Page 1

5335B

User Manual

Power Meter

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be followed during

all phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

• Read and understand the safety and operational information in this manual.

• Apply all the listed safety precautions.

• Verify that the voltage selector at the line power cord input is set to the correct line voltage. Operating the

instrument at an incorrect line voltage will void the warranty.

• Make all connections to the instrument before applying power.

• Do not operate the instrument in ways not specified by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the safety standards

of design, manufacture, and intended use of the instrument. B&K Precision assumes no liability for a

customerâĂŹs failure to comply with these requirements.

Category rating

The IEC 61010 standard defines safety category ratings that specify the amount of electrical energy available and

the voltage impulses that may occur on electrical conductors associated with these category ratings. The category

rating is a Roman numeral of I, II, III, or IV. This rating is also accompanied by a maximum voltage of the circuit to

be tested, which defines the voltage impulses expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be connected to the

mains supply. The voltages in the environment are typically derived from a limited-energy transformer or a baery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be connected to the

mains supply at a standard wall outlet or similar sources. Example measurement environments are portable tools

and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be connected to the

mains installation of a building. Examples are measurements inside a building’s circuit breaker panel or the wiring

of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be connected to the

primary power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is specified in

this manual for this instrument.

i

Page 3

SAFETY SUMMARY ii

You must ensure that each accessory you use with this instrument has a category rating equal to or higher than

the instrument’s category rating to maintain the instrument’s category rating. Failure to do so will lower the

category rating of the measuring system.

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains power

should be 115 V RMS or 230 V RMS. Use only the power cord supplied with the instrument and ensure it is

appropriate for your country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical safety ground.

This instrument is grounded through the ground conductor of the supplied, three-conductor AC line power cable.

The power cable must be plugged into an approved three-conductor electrical outlet. The power jack and mating

plug of the power cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible conductive

parts (including control knobs) may provide an electric shock. Failure to use a properly-grounded approved outlet

and the recommended three-conductor AC line power cable may result in injury or death.

Unless otherwise stated, a ground connection on the instrument’s front or rear panel is for a reference of potential

only and is not to be used as a safety ground. Do not operate in an explosive or flammable atmosphere.

Do not operate the instrument in the presence of flammable gases or vapors, fumes, or finely-divided particulates.

The instrument is designed to be used in oice-type indoor environments. Do not operate the instrument

• In the presence of noxious, corrosive, or flammable fumes, gases, vapors, chemicals, or finely-divided

particulates.

• In relative humidity conditions outside the instrument’s specifications.

• In environments where there is a danger of any liquid being spilled on the instrument or where any liquid

can condense on the instrument.

• In air temperatures exceeding the specified operating temperatures.

• In atmospheric pressures outside the specified altitude limits or where the surrounding gas is not air.

• In environments with restricted cooling air flow, even if the air temperatures are within specifications.

• In direct sunlight.

Page 4

SAFETY SUMMARY iii

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating temperature

range is 0◦C to 40◦C and 20% to 80% relative humidity, with no condensation allowed. Measurements made by

this instrument may be outside specifications if the instrument is used in non-oice-type environments. Such

environments may include rapid temperature or humidity changes, sunlight, vibration and/or mechanical shocks,

acoustic noise, electrical noise, strong electric fields, or strong magnetic fields.

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets on or inside

the instrument, remove the instrument’s power cord, remove the instrument from service, label it as not to be

operated, and return the instrument to B&K Precision for repair. Notify B&K Precision of the nature of any

contamination of the instrument.

Clean the instrument only as instructed

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants, solvents,

acids/bases, or other such chemicals. Clean the instrument only with a clean dry lint-free cloth or as instructed in

this manual. Not for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component in a

life-support device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and internal

adjustments must be made by qualified service-trained maintenance personnel who are aware of the hazards

involved when the instrument’s covers and shields are removed. Under certain conditions, even with the power

cord removed, dangerous voltages may exist when the covers are removed. To avoid injuries, always disconnect

the power cord from the instrument, disconnect all other connections (for example, test leads, computer interface

cables, etc.), discharge all circuits, and verify there are no hazardous voltages present on any conductors by

measurements with a properly-operating voltage-sensing device before touching any internal parts. Verify the

voltage-sensing device is working properly before and aer making the measurements by testing with

known-operating voltage sources and test for both DC and AC voltages. Do not aempt any service or adjustment

unless another person capable of rendering first aid and resuscitation is present.

Do not insert any object into an instrument’s ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault condition in the

circuit exists. Fuse replacement

Fuse replacement must be done by qualified service-trained maintenance personnel who are aware of the

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 5

SAFETY SUMMARY iv

instrument’s fuse requirements and safe replacement procedures. Disconnect the instrument from the power line

before replacing fuses. Replace fuses only with new fuses of the fuse types, voltage ratings, and current ratings

specified in this manual or on the back of the instrument. Failure to do so may damage the instrument, lead to a

safety hazard, or cause a fire. Failure to use the specified fuses will void the warranty. Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the instrument

to B&K Precision for service and repair to ensure that safety and performance features are maintained.

For continued safe use of the instrument

• Do not place heavy objects on the instrument.

• Do not obstruct cooling air flow to the instrument.

• Do not place a hot soldering iron on the instrument.

• Do not pull the instrument with the power cord, connected probe, or connected test lead.

• Do not move the instrument when a probe is connected to a circuit being tested.

Page 6

SAFETY SUMMARY v

CE Declaration of Conformity

This instrument meets the requirements of:

EMC Directive

• EN 61326-1 2006

• EN 61000-3-2-2006

• EN 61000-3-3:1995

Page 7

SAFETY SUMMARY vi

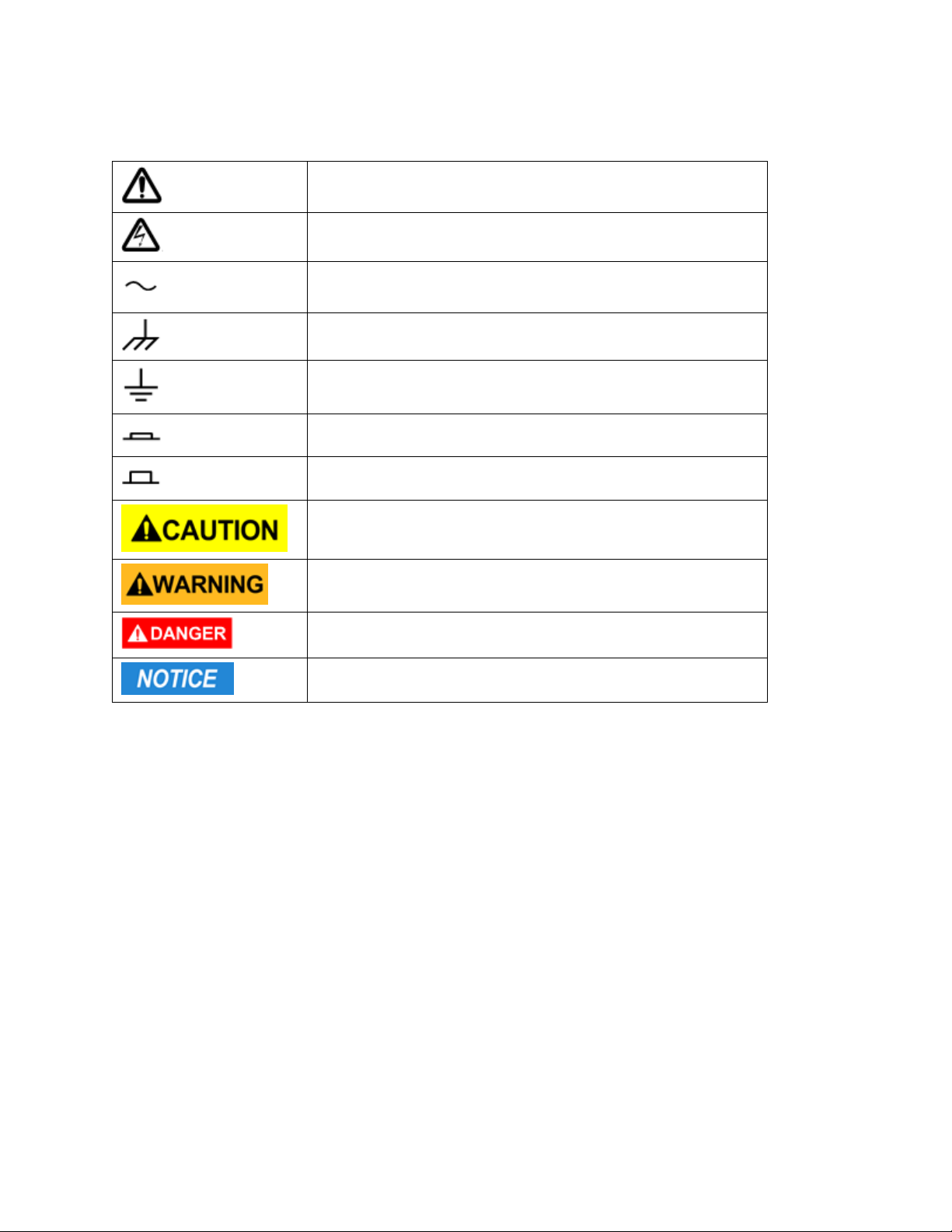

Safety Symbols

Refer to the user manual for warning information to avoid hazard or

personal injury and prevent damage to instrument.

Electric Shock hazard

Alternating current (AC)

Chassis (earth ground) symbol.

Ground terminal

On (Power). This is the In position of the power switch when instrument is ON.

O (Power). This is the Out position of the power switch when instrument is OFF.

CAUTION indicates a hazardous situation which, if not avoided, will

result in minor or moderate injury

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

NOTICE is used to address practices not related to physical injury.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 8

Contents

Safety Summary i

CE Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Contents vii

1 General Information 1

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Rear Panel Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Measurement Connection Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Wiring External Current Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Power up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.1 Power Line Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.2 Fuse Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6.3 Power-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Menu 7

2.1 MENU > SYSTEM menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 System Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Communication Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.3 System Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.4 Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.5 System Initialize Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 MENU > SETUP menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 Averaging Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.2 External Sensor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.3 Other seings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.4 Inrush Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 CAL ZERO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 RATIO SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 External Current Sensor 16

4 Front Panel Operation 17

4.1 Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1 Crest factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.2 Set Measurement Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Voltage and current range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.1 Fixed range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.2 Auto Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Measurement interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Filter and Crest Factor Seing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

vii

Page 9

CONTENTS viii

4.4.1 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Averaging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.5.1 Index averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5.2 Linear averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5.3 Harmonic measurement averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Meter Display 23

5.0.1 Operation steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 Waveform Display Function 25

6.1 Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.1 Introduction of so keys on the interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.2 Vertical calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.3 Horizontal calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.4 Trigger delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.5 Trigger waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Adjustment of Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.1 Operation steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 Seing of Trigger Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.1 External trigger input (Ext) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7 Harmonic Measurement Function 30

7.1 Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1.1 Introduction of harmonic information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2 Seing of Harmonic Measurement Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2.1 Parameter descriptions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2.2 PLL source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2.3 Harmonic analysis order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Integral Operation Function 36

8.1 Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.2 Introduction of so keys on the interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.3 Integral measurement display information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.3.1 Integral operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.4 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.5 Seing of Integral Measurement Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.5.1 Parameter descriptions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.6 Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 Remote Operation 42

9.1 RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.1.1 RS-232 troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.1.2 RS-232 Communication seings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2 USB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.3 GPIB interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.4 LAN interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

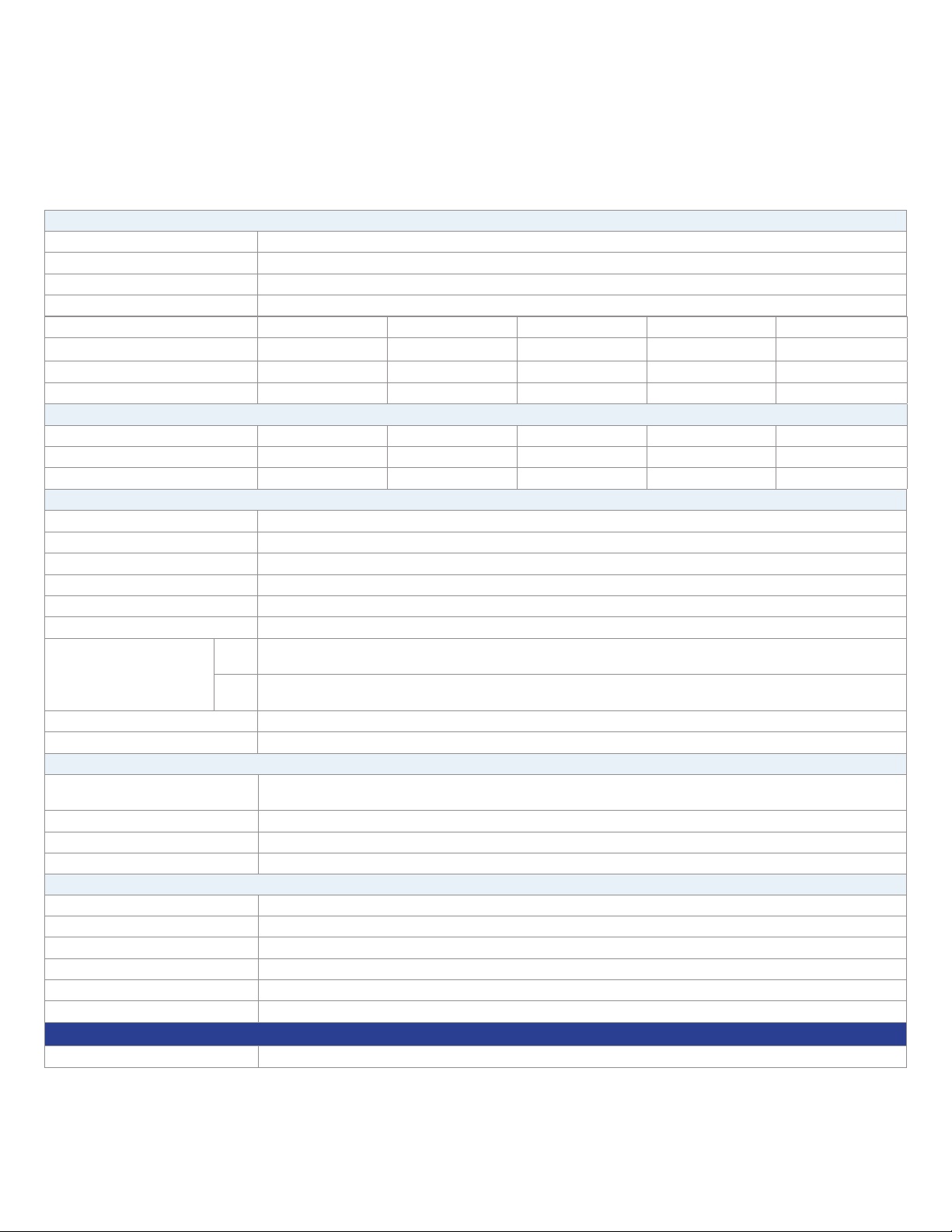

10 Specifications 45

11 Routine Maintenance 49

11.1 Self-inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.2 Error Information References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.2.1 Prompt Message List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.2.2 Error information list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11.3 Daily maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 10

CONTENTS ix

11.3.1 Equipment cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.3.2 Initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

12 LIMITED THREE-YEAR WARRANTY 54

13 Service Information 55

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 11

Chapter 1

General Information

Note: The contents of this manual and included specifications are subject to change go to for the latest version.

(Manual version: 2017-10-13 )

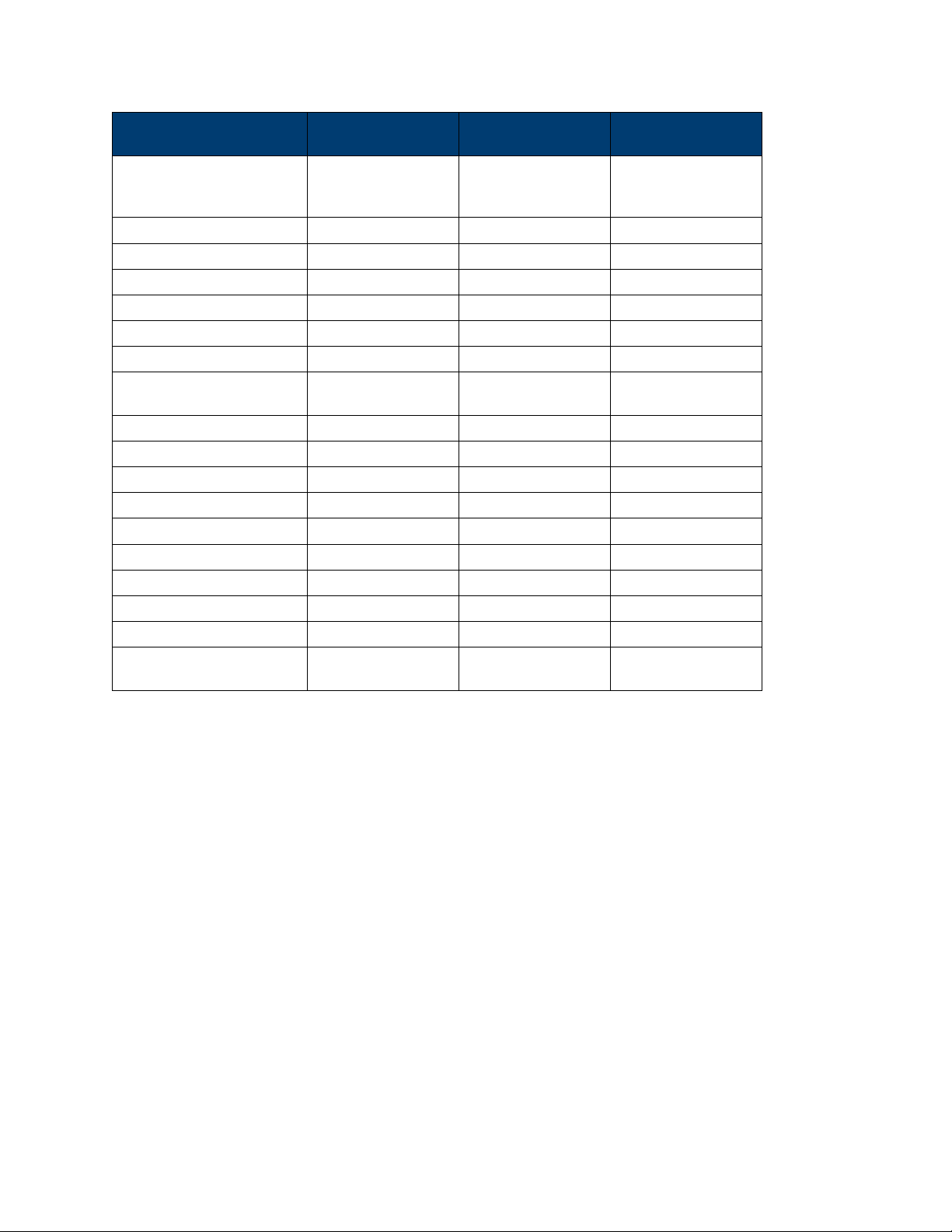

Figure 1.1 shows a schematic Diagram of Front Panel of BK5335B Series Power Meter and Diagram of Key

Functions.

The BK5335B power meter measures AC and DC inputs up to 600 Vrms and 20 Arms from DC to 100kHz. It

measures voltage, current, power, frequency, power factor, phase and harmonic parameters up to the 50th order.

Remote control is available over USB, GPIB, RS232 and LAN communication interfaces. Screen captures are saved

via the USB peripheral port located on the front panel. Voltage and current measurement precision is nominally

0.1%.

1.1 Features

• 4.3-inch color LCD

• Configurable display of measurements in 3 formats

• Input range: 600Vrms/20Arms from DC to 100kHz

• Voltage, current, power, harmonics and other parameters are measured at the same time simultaneously

• Up to 0.1% voltage and current measurement accuracy

• Harmonic measurement up to the 50th-order harmonic

• Screen captures are saved to USB via the front panel connector

• Integration measurement of power produced or consumed

• Frequency measurement

• Remote control via USB, GPIB, RS232 and LAN communication interfaces

1

Page 12

CHAPTER 1. GENERAL INFORMATION 2

1.2 Front Panel

Figure 1.1: Front Panel

Power Buon Rotary Knob

4.3” LCD Arrow Keys

USB So-keys

Main Functions So-keys

Menu, Enter, ESC Print (Screen Capture)

Key Name and function

Waveform Display key: press to view waveforms. See Chapter 6

Harmonic Measurement key: For viewing harmonic measurements. See Chapter 7

Basic Measurement key: The normal measurement screen. See Chapter ??

Integral Measurement key: Measurements over time. See Chapter 8

Menu key, Press to view and configure seings. See Chapter 2

Enter key: Press to commit a seing or value.

Image Save key: press to save a hardcopy of the screen to the USB host port on the front panel.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 13

CHAPTER 1. GENERAL INFORMATION 3

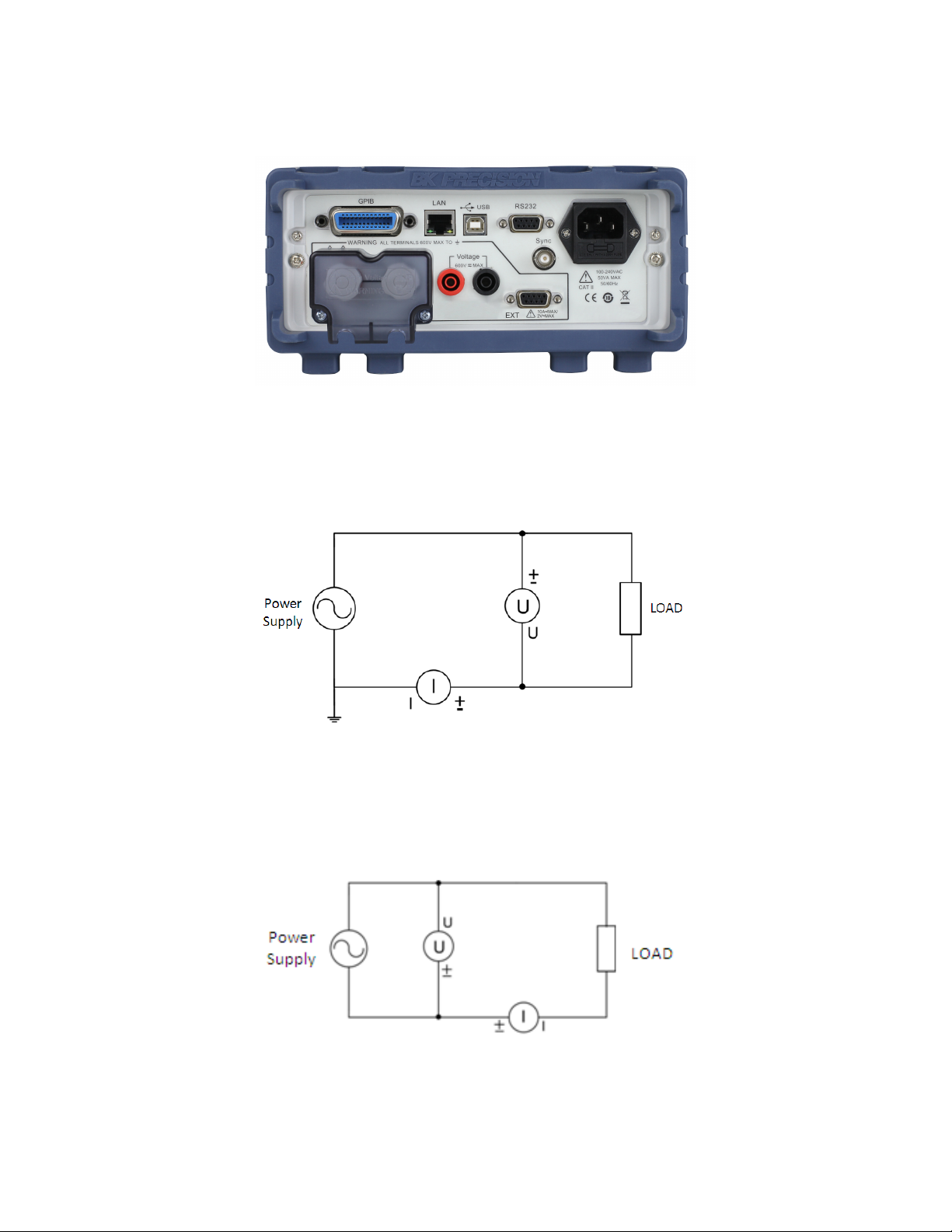

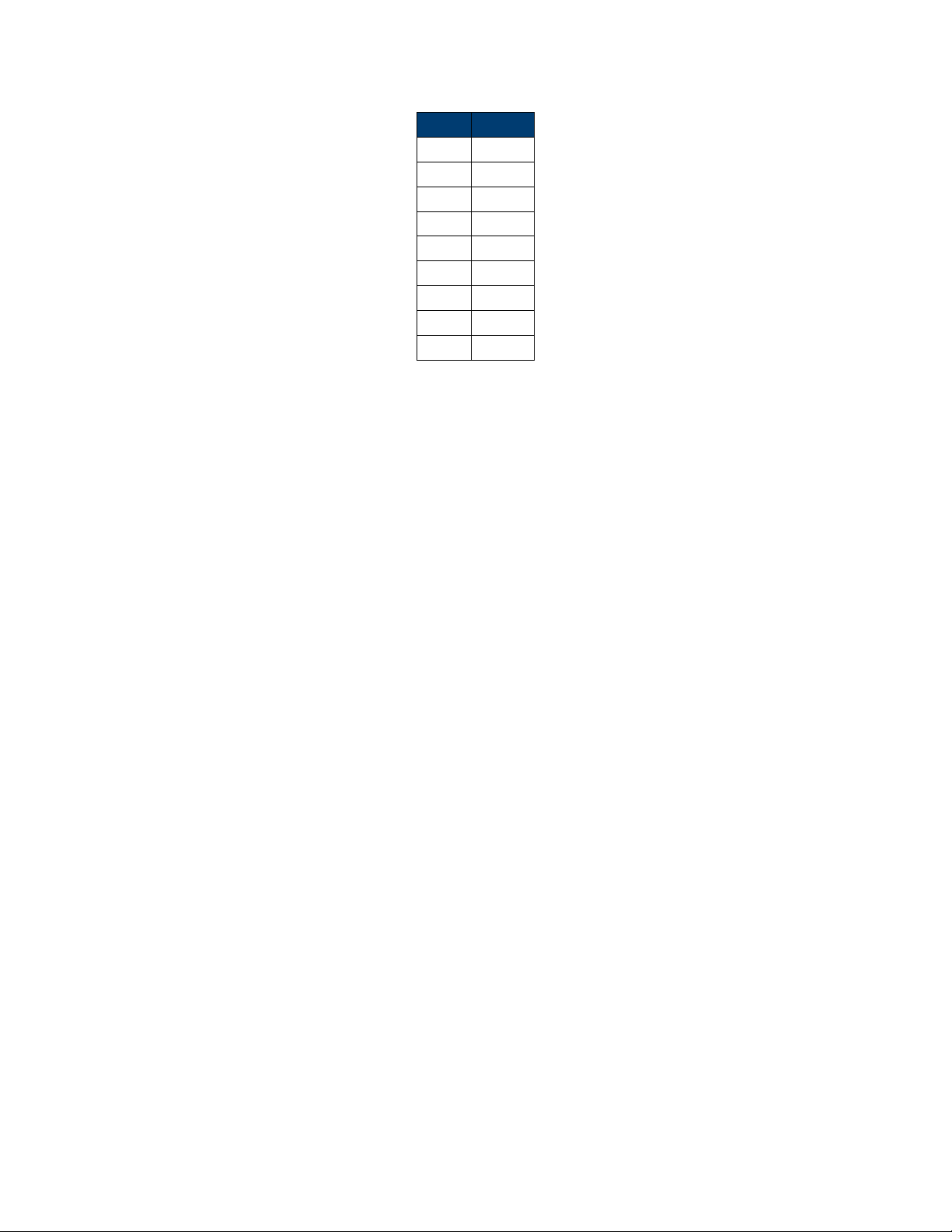

1.3 Rear Panel Summary

Figure 1.2: Rear View

1 GPIB Connector 6 AC Line

2 LAN Connector 7 External Current Sensor

3 USB Connector 8 Voltage Input

4 RS-232 Connector 9 Current Shunt Input

5 Synchronization BNC

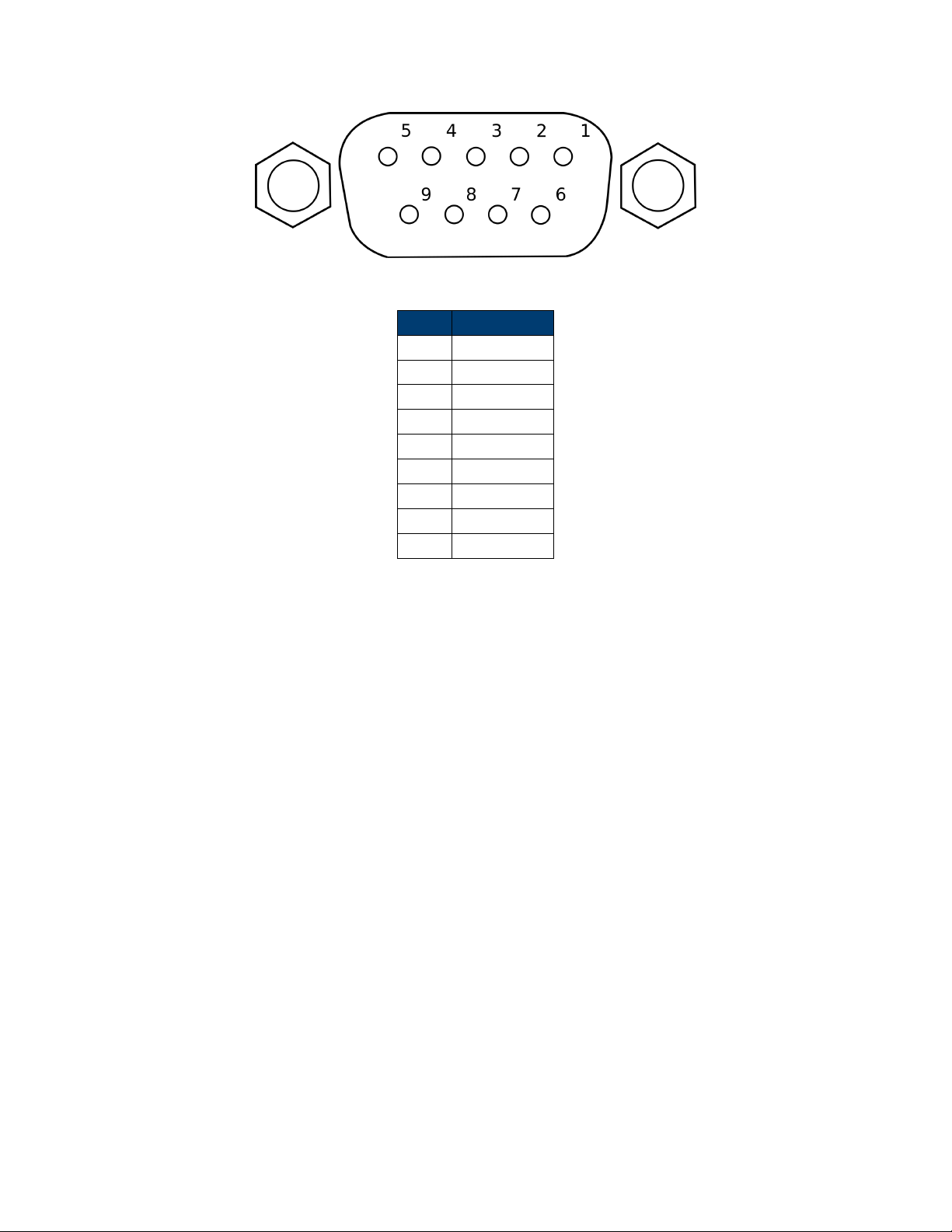

1.4 Measurement Connection Setup

Depending on the amount of current that will flow through the meter, 2 configurations are specified.

1. Remove the protective cover over the current input terminals. See Figure 1.3

2. Connect the circuit under measurement as shown in the wiring diagrams, Low current, see Figure 1.4, high

current see Figure 1.5.

3. Use cables rated to conduct the current and withstand the voltage being measured.

4. For safety, re-aach the protective covers over the input terminals.

Page 14

CHAPTER 1. GENERAL INFORMATION 4

Figure 1.3: Current terminal cover

Figure 1.4: Low Current Wiring Setup

Figure 1.5: High Current Wiring Setup

Page 15

CHAPTER 1. GENERAL INFORMATION 5

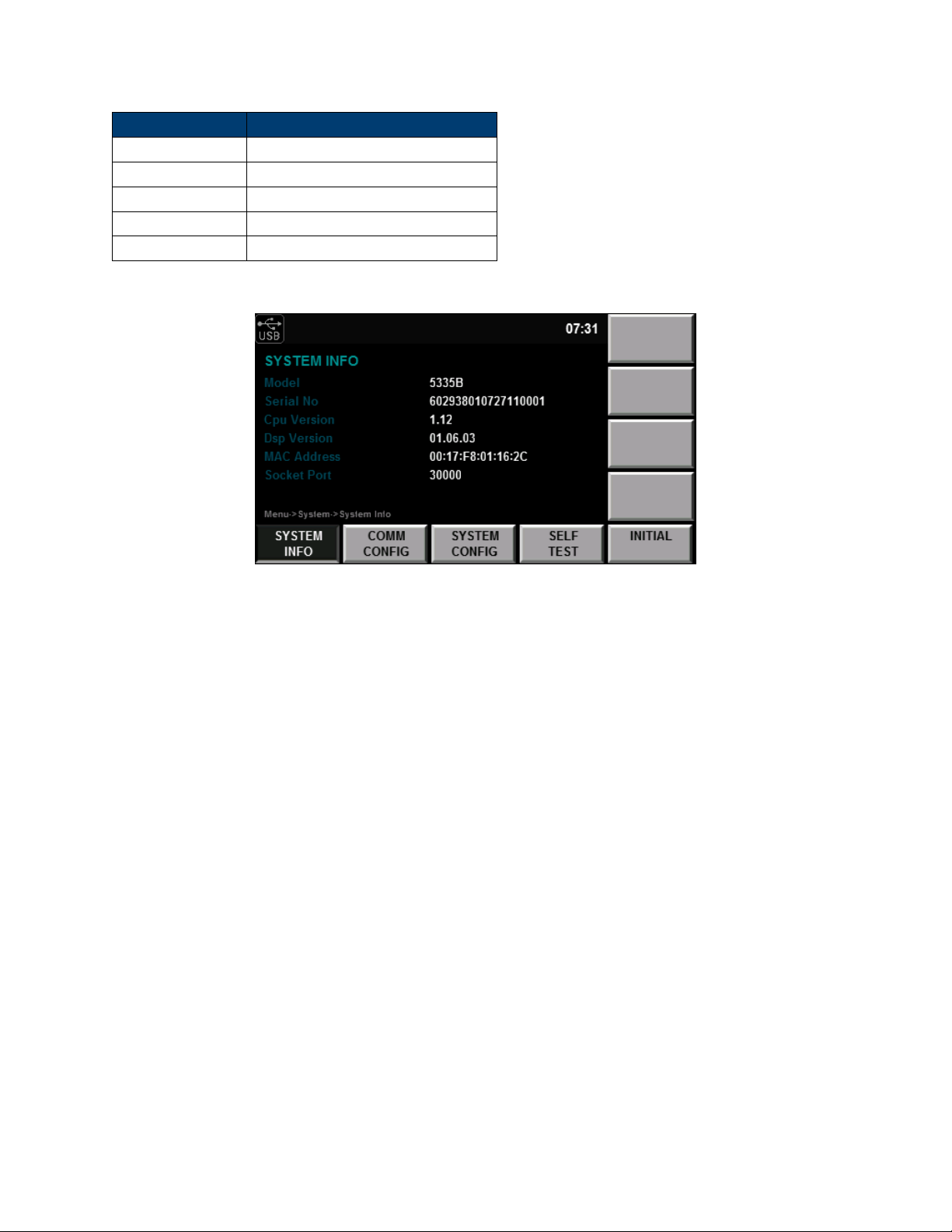

Figure 1.6: External Sensor Interface: DE-9 Connector

Pin # Description

1 +12 V

2 GND

3 -12 V

4 Signal GND

5 Voltage

6 NC

7 Current

8 NC

9 NC

Table 1.1: External Sensor Connector Pinout

1.5 Wiring External Current Sensors

This power meter accepts a wide range of external current sensors. Measurement is achieved by applying a scaling

factor to the voltage sensed at the external sensor input. A ratio of Volts to Amps is set in the EXSENSOR SET

menu of the instrument. See Section 3 for details. Always disconnect the main current input when using an

external sensor. The ports are electrically connected and if both are connected, measurement error and damage

may occur.

1. Connect the power supply, external current sensor, electronic load and BK5335B Power Meter as shown in

Figure 1.6

2. Turn on the power meter

3. Select Menu > SETUP > EXT SEN SET to access the External Sensor Setup interface

4. Use the arrow keys to select ExSENSOR2 or EXSENSOR1, and then press ON from the so-keys to enable

the external current sensor.

5. Set the “Ratio” using the arrow keys and knob to set the value in V/A (EXSENSOR1) or mV/A (ExSENSOR2)

6. Press Enter to save the seings

7. Press Esc to exit the seings

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 16

CHAPTER 1. GENERAL INFORMATION 6

Figure 1.7: Fuse Holder

1.6 Power up

1.6.1 Power Line Connection

Input power requirements:

AC Voltage 110 V ±10% or 220 V ±10%

Frequency 47 Hz – 63 Hz

1.6.2 Fuse Requirements

An AC input fuse is necessary when powering the instrument. Refer to Table 1.2 for the fuse requirements.

Model Fuse Specification (110 V) Fuse Specification (220 V)

5335B T 10 A, 250 V T 6.3 A, 250 V

Table 1.2: Required Fuses

1.6.2.1 Fuse Replacement

1. Disconnect the power cord.

2. Locate the fuse box in the rear panel, beneath the AC power socket. Figure 1.7

3. With a small flat blade screwdriver, insert the blade into the fuse box slit to pull and slide out the fuse box.

4. Pull out the fuse inside to check and/or replace with the appropriate fuse for the line voltage used.

5. Insert the fuse in the same location.

1.6.3 Power-up Sequence

Connect AC power cord to the AC receptacle in the rear panel and press the power switch to the (ON) position to

turn ON the instrument. It will display the BIOS version then run through a self-test procedure, Figures ??, 2.9.

Page 17

Chapter 2

Menu

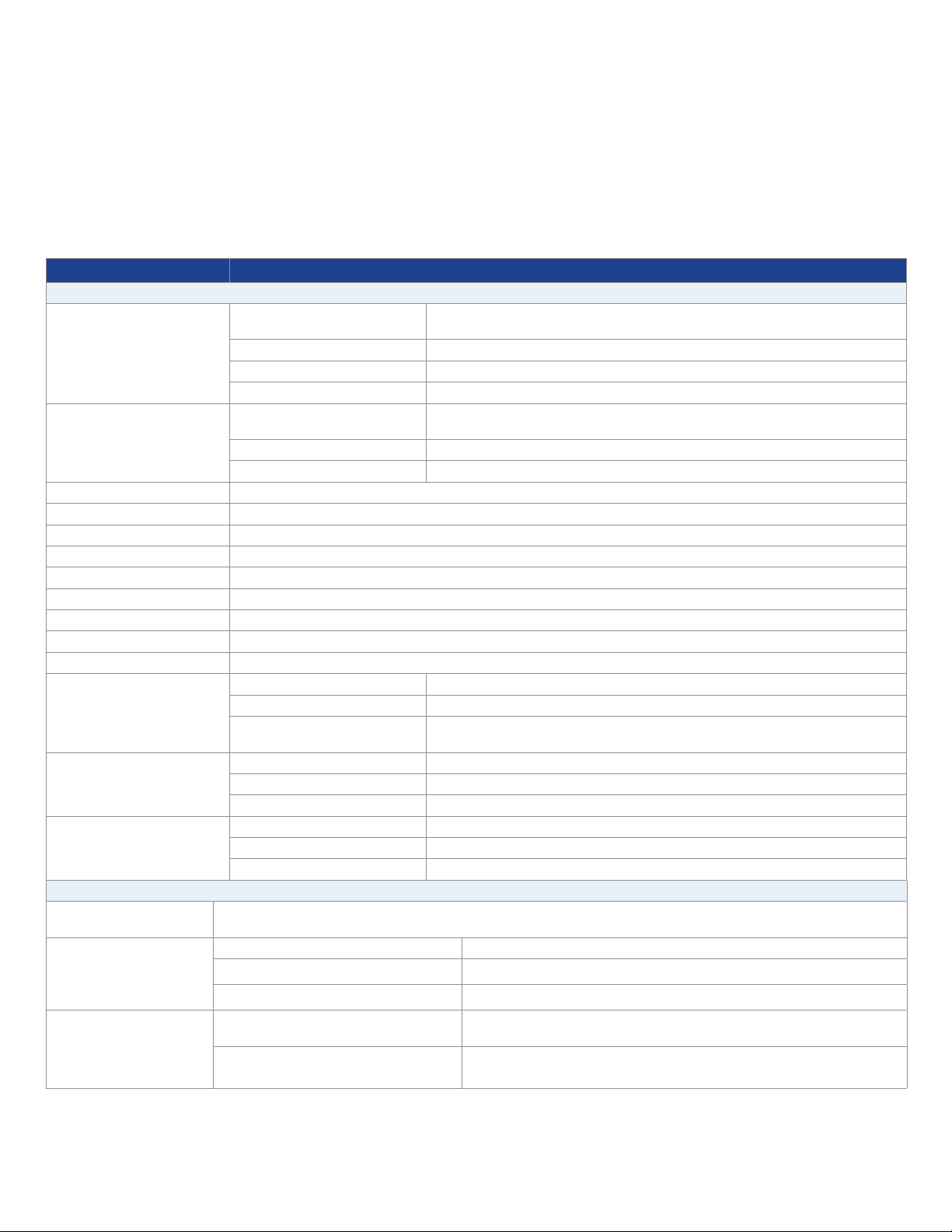

Configuration of system-wide seings is done from the “Menu”. Pressing the buon enters the

configuration/system menu, Figure 2.1.

From the main menu, the so-keys at the boom of the screen provide access to the configuration screens. See

Table 2.1

2.1 MENU > SYSTEM menus

From the system menu, system-wide functions are set and viewed. Figure ??, details such as the LAN MAC

address, date, screen brightness, system initialization (seings reset), and self test are accessed here. See Table 2.2

Figure 2.1: Configuration/System Menu

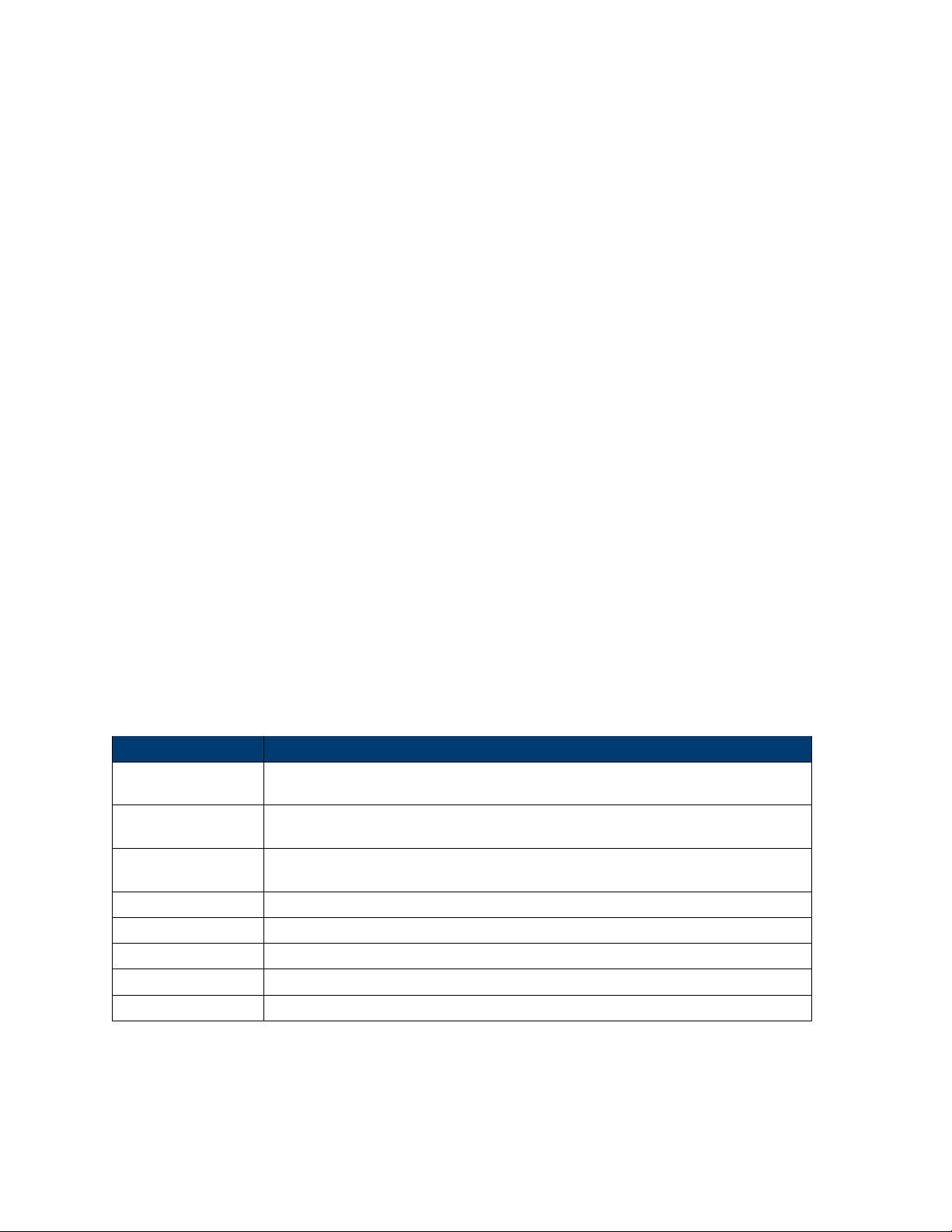

Function Description

SYSTEM View and change overall system information and parameters

SETUP Device measurement and measurement configuration seings

CAL ZERO Zero the meter

RATIO SET Change the overall scaling factor for measurements

Table 2.1: Main “Menu” functions

7

Page 18

CHAPTER 2. MENU 8

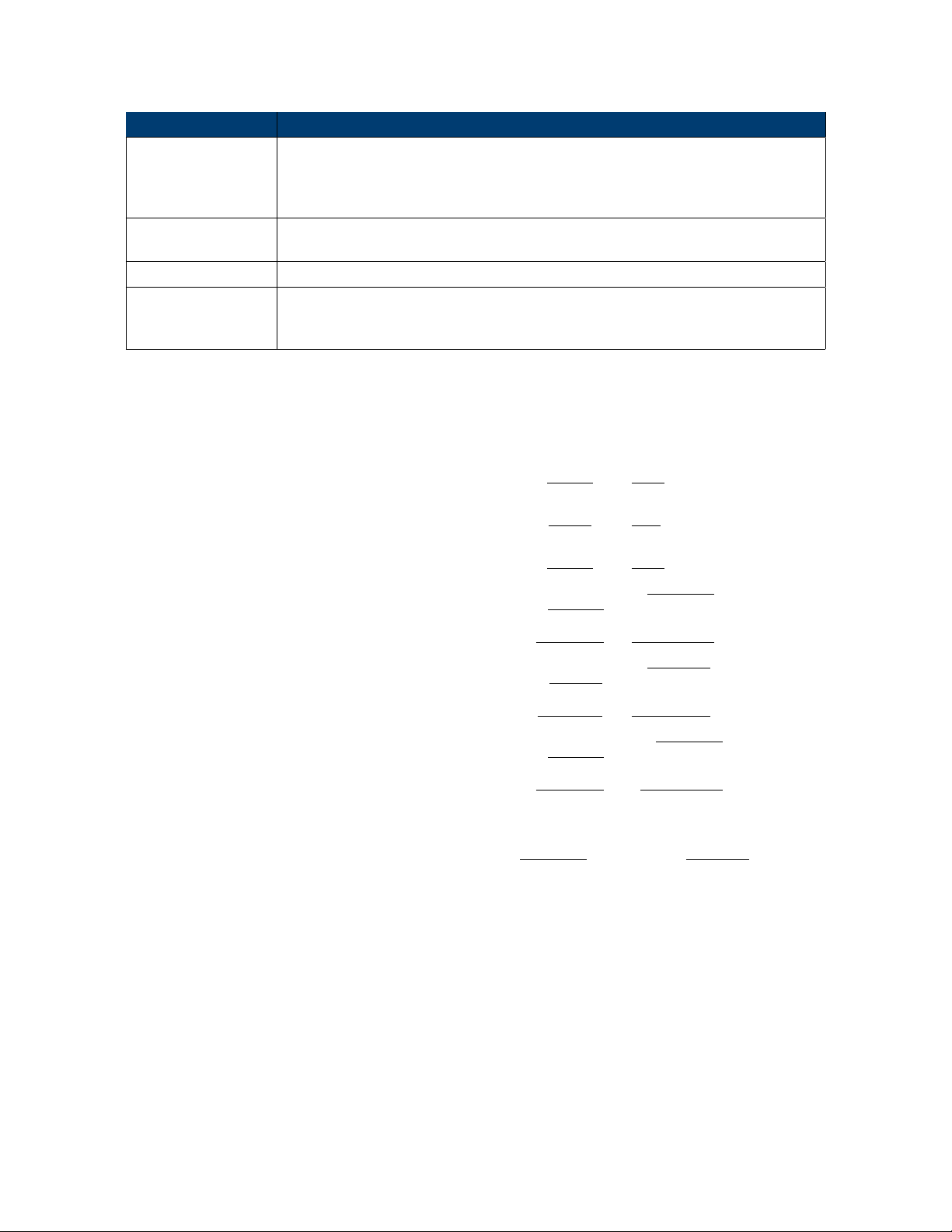

Function Description

SYSTEM INFO System details, Model, Serial, etc.. .

COMM CONFIG Setup the communication interfaces

SYSTEM CONFIG Set date, time, beep and brightness

SELF TEST Perform a self diagnostic

INITIAL Reset device seings

Table 2.2: System Menu sub-menus

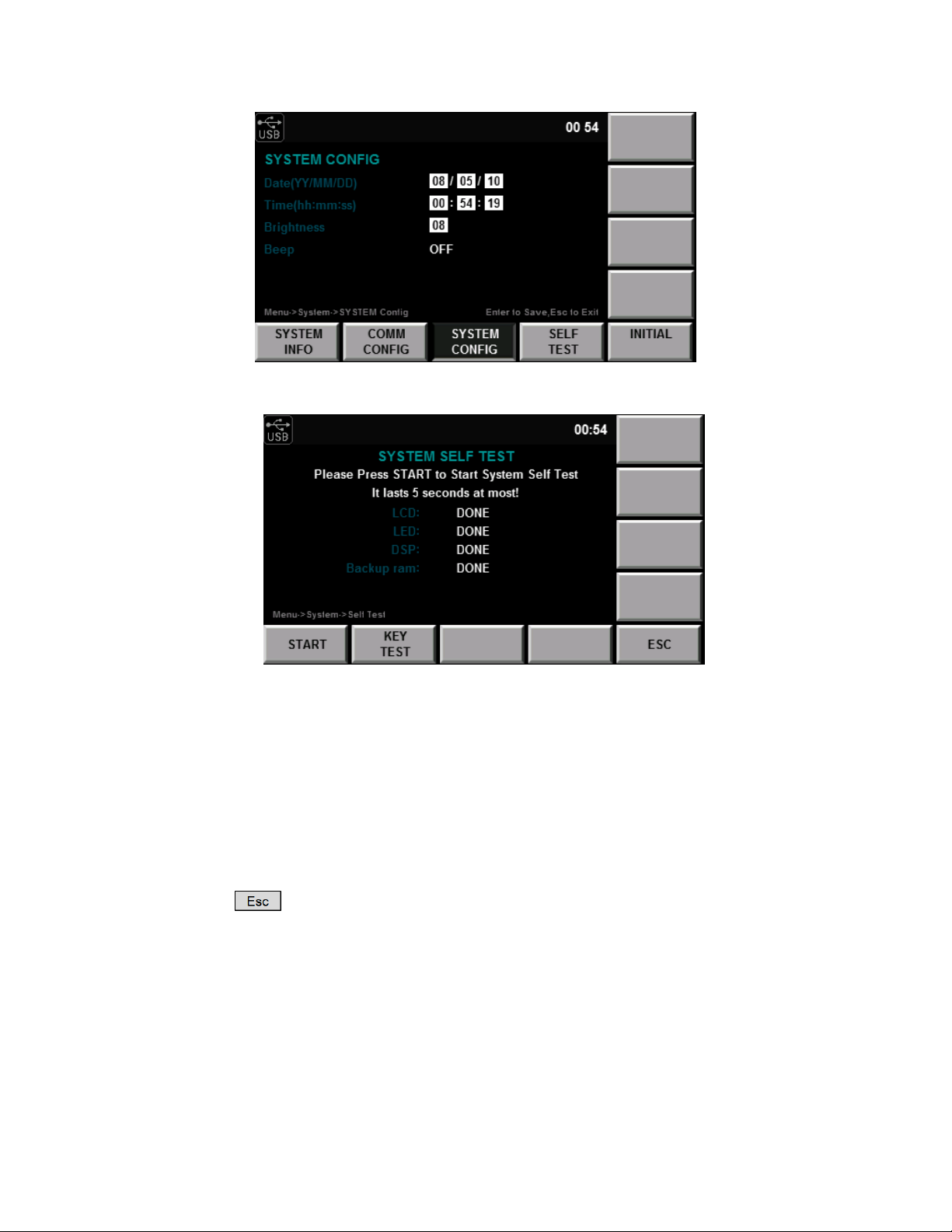

Figure 2.2: System Info Screen

2.1.1 System Information Menu

Information about the device is listed in this menu. The serial number listed is that used in production at the

factory and does not match the label. When contacting B+K, use the serial number on the label.

2.1.2 Communication Configuration Menu

Available remote interfaces are RS-232, USBTMC, GPIB and LAN. For details about commands and use of the

remote interfaces, see the programming manual. The manual is found on the product page of the 5335B at

www.bkprecision.com

2.1.2.1 RS-232

This interface support 6 common baudrates: 4800, 9600, 19200, 38400, 57600, 115200. Use the arrow keys to

navigate the menu screen and the so-keys to select the desired baudrate. The number of data bits, parity and

stop bits are preset and unchangeable. (8 bits, no parity, and 1 stop bit, so called N-8-1). See Figure 2.3.

2.1.2.2 USB

This unit operates as a USBTMC (USB Test and Measurement) device. There are no configuration options for this

interface. Figure 2.4

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 19

CHAPTER 2. MENU 9

Figure 2.3: COMM Configuration - RS-232

Figure 2.4: COMM Configuration - USB

2.1.2.3 GPIB

The GPIB interface may be configured to addresses 1 through 30. Use the arrow keys to select the numeric field

beside “GPIB Address” and use the rotary knob to change the value. The user may select each digit by the arrow

keys as well. Figure 2.5

2.1.2.4 LAN

The LAN (Ethernet) interface may be configured as either DHCP or static. Use the arrow keys to select the IP

Mode field. When DHCP is selected, the current IP, subnet, and gateway are shown on screen (Figure 2.6). When

“MANU” is selected (static mode) (Figure 2.7), the screen shows fields for seing the IP, subnet, and gateway.

Using the arrow keys and the rotary knob allows the user to move between fields and digits, and use the rotary

knob to change the value.

2.1.3 System Configuration Menu

From this menu, seing the date, time, brightness, and the state of the beep function is set. Use the arrow keys to

navigate the fields, and the rotary knob to change the value. For the beep function, the so keys are used to

change the value. When seings are changed, press the key to commit the changes. See Figure 2.8.

Page 20

CHAPTER 2. MENU 10

Figure 2.5: COMM Configuration - GPIB

Figure 2.6: COMM Configuration - LAN (DHCP)

Figure 2.7: COMM Configuration - LAN (Manual (static))

Page 21

CHAPTER 2. MENU 11

Figure 2.8: System Config Menu

h!

Figure 2.9: System Self Test

2.1.4 Self Test

The unit has a built in self test. This function tests the LEDs, the screen and some of the internal electronics,

Figure 2.9. When the test is running, it cycles through colors on the LCD, and lights up the individual LEDs that

illuminate the front panel buons. When complete, the results are displayed on screen, DONE for the LCD and

LEDs, and OK for the internal electronic tests.

From this screen, a test of each buon is also available. A representation of all the buons appears on screen aer

selecting the “KEY TEST” key, pressing the individual keys will highlight the text on screen indicating the buon is

working. Press the to exit the test.

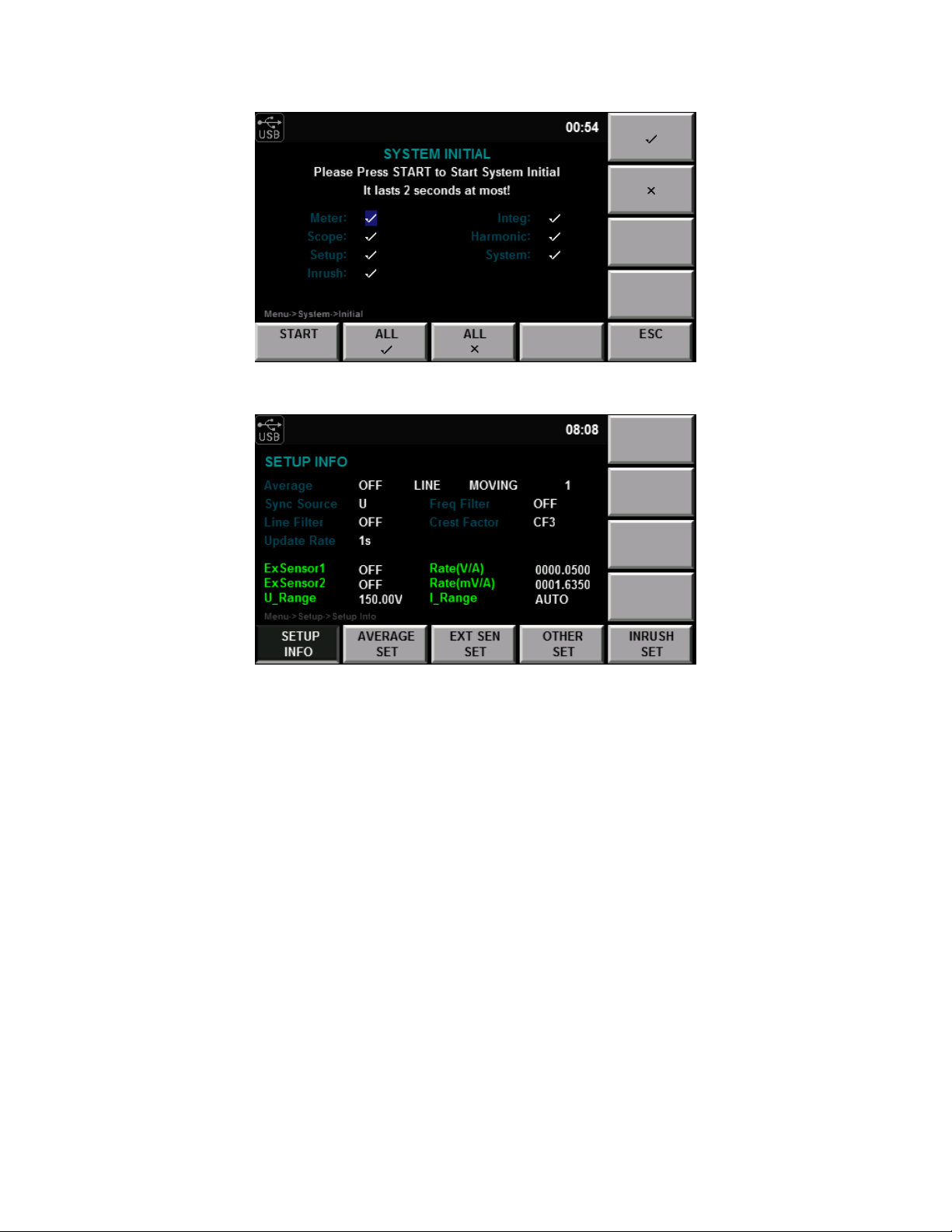

2.1.5 System Initialize Menu

System initialization will bring the manifold functions to their initial states. By navigating the functions listed

on-screen and either selecting the check mark or the “x” via the so-keys, the function will be initialized or le

alone respectively. Figure 2.10

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 22

CHAPTER 2. MENU 12

Figure 2.10: System Initialize Menu

Figure 2.11: Setup Information Screen

2.2 MENU > SETUP menus

From the “MENU” function, the next page is the “SETUP” so-key (Figure 2.11. This screen essentially gives a

summary of the seings controlling measurements.

Page 23

CHAPTER 2. MENU 13

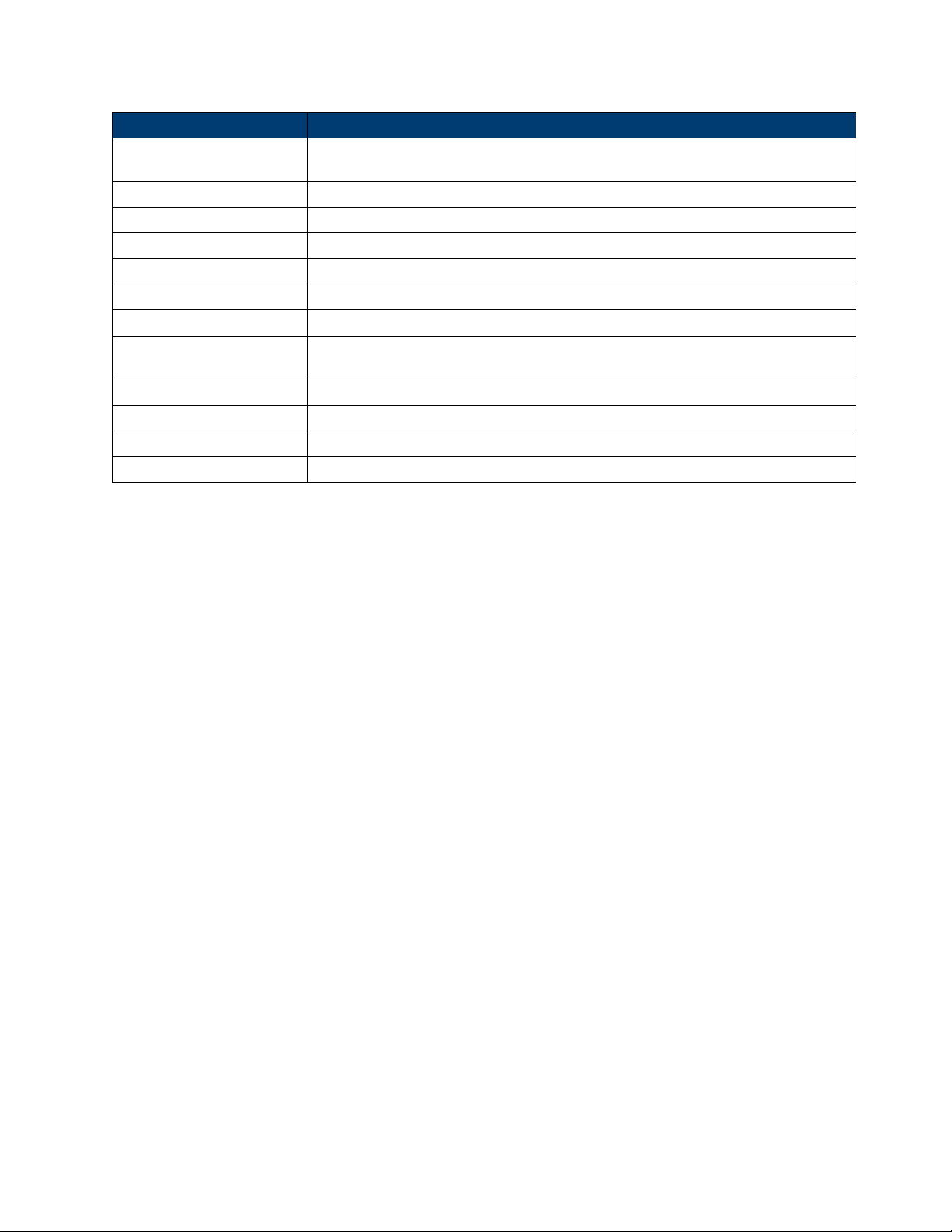

Field Description

Average Listing of the average mode seings. See Averaging Setup

Sync Source The measurement synchronization signal source. See ??

Line Filter The state of the line filter.

Update rate How oen to measure?

Freq Filter The state of the frequency filter.

Crest Factor The Crest Factor seing state

ExSensor1 External Sensor 1 state (on/o)

ExSensor2 External Sensor 2 state (on/o)

U_Range The voltage range seing.

Rate(V/A) External Sensor 1’s scale value

Rate(mV/A) External Sensor 2’s scale value

I_Range The current range seing.

Figure 2.12: Ratio Set Menu

Figure 2.13: Ratio Set Menu

Page 24

CHAPTER 2. MENU 14

Figure 2.14: Ratio Set Menu

Figure 2.15: Ratio Set Menu

Figure 2.16: Calibration Menu

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 25

CHAPTER 2. MENU 15

Figure 2.17: Ratio Setup Menu

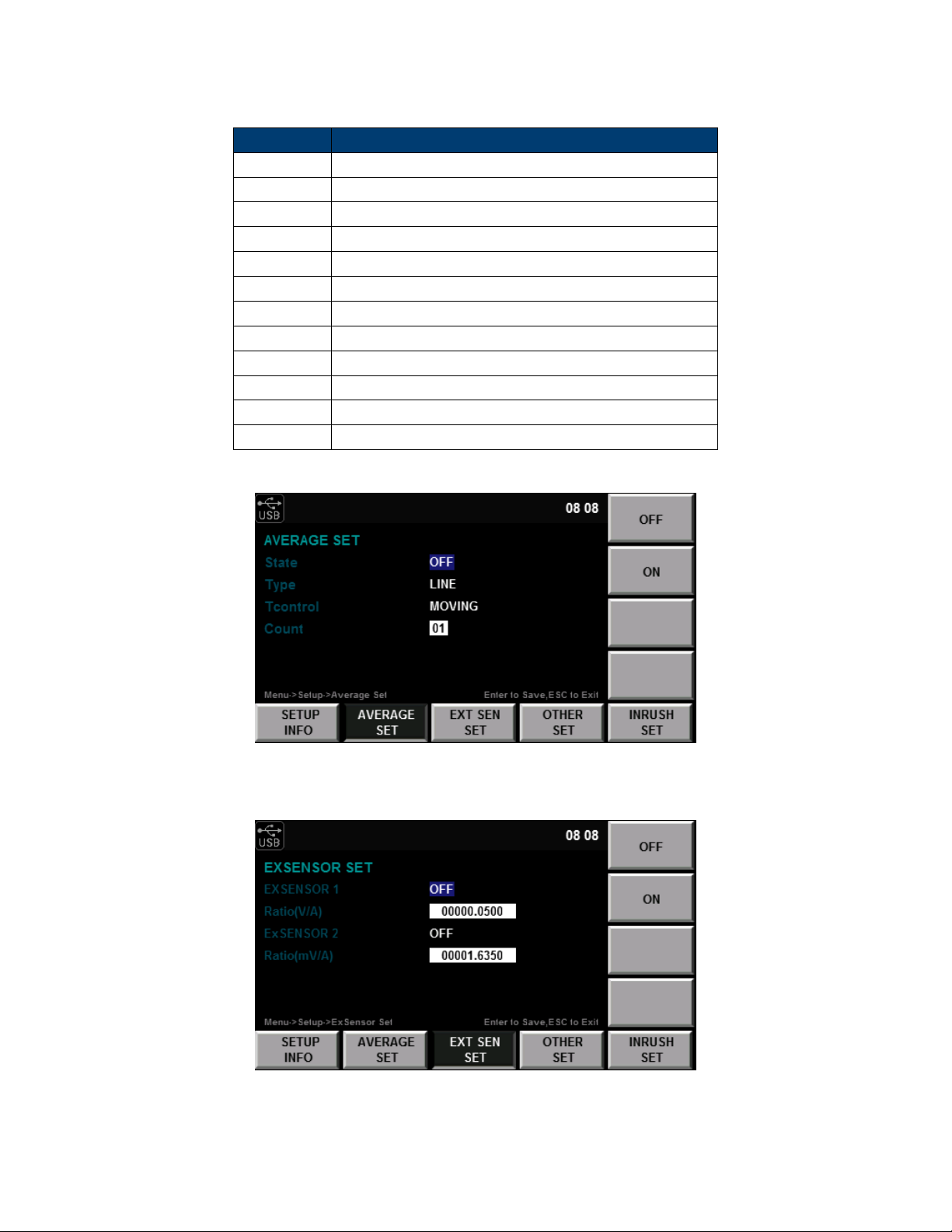

2.2.1 Averaging Setup

2.2.2 External Sensor Setup

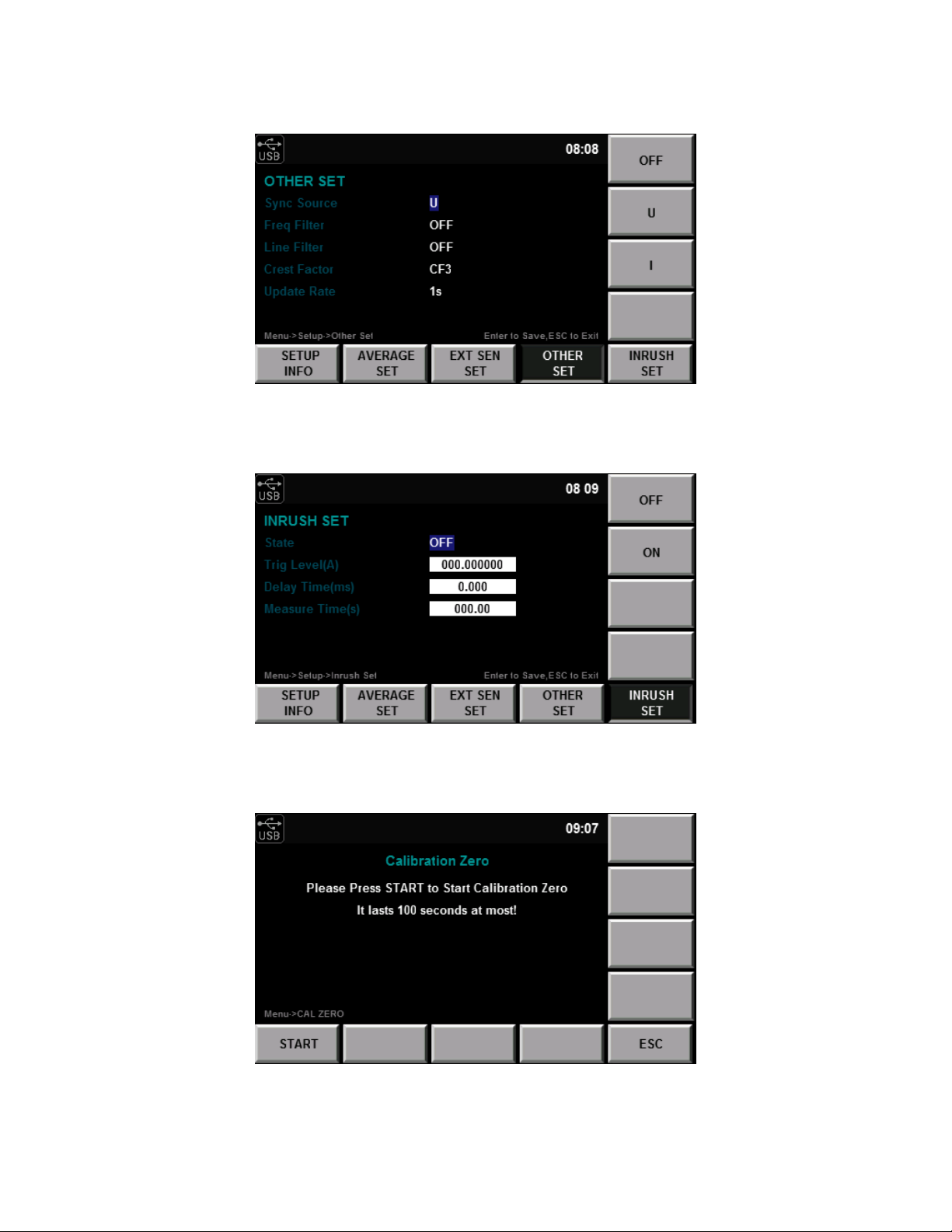

2.2.3 Other seings

2.2.4 Inrush Measurement Setup

2.3 CAL ZERO

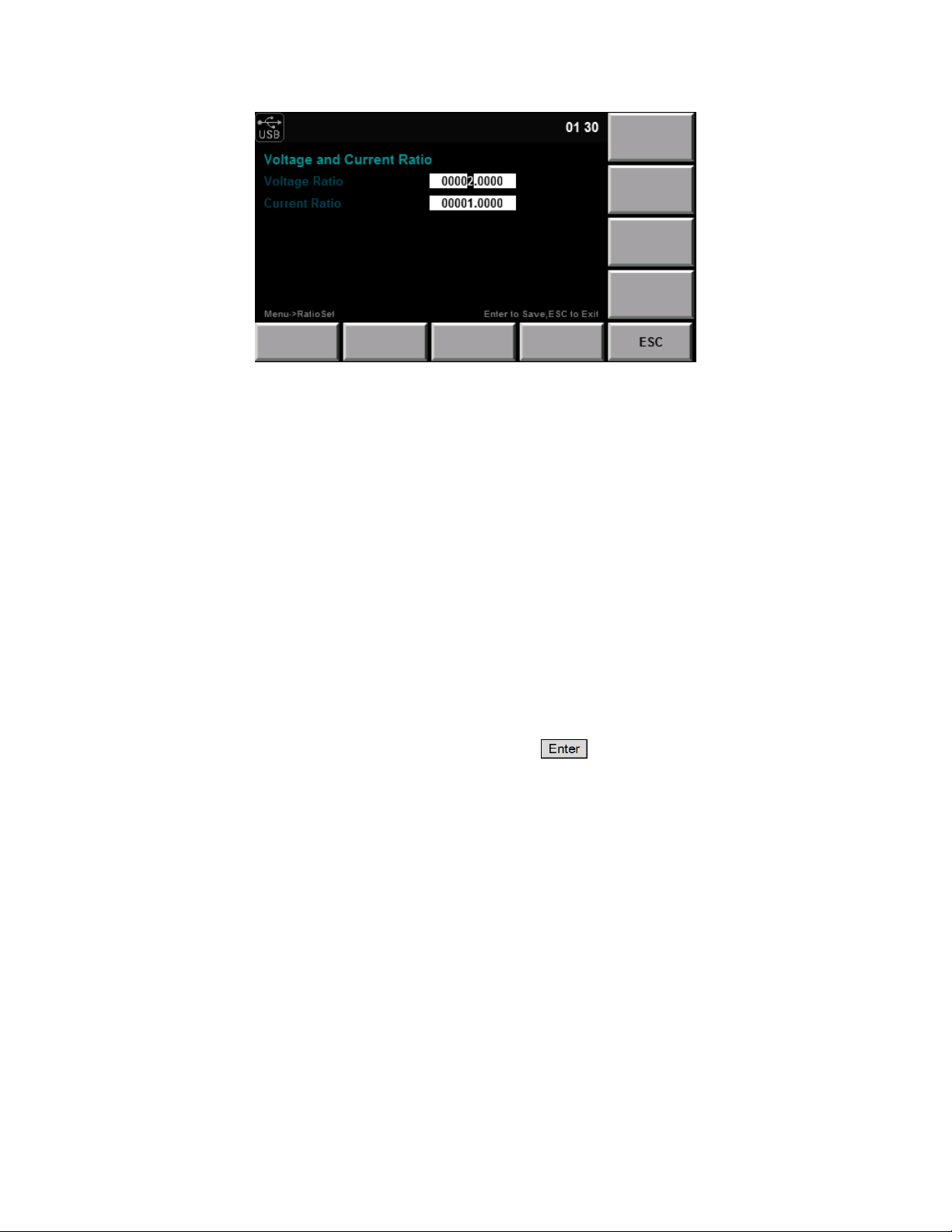

2.4 RATIO SET

This seing has the eect of scaling the measured value of the current and voltage. For example, a 116 V signal

becomes 232 V when the “Voltage Ratio” is set to 2. The Ranges are not eected by this seing, so the 150V range

is still shown and used. Use the arrow keys to move between parameters and digits. Use the knob to change the

value of the selected digit. To commit the seing change, press the buon. See Figure 2.17

Page 26

Chapter 3

External Current Sensor

More information to be added in future versions of this documentation.

When using an external current sensor, the power meter has more current range options. See details Section ??.

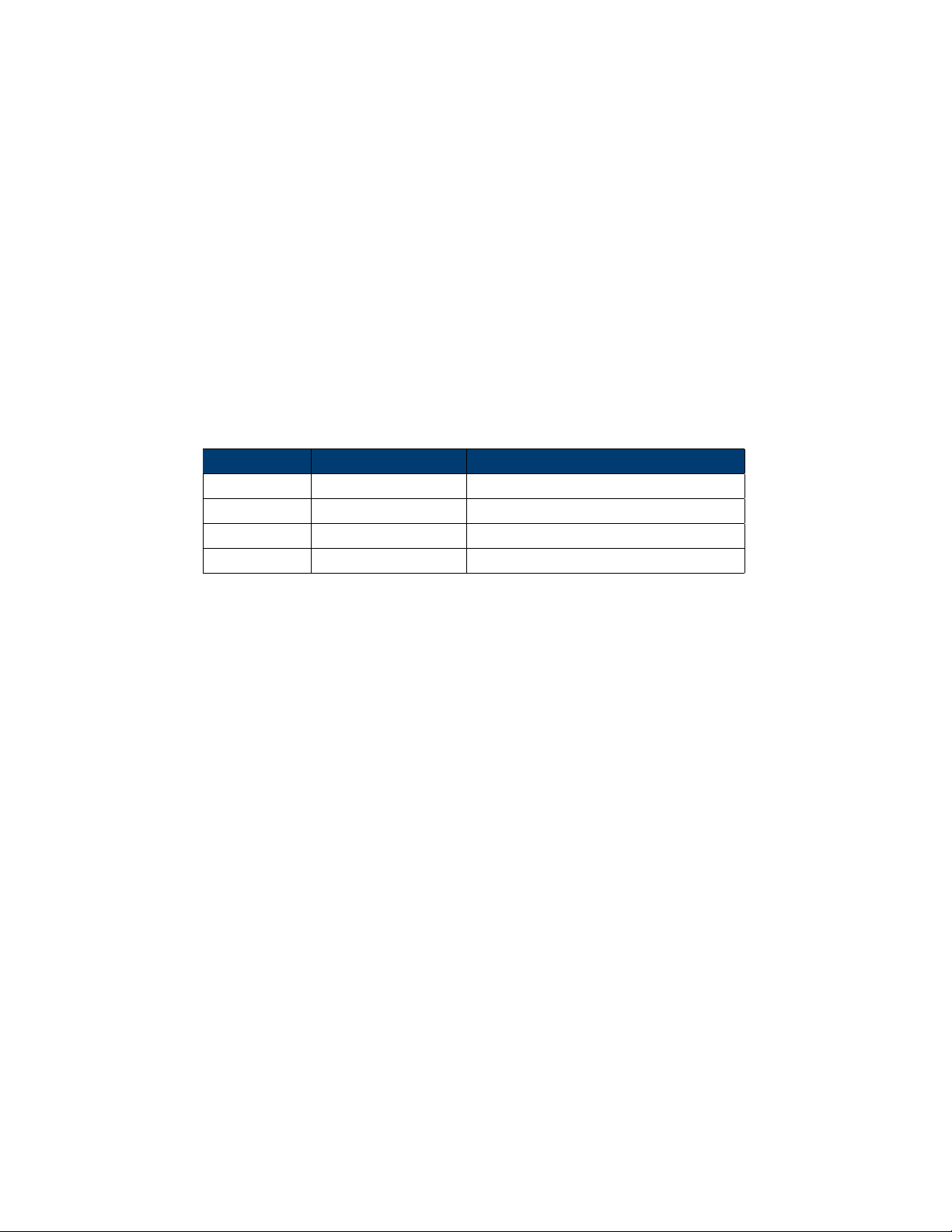

Sensor Input Crest Factor Ranges

EXT1 Crest Factor 3 (CF=3) 2.5 V, 5 V, 10 V

EXT1 Crest Factor 6 (CF=6) 1.25 V, 2.5 V, 5 V

EXT2 Crest Factor 3 (CF=3) 50 mV, 100 mV, 200 mV, 500 mV, 1 V, 2 V

EXT2 Crest Factor 6 (CF=6) 25 mV, 50 mV, 100 mV, 250 mV, 0.5 V, 1 V

Table 3.1: External Sensor Ranges

16

Page 27

Chapter 4

Front Panel Operation

4.1 Measurement Setup

Central to seing the proper range of the instrument is the Crest Factor. Crest factor is the ratio of the peak value

of a waveform to the RMS value of the waveform. For example, a perfect sine wave crest factor RMS value is

0.707*Peak. The crest factor is the inverse of the normalized RMS value, 0.707−1= 1.414. In many cases, like the

current waveform of a AC-DC power supply, the crest factor is a larger value. For accurate measurement, the

signal measured should stay within the measurement range of the instrument. For example, a 100V RMS signal

with a crest factor of 5 has peaks of 500V. If the range selected is smaller than 500V than inaccuracy will occur as

the signal will be clipped.

4.1.1 Crest factor

The Crest Factor, the ratio of the peak to the RMS value, has two seings, 6 or 3. This seing applies to both

current and voltage simultaneously, and modifies the available ranges listed in Section 4.1.2. Essentially, by

knowing the RMS signal level and the peak value, the seing of this parameter is determined. For an 117V RMS AC

line signal with lile distortion and a purely real load (power factor = 1), the peak value is 1.414 ∗ 117V = 165V .

1.414 is the approximate Crest Factor of a Sine wave. So, the appropriate seing will be 3 (CF3).

CrestF actor(CF ) =

As this meter also measures the DC level of the signal, this must also be accounted for when choosing the Crest

Factor. If the the signal will exceed the range of the unit (crest factor * range) then the measurement value will be

clipped and the value inaccurate. Conversely, by choosing a Crest Factor and Range combination that

accommodates the peak value of the signal, a larger crest factor than set may be measured. The trade-o is then

the accuracy, and is listed in the specifications, Chapter 10.

Example (Range=150 V, CF = 6): The maximum input signal and crest factor are as follows:

V

= 100 Range = 150V V

rms

So, a signal with a peak that is 9 times that of the RMS value (Crest Factor 9) is measurable using these seings.

P eak

RM S

maxrange

= 900V

4.1.2 Set Measurement Range

The appropriate measurement range (voltage and current range) must be set for accurate measurement.

17

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 28

CHAPTER 4. FRONT PANEL OPERATION 18

1. In the “Meter” interface Press the so key corresponding to either “U-RANGE” or “A-RANGE”, and use the

knob or the arrow keys to select the voltage or current range desired. See Table 4.1

2. Press the “Enter” key to confirm the seing. Otherwise the instrument will automatically confirm and exit

the seing aer 5 seconds of no activity.

CF 3 CF6

Voltage 15, 30, 60, 150, 300, 600 V 7.5, 15, 30, 75, 150, 300 V

Current 5, 10, 20, 50, 100, 200, 500 mA, 1, 2, 5, 10, 20 A 2.5 ,5 ,10 ,25 ,50 ,100 ,250 mA, 0.5, 1, 2.5, 5, 10 A

Table 4.1: Current and Voltage Ranges per Crest Factor seing

4.2 Voltage and current range

4.2.1 Fixed range

Select the required range from a number of options. For the voltage range, when the crest factor is 3, the

maximum option is “600V” and the minimum option is “15V”. When the crest factor is 6, the maximum option is

“300V” and the minimum option is “7.5V”. See Table 4.1

Measurement accuracy is improved by minimizing the range for a

given input signal.

4.2.2 Auto Range

The measurement range adjusts automatically according to the input signal, and uses same ranges as in Fixed

range mode. See Table 4.1.

Adjustment of the range occurs when the following conditions occur:

Increasing range

• Urms or Irms exceeds 110% of the current range seing.

• When the crest factor is 3, and the peak voltage or current exceeds 330% of the range currently set.

• When the crest factor is 6, and the peak voltage or current exceeds 660% of the range currently set.

Decreasing range

• Urms or Irms is less than or equal to 30% of the current measurement range.

• The crest factor is 3. The value Upk or Ipk of the input signal is less than 300% of the range at the following

level.

• The crest factor is 6. The value Upk or Ipk of the input signal is less than 600 % of the range at the following

level.

The selected automatic range may change when the input is a random

pulse. In this case, a fixed range should be used.

Page 29

CHAPTER 4. FRONT PANEL OPERATION 19

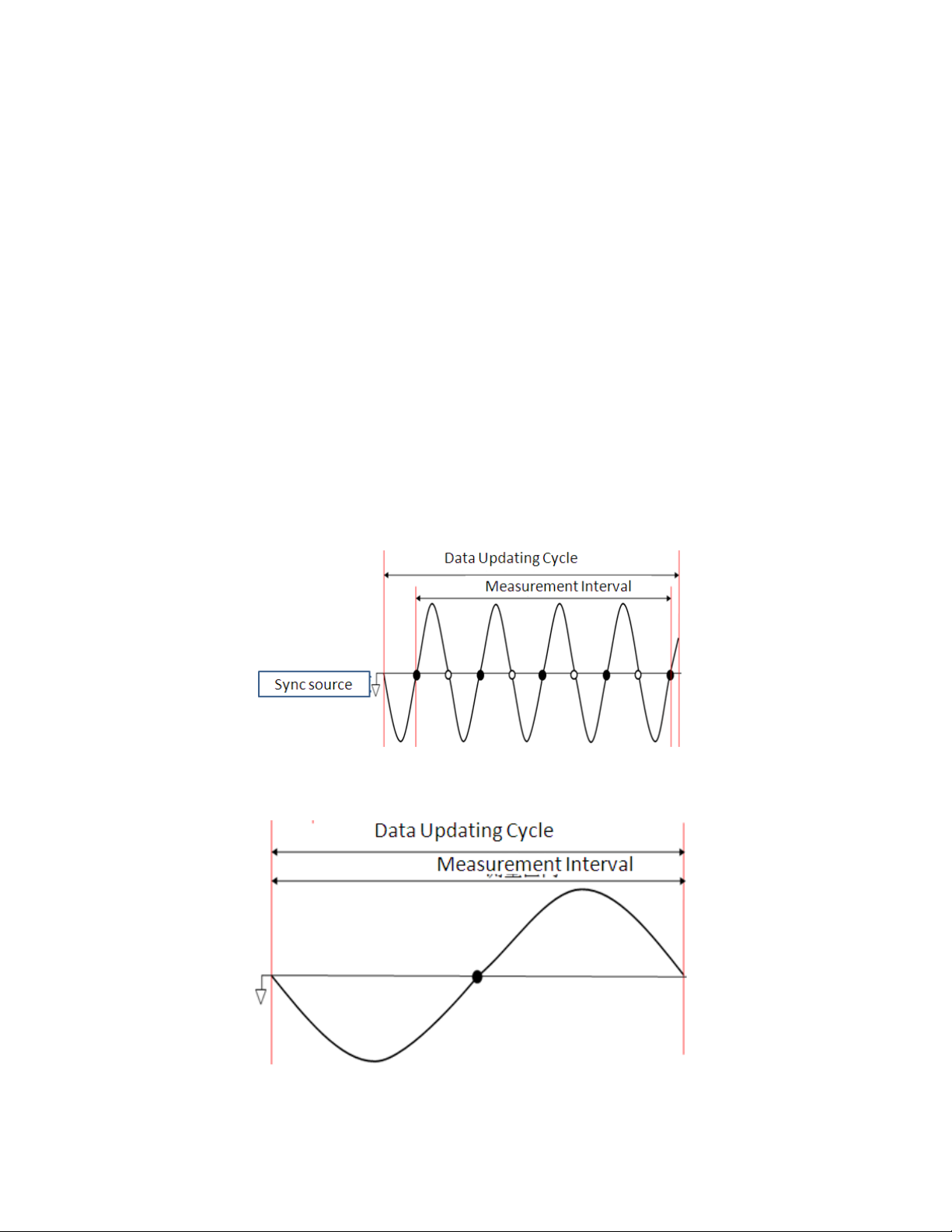

4.3 Measurement interval

The measurement interval, the time during which data is taken. The fundamental frequency of the measured

signals restricts the measurement intervals that yield meaningful results. For example, measuring 10Hz with an

interval of less than the 0.5s seing will not yield stable results. The unit needs a number of cycles to be present to

determine the frequency, and measurement intervals are not synchronized to the input.

Note: The scope timing parameters do not control the measurement interval.

• A cycle is determined by detecting zero crossings.

• Either positive, or negative going transitions of the synchronization source determine the measurement

timing. If the zero crossings do not occur within the set update interval, the entire interval is used for

calculating the various measurements. See Figure 4.1.

The choice of rising or falling transition is determined as that which gives the greatest amount of time.

• For peak value measurements (Ipk+, Upk-, etc.. .), the entire update interval is used. Measurements of Crest

Factor, as it is the Peak to RMS ratio, are also determined using the entire measurement update interval.

• The input signal used as the synchronization source is configurable, and determines the synchronization

with the zero point of that input signal. The overall interval of the voltage, current or data updating cycle

may be selected as the synchronization source.

Figure 4.1: Measurement Timing

Figure 4.2: Measurement Timing 2

Page 30

CHAPTER 4. FRONT PANEL OPERATION 20

The data updating cycle refers to the cycle used for calculating sampling data of the measurement function. It is identical to the set value

of the data updating rate.

The slope refers to signal changes from low level to high level (rising

edge) or from high level to low level (descending edge).

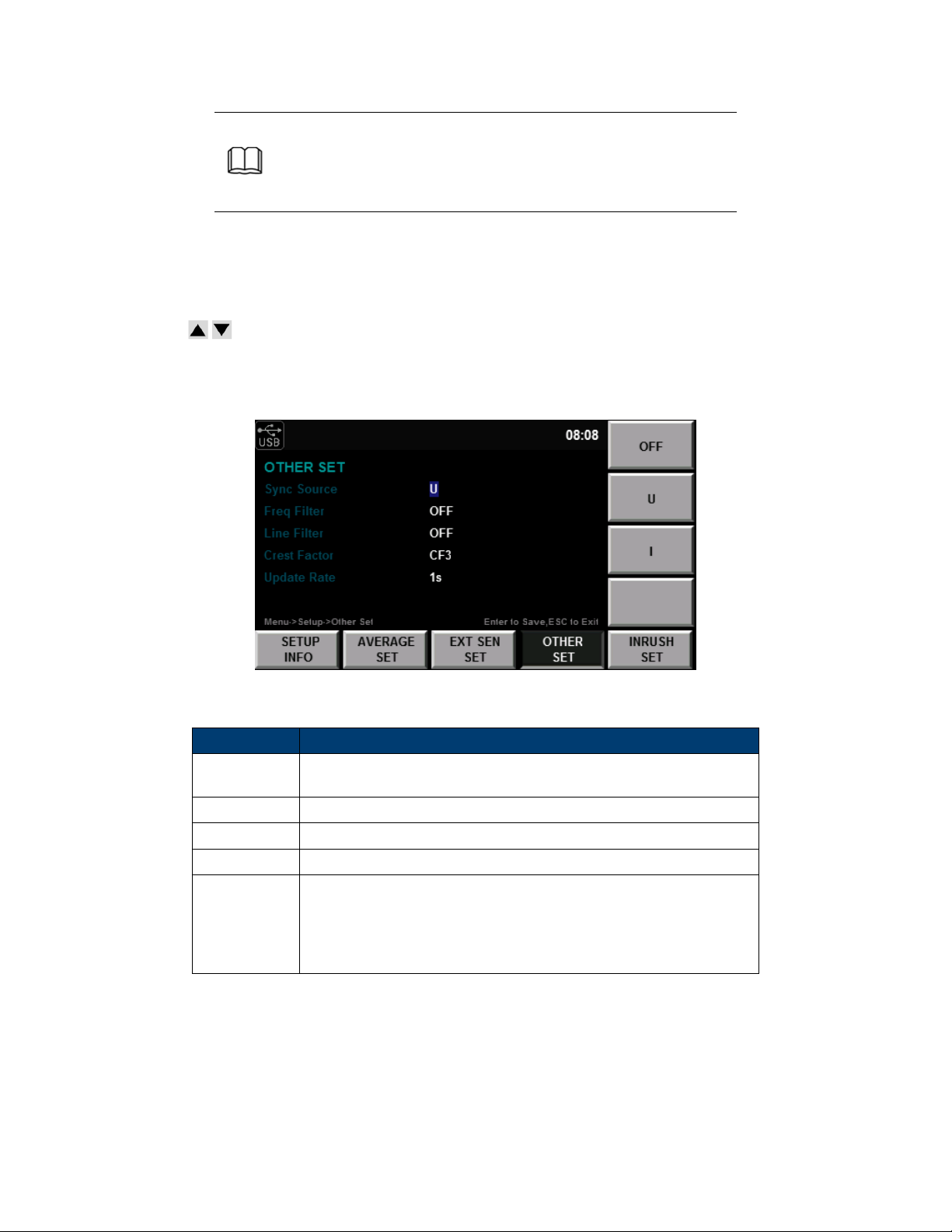

4.4 Filter and Crest Factor Seing

1. Select Menu → SET UP → OTHER SET and enter the OTHER configuration page.

2. Press to select the parameter to be configured (blue font background), and then press the so key

corresponding to the parameter on the right to set the required value, as shown in the Figure ??.

3. Press the Enter key to save the seings.

Figure 4.3: Other Seings Display

Function Description

Sync Source

Freq Filter Enable or disable the Frequency Filter.

Line Filter Enable or disable the Line Filter.

Crest Factor Set the crest factor to 3(CF3), or 6 (CF6) (See Section 4.1.1)

Update Rate

Synchronization Source, the source used to determine the measurement interval. May be set to voltage (U), current (I) or turned o.

Data Update Rate: the capture interval of the voltage, current, power

and other data can be set. When the data updating rate is increased,

rapid load changes of the power system can be measured. Conversely,

when decreased, relative low-frequency signals can be measured. Values = 0.1, 0.25, 0.5, 1, 2, and 5 seconds

Table 4.2: Other Set configuration seings

4.4.1 Filter

Frequency Filter It is inserted in the frequency measurement circuit and may aect frequency measurement. It

can be used for filtering high-frequency components of interference to make the measured frequency parameter

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 31

CHAPTER 4. FRONT PANEL OPERATION 21

more accurate. When the frequency filter is switched on, the voltage or current of no more than 200Hz can be

measured. The cuto frequency is 500HZ.

Line filter It is inserted in the voltage and current measurement circuit and has direct influence on

measurement of the voltage, current and power. When the line filter is switched on, noise and high-frequency

components from the inverter or distortion waveform can be filtered. The cuto frequency is 500HZ.

4.5 Averaging Function

1. Select ⇒ SET UP ⇒ AVERAG SET to enter the configuration page of the averaging function.

2. Press to select the parameter to be configured (blue background), and press the so key

corresponding to the required value. See Figure 4.4.

3. Press the Enter buon to confirm the seing.

Figure 4.4: Averaging Seings

Character Function description

State Enable or disable averaging.

Mode Average mode Line=linear or Exp=cumulative moving average

Type Averaging type. MOVING: moving averaging REPEAT: repeated averaging

Count Set the times of the averaging function.

Table 4.3: Average Seings Menu

Note:

• If the mode of the averaging function is set as EXP (index averaging), the aenuation constant can be set.

• If the mode of the averaging function is set as LINE (linear averaging), the averaging times can be set.

Page 32

CHAPTER 4. FRONT PANEL OPERATION 22

4.5.1 Index averaging

D

n

D

n−1

M

n

k aenuation constant (1-64)

4.5.2 Linear averaging

D

n

M

n−(m−1)

M

n−2

M

n−1

M

n

M the number of average values (1-64)

Dn= D

n−1

Mn− D

+

n−1

k

The value displayed aer the nth index averaging, (D1, the value displayed aer the first averaging, is equal to M1)

The value displayed aer the (n-1)th index averaging

the nth measured data.

Dn=

M

n−(m−1)

+ . . . + M

m

n−2

+ M

n−1

+ M

n

linear average of m values from the (n − (m − 1))thto nthvalue

(n − (m − 1))thmeasured data

(n − 2)thmeasured data

(n − 1)thmeasured data

nthmeasured data

When m can be divided exactly by n, the calculated value is the moving average; when there is no particular

relationship between m and n, the calculated value is the repeated average.

When index averaging is set, averaging is implemented under the harmonic measurement function.

When linear averaging is set, averaging can only be implemented in the conventional measurement function and this mode is not applicable to the harmonic measurement function.

The following measurements are subject to direct averaging:

1. Urms, Umn, Udc, Urmn, Uac, Irms, Imn, Idc, Irmn, Iac, P, S and Q.

2. Ucf, Icf, λ and WPAV are calculated by operation of the averaged Urms, Irms, P and S.

4.5.3 Harmonic measurement averaging

The following measurement functions are subject to direct averaging:

1. U(k), A(k),W(k), S(k) and Q(k).

2. λ(k) is calculated via operation of the averaged W(k) and Q(k).

3. U(%r), A(%r), W(%r) , U(%f), A(%f) and W(%f) are calculated via operation of the averaged U(k), A(k) and

W(k). (k indicates the harmonic times.)

Page 33

Chapter 5

Meter Display

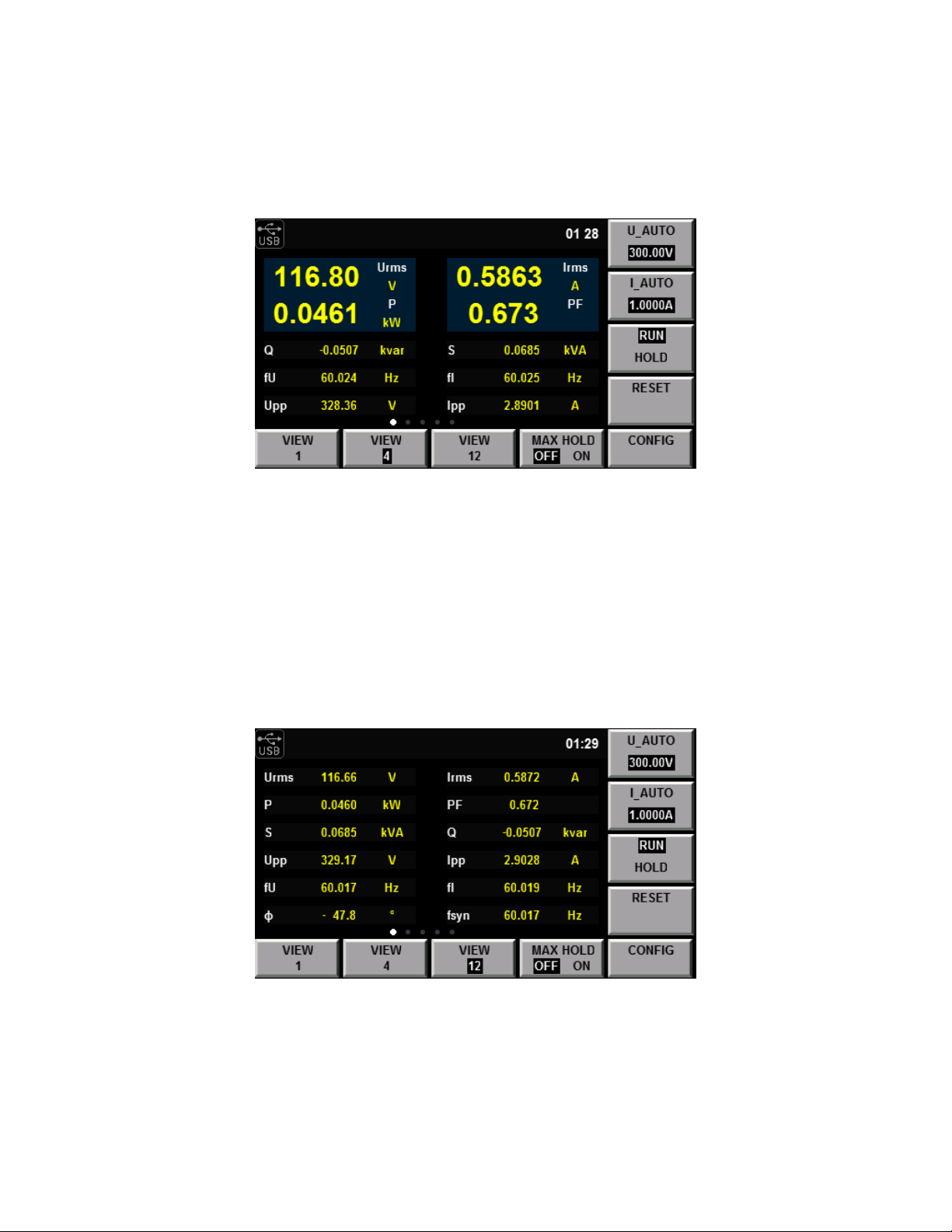

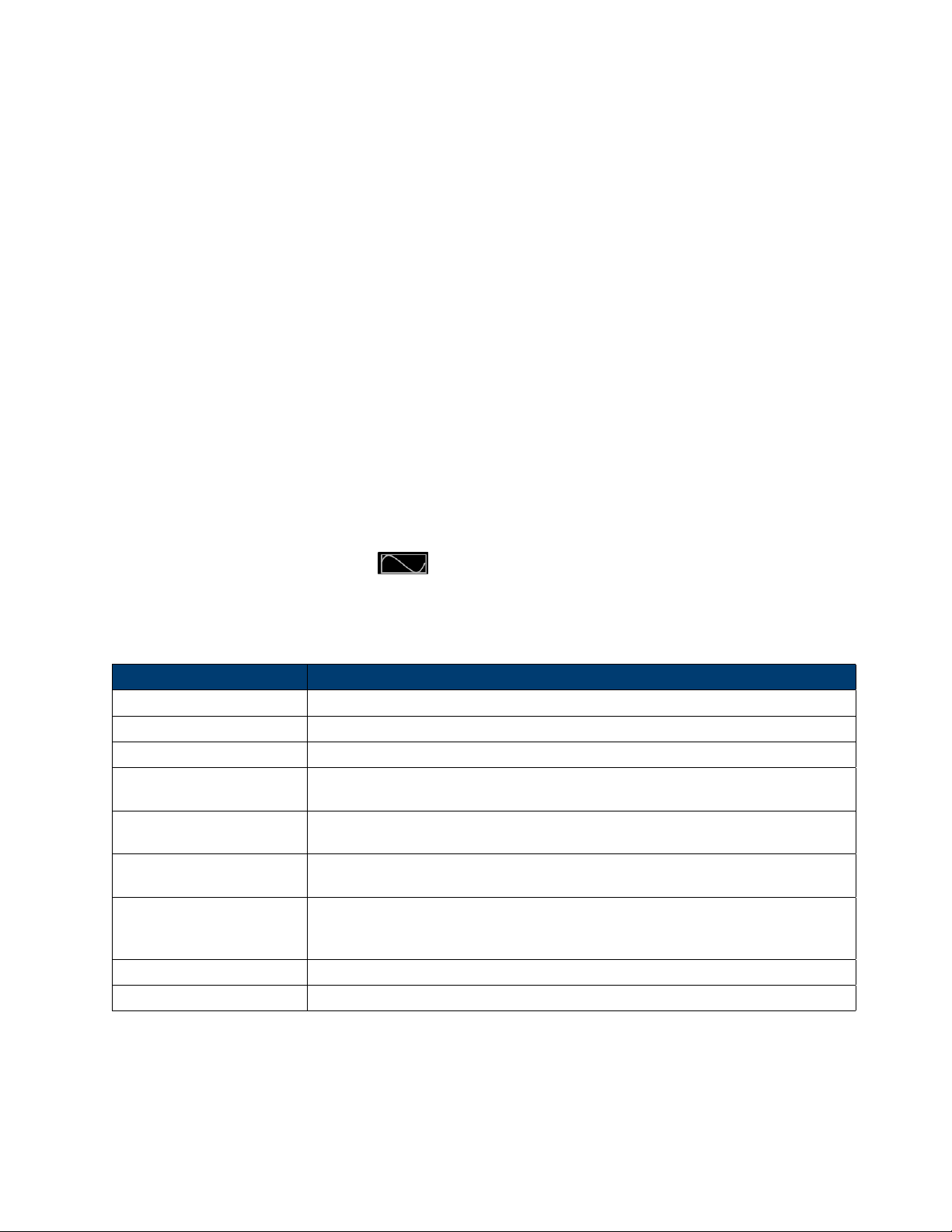

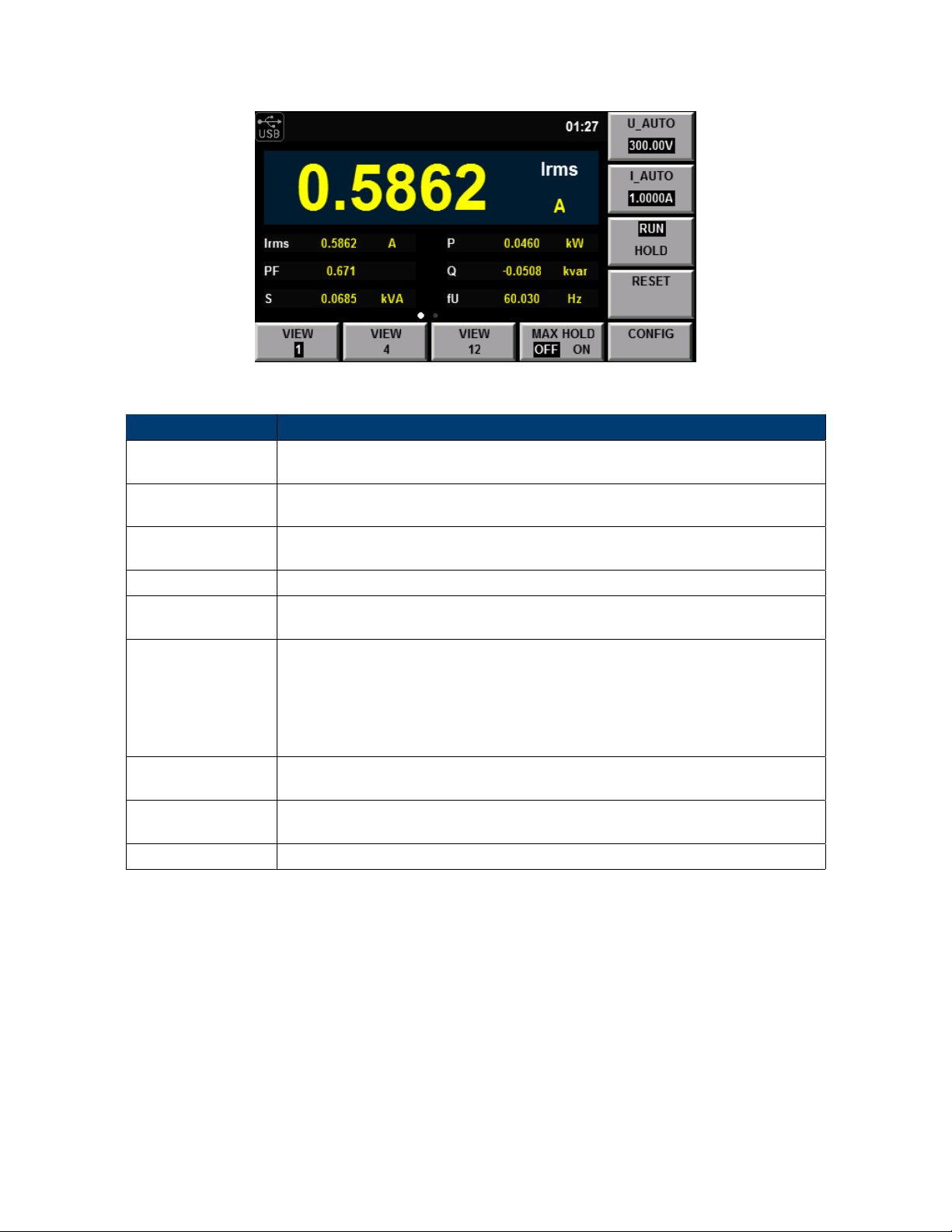

The 5335B has 3 configurable display formats. Each format also allows for 5 dierent configured sets of

measurement. 1 large and 6 small, 4 large and 6 small, or 12 small measurements may be displayed. See

Figures 5.1, 5.2, 5.3.

5.0.1 Operation steps

1. Press

2. The “View” so-keys select the display format (1,4,12). Repeated press of the so-key cycles through the

dierent configurations, up to 5 of them.

3. The “CONFIG” so-key enters the configuration mode for that set of pages.

4. The “FUNC” so-key cycles through the sets of measurements available for Power (P), Current (I), and

Voltage (U).

5. To change the measurements shown on a page, use the arrow keys and move the cursor to an on-screen

parameter, and select the desired measurement from the so-keys on the right of the display.

6. To add or remove a page press the “INSERT PAGE” or “DELETE PAGE” respectively. 1 to 5 pages are

supported.

Figure 5.1: 1 main measurement

23

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 34

CHAPTER 5. METER DISPLAY 24

Figure 5.2: 4 main measurements

Figure 5.3: 12 main measurements

Page 35

Chapter 6

Waveform Display Function

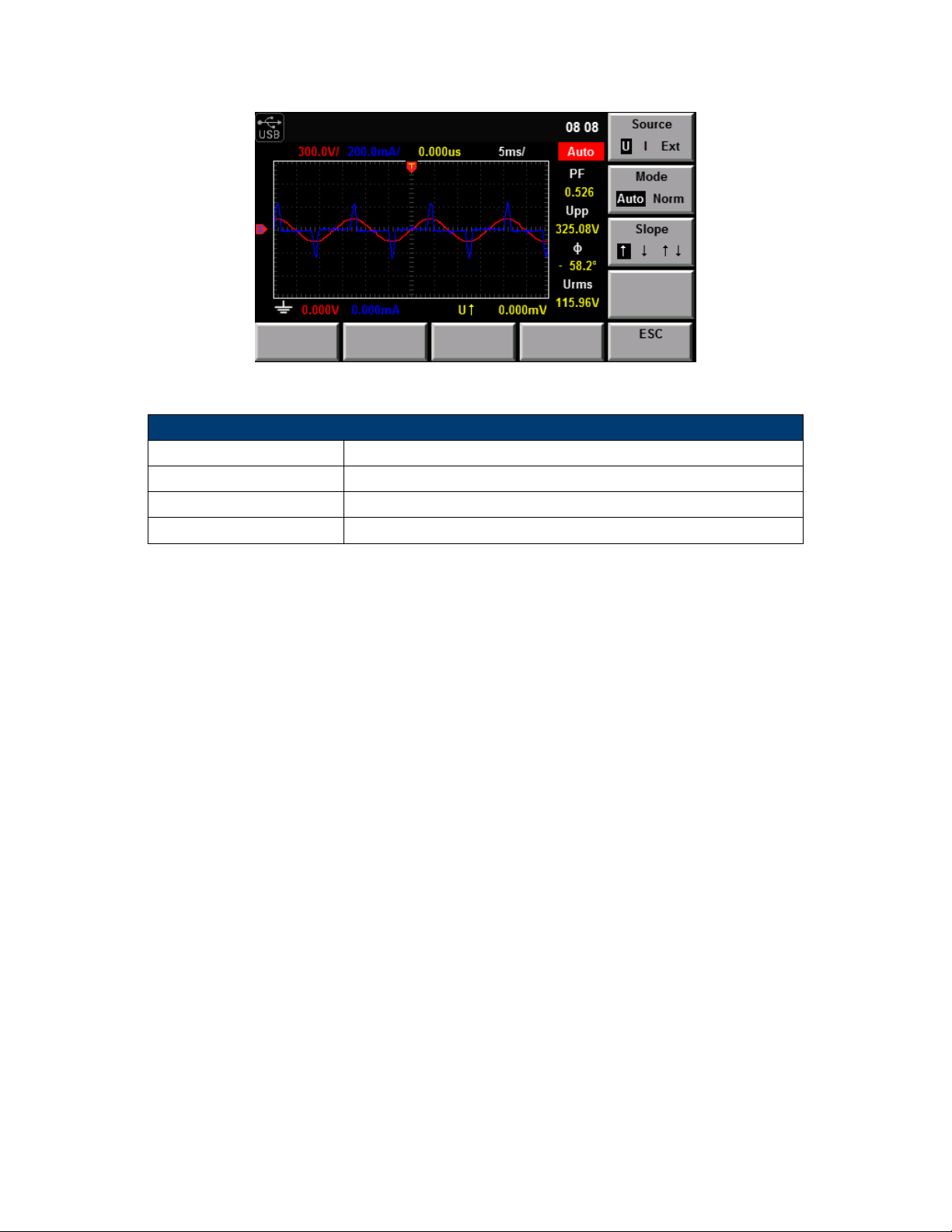

The 5335B power meter displays waveform representations of the sampled data measured. This function is

designed to be similar to an oscilloscope with many of the typical functions of oscilloscopes available, like trigger,

run/stop and single trigger. The capture of data is not limited to that displayed onscreen, the measurement

interval is also involved. For example, measuring a 15Hz signal with the interval set to 0.1s does not allow for

stable measurement of the frequency. The waveform is however still viewable.

6.0.1 Introduction of so keys on the interface

To enter the waveform function press the buon.

Introduction of waveform display interface

The trigger status is described as follows:

Parameter name Parameter descriptions

V_RANGE Voltage range seing: press to set the voltage range

A_RANGE Current range seing: press to set the current range

RUN/STOP Run/stop: press to run or stop waveform capture

SINGLE

SCOPE(U/A/UA)

KNOB SEL (U/A/TL/TD/Td)

AUTO

TRIG SET Trigger seing

MEASURE SET Measurement seing

Single measurement: pressing this stops capture and proceeds with a single capture

of data following a trigger event.

Select the waveform to be displayed on the screen: voltage/current/voltage and current.

Knob selection: the following variables can beadjusted by rotating the knob: vertical

voltage position/vertical current position/trigger level/trigger delay/level calibration.

Automatic adjustment: when the so key corresponding to this parameter is

pressed, the power meter will automatically calibrate the input signal to display

the best eect of the input signal.

Table 6.1: Waveform Display Parameters

25

Page 36

CHAPTER 6. WAVEFORM DISPLAY F UNCTION 26

Figure 6.1: Waveform Display Details

Trigger status Instruction

Auto

Auto?

Trig

Trig?

Stop

When the trigger mode is set as Auto, the trigger status Auto will be displayed aer

triggering.

When the trigger mode is set as Auto, the trigger status will be Auto in the case of

no triggering?

When the trigger mode is set as Normal, the trigger status Trig will be displayed

aer triggering.

When the trigger mode is set as Normal, the trigger status will be Trig in the case of

no triggering?

When the “Stop” so key in the waveform display interface is pressed, the trigger

status Stop will be displayed.

Table 6.2: Trigger Statuses

6.0.2 Vertical calibration

When the crest factor CF is 3, the selected voltage range and current range will be subject to vertical calibration

(voltage/grid, current/grid). When CF is 6, the selected voltage range and current range will be subject to two-time

vertical calibration (voltage/grid, current/grid).

6.0.3 Horizontal calibration

When the “KNOB SEL” so key is pressed and “T/d” is selected, horizontal calibration (scanning speed) adjusted

by rotating the knob. In this case, time/grid information changes can be observed on the screen by rotating the

knob and changing the horizontal (time/grid) seing. When acquisition is run, the sampling rate can be changed

by adjusting the horizontal calibration knob. When acquisition is stopped, sampling data can be amplified by

adjusting the horizontal calibration knob.

6.0.4 Trigger delay

When the KNOB SEL so key is pressed and “TD” is selected, the trigger delay can be adjusted by rotating the

knob. In this case, when the knob is rotated, the trigger point will move horizontally and the delay time will be

displayed on the screen. When the delay time is changed, the trigger point ( ) will move horizontally, and the

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 37

CHAPTER 6. WAVEFORM DISPLAY F UNCTION 27

distance between the trigger point and the horizontal center will be indicated. The trigger point is displayed along

the top of the display grid.

6.0.5 Trigger waveform

When the specified trigger conditions are satisfied, the trigger waveform will be displayed, and the triggering time

point is called trigger point. The trigger point is generally displayed in the le of the display screen. Following the

trigger point, the waveform is displayed on the display screen from le to right over time. Before using the trigger

function, the user needs to configure the following parameters:

Trigger mode The trigger mode refers to conditions for updating the contents displayed on the screen. Including

the Auto model and Normal mode Auto mode: the displayed waveform is updated in case of triggering in

the pause time and automatically updated in case of no triggering in the pause time. Normal mode: the

displayed content is updated in case of triggering and not updated in case of no triggering.

Trigger source The trigger source is used for generating triggering conditions. The user can select the trigger

source from the input signal of the input unit and the external clock signal.

Trigger slope The slope refers to signal changes from low level to high level (rising edge) or from high level to

low level (descending edge). When used as a triggering condition, the slope is called trigger slope.

Trigger level Level of trigger slope: triggering occurs when the level of the signal of the trigger source reaches

the set trigger level under the specified trigger slope conditions. When the “KNOB SEL” so key is pressed

and “TL” is selected, the trigger level can be adjusted by rotating the knob. In this case, the trigger level can

be changed by rotating the knob, and changes in the trigger level can be observed on the screen.

6.1 Adjustment of Measurement Parameters

You can rotate the knob to adjust the vertical calibration, horizontal calibration, trigger delay and trigger level of

the waveform display interface. Detailed steps are as follows:

6.1.1 Operation steps

1. Press to enter the waveform display interface.

2. In the waveform display interface Press the so key corresponding to the “KNOB SEL” parameter and select

the parameter to be adjusted. When “KNOB SEL” is pressed once, the parameter to be adjusted via the knob

will be switched in sequence among U/A/TL/TD/Td.

3. When the parameter is adjusted by rotating the knob, the interface will display changes of the

corresponding value.

6.2 Seing of Trigger Configuration

When you need to enable the trigger function, you should select the trigger source, trigger mode, trigger slope and

other trigger-related configuration. Detailed steps are as follows:

Operation steps

1. Press to enter the waveform display interface.

Page 38

CHAPTER 6. WAVEFORM DISPLAY F UNCTION 28

Figure 6.2: Trigger Setup Screen

Projects Specification

Interface type BNC interface

Input level TTL

Minimum pulse width 1µs

Trigger delay time Within (1µs + 3 sampling cycles)

Table 6.3: External Trigger Input Specifications

2. In the waveform display interface Press the so key corresponding to the “TIRG SET” parameter to enter the

trigger seing interface, as shown below.

3. Press the right so key corresponding to the parameter to select the required trigger configuration.

Source trigger source

Mode trigger mode

Slope trigger slope

6.2.1 External trigger input (Ext)

When the trigger source is set as Ext, input the trigger signal into the external signal input interface

(Synchronous) of the rear panel according to the following specifications.

NOTE: When the voltage higher than 0-3.3V is applied on the external signal input interface (Synchronous), the

instrument may be damaged.

Minimum pulse width refers to the width of the high or low trigger level, at least 1µs.

Trigger delay time refers to the delay between the appearance of the trigger level and the response of CPU,

within (1µs + 3 sampling cycles).

Page 39

Chapter 7

Harmonic Measurement Function

This chapter describes the features and use of the harmonic measurement function of the 5335B power meter in

details.

7.1 Basic Concepts

With the 100kHZ bandwidth, the 5335B power meter can realize harmonic measurement of high speed and wide

dynamic range. The voltage, current, active power, reactive power and phase of harmonics and total harmonic

distortion (THD) factor can be tested in the harmonic mode. In addition, the 5335B power meter can be used for

multiple harmonic measurements, 50-order harmonics of the fundamental frequency at most.

The 5335B power meter displays harmonic parameters in the list or bar chart form so as to provide clear analysis

of test results.

Introduction of so keys on the interface

Select the !@!@! buon, and the initial harmonic measurement interface below will appear.

Description of information of harmonic measurement interface:

Parameter name Parameter descriptions

V_RANGE

A_RANGE

RUN/HOLD

RESET Reset.

FUNC(W/A/V) Function options (power/current/voltage)

BAR Displayed in the bar chart form

LIST Displayed in the list form

SETUP Parameter seing.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

Voltage range seing: press the so key corresponding to this parameter to set the

voltage range.

Current range seing: press the so key corresponding to this parameter to set the

current range.

RUN/HOLD: press the so key corresponding to this parameter to run/hold the harmonic status.

Table 7.1: Harmonic Measurement Parameters

29

TestEquipmentDepot.com

Page 40

CHAPTER 7. HARMONIC MEASUREMENT F UNCTION 30

7.1.1 Introduction of harmonic information

When the “BAR” buon is selected in the harmonic measurement interface, the bar chart of harmonic

measurement results will be displayed. The bar chart is used for displaying the percentage of dierent harmonics.

Harmonics can be displayed in the whole sequence, odd sequence and even sequence. The following is the

whole-sequence harmonic bar chart.

Description of interface information:

Total harmonic parameter: including the total harmonic distortion (THD) factor and total harmonic content.

When dierent measurement functions are selected, dierent harmonic parameters will be displayed. When the

so key corresponding to the “FUNC” parameter is pressed, dierent measurement functions can be selected.

W/A/U can be selected as the measurement function in sequence when this buon is pressed once. Parameter

meanings of dierent functions are as follows:

Power (W) total harmonic distortion rate of power and total harmonic power

Current (A) total harmonic distortion rate of current and total harmonic current

Voltage (U): total harmonic distortion rate of voltage and total harmonic voltage

Single-order harmonic parameters: displaying the frequency, harmonic content, harmonic distortion factor and

phase of single-order harmonics. The user can rotate the knob to select the single-order harmonics to be

displayed. The selected harmonics are displayed in red in the bar chart form.

Description of harmonic list interface

When the “LIST” buon is selected in the harmonic measurement interface, the list of harmonic measurement

results will be displayed. This list is used for showing the voltage, current, active power, reactive power, phase and

total harmonic distortion (THD) factor of dierent harmonics. Harmonic lists can be displayed in the whole

sequence, odd sequence and even sequence. Below is a whole-sequence harmonic list.

Harmonic content: this list is used for showing all harmonic contents of single-order harmonics, including the

voltage, current and power. You can view other harmonic parameters by operating the Le/Right buon to turn

pages. In this case, the line scroll bar and current page are shown in bright white circles. Measurement parameters

are described in the following table:

Harmonic order list: this LIST can show the data of one-order to 50-order harmonic signals. These data can be

displayed in the whole sequence, odd sequence and even sequence. The rows which are not displayed, i.e.

single-order harmonic data which are not displayed, can be presented by operating the Up/Down buon. In this

case, the row scroll bar and current page in displayed in bright blue bars.

7.2 Seing of Harmonic Measurement Configuration

You can set the distortion factor calculation formula, PLL source, harmonic sequence and harmonic analysis times

of harmonic measurement. Specific steps are as follows:

Operation steps

1. Press to enter the harmonic measurement interface.

2. Press the so key corresponding to the “SETUP” parameter in the harmonic measurement display interface

to enter the harmonic parameter configuration interface. Press the “ ” buon to select the required

parameter, as shown in Figure 7.1.

Page 41

CHAPTER 7. HARMONIC MEASUREMENT F UNCTION 31

Abbreviations Instruction

U(V) Voltage

φUI(◦) Phase dierence of k-order harmonic voltage and harmonic current

A(mA) Current

φUU(◦) Phase dierence of harmonic voltage U(k) and fundamental wave U(1)

W(W) Active power

φII(◦) Phase dierence of harmonic current I(k) and fundamental waveI(1)

S(VA) Apparent power

U(%r)/ U(%f) Harmonic distortion factor of voltage

Q(var) Reactive power

A(%r)/ A(%f) Harmonic distortion factor of current

λ() Power factor

W(%r)/W(%f) Harmonic distortion factor of active power

Table 7.2: Measurement Parameters

Figure 7.1: Harmonic Measurement Setup Menu

7.2.1 Parameter descriptions:

Distortion factor calculation formula:

The following two formulas can be selected for calculation of the distortion factor.

%r using all harmonic measurement data from the minimum harmonic order (0) to the maximum harmonic order

(within the upper limit of analysis orders) as the denominator.

%f using the data of fundamental wave (1-order) components as the denominator.

Page 42

CHAPTER 7. HARMONIC MEASUREMENT F UNCTION 32

Parameters Instruction

Distortion factor calculation formula. % r: displaying harmonics in the form of per-

THD Formal

centage to the overall current (voltage, power) amplitude of all harmonics. % f: displaying harmonics in the form of percentage to the fundamental wave current (voltage, power).

PLL Source

Select the PLL (Phase Locked Loop) source: U/I/OFF. Used for determining the fundamental wave cycle as the reference for analysis of harmonic orders.

Serial Harmonic sequence: whole sequence/odd sequence/even sequences

Set the harmonic analysis orders (1-50). You can specify the harmonic measure-

Order Max

ment range. These specified analysis orders are used for calculating the value of the

distortion factor.

Table 7.3: Harmonic Parameters

The distortion factor calculation formulas and methods of dierent measurement functions are as follows:

Measurement function %r %f (7.1)

Harmonic distortion factor of voltage

Harmonic distortion factor of current

Harmonic distortion factor of active power

Total harmonic distortion rate of voltage

Total harmonic distortion rate of current

Total harmonic distortion rate of active power

s

s

U(k)

U(total)

I(k)

I(total)

P (k)

P (total)

max

P

k=2

U(total)

s

max

P

k=2

I(total)

max

P

k=2

P (total)

U(k)

I(k)

P (k)

U(k)

U(1)

I(k)

I(1)

P (k)

P (1)

s

max

P

2

2

2

k=2

U(1)

s

max

P

k=2

I(1)

s

max

P

k=2

U(k)

I(k)

P (k)

P (1)

2

2

2

(7.2)

(7.3)

(7.4)

(7.5)

(7.6)

(7.7)

NOTE Total harmonics are calculated as follows: U (total) =

max

P (total) =

P

P (k) . k indicates the harmonic order, and max indicates the upper limit of analysis orders. max is

k=0

s

max

P

U(k)2, I(total) =

k=0

s

max

P

k=0

I(k)2,

determined by the frequency of PLL source automatically, 50 orders at most.

7.2.2 PLL source

In the harmonic mode, 5335B adopts PLL to multiply the frequency of the input signal. The frequency

multiplication output signal is used as the A/D sampling clock in the instrument so as to achieve the purpose of

synchronous sampling. Therefore, the frequency of the signal of the PLL source can determine the A/D sampling

clock in the instrument. However, the quality of the signal of the PLL source may aect the stability and accuracy

of sampling data.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 43

CHAPTER 7. HARMONIC MEASUREMENT F UNCTION 33

7.2.2.1 PLL source selection

The voltage or current of the input unit can be selected as the PLL source. Used for determining the fundamental

wave cycle as the reference for analysis of harmonic orders. The fundamental wave frequency of the PLL source is

10Hz to 1.2kHz.

7.2.2.2 Considerations for selection of PLL source

Please select the signal with the same cycle as that of the harmonic measurement object signal. In order to stably

measure harmonics, select the input signal with lile distortion as the PLL source. If the fundamental wave

frequency of the PLL source changes or the fundamental wave frequency cannot be measured as a result of

waveform distortion, accurate measurement results may not be obtained. When the test object is a switch type

power supply and the voltage signal is subject to less distortion than the current signal, it is recommended to use

the voltage as the PLL source.

7.2.2.3 Signal level of PLL source

If the amplitude level of the signal input into the unit as the PLL source is small relative to the range,

synchronization with PLL will fail. If the crest factor is set as 3, the amplitude level of the PLL source should

exceed 50% of the range at least during seing of the range. If the crest factor is set as 6, the amplitude level of the

PLL source should exceed 100% of the range at least during seing of the range.

1

When the fundamental wave frequency is lower than 440Hz and contains high-frequency components, it is

recommended to turn on the frequency filter. This filter only applies to the frequency measurement circuit.

If the frequency of the PLL source changes, the correct measured value will be displayed aer data are updated

several times. The frequency of the PLL source needs to be tested again via the PLL circuit in the instrument in

case of changes of the PLL source or its frequency, the correct measured value cannot be obtained at once.

7.2.3 Harmonic analysis order

The harmonic analysis order k is an integer number ranging from 0 to the upper limit of analysis orders. Zero

indicates the DC component. The upper limit of analysis orders is automatically determined by the frequency of

the PLL source. The upper limit of harmonic analysis orders can be determined automatically or set manually.

Take the smaller value. 50 orders at most The relationship between the upper limit of harmonic analysis orders

and the fundamental wave frequency of the PLL source is shown in the table below.

PLL fundamental frequency

10Hz – 75Hz

75 Hz – 150 Hz

150 Hz – 300 Hz

300 Hz – 600 Hz

600 Hz – 1200 Hz

Sampling rate Window width Harmonic order upper limit

f*1024 1 50

f*512 2 32

f*256 4 16

f*128 8 8

f*64 16 4

NOTE The upper limit of analysis orders may be reduced.

NOTE If the analysis window determined by the fundamental wave frequency of the PLL source is longer than the

data updating cycle, no harmonic data will be detected. In this case, the data updating cycle should be reduced.

For example, when the fundamental wave frequency of the PLL source is 10Hz (cycle: 100ms), the analysis window

1

When the fundamental wave frequency is no more than 200Hz, the frequency filter must be turned on.

Page 44

CHAPTER 7. HARMONIC MEASUREMENT F UNCTION 34

is one-wave long, and the data measurement interval is 100ms. In this case, the harmonic measurement time is

approximately morethan or equal to 150ms (data measurement interval and data processing time). Therefore,

please select the data updating rate of 250ms or more for measurement and display of harmonic data.

Page 45

Chapter 8

Integral Operation Function

This chapter describes the features and use of the integral function of the 5335B power meter in details.

8.1 Basic Concepts

The 5335B power meter can be used for integral operation of the current and power of the input unit. Technical

indicators can be calculated. In addition, the range can be switched automatically in the Buy and Sell modes

according to the input level so as to accurately complete integrate measurement.

During operation of the air-conditioner, refrigerator, induction cook and other household appliances, the working

status will change frequently, resulting in changes of the working current in a large scale. The current may

decrease of dozens of amperes to a few milliamperes. Ordinary power measuring instruments can only be used for

integral measurement within one range. If the measured value exceeds the current maximum range, the

measurement result is inaccurate. You need to manually switch the range before integral measurement. Integral

measurement of equipment subject to large current changes cannot be performed continuously. The IT9120 series

power meter can automatically switch the range in the integral mode. Therefore, errors of integral measurement

caused by manual range switching can be eliminated, and the power consumption of household appliances can be

measured more accurately. See the schematic diagram below.

Figure 8.1: Range Switching

35

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 46

CHAPTER 8. INTEGRAL OPERATION FUNCTION 36

Figure 8.2: Meter Display

Parameter name Parameter descriptions

V_RANGE

A_RANGE

RUN/HOLD

RESET Reset.

FUNC(w/q/AV)

LARGE(WP/WP+/WP, q/q+/q-, WPAV)

START

STOP

SETUP Set relevant parameters of integral measurement.

Voltage range seing: press the so key corresponding to this parameter to set the

voltage range.

Current range seing: press the so key corresponding to this parameter to set the

current range.

Run/hold: press the so key corresponding to this parameter to run or hold the

integral function.

Selection of the integral function: active power integral (W), current integral (q) and

average active power integral (AV).

Selection of the item to be displayed in a amplified manner: WP (wa hour, the sum

of positive and minus wa hours), WP+ (the consumption of positive wa hours),

WP- (the negative wa hours of feedback power), q (ampere hour, the sum of positive and negative Ampere hours), q+ (the consumption of positive Ampere hours),

q- (the negative ampere hours of feedback power) and WPAV (average active powerintegral).

Integral Start buon In the manual start mode, the integral function can be enabled

by pressing the so key corresponding to this parameter.

Integral Stop buon In the manual stop mode, the integral function can be disabled

by pressing the so key corresponding to this parameter.

Table 8.1: Integral Measurement So Keys

8.2 Introduction of so keys on the interface

When the “Integ” buon is pressed, the initial integral measurement interface below will appear.

Description of information of integral measurement interface:

8.3 Integral measurement display information

Description of measurement information:

Page 47

CHAPTER 8. INTEGRAL OPERATION FUNCTION 37

Character Function description

Mode

State Display the current status of the integral function.

Start: displayed when the integral function is working.

Stop: displayed when the integral function is interrupted, canceled or stopped.

Ready: displayed in the ready state of the real-time start mode.

Time Up: displayed when it reaches the specified time of the integral timer.

Reset: displayed when the integral value and integral time are reset via integral reseing.

Error:

Time Display the integral time.

St Display the set integral time.

Et Display the set integral ending time.

Timer Display the fixed integral time.

Display the integral start and stop mode. Start mode: MANUAL and TIME

Stop mode: MANUAL, TIME and TINTerval.

when thepower supply is recovered, the integral function is stopped and the integral

result before power failure is displayed. This integral state is called Error state.

Table 8.2: Measurement Information

8.3.1 Integral operation

• Active power integral

In wa hour, displayed as WP (wa hours, the sum of positive and negative wa hours), WP+ (the

consumption of positive wa hours) and WP- (the negative wa hours of feedback power).

• Current integral

In q, displayed as q (ampere hours, the sum of positive and negative ampere hours), q+ (the consumption of

positive ampere hours) and q- (the negative ampere hours of feedback power)

• Average active power integral

In wa, displayed as WPAV (average active power integral)

• Integration time

Displayed as Time, in the format of hhhh:mm:ss.

8.4 Specification

• Save in case of power failure

The integral result can be kept in the memory even in case of power failure during operation of the integral

function. When the power supply is recovered and the integral function is disabled, the integral result

before power failure is displayed. When the power supply is recovered and the integral is rest, the integral

function is enabled again.

• Display resolution

The maximum display resolution of the integral value is 99999. When the integral value reaches 100000, the

decimal point will move automatically. For example, when 0.01mwh is added to 999.99mwh, 1.0000wh will

be displayed.

• Display in case of overflow

When the integral value meets the following overflow conditions, the integral function will be disabled, and

the integral time and integral value at this point will be kept.

Page 48

CHAPTER 8. INTEGRAL OPERATION FUNCTION 38

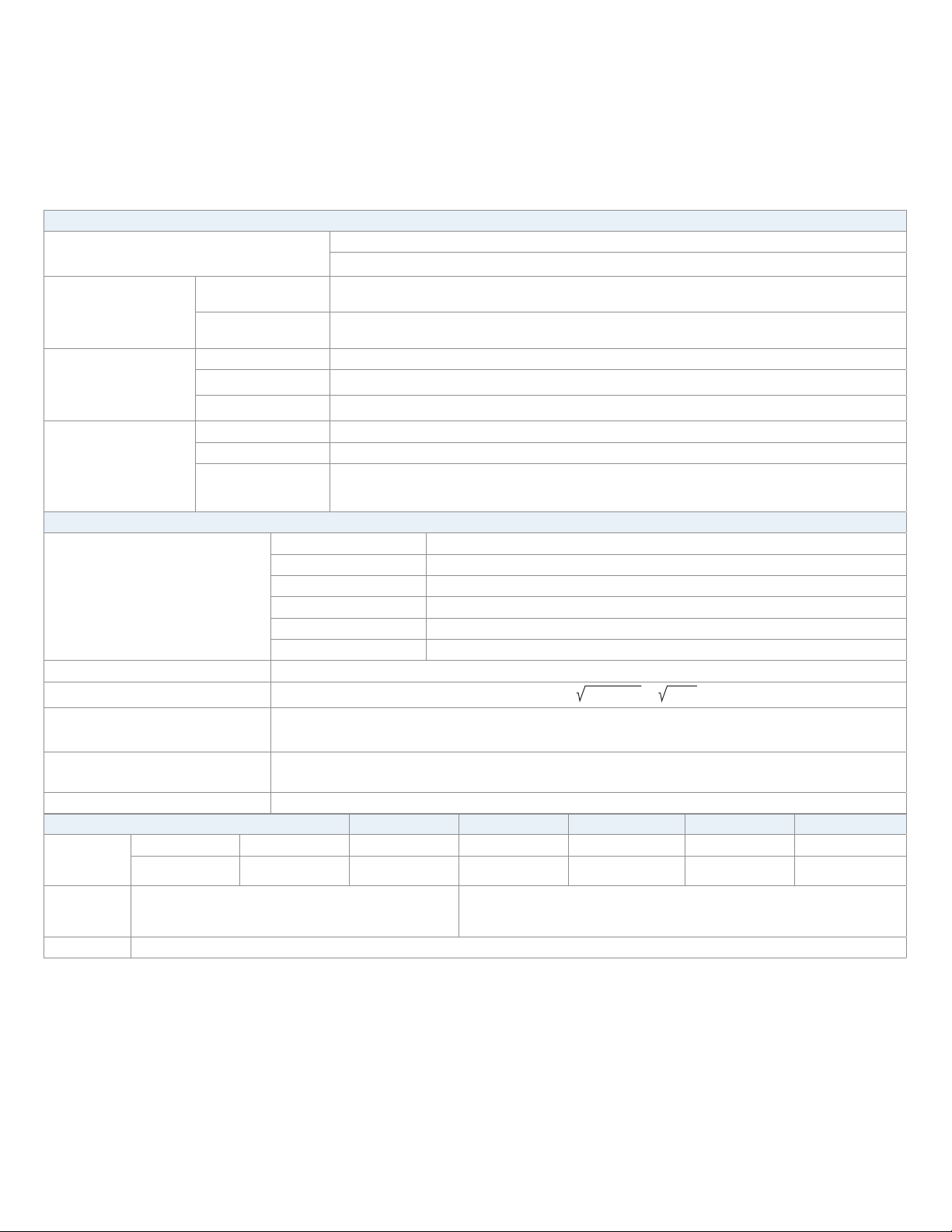

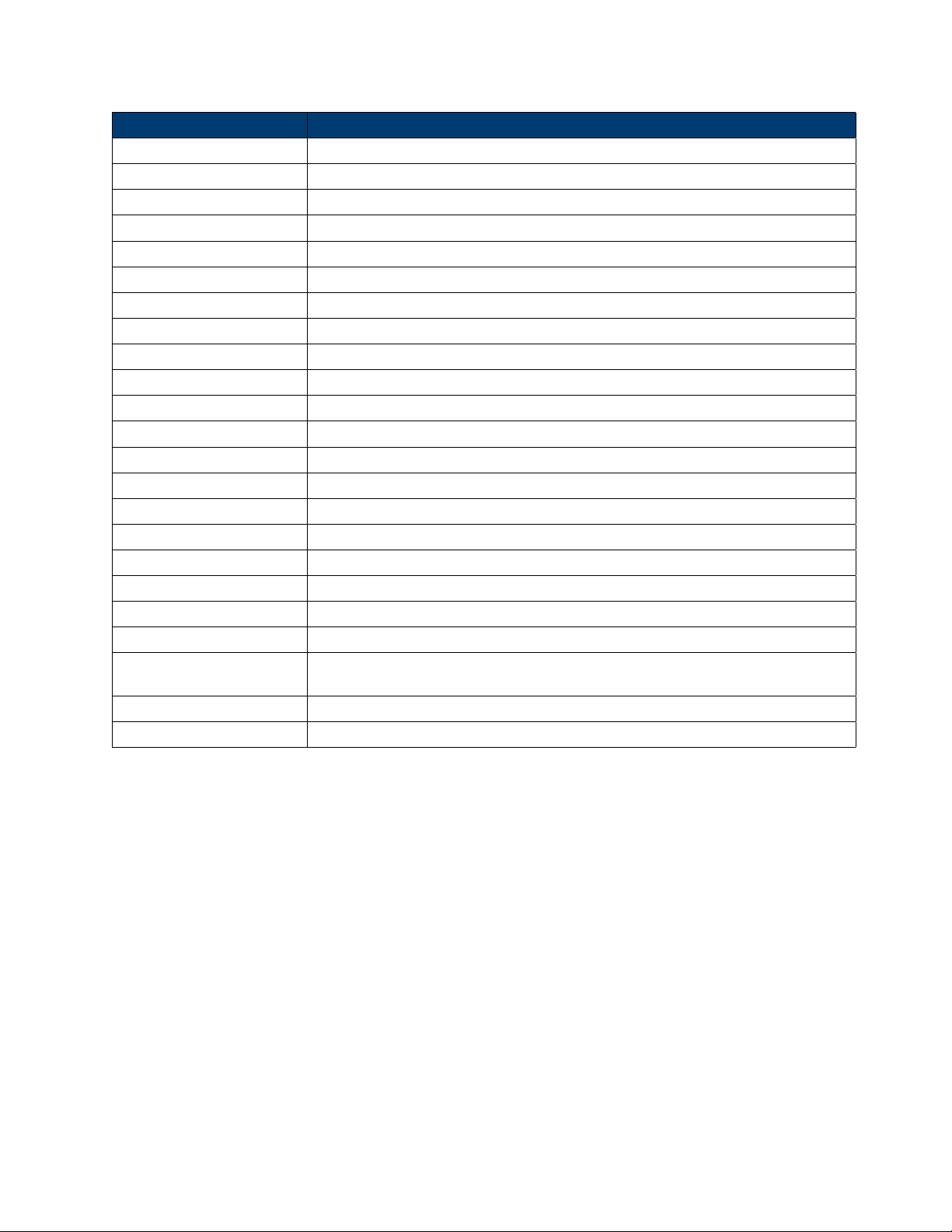

Function Integral reseing

Functions related to settings of measurement parameters

Wiring Executable Unenforceable Unenforceable

Measurement range Executable Unenforceable Unenforceable

Filter Executable Unenforceable Unenforceable

Averaging function Executable Unenforceable Unenforceable

Synchronization Executable Unenforceable Unenforceable

Data updating rate Executable Unenforceable Unenforceable

Integral function parameter

seing

Integral mode Executable Unenforceable Unenforceable

Integral timer Executable Unenforceable Unenforceable

Integral operation

Integral start Executable Unenforceable Executable

Integral stop Unenforceable Executable Unenforceable

Integral reseing Executable Unenforceable Executable

Other operations

Save operation Executable Executable Executable

Hold operation Executable Executable Executable

Single measurement opera-

tion

Executable Executable Executable

Current integral

status

Integral interruption

Table 8.3: Seings configurability per mode

– The integral time reaches the maximum value (10000 hours).

– The integral values of WP, q and WPAV reach the maximum/minimum display integral values.

• Maximum/minimum display integral value

– Active power integral (WP): ±99999 Mwh

– Current integral (q): ±99999 MAh

– Average power integral (WPAV): ±99999 Mw

• Restricted implementation

Seings of the following functions cannot be changed during integral operation.

NOTE In addition to the above items, other seings (such as self-testing and date/time seing) or operations with

influence on the integral cannot be executed; otherwise, errors may be caused.

8.5 Seing of Integral Measurement Configuration

You can set the start mode, stop mode, automatic zero seing, automatic calibration, wa-hour integration,

current integration and other parameters of integral measurement. Specific steps are as follows:

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 49

CHAPTER 8. INTEGRAL OPERATION FUNCTION 39

Operation steps

1. Press “Integ” to enter the integral measurement interface.

2. Press the so key corresponding to the “SETUP” parameter in the integral measurement interface to enter

the integral parameter configuration interface. Press the “ ” buon to select the required parameter, as

shown in the figure below.

8.5.1 Parameter descriptions:

Start set in the MANUAL mode or TIME mode via the right so key.

MANUAL press the “START” so key in the integral measurement interface in the manual start mode to trigger

the manual start of the integral function.

TIME: the date on which the integral mode is started can be set in the real-time start mode. Integration will be

started on the set date. When the time/date combination is set in the real-time start mode, integration will

not be started before the current time and date. Integration will be started when the screen is updated once

at least before the start time.

Stop: set in the MANUAL mode, TIME mode and TINTerval mode via the right so key.

MANUAL: press the “STOP” so key in theintegral measurement interface in the manual stop mode tomanually

stop integration. When the integration time reaches the maximum integration time (10,000 hours) or the

integral value reaches the maximum/minimum display value, integration will be stopped, and the current

integral time and integral value will be kept.

TIME The date for stop of the integral mode can be set in the real-time stop mode. Integration will be stopped on

the set date. When it reaches the set time or the integral value reaches the maximum/minimum display