Model: XLN3640, XLN6024, XLN8018, XLN10014

High Power Programmable

DC Power Supply

Click for models XLN15010, XLN30052 & XLN60026

USER MANUAL

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Safety Summary

The following safety precautions apply to both operating and maintenance personnel

and must be observed during all phases of operation, service, and repair of this

instrument. Before applying power, follow the installation instructions and become

familiar with the operating instructions for this instrument.

Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the

instrument. B&K Precision assumes no liability for a customer’s failure to comply

with these requirements. This is a Safety Class I instrument.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be

connected to an electrical ground. This instrument is grounded through the

ground conductor of the supplied, three-conductor ac power cable. The

power cable must be plugged into an approved three-conductor electrical

outlet. Do not alter the ground connection. Without the protective ground

connection, all accessible conductive parts (including control knobs) can

render an electric shock. The power jack and mating plug of the power cable

meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component

replacement and internal adjustments must be made by qualified maintenance

personnel. Disconnect the power cord before removing the instrument

covers and replacing components. Under certain conditions, even with the

power cable removed, dangerous voltages may exist. To avoid injuries,

always disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt any internal service or adjustment unless another person,

capable of rendering first aid and resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

tive ground

connection, all accessible conductive parts (including control knobs)

can render an electric shock. The power jack and mating plug of the

before

Before connecting the line cord to the AC mains, check the rear panel

AC line voltage indicator. Applying a line voltage other than the

fuses. For continued fire

protection, replace fuses only with those of the specified voltage and

This product uses components which can be damaged by

static discharge (ESD). To avoid damage, be sure to follow

ocedures for handling, storing and transporting parts and

Do not install substitute parts or perform any unauthorized modifications to

this instrument. Return the instrument to B&K Precision for service and

repair to ensure that safety features are maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the following examples,

denote a hazard and appear throughout this manual. Follow all instructions

contained in these statements.

A WARNING statement calls attention to an operating procedure, practice, or

condition, which, if not followed correctly, could result in injury or death to

personnel.

A CAUTION statement calls attention to an operating procedure, practice, or

condition, which, if not followed correctly, could result in damage to or

destruction of part or all of the product.

WARNING: Do not alter the ground connection. Without the protec

power cable meet IEC safety standards.

WARNING: To avoid electrical shock hazard, disconnect power cord

removing covers. Refer servicing to qualified personnel.

CAUTION:

indicated voltage can destroy the AC line

current ratings.

CAUTION:

electroproper pr

subassemblies which contain ESD-sensitive components.

Store/Move/Maintain

Storage

When this device is not in use, properly package it and store it in an

environment suitable for storage (if present in a good preserving environment,

the packaging process can be waived).

Freight

While moving this product, move it by using the original packaging to pack

this product in advance. If the packaging material is lost, use an equivalent

buffer material to replace it in packaging; and with external marks indicating

“fragile & water-prevention”.

Maintenance

Please return the power supply to factory for any repair, service, or

maintenance.

Disposal

When the device is in an unusable condition and can’t be repaired, please

discard it according to your company’s disposal procedures or local legal

procedures. Don’t discard arbitrarily to avoid polluting the environment.

1

Table of Contents

1. Preface ...................................................................................................... 1

1.1 Products Outline ................................................................................ 1

1.2 Features ............................................................................................. 2

1.3 Specifications .................................................................................... 4

2. Cautions Before Using ............................................................................ 9

2.1 Check and Confirm Accessories before Using .................................. 9

2.2 Operation Instructions ....................................................................... 9

2.3 Ambient Environment ....................................................................... 9

2.4 Storage ............................................................................................. 10

2.5 Power-line voltage ........................................................................... 10

2.6 Fuses ................................................................................................ 10

2.7 War m -up Time ................................................................................. 11

2.8 Power-off procedure ........................................................................ 11

2.9 Cautions in Operation ...................................................................... 11

3. Front Panel Operation .......................................................................... 12

3.1 XLN3640/XLN6024/XLN8018/XLN10014 Panel ......................... 12

3.1.1 Front Panel ................................................................................. 12

3.1.2 Rear Panel .................................................................................. 30

4. Operation Instructions ......................................................................... 34

4.1 Voltage Setting................................................................................. 34

4.2 Current Setting ................................................................................ 34

4.3 Over-voltage Protection OVP .......................................................... 34

4.4 Over-current Protection OCP .......................................................... 34

4.5 Voltage Output ................................................................................. 35

2

4.6 Control Voltage Output with Rotary knob ....................................... 35

4.7 Timer Function ................................................................................ 35

4.8 Series (cascade) / Parallel Mode Setting ......................................... 36

4.8.1 Parallel Connection Setting ........................................................ 36

4.8.2 Series Mode Setting ................................................................... 38

4.8.3 Error Message of Series/Parallel Connection ............................ 41

4.9 External Tuning Setting ................................................................... 42

4.10 Timer of Current Flow ..................................................................... 43

4.11 Programmable Capability (SCPI Command Only) ......................... 44

4.12 Multi-unit Connection mode (RS485) ............................................. 50

5. Protection and Error Messages............................................................ 54

5.1 Over-voltage Protection (OVP) ....................................................... 54

5.2 Over-current Protection (OCP) ........................................................ 54

5.3 Overpower Protection (OPP) ........................................................... 54

5.4 Constant Voltage Protection (CV TO CC) ....................................... 55

5.5 Constant Current Protection (CC TO CV)....................................... 55

5.6 Over-temperature Protection (OTP) ................................................ 55

5.7 Low Voltage Protection (ACD) ....................................................... 56

5.8 Error Input Message ........................................................................ 56

6. Remote Interface communication protocol ........................................ 57

6.1 Prefaces ........................................................................................... 57

6.2 Parameters Definition ...................................................................... 57

6.3 The Error/Event List ........................................................................ 58

6.4 Remote Communication Protocol ................................................... 59

6.5 SCPI Conformity Information ......................................................... 62

6.5.1 Common SCPI commands ......................................................... 62

6.5.2 SCPI Command subsystem ........................................................ 63

3

6.6 State Bit Definition .......................................................................... 74

6.7 LAN Communication (-GL versions) .............................................. 75

Using Web Server........................................................................................... 75

Main Page (Home) .................................................................................. 75

Using Telnet ............................................................................................ 78

Using Sockets .......................................................................................... 78

7. Assemble Accessories ............................................................................ 79

7.1 Assemble Rack Mount Brackets ..................................................... 79

7.2 Assembly of Output Protective Cover

(XLN6024/XLN8018/XLN10014) .................................................. 80

7.3 Assembly of Remote Sense Protective Cover

(XLN6024/XLN8018/XLN10014) .................................................. 81

8. Accessories ............................................................................................. 82

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

4

1. Preface

1.1 Products Outline

B&K Precision models XLN3640/XLN6024/XLN8018/XLN10014 are

programmable DC power supplies with single outputs that offer the

maximum power output up to 1440 watts (0 -- 36 V/40 A or 0 -- 60 V/24 A

or 0 -- 80 V/18 A or 0 -- 100 V/14.4 A). With a 16-bit D/A, A/D converter

embedded, the power supplies come with the resolution of 1mV in voltage

setting and 1mA in current setting. By connecting up to 4 power supplies in

parallel or series, a maximum power output up to 5760 watts can be

generated. With four XLN10014 connected in series, the maximum output

voltage can reach 400 V. With four XLN3640 connected in parallel, the

output current can reach up to 160 A.

The XLN series provides a rotary control knob and numerical and function

keys to make the instrument convenient and easy to use. Additionally, the

power supplies provide a memory space for storage of 10 instrument settings

that can be recalled directly. This feature offers an easy way to restore the

application settings. In addition, users can program to control when to cut off

the output. This feature provides extra safety for burn-in and electroplating

applications. The supplies also provide over voltage protection (OVP), over

current protection (OCP), and over power protection (OPP) features used to

keep the output voltage and current within safety level and preventing

damage to the UUT (Unit Under Test) due to excessive current. The key lock

feature is added to avoid accidental setting changes to the XLN series. When

the input power and the load change, the power supplies maintain a stable

output due to load and line regulation of less than 0.05%; the transient time

less than 1 ms. In remote mode, the supplies can output a new

voltage/current setting 50 ms after receiving a command, which can increase

the throughput on production lines.

1

1.2 Features

1) Output Voltage & Current

Voltage output range: 0 -- 36V (XLN3640) / 0 -- 60V (XLN6024)

0 -- 80V (XLN8018) / 0 -- 100V

(XLN10014)

Current output range: 0 -- 40A (XLN3640) / 0 -- 24A (XLN6024)

0 -- 18A (XLN8018) / 0 -- 14.4A

(XLN10014)

Power output range: 0 -- 1440W

2) Rotary knob, numerical keys and functions keys

The rotary knob can be used to rapidly change the output voltage setting

and simulate the surge of the voltage output. It offers a good solution for

testing triggering circuits. Numerical keys allow for direct entry of

parameters. Using function keys to switch modes makes the overall

operation more convenient.

3) Precise voltage and current measurement

Besides the precise output, the XLN series also offers the capability to

measure voltage & current accurately (read back), saving users the extra

expense and space for extra measuring instruments.

4) Internal memory and timer function

The XLN series provides a memory space for storage and retrieval of 10

instrument settings. The instruments provide one (1) timer with the

resolution of 1 second. The timers are used to time the outputs. When the

timer counts down to zero the power supply will automatically turn the

output off. This feature is useful when the supply is providing power to the

test object in a burn-in room where operators can precisely set the time

when the equipment is to shut off.

5) OVP (over voltage protection), OCP (over current protection) and OPP

(over power protection) and key lock functions

The over voltage protection (OVP), over current protection (OCP) and over

power protection (OPP) features limit the maximum output current and

voltage to avoid damages to the unit under test (UUT). The key lock

feature disables all keys except the CLR key. It prevents damaging the

2

UUT by accidentally entering the wrong settings.

6) Series & parallel connection mode

The series-parallel connection mode of two or more units (maximum to 4

units) significantly increases the combined output power to a maximum of

5760 W. In parallel connection mode of four XLN3640 the maximum

output is 36 V/160 A; and in series connection mode of four XLN10014,

the maximum output is 400 V/14.4 A.

7) Multi-unit connection mode

The RS 485 interface can be used to connect multiple power supplies in

series, up to maximum of 30 units. They can be controlled via USB

interface with a computer.

3

Output Protection

OVP Adjustment Range

2--38 V

3--64 V

OVP Accuracy

200 mV

300 mV

Line Regulation

Current

≤ 8 mA

≤ 7 mA

Ripple/Noise (20Hz-20MHz)

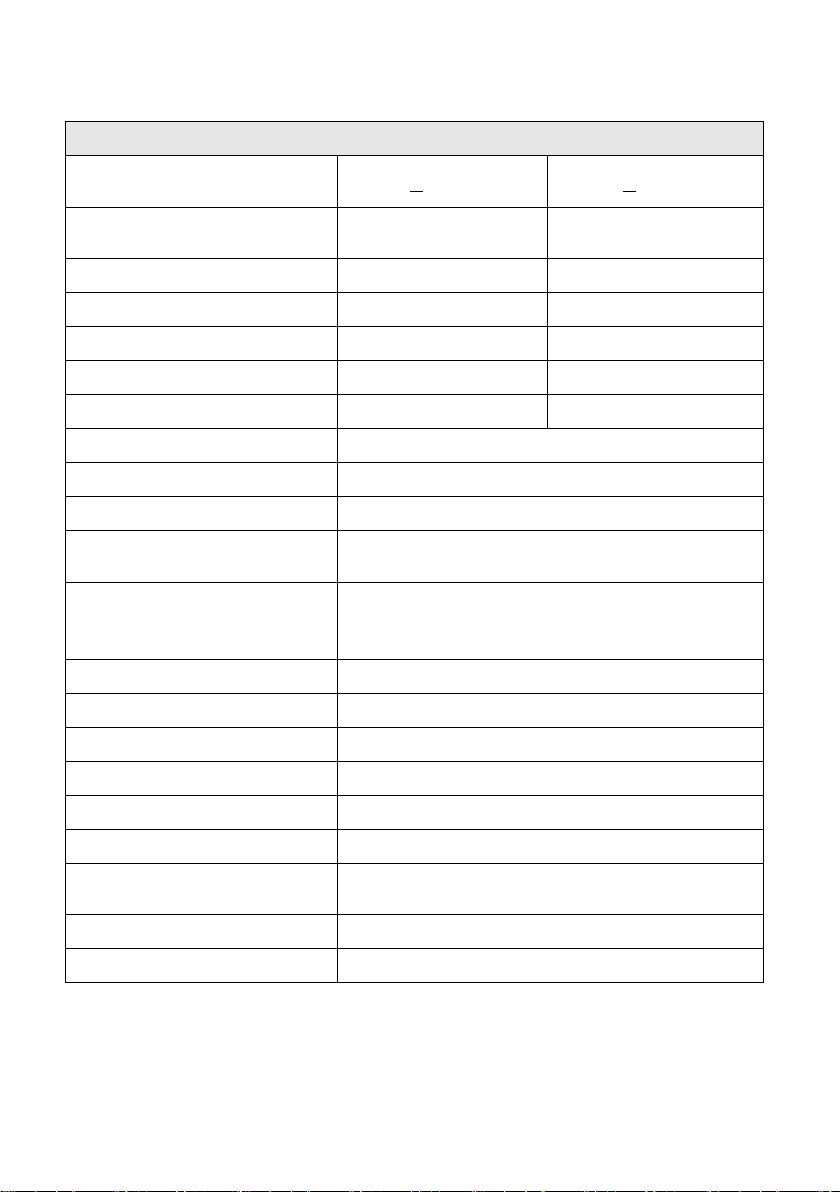

1.3 Specifications

XLN3640/XLN6024 Specifications

Output Rating

Output Voltage 0--36 V 0--60 V

Output Current 0--40 A 0--24 A

Output Power 1440 W 1440 W

Voltage ≤ 4 mV ≤ 6 mV

Current ≤ 4 mA ≤ 4 mA

Load Regulation

Voltage ≤ 8 mV ≤ 8 mV

XLN3640 XLN6024

Normal Mode Voltage

( ≥ 0.5 % of max. power)

Normal Mode Current ≤ 90 mA ≤ 70 mA

Programming Resolution

Programming 1 mV/1 mA 1.5 mV/1 mA

Readback 1 mV/1 mA 1.5 mV/1 mA

Programming Accuracy ±(% output+offset)

Voltage 0.05 %+10 mV 0.05 %+15 mV

Current 0.05 %+10 mA 0.05 %+18 mA

Readback Accuracy ±(% output+offset)

Voltage 0.05 %+10 mV 0.05 %+15 mV

Current 0.05 %+10 mA 0.05 %+18 mA

≤ 5 mVrms/≤ 60 mVpp ≤ 6 mVrms/≤ 70 mVpp

4

General

Average Command Response

Time

0.99

(Full load)

0.99

(Full load)

100--240 VAC

(Full load)

-15% -- +10%

when voltage under 95 VAC)

Power Cord, Terminal Blocks for Rapid Plug

Connector, Rackmount Kit, Manual

<50 ms <50 ms

Power Factor Correction

Remote Sense Compensation 2V 2V

Rising Time at Full Load ≤ 15 ms ≤ 20 ms

Rising Time at No Load ≤ 15 ms ≤ 20 ms

Falling Time at Full Load ≤ 15 ms ≤ 20 ms

Falling Time at No Load ≤ 1000 ms ≤ 1000 ms

Standard Interface USB

Transient Response Time ≤ 1 ms

Efficiency 80 %

AC Line Rated Input Voltage

Tolerance/Variation in

Voltage

(10% power de-rating mode

Rated Frequency 47 Hz--63 Hz

Maximum Rated Input Power 1700 VA

Temperature Ratings(O) Operation (0 °C -- 40 °C)

Temperature Ratings(S) Storage (-10 °C -- 70 °C)

Dimensions(W*H*D) 16.5 x 1.7 x 17 inch(420 x 43.6 x 432 mm)

Weight 19.8 lbs. (9 kg)

Standard Accessories

Standard Interface USB

Optional Interface LAN & GPIB

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

5

Normal Mode Voltage

( ≥ 0.5 % of max. power)

≤ 7 mVrms/≤ 80

mVpp

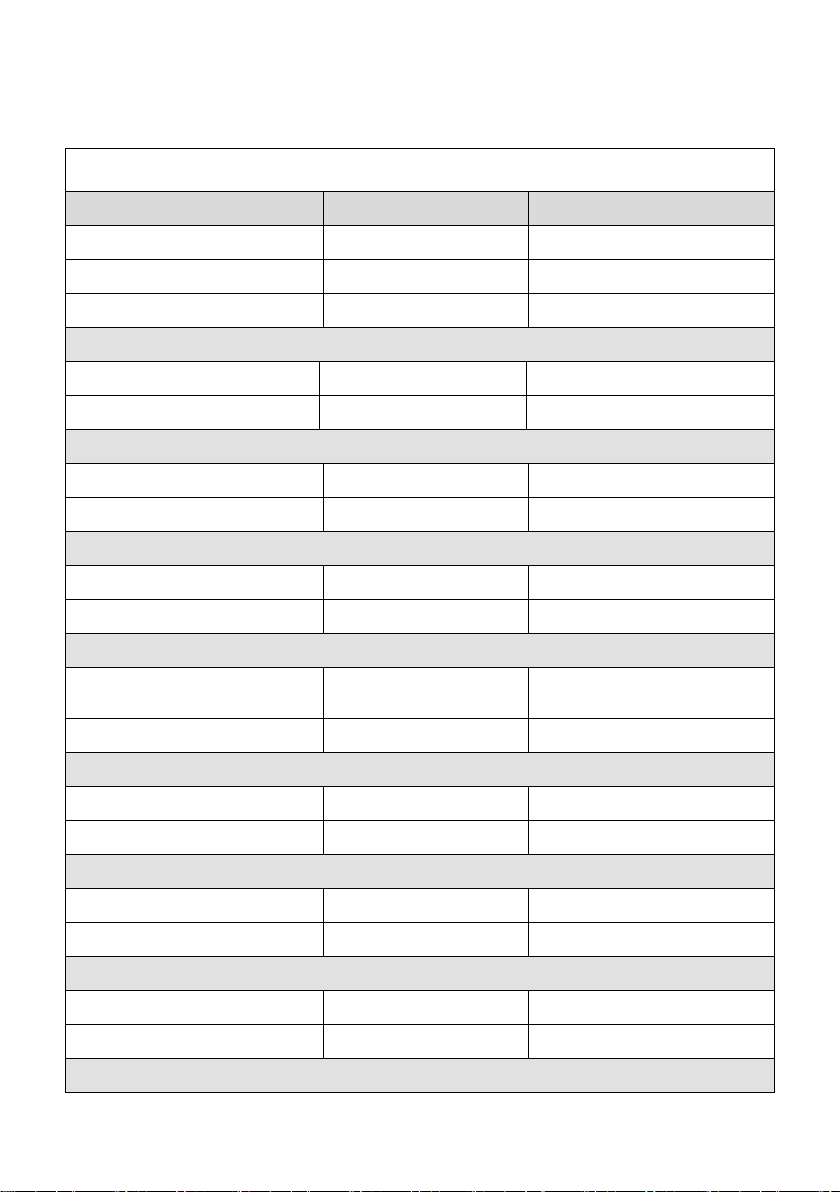

XLN8018/XLN10014 Specifications

Output Rate

Output Voltage

Output Current

XLN8018 XLN10014

0~80 V 0~100 V

0~18 A 0~14.4 A

Output Power 1440 W 1440 W

Output Protection

OVP Adjustment Range

4~85 V 5~105 V

OVP Accuracy 400 mV 500 mV

Line Regulation

Voltage ≤ 8 mV ≤ 10 mV

Current ≤ 4 mA ≤ 4 mA

Load Regulation

Voltage ≤ 10 mV ≤ 12 mV

Current ≤ 6.5 mA ≤ 6 mA

Ripple/Noise (20Hz-20MHz)

≤ 8 mVrms/≤ 80 mVpp

Normal Mode Current ≤ 50 mA ≤ 40 mA

Programming Resolution

Programming 2 mV/1 mA 2.5 mV/1 mA

Readback 2 mV/1 mA 2.5 mV/1 mA

Programming Accuracy ±(% output+offset)

Voltage 0.05 %+20 mV 0.05 %+25 mV

Current 0.05 %+7 mA 0.05 %+6 mA

Readback Accuracy ±(% output+offset)

Voltage 0.05 %+20 mV 0.05 %+25 mV

Current 0.05 %+7 mA 0.05 %+6 mA

General

6

Average Command

Response Time

Power Factor Correction

≥ 0.99

(Full load)

≥ 0.99

(Full load)

Remote Sense

100~240 VAC

( Full load )

-15 %~+10 %

when voltage under 95 VAC )

Power Cord, Terminal Blocks for Rapid Plug

Connector, Rackmount Kit, Manual

<50 ms <50 ms

Compensation

2 V 2 V

Rising Time at Full Load ≤ 25 ms ≤ 30 ms

Rising Time at No Load ≤ 25 ms ≤ 30 ms

Falling Time at Full Load ≤ 25 ms ≤ 30 ms

Falling Time at No Load ≤ 1000 ms ≤ 1000 ms

Transient Response Time ≤ 1 ms

Efficiency ≥ 80 %

AC Line Rated Input

Vo l t a g e

Tolerance/Variation in

Voltage

Rated Frequency

Maximum Rated Input

Power

( 10 % power de-rating mode

47 Hz~63 Hz

1700 VA

Temperature Ratings(O) Operation (0 °C -- 40 °C)

Temperature Ratings(S) Storage (-10 °C -- 70 °C)

Dimensions(W*H*D) 16.5 x 1.7 x 17 inch (420 x 43.6 x 432 mm)

Weight 19.8 lbs. (9 kg)

Standard Accessories

Standard Interface USB

Option Interface LAN & GPIB

Specifications and information is subject to change without notice

7

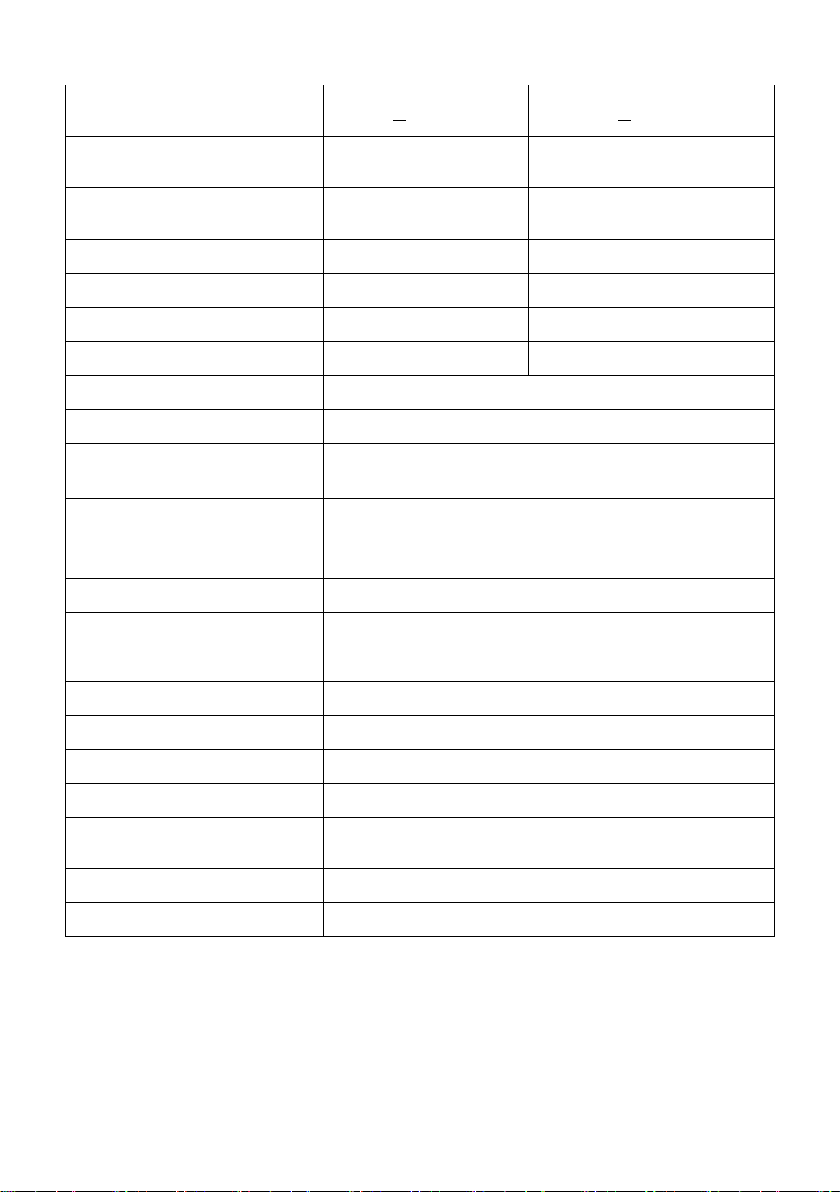

Features of models XLN3640/XLN6024/XLN8018/XLN10014:

Graphical, easy to read LCD display

Compact, high efficiency and power density

40 A output connector for quick connectivity

Convenient numerical & function keys

Store and recall 10 instrument settings

Timer (1 sec -- 100 hours)

Programmable (SCPI command only)

List mode supports up to 10 sets of program and maximum 150 steps in

total

Auxiliary 5 V/1 A output

Built-in precise voltage and current measurement

OVP, OCP, OPP and key-lock function

Series & parallel connection setup (up to 4)

Multi-unit connection mode via RS485 interface allows connection of up

to 30 power supplies.

Average measuring time per measurement is 50 ms

Standard USB interface

Optional interfaces: GPIB, LAN (order models XLN3640-GL,

XLN6024-GL, XLN8018-GL, XLN10014-GL)

8

2. Cautions Before Using

2.1 Check and Confirm Accessories before Using

After receiving this product, please verify the items received in accordance

with the ones listed below:

1. The appearance of the products is without scratch or other damages.

2. Standard parts as shown in parts list of section 8.

2.2 Operation Instructions

In order to avoid damaging the instrument due to improper operation, be

sure to read this user manual. To maintain the specified accuracy, factory

calibration should be performed annually.

2.3 Ambient Environment

1. Do not locate or operate this product in an environment with dust,

vibration, or corrosive gas and do not expose this product directly to

the sunlight. Operate it in an environment with temperature 0--40

& relative humidity 20%--80%. Pause the operation when ambient

temperature is over 40

temperatures drops to the acceptable temperature range. Operating

temperature over the above range would damage the instrument.

2. This product is equipped with one blow-out type cooling fan on the

back board and three in-take cooling fans on inner side of front board.

Provide room for good ventilation near the cooling fans and keep the

boards with a space above 10cm away from wall. To maintain good

accuracy, do not block the ventilation holes in the front and the rear

parts of the unit.

3. Although the product is designed with filters to minimize noise from

AC power source, it is recommended that it be operated in a low

power noise environment with proper earth ground. If the power

noise is unavoidable, please install a power filter.

o

C; undo the operation only after the ambient

o

C

9

2.4 Storage

The storage temperature range of this product is within -10ºC - 70ºC and

R.H. should be within 80% without moisture condensing. If not operating

this product for a long time interval, pack it with original packaging or

similar one and put it in a dry place without exposure to direct sunlight.

2.5 Power-line voltage

Rated AC power source connected to this product is within 100 V-240 V

(refer to the Product Specification for details). Before connecting to external

power source, be sure that the power switch is in OFF state and verify the

suitability of power cable (including the extension line). It should be

compatible with the rated voltage/current and should be firmly connected.

Warning :

The power cable attached with this product is certified

for safety. To change a cable or add an extension cable,

be sure that it can meet the required power ratings of

this product. Any misuse with an additional cable

would void the warranty of this product.

2.6 Fuses

This product is a switching mode power supply. The fuse installed inside is a

multi-barrier protection hardware design. It should not break under normal

operation. In case the fuse does melt, it indicates another malfunction that

causes the fuse to break. In this case, it is suggested to send this product

back to service.

Warning :

Any disassembling of the casing or changing the fuse not

performed by an authorized service technician will void

the warranty of the instrument.

10

2.7 Warm-up Time

The XLN series is fully operable upon switching the power on. However, to

reach the specified equipment accuracy, please allow the supply to warm up

for at least 30 minutes.

2.8 Power-off procedure

When the supply is not in use, be sure to turn the power switch on the panel

to the OFF position to turn off the power. After the power switch is turned to

the OFF position, the inner fans will still run for approximately 10-15

seconds to carry on the inside electric capacitor discharge process per safety

code requirement. Once the discharge process is complete, this product will

carry out the automatic shut-down process

2.9 Cautions in Operation

A. While connected in series, each power supplies should be in power-on

state and output should be "ON". In case there is any one supply that is

in power-off state or output is "OFF", the associated output current will

flow over the output bypass diode of the power-off unit and burn it out.

B. While in parallel connection mode, the output voltage of each power

supplies should be set to equal values. If the setting value of each unit is

not the same, the higher output voltage will feed back to the smaller unit

and destroy its inner parts.

C.

When the AC input voltage is lower than the full-load voltage which is

100 VAC, the supplies will activate an inner over temperature protector

and cut off the output in response to the condition. To ensure that the

entire test process can be complete smoothly, confirm that the input AC

voltage is within the specified range.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

11

3. Front Panel Operation

1 2 3 4 5 6 7

8

9

10

11

12 13 14

3.1 XLN3640/XLN6024/XLN8018/XLN10014 Panel

15

3.1.1 Front Panel

(1) Power switch:

Please consult the “Cautions before use” section before turning on power

switch.

(2) Display:

192x32 Graphic LCD Module

(3) Current setting

Press

to set up the current limit.

(4) Voltage setting

Press

to set up the output voltage.

:

:

(5) Dot/Local :

This button is applied as a decimal point. Or push this button after

entering REMOTE online state to revert back to LOCAL mode

(unit-operation mode). Or press this button to release after entering

LOCK mode.

12

(6) ESC/CLR :

In “Menu Setting” status, use this “Down” key to move cursor

Under Memory Setting status, use this key to store setting to

the selected memory set.

Setting” status, use this “Down” key to move cursor

Under Memory Setting status, use this key to recall setting

from the selected memory set.

=

36

. FF

5

1

.

=

.

.

Press this button to clean up numerical setting or jump to the previous

screen.

(7) Numerical keys

They are used to directly input the voltage or current value or choose the

setting option in Menu screen.

(8) Down/Right/Store

This key is a multi-function key for the following three functions:

Down:

to the next item.

Right: Under “Output” status, use this key to move cursor right.

Store:

(9) Up/Left/Recall :

This key is a multi-function key for the following three functions:

Up:

Left: Under “Output” status, use this key to move cursor left.

Recall:

In “Menu

to the up item.

- :

:

(10) Display :

In “Menu Setting”, press

the display to show voltage and current or power and load resistance as

shown below:

to return to main screen or toggle

13

.

1= .

5

FF

.

3=6

.

(11) Output :

=

FF

.

.

Control the On/Off of the output power.

(12) The rotary knob:

Use this knob to adjust voltage or current (press

cursor display first). This is adjustable when output is ON.

first to let

(13) Enter

This key is the confirmation key of current or voltage setting value; or

press

mode) or current (at CC mode).

(14) Mem

Press this key to enter access the storage memory. Users can then use the

numerical key or knob to select the target memory set to save or recall

the configuration by pressing the STORE or RECALL key. Ten sets are

available in selection.

(15) Menu :

Use this key to enter system parameter settings. There are eight (8) major

items under operation. Users may press

through the menu list or the numerical keys to enter the corresponding

item number in the menu list.

:

under output status to dynamically adjust voltage (at CV

:

,

to scroll

14

L=

= 1

T

=L

FF

1 . SYSTEM SETTING

2 . OUTPUT SETTING

3 . PROTECTION

4

.

F

5

.

6

.

L T T F

LL L

T

7 . TIMER CONTROL

8 . CALIBRATION

9 . CHAIN SETTING

1. SYSTEM SETTING:

Pressing

following “SYSTEM SETTING” menu.

REMOTE CONTROL:

key in the first page of Menu Setting will enter the

Choose the remote interface

(USB/GPIB/ETHERNET)

*GPIB and ETHERNET available only

with on models with “-GL” suffix

*USB control requires installing USB

drivers first. Download USB driver

from

www.bkprecision.com

*USB interface is a virtual COM port. T he settings are:

Baudrate : 57600 bps

15

Data bit : 8

1

.

= .

5

F

F

3

.

= .

6

control to voltage

istance

=

5

F

52=

= F

552. 552. 552

.

F

L

a

If you are not sure of the IP settings, consult

able KEY

are locked.

Parity check : none

Stop bit : 1

*When entering the Remote mode, screen will present RMT indicator as

shown in the following picture.

GPIB ADDRESS:

EXTERN CONTROL:

Set up GPIB ADDRESS (1-30)

Set up the external

control (VOLT 0-10 V or 0-5 V), res

control (RES 0-5K) or off (OFF).

IP CONFIG:

IP ADDRESS:

KEY LOCK:

*Simultaneously pressing both and keys in the main

screen can also lock keys.

STATIC : User can input IP address

If IP CONFIG is set to STATIC, users can enter

static IP address here.

Note:

your network administrator.

While exiting the setting screen after en

LOCK, all keys except the key

Only this key can disable KEY LOCK.

*While entering KEY LOCK state, screen will present LCK indicator in

the bottom right corner.

16

L

=

F

L

L

=

=

L

L

L

Set the backlight of the LCD to Always

default

.

FF=

F

=

,

=.F

=,FF

5

=

(on the rear

of the supply

If

the

use the last setting before it

a prompt will ask for setting

Once set, these values are then used the next

f the

9

number keys to recall the voltage and current

BEEP:

LCD BACKLIT:

RECALL DEFAULT:

Ext 5V OUTPUT:

POWER ON STATE:

Turns the Buzzer ON/OFF

ON or OFF after 1/5/10/30 minutes

Restores the manufacturer

settings

Turns the extra 5V power output

panel) ON/OFF.

Users can set the output state

when powered on. When OFF is selected, the

XLN series will do nothing after power on.

LAST is selected, then at power on

supply will

turned off previously. If USER (user defined)

is selected,

output voltage, current, and output state.

time the supply is powered on.

HOT KEY:

HOT KEY = OFF

Set the HOT KEY function ON/OFF. I

HOT KEY function is ON, user can use 0 –

17

setting values stored inside internal memory.

*If entering the HOT KEY mode, screen will indicate HOT symbol as

6

.

=

3

.

4

.

=

.

F

F

VOLT LIMIT:

Upper limit of the output voltage setting

CURR LIMIT:

Upper limit of the output current setting

VOLT SLEW RATE:

Voltage ascending/descending slope

(XLN3640: 0.01 - 2.4V/ms)

(XLN 6024:0.01 - 3V/ms)

(XLN 8018:0.01 - 3.2V/ms

(XLN 10014:0.01 - 3.3V/ms)

shown in the following illustration.

2. OUTPUT SETTING:

Press

SETTING menu.

in the first page of Menu Setting to enter OUTPUT

VOLT LIMIT MAX = 60.500 V

CURR LIMIT MAX = 24.500 A

VOLT LIMIT MIN = 0.000 V

CURR LIMIT MIN = 0.010 A

VOLT SLEW RATE = 3.0000 V/mS

CURR SLEW RATE = 1.2000 A/mS

CONNECTOR DROP = DISABLE

EXT FULL VOLT = 10 V

18

CURR SLEW RATE:

Current ascending/descending slope

(XLN 3640:0.01 - 2.5A/ms)

(XLN 6024:0.01 - 1.2A/ms)

(XLN 8018:0.01 - 0.72A/ms

(XLN 10014:0.01 - 0.48A/ms)

control.

overvoltage protection

point.

overcurrent protection

set up the overcurrent protecting

protection

point.

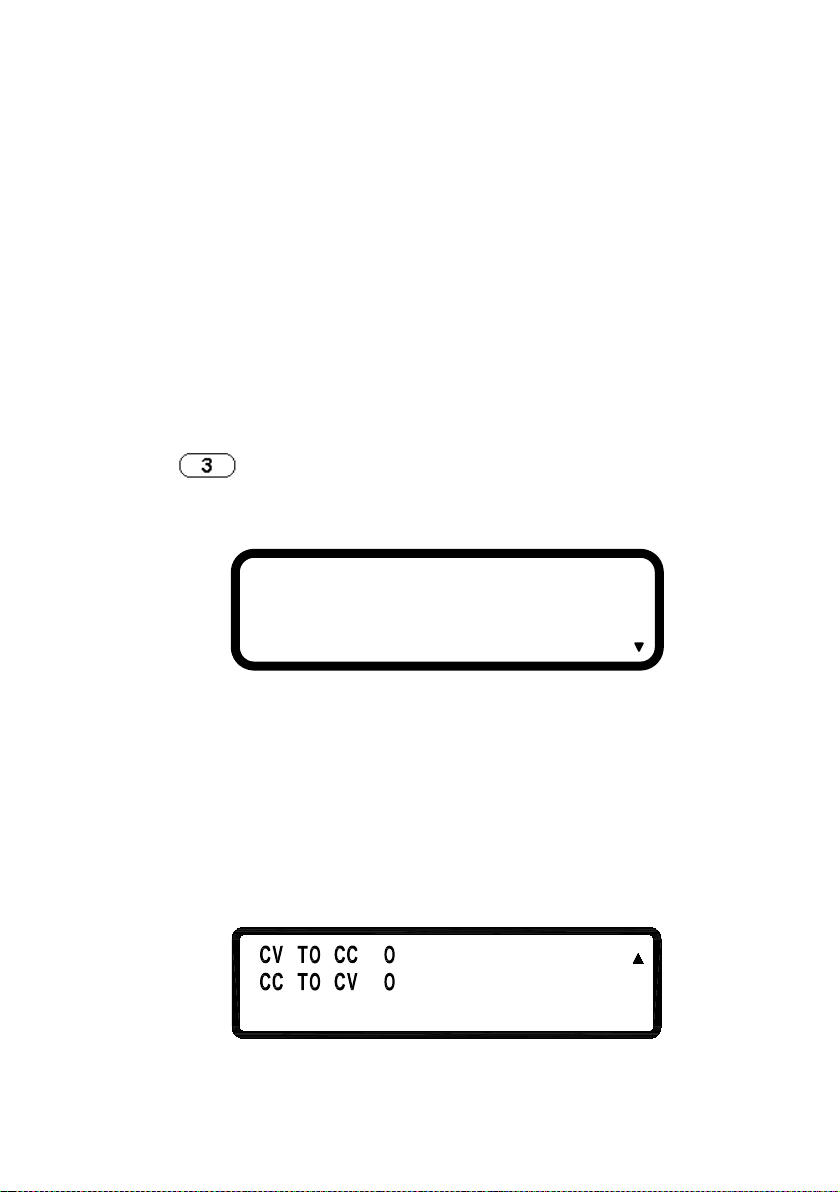

CV TO CC:

Enable/disable the protection of the change

CONNECTOR DROP:

EXT FULL VOLT:

3. PROTECTION SETTING (PROTECTION)

Press

PROTECTION menu.

key in the first screen of “Menu Setting” to enter

Turns on/off the connector drop calibration

function

External voltage control full-scale setting.

Select between 10 V or 5 V for full-scale

OVP = OFF SET = 38.000 V

OCP = OFF SET = 42.000 A

OPP = OFF SET = 1440.000 W

OVP:turns on/off the

OCP:turns on/off the

OPP:turns on/off the overpower

SET: set up the overvoltage protecting

SET:

point.

SET: set up the overpower protecting

FF

=

FF

=

19

from CV to CC mode

from CC to CV mode

L

T

L

T

FF

=

=

T

series or parallel operation

for the detailed setting

procedure of MASTER/SLAVE mode.

F

463L

L

:

1

31

.

L

CC TO CV:

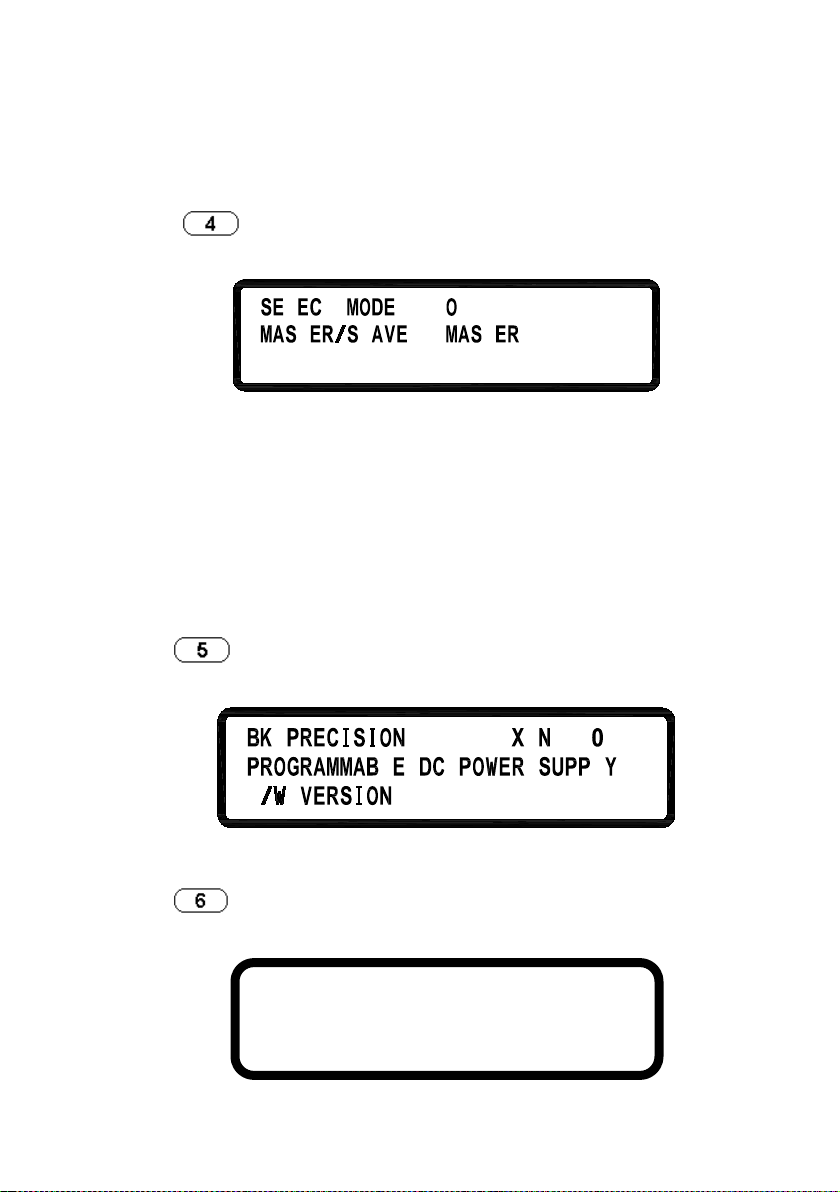

4. SERIES/PARALLEL SETTING

Press

SERIES/PARALLEL menu.

SELECT MODE: Choose

MASTER/SLAVE:

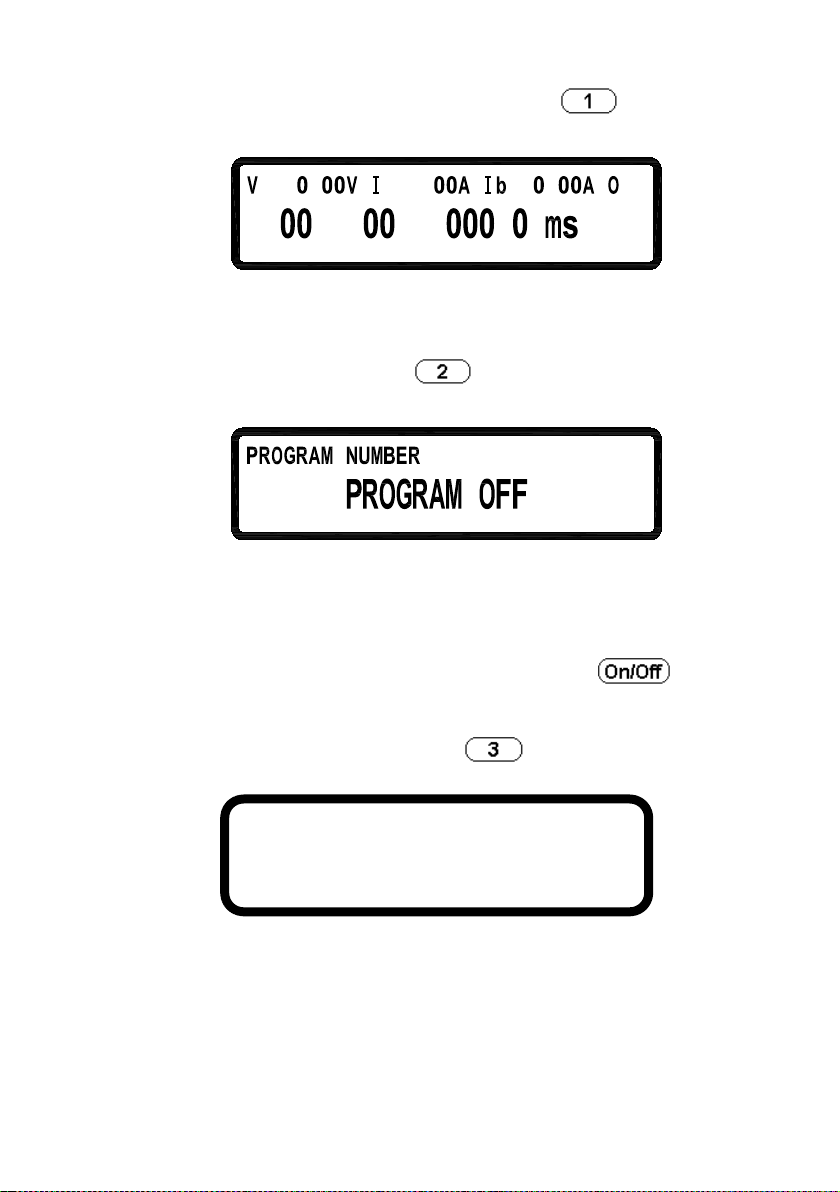

5. INFORMATION

Press

INFORMATION screen.

in the second screen of “Menu Setting” to enter

Enable/disable the protection of the change

in the second screen of Menu Setting to enter

mode.

Refer to “Series/Parallel Setting”

section

6. SPECIAL TEST FUNCTION

Press

TEST FUNCTION menu.

in the second screen of “Menu Setting” to enter SPECIAL

1. CURRENT COUNTER TEST

2. PROGRAM MODE

3. MEASURE AVERAGE

20

6.1 CURRENT COUNTER TEST: Press to enter the

= 1 . = .

:

.

FF

= 1 .

:

CURRENT COUNTER TEST screen.

Refer to “Current Counting” section for the detailed setting procedure.

6.2 PROGRAM MODE: Press

menu.

Before running the program, user needs to input the programmed

values through the USB or GPIB interface into the power supplies.

Users may save up to 10 programs (program number 1 through 10)

inside the memory and recall them in this Program Mode screen by

selecting the program number and then pressing

the program.

6.3 MEASURE AVERAGE: Press

AVERAGE page.

AVERAGE TIME = 2

AVERAGE TIME:

to enter the PROGRAM MODE

1=

Set the average measure time.

to enter the MEASURE

to execute

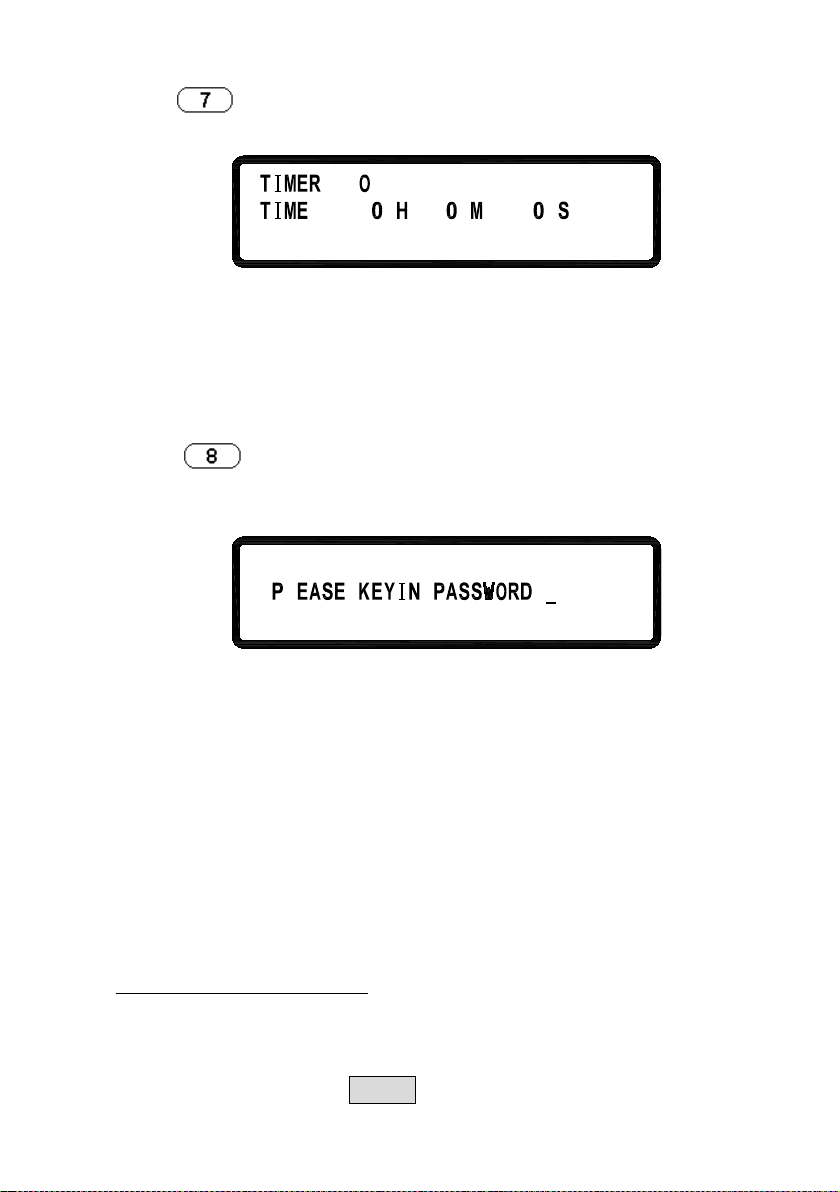

7. TIMER CONTROL

21

Press

CONTROL screen.

in the third page of Menu Setting to enter TIMER

FF

=

=

r

ni ec

TIMER:

TIME:

8. CALIBRATION

Press

CALIBRATION menu. Users must enter the password to access

calibration mode.

in the third page of “Menu Setting” to enter

L

8.1 Equipment Requirements

1. 5 ½ Digital Volt meter.

2. Shunt for current calibration (100 A/ 10 m Ω)

Turn on/off TIMER function.

Set up OUTPUT ON time (Max:999Hr 59Min

59Sec)

:

8.2 Calibration Procedure

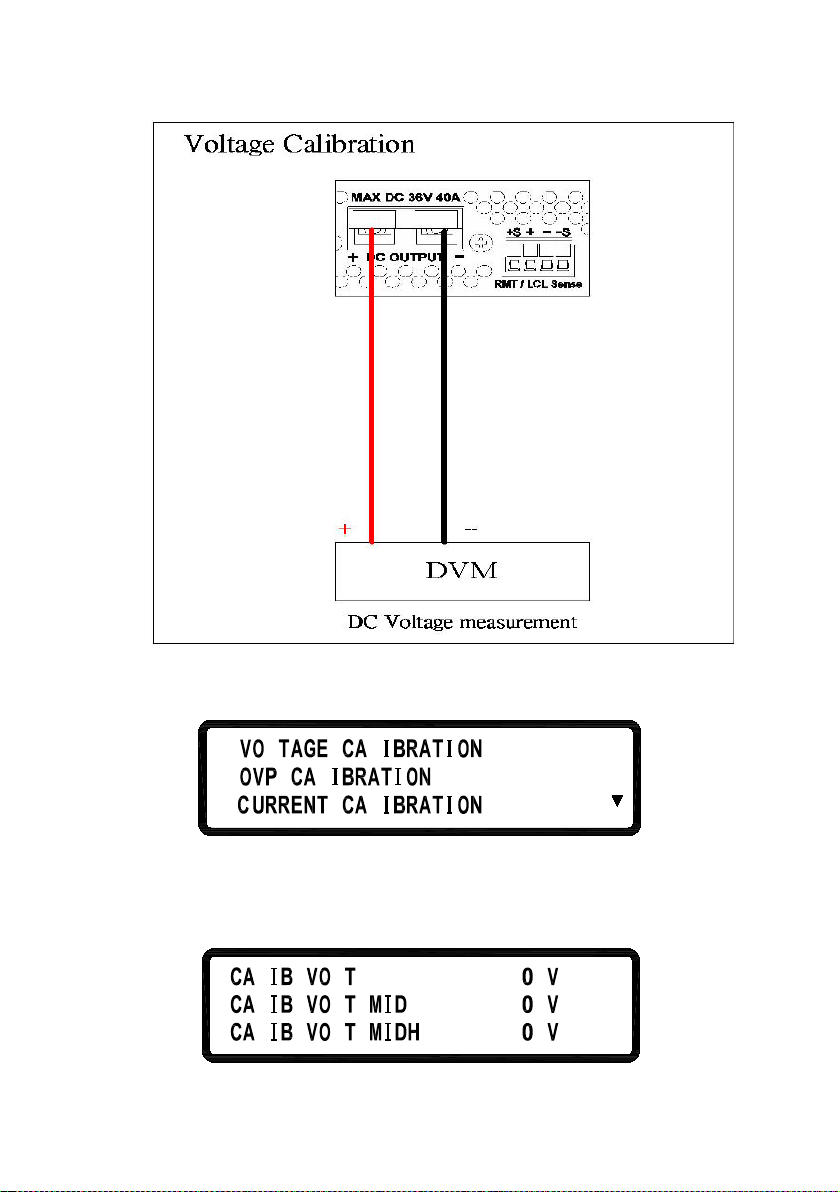

VOLTAGE CALIBRATION

A. Connect power supply output terminal to DVM (as shown in

Figure 1 below). Turn on the supply. Once the unit enters the

main page, press MENU and select “8. Calibration” and key in

22

password “13579” to enter the following calibration menu screen:

L

1

.

3

2

.

.

L

L

L

Figure 1

B. Press “1” to access Voltage Calibration Procedure.

C.

L

L

L

L

o

L

1=L

2 4

=

23

468.1=L

2

455

.

5

11L

Loading...

Loading...