Page 1

Model: 392 and 393

Handheld Digital

Multimeters

USER MANUAL

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Page 2

2

Page 3

Safety Summary

The following safety precautions apply to both

operating and maintenance personnel and must

be observed during all phases of operation,

service, and repair of this instrument. Before

applying power, follow the installation

instructions and become familiar with the

operating instructions for this instrument.

If this device is damaged or something is missing,

contact the place of purchase immediately.

This manual contains information and warnings

that must be followed to ensure safe operation as

well as maintain the meter in a safe condition.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of

flammable gases or fumes. Operation of any

electrical instrument in such an environment

constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS

Instrument covers must not be removed by

operating personnel. Component replacement

and internal adjustments must be made by

qualified maintenance personnel. Disconnect the

power cord before removing the instrument

covers and replacing components. Under certain

conditions, even with the power cable removed,

dangerous voltages may exist. To avoid injuries,

always disconnect power and discharge circuits

before touching them.

DO NOT SUBSTITUTE PARTS OR MODIFY THE INSTRUMENT

Do not install substitute parts or perform any

unauthorized modifications to this instrument.

Return the instrument to B&K Precision for

service and repair to ensure that safety features

are maintained.

3

Page 4

WARNINGS AND CAUTIONS

WARNING and CAUTION statements, such as the

following examples, denote a hazard and appear

throughout this manual. Follow all instructions

contained in these statements.

A WARNING statement calls attention to an

operating procedure, practice, or condition,

which, if not followed correctly, could result in

injury or death to personnel.

A CAUTION statement calls attention to an

operating procedure, practice, or condition,

which, if not followed correctly, could result in

damage to or destruction of part or all of the

product.

WARNING

To avoid potential fire or shock hazard:

• Disconnect all leads, power adapter, and USB cable before

opening the battery cover.

• Do not turn on the instrument while the battery cover is

removed.

• Use only the included insulated test leads and power

adapter supplied with the instrument.

• Observe all markings and ratings on the instrument before

connecting to the instrument.

• While making measurements, verify that the performance

ratings of instruments and accessories that are used meet

the correct safety levels of the instrument.

• Do not insert metal objects into any of the connectors.

• Use the meter only as specified in this manual

• Test the meter on a known voltage before using it to

determine if hazardous voltage is present.

• Never ground yourself when taking electrical

measurements.

4

Page 5

Compliance Statements

This product is subject to

Disposal of Old Electrical & Electronic Equipment (Applicable

in the European Union and other European countries with

separate collection systems)

Directive 2002/96/EC of the

European Parliament and the

Council of the European Union

on waste electrical and

electronic equipment (WEEE) ,

and in jurisdictions adopting

that Directive, is marked as

being put on the market after

August 13, 2005, and should

not be disposed of as unsorted

municipal waste. Please utilize

your local WEEE collection

facilities in the disposition of

this product and otherwise

observe all applicable

requirements.

5

Page 6

CE Declaration of Conformity

The power supply meets the requirements of 2006/95/EC Low

Voltage Directive and 2004/108/EC Electromagnetic

Compatibility Directive with the following standards.

Low Voltage Directive

- EN 61010-1

Safety requirements for electrical

equipment for measurement, control, and

laboratory use-Part 1: General

requirements

EMC Directive

- EN 61326-1: 2006

6

Test Equipment Depot - 800.517.8431

99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 7

Safety Symbols

CATI

Category I overvoltage conditions.

supply at a standard wall outlet or similar sources.

CATIII

Category III overvoltage conditions.

installation of a building.

CATIV

Category IV overvoltage conditions.

power for a given building.

Storage Humidity

0 – 85% R.H.

Storage Environment

-20 °C to +70 °C

Pollution degree

Pollution degree 2

Caution, refer to the operating user manual for

warning information to avoid hazard or personal

injury and prevent damage to instrument.

Electrical Shock hazard.

CATII

Measurement instruments whose measurement

inputs are not intended to be connected to the

mains supply. The voltages in the environment

are typically derived from a limited-energy

transformer or a battery.

Category II overvoltage conditions.

Measurement instruments whose measurement

inputs are meant to be connected to the mains

Measurement instruments whose measurement

inputs are meant to be connected to the mains

Measurement instruments whose measurement

inputs are meant to be connected to the source of

Environmental Conditions

The instrument may be operated in the following environment.

Operating Environment

0 °C to 40 °C

Measurement Category CAT III, CAT IV

7

Page 8

Table of Contents

Safety Summary .......................................................................... 3

1 General Information ............................................................. 9

1.1 Product Overview ......................................................... 9

1.2 Package Contents ......................................................... 9

1.3 Front Panel Overview ................................................. 10

Front Panel Description ................................................... 11

2 Getting Started ................................................................... 13

2.1 Using the Digital Multimeter ...................................... 13

2.2 DC and AC Voltage Measurements ............................ 13

2.3 DC and AC Current Measurements ............................ 14

2.4 Make Resistance Measurements ............................... 16

2.5 Make Diode Measurements ....................................... 17

2.6 Continuity Test ........................................................... 17

2.7 Make Capacitance Measurements ............................. 18

2.8 Make Temperature Measurements ........................... 19

2.9 Make Frequency Measurements ................................ 20

2.10 Percent Duty Cycle Measurements .......................... 20

2.11 Auto Power Off ......................................................... 21

3 PC Communication ............................................................. 21

4 Specifications ..................................................................... 22

10 Maintenance .................................................................... 28

Cleaning ................................................................................ 28

BATTERY AND FUSE REPLACEMENT ..................................... 28

SERVICE INFORMATION ............................................................ 29

LIMITED THREE-YEAR WARRANTY............................................. 30

8

Page 9

1 General Information

1.1 Product Overview

The B&K Precision 392 and 393 handheld digital multimeters

provide standard measurement functions, which include AC and

DC voltage, AC and DC current, resistance, capacitance, diode,

and continuity.

Features:

• 60,000 Count display resolution

• DC Voltage measurement up to 1000 V

• AC Voltage measurement up to 750 V

• AC and DC Current up to 20 A

• USB interface for remote communication (model 393)

1.2 Package Contents

Please inspect the instrument mechanically and electrically

upon receiving it. Unpack all items from the shipping carton,

and check for any obvious signs of physical damage that may

have occurred during transportation. Report any damage to the

shipping agent immediately. Save the original packing carton for

possible future reshipment. Every multimeter is shipped with

the following contents:

• 1 x 392 or 393 Digital Multimeter

• 1 x 9 V Battery (inside battery compartment)

• 1 x User Manual

• 1 x Pair of TL 35A DMM test leads

• 1 x USB cable (model 393 only)

• 1 x CD utility software (model 393 only)

• 1 x Replacement fuse (500 mA)

• 1 x K-Type thermocouple

• 1 x Certificate of Compliance card

• 1 x Accessories pamphlet

9

Page 10

16

11

10

9

8

7

6

2

1

(6000 or RS232)

15

14

13

12

5

4

3

cal>2s

±

+

+

ns

mV

+

V

+

mV

MAX 400mA

TRUE RMS AC+DC

Digital Multimeter

30V

MAX

%

AUTO POWER OFF

CAT.III

V

Ω

Hz %

µ

SHIFT

C

F

K-Type

+

CATIV 600V

0

10 20

50

30

40

60

HOLD

MIN/MAX

RANGE

REL

COM

mAµA20A

20A/30sec

FUSED

MAX

FUSED

Ω

V

750V

MAX

1000V

CATIII 1000V

1.3 Front Panel Overview

Figure 1 - Front Panel View

10

Page 11

The positive input terminal for

using the red test lead.

The negative (ground) input terminal

black test lead.

The positive input terminal for up to

20 A current measurement.

The positive input terminal for μA, up

measurements.

The thermocouple input terminal for

temperature measurements.

Function/Range

Rotary Switch

Selects the function and desired

range.

392 models, this switches between

this enables computer interface.

Cycles through the available

indicator.

Press to activate LCD backlight for

approximately 3 minutes.

“MAX” displays the maximum value

this mode.

Displays the current value on the

reading measurement mode.

Toggles between “HFR1” (High

100kHz) on AC voltage ranges.

1

2

3

4 5 6

7

8

12 9 10

11

Front Panel Description

Voltage, Ohms, Frequency, Duty

VΩHz%ns

Cycle, Conductance, Diode

measurements. Connection is made

COM

20A

μAmA

K-Type

6000/RS232

Shift

Backlight

MAX/MIN

for all measurement modes.

Connection is made to it using the

to 400 mA, and capacitive

6000 and 60000 counts. 393 models

secondary options of each function

measured. “MIN” displays the

minimum value measured. Pressing

button for more than 2 seconds exits

display even if the leads are removed

HOLD

from device under test. Pressing the

button again returns to current

HFR

Frequency Rejection > 1kHz and

“HFR2” (High Frequency Rejection >

11

Page 12

Records the peak+ and peak- values

exit the mode.

Pressing the REL button enters the

seconds exits the mode.

Press the Range button to select the

go back to the Auto Range mode.

Displays the measured values,

annunciators.

13

14

15

16

PEAK+ Cal>2S

REL Δ

RANGE

of a measurement with a response

time as low as 1ms. Pressing the

button for more than 2 seconds will

Relative mode where the meter will

use the displayed value at the time of

the button press an offset value and

that value will be subtracted from the

display of future measurements.

While taking measurements in REL

mode you can press the REL button

again to show the measured value

without the REL offset value. Pressing

the REL button for more than 2

Manual Range mode. The meter

remains in the range it was in when

the button is pressed. Each press of

the RANGE button will cycle through

the available ranges. Pressing the

button for more than 2 seconds will

exit the Manual Range mode and will

Display

selected function mode, and

Test Equipment Depot - 800.517.8431

99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

12

Page 13

WARNING:

across the input terminals.

uAmA

COM

V.Ω

2 Getting Started

2.1 Using the Digital Multimeter

With no signal present, set the rotary switch to the desired

measurement function. Ensure proper insertion of the test

leads so they correspond with the type of measurement you

wish to perform, see the following instructions to understand

the proper lead configuration for each measurement type.

2.2 DC and AC Voltage Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform.

Follow these steps to make a measurement.

1. Connect the negative (-) side with the black test lead to

the COM input.

2. Connect the positive (+) side with the red test lead to

the VΩHz%ns input.

3. Probe with the test leads to the DUT and take the

measured reading on display.

Figure 2 - Connection for AC or DC Voltage Measurement

Never connect more than 750 V AC or 1000 V DC

13

Page 14

CAUTION:

potential shock hazard.

+

-

2.3 DC and AC Current Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform.

Current measurements can be made in low current or high

current mode. In low current measurement mode, you can

measure up to 400 mA. Connect to the low current mA terminal

and select one of the two ranges. In high current measurement

mode, you can measure up to 20 A by selecting one of the two

ranges and connecting to the 20 A input terminal.

DC Current ranges: 600 uA (low), 6000 uA (low), 60 mA (low),

400 mA (low), and 20 A (high).

Always connect the test leads to the instrument

inputs first before connecting the DUT to avoid

Low Current Measurements (< 400 mA)

Follow these steps to make measurements < 400 mA.

1. Connect the negative (-) side with the black test lead to

the COM input.

2. Connect the positive (+) side with the red test lead to

the mA input.

3. Probe with the test leads to the DUT and take the

measured reading on display.

Figure 3 - Connection for Low AC or DC Current Measurement

14

Page 15

WARNING:

fuse will be tripped.

WARNING:

be tripped.

20 A

uAmA

+

-

Do not connect more than 400 mA DC current

across the mA input terminal or the protection

Higher Current Measurements (Up to 20 A)

Follow these steps to make measurements up to 20 A.

1. Connect the negative (-) side with the black test lead to

the COM input.

2. Connect the positive (+) side with the red test lead to

the 20 A input.

3. Probe with the test leads to the DUT and take the

measured reading on display.

4. If measuring more than 10 A, keep measurement time

shorter than 30 seconds followed by a 10 minute cool

down period.

Figure 4 - Connection for Higher AC or DC Current

Measurement

Do not connect more than 20 A DC current across

the 20 A input terminal or the protection fuse will

15

Page 16

CAUTION:

potential shock hazard.

WARNING:

terminals or they will be damaged.

uAmA

2.4 Make Resistance Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform.

Always connect the test leads to the instrument

inputs first before connecting the DUT to avoid

Follow these steps to make a measurement.

1. Connect the black test lead to the COM input. Note

that the measurement voltage polarity is positive on

COM input.

2. Connect the red test lead to the VΩHz%ns input.

3. Probe with the test leads to the DUT and take the

measured reading on display.

Figure 2 - Connection for Resistance Measurement

Do not apply more than 1000 V DC across the

16

Page 17

CAUTION:

Always connect the test leads to the instrument

potential shock hazard.

WARNING:

terminals or they will be damaged.

uAmA

V.Ω

Diode

2.5 Make Diode Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform. Press the shift button

to cycle to the diode function.

Follow these steps to make a measurement.

inputs first before connecting the DUT to avoid

1. Connect the black test lead to the COM input.

2. Connect the red test lead to the VΩHz%ns input.

3. Probe with the test leads to the DUT and take the

measured reading on display.

Figure 3 - Connection for Diode Measurement

Do not apply more than 1000 V DC across the

2.6 Continuity Test

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform. Press the shift button

to display the continuity icon .

17

Page 18

WARNING:

terminals or they will be damaged.

WARNING:

instrument.

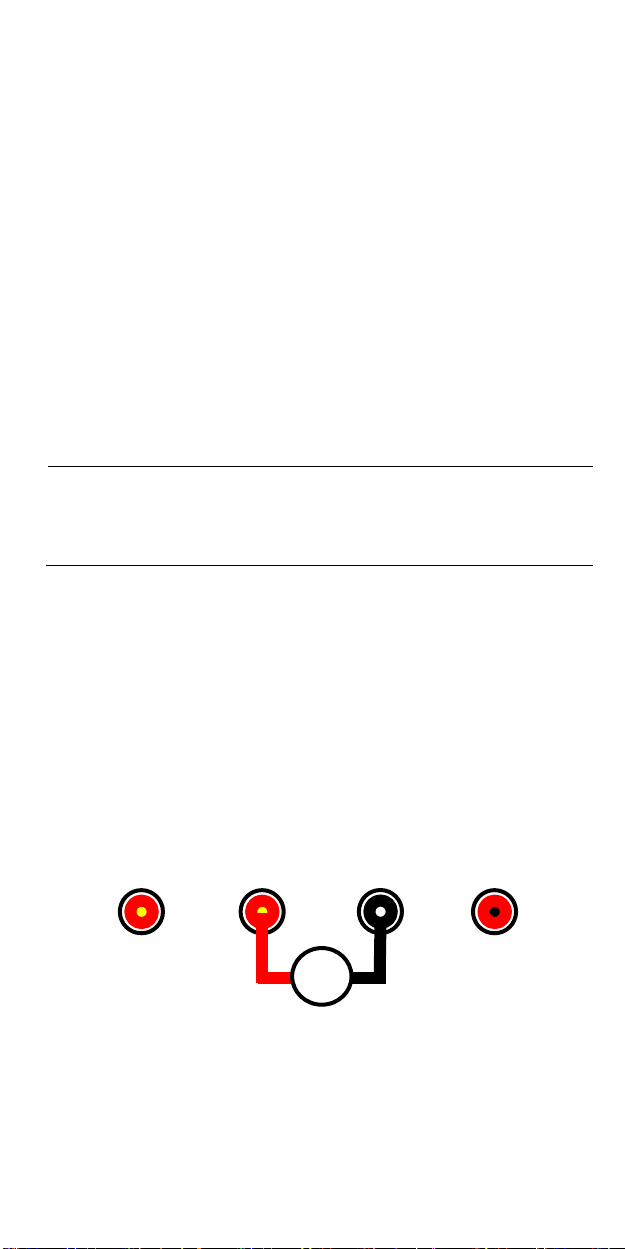

uAmA

COM

V.Ω

Follow these steps for continuity testing:

1. Connect the black test lead to the COM input.

2. Connect the red test lead to the VΩHz%ns input.

3. Connect the two leads together to verify that the

continuity function is working properly. The

instrument should have a continuous beep sound.

4. Probe with the test leads to the DUT and take the

measured reading on display.

5. If continuity is good, it will have a continuous beep

sound.

Figure 4 - Connection for Continuity Test

Do not apply more than 1000 V DC across the

2.7 Make Capacitance Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform.

Fully discharge the capacitor before connecting it

to any of the inputs or it may damage the

18

Test Equipment Depot - 800.517.8431

99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 19

CAUTION:

potential shock hazard.

WARNING:

terminals or they will be damaged.

uAmA

Capacitor

Follow these steps to make a capacitance measurement.

Always connect the test leads to the instrument

inputs first before connecting the DUT to avoid

1. Connect the black test lead to the COM input. This will

connect to the negative side of your capacitor.

2. Connect the red test lead to the uAmA input. This

will connect to the positive side of your capacitor.

3. Probe with the test leads to the DUT and take the

measured reading on display.

4. When the capacitor to be tested is connected, if

“dIS.C” symbol is indicated on the LCD, it means there

is voltage present in the capacitor under test and it

needs to be discharged before testing can continue.

Figure 5 - Connection for Capacitance Measurement

Do not apply more than 1000 V DC across the

2.8 Make Temperature

Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform. Press the shift button

to switch between C and F.

19

Page 20

20 A

uAmA

Frequency

Follow these steps to make a temperature measurement.

1. Plug the K-type thermocouple directly into the meter.

2. Apply the thermocouple bead tip to the sample you

would like to measure the temperature of.

3. Take measured reading from the display.

2.9 Make Frequency Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform.

Follow these steps to make a temperature measurement.

1. Connect the black test lead to the COM input.

2. Connect the red test lead to the VΩHz%ns input.

3. Probe with the test leads to the DUT and take the

measured reading on display.

2.10 Percent Duty Cycle Measurements

Turn the rotary switch to the corresponding symbol for the

measurement you would like to perform. Press the shift button

to switch between Hz and %.

1. Connect the black test lead to the COM input.

2. Connect the red test lead to the VΩHz%ns input.

3. Probe with the test leads to the DUT and take the

measured reading on display.

20

Page 21

20 A

uAmA

COM

V.Ω

% Duty Cycle

2.11 Auto Power Off

Auto power off occurs approximately after 30 minutes when

there has been no interaction with the meters knobs or

buttons. If an auto power off event occurs, change the position

of the rotary knob to turn the meter back on again. To disable

the auto power off feature, press and hold the MAX/MIN

button while rotating the rotary switch from off to any position.

When the auto power off feature is disabled, the LCD will no

longer display the APO annunciator on the left side of the

display.

3 PC Communication

The 393 digital multimeter comes with application software,

which provides most of the controls that emulate the front

panel of the instrument.

Remote communication is supported using the software only.

Remote commands are not available.

21

Page 22

Voltage

DC Volts

RANGE

RESOLUTION

Accuracy

Input Impedance

600 mV

0.01 mV

10 MΩ

6 V

0.1 mV

11 MΩ

60 V

1 mV

10 MΩ

600 V

10 mV

10 MΩ

1000 V

100 mV

10 MΩ

Overload protection: 1000 V DC or 750 V AC RMS

4 Specifications

Display: 60000 counts, 60 segments analog bar graph

Polarity: Automatic, (-) negative polarity indication

Overrange Indication: (OL) or (-OL) is displayed

Low Battery Indication: Indicates current capacity of battery.

When BATTERY is fully depleted, the display will show " bAtt "

with a continuous beep sound. The meter then shuts down in

5 seconds and no further measurement is allowed.

Measurement Rate: 2 measurements/sec nominal, 20

measurements/sec for analog bar graph

Operating Environment: 0°C to 50°C at < 70% R.H

Storage Environment: -20°C to 60°C at < 80% R.H

Temperature Coefficient: 0.1 × (specified accuracy) Per °C.

(0°C to 18°C, 28°C or 50°C)

Auto Power Off: Approx. 30 minutes

Altitude: 6561.7 ft (2000 m)

Power: single 9V battery

Battery Life: 50 hours typical with alkaline

Size (H × W × D): 7.8 × 3.6 × 1.7 inches (198 × 90 × 44 mm)

Weight: Approx. 14.1 oz. / 400 grams (including battery)

Accuracy is given as ± (% of reading + number of least

significant digits) at 18°C to 28°C, with relative humidity up to

70%.

+(0.08% rdg +

5 dgt)

22

Page 23

AC Volts (True RMS)

Range

Resolution

(45 Hz - 2 kHz) / HFR2

Impedance

600 mV

0.01 mV

10 MΩ

6 V

0.1 mV

11 MΩ

60 V

1 mV

+(1.0% rdg + 20 dgt)(1)

+(2.0% rdg + 20 dgt)(3)

10 MΩ

600 V

10 mV

10 MΩ

750 V

100 mV

+(2.0% rdg + 20 dgt)(4)

10 MΩ

Range

Resolution

(45 - 60 Hz) / HFR1

Impedance

600 mV

0.01 mV

10 MΩ

6 V

0.1 mV

11 MΩ

60 V

1 mV

10 MΩ

600 V

10 mV

10 MΩ

750 V

100 mV

10 MΩ

AC+DC Volts (True RMS)

Range

Resolution

Accuracy (45 Hz - 2 kHz)

Input

Impedance

600 mV

0.01 mV

+(2.0% rdg + 30 dgt)(2)

10 MΩ

6 V

0.1 mV

11 MΩ

60 V

1 mV

+(1.0% rdg + 30 dgt)(1)

+(2.5% rdg + 30 dgt)(3)

10 MΩ

600 V

10 mV

10 MΩ

750 V

100 mV

+(2.5% rdg + 30 dgt)(4)

10 MΩ

(1) For frequency range 45 Hz to 500 Hz.

(2) For frequency range 500 Hz to 1 kHz.

(3) For frequency range 1 kHz to 2 kHz.

(4) For frequency range 45 Hz to 1 kHz.

Crest factor: 3 at full scale and 6 at half scale

AC Coupled True RMS specified from 2% to 100% of range

HFR1 (High Frequency Reject): >1 kHz

HFR2 (High Frequency Reject): >100 kHz

Peak hold accuracy: +(3.0% rdg + 500 dgt) for frequency 45 Hz to

500 Hz at 60 V AC to 750V AC

Overload protection: 1000 V DC or 750 V AC RMS

Accuracy

+(1.0% rdg + 20 dgt)(1)

+(1.5% rdg + 20 dgt)(2)

+(1.5% rdg + 20 dgt)(2)

Accuracy

+(2.0% rdg + 20 dgt)

+(1.5% rdg + 30 dgt)(1)

Input

Input

+(2.0% rdg + 30 dgt)(2)

23

Page 24

Current

DC Current

Range

Resolution

Accuracy

600 μA

0.01 μA

6000 μA

0.1 μA

60 mA

1 μA

400 mA

10 μA

20 A

1 mA

AC Current (True RMS)

Range

Resolution

Accuracy (45 Hz - 1

kHz)

600 μA

0.01 μA

6000 μA

0.1 μA

60 mA

1 μA

400 mA

10 μA

20 A

1 mA

AC+DC Current (True RMS)

Range

Resolution

Accuracy (45 Hz - 1

kHz)

600 μA

0.01 μA

6000 μA

0.1 μA

60 mA

1 μA

400 mA

10 μA

20 A

1 mA

Burden Voltage:

500 mV on 600 μA & 60 mA ranges

2 V on 6000 μA, 400 mA, 20 A ranges

Input protection:

0.5 A/1000 V fast blow ceramic fuse (6.3x32mm) on μA/mA

input.

20 A/600 V fast blow ceramic fuse (10x38mm) on 20 A input.

20 A Input: >10 A for 30 sec. max, then a 10 min. cooling period.

Crest factor: 3 at full scale and 6 at half scale

AC Coupled True RMS specified from 2% to 100% of range

Peak hold accuracy: +(3.5% rdg + 500 dgt) at 45 Hz to 500 Hz on

AC current ranges

+(0.5% rdg +10 dgt)

+(1.0% rdg + 10 dgt)

+(2.0% rdg + 10 dgt)

+(1.5% rdg + 20 dgt)

+(2.5% rdg + 20 dgt)

+(2.0% rdg + 30 dgt)

+(3.0% rdg + 30 dgt)

24

Test Equipment Depot - 800.517.8431

99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Page 25

Resistance

Range

Resolution

Accuracy

Open Circuit

Voltage

600 Ω

0.01 Ω

-3.0 V DC typical

6 kΩ

0.1 Ω

-1.2 V DC typical

60 kΩ

1 Ω

-1.2 V DC typical

600 kΩ

10 Ω

-1.2 V DC typical

6 MΩ

100 Ω

-1.2 V DC typical

60 MΩ

1 kΩ

-1.2 V DC typical

Overload protection: 600 V DC or 600 V AC RMS

Continuity Test

Range

Threshold

Time

Voltage

600 Ω

<40 Ω

-3.0 V DC typical

Overload protection: 600 V DC or 600 V AC RMS

Diode Test

Resolution

Current

Accuracy

Voltage

0.5 mA

typical

+(2.0% rdg + 10dgt)

Audible indication: Less than 0.05 V DC

Overload protection: 600 V DC or 600 V AC RMS

Conductance (6000 counts)

Range

Resolution

Accuracy

Voltage

60 nS

0.01 nS

-0.7 V DC typical

Equivalent resistance range: 16.7 MΩ to 100 GΩ

(S = Siemens = 1 / Ω )

Overload protection: 600 V DC or 600 V AC RMS

+(0.3% rdg + 20 dgt)

+(0.3% rdg + 10 dgt)

+(0.3% rdg + 10 dgt)

+(0.3% rdg + 10 dgt)

+(1.0% rdg + 10 dgt)

+(3.0% rdg + 20 dgt)

Range/

2 V / 1 mV

Audible

Test

Response

Approximately 100 ms

+(1.0% rdg + 10 dgt)

Open Circuit

Open Circuit

3.0 V DC typical

Open Circuit

25

Page 26

Capacitance (6000 counts)

Range

Resolution

Accuracy

6 nF

0.001 nF

60 nF

0.01 nF

600 nF

0.1 nF

6 μF

0.001 μF

60 μF

0.01 μF

600 μF

0.1 μF

6 mF

1 μF

Overload protection: 600 V DC or 600 V AC RMS

Temperature

Range

Resolution

Accuracy

Sensor Type

-50°C - 0°C

0.1° C

0°C -

400°C

0.1° C

400°C 1300°C

0.1° C

-58°F 32°F

0.1° F

32°F 750°F

0.1° F

750°F 2372°F

0.1° F

Overload protection: 30 V DC or 30 V AC RMS

% Duty Cycle

Range

Resolution

Accuracy (5V logic)

Pulse

Width

0.1%

+(2.0% rdg + 10 dgt)

Frequency range:

5% to 95% (40 Hz to 1 kHz)

10% to 90% (1 kHz to 10 kHz)

20% to 80% (10 kHz to 20 kHz)

Overload protection: 600 V DC or 600 V AC RMS

+(3.0% rdg + 30 dgt)

+(3.0% rdg + 10 dgt)

+(3.0% rdg + 10 dgt)

+(3.0% rdg + 10 dgt)

+(3.0% rdg + 10 dgt)

+(3.0% rdg + 10 dgt)

+(5.0% rdg + 10 dgt)

+(2.0% rdg + 3°C)

+(1.0% rdg + 1°C)

+(2.0% rdg + 3°C)

+(2.0% rdg + 6°F)

+(1.0% rdg + 2°F)

+(2.0% rdg + 6°F)

5% to 95%

26

K-type

Thermocouple

>10 μs

Page 27

Frequency

Range

Resolution

Accuracy

Trigger

Level 1

60 Hz

0.001 Hz

>1.5 V

600 Hz

0.01 Hz

>1.5 V

6 kHz

0.1 Hz

>1.5 V

60 kHz

1 Hz

>1.5 V

600 kHz

10 Hz

>1.5 V

6 MHz

100 Hz

>2.5 V,

<5.0 V

10 MHz

1 kHz

>2.5 V,

<5.0 V

Minimum input range: >6 Hz

Minimum pulse width: >100 ns

Duty cycle limits: >30% and <70%

Overload protection: 600 V DC or 600 V AC RMS

+(0.1% rdg + 10 dgt)

27

Page 28

10 Maintenance

Do not expose the LCD display to direct sunlight for long periods

of time.

Cleaning

If the instrument requires cleaning, disconnect it from all power

sources and clean only with a mild detergent and water. Be

sure the instrument is completely dry before reconnecting it to

any power source.

To clean the exterior surface:

1. Remove loose dust on the outside of the instrument

and probes with a lint-free cloth.

2. Use a soft cloth dampened with water to clean the

instrument.

Note: To avoid damaging the surface of the instrument and

probes, do not use any chemically abrasive cleaning agents.

BATTERY AND FUSE REPLACEMENT

WARNING

TO AVOID ELECTRICAL SHOCK, DISCONNECT THE TEST LEADS

AND ANY INPUT SIGNALS BEFORE REPLACING THE BATTERY.

REPLACE ONLY WITH SAME TYPE OF BATTERY.

1. Disconnect test leads from any live source, turn the rotary

switch to OFF, and remove the test leads from the input

terminals.

2. The bottom case is secured to the top case by four screws.

Using a Phillips-head screwdriver, remove the screws from the

bottom case and remove the bottom case.

3. Remove battery and replace with a new equivalent " NEDA

1604 " 9-volt battery.

4. Fuse: F1 / 0.5A / 1000V fast blow ceramic fuse (6.3 x 32 mm

size)

5. Fuse: F2 / 20A / 600V fast blow ceramic fuse (10 x 38 mm

size).

6. Replace the bottom case and reinstall the screws.

28

Page 29

SERVICE INFORMATION

Warranty Service: Please go the support and service section on our

website www.bkprecision.com

in the original packaging with proof of purchase to the address below.

Clearly state on the RMA the performance problem and return any

leads, probes, connectors and accessories that you are using with the

device.

Non-Warranty Service: Please go the support and service section on

our website www.bkprecision.com

product in the original packaging to the address below. Clearly state on

the RMA the performance problem and return any leads, probes,

connectors and accessories that you are using with the device.

Customers not on an open account must include payment in the form

of a money order or credit card. For the most current repair charges

please refer to the service and support section on our website.

Return all merchandise to B&K Precision Corp. with pre-paid shipping.

The flat-rate repair charge for Non-Warranty Service does not include

return shipping. Return shipping to locations in North America is

included for Warranty Service. For overnight shipments and non-North

American shipping fees please contact B&K Precision Corp.

to obtain an RMA #. Return the product

to obtain an RMA #. Return the

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

714-921-9095

Include with the returned instrument your complete return shipping

address, contact name, phone number and description of problem.

29

Page 30

LIMITED THREE-YEAR WARRANTY

B&K Precision Corp. warrants to the original purchaser that its products

and the component parts thereof, will be free from defects in

workmanship and materials for a period of three years from date of

purchase.

B&K Precision Corp. will, without charge, repair or replace, at its

option, defective product or component parts. Returned product must

be accompanied by proof of the purchase date in the form of a sales

receipt.

Exclusions: This warranty does not apply in the event of misuse or

abuse of the product or as a result of unauthorized alterations or

repairs. The warranty is void if the serial number is altered, defaced

or removed.

B&K Precision Corp. shall not be liable for any consequential damages,

including without limitation damages resulting from loss of use. Some

states do not allow limitations of incidental or consequential damages.

So the above limitation or exclusion may not apply to you.

This warranty gives you specific rights and you may have other rights,

which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

714-921-9095

30

Test Equipment Depot - 800.517.8431

99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Loading...

Loading...