Pm: measurement accuracy of the equivalent voltage

The total accuracy Pt is then: 𝑃𝑡=𝑃𝑙+𝑃𝑠+𝑃𝑚

For the recorder:

• Pl = + 0.25

• Ps = + 0.5

• Pm = 0.1% of the voltage caliber + 10𝜇V) divided by the slope of the thermocouple in 𝜇V/

∘

C for all thermocouples

∘

C for all thermocouples

∘

C

15.2 Measurement Accuracy: Pm

The measurement accuracy Pm depends on the voltage caliber of the appliance (see the previous paragraph) and on

the slope of the thermocouple. You shall take the slope at 0∘C while knowing that it will vary as a function of the

temperature, but this variation is generally of the second order for the accuracy calculation.

15.3 Voltage of Thermocouple (mV)

Slope of the thermocouples (𝜇V)

55

Page 61

• At 100∘C the slope of thermocouple J is 55𝜇V

• At -100∘C slope is 30𝜇V .

• So the error is 2 time greater then 100

∘

C to -100∘C.

15.3.1 Example of Accuracy Calculation

You make a welding between -50∘C and +50∘C with a J thermocouple with compensation of cold welding.

𝑃𝑡=𝑃𝑙+𝑃𝑠+𝑃𝑚 (15.1)

Linearization accuracy 𝑃𝑙=+0.25∘𝐶

Compensation of cold welding 𝑃𝑠=+0.5∘𝐶

Used caliber 10mV - (see previous example)

Accuracy for voltage measurement 0.1%∗10𝑚𝑉 +10𝜇𝑉 =20𝜇𝑉

Slope of J thermocouple 50𝜇𝑉/∘𝐶

Accuracy Pm 𝑃𝑚=20/50=0.4∘𝐶

Total accuracy 𝑃𝑡=0.25+0.5+0.4=1.15∘𝐶

15.4 Accuracy Class - Class Index

This is one of the most important concepts of the CEI recommendation; it tends to shorten the list of specications. To

do so, it introduces the concept of PREDICTIVE CLASS that depends on the C CLASS INDEX.

The normalized values of the class index are: C = 0.1, 0.25, 0.5 and 1.

The intrinsic error (in the reference conditions) does not exceed + C% (the manufacturer may also specify this limit of

the intrinsic error as an absolute value (ex. + 5 𝜇V) for the rst calibers).

The variations (of the measured value) with the variations of one of the inuential variables in the nominal range of use

do not exceed:

• C % for the position for the magnetic induction with external source and parasite voltages

• 0.5 C% for the power supply source

• 0.3 C% according to the class index at ambient temperature (0.15% for the 0.25 class).

In addition, the insensitivity range should not exceed:

• C% in the reference conditions

• 1.5C% for the maximal resistance of the external measurement circuit

• 2C% for parasite voltages

And the excess should not be more than 2C% (4C% within the limits of the power supply source). %

56

Page 62

15.5 Grounding

• If the source of the signal you have to record has low internal impedance, you shall use twisted wires. In case of high

impedance, you shall use shielded wires.

• When gathering grounds from the various items on the measurement line, it is good to check that there is no voltage

difference between them, in order to prevent any shortcut. If any doubt, make a measurement with a voltmeter on a

low resistance (i.e. 1kΩ) between the terminals.

• If any important noise,

− When using the battery , connect the GND connection to the ground

− use the sampling period for each channel >20ms

− an appropriate capacity can be placed between the ground and the - wire of the signal.

57

Page 63

LIMITED TWO-YEAR WARRANTY

B&K Precision Corp. warrants to the original purchaser that its products and the component parts thereof, will be free

from defects in workmanship and materials for a period of two years from date of purchase.

B&K Precision Corp. will, without charge, repair or replace, at its option, defective product or component parts. Returned

product must be accompanied by proof of the purchase date in the form of a sales receipt.

To help us better serve you, please complete the warranty registration for your new instrument via our website www.bkprecision.com

Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of

unauthorized alterations or repairs. The warranty is void if the serial number is altered, defaced or removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages resulting

from loss of use. Some states do not allow limitations of incidental or consequential damages. So the above limitation

or exclusion may not apply to you.