Page 1

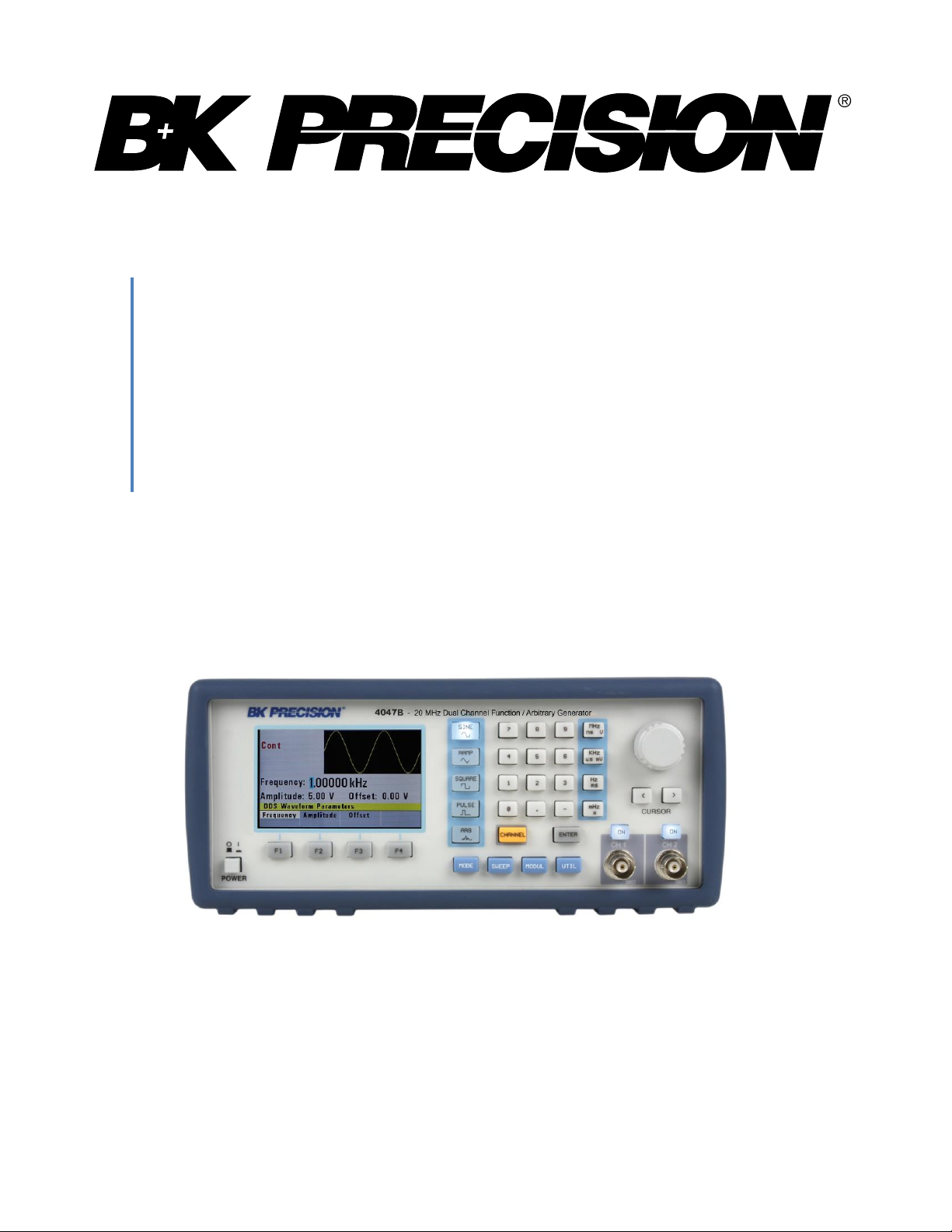

Model: 4047B

Dual Channel Function/Arbitrary

Waveform Generator

USER MANUAL

Page 2

Safety Summary

The following safety precautions apply to both operating and maintenance personnel and must be

followed during all phases of operation, service, and repair of this instrument.

Before applying power to this instrument:

Read and understand the safety and operational information in this manual.

Apply all the listed safety precautions.

Verify that the voltage selector at the line power cord input is set to the correct line voltage.

Operating the instrument at an incorrect line voltage will void the warranty.

Make all connections to the instrument before applying power.

Do not operate the instrument in ways not specified by this manual or by B&K Precision.

Failure to comply with these precautions or with warnings elsewhere in this manual violates the

safety standards of design, manufacture, and intended use of the instrument. B&K Precision assumes

no liability for a customer’s failure to comply with these requirements.

Category rating

The IEC 61010 standard defines safety category ratings that specify the amount of electrical energy

available and the voltage impulses that may occur on electrical conductors associated with these

category ratings. The category rating is a Roman numeral of I, II, III, or IV. This rating is also

accompanied by a maximum voltage of the circuit to be tested, which defines the voltage impulses

expected and required insulation clearances. These categories are:

Category I (CAT I): Measurement instruments whose measurement inputs are not intended to be

connected to the mains supply. The voltages in the environment are typically derived from a limitedenergy transformer or a battery.

Category II (CAT II): Measurement instruments whose measurement inputs are meant to be

connected to the mains supply at a standard wall outlet or similar sources. Example measurement

environments are portable tools and household appliances.

Category III (CAT III): Measurement instruments whose measurement inputs are meant to be

connected to the mains installation of a building. Examples are measurements inside a building's

circuit breaker panel or the wiring of permanently-installed motors.

Category IV (CAT IV): Measurement instruments whose measurement inputs are meant to be

connected to the primary power entering a building or other outdoor wiring.

Do not use this instrument in an electrical environment with a higher category rating than what is

2

Page 3

specified in this manual for this instrument.

You must ensure that each accessory you use with this instrument has a category rating equal to or

higher than the instrument's category rating to maintain the instrument's category rating. Failure to

do so will lower the category rating of the measuring system.

Electrical Power

This instrument is intended to be powered from a CATEGORY II mains power environment. The mains

power should be 120 V RMS or 240 V RMS. Use only the power cord supplied with the instrument and

ensure it is appropriate for your country of use.

Ground the Instrument

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical

safety ground. This instrument is grounded through the ground conductor of the supplied, threeconductor AC line power cable. The power cable must be plugged into an approved three-conductor

electrical outlet. The power jack and mating plug of the power cable meet IEC safety standards.

Do not alter or defeat the ground connection. Without the safety ground connection, all accessible

conductive parts (including control knobs) may provide an electric shock. Failure to use a properlygrounded approved outlet and the recommended three-conductor AC line power cable may result in

injury or death.

Unless otherwise stated, a ground connection on the instrument's front or rear panel is for a

reference of potential only and is not to be used as a safety ground.

Do not operate in an explosive or flammable atmosphere

Do not operate the instrument in the presence of flammable gases or vapors, fumes, or finely-divided

particulates.

3

Page 4

The instrument is designed to be used in office-type indoor environments. Do not operate the

instrument

In the presence of noxious, corrosive, or flammable fumes, gases, vapors, chemicals, or finely-

divided particulates.

In relative humidity conditions outside the instrument's specifications.

In environments where there is a danger of any liquid being spilled on the instrument or

where any liquid can condense on the instrument.

In air temperatures exceeding the specified operating temperatures.

In atmospheric pressures outside the specified altitude limits or where the surrounding gas is

not air.

In environments with restricted cooling air flow, even if the air temperatures are within

specifications.

In direct sunlight.

This instrument is intended to be used in an indoor pollution degree 2 environment. The operating

temperature range is 0 °C to 50 °C and the operating humidity is ≤ 95 % relative humidity at < 30 °C,

with no condensation allowed.

Measurements made by this instrument may be outside specifications if the instrument is used in

non-office-type environments. Such environments may include rapid temperature or humidity

changes, sunlight, vibration and/or mechanical shocks, acoustic noise, electrical noise, strong electric

fields, or strong magnetic fields.

Do not operate instrument if damaged

If the instrument is damaged, appears to be damaged, or if any liquid, chemical, or other material gets

on or inside the instrument, remove the instrument's power cord, remove the instrument from

service, label it as not to be operated, and return the instrument to B&K Precision for repair. Notify

B&K Precision of the nature of any contamination of the instrument.

Clean the instrument only as instructed

4

Page 5

Do not clean the instrument, its switches, or its terminals with contact cleaners, abrasives, lubricants,

solvents, acids/bases, or other such chemicals. Clean the instrument only with a clean dry lint-free

cloth or as instructed in this manual.

Not for critical applications

This instrument is not authorized for use in contact with the human body or for use as a component

in a life-support device or system.

Do not touch live circuits

Instrument covers must not be removed by operating personnel. Component replacement and

internal adjustments must be made by qualified service-trained maintenance personnel who are

aware of the hazards involved when the instrument's covers and shields are removed. Under certain

conditions, even with the power cord removed, dangerous voltages may exist when the covers are

removed. To avoid injuries, always disconnect the power cord from the instrument, disconnect all

other connections (for example, test leads, computer interface cables, etc.), discharge all circuits, and

verify there are no hazardous voltages present on any conductors by measurements with a properlyoperating voltage-sensing device before touching any internal parts. Verify the voltage-sensing device

is working properly before and after making the measurements by testing with known-operating

voltage sources and test for both DC and AC voltages. Do not attempt any service or adjustment unless

another person capable of rendering first aid and resuscitation is present.

Do not insert any object into an instrument's ventilation openings or other openings.

Hazardous voltages may be present in unexpected locations in circuitry being tested when a fault

condition in the circuit exists.

Fuse replacement

Fuse replacement must be done by qualified service-trained maintenance personnel who are aware

of the instrument's fuse requirements and safe replacement procedures. Disconnect the instrument

from the power line before replacing fuses. Replace fuses only with new fuses of the fuse types,

voltage ratings, and current ratings specified in this manual or on the back of the instrument. Failure

to do so may damage the instrument, lead to a safety hazard, or cause a fire. Failure to use the

specified fuses will void the warranty.

5

Page 6

Servicing

Do not substitute parts that are not approved by B&K Precision or modify this instrument. Return the

instrument to B&K Precision for service and repair to ensure that safety and performance features are

maintained.

Cooling fans

This instrument contains one or more cooling fans. For continued safe operation of the instrument,

the air inlet and exhaust openings for these fans must not be blocked nor must accumulated dust or

other debris be allowed to reduce air flow. Maintain at least 25 mm clearance around the sides of the

instrument that contain air inlet and exhaust ports. If mounted in a rack, position power devices in

the rack above the instrument to minimize instrument heating while rack mounted. Do not continue

to operate the instrument if you cannot verify the fan is operating (note some fans may have

intermittent duty cycles). Do not insert any object into the fan's inlet or outlet.

For continued safe use of the instrument

Do not place heavy objects on the instrument.

Do not obstruct cooling air flow to the instrument.

Do not place a hot soldering iron on the instrument.

Do not pull the instrument with the power cord, connected probe, or connected test lead.

Do not move the instrument when a probe is connected to a circuit being tested.

6

Page 7

This product is subject to Directive 2002/96/EC of the European

Parliament and the Council of the European Union on waste electrical

and electronic equipment (WEEE), and in jurisdictions adopting that

Directive, is marked as being put on the market after August 13, 2005,

and should not be disposed of as unsorted municipal waste. Please

utilize your local WEEE collection facilities in the disposition of this

product and otherwise observe all applicable requirements.

Compliance Statements

Disposal of Old Electrical & Electronic Equipment (Applicable in the European

Union and other European countries with separate collection systems)

7

Page 8

CE Declaration of Conformity

This instrument meets the requirements of 2006/95/EC Low Voltage Directive and 2004/108/EC

Electromagnetic Compatibility Directive with the following standards.

Low Voltage Directive

- EN61010-1: 2001

EMC Directive

- EN 61000-3-2: 2006

- EN 61000-3-3: 1995+A1: 2001+A2: 2005

- EN 61000-4-2 / -3 / -4 / -5 / -6 / -11

- EN 61326-1: 2006

8

Page 9

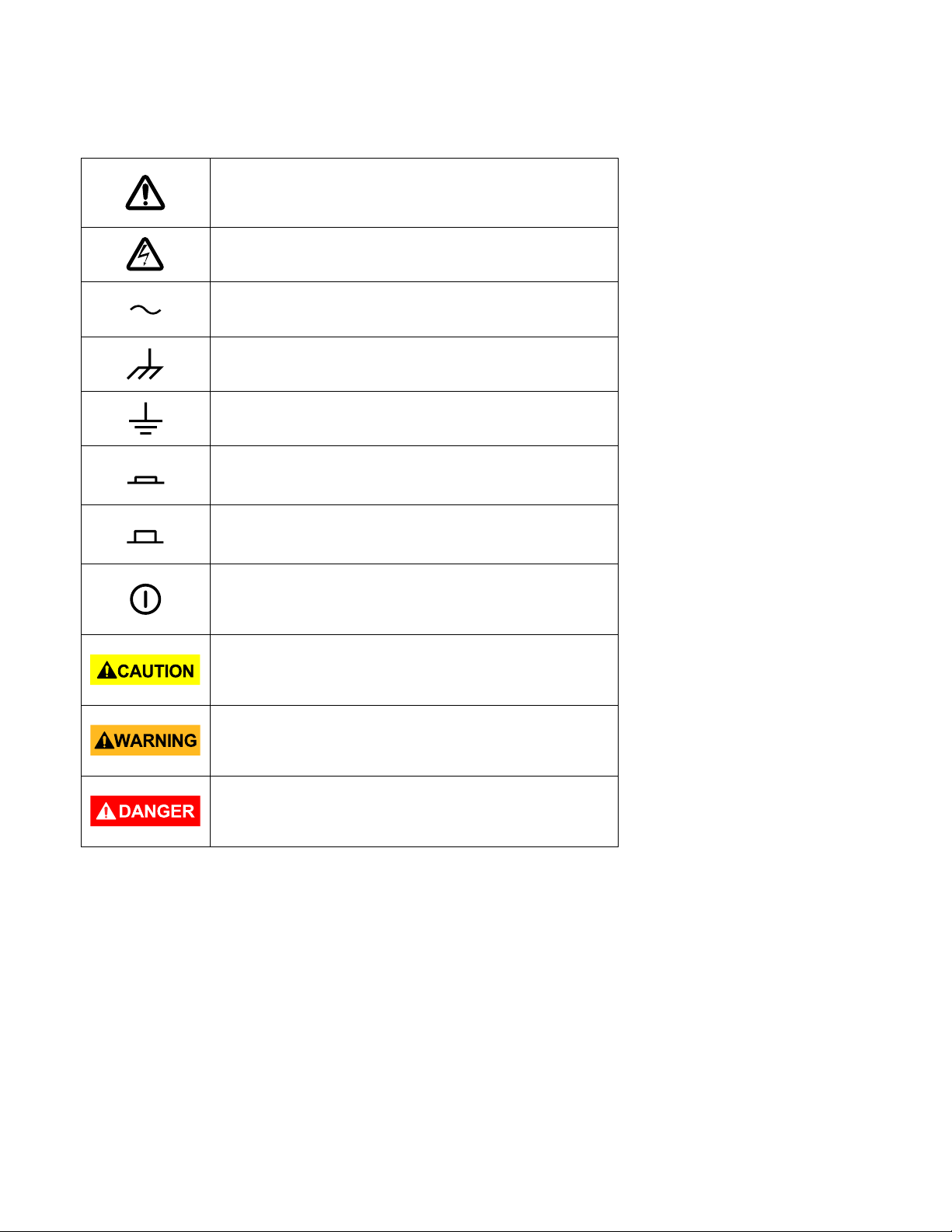

Refer to the user manual for warning information

to avoid hazard or personal injury and prevent

damage to instrument.

Electric Shock hazard

Alternating current (AC)

Chassis (earth ground) symbol.

Ground terminal

On (Power). This is the In position of the power

switch when instrument is ON.

Off (Power). This is the Out position of the power

switch when instrument is OFF.

Power Switch (On/Off). This is the power switch

located in front of the instrument.

CAUTION indicates a hazardous situation which, if

not avoided, will result in minor or moderate injury

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury

DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

Safety Symbols

9

Page 10

Contents

Safety Summary ............................................................................................. 2

Compliance Statements ......................................................................................................... 7

Safety Symbols ....................................................................................................................... 9

1 General Information ......................................................................... 13

1.1 Product Overview ......................................................................................................... 13

1.2 Package Contents .......................................................................................................... 13

1.3 Front Panel Overview .................................................................................................... 14

1.4 Rear Panel Overview ..................................................................................................... 15

1.5 Display Overview........................................................................................................... 16

2 Getting Started ................................................................................. 17

2.1 Input Power and Fuse Requirements ............................................................................ 17

2.2 Connectors .................................................................................................................... 18

2.3 Output Connections ...................................................................................................... 18

2.4 Preliminary Check ......................................................................................................... 19

3 Operating Instructions ...................................................................... 21

3.1 Menu Keys ..................................................................................................................... 21

3.1.1 WAVEFORM Keys ............................................................................................. 21

3.1.2 MODE Key ........................................................................................................ 22

3.1.3 UTILITY Key ...................................................................................................... 24

3.1.4 SWEEP Key ....................................................................................................... 25

3.1.5 MODULATION Key............................................................................................ 26

3.1.6 ARBITRARY Key ................................................................................................ 31

3.1.7 Arbitrary EDIT Menu ........................................................................................ 33

3.2 ON Key........................................................................................................................... 36

3.3 Cursor Keys .................................................................................................................... 36

3.4 Rotary Input Knob ......................................................................................................... 36

3.5 Power-On Settings ........................................................................................................ 36

3.6 Memory......................................................................................................................... 37

3.7 Displaying Errors ........................................................................................................... 37

3.8 Quick Start ..................................................................................................................... 38

3.8.1 Selecting a Standard Waveform ..................................................................... 38

10

Page 11

3.8.2 Setting the Output .......................................................................................... 38

3.8.3 Using Voltage Offset ....................................................................................... 38

3.8.4 Storing and Recalling a Waveform Generator Setup ...................................... 39

3.8.5 Creating an Arbitrary Waveform ..................................................................... 40

3.8.6 Entering Individual Data Points ....................................................................... 40

3.8.7 Setting the Arbitrary Frequency ...................................................................... 41

3.8.8 Setting the Amplitude ...................................................................................... 41

3.8.9 Executing an Arbitrary Waveform .................................................................... 42

4 Programming .................................................................................... 43

4.1 Overview ...................................................................................................................... 43

4.1.1 Connecting to USB (Virtual COM) Interface..................................................... 43

4.1.2 USB (Virtual COM) Settings ............................................................................. 46

4.2 Device States ................................................................................................................ 47

4.2.1 Local State (LOCS) ............................................................................................ 47

4.2.2 Remote State (REMS) ....................................................................................... 47

4.3 Message Exchange Protocol ......................................................................................... 47

4.3.1 The Input Buffer ............................................................................................... 47

4.3.2 The Output Queue ........................................................................................... 48

4.3.3 Response Messages ......................................................................................... 48

4.4 Instrument Identification ............................................................................................. 48

4.5 Instrument Reset .......................................................................................................... 48

4.6 Command Syntax ........................................................................................................ 48

4.6.1 General Command Structure ........................................................................... 48

4.7 Status Reporting ........................................................................................................... 51

4.7.1 The Error Queue ............................................................................................... 51

4.7.2 Error Codes ...................................................................................................... 51

4.8 Common Commands ................................................................................................... 54

4.8.1 System Data Commands .................................................................................. 54

4.8.2 Internal Operation Commands ........................................................................ 55

4.8.3 Device Trigger Commands ............................................................................... 55

4.8.4 Stored Settings Commands .............................................................................. 55

4.9 Instrument Control Commands ................................................................................... 56

4.9.1 Default Subsystem ........................................................................................... 57

4.9.2 Arbitrary Subsystem ........................................................................................ 67

11

Page 12

5 Troubleshooting Guide ...................................................................... 72

6 Specifications .................................................................................... 74

SERVICE INFORMATION ............................................................................... 78

LIMITED THREE-YEAR WARRANTY ................................................................ 79

12

Page 13

1 General Information

1.1 Product Overview

The 4047B is a versatile dual-channel function generator with arbitrary capabilities. Implemented

using a DDS (direct digital synthesis) architecture, this instrument generates stable and precise sine,

square, triangle, and arbitrary waveforms. The unit also provides linear and logarithmic sweep for

users needing sweep capability. An auxiliary TTL output at the generator’s set frequency is available to

synchronize external devices. The instrument can also be remotely operated via the USB interface and

is SCPI compatible.

1.2 Package Contents

Please inspect the instrument mechanically and electrically upon receiving it. Unpack all items from

the shipping carton, and check for any obvious signs of physical damage that may have occurred

during transportation. Report any damage to the shipping agent immediately. Save the original

packing carton for possible future reshipment. Every generator is shipped with the following contents:

4047B DDS function generator

AC Power Cord

USB (type A to B) interface cable

Certificate of Calibration

Verify that all items above are included in the shipping container. If anything is missing, please contact

B&K Precision.

13

Page 14

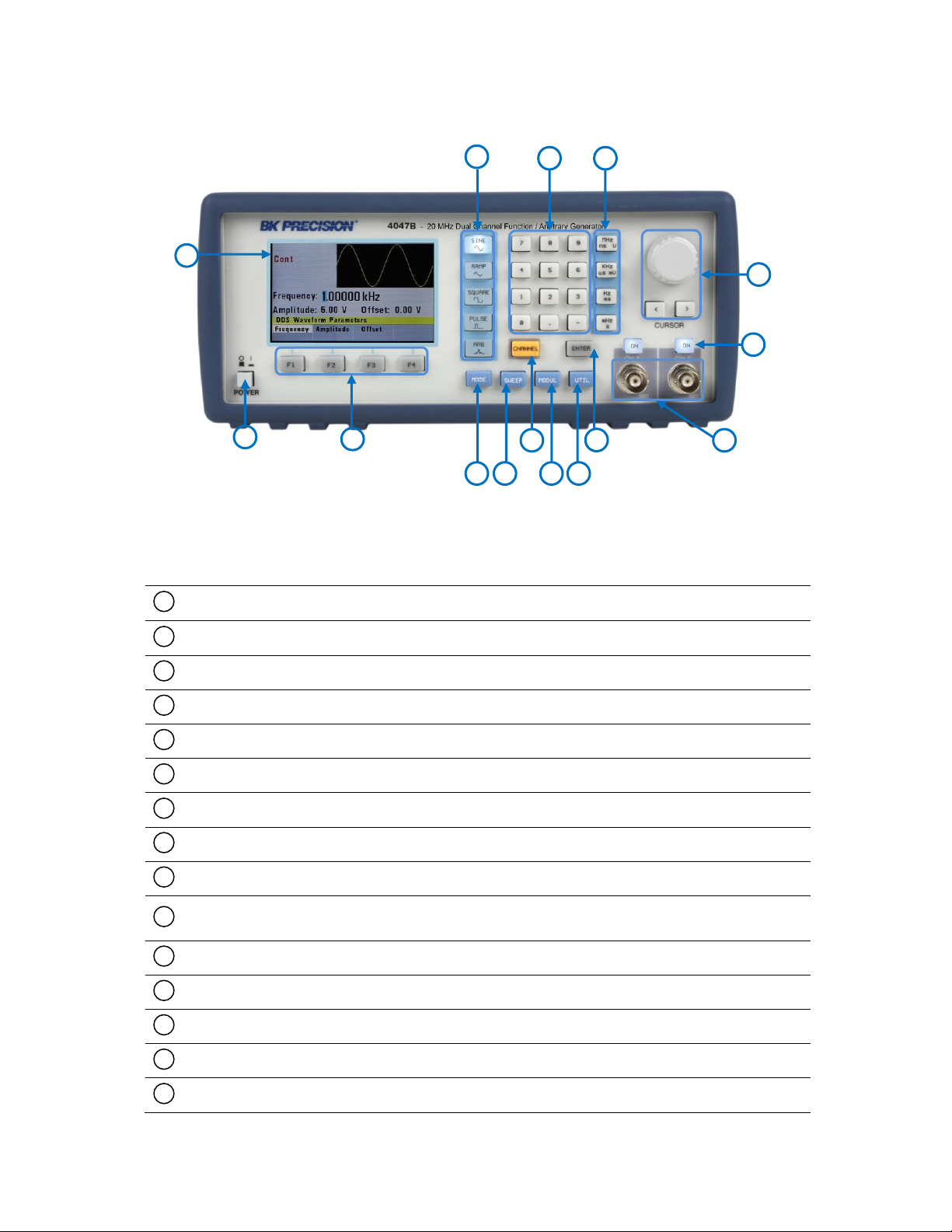

Power On/Off Switch

Function Keys (F1-F4)

Mode Key

Sweep Key

Channel Key

Modulation Key

Utility Key

Enter Key

Output BNCs

Output On/Off Key

Rotary Knob and Cursor Keys

Units Keys

Numeric Keypad

Waveform Keys

LCD Display

1 2 3 4 5

6 7 8 9 10

11

12

13

14

15

1

2

3 5 8

11

12

13

15

14 9 10

4 6 7

1.3 Front Panel Overview

Front Panel Description

Figure 1 - Front Panel Overview

14

Page 15

Modulation Input BNC

External Trigger Input and Counter BNC

CH1 Sync Output BNC

CH2 Sync Output BNC

USB Interface

Earth Ground

AC Power Connector and Fuse Box

Rear Cooling Fan

1 2 3

4

5 6 7

8

8

7

1

2 3 4

5

6

The front-panel controls select, display, and change parameter, function, and mode settings.

Use the numerical keypad, rotary input knob and the cursor movement keys to enter data into the

waveform generator.

To change a setting:

1. Press the key that leads to the parameter to change.

2. Move cursor using cursor keys to the appropriate position in the numeric field (if applicable).

3. Use the rotary input or the numerical keyboard to change the value of the displayed parameter.

Changes take effect immediately.

1.4 Rear Panel Overview

Rear Panel Description

Figure 2 - Rear Panel Overview

15

Page 16

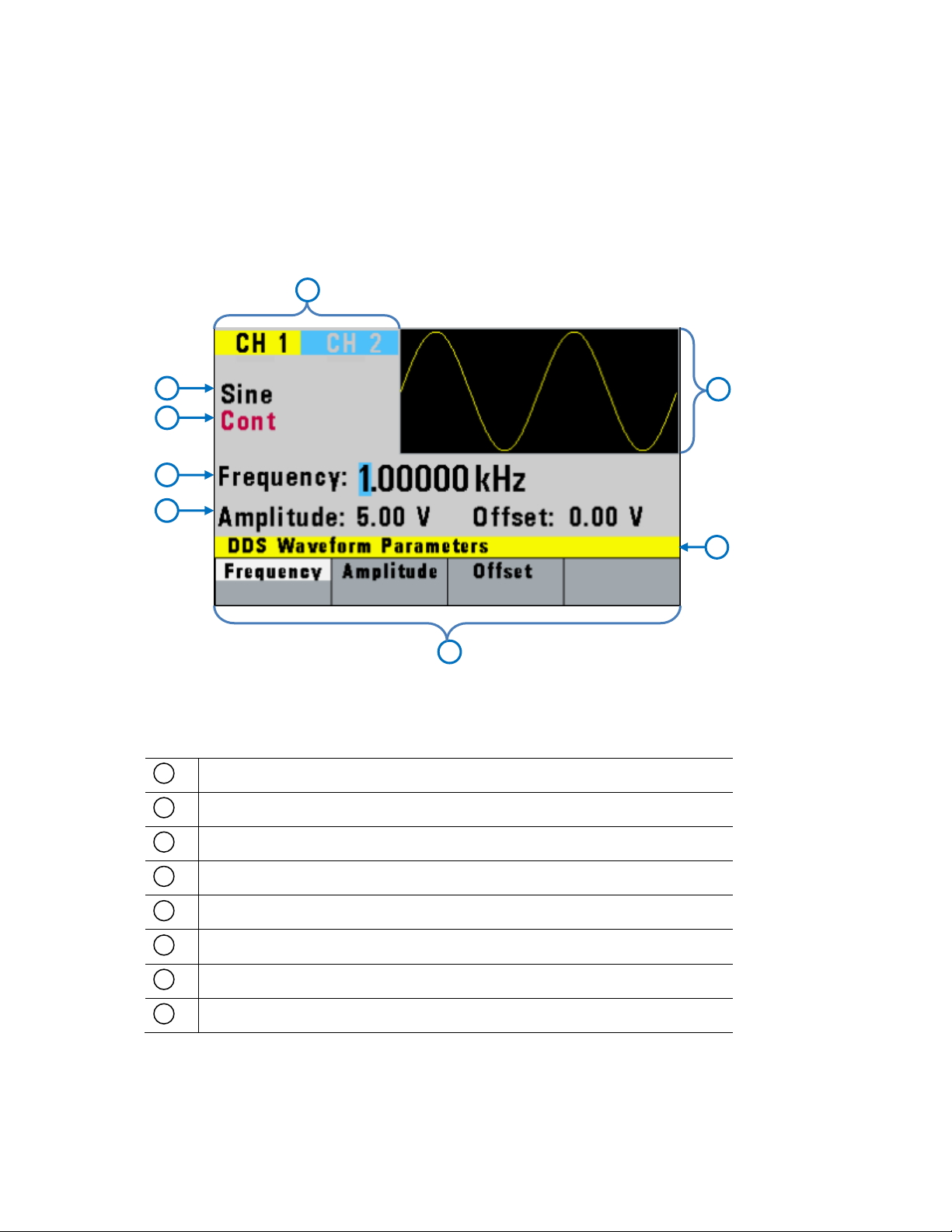

Wave Type

Trigger Mode

Frequency

Menu Parameters Values

Menu Options

Menu Title

General Waveform Display

Channel Selection Indicator

1 2 3 4 5

6 7 8

5

4 8 2 1 3 7 6

1.5 Display Overview

The function generator has a color LCD display that can display up to 400 x 240 dots. When powering

on the unit, sine waveform is selected and current settings will appear in the display. The bottom of

the display shows a menu (selectable with function keys) that corresponds to the function, parameter,

or mode display selected.

Display Description

Figure 3 - Display Overview

16

Page 17

The included AC power cord is safety certified for this

instrument operating in rated range. To change a

cable or add an extension cable, be sure that it can

meet the required power ratings for this instrument.

Any misuse with wrong or unsafe cables will void the

warranty.

2 Getting Started

Before connecting and powering up the instrument, please review and go through the instructions in

this chapter.

2.1 Input Power and Fuse Requirements

Input Power

The instrument has a universal AC input that accepts line voltage and frequency input within:

90 V to 264 V, 48 Hz to 66 Hz

The maximum power consumption is 30 VA. Use a slow blow fuse of 1A, UL/CSA approved as

indicated on the rear panel of the instrument.

Before connecting to an AC outlet or external power source, be sure that the power switch is in the

OFF position and verify that the AC power cord, including the extension line, is compatible with the

rated voltage/current and that there is sufficient circuit capacity for the power supply. Once verified,

connect the cable firmly.

Fuse Requirements

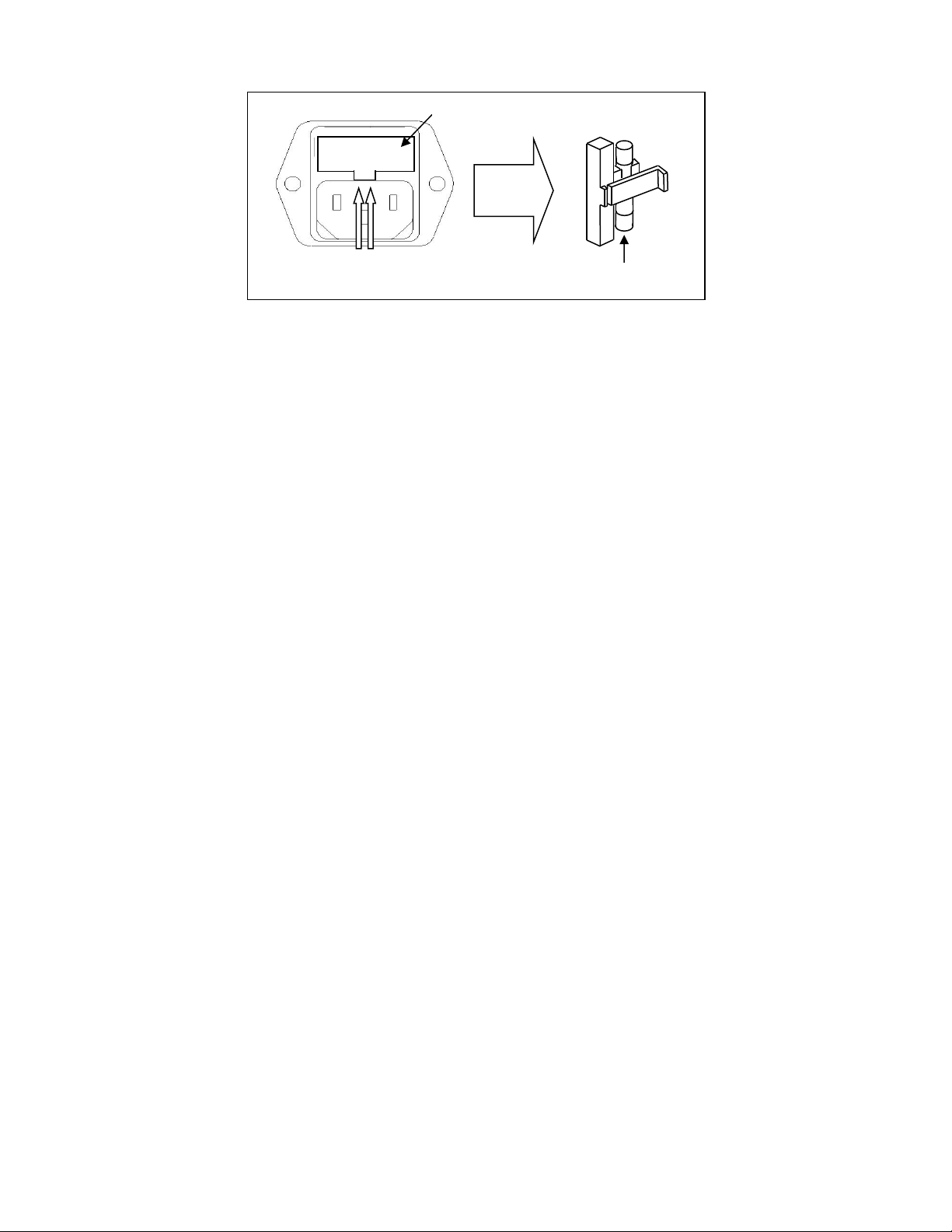

The instrument power fuse is located in the AC input plug. To access the fuse, first disconnect the

power cord and then remove the fuse box.

There is a 1A, 250V rated slow blow fuse at the AC input. Should the fuse ever get blown, follow the

steps below to replace:

1. Locate the fuse box next to the AC input connector in the rear panel.

2. With a small flat blade screwdriver, insert into the fuse box slit to pull and slide out the fuse

box as indicated below.

3. Check and replace fuse if necessary.

17

Page 18

Fuse box slit

Fuse box

Check/Remove Fuse

Figure 4 - Fuse Replacement

2.2 Connectors

The function generator has two BNC connectors on the front panel where you can connect coaxial

cables. These coaxial cables serve as carrier lines for output signals delivered from the function

generator.

Output Connector

Use this connector to transfer the main output signal from the function generator. One connector is

available for each channel.

Trig In Connector

Use this connector to apply an external trigger or gate signal, depending on the waveform generator

setting, to the generator. When the built-in frequency counter is enabled, this connector becomes an

input for the counter. The connector is common to both channels acting as the MODE selected for

each channel.

Sync Out Connector

Use this connector to output a positive TTL sync pulse generated at each waveform cycle. One

connector is available for each channel.

Modulation In Connector

5V p-p signal for 100% modulation, 10Kohms input impedance with DC - >20 KHz bandwidth. The

connector is common to both channels acting as the MODULATION function selected for each

channel.

2.3 Output Connections

The waveform generator output circuits operate as a 50 Ω voltage source working into a 50 Ω load. At

higher frequencies, non-terminated or improperly terminated output causes aberrations on the

output waveform. In addition, loads less than 50 Ω reduce the waveform amplitude, while loads

more than 50 Ω increase waveform amplitude.

18

Page 19

Excessive distortion or aberrations caused by improper termination are less noticeable at lower

frequencies, especially with sine and triangle waveforms. To ensure waveform integrity, follow these

precautions:

1. Use good quality 50 Ω coaxial cable and connectors.

2. Make all connections tight and as short as possible.

3. Use good quality attenuators if it is necessary to reduce waveform amplitudes applied to

sensitive circuits.

4. Use termination or impedance-matching devices to avoid reflections.

5. Ensure that attenuators and terminations have adequate power handling capabilities.

If there is a DC voltage across the output load, use a coupling capacitor in series with the load. The

time constant of the coupling capacitor and load must be long enough to maintain pulse flatness.

Impedance Matching

If the waveform generator is driving a high impedance, such as a 1 MΩ input impedance (paralleled by

a stated capacitance) of an oscilloscope vertical input, connect the transmission line to a 50 Ω

attenuator, a 50 Ω termination and to the oscilloscope input. The attenuator isolates the input

capacitance of the device and terminates the waveform generator properly.

2.4 Preliminary Check

The 4047B is intended for bench use. The instrument includes a front feet tilt mechanism for

optimum panel viewing angle. The instrument does not require special cooling when operated within

conventional temperature limits. It may be installed in a closed rack or test station if proper air flow

can assure removing about 15 W of power dissipation.

Complete the following steps to verify that the generator is ready for use.

1. Verify AC Input Voltage

Verify and check to make sure proper AC voltages are available to power the instrument.

The AC voltage range must meet the acceptable specification as explained in 2.1 Input

Power and Fuse Requirements.

2. Connect Power

Connect AC power cord to the AC receptacle in the rear panel and press the power switch

to the ON position to turn ON the instrument. The instrument will have a boot screen

while loading, after which the main screen will be displayed.

3. Self Adjust

At power-on, the waveform generator performs a diagnostic self-test procedure to check

itself for errors. If it finds an error, an error code and text will appear in the display

window. Other error codes appear when you enter an invalid front-panel setting. For more

information on error codes, see the 3.7 Displaying Errors. When the waveform generator

19

Page 20

finishes the diagnostic self-test routine, it enters the local state (LOCS) and assumes

power-on default settings.

Output Check

Follow the steps below to do a quick check of the settings and waveform output.

1. Turn on the instrument and set the instrument to default settings. To set to default, press

Setups, press Recall, and select 0 Default Setup. The instrument will set both channels

with the following parameters:

Waveform Shape: Sine

Frequency: 1.000000000 kHz

Amplitude: 5 .000 Vpp

Offset: 0.000 Vdc

Phase: 0.0 °

Output Impedance: 50 OHM

2. Connect the BNC output of CH1 into an oscilloscope.

3. Press the On button on top of CH1 output BNC to turn on the output and observe a sine

wave with the parameters above.

4. Press the Freq option in the menu and use the rotary knob or the numeric keypad to

change frequency. Observe the changes on the oscilloscope display.

5. Press the Ampl option in the menu and use the rotary knob or the numeric keypad to

change the amplitude. Observe the changes on the oscilloscope display.

6. Press the Offset option in the menu and use the rotary knob or the numeric keypad to

change the DC offset. With the oscilloscope set for DC coupling, observe the changes on

the display.

7. Now, connect the BNC output of CH2 into an oscilloscope and follow steps 3 to 6 to check

its output.

20

Page 21

3 Operating Instructions

3.1 Menu Keys

These keys select the main menus for displaying or changing a parameter, function, or mode.

3.1.1 WAVEFORM Keys

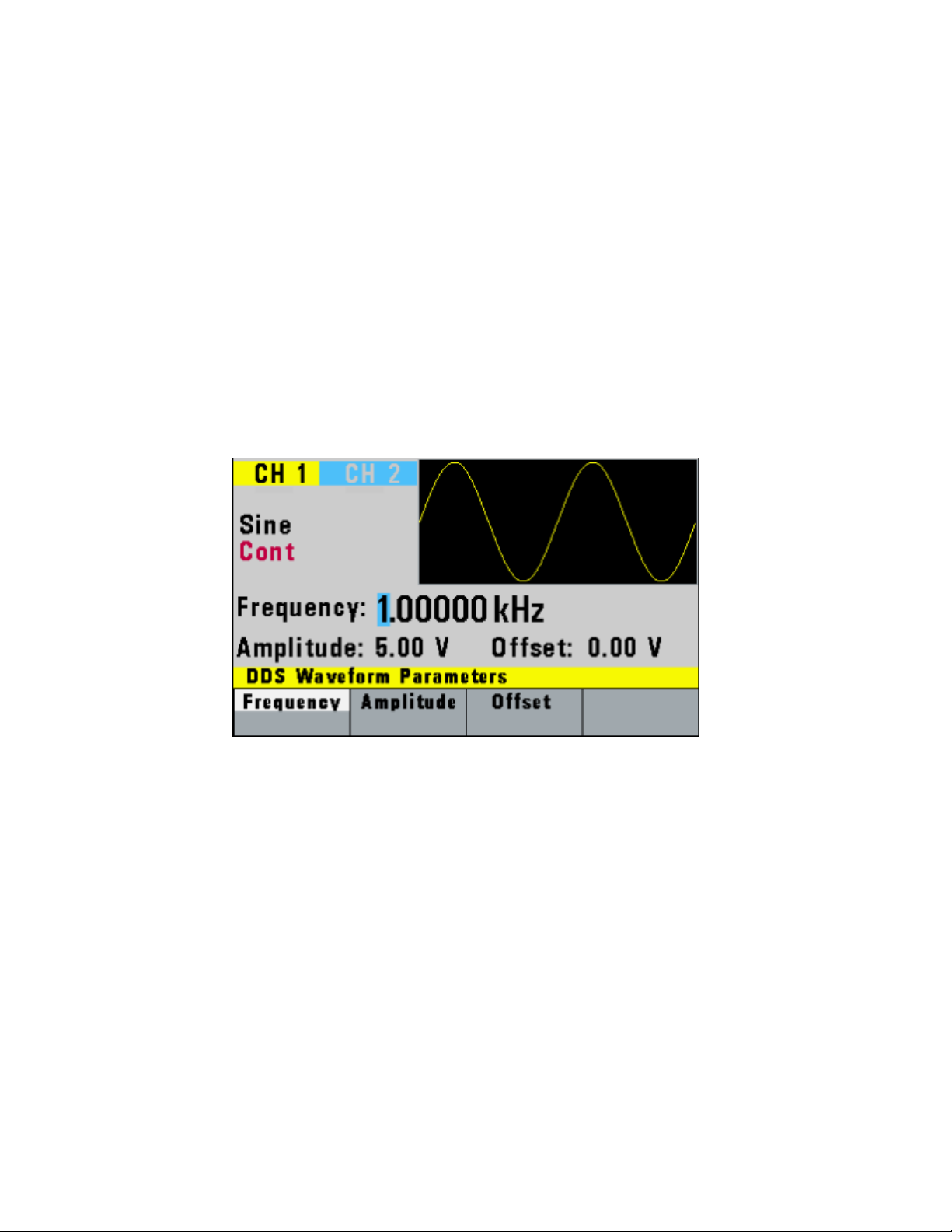

These keys select the waveform output and display the waveform parameter menu (frequency,

amplitude and offset).

F1: Frequency – Selects and displays the frequency. Change the frequency setting using the

cursor keys, rotary knob, or numerical keys.

F2: Amplitude – Selects and displays the amplitude. Change the amplitude setting using the

cursor keys, rotary knob, or numerical keys.

F3: Offset – Selects and displays the offset parameter. Change the offset by using the

cursor keys, rotary knob, or numerical keys. If a certain setting cannot be

produced, the waveform generator will display a “Setting Conflict” message.

Amplitude and offset settings interact and are bound by hardware restrictions.

To obtain the desired waveform, the amplitude and offset must satisfy the

following formula:

Figure 5 - Sine Menu

21

Page 22

(Vp-p)/2 + |offset| <= 5 volts

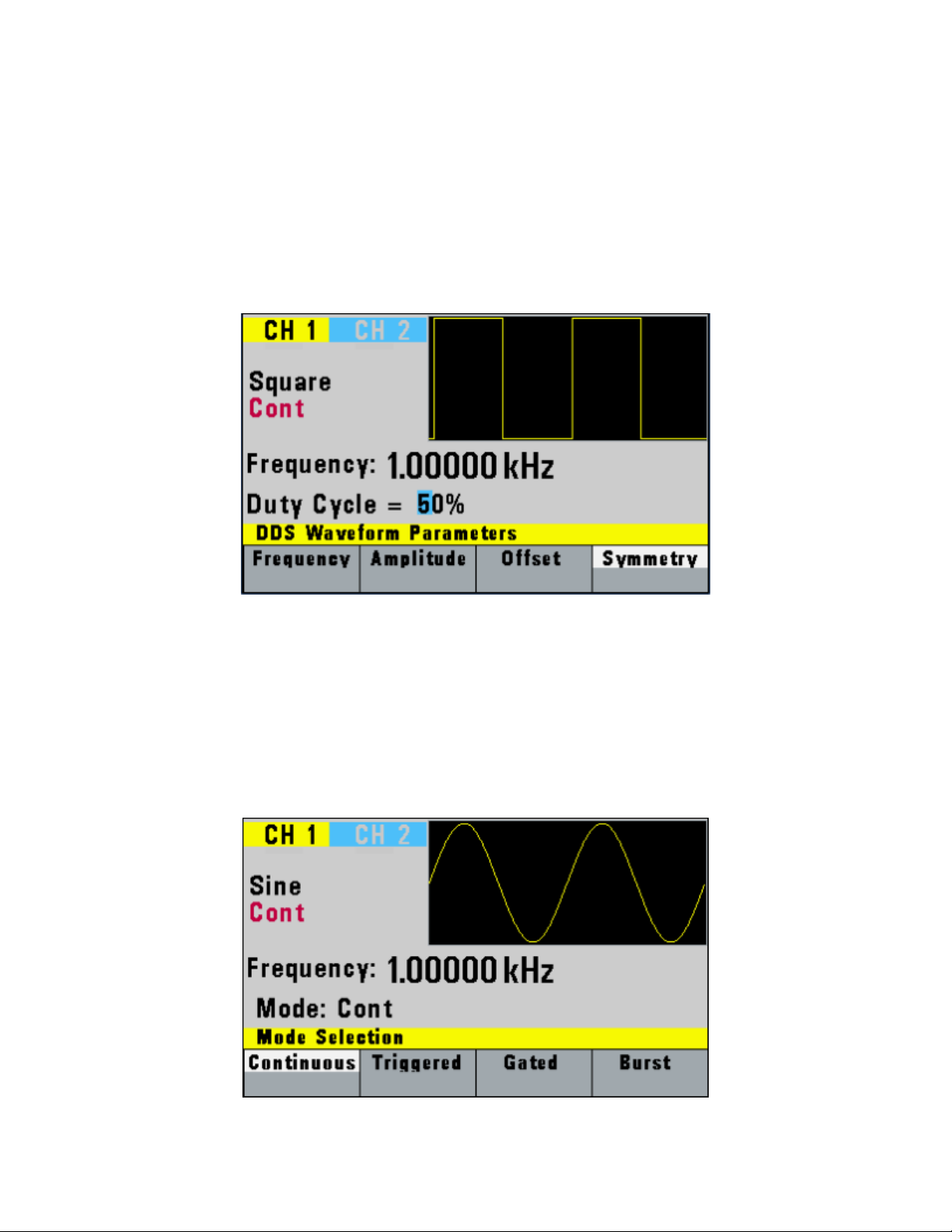

F4: Symmetry – When the Square or Triangle waveforms are selected, the SYMMETRY (duty

cycle) parameter is available. Change the symmetry (Triangle) or duty cycle

(Square) by using the cursor keys, rotary knob, or numerical keys. If a certain

setting cannot be produced, the waveform generator will display a warning

message.

Figure 6 - Square Menu

3.1.2 MODE Key

Selects the output mode: CONT (Continuous), TRIG (Triggered), GATE (Gated), and BRST (Burst).

To select the output mode, press MODE, then press the function key that corresponds to the desired

Mode menu option, as shown:

Figure 7 - Mode Menu

22

Page 23

F1: Continuous – Selects continuous output.

F2: Triggered – Triggers one output cycle of the selected waveform for each trigger event.

F3: Gated – Triggers output cycles as long as the trigger source asserts the gate signal.

F4: Burst – Triggers ‘N’ number of output cycles for each trigger event, where N ranges

from 2 to 65,535.

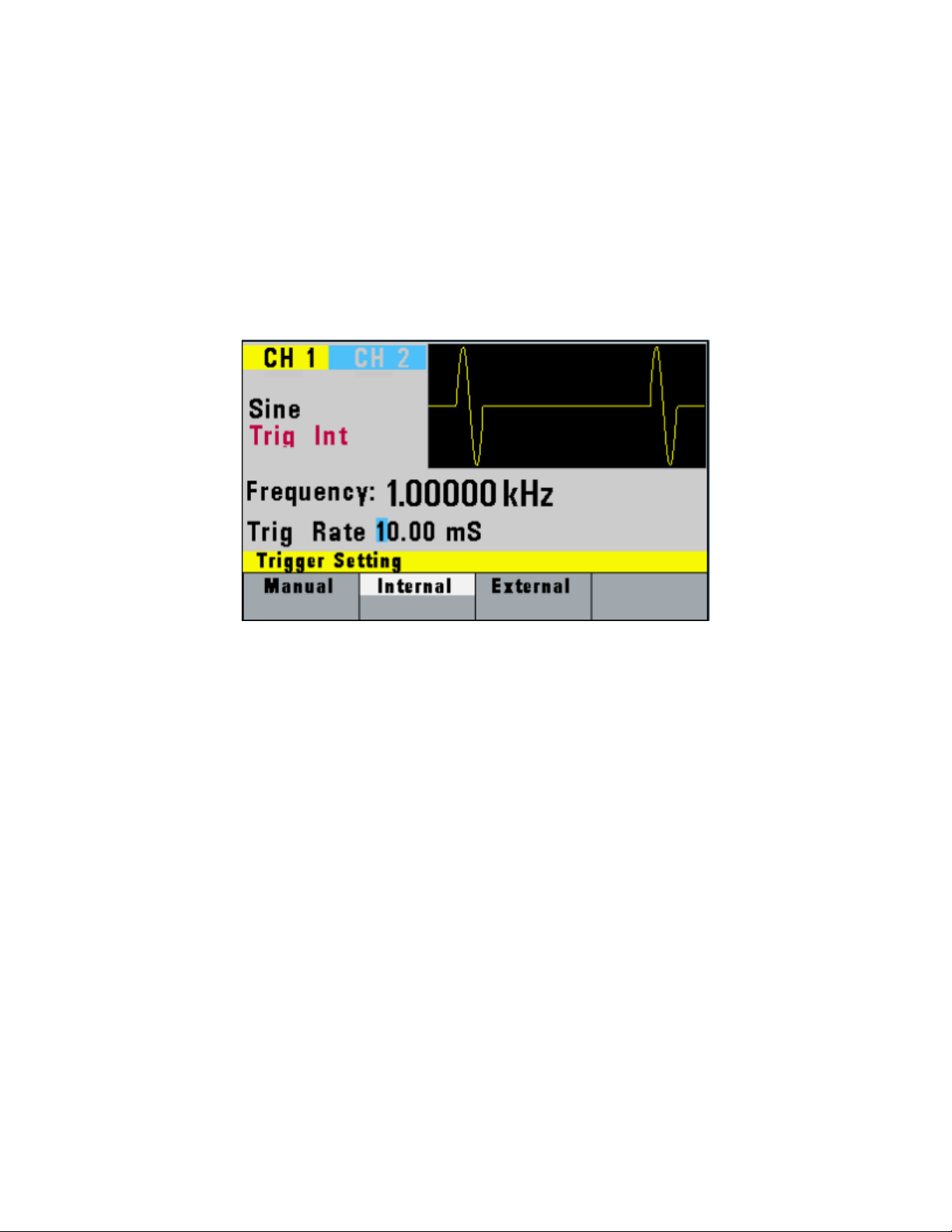

After selecting the TRIGGERED, GATED, or BURST menu, the trigger source menu is available:

Figure 8 - Trigger Menu

F1: Manual – Selects manual as the trigger source. To trigger the waveform generator, press

this MANUAL trigger button again.

F2: Internal – Selects the internal trigger generator as the trigger source. Change the

internal trigger rate displayed with the rotary input knob.

F3: External – Selects the external trigger signal as the trigger source. The trigger source is

supplied through the TRIG IN connector.

In BURST MODE, the F4 key displays N-Burst, representing the number of burst cycles to output with

each trigger. The N value can be changed from 2 to 65,535.

23

Page 24

Figure 9 - Burst Menu

3.1.3 UTILITY Key

Utility Menu

F1: Recall/Store – Recalls a previously stored front-panel setup from the selected buffer.

Change the buffer number by using the rotary input knob. Valid storage

buffer numbers are from 1 to 19 Buffer 0 is the factory default setup.

– Stores the current front-panel setup to the specified storage buffer.

Change the buffer number by using the data keys or the rotary input knob.

Valid storage buffer numbers range from 1 to 19.

F2: Sync Phases – Synchronizes both channels with a phase shift as in the Phase

parameter entered.

24

Page 25

F4: COUNTER – Enables the built-in frequency counter. The frequency of the signal

connected to the TRIG IN connector will be displayed. The counter is

auto ranging with up to 8 digits of resolution.

Figure 10 - Counter Screen

Press F1 - Off to turn off the counter.

3.1.4 SWEEP Key

Selects the Sweep Mode and allows entering of sweep parameters: Sweep Start, Sweep Stop, and

Sweep Rate.

To select the sweep mode, press SWEEP, then press the function key that corresponds to the desired

Sweep menu option, as shown:

Figure 11 - Sweep Menu

F1: Off – Disables the sweep function.

F2: Linear – Selects the Linear sweep shape.

25

Page 26

F3: Logarithmic – Selects the Logarithmic sweep shape.

F4: Set – Defines the Sweep Start and Stop frequencies.

Figure 12 - Set Sweep Menu

3.1.5 MODULATION Key

Selects the AM, FM, FSK, PM, or PWM modulation mode. To select the output mode, press MODUL

key, then press the function key that corresponds to the desired menu option, as shown:

Press F2 to select AM menu:

Figure 13 - Modulation Menu 1 of 2

26

Page 27

F1: % - Defines the modulation depth (from 0 to 100%)

F2: Frequency - Selects the modulation frequency, from 0.1 Hz to 20.00 kHz.

F3: Shape - Selects the modulating waveform between Sine, Square, or Triangle.

F4: External - Selects and enables the external modulation by an external signal

applied to the Modulation In connector on the rear panel.

Press F3 to select FM menu:

Figure 14 - AM Menu

Figure 15 - FM Menu

F1: Deviation - Defines the FM deviation frequency.

F2: Frequency - Selects the modulation frequency, from 0.1 Hz to 20.00 kHz.

F3: Shape - Selects the shape of the modulating waveform between Sine, Triangle, or

Square.

27

Page 28

F4: External - Selects and enables the external modulation by an external signal

applied to the Modulation In connector on the rear panel.

Press F1 to select FSK menu:

F1: F-LO - Defines the low frequency of the FSK.

F2: F-HI - Defines the high frequency of the FSK.

F3: Rate - Selects the rate of the alternating between the low and high frequencies.

F4: External - Selects and enables the external modulation by an external signal

applied to the Modulation In connector on the rear panel.

Press F2 to select PM menu:

Figure 16 - Modulation Menu 2 of 2

Figure 17 - FSK Menu

28

Page 29

F1: Deviation - Defines the phase deviation of the PM in degrees.

F2: Frequency - Defines the PM frequency.

F3: Shape - Selects the shape of the modulating waveform between Sine, Triangle, or

Square.

F4: External - Selects and enables the external modulation by an external signal

applied to the Modulation In connector on the rear panel.

Press F3 to select PWM menu:

Figure 18 - PM Menu

Figure 19 - PWM Menu

F1: Width - Defines the pulse width of the PWM.

F2: Deviation - Defines the pulse width deviation of the PWM.

F3: Frequency/Shape - Adjusts the PWM frequency. Selects the shape of the

modulating waveform between Sine, Triangle, or Square.

F4: External - Selects and enables the external FSK when the unit frequency is

alternating between the low and high frequencies by an external signal applied to the

Trig In connector.

29

Page 30

3.1.6 PULSE Key

Selects the Pulse waveform menu shown below:

Figure 20 – Pulse Menu

F1: Frequency/Period - Selects the parameter definition of the Pulse repetition period.

F2: Amplitude - Selects the Amplitude parameter.

In Arbitrary mode, this setting defines the maximum peak-to-peak amplitude of

a full-scale waveform. If the waveform does not use the full scale (data points

from -8191 to +8191), then its actual amplitude will be smaller.

F3: Offset - Selects the Offset parameter. Change the offset by using the cursor keys,

rotary dial or numerical keys. If a certain setting cannot be produced, the

waveform generator will display a “Setting Conflict” error message.

F4: Pulse - Selects the Pulse Width and edge edit menu

30

Page 31

3.1.7 Pulse Width and Edge Edit Menu

Figure 21 - Pulse Width and Edge Edit Menu

F1: Width - Selects the Width of the generated pulse.

F2: Equal Edge - Selects equal Rise (Leading edge) and Fall (Trailing edge) times of the pulse.

F3: Lead/Trail - Selects different Rise and Fall times of the Pulse.

F4: Prev - Returns to previous menu.

3.1.8 ARBITRARY Key

Selects the Arbitrary waveform menu shown below:

Figure 22 - Arbitrary Menu

F1: Frequency/Rate - (Frequency) Selects and displays the frequency. Change the frequency setting

using the cursor keys, rotary knob or numerical keys. If a certain wavelength

31

Page 32

can't produce the waveform at the desired frequency, the waveform generator

will display an “Out of Range” error message.

Displays the Point Rate (for Arbitrary Waveform only). The Rate parameter

governs the rate at which waveform points are executed and thus the

frequency of the output. When you set this parameter, the waveform

generator will keep that execution rate for all waveform lengths until it is

changed.

F2: Amplitude - Selects the Amplitude parameter.

In Arbitrary mode, this setting defines the maximum peak-to-peak amplitude of

a full-scale waveform. If the waveform does not use the full scale (data points

from -8191 to +8191), then its actual amplitude will be smaller.

F3: Offset - Selects the Offset parameter. Change the offset by using the cursor keys,

rotary dial or numerical keys. If a certain setting cannot be produced, the

waveform generator will display a “Setting Conflict” error message.

F4: Arb - Selects the Arbitrary waveform editing menu:

Figure 23 - Arbitrary Editing Menu

F1: Start - Selects the arbitrary waveform start address.

F2: Length - Selects the arbitrary waveform length. Use the START and LENGTH keys to

mark a selection of the waveform memory that will be executed.

Changing one of the arbitrary parameters as start and length cause an updating of the

output waveform to the new parameters. When exiting the Arbitrary Menu by

selecting a different waveform, a message to save the Arbitrary wave will be displayed.

Select YES or NO to save the new waveform.

F3: Edit – Enters the Arb Edit menu.

32

Page 33

3.1.9 Arbitrary EDIT Menu

Enters data for creating arbitrary waveforms. You can enter data one point at a time, as a value at an

address, draw a line from one point (a value at an address) to another point, create a predefined

waveform, or combine these to create complex waveforms. The valid data values range is -8191 to

8191. The valid waveform memory addresses range from 1 to 16,382.

The data value governs the output amplitude of that point of the waveform, scaled to the instrument

output amplitude. Therefore, a value of 8191 corresponds to positive peak amplitude, 0 corresponds

to the waveform offset, and -8191 corresponds to the negative peak amplitude.

Figure 24 - Edit Menu

F1: Point - This menu allows point-by-point waveform editing. When selected, the following

menu is displayed:

Figure 25 - Point Menu

F1: Adrs - Select the current address in the arbitrary waveform memory.

F2: Data - Selects the data point value at the current address. You can change the point

33

Page 34

value from -8191 to 8191.

F2: Line - This menu allows a line to be drawn between two selected points.

When selected, the following menu is displayed:

Figure 26 - Line Menu

F1: From - Selects the starting point address.

F2: To - Selects the ending point address.

F3: Exec - Displays the Confirmation menu, F1:NO and F2:YES

Figure 27 - Confirmation Menu

F3: Predef - (Predefined Waveforms) Selects one of the predefined waveforms: Sine, Triangle,

Square and Noise. Displays the Predefined waveforms menu:

34

Page 35

Wave

Minimum Length

Divisible by

Sine

16

4

Triangle

16

4

Square

2 2 Noise

16

1

Figure 28 - Predefined Menu

F1: Type - Use the rotary dial to select the waveform Sine, Triangle, Square or Noise. If

Noise function is selected, a submenu is displayed to allow adding the noise to an

available waveform or to generate it as a new noise waveform.

F2: From Data - Selects the starting point of the generated waveform and data value.

F3: Leng/Scale - Selects the length of the predefined waveform (number of points for a

full wave). Different waveforms have different limitations on the length, as shown in

Table 3-1.

Table 3-1: Waveform Length Limits for Predefined Waveforms

F3: Scale - Selects the scale factor of the waveform. 100% means that the waveform

F4: Show - Displays the Arbitrary waveform on the full LCD display. Press any button to return to

spans the full scale of -8191 to 8191. Scale factors are limited by the point data value

of the starting point and automatically calculated by the unit.

F4: Exec - Prompts you to confirm whether to execute the selected predefined

waveform. Press NO to abort executing the predefined waveform; press YES to

execute the predefined waveform. On the NOISE function menu options, ADD and

NEW are available. Select ADD to add noise to an existing waveform, or NEW to

create a new noise waveform.

35

Page 36

the MENU selection display.

Full Display

3.2 ON Key

Use this key to control the main output signal. When the output is active, the ON key will be lit. By

default, this will be OFF (disabled) from a power-up.

3.3 Cursor Keys

Use these keys to move the cursor (when visible) either left or right. They are used in conjunction

with the rotary input knob to set the step size of the rotary input knob.

3.4 Rotary Input Knob

Use this knob to increase and decrease numeric values. The cursor indicates the low-order position of

the displayed value which changes when you rotate the knob (for straight numeric entries only). For

other types of data, the whole value changes when you rotate the knob.

3.5 Power-On Settings

At power-on, the waveform generator performs a diagnostic self-test procedure to check itself for

errors. If an error is found, an error code and text will appear in the display window. Other error codes

appear when you enter an invalid front-panel setting. For more information on error codes, see the

Error Indication section.

36

Page 37

Key Function

Value

Description

Function

Sine

Output Waveform

Frequency

1.0000 kHz

Waveform Frequency

Amplitude

5.00 V

Peak-to-peak output amplitude

Offset

0.00 V

Zero DC offset

Output

OFF

Output disabled

Sweep

OFF

Sweep function disabled

Modulation

OFF

Modulation function disabled

N-BURST

2

Wave per burst for burst mode

Trig Source

Continuous

Continuous trigger

Trig Rate

10 ms

Internal trigger rate

Message Text

Description

Out of range

The set value is out of the instrument’s limits.

Setting conflict

Settings conflict with another parameter setting or value.

Empty location

Attempt to recall settings from an empty storage location.

Trig rate short

Internal trigger rate is too short to output waveform or burst.

Save RAM

New firmware installed.

Must divide by 4

Predefined wave length must be divisible by 4.

Must divide by 2

Predefined wave length must be divisible by 2.

When the waveform generator finishes the diagnostic self-test routine, it enters the local state (LOGS)

and assumes power-on default settings. Table 1 lists the factory default settings or selected after

RECALL 0.

Table 1 – Power-on Default Settings

3.6 Memory

The waveform generator uses non-volatile flash memory for storing the front panel settings.

Up to 20 front panel settings can be stored (includes storage location 0 for factory default settings).

One 16382-point arbitrary waveform is stored in the flash non-volatile memory.

3.7 Displaying Errors

The waveform generator displays error messages when front-panel settings are either invalid or may

produce unexpected results.

Table 2 – Error Messages

37

Page 38

3.8 Quick Start

This section explains how to generate various waveforms and modify the output waveform.

* Generating a waveform output

* Modifying waveform output

* Storing and recalling a waveform generator setup

3.8.1 Selecting a Standard Waveform

You can select several standard waveforms as: sine, triangle, square. Creating a standard waveform

requires selecting the waveform type, parameters and their settings that define the waveform.

Generating a standard waveform requires the following:

* Selecting the waveform

* Setting the output frequency

* Setting the output amplitude and offset

3.8.2 Setting the Output

To set the output channel, press the Output ON key. The key will lit indicating the output is enabled.

3.8.3 Using Voltage Offset

Through the offset parameter you can add a positive or negative DC level to the output waveform.

To set voltage offset:

1. Select a waveform to display its menu.

2. Press F3: Offset to display the offset setting.

3. Use the rotary input knob or the numerical keys to set the voltage offset.

To turn the voltage offset OFF, repeat the steps above, but set the offset voltage level to 0.

38

Page 39

3.8.4 Storing and Recalling a Waveform Generator Setup

You can store front-panel setups inside the internal non-volatile flash memory. When you recall a

stored setup, the front-panel settings change to match the settings in the stored setup.

Storing Setups

To store the front-panel setup:

1. Press UTILITY to display the menu.

2. Press F1:Store to select the Store mode.

3. Use the rotary input knob to select a buffer number. Valid buffer numbers range from 1 to 19

Buffer 0 is a read-only buffer that contains the default setup/power-on settings from Table 1.

The function generator will overwrite and store settings into a buffer that had settings previously

stored inside without a warning.

Recalling Setups

To recall stored front-panel setup:

1. Press UTILITY to display the menu.

2. Press F1:Recall to select the Recall mode.

3. Use the rotary input knob to select a buffer number. Valid buffers numbers range from 0 to

19. Buffer 0 is a read-only buffer that contains the default power-on setup.

39

Page 40

3.8.5 Creating an Arbitrary Waveform

You can create an arbitrary waveform using the following methods:

* Enter individual data points

* Draw lines between data points

* Create a predefined waveform

* Combine any of these methods

NOTE:

You can program any number of waveforms into waveform memory, keeping in mind the addresses

where one waveform ends and the other begins.

The waveform's frequency and amplitude are influenced by the number of data points and their

value in the waveform.

3.8.6 Entering Individual Data Points

The most basic way to program an arbitrary waveform is to enter data points for the waveform, one

data point at a time. While this can become tedious the auto-increment function helps this process.

To enter individual data points into waveform memory, follow these steps:

1. Press ARB main key to display the selection menu.

2. Press F4:ARB to display the Arbitrary menu.

3. Press F3:EDIT to display the Edit menu.

4. Press F1:POINT, to select the point by point programming mode.

5. Press F1:ADDRESS.

6. Use the rotary knob or the numerical keys to enter the address.

7. Press F2:DATA.

8. Use the rotary knob or the numerical keys to enter the value for the data point. Valid

entries range from –8191 to 8191.

9. Repeat steps 5 through 9 until you finish programming your arbitrary waveform.

NOTE:

Each time you press ENTER to complete a data point entry in numerical mode, the auto-increment

address advances by one.

40

Page 41

ACTION

KEYSTROKES

Step 1: Set the output rate to 1 us

(equivalent to 1000 Hz output

frequency

PARAMETER

F1:RATE

1

kHz/us

3.8.7 Setting the Arbitrary Frequency

The arbitrary waveform frequency is a function of the number of data points used to run the

waveform (the length parameter in the ARBITRARY menu) and the waveform execution point rate.

The waveform execution point rate is the execution time between each point in the waveform. The

total time taken to run one period of the waveform is given by:

number of points X rate

Because the output frequency is a function of the rate and the number of points being executed, the

formula is given as:

𝑓𝑟𝑒𝑞𝑢𝑒𝑛𝑐𝑦 =

𝑁𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑝𝑜𝑖𝑛𝑡𝑠 𝑥 𝑟𝑎𝑡𝑒

For example, to set the output frequency to 1000Hz, given the number of data points used for the

waveform output is 1000, calculate:

1

𝑟𝑎𝑡𝑒 =

1000 𝑝𝑜𝑖𝑛𝑡𝑠 𝑥 1000 𝐻𝑧

EXAMPLE: Setting the Output Frequency

To set the output frequency of a 1000 point waveform in execution memory to 1000Hz, set the rate to

1us:

1

= 1𝜇𝑠

3.8.8 Setting the Amplitude

The following equation represents the relative output amplitude voltage relationship between the

front-panel amplitude peak-to-peak setting and the data point values in waveform memory:

𝑜𝑢𝑡𝑝𝑢𝑡 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 =

Where 16382 is the data point value range in waveform memory.

𝐴𝑚𝑝𝑙𝑖𝑡𝑢𝑑𝑒 𝑝 − 𝑝 𝑠𝑒𝑡𝑡𝑖𝑛𝑔 𝑥 𝑑𝑎𝑡𝑎 𝑝𝑜𝑖𝑛𝑡 𝑣𝑎𝑙𝑢𝑒

+ 𝑜𝑓𝑓𝑠𝑒𝑡

16382

41

Page 42

Front Panel

Amplitude Setting

Data Point

Value

Relative Output

Amplitude Voltage

5 Vp-p

8191

+2.5 V

5 Vp-p

4095

+1.25 V

5 Vp-p

0

0V (offset voltage)

4 Vp-p

-8191

-2 V

Table 3-4: Relative Amplitude for Waveform Output (Examples)

3.8.9 Executing an Arbitrary Waveform

To load a waveform into execution memory, specify its starting address and length in the

ARBITRARY menu.

1. Select the channel to ON.

2. Press the ARB key and select the F4:ARB function.

3. Press F1:START to set the address. Valid entries range from 1 to 999.

4. Press F2:LENGTH to display the length of the waveform.

6. Use the rotary input knob or the numerical keys to enter the waveform length. Valid entries

range from 2 to 16382.

42

Page 43

4 Programming

4.1 Overview

This section provides detailed information on programming the generator via the USB (virtual COM)

interface.

4.1.1 Connecting to USB (Virtual COM) Interface

Currently, the USB (virtual COM) interface supports Windows® XP/7 operating systems.

To connect to a PC for remote communication, please follow the steps below:

For Windows 7:

1. The USB driver is included in the CD that comes with the instrument.

2. Connect the included USB Type A to Type B cable to the generator and the computer, then

power on the instrument.

3. On most operating systems, it will attempt to automatically install, showing the following

screen:

4. Click the “Close” button to stop the automatic search of the driver from Windows Update.

5. Now, go to Device Manager on the computer (Open up the “start” button, and right-click

“Computer” and select “Properties”. Click “Device Manager” link on the top left of the side

menu)

6. There will be an item listed under “Other devices” labeled “AT91USBSerial”. Right-click the

item and select “Update Driver Software…”

43

Page 44

7. In the following window, select “Browse my computer for driver software”, and following this,

select “Let me pick from a list of device drivers on my computer”.

8. Now there will be a window listing Common hardware types. Click the “Next” button and

select on the following screen “Have Disk…”

9. From the “Install From Disk” window, click “Browse…” and locate and double-click the USB

driver file downloaded from the website labeled “atm6124_cdc.inf”.

10. Now click “OK”. It will show in the window under Model “AT91 USB to Serial Converter”. Click

“Next” and you will get the following note:

11. Go ahead and click “Yes”. When you get the following prompt, select “Install this driver

software anyway”.

44

Page 45

12. The driver will now install. Once finished, under “Device Manager”, you should see under

“Ports (COM & LPT)” an item labeled “BK Precision USB to Serial Converter (COM#)”. The

“COM#” is the com port that can be used to access the virtual COM port for remote

communication.

For Windows XP:

1. The USB driver is included in the CD that comes with the instrument.

2. Connect the included USB Type A to Type B cable to the generator and the computer, then

power on the instrument.

3. The following screen will appear.

4. Select “No, not this time” and click “Next”.

5. In the following screen, select “Install from a list or specific location (Advanced)” and click

“Next”.

6. In the next screen, select “Don’t search. I will choose the driver to install.” and click “Next”

again.

7. In the following screen, click “Have Disk…”

45

Page 46

8. From the “Install From Disk” window, click “Browse…” and locate and double-click the USB

driver file downloaded from the website labeled “atm6124_cdc.inf”. Select it and click “OK”.

9. The following screen will appear.

10. Click “Next”, and a prompt will appear:

11. Click on “Continue Anyway” and the driver will now install.

12. The driver will now install. Once finished, under “Device Manager” (This can be opened by:

Right-click “My Computer”->Select “Properties”->Select “Hardware” tab->Click “Device

Manager”), you should see under “Ports (COM & LPT)” an item labeled “BK Precision USB to

Serial Converter (COM#)”. The “COM#” is the com port that can be used to access the virtual

COM port for remote communication.

4.1.2 USB (Virtual COM) Settings

46

Page 47

The USB (virtual COM) interface settings for the communication port are as follows:

BAUDRATE: 115200

PARITY: NONE

DATA BITS: 8

STOP BIT: 1

FLOW CONTROL: NONE

4.2 Device States

The device may be in one of the two possible states described below.

4.2.1 Local State (LOCS)

In the LOCS state, the device may be operated from the front panel.

4.2.2 Remote State (REMS)

In the REMS state, the device may be operated from the USB interface. Actuating any front panel key

will cause the device state to revert to the LOCS.

4.3 Message Exchange Protocol

The device decodes messages using the Message Exchange Protocol similar to the one defined in IEEE

488.2. The following functions implemented in the MEP must be considered:

4.3.1 The Input Buffer

The device has a 128-byte long cyclic input buffer. Decoding of remote messages is begun as soon as

the input buffer is not empty, that is, as soon as the controller has sent at least one byte to the device.

Should the input buffer be filled up by the controller faster than the device can remove the bytes and

decode them, the bus handshake (CTS/RTS) is used to pause data transfer until room has been made

for more bytes in the buffer. This prevents the controller from overrunning the device with data.

47

Page 48

4.3.2 The Output Queue

The device has a 100-byte long output queue in which it stores response messages for the controller

to read. If at the time a response message is formatted the queue contains previously formatted

response messages, such that there are not enough places in the queue for the new message, the

device will hold off putting the message in the queue until there is a place for it.

4.3.3 Response Messages

The device sends a Response Message in response to a valid query. All queries return a single

Response Message Unit.

4.4 Instrument Identification

The *IDN? common query is used to read the instrument's identification string. The string returned is

as follows:

B&K Precision, 4047B, 0, 0.33

The “0.33” reflects the firmware version number and will change accordingly.

4.5 Instrument Reset

The *RST common command effects an instrument reset to the factory default power up state.

4.6 Command Syntax

4.6.1 General Command Structure

A Program Message is defined as a string containing one Program Message Units, which is an

instrument command or query. The Program Message is terminated by the Program Message

Terminator.

The Program Message Terminator consists of optional white space characters, followed by the

Linefeed (LF) character (0x0A).

48

Page 49

The Program Message Unit can be divided into three sections as follows:

a) Program Header

The Program Header represents the operation to be performed, and consists of ASCII character

mnemonics. Two types of Program Headers are used in the MODEL 4047B: Instrument-control

headers and Common Command and Query headers. Common Command and Query Program

Headers consist of a single mnemonic prefixed by an asterisk ('*').

The mnemonics consist of upper - or lower-case alpha characters.

Example: The command to set the frequency to 1KHZ may be written in the following ways:

FREQ 1KHZ

FREQ 1000HZ

FREQ 1000

FREQ 1E3

freq 1khz

freq 1000hz

freq 1000

freq 1e3

b) Program Header Separator

The Program Header Separator is used to separate the program header from the program data. It

consists of one or more white space characters, denoted as <ws>. Typically, it is a space.

c) Program Data

The Program Data represent the values of the parameters being set, for example, the '1KHZ' in the

above examples. Different forms of program data are accepted, depending on the command. The

Program Data types used in the instrument are:

i) Character program data

This form of data is comprised of a mnemonic made up of lower - or upper-case alpha characters. As

with Program Header mnemonics, some Character Data mnemonics have short and long forms. Only

the short or the long form may be used.

ii) Boolean data

Boolean data indicate that the parameter can take one of two states, ON or OFF. The parameter may

be character type

ON or OFF

49

Page 50

or numeric. A numeric value is rounded to an integer. A non-zero result is interpreted as 1 (ON), and a

zero result as 0 (OFF).

Queries return the values 0 or 1.

iii) NRf

This is a decimal numeric data type, where

NR1 indicates an integer number,

NR2 indicates a fixed point real number, and

NR3 indicates a floating point real number.

iv) Numeric value program data

This data type defines numeric values, as well as special cases of Character Data. Numeric values may

be specified in any of Integer, Fixed Point or Floating Point format. All parameters which have

associated units accept a suffix, which may be specified using upper or lower-case characters. When

the suffix is not specified, the numeric value is accepted in the default units, which are Hertz for

frequency, Seconds for time, and Volts for voltage. To set the frequency to 1KHz we can send one of

the following commands:

FREQ 1000

FREQ 1E3

The special forms of character data accepted as numbers are

MAXimum: sets the parameter to its maximum value.

MINimum: sets the parameter to its minimum value.

For example, to set the frequency to its maximum value we can send the command

FREQ MAX

Some Program Message Units either require, or can accept, more than one data element. Program

data elements are separated from each other by the Program Data Separator. It is defined as optional

white space characters followed by a comma (','), which in turn is followed by optional white space

characters.

There are two types of Program Message Units: Command Message Units and Query Message Units.

A Query differs from a Command in that the Program Header is terminated with a question mark ('?').

For example, the frequency might be queried with the following query:

FREQ?

Some Query Message Units accept data, giving the device more specific information about what is

50

Page 51

being queried. In many cases the Query Message Unit may optionally be supplied with the MIN or

MAX mnemonics as data. This tells the device to return the minimum or maximum value to which the

parameter may currently be set. For example,

FREQ? MAX

will return the maximum value to which the frequency may currently be set.

Not all Program Message units have query forms (for example, SAV), and some Program Message

Units might have only the query form (for example IDN?).

The instrument puts the response to the query into the output queue, from where it may be read by

the controller.

NOTE: All commands should be terminated with a <CR> carriage return or <LF> line feed character.

Any response string from a query command has both <CR> and <LF> characters appended. For

example, an amplitude query command will return 1.23<CR><LF>.

4.7 Status Reporting

The instrument is capable of reporting status events and errors to the controller.

4.7.1 The Error Queue

The error queue is used to store codes of errors detected in the device. It is implemented as a cyclic

buffer of length 10. The error queue is read with the following query:

ERR?

The first error in the queue is returned, and the queue is advanced.

4.7.2 Error Codes

The negative error codes are defined by SCPI. Positive codes are specific to the instrument.

The error message is returned in the form

<error number>,"<error description>"

A table of error numbers and their descriptions is presented here.

51

Page 52

No error reported

0 - No error

Command Errors

A command error is in the range -199 to -100, and indicates that a syntax error was detected. This

includes the case of an unrecognized header.

-100 Command Error

-101 Invalid character

-102 Syntax error

-103 Invalid separator

-104 Data type error

-108 Parameter not allowed

More parameters than allowed were received

-109 Missing parameter

Fewer parameters than necessary were received

-110 Command header error

-111 Header separator error

-112 Program mnemonic too long

The mnemonic must contain no more than 12 characters.

-113 Undefined header

-120 Numeric data error

-121 Invalid character in number

-123 Exponent too large

-124 Too many digits

-128 Numeric data not allowed

A different data type was expected

-131 Invalid suffix

-134 Suffix too long

-138 Suffix not allowed

-140 Character data error.

-141 Invalid character data.

Incorrect character data were received.

-144 Character data too long

Character data may contain no more than 12 characters.

-148 Character data not allowed

-158 String data not allowed

-161 Invalid block data

An error was found in the block data

-168 Block data not allowed

-178 Expression data not allowed

52

Page 53

Execution Errors

An execution error indicates that the device could not execute a syntactically correct command, either

since the data were out of the instrument's range, or due to a device condition.

-200 Execution error

An attempt was made to RECALL the contents of an uninitialized

stored setting buffer.

-211 Trigger ignored.

The *TRG common command was ignored due to the device not

being in the correct state to execute the trigger.

-220 Parameter error.

A parameter is in the correct range, but conflicts with other

parameters.

-221 Settings conflict.

The parameter is out of range due to the current instrument

state.

-222 Data out of range.

-223 Too much data.

The arbitrary waveform memory limit has been exceeded.

-224 Illegal parameter value.

The parameter value must be selected from a finite list of

possibilities.

Device-Specific Errors

An error specific to the device occurred.

-315 Configuration memory lost.

Device memory has been lost.

-330 Self-test failed.

-350 Queue overflow.

Error codes have been lost due to more than 10 errors being

reported without being read.

Query Errors

A query error indicates that the output queue control has detected a problem. This could occur if

either an attempt was made to read data from the instrument if none was available, or when data

were lost. Data could be lost when a query causes data to be formatted for the controller to be read,

53

Page 54

and the controller sends more commands without reading the data.

-410 Query INTERRUPTED.

Data were sent before the entire response of a previous query was read.

-420 Query UNTERMINATED.

An attempt was made to read a response before the complete program

message meant to generate that response was sent.

Warnings

The execution of some commands might cause an undesirable instrument state. The commands are

executed, but a warning is issued.

500 Trigger rate short

510 Output overload

"Trigger rate short" means that the period of the waveform is larger than the value of the internal

trigger rate. Thus not every trigger will generate a cycle (or burst) of the waveform.

4.8 Common Commands

4.8.1 System Data Commands

*IDN? - Identification query

The identification query enables unique identification of the device over the GPIB. This query should

always be the last in a program message. It returns a string with four fields:

Manufacturer name

Model name

Serial number (0 if not relevant)

Version number

Command

Type: Common Query

Syntax: *IDN?

Response: BK, MODEL 4047B,0,V1.1

54

Page 55

4.8.2 Internal Operation Commands

*RST - Reset command

The Reset command performs a device reset. It causes the device to return to the factory default

power up state.

Type: Common Command

Syntax: *RST

4.8.3 Device Trigger Commands

*TRG - Trigger command

This command is analogous to the IEEE 488.1 Group Execute Trigger interface message, and has the

same effect. It is used to trigger the device to output a wave, and is accepted only when the trigger

mode is set to Trigger, Gate or Burst, and the trigger source is set to BUS.

Type: Common Command

Syntax: *TRG

4.8.4 Stored Settings Commands

*RCL - Recall instrument state

This command is used to restore the state of the device to that stored in the specified memory

location.

Arguments

Type <NRf>

Range 0 to 19 (4047B). Non integer values are rounded before execution

Type: Common Command

Syntax: *RCL<ws><NRf>

Example: *RCL 0 (Recall default state)

*RCL 9

*SAV - Save instrument state

55

Page 56

This command is used to store the current instrument state in the specified memory location.

Arguments

Type: <NRf>

Range: 0 to 9. Non integer values are rounded before execution

Type: Common Command

Syntax: *SAV<ws><NRf>

Example: *SAV 2

Stored setting location 0 stores the factory defaults, and is a read-only location.

4.9 Instrument Control Commands

Instrument control commands are grouped into logical subsystems according to the SCPI instrument

model. The commands are comprised of mnemonics indicating the subsystem to which the command

belongs, and the hierarchy within that subsystem. When the command is to be referred to the Root

node, it should be prefixed with a colon (:). Mnemonics appearing in square brackets [...] are optional.

The '|' character is used to denote a choice of specifications. The '<ws>' is used to denote a white

space character.

The selection of which channel to use is achieved through the use of a numeric suffix indicating the

channel, attached to the root level mnemonic. When the channel is not specified, channel 1 is

assumed. Program message units that are referred back to a specific root level mnemonic operate on

the channel specified in that mnemonic.

Examples:

a) FREQ 5KHZ;AMPL 3V

Sets the frequency and amplitude of the first channel (default).

b) FREQ2 5KHZ;AMPL 3V

Sets the frequency and amplitude of channel 2.

c) ARB2:START 100;LENGTH 50

Sets the start address and length of the waveform being output on channel 2.

Note: When controlling the instrument remotely, do not interrupt the instrument with front panel

interactions. Although the instrument will be automatically changed back to LOCS (local) mode,

subsequent remote commands may cause errors during communication, in which will require a

need of restarting the instrument before continuing again with remote operations.

56

Page 57

4.9.1 Default Subsystem

The Source Subsystem controls the frequency, voltage, amplitude modulation and clock source. The

command structure is as follows:

FUNCtion SINusoid|SQUare|TRIangle|

FREQuency <numeric value>

AMPLitude <numeric value>

OFFSet <numeric value>

DCYCle <numeric value>

OUTPUT ON/OFF

MODULation OFF/AM/FM/INT/EXT

DEPTh <numeric value>

MODFRequency <numeric value>

MODSHape SIN/TRI/SQU

DEViation <numeric value>

SWEep ON/OFF/LIN/LOG

SWRAte <numeric value>

SWSTArt <numeric value>

SWSTOp <numeric value>

MODE CONT/TRIG/GATE/BRST

TRIG INT/EXT

TRAte <numeric value>

BURSt <numeric value>

FREQuency <frequency>

The frequency command controls the frequency of the output waveform.

Arguments

Type: Numeric

Units: MHz, KHz, Hz (default)

Range: For SIN and SQU – 0.1 Hz to 20 MHz,

For TRI – 0.1 Hz to 2 MHz,

For ARB - Dependent on the Point Rate and Wavelength.

Fmax = 1/(8ns * Wavelength)

Fmin = 1/(100s * Wavelength)

Rounding: The value is rounded to 8 digits or 100 mHz (DDS) or 4 digits (ARB)

Command Type: Setting or Query

Setting

57

Page 58

Syntax: FREQuency<ws><frequency>[units]

FREQuency<ws>MINimum|MAXimum

Examples: FREQ 5KHZ

FREQ 5E3

FREQ MAXIMUM

FREQ MIN

Query

Syntax: FREQuency?[<ws>MAXimum|MINimum]

Examples: FREQ?

FREQ? MAX

Response: NR3

Considerations:

1) The MIN and MAX arguments refer to currently settable minimum or maximum.

2) FIXed is alias for CW.

Point Rate

RATE <point rate>

This command is used to set the point rate. It is coupled with the frequency of the waveform by the

relation:

Frequency = 1/(Point Rate * Wavelength)

Thus changing the point rate will result in a change in frequency.

Arguments

Type: Numeric

Units: s, ms, us, ns

Range: 8ns to 100s

Rounding: to 4 digits

Command Type: Setting or Query

Setting

Syntax: RATE<ws><point rate>[units]

RATE<ws>MINimum|MAXimum

Examples: RATE 100NS

Query

Syntax: RATe?[<ws>MINimum|MAXimum]

Response: NR3

Note: You can alternately use the :ARB:PRATe command.

AMPLitude <p-p amplitude>

58

Page 59

The amplitude command is used to set the peak-to-peak amplitude of the output waveform. Note

that the amplitude and the offset are limited by the relation:

Peak Amplitude + |Offset| <= 5V

Arguments

Type: Numeric

Units: V, mV, VPP, mVPP

Range: 10mV to 10V

Rounding: 1mV for 10mV to 999mV. 10mV for 1V to 10V.

Command Type: Setting or Query

Setting

Syntax: AMPLitude<ws><amplitude>[units]

AMPLitude<ws>MINimum|MAXimum

Examples: AMPL 2.5

AMPL 2.5V

AMPL MAX

Query

Syntax: AMPLitude? <ws>MINimum|MAXimum]

Examples: AMPL?

AMPL? MAX

Response: NR2

Considerations:

1) The MAXimum amplitude is dependent on the offset.

2) The MAX and MIN arguments should not be used in a program message containing an OFFSet

command, since these values are evaluated during parsing, based on the current value of the offset.

OFFSet <offset>

The offset command is used to set the DC offset of the output waveform. Note that the amplitude

and the offset are limited by the relation:

Peak Amplitude + |Offset| ≤ 5V

Arguments

Type: Numeric

Units: V, mV

Range: 10mV to 5V

Rounding: To 10mV

Command Type: Setting or Query

Setting

Syntax: OFFSet<ws><offset>[units]

59

Page 60

OFFSet<ws>MINimum|MAXimum

Examples: OFFS 2.5

OFFS 2.5V

OFFS MAX

Query

Syntax: OFFSet?[<ws>MINimum|MAXimum]

Examples: OFFS?

OFFS? MAX

Response: NR2

Considerations:

1) The MAXimum offset is dependent on the amplitude.

2) The MAX and MIN arguments should not be used in a program message containing an AMPLitude

command, since these values are evaluated during parsing, based on the current value of the

amplitude.

FUNCtion

The function command is used to set the type of waveform to be generated by the instrument.

Command Type: Setting or Query

Setting Syntax: FUNCtion<ws><SIN|SQU|TRI>