Page 1

Single Revolving Oven

MODEL SR, SR-2, SRW, SRC, KS & LMWS

Service Manual

Page 2

Warranty Information

LIMITED ONE YEAR WARRANTY

BKI (The "Company") warrants to the original purchaser that at time of shipment from the

Company factory, this equipment will be free from defect in materials and workmanship. Written

notice of a claim under this warranty must be received by the Company within ONE YEAR from

the date of installation, but no longer than ONE YEAR AND THREE MONTHS from date of

shipment from the factory. Defective conditions caused by abnormal use or misuse, lack of or

improper maintenance, damage by third parties, alterations by unauthorized personnel, acts of

God, failure to follow installation and/or operating instructions, or any other events beyond the

reasonable control of the Company will NOT be covered under this warranty. The obligation of

the Company under this warranty shall be limited to repairing or replacing (at the option of the

Company) any part, with the exception of lamps, fuses, and glass (which are not covered under

warranty), which is found defective in the reasonable opinion of the Company. Any part found

defective by the Company will be repaired or replaced without charge F.O.B. factory,

Simpsonville, South Carolina or F.O.B. authorized BKI Distributor. The Company and/or its

authorized representatives will assume the normal replacement labor expense for the defective

part for the period of the warranty as stated above, excluding travel and/or other expenses

incidental to the replacement of the defective part, where replacement work is performed during

standard business hours and not subject to overtime, holiday rates, and/or any additional fees. IN

NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, LOSS OF REVENUE OR

LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT OR CONSEQUENTIAL DAMAGES

INCLUDING BUT NOT LIMITED TO, FOOD SPOILAGE OR PRODUCT LOSS. WARRANTY

DOES NOT COVER GLASS BREAKAGE. THE ABOVE WARRANTY IS EXCLUSIVE AND ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

REPLACEMENT PARTS

Any appliance replacement part, with the exception of lamps, fuses, and glass, which proves to

be defective in material or workmanship within ninety (90) days of installation will be replaced

without charge F.O.B. Factory, Simpsonville, SC or F.O.B. authorized BKI Distributor. The user

shall have the responsibility and expense of removing and returning the defective part to the

Company as well as the cost of reinstalling the replacement or repaired part.

Page 3

Single Revolving Oven Table of Contents

Table of Contents

Table of Contents .................................................................................................................................................... 1

Introduction.............................................................................................................................................................. 2

Safety Precautions................................................................................................................................................ 2

Safety Signs and Messages ............................................................................................................................. 2

Safe Work Practices ......................................................................................................................................... 3

Health And Sanitation Practices............................................................................................................................ 5

Food Handling................................................................................................................................................... 5

Storage Of Raw Meats...................................................................................................................................... 5

Coding Cooked Foods......................................................................................................................................5

Storage Of Prepared Foods.............................................................................................................................. 5

Maintenance............................................................................................................................................................. 6

Scheduled Maintenance........................................................................................................................................ 6

Oven Cleaning .................................................................................................................................................. 6

Troubleshooting..................................................................................................................................................... 7

Replacement Parts .................................................................................................................................................. 8

SR Parts List ......................................................................................................................................................... 8

KS Parts List........................................................................................................................................................ 16

SR-2 Parts List.................................................................................................................................................... 20

SRC Parts List..................................................................................................................................................... 26

SRW Parts List.................................................................................................................................................... 32

LMWS Parts List.................................................................................................................................................. 35

Accessories......................................................................................................................................................... 37

Wiring Diagrams.................................................................................................................................................... 38

1

Page 4

Single Revolving Oven Introduction

Introduction

The units covered in this manual are single revolving rotisserie ovens containing tubular heating elements,

manual electronic controls, quarts tube lamps and doors with tempered glass.

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has been

built with care and dedication -- using the best materials available. Attention to the operating instructions

regarding proper installation, operation, and maintenance will result in long lasting dependability to ensure the

highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you have

any questions, please contact your BKI Distributor. If they are unable to answer your

questions, contact the BKI Technical Service Department, toll free: 1-800-927-6887.

Outside the U.S., call 1-864-963-3471.

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol. When you

see this symbol on your equipment, be alert to the potential for personal injury or property damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify specific

areas where potential hazards exist and special precautions should be taken. Know and un derstand the meaning

of these instructions, signs, and messages. Damage to the equipment, death or serious injury to you or other

persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe practices.

This message is used when special information, instructions or identification are required

relating to procedures, equipment, tools, capacities and other special data.

2

Page 5

Single Revolving Oven Introduction

Safe Work Practices

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling hot racks or touch any hot metal

surface. If you lose or damage your mitts, you can buy new ones at your local

restaurant equipment supply store or from your local BKI Distributor.

Always wear non-skid shoes when working around the oven or any other

equipment.

Never wear loose clothing such as neckties or scarves while opera ting this

equipment. Keep loose hair tied back or in a hair net while operating this

equipment.

Always wear appropriate personal protection equipment during the cleaning

process to guard against possible injury from hot cleaning solution.

Beware of High Voltage

This equipment uses high voltage. Serious injury can occur if you or any untrained

or unauthorized person installs, services, or repairs this equipment. Always Use an

Authorized Service agent to Service Your Equipment.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it near for easy

access. If you need to replace this manual, contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not understand that this

equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep all safety labels

clean and in good condition. Replace any damaged or missing safety labels. If you

need a new safety label contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

3

Page 6

Single Revolving Oven Introduction

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You must use a 40-

pound Type BC fire extinguisher and keep it within 25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services, hospitals, and the fire

department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the equipment.

• Make certain your employees are aware of the safety precautions on the

equipment and in this manual.

• Make certain that you have thoroughly trained your employees about operating

the equipment safely.

• Make certain the equipment is in proper working condition. If you make

unauthorized modifications to the equipment, you will reduce the function and

safety of the equipment.

4

Page 7

Single Revolving Oven Introduction

Health And Sanitation Practices

BKI Rotisserie Ovens are manufactured to comply with health regulations and are tested and certified to NSF

standards. You must operate the equipment properly, using only quality products and use meat thermometers to

insure meats are thoroughly cooked.

Food Handling

• Wash hands thoroughly in warm, soapy water after handling raw poultry or meats.

• Clean and sanitize all utensils and surfaces that have been in contact with raw products. Clean and

sanitize the meat forks or baskets between cooking.

• Never place cooked meats on the same surfaces used to prepare raw meats, unless the area has been

thoroughly cleaned and sanitized.

Storage Of Raw Meats

• Designate an area or shelf strictly for the storage of all raw meats to be used in the rotisserie.

• Raw product must always be stored at temperatures below 38° F. (3° C.).

• Never store or mix raw foods above cooked foods, as this is a health hazard.

foods contaminate cooked or processed foods.

• All chicken and chicken parts to be stored overnight must be thoroughly iced down and refrig erated.

The drippings from raw

Coding Cooked Foods

All products cooked during the day should be sold the same day.

NOTE: It is not the intent of the rotisserie program to have unsold merchandise at the end of the cooking day.

Follow your company’s procedures for the handling of any leftover product.

Storage Of Prepared Foods

• Cold foods should be kept at or below 38° F. (3° C.).

• Hot foods must be maintained to meet local health codes, usually a minimum 145° F. (63° C.).

5

Page 8

Single Revolving Oven Maintenance

Maintenance

Failure to comply with the maintenance below could result in a serious accident or

equipment damage.

Failure to remove power from this unit before performing maintenance may cause severe

electrical shock. This unit may have more than one disconnect switch.

Scheduled Maintenance

Oven Cleaning

The oven must be cleaned at the end of each business day. Cleaning is not only necessary for sanitary reasons,

but will increase sales appeal and maximize operating efficiency.

Failure to remove power from this unit may cause severe electrical shock. This unit may

have more than one disconnect switch.

Using abrasive cleaners may damage the cabinet finish. Use only a mild soap and water

solution.

DO NOT USE OVEN CLEANER on this machine. Caustic cleaners can cause damage to

the machine.

Never steam clean or get excess water in the interior of the cabinet as this can damage

unit.

Always wear appropriate personal protection equipment during the cleaning process to

guard against possible injury from hot cleaning solution.

1. Turn off all switches and controls.

2. Let the oven cool to room temperature.

3. Pull grease drawer out of oven and empty it’s contents.

4. Clean grease drawer and tray area with hot soapy water.

5. Remove all food products from the unit. Remove all racks, trays, spits and frames from the unit and place

them in a large sink to soak in hot cleaning solution (BKI Cleaner).

6. Clean the outside and inside of the rotisserie oven with warm water, a sponge and an approved cleaner

which is authorized for use on food surface areas.

7. Clean racks, trays, spits and frames with warm water, a sponge and BK Cleaner. Wipe dry with a clean

cloth.

8. Reassemble the oven.

6

Page 9

Single Revolving Oven Maintenance

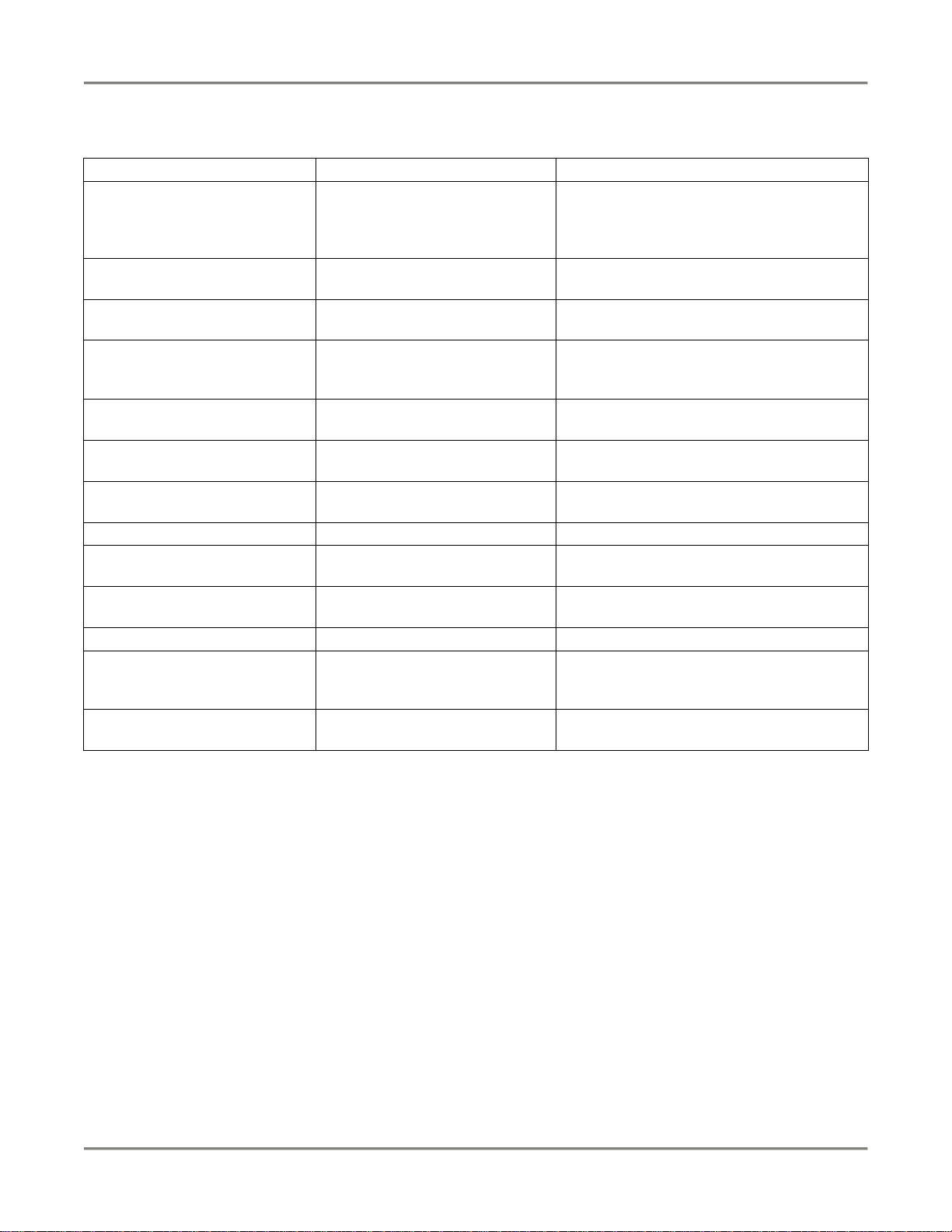

Troubleshooting

Problem Cause Possible Solution

Unit will not turn on. Power to unit is not on. Problem

with building power panel,

circuit breaker or fuse.

Power cord may not be plugged

into outlet.

Blown fuse. Contact an authorized BKI service agent

Not rotating. Motor circuit breaker tripped. Press the reset button. If problem persists,

ROTOR switch may not be

activated.

V-belt is loose or broken. Contact an authorized BKI service agent

Rotor switch not functioning. Defective switch. Contact an authorized BKI service agent

Oven does not heat at all. Improper program settings. Check program settings.

Heating elements not

functioning.

Bad relay. Contact an authorized BKI service agent

Doors may not be closed. Close the doors.

Oven heats up slowly. Improper line voltage. Check incoming voltage. If problem

Heating elements not

functioning.

Check circuit breaker or fuses at building

power panel. If problem persists, contact

an authorized electrician for corrective

action.

Plug cord into outlet.

for corrective action.

contact an authorized BKI service agent

for corrective action.

Make sure the ROTOR switch is on.

for corrective action.

for corrective action.

Contact an authorized BKI service agent

for corrective action.

for corrective action.

persists, contact an authorized BKI

service agent for corrective action.

Contact an authorized BKI service agent

for corrective action.

7

Page 10

Single Revolving Oven Replacement Parts

Replacement Parts

Use the information in this section to identify replacement parts. To order replacement parts, call your local BKI

sales and service representative. Before calling, please note the serial number on the rating tag affixed to the unit.

SR Parts List

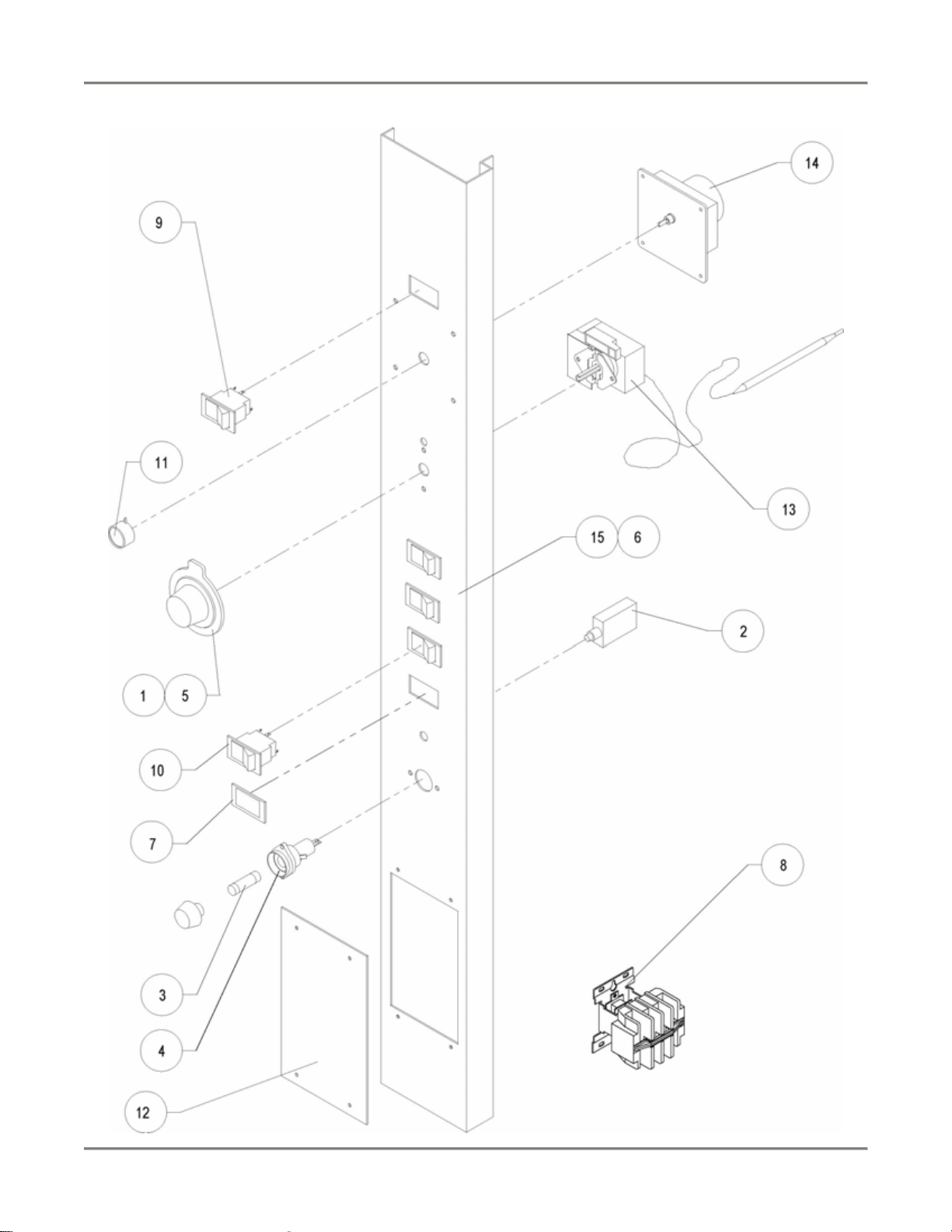

Figure 1. SR Oven

8

Page 11

Single Revolving Oven Replacement Parts

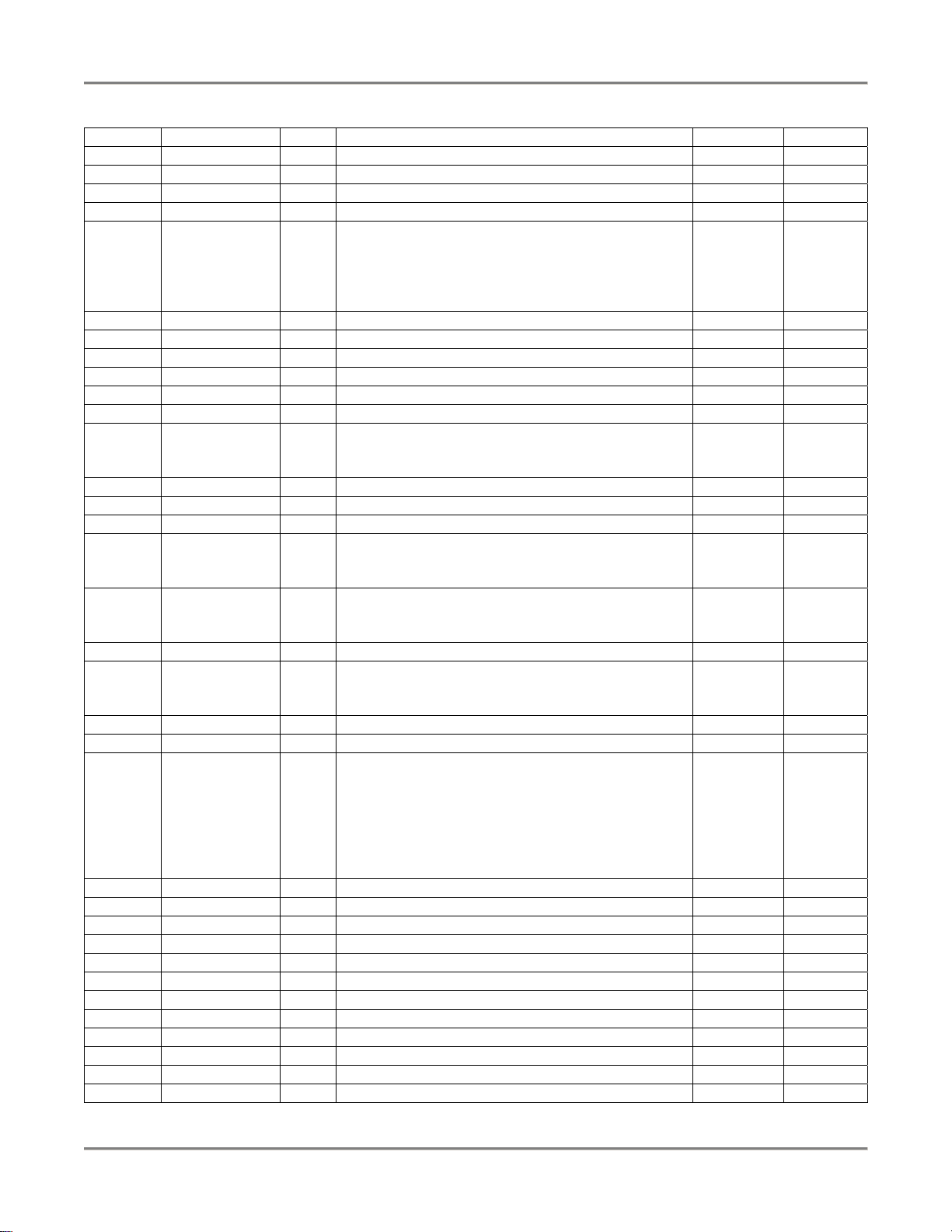

Table 1. SR Oven Parts

ITEM # PART # QTY DESCRIPTION FIGURE # TABLE #

1 B0452B 2 CALROD BRACKET ASSY, SR Figure 1 Table 1

2 C0001

or

C0004

or

C0002

2 CALROD, 208V 2500W OFFSET

or

CALROD, 208V 2500W STRAIGHT

or

CALROD, 240V 2500W OFFSET

Figure 1 Table 1

3 SB0045 2 CATCH SPRING SUBASSY Figure 1 Table 1

4 AN10100100 1 CTL PNL SR 120/208/60/3 N0 H/S Figure 1

Figure 2

Table 1

Table 2

5 SB0049 1 DOOR ASSY, LH SR Figure 1 Table 1

6 SB0005 1 DOOR ASSY, RH SR Figure 1 Table 1

7 SB0218 2 DROP DOWN PNL ASSY S/S SR Figure 1 Table 1

8 SB0085 2 DROP DOWN PNL LESS CATCH S/S Figure 1 Table 1

9 SB0222 1 GREASE DRAWER ASSY, S/S SR'S Figure 1 Table 1

10 G0022 2 GUARD, GRILL 6 BAR (BOTTOM) Figure 1 Table 1

11 LMWSA019 2 GUARD, QUARTZ TUBE (1000W) Figure 1 Table 1

12 KSA039 2 GUARD, QUARTZ TUBE (500W) Figure 1 Table 1

13 H0001 2 HINGE, DOOR 7/8 OFFSET Figure 1 Table 1

14 SRA061 2 HEAT LOC STRIP, 7 7/8" Figure 1 Table 1

15 H0061 1 HINGE, DRP DN OLF SS PIN 1267A Figure 1 Table 1

16 LH0003 4 LAMPHOLDER, QUARTZ TUBE Figure 1 Table 1

17 L0004 1 LATCH, #533D Figure 1 Table 1

18 1 MOTOR MOUNT Figure 1

Figure 3

Table 1

Table 3

19 SRA033 2 MOTO R COVER SR Figure 1 Table 1

20 SRA076 1 OUTSIDE TOP, Figure 1 Table 1

21 HT0016 1 QUARTZ TUBE, 115-125V QH500T3 Figure 1 Table 1

22 HT0002

or

HT0003

23 1 ROTOR ASSEMBLY Figure 1

1 QUARTZ TUBE, 200-220V QH1000T3

or

QUARTZ TUBE, 230-250V QH1000T3

Figure 1 Table 1

Table 1

Figure 4

Table 4

24 SB0007 2 SIDE STIFFENER ASSY SR Figure 1 Table 1

25 SB0111 1 TOP OUTSIDE FRAME WELD ASSY

Figure 1 Table 1

KS

26 SRWA026 1 TOP STIFFNER SRW Figure 1 Table 1

27 VB0005 1 V-BELT, 4L-740 Figure 1 Table 1

9

Page 12

Single Revolving Oven Replacement Parts

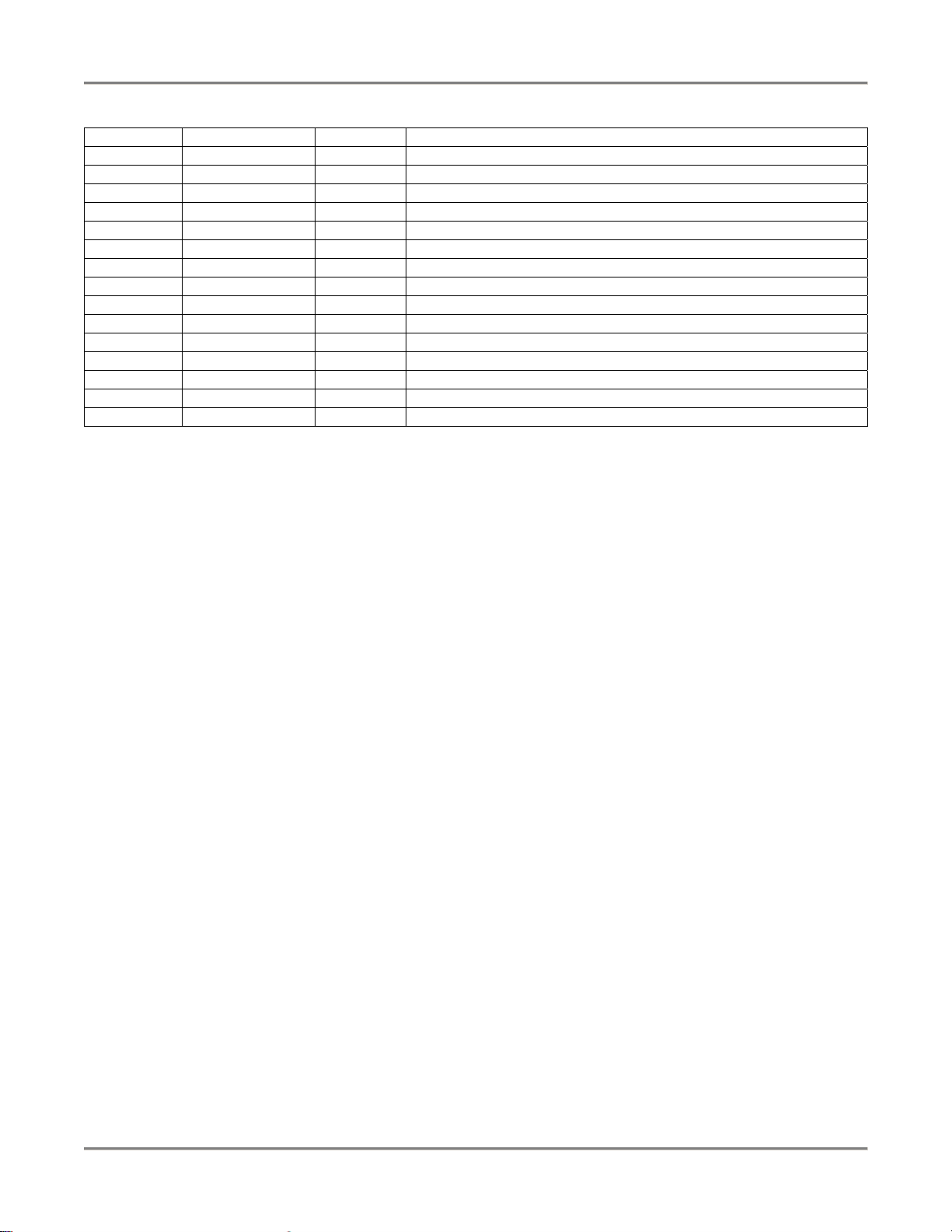

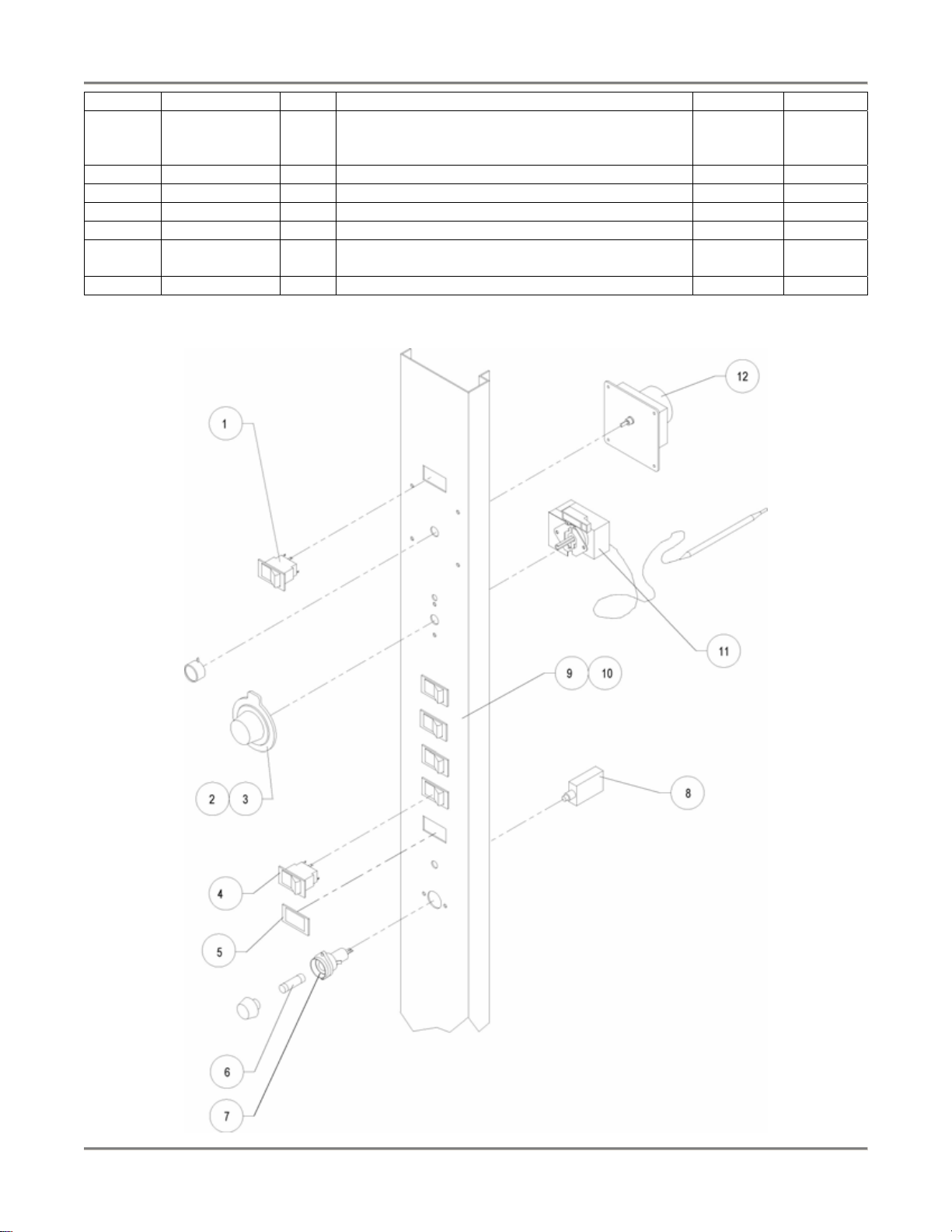

Figure 2. SR Control Panel

10

Page 13

Single Revolving Oven Replacement Parts

Table 2. SR Control Panel Parts

ITEM # PART # QTY DESCRIPTION

1 B1050 1 BEZEL, ROBERTSHAW THERMOSTAT

2 CB0050 1 BREAKER, CIRCUIT 3 AMP 250V

3 F0097 1 FUSE, 15A 300V SC15 TIME DELAY

4 FH0001 1 FUSE HOLDER, 15A 300V HPF-EE

5 K0028 1 KNOB, T-STAT BLK 450DEG

6 N0232 1 DECAL, CONTROL PANEL SR

7 P0084 1 PLUG, DUMMY 5X2-71-XX BL MATTE

8 R0001 1 RELAY, 4 POLE 110/120V

9 S0103 1 SWITCH, RKR DPST 15A 250V LAMP

10 S0107 3 SWITCH, RKR SPST 15A 125V LAMP

11 K0033 1 KNOB, 3 HR TIMER TI0009

12 SRA089 1 INSPECTION PLATE CONTROL PANEL

13 T0005 1 THERMOSTAT, 115-277V 450 DEG SGLPOLE

14 TI0009 1 TIMER, 3 HR

15 SRA047 1 PANEL, CONTROL SR

11

Page 14

Single Revolving Oven Replacement Parts

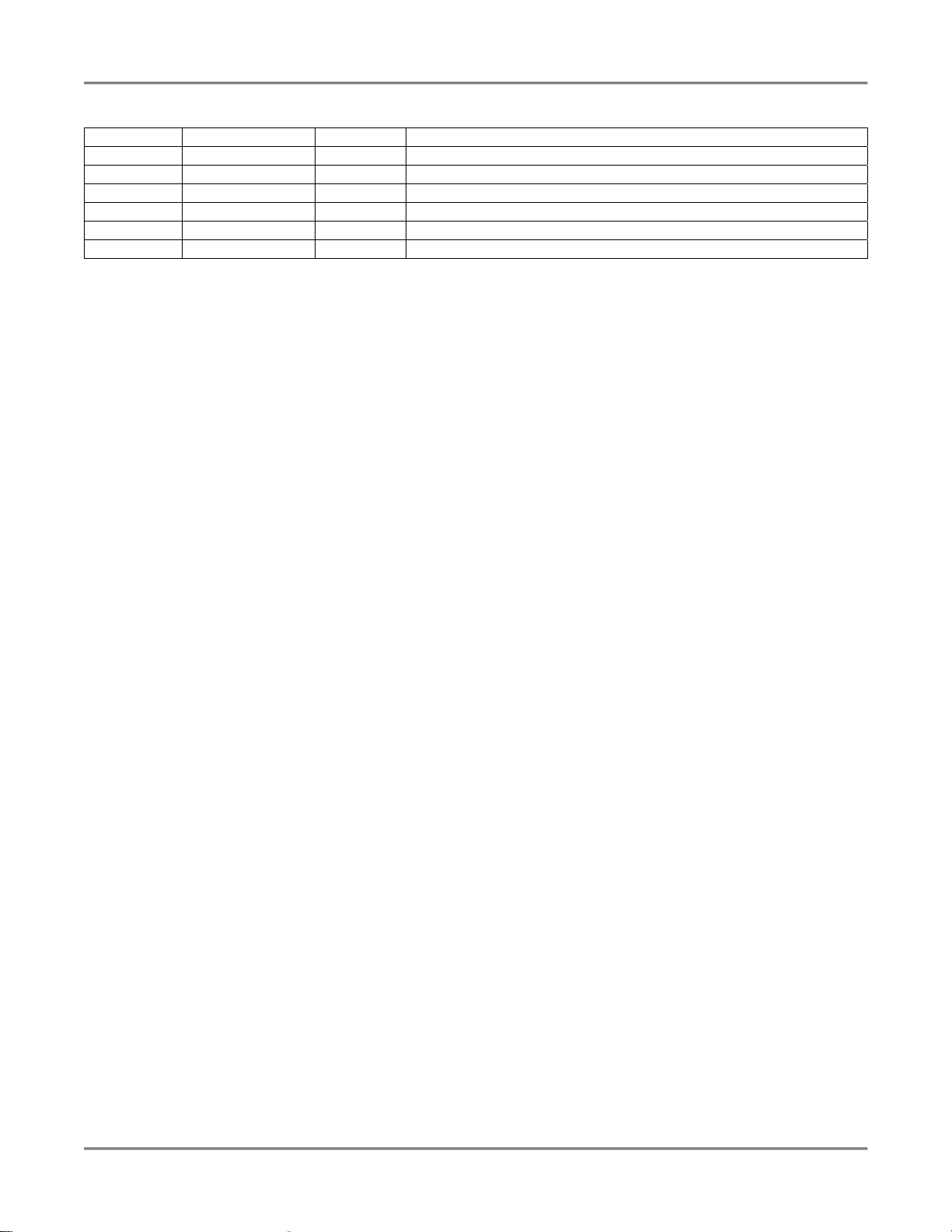

Figure 3. SR Motor Mount

12

Page 15

Single Revolving Oven Replacement Parts

Table 3. SR Motor Mount Parts

ITEM # PART # QTY DESCRIPTION

SB0034 1 MOTOR MTG ASSY, 115V SR LMWS

1 M0064 1 MOTOR, 42R3BFSI-5L 115V 50/60

2 H0019 1 HINGE, 3 1/8" BUTT

3 SR2A037 1 MOTOR MOUNT PLATE, BB, LMWS

4 P0017 1 PULLEY, AS 20 X 5/8

5 SB0025 1 MTG PLATE & SCREW WELD, SR

13

Page 16

Single Revolving Oven Replacement Parts

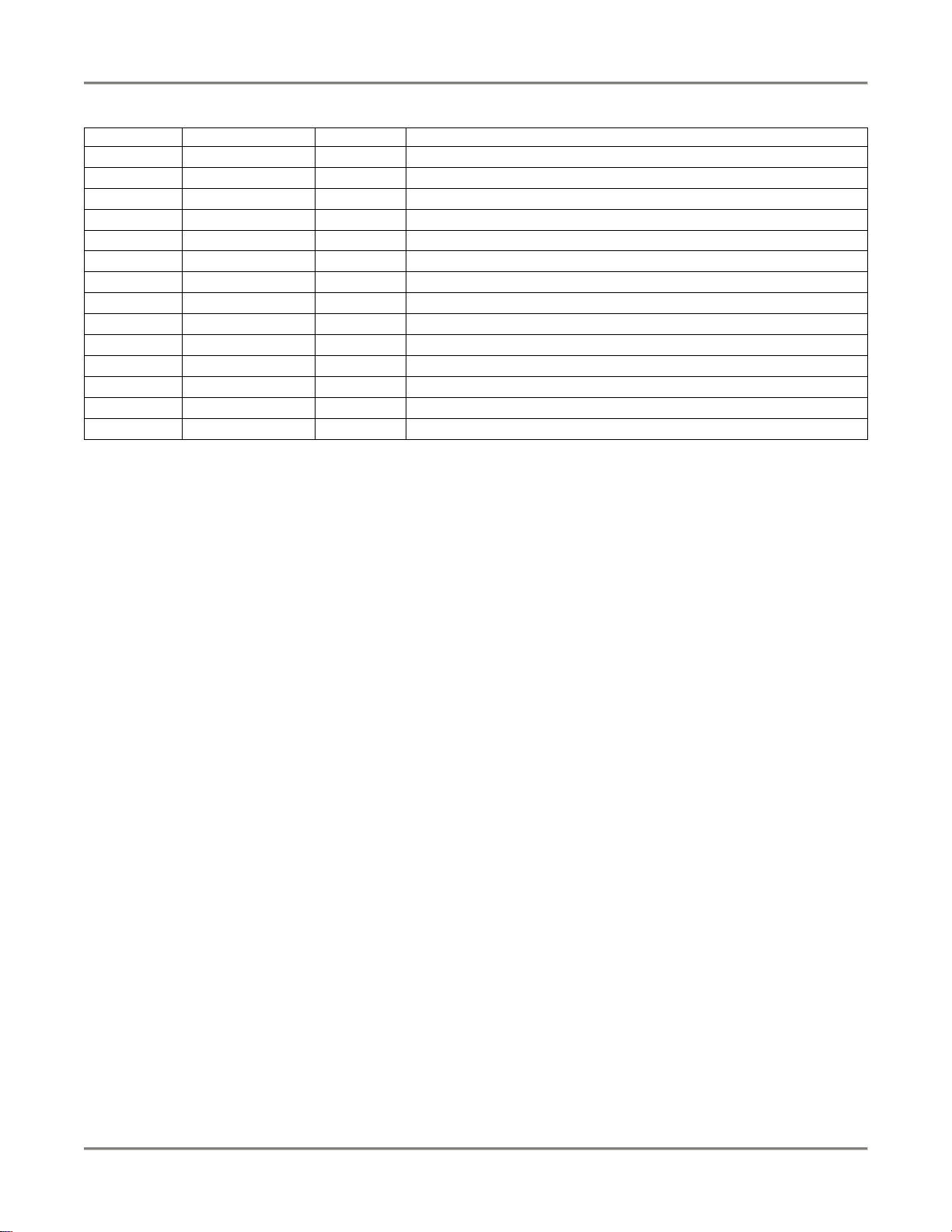

Figure 4. SR Rotor Assembly

14

Page 17

Single Revolving Oven Replacement Parts

Table 4. SR Rotor Assembly Parts

ITEM # PART # QTY DESCRIPTION

a & b

1

SCR384 12 SCREW, 5/16-18 X 1/2 S/S HEX

2 SRA058 4 BEARING BLOCK 5/8 SHAFT

3 B0204 4 BEARING, TZ002591

4 H0081 2 HUB, SR KNOCK OFF SPIDER TYPE

5 F0077 2 ROLL PIN, 5/32 X 1 1/8

6 AN10504800 1 ROTOR ASSY, “V” SIDE

7 AN10513900 1 ROTOR ASSY, PIN SIDE

8 a RO0036 1 ROTOR, PIN SIDE SR MSR (AN10513900)

9b RO0023 1 ROTOR, POINT SIDE MODULAR UNIT (AN10504800)

10 FT0031 1 COLLAR, 5/8 SET LSC-10

11 WN10504600 1 SHAFT/PULLEY WELD

12 H0082 2 SPINNER, SR KNOCK OFF HUB

a & b

13

P0085 6 PIN, STAND OFF 1.125"

a & b

14

WSH101 12 WASHER, 5/16 INT LOCK

a - Part of AN10513900.

b - Part of AN10504800

15

Page 18

Single Revolving Oven Replacement Parts

KS Parts List

Figure 5. KS Oven

16

Page 19

Single Revolving Oven Replacement Parts

Table 5. KS Oven Parts

ITEM # PART # QTY DESCRIPTION FIGURE # TABLE #

1 KSA110 2 TOP INSIDE PANEL, S/S Figure 5 Table 5

2 SB0111 1 TOP OUTSIDE FRAME WELD ASSY KS Figure 5 Table 5

3 SRWA026 1 TOP STIFFNER SRW Figure 5 Table 5

4 SB0112 1 TOP, OUTSIDE W/STAND OFF ROD Figure 5 Table 5

5 HT0016

or

HT0002

or

HT0003

1 QUARTZ TUBE, 115-125V QH500T3

or

QUARTZ TUBE, 200-220V QH1000T3

or

QUARTZ TUBE, 230-250V QH1000T3

Figure 5 Table 5

6 HCA014 4 GUARD, LAMPHOLDER PLATE SR KS LMWS Figure 5 Table 5

7 KSA035 2 MOTOR COVER, KS Figure 5 Table 5

8 H0001 2 HINGE, DOOR 7/8 OFFSET Figure 5 Table 5

9 SB0608 2 CHAIN ASSY, KS 13 LINK Figure 5 Table 5

10 S0023B 4 SPROCKET, KS TEFLON COATED Figure 5 Table 5

11 S0034 2 SEAL, RULON "A" BUSHING Figure 5 Table 5

12 C0001

or

C0002

2 CALROD, 208V 2500W OFFSET

or

CALROD, 240V 2500W OFFSET

Figure 5 Table 5

13 B0452B 2 CALROD BRACKET ASSY, SR Figure 5 Table 5

14 G0022 2 GUARD, GRILL 6 BAR (BOTTOM ) Figure 5 Table 5

15 KSA080 2 HEAT LOC STRIP Figure 5 Table 5

16 SB0602

or

SB0683

17 SB0627

or

SB0684

1 DOOR ASSY RH KS L0004 LATCH

or

DOOR ASSY RH KS L0103 LATCHKET

1 DOOR ASSY LH KS L0004 LATCH

or

DOOR ASSY LH KS L0103 LATCH

Figure 5 Table 5

Figure 5 Table 5

18 L0004 1 LATCH, #533D Figure 5 Table 5

19 SB0678

or

SB0601

1

DROP DOWN PANEL ASSY S/S

or

or

2

DROP DOWN PNL S/S KS

Figure 5 Table 5

20 KSA009 1 DRAWER, GREASE, FRONT Figure 5 Table 5

21 SB0221 1 GREASE DRAWER WELD, S/S SR Figure 5 Table 5

22 AN60000100

or

AN60000200

or

AN60000300

or

SB0644

1 CTL PNL KS 120/208/60/3 NO H/S&G/S

or

CTL PNL KS 220/380/50/3 NO H/S&G/S

or

CTL PNL KS 220/60/3

or

CTL PNL KS 220/60/3

Figure 5

Figure 6

Table 5

Table 6

23 SB0620 1 MOTOR MOUNT ASSY, KS Figure 5 Table 5

24 KSA099 1 SHAFT 1 X 38.062 W/KEYWAY KS Figure 5 Table 5

25 C0406 4 CASTER, W/TOP PLATE 5" Figure 5 Table 5

26 S0024 1 SPROCKET, DRIVE 50B70 Figure 5 Table 5

27 SB0607 1 LOWER BEARING ADJ. WELD, KS Figure 5 Table 5

28 KSA033 1 BRACKET, UPPER BEARING, KS Figure 5 Table 5

29 B0212 1 BEARING, FAFNIR VCJT-1 Figure 5 Table 5

30 KSA027 1 SIDE STIFFENER KS Figure 5 Table 5

31 R0001 1 RELAY, 4 POLE 110/120V Figure 5 Table 5

32 R0002 1 RELAY, 2 POLE 110/120V Figure 5 Table 5

33 KSA098 1 SHAFT 1 X 35.625 KS TOP Figure 5 Table 5

34 B0451 1 BRACKET, KS CTR CALROD Figure 5 Table 5

17

Page 20

Single Revolving Oven Replacement Parts

ITEM # PART # QTY DESCRIPTION FIGURE # TABLE #

35 C0004

or

C0005

2 CALROD, 208V 2500W STRAIGHT

or

CALROD, 240V 2500W STRAIGHT

Figure 5 Table 5

36 LH0021 2 LAMPHOLDER, #62602 HI TEMP Figure 5 Table 5

37 SPCA062 2 TUBING, KS TOP STAND OFF Figure 5 Table 5

38 SPC309 2 BRACKET, STAND OFF SR Figure 5 Table 5

39 SB0625 1 MICRO SWITCH BRKT ASSY KS (operator side) Figure 5 Table 5

40 SB0626 1 MICRO SWITCH BRKT ASSY KS (customer

Figure 5 Table 5

side)

41 SB0612 1 COVER, CALROD ASSY, KS Figure 5 Table 5

Figure 6. KS Control Panel

18

Page 21

Single Revolving Oven Replacement Parts

Table 6. KS Control Panel Parts

ITEM # PART # QTY DESCRIPTION FIGURE # TABLE #

1 S0103 1 SWITCH, RKR DPST 15A 250V LAMP Figure 6 Table 6

2 B1050 1 BEZEL, ROBERTSHAW THERMOSTAT Figure 6 Table 6

3 K0028

or

K0025

1 KNOB, T-STAT BLK 450DEG

or

KNOB, T-STAT 450 DEG FLAT@12

Figure 6 Table 6

4 S0107 4 SWITCH, RKR SPST 15A 125V LAMP Figure 6 Table 6

5 P0084 2 PLUG, DUMMY 5X2-71-XX BL MATTE Figure 6 Table 6

6 F0097 1 FUSE, 15A 300V SC15 TIME DELAY Figure 6 Table 6

7 FH0001 1 FUSE HOLDER, 15A 300V HPF-EE Figure 6 Table 6

8 CB0050 1 BREAKER, CIRCUIT 3 AMP 250V Figure 6 Table 6

9 N0235 1 DECAL, CONTROL PANEL KS Figure 6 Table 6

10 KSA021 1 PANEL, CONTROL KS Figure 6 Table 6

11 T0005

or

T0001

12 TI0009

or

TI0018

1 THERMOSTAT, 115-277V 450 DEG SGLPOLE

or

THERMOSTAT, 450 DEG 208V

1 TIMER, 3 HR

or

TIMER, 180 MIN 115V 50HZ

Figure 6 Table 6

Figure 6 Table 6

19

Page 22

Single Revolving Oven Replacement Parts

SR-2 Parts List

Figure 7. SR-2 Oven (Sheet 1 of 2)

20

Page 23

Single Revolving Oven Replacement Parts

Figure 7. SR-2 Oven (Sheet 2 of 2)

21

Page 24

Single Revolving Oven Replacement Parts

Table 7. SR-2 Oven Parts

ITEM # PART # QTY DESCRIPTION FIGURE # TABLE #

1 SPCA062 1 TUBING, KS TOP STAND OFF Figure 7 Table 7

2 SPC309 2 BRACKET, STAND OFF SR Figure 7 Table 7

3 HT0002

or

HT0003

2 QUARTZ TUBE, 200-220V QH1000T3

or

QUARTZ TUBE, 230-250V QH1000T3

Figure 7 Table 7

4 LMWSA019 4 GUARD, QUARTZ TUBE (1000W) Figure 7 Table 7

5 R0001

or

R0003

or

R0150

2 RELAY, 4 POLE 110/120V

or

RELAY, 4 POLE 240V

or

RELAY, 4 POLE 208-240 60 HZ

Figure 7 Table 7

6 SR2A035 2 MOTOR COVER SR2 Figure 7 Table 7

7 MOTOR MOUNT Figure 7

Figure 8

Table 7

Table 8

8 VB0006 V-BELT, A-135D Figure 7 Table 7

9 C0415 4 CASTER, 3"SWIVEL W/BREAK Figure 7 Table 7

10 SB0107 1 GREASE DRAWER ASSY, BTM SR2 Figure 7 Table 7

11 ROTOR ASSEMBLY Figure 7

Figure 4

12 AN11100100

or

AN11100200

or

AN11100300

or

AN11100400

1 CTL PNL SR2 120/208-240/1-3 NO H/S

or

CTL PNL SR2 208-240 NO H/S

or

CTL PNL SR2 220/380/50/3 NO H/S

or

CTL PNL SR2 120/240/50/1 NO H/S

Figure 7

Figure 9

Table 7

Table 4

Table 7

Table 9

13 L0004 1 LATCH, #533D Figure 7 Table 7

14 G0022 2 GUARD, GRILL 6 BAR (BOTTOM) Figure 7 Table 7

15 H0061 4 HINGE, DRP DN OLF SS PIN 1267A Figure 7 Table 7

16 SB0045 8 CATCH SPRING SUBASSY Figure 7 Table 7

17 SB0085

or

SB0218

4 DROP DOWN PNL LESS CATCH S/S

or

DROP DOWN PNL ASSY S/S SR

Figure 7 Table 7

18 SRA061 8 HEAT LOC STRIP, 7 7/8" Figure 7 Table 7

19 SB0005

and

SB0049

2

and

2

DOOR ASSY, RH SR

and

DOOR ASSY, LH SR

Figure 7 Table 7

20 H0061 8 HINGE, DRP DN OLF SS PIN 1267A Figure 7 Table 7

21 B0452B 4 CALROD BRACKET ASSY, SR Figure 7 Table 7

22 SB0126 1 SIDE GREASE DRAWER ASSY, SR'S Figure 7 Table 7

23 C0001

or

C0002

4 CALROD, 208V 2500W OFFSET

or

CALROD, 240V 2500W OFFSET

Figure 7 Table 7

24 KSA039 4 GUARD, QUARTZ TUBE (500W) Figure 7 Table 7

25 HT0016 2 QUARTZ TUBE, 115-125V QH500T3 Figure 7 Table 7

26 G0023 2 GUARD, GRILL 9 BAR (TOP) Figure 7 Table 7

27 LH0003 4 LAMPHOLDER, QUARTZ TUBE Figure 7 Table 7

28 SB0112 1 TOP, OUTSIDE W/STAND OFF ROD Figure 7 Table 7

29 VB0005 1 V-BELT, 4L-740 Figure 7 Table 7

22

Page 25

Single Revolving Oven Replacement Parts

Figure 8. SR-2 Motor Mount

Table 8. SR-2 Motor Mount Parts

ITEM # PART # QTY DESCRIPTION

1 M0033

or

M0064

2 MOTOR, 208/230V 50/60 CYCLE

or

MOTOR, 42R3BFSI-5L 115V 50/60

2 H0019 2 HINGE, 3 1/8" BUTT

3 SR2A037 2 MOTOR MOUNT PLATE, BB, LMWS

4 P0017 2 PULLEY, AS 20 X 5/8

5 SB0026 4 MTG PLATE & SCREW WELD, SR-2

23

Page 26

Single Revolving Oven Replacement Parts

Figure 9. SR-2 Control Panel

24

Page 27

Single Revolving Oven Replacement Parts

Table 9. SR-2 Control Panel Parts

ITEM # PART # QTY DESCRIPTION

1 TI0009

or

TI0018

2 T0001

or

T0005

3 CB0050

or

CB0058

2 TIMER, 3 HR

or

TIMER, 180 MIN 115V 50HZ

2 THERMOSTAT, 450 DEG 208V

or

THERMOSTAT, 115-277V 450 DEG SGLPOLE

2 BREAKER, CIRCUIT 3 AMP 250V

or

BREAKER, CIRCUIT 1 AMP 250V

4 SR2A010 1 CTL PNL SR2

5 N0232

and

N0422

1 DECAL, CONTROL PANEL SR

and

DECAL, CONTROL PANEL BOTT SR2

6 P0084 2 PLUG, DUMMY 5X2-71-XX BL MATTE

7 S0107 6 SWITCH, RKR SPST 15A 125V LAMP

8 F0097 2 FUSE, 15A 300V SC15 TIME DELAY

9 FH0001 2 FUSE HOLDER, 15A 300V HPF-EE

10 B1050 2 BEZEL, ROBERTSHAW THERMOSTAT

11 K0025

or

K0028

2 KNOB, T-STAT 450 DEG FLAT@12

or

KNOB, T-STAT BLK 450DEG

12 S0103 2 SWITCH, RKR DPST 15A 250V LAMP

25

Page 28

Single Revolving Oven Replacement Parts

SRC Parts List

Figure 10. SRC Oven (Sheet 1 of 2)

26

Page 29

Single Revolving Oven Replacement Parts

Figure 10. SRC Oven (Sheet 2 of 2)

27

Page 30

Single Revolving Oven Replacement Parts

Table 10. SRC Oven Parts

ITEM # PART # QTY DESCRIPTION FIGURE # TABLE #

1 SPCA062 1 TUBING, KS TOP STAND OFF Figure 10 Table 10

2 SPC309 2 BRACKET, STAND OFF SR Figure 10 Table 10

3 HT0016 1 QUARTZ TUBE, 115-125V QH500T3 Figure 10 Table 10

4 LH0003 4 LAMPHOLDER, QUARTZ TUBE Figure 10 Table 10

5 KSA039 2 GUARD, QUARTZ TUBE (500W) Figure 10 Table 10

6 SRCA083 1 INSIDE TOP, S/S Figure 10 Table 10

7 ROTOR ASSEMBLY Figure 10

Figure 4

8 F0099 1 FAN, 9" TORIN AIROTOR SRC Figure 10 Table 10

9 SRCA037 1 COVER, BLOWER MOTOR Figure 10 Table 10

10 SRCA036 1 TOP, BLOWER COVER SRC Figure 10 Table 10

11 M0032 1 MOTOR, HOWELL FAN 115/230 Figure 10 Table 10

12 B0204 2 BEARING, TZ002591 Figure 10 Table 10

13 SRA058 2 BEARING BLOCK 5/8 SHAFT Figure 10 Table 10

14 C0406

or

C0415

15 R0001

or

R0003

16 SRCA063 2 RELAY PLATE, SRC Figure 10 Table 10

17 AN30100100

or

SB0338

or

AN30100300

or

SB0342

or

AN30100200

18 SB0045 2 CATCH SPRING SUBASSY Figure 10 Table 10

19 G0023 1 GUARD, GRILL 9 BAR (TOP) Figure 10 Table 10

20 SB0301 1 DOOR ASSY, RH BOTTOM SRC Figure 10 Table 10

21 SB0312

or

SB0341

22 H0001 8 HINGE, DOOR 7/8 OFFSET Figure 10 Table 10

23 SB0003

or

SB0218

or

SB0085

24 SB0343

or

SB0625

25 SB0126 1 SIDE GREASE DRAWER ASSY, SR'S Figure 10 Table 10

26 C0001

or

C0002

27 B0452B 2 CALROD BRACKET ASSY, SR Figure 10 Table 10

28 SB0049 2 DOOR ASSY, LH SR Figure 10 Table 10

29 SRA061 8 HEAT LOC STRIP, 7 7/8" Figure 10 Table 10

30 SR2A035 2 MOTOR COVER SR2 Figure 10 Table 10

4 CASTER, W/TOP PLATE 5"

or

CASTER, 3"SWIVEL W/BREAK

2 RELAY, 4 POLE 110/120V

or

RELAY, 4 POLE 240V

1 CTL PNL SRC 120/208-240/3 NO H/S

or

CTL PNL SRC 220/380/50/3

or

CTL PNL SRC 220/380/50/3 NO H/S

or

CTL PNL SRC STR 240V 3PH

or

CTL PNL SRC STR 240V 3PH NO H/S

1 DOOR ASSY, LH BOTT SRC

or

DOOR ASSY, LH BOTT SRC

2 DROP DOWN PNL ASSY PORC SR

or

DROP DOWN PNL ASSY S/S SR

or

DROP DOWN PNL LESS CATCH S/S

1 MICRO SWITCH BRKT ASSY SRC

or

MICRO SWITCH BRKT ASSY KS

2 CALROD, 208V 2500W OFFSET

or

CALROD, 240V 2500W OFFSET

Figure 10 Table 10

Figure 10 Table 10

Figure 10

Figure 11

Figure 10 Table 10

Figure 10 Table 10

Figure 10 Table 10

Figure 10 Table 10

Table 10

Table 4

Table 10

Table 11

28

Page 31

Single Revolving Oven Replacement Parts

ITEM # PART # QTY DESCRIPTION FIGURE # TABLE #

31 HT0002

or

HT0003

1 QUARTZ TUBE, 200-220V QH1000T3

or

QUARTZ TUBE, 230-250V QH1000T3

Figure 10 Table 10

32 LMWSA019 4 GUARD, QUARTZ TUBE (1000W) Figure 10 Table 10

33 SRWA026 1 TOP STIFFNER SRW Figure 10 Table 10

34 SB0111 1 TOP OUTSIDE FRAME WELD ASSY KS Figure 10 Table 10

35 SB0112 1 TOP, OUTSIDE W/STAND OFF ROD Figure 10 Table 10

36 SRCA066 1 CALROD ACCESS PANEL RS CUST Figure 10 Table 10

37 SRCA031 1 PANEL, OUTSIDE MOTOR SRC Figure 10 Table 10

38 SRCA026 1 CALROD ACCESS PANEL LS CUST Figure 10 Table 10

39 SRCP038B 1 CABINET, PORC INSIDE BLOWER Figure 10 Table 10

40 SB0305B 2 SIDE INSERT ASSY, ELEC NKL SRC Figure 10 Table 10

41 SRCP027B 1 CONVECTION INSIDE TOP, PORC. Figure 10 Table 10

42 SR1003 2 RACK, SIDE TRAY SRC Figure 10 Table 10

43 R0029 5 RACK, 19 1/4 X 25 3/4 Figure 10 Table 10

44 SRCA041 1 STOP, BOTTOM DOOR SRC Figure 10 Table 10

45 SRCA057 1 BRACKET, BOTTOM DOOR HANDLE Figure 10 Table 10

46 H0211 1 HANDLE, SRC DOOR, 8.5X1 Figure 10 Table 10

47 NUT187 2 NUT, CAP 1/4-20 NC 1/2" HEAD Figure 10 Table 10

48 SCR257 2 SCREW, 1/4-20 X 1/2 PHIL FLT Figure 10 Table 10

49 SRCA086 1 INSIDE BLOWER CABINET, SRC Figure 10 Table 10

50 SB0340 1 CALROD PIGTAIL ASSY SRC 220/380 Figure 10 Table 10

51 SB0332 1 CALROD PIGTAIL ASSY SRC120/208 Figure 10 Table 10

52 SB0333 1 CALROD PIGTAIL ASSY SRC120/240 Figure 10 Table 10

53 SP0004 12 SPACER, ALUM 3/4 X 1 1/2 Figure 10 Table 10

54 SB0304 2 CALROD COVER WELD ASSY, SRC Figure 10 Table 10

55 SB0120

or

SB0034

1 MOTOR MOUNT ASSY 240V

or

MOTOR MTG ASSY, 115V SR LMWS

Figure 10 Table 10

56 VB0006 1 V-BELT, A-135D Figure 10 Table 10

57 B0066

or

B0553

4 BULB, 40A15 130V TEFLON COATED

or

BULB, TUFFSKIN 40W 250V

Figure 10 Table 10

58 LH0001 4 LAMPHOLDER, RD PORCELAIN Figure 10 Table 10

59 SRCA034 4 BRACKET, LIGHT SOCKET SRC Figure 10 Table 10

60 SRCA032 1 PANEL, REAR INSIDE BLWR MTG Figure 10 Table 10

29

Page 32

Single Revolving Oven Replacement Parts

Figure 11. SRC Control Panel

30

Page 33

Single Revolving Oven Replacement Parts

Table 11. SRC Control Panel Parts

ITEM # PART # QTY DESCRIPTION

1 S0103 1 SWITCH, RKR DPST 15A 250V LAMP

2 B1050 2 BEZEL, ROBERTSHAW THERMOSTAT

3 K0028 2 KNOB, T-STAT BLK 450DEG

4 S0107 6 SWITCH, RKR SPST 15A 125V LAMP

5 P0084 1 PLUG, DUMMY 5X2-71-XX BL MATTE

6 FH0001 1 FUSE HOLDER, 15A 300V HPF-EE

7 F0097 1 FUSE, 15A 300V SC15 TIME DELAY

8 FH0003 1 FUSE HOLDER, 20A 300V HPS-JJ

9 F0104 1 FUSE, 20A 300V SC20 TIME DELAY

10 SRCA048 1 PANEL, CONTROL SRC

11 N0234 1 DECAL, CONTROL PANEL SRC LOGO

12 CB0050 1 BREAKER, CIRCUIT 3 AMP 250V

13 T0005 2 THERMOSTAT, 115-277V 450 DEG SGLPOLE

14 TI0018

or

TI0009

2 TIMER, 180 MIN 115V 50HZ

or

TIMER, 3 HR

15 N0232 1 DECAL, CONTROL PANEL SR

31

Page 34

Single Revolving Oven Replacement Parts

SRW Parts List

SRW Part # SRW Part Description

SB0237 BASE ASSY 208 240V SRW CASTERS

SB0217 BASE ASSY SRW 115V CASTERS

SB0233 BOTTOM RACK ASSY, SRW

SR2A056 BRACE, MOTOR COVER SR2

SPCA162 BRACKET, CALROD MTG CANADA

B0453 BRACKET, SRW CALROD

B0066 BULB, 40A15 130V TEFLON COATED

B0553 BULB, TUFFSKIN 40W 250V

SR2A051 BUMPER, KS

F0158 BUSHING, BLK 1/2 HEYCO SNAP

F0155 BUSHING, BLK 7/8 HEYCO SNAP

SB0290A CAB ASSY SRW S/S NO CAM

SB0292A CAB ASSY SRW SOL BACK NO CAM

SB0296A CAB ASSY SRW SOL BACK NO CAM

B0452B CALROD BRACKET ASSY, SR

SRWA131 CALROD GROUNDING CLIP, CANADA

C0221 CALROD, 208V 2000W

C0001 CALROD, 208V 2500W OFFSET

C0222 CALROD, 240V 2000W

C0002 CALROD, 240V 2500W OFFSET

F0063 CLAMP, SAFETY 16101-S 1/4 DIA

FT0031 COLLAR, 5/8 SET LSC-10

SB0289 CORD SET, 7' ALBERTSON SRW MSR

SRWA077 CORNER POST SRW

SRWA008 COVER, MOTOR SRW

AN20100100 CTL PNL SRW 120/208/60/1-3 NO H/S

SB0295 CTL PNL SRW 220/380/60/1-3

SB0293 CTL PNL SRW 220/60/1

AN20100200 CTL PNL SRW 240/60/3 NO H/S

N0202 DECAL, DANGER HIGH VOLTAGE

N0166 DECAL, DO NOT USE HARSH CLEANERS

N0409 DECAL, LOGO LARGE DIE CAST

N0022 DECAL, NSF

N0444 DECAL, NSF TREATED LAMP NOTICE

N0363 DECAL, REMOVABLE ROTORS

N0034 DECAL, WATER PAN NOTICE

SB0210 DOOR ASSY, LH BOTT SRW

SB0049 DOOR ASSY, LH SR

SB0202 DOOR ASSY, RH BOTT SRW

SB0005 DOOR ASSY, RH SR

SB0218 DROP DOWN PNL ASSY S/S SR

SB0085 DROP DOWN PNL LESS CATCH S/S

FT0255 ELL, 3/4 90 DEG

32

Page 35

Single Revolving Oven Replacement Parts

SRW Part # SRW Part Description

SRWA058 FLANGE, FLEXIBLE TUBING

SRWA059 FLEX HOSE STRAP

KSA071 GASKET, GREASE SMOKER

SB0222 GREASE DRAWER ASSY, S/S SR'S

G0022 GUARD, GRILL 6 BAR (BOTTOM)

HCA014 GUARD, LAMPHOLDER PLATE SR KS LMWS

SRA053 HINGE BLOCK, KS, SP, DP

H0081 HUB, SR KNOCK OFF SPIDER TYPE

SRWA073 INSIDE H/S COVER PLATE

SRA089 INSPECTION PLATE CONTROL PANEL

SRWA087 INSUL PANEL, WARMER W/LIGHTS

G0052 INSULATED MITT 13"

I0011 INSULATION, KAOWOOL STRIP

I0002 INSULATION, PEERLESS FIBER 3"

I0010 INSULATION, RANGE 1" FIBERGLASS

LH0021 LAMPHOLDER, #62602 HI TEMP

LH0001 LAMPHOLDER, RD PORCELAIN

SRA056 LATCH BLOCK, KS

SRWA039 LID, SMALL LOUVER SRW

SRWA098 LIGHT GUARD, SRW

SRA108 MOTOR COVER SPACER, SR SERIES

N0023 NAME & RATING TAG, UL

NUT076 NUT, 10-24 PALNUTS

NUT083 NUT, SPEED PS-312010-S

NUT082 NUT, SPEED PS-438014-S

SRWA072 OUTSIDE H/S COVER PLATE

SRA076 OUTSIDE TOP,

SRWA038 PANEL, MDL LOUVERED SRW

SRA046 PANEL, SIDE INSL SR

SRWA124 PANEL, TOP INSULATION

SRA052 PLATE, OUTSIDE CALROD KS SR SERIES

FT0015 PLUG, HOLE 1/2"

HT0016 QUARTZ TUBE, 115-125V QH500T3

HT0002 QUARTZ TUBE, 200-220V QH1000T3

HT0003 QUARTZ TUBE, 230-250V QH1000T3

R0022 RACK, 24 1/2 X 26

RC0009 RECEPTACLE, FLUSH 60A 250V

RIV170 RIVET, 1/8 ALUM (.063-.125)

F0024 RIVNUT, #10-24

F0025 RIVNUT, 5/16"-18

F0015 ROLL PIN, 5/32 X 1 1/4

F0077 ROLL PIN, 5/32 X 1 1/8

SB0011B ROTOR ASSY 6 TRAY LHW/SPRINGS

AN10513900 ROTOR ASSY MSR

AN10504800 ROTOR ASSY, W/O SPRINGS

33

Page 36

Single Revolving Oven Replacement Parts

SRW Part # SRW Part Description

SRWA067 S/S SLIDE FOR RACK

SCR244 SCREW, 10-24 X 1/2 SLTD TRUSS

SCR369 SCREW, 10-24 X 3/4 PHIL RD

SCR136 SCREW, 10-24 X 3/8 SLTD TRUSS

SCR356 SCREW, 5/16-18 X 5/16 SOC SET

SCR118 SCREW, 6-32 X 5/8 SLTD RD

SCR006 SCREW, 8 X 1/2 PHIL PAN

SCR448 SCREW, STUD 10-24 X 1-1/4 WELD

SCR067 SCREW,5/16-18 X 2 1/2 SLTD TRUSS

WN10504600 SHAFT/PULLEY WELD MSR SR SR2 SRW

SB0206 SIDE STIFFENER ASSY SRW

KSA096 SKIRT, BOTTOM

SB0219 SOLID PANEL, S/S SR

SP0007 SPACER, ALUM 11/16"

H0082 SPINNER, SR KNOCK OFF HUB

SB0209 SRW S/S SOLID DOOR PNL, BOTTOM

SRA091 STAND OFF STRIP

SB0008 TERM BLOCK ASSY, 4 TB0001

SB0008A TERM BRKT ASSY 1 0R 3P

F0294 TERMINAL, RING TONGUE

F0081 THREAD INSERT 3/8-16 STEEL

SB0111 TOP OUTSIDE FRAME WELD ASSY KS

SRWA026 TOP STIFFNER SRW

SB0112 TOP, OUTSIDE W/STAND OFF ROD

TF0035 TRANSFORMER, 230V 50/60HZ TO

VB0009 V-BELT, A-120

F0126 WASHER, REDUCER #125-75 APP

WSH252 WASHER, TEFLON SR SERIES

WSRWA079 WATER PAN WELDMENT, SRW

SB0203 WELL ASSY, SRW 120/208

SB0239 WELL ASSY, SRW 208 OR 240V

34

Page 37

Single Revolving Oven Replacement Parts

LMWS Parts List

LMWS Part # LMWS Part Description

SB5318 BASE ASSY, CASTERS LMWS 115V

SB5325 BASE ASSY, CASTERS LMWS 220V

SB5308 BLOWER MOTOR ASSY, LMWS

SPCA162 BRACKET, CALROD MTG CANADA

SR2A043 BRACKET, GREASE DRAWER SR2

B0066 BULB, 40A15 130V TEFLON COATED

B0553 BULB, TUFFSKIN 40W 250V

F0156 BUSHING, BLK 5/8 HEYCO SNAP

SB5331 CAB ASSY LMWS S/S

SRWA131 CALROD GROUNDING CLIP, CANADA

C0215 CALROD, 208V 1100W

C0216 CALROD, 240V 1100W

F0063 CLAMP, SAFETY 16101-S 1/4 DIA

FT0049 COLLAR, 1/2" SET BRIGHT

LMWSA022 CORNER POST

AN53000300 CTL PNL LMWS 1 PH NO H/S

AN53000500 CTL PNL LMWS 220/50/1 NO H/S

AN53000400 CTL PNL LMWS 220/60/1 NO H/S

AN53000200 CTL PNL LMWS 230V NO H/S

AN53000600 CTL PNL LMWS 3 PH NO H/S

N0387 DECAL, 300 DEG MAX FOR DR34

N0517 DECAL, BKI LOGO ADHESIVE BACK

N0202 DECAL, DANGER HIGH VOLTAGE

N0409 DECAL, LOGO LARGE DIE CAST

N0022 DECAL, NSF

N0444 DECAL, NSF TREATED LAMP NOTICE

N0363 DECAL, REMOVABLE ROTORS

N0034 DECAL, WATER PAN NOTICE

SB5319 DOOR ASSY LH OPER LMWS

SB5307 DOOR ASSY RH CUST LMWS

SRWA059 FLEX HOSE STRAP

KSA071 GASKET, GREASE SMOKER

SB5304 GREASE DRAWER ASSY, LMWS

HCA014 GUARD, LAMPHOLDER PLATE SR KS LMWS

H0101 HUB SPINNER, QUIK RELEASE FS/LMWS

H0100 HUB, QUIK RELEASE (FS &LMWS)

SRWA073 INSIDE H/S COVER PLATE

SRA089 INSPECTION PLATE CONTROL PANEL

G0052 INSULATED MITT 13"

I0011 INSULATION, KAOWOOL STRIP

I0002 INSULATION, PEERLESS FIBER 3"

I0010 INSULATION, RANGE 1" FIBERGLASS

I0005 INSULATION,1"TK

35

Page 38

Single Revolving Oven Replacement Parts

LMWS Part # LMWS Part Description

LH0001 LAMPHOLDER, RD PORCELAIN

SRA056 LATCH BLOCK, KS

LMWSA009 LID, CENTER LOUVER LMWS

LMWSA026 LID, LOUVER R&L

SB5315 LMWS OUTSIDE TOP FRAME WELD

SB5317 LMWS SIDE RACK ASSY

SB5324 MOTOR BLOWER ASSY, LMWS 220V

LMWSA031 MOTOR COVER

LMWSA059 MOTOR COVER BRACE

LMWSA069 MOTOR COVER SPACER

N0023 NAME & RATING TAG, UL

NUT076 NUT, 10-24 PALNUTS

NUT083 NUT, SPEED PS-312010-S

SRWA072 OUTSIDE H/S COVER PLATE

LMWSA058 OUTSIDE TOP

LMWSA082 PANEL, INSULATION

FT0015 PLUG, HOLE 1/2"

HT0002 QUARTZ TUBE, 200-220V QH1000T3

HT0003 QUARTZ TUBE, 230-250V QH1000T3

R0009 RACK, 19 3/8 X 20

SB5333 REMOV DISC ROTOR W/SPRING LMWS

SB5334 REMOV ROTOR PLAIN SIDE LMWS

RIV170 RIVET, 1/8 ALUM (.063-.125)

RIV172 RIVET, 1/8 CS ZINC (.187-.250)

RIV173 RIVET,1/8 SS (.187-.250)

SCR017 SCREW, 10 X 1 SLTD HEX WASHER

SCR008 SCREW, 10 X 1/2 PHIL TRUSS

SCR025 SCREW, 10-24 X 3/4 PHIL FL HD

SCR031 SCREW, 10-24 X 3/4 PHIL RD

SCR369 SCREW, 10-24 X 3/4 PHIL RD

SCR236 SCREW, 5/16-18 X 1 WHIZ'LOC

SCR356 SCREW, 5/16-18 X 5/16 SOC SET

SCR448 SCREW, STUD 10-24 X 1-1/4 WELD

SB5313 SHAFT & PULLEY WELD ASSY, LMWS

LMWSA077 SKIRT, BOTTOM LMWS

SB5336 SOLID BACK ASSY, LMWS BOTT SECTION

SB5306 SOLID BACK ASSY, LMWS TOP SECTION

SB0008 TERM BLOCK ASSY, 4 TB0001

F0051 TERMINAL, ELEC RING TONGUE

F0294 TERMINAL, RING TONGUE

VB0004 V-BELT, 4L-910

WLMWSA012 WATER PAN WELDMENT, LMWS

LMWSA002 WELL, CALROD, LMWS

W0012 WIRE, #12 GREEN

36

Page 39

Single Revolving Oven Replacement Parts

Accessories

Part # Description

SR, SR-2, SRW AND SRC

G0052 INSULATED MITT 13"

MF001 MEAT FORK

MB0016 MEAT BASKET

MB0018 CHICKEN BASKET WITH PRONGS

MF0026 “V” SPIT

KS

G0052 INSULATED MITT 13"

FR0001 FRAME

MF0004 MEAT FORK (SINGLE SPIT)

MB0001 MEAT BASKET (FR0001 FRAME NEEDED)

MB0012 CHICKEN RACK BASKET (SB0680S KIT NEEDED)

MB0016 MEAT BASKET (SB0680S KIT NEEDED)

WASCA003 ROASTING PAN (FR0001 FRAME NEEDED)

ASCA005B BAKING TRAY (FR0001 FRAME NEEDED)

KSA059 COOKIE SHEET (FR0001 FRAME NEEDED)

SB0680S PIN/NUT/WASHER KIT FOR KS CHAIN

LMWS

G0052 INSULATED MITT 13"

MF0002 MEAT FORK

MB0007 MEAT BASKET

37

Page 40

Single Revolving Oven Wiring Diagrams

Wiring Diagrams

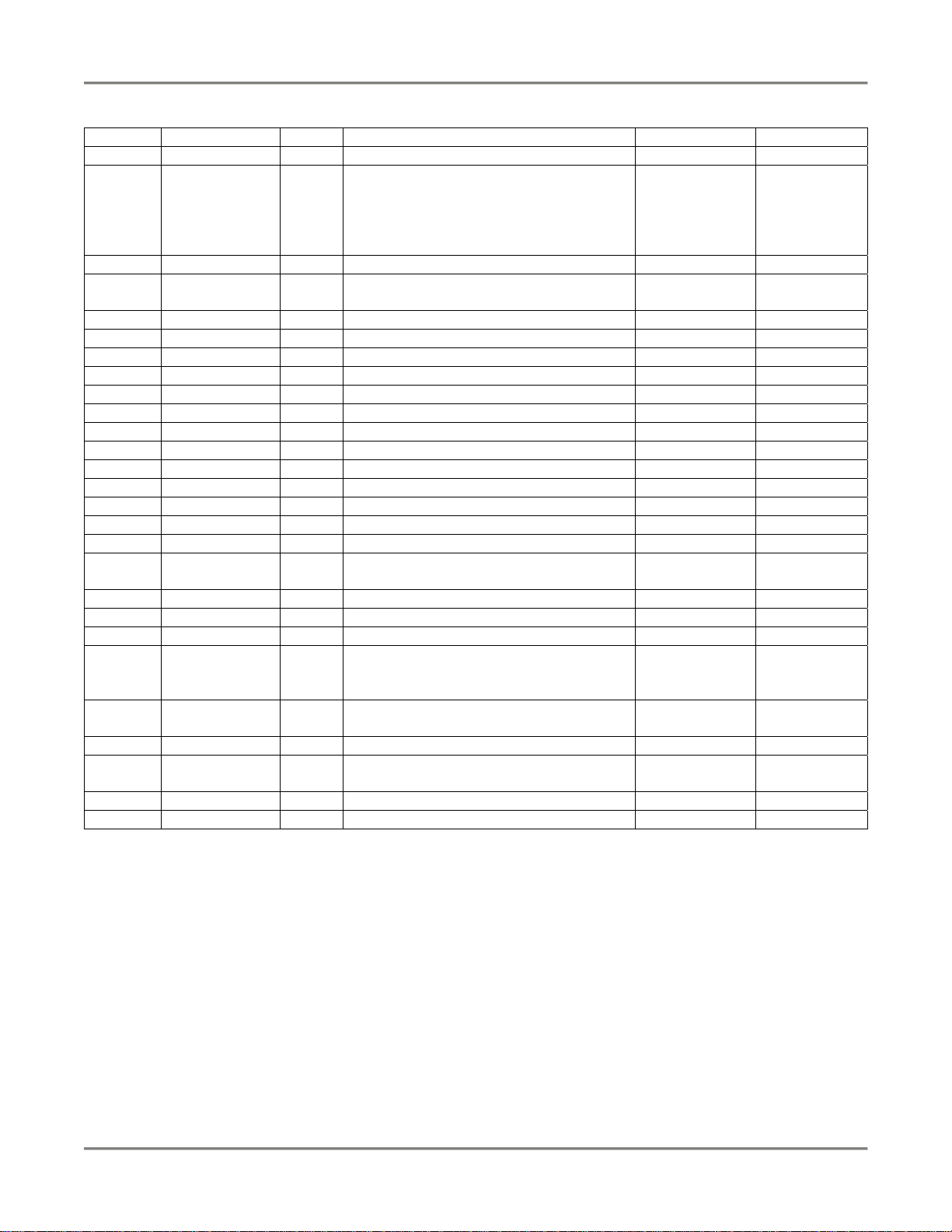

Model Part # Description Figure #

SR SB10190000 120V/208V/240V/1-3 Phase Figure 12

SR-2 SB11190100 120V/208V and 120V/240V/1-3 Phase Figure 13

SR-2 SB11190000 208V/220V/240V/1-3 Phase Figure 14

SR-2 SB11190200 220V/380V/3 Phase Figure 15

SRC SB30190000 120/208V and 120/240V/3 Phase Figure 16

SRC SB30190300 220V/380V/50 HZ/3 Phase Figure 17

SRC SB30190200 240V/3 Phase Figure 18

SRW SB20190100 120V/208V/240V/1-3 Phase Figure 19

SRW SB20190000 208V/220V/240V/1-3 Phase Figure 20

KS SB60090200 220V/380V/50 HZ/3 Phase Figure 21

KS SB60090300 208V/220V/240V/3 Phase Figure 22

KS SB60090000 120V/208V and 120V/240V/1-3 Phase Figure 23

LMWS SB53090000 120V/208V and 120V/240V/1 Phase Figure 24

LMWS SB53090200 120V/208V/60 HZ/3 Phase Figure 25

LMWS SB53090100 208V/220V/230V/1 Phase Figure 26

LMWS SB53090300 220V/50 HZ/1 Phase Figure 27

38

Page 41

Single Revolving Oven Wiring Diagrams

Figure 12. SR 120V/208V/240V/1-3 Phase

39

Page 42

Single Revolving Oven Wiring Diagrams

Figure 13. SR2 120V/208V and 120V/240V/1-3 Phase (Sheet 1 of 2)

40

Page 43

Single Revolving Oven Wiring Diagrams

Figure 13. SR2 120V/208V and 120V/240V/1-3 Phase (Sheet 2 of 2)

41

Page 44

Single Revolving Oven Wiring Diagrams

Figure 14. SR2 208V/220V/240V/1-3 Phase (Sheet 1 of 2)

42

Page 45

Single Revolving Oven Wiring Diagrams

Figure 14. SR2 208V/220V/240V/1-3 Phase (Sheet 2 of 2)

43

Page 46

Single Revolving Oven Wiring Diagrams

Figure 15. SR2 220V/380V/3 Phase (Sheet 1 of 2)

44

Page 47

Single Revolving Oven Wiring Diagrams

Figure 15. SR2 220V/380V/3 Phase (Sheet 2 of 2)

45

Page 48

Single Revolving Oven Wiring Diagrams

Figure 16. SRC 120/208V and 120/240V/3 Phase (Sheet 1 of 2)

46

Page 49

Single Revolving Oven Wiring Diagrams

Figure 16. SRC 120/208V and 120/240V/3 Phase (Sheet 2 of 2)

47

Page 50

Single Revolving Oven Wiring Diagrams

Figure 17. SRC 220V/380V/50 HZ/3 Phase (Sheet 1 of 2)

48

Page 51

Single Revolving Oven Wiring Diagrams

Figure 17. SRC 220V/380V/50 HZ/3 Phase (Sheet 2 of 2)

49

Page 52

Single Revolving Oven Wiring Diagrams

Figure 18. SRC 240V/3 Phase (Sheet 1 of 2)

50

Page 53

Single Revolving Oven Wiring Diagrams

Figure 18. SRC 240V/3 Phase (Sheet 2 of 2)

51

Page 54

Single Revolving Oven Wiring Diagrams

Figure 19. SRW 120V/208V/240V/1-3 Phase

52

Page 55

Single Revolving Oven Wiring Diagrams

Figure 20. SRW 208V/220V/240V/1-3 Phase

53

Page 56

Single Revolving Oven Wiring Diagrams

Figure 21. KS 220V/380V/50 HZ/3 Phase

54

Page 57

Single Revolving Oven Wiring Diagrams

Figure 22. KS 208V/220V/240V/3 Phase

55

Page 58

Single Revolving Oven Wiring Diagrams

Figure 23. KS 120V/208V and 120V/240V/1-3 Phase

56

Page 59

Single Revolving Oven Wiring Diagrams

Figure 24. LMWS 120V/208V and 120V/240V/1 Phase

57

Page 60

Single Revolving Oven Wiring Diagrams

Figure 25. LMWS 120V/208V/60 HZ/3 Phase

58

Page 61

Single Revolving Oven Wiring Diagrams

Figure 26. LMWS 208V/220V/230V/1 Phase

59

Page 62

Single Revolving Oven Wiring Diagrams

Figure 27. LMWS 220V/50 HZ/1 Phase

60

Page 63

Single Revolving Oven Notes

Notes

61

Page 64

P.O. Box 80400, Simpsonville, S.C. 29680-0400, USA

http://www.bkideas.com

Made and printed in the U.S.A

LI0276/0407

Loading...

Loading...