Page 1

INSTRUCTION

MANUAL

4080 Series

Function and Arbitrary/Function Generators

Model 4084AWG, 4086AWG, 4084, 4085, 4086, 4087

99 Washington Street

Melrose, MA 02176

Fax 781-665-0780

TestEquipmentDepot.com

Page 2

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

d

r

g

C

d

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be

observed during all phases of operation, service, and repair of this instrument. Before applying power,

follow the installation instruc tions and become familiar with the operating instruc tions for this

instrument.

Failure to comply with these precautions or with specific warnings elsewhere in this manual violates

safety standards of design, manufacture, and intended use of the instrum ent. B&K Precision Corpor ation

assumes no liability for a customer’s failure to comply with these requirements. This is a Safety Class I

instrument.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and c abinet must be connecte d to an electrical groun d.

This instrument is grounded through the ground conductor of the supplied, three-conduct or ac power

cable. The power cable must be plugged into an appr oved three-con ductor elec trical outlet. D o not alter

the ground connection. Without the protective ground connect ion, all acc essible con duc tive parts

(including control knobs) can render an elect r ic shock. The power jack and mating plug of the power

cable meet IEC safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electrical

instrument in such an environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by operating personnel. Component replacement and interna l

adjustments must be made by qualified maintenance personnel. Discon ne ct the power cord before

removing the instrument covers and replacing components. Under certain conditions, even with the

power cable removed, dangerous voltages may exist. To avoid i njuries, always disconnect power and

discharge circuits before touching them.

WARNINGS AND CAUT I O N S

WARNING and CAUTION statements denote a hazard. Follow all instructions contained in these

statements.

A WARNING statement calls attention to an operating procedure, practice, or conditi on, whic h, if not

followed correctly, could result in injury or death to personnel.

A CAUTION statement calls attention to an operating procedure, practice, or condition, which, if not

followed correctly, could result in damage to or destruction of part or all of the product.

WARNING:

WARNING:

CAUTION:

Do not alter the ground connection. Without the protective groun

connection, all accessible conductive parts (including control knobs) can

render an electric shock. The power jack and mating plug of the powe

cable meet IEC safety standards.

To avoid electrical shock hazard, disconnect power cord before removin

covers. Refer servicin g to qualified personnel.

Before connecting the line cord to the AC mains, check the rear panel A

line voltage indicator. Applying a line voltage other than the indicate

voltage can destroy the AC line fuses. For continued fire protection, replace

fuses only with those of the specified voltage and current ratings.

2

Page 3

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Table of Contents

1. PRODUCT INTRODUCTION................................................................................................5

1.1 Description .......................................................... .............................. ...............................5

1.2 Key features..................... ... .. ... .. ............................ ... .. ... .. ... ..............................................5

2. SPECIFICATIONS..................................................................................................................6

2.1 Function Generator... .. ... .. ........................................................ .. ... .. ... ............................. ..6

2.2 Universal Counter .. ...........................................................................................................9

2.3 General ... ............................ .. ... .. ... ....................................................................................10

3. PANEL DESCRIPTION..........................................................................................................11

3.1 Front Panel.................. ... .. ... ..............................................................................................11

3.1.1 Overview of Keys ....................................................................................................11

3.1.2 Display Annunciators..................... ... .. ... .. ............................ .. ... .. ... ..........................12

3.1.3 Description of front panel keys................................................................................13

3.1.3 Description of menu parameters ........................... .. ... .. ... .........................................14

3.2 Rear Panel.............. ............................... .......................................................... ..................17

4. OPERATING INSTRUCTIONS.................. ............................................................................18

4.1 Installation.................................... .............................. ............................... .......................18

4.2 Main operating modes............................ ... .............................. .............................. ...........18

4.3 W aveform Selection..........................................................................................................19

4.4 Data entry .........................................................................................................................20

4.5 Output Configuration..... .. ............................ ... .. ... ........................... ... .. ... ..........................21

4.5.1 Set Frequency and Period.........................................................................................21

4.5.2 Set Amplitude...........................................................................................................21

4.5.3 Set DC Offset Voltage..............................................................................................22

4.5.4 Adjust duty cycle......................................................................................................22

4.5.5 Sync/TTL Signal......................................................................................................23

4.5.6 Signal Store and Recall ............................................................................................23

4.6 Set Modulation and Sweep Parameters ............................................................................24

4.6.1. Sweep mode............................................................................................................24

4.6.2 FM modulation.........................................................................................................26

4.6.3 AM modulation ........................................................................................................27

4.6.4 Burst modulation......................................................................................................28

4.6.5 FSK modulation.......................................................................................................30

4.6.6 PSK modulation.......................................................................................................31

4.7 Set System Parameters............................... .. .............................. ... .. ... .............................. .32

4.8 Universal Counter .. ...........................................................................................................34

5. REMOTE INTERFACE REFERENCE...................................................................................35

5.1 Introduction ........... ...........................................................................................................35

5.2 Overview and syntax of SCPI instructions.......................................................................35

5.3 Detailed description of SCPI Instructions ........................................................................39

6. USER PROGRAMMABLE ARBITRARY WAVEFORM MODULE ............... ... .. ... .. ... ........47

7. APPENDIX..............................................................................................................................57

A) Declaration of conformity .......................... .. .............................. ... .............................. ... .. .58

B) Service and Warranty Information.....................................................................................57

3

Page 4

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Intentionally left blank

4

Page 5

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

1. PRODUCT INTRODUCTION

1.1 Description

The B+K Precision 4080 Series are laboratory grade synthesized function generators with a wide

frequency range of up to 120 MHz. Direct digital synthesis (DDS) techniques are used to create

stable, accurate output signals fo r clean, low distortion sine waves and an extensive selection of

built-in standard and arbitrary waveform s. The ins tr ument supports AM, FM, FSK, PSK and pu lse

modulation and linear and logarithmic sweep. Modulation parameters can be set precisely and are

adjustable over a wide range. Th e 4080 Series supports internal an d externa l modulat ion sources as

well as internal, external and gated trigger sources.

All models are capable of generating complex, predefined arbitrary waveforms. Additionally,

models 4084AWG and 4086AWG provide the flexibility to create custom waveforms. The AWG

module includes an intuitive, graphical Windows based software tool for creating and editing

custom arbitrary waveforms and transferring the waveforms to the instrument’s non-volatile

memory. The software also provides a direct interface to Tektronix® TDS1000, TDS2000

TPS2000 and TDS3000 series digital storage oscilloscopes offering users a convenient means to

recreate waveforms originating from the DSO’s display or internal memory.

The 4080 Series front-panel operation is straightforward. Parameters can be entered using the knob

or directly via the numerical keypad and unit keys.

The instruments are fully programmable via the standard RS232 interface. The command set is

SCPI (standard Commands for Prog rammable Instruments) compatible.

The combination of classical function and arbitrary waveform generator makes this series a versatile

solution for many applications in Electronic Test and Design, Sensor Simulation, Education and

Training.

1.2 Features

• Direct Digital Synthesis (DDS) architecture

• Wide frequency range of 1µHz ~ 120MHz (model 4087, sine wave only)

• Clean and stable output of very small signals down to 1mV (50)

• 27 build-in standard and complex waveforms.

• Eight downloadable 16000 point memories for custom arbitrary waveforms (models

4084AWG and 4086AWG only)

• Graphical Arbitrary Waveform Generation Software tool for Microsoft

(models 4084AWG and 4086AWG only)

• Convenient data input via knob or numerical keypad.

• Bright, easy to read display using VFD (Visible Vacuum Fluorescent) technology

• Fully programmable via SCPI compatible command set

• 100 MHz Universal Counter with frequency measurement and totalize function

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

5

®

WindowsTM

Page 6

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

2. SPECIFICATIONS

2.1 Function Generator

Waveform Characteristics

Main Waveforms

W aveform Am plitude resolution: 12 bits

Sample Rate: 200MSa/s (4084, 4084AWG, 4085, 4086, 4086AWG)

Sine

:

Square

Rise and Fall Time of Square Wave: 15ns

Note: Test conditions for harmonic distortion, sine distortion, rise/fall time: Output

Amplitude 2Vp-p, Environmental temperature: 25℃±5℃

Build in standard and complex (arbitrary) waveforms

27 build-in standard and complex waveforms.

Waveform Length: 4096 dots

Amplitude Resolution: 10 bits

Pulse W ave :

DC signal characteristics:

Module for user defined arbitrary waveform generation (models 4084AWG and 4086AWG only)

Number of memory locations for arbitrary waveforms: 8

Length of waveforms:8~16 000 points

Resolution of wavefo rm a m p litude:10 bits

Frequency range:100µHz~100kHz

Sample rate:200MSa/s

: Sine, square

300MSa/s (4087)

Harmonic Distortion of Sine Wave:

- 50dBc (frequency 5MHz)

- 45dBc (frequency 10MHz)

- 40dBc (frequency 20MHz)

- 35dBc (frequency 40MHz)

- 30dBc (frequency > 40MHz)

Total Harmonic distortion: 0.1% (20Hz ~ 100kHz)

:

:

Sine, Square, Triangle, Positive Ramp, Falling Ramp, Noise, Positive Pulse, Negative

Pulse, Positive DC, Negative DC, Stair wave, Coded Pulse, Full wave rectified,

Half-wave rectified, Sine transverse cut, Sine vertical cut, Sine phase modulation,

Logarithmic, Exponent ial, Half-round, SINX/X, Square root, Tangent, Cardiac,

Earthquake, Combination

Duty Cycle: 0.1% ~ 99.9% (below 10kHz), 1% ~ 99% (10kHz ~ 100kHz)

Rise/Fall Time: 100ns (Duty cycle 20%)

DC range: 10mV – 10V (high impedance)

DC Accuracy: ±5% of setting +10mV (high impedance)

6

Page 7

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Frequency Characteristics

Frequency Range:

Main waveforms (sine, square)

:

Model 4084/4084AWG: 1µHz ~ 20MHz

Model 4085: 1µHz ~ 40MHz

Model 4086/4086AWG 1µHz ~ 80MHz (sine wave)

1µHz ~ 40MHz (square wave)

Model 4087 1µHz ~ 120MHz (sine wave)

1µHz ~ 40MHz (square wave)

All other waveforms

:

All models: 1µHz ~ 100kHz

Frequency Stability: ±1×10

-6

(22℃±5℃)

Resolution: 1µHz

Frequency Accuracy: ± 5×10

-6

(22℃±5℃)

Data entry Units: s, ms, Hz, kHz, MHz

Amplitude Characteristics

Amplitude Range:

4084, 4084AWG: 2mV ~ 20Vpp (open circuit), 1mV ~ 10Vpp (50)

4085

4086, 4086AWG: for Freq 40MHz: 2mV ~ 20Vpp (open circuit), 1mV ~ 10Vpp (50)

for Freq > 40MHz: 2mV ~ 4Vp-p (open circuit), 1mV ~ 2Vpp (50)

4087: for Freq 40MHz: 2mV ~ 20Vpp (open circuit), 1mV ~ 10Vpp (50)

for Freq > 40MHz: -76dBm ~ +13.5 dBm(50)or 0.1mV ~ 3Vpp(50)

Max. Resolution: 2µVpp (open circuit), 1µVpp (50)

Amplitude Accuracy: ± 1%+0.2mV (sine wave relative to 1kHz)

Amplitude Stability: ±0.5 % /3 hours

Flatness:

For amplitude 2Vpp: ±3% (frequency5MHz), ±10% (5MHz<frequency40MHz)

For amplitude >2Vpp: ±5% (frequency5MHz), ±10% (5MHz<frequency20MHz)

±20% (frequency>20MHz)

Models 4086/AWG, 4087 only: ±1dBm (frequency>40MHz)

Output Impedance: 50

Output Units: Vpp, mVpp, Vrms, mVrms, dBm

7

Page 8

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

DC Offset Characteristics

Offset Range (open circuit)

Freq 40MHz): ±10Vpk ac + dc (Offset 2×peak-to peak amplitude)

Freq > 40MHz): ±2Vpk ac + dc (Offset 2×peak-to peak amplitude)

Resolution: 2µV (open circuit), 1µV (50)

Offset Error: ±5% of setting +10mV (Ampl. 2Vpp into open circuit)

±5% of setting +20mV (Ampl. > 2Vpp into open circuit)

AM Characteristics

Carrier Waveforms: sine or square

Carrier Frequency Range: same as main waveforms

Modulation Source internal or external

Modulating Waveform: 5 internal waveforms (sine, square, triangle, rising/falling ramp)

Frequency of modulating signal: 100µHz ~ 20kHz

Distortion: 2%

Modulation Depth: 1% ~ 120%

1% ~ 80% (frequency>40MHz, Ampl > 2Vpp into open circuit)

Modulation Error: ± 5%+0.2% (100µHz < frequency 10kHz)

±10%+2% (10kHz < frequency 20kHz)

Amplitude of ext. input signal: 3Vp-p (-1.5V~ +1.5V)

FM Characteristics

Carrier Waveforms sine or square

Carrier Frequency Range: same as main waveforms

Modulation Source: internal or external

Modulating Waveform: 5 internal waveforms (sine, square, triangle, rising/falling ramp)

Frequency of modulating signal: 100µHz ~ 10kHz

Peak Frequency Deviation: Max. 50% of carrier frequency for internal FM

Max 100kHz (carrier frequency5MHz) for external FM,

with input signal voltage 3Vp-p ( -1.5V~+1.5V)

FSK Characteristics

Carrier Waveform sine or square

Carrier Frequency Range: same as main waveforms

Control Mode internal or external trigger (external: TTL level, low level F1,

high level F2)

FSK Rate: 0.1ms ~ 800s

PSK Characteristics

Waveform: sine or square

Frequency Range: same as main waveforms

PSK: Phase 1 (P1) and Phase 2 (P2), range: 0.0 ~ 360.0°

Resolution: 0.1°

PSK rate: 0.1ms ~ 800s

8

Page 9

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Control Mode: internal or external trigger (external: TTL level, low level P1,

high level P2)

Burst Characteristics

Waveform: sine or square

Frequency Range: same as main waveforms

Burst Counts : 1 ~ 10000 cycles

Time interval between bursts: 0.1ms ~ 800s

Control Mode: internal, single or external gated trigger

Frequency Sweep Characteristics

Waveform: sine or square

Start/Stop Freq.: same as main waveforms

Sweep Time: 1ms ~ 800s (linear), 100ms ~ 800s (log)

Sweep Mode: Linear or Logarithmic

External trigger signal frequency: DC ~ 1kHz (linear) DC~10Hz (log)

Control Mode: internal or external trigger

Rear Panel Terminals (for modulation and sweep)

Output MOD OUT

Frequency: 100µHz ~ 20kHz

Waveform: sine, square, triangle, rising/falling ramp

Amplitude: 5Vp-p ± 5%

Output Impedance: 600

Modulation IN

3 Vpp = 100% Modulation

External Input Trig/FSK/Burst

Level: TTL

Main OUTput

Impedance: 50Ω

Protection: Short circuit and overload protected

State Storage Characteristics

Storage Parameters: frequency, amplitu de, waveform, DC offset values, modula tion

parameters

Storage Capacity: 10 user configurable stored states

Storage Time: more than 10 years

2.2 Universal Counter

Frequency Range

Frequency Measurement: 1Hz ~ 100MHz

Totalize mode: 50MHz max

9

Page 10

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Input Characteristics

Sensitivity

Input attenuator disabled: 50mVrms (f: 10Hz ~ 50MHz), 100mVrms (f: 1Hz ~ 100MHz)

Input attenuator enabled: 0.5Vrms (f: 10Hz ~ 50MHz), 1Vrms (f: 1Hz ~ 100MHz)

Max. Input Voltage Allowed: 100Vp-p (f100kHz), 20Vp-p (1Hz~100MHz)

Input Impedance: R>500k, C<30pF

Coupling: AC

Waveform: sine or square

Low Pass Filter: cut off frequency about 100kHz (with internal attenuation: -3dB)

with external attenuation: -30 dB (f >1MHz)

Gate Time Setting: 10ms ~ 10s continuous ly adjustable

Display Bits: 8 (for gate Time>5s)

To talize Capacity: 4.29×10

9

Control Mode: manual or external gate control

Accuracy: time base error ± trigger error (when signal SNR > 40dB,

trigger error 0.3)

Time base:

Type: small TCXO

Frequency: 10MHz

Stability: ±1 × 10

-6

(22°C±5°C)

2.3 General

Power Supply 198~242V or 99~121V, Frequency: 47~ 63Hz

Power Consumption: <35VA

Operating Te mperature

0° to +40 °C

Operating Humidity 80% R.H

Storage Temperature

-40℃ to 70℃

Dimensions (W x H x D): 255 mm x 100 mm x 370 mm (10.0 x 3.93 x 14.56 inch)

Weight: 3 kg (6.6 lbs): models 4084, 4084AWG, 4085, 4086, 4086AWG

3.5 kg (7.7 lbs) model 4087

Remote Interface RS232

Accessories included

BNC to alligator cable

BNC to BNC cable

RS232 communication cable

Power line cord

Test report

Spare fuse

Installation disk for Arbitrary Waveform Creation Software (models 4084A WG or 4086AWG only)

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

10

Page 11

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

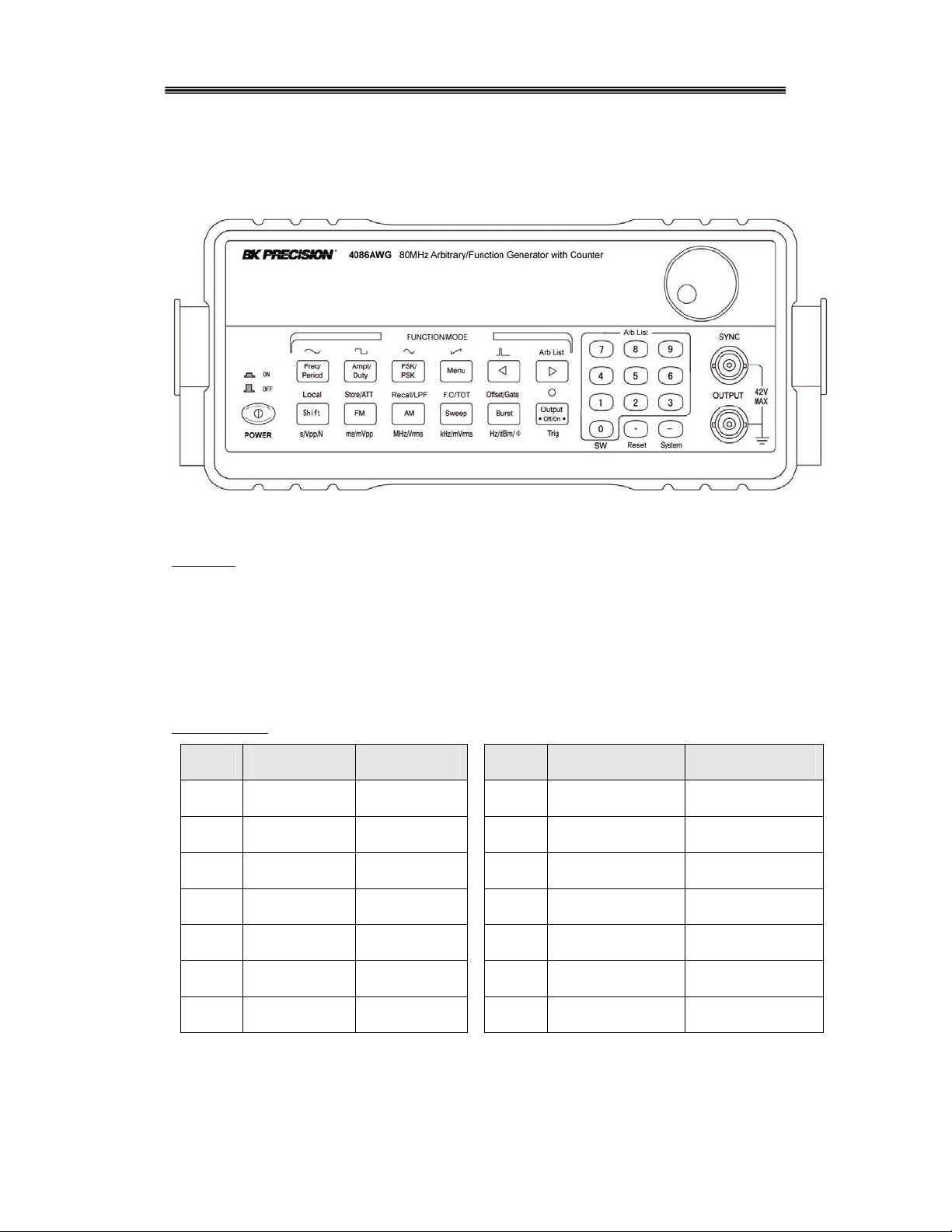

3. PANEL DESCRIPTION

3.1 Front Panel

3.1.1 Overview of Keys:

Summary: Most keys have multiple functions. Primary functions are written on the key. Sim ply

press the respective key to enable a primary functions. All Function/Mode keys and some of the

numerical entry keys have associated secondary functions indicated above each key in blue. To

activate a secondary function, press the 【shift】key followed by the desired key. The bottom row

of the Function/Mode keys can be used to enter units directly. The unit is indicated below each key.

To enter a unit, enter a numerical value via the numerical keypad then press the corresponding unit

key. The unit key also serves as Enter function.

Data entry keys

Key

Name

0 Input Digit 0 Enter SW mode 7 Input Digit 7

1 Input Digit 1

2 Input Digit 2

3 Input Digit 3

4 Input Digit 4

5 Input Digit 5

6 Input Digit 6

*: Direct number entry: Press this key to clear the least significant bit of the displayed number.

Useful for correcting number entry before entry is confirmed with unit key.

External totalize mode: Press this key to stop counting and display present counting value.

Press again to resume counting.

:

Main

Function

Secondary

Function

Enable ARB1

waveform ***

Enable ARB2

waveform ***

Enable ARB3

wave ***

Enable ARB4

waveform***

Enable ARB5

waveform ***

Enable ARB6

waveform***

Key

Name

Main function

Enable ARB7

waveform ***.

8 Input Digit 8

9 Input Digit 9 Not available

Input decimal point Reset Unit

Input negative

symbol

Move arrow key to

left *

Move arrow key to

right **

Enable ARB8

waveform ***

Enter system menu

Select pulse

Select Arblist

waveform

Secondary

Function

11

Page 12

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

**: External totalize mode: Press this key to reset and resume event counter

*** models 4084AWG and 4086AWG only

Function/Mode Keys:

Key name Main Function

Freq./Period

Ampl./Pulse

width

FSK/PSK

Menu Menu Selection

FM Enable FM mode

AM Enable AM mode Enter Recall menu Low Pass Select MHz, Vrms

Sweep

Burst

Other Keys

Key Name Main Function Other Function

Output Main OUTPUT signal On/Off

Shift Select secondary function Enter units in s, Vpp, N

:

Toggle between

Frequency &

Period.

Amplitude Select.

FSK/PSK

Function Select

Enable Sweep

mode

Enable Burst

mode

Secondary

Function

Enable Sine Wa ve Not A vailable Not A vailable

Enable Square

Wave.

Enable Triangle

Wave

Enable positive

ramp

Enter Storage

menu

Enter Counter

Mode

DC Offset Select Gate Select Hz, dBm

Secondary

Function for

Counter Mode

Not A vailable Not A vailable

Not A vailable Not A vailable

Not A vailable Not A vailable

Attenuation

Selection

Freq. Meas./

Totalize Enable

Generate single trigger in sweep and

burst mode

3.1.2 Display Annunciators:

Unit Entry

ms, mVpp

kHz, mVrms

Display areas:

① Waveform Indication

② Main Alphanumeric Display

③ Frequency Measurement/Totalize Settings

④ Instrument states

12

Page 13

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Waveform states

Sine waveform is enabled (,main waveform)

Square waveform is enabled (main waveform)

Triangle waveform is enabled

Ramp waveform is enabled

Arb Arbitrary waveform mode is enabled

Frequency Measurement/Totalize states

Filter: Low Pass Filter is enabled

ATT: Input Attenuator is enabled

GATE: Gate received trigger

Function Generator states

Adrs: The instrument is in remote state.

Trig: Function Generator is waiti ng for a single trigger or external trigger.

FM: FM modulation is enabled

AM: AM modulation is enabled

Sweep: Sweep mode is enabled

Ext: Generator is configured for external signal input

Freq: Frequency measurement function is enabled

Count: Totalize function is enabled

FSK: FSK (frequency shift keying) modulation is enabled

FSK: PSK modulation is enabled

Burst: Burst mode enabled.

Offset: DC offset of output signal is not 0.

Shift: Shift key has been pressed, Shift mode is active

Rmt: The instrument is in remote state.

3.13 Description of front panel keys

【shift】key

Access secondary functions or to enter units “sec onds”, Vpp and “N”

Numerical key pad:

Keys are used for direct entry of numerica l values. Keys【0】【】【-】are assigned secondary

functions to enter the systems menu, reset the unit to its default values or revert to Standard

Waveform (“SW”) mode.

【】【】arrow keys

The primary function is to move th e flas hing di git lef t or right or to s elec t the desired ar bitrary

waveform from the Arb List (secondary function). When in Counter Mode, these 2 keys are

used to start/stop or reset/resume the counter.

【Freq/Period】key:

Toggle between frequency and period display (primary function) or to enable sine waveform.

【Ampl/Pulse Width】key:

Display and adjust the amplitude of waveforms or, when in pulse mode, toggle the display

13

Page 14

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

between amplitude and pulse width. The secondary function activates the square waveform

【FSK/PSK】key:

Toggle between FSK and PSK modulation (primary function). Activate triangle waveform

【Menu】key:

Enter modulation parameters for FSK, PSK , FM, AM and burst modulation and for sweep

mode. When in standard wa veform mode (no modulation, main waveforms enabled), this key

can also be used to toggle the units for the amplitude display value bet w een Vpp, Vrms and

dBm. (Press the Amplitude key first, then the Menu key to toggle between the units). The

secondary function enables the ramp waveform.

【FM】key:

Activate FM modulation (primary function). Enter Storage mode (secondary function). Enter

units ms or mVpp after entering the desired value by nu merical key pad. In Coun ter Mode, this

key turns the input attenuator o n or off.

【AM】key:

Activate AM modulation (primary function). The secondary function is used to recall and

recreate signals stored in status memory. Enter units “MHz and “Vrms” after entering the

desired value by numerical key pad. Enable the low pass filter when in Counter mode.

【Sweep】 key:

Activate sweep mode. Select frequency measuring and totalize mode (secondary function) .

Enter units kHz or mVrms after entering the desired numerical value directly via the keypad.

Use the Shift key to toggle between frequency measurements and totalize mode.

【Burst】key:

Activate burst mode (primary function). Enter DC offset mode (secondary function). Enter

units Hz or dBm. When in frequency measurem en t m ode, press t his key to enter the g ate tim e.

【Output】key

Press this key to toggle the main OUTPUT signal between the ON and OFF state. By default

the output is turned on, indicated by the green LED and the currently active wave form is

available at the OUTPUT terminal. In Burst or Sweep m ode, this key is also used to generate a

single trigger.

3.14 Description of menu parameters

Use this key to configure modulation parameters, sweep mode parameters and system parameters.

Modulation and Sweep mode: After enabling modulation or sweep mode, press “menu” to

configure the related parameters. Each time you press the menu key, the parameter will flash for 1

second, followed by the currently act ive value of that param eter. Use the knob or numerical keys to

enter a new value. Once the parameter is set, press 【menu】 to advance to the next parameter.

Continue pressing the menu key to cycle throug h all parameters. Press 【Shift】【SW】to return to

the main waveform mode and to set the carrier waveform parameters.

Sweep Mode:

MODE —> START F —> STOP F —> TIME —>TRIG

14

Page 15

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

MODE: Select LINEAR or LOGarithmic sweep

START F :Sweep start frequency

STOP F: Sweep stop frequency

TIME: Sweep time

TRIG: Select trigger source, INTernal or EXTernal

FM modulation:

FM DEVIA—> FM FREQ —> FM WAVE —> FM SOURCE

FM DEVIA: Peak frequency deviation

FM FREQ: Modulating signal frequency

FM WAVE: Modulating signal waveform (sine, square, triangle rising or falling ramp)

FM SOURCE: Toggle between internal and external modulating signal.

AM modulation:

AM LEVEL —> AM FREQ —> AM W AVE —> AM SOURCE

AM LEVEL: Modulation depth

AM FREQ: Frequency of modulating signal

AM WAVE: Modulating signal waveform (sine, squar e, triangle rising or falling ramp)

AM SOURCE Select internal or external modulating signal

Burst modulation:

TRIG —> COUNT —> SPACE T —> PHASE

TRIG Select trigger source, internal or external

COUNT: Number of burst cycles

SPACE T:Burst time spacing

PHASE: starting phase of the burst

FSK modulation:

ST ART F —> STOP F—> SPACE T —> TRIG

START F Primary frequency (same as carrier wave)

STOP F the second frequency (hop frequency)

SPACE T FSK rate

TRIG Select trigger source, external or internal

PSK modulation

P1 —> P2 —> SPACE T —> TRIG

P1 phase value #1

P2: phase value #2

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

15

Page 16

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

SPACE T: PSK rate

TRIG: trigger mode, internal or external

System Function Mode:

POWER ON —> ADDRESS —> OUT Z —> INTERFACE—>…..

…………BAUD —> PARITY

POWER ON “Power on” state

ADDRESS: set GPIB address (option)

OUT Z: Configure amplitude display valu e for 50Ω or high impedance load termination

INTERFACE: Select RS232 or GP-IB (IEEE-488) interface (option)

BAUD: Baud rate for the RS232 interface

PARITY: Parity and Data Bits configuration for RS232

16

Page 17

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

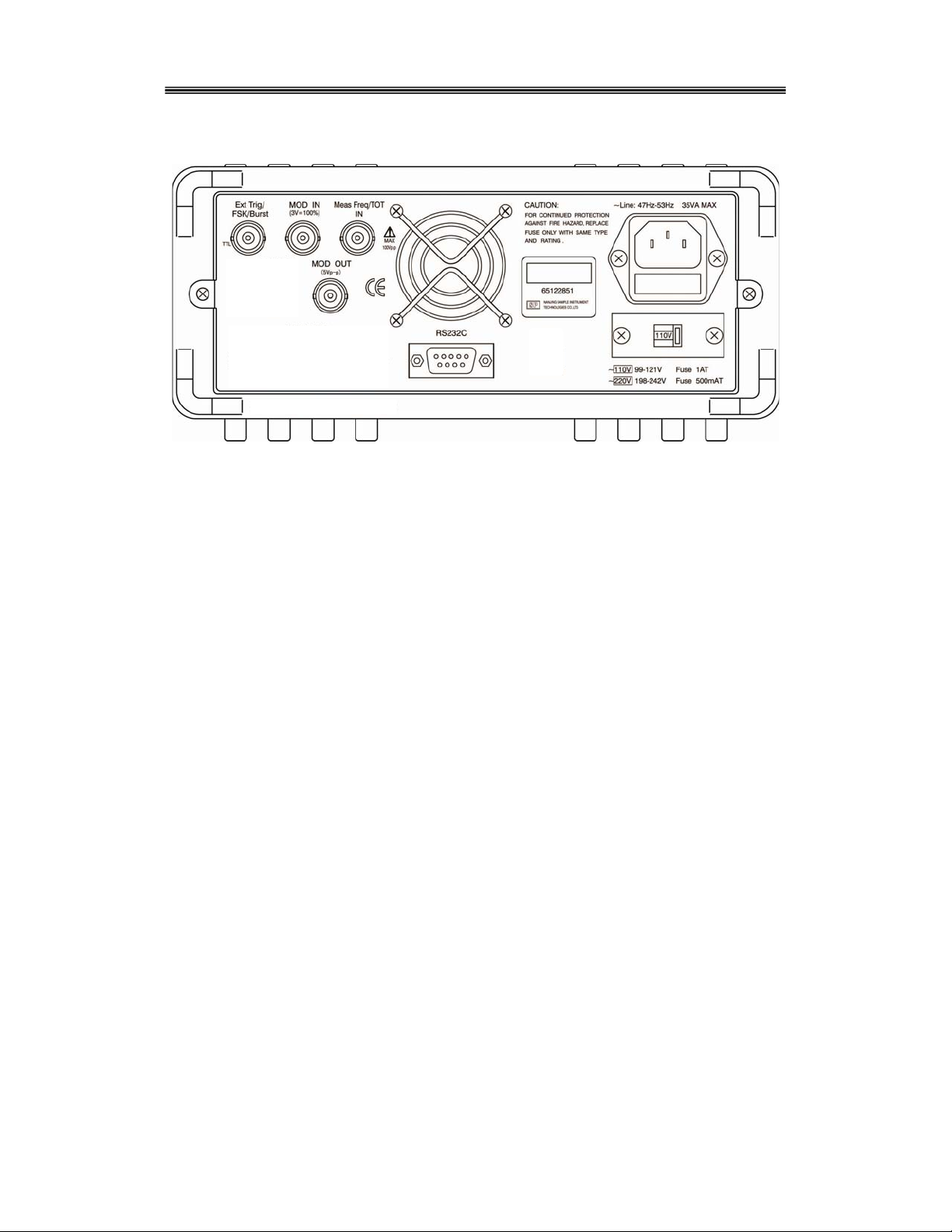

3.2 REAR PANEL

Ext. Trig/FSK/Burst :

Input Terminal for external trigger signals for FSK/PSK Burst modulation and sweep mode

MOD In

Apply modulating signal for AM and FM to this Input terminal

Meas Freq/TOT In

Input terminal for Universal Counter which operates in frequency measurement or Totalize

mode

MOD OUT

The internally generated modulating signal when in AM mode will be available at this output

RS232C

RS232 interface for remote control of instrument (all models) or for download of custom

arbitrary waveforms (models 4084AWG and 4086AWG only)

AC Socket and fuse co mpartment

Connect the supplied power line cord to this receptacle. Make sure to install the appropriate

fuse according to the selected AC voltage.

AC Input Selector switch

Set this switch to the corresponding AC voltage in your area

17

Page 18

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

4. OPERATING INSTRUCTIONS

4.1 Installation

This section contains installation information, power requirements and initial inspection and signal

connections for the 4080 series generators.

Mechanical Inspection

This instrument was carefully inspected before shipment. Upon receipt, inspect the instrument for

damage that might have occurred in transit. If any sign of damage is found, notify your B+K

Precision distributor .

Instrument Mounting

The 4080 Series is intended for bench use. The instrument includes a handle adjustable for

optimum panel viewing angle. The instrument does not require special cooling when operated

within conventional temperature limits.

Power Requirements

The 4080 Series can be operated from any source of 99V to 242V AC and frequency of 48Hz to

63Hz. The maximum power con sumption is 35 VA. Replace fuses with the same type, according to

the rating indicated on the rear panel of the instrument.

The instrument power fuse is located in a fuse compartment below the AC input receptacle. To

access the fuse, first disconnect the power cord and then remove the fuse cartridge.

Power-on procedure

Turn on the instrument by pressing the power key on the front panel of the unit. The display should

be flashing “BK PRECISION” for 2 seconds followed by the model number. e.g. .“4084AWG” for 1

second. By default, the instrument will enter the standard waveform (“SW”) mode with the

frequency set to 10.00000000 kHz and the waveform annunciator displaying the “~ “ symbol. If

the Power ON configuration in the systems menu was modified, the parameters of th e last operat ion

before power-down will be displayed.

4.2. Main operating modes

“SW” standard waveform mode

In this mode, the generator outputs any of the 27 build-in waveforms, including the 2 “main

waveforms” sine and square. This also includes the 8 user programmable arbitrary waveform s

(models 4084AWG and 4086AWG only). For most waveforms, you can set frequency, amplitude

and DC offset. In this mode, modulation and sweep is not active and all annunciators in status area 4

are turned off . When modulation or sw ee p is en abled, press【shift】【SW】to return to this mode.

Modulation, Pulse and Sweep Mode

In this mode, the generator operates like a conventional function generator and the Arb annu nci ator

is turned off. The user can selec t one of t he modu lation m odes AM, FM, FSK, PSK, Burst or sweep

mode. The 2 main waveforms sine and square can be used as carrier signal.

There is a close, reciprocal relationship between the modulation/sweep mode and the standard

18

Page 19

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

waveform mode used to set the sine or sq uare wave parameter s. When one of the modulation m odes

is active, the parameters of the carrier wave are carried over from the Standard Waveform Settings

(for sine or square). Press 【shift】【SW】to toggle between any of the m odulation/sweep m odes (to

set the modulation parameters) and the standard waveform mode (to define the carrier settings for

frequency , am plitude a nd DC of fset). On the ot her ha nd, the car rier frequ ency c an also be set in th e

modulation/sweep menus and if changed, will overwrite the standard waveform frequency setting.

Example: When transitioning f rom standard wavefor m mode to FM modulation mode , (by pressing

the FM button) the parameters set previous ly in “SW” mode car ry over to the F M mode and are now

defining the FM carrier. If the FM carrier frequency in the FM modulation menu is changed, it will

also “overwrite” the frequency setting of the standard waveform” settings.

To adjust the duty cy cle, enable pulse m ode by pressing 【shift】 【】. Note that the duty cycle

can only be adjusted in pulse mode.

4.3 W aveform Selection:

Enabling common waveforms

Press【shift】 followed by the waveform key to select one of the 5 common wavefo rms sine, square,

triangle, ramp and pulse. The corresponding waveform annunciator will be displayed in the

waveform display area. Note that the instrument operates in Function Generator mode when

selecting sine and square and in ARB mode for the remaining functions. (Arb annunciator is lit).

Note: The 5 common waveforms can also be output by selecting the corresponding number from the

ArbList in this section.

Example: Press 【Shift】【FSK/PSK】to enable the triangle waveform

Enabling stored waveforms from the Arb List

Make sure you are in “SW” mode. (All area 4 status annunciators are of f) . If modul ation or sweep

is active, press【shift】 【SW】to return to the standard waveform mode.

Press【shift】 【】to enter the ArbList: W aveform,”6: NOISE” is enabled and appears on the display.

Use the knob or the numeric keypad to select one of the 27 stored waveforms from the ArbList

according to the table in this section.

Example: To select negative ramp DOWN_RAMP, do the following:

Press 【shift】 【】(enter ArbList)

Press 【5】【N】(enable DOWN_RAMP)

or

select waveform with the knob

Models 4084AWG and 4086AWG only: Locations 28-35 are reserved for the storage of user

defined arbitrary waveforms. The display name for these waveforms is ARB1-ARB8. These

memory locations can be accessed in one of 2 ways:

a) Enter the ArbList, then use the knob or the numeric keypad to enable waveforms ARB1 – ARB8

b) Press 【Shift】followed by any number between 1-8.

Example: Press 【Shift】【2】to enable waveform stored in memory location ARB2

19

Page 20

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Table of stored waveforms (ArbList) and their memory locations

No. Waveform Display Name No. Waveform Display Name

1 Sine wave SINE 15 Half-wave rectified COMMUT_HA

2 Square wave SQUARE 16 Sine transverse cut SINE_TRA

3 Triangle wave TRIANG 17 Sine vertical cut SINE_VER

4 Ramp UP_RAMP 18 Sine phase modulation SINE_PM

5 Falling ramp DOWN_RAMP 19 Logarithmic function LOG

6 Noise NOISE 20 Exponential function EXP

7 Pulse wave PULSE 21 Half-round function ROUND_HAL

8 Positive pulse P_PULSE 22 SINX/X function SINX/X

9 Negative pulse N_PULSE 23 Square root function SQU_ROOT

10 Positive DC P_DC 24 Tangent function TANGENT

11 Negative DC N_DC 25 Cardiac wave CARDIO

12 Stair wave STAIR 26 Earthquake wave QUAKE

13 Coded pulse C_PULSE 27 Combinati on wave COMBIN

14

Full wave

rectified

COMMUT_FU 28~35*

User programmable

Arbitrary waveforms

ARB1~ARB8

Note:

*No 28~35: memory location for user programmable waveforms, models 4084AW G and 4086AW G only. Refer to

chapter 7 for more details

4.4 Data entry

Using the arrow keys and the knob

Use the knob and arrow keys to modify the displayed number.

Use the 【】【】 keys to move the flashing digits left or right then adjust the value with the knob.

Using this method of entry, the output signal will be updated immediately. Move the arrow keys left

for coarse adjustment and right for fine adjustment.

To disable the knob, use the【】【】 key to move the cursor all the way to the left or right until

the digits stop flashing. Now data entry via the knob is disabled.

Direct entry using the numerical key pad

Use the numerical keypad to enter a number with the appropriate unit.

Enter numbers from left to right. Use the 【】key to enter a decimal point. Enter 【-】for negative

numbers. Repeatedly pressing this key will toggle between positive (no sign visible) and negative

numbers. Numerical entries do no t updat e the o utput si gnal until a unit k ey has bee n pressed. O nce

you entered the correct numerical value, press the appropriate unit key to assign a unit and to make

the entry effective. The instrument will now output a signal according to the displayed data.

For entries not associated with a unit, press the shift key (“N” = “no unit”) to make the entry

effective.

Note: Numerical values entered via the keypad ar e not effective

has been pressed.

20

until a valid unit key or shift (“N”)

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 21

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Entry of invalid key presses or invalid values

If the entered value exceeds the rated range, a beep sound will be heard. If the entered value is below

the lower limit, the instrument will automatically change the entry to the lowest possible value. If

the entered value exceeds the upper limit, the instrument will automatically revert to the maximum

value.

Example: When trying to entering 90MHz in a model 4086 (80 MHz max), a beep will be heard and

the value will be forced to 80 MHz.

Invalid keys: A beep sound will inform the user that the key entry is invalid. The instrument will

simply ignore the key pressed.

Example: Key【-】is pressed when trying to enter a frequency value. The instrument will ignore the

entry and respond with a “beep” sound.

4.5 Output Configuration

4.5.1 Set Frequency and Period

The【frequency/period】key is used to toggle between Frequency and Period display of the standard

waveform or the carrier wa veform.

Frequency

Press the 【frequency】 key to display the current frequency val ue. The value can be m odified using

the numerical keypad or the knob.

Example: To set a frequency value of 5.8 kHz, enter the following key sequence:

The display will be 5.80000000 kHz.

Period Setting

The signal frequency can also be displayed or entered as a period value. If the current display is

frequency, press the【frequency/period】key to display the current period value. Values can be

entered with the numerical key pad or using the knob.

Example: To set a period value of 10ms, enter the following sequence of keys:

4.5.2 Set Amplitude

Press the 【Amplitude】key to display the current amplitude value. Modify the value using the knob

or the numerical keypad.

Example: Set amplitude to 4.6V peak-to-peak:

【frequency】【5】【】【8】【kHz】

or

【frequency】【5】【8】【0】【0】【Hz】

or

use the knob and 【】【】 keys

:

【Period】【1】【0】【ms】

Or

use the knob and【】【】 keys

Press【Amplitude】【4】【】【6】【Vpp】

or

modify values using the knob and arrow keys

21

Page 22

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

In case of standard waveforms “sine”, “square”, “triangle”, “rising ramp” and “pulse”, num bers can

be entered and displayed as Peak-to-peak value (Vpp or m Vpp) , root me an square value (Vrms and

mVrms) or dBm value.

All other waveforms can only be edited or displayed using Vpp or mVpp units only.

4.5.3 Set DC Offset Voltage

Press【shift】【offset】to display the current DC offset value. If the current DC offset value is not

equal to zero, the annunciator “Offset” will turn on. The DC offset value can be entered directly or

using the knob.

Example: Set an offset value -1.6V peak-to-peak

Press【shift】【offset】【-】【1】【】【6】【Vpp】

or

【shift】【offset】【1】【】【6】【-】【Vpp】

or

use the knob for value entry

Zero Point Adjustme nt

For zero point adjustment of the output signal, using the knob is more convenient than direct entry

via the numerical keypad. The transition of the DC offset Voltage from plus to minus sign will be

automatic when passing through the zero point. The input range of the signal amplitude and DC

offset should satisfy the following equation: |Voffset| + Vpp/2 ≤ Vmax, with the parameters

defined as followed:

Vpp is the peak-to-peak value of the amplitude

|Voffset| is the absolute value of the DC offset

Vmax is 10V at high impedance and 5V at 50Ω load.

The following table shows the corresponding relationship between the Vp-p value of the amplitude

and the absolute DC offset value at high impedance:

1.001 V ~ 20.00 V 0 ~ (10.000-Vpp/2) V

316.1 mV ~ 1.000 V 0 ~ 2.000 V

100.1 mV ~ 316.0 mV 0 ~ 632.9 mV

31.01 mV ~ 100.0 mV 0 ~ 200.9 mV

2.000 mV ~ 31.00 mV 0 ~ 62.99 mV

4.5.4 Adjustment of duty cycle

If the current waveform is pulse, and the current display value is amplitude, use the 【Ampl/Duty】

button to toggle between Amplitude and Duty cycle display. When the pulse width is displayed,

enter a value via the numeric keypad or the knob. The valid range is 0.1% ~ 99.9% for frequencies

below 10kHz with a maximum resolution of 0.1%. For frequencies between 10kHz~100kHz the

range is 1% ~ 99% and the maximum resolution is 1%.

Example: Enter a duty cycle value of 60.5%

Press 【Pulse】【6】【0】【】【5】【N】

or

use the knob and arrow keys

:

Vp-p value of AC signal Absolute value of DC offset

22

Page 23

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

4.5.5 Sync/TTL Signal

A TTL signal output is provided on the front-panel SYNC terminal. All signals, including

modulated signals and arbitrary waveforms (except DC and noise) have an associated TTL signal.

This signal is a TTL “high” when the waveform’s output (on the main terminal) is positive, relative

to zero volts. The signal is a TTL “low” when the output is negative. The TTL signal is generated by

passing the main output signal through a comparator configured as a Schmitt Trigger. The TTL

signal will transition to high or low once the main output signal exceeds a certain threshol d value,

which causes a time delay between the main output signal and the TTL signal.

4.5.6 Signal Store and Recall

Up to 10 different instrument states can be stored in non-volatile memory. T his enables you to rec all

the entire instrument configuration with a single command from the remote interface or with just a

few key presses from the front panel.

The state storage feature “remembers” the function (including arbitrary waveforms), frequency,

amplitude, DC offset, duty cycle, as well as any modulation param eters. To recall a stored state, you

must use the same memo r y l ocation used previously to store the state.

The last state of the instrument before power-off is automatically stored in location #0, therefore a

total of 11 groups locations ranging from 0 ~ 10 can be recalled.

Example:

Store the current output signal in group location #1:

【Shift】【Store】【1】【N】

The following prompt will be displayed for a few seconds: “STORE 1”

Previously stored signal configurations will be overwritten.

To recall group location #1 and make it the active output signal:

Press【Shift】【recall】【1】【N】

The following prompt will be displayed for a few secon ds: “RECALL: 1”

The stored signals can be continuously recalled and reproduced by scrolling through each location

using the knob.

23

Page 24

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

4.6 Set Modulation and Sweep Parameters

4.6.1. Sweep mode

In the frequency sweep mode, the function generator “steps” from the start frequency to the stop

frequency at a sweep rate which you specify. You can sweep up or down in frequency, and with

either linear or logarithmic spacing. Y ou can also configure the function generator to output a single

sweep (one pass from start frequency to stop frequency) by applying an external trigger. The

function generator can produce a frequency sweep for sine or square waveforms.

Press 【Sweep】 to enable the frequency sweep mode. The display shows a preset frequency (start

frequency) and the “Sweep” symbol appears i n the state display area. The carrier frequency will be

displayed and the frequency, amplitude, waveform and DC offset of the carrier signal can be set as

described in previous sections of this chapter. The main functions sine or square wave can be

selected as a carrier signal.

Press the 【menu】key repeatedly to cycle through the sweep menu parameters listed below.

MODE —> START F —> STOP F —> TIME —>TRIG

MODE Select LINEAR or LOGarithmic sweep mode

START F sweep start frequency

STOP F: sweep stop frequency

TIME: sweep time

TRIG: Select trigger source INTernal or EXTernal

Each time you press the menu key, the parameter will flash for 1 second, followed b y the value

of that parameter. Sweep mode parameters can be entered via numerical keypad or the knob.

Once the parameter is set, press 【menu】 to advance to the next parameter.

Sweep mode

MODE parameter: Select LINear (No.1) or LOGarthimic (No.2). In linear sweep mode, the output

frequency changes in a linear fashion during a sweep, whereas in LOG mode the frequency changes

exponentially. The spacing is calculated automatically based on start frequencies, stop frequencies

and sweep time.

Start frequency “START F”

The frequency where the sweep starts is the start frequency.

After displaying “START F” for 1 seco nd, the curr ent start frequency is displayed automatically and

can be modified via knob or direct data entry. By default, the start frequency will carry over from

the setting for the main wave form

.

Stop frequency “STOP F”

The sweep stops at the frequency “STOP F”

When the start frequency is lower than the stop frequency , the fre que ncy sweep incr eases gradu ally

from start frequency (low frequency) to stop frequency (high frequency); When the start frequency

is higher than stop frequency, the frequency sweep decreases gradually from the start frequency

(high frequency) to stop frequency (low frequency).

:

24

Page 25

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

The frequency range from start f requency to stop frequency is 1µHz ~ Fmax in linear sweep mode

and 1mHz ~ Fmax in log sweep mode. (Fmax see specification sect ion for main waveform)

Sweep time “TIME”

The time needed to complete one sweep from start to stop frequency is called sweep time.

The sweep time range is 1ms ~ 800s in linear sweep mode or 100ms ~ 800s in LOG sweep mode.

Trigger mode “TRIG”

:

A sweep can be triggered internally or externally. The corresponding display values are “1: INT”

and “2: EXT”. The default value is INTernal trigger . In internal trigger mode, the instrument will

continuously sweeps from the start frequency to the stop frequency according to the Sweep

parameters. An external trigger signal can be generated in one of two ways.

a) Press the 【output】 key to trigger a single sweep. The signal frequency will in/decrease fr om start

frequency to stop frequency, then sweep will stop.

b) Apply an input trigger signal to the “EXT Trig” terminal on the rear panel. A rising edge will

trigger a single sweep. In external trigger mode, symbols “Trig” and “Ext” are displayed in the

status field.

Start and stop of sweep

The sweep will start automatically once sweep mode is selected. If you don’t want to output the

sweep signal, simply press the 【output】key to disable the signal output (LED above Output button

is OFF). Once all the parameters are set, you can make the sweep signal available at the output by

pressing the Output button again. In external trigger mode, the 【Output】key functions only as a

single pulse trigger key, the Output On/Off functionality is now disabled and the output LED will

always be lit.

Sweep configuration example

Sweep parameters are as followed: Frequency range 100Hz~200kHz, sweep time 10s, linear sweep,

internal trigger mode.

Set the carrier frequency parameters

Press【sweep】

Press【menu】

Select “MODE”, wait, then enter【1】【N】(linear sweep)

Press【menu】to select “START F”, press【1】【0】【0】【Hz】

Press【menu】to select “STOP F”, press【2】【0】【0】【kHz】

Press【menu】to select “TIME, press【1】【0】【s】

Press【menu】 to select “TRIG”, press【1】【N】

Hint: The fr equency displayed immediately after pressing [Sweep] is the start freq uency. Any

changes to that value will automatically update parameter “START F”

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

25

Page 26

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

4.6.2 FM modulation

A mod ulated waveform consists of a carrier waveform and a modulating waveform. In FM, the

frequency of the carrier is varied by the amplitude of the modulating waveform. The function

generator will accept an internal or external FM modulating signal.

Press the 【FM】key to enter into FM mode. The display will indicate the carrier frequency and the

“FM” annunciator will be lit. The frequency, amplitude, waveform and DC offset of the carrier

signal can be set as described in th e previous section. Only the main functions sine or square wave

can be selected as a carrier signal.

Press the 【menu】 key repeatedly to cycle through the FM modulation parameters listed below.

FM DEVIA —> FM FREQ —> FM WAVE —> FM SOURCE

FM DEVIA Peak frequency deviation

FM FREQ: Frequency of modulating signal

FM WAVE: Waveform of modulating signal

FM SOURCE Toggle between internal or external modulating signal

Each time you press the menu key, the parameter will flash for 1 second, followed by the val ue of

that parameter. FM modulation parameters can be entered directly or via the knob. Once the

parameter is set, press 【menu】 to advance to the next parameter.

Peak frequency deviation ”FM DEVIA”

Explanation: The variation in freq uency of the modulating waveform from the carrier freque ncy

(center frequency).

Range of deviation: For internal FM modulation, th e maximum value s hould not exceed 50 % of the

carrier frequency. In external FM mode, the maximum deviation is 10% of the carrier frequency.

Additionally, the frequency deviation plus carrier frequency should not excee d the maximum

operating frequency of the instrument. (F

specifications for main waveforms.

This parameter applies only when “FM SOURCE” is set to “INTernal”.

Modulating signal frequency “FM FREQ

The frequency range of the modulating signal is 100µHz ~ 10kHz.

This parameter applies only when “FM SOURCE” is set to “INTernal”.

Modulating signal waveform “FM WAVE”

Waveform of the modulating signal: Waveforms sine, square, triangle, rising and falling ramp can

be used as the modulating signal. Waveforms are selected by entering the corresponding number,

numbers 1 – 5.

This parameter applies only when “FM SOURCE” is set to “INTernal”.

Modulating signal source “FM SOURCE”

The modulating signal could be an internal signal and external input signal. The corresponding

prompts are “1: INT” and “2: EXT”, the default is INTernal signal. The external modulating signal

is applied to terminal “Mod In” on the rear panel (max signal amplitude is 3Vp-p). When

+ Fd <= F

c

”:

:

+ 100 kHz) For Fmax refer to the

max

26

Page 27

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

modulating signal source “external” is selected, the symbol “Ext” is displaye d and parameters FM

DEVIA, FM FREQ and FM WAVE do not apply (disabled)

Start and stop of FM modulation

An FM signal is generated once FM function mode is selected. The instrument will automatically

output a signal according to the preset parameters. If you do not want to output the FM signal,

simply press the 【output】key to disable the signal output (LED above Output button is OFF). Once

all the parameters are set, you can turn make the FM signal available at the output by pressing the

Output button again.

FM example:

Example configuration: Carrier signal is square, frequency is 1MHz, amplitude is 2V, modulating

signal is generated internally . Carrier waveform is sine (N o. 1), Frequ ency is 5kH z. Peak fr equen cy

deviation is 200kHz.

Press【FM】

Press【frequency】then【1】【MHz】 (set carrier frequency)

Press【amplitude】, then【2】【V】 (set carrier amplitude)

Press【Shift】and 【square】 (set carrier waveform)

Press【menu】, select “FM DEVIA”, enter【2】【0】【0】【kHz】 (set FM deviation)

Press【menu】, select “FM FREQ”, press【5】【kHz】 (set FM frequency)

Press【menu】, select “FM WAVE, press【1】【N】 (set FM waveform as sine)

Press【menu】, select “FM SOURCE”, press【1】【N】 (set FM source as internal)

4.6.3 AM modulation

AM stands for amplitude modulation.

Press【AM】to enable AM modulation. The carrier frequency and the AM annunciator is displayed.

Frequency, amplitude, waveform and DC offset of the carrier signal can be set as described in the

previous section of this chapter. The parameters carry over from the parameter settings of the main

waveforms sine and square. In AM only sine and square waves can be selected for carrier.

Press the 【menu】 key repeatedly to cycle through the AM modulation parameters listed below.

AM LEVEL—> AM FREQ —> AM W AVE—>AM SOURCE

AM LEVEL: Modulation depth

AM FREQ: Frequency of modulating signal

AM WAVE: Waveform of modulating signal

AM SOURCE: internal or external modulating signal

In AM mode, to e nsure n or m al signa l out pu t at 100 % modulation depth, the instrument reduces th e

peak-to-peak value of the carrier by 50%. Only sine and square waves can be selected as AM

carrier.

27

Page 28

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Modulation depth “AM LEVEL”:

The range of modulation depth is 1% ~ 120%.

Modulating frequency “AM FREQ”

Frequency of the modulating signal. Range is 100µHz ~ 20kHz. Parameter does not apply when

“AM SOURCE” is set to “E XTernal”

Modulating signal waveform “AM WAVE”:

Waveforms sine, square, triangle, rising and falling ramp can be used as the modulating signal .

Waveforms are selected by entering the corresponding number, numbers 1 – 5. Parameter does not

apply when “AM SOURCE” is set to “EXTernal”

Modulating signal source “AM SOURCE”

Select internal signal and external input signal. The number and prompt symbols are 1: INT, 2: EXT .

The default of the instrument is internal signal. The external modulating signal is input through the

rear panel “Modulation Input” terminal (with a maximum signal amplitude of 3Vp-p).

Enabling and disabling the AM signal:

An AM signal is generated once AM modulation is selected. The instrument will automatically

output a signal according to the preset parameters. If you do not want to output the AM signal,

simply press the 【output】key to disable the signal output (LED above Output button is OFF). Once

all the parameters are set, you can m ake the AM signal a vailable at the outpu t by pressing the Output

button again.

AM example

:

Configuration: carrier signal is square wave, frequency 1MHz, amplitude 2V, internal signal,

modulating waveform sine wave (No.1), modulating signal frequency 5kHz, modulation depth

50%:

Press【AM】 (activate AM modulation)

Press【frequency】, then【1】【MHz】 (set carrier frequency)

Press【amplitude】, then【2】【V】 (set carrier amplitude)

Press【shift】 then【square】 (set carrier waveform)

Press【menu】, select “AM LEVEL”, press【5】【0】【N】 (set modulation depth)

Press【menu】, select “AM FREQ”, press【5】【kHz】 (set modulating signal frequency)

Press【menu】, select “AM WAVE”, press【1】【N】 (set AM wave as sine)

Press【menu】 select “AM SOURCE”, press【1】【N】 (set AM source to internal)

4.6.4 Burst modulation

You can configure the function generator to output a waveform with a specified number of cycles,

called a burst. You can output the burst at a rate determined by the internal rate generator or an

external signal applied to the rear-panel connector. The function generator can produce a burst using

sine or square waveforms.

Press【Burst】to enter into burst mode. The carrier frequency and the Burst annunciator are

displayed. Frequency, amplitude, waveform and DC offset of the carrier signal can be set as

28

Page 29

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

described in the previous se ction of this chapter. The parameters carry over from the paramete r

settings of the main waveforms sine and square. Press the 【menu】 key repeatedly to cy cle through

the burst menu parameters listed below.

TRIG —> COUNT —> SPACE T —> PHASE

TRIG: Trigger source

COUNT: Number of cycles

SPACE T: Burst time spacing

PHASE: The starting phase of the burs t

Select trigger source “TRIG”

Three trigger sources are available. Internal trigger and 2 types of external triggers sources, external

gated and single. The corresponding menu parameters are 1: INT, 2: EXT and 3: SINGLE. The

default is internal triggering.

a) Internal trigger

When the internal trigger source is selected, the frequency at which the burst is generated depends

on parameter SPACE_T, burst count and the burst carrier frequency.

b) Single trigger mode

Generate a single trigger event by pushing the 【output】key once or by applying a single TTL pulse

at the “Ext.Trig” input t erm inal in the rear panel. A single burst with predefined parameters will be

generated.

c) External gated burst mode

The TTL signal applied to “Ext. Trig” input terminal in the rear panel will enable or disable the

output of the generator. When the TTL level of the gate signal is high, the generated will generate

burst pulses according to the parameters of the set carrier frequency . Burst param eters COUNT and

SP ACE_T are ignored in this mode. Anunciators “T rig” and “E xt” t urn on whe n this mo de is active .

Burst count “COUNT”:

Definition: The number of cycles to be output per burst.

Range: 1 ~10000 cycles in 1 cycle increments. Additionally, the minimum number of cycles must

also satisfy F

/50khz +1。Parameter does not apply when “TRIG” is set to “EXTernal”.

C

Burst spacing time “SPACE T”:

Definition: Tim e interval between the 2 consecutive groups of bursts (time interval during which

there is no burst signal present) Parameter does not apply when “TRIG” is set to “EXTernal” or

“SINGle”.

Range: 0.1ms ~ 800s.

Starting phase of the burst “PHASE”

Burst phase: 0.0º ~ 360.0º in 0.1º increments

29

Page 30

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Enabling/disabling the burst signal

The generator outputs a burst as soon as the burst key is pressed. The instrument will automatically

output a signal according to the preset parameters. If you do not want to output the burst signal,

simply press the 【output】key to disable the signal output (LED above Output button is OFF). Once

all the parameters are set, you can make the burst signal available at the output by pressing the

Output button again. Note that the output on/off function does not apply when single trigger mode

is selected.

Burst example:

Configuration: Burst is sine wave with frequency 20kH z, amplitude 2V, 10 cycles per group,

spacing time between each group 10 ms, start phase 90.0º

Press【burst】 (enter into burst mode)

Press【frequency】, press【2】【0】【kHz】 (set wave form frequency)

Press【amplitude】, press【2】【V】 (set waveform amplitude)

Press【shift】and【sine】 (set waveform)

Press【menu】, select “TRIG”, press【1】【N】 (set trigger mode as internal)

Press【menu】, select “COUNT”, press【1】【0】【N】 (set number of bursts/cycles)

Press【menu】, select “SP ACE T”, press【1】【0】【ms】 (set space time)

Press【menu】, select “PHASE”, press【9】【0】【N】

(set the start phase of burst)

4.6.5 FSK modulation

You can configure the function generator to “shift” its output frequency between two preset values

using FSK modulation. The rate at whic h the output shifts between the two frequencies (“carrier

frequency” and “hop frequency”) is determined by the internal rate generator or the signal level on

the rear-panel ext Trig/FSK/Burst terminal.

Press【FSK/PSK 】to enable FSK modulation. A preset frequency and the FSK annunciator is

displayed. The preset frequency is identical to the “START F” parameter. Any changes

automatically update “START-F” and vice versa. Frequency , amplitude , waveform and DC of fset of

the carrier signal can be set as described in the previous section of this chapter. In FSK/PSK only

sine and square waves can be selected as carrier wave.

Press the 【menu】 key repeatedly to cycle through the FSK menu parameters listed below.

ST ART F —> STOP F—> SPACE T —> TRIG

START F: First frequency or carrier frequency

STOP F: Second frequency (hop frequency)

SP ACE T: FSK rate

TRIG: Trigger source

Trigger source “TRIG”

Select internal signal and external input signal, 1: INT or 2: EXT. The default of the instrument is

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

30

Page 31

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

“internal”.

In internal mode, the rate at which the signal shifts between the carrier and hop frequency is

determined by the FSK rate.

In external trigger mode, the trigger signal applied to the trigger input terminal on the rear panel

determines the FSK rate. Logical “high” of the trigger signal is associated with frequency 2, while

the “Low” level of the trigger signal is associated with frequency 1.

Frequency 1 “START F”

The first frequency or carrier frequency.

Frequency 2 “STOP F”

Second frequency or hop frequency

Frequency input range of frequency 1 and frequency 2 is 1µHz ~ Fmax.

Spacing time “SPACE T”

:

This parameter sets the FSK rate with a range of 1m s ~ 800s.

FSK example

:

Configuration: Sine signal of 2V output amplitude, carrier frequency 20kH z and hopping frequency

600 kHz, FSK rate 10ms

Press【FSK/PSK】 (enter into FSK function mode)

Press【Ampl/Duty】, press【2】【V】 (set waveform amplitude)

Press【shift】and【sine】 (set waveform)

Press【menu】, select “TRIG”, enter【1】【N】 (set trigger mode as internal)

Press【menu】, select “START F”, enter【2】【0】【kHz】 (set carrier frequency F1)

Press【menu】, select “STOP F”, enter【6】【0】【0】【kHz】 (set hop frequency F2)

Press【menu】, select spacing time “SPACE T”, press【1】【0】【ms】 (set spacing time)

4.6.6 PSK modulation

You can configure the functi on generator t o “shift” its ou tput phase bet ween two preset values using

P

SK modulation. The rate at which the output shifts between the two phases is determined by the

internal rate generator or the signal level applied to the trigger input terminal on the rear-panel.

Press 【FSK/PSK】 twice to enter phase shift keying (PSK) mode. The carrier frequency will be

displayed along with the symbol “” and “FSK”. Frequency, amplitude, waveform and DC offset

of the carrier signal can be set as described in the previous section of this chapter. The parameters

carry over from the parameter settings of the ma in waveforms sine and square. If FSK mode was

already active, press this key only once, (this key toggles the modulation between FSK and PSK

mode). In FSK mode only sine and square waves can be selected as a carrier signal.

Press the 【menu】 key repeatedly to cycle through the burst menu parameters listed below.

P1 —> P2 —> SPACE T —> TRIG

P1 Phase value #1

31

Page 32

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

P2: phase value #2

SP ACE T PSK rate

TRIG Trigger source for PSK

Trigger source “TRIG”

Select internal signal and external input signal 1: INT or 2: EXT. The default of the instrument is

internal. In internal mode, the phase of t he output si gna l shifts according to the PSK rate parameter.

In external trigger mode, the trigger s ignal is applied to the Ext. Trig” Input terminal on the rear

panel. In external trigger mode, the trigger signal applied to the trigger i nput term inal on the rear

panel determines the PSK rate. Logical “hi gh” of the trigger signal is associated with phase value #2,

while the “Low” level of the trigger signal is associated with phase value #1.

Phase 1 “P1”

The first start phase value of the PSK output signal.

Input range of phase 1 and phase 2 is º0.0º~ 360.0º.

Phase 2 “P2”

The second start phase value of the PSK output signal.

Input range of phase 1 and phase 2 is 0.0º~ 360.0º.

Spacing time “SPACE T”

PSK rate: Range is 0.1ms ~ 800s.

PSK example

Configuration: Sine signals with 600 kHz output frequency, 2V amplitude, phase alternating

between 90.0º and 180.0º, PSK rate is 10ms

Press【FSK/PSK】 (2 times if necessary to enter PSK mode)

Press【Freq/Period】, enter【6】【0】【0】【kHz】 (set waveform frequency)

Press【Ampl/Duty】, enter【2】【V】 (set waveform amplitude)

Press【shift】【sine】 (set waveform)

Press【menu】, select “TRIG”, enter【1】【N】, (set trigger mode as internal)

Press【menu】, select “P1”, enter【9】【0】【N】 (set phase 1)

Press【menu】key, select “P2”, enter【1】【8】【0】【N】 (set phase 2)

Press【menu】, select “SPA CE T” , e nter【1】【

0】【ms】 (set PSK rate)

4.7 Set System Parameters

Press【Shift】and【system】to enter the Systems menu. “SYSTEM” will flash on the display.

Repeatedly press【menu】to cycle through the system parameters indicated below.

POWER ON —> ADDRESS —> OUT Z —> INTERFACE—>….

…………BAUD —> PARITY

POWER ON “Power on” state

32

Page 33

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

ADDRESS: set GPIB address (option)

OUT Z: Configure amplitude display for 50Ω or high impedance load termination

INTERFACE: Select RS232 or GP-IB (IEEE-488) interface (option)

BAUD: Baud rate for the RS232 interface

PARITY: Parity and Data Bits configuration for RS232

After the selected system parameter f lashes f or 1 second, the parameter value will be displayed and

the value can be edited using the knob or via direct entry using the numerical keypad.

Power on state “POWER ON:

This parameter has 2 possible values, “1: DEFAULT” or “2: LAST STATE”. In determines the

initial setting of the instrument after power up. The factory setting is “1: DEFAULT”. The default

state is main waveform sine wave, 10kHz, 2Vpp which is identical to the state the instrument is in

after pressing “Rese t”. Whe n selecti ng “2: LAST STATE”, the instrument will “remember” the l ast

state the unit was in before power was turned off. The power on state is stored in non-volatile

memory, location 0 (see Store/Recall section)

GPIB address “ADDRESS”

The default of GP-IB interface address is 1. It can be set within 0 ~ 30.

Output impedance “OUT Z”

The generator has a fixed output impedance of 50 ohms on the OU TPUT terminal. You can specify

whether you are terminating the output into a 50 ohm load or an open circuit. Incorrect impedance

matching between the function generator and y our load will res ult in amplitude or offset which does

not match the specified signal level.

Select “1: HIGH Z” or “2: 50 OHM” according to your load configuration.

“INTERFACE” selection

Select RS232 (“2: RS232”), GPIB (“1: GP-IB”) or USB (“3: USB”). The default is RS232.

“BAUD” rate setting

Set the baud rate for the RS232 interface. Possi bl e baud rates are 9600, 4800, 2400, 1200, 60 0 a nd

300. The default rate is 9600 (“1: 9600”)

“PARITY” setting

Set parameters parity bit and n umber of data bits. Possible configurat ions are:

None/ 8 data bits (“1: NONE 8 BITS”)

Odd/ 7 data bits (“2: ODD 7 BITS”

Even/ 7 data bits (“3: EVEN 7 BITS”).

The default setting is None/ 8 data bits.

Example for system function setting

Configuration: Set power on state [POWER ON] to default and output impedance to 50

Press【Shift】【system】 (enter systems menu)

Press【menu】, “POWER ON”, press【1】【N】 (set power on state to default)

33

Page 34

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

Press【menu】, select “OUT Z”, press【2】【N】 (configure for load impedance of 50)

4.8 Universal Counter

Overview of Counter functions

This instrument contains a counter with frequency measurement and totalize functionality which is

completely independent from the Arbitrary/function generator section. The range of the frequency

measurement function is 1Hz ~ 100MHz. Repeatedly pressing 【Shift】【Count】will toggle between

Frequency measurement and Totalize mode.

Press【Shift】and【F.C./TOT】once to activate the frequency measurem ent mode . Symbols “E xt”

and “Freq” will be displayed in the state field and “WAITING” will flash on the main display. The

unit is now ready to measure and display t he frequency of a signal applied to the input term inal

“Meas Freq/TOT IN” in the rear panel. When totalize mode is active, sym bols “Ext” and “Count”

will be displayed on the status field along with the result for the count on the main display (“0” is

displayed until a valid signal is detected). The unit is now ready to totalize events represented by the

signal applied to input terminal “Meas Freq/TOT IN” in the rear panel

In event counting mode, press the 【】key to start and stop the event counter . When stopped, the

current count will be displayed. Press【】key to reset the event counter to zero and resume

counting.

Gate time

Only applies to frequency measurement mode. Press【Shift】【gate】to enter a gate time setting.

Either the numerical keypad or the knob can be used to enter a gate time value. If the gate is open,

the symbol “GATE” is displayed in the counter state field on the right. The range of gate times is

10ms ~ 10s

Low pass filte

r

By pressing 【Shift】【LPF】, the input signal will be passed through a low pass filter before being

passed onto the counter circuit. T he word “Filter ” ap pears on t he righ t dis play fiel d to ind ica te that

the Low Pass Filter is active.

Attenuation

Press【Shift】【ATT】 to activate the attenuator which attenuates the input signal by a factor 10:1.

“ATT” is displayed on the right to indicate that the input attenuator is active.

34

Page 35

4080 series Arbitrary/Function Generator with Counter –Instruction Manual

5. REMOTE INTERFACE REFERENCE

5.1 Introduction

An Introduction to the SCPI Language

SCPI (Standard Commands for Programmable Instruments) is an ASCII-based instrument

command language designed for test and m easurement instr uments . SCPI comm ands are based on

a hierarchical structure, also known as a tree system. In this system, associated commands are

grouped together under a common node or root, thus forming subsystems. A portion of the

SOURCE subsystem is shown below to illustrate the tree system.

SOURce:

FREQuency:

STARt {<frequency>|MINimum|MAXimum}

FREQuency:

STARt? [MINimum|MAXimum]

FREQuency:

STOP {<frequency>|MINimum|MAXimum}

FREQuency:

STOP? [MINimum|MAXimum]

SOURce is the root keyword of the command, FREQuency is the second-level keywords, and