Page 1

Model 878B, 879B

Dual Display LCR

INSTRUCTION MANUAL

METER

Visit us at www.TestEquipmentDepot.com

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Page 2

Page 3

Safety Summary

The following safety precautions apply to both

operating and maintenance personnel and

must be observed during all phases of

operation, service, and repair of this

instrument.

DO NOT OPERATE IN AN EXPLOSIVE

ATMOSPHERE

Do not operate the instrument in the presence

of flammable gases or fumes. Operation of

any electrical instrument in such an

environment constitutes a definite safety

hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by

operating personnel. Component

replacement and internal adjustments must be

made by qualified maintenance personnel.

DO NOT SUBSTITUTE PARTS OR MODIFY

THE INSTRUMENT

Do not install substitute parts or perform any

unauthorized modifications to this instrument.

Return the instrument to B&K Precisi on for

1

Page 4

service and repair to ensure that safety

features are maintained.

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such

as the following examples, denote a hazard

and appear throughout this manual. Follow all

instructions contained in these statements.

A WARNING statement calls attention to an

operating procedure, practice, or condition,

which, if not followed correctly, could result in

injury or death to personnel.

A CAUTION statement calls attention to an

operating procedure, practice, or condition,

which, if not followed correctly, could result in

damage to or destruction of part or all of the

product.

Safety Guidelines

To ensure that you use this device safely,

follow the safety guidelines listed below:

2

Page 5

This meter is for indoor use, altitude up to

2,000 m.

The warnings and precautions should be

read and well understood before the

instrument is used.

When measuring in-circuit components, first

de-energize the circuits before connecting to

the test leads.

Discharge capacitor before testing.

The meter is safety-certified in compliance

with EN61010 (IEC 1010-1) Installation

Category II (CAT. II) 50 V, Pollution Degree

2 environment.

Use the meter only as specified in this

manual. Otherwise, the protection provided

by the meter may be impaired.

The power for the meter is supplied with a

single standard 9V battery. But also a line

operation is possible using a 12V AC to DC

adaptor. If a power adaptor is selected,

please be sure to use fulfilled the safety

requirements of a relevant IEC standard.

3

Page 6

outside is negative (-)

Safety Symbols

This symbol is a warning and

indicates that the user should refer to

the operating instructions located in

the manual.

DC Current

Indicates inside pin is positive (+),

Compliance Statements

Disposal of Old Electrical & Electronic Equipment

(Applicable in the European

Union and other European countries with separate

collection systems)

4

Page 7

This product is subject

Council of the European

equipment (WEEE) , and

to Directive 2002/96/EC

of the European

Parliament and the

Union on waste

electrical and electronic

in jurisdictions

adopting that Directive,

is marked as being put

on the market after

August 13, 2005, and

should not be disposed

of as unsorted

municipal waste. Please

utilize your local WEEE

collection

facilities in the

disposition of this

product and otherwise

observe all applicable

requirements.

5

Page 8

Storage Humidity

0 – 80% R.H.

Storage Environment

-20 °C to +50 °C

Pollution degree

Pollution degree 2

Environmental Con diti ons

Operating Environment

0 °C to 40 °C

6

Page 9

TABLE OF CONTENTS

Safety Summar y ........................................................ 1

Safety Guidelines ...................................................... 2

Compliance Statements ........................................... 4

INTRODUCTION ....................................................... 10

PACKAGE CONTENTS ........................................... 11

FRONT PANEL OVERVIEW .................................... 12

Front Panel Display Descriptions .................................. 13

Front Panel Buttons ...................................................... 15

LCD DISPLAY OVERVIEW ...................................... 17

LCD Display Descriptions ............................................. 17

Special Display Indicators ............................................. 19

POWERING INSTRUMENT ..................................... 20

Installing Battery ........................................................... 20

Connecting External Power Source .............................. 22

Low Battery Indication .................................................. 24

Backlit Display (model 879B only) ................................ 25

OPERATION INSTRUCTIONS ................................. 27

Data Hold ...................................................................... 27

Static Recording ........................................................... 27

7

Page 10

L/C/R/Z Select Mode .................................................... 30

D/Q/θ/ESR Select Mode ............................................... 31

Test Frequency ............................................................. 31

Relative Mode ............................................................... 50

Tolerance ...................................................................... 52

Utility Menu ................................................................... 56

Parallel and Series Measurement Mode ....................... 67

Calibration..................................................................... 85

USB .............................................................................. 90

Automatic Fuse Detection ............................................. 91

QUICK START GUIDE ............................................. 93

CAUTION...................................................................... 93

Inductance Measurement ............................................. 94

Capacitance Measurement ........................................... 96

Resistance Measurement ............................................. 98

Impedance Measurement (Model 879B only) ............... 99

REMOTE COMMUNICATION ................................ 101

Connecting Instrument to PC ...................................... 101

USB (Virtual COM) Configuration ............................... 103

USB Operation ............................................................ 103

Command Protocols ................................................... 105

8

Page 11

SUPPLEMENTAL INFORMATION ........................ 118

Selecting Test Frequency ........................................... 118

Selecting Series or Parallel Mode ............................... 120

Accuracy Discrepancies.............................................. 121

Guard Terminal ........................................................... 123

SPECIFICATIONS .................................................. 125

General Specifications ................................................ 126

Accuracy Specifications .............................................. 127

MAINTENANCE ...................................................... 133

Service ........................................................................ 133

Cleaning...................................................................... 133

SERVICE INFORMATION ...................................... 135

LIMITED WARRANTY ............................................ 136

9

Page 12

INTRODUCTION

B&K Precision’s 878B and 879B 40,000-count L/C/R

hand-held meter is designed ideally for measuring

inductance, capacitance and resistance components.

Simple to operate, the instrument not only takes

absolute parallel m ode m easur em ents, but a lso series

mode measurement. The meter provides direct and

accurate measurements with selectable testing

frequencies.

Front panel push buttons maximize the convenience

of function and feature selection such as data hold,

maximum, minimum and average record mode,

relative mode, tolerance s orting mode, fr equency and

L/C/R selection.

The test data can be transferred to PC through a Mini

USB connection, great for applications that require

data logging

A tilt stand provides position flexibility for viewing and

operating the meter. The over-molding rubber case

protects the meter for better durability. Additionally,

top rubber visor molding above the screen is designed

to prevent scratches on the display when meter is

positioned upside down.

10

Page 13

A single 9V battery or the included DC 12V power

adaptor (model 879B only) can be used to power the

meter. This gives user flexibility for portable or benchtop use.

PACKAGE CONTENTS

Each 878B and 879B LCR meters are shipped with

the following contents.

• 878B or 879B LCR meter

• Instruction Manual

• Mini USB Interface Cable

• Red & Black Banana to Alligator Test Leads

• 9V Batt ery

• *AC Ad apter (m odel 879 B only)

*This can be purchased as an optional accessory for

model 878B.

Please locate them from the original packaging to

ensure nothing is missing. If in the case that an item

is missing, please contact B&K Precision immediately.

11

Page 14

+ -

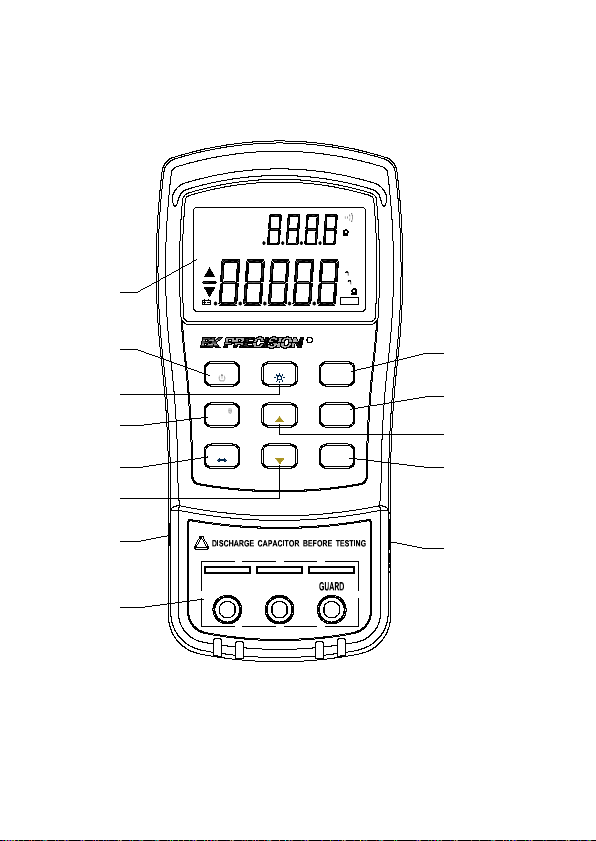

FRONT PANEL OVERVIEW

LCR Meter

REL

LCR

Z

ESR

MAX

MIN

AVG

¦ÈQ

DH

AUTO

TOL

D

1%5%10%20%

OFF

@

1

2

3

POWER

D/Q/

P

/ESR

FREQ

S

4

5

L/C/R/Z

USB

TOL

879B

deg

%

kHz

PAL

SER

n

¦ÌH

n

p F

¦Ì

Mk

RMT

R

HOLD

REC

UTIL

REL

CAL

7

8

9

10

6

13

!

11

12

Figure 1 - Front Panel Display (model 879B shown)

12

Page 15

Front Panel Display Descriptions

1. LCD Display

2. Power ON/OFF Button

3. USB Communication / *Back light button

4. Secondary Display mode (for dissipation

factor(D), quality factor (Q), *phase angle (θ),

*equivalent series resistance (ESR)

measurement) selection button

5. Primary Display mode (for inductance,

capacitance, resistance, and *impedance

measurements) / Parallel or Series

measurement method selection button

6. Tolerance mode / Utility down arrow selection

button

7. Hold Display mode / Record mode selection

button

8. Utility menu button

9. Test Frequency / Utility up arrow select ion

button

10. Relative mode / Calibration mode selection

button

11. 12V DC adapter input (use with an external

power adapter (rated 12VDC, 150mA, 4mm

power plug))

Note: Use with included power adapter only.

Use with improper power adapters may

damage instrument.

13

Page 16

WARNING: Before connecting an external

power adapter, please check the battery

compartment in the rear side of the unit. If

a battery is installed, be sure that the

polarity matches the (+) and (-) labels as

indicated inside the battery compartment.

If it is not installed correctly , please

remove the battery and install it with

correct matching polarity as indicated in

the compartment. See “Installing Battery

section for details. DO NOT, at any time,

connect an external power adapter when a

battery is installed incorrectly. Doing so

will damage the instrument and void its

warranty.

Input sockets (banana jack inputs) and terminals for

positive, negative, and guard (see “Guard Terminal” in

“

”

14

Page 17

12. SUPPLEMENTAL INFORMATION” section for

details)

13. Standard mini USB port (for remote

controllability)

For model 879B only. Not included on model 878B.

*

Front Panel Buttons

All front panel buttons have specific colored labels on

them. They are all marked in white, blue, or yellow

color. Each color has a specific representation, as

described below:

White – With the exception of the

button, all white colored labels

represent the primary function of that

button; meaning that function will be

set or configured upon pressing it.

Blue – Some of the buttons have a blue label

underneath a white label. This means

the function indicated by the blue

label will be set or configured if that

button is pressed and hold down for 2

seconds.

Yellow – There are total of 3 buttons with

yellow labels. They are

15

Page 18

exclusively for use when entering

UTIL menu only. See “Utility Menu”

section for details.

. These functions are

16

Page 19

LCR

REL

ESR

MAX

AVG

MIN

¦ÈQ

AUTO

D

1%5%10%20%

deg

kHz

PAL

SER

¦ÌH

p F

¦Ì

RMT

Mk

TOL

DH

n

n

@

OFF

Z

1

2 5 9 10

12

14

16

202126

27

28

83

232425

4

15

11

13

6 7

22

17

18

19

%

29

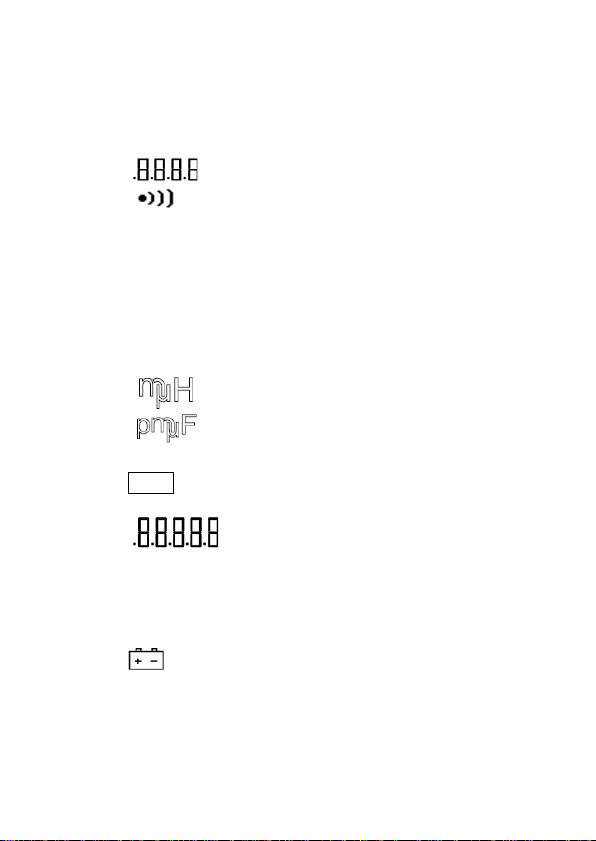

LCD DISPLAY OVERVIEW

Figure 2 - LCD Indicator Display

LCD Display Descriptions

1. LCRZ – Primary display funct ion indic ator (*Z

2. MAX – Maximum reading indicator

3. AVG – Average reading indicator

4. MIN – Minimum reading indicator

5. REL – Relative mode indicator

display)

17

Page 20

6. Θ – *Phase angle indicator f or sec ondary

display

7. Q – Quality factor indicator

8. ESR – *Equivalent series resistance indicator

9. – Secondary display

10. – Beeper tone indicator for tolerance

mode

11. deg – *Phase angle degree indicator

12. Ω – *ESR(ohm) units indicator

13. % - Tolerance percentage indicator

14. kHz – Frequency units indicator

15. PAL – Parallel mode indicator

16. SER – Series mode indicator

17. – Inductance units (Henry) indicator

18. – Capacitance units (Farad) indicator

19. MkΩ – Resistance units (Ohm) indicator

20. RMT – Remote mode indicator

21. – Primary display

22. D – Dissipation factor indicator

23. DH – Data hold indicator

24. AUTO – Auto-ranging indicator

25. TOL – Tolerance mode indicator

26.

27. @OFF – Auto power-off indicator

28. 1%5%10%20% - Tolerance sorting

– Low battery indicator

percentage indicator

18

Page 21

29. MAX AVG MIN – Recording mode indicators

For model 879B only. Not included on model 878B.

*

Special Display Indicators

Indicates short connectors

Indicates open connectors

Error indication

Indicates calibration mode

Indicates damaged or open fuse

AD converter error

AD converter error

19

Page 22

POWERING INSTRUMENT

Before beginning to operate the instrument, a power

source is necessary for it to turn on. There are two

methods to power the instrument: Battery and

external source.

Installing Battery

The 878B and 879B LCR meters can use a battery to

provide power to the instrument so that it can be

portable.

The meters use a standard 9V size battery (or

NEDA 1604, JIS006P, IEC6F22 carbon-zinc or

alkaline battery).

To install the battery:

1. Place the meter upside down. Open up the

back-flip stand, and locate the screw that

tightens the battery compartment cover as

indicated in Figure 3. Use a screwdriver to

unscrew and remove the cover.

20

Page 23

Figure 3 - Back Cover

2. Insert 9V battery into compartment. Note the

positive (+) and negative (-) terminals as

indicated inside the battery compartment (See

Figure 4). Be sure to insert the batter y with

matching polarity.

21

Page 24

Figure 4 - Battery Compartment

3. Place the battery compartment cover piece by

sliding it into the top slid first. Place screw at

the bottom of the cover piece and tighten

down with a screw driver.

4. Push and hold down the button for 2

seconds to turn on the instrument.

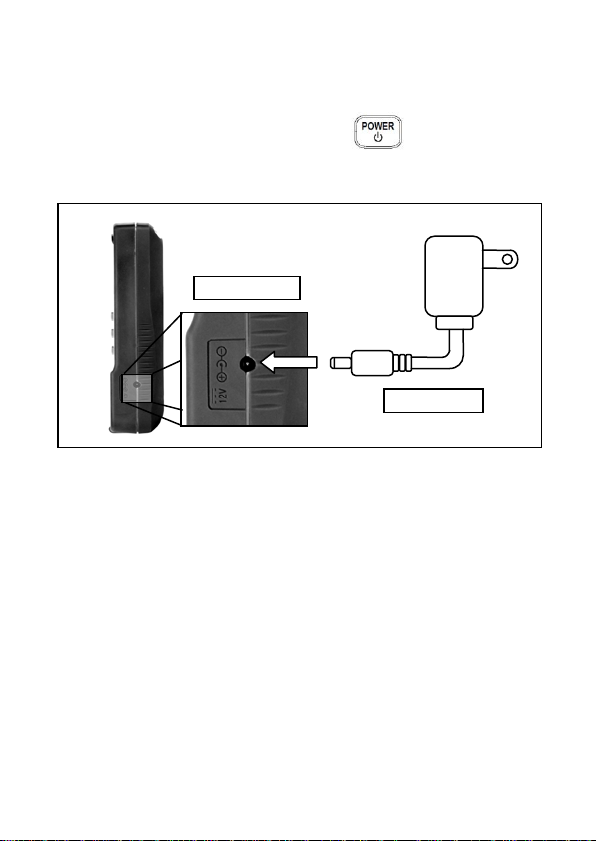

Connecting External Power Source

The 878B and 879B can also be powered using an

external AC adapter. The model 879B comes with

this adapter included in the pac kage, while it is

optional

for model 878B.

22

Page 25

For external power, use AC adapter rate d for

output 12VDC, 150mA, with a standard 4mm

connector only.

WARNING: Use of incorrect adapters may damage

the instrument. Please use B&K Precision’s adapter

only.

To connect the adapter, do the following:

1. If a battery is installed, please check the

battery compartment again that the polarity of

the battery matches the polarity as indicated

by the labels inside the compartment. If it is

not, please remove and insert the battery with

matching polarity. If a battery is not installed,

continue to the next step.

WARNING: DO NOT, at any time, connect

an external power adapter when a battery

is installed incorrectly (reverse polarity or

non-matching polarity to indicator of

battery compartment). Doing so will

damage the instrument and void its

warranty.

2. Connect the AC adapter connector into the

right side panel of the instrument. See Figure

5 below.

23

Page 26

AC Adapter

Figure 5 - Connecting AC Adapter to Meter

3. Now, connect the AC Adapter socket into an

electrical outlet.

4. Push and hold down the button for 2

seconds to turn on the instrument.

12VDC Input

Note: The meter can be operated with a battery

installed while an AC adapter is plugged in at the

same time (As long as the battery is inserted properly

with correct polarity). In this event, the meter will

automatically switch to consume power from the AC

adapter instead of the battery to preserve battery life.

Low Battery Indication

The LCR meter has a low battery indicator to notify

the user when to replace battery. When the display

24

Page 27

starts flashing the indicator, the battery voltage

is below normal working voltage. In this case,

accuracy of the meter will also decrease. It is

recommended that the battery be replaced as soon as

possible before continuing operation. See “Installing

Battery” for instructions.

Backlit Display (model 879B only)

Model 879B LCR meter has a backlit display that

allows you to see the LCD display in dark conditions.

To turn on the back light, press and hold down

button for 2 seconds. Back light will turn on and

brighten the LCD display.

To turn off the back light at any time, press and hold

down button for 2 seconds again. Back light

will turn off and return to normal display.

When Using Battery Power

When the meter is powered using 9V battery, the back

light display will turn on upon holding down the

button for 2 seconds. It will stay at maximum

25

Page 28

brightness for 15 seconds. After another 15 seconds

(30 seconds total from the time of turning on), the

back light will automatically turn off to conserve

battery power.

When Using External Power

When the meter is powered using an external AC

adapter, the back light display will turn on upon

holding down the button for 2 seconds. It will

stay at maximum brightness continuously until the

user presses and holds down the button for 2

seconds again.

Note: If a battery is installed while using an AC

adapter simultaneously, un plu ggi ng the AC ada pter

will automatically turn off the back light after it has

been lit for 30 seconds.

26

Page 29

OPERATION INSTRUCTIONS

Data Hold

The data hold function allows the user to freeze the display

when pressed, holding the measured value until data hold is

turned off.

Turn On Data Hold

To use data hold, press the button once. The “DH”

indicator will display on the screen when data hold is active.

Turn Off Data Hold

To disable the data hold, press again. The “DH”

indicator will disappear on the screen, and meter will remain

in normal operation mode.

Note: Changing the primary function, secondary function,

or test frequency will automatically turn off the data hold.

Static Recording

This mode is used for recording maximum, minim um, and

average values. It is often useful for testing the range of

values in which a component is expected to fall within upon

measurement.

27

Page 30

Enable Static Recording

Press and hold down the button for two seconds to

enter the static recording mode. The display should indicate

“MAX AVG MIN” simultaneously. This indicates the meter is

in static recording mode and recording is performed

immediately.

Using Static Recording

There are four different modes that can be selected in

static recording. They are indicated by the

descriptions below. These modes can be changed

with each button press. Per each press of the

button, the modes will change and repeat in

the following order:

Recording Mode Maximum Mode Minimum

Mode Average Mode

Recording Mode

This is the default mode when first enabling static

recording. In this mode, the screen will display “MAX

AVG MIN” indicator. At this point, the meter will start

making recordings based on measured values from

28

Page 31

the input sockets or terminals. As recording is

performed, maximum, minimum, and average values

will be stored after a brief moment. A beep tone will

sound once a recording has been stored.

Note: Subsequent beep tones may occur in this mode if

there are new values that are recorded. For example, if a

new maximum is detected, it will beep once again to indicate

that the new value has been stored. Any previously stored

values will be overwritten with the new recorded values.

Maximum Mode

In this mode, the “MAX” indicator will be shown on display.

This indicates that the value in the primary display

represents the recorded maximum value.

Minimum Mode

In this mode, the “MIN” indicator will be shown on display.

This indicates that the value in the primary display

represents the recorded minimum value.

Average Mode

In this mode, the “AVG” indicator will be shown on display.

This indicates that the value in the primary display

represents the recorded average value. This average value

is obtained by taking the maximum and minimum recorded

values and taking the average of the two values.

29

Page 32

Disable Static Recording

To exit this mode, press and hold the button for two

seconds. The “MAX AVG MIN”, “MAX”, “MIN”, or “AVG”

indicator will disappear on screen.

Note: Changing the primary function, secondary function,

or test frequency will automatically turn off static recording.

L/C/R/Z Select Mode

The primary display of the LCR meter is used to

indicate measured values under four different modes

(three modes for model 878B, which excludes Z

(impedance) measureme nt s ). These modes are:

L (inductance), C (capacitance), R (resistance), and Z

(impedance).

To change between these four primary modes of

measurement, press the (or for model

878B) button. The modes will change and repeat

upon each button press. On the screen, the indicators

“L”, “C”, “R”, or “Z” (model 879B only) will be

displayed to indicate which mode the meter is in.

30

Page 33

D/Q/θ/ESR Select Mode

The secondary display of the LCR meter is used to

indicate measured values for four various parameters

(two for model 878B, which excludes θ and ESR

measurement mode), which provide additional

information of the component being tested and is

supplementary to the primary mode measurements.

These modes are: D (Dissipation factor), Q (Quality

factor), θ (Phase angle), and ESR (Equivalent series

resistance).

To change between these measurement parameters,

press the (or for model 878B) button.

The parameters for measurement will change and

repeat upon each button press. On the screen, the

indicators “D”, “Q”, “θ” (model 879B only), or “ESR”

(model 879B only) will be dis played to indicate which

secondary mode the meter is in.

Test Frequency

The 879B and 878B LCR meters use an AC signal to test

and measure components at the input sockets or

terminals. With this measurement method, a test

frequency must be selected. The test frequency can

affect the accuracy of the results depending on what

frequency is selected and what type and value of a

31

Page 34

component is being measured or tested. For details on

selecting the optimal test frequency for measurement,

refer to the “

32

Page 35

REMOTE COMMUNICATION

The meter has the capability to communicate with a

PC over the mini USB interface. Upon installation of a

USB driver, the PC can control the instrument over

virtual COM (RS-232). The mini USB communication

interface of the meter is designed in full duplex and

has a 64-byte input and output buffer, making it

reliable and efficient for data transmission.

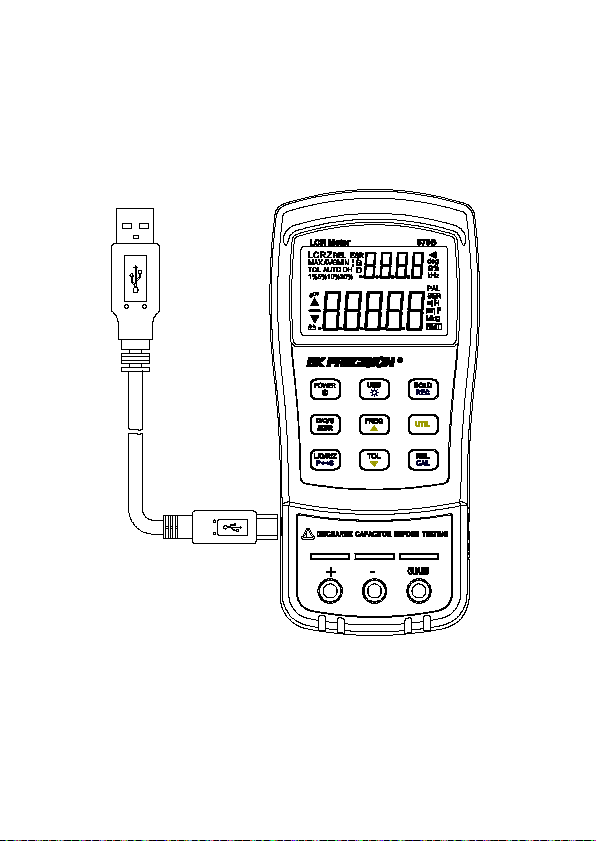

Connecting Instrument to PC

Follow the below procedures for connection setup.

1. Download the USB drivers from

www.bkprecision.com .

2. With the included mini USB cable, connect the

mini USB end to the LCR meter and the other

end to an available USB port on the PC (see

Figure 14).

3. When Windows recognize the USB

connection, do not follow the default Windows

driver installation wizard. Simply run the

setup file from the downloaded USB drivers

and follow the prompt to install drivers.

4. When completed, the computer will recognize

the instrument as a USB (virtual COM) device,

meaning it will be detected as a serial COM

33

Page 36

port. Windows will automaticall y assign a

COM port to the instrument. Please verify

which COM port Windows has assigned by

going into “Device Manager”.

Figure 14 - USB Connection

34

Page 37

USB (Virtual COM) Configuration

The USB will be recognized as a virtual COM on the

PC, thus serial port settings must be configured

properly for remote communication to be successful.

Below are the settings used by the 878B and 879B

meters.

• Baudrate: 9600

• Dat a bits: 8

• Parity: None

• Stop bits: 1

• Flow Control: None

USB Operation

There are two modes that describe the operation of

the meter when it is setup for remote communication.

They are remote mode and auto fetching mode.

Remote Mode

Upon connecting to the instrument, sending any

commands listed in the “Command Protocols” section

will automatically set the LCR meter into remote

mode. In remote mode, the LCD display will show the

RMT indicator. When this is shown, all front panel

35

Page 38

buttons will be disabled, except for the (or

for model 878B) button.

To exit remote mode and go back to local mode,

press the (or for model 878B) button

once. The

display. Pushing the same button once more will put

the meter into auto fetching mode, which is described

in the next section.

Auto Fetching Mode

When connected to a PC, the meter can be

configured to auto-fetching mode. This means, the

meter will continuously fetch data to the PC after

every measurement cycle is completed. It fetches

data from measured readings of primary display and

secondary display, as well as tolerance compared

results. This mode is useful when doing quick data

logging using PC.

RMT indicator will disappear on the LCD

36

Page 39

Enable/Disable Auto Fetching

To toggle between enabling and disabling auto

fetching, press the (or for model

878B) button. When enabled, data will be fetched

constantly after every measurement cycle is

completed. When disabled, no fetched data will be

available.

Note: Alternatively, auto fetching mode can be

disabled when a remote command is sent to the

instrument, turning it back into remote mode. In this

event, the

display, and auto fetching will be disabled

automatically. To re-enabled auto fetching again in

this state, first press the (or for model

878B) button once to exit out of remote mode and

return to local mode. Then, press the button once

more to have it set to auto fetching mode again.

RMT indicator will appear on the LCD

Command Protocols

Overview of Command Type and Format

All commands are entered in either the upper case or

the lower case. There are two types of the meter

programming commands: IEEE 488 common

37

Page 40

commands and Standard Commands for

Programmable Instruments (SCPI). Some commands

are device-specific to the meter. They are not included

in the version 1999.0 of the SCPI standard. However,

these commands are designed with the SCPI format

in mind and they follow the syntax rules of the

standard.

Common Command Format

The IEEE 488 standard defines the common

commands as commands that perform functions like

reset and system query. Common commands usually

come with the asterisk “*” character, and may include

parameters. Some examples of Common command

like: *IDN?, *GTL, *LLO.

SCPI Command Format and Query Format

The SCPI commands control instrument

functions. A subsystem command has a hierarchical

structure that usually consists of a top-level (or root)

keyword, one or more lower level keywords, and

parameters. The following example shows a

command and its associated query:

A. FUNCtion:impa L

Select L as primary parameter

B. FUNCtion:impa?

Return primar y parameter

38

Page 41

function is a root level keyword with the second level

keyword, impa, and L is the command parameter. The

query command ends with a question mark “?”.

Note: SCPI stems from IEEE488.1 and IEEE 488.2.

Although the IEEE 488.2 standard addressed some

instrument measurements , it princ ip al ly dealt with

common commands and syntax or data formats.

Please refer to the IEEE488.2 and SCPI reference

manual for more information.

Termination Character

A terminator is a character sent by a host, which

identifies the end of a command string. A valid

terminator consists of two-byte data:

<CR> (Carriage Return, ASC(&H0D)) or <LF> (Line

Feed, ASC(&H0A) ) o r <CR><LF>

Responding Message

Returned result

After the meter executes a query command, the return

of the result will be in the following format:

<Result> + <CR> <LF>

For example, in auto fetching mode, the meter will

send the measured data automatically when the

39

Page 42

Data Type

Explanation

Example

<NR1>

An integer

+800,-200,100,-50

This numeric

point

This representation

exponent

A parameter for

or “1” for Boolean

measurement cycle is completed. The format of the

printed data will be shown as the following:

<Primary measured data, Secondly measured

data, Tolerance Result > + <CR> <LF>

Data Types

Returned message is an ASCII string from the meter

responding to a query. A query is a command

accompanied a “?” mark. Table 4 below explains the

different data types.

Table 4 - Data Type of Responded Message s

<NR2>

<NR3>

<Boolean>

representation has

an explicit radix

has an explicit

radix point and an

Boolean setting.

Always return “0”

40

+1.56,-0.001,10.5

+2.345678E+04

-1.345678E-01

ON or OFF

Page 43

query command

short literal form

Text Symbol

Meaning

[ ]

Option; can be omitted

|

Exclusive OR

< >

Defined element

( )

Comment

?

Question mark

Separated two command

keywords

A string is used as

<Literal>

command

parameters with

HOLD

SCPI Commands

This section described all the SCPI commands

supported by the meter. The meter can accept both

upper case and lower case commands.

Table 5 - SCPI Symbol Conventions

:

41

Page 44

Description: Queries the instrument ID.

version>, <serial number>

Set 100Hz frequency

Description: Query the measurement frequency

only)

*IDN?

Response: <instrument model>, <firmware

*LLO

Local Lockout. This means that all front panel

buttons, including the "USB" key is not available.

*GTL

Go to local.

Puts the meter into the local state,

clearing the remote state and front panel lockout.

FREQuency Subsystem

FREQuency <value>

Description: Set measurement frequency

Parameters: Parameters are 100, 120, 1000,

10000 (879B only) or

100hz,120hz,1khz,10khz (879B

only)

Example: FREQuenc y 100hz

FREQuency?

Response: 100hz, 120hz, 1khz, 10khz (879B

42

Page 45

Description: Select primary parameter

Selects L as primary parameter

only),NULL

Select D as secondly parameter

Description: Query secondly parameter

ESR (879B only), NULL

FUNCtion subsystem

FUNCtion:impa < L | C | R | Z >

(Z for model 879B only)

Example: FUNCtion:impa L

FUNCtion:impa?

Description: Query primary parameter

Response: Return L, C, R, Z (879B

FUNCtion:impb < D | Q | THET A | ESR >

(THETA and ESR for model879B on ly)

Description: Select secondly parameter

Example: FUNCtion:impb D

FUNCtion:impb?

Response: Return D, Q, THETA (879B only),

43

Page 46

Set series mode

string

Description: Enable or disable relative

CALCulate:RELative:STATe ON

Description: Query the relative state

Response: Return ON or OFF

FUNCtion:EQUivalent < SERies | parallel |

PAL >

Description: Set equivalent mode

Parameters: SERies — serial mode

Parallel — parallel mode

Pal — parallel mode

Example: FUNCtion:EQUivalent SERies

FUNCtion:EQUivalent?

Description: Query the equivalent mode

Response: Return “SER” or “PAL” format

CALCulate subsystem

CALCulate:RELative:STATe < ON | OFF >

function

Example:

CALCulate:RELative:STATe?

44

Page 47

Description: Quer y the relative val ue

Response: Return <NR3 > or “-----” format string

Description: Enable or disable tolerance function

Example: CALCulate:TOLerance:STATe ON

Description: Quer y the tole ranc e state

Response: Return ON or OFF

Description: Quer y the nominal value of

Response: Return <NR3 > or “-----” format string

Response: Return <NR3 > or “-----” format string

Description: Set tolerance range

Set 1% tolerance range

CALCulate:RELative:VALUe?

CALCulate:TOLerance:STATe < ON | OFF >

CALCulate:TOLerance:STATe?

CALCulate:TOLerance:NOMinal?

tolerance

CALCulate:TOLerance:VALUe?

Description: Query the percent value of

tolerance

CALCulate:TOLerance:RANGe < 1 | 5 | 10 |

20 >

Parameters: 20 (879B only)

Example: CALCulat e:T O Leranc e:RANGe 1

45

Page 48

Description: Quer y the tole ranc e range

“BIN4” or “----” format string

ON

Response: Return ON or OFF

string

Description: Query the minimum value of

string

CALCulate:TOLerance:RANGe?

Response: Return “BIN1”, “BIN2”, “BIN3”,

CALCulate:RECording:STATe < ON | OFF >

Description: Enable or disable recording

function

Example: CALCulate:RECording:STATe

CALCulate:RECording:STATe?

Description: Query the recording state

CALCulate:RECording:MAXimum?

Description: Query the maximum value of

recording function

Response: Return <NR3 , NR3> or “-----” format

CALCulate:RECording:MINimum?

recording function

Response: Return <NR3 , NR3> or “-----” format

46

Page 49

Description: Quer y the aver age value of

string

Description: Query the present value of

string

Example: FETCh?

CALCulate:RECording:AVERage?

recording function

Response: Return <NR3 , NR3> or “-----” format

CALCulate:RECording:PRESent?

recording function

Response: Return <NR3 , NR3> or “-----” format

FETCh Subsystem

FETCh?

Description: Returns the primary, secondary

display value and tolerance

compared result of device’s output

buffer.

Response: Return <NR3, NR3, NR1> format

string

47

Page 50

Command

Parameter

Explanation

FREQuency

<Value>

Set Test Frequency

FUNCtion

:impa

<Literal>

Select primary display

parameter

:impa?

Query primary display

parameter

:impb

<Literal>

Select secondary display

parameter

parameter

:EQUivalent?

Query equivalent mode

CALCulate

:STATe

<Boolean>

Enable/disable relative

:STATe?

Query relative state

:VALUe?

Query relative value

:STATe

<Boolean>

Enable/disable tolerance

:STATe?

Query tolerance state

:NOMinal?

Query nominal value of

tolerance

:VALUe?

Query percent of tolerance

:RANGe?

Query tolerance range

:RECording

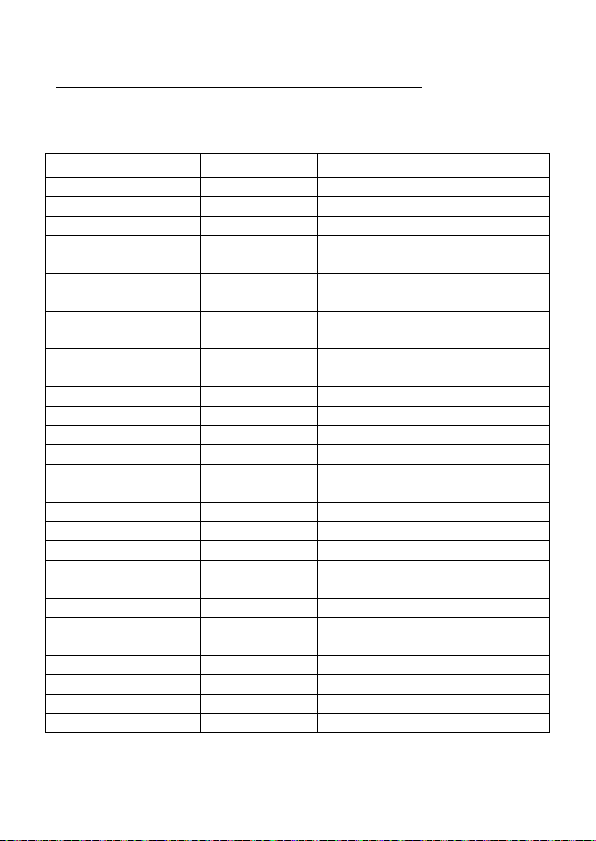

Summary of Supported SCPI Commands

Table 6 - Summary of SCPI Commands

FREQuency? Query Test Frequency

:impb? Query s econdary display

:EQUivalent <Literal> Set equivalent mode

:RELative

function

:TOLerance

function

:RANG <Value> Set tolerance range

48

Page 51

function

:STATe?

Query recording state

:MAXimum?

Query max. value of

recording

:MINimum?

Query min. value of recording

:AVERage?

Query average value of

recording

recording

:STATe <Boolean> Enable/disable recording

:PRESent? Query present value of

FETCh? Ret urn dat a any tim e last

reading is valid

Error Codes

In certain situations, errors may occur, and an error

code will be displayed on the meter. Below defines

the error description based on the error code.

E10: Unknown command

E11: Parameter Error

E12: Syntax Error

49

Page 52

SUPPLEMENTAL INFORMATION” section.

Selecting Frequency

To select or change the test frequency, push the

button once. With each press, the test

frequency will be indicated on the secon dary display

of the meter. This will remain displayed until a

different function for the secondary display is selected.

The selectable test frequencies for 879B meter are:

100 Hz, 120 Hz, 1 kHz, and 10 kHz.

The selectable test frequencies for 878B meter are:

120 Hz and 1 kHz.

Relative Mode

Relative mode is used when the user wants to “zero”

the meter based on a reference value or wants to

obtain a reading that is relative to a reference value.

For example, if test leads are used in the

measurement, the user may want to set a reference

with the test leads inserted into the input terminals so

that any measurements taken will not take into

account the test leads.

50

Page 53

Setup Relative Mode

To setup the relative mode, simply press the

button once. The value that is on the display will

immediately be stored as the “reference” value. This

reference value will be used for all measurements so

as long as the meter is in relative mode, which is

indicated by the “REL” indicator on the display.

A common use of relative mode is to “zero” out the

meter. With nothing connected to the input sockets

and terminals, simply press the button once and

the meter will “zero” out, meaning all display reading

will become 0.

To make measurements within a specific test setup or

with test leads, it is recommended that the user fir st

have test leads or wires connected to the meter in the

fashion that they desire. Then, press the button

once to “zero” out the meter as reference. This way,

any measurements taken would not be affected by the

test leads or setup.

Disable Relative mode

To disable relative mode, simply press the

button once more. The “REL” indicator will disa ppe ar ,

which indicates the relative mode is disabled.

51

Page 54

Note: Changing the primary function, secondary function,

or test frequency will automatically disable relative mode.

Tolerance

The tolerance mode feature is specifically used for

component sorting purposes. Users who need to test

and sort through a large number of components will

find this function qu ite he lpf ul.

Tolerance Range

The tolerance function is configured primarily by range

in percentage, meaning a percentage is used to

define whether a measured value is within tolerance

or out of tolerance.

(for model 879B) Selectable tolerance range is: 1%,

5%, 10%, and 20%.

(for model 878B) Selectable tolerance range is: 1%,

5%, and 10%.

Setup Tolerance

1. Select the primary measurement mode based

on the type of components to be measured.

52

Page 55

This is done by pressing the (or

for model 878B) button to configure the

desired measurement mode.

Note: Be sure to select the correct

measurement mode, as tolerance mode

cannot be activated unless the correct mode

is selected. For example, if the component is

a capacitor, be sure to select “C” for

capacitance. If not, tolerance mode will not

be activated following the proceeding steps

below.

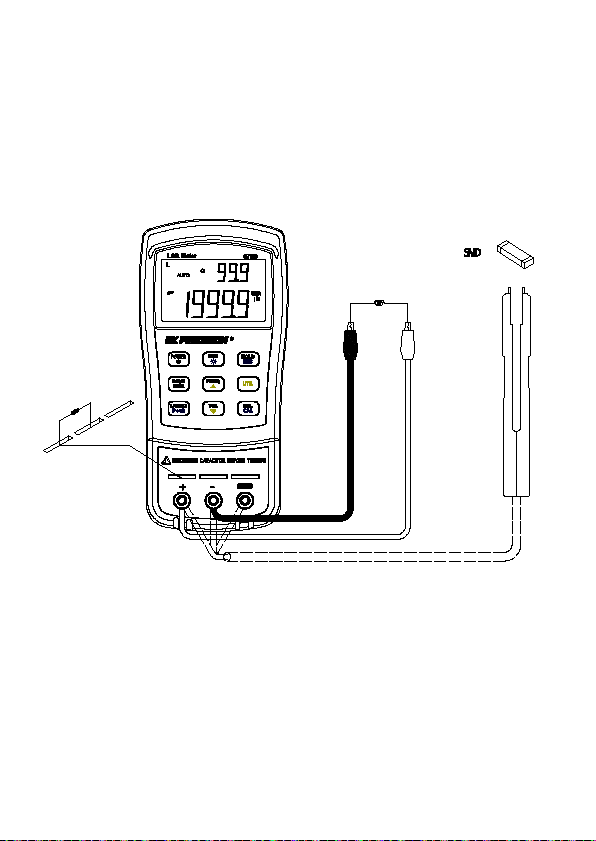

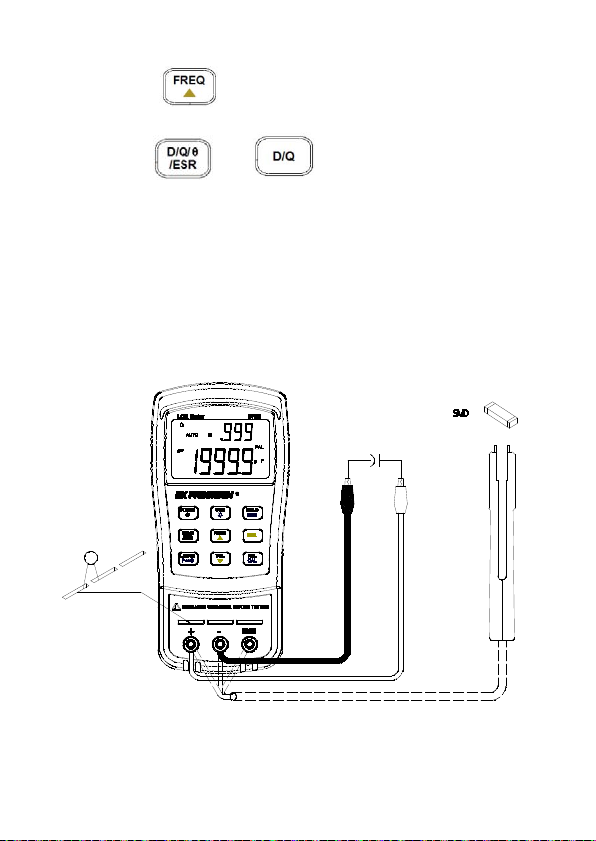

2. Insert the component to be used as the

“standard” reference value. Another words ,

insert a known “good” component that will be

used for testing against all other components.

(See Figure 6 for illustration)

Note: The tolerance mode cannot be

activated unless the meter senses a

component is connected to either the input

sockets or terminals.

WARNING: If the component to be measured

is a capacitor

fully discharged BEFORE

, be sure that the capacitor is

inserting it into the

53

Page 56

input sockets or terminals. For large

capacitors, it may take longer periods of time

for a full discharge. Inserting a charged or

partially charged capacitor into the meter’s

input sockets or terminals may produce an

electric hazard and may also damage the

instrument, making it unusable.

Figure 6 - Inserting Component to Inputs

3. Once the desired measured reading is

displayed, press the button once to

store the reading as the “standard” value or

test reference value. At this point, the “TOL”

54

Page 57

will be displayed on the screen, indicating that

the tolerance mode is activated.

Note: Any value which appears on the LCD

display, such as DH (data hold) or

MAX/MIN/AVG, can also be used as the

“standard” value or test reference value for

sorting components.

4. To select the tolerance range, press the

button once more. For each button

press, the meter will cycle through the

tolerance range percentage in this order: 1%,

5%, 10%, 20% (model 879B only). These

percentage ranges will also be indicated on

the LCD display by the indicators “1%”, “5%”,

“10%”, or “20%” (model 879B only)

respectively. The component to be tested for

will be verified with the tolerance within the

selected % of the “standard” value or test

reference value (as configured from step 3).

5. Within a few seconds, an audible tone will be

heard.

One single “beep” or tone means the

component is within tolerance

.

55

Page 58

Three “beeps” or tone means the component

is out of tolerance

.

Disable Tolerance Mode

To disable or exit out of tolerance mode, simply press

and hold down the button for two seconds. The

“TOL” and/or the percentage indicators “1%”, “5%”,

“10%”, or “20%” (for model 879B only) will disappear

on the LCD display.

Note: Changing the primary function, secondary function,

or test frequency will automatically disable tolerance mode.

Utility Menu

The LCR meter has a built-in utility menu that allows

you to con figure some user preferences and settings.

The buttons used to set and control the menu are

colored in yellow. They are , , and

. User can configure the beep sound, auto

power-off timing, power-up state, and reset instrument

to default settings.

56

Page 59

SETTINGS /

PARAMETERS

bEEP

ON / OFF

AoFF

5 / 15 / 30 / 60 / OFF

PuP

PrE / Set

dEF

yES / NO

Entering Utility Menu

Press and hold down the button for two

seconds or until the primary display shows “bEEP”.

This indicates the meter is currently in the utility menu.

Configuration and Settings

There are four different menu options and

configurable settings under each option. Below is a

table that lists these options and settings.

Table 1 - Utility Menu Options and Settings

MENU OPTIONS

The four menu options allow users to control the beep

sound setting (bEEP), auto power off setting (AoFF),

power-up state settings (PuP), and resetting

instrument to default settings (dEF).

57

Page 60

By default, the first option after entering the utility

menu is “bEEP”. The primary display indicates the

menu option, and the secondary display indicates the

current settings or parameters configured for the

selected option. To change the settings or

parameters, use the and arrow keys. To

change or select a different menu option, press the

button once. For each button press, the

meter will traverse through each menu options and

will repeat itself in the following order:

bEEP AoFF PuP dEF

Note: The settings and parameters are temporarily

“remembered” once the button is pressed to

select a different menu option. To save all settings

permanently, exit the menu using the save and exit

method. With the exception of “bEEP” and “AoFF”

settings, in which case under these settings, changes

are temporarily saved even when exiting the menu

without saving. (See “Exit Utility Menu” section for

details).

Beep Sound Setting (bEEP)

The “bEEP” menu option allows the user to enable or

disable the beep sound for every key press.

58

Page 61

Note: This option only disables the beep sound for

each key press. It does not

for “Static Recording” and “Tolerance” mode, as well

as the “auto power-off” warning.

To turn ON the beep, push either the or

arrow keys until the secondary display shows “ON”.

To turn OFF the beep, push either the or

arrow keys until the secondary display shows “OFF”.

Default Setting: ON

Auto power-off Setting (AoFF)

The “AoFF” menu option allows the user to select the

auto power-off timer. This timer is always counting

continuously. It resets every time a button is pressed

or if an action occurred. If the meter is left untouched

or unattended, the timer will count until the configured

time is up. This is particularly important if the user

wants to preserve battery life or run the meter

continuously without interruption.

Note: When the timer has reached the configured

time, the meter will make an audible “beep” sound

continuously for 10 seconds before auto power-off.

disable the beep sound

59

Page 62

SECONDARY

DISPLAY

REPRESENTATION

5

5 minutes

15

15 minutes

30

30 minutes

60

60 minutes

OFF

No timer. Manual

power off only

To stop the “beep” sound, simply press any button to

resume operation and reset the timer count.

The available timer settings are: 5 minutes, 15

minutes, 30 minutes, 60 minutes, and off.

When the primary display shows “AoFF”, push the

or button to select the timer setting. The

settings will be shown on the secondary display as

follows:

Table 2 - Auto Power-off Options

Default Setting: 15

When the auto power-off option is set to any of the

configured settings in Table 2 (except for “OFF”),

upon exiting the utility menu the LCD display will have

60

Page 63

a “@OFF” indicator. This means a timer has been set

for auto power-off.

Note: When an external 12VDC AC adapter is used

to power the instrument, the auto power-off feature

will automatically be disabled

LCD display when the “@OFF” indicator disappears.

Under this condition, the meter will remain powered

continuously. In this state, powering off the

ON

instrument would require manually pushing and

holding down the button for 2 seconds.

When external power is removed, the meter will

automatically re-enable auto power-off again and

“@OFF” indicator will re-appear if a time has been set

from the “AoFF” option of the utility menu.

Power-up State (PuP)

The “PuP” menu option allows user to configure the

power-up state of the LCR meter, allowing user to

restore settings sa ved into internal EEPROM memory

at power-up.

In the utility menu, when the primary display shows

“PuP”, there are two settings selectable and shown on

the secondary display. “PrE” and “SEt”.

Default Setting: PrE

. This is indicated on the

61

Page 64

Storable Settings

• Primary function mode (i.e. L/C/R)

• Test frequency

• Secondary function mode (i.e. D/Q)

• Tolerance mode state

• Reference value for Tolerance mode

• Relative mode state

• Reference value for Relative mode

Configure and Save Power-up State

Follow the below procedure to setup and store a

power-up state into internal memory.

1. Before entering into the utility menu, configure

all the settings and parameters desired for

power up state. Do this by turning on any

modes and setting values as desired. (Only

the settings listed above in “Storage Settings”

are stored). If the meter is currently in the

utility menu, exit first and setup the desired

settings for recalling at power-up. (see “Exit

Utility Menu” for details)

2. Once settings are configured, enter/re-enter

the utility menu by holding down the

button for 2 seconds.

62

Page 65

3. Traverse through the utility menu until you see

“PuP” on the primary display. The secondary

display should also show “PrE”.

4. In order to save the current meter settings for

power-up state into internal memor y, use

either or button to change the

settings so that the secondary display shows

“SEt”.

5. Press button to select the next menu

option. Once all other utility options are

configured, exit the utility menu b y holding

down button for 2 seconds.

6. The meter has now saved all current settings

into internal memory. At next power-up, the

meter will turn on and recall the saved

settings.

Note: The meter allows one set of settings to be

stored into memory. Therefore, the same

procedure is used to overwrite previously stored

settings into memory.

Prevent Overwrite of Stored Setting s

63

Page 66

In the utility menu, the “PuP” option default setting is

always “PrE”. This represents “previous settings”.

Keeping this setting will prevent the meter from

overwriting previously stored settings for power-up

state. Therefore, when ent ering the uti l it y menu, be

sure not to change to “SEt” to prevent overwriting any

previously stored power-up settings.

Reset Default Settings (dEF)

The last option in the utility menu allows you to reset

the meter to default settings. When the primary

display shows “dEF”, the secondary display will show

“NO” by default. The meter will also default this

setting to “NO” to prevent accidental reset of

instrument settings.

Default Setting: No

To reset the meter to default settings, first select the

“dEF” menu option by using the use button to

browse through the utility menu. When the primary

display shows “dEF”, either press or

button to change the setting so that the secondary

display shows “yES”. Upon saving and exiting the

utility menu, the instrument will automatically reset

64

Page 67

Settings

Default Configuration

Measurement Method

SER (Series)

Test Frequency

1 kHz

Auto Power-off

15 (15 minutes)

Power-up State

PrE

Reset Default Settings

No

back to its original settings. Below is a table of all the

settings that will be restored.

Table 3 - Instrument Default Settings

Primary Function C (Capacitance)

Secondary Function None

Beep On

Note: In the case where under “PuP” option, “SEt” is

selected and “dEF” is set to “yES”, the “PuP” setting

has priority over the “dEF” setting. This means the

instrument will not

be set back to default upon saving

and exiting the utility menu. Instead, the power-up

settings will be stored and will be recalled upon the

next power-up of the instrument.

Exit Utility Menu

65

Page 68

There are two methods for exiting the utility menu.

One saves all the changed settings before exiting, and

the other exits the menu without saving any changes.

Saving and Exiting

To save all utility menu option settings and to exit the

menu, press and hold down the button for 2

seconds. After this, the meter will exit the menu, and

all settings will be saved.

Exiting without Saving

If user decides to exit the utility menu without making

any changes or saving any changes to “PuP” or

“dEF”, it can be done by simply pressing any front

panel buttons except , , , and

. Note that settings that are changed under

“bEEP” and “AoFF” options are still temporarily set

until the next power-up of the instrument.

66

Page 69

Parallel and Series Measurement Mode

The LCR meter offers the option to select between

parallel or series measurement mode. Depending on

which mode is selected, the method to measure the

component will be different. Additionally, one

measurement mode may provide better accuracies over

the other measurement mode depending on the type of

component and the value of the component to be

tested. For more details, refer to the “

67

Page 70

REMOTE COMMUNICATION

The meter has the capability to communicate with a

PC over the mini USB interface. Upon installation of a

USB driver, the PC can control the instrument over

virtual COM (RS-232). The mini USB communication

interface of the meter is designed in f ull dup lex and

has a 64-byte input and output buffer, making it

reliable and efficient for data transmission.

Connecting Instrument to PC

Follow the below procedures for connection setup.

5. Download the USB drivers from

www.bkprecision.com .

6. With the included mini USB cable, connect the

mini USB end to the LCR meter and the other

end to an available USB port on the PC (see

Figure 14).

7. When Windows recognize the USB

connection, do not follow the default Windows

driver installation wizard. Simply run the

setup file from the downloaded USB drivers

and follow the prompt to install drivers.

8. When completed, the computer will recognize

the instrument as a USB (virtual COM) device,

meaning it will be detected as a serial COM

68

Page 71

port. Windows will automaticall y assign a

COM port to the instrument. Please verify

which COM port Windows has assigned by

going into “Device Manager”.

Figure 14 - USB Connection

69

Page 72

USB (Virtual COM) Configuration

The USB will be recognized as a virtual COM on the

PC, thus serial port settings must be configured

properly for remote communication to be successful.

Below are the settings used by the 878B and 879B

meters.

• Baudrate: 9600

• Dat a bits: 8

• Parity: None

• Stop bits: 1

• Flow Control: None

USB Operation

There are two modes that describe the operation of

the meter when it is setup for remote communication.

They are remote mode and auto fetching mode.

Remote Mode

Upon connecting to the instrument, sending any

commands listed in the “Command Protocols” section

will automatically set the LCR meter into remote

mode. In remote mode, the LCD display will show the

RMT indicator. When this is shown, all front panel

70

Page 73

buttons will be disabled, except for the (or

for model 878B) button.

To exit remote mode and go back to local mode,

press the (or for model 878B) button

once. The

display. Pushing the same button once more will put

the meter into auto fetching mode, which is described

in the next section.

Auto Fetching Mode

When connected to a PC, the meter can be

configured to auto-fetching mode. This means, the

meter will continuously fetch data to the PC after

every measurement cycle is completed. It fetches

data from measured readings of primary display and

secondary display, as well as tolerance compared

results. This mode is useful when doing quick data

logging using PC.

RMT indicator will disappear on the LCD

71

Page 74

Enable/Disable Auto Fetching

To toggle between enabling and disabling auto

fetching, press the (or for model

878B) button. When enabled, data will be fetched

constantly after every measurement cycle is

completed. When disabled, no fetched data will be

available.

Note: Alternatively, auto fetching mode can be

disabled when a remote command is sent to the

instrument, turning it back into remote mode. In this

event, the

display, and auto fetching will be disabled

automatically. To re-enabled auto fetching again in

this state, first press the (or for model

878B) button once to exit out of remote mode and

return to local mode. Then, press the button once

more to have it set to auto fetching mode again.

RMT indicator will appear on the LCD

Command Protocols

Overview of Command Type and Format

All commands are entered in either the upper case or

the lower case. There are two types of the meter

programming commands: IEEE 488 common

72

Page 75

commands and Standard Commands for

Programmable Instruments (SCPI). Some commands

are device-specific to the meter. They are not included

in the version 1999.0 of the SCPI standard. However,

these commands are designed with the SCPI format

in mind and they follow the syntax rules of the

standard.

Common Command Format

The IEEE 488 standard defines the common

commands as commands that perform functions like

reset and system query. Common commands usually

come with the asterisk “*” character, and may include

parameters. Some examples of Common command

like: *IDN?, *GTL, *LLO.

SCPI Command Format and Query Format

The SCPI commands control instrument

functions. A subsystem command has a hierarchical

structure that usually consists of a top-level (or root)

keyword, one or more lower level keywords, and

parameters. The following example shows a

command and its associated query:

A. FUNCtion:impa L

Select L as primary parameter

B. FUNCtion:impa?

Return primar y parameter

73

Page 76

function is a root level keyword with the second level

keyword, impa, and L is the command parameter. The

query command ends with a question mark “?”.

Note: SCPI stems from IEEE488.1 and IEEE 488.2.

Although the IEEE 488.2 standard addressed some

instrument measurements , it principally dealt with

common commands and syntax or data formats.

Please refer to the IEEE488.2 and SCPI reference

manual for more information.

Termination Character

A terminator is a character sent by a host, which

identifies the end of a command string. A valid

terminator consists of two-byte data:

<CR> (Carriage Return, ASC(&H0D)) or <LF> (Line

Feed, ASC(&H0A) ) o r <CR><LF>

Responding Message

Returned result

After the meter executes a query command, the return

of the result will be in the following format:

<Result> + <CR> <LF>

For example, in auto fetching mode, the meter will

send the measured data automatically when the

74

Page 77

Data Type

Explanation

Example

<NR1>

An integer

+800,-200,100,-50

This numeric

point

This representation

exponent

A parameter for

or “1” for Boolean

measurement cycle is completed. The format of the

printed data will be shown as the following:

<Primary measured data, Secondly measured

data, Tolerance Result > + <CR> <LF>

Data Types

Returned message is an ASCII string from the meter

responding to a query. A query is a command

accompanied a “?” mark. Table 4 below explains the

different data types.

Table 4 - Data Type of Responded Messages

<NR2>

<NR3>

<Boolean>

representation has

an explicit radix

has an explicit

radix point and an

Boolean setting.

Always return “0”

75

+1.56,-0.001,10.5

+2.345678E+04

-1.345678E-01

ON or OFF

Page 78

query command

short literal form

Text Symbol

Meaning

[ ]

Option; can be omitted

|

Exclusive OR

< >

Defined element

( )

Comment

?

Question mark

Separated two command

keywords

A string is used as

<Literal>

command

parameters with

HOLD

SCPI Commands

This section described all the SCPI commands

supported by the meter. The meter can accept both

upper case and lower case commands.

Table 5 - SCPI Symbol Conventions

:

76

Page 79

Description: Queries the instrument ID.

version>, <serial number>

Set 100Hz frequency

Description: Query the measurement frequency

only)

*IDN?

Response: <instrument model>, <firmware

*LLO

Local Lockout. This means that all front panel

buttons, including the "USB" key is not available.

*GTL

Go to local.

Puts the meter into the local state,

clearing the remote state and front panel lockout.

FREQuency Subsystem

FREQuency <value>

Description: Set measurement frequency

Parameters: Parameters are 100, 120, 1000,

10000 (879B only) or

100hz,120hz,1khz,10khz (879B

only)

Example: FREQuenc y 100hz

FREQuency?

Response: 100hz, 120hz, 1khz, 10khz (879B

77

Page 80

Description: Select primary parameter

Selects L as primary parameter

only),NULL

Select D as secondly parameter

Description: Query secondly parameter

ESR (879B only), NULL

FUNCtion subsystem

FUNCtion:impa < L | C | R | Z >

(Z for model 879B only)

Example: FUNCtion:impa L

FUNCtion:impa?

Description: Query primary parameter

Response: Return L, C, R, Z (879B

FUNCtion:impb < D | Q | THETA | ES R >

(THETA and ESR for model879B on ly)

Description: Select secondly parameter

Example: FUNCtion:impb D

FUNCtion:impb?

Response: Return D, Q, THETA (879B only),

78

Page 81

Set series mode

string

Description: Enable or disable relative

CALCulate:RELative:STATe ON

Description: Query the relative state

Response: Return ON or OFF

FUNCtion:EQUivalent < SERies | parallel |

PAL >

Description: Set equivalent mode

Parameters: SERies — serial mode

Parallel — parallel mode

Pal — parallel mode

Example: FUNCtion:EQUivalent SERies

FUNCtion:EQUivalent?

Description: Query the equivalent mode

Response: Return “SER” or “PAL” format

CALCulate subsystem

CALCulate:RELative:STATe < ON | OFF >

function

Example:

CALCulate:RELative:STATe?

79

Page 82

Description: Quer y the relative val ue

Response: Return <NR3 > or “-----” format string

Description: Enable or disable tolerance function

Example: CALCulate:TOLerance:STATe ON

Description: Quer y the tole ranc e state

Response: Return ON or OFF

Description: Query the nominal value of

Response: Return <NR3 > or “-----” format string

Response: Return <NR3 > or “-----” format string

Description: Set tolerance range

Set 1% tolerance range

CALCulate:RELative:VALUe?

CALCulate:TOLerance:STATe < ON | OFF >

CALCulate:TOLerance:STATe?

CALCulate:TOLerance:NOMinal?

tolerance

CALCulate:TOLerance:VALUe?

Description: Query the percent value of

tolerance

CALCulate:TOLerance:RANGe < 1 | 5 | 10 |

20 >

Parameters: 20 (879B only)

Example: CALCulat e:T O Leranc e:RANGe 1

80

Page 83

Description: Quer y the tole ranc e range

“BIN4” or “----” format string

ON

Response: Return ON or OFF

string

Description: Query the minimum value of

string

CALCulate:TOLerance:RANGe?

Response: Return “BIN1”, “BIN2”, “BIN3”,

CALCulate:RECording:STATe < ON | OFF >

Description: Enable or disable recording

function

Example: CALCulate:RECording:STATe

CALCulate:RECording:STATe?

Description: Query the recording state

CALCulate:RECording:MAXimum?

Description: Query the maximum value of

recording function

Response: Return <NR3 , NR3> or “-----” format

CALCulate:RECording:MINimum?

recording function

Response: Return <NR3 , NR3> or “-----” format

81

Page 84

Description: Quer y the aver age value of

string

Description: Quer y the pres ent value of

string

Example: FETCh?

CALCulate:RECording:AVERage?

recording function

Response: Return <NR3 , NR3> or “-----” format

CALCulate:RECording:PRESent?

recording function

Response: Return <NR3 , NR3> or “-----” format

FETCh Subsystem

FETCh?

Description: Returns the primary, secondary

display value and tolerance

compared result of device’s output

buffer.

Response: Return <NR3, NR3, NR1> format

string

82

Page 85

Command

Parameter

Explanation

FREQuency

<Value>

Set Test Frequency

FUNCtion

:impa

<Literal>

Select primary display

parameter

:impa?

Query primary display

parameter

:impb

<Literal>

Select secondary display

parameter

parameter

:EQUivalent?

Query equivalent mode

CALCulate

:STATe

<Boolean>

Enable/disable relative

:STATe?

Query relative state

:VALUe?

Query relative value

:STATe

<Boolean>

Enable/disable tolerance

:STATe?

Query tolerance state

:NOMinal?

Query nominal value of

tolerance

:VALUe?

Query percent of tolerance

:RANGe?

Query tolerance range

:RECording

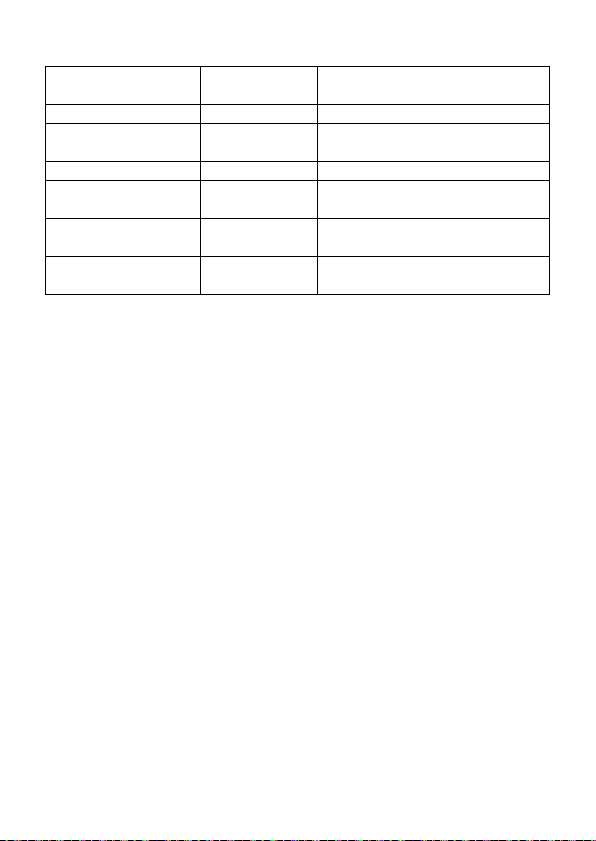

Summary of Supported SCPI Commands

Table 6 - Summary of SCPI Commands

FREQuency? Query Test Frequency

:impb? Query s econdary display

:EQUivalent <Literal> Set equivalent mode

:RELative

function

:TOLerance

function

:RANG <Value> Set tolerance range

83

Page 86

function

:STATe?

Query recording state

:MAXimum?

Query max. value of

recording

:MINimum?

Query min. value of recording

:AVERage?

Query average value of

recording

recording

:STATe <Boolean> Enabl e/ disabl e recording

:PRESent? Query present value of

FETCh? Ret urn dat a any tim e last

reading is valid

Error Codes

In certain situations, errors may occur, and an error

code will be displayed on the meter. Below defines

the error description based on the error code.

E10: Unknown command

E11: Parameter Error

E12: Syntax Error

84

Page 87

SUPPLEMENTAL INFORMATION” section.

Default Settings

For Capacitance and Resistance measurements, the

default measurement mode is parallel

For Inductance measurements, the default

measurement mode is series

Selecting Measurement Mod e

The measurement mode of the meter is displayed by

the indicators “SER” or “PAR” on the LCD screen.

“SER” means meter is in series measurement mode.

“PAR” means meter is in parallel measurement mode.

To toggle between the two modes, press and hold

down (or for model 878B) button for 2

seconds. The indicators on the display should toggle

between “SER” and “PAR”.

.

.

Calibration

Calibration is available on all modes. It is

recommended that to achieve optimal readings,

85

Page 88

calibration should be done before making any

measurements.

To enter calibration mode, simply press and hold

down the button for 2 seconds. A calibration

prompt will be displayed. There are two types of

calibration available. One is the open circuit

calibration. The other is the short circuit calibration.

To exit calibration mode, simply press and hold down

the button for 2 seconds again.

Open Calibration

Open calibration can be done when meter first enters

into calibration mode. If the input sockets or terminals

have nothing connected, the display should show

Figure 7. Also, “REL” indicator will be blinking on the

display. This is to prompt the user that the meter is

waiting for an action. At this point, open calibration

will be done when the button is pressed once.

Within a few seconds, the meter will return to normal

display and meter will be calibrated based on the test

frequency and settings selected prior to entering the

calibration mode.

86

Page 89

Figure 7 - Open Calibration

Short Calibration

Short calibration can be done when meter first enters

into calibration mode. If the input sockets or terminals

have nothing connected, the display will be like Figure

7. For short calibration, simply put a shorting bar or a

short piece of conductive metal (i.e. paper clip) across

the “+” and “-“ input sockets or terminals. Within 2

seconds, the meter will display the same screen as

Figure 8, which prompts for a “short”. Also, “REL”

indicator will be blinking on the display. This is to

prompt the user that the meter is waiting for an action.

At this point, short calibration will be done when the

button is pressed once. Within a few seconds,

the meter will return to normal display and meter will

87

Page 90

be calibrated based on the test frequency and settings

selected prior to entering the calibration mode.

Figure 8 - Short Calibration

Quick Procedure

Below is an example of steps to follow to do both

open and short calibration.

1. Select the primary function mode for

measurement (i.e. L/C/R/Z).

2. Select the test frequency for measurement.

3. Select the measurement mode (i.e. Series or

Parallel)

4. Once all settings are configured, hold down

button for 2 seconds to enter into

calibration mode.

5. First, do open calibration. Follow instructions

under “Open Calibration” section.

88

Page 91

6. Next, do short calibration. Follow instructions

under “Short Calibration” section.

7. Now, the meter should go back to normal

display and user may proceed to take

measurements of components.

Recommendations

To achieve optimal measurement results, both open

and short calibration should be done. It is highly

recommended to calibrate extremely high or low

values for L, C, R and Z before making precision

measurements.

Notes:

1. If test frequency is changed, calibration

should be done again before making precision

measurements. Once calibration is done on a

selected test frequency, calibration data will

remain until power off.

2. Either open or short calibration is not

associated with measurement function,

therefore changing the test function does not

require re-calibration.

3. Re-calibration may be necessary depending

on many factors such as prolonged use,

changing environments, and contact variation

(i.e. alligator test leads or socket contacts).

89

Page 92

USB

The USB button (or for model 878B) are

used for remote communication. See “

90

Page 93

REMOTE COMMUNICATION” section for details.

Automatic Fuse Detection

The LCR meter has an internal fuse that protects the

inputs from severely damaging the instrument. When

the meter detects that the protective fuse is open, the

“FUSE” indicator will appear on the primary display

(see Figure 9) and an internal “beep” will sound

continuously. In this situation, none of the function

buttons can be operated and all other meter functions

will be disabled.

Figure 9 - Fuse Display

In the event that the above screen is displayed, a fuse

replacement is required. Turn off the meter by

91

Page 94

pressing and holding down the button for 2

seconds. If this does not power off the meter, remove

external AC adapter if that is used and/or remove the