Page 1

Powered Disposal Caddy

Series: PDC-14/PDC-14B

Service Manual

Page 2

BKI LIMITED WARRANTY

2812 Grandview Dr. • Simpsonville, SC 29680 • USA

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS

WHO IS

COVERAGE PERIOD

WARRANTY COVERAGE

EXCEPTIONS

EXCLUSIONS

INSTALLATION

REPLACEMENT PARTS

COVERED

COVERED

This warranty covers defects in material and workmanship under normal use, and applies

only to the original purchaser providing that:

អ The equipment has not been accidentally or intentionally damaged, altered or misused;

អ The equipment is properly installed, adjusted, operated and maintained in accordance with

national and local codes, and in accordance with the installation and operating instructions

provided with this product.

អ The serial number rating plate affixed to the equipment has not been defaced or removed.

This

warranty

purchased

អ Warranty claims must be received in writing by BKI within one (1) year from

date of installation or within one (1) year and three (3) months from data of

shipment from the factory, whichever comes first.

អ COB Models: One (1) Year limited parts and labor.

អ COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a

two (2) year door warranty.

អ CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door

warranty.

អ Warranty period begins the date of dealer invoice to customer or ninety (90) days

after shipment date from BKI, whichever comes first.

This

warranty

e

xpenses

hours

travel time and

Any exceptions must be pre-approved in advance and in writing by BKI. The extended

door warranty on convection ovens years 3 through 5 is a parts only warranty and does not

include labor, travel, mileage or any other charges.

អ Negligence

អ Thermostat calibrations

អ Air and gas

អ Light

អ Glass doors and

អ Fuses,

អ Adjustments

អ Tightening

អ Failures

អ Unauthorized

អ Damage

អ Alteration,

អ Thermostats

អ Freight –

អ Ordinary

អ Failure to follow

អ Events

Leveling, as well as

appropriate installation

installer, not the

BKI genuine

date of

is

extended

for use in the U.S.A.

covers on-site labor, parts and

of the

authorized

or acts of

adjustments,

bulbs,

beyond control

installation

door adjustments,

to

burner

of screws or

caused

by erratic

repair by

in

shipment,

misuse or

and safety valves with

other than normal UPS charges,

wear and

installation and/or operating instructions,

proper installation

manufacturer.

Factory OEM parts receive a (90) day

by a BKI F

to the original

service

performed during regular, weekday business hours.

God,

after (30) days

flames and

fasteners,

voltages

anyone other than

improper installation,

tear,

of the

company.

and use materials – is the responsibility of the

actory Authorized

purchaser

reasonable

representative

from equipment installation date,

cleaning of

or gas

broken

and check out of all

and applies only to

travel

up to (100) miles

pilot

burners,

suppliers,

a BKI F

actory Authorized

capillary tubes,

new equipment -

materials warranty

Service

Center.

time

equipment

and travel

round

trip and (2)

Service Center,

per

dealer

or

effective from the

CS-TM-027.02 Revised 3/31/17

Page 3

Mobile Merchandiser Table of Contents

Table of Contents

Table of Contents ........................................................................................................................................ 1

Introduction ................................................................................................................................................. 2

Safety Precautions .................................................................................................................................... 2

Safety Signs and Messages ................................................................................................................. 2

Safe Work Practices ............................................................................................................................. 3

Operation ..................................................................................................................................................... 4

Safety Labels ........................................................................................................................................ 4

Controls ..................................................................................................................................................... 5

Hardware Controls................................................................................................................................ 5

Extracting Renderings from an Oven Drawer ........................................................................................... 6

Ovens Equipped with Extraction Drawer and Coupler Nipple .............................................................. 6

Ovens using the accessory Hand Wand .............................................................................................. 6

Discharge Fryer Oil into the Disposal Caddy ............................................................................................ 6

Discharging the Disposal Caddy Onboard Tank ...................................................................................... 7

Receptacles with a Coupler Nipple ...................................................................................................... 7

Ovens using the accessory Hand Wand .............................................................................................. 7

Operational Guidelines ............................................................................................................................. 7

Installation ................................................................................................................................................... 8

Instructions for Shipping Damage............................................................................................................. 8

Location and Placement ........................................................................................................................... 8

Electrical Information ................................................................................................................................ 8

Dimensions & Specifications .................................................................................................................... 9

Maintenance .............................................................................................................................................. 10

Scheduled Maintenance ......................................................................................................................... 10

Cleaning ............................................................................................................................................. 10

Troubleshooting ...................................................................................................................................... 11

Replacement Parts .................................................................................................................................... 12

General ................................................................................................................................................... 12

Pump with Bypass Valve ........................................................................................................................ 13

Tank Lid .................................................................................................................................................. 13

................................................................................................................................................................ 13

Accessories ............................................................................................................................................. 14

Wiring Diagram .......................................................................................................................................... 15

.............................................................................................................. Error! Bookmark not defined.

Notes .......................................................................................................................................................... 16

1

Page 4

Mobile Merchandiser Introduction

Introduction

Your BKI Powered Disposal Caddy safely extracts, transports and disposes of liquid cooking byproducts and frying oil. The caddy can be easily disassembled without the use of tools for maintenance

and cleaning.

The BKI name and trademark on this unit assures you of the finest in design and engineering — that it

has been built with care and dedication — using the best materials available. Attention to the operating

instructions regarding proper installation, operation, and maintenance will result in long lasting

dependability to insure the highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

you have any questions, please contact your BKI Distributor. If they are unable to

answer your questions, phone the applicable BKI Technical Services

Department:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know and

understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other special

data.

2

Page 5

Mobile Merchandiser Introduction

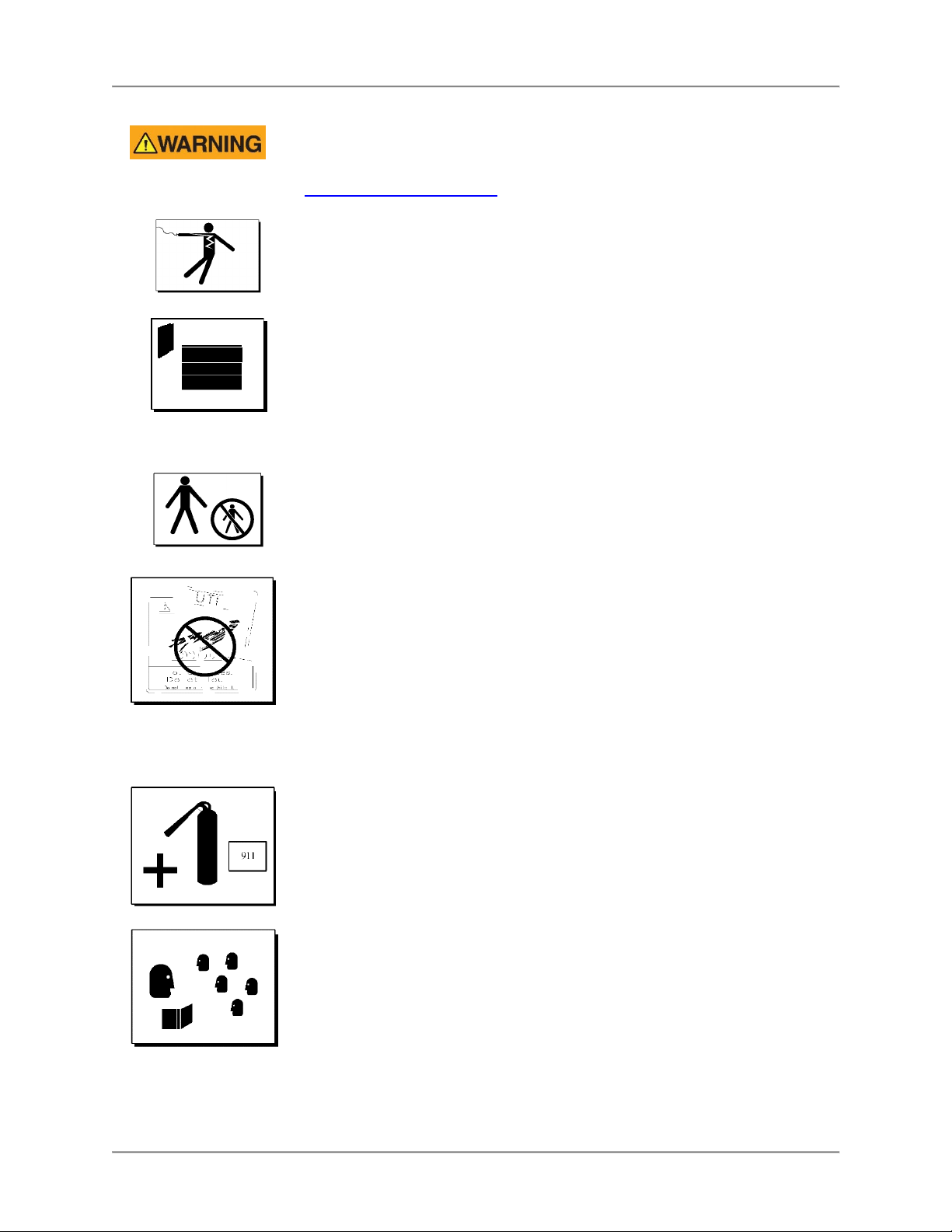

California Residents Only.

This product can expose you to chemicals including

Beware of High Voltage

Keep this manual with the Equipment

Protect Children

Keep Safety Labels Clean and in Good Condition

Be Prepared for Emergencies

Know your responsibilities as an Employer

Safe Work Practices

chromium, and lead which are known to the State of California to cause cancer

and birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

This equipment uses high voltage. Serious injury can occur if you or any untrained or

unauthorized person installs, services, or repairs this equipment. Always Use an

Authorized Service agent to Service Your Equipment.

This manual is an important part of your equipment. Always keep it near for easy

access. If you need to replace this manual, contact:

BKI

Technical Services Department

2812 Grandview Drive, Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887 , Outside the U.S., call 864-963-3471

Keep children away from this equipment. Children may not understand that this

equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Do not remove or cover any safety labels on your equipment. Keep all safety labels

clean and in good condition. Replace any damaged or missing safety labels. Refer to

the Safety Labels section for illustration and location of safety labels on this unit. If you

need a new safety label, obtain the number of the specific label illustrated on page

Error! Bookmark not defined., then contact:

BKI

Technical Services Department

2812 Grandview Drive, Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887, Outside the U.S., call 864-963-3471

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You must use a 40-

pound Type BC fire extinguisher and keep it within 25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services, hospitals, and the fire

department near your telephone.

• Make certain your employees know how to operate the equipment.

• Make certain your employees are aware of the safety precautions on the

equipment and in this manual.

• Make certain that you have thoroughly trained your employees about operating the

equipment safely.

• Make certain the equipment is in proper working condition. If you make

unauthorized modifications to the equipment, you will reduce the function and

safety of the equipment.

3

Page 6

Mobile Merchandiser Operation

Operation

Safety Labels

CAUTION

Hot surface can cause

severe burns.

La surface Chaude peut

causer des brulures severes.

Ne pas toucher.

Do not touch.

N0645

Maximum Tank Capacity

13 gallons (49 liters)

Transfer oil from only (1) fryer

containing max.13 gal. (49 L)

[max. 100 lb. (45 Kg)] of oil.

DANGER

HIGH VOLTAGE.

Turn power off before

servicing. May have more than

one disconnec t switch.

HAUTE TENSIO N.

Mettez l'appareil ho rs tension avant

de proceder a l'e ntretien. Peut-etre

d'u commutateur de deconnexion.

Electrical G rounding Instructions

three-prong (grounding) plug for your protection again st shock hazard and should be

plugged direct ly into a properly g rounded three-prong receptacle. Do not cut or

remove the gr ounding prong from this plug.

Mise à la te rre

mise à la ter re assurant une pro tection contre les cho cs électriques. La pris e dans

laquelle elle est branchée doit êt re correctement mis e à la terre. Ne pas co uper ni

enlever la bro che de mise à la te rre de la fiche.

DO NOT COVER or REMOVE THIS LABEL NE RECO UVREZ PAS ou ENLE VEZ PAS CETTE ÉTI QUETTE

CAUTIO N

- This applia nce is equipped with a

AVERTIR

- Cet appare il est pourvu d’une fi che à trois broches don t une

4

Page 7

Mobile Merchandiser Operation

Item #

Description

Function

1

2

Controls

Operator controls for the Powered Disposal Caddy are located as illustrated in the diagram below.

Hardware Controls

1 Pump Power Switch Controls power to the onboard pump. When the Switch is placed

in the Extract position the pump will energize suctioning liquids

through the long hose into the onboard tank. When the Switch is

placed in the Discharge position the pump will energize suctioning

liquids out of the onboard tank out through the long hose. When

the Switch is placed in the center Off position the pump is deenergized.

2 Bypass Valve

(optional)

Controls liquid flow through or around the onboard pump. When

the handle is in the Onboard Pump position the pump can be

energize to transfer liquid to and from the onboard tank. When the

handle is in the Fill From Fryer position liquid can be pumped into

the onboard tank from a peripheral appliance such as a fryer.

5

Page 8

Mobile Merchandiser Operation

Extracting Renderings from an Oven Drawer

Ovens Equipped with Extraction Drawer and Coupler Nipple

1. Open the oven door and move the Disposal Caddy into position near the oven.

2. Lock at least (2) of the casters on the Disposal Caddy.

3. Plug the Disposal Caddy power cord into a 115V receptacle.

4. Put on high temperature gloves and any other protective equipment prescribed by your employer.

5. Move the Bypass Valve handle to the Onboard Pump position.

6. Connect the coupler on the end of the Disposal Caddy’s long hose to the nipple on the oven

Drawer. Make certain the coupler is fully seated on the nipple.

7. Move the Disposal Caddy Power Switch to the Extract position. The pump will start, suctioning

out the contents of the Drawer.

8. When the Drawer has been emptied move the Disposal Caddy Power Switch to the center Off

position.

9. Disconnect the Disposal Caddy hose coupler from the oven Drawer and stow it in the cup in the

onboard tank.

10. Unplug the Disposal Caddy power cord and stow it on the hanger on the back of the unit.

11. Release the caster brakes and move the Disposal Caddy to its storage location.

Ovens using the accessory Hand Wand

1. Open the oven door and move the Disposal Caddy into position near the oven.

2. Lock at least (2) of the casters on the Disposal Caddy.

3. Plug the Disposal Caddy power cord into a 115V receptacle.

4. Put on high temperature gloves and any other protective equipment prescribed by your employer.

5. Move the Bypass Valve handle to the Onboard Pump position.

6. Connect the coupler on the end of the Disposal Caddy’s long hose to the nipple on the Hand

Wand. Make certain the coupler is fully seated on the nipple.

7. Move the Disposal Caddy Power Switch to the Extract position. The pump will start.

8. Use the Hand Wand to suction out the contents of the Drawer

9. When the Drawer has been emptied move the Disposal Caddy Power Switch to the center Off

position.

10. Disconnect the Disposal Caddy hose coupler from the Hand Wand. Stow the hose coupler in the

cup in the onboard tank.

11. Unplug the Disposal Caddy power cord and stow it on the hanger on the back of the unit.

12. Release the caster brakes and move the Disposal Caddy to its storage location.

Discharge Fryer Oil into the Disposal Caddy

Transfer the oil from only one (1) fryer at a time into the tank. Completely discharge this oil from the

Disposal Caddy tank before transferring additional oil.

1. Open the fryer door and move the Disposal Caddy into position near the fryer.

2. Lock at least (2) of the casters on the Disposal Caddy.

3. Plug the Disposal Caddy power cord into a 115V receptacle.

4. Put on high temperature gloves and any other protective equipment prescribed by your employer.

5. Move the Bypass Valve handle to the Fill From Fryer position.

6. Connect the coupler on the end of the Disposal Caddy’s long hose to the nipple on the Fryer

filtration system. Make certain the coupler is fully seated on the nipple.

7. Start the Fryer filtration system to pump the oil into the Disposal Caddy onboard tank.

8. When the oil has been transferred to the Disposal Caddy turn the Fryer filtration pump Off.

9. Disconnect the Disposal Caddy hose coupler from the Fryer and stow it in the cup in the onboard tank.

10. Unplug the Disposal Caddy power cord and stow it on the hanger on the back of the unit.

11. Release the caster brakes and move the Disposal Caddy to its storage location.

6

Page 9

Mobile Merchandiser Operation

Discharging the Disposal Caddy Onboard Tank

Receptacles with a Coupler Nipple

1. Move the Disposal Caddy into position near the Receptacle connection.

2. Lock at least (2) of the casters on the Disposal Caddy.

3. Plug the Disposal Caddy power cord into a 115V receptacle.

4. Put on high temperature gloves and any other protective equipment prescribed by your employer.

5. Move the Bypass Valve handle to the Onboard Pump position.

6. Connect the coupler on the end of the Disposal Caddy’s long hose to the nipple on the

Receptacle plumbing. Make certain the coupler is fully seated on the nipple.

7. Move the Disposal Caddy Power Switch to the Discharge position. The pump will start,

suctioning out the contents of the onboard tank into the Receptacle.

8. When the onboard tank has been emptied move the Disposal Caddy Power Switch to the center

Off position.

9. Disconnect the Disposal Caddy hose coupler from the nipple on the Receptacle plumbing and

stow it in the cup in the onboard tank.

10. Unplug the Disposal Caddy power cord and stow it on the hanger on the back of the unit.

11. Release the caster brakes and move the Disposal Caddy to its storage location.

Receptacles using the accessory Hand Wand

1. Move the Disposal Caddy into position near the Receptacle connection.

2. Lock at least (2) of the casters on the Disposal Caddy.

3. Plug the Disposal Caddy power cord into a 115V receptacle.

4. Put on high temperature gloves and any other protective equipment prescribed by your employer.

5. Move the Bypass Valve handle to the Onboard Pump position.

6. Connect the coupler on the end of the Disposal Caddy’s long hose to the nipple on the Hand

Wand. Make certain the coupler is fully seated on the nipple.

7. Insert the Hand Wand in the Receptacle and hold it securely in place.

8. Move the Disposal Caddy Power Switch to the Discharge position. The pump will start,

suctioning out the contents of the onboard tank into the Receptacle.

9. When the onboard tank has been emptied move the Disposal Caddy Power Switch to the center

Off position.

10. Disconnect the Disposal Caddy hose coupler from the Hand Wand. Stow the hose coupler in the

cup in the onboard tank.

11. Unplug the Disposal Caddy power cord and stow it on the hanger on the back of the unit.

12. Release the caster brakes and move the Disposal Caddy to its storage location.

Operational Guidelines

• This appliance is not for use with products intended for human consumption.

• The onboard tank must be emptied and cleaned daily.

• Do not start the pump unless the hose is connected to an oven drawer, hand wand or receptacle

tank with a mating coupler nipple.

• Transfer the oil from only one (1) fryer at a time into the tank. Completely discharge this oil from

the tank before transferring additional oil.

7

Page 10

Mobile Merchandiser Installation

Installation

This appliance is equipped with a 3-prong grounding plug for your protection

against electrical shock hazard. It should be plugged directly into a properly

grounded 3-prong receptacle. Do not cut or remove the grounding prong from

this plug.

Instructions for Shipping Damage

You are responsible for filing all freight claims with the delivering truck line. Inspect all cartons and crates

for damage when they arrive. If there is damage noted to shipping crates or cartons, or, if a shortage is

found, note this on the bill of lading (all copies) before signing.

If damage is detected when the equipment is uncrated, immediately call the delivering truck line and

follow up the call with a written report indicating concealed damage to your equipment. Ask for an

immediate inspection of your concealed damage item. Crating material MUST be retained to show the

inspector from the truck line.

Location and Placement

After moving the unit into position lock the swivel casters before using.

Electrical Information

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs the electrical installation. Ensure that a licensed electrician

perform the electrical installation in accordance with local codes, or in the

absence of local codes, with the National Electrical Code, ANSI NFPA 70-20XX.

This appliance must be connected to a receptacle wired in accordance with all applicable local, state, and

federal codes. Use of an extension cord with this appliance is not recommended. It should be plugged

directly into a properly grounded 3-prong receptacle.

8

Page 11

Mobile Merchandiser Installation

PDC

-

14 & PDC

-

14B

Dimension

Uncrated

Crated

Electri

cal

Specifications:

PDC

-

14 & PDC

-

14B

Volts

Amps

Watts

Breaker

Dimensions & Specifications

386.8mm

15 1/4in

39 11/16in

1008.4mm

Height 39 11/16 in [1008.4 mm] 54 in [1372 mm]

Width 15 1/4in [386.8 mm] 32 in [813 mm]

Depth 29 5/8 in [752.3 mm] 44 in [1112 mm]

Floor Space 3.1 sq ft [0.29 m2] 9.8 sq ft [0.91 m2]

Weight 110 lb[50 kg] 160 lb [73 kg]

29 5/8in

752.3mm

120 5.6 670 15

9

Page 12

Mobile Merchandiser Maintenance

Draw Latch

Tank Drain

Tank Hose Coupler

Maintenance

Failure to comply with the maintenance below could result in a serious accident.

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs electrical repair. Ensure that a licensed electrician perform

electrical repair.

Scheduled Maintenance

Failure to remove power from this unit may cause severe electrical shock. This

unit may have more than one disconnect switch.

Always wear appropriate personal protection equipment (googles, rubber glove &

long sleeved garments) when cleaning the oven to guard against possible injury.

Using abrasive cleaners will damage the cabinet finish. Use only a mild soap and

water solution or cleaner approved for stainless steel.

DO NOT USE OVEN CLEANER on this machine. Caustic cleaners will cause

damage to the machine.

NEVER USE A WATER HOSE OR A STEAM CLEANER TO WASH THIS

UNIT. Excess water can get into the interior of the cabinet and cause damage.

Cleaning

For sanitary reasons this unit must be cleaned at

the end of each business day.

1. Make certain the Disposal Caddy power cord

is unplugged.

2. Disconnect the Tank Hose Coupler by lifting

up on release ring.

3. Remove the Onboard Tank from the Caddy.

4. Release the Draw Latch on each side of the

Onboard Tank and remove the Tank Lid.

5. Wash the inside and outside of the Onboard

Tank and Lid with a mild soap and water

solution, being sure to clean all areas. Open

the Tank Drain to aid in draining the Tank

during cleaning.

6. Wash the exterior of the Disposal Caddy with

a mild soap and water solution, being sure to

clean all areas..

7. Wipe the parts and unit dry with a soft, clean

cloth.

8. Make certain the Tank Drain is tightly closed.

9. Place the Tank Lid onto the Onboard Tank with the coupler nipple on the Lid oriented to the Drain

side of the Tank. Secure the Draw Latches on each side of the Tank.

10. Slide the Onboard Tank onto the Caddy with the Tank Drain oriented to the open end of the Caddy.

11. Connect Tank Hose Coupler to the nipple on the Onboard Tank.

ONBOARD

TANK

10

Page 13

Mobile Merchandiser Maintenance

Problem

Cause

Possible Solution

Troubleshooting

Refer to the table below for troubleshooting information.

Pump does not operate. Power supply cord is

disconnected.

Problem with building

power supply.

Pump motor thermal

overload tripped.

Defective power cord,

motor or other component.

Pump energizes but unit

does not transfer fluid.

Hose coupler not

Blockage in unit plumbing. Contact BKI authorized service agency

Bypass Valve set to Fill

From Fryer position.

completely connected.

Plug power supply cord into mating

receptacle.

Check circuit breaker at building power

panel. If problem persists, have

customer contact building maintenance

for corrective action.

Allow motor to cool 20 – 30 minutes then

press motor reset button on the back of

the unit below the motor.

Contact BKI authorized service agency.

Rotate Bypass Valve handle to the

Onboard Pump position.

Check the tank coupler and hose

coupler connections.

11

Page 14

Mobile Merchandiser Replacement Parts

Replacement Parts

Use the information in this section to identify replacement parts. To order replacement parts, call your

local BKI sales and service representative. Before calling, please note the serial number on the rating tag

affixed to the unit.

General

15

14

12

13

1

3

11

17

2

4

9

7

10

16

8

6

5

Item

Qty Part No. Description

1 1 AB16117200 ASSEMBLY, PUMP w/ BYPASS VALVE

2 1 H0135 HOSE, 1/2" ID x 35" HOT LIQUID

3 2 S0136 COUPLER, 1/2" NPTF

4 4 C0406 CASTER, 5" SWIVEL

5 1 CS0005 CORDSET, 14/3 x 90", NEMA 5-15

6 1 F0406 CORD GRIP, STRAIGHT, 025-038

7 1 S0104 SWITCH, RKR DPDT 15A 250V LAMP

8 1 R0197 RELAY, DPDT, 115V, 15A

9 2 TB0124 TERMINAL BLOCK, 2 CONDUCTOR

10 5 TB0123 TERMINAL BLOCK, 3 CONDUCTOR

11 1 MA16117100 HANDLE, VALVE

1 F0255 PIN, CLEVIS, 3/16 x 1-1/4

2 SP0014 SPACER, ALUM .5 X .125

1 F0254 PIN, COTTER HAIRPIN #213

12 1 WB16115200 WELDMENT, TANK

13 1 V0041 VALVE, DRAIN, 3/8 NPT

14 1 P0081 NIPPLE, QUIK DISCONNECT

15 1 AB16116200 ASSEMBLY, LID

16 1 FB16116903 COVER, PUMP

17 1 N0716 DECAL PDC-B OPERATION

12

Page 15

Mobile Merchandiser Replacement Parts

Pump with Bypass Valve

7

8

3

10

6

2

5

11

1

4

Item Qty Part No. Description

1 1 M0047 PUMP / FILTER ASSEMBLY

9

2 1 V0040 VALVE, 1/2" BALL

3 1 LZ0105 FILL VALVE BRACKET

4 1 H0172 HOSE, 1/2" ID x 14" OAL

5 1 TU0205 TUBING, 12" 1/2" ID

6 2 FT0536 COUPLING, 1/2" MPT x FLARE

7 2 FT0643 TEE, 1/2" BLACK IRON

8 2 FT0235 NIPPLE, 1/2" x CLS,

9 1 FT0132 ELBOW, 1/2 STREET x 90

10 1 FT0644 NIPPLE, 1/2" x 3"

11 1 F0155 BUSHING, 7/8" SNAP (BLACK)

Tank Lid

2

1

3

Item Qty Part No. Description

1 1 WB16115900 WELDMENT, PDC LID

2 1 TP0041 TAPE, 1/16 x 1/2 SILICONE

3 1 MA16116000 TUBE, PICKUP

13

Page 16

Mobile Merchandiser Replacement Parts

EXTRACTION DRAWERS for OVENS

PART NO.

DESCRIPTION

HAND WAND ASSEMBLY

Accessories

AA16117400

AB16117400 HAND WAND

AB55013300 VGG8 ROTISSERIE OVEN

AB55013700 VGG5 ROTISSERIE OVEN

AB10231800 102 COMBI OVEN

AB10232100 101 COMBI OVEN

14

Page 17

Mobile Merchandiser Wiring Diagram

Wiring Diagram

SB16190200

WRITTEN PERMISSION FROM STANDEX CSG. ALL RIGHTS ARE RESERVED.

THE COMBINATION OF FACTS, DATA, DESIGN ELEMENTS, ENGINEERING

CONTAINED IN THIS DRAWING ARE OF A PROPRIETARY NATURE TO BKI.

THESE MATERIALS ARE NOT TO BE USED OR COPIED WITHOUT PRIOR

DATA, MANUFACTURING DATA AND ASSEMBLY DATA WHICH MAY BE

Drawing Number

REV ECO DESCRIPTION DATE

3

T5

T4

T2

M1

T3

P2

1

1

L1

L2

T8

P1

3

L2

L2

T5

T8

3

T8

R1

23

T5

1

L2

L1

BLK

110-120V

WHT

1 Ph

CS1

0.7 1531PDC-14

KILLOWATTS

120 5.6

VOLTAGEPHASE AMPSNO. of WIRES BREAKER SIZE

S1

Model

LEGEND

F 04 06 CORD RE STR AINT

M 1 - M0 0 47 MO T OR/ PUM P, 115 /23 0V

R 1 - R01 97 REL AY, DP D T, 115 V

CS 1- 12 0V - C S000 5 C ORD S ET, 8 6" N EMA 5- 20

S 1- S01 0 4 S WIT CH, RO C KER , D PDT

TAH 3/29/2018

Drawn By Date

15

Page 18

Mobile Merchandiser Notes

Notes

2812 Grandview Dr., Simpsonville, S.C. 29680, USA

http://www.bkideas.com

Made and printed in the U.S.A

Page 19

Mobile Merchandiser Notes

REVISION

DATE

REVISED BY

DESCRIPTION

REVISION HISTORY

01 03/27/13 KW Initial Release-Supersedes all previous

releases

Loading...

Loading...