Page 1

Hot Case Series

SERIES: WDCG

Operation Manual

Page 2

2812 Grandview Drive • Simpsonville, SC 29680 • USA

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS

WHO IS

COVERAGE PERIOD

WARRANTY COVERAGE

EXCEPTIONS

EXCLUSIONS

INSTALLATION

REPLACEMENT PARTS

COVERED

COVERED

This warranty covers defects in material and workmanship under normal use, and applies only to the

original purchaser providing that:

អ The equipment has not been accidentally or intentionally damaged, altered or misused;

អ The equipment is properly installed, adjusted, operated and maintained in accordance with national

and local codes, and in accordance with the installation and operating instructions provided with this

product.

អ The serial number rating plate affixed to the equipment has not been defaced or removed.

This

warranty

purchased

អ Warranty claims must be received in writing by BKI within one (1) year from date of

installation or within one (1) year and three (3) months from data of shipment from the

factory, whichever comes first.

អ COB Models: One (1) Year limited parts and labor.

អ COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a two (2)

year door warranty.

អ Warranty period begins the date of dealer invoice to customer or ninety (90) days after

shipment date from BKI, whichever comes first.

This

authorized

performed during regular, weekday business hours.

Any exceptions must be pre-approved in advance and in writing by BKI.

អ Negligence

អ Thermostat calibrations

អ Air and gas

អ Light

អ Glass doors and

អ Fuses,

អ Adjustments

អ Tightening

អ Failures

អ Unauthorized

អ Damage

អ Alteration,

អ Thermostats

អ Freight –

អ Ordinary

អ Failure to follow

អ Events

Leveling, as well as

installation

BKI genuine

installation

for use in the U.S.A.

warranty

covers on-site labor, parts and

service

representative

or acts of

adjustments,

bulbs,

caused

beyond control

door adjustments,

to

burner

of screws or

by erratic

repair by

in

shipment,

misuse or

other than normal UPS charges,

wear and

and use materials – is the responsibility of the

Factory OEM parts receive a (90) day

by a BKI F

improper installation,

and safety valves with

tear,

installation and/or operating instructions,

proper installation

actory Authorized

is

extended

God,

after (30) days

flames and

fasteners,

voltages

anyone other than

of the

to the original

up to (100) miles

cleaning of

or gas

broken

company.

and check out of all

Service

purchaser

reasonable

from equipment installation date,

round

pilot

burners,

suppliers,

a BKI F

actory Authorized

capillary tubes,

materials warranty

Center.

and applies only to

travel

time

trip and (2)

new equipment -

dealer

and travel e

or installer, not the

hours

Service Center,

effective from the date of

equipment

xpenses

travel time and

per

appropriate

of the

manufacturer.

Warranty

part. BKI shall in no

excess of the

all

BKI Worldwide, Inc. is a wholly owned subsidiary of Standex International Corporation.

is in lieu of all

purchase

obligations under

other warranties, expressed

event

be liable for any

price of the unit. The repair or

the terms of this

special, indirect

warranty.

or implied, and all

or

consequential damages,

replacement

of

other obligations

proven defective

or liabilities on the

or in any

parts shall

event

constitute a

manufacturer’s

for

damages

fulfillment of

SM-OM-012.02 Revised 01/05/17

in

Page 3

Table of Contents

Tab

le of Contents ........................................................................................................................................ 1

Introduction ................................................................................................................................................. 2

Safety Precautions .................................................................................................................................... 2

Operation ..................................................................................................................................................... 5

Controls and Indicators .............................................................................................................................

Preheating ................................................................................................................................................. 8

Temperature Adjustment .......................................................................................................................... 8

Operational Guidelines ............................................................................................................................. 8

Unit Shutdown........................................................................................................................................... 8

Installation ................................................................................................................................................... 9

Unpacking and Handling ........................................................................................................................... 9

Floor Model ............................................................................................................................................... 9

Pedestal Model ....................................................................................................................................... 12

Counter Model ........................................................................................................................................ 13

Front Glass Adjustment .......................................................................................................................... 13

Wiring ...................................................................................................................................................... 14

Case Joining Trim ................................................................................................................................... 15

Case Divider Glass ................................................................................................................................. 16

Maintenance .............................................................................................................................................. 17

Scheduled Maintenance ......................................................................................................................... 17

Well Numbering Convention ................................................................................................................... 18

Troubleshooting ...................................................................................................................................... 18

Wiring Diagrams ....................................................................................................................................... 20

Notes ............................................................................................................................................................ 1

5

1

Page 4

Introduction

PLEASE READ THIS ENTIRE MANUAL BEFORE SERVICING THE UNIT. If you

have any questions, contact the BKI Technical Service Department, toll free:

1-800-927-6887. Outside the U.S., call 1-864-963-3471.

This unit is to be sealed to the floor after installation to conform to NSF

requirements. (Dow Corning RTV #732 Multi purpose Sealant.)

Congratulations on your purchase of a BKI® WDCG Hot Case.

Safety Precautions

lways follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

A

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know and

understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against unsafe

practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other special

data.

2

Page 5

Specific Precautions

Equipotential Ground Plane

When a high current flows through a conductor, differences in potential appear

between the conductor and nearby metallic surfaces near the appliance. As a

result, sparks may be produced between the appliance and surrounding metal

surfaces. These sparks could cause serious injury, damage, or fire.

BKI provides an Equipotential ground terminal for the connection of a bonding

conductor after the installation of the appliance per lEC60417-1. This terminal is

located on the inside of the Power Entry Supply box near the Earth connection

and is marked with this symbol.

Safe Work Practices

Beware of High Voltage

This equipment uses high voltage. Serious injury can occur if any

untrained or unauthorized person installs, services, or repairs this

equipment. Advise your customer to always use an Authorized

Service agent to Service this Equipment

Your Customer Should have an Operators Manual

The operators manual is an important part of this equipment. Your

customer should keep it near for easy access.

If your customer needs a replacement operators manual, contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

3

Page 6

Safety Labels Must be Clean and in Good

Condition

Make sure all safety labels are in place, clean and in good condition.

Replace any damaged or missing safety labels.

If you need new safety labels, contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

4

Page 7

Item #

Description

Function

Operation

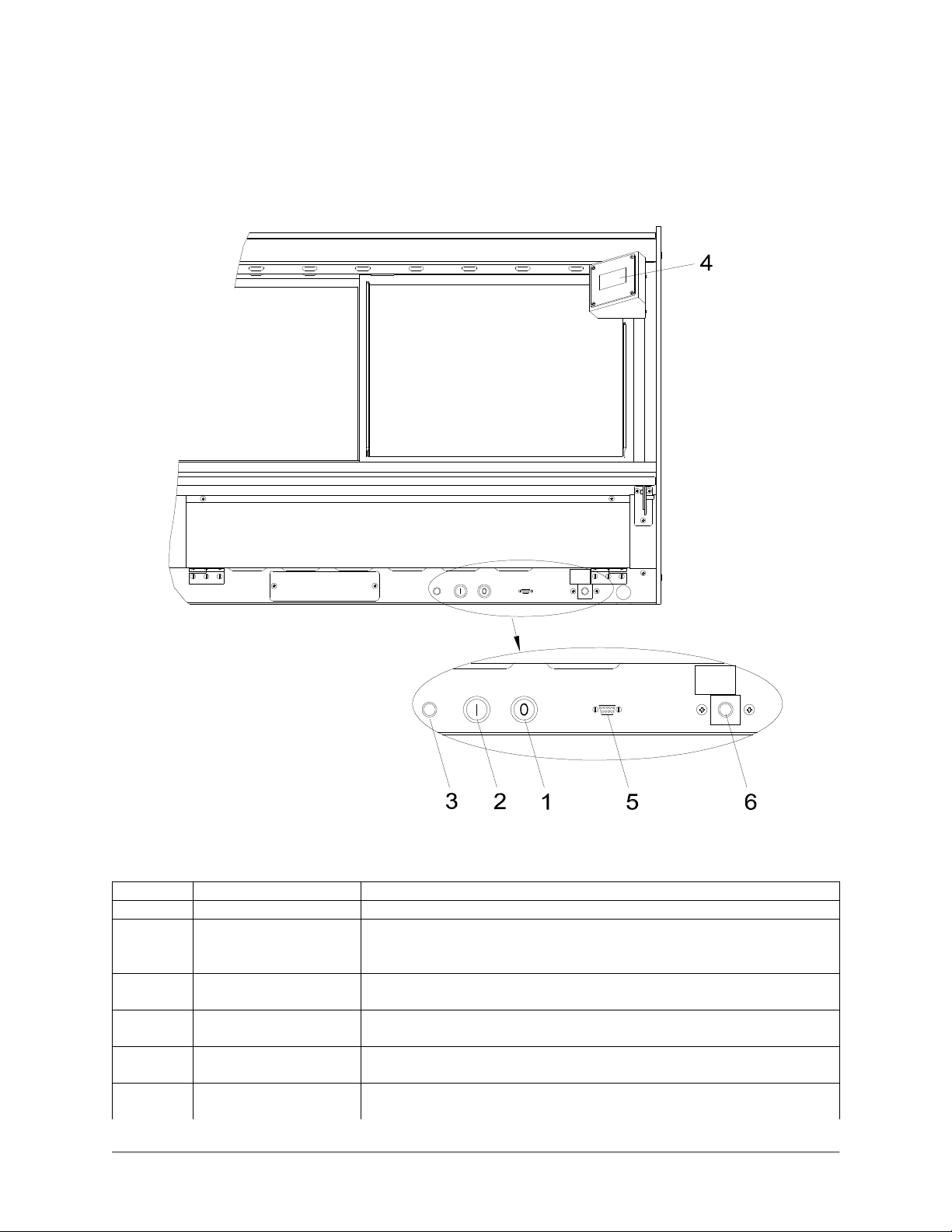

Controls and Indicators

The deli case controls are shown in the figure below. The pushbutton switches turn the power supply to

the case on and off. The touchscreen interface is used to operate the case and display temperatures.

WHEN LIT

ADD

WATER

WHEN LIT

ADD

WATER

Hardware Controls

1 Power OFF Switch Depressing the switch turns power OFF to the entire unit.

2 Power ON Switch Depressing the switch turns power ON to the entire unit. When the

unit is ON the touchscreen controller is powered & the lights

illuminate.

3 Main Power Isolator

Light

4 Analog Touchscreen

Interface

5 Controller RS-232

Interface

6 Water Level Indicator (Optional) This light illuminates when the water level in the optional

This light illuminates to indicate that power is being applied to the

unit from the main power isolator (circuit breaker).

Used for the operation of the unit and to measure & record product

temperatures.

Allows user to download saved product temperatures to a laptop

PC using the supplied software. Optional food probe required.

humidity water pan is low to indicate to add more water to the pan.

5

Page 8

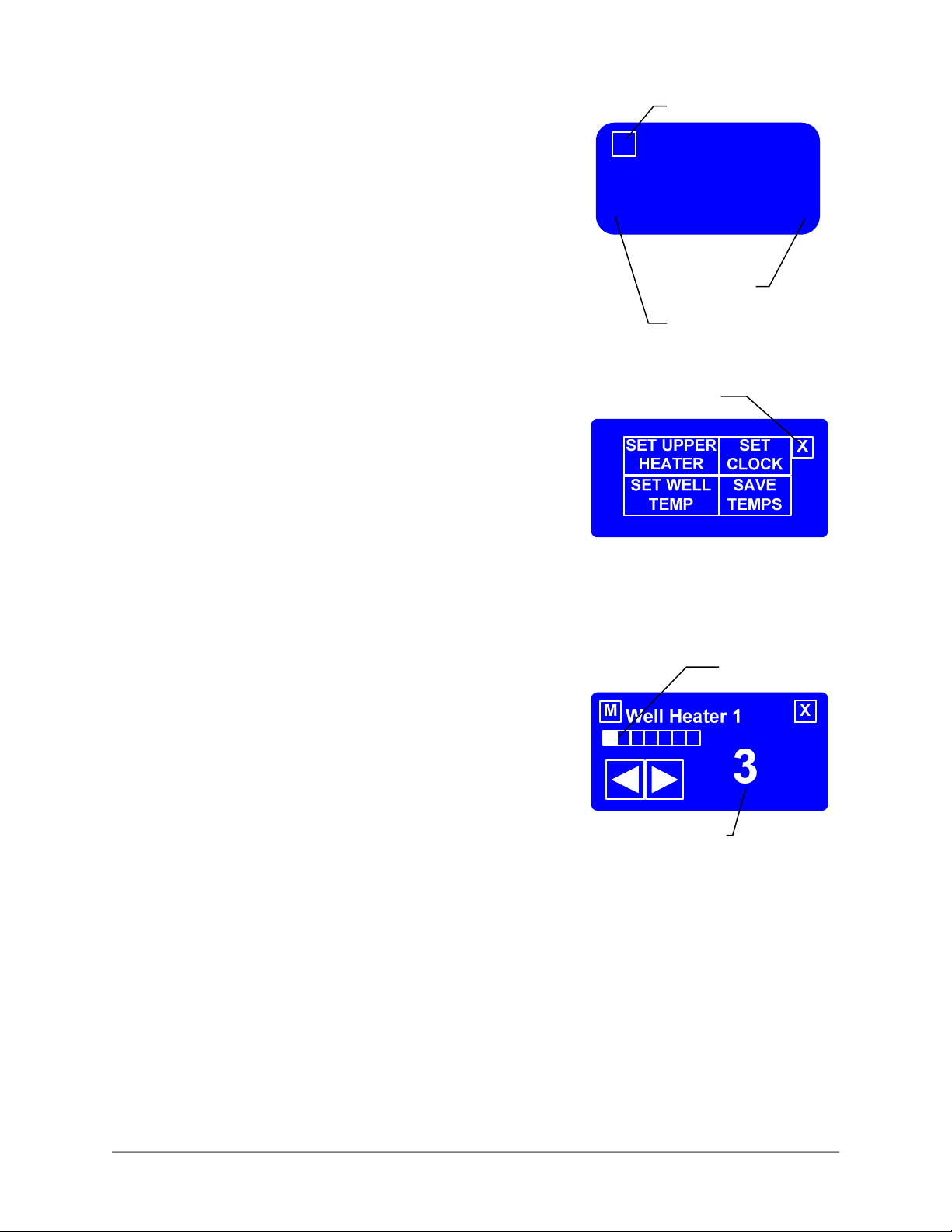

Software Controls - Default Screen

M

Lower Right

Lower Left

The Default Screen appears on the touchscreen during normal

operation. The screen shows the menu button and the heating

status of the unit.

When the unit is first powered up, “Warming” will be displayed.

When the unit reaches operating temperature, “Ready” will be

displayed as shown at the right.

If the display does not change from “Warming” to “Re

45 minutes there is a problem with the unit. A qualified BKI

service representative should be contacted.

ady” after

Software Controls - Viewing Settings

The current heater settings can be viewed by touching the Menu

Button [M] on the Default Screen. The Menu Screen will then be

displayed.

To view the current settings for either Well Temp or Upper Heater

touch the appropriate button on the Menu Screen. The View

Setting Screen for the selected heaters will be displayed.

Menu Button

Ready

Default Screen

Exit Button

To return to the Default Screen, touch the Exit Button [X].

If the controller is configured to control each well position

independently the View Setting Screen as shown at right will be

displayed. Use the left and right arrows to display the heater

setting for the various well positions of the unit. The progress bar

gives a visual representation of the well location for which the

setting is being displayed.

The current heater setting is displayed on the right side of the

screen. The setting is a numeric value between 1 and 10 where

10 is the hottest setting.

If the controller is configured to control all of the well positions at

the same setting, the progress bar will be solid and the left and

right arrows will not be displayed. The setting shown will be for

the heaters at all of the well positions.

To return to the Menu Screen, touch the Menu Button [M]. To

return to the Default Screen, touch the Exit Button [X].

Touching [Set Clock] on the Menu Screen will display the time

and date. To return to the Menu Screen, touch the Menu Button

[M]. To return to the Default Screen, touch the Exit Button [X].

Menu Screen

Progress Bar

Current Setting

View Setting Screen

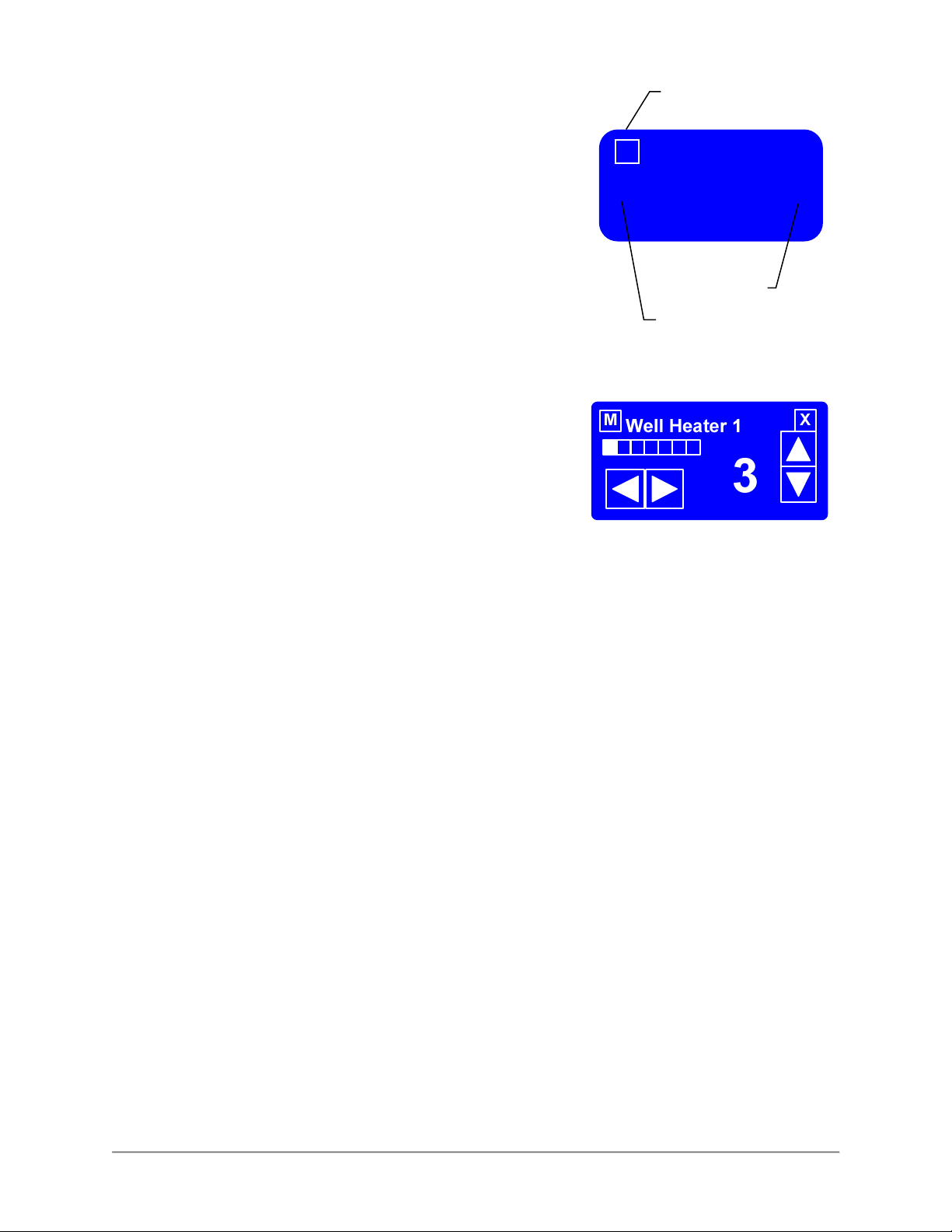

Software Controls - Programming the

6

Page 9

M

Lower Left

Lower Right

Controller

There is a unique set of touches to enter the programming mode.

This prevents the case settings from being inadvertently

changed.

Enter the programming mode from the Default Screen by

touching the lower left of the touchscreen, then the lower right

and then the Menu Button [M] in that order. The Menu Screen

will then be displayed.

To edit the current settings for either Well Temp or Upper Heater

touch the appropriate button on the Menu Screen. The Edit

Setting Screen for the selected heaters will be displayed.

To return to the Default Screen, touch the Exit Button [X].

If the controller is configured to control each well position

independently the Edit Setting Screen as shown at right will be

displayed. Use the left and right arrows to display the heater

setting for the various well positions of the unit. The progress bar

gives a visual representation of the well location for which the

setting is being displayed.

The current heater setting is displayed on the right side of the

screen. Use the up and down arrows to edit the heater setting.

The setting is a numeric value between 1 and 10 where 10 is the

hottest setting.

If the controller is configured to control all of the well positions at

the same setting, the progress bar will be solid and the left and

right arrows will not be displayed. Use the up and down arrows

to edit the heater setting for all of the well positions.

To return to the Menu Screen, touch the Menu Button [M]. To

return to the Default Screen, touch the Exit Button [X].

To edit the controller time and date settings touch [Set Clock] on

the Menu Screen while in the program mode. The time and date

will need to be reset if the power supply to the case has been

disconnected.

Use the left and right arrows to move the cursor under the value

to be edited. Use the up and down arrows to edit the value.

Continue until the current date and time is displayed.

To return to the Menu Screen, touch the Menu Button [M]. To

return to the Default Screen, touch the Exit Button [X].

Menu Button

Ready

Default Screen

Edit Settings Screen

7

Page 10

Preheating

You should allow the equipment to preheat at the programmed temperature settings for a minimum of 30

minutes before loading it with product. For initial start up, program the controller for each well heater to a

setting of 7 and each upper heater to a setting of 5.

If equipped with the optional humidity water pan, fill the pan with 6 quarts (5 1/2 liters) of water before

preheating the equipment.

Check Federal and State Health and Sanitation Regulations for internal temperature required for holding

cooked foods for sale. Maintaining these temperatures often tend to allow continued cooking of certain

products. Therefore, smaller amounts of bulk foods should be displayed at non-peak periods and the

warmer refilled as needed.

All meats and vegetables should be preheated to 160°F (70°C). before being placed in the case.

A screen liner can be used in the bottom of the display pans that are used for holding meats. This will

keep meats from sticking to the bottom of the pans.

Temperature Adjustment

After placing the product into the equipment, it may be necessary to adjust the programmed settings in

order to maintain the proper internal temperature for the product on display. The optional built-in product

temperature probe or a portable meat thermometer should be used to read the internal temperature of

each product. The programmed settings should be set to the lowest possible number that will maintain

the proper product temperature.

Operational Guidelines

Keep the optional built-in product temperature probe or a portable meat thermometer on hand. Check the

food temperatures hourly.

Rotate the food products. Foods loaded in first should be served first as much as is practical.

Foods held for long periods of time are more difficult to maintain at proper temperature. Also, freshness

and product quality diminish if foods are held too long. Most areas of the country have sanitation

regulations governing how long foods can be held. Make certain to check with your local authorities.

If equipped with the optional humidity water pan, add 4 quarts (4 liters) of water to the water pan when the

“Add Water” indicator lamp illuminates. If equipment has the remote water fill tube on the back of the

counter top add water through this tube. Otherwise, it will be necessary to remove a food pan above the

water pan to add water.

Unit Shutdown

Remove all food pans holding the food product from the equipment. Depress the OFF pushbutton switch

to turn the power to the heaters and lights off. After the temperature has cooled below 120°F (50°C),

remove any residue from the wells and clean the equipment thoroughly.

8

Page 11

Installation

Serious injury, equipment damage or death could result if attempting to install

this unit yourself. Ensure that an authorized BKI service agent installs the unit.

Unpacking and Handling

The company taking delivery of this equipment is responsible for filling all freight claims with the delivering

truck line. Inspect all cartons and crates for damage as soon as they arrive. If damage to cartons or

crates is found, or if a shortage is found, note this on the bill of lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the delivering truck line and follow up

the call with a written report indicating concealed damage to your shipment. Ask for an immediate

inspection of your concealed damage item. Packaging material MUST be retained to show the inspector

from the truck line.

Do not walk on top of deli cases or damage to the cases and serious personal

injury could occur. The cases are not structurally designed to support excessive

external loading such as the weight of a person. Do not place heavy objects on

the deli cases.

Move the deli case as close as possible to its permanent location before moving the case off of the

shipping pallet. Shipping braces are installed on each end of the deli case. Leave these braces in place

while moving and leveling the deli case.

Make certain there are no separately packed accessories before discarding packaging.

During shipment, the lubricant in the gas springs may have settled. This can cause the glass not to

remain open in the raised position. To avoid this, fully raise and lower the glass manually 4 or 5 times.

This unit is designed to be sealed to the floor after it is installed – to conform to

NSF Standard 4. Use Dow Corning RTV # 732 Multi-purpose Sealant.

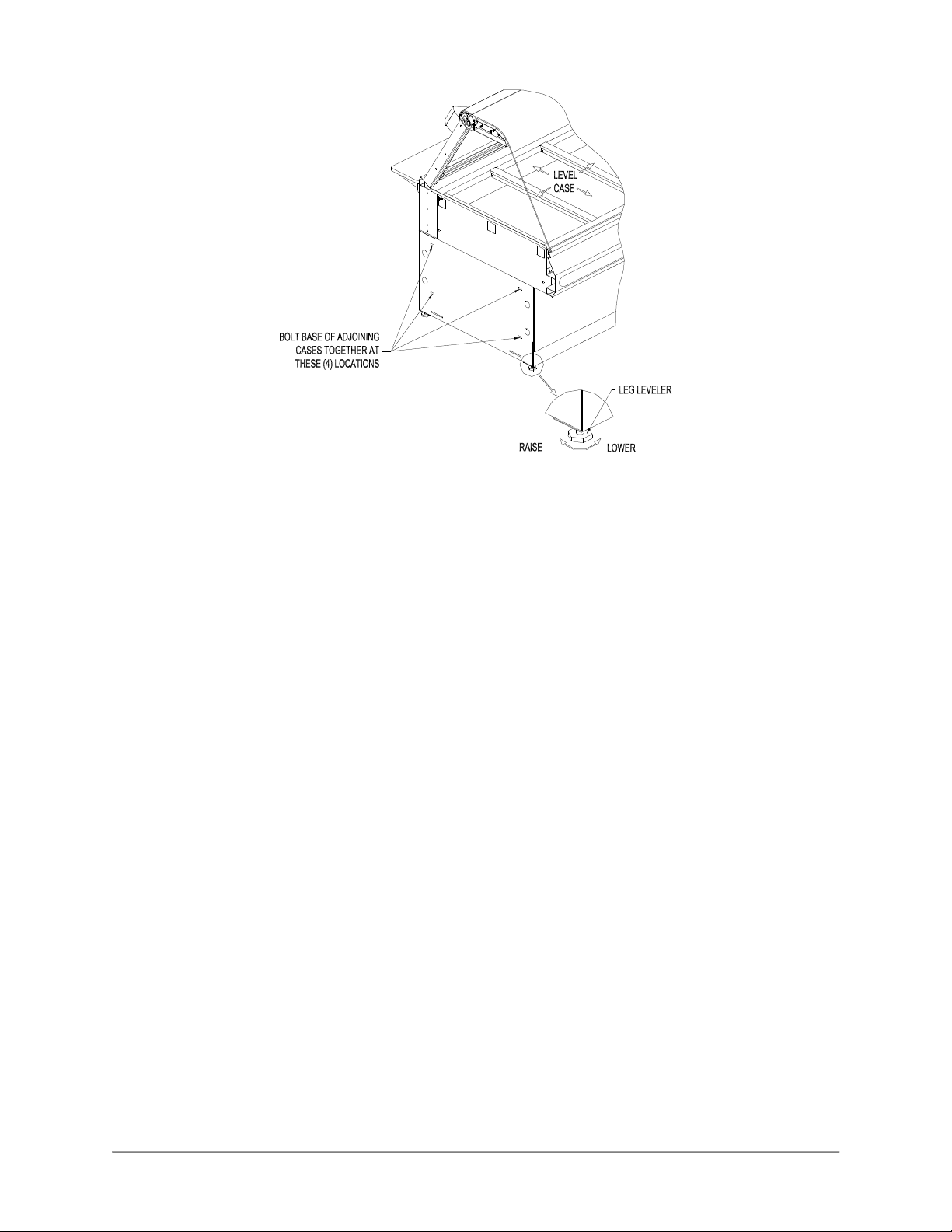

Floor Model

Leveling

Deli cases must be installed level to insure proper operation and alignment to adjoining equipment. Use a

carpenter’s level as shown in Figure 1. Begin lineup leveling from the highest point of the store floor.

1. Level the case using the leg levelers at the corners of the case (Figure 1).

2. Raise the low end of the case, do not lower the high end.

3. Check for level side-to-side and front-to-back.

4. If you are installing adjoining cases, position the next case in line beside the level case and

proceed to the next step.

5. Level this case in the same manner.

6. When level, bolt the two cases together at the locations shown in Figure 1.

NOTE: None of the end components shown in Figure 2 should be attached to adjoining case

ends

If the cases have been properly leveled, the front panels and counter tops should align with a

small, uniform gap between the front panels of the two cases.

7. Proceed in the same manner until all the cases in the line are level and bolted together.

9

Page 12

Figure 1. Floor Models - Leveling

Kick Plate Mounting

A black vinyl-covered kick plate is provided for the front, back and ends of each case.

1. In order to install the Kick Plates it will be necessary to remove the End Trim Panels (see

Figure 2). Remove the retaining nuts located inside the base with a 3/8” wrench. From

outside of the case pull the End Trim Panels away from the case.

2. Slide the front kick plate (the wider of the two) behind the lower finished front panel of the case

(see Figure 2).

3. Make certain that the ends of the kick plate are flush with the ends of the lower finished front

panel and that the kick plate is flush to the floor.

4. Drill 5/32” diameter holes in the case base to match the pre-drilled holes in the kick plate.

5. Attach the kick plate to the case base with the black sheet metal screws provided.

6. Mount the back kick plate to the case in the same manner.

7. Set the End Kick Plates into position on the ends of the case flush with the floor (see Figure 2).

NOTE: There are left and right hand End Kick Plates. The longer end flange faces toward the front of

the case with the black side out. The End Kick Plates fit over the ends of the front and back kick

plates and flush to the floor.

8. Carefully slide the End Trim Panels back into position on the case and push and reinstall the

retaining nuts.

9. This unit is designed to be sealed to the floor after it is installed – to conform to NSF Standard 4.

Use Dow Corning RTV # 732 Multi-purpose Sealant or equivalent silicone sealant to seal the Kick

Plates to the floor around the full perimeter of the case.

10

Page 13

End Panel Mounting

Attach the End Panels to the ends of the case(s) as shown in Figure 2 using the shoulder screws

provided. For Glass End Panels only, slide the plastic bushings provided over the shoulder screws

before inserting the screw into the glass panel. Be careful that the screws do not bind in the holes in

the glass panel.

Figure 2. Floor Model - End Kick Plate & End Panel Mounting

11

Page 14

Pedestal Model

Leveling

Deli cases must be installed level to insure proper operation and alignment to adjoining equipment. Use a

carpenter’s level and begin leveling from the highest point of the store floor.

1. Level the case using the leg levelers at the corners of the pedestals (see Figure 3).

2. Raise the low end of the case to level it, do not lower the high end.

3. Check for level side-to-side and front-to-back.

Figure 3. Pedestal Model - Leveling and Cover Attachment

Pedestal Wrap Installation

1. Remove the Rear Trim from the back of each Pedestal by removing the (4) retaining screws on

each Rear Trim.

2. Spread the side panels of the Pedestal Wraps apart far enough to fit around Pedestal and slide

the Pedestal Wrap around the Pedestal from the front as shown in Figure 3. Make certain the

Pedestal Wrap fits flush to the floor.

NOTES: There are left and right hand Pedestal Wraps. The taller side panel on each Pedestal

Wrap is oriented to the end of deli case.

The short return flange on the front of each Pedestal Wrap side Panel will insert into the large cut

out in the front of the Pedestal. The back flange of each Pedestal Wrap side Panel will wrap

around the back of the Pedestal.

12

Page 15

3. Place the Rear Trim in position on the back of each Pedestal. The Pedestal Wraps fit inside of

the side flanges of the Rear Trim. Thread the Rear Trim retaining screws into the J nuts on the

Pedestal. Make certain the Rear Trim is flush with the floor and tighten the retaining screws.

The Pedestals are to be sealed to the floor if required by local health codes. Seal the pedestal

covers to the floor using a silicone-type sealant (Dow Corning RTV #732 or equivalent).

End Panel Mounting

Attach the End Panels to the ends of the case(s) as shown in Figure 2 using the shoulder screws

provided. For Glass End Panels only, slide the plastic bushings provided over the shoulder screws

before inserting the screw into the glass panel. Be careful that the screws do not bind in the holes in

the glass panel.

Counter Model

Counter Mounted cases must be mounted on a level surface that can support the weight of the case and

it contents. Use a carpenter’s level as shown in Figure 1 to level the case.

These cases are to be sealed to the counter if required by local health codes. Seal the perimeter of the

case to the counter using a silicone-type sealant (Dow Corning RTV #732 or equivalent).

Attach the End Panels to the ends of the case as shown in Figure 2 using the shoulder screws provided.

For Glass End Panels only, slide the plastic bushings provided over the shoulder screws before inserting

the screw into the glass panel. Be careful that the screws do not bind in the holes in the glass panel.

Front Glass Adjustment

During shipment, the lubricant in the gas springs may have settled. This can cause

the glass not to remain open in the raised position. To avoid this, fully raise and

lower the glass manually 4 or 5 times

Alignment of the front glass(es) may change during shipment and installation. After the case is in its final

location and leveled check the distance between

the ends of the glass(es) and the end panels.

On single front glass cases the distance between

each end of the glass and the end panels should

be the same.

On cases with two front glasses the space at the

joint between the two glasses and the distance

between the glass ends and the end panels

should all be the same.

HINGE ELEMENT

CLAMP SCREW

The front glass spacing can be adjusted by

raising the front glass(es) and loosening the

hinge element clamp screws on all of the front

glass hinge elements using a 4 mm hex wrench.

(Refer to the illustration on the right.)

SNEEZE GLASS

ADJUSTMENT SCREW

Move the glass as required and tighten the

clamp screws. Close the front glass(es) to verify the spacing. If necessary repeat the procedure above

until the proper glass alignment is achieved.

The height of the partial sneeze glass on self-service cases can be adjusted using the adjustment

screw(s) located in front of the glass hinge element(s). Raise or lower the screw to make the top of the

sneeze glass horizontal or align it with adjoining glasses.

13

Page 16

Wiring

A wiring diagram for the specific model is shipped with the deli case. The wiring diagram provides

electrical specifications, an electrical schematic and a parts list. Refer to this wiring diagram and the deli

case serial number plate for electrical information.

Field wiring must be sized for the components amperes printed on the serial number plate. Actual ampere

draw may be less than specified.

All electrical connections should be in compliance with the NEC and all applicable local codes by a

licensed electrician. Refer to the wiring diagram furnished with your case for the electrical specifications.

The power supply connection is located on the bottom or back of the well compartment of the case (see

Figure 4). A ¾ knockout is provided at each location for the required conduit connection. A second power

supply connection for the oven is provided on oven combo cases.

A wiring cutout is provided in the base bottom pan on floor model cases (see Figure 5). Refer to the case

specification sheet for the location of this cutout. Remove the cover over the wiring cutout and route the

wiring through the cutout. Cut a hole of the proper size and location in the cover for the conduit to pass

through and reinstall the cover.

Figure 4. Wiring Access

14

Page 17

Case Joining Trim

1. After leveling the cases and bolting the bases together, bolt the canopies together as shown in

Fig. 6 with a ¼”-20 x ¾” Hex Head Screw and Keps Nut.

2. Mount the Upper Front & Base Front Joint Trims by holding them in place and marking the hole

locations on the case.

3. Make certain the joint covers are centered on the joint and that they align vertically with each

other.

4. Drill the case holes 5/32” and attach joint covers with screws provided. Before tightening the top

screws of the Upper Front Trim, slide the Counter Front Trim in place between the screw head

and the Upper Front Trim.

5. Apply a bead of silicone sealant inside the Counter End Joint Cover and slide the cover over both

counter end walls. Apply a bead of silicone sealant to seal the open front of the Counter End

Joint Cover.

6. Attach Bumper Ends and Bumper Mounting Base to the front of the cases, centered on the

vertical surface of the upper front of the case. Cut the Bumper Top to length to fit between the

Bumper Ends and snap into place.

Figure 5. Joining Cases

15

Page 18

Case Divider Glass

A Divider Glass is typically installed between a self-service case with reach-in front glass and a full

service case with full front glass. The Divider Glass is installed on the full service case side of the joint.

1. Mount the Upper Glass Retainer by first removing the outer (2) retaining screws from the canopy

heater reflector on the end of the deli case the Divider Glass is being installed. Insert the screws

through the outer set of holes in the Upper Glass Retainer (see Figure 6) and attach the Upper

Glass Retainer to the canopy.

2. Place the Lower Glass Retainer in position against the inside of the counter end wall on the end

of the deli case the Divider Glass is being installed. The side of the Lower Glass Retainer with (2)

vertical walls is placed against the counter end wall.

3. Apply a bead of silicone sealant inside the Counter End Joint Cover and slide the cover over both

counter end walls and the Lower Glass Retainer. Apply a bead of silicone sealant to seal the

open front of the Counter End Joint Cover.

4. Slide Divider Glass in place through the Upper and Lower Glass Retainers.

Figure 6. Divider Glass Installation

16

Page 19

Frequency

Performed By

Part Activity

Maintenance

Failure to comply with the maintenance below could result in a serious accident.

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs electrical repair. Ensure that a licensed electrician perform

electrical repair.

Scheduled Maintenance

Use the following table to help manage scheduled maintenance activities.

Daily User Case Clean the entire Case. Refer to the

cleaning procedure below.

Cleaning

This unit should be cleaned at the end of each day. Use the following procedure:

Failure to remove power from this unit may cause severe electrical shock. This

unit may have more than one disconnect switch.

1. Turn the machine ‘off ‘ and allow it to cool down.

2. Remove any food pans.

Using abrasive cleaners may damage the cabinet finish. Use only a mild soap and

water solution.

Never steam clean or get excess water in the interior of the cabinet as this can

damage unit.

This appliance is not intended to be cleaned with a water jet.

3. Use a mild soap and water solution to clean parts.

4. Sponge the inside and outside with a mild soap and water solution.

5. Wipe the parts and cabinet dry with a soft, clean cloth.

17

Page 20

Problem

Cause

Possible Solution

Case Not Operating

Case

Not Operating

Holding Temperature Not

Individual Heating Element Not

Control displays PL# and

bee

ps

Control displays P

H

# and

bee

ps

PL and PH messages can appear shortly after case is turned ON.

Control displays

T

L# and

bee

ps

Control displays

TH

# and

bee

ps

Well Numbering Convention

Facing the case from the Customer side, Well 1 is on the far right-hand end of the case. The well number

increase sequentially from right to left.

Troubleshooting

Refer to the table below for troubleshooting information.

Disconnect the case power supply by turning OFF the circuit breaker in the power supply service panel

before performing any diagnostic testing.

No Power to the case. Check circuit breaker or fuses at

(Clear pilot light not illuminated)

Power switch is off. Reset the power switch.

(Clear pilot light illuminated)

building power panel.

Adequate

Heating

every second (# specifies

number problem well).

Control Safety Interlock

circuit has shut case off

because one of the well

temperature probes reached

a preset value.

Case and food pans have not

been preheated.

Product is below 160° F when

loaded into case.

One or more heating

elements not operating

properly.

Loose wire or bad

connection.

Failed Heating Element. Replace failed Heating Element.

Failed Output on Control

Board.

Probe low, shorted.

Measured temperature

< 40°F.

Failed temperature probe,

temperature probes not

connected to control in proper

sequence, well heating elements

not connected to control in proper

sequence.

Refer to the preheating section of

Operators Manual.

Check product temperature

before loading the case.

Troubleshoot as described below.

Identify and repair wire

connection.

Replace entire Control Board.

Replace failed temperature probe

for specified well.

Probe high, open. Measured

every second (# specifies

number problem well).

every second (# specifies

number problem well).

every second (# specifies

number problem well).

TL and TH messages will not appear until after the 20 minute stabilization period.

temperature

> 550°F.

Temperature low, well probe

temperature more than 25°F

below set point.

Temperature high, well probe

temperature more than 40°F

above set point.

Replace failed temperature probe

for specified well.

Loose wire, failed heating element,

failed controller.

18

Page 21

Touch Screen Display Not

Light

Bulb(s) Do Not Illuminate

Functioning (Properly)

Damaged communication

cable.

Replaced damaged cable.

Failed Control Touch Screen

Display.

Failed Control I/O Board. Replace failed Control I/O Board.

Failed Light Bulb(s) Replace failed Light Bulb(s)

when Power is turned On

Fuse(s) Blown Locate and correct cause, then

Failed Ballast Replace failed Ballast

Replace failed Control Touch

Screen Display.

replace blown fuse(s).

19

Page 22

Wiring Diagrams

20

Page 23

21

Page 24

22

Page 25

23

Page 26

24

Page 27

25

Page 28

26

Page 29

27

Page 30

28

Page 31

29

Page 32

30

Page 33

31

Page 34

32

Page 35

33

Page 36

34

Page 37

CP0064

PL0004

MB69008200

CONTROL PANEL, TB2

CONNECT TO DELI CASE

ON WDCG-6 & 7 CASES

SPLITTER WIRES REQ'D

35

Page 38

Notes

2812 Grandview Drive, Simpsonville, S.C. 29680, USA

http://www.bkideas.com

Made and printed in the U.S.A.

SM-OM-012.02 Revised 01/05/17

Loading...

Loading...