Page 1

INSTRUCTION MANUAL

FOR

B & K-PRECISION

MODEL 1601

SOLID STATE

REGULATED DC POWER

SUPPLY

DYNASCAN

CORPORATION

6460 West

Cortland

Street

Chicago, Illinois 60635

Page 2

CONTENTS

Page

SPECIFICATIONS

. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

FEATURES . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

3

INTRODUCTION

.....................................................

4

CONTROLS AND INDICATORS

........................................

4

OPERATING INSTRUCTIONS

.........................................

5

APPLICATIONS

.....................................................

6

General

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Electronic Servicing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Servicing Battery Operated Equipment

.........................

6

Servicing Vehicular Electronics Equipment

.....................

7

Servicing Plug-In Modules.................................... 9

Using Two Power Supplies For Two Output Voltages............9

Two Power Supplies In Series For O-100 Volt Output . . . . . . . . . . . . 9

Using The Power Supply As A Battery Charger

. . .

. . . . . . ... ........... 10

Other Servicing Applications

.................................

10

Electronics Manufacturing

........................................

10

Electronics Design Engineering

.

....................................

11

Electronics Education

............................................

11

CIRCUIT DESCRIPTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

MAINTENANCE

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . ..*.................

14

Page 3

OUTPUT VOLTAGE

OUTPUT CURRENT

CUMNF&~

LOAD REGULATION

FULLY SOLID STATE

CURRENT LIMITING/

OVERLOAD

PROTECTION

SIMPLIFIED

ZZll&TING

(0-50 VDC

0-2

AMPS

DUAL

METERS

SPECIFICATIONS

O-SO VDC, continuously

var-

iable. Two ranges,

0-25

and

O-50 VDC.

O-2 amperes. Four ranges:

O-SO

mA, 0-0.2A. 0-0.5A,

and

0-2A.

5% to 100% of each current

range.

Maximum 0.1%. typical

0.07%.

LINE REGULATION

RIPPLE

CURRENT DERATING

SIZE

NET WEIGHT

FEATURES

Uses integrated circuits, silicon transistors and diodes,

and an SCR. All the advan-

tages of solid state construction are utilized, including:

Dependability-reliability

No warm up time or stab-

ilization delay

Ruggedness

Compact size

Protects load and instrument

against overload.

Curr

ent

limit is fully adjustable from

approximately 2.5 mA to 2

A. The power supply automatically shuts down and

the OVERLOAD lamp lights

if the preset current limit is

exceeded. After clearing the

cause of the overload, simply push the set/reset button

to restore normal operation.

Permits setting current limit

without disturbing external

load connections or output

voltage settings: does not

re-

quire

application of short

circuit to output terminals.

Simply

push the set/reset

button and adjust the

current limit while reading the

setting on the current meter.

Continuously adjustable over

entire range with a single

control; no range switching

required.

Divided into four ranges.

Fully regulated output at all

current levels.

Allows output voltage and

current to be monitored simultaneously without

switch-

ing

ranges from current to

voltage. Both meters have

overload protection to pre-

vent damage from incorrect

range selection.

FOUR CURRENT

METER RANGES

TWO VOLTMETER

RANGES

STANDBY-DC

ON SWITCH

ON-OFF CONTROL

PILOT LAMP

MECHANICAL

PREREGULATOR

FLOATING OUTPUT

REVERSE POLARITY

PROTECTION

BINDING POSTS

ATTRACTIVE

APPEARANCE

EASY TO OPERATE

Maximum 0.1%. 0.02%

typ-

ical, at output Voltage of

50

VDC and output current of 2

amps

from

105-125

VAC.

5

millivolts peak-to-peak

maximum.

.02 A/°C

above

25°

C am-

bient. (2 A Range only).

14 1/8"

x

3 7/8"

x 10” deep.

11 lbs.

Provides maximum meter

resolution. Selection of meter range also selects coarse

current limit setting.

0-25V and

0-5OV

ranges pro-

vide maximum meter resolution. A mechanical stop

prevents the voltage level

control from exceeding

ap-

proximately 25 volts when

the O-25 V range is selected.

Standby mode disconnects

power

supply from load

without disturbing voltage

or current control settings.

On-off switch is combined

with voltage level control to

assure voltage setting of

zero when unit is turned on.

Lights to indicate at a glance

that the unit is turned on.

Power supply’s rectifier input voltage increases in progressive steps as output

voltage setting is increased.

Improves efficiency; less

power is converted to heat

at low voltage operation.

Permits referencing the positive or negative output to

any external dc potential or

ground.

Protects against accidental

damage from reverse polarity connection to external

power source.

Heavy duty

5-way

binding

posts for positive cmd

negative polarity output and earth

ground.

Modem, functional design.

When more

than

one unit

is

used, units may be stacked.

All controls are

identified

and easy to read. Simplified

operation helps prevent op

erator

mistakes that might

damage equipment.

3

Page 4

INTRODUCTION

The B & K Precision Model 1601 Regulated DC

Power Supply is a versatile, laboratory quality instrument which provides regulated dc voltage and

current outputs of 0 to 50 volts and 0 to 2 amperes

respectively. Its high specifications, operating ease,

and special features make it an excellent choice

for most applications requiring a dc power source.

It is especially well suited for powering transistorized and fully solid state electronic equipment

such as automobile radios and sound systems, battery operated radio receivers, portable radios,

mobile citizen’s band transceivers and Walkie-Talkie

transceivers.

The following list is ‘but a small sample of the

most popular applications for the instrument:

-Service Technicians

-Factory Technicians

-Engineers and

Laboratory

Technicians

-Electronics

Instructors

and Students

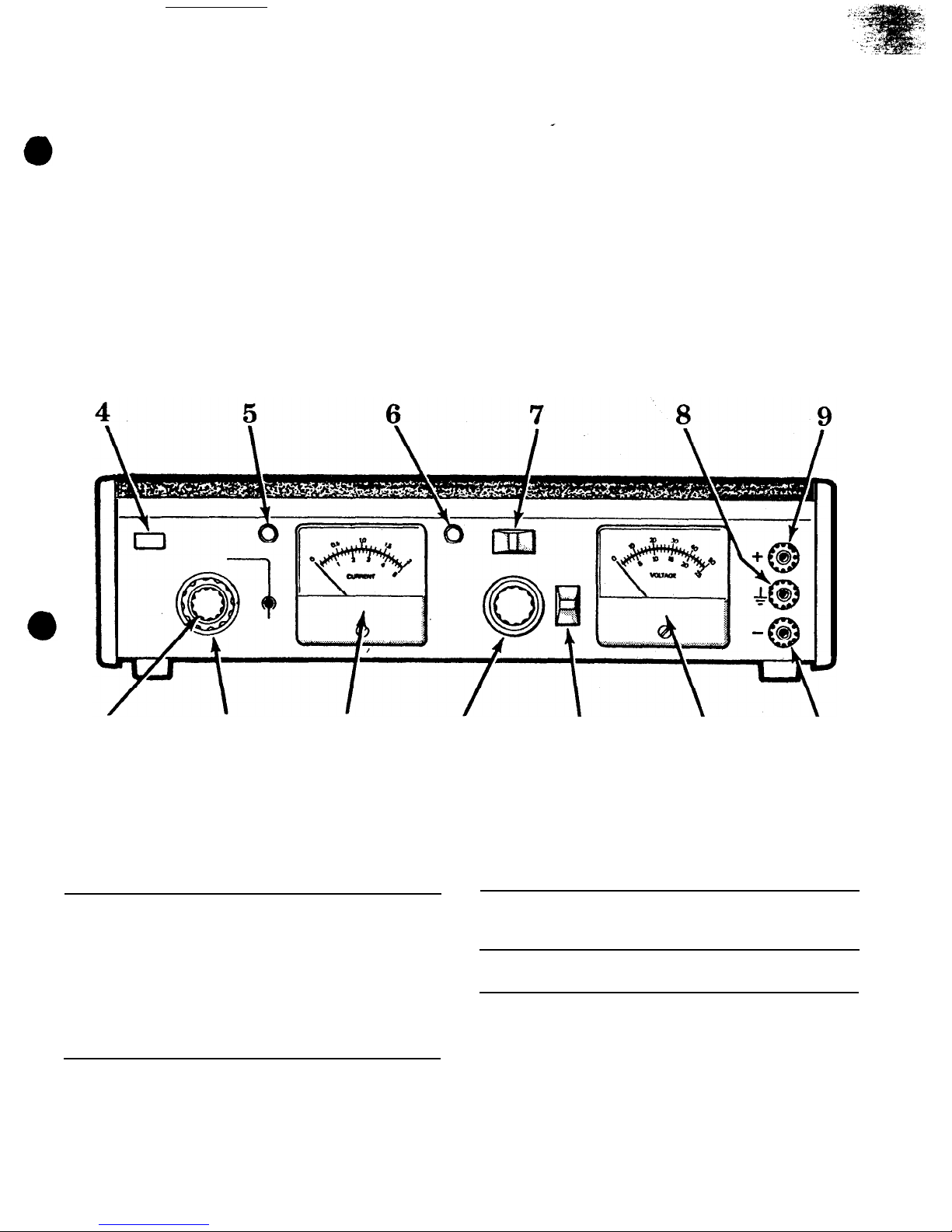

CONTROLS AND INDICATORS

Powering equipment or individual circuits during testing

and trouble-shooting in the

service shop.

Powering complete

equipments or individual assemblies during testing in the

factory.

Powering prototype and experimental circuits and

equipments.

Laboratory exercises in basic

and

advanced electronics.

3

2

1

13

12

11

io

Controls and Indicators

1 current meter

Measures actual output load

4 Push to set

current during normal oper-

CURRENT

ation.

LIMIT or to reset

Indicates current limit value

OVERLOAD

when set/reset button 4 is

button (set/

pushed. reset button)

2 CURRENT

Selects range for current

RANGE switch

meter 1 and coarse setting

of current limit. Full scale

meter

reading

and maxi-

mum current limit of:

0.05A

position

0.2A

position

0.05 ampere

(50

milliamps)

0.5A

position

0.2 ampere

(200

milliamps)

2A position

0.5 ampere

(500

milliamps)

2 amperes

5 OVERLOAD

indicator

(red)

6 POWER indicator Lights continuously while

power supply is turned on.

7 STBY-DCON

switch;

STBY position

l

3 SETCURRENT

LIMIT control

Fine adjustment of current

limit setting. Continuously

adjustable from 5% to 100%

of range which is selected

by CURRENT RANGE switch

2

DC ON position

4

When fully depressed and

held, connects current meter

1

to read the current limit

setting. When pressed and

released, resets overload circuit if it has been tripped.

Lights when current limit has

been exceeded and power

supply output has shut down.

Removes power from output

terminals 9 and 10 and

voltmeter

11 but leaves

power supply activated in a

standby condition.

Applies power to output ter-

minals 9 and

10

and

voltmeter

11

Page 5

*

c

termina1

Earth and chassis ground

terminal.

9 + terminal

Positive polarity Output terminal.

10

-

terminal

Negative polarity output

terminal.

11

voltmeter

Indicates power supply output voltage.

12

1.

2.

3.

4.

METER

RANGE

switch

0-5OV

position

Selects full scale range of

50 volts for voltmeter 11

0-25V

position

Selects full scale range of

25 volts for voltmeter

11

OPERATING INSTRUCTIONS

a.

b.

C.

d.

13 LEVEL control

Turn off the power supply before plugging it

into an ac outlet. Turn off by

rotating

the LEVEL

control

13 fully counterclockwise until it

“clicks” off.

Connect the power cord to a 105-125 volt 60 Hz

ac outlet.

WARNING

Use only a polarized

3-wire

outlet. This

assures that the power supply chassis is

connected to a good earth ground and prevents danger from electrical shock. If a

2-wire

to

3-wire

adapter must be used, be

sure the ground wire of the adapter is

attached to a good earth ground.

Turn on the power supply by rotating the

LEVEL control 13 slightly clockwise past the

“click”. The POWER indicator 6 will light.

Determine the maximum safe load current for

the device to be powered and set the current

limit for that value as follows:

Set the coarse current limit with the CUR-

RENT RANGE switch 2 . When possible,

select a range that provides the desired current liiit at a value above 20% of the full

scale

reading.

7

.

Return the “STBYDC ON” switch 7 to the

DC ON position and set the output voltage as

follows:

Push and hold the set/reset button 4 while

making

fine

current limit adjustment with

the SET CURRENT

LIMIT

control 3 for the

desired current limit as read on the current

meter

1 .

a.

Release the set/reset button 4 .

b.

If the maximum safe load current is

un-

known,

start with a low current

lit

setting.

If the setting is too low, the overload circuit

will merely trip when power is applied to

the

load in steps 7 and 8. If so, increase the

current limit setting in small steps until the

overload circuit does not trip during normal

operation.

8. If the load current exceeds the current limit, the

OVERLOAD lamp 5 will light and the power

supply will shut down

.(the

current meter 1

and voltmeter 11 will drop to zero). Restore

;~Iowyw=r supply

to normal operation as

.

.

and prevents LEVEL control

13 from increasing the

voltage above approximately

25 volts.

Turns off power supply at

extreme counterclockwise ro-

tation. Clockwise rotation

turns on power supply and

adjusts output voltage (volt-

age output level is not

changed by the METER

RANGE switch 12 ). Also,

prevents METER RANGE

switch from being set to O-25

V position when LEVEL control is advanced beyond

ap-

proximately 25 volt output.

5.

6.

Set the “STBY-DC ON’ switch 7 to the STBY

position

while

connecting the test leads.

Connect the power supply output to the device

being powered with test leads as follows:

a.

b.

C.

Connect the positive polarity input of the

device being powered to the (+) terminal

9 of the power supply.

Connect the negative polarity input of the

device being powered to the

(-)

terminal

10 of the power supply.

If the positive polarity of the device beiig

powered is also to be ground reference,

jumper the (+) terminal 9 to the

(+ )

ter-

minal 8

.

If the negative polarity of the

device being powered is to be ground reference, jumper the

(-)

terminal 10 to the

(hlterminal

8

.

If neither the positive nor

negative polarity of the device bemg pow-

ered is to be grounded, but the chassis of

the device needs grounding, connect a separate test lead from the chassis of the device

to the ( * 1 terminal8of the power supply.

Set the METER RANGE

switch

12 to the

0-25V

position if the output voltage is to be

set for 25 volts or

less,

or to the

0-50V

position if the output voltage is to be sat for

more than 25 volts.

Turn LEVEL control 13 clockwise until the

desired output voltage is read on the volt-

meter 11 .

5

Page 6

a.

b.

To reset the power supply, press and release

the

set/reset

button 4 . If the overload

condition was intermittent, this action will

restore operation.

If the OVERLOAD lamp 5 remains lighted,

use one of the three following

techniques

before resetting the power supply again:

-Reduce the load current.

-Reduce the voltage slightly with the

LEVEL control 13

.

-Increase the current limit slightly with the

SET CURRENT LIMIT control 3

.

If the

normal load current is unknown, this technique may be used; but, if the current limit

was already set for the maximum safe

load current, do not increase the current

limit further.

NOTE:

input which results in a surge current

when power is intially applied. When

powering such equipment, the overload

may activate when the STBY-DC ON switch

is placed in the DC ON position with full

operating voltage previously set. If this

occurs, reduce the voltage setting and

bring it up gradually to allow the capaci-

tors in the equipment to charge; this eliminates the surge current.

c. If the power supply continues to shut

down

at the correct current limit value, check the

LOAD current to determine the reason for

the overload.

9. To remove power from the load without dii

turbing the voltage or current limiting settings,

merely set the “STBY-DC ON” switch 7 in the

Some equipment has a highly capacitive

STBY position.

APPLICATIONS

GENERAL

This instrument may be used to power a vast

assortment of items in the fields of electronics servicing, electronics manufacturing, electronics design

engineering and electronics education. The power

suply output is fully adjustable from

0

to 50 volts,

and 0 to 2 amperes. This flexibility makes it suitable

for most applications requiring a dc power source.

ELECTRONICS SERVICING

The electronics technician uses the power supply

as

the power source for much dc and battery

powered equipment being tested and serviced. It

may also be used as the power source for testing

modules or circuits that are removed from the equip

ment where it normally receives its power.

SERVICING BATTERY OPERATED EQUIPMENT

Most equipment which operates from internal batteries can be tested and serviced using this power

supply as its power source. The excellent filtering

characteristics makes the power supply a suitable

substitute for batteries, with the added

advantage

that the effects of

varying

the voltage can be

checked. The following items are among the more

6

POKER SUPPLY

common types that may be powered from this

power supply:

Portable

AM or AM/FM radio receivers

Portable short wave and multi-band radio receivers

Portable paging receivers

Portable monitor receivers

Walkie

Talkie type transceivers

Portable two-way communications transceivers

Portable cassette recorders and players

Portable calculators

Other battery operated electrical or electronic

devices

CAUTION

Observe correct polarity. Some equipment

may not contain reverse polarity protec-

tion, and may be damaged if polarities are

reversed.

When servicing this type of equipment, remove

the batteries and connect test leads from the

(+)

and

(-)

terminals of the power supply to the

(+)

and (-)

power input points of the equipment being serviced

as shown in Figure 1. The earth ground terminal of

EQUIPMENT

BEING SERVICED

t

CURRENT LIMIT

Set VOLTAGE to the

to maximum

input

terminal voltage

value

of

fully

charged batteries.

Figure 1. Typical Power Supply Connections to

Battery Operated Equipment

COMPARTMENT

Page 7

the power supply is not normally used nor required

in this application.

Using separate test lead colors,

such

as red and black, reduces the chance of acci-

dental

reverse polarity connection. Set the current

limit to the maximum input current specification of

the equipment being serviced. If this figure is unkn

o

wn, start with a low current limit and increase

the setting in small increments until the overload

circuit in the power supply does not trip when power

is applied to the unit under test. Set the voltage to

the same value that would be present if a full set of

fully charged batteries were installed. Flashlight

cells of all sizes are rated at 1.5 volts ‘each. Other

batteries normally state the voltage on the label,

and

the required operating voltage for the equip

ment being serviced is often stated on a label in

the equipment. For units using more than one bat-

tery, check whether the batteries are connected in

series or parallel. For the parallel connected arrangement, set the power supply voltage to that of

a single cell; a higher voltage may damage the

equipment. For the series connected arrangement,

add the voltages of all cells and set the power sup

ply voltage to that sum.

A simplified method of making connections to the

power input points of battery operated equipment

may be to use a “dummy” battery. A dummy bat-

tery sits in the battery compartment and makes

good electrical contacts with the power input points,

but has readily accessible terminals or test leads

for interconnection to the power supply. The body

of the dummy battery may be made from wood or

other nonconductive material. The end caps must

be good electrical conductors which are connected

to terminals or test leads. The unit must fig snugly

in the battery compartment to assure good electrical

contact. An improved version may include a spring

to insure a snug fit.

SERVICING VEHICULAR

ELECTRONICS EQUIPMENT

When servicing electronics equipment for auto.

mobiles. trucks, and other vehicles, the equipment

is normally removed from the vehicle for bench

testing.

This power supply is an excellent dc power

source for bench testing such equipment. The

fol-

lowing items are among the more common types of

vehicular electronics equipment that may be

powered from this power supply:

POWER

SUPPLY

AM, AM/FM and AM/FM/Stereo automobile

receivers

*Tape players

Citizen’s band transceivers

Monitor receivers

Automobile amateur radio receivers

*Some aircraft equipment

*Some ship-to-shore and ship-to-ship marine band

transceivers

*Some vehicular two-way communications trans-

ceivers

*Some automotive amateur radio transceivers

‘Maximum current 2 amperes unless special procedures are

used as described in this section of the

manual.

Most automobiles and other vehicles use

12-volt

electrical systems. Although the electrical system is

normally referred to as a

12-volt

system, actual bat-

tery voltage when fully charged is approximately

14 volts. The power supply may be set

at

14 volts

for servicing equipment from vehicles with

12-volt

electrical systems.

Some trucks use a 24-volt

elec-

trical

system; bench testing of equipment from these

systems should be performed at 28 volts. Aircraft

normally use a 28-volt electrical system, and a

bench test voltaqe of 32 volts is used.

Practically all vehicles use a negative ground

electrical system, althouqh a positive ground system

is occasionally found. Electronic equipment which

is built for use only in negative ground vehicles

usually has its chassis common with the negative

polarity of input power. In some cases, there is no

separate negative polarity power cable, since the

chassis

becomes

grounded

when the equipment is

installed in the vehicle. Some equipment is built for

use in either neqative or positive ground electrical

systems, in which case the chassis may be isolated

from both the positive and ‘negative input polarities.

There is virtually no equipment built for positive

ground electrical systems only, although some elec-

tronics equipment may use its ungrounded positive

polarity as reference for circuit operation.

CAUTION

Carefully observe polarity of connections.

Equipment may be damaged if polarities

are reversed.

When servicing this type of equipment, the

(+)

and

(-)

terminals of the power supply should be

connected to the

(+)

and

(-)

power input points of

the equipment being serviced with test leads.

Fig-

EQUIPMENT BEING

SERVICED

to

maximum

input

current

specifi-

cation of

eguipme

being

serviced

+5

Figure 2. Typical Power Supply Connections to Vehicular Equipment

(Negative Ground System, Grounded Chassis Shown]

7

Page 8

ure 2 shows a typical example. The power supply

offers overload protection; therefore, any fuse in the

equipment’s power cable is not required during

testing. In fact, a convenient connection point may

be to the fuseholder. Normally, the equipment chassis should be grounded. Usually, the negative po-

larity of the equipment is common with the chassis

and a jumper may be connected between the

(* )

and

(-)

terminals of the power supply.

In those cases where the chassis is not common

with the negative polarity, connect a separate test

lead free from the

(

-h- )

terminal of the power supply

to the chassis of the equipment being serviced.

Figure 3 shows the proper interconnection between

the power supply and the equipment under test for

all possible situations.

8

POWER

SUPPLY

EQUIPMENT

BEING

POWERED

EQUPMENT

POWER

BEING

SUPPLY

POWERED

-F'

If there is any doubt that the chassis

may not be

common with the negative polarity, use a seground connection from the

(*l

terminal

equipment chassis. No damage can result

technique is used.

Set the power supply voltage to the specification

voltage for the equipment being serviced

(normally

the voltage value of a fully charged vehicle

battery).

Set the current limit to the maximum input

current

specification plus 5%.

If specification information

is unavailable, start with a moderate current

limit

and find the overload threshold. Increase the

cur-

rent limit 5% above threshold to prevent

overload

turn-off during testing.

Note that most solid

state

receivers have a much higher load current

with

strong audio output. Therefore, the threshold

should

EQUIPMENT

POWER

BEING

POWERED

POWER

EQUIPMENT

BEING

SUPPLY

Figure 3. Power Supply Interconnect Possibilities

POWER SUPPLY

#l

f

RECOMMENDED ONLY FOR

POWER SUPPLY

#2

Figure 4. TWO Power Supplies Connected in Parallel for 4 Amp Output

Page 9

be determined with audio output: otherwise, the

overload circuit will be activated upon reception of

audio.

Some of the vehicular equipment listed may re-

quire more than 2 amperes of load current. This is

especially true

of transceivers during the transmitting mode and some tape players in the track

change

mode. If you have only occasional need to

service

such equipment, another power supply is

not

necessarily required.

A vehicular battery of the

correct voltage and of sufficient capacity will suffice.

During

testing, the transmitter does not normally

need to be keyed except for short periods. The battery will provide adequate power for such testing.

The power supply can be used as a battery charger

to restore the battery to full charge, and all non-

transmit testing can be done using the power supply

as the dc power source.

Refer to Figure 4. Although it is Possible to obtain

up to 4 amperes load current from two power sup

POWER SUPPLY

MODULE BEING

SERVICED

Set CURRENT LIMIT

to

specification

for module being

serviced.

Figure 5.

Typical Power Supply

quired for bench testing modules. Figure 5 shows a

typical test set-up. Connect the

(+)

and

(-)

outputs

of the power supply to the (+) and

(-)

power terminals of the module. Identical power is sometimes

required at two or more terminals of a module. If

so, jumper together these terminals. An earth

ground may or may not be required. A test hook-up

diagram for

bench

testing the module should be

obtained. It should specify the operating voltage

and current limit. The current limit will typically be

lower than those previously described for battery

operated and vehicular equipment, since only a

single module is being powered.

Module testing is more likely to require two separate dc voltages simultaneously. Refer to the next

paragraph for information.

USING TWO POWER SUPPLIES

FOR TWO OUTPUT VOLTAGES

When two separate dc voltages are

required

Set VOLTAGE to

specification for

module being serviced.

plies connected in parallel, it is not recommended

except for use by highly experienced personnel.

The power supplies should not be connected directly

in parallel, but should be isolated by very low resistance so that balance is not so critical. Even with

this technique, the power supplies must be well

balanced or the unit carrying the heavier load will

overload and turn off, which, in turn, will cause the

other Power supply to overload and turn off. It is

very difficult to bring the power supply output of

both units up to operating voltage without disturbing the balance. One method to achieve balance is

to use an external switching arrangement which

allows selection of the load or a dummy load. The

dummy

load should be selected to draw approx-

imately 1

ampere at the operating voltage of the

main load:

½

ampere from each power supply. The

Power

supplies

can be accurately balanced into the

dummy

load without fear of overload, then switched

to the main load.

SERVICING PLUG-IN MODULES

Equipment containing plug-in modules is often

repaired

by replacing a malfunctioning module.

then servicing the defective module on the bench.

A dc Power source such as this power supply is

re-

Connection to Module For Bench Testing

simultaneously for testing equipment, two power

supplies may be used. Set the voltage and current

limit for each power supply independently as required by each circuit.

Only the circuit reference

point must be common between the two supplies.

Figure 6 shows some typical examples of proper

power supply connections when using two units.

Take extra precaution to prevent reverse polarity

connections in’ such situations. The numerous connections can become confusing. Additional colors

for the test leads will be helpful. The power sup

plies are protected from reverse polarity damage

from an external voltage source (such as the other

power supply).

TWO POWER SUPPLIES IN SERIES

FOR O-100 VOLT OUTPUT

The power supplies may be connected in series

for output voltages over 50 volts at 0 to 2 amperes.

Figure 7 shows the correct connections. Set the

current limit for both supplies at the same value and

equalize the voltage between the two units. Since

both units are connected in series, an overload in

either unit will shut down the output from both

sup-

plies, The power supplies are built to permit stacking when two units are used.

9

Page 10

EQUIPMENT

BEING

POWERED

NO. 2 (3

V)

POWER

NO. 2

POWER

NO. 2

POWER

NO. 1

POWER

NO. 2

SUPPLY

(15 V)

SUPPLY

(10 V)

Figure 6. Using Two Power Supplies for Two Output Voltages (Typical Examples1

USING

THE POWER SUPPLY

AS A BATTERY CHARGER

The power supply can be used as a battery

charger to restore the charge in rechargeable batteries such as lead-acid, nickel-cadmium and some

alkaline types. Refer to the battery manufacturer’s

charging specifications for proper voltage and current settings. Charging information is often printed

on the batteries. For batteries that specify maximum

charge currents of less than 2 amperes, set the current limit to the specified value. For batteries with

higher charge current capacities, set the current

limit to maximum. The charging current of a bat-

tery is highest when the charger (power supply) is

initially connected.

As a result, current overload

can occur before voltage is brought up to specified

charging voltage. If this happens, reduce the power

supply voltage slightly so the power supply does

not shut down. After a period of time, increase the

voltage until the full charge value can be obtained

without shutdown.

OTHER SERVICING APPLICATIONS

The instrument can be used as

a bias supply to

test the effects of varying the dc bias, such as the

AGC bias in a television receiver. Typically, the

equipment being tested contains its own power sup

ply and operates from ac power. DC voltages are

present in the circuits.

The power supply is floated

from an appropriate point in the circuit, such as the

emitter of a transistor. The power supply output is

then

applied

to another point, such as the base of

that transistor. Varying the power supply voltage

then varies the dc bias on that stage,

and

the effects

POWER SUPPLY

#l

POWER

SUPPLY #2

Figure 7. Two Power Supplies in Series

for Cl-100 Volt Output

may be noted.

A series limiting resistor is often

used to protect circuits from overdissipation.

ELECTRONICS MANUFACTURING

In electronics manufacturing, the power supply is

most often used as a dc power source to test

completed units for proper operation and compliance with specifications.

The

instrument could also

be used in incoming inspection to test purchased

equipments or subassemblies. The use of the power

supply for testing complete units is very similar to

that previously described for servicing battery op

Page 11

erated

and vehicular equipment, while its use for

testing subassemblies is very similar to that described for servicing modules.

This power supply is particularly well suited for

manufacturing. applications because of its ease of

operation and the speed at which it will accomplish

its

job, in

addition to its other features. When load

current or total power dissipation are among the

main characteristics to be measured, the total load

current

and

voltage are instantly displayed on the

two meters.

The current limit can be adjusted so

that all units which do not meet the load current

specification will cause the overload to trip, and

the unit can be rejected.

ELECTRONICS

DESIGN ENGINEERING

The technician or engineer working in an

engi-

neering laboratory requires a power supply to

power prototype and experimental circuits. This

power supply is ideal because it monitors both current and voltage simultaneously, limits current to

protect the circuit, is adjustable over such a wide

range, and has excellent regulation and very low

ripple.

Use of the instrument in an engineering laboratory

is very similar to that previously described for servicing electronics equipment and modules, except

that lower currents may be prevalent when powering single stage experimental circuits. The current

limiting feature is very valuable in this application

because it protects the unproven circuit from

damage.

ELECTRONICS EDUCATION

The student in an electronics school may use the

power supply for powering equipment and circuits

as previously described for all other applications.

In addition, the power supply will be used in the

laboratory classroom to conduct experiments in fundamental electronics. In learning

Ohm's

law, for

example, the relationships of resistance, current and

voltage are vividly demonstrated by the use of the

power supply. Being able to observe both the current and voltage meters simultaneously is a great

aid in such experiments. Figure 8 shows typical

examples of the types of experiments and exercises

that may be conducted.

!

POWER SUPPLY

OBSERVE

OHMS

LAW

BASIC VOLTAGE DIVIDER

R1

BASIC CURRENT DIVIDER

*xa

x1+12'11N

POWER SUPPLY

SERVE

STIC

OF DIODE

MEASURE VDI &

I

VARY

EIN

CHARACTERISTIC

OF

ZENER

DIODE

xi--~$~;:-~I

Rl

Figure

8.

Typical Laboratory Classroom Experiments Using The Power Supply

11

Page 12

CIRCUU

IT DESCRIPTION

GENERAL

The power supply converts a 117 VAC input to a

highly regulated and filtered dc output that is fully

adjustable from 0 to 50 volts and 0 to 2 amperes.

The circuits that accomplish this action may be

divided into five main groups as follows:

-Unregulated B+ Source. Converts the ac input

into a raw, unregulated dc voltage.

_V+

and V- Source.

Converts the ac input to

+15

VDC (V+) and -15 VDC

(V-)

for powering

active elements ICI and IC2 in the control circuits

and control sensing circuits group.

-Control Circuits.

Controls the unregulated B+

source to provide a highly regulated B+ output

that is adjustable from 0 to 50 volts.

-Current

Sensing Circuits. Establishes the current

limit, senses the load current, and activates

an

overload detector that shuts down the power

supply if the current limit is exceeded.

-Metering. Monitors the output voltage and

current.

Refer to Figure 9, the functional diagram, and to

the schematic diagram. Circuit descriptions make

constant reference to these diagrams.

NOTE

The voltages in the following circuit descriptions, and on the diagrams, are measured with respect to the regulated B+

output (the + terminal). Note that this

point is floating independent of the chassis

of the power supply.

UNREGULATED B+ SOURCE

The unregulated B+ source circuit converts the

117 volt ac input to a raw, unregulated B+ output.

Later,

in the control circuits, the unregulated B+ is

converted into the regulated B+ output of the power

supply.

The unregulated B+ output level is

pre-regulated

in coarse steps. As the LEVEL control is rotated

clockwise from zero to maximum, the unregulated

B+ voltage changes from its lowest to its

highest

value in four steps.

This minimizes the

difference

between the unregulated B+ and the regulated B+

output, which always keeps power dissipation

with-

in safe limits.

The main components which make up

this circuit

are power transformer

Tl,

pre-regulator switch

as-

sembly S5, bridge rectifier

BRl,

and filter capacitor

C8.

The ac input is applied to the unregulated

B+

circuit through on-off switch S4 (which is

part

of the

LEVEL control), across neon POWER lamp

NE1

(which glows continuously as a pilot lamp to

show

that power is on), to power transformer

Tl.

Power

transformer

Tl

has four taps in its

main

power output winding. At the lowest voltage setting, only the

low voltage portion of the

transformer

is connected

into the rectifier (this is the condition shown on the

schematic diagram). As the LEVEL control is rotated

clockwise, cams operate microswitches

S5-C,

then

S5-B,

and finally

S5-A.

Each cam-operated

microswitch selects another tap on the secondary of the

power transformer and sequentially steps the rectifier input voltage to a higher value.

Bridge rectifier BRl converts the ac power to full

wave dc, which is filtered by C8. The unregulated

B+ output at C8 is regulated and filtered by the

control circuits.

V+ AND V- SOURCE

The V+ and V- source is a completely separate

power source for powering comparator

IC1.

and

voltage reference and error amplifier

IC2.

These

circuits must be free from the extreme voltage

var-

iations found in the other power source circuits.

Figure 9. Power Supply Functional Diagram

12

Page 13

The control Power winding of

Tl.

diodes D9 and

DlO,

and filter capacitors Cl0 and

C11

form the

V+

and V- voltage source. These power source Circuits provide

+

15 and -15 volts respectively. Both

the

V+

and

V-

voltages float with respect to the

regulated output, and are also independent of the

variable unregulated B+ voltage.

CONTROL CIRCUITS

The control circuits convert the unregulated B+

voltage

into

the regulated B+ voltage. The control

circuits establish the reguiated B+ level in

response

to the

setting

of LEVEL control R27. When R27 is

set for

O

volts, the following circuit conditions

exist:

__Voltage

reference IC2 provides a stable +7 V

reference at

IC2-6.

_The +7 V reference is divided across R13 and

Rl4 to

place

+3.5

V on the inverting input (pin

4)

of

error amplifier IC2.

_The regulated B- output voltage is

0

V.

_The

+7

V reference is divided across current

path

I,.

which consists of

R15,

R27 (Approximately 0 ohms at this time), R37 and R34. This

places approximately

+3.5

volts on the

non-

inverting input (pin 5) of error amplifier IC2.

__Since

the inverting and non-inverting inputs

to

IC2

are equal, no output is developed at

IC2-9.

_No

drive is applied to series pass regulator

Q1,

Q2 and the output remains at zero volts.

When LEVEL control Fi27 is increased to a higher

voltage level, the following circuit action

occurs:

__The

resistance of R27 is added to the voltage

divider network, decreasing current I,.

__The

voltage at

IC2-5

increased (less drop across

R15), and error amplifier IC2 produces an out-

put which biases regulator

Ql, Q2

into oper-

ation.

__The

regulator allows some of the unregulated

B+

to pass to the output terminals and the out-

put voltage rises.

-As

the output voltage rises, the B- becomes

more negative.

-Current

Jr

increases as B- becomes more nega-

tive,

and the voltage at

IC2-5

decreases until

balance is achieved.

When LEVEL control R27 is decreased, the oppo-

site action occurs. Once

R27

is set and balance is

achieved, any load current changes that tend to

change the

output

voltage are sensed and corrected.

CURRENT SENSING CIRCUITS

The major components in the current sensing cir-

cui

t

s are comparator

IC1.

overload switch

SCRl,

and current sensing resistors R1 thru R4. These

circuits monitor the load current and shut down the

power supply

if the preset current limit is exceeded.

First, let us examine the current sensing resistors

R1

thru R4.

These precision, low value resistors are

in

series with the

output

load current. The values

are

chosen so that the maximum current for a

chosen

range Produces exactly 1 volt drop

across

the

resistor (for example, if the 2A range is

selected

2 amps

through resistor R4 develops exactly

1

volt).

The voltage developed across the current

sensing resistor is applied as the non-inverting input

(pin 2) to comparator ICI.

The inverting input at pin 3 of comparator

ICl

is

a 0 to 1 volt dc potential selected by the SET CURRENT LIMIT control R8.

Whenever the output load current produces a

voltage drop across the selected current sensing

resistor

(R1

thru R4) that is greater than the preset

voltage on the inverting input of

IC1,

a Positive out-

put voltage of approximately 1 volt appears at the

output (pin 7) of comparator

ICl.

This voltage

drives the gate of overload switch

SCR1

and turns

it on. Overload switch

SCRl

grounds pin 10 of error

amplifier IC2, which inhibits its operation regardless

of all other inputs and shuts down the power supply.

SCR1

also provides the ground path which allows

the OVERLOAD lamp to light. Set/reset switch S3

opens the voltage path to SCRI to reset it to an off

condition.

The STBY-DC ON switch

(S6)

is also connected to

pin

10

of error amplifier IC2. In the STBY position,

this switch grounds

IC2-10

and inhibits its operation,’

thus disabling the power supply output.

METERING

Voltmeter Ml is connected directly across the output terminals to measure output voltage. Series

resistors, as selected by METER range switch S2,

calibrate the meter to read 0-25V or 0-5OV. A mechanical interlock prevents the LEVEL control from

being increased above approximately 25 volts when

S2 is in the 0-25V range.

Current meter M2 is actually a voltmeter that is

calibrated to accurately measure output load cur-

rent. The meter measures the voltage that is de

veloped across the current sensing resistor, which

is exactly 1 volt for a full scale meter reading.

When setting the current limit, switch S3 is actuated,

which connects the current meter directly across the

SET CURRENT LIMIT control R8. This control se-

lects a voltage from 0 to

lV,

which very accurately

corresponds to the current limit value read on the

meter.

Page 14

MAINTENANCE AND CALIBRATION

WARNING

-

THE FOLLOWING INSTRUCTIONS ARE FOR USE BY

QUALIFIED PERSONNEL ONLY. TO AVOID ELECTRICAL SHOCK, DO NOT

PERFORM ANY SERVICING OTHER THAN THAT CONTAINED IN THE OPERATING INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO.

This power supply is built to provide long,

trouble-free service and does not require periodic

maintenance. If the unit malfunctions, use conventional troubleshooting techniques, such as voltage

and resistors checks, to isolate the defective component. If electrical components are replaced, the

unit should be recalibrated.

CALIBRATION

To gain access to the calibration adjustments, re-

move the 3 screws at the rear of the top cover, then

lift the top cover at the rear and slide the front lip

of the cover from the retaining bosses on the front

panel. Refer to Figure

10

for locations of calibration

adjustments.

MAX OUTPUT ADJ

(R24)

1. Connect an accurate, calibrated voltmeter to the

output terminals of the power supply.

2. Set the LEVEL control of the power supply to

maximum.

3. Adjust the MAX OUTPUT ADJ potentiometer

(R24)

for exactly 50.5 volts on the external volt-

meter.

25V CAL

(R33)

Connect an accurate, calibrated voltmeter to the

output terminals of the power supply.

Set the METER RANGE switch of the power supply to the 25V position.

Adjust the LEVEL control of the power supply for

exactly 20 volts on the external voltmeter.

Adjust 25V CAL potentiometer

(R33)

for exactly

20 volts on the voltmeter of the power supply.

50 VOLT

25 VOLT

CURRENT

5OV

CAL

(R30)

1.

2.

3.

4.

Connect an accurate, calibrated voltmeter to the

output terminals of the power supply.

Set the METER RANGE switch of the power

sup-

ply to the

5OV

position,

Adjust the LEVEL control of the power supply for

exactly 50 volts on the external voltmeter.

Adjust

5OV

CAL potentiometer

(R30)

for exactly

50

volts on

the voltmeter of the power supply.

CURRENT

METER CAL (R-29)

1. Connect an accurate, calibrated ammeter capable of 2A in series with an appropriate load

(1 ohm, 4 watts) to the output terminals of the

power supply.

2. Adjust the LEVEL control of the power supply

for exactly 2A on the external ammeter.

3. Adjust CURRENT METER CAL potentiometer

(R29)

for exactly 2A on the current meter of the

power supply.

INTERNAL CURRENT LIMIT ADJ. (R-21)

1. Turn SET CURRENT LIMIT (3) to full C.W.

2. Adjust R-21 to full scale when pressing the set/

reset button (4).

FUSE REPLACEMENT

If these is no power supply output and the

POWER lamp does not light, check fuse

Fl.

The

fuse

Fl

is located inside the cabinet, which is made

accessible by removing the 3 screws at the rear of

the top cover, then lifting the top cover at the rear

to slide the front lip of the cover from the retaining

bosses on the front panel.

Fuse

Fl

is soldered to a terminal strip at the right

of the main power transformer. Figure 10 shows the

location of the fuse.

INTERNAL CURRENT LIMIT ADJ

\

-ERChL

14

Figure

10.

Location of Calibration Adjustments and Fuses

Page 15

Page 16

Loading...

Loading...