BKI KS Installation Manual

Single Revolving Oven

MODEL SR, SR-2, SRW, SRC, KS & LMWS

OPERATION AND MAINTENANCE

Warranty Information

LIMITED ONE YEAR WARRANTY

BKI (The “Company”) warrants to the original purchaser/user, that at time of shipment from the

Company factory, this equipment will be free from defect in materials and workmanship. Written

notice of a claim under this Warranty must be given within ONE YEAR AND THREE MONTHS

from date of shipment from the factory. Defective conditions caused by abnormal use or misuse,

lack of maintenance, damage by third parties, alterations by unauthorized personnel, acts of God,

failure to follow installation instructions or any other events beyond the control of the company will

NOT be covered under Warranty. The obligation of the Company under this Warranty shall be

limited to repairing or replacing (at the option of the company) any part which is defective in

reasonable opinion of the Company. The user will have the responsibility and expense of

removing and returning the defective part to the Company as well as the cost of reinstalling the

replacement or repaired part.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, LOSS OF REVENUE

OR LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT OR CONSEQUENTIAL DAMAGES

INCLUDING BUT NOT LIMITED TO, FOOD SPOILAGE OR PRODUCT LOSS . WAR RANTY

DOES NOT COVER GLASS BREAKAGE. THE ABOVE WARRANTY IS EXCLUSIVE AND ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

THIS WARRANTY SHALL APPLY ONLY WITHIN THE CONTINENTAL UNITED STATES, ITS

TERRITORIES, AND POSSESSIONS AND IN CANADA.

LIMITED NINETY DAY LABOR WARRANTY

All labor necessary to repair or replace factory defective parts will be performed, without charge,

to the end user, by service personnel of a BKI Authorized Distributor during the first ninety days

after the date of installation of the new equipment.

Replacement parts: Any appliance replacement part, except lamps and fuses, which proves to

be defective in material or workmanship within 90 days from date of original installation will be

repaired or replaced without charge F.O.B. Factory, Simpsonville, S.C. or F.O.B. authorized

distributor.

Single Revolving Oven Table of Contents

Table of Contents

Table of Contents .................................................................................................................................................... 1

Introduction.............................................................................................................................................................. 2

Safety Precautions................................................................................................................................................ 2

Safety Signs and Messages ............................................................................................................................. 2

Safe Work Practices ......................................................................................................................................... 3

Health And Sanitation Practices............................................................................................................................ 5

Food Handling................................................................................................................................................... 5

Storage Of Raw Meats...................................................................................................................................... 5

Coding Cooked Foods......................................................................................................................................5

Storage Of Prepared Foods.............................................................................................................................. 5

Operation.................................................................................................................................................................. 6

Controls and Indicators ......................................................................................................................................... 6

Cooking Recommendations.................................................................................................................................. 7

Basic Rules.................................................................................................................... ...................................7

Supplies Needed............................................................................................................................................... 8

Instructions for Chicken .................................................................................................................................... 8

Instructions for Chicken Parts........................................................................................................................... 8

Instructions for Rock Cornish Hens .................................................................................................................. 9

Instructions for Spare Ribs................................................................................................................................ 9

Instructions for Danish Baby Back Ribs............................................................................................................ 9

Instructions for Roast Beef................................................................................................................................ 9

Instructions for Turkeys................................................................................................................................... 10

Instructions for Baked Potatoes...................................................................................................................... 10

Installation.............................................................................................................................................................. 11

Unpacking and Handling..................................................................................................................................... 11

Location and Clearance ...................................................................................................................................... 11

Wiring .................................................................................................................................................................. 11

Maintenance........................................................................................................................................................... 12

Scheduled Maintenance...................................................................................................................................... 12

Oven Cleaning ................................................................................................................................................ 12

Troubleshooting................................................................................................................................................... 13

Replacement Parts ................................................................................................................................................ 14

SR Parts List ....................................................................................................................................................... 14

SR-2 Parts List.................................................................................................................................................... 16

SRC Parts List..................................................................................................................................................... 18

SRW Parts List.................................................................................................................................................... 22

KS Parts List........................................................................................................................................................ 25

LMWS Parts List.................................................................................................................................................. 28

Accessories......................................................................................................................................................... 30

Wiring Diagrams.................................................................................................................................................... 31

1

Single Revolving Oven Introduction

Introduction

The units covered in this manual are single revolving rotisserie ovens containing tubular heating eleme nts,

manual electronic controls, quarts tube lamps and doors with tempered glass.

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has been

built with care and dedication -- using the best materials available. Attention to the operating instruction s

regarding proper installation, operation, and maintenance will result in long lasting dependability to ensure the

highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you have

any questions, please contact your BKI Distributor. If they are unable to answer your

questions, contact the BKI Technical Service Department, toll free: 1-800-927-6887.

Outside the U.S., call 1-864-963-3471.

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol. When you

see this symbol on your equipment, be alert to the potential for personal injury or property damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify specific

areas where potential hazards exist and special precautions should be taken. Know and un derstand the meaning

of these instructions, signs, and messages. Damage to the equipment, death or serious injury to you or other

persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe practices.

This message is used when special information, instructions or identification are required

relating to procedures, equipment, tools, capacities and other special data.

2

Single Revolving Oven Introduction

Safe Work Practices

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling hot racks or touch any hot metal

surface. If you lose or damage your mitts, you can buy new ones at your local

restaurant equipment supply store or from your local BKI Distributor.

Always wear non-skid shoes when working around the oven or any other

equipment.

Never wear loose clothing such as neckties or scarves while operating this

equipment. Keep loose hair tied back or in a hair net while operating this

equipment.

Always wear appropriate personal protection equipment during the cleaning

process to guard against possible injury from hot cleaning solution.

Beware of High Voltage

This equipment uses high voltage. Serious injury can occur if you or any untrained

or unauthorized person installs, services, or repairs this equipment. Always Use an

Authorized Service agent to Service Your Equipment.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it near for easy

access. If you need to replace this manual, contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not understand that this

equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep all safety labels

clean and in good condition. Replace any damaged or missing safety labels. If you

need a new safety label contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

3

Single Revolving Oven Introduction

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You must use a 40-

pound Type BC fire extinguisher and keep it within 25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services, hospitals, and the fire

department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the equipment.

• Make certain your employees are aware of the safety precautions on the

equipment and in this manual.

• Make certain that you have thoroughly trained your employees about operating

the equipment safely.

• Make certain the equipment is in proper working condition. If you make

unauthorized modifications to the equipment, you will reduce the function and

safety of the equipment.

4

Single Revolving Oven Introduction

Health And Sanitation Practices

BKI Rotisserie Ovens are manufactured to comply with health regulations and are tested and certified to NSF

standards. You must operate the equipment properly, using only quality products and use meat thermometers to

insure meats are thoroughly cooked.

Food Handling

• Wash hands thoroughly in warm, soapy water after handling raw poultry or meats.

• Clean and sanitize all utensils and surfaces that have been in contact with raw products. Clean and

sanitize the meat forks or baskets between cooking.

• Never place cooked meats on the same surfaces used to prepare raw meats, unless the area has been

thoroughly cleaned and sanitized.

Storage Of Raw Meats

• Designate an area or shelf strictly for the storage of all raw meats to be used in the rotisserie.

• Raw product must always be stored at temperatures below 38° F. (3° C.).

• Never store or mix raw foods above cooked foods, as this is a health hazard.

foods contaminate cooked or processed foods.

• All chicken and chicken parts to be stored overnight must be thoroughly iced down and refrigerated.

The drippings from raw

Coding Cooked Foods

All products cooked during the day should be sold the same day.

NOTE: It is not the intent of the rotisserie program to have unsold merchandise at the end of the cooking day.

Follow your company’s procedures for the handling of any leftover product.

Storage Of Prepared Foods

• Cold foods should be kept at or below 38° F. (3° C.).

• Hot foods must be maintained to meet local health codes, usually a minimum 145° F. (63° C.).

5

Single Revolving Oven Operation

Operation

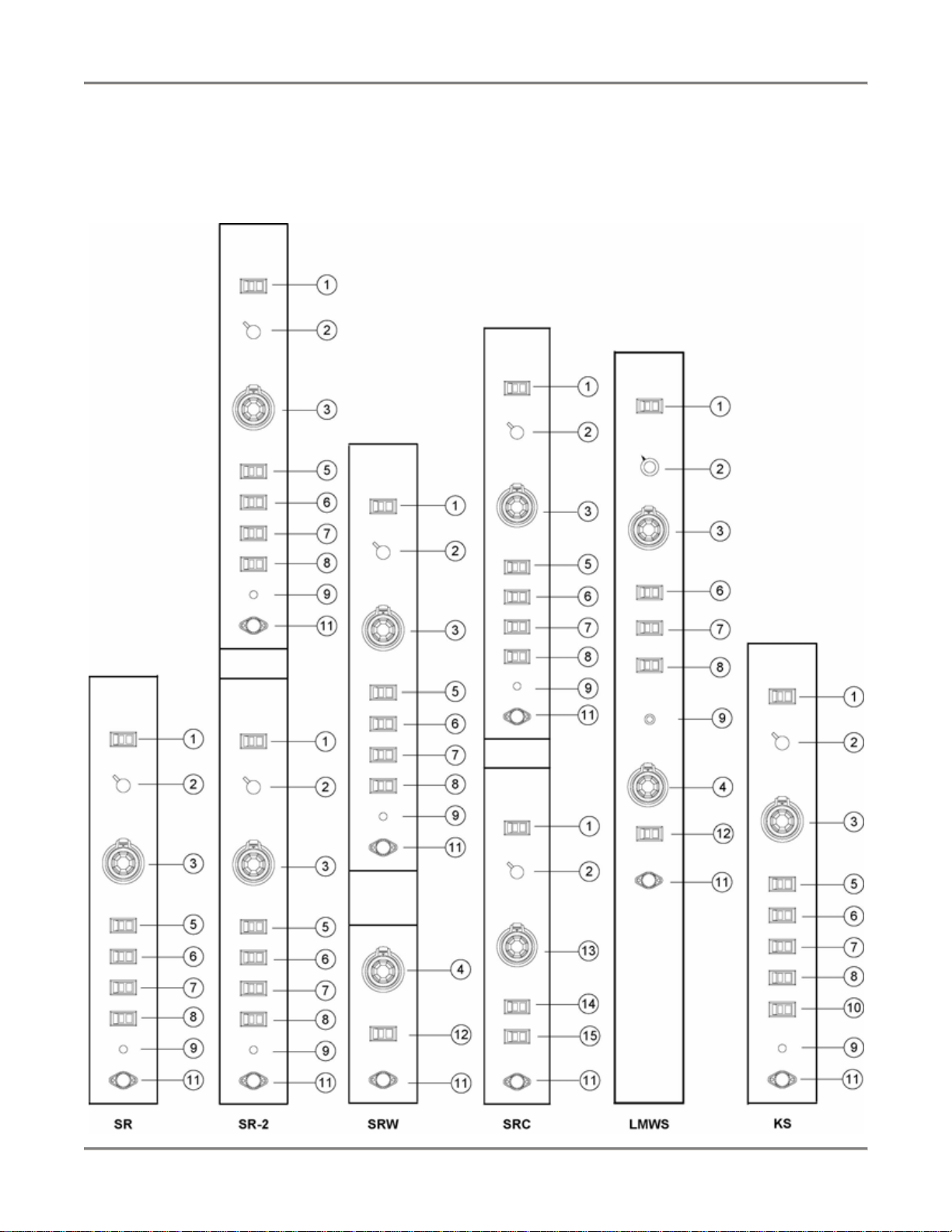

Controls and Indicators

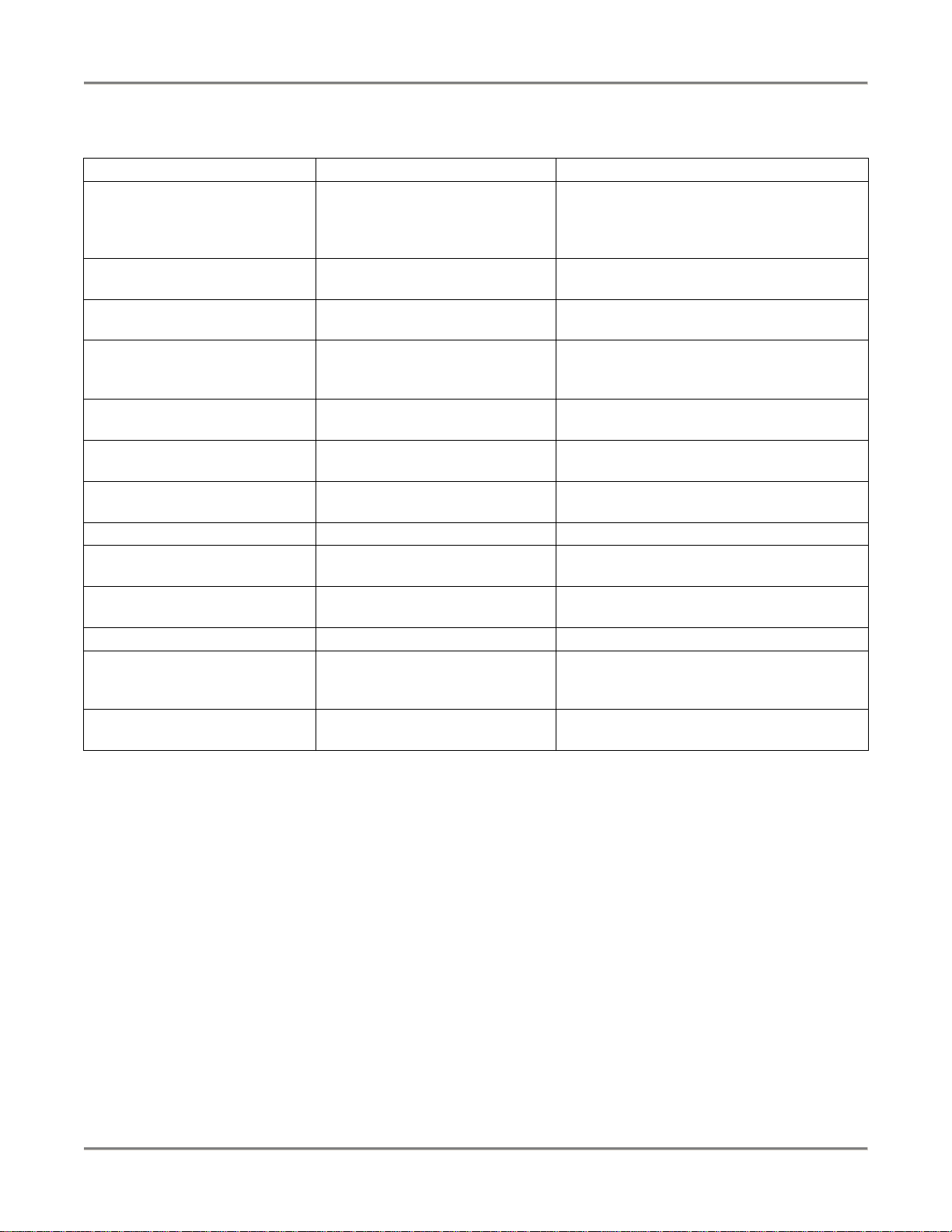

Refer to the figure and table below for an explanation of controls and indicators for a specific oven model.

6

Single Revolving Oven Operation

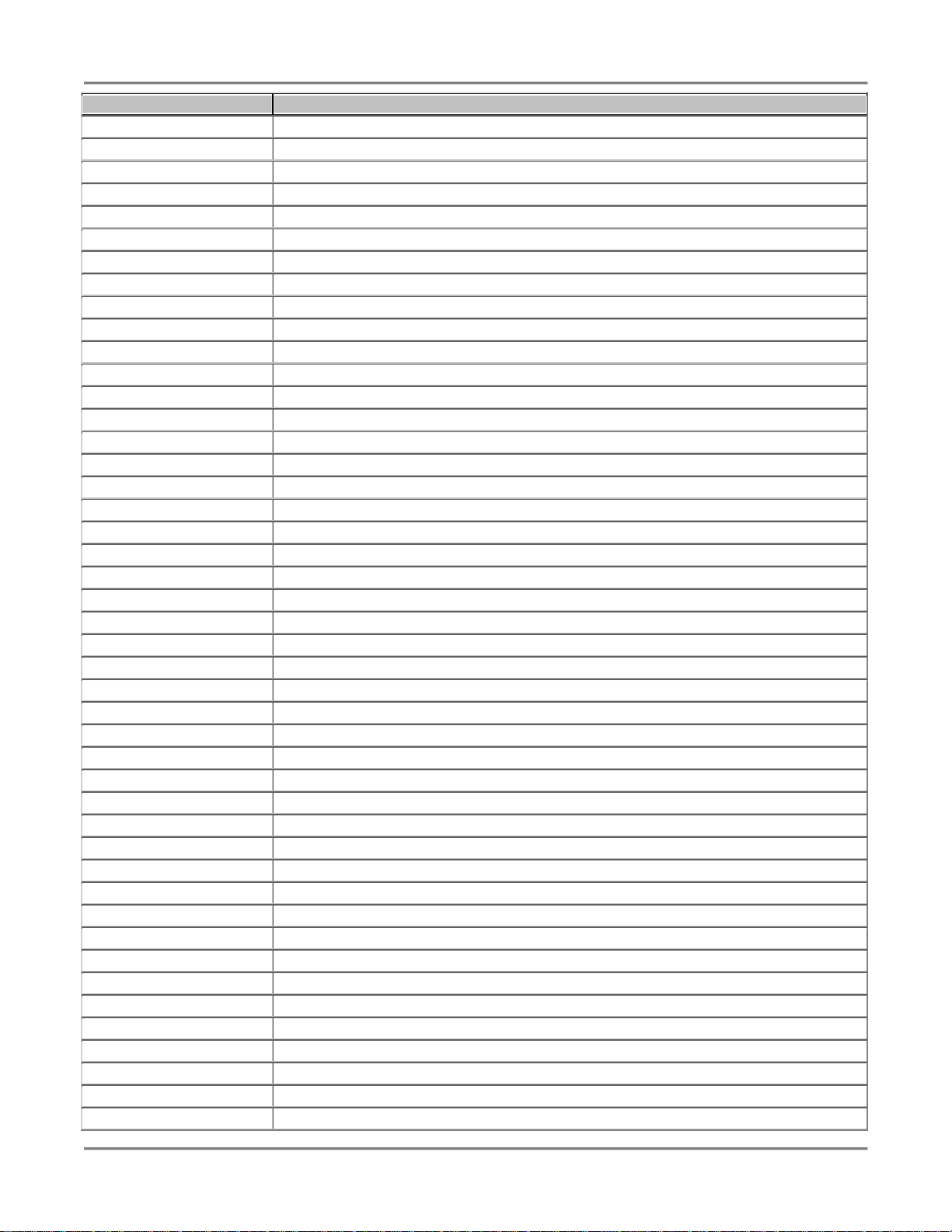

Item # Description Function

1

Timer Switch

2

Timer

3

Oven Thermostat

4

Warmer Thermostat

5

1000 Watt Quartz Tube

Switch

6

Rotor Switch

7

500 Watt Quartz Tube

Switch

8

Hickory Smoke Switch

9

Minibreaker

10

Grease Smoke Switch

11

Fuse

12

Warmer Light Switch

13

Convection Oven

Thermostat

14

Oven Light Switch

15

Blower Switch

This switch starts the timer. When the timer reaches 0, a buzzer will

sound. Turn the timer switch off to stop the buzzer.

Turn the timer knob clockwise to the desired cooking time. When the

timer counts down to 0, a buzzer will sound to call attention to the

rotisserie. Turn the timer switch off to stop the buzzer.

NOTE: The timer does not turn off the heating elements.

Turn the thermostat knob clockwise to the desired cooking temperature.

It has a maximum range of 450° F.

(Model SRW & LMWS only) – Turn the thermostat knob clockwise to

the desired setting to maintain the cooked product at the temperature

required by the state and local codes.

When this switch is on, the quartz tube on the operator side of the

rotisserie will cycle on and off with the thermostat.

This switch allows you to stop the rotors at any position for loading and

unloading the product.

This switch allows you to turn the quartz tube on the customer side of

the rotisserie on and off for lighting the display area.

Turn this switch on to heat the hickory smoke element using hickory

chips to smoke the meat in the rotisserie.

This is a 3-amp minibreaker that acts as an overcurrent protector for

the rotisserie drive motor.

(Model KS only) - Turn this switch on to add additional smoke to the

product.

A fuse is provided for overcurrent protection on the electronic circuitry.

Push in and twist the cap to remove the fuse.

(Model SRW & LMWS only) - This switch provides lighting for the

warmer oven section of the unit.

(Model SRC only) – Turn the thermostat knob clockwise to the desired

cooking temperature. It has a maximum range of 450° F.

(Model SRC only) – This switch turns on four 40-watt bulbs in the

convection oven section of the Model SRC.

(Model SRC only) – This switch turns on a fan to provide even baking in

the convection oven section of the model SRC. A limit switch also turns

off the fan when the doors are opened.

Cooking Recommendations

Before using your revolving oven for the first time, become familiar with the safety

features and warnings that are on the machine.

Basic Rules

1. Never let the warmer temperature go below 150° F.

2. All poultry must be cooked to a minimum internal temperature of 175° F.

3. Cycle cook your foods so that the rotisserie is continuously working ans selling for you.

4. Never let the rotisserie oven temperature drop below 325° F.

5. Do not cook above 375° F.

6. Do not cook different types of meat at the same time, (i.e., poultry/beef/pork)

7

Single Revolving Oven Operation

Supplies Needed

1

Meat Thermometer

2

Oven Mitts

3

Large Pan

For testing the internal temperature of a product.

For handling hot items

For barbeque sauce. Immediately after cooking product, dip it in babeque

sauce for a delicious flavor.

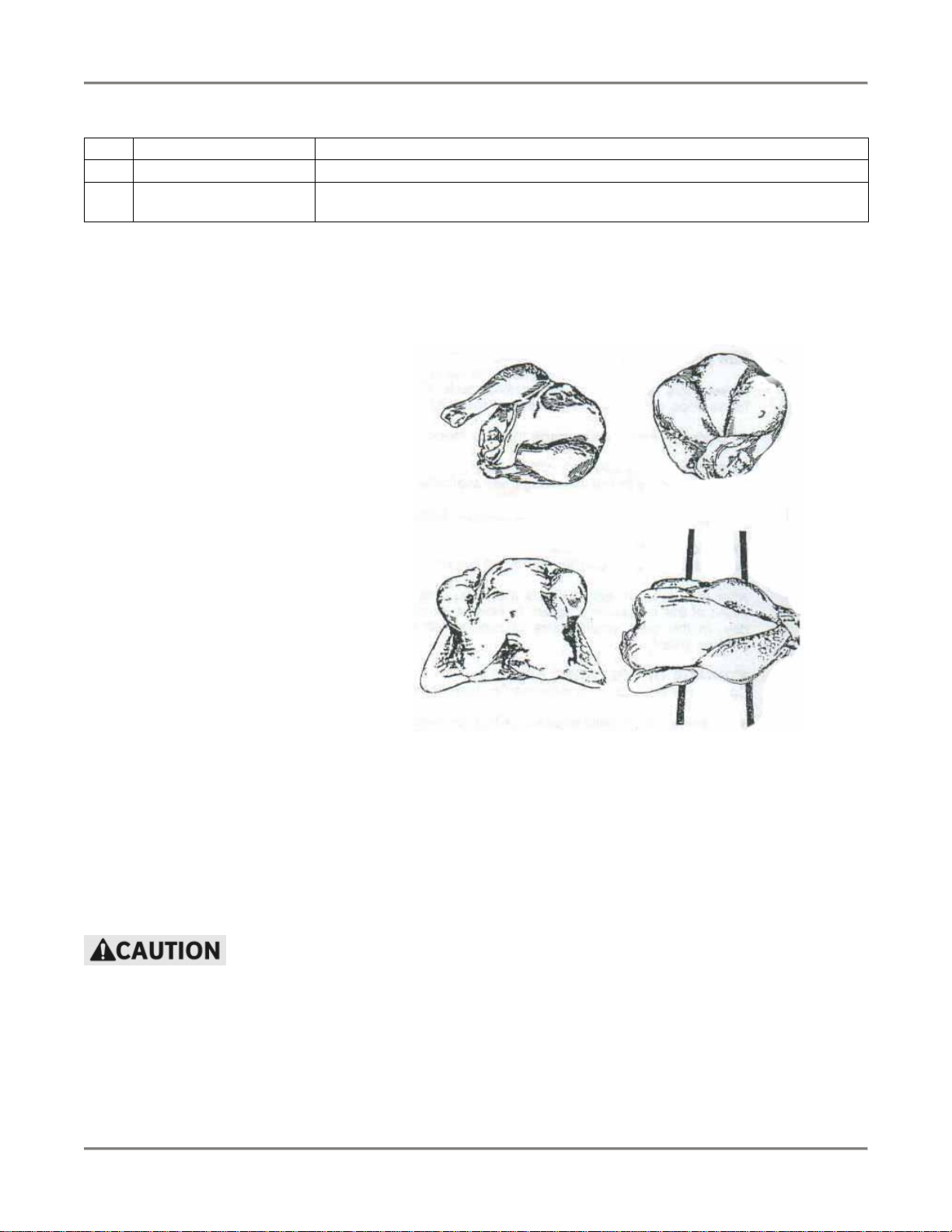

Instructions for Chicken

1. Preheat the oven to 325°F. Preheat the warmer to 150°F.

2. Prepare whole birds for cooking:

a. Cut off excess skin along

the neck.

b. Remove excess fat

around the cavity

opening.

c. Cut slit into tail skin.

d. Push down and break

the breast bone.

e. Tuck the end of the legs

into slit made in tail skin.

f. Fold back the wings and

lock under the back.

g. Secure chickens on

cooking forks or in

baskets. For cooking

forks, thread spits

between leg joints and

wing joints. Display in

oven with legs out and

breast down.

3. Sprinkle Seasoning over outside of chicken and into cavity. Rub seasoning thoroughly over entire

chicken.

4. Roast chickens approximately 1.25 to 1.5 hours at 325°F. Check internal temperature of chicken with

meat thermometer before removing from oven. If internal temperature is not at least 175°F, continue to

cook until this internal temperature is reached.

5. Cycle cook your foods. The rotisserie must be in use at all times for best merchandising results. Each

cooking fork can hold up to five chickens.

Never mix raw chicken and cooked chicken together. Never place cooked chicken in

pans where raw chicken has been unless the pans have been thoroughly washed and

sanitized. Always wash and sanitize pans before reusing.

Instructions for Chicken Parts

1. Chicken parts are to be cooked in rotisserie baskets.

2. Sprinkle Seasoning over chicken pieces and rub seasoning thoroughly over chicken pieces.

OPTION: Chicken parts can be marinated overnight. Place in a covered container and refrigerate.

8

Single Revolving Oven Operation

3. Cook at 325°F for approximately 45 minutes. Check internal temperature of chicken with meat

thermometer before removing from oven. If internal temperature is not at least 175°F, continue to cook

until this internal temperature is reached.

4. Dip chicken pieces in barbecue sauce after cooking.

Instructions for Rock Cornish Hens

1. Rock Cornish hens will arrive at your store frozen. Thaw out only amount of hens you wish to cook that

day.

2. Prepare hens in the same manner as the instructions for chickens. Cook in baskets.

3. Cook at 325°F for approximately 1.25 to 1.5 hours. Check internal temperature of hens with meat

thermometer before removing from oven. If internal temperature is not at least 175° F, continue to cook

until this internal temperature is reached.

Instructions for Spare Ribs

1. Marinate ribs overnight if desired. (Marinating is optional).

2. Rub Seasoning on ribs.

3. Lace ribs on cooking forks.

4. Cook at 325°F for approximately 1.25 to 1.5 hours. Check internal temperature of ribs with meat

thermometer before removing from oven. If internal temperature is not at least 175°F, continue to cook

until this internal temperature is reached.

5. Dip ribs in barbecue sauce after cooking.

Instructions for Danish Baby Back Ribs

1. Marinate ribs overnight if desired. (Marinating is optional).

2. Rub Seasoning on ribs.

3. Danish Baby Back Ribs must be cooked in rotisserie baskets.

4. Cook at 325°F for approximately 1.25 to 1.5 hours. Check internal temperature of ribs with meat

thermometer before removing from oven. If internal temperature is not at least 175°F, continue to cook

until this internal temperature is reached.

5. Dip ribs in barbecue sauce after cooking.

Instructions for Roast Beef

1. The roast beef will be cut and ready for cooking.

2. Open packaging. Lift roast beef out of natural juices and pat dry.

3. Tie roast beef to ensure original shape while cooking.

4. Cook at 325°F. Set cooking time for 20 minutes per pound. Check internal temperature of meat with meat

thermometer for doneness. The desired temperature for “medium” roast beef is 1 50°F. (C heck local

health code guidelines for proper temperature.)

9

Single Revolving Oven Operation

Instructions for Turkeys

1. Rub Seasoning on turkeys.

2. Use meat forks inserted into rotor fork holes nearest center shaft to allow room for large turkeys.

3. Cook at 325°F. Set cooking time for 15 minutes per pound. Check internal temperature of meat with meat

thermometer before removing from oven. If internal temperature is not at least 175°F, continue to cook

until this internal temperature is reached.

Instructions for Baked Potatoes

1. Use large Idaho baking potatoes.

2. Wash potatoes thoroughly and wrap in foil.

3. Place wrapped potatoes in rotisserie basket.

4. Cook at 325°F for 45 minutes to an hour.

5. Cover rotisserie basket with foil to prevent grease from meats dripping onto potatoes.

10

Single Revolving Oven Installation

Installation

Serious injury, equipment damage or death could result if attempting to install this oven

yourself. Ensure that an authorized BKI service agent installs the oven.

Unpacking and Handling

It is the owners’ responsibility to file all freight claims with the delivering truck line. Inspect all cartons and crates

for damage as soon as they arrive. If damage to cartons or crates is found, or if a shortage is found, note this on

the bill of lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the delivering truck line and follow up the call

with a written report indicating concealed damage to your shipment. Ask for an immediate inspection of your

concealed damage item. Packaging material MUST be retained to show the inspector from the truck line.

Remove all packing from the interior and exterior of the oven.

Location and Clearance

Underwriters Laboratories requires that the oven have at least 16" clearance between the rear of the unit and any

combustible surfaces.

Wiring

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs the electrical installation. Ensure that a licensed electrician perform

the electrical installation.

The oven, when installed by an authorized BKI service agent, must be wired in accordance wit h local codes, or in

the absence of local codes, with the National Electrical Code, ANSI/NFPA 70-2002.

11

Single Revolving Oven Maintenance

Maintenance

Failure to comply with the maintenance below could result in a serious accident or

equipment damage.

Failure to remove power from this unit before performing maintenance may cause severe

electrical shock. This unit may have more than one disconnect switch.

Scheduled Maintenance

Oven Cleaning

The oven must be cleaned at the end of each business day. Cleaning is not only necessary for sanitary rea son s,

but will increase sales appeal and maximize operating efficiency.

Failure to remove power from this unit may cause severe electrical shock. This unit may

have more than one disconnect switch.

Using abrasive cleaners may damage the cabinet finish. Use only a mild soap and water

solution.

DO NOT USE OVEN CLEANER on this machine. Caustic cleaners can cause damage to

the machine.

Never steam clean or get excess water in the interior of the cabinet as this can damage

unit.

Always wear appropriate personal protection equipment during the cleaning process to

guard against possible injury from hot cleaning solution.

1. Turn off all switches and controls.

2. Let the oven cool to room temperature.

3. Pull grease drawer out of oven and empty it’s contents.

4. Clean grease drawer and tray area with hot soapy water.

5. Remove all food products from the unit. Remove all racks, trays, spits and frames from the unit and place

them in a large sink to soak in hot cleaning solution (BKI Cleaner).

6. Clean the outside and inside of the rotisserie oven with warm water, a sponge and an approved clea ner

which is authorized for use on food surface areas.

7. Clean racks, trays, spits and frames with warm water, a sponge and BK Cleaner. Wipe dry with a clean

cloth.

8. Reassemble the oven.

12

Single Revolving Oven Maintenance

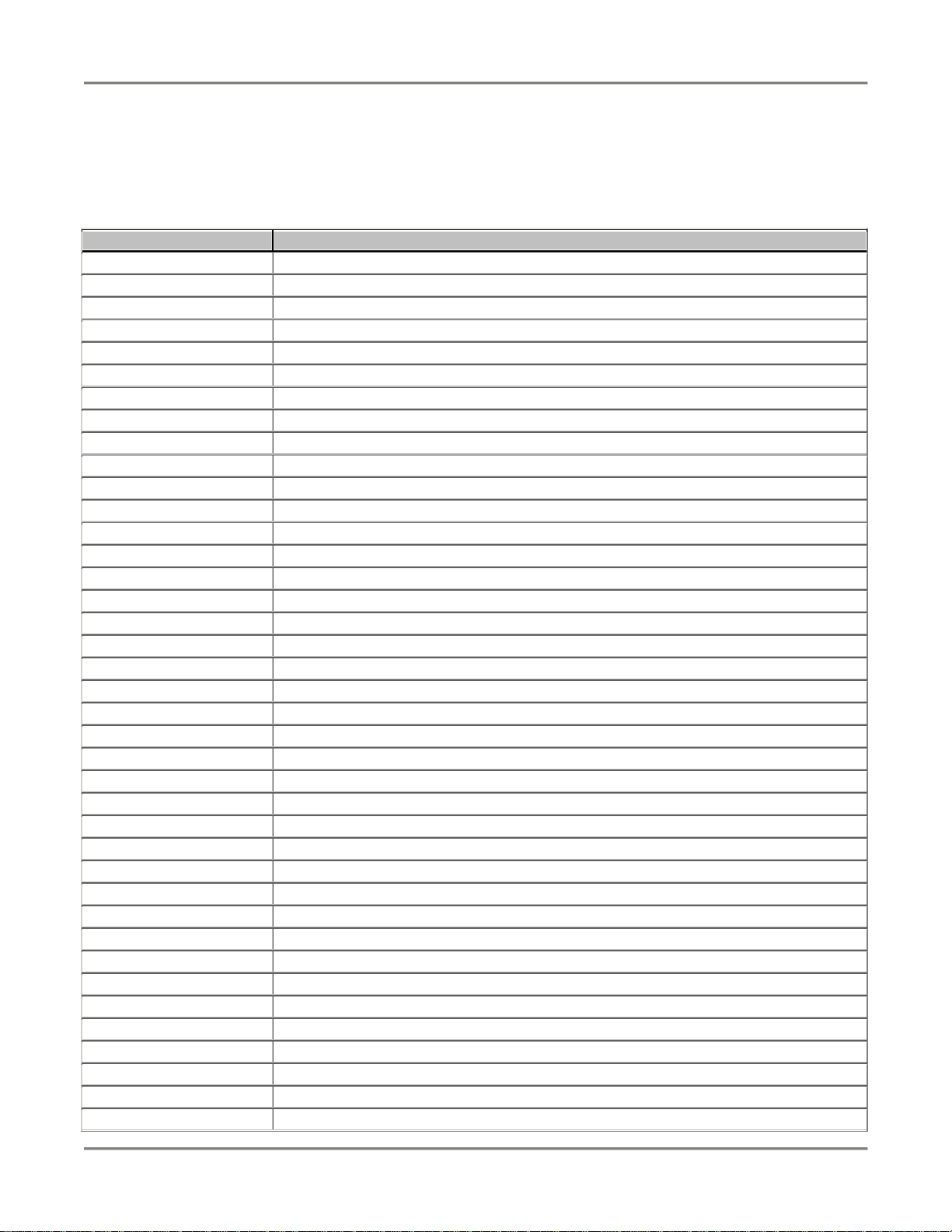

Troubleshooting

Problem Cause Possible Solution

Unit will not turn on. Power to unit is not on. Problem

with building power panel,

circuit breaker or fuse.

Power cord may not be plugged

into outlet.

Blown fuse. Contact an authorized BKI service agent

Not rotating. Motor circuit breaker tripped. Press the reset button. If problem persists,

ROTOR switch may not be

activated.

V-belt is loose or broken. Contact an authorized BKI service agent

Rotor switch not functioning. Defective switch. Contact an authorized BKI service agent

Oven does not heat at all. Improper program settings. Check program settings.

Heating elements not

functioning.

Bad relay. Contact an authorized BKI service agent

Doors may not be closed. Close the doors.

Oven heats up slowly. Improper line voltage. Check incoming voltage. If problem

Heating elements not

functioning.

Check circuit breaker or fuses at building

power panel. If problem persists, contact

an authorized electrician for corrective

action.

Plug cord into outlet.

for corrective action.

contact an authorized BKI service agent

for corrective action.

Make sure the ROTOR switch is on.

for corrective action.

for corrective action.

Contact an authorized BKI service agent

for corrective action.

for corrective action.

persists, contact an authorized BKI

service agent for corrective action.

Contact an authorized BKI service agent

for corrective action.

13

Single Revolving Oven Replacement Parts

Replacement Parts

Use the information in this section to identify replacement parts. To order replacement parts, call your local BKI

sales and service representative. Before calling, please note the serial number on the rating tag affixed to the unit.

SR Parts List

SR Part # SR Part Description

SB0061 5 TRAY FREE SWINGING ROTOR

SB0004 BASE ASSY, SR

SRA058 BEARING BLOCK 5/8 SHAFT

SR2A056 BRACE, MOTOR COVER SR2

F0158 BUSHING, BLK 1/2 HEYCO SNAP

F0155 BUSHING, BLK 7/8 HEYCO SNAP

SB0086A CAB ASSY SR S/S NO CAM

SB0087A CAB ASSY SR S/S SOL BACK NO CAM

F0064 CABLE TIES, 7 1/2" NO EYELET

F0096 CABLE TIES, 7 1/2" W/EYELET

B0452B CALROD BRACKET ASSY, SR

C0001 CALROD, 208V 2500W OFFSET

C0004 CALROD, 208V 2500W STRAIGHT

C0002 CALROD, 240V 2500W OFFSET

F0063 CLAMP, SAFETY 16101-S 1/4 DIA

FT0031 COLLAR, 5/8 SET LSC-10

SRA059 CORNER POST, SR

AN10100100 CTL PNL SR 120/208/60/3 N0 H/S

N0202 DECAL, DANGER HIGH VOLTAGE

N0166 DECAL, DO NOT USE HARSH CLEANERS

N0409 DECAL, LOGO LARGE DIE CAST

N0022 DECAL, NSF

N0363 DECAL, REMOVABLE ROTORS

SB0049 DOOR ASSY, LH SR

SB0005 DOOR ASSY, RH SR

SB0218 DROP DOWN PNL ASSY S/S SR

SB0085 DROP DOWN PNL LESS CATCH S/S

KSA071 GASKET, GREASE SMOKER

SB0222 GREASE DRAWER ASSY, S/S SR'S

G0022 GUARD, GRILL 6 BAR (BOTTOM)

HCA014 GUARD, LA MPHOLDER PLATE SR KS LMWS

SRA053 HINGE BLOCK, KS, SP, DP

H0081 HUB, SR KNOCK OFF SPIDER TYPE

SRWA073 INSIDE H/S COVER PLATE

SRA089 INSPECTION PLATE CONTROL PANEL

G0052 INSULATED MITT 13"

I0011 INSULATION, KAOWOOL STRIP

I0002 INSULATION, PEERLESS FIBER 3"

I0010 INSULATION, RANGE 1" FIBERGLASS

14

Single Revolving Oven Replacement Parts

SR Part # SR Part Description

I0005 INSULATION,1"TK

SRA056 LATCH BLOCK, KS

SRA033 MOTOR COVER SR

SRA108 MOTOR COVER SPACER, SR SERIES

N0023 NAME & RATING TAG, UL

NUT052 NUT, 10-24 ALUM CAP

NUT050 NUT, 10-24 FLEX LOCK

NUT076 NUT, 10-24 PALNUTS

NUT086 NUT, 5/16-18 ALUM CAP

NUT055 NUT, 5/16-18 FINISHED HEX

NUT081 NUT, SPEED C-83410-A-67

NUT082 NUT, SPEED PS-438014-S

F0049 NUT, TRUSEAL BRASS 1/2-14 NPT

SRWA072 OUTSIDE H/S COVER PLATE

SRA076 OUTSIDE TOP,

SRA046 PANEL, SIDE INSL SR

SRWA124 PANEL, TOP INSULATION

SRA052 PLATE, OUTSIDE CALROD KS SR SERIES

FT0015 PLUG, HOLE 1/2"

HT0016 QUARTZ TUBE, 115-125V QH500T3

HT0002 QUARTZ TUBE, 200-220V QH1000T3

HT0003 QUARTZ TUBE, 230-250V QH1000T3

RIV170 RIVET, 1/8 ALUM (.063-.125)

RIV171 RIVET, 1/8 ALUM (.187-.250)

F0077 ROLL PIN, 5/32 X 1 1/8

SB0011B ROTOR ASSY 6 TRAY LHW/SPRINGS

AN10513900 ROTOR ASSY MSR

AN10504800 ROTOR ASSY, W/O SPRINGS

SCR017 SCREW, 10 X 1 SLTD HEX WASHER

SCR008 SCREW, 10 X 1/2 PHIL TRUSS

SCR135 SCREW, 10 X 1/2 PHIL TRUSS

SCR015 SCREW, 10 X 1/2 SLTD HEX

SCR027 SCREW, 10-24 X 1 SOC FLT

SCR369 SCREW, 10-24 X 3/4 PHIL RD

SCR075 SCREW, 10-24 X 3/8 SHOULDER

SCR137 SCREW, 10-24 X 5/8 SLTD TRUSS

SCR114 SCREW, 4 X 3/8 SLTD OVAL BLK

SCR063 SCREW, 5/16-18 X 1 1/2 HEX CAP

SCR062 SCREW, 5/16-18 X 1 HEX CAP

SCR236 SCREW, 5/16-18 X 1 WHIZ'LOC

SCR061 SCREW, 5/16-18 X 1/2 HEX CAP

SCR065 SCREW, 5/16-18 X 2 HEX CAP

SCR356 SCREW, 5/16-18 X 5/16 SOC SET

SCR005 SCREW, 8 X 1/2 PHIL TRUSS

SCR007 SCREW, 8 X 3/4 PHIL TRUSS HD

15

Loading...

Loading...