Page 1

TECHNICAL

TRAINING

COURSE

REV. 01/2015

USA

IT | GB

Page 2

2

TECHNICAL TRAINING COURSE

INDEX

1.0 OVEN INSTALLATION 4

1.1 POSITIONING 4

1.2 Water connection 4

1.3 Drain connection 5

1.4.1 Electric connection 5

1.4.2 Electric connection 6

1.5 Gas connection (gas ovens only) 6

1.6 Fumes exhaust 7

1.7 Adjust trolley of 20 1/1 and 20 2/1 ovens 8

2.0 OVEN START-UP 8

3.0 ELECTRICAL COMPONENTS IDENTIFICATION 9

3.1 Water electrovalves and injector codication (EU,EV,EL,ES,EA,ESH) 9

3.2 Transformers 10

3.3 Door micro-switch - SP 10

3.4 Resistance Elements contactor - KR 10

3.5 Motor thermal protection 11

3.6 Motor Inverter - power supply relay 11

Page

3.7 Fuses 11

3.8 Automatic security thermostat of the boiler 11

3.9 Cavity security thermostat - F1 12

3.10 Water pressostat - PA (direct steam oven with washing system) 12

3.11 Meteo System probes 12

3.12 EMC lters - PFC, FLC 12

3.13 Air pressostat - P1 (gas ovens) 13

3.14 Gas blower - MB, control board PWM 13

3.15 Burner control - IGN 13

3.16 Gas valve - EVG 13

3.17 Motorized discarging valve - MS 14

3.18 Washing pump - PL 14

3.19 Detergent pump - PD 14

3.20 Flowmeter - HALL 14

3.21 Buttery valve - MV 15

4.0 GAS OVEN - SETUP 15

4.1 Combustion analysys 15

4.2 Gas reference table 18

4.3 Setting ignition probes and detecting ame probe 18

4.4 Gas change procedure 19

4.5.1 Fixing the burner to the exchanger : GASKET SEQUENCE 21

4.5.2 Fixing the burner to the exchanger : NOTES 22

5.0 ELECTRONIC BOARDS and congurations 23

5.1 Conguration of electronic boards serial connections 24

Page 3

TECHNICAL TRAINING COURSE

3

INDEX

5.2 I-O Check 26

5.2.1 I-O Check - Probes 26

5.2.2 I-O Check - Digital inputs 27

5.2.3 I-O Check - Digital outputs 28

5.3 HACCP recording (touch board) 29

5.3.1 Cooking log memorisation 29

5.3.2 Print-out example 29

5.3.3 HACCP parameters 29

5.3.4 Download HACCP log ---> USB pen drive 30

5.4 Wash log - download - erase 30

5.5 Upload-download recipes 31

5.5.1 Upload recipes 31

5.5.2 Download recipes 31

5.6 Wash log - download - erase 32

5.7 ALARMS DESCRIPTION 33

5.8 Alarm log - download - erase 34

5.9 System info menu 35

Page

5.10 Inverter alarm signal diagnostic 35

5.11 Technical parameters 36

5.12 Firmware upgrade 37

5.13.1 Upload new parameters 38

5.13.2 Download parameters le from the oven 38

5.13.3 Upload new parameters 39

5.13.4 Download parameters from the oven 40

6.0 MAINTENANCE 41

6.1 Boiler descaling 41

6.2 Cleaning oven cavity 43

6.3 Cleaning panel air lter 44

6.4 Adjustment of the hinges and the closing pivot of the door 44

6.5 Changing door lights and glass cleaning 45

6.6 Washing sprinkler cleaning 45

7.0 SPECIAL MAINTENANCE 46

7.1 Boiler opening and check 46

7.2 Fans replacement

7.3 Door gasket replacement

7.4 Complete door handle replacement

8.0 ELECTRICAL DRAWINGS

9.0 SPARE PARTS EXPLODED VIEW

47

51

52

54

62

Page 4

4

TECHNICAL TRAINING COURSE

1 INSTALLATION

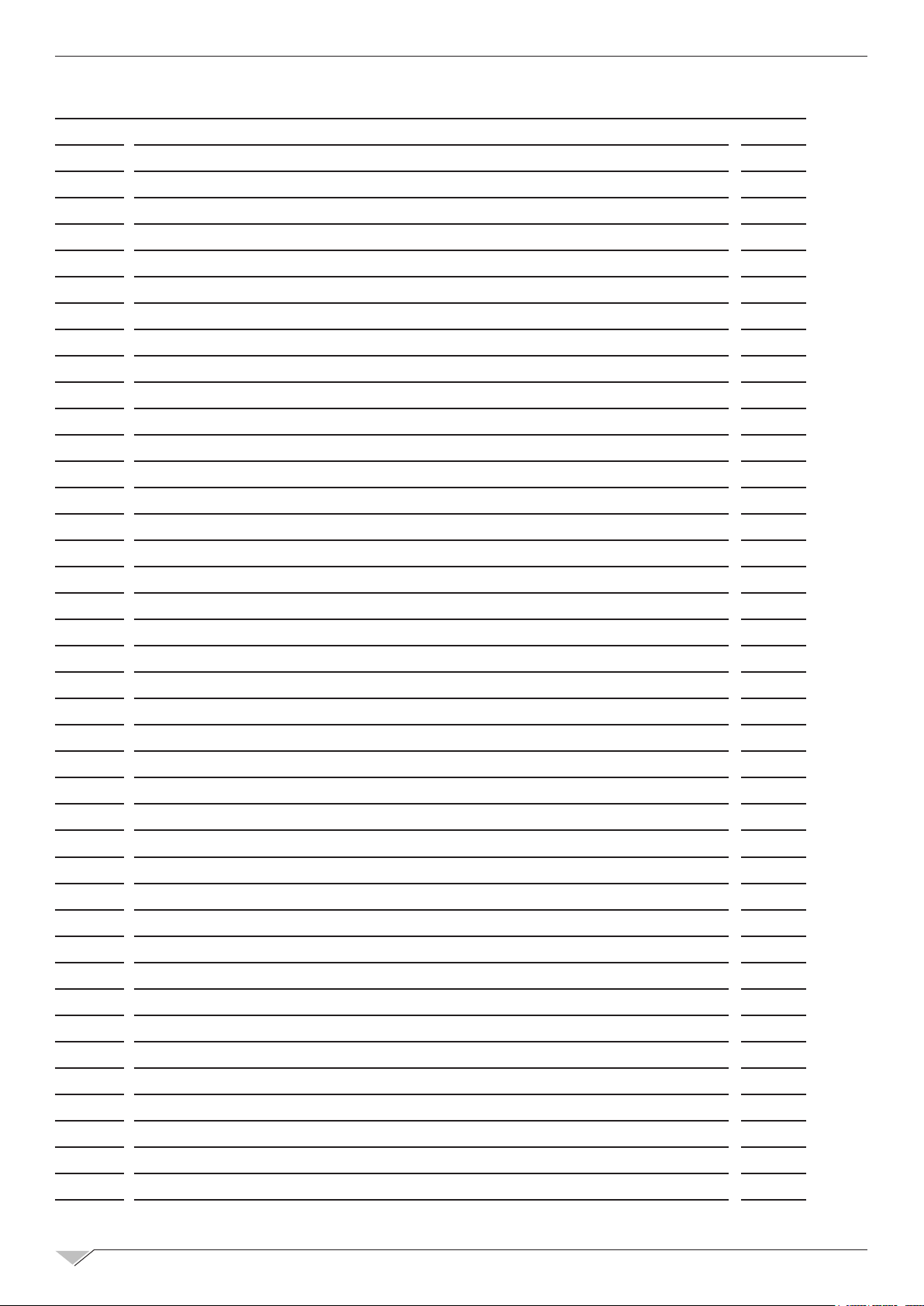

1.1 POSITIONING

The appliances have been designed for installation in

closed premises, they cannot be used in the open air

and cannot be exposed to rain.

The place of installation of the oven must have a solid,

at and horizontal surface able to safely support both

the mass weight of the appliance/support and that of

maximum load capacity.

The appliance must be placed in adequately ventilated

premises.

The oven must only be installed on a stable support. The appliance must be removed from its

packaging, its integrity checked and arranged in the place of use, being careful not to position it

above or against walls, sides, partition walls, kitchen cabinets or covers in ammable material.

We recommend scrupulously complying with the reproof Standard in force.

There must be a minimum distance of 2” on all sides

between the oven and the walls or other equipment.

We recommend leaving 20” of space between the left

side of the oven and the corresponding room wall, for

easy oven installation and its subsequent maintenance.

All materials used for packaging are compatible with

the environment; they must be safely kept and disposed of according to the Standard in force.

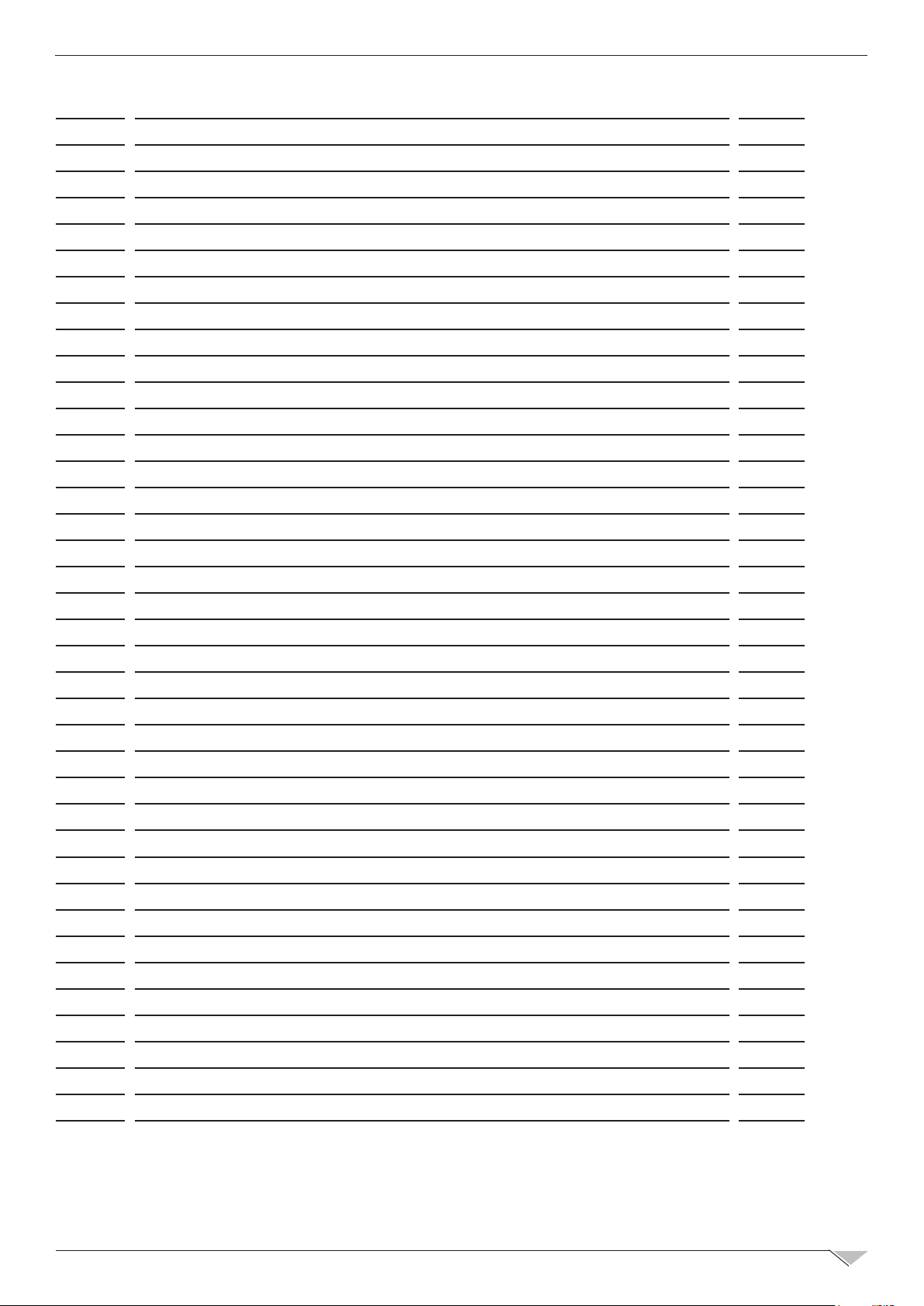

The oven must be levelled: to regulate the height of

the adjustable feet act, using as reference a spirit le-

vel. Signicant unevenness or inclinations can negatively inuence the functioning of the oven. Slowly remove all protective lm from the appliance

external panels, being careful not to leave traces of adhesive. Check that the heat disposal or

inlet slots and openings are not obstructed.

1.2

WATER CONNECTION

The water pressure must be max. 6 bar. Should the wa-

ter pressure from the mains be higher than such value,

install a pressure reducer upstream of the oven. The

minimum water temperature for the correct functioning

of the oven must be higher than 0.5 bar. The oven has a

softened water inlet. Always install a water softener to

bring the hardness of the water at appliance inlet within

the values of between 5 TH and 10 TH. If the oven is

equipped with automatic washing system and the water

hardness is greater then 10 TH it racommanded to use

softened water for the second water inlet. Connect the

Page 5

TECHNICAL TRAINING COURSE

"Water" duct to the specic cold water mains, and interpose a shut-off cock and lter. Before

connecting, let sufcient amount of water ow to clean the duct from any iron residues.

Ensure the shut-off cock is located in a place and in a manner to be easily activated at any

momentby the operator.

Attention: in case of water drain pipe fault, it must be replaced with a new one and the old and

faultyone must never be re-used.

5

1.3

1.4.1

The electric system, as prescribed and specied by the Standard in force, must be equipped

Have professionally qualied staff check that the plug cables section is adequate to the power

absorbed by the appliance.

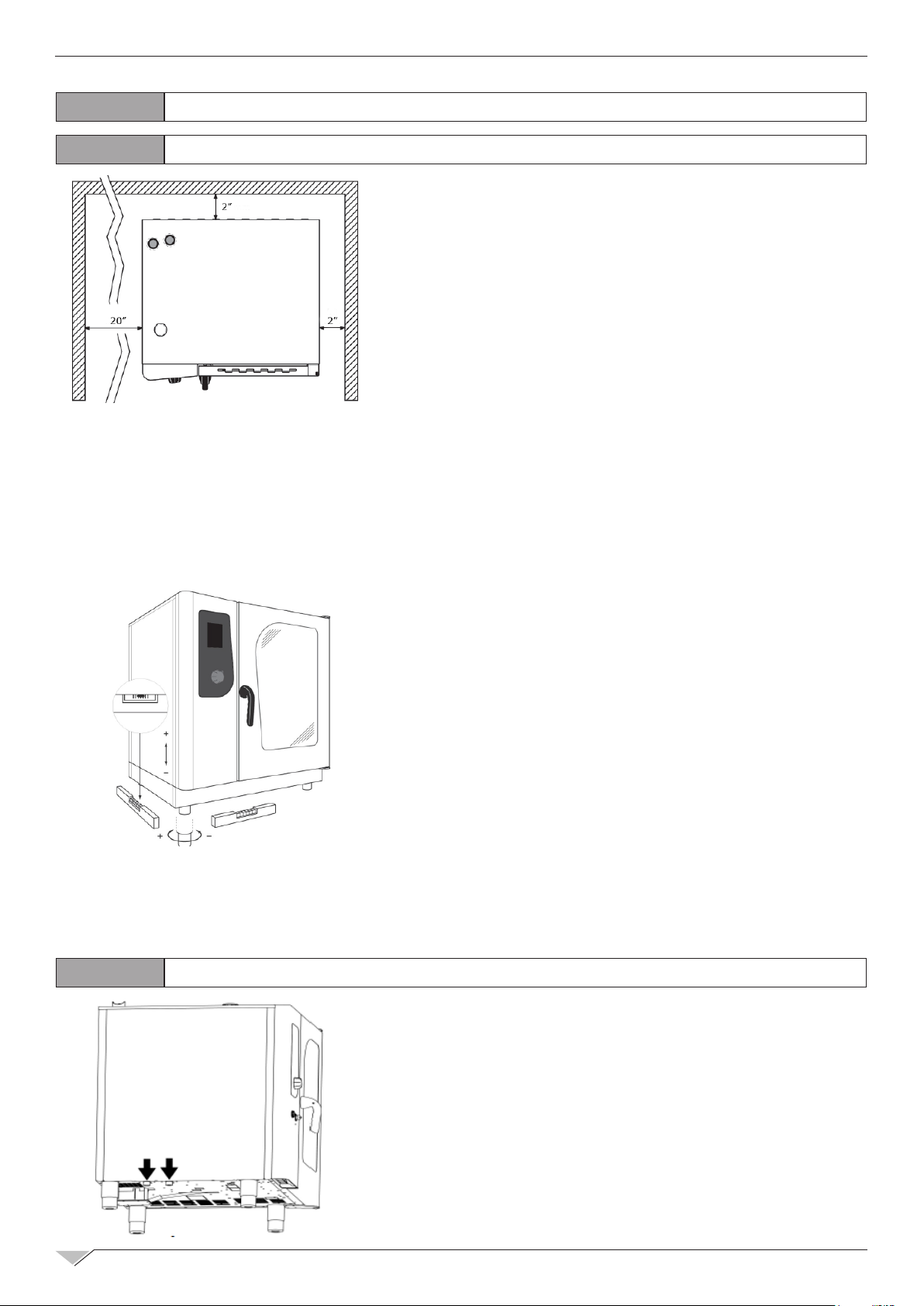

Loosen the screws xing the left side of the oven and extract it.

Place the power supply cable inside the cable gland hole in the lower part, on the left of the

oven.Connect the cable to the terminal board following the indications on “tab 1”.

Lock the cable with the cable gland.

ELECTRIC OVENS GAS OVENS

L1 L2 L3 N L N X

tab 1

DRAIN CONNECTION

The oven is equipped with a water draining device;such

device is located at the bottom in the rear part of the

appliance and has a tube with a 2” diameter.

Connect the tube that protrudes from the draining device .The draining device is a siphon; we recommend

connecting the tube on an open funnel.

Check that the internal siphon is full of water and, if

not, ll it by introducing water through the drain in the

cooking compartment.

ELECTRIC CONNECTION

with an efcient ground. It is possible to guarantee the

electric safety of the appliance only in the presence of

Standard electric system.

For direct connection to the mains it is necessary to interpose a device between the equipment and the same

mains, dimensioned depending on the load, that ensures

its disconnection and which contacts have an opening

distance enabling the full disconnection, in compliance

with the installation regulations; this device also must be

located in a place and in a manner to be easily accessible

at any moment by the operator.

Bring the main switch, to which the power supply cable

plug will be collected, in position 0 (zero).

The power supply voltage with machine

funcioning,must not be different from the nominal

voltage value of ±10%.

Page 6

6

TECHNICAL TRAINING COURSE

1.4.2

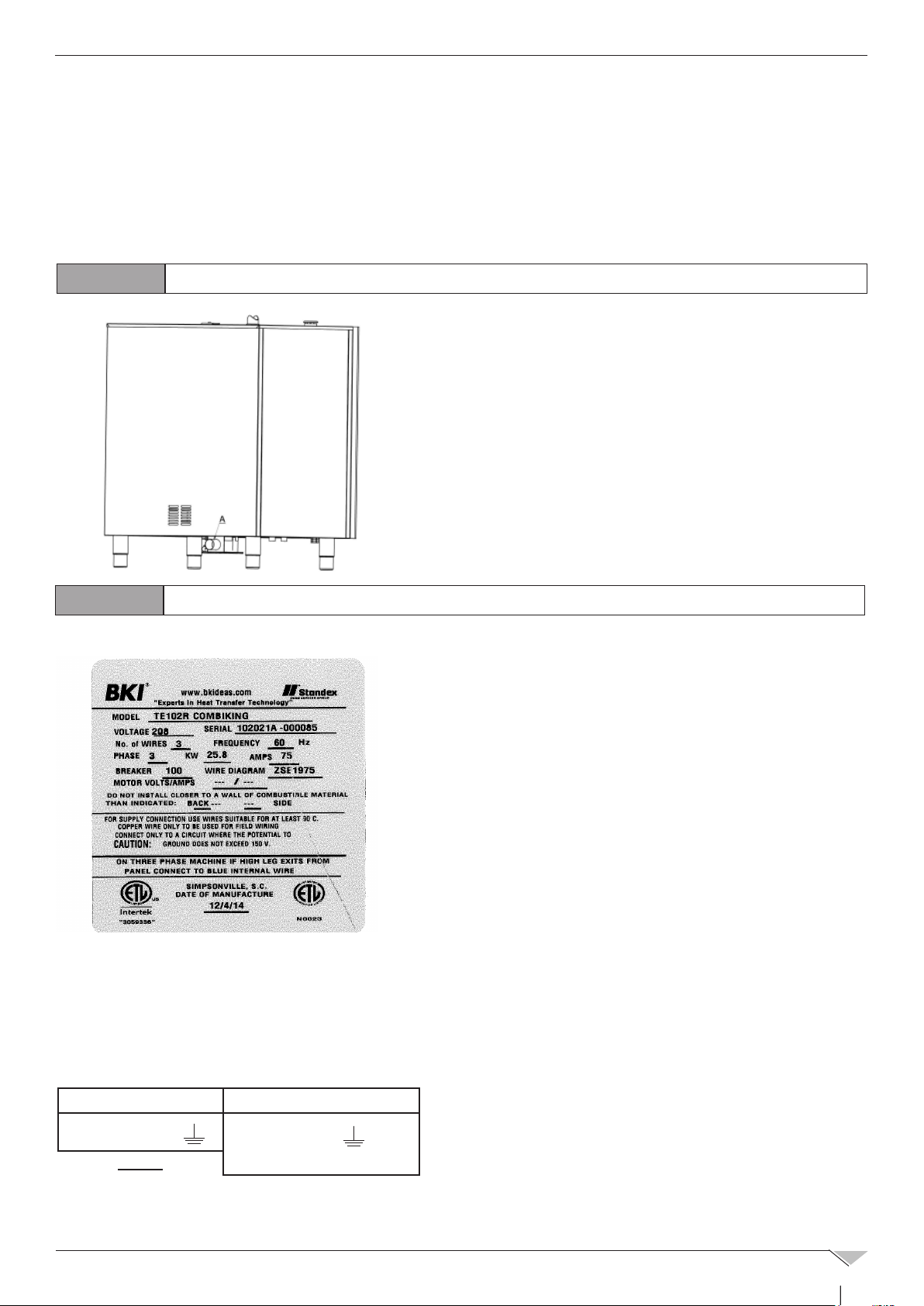

When a high current ows through a conductor, differences in potential appear between the

conductor and nearby metallic surfaces near the appliance. As a result, sparks may be produ-

ced between the appliance and surrounding metal surfaces. These sparks could cause serious

injury, damage, or re.

BKI provides an Equipotential ground terminal for the connection of a bonding conductor after

the installation of the appliance per lEC60417-1. This terminal is located on the inside of the

Power Entry Supply box near the Earth connection and is marked with this symbol:

For gas ovens, complete gas connection to the appliance before assembling

the oven side again; for electric ovens assemble the oven side.

1.5

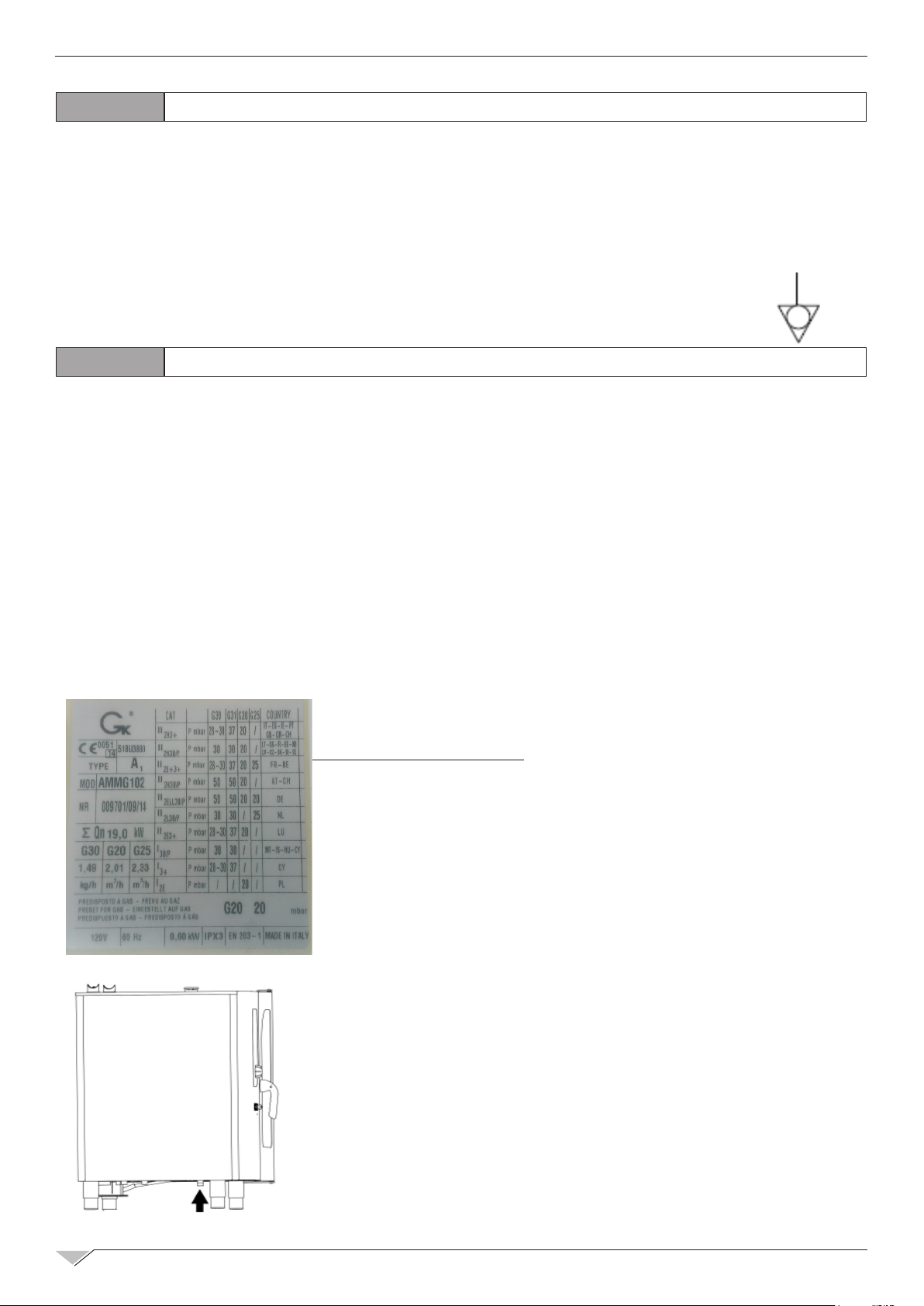

The oven is originally calibrated for functioning with the gas type specied during ordering.

The type of gas for which the oven is adjusted is reported on the technical place on the appliance

During testing, ascertain the factory calibrations carried out on the burners are appropriate for

the specic installation type, by means of analysis of the gases produced by combustion (CO2

and CO) and check of the thermal capacity.

Specically, with oven functioning at full capacity, the values of the undiluted CO present during

draining, must be within 300 ppm (normally a well calibrated pre-mix system does not produce

CO which mean the value should be 0).

If the presence of undiluted CO over such limit is detected, the adjustment of the burners must

be checked by a technician authorised by the manufacturer, who will make all due amendments

ELECTRIC CONNECTION

GAS CONNECTION (GAS OVENS ONLY)

to the devices governing combustion and to the relative parameters. The detected data must be

recorded and become integrating part of the technical documentation of that appliance.

Installation prescriptions

The oven installation and commissioning operations must be

carried out only by qualied staff according to regulations and

standards in force.

The gas systems, the electric connections and the installation

premises of the appliances must be compliant with regulations

and Standards in force.

Bear in mind that the air necessary for combustion of the burners

is of 2 m3/h per kW of installed power.

In activities open to the public, the Standards for the safety

prevention of accidents and re and panic must be complied with.

The connection to the gas supply tting can be carried out using

exible metal piping, interposing an approved shut-off cock in an

easily accessible point.

Ensure that the exible metal connection tube to the gas inlet

tting does not touch overheated parts of the oven and that it is

not submitted to torsion or extension stresses.

Use securing clips compliant with installation Standards.

Page 7

TECHNICAL TRAINING COURSE

Checks to be carried out before installation

On the technical plate located on the left side of the

oven check that the appliance has been tested for

the type of gas available with the user.

Check the data on the technical plate that the pressure reducer capacity is sufcient for powering

the equipment.

Avoid interposing section reductions between the reducer and the appliance.

We recommend mounting a gas lter upstream of the pressure regulator to guarantee optimal

oven functioning.

Connect the oven to the gas supply system by means of special 1/2” NPG tube.

After gas connection, check there are no leaks on the joints and ttings. For this purpose, use

soapy water or a specic foamy product to detect leaks.

It is opportune for the routine maintenance of the gas ovens to be carried out yearly, in

compliance with specic Standards, by an authorised technician; during which the fuel gas will

be analysed and the thermal power checked.

7

1.6

a) the extracted volume must be above that of the generated fuel gas (see Standard in force);

b) the material with which the hood lter is made must resist the fuel gas temperature that, at

conveyor outlet, can reach 572°F;

FUMES EXHAUST

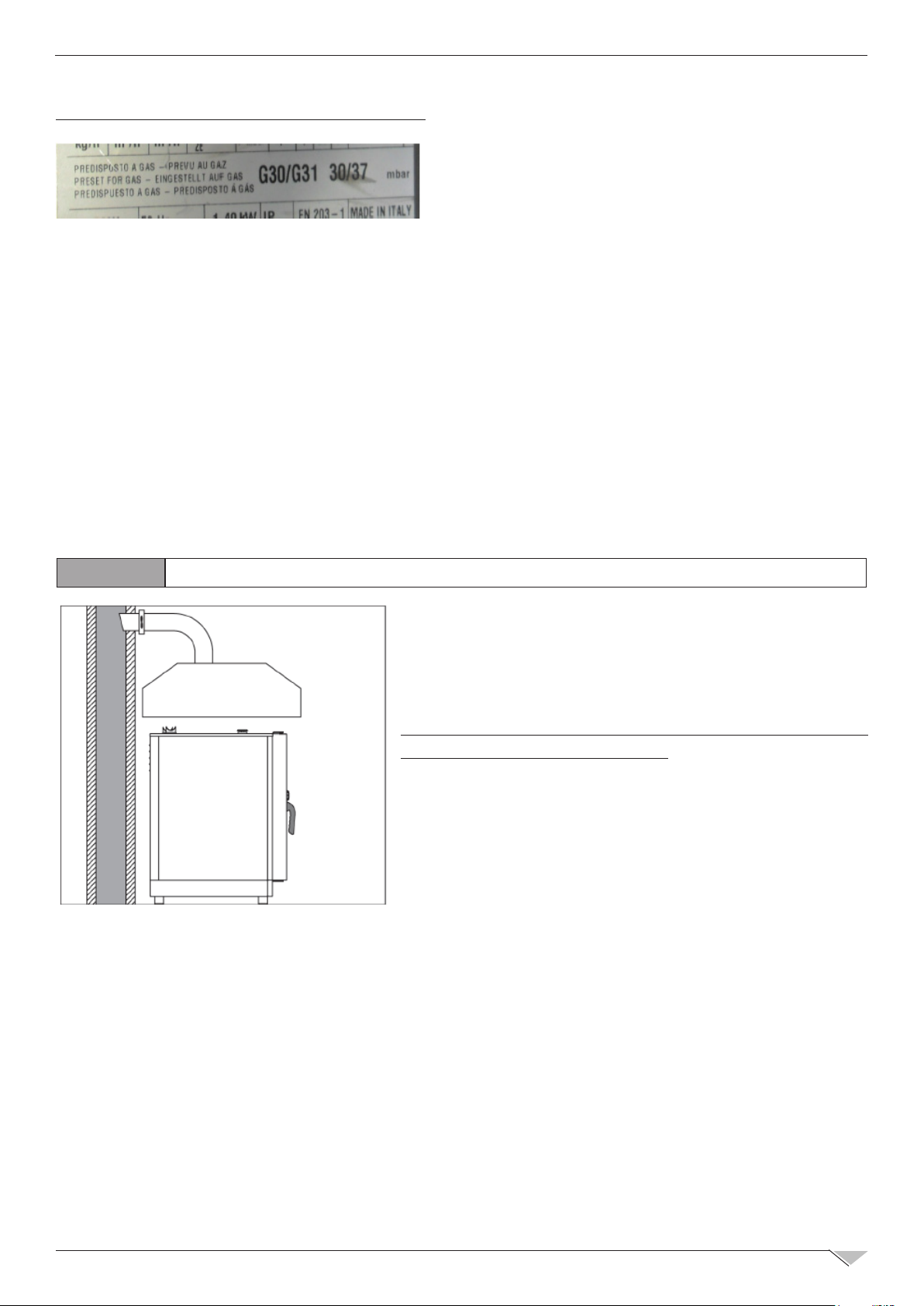

In compliance with installation Standards, the ovens

must be started in premises suitable for evacuation of

the combustion products.

It is possible to connect the ue passage by means

of a forced evacuation system, like a hood equipped

with mechanical extractor fan. In this case, the gas

supply to the appliance must be directly controlled by

such system and must interrupt should capacity drop

below the prescribed values. When the appliance is

installed underneath the extractor hood, check that

the following indications are complied with:

c) the end of the evacuation duct of the appliance must be positioned inside the projection of

the hood base perimeter;

d) the re-admission of the gas to the appliance must only be possible manually.

Page 8

8

TECHNICAL TRAINING COURSE

1.7

A correct adjustment of the coupling between trolley and oven allows to prevent steam or water

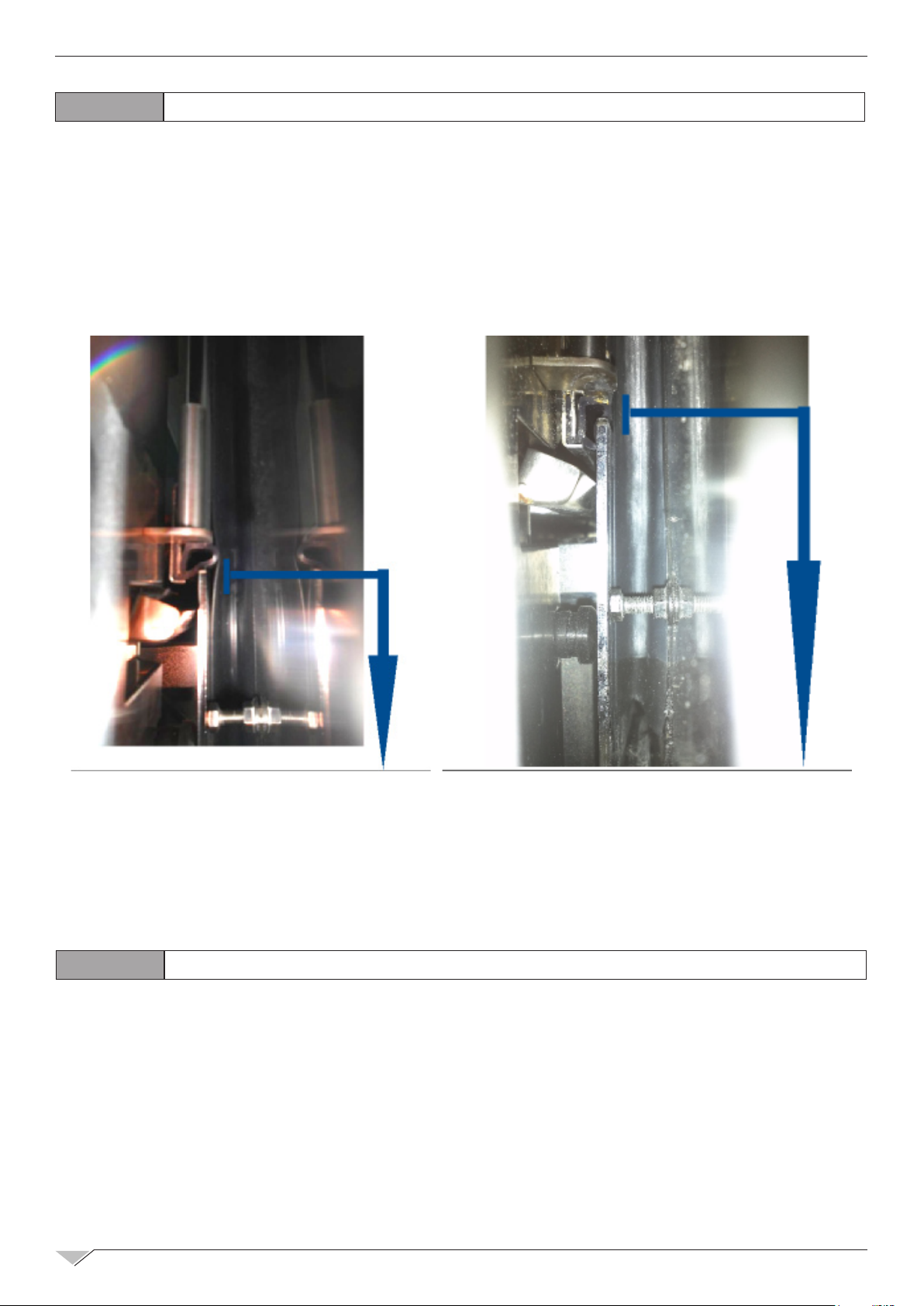

leakage, when the trolley is inserted inside the oven with the door closed.

1. The oven must be levelled to allow the edge of the sheet metal seal of the trolley to remain

about 3 mm under the glass limit of the oven door.

2. Then screw spacers must be adjusted between the front and the stop of the trolley, at

13 - 15 mm height.

ADJUST TROLLEY OF 20 1/1 AND 20 2/1 OVENS

NO

In this picture the gasket placed under

the glass is too compressed and so the

front gasket crushes until drawing.

2.0

Before commissioning the oven, scrupulously carry out the necessary checks to ensure the

compliance of the systems and installation of the appliance with the legal Standards and

technical and safety indications in the user manual.

The following points must also be satised:

• The ambient temperature of the place of installation of the oven must be higher than 4°F.

• The cooking compartment must be empty.

• All packaging must be fully removed, including the protective lm applied on the oven walls.

• The air vents and louvers must be open and not obstructed.

• The eventually dismantled oven pieces must be, for installation purposes, re-mounted.

• The main electric switch must be closed and the water and gas shut-off cocks upstream of

the appliance must be open.

OVEN START-UP

In this picture the distance between the trolley

and the door glass has been reduced, the gasket

is less compressed and it does not overhang. In

this way the front gasket does not deform itself.

YES

Page 9

TECHNICAL TRAINING COURSE

9

3.0

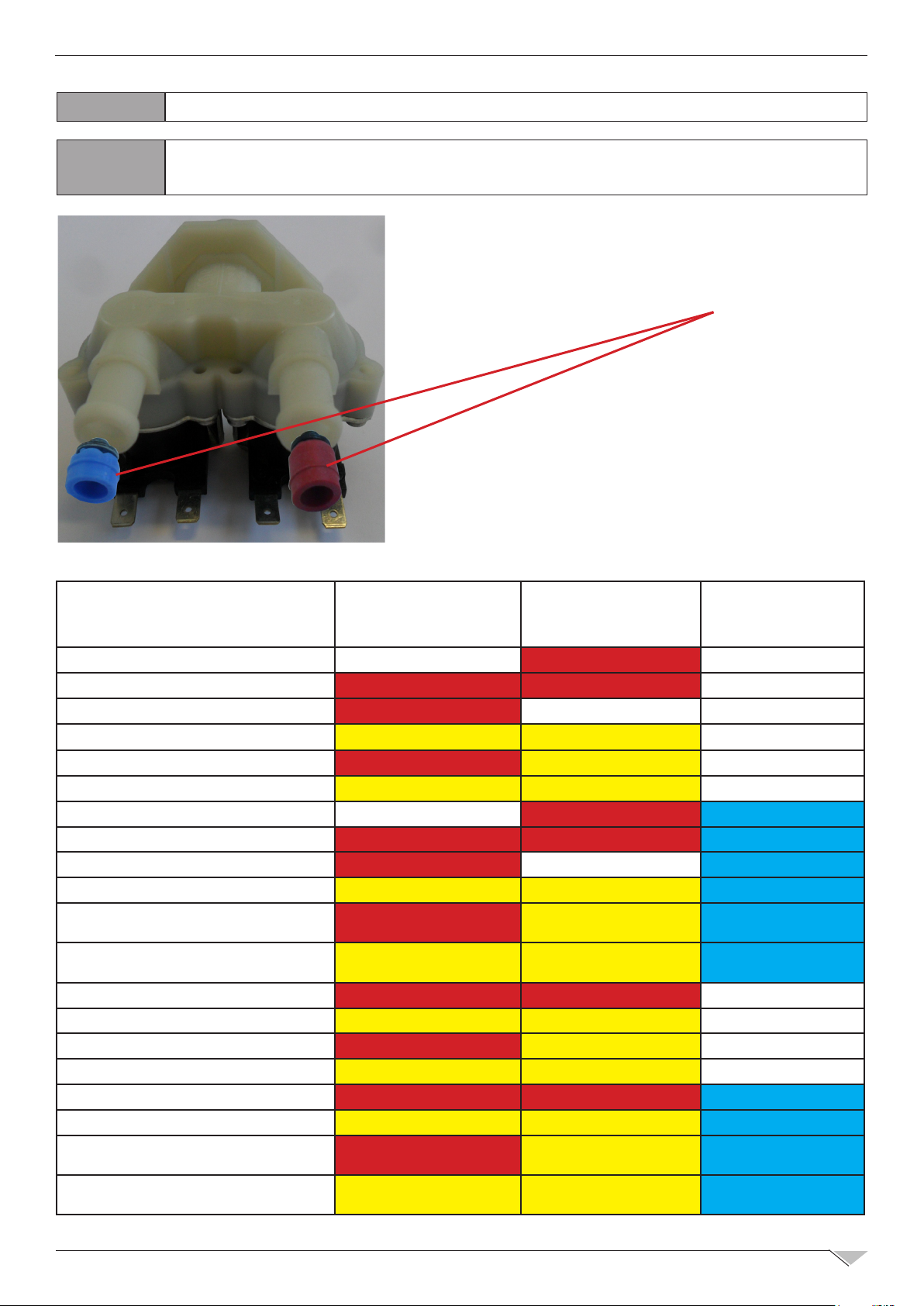

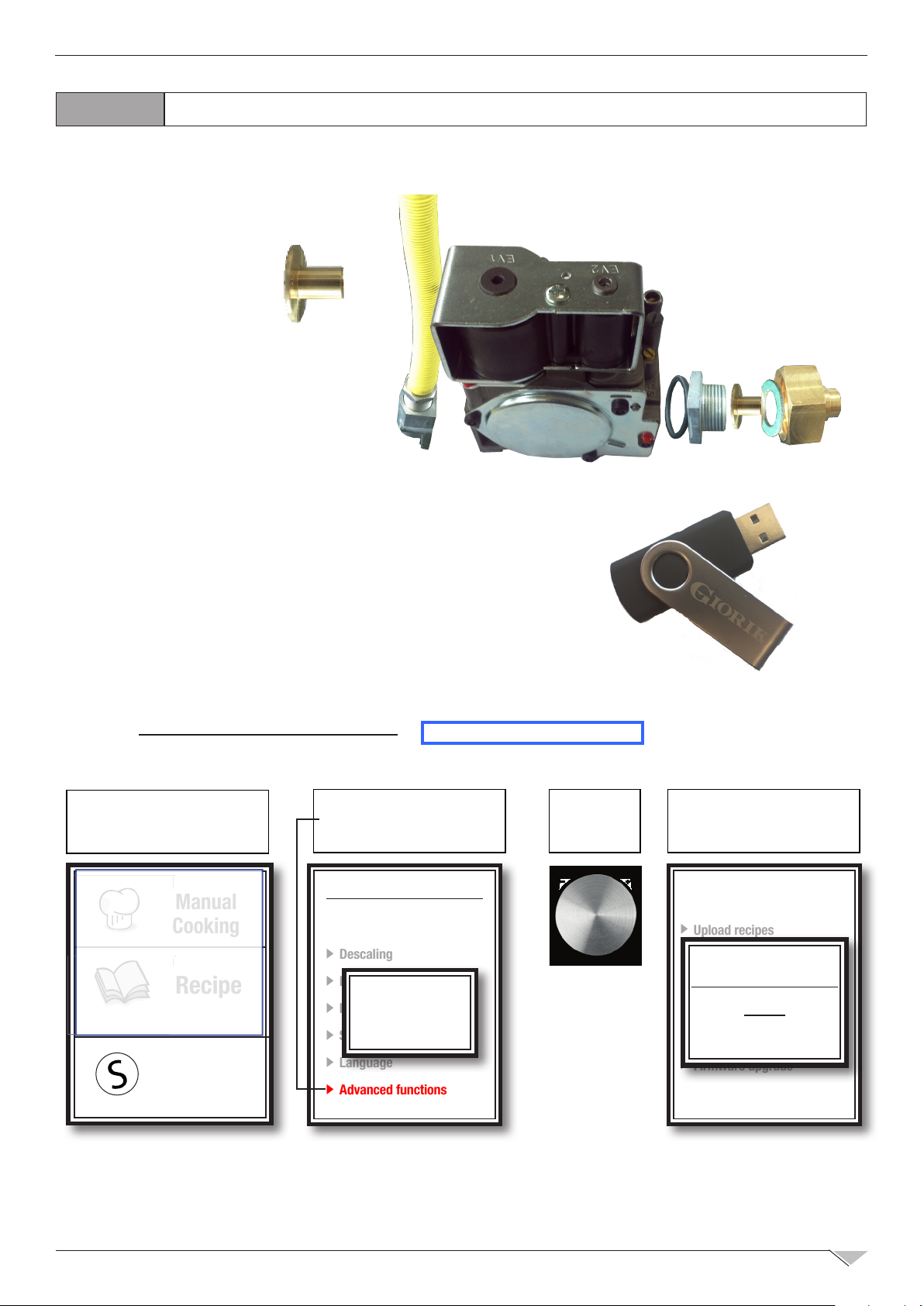

3.1

ELECTRICAL COMPONENT IDENTIFICATIONS

WATER ELECTRO-VALVES AND INJECTOR CODIFICATION

(EU, EV, EL, ES, EA, ESH)

The solenoid valve is the device that supplies water in

the pre-established times and methods.

At the electro-valve outlet a injector (nozzle) is normally

applied.

STEAMBOX VALVE, NOZZLE:

HUMIDIFIER

BOILER

(VER. ‘H’ ONLY)

WASHING

SYSTEM

ABHE061 BROWN 0,07 ÷ 0,14 L/min RED 0,2 ÷ 0,3 L/min NO WASH. SYS.

ABHE062-101 RED 0,2 ÷ 0,3 L/min RED 0,2 ÷ 0,3 L/min NO WASH. SYS.

ABTE061-062-101 RED 0,2 ÷ 0,3 L/min

ABTE102-ABHE102

YELLOW 0,32 ÷ 0,42 L/min

ABTE201-ABHE201 2 X RED 0,2 ÷ 0,3 L/min

ABTE202-ABHE202

2 X YELLOW 0,32 ÷ 0,42 L/min YELLOW 0,32 ÷ 0,42 L/min

ABHE061R BROWN 0,07 ÷ 0,14 L/min RED 0,2 ÷ 0,3 L/min

ABHE062R-ABHE101R

ABTE061R-ABTE061R-062R-101R

ABHE102R

RED 0,2 ÷ 0,3 L/min RED 0,2 ÷ 0,3 L/min

RED 0,2 ÷ 0,3 L/min

YELLOW 0,32 ÷ 0,42 L/min

ABTE201R-ABHE201R 2 X RED 0,2 ÷ 0,3 L/min

ABTE202R-ABHE202R

2 X YELLOW 0,32 ÷ 0,42 L/min

NO BOILER

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

NO WASH. SYS.

NO WASH. SYS.

NO WASH. SYS.

NO WASH. SYS.

BLU 4,5 ÷ 6 L/min

BLU 4,5 ÷ 6 L/min

NO BOILER BLU 4,5 ÷ 6 L/min

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

BLU 4,5 ÷ 6 L/min

BLU 4,5 ÷ 6 L/min + 2

NERO 1,9 ÷ 3,5 L/min

BLU 4,5 ÷ 6 L/min + 2

NERO 1,9 ÷ 3,5 L/min

ABHG061-062-101 RED 0,2 ÷ 0,3 L/min RED 0,2 ÷ 0,3 L/min NO WASH. SYS.

ABHG102

YELLOW 0,32 ÷ 0,42 L/min

ABHG201 2 X RED 0,2 ÷ 0,3 L/min

ABHG202

2 X YELLOW 0,32 ÷ 0,42 L/min

ABHG061R-062R-101R RED 0,2 ÷ 0,3 L/min RED 0,2 ÷ 0,3 L/min

ABHG102R

YELLOW 0,32 ÷ 0,42 L/min

ABHG201R 2 X RED 0,2 ÷ 0,3 L/min

ABHG202R

2 X YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

YELLOW 0,32 ÷ 0,42 L/min

NO WASH. SYS.

NO WASH. SYS.

NO WASH. SYS.

BLU 4,5 ÷ 6 L/min

BLU 4,5 ÷ 6 L/min

BLU 4,5 ÷ 6 L/min + 2

NERO 1,9 ÷ 3,5 L/min

BLU 4,5 ÷ 6 L/min + 2

NERO 1,9 ÷ 3,5 L/min

Page 10

10

TECHNICAL TRAINING COURSE

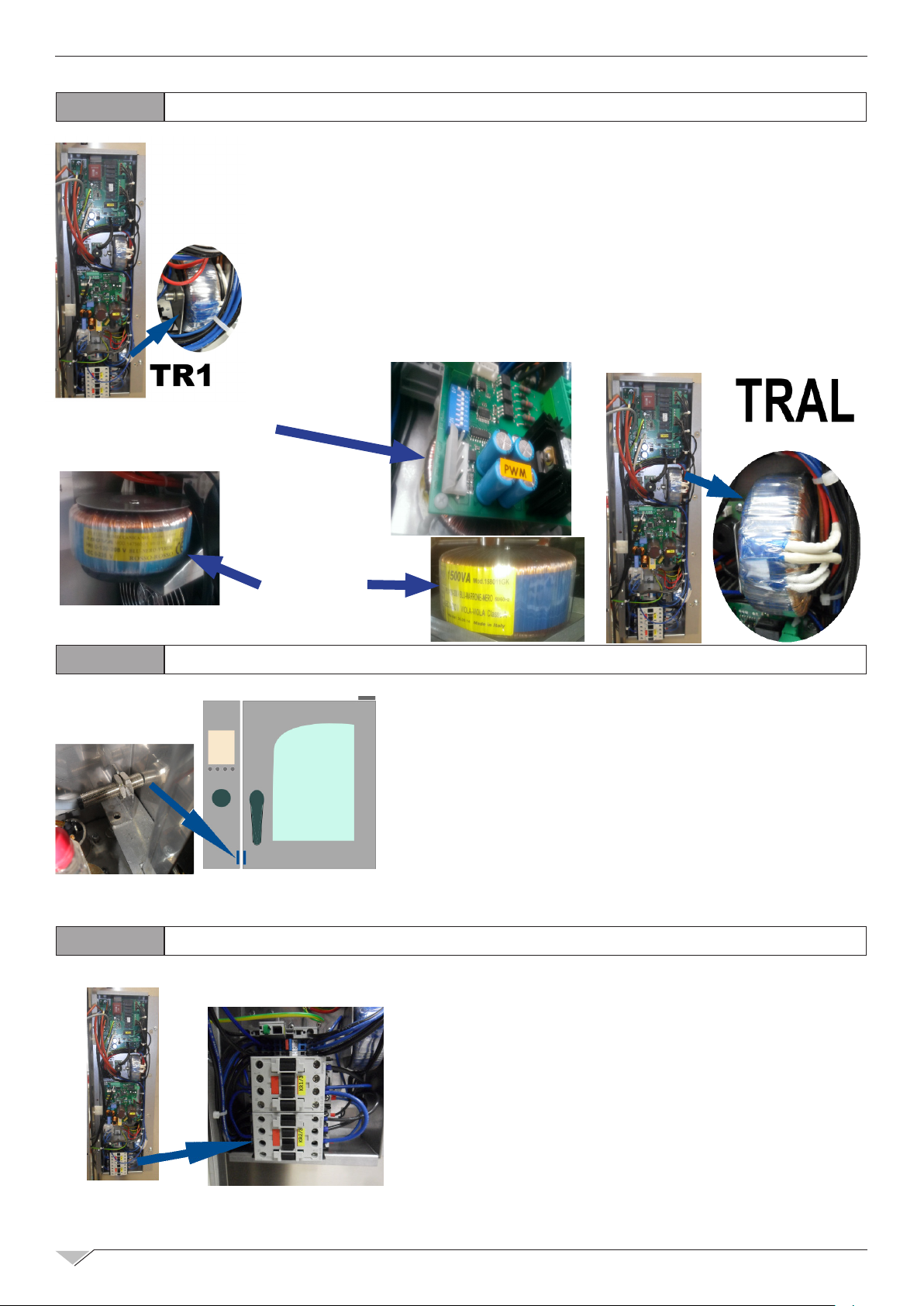

3.2

TRANSFORMERS

TR1 – Electronic board transformer (for main card and power cards): power 17 VA, PRY 230

Volts - SEC 2 x 12Volt (12VA + 5VA)

TR2-TR3 – PWM card and fan blower transformer: power 60 VA, PRY 230 Volts - SEC

24Volt.

TRAL - Halogen light transformer: power 60 VA , PRY 230 Volts - SEC 12 Volt

TRAF (ELE ovens) -

TRAF (GAS ovens) -

TR2

Main power supply transformer: power 250 VA , PRY 208 Volts - SEC 230 Volt

Main power supply transformer: power 1500 VA , PRY 120 Volts - SEC 230 Volt

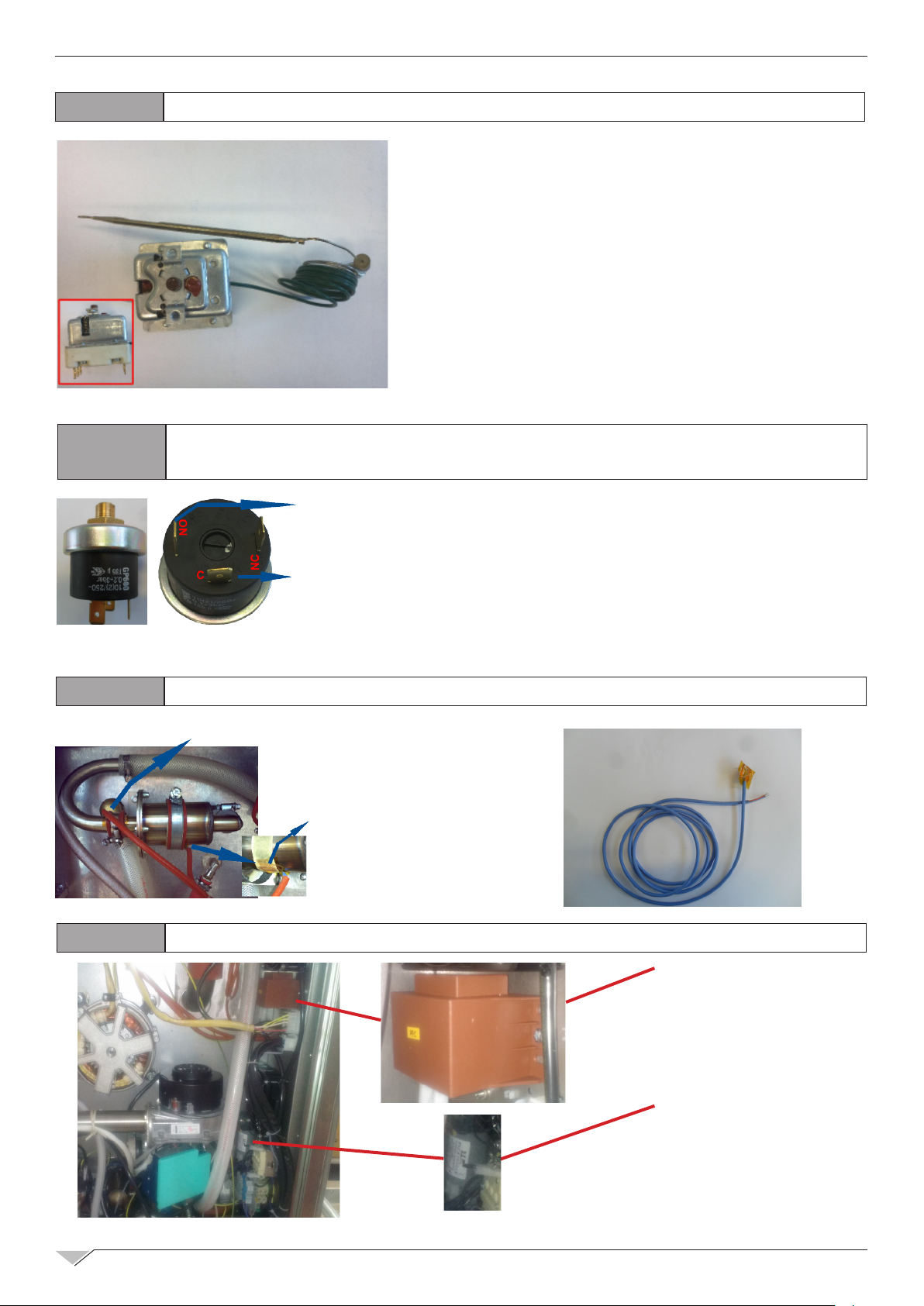

3.3

3.4

TRAF

DOOR MICRO-SWITCH - SP

The door micro-switch is a magnetic type. The magnet is applied

inside the door. The sensor is xed inside the main control panel.

RESISTANCE ELEMENTS CONTACTOR - KR

KR 1/3 = 1 elements of the resistance

KR 2/3 = 2 elements of the resistance

FULL POWER = KR 1/3 + KR 2/3

or

KR 1/2 = 1/2 elements of the resistance

KR 2/2 = all elements of the resistance

FULL POWER = KR 1/2 + KR 2/2

Page 11

TECHNICAL TRAINING COURSE

11

3.5

3.6

The Inverter CARD INV control the functionament of the oven motor/s.

The Relay K0 switch on/off the main power supply of the Inverter.

MOTOR THERMAL PROTECTION

The white wires are connected to a temperature

sensor inside the motor (clikson)

MOTOR INVERTER - POWER SUPPLY RELAY - FUSE

FU3/FU4): Inverter power supply

protection->T10A (slow blow)

3.7

FU0 : Power supply transformer protection

TRAF 208/230 250VA -> T2A (slow blow)

TRAF 120/230 1500VA -> T15A (slow blow)

FU1 or FU2: gas burner control protection ->F2A (fast)

FU5 : Main board transformer protection (TR1)->T200mA (slow blow)

FU6 : Light transformer protection (TRAL)->T315mA (slow blow)

FU7 : Pwm board transformer protection (TR2)->T315mA (slow blow)

3.8

FUSES

AUTOMATIC SECURITY THERMOSTAT OF THE BOILER

The automatic security thermostat prevent functioning

of the boiler without water. It reset itself.

1

BOILER ELEMENTS PHASE CONNECTION

P(L)

ELECTRONIC BOARD RELAY

Page 12

12

TECHNICAL TRAINING COURSE

3.9

3.10

CAVITY SECURITY THERMOSTAT - F1

If the temperature inside the cooking compartment

reaches 662°F, the safety thermostat interrupts supply

to the oven’s heating elements.

To reset it push the red (or brown) button.

WATER PRESSOSTAT - PA (DIRECT STEAM OVEN WITH

WASHING SYSTEM)

CONTROL

LEVEL BOARD

Connect ‘C’ plug to the ground cable and ‘NO’ plug to

main board control level.

3.11

3.12

GROUND

METEO SYSTEM PROBES

ALARM PROBE 4: UPPER PROBE

FOR METEO SYSTEM

ALARM PROBE 5: LOWER PROBE

FOR METEO SYSTEM

EMC FILTERS - PFC, FLC

PFC = Inductance

for Harmonic noise of

Inverter

FLC = Line lter

Page 13

TECHNICAL TRAINING COURSE

13

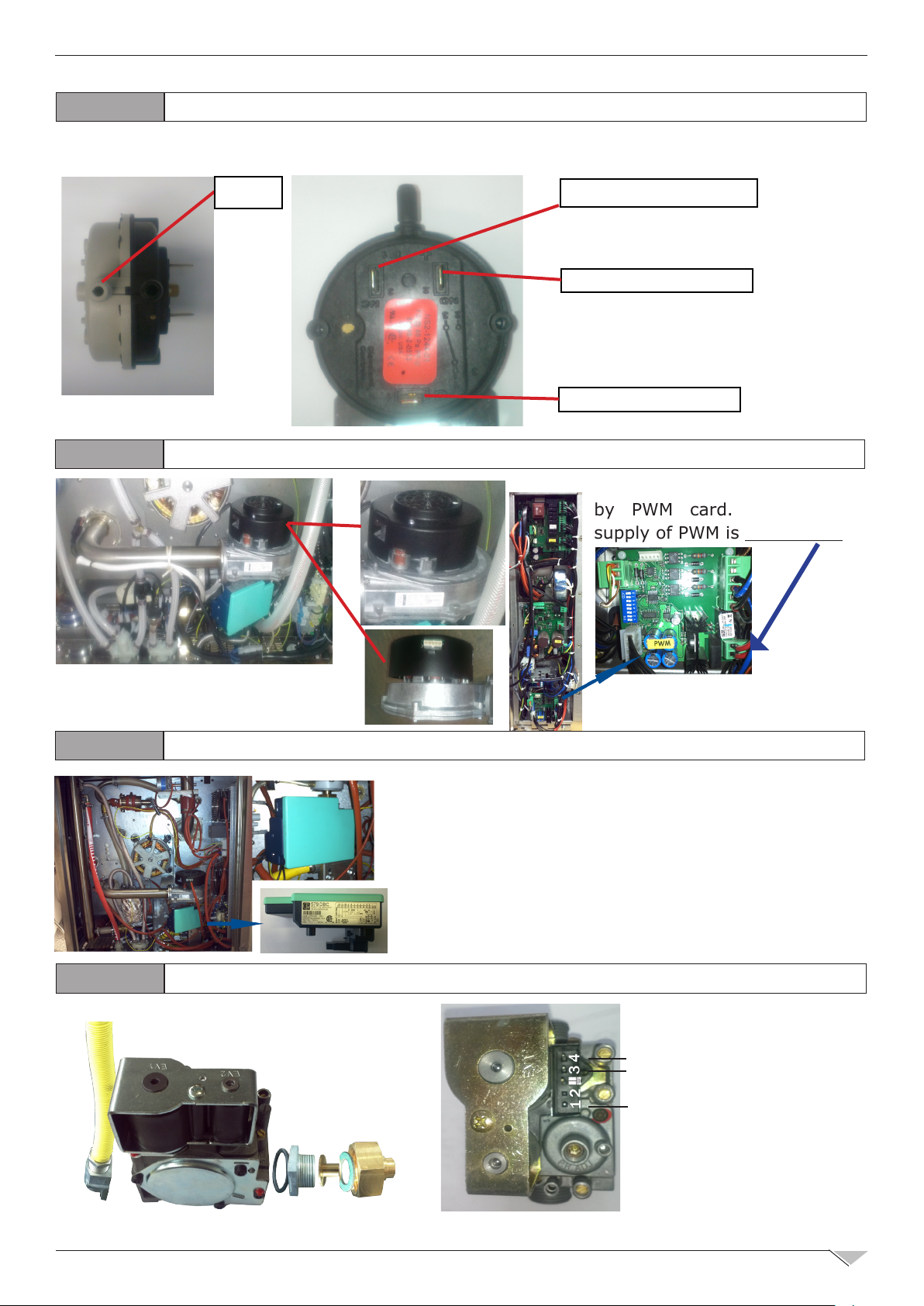

3.13

The air pressostat control the correct chimney evacuation

AIR PRESSOSTAT - P1 (gas ovens)

AIR

3.14

GAS BLOWER - MB / CONTROL BOARD - PWM

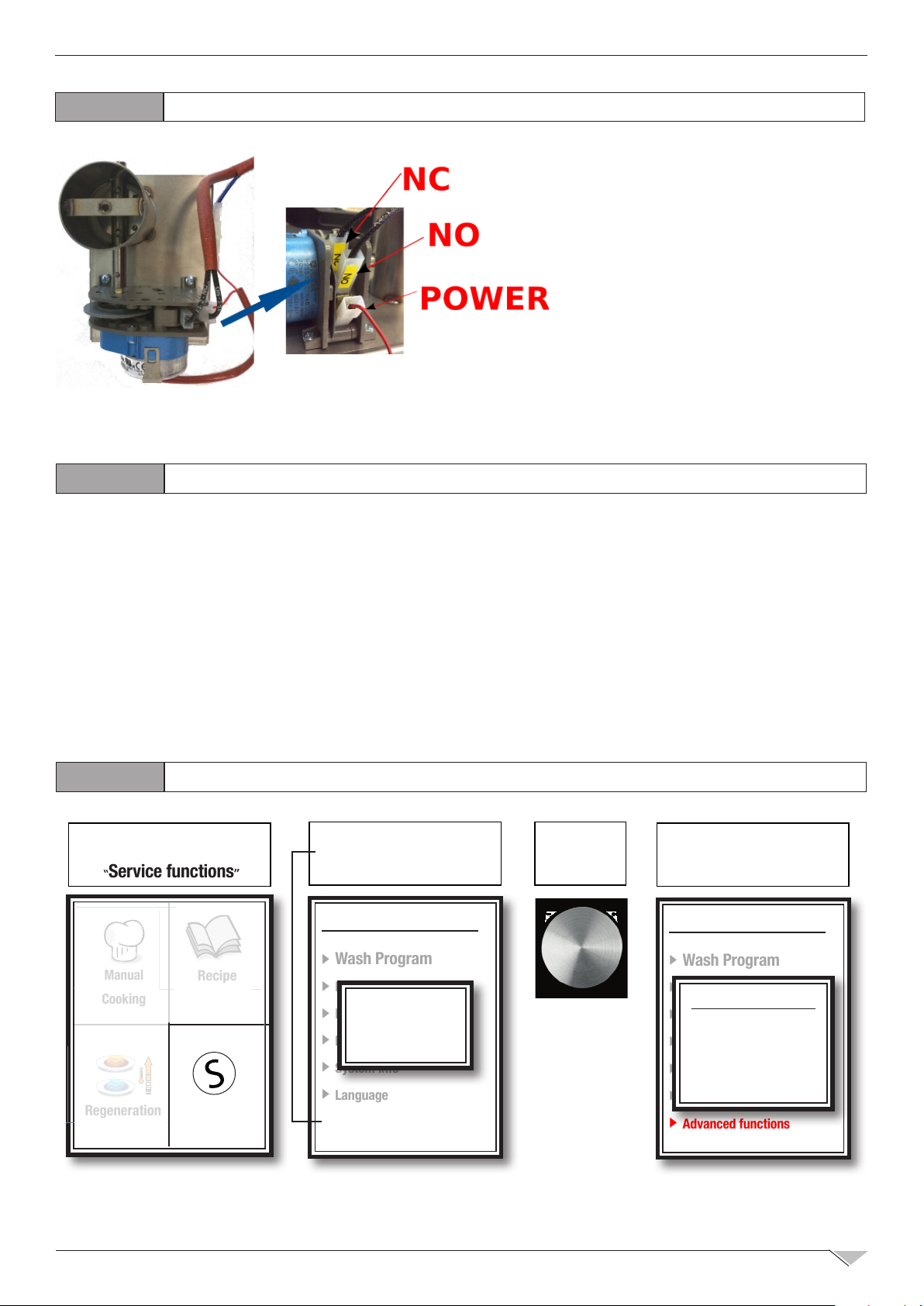

NC/2 : disconnected

NO/2 : connected

C/1 : connected

The gas blower is controlled

by PWM card. The power

supply of PWM is 24Volt - AC.

3.15

3.16

BURNER CONTROL - IGN

This electronic card switch on the burner (make the

spark between two probes) and also detect the ame

with a special probe.

GAS VALVE - EVG

Coil functionality test:

To verify the coils

600Ω (3-4)

3,7kΩ (3-1)

functionality must be

measured resistance

values. Please see

reference values

(cold coil)

Page 14

14

TECHNICAL TRAINING COURSE

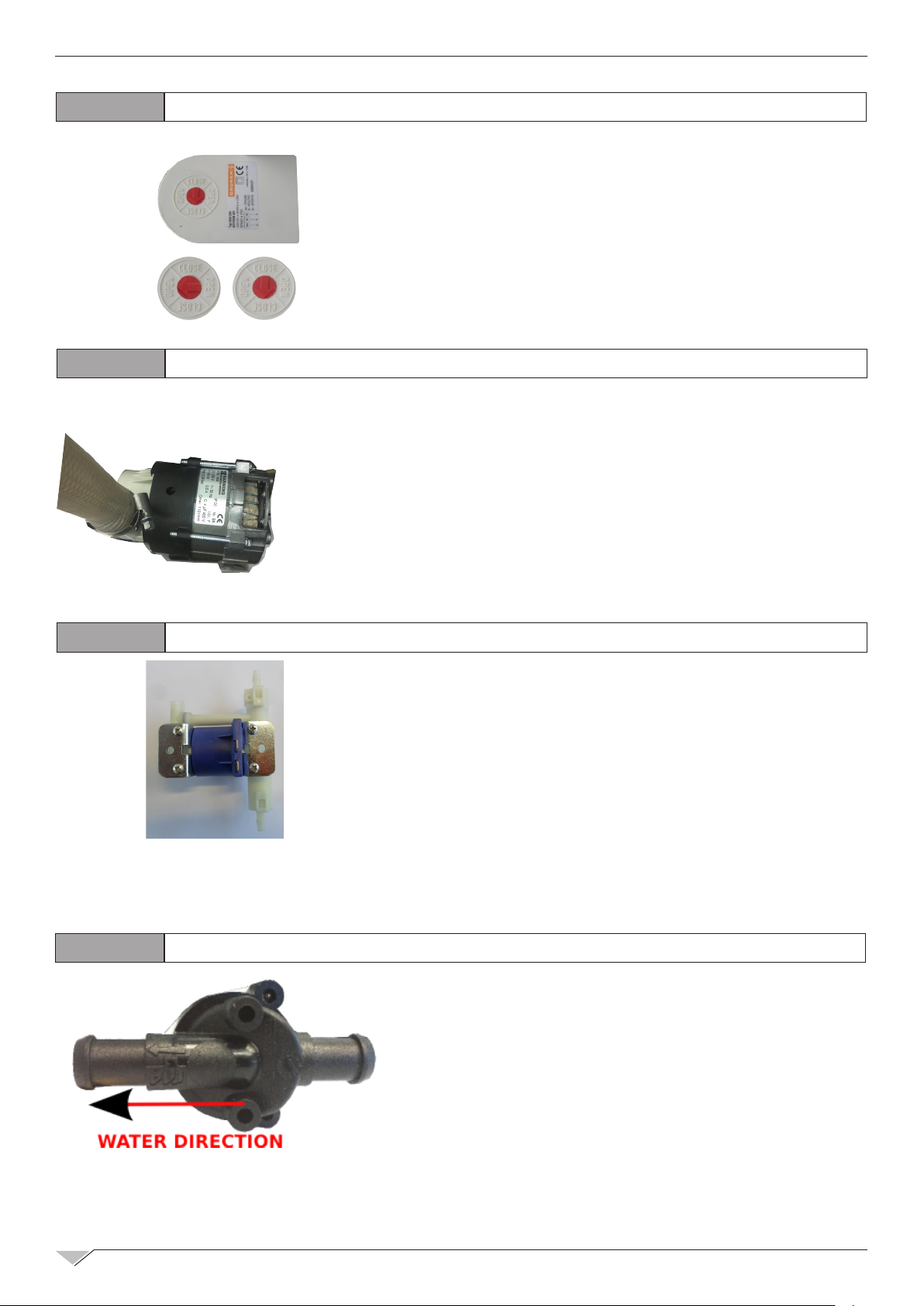

3.17

3.18

MOTORIZED DISCARGING VALVE - MS

Automatic operations:

Cooking mode : valve open

Automatic washing mode : valve close

WASHING PUMP - PL

The washing pump working when the water discarge is

closed and a ll of water is charged in the cavity. It’s

termically protected and the reset is automatic when

the temperature of the pump cool down.

3.19

3.20

DETERGENT PUMP - PD

Detergent pump for the automatic washing system.

FLOWMETER WASHING SYSTEM

The owmeter control the quantity of water is load

during a washing cycle.

Page 15

TECHNICAL TRAINING COURSE

Rigenerazione

Cottura manuale Rigenerazione

Service

15

3.21

BUTTERFLY VALVE - MV

The buttery valve open or

close the air inlet to regulate the

humidity in the cavity.

It’s normally closed when the

oven is switch on in STOP mode.

To correct CLOSE position is

showed in the picture.

4.0

GAS OVEN SETUP

The oven is originally calibrated for functioning with the gas type specied during ordering.

The type of gas for which the oven is adjusted is reported on the technical place on the

appliance.

During testing, ascertain the factory calibrations carried out on the burners are appropriate for

the specic installation type, by means of analysis of the gases produced by combustion (CO2

and CO) and check of the thermal capacity.

The detected data must be recorded and become integrating part of the technical documentation

of that appliance.

4.1

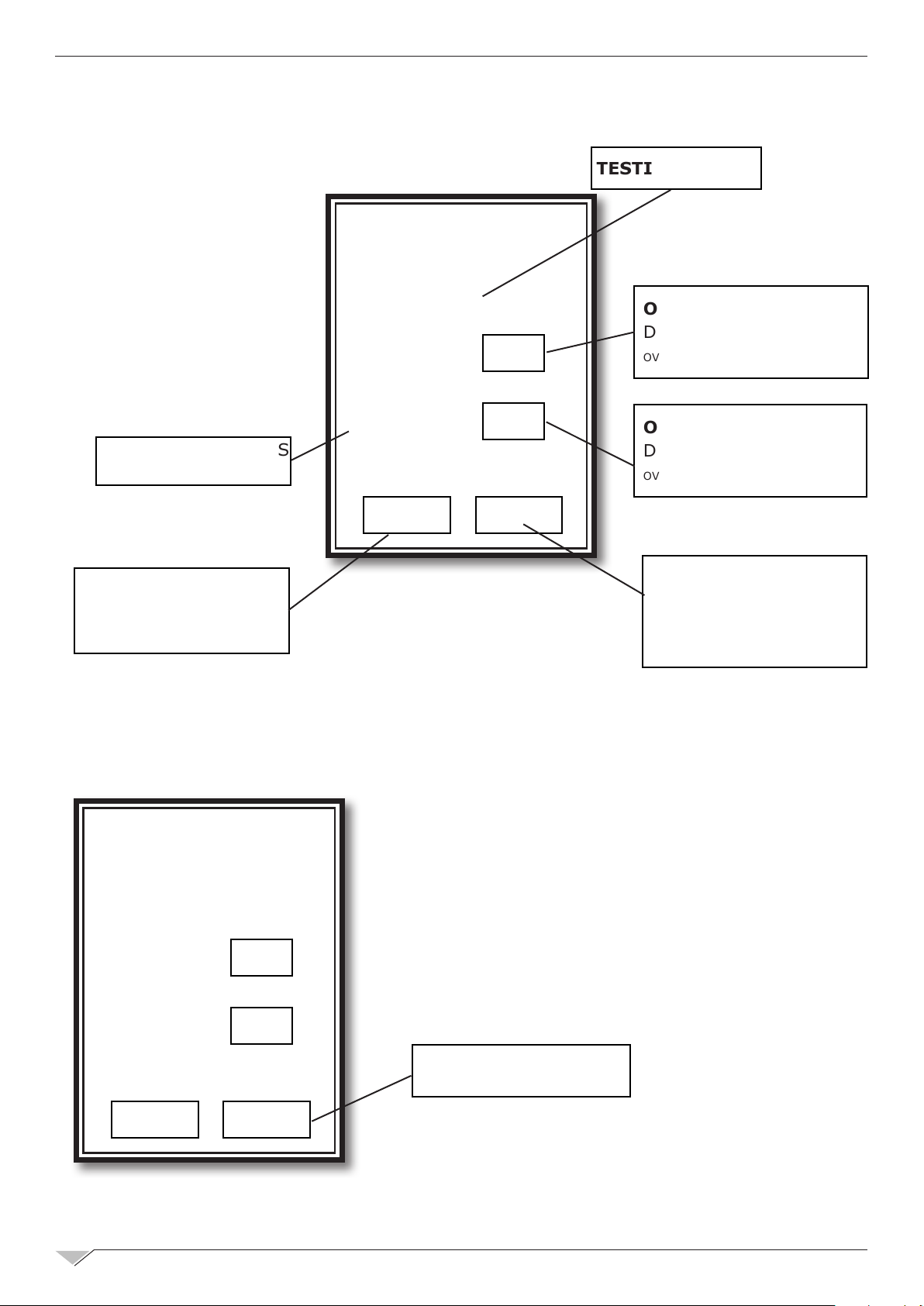

STEP 1 : SELECT

“

Service

“

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

COMBUSTION ANALISYS

STEP 2 : SELECT

“

” TO OPEN:

Recipe

Ricette

Service

”

Advanced functions

INSERT PASSWORD ‘156’

Service functions

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

” AND

STEP 3 :

PRESS KNOB

TO CONFIRM

STEP 4 :

SELECT

“

Gas test

”

Service functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

Page 16

16

1. The gas test must be carried out with the door open.

TECHNICAL TRAINING COURSE

Gas test

Testing stage:

Please open the door

Burner 1

ON

TESTING PHASE

ON/OFF: ENABLE OR

DISABLE BURNER 1

OVENS 20 GN 1/1 e 2/1 ONLY

20 RACK CAP. OVENS

ONLY

PRESS TO RETURN TO

THE PREVIOUS “STATE”

2. Starting gas test procedure:

After opening the oven door the testing procedure can be started by pressing the “NEXT”key.

Gas test

Burner 2

OFF

Back Next

ON/OFF: ENABLE OR

DISABLE BURNER 2

OVENS 20 GN 1/1 e 2/1 ONLY

FORWARD/START:

START THE TEST OR

GOES TO THE NEXT

PHASE

Testing stage:

Ready to start

Burner 1

Burner 2

ON

OFF

Back Next

GAS TEST START KEY

Page 17

TECHNICAL TRAINING COURSE

3. Adjustment of burners to minimum and maximum power:

17

Gas test

Testing stage:

Firing

Burner 1

Burner 2

ON

OFF

Back Next

Gas test

Testing stage:

Maximum speed

Burner 1

ON

Gas test

STATE:

BURNER

IGNITION

STATE:

BURNER/S

AT

MAXIMUM POWER

Testing stage:

Minimum speed

Burner 1

Burner 2

ON

OFF

Back Next

STATE:

BURNER/S

AT

MINIMUM

POWER

Burner 2

OFF

PRESS ON/OFF TO SWITCH

ON OR OFF THE CORRESPONDING BURNER (1 OR 2)

Back Next

PRESS BACK NEXT TO MOVE

FROM MINIMUM TO MAXIMUM

POWER AND VICE-VERSA

To end the GAS test procedure press NEXT until exiting the main menu screen

Page 18

18

TECHNICAL TRAINING COURSE

4.2

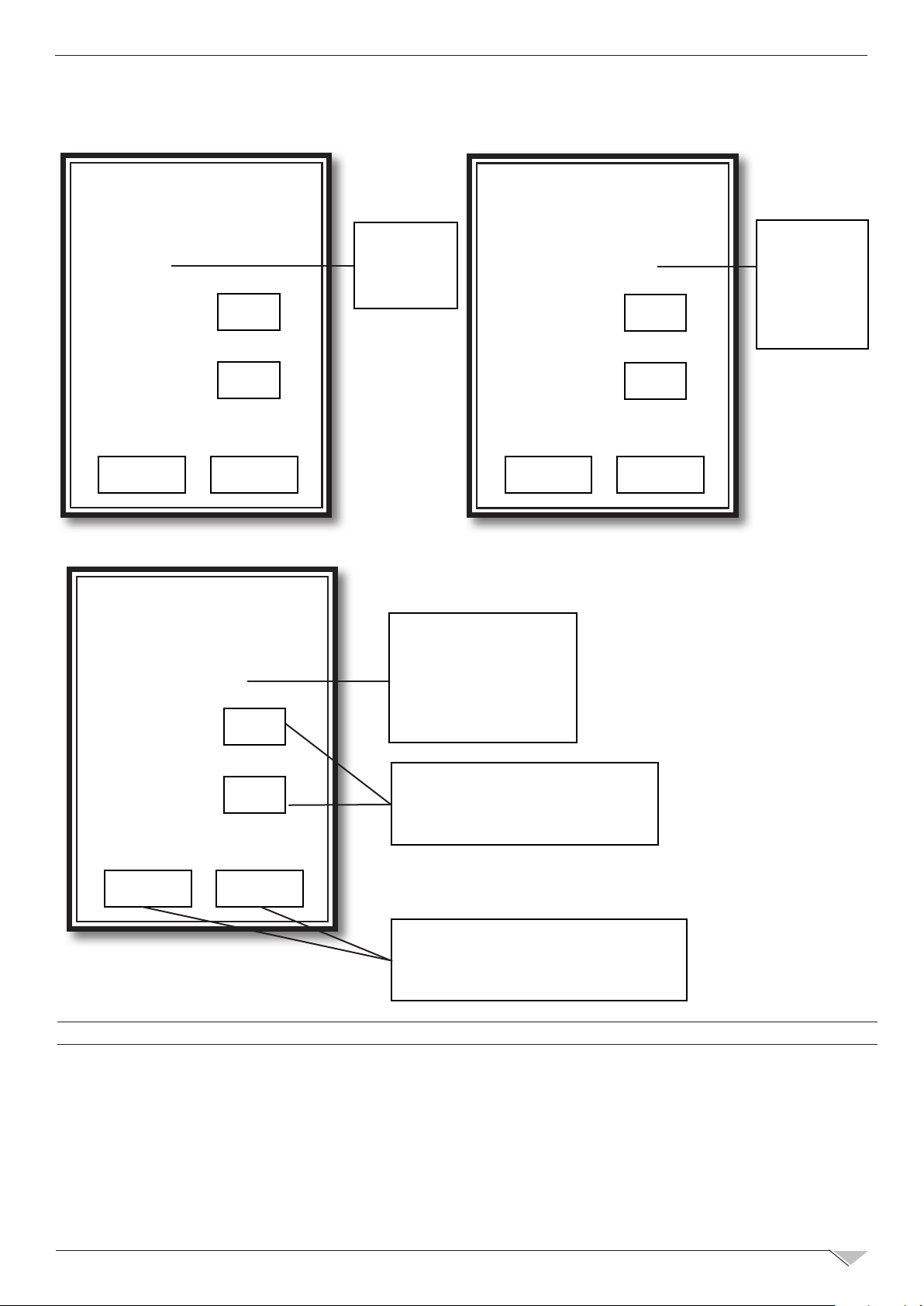

GAS REFERENCE TABLE

ADJUSTEMENT COMBUSTION VALUES #

OVEN

MODEL

6 GN

1/1

6 GN

2/1

10 GN

1/1

10 GN

2/1

TYPE OF GAS

TYPE OF

GAS

NATURAL G20 43 44 8 12 9,5 % 9,2 %

LPG

NATURAL G20 43 44

LPG

NATURAL G20 44 45 13 19 9,8% 9,4%

LPG

NATURAL G20 44

LPG

TO MAKE

REFERENCE

FOR THERMAL

CAPACIT

G30

G31

G30

G31

G30

G31

G30

G31

NOZZLE

1/10 mm

35 34 - 36 8,5 12

35 34 - 36

35 34 - 36 13,5 19

35

ALTERNA-

TIVE

NOZZLES

45 22 27

34 - 36 22 27

POWER

MAX

16,5 20 9,6 % 9,6 %

16,5 20

POWER

MAX

REFERENCE

11%-11,8%

G31 - G30

11,2%-11,5%

G31 - G30

11,5%-11,8%

G31 - G30

11,4%-11,7%

G31 - G30

CO2

MIN

9,8 10,2

CO2

REFERENCE

MAX

10,7 %-11,3%

G31 - G30

11,2%-11,5%

G31 - G30

10,9%-11,5%

G31 - G30

11,6%-11,9%

G30 - G31

B

U

R

N

E

R

S

1

1

1

1

4.3

DETECTING

FLAME PROBE

SETTING IGNITION PROBES AND DETECTING FLAME PROBE

IGNITION

PROBES

5mm

5mm

3,5mm

Page 19

TECHNICAL TRAINING COURSE

Rigenerazione

Cottura manuale Rigenerazione

Service

19

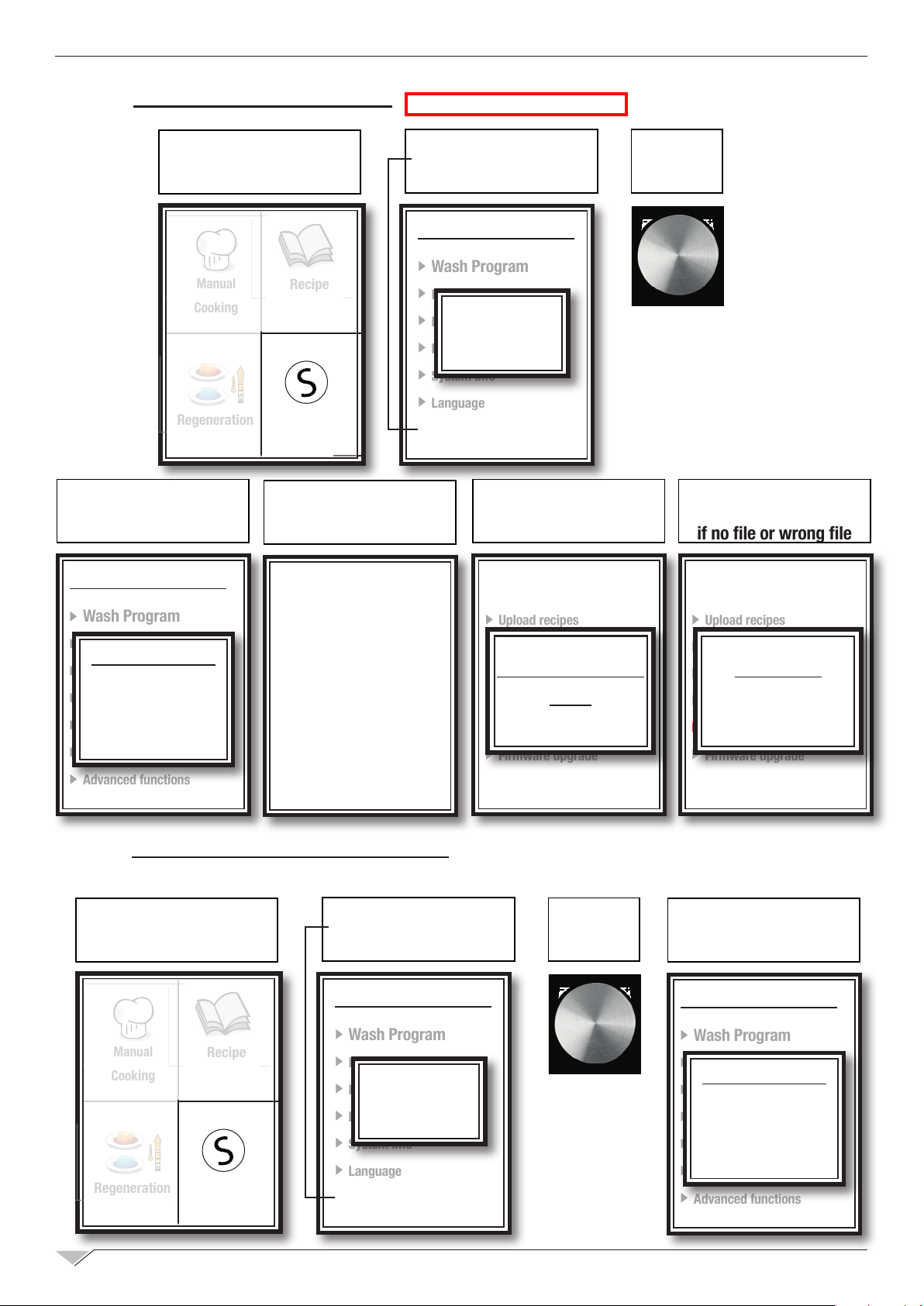

4.4

GAS CHANGE PROCEDURE

1. Replace nozzle (injector) on gas valve

2. Insert the USB drive in the oven USB port (the PARAMETERS

FILE loaded is specic for each oven model and gas

setting: FILE “PARXXX.CSV).

3.1.a UPLOAD GAS PARAMETERS

STEP 1 : SELECT

“

Service

” TO OPEN:

“

Service functions

”

STEP 2 : SELECT

“

Advanced functions

INSERT PASSWORD ‘114’

Service functions

Manual

ttura manuale

Ricette

Cooking

Recipe

Service

Wash Program

Descaling

Date and Time

Password

Parameters

114

System info

Language

Advanced functions

Ver 250 : OLD BOARD

STEP 3 :

” AND

PRESS KNOB

TO CONFIRM

A pop-up stating that

the transfer is complete

appears

Log & USB

Upload recipes

Download recipes

USB UPDATE

Download HACCP log

Download parameters

Upload parameters

OK

Firmware upgrade

OK!

Page 20

20

Rigenerazione

Cottura manuale Rigenerazione

Service

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

3.1.b UPLOAD GAS PARAMETERS

STEP 1 : SELECT

“

Service

” TO OPEN:

“

STEP 4 :

SELECT

“

Log & USB

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

”

Recipe

Service

”

Ricette

STEP 5 :

SELECT

“

Upload parameters

Ver 344 : NEW BOARD

STEP 2 : SELECT

“

Advanced functions

INSERT PASSWORD ‘156’

” AND

Service functions

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

A pop-up stating that

the transfer is complete

”

appears

STEP 3 :

PRESS KNOB

TO CONFIRM

ERROR

pop-up appears

if no le or wrong le

Service functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

Log & USB

Upload recipes

Download recipes

Download HACCP log

Download parameters

Upload parameters

Firmware upgrade

4.1 ACTIVATE GAS TEST PROCEDURE

STEP 1 : SELECT

“

Service

” TO OPEN:

“

Service functions

”

STEP 2 : SELECT

“

Advanced functions

INSERT PASSWORD ‘156’

Service functions

Log & USB

Upload recipes

Download recipes

USB UPDATE

Download HACCP log

Download parameters

Upload parameters

OK

Firmware upgrade

” AND

OK!

STEP 3 :

PRESS KNOB

TO CONFIRM

Log & USB

Upload recipes

Download recipes

ERROR!

Download HACCP log

Download parameters

Upload parameters

OK

Firmware upgrade

STEP 4 :

SELECT

“

Gas test

”

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

Recipe

Service

Ricette

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

Page 21

TECHNICAL TRAINING COURSE

5. Check the combustion and, if

necessary, change the nozzle.

21

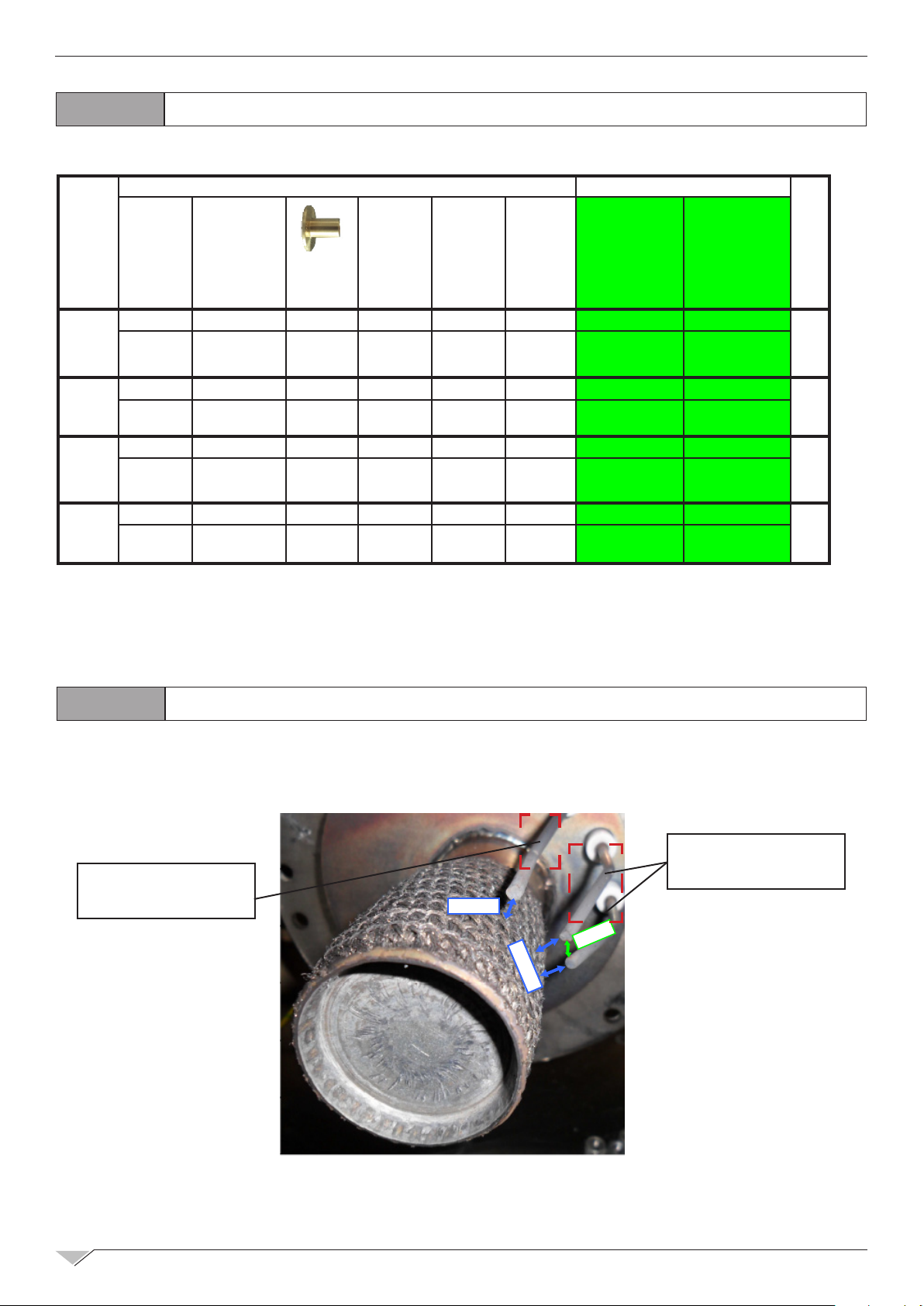

4.5.1

FIXING THE BURNER TO THE EXCHANGER: GASKET SEQUENCE

EXCHANGER

GRAPHITE GASKET

OVEN CHAMBER

GRAPHITE GASKET

Page 22

22

TECHNICAL TRAINING COURSE

4.5.2

FIXING THE BURNER TO THE EXCHANGER: NOTES

SPECIAL GREASE

SELF BLOCKING NUT M6

WASHER

Page 23

TECHNICAL TRAINING COURSE

23

NUTS M6 MUST BE

CLOSED BY USING

A TORQUE WRENCH

5.0

SET TORQUE AT

6 N/m

ELECTRONIC BOARDS AND CONFIGURATION

TOUCH BOARD

MAIN POWER BOARD

EXPANSION CARD

Page 24

24

TECHNICAL TRAINING COURSE

5.1

RULES OF SERIAL CONNECTION

KEYBOARD

BOARD

CONFIGURATION OF ELECTRONIC BOARDS SERIAL CONNECTION

“A” BOARD

“B” BOARD

1. All electronic boards of the SteamBox ovens

‘component panel’ area communicate with the

keyboard motherboard (touch or programmable)

via RS485 serial connection

2. ‘Keyboard’ board is the main board and the

operation conguration of other boards connected

in serial depends on it.

3. The beginning and the end of the serial connection

must always be completed by means of dip-

switch activation

4. In case that more than one board of the same

type are present in the system, these must be

addressed in a different way, by using another

dip-switch

485 SERIAL CONNECTION

Keyboard board is always at the BEGINNING of the

serial connection and so they must be completed by

activating the corresponding DIP-SWITCH in ON

The type of serial connection termination must be

start:ON –OFF – OFF ……OFF – ON:end. Therefore,

the board at the end of the serial connection ‘chain’

must be completed.

Page 25

TECHNICAL TRAINING COURSE

25

PWM “8” BOARD TERMINATOR

Switch ON

if it is the

end of the

serial line

INVERTER BOARD TERMINATOR

Switch ON

if it is the

end of the

serial line

Address in different way in case there are more than one board of the same type:

PWM “6” BOARD ADDRESS

INVERTER BOARD ADDRESS

Switch ON

if it is the 2nd

board of the

serial line of

this type

Switch ON

if it is the 2nd

board of the

serial line of

this type

Page 26

26

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

5.2

STEP 1 : SELECT

“

Service

” TO OPEN:

“

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

5.2.1

I/O CHECK

“

Advanced functions

”

INSERT PASSWORD ‘156’

Service functions

Wash Program

Recipe

Ricette

Service

Descaling

Date and Time

Parameters

System info

Language

Advanced functions

I/O CHECK - PROBES

STEP 2 : SELECT

Password

156

” AND

STEP 3 :

PRESS KNOB

TO CONFIRM

STEP 4 :

SELECT

“

I/O Check

”

Service functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

Identication Probe Clamp

S1 – probe 1

NTC on board - power card temperature (ALARM: Hi-

Temp)

---

S2 – probe 2 // //

S3 – probe 3 CORE thermocouple J 14 – 15

S4 – probe 4 FREE 12 – 13

S5 – probe 5 cavity thermocouple J 10 – 11

S6 – probe 6 FREE 20 – 21

S7 – probe 7 Humidity probe 2 thermocouple J (ALARM: PROBE 5) 18 – 19

S8 – probe 8 Humidity probe thermocouple J (ALARM : PROBE 4 ) 16 – 17

S9 – probe 9 // //

S10 – probe 10 // //

S11 – probe 11 // //

S12 – probe 12 // //

Page 27

TECHNICAL TRAINING COURSE

27

5.2.2

Identication Input Clamp

I1 – Motor safety 1

I2 – Motor safety 2

(2 motors ovens only)

I3 – Safety

thermost

I4 – Alarm burner 1 Burner 1 block (230Vac) 36 – 37

I5 – Alarm burner 2 Burner 2 block (230Vac) 35 – 37

I7 – Door switch

I8 – Air safety 1

I9 – Air safety 2

I10 – Boiler level

I/O CHECK - DIGITAL INPUTS

Motor 1 thermal protection (230Vac)

0= open/faulty

1= close/active

Motor 2 thermal protection (230Vac)

0= open/faulty

1= close/active

Chamber safety (230Vac) 38 – 41

Door input

1 = door open

0 = door closed

Air ow inlet 1

1 = contact open

0 = close if vacuum

Air ow inlet 2

1 = contact open

0 = close if vacuum

Level 1 input

1 = boiler empty

0 = boiler full

40 – 41

39 – 41

6 – 9

7 – 9

8 – 9

44 – 45

I11 – L2 not used 43 – 45

I12 – L3 not used 42 – 45

I13 not used 60 – 61

example: BOILER TEST

1) Make sure that boiler is empty verifying I10 = 1 or activate R17 for almost 15 seconds to drain water

from the boiler

2) Activate R18 to load boiler water

3) Check I10: in almost 60 second boiler level will change to ---> =0 boiler full. Boiler level must be ‘0’

and has not to change itself, otherwise there is a leakage into boiler or solenoid valve.

If the level does not change please verify water loading system (water inlet , lime,obstructions..etc ) and

check the functionality of level control system (probe cleaning, control board ‘ok’)

4) Activate R20 and verify Amperage with a clamp meter (boiler 6/10 gn1/1, 6 gn2/1 = 4,3A ; boiler 20

gn1/1, 10/20 gn2/1 = 10.8A)

Page 28

28

TECHNICAL TRAINING COURSE

5.2.3

I/O CHECK - DIGITAL OUTPUTS

In this section one can pilot some utilities manually by positioning the cursor on the desired

utility and pressing the encoder key. By pressing the encoder key again the utility is deactivated.

Identication Relay Notes Clamp

R1:

Resist 1

R2:

Resist 1+2

R4:

Humidity disch.

Chamber 1

Chamber 2

Buttery valve

Electric oven actionable only remains active for max. 10s. The fan

is activated as well.

Electric oven actionable only remains

active for max. 10s. The fan is activated as well.

Commands opening and closing.

Command active only with discharge

stopped. Positioning change occurred

display.

33 – 34

32 – 34

29 – 31

door open : active

R5:

Hand shower

Shower

electrovalve

door closed : inactive

(to protect hand shower hose from

28 - 31

over pressure)

R9:

Steam kill

R10:

Humidif

R11:

Discharge

R12:

Washing water

R13:

Washing pump

R17:

Boiler discharg

R18:

Boiler water

R19:

Detergent

R20:

Boiler resist.

Quencing

electrovalve

23 – 26

Humidier 22 – 26

Chamber

discharge

46–47–50

motorised valve

Load solenoid

valve

48 – 50

washing water

Washing pump 49 – 50

Boiler Discharge

solenoid valve

Boiler Load

solenoid valve

Pump

Detergent load

Boiler

resistances

0.85 oz/sec (0.025 liter/sec)

54 – 57

55 – 57

56 – 57

58 – 59

H1:

Pulse counter

600 Pulses = 2.1 pt lqd

(1liter)

Washing water

liter counter

Increases its value if water from the

R12 solenoid valve is loaded

JST – J5

Page 29

TECHNICAL TRAINING COURSE

29

5.3

• After the number of minutes since the last recording, as set in the

parameter.

• In cooking mode with core probe: when the core temperature since the last re-

cording differs by the number of degrees set in the parameter

• In "timed" cooking when the chamber temperature since the last recording differs

by the number of degrees set in the parameter

• When the oven stops or at the end of the cooking program.

5.3.1

The printout data are logged in a different le for each day. All of the cooking cycles performed in the same day (taking into consideration the start time) are saved progressively in

the same le. The name of the le will be "yy_mm_dd.log where yy = year, mm = month and

dd = day. The le is in text format.

HACCP RECORDING (TOUCH BOARD)

If printouts are enabled through the

"start" is pressed on the oven, it begins recording the cooking.

The cooking data are: time, chamber temperature and, if present, core probe temperature. Recording is done at the follow-

ing times:

• At start. At automatic pre-heating as indicated.

• Switching from pre-heating to cooking (when the door is

opened and closed at the end of pre-heating).

• At every phase change.

DeltaTHACCP

COOKING LOG MEMORISATION

EnHACCP

DeltaTHACCP

.

parameter when

TimeStHACCP

.

5.3.2

**************************************** Separator

Start Log 10/09/2010 15:23 Start

Roast Program name

Core Chamber Time Column Name

Phase 1 Phase no.

15:23:32 084 --- Date

15:23:35 084 ---

End Log End

5.3.3

P500 - HACCP enabling:

0 = disabled (default)

1 = enabled only for probe cooking (WITH USB pen-drive connected)

2 = enabled for all cooking (WITH USB pen-drive connected)

ONLY:

Ver 344 : NEW BOARD

PRINTOUT EXAMPLE

HACCP PARAMETERS

3 = enabled only for probe cooking (WITHOUT USB pen-drive connected,download after)

4 = enabled for all cooking (WITHOUT USB pen-drive connected,download after)

P501 = Maximum time between HACCP data (1-20 minutes): default ‘5’

P502 = Maximum temperature difference (at core if cooking with probe or chamber if

timed cooking between HACCP data saves (1-20° C): default ‘5’

Page 30

30

Rigenerazione

Cottura manuale Rigenerazione

Service

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

5.3.4

STEP 1 :

INSERT A EMPTY

USB PENDRIVE

DOWNLOAD HACCP LOG--->USB

STEP 2 : SELECT

“

Service

” TO OPEN:

“

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

Recipe

Service

Ricette

”

Service functions

Date and Time

Parameters

System info

Language

Advanced functions

Wash log - Download

USB

STEP 3 :

SELECT

“

USB

”

Ver 344 : NEW BOARD

STEP 4 :

SELECT

“

Download log HACCP”

USB

Download log HACCP

Upload recipes

Download recipes

Firmware upgrade

USB

5.4

STEP 1 :

INSERT A EMPTY

USB PENDRIVE

A pop-up stating that

the transfer is complete

appears

WASH LOG - DOWNLOAD - ERASE

STEP 2 : SELECT

“

Service

” TO OPEN:

“

“

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

Recipe

Ricette

Service

”

Wash log - Download

Service functions

Date and Time

Parameters

System info

Language

Advanced functions

Wash log - Download

USB

STEP 3 :

SELECT

Upload recipes

Download recipes

USB UPDATE

Download HACCP log

OK!

Ver 344 : NEW BOARD

”

Wash log

Soft - 18/07/14 - 11:11

Hard - 20/07/14 - 19:15

AVAILABLE ONLY IF THE

PASSWORD ‘156’

WAS INSERTED BEFORE

Wash log

USB UPDATE

OK!

Wash log

Soft - 18/07/14 - 11:11

Hard - 20/07/14 - 19:15

Erase LOG?

Yes No

Page 31

TECHNICAL TRAINING COURSE

Rigenerazione

Cottura manuale Rigenerazione

Service

Co

Rigenerazione

Cottura manuale Rigenerazione

Service

31

5.5

5.5.1

STEP 1 : INSERT

USB PENDRIVE WITH

RECIPES FILE

“GRECIPE.CSV”

UPLOAD - DOWNLOAD RECIPES

UPLOAD RECIPES

STEP 2 : SELECT

“

Service

” TO OPEN:

“

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

Recipe

Ricette

Service

STEP 3 :

SELECT

”

“

USB

”

Service functions

Date and Time

Parameters

System info

Language

Advanced functions

Wash log - Download

USB

Download log HACCP

Upload recipes

Download recipes

Firmware upgrade

STEP 4 :

SELECT

“

Upload recipes”

USB

5.5.2

STEP 1 :

INSERT A EMPTY

USB PENDRIVE

DOWNLOAD RECIPES

STEP 2 : SELECT

“

Service

” TO OPEN:

“

Service functions

ttura manuale

Manual

Cooking

Rigenerazione

Regeneration

Recipe

Service

”

Ricette

USB

ERROR!

OK

ERROR

pop-up appears

if no le or wrong le

STEP 3 :

SELECT

“

USB

”

Service functions

Date and Time

Parameters

System info

Language

Advanced functions

Wash log - Download

USB

USB

Upload recipes

USB UPDATE

Download recipes

Download HACCP log

OK!

A pop-up stating that

the transfer is complete

appears

STEP 4 :

SELECT

“

Download recipes”

USB

Download log HACCP

Upload recipes

Download recipes

Firmware upgrade

USB UPDATE

OK!

Page 32

32

Co

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

5.6

WASH LOG - DOWNLOAD/ERASE

STEP 1 : INSERT

A EMPTY USB

PENDRIVE

STEP 5 :

SELECT

“

Log & USB

“

ttura manuale

Cooking

Rigenerazione

Regeneration

”

STEP 2 : SELECT

“

Service

” TO OPEN:

Service functions

Manual

Recipe

Ricette

Service

STEP 6 :

SELECT

“

Wash log - Download”

Ver 344 : NEW BOARD

STEP 3 : SELECT

“

Advanced functions

”

INSERT PASSWORD ‘156’

” AND

STEP 4 :

PRESS KNOB

TO CONFIRM

Service functions

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

“

Wash log - Download”

STEP 7 :

SELECT

Service functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

Log & USB

HACCP log - Download

Wash log - Download

Alarm log - Download

Upload recipes

Download recipes

Upload parameters

USB

Upload recipes

USB UPDATE

Download recipes

Download HACCP log

A pop-up stating that

the transfer is complete

OK!

appears

Wash log

Soft - 18/07/14 - 11:11

Hard - 20/07/14 - 19:15

Wash log

Soft - 18/07/14 - 11:11

Hard - 20/07/14 - 19:15

Erase LOG?

Yes No

STEP 8 :

SELECT AND CONFIRM

PRESSING KNOB

Page 33

TECHNICAL TRAINING COURSE

33

5.7

ALARMS DESCRIPTION

In case of alarm the identifying name of the alarm in progress appears on temperature display and on time display. The following alarms are managed:

Name Description Actions SOLUTION

Chamber

probe

Core

probe

GAS Gas burner block Cooking block, manual restore.

GAS 2 Gas second burner block. Cooking block, manual restore.

Motor

safety

Inverter

code:

Chamber

safety

PWM

PWM 2

Air Flow

Air

Flow 2

Hi temp

No water

Chamber probe error

Core probe error Manual restore. Replace core probe.

Motor Alarm Cooking block, automatic re-arm

Motor Inverter Alarm Cooking block, automatic re-arm

Chamber safety thermal. Cooking block, manual re-arm.

PWM board error

(communication timeout

or problems on fan speed)

PWM second board error

(communication timeout

or problems on fan speed)

Air capacity on gas

burner alarm

Air capacity on second

gas burner alarm

Technical compartment

temperature too high.

No water for the

production of steam.

Cooking block, automatic

restore.

Cooking block.

Cooking block.

Cooking block, manual restore.

Cooking block, manual restore.

Cooking is blocked, automatic

restore.

Cooking is blocked, automatic

restore.

Replace chamber probe.

Press manual restore.

(encoder button for 1 Second)

Press manual restore.

(encoder button for 1 Second)

If continuous, contact after-sales

assistance.

Check the inverter error table at

page 36.

Check the safety thermostat (par.

3.8 page 12).

Check 24 volt power supply,pwm,

connection cables and fan blower

Check 24 volt power supply,pwm,

connection cables and fan blower

Check obstructions to combu-

stion fumes exhaust ue, check

pressostat at the and of the gas

blower.

Check obstructions to combustion

fumes exhaust ue, otherwise

contact after-sales assistance.

Check oven's perimeter ventilation,

the lower air lter (pag. 46) and the

correct functioning of the cooling fans

of the components.

Check connection to water duct, the

boiler and water presostat. Check

opening of the shut-off cook.

No water

owmeter

Com

PWM

Com

PWM2

Communication

No drain Boiler water did not drain

Power fail Electrical power failure Cooking block. Press encoder button for 1 Second.

Probe 4 Humidity control probe 4

Probe 5 Humidity control probe 5

Washing owmeter alarm Washing is blocked.

PWM board

communication error

PWM2 board

communication error

Main board

communication error

correctly

alarm

alarm

Cooking block.

Cooking block. Check cleaness of the lower fan

Cooking block. Remove power and then give back.

Cooking block. Remove power and then give back.

Cooking block. Replace humidity probe 4

Cooking block. Replace humidity probe 5

Check connection to water duct and

opening of the shut-off cook Check

the owmeter.

Check cleaness of the upper fan

blower and fan power connection.

Remove power and give back.

blower and fan power connection.

Remove power and give back.

If continuous, contact after-sales

assistance.

Check cleaness and operation of

the boiler diascharge valve.Check

te boiler.

Page 34

34

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

5.8

ALARM LOG - DOWNLOAD/ERASE

STEP 1 : INSERT

A EMPTY USB

PENDRIVE

STEP 5 :

SELECT

“

Log & USB

STEP 2 : SELECT

“

Service

“

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

”

” TO OPEN:

”

Recipe

Ricette

Service

STEP 6 :

SELECT

“

Wash log - Download”

Ver 344 : NEW BOARD

STEP 3 : SELECT

“

Advanced functions

INSERT PASSWORD ‘156’

Service functions

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

“

Alarm log - Download”

” AND

STEP 7 :

SELECT

STEP 4 :

PRESS KNOB

TO CONFIRM

Service functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

Log & USB

HACCP log - Download

Wash log - Download

Alarm log - Download

Upload recipes

Download recipes

Upload parameters

USB

Upload recipes

USB UPDATE

Download recipes

Download HACCP log

A pop-up stating that

the transfer is complete

OK!

appears

Alarm log

18/07/14 11:11

E03 Inverter code: 08

20/07/14 08:13

E16 Comunication

Alarm log

18/07/14 11:11

E03 Inverter code: 08

Erase LOG?

Yes No

STEP 8 :

SELECT AND CONFIRM

PRESSING KNOB

Page 35

TECHNICAL TRAINING COURSE

35

5.9

5.10

SYSTEM INFO MENÙ

System info

Keyboard:

Ver 344 Rev 001d

RevE2 000

08/07/14

Base:

Ver 240 Rev 003

02/08/10

SR.N. 001234/05/14

Boiler: 23hr

INVERTER ALARM SIGNAL DIAGNOSTIC

A page appears showing:

Keyboard rmware version:

Base rmware version.

Ver 344 : NEW BOARD

Ver 250 : OLD BOARD

The oven serial number and the boiler operating hours

(after the last discaling) are also given.

If the advanced services menu has been previously

accessed by introducing the line end inspection

password “956”, by pressing the touch screen, access

the oven serial number setting menu, otherwise go

back to the service menu.

In case the oven main board signals an INVERTER

alarm (or 1nv on programmable version) can open the

panel compartment to detect the number of ‘ashes’

indicated by the RED LED

(code error appear on display)

The type of ashes sequence is: 1.5s pause followed

by 0.5s ash 0,5s pause.

ERROR CODIFICATION (code number = number

of ashes):

code 1: Error inside the Inverter. Disconnect the power supply of the oven and power it

again, if the inverter must be replaced.

code 2: Failure on the motor (short), overcharged, or blocked motor. Perhaps the motor has

some internal problems or something has blocked it.

code 3: The dissipator temperature of the inverter is too high: verify the ventilation of the

technical compartment.

code 4: Error inside the Inverter. Disconnect the power supply of the oven and power it again,

if the inverter must be replaced.

code 5: Inverter parameterization error. Disconnect the power supply of the oven and power

it again, if the inverter must be replaced.

code 6: The motor is overcharged or blocked: ensure if it can be rotated in vain.

code 7: The motor presents little connection with the burnt or removed inverter. A failure

could have occurred inside the winding

code 8 : Inverter communication error: verify the serial connection and RS485 connection

conguration (also verify the inverter power supply : green led ON)

Page 36

36

Co

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

5.11

STEP 1 : SELECT

“

Service

“

Service functions

ttura manuale

Manual

Cooking

Rigenerazione

Regeneration

TECHNICAL PARAMETERS

” TO OPEN:

“

Parameters

Service functions

Wash Program

Descaling

Date and Time

Parameters

System info

Language

Advanced functions

Recipe

Ricette

Service

”

STEP 2 :

SELECT

STEP 3 :

INSERT

”

PASSWORD ‘156’

Service functions

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

P5 = Activation time cooking chamber lighting (0 – 255 seconds):

- default ‘45’. 254 = light ON during cooking

STEP 4 :

PRESS KNOB

TO CONFIRM

P14 = External buzzer activation:

0 = deactivated (the buzzer on the keyboard works, in this case the external buzzer MUST

be removed physically)

1-2 = activated

P15 = Screen saver:

0 = screen saver deactivated

1-120 = delay time to activate (seconds)

121 - 240 = delay time to activate (0-120 seconds) but the touch screen shows the total

remaing time to nish cooking cycle

P18 = Date Type:

0 = EU date

1 = US date

P70 = Steam condensation enabling (Quencing):

0 = deactivated

1 = activated (default)

P75 = Condensation activation time ( 0 – 10 ) : default ‘6’ (=60%)

0% - 100% (0-10)

P400 = Boiler descaling product reaction time ( 0 – 600 minutes ) : default is ‘360’.

The default time is set for vinegar. If other faster descaling products are used you can, for

example, decrease the value of this parameter.

P404 = Stand-by time for “boiler descaling” warning (0 – 2000 hours) : default ‘250’

The default time is set for softened water.(approximately 5 TH). If water hardness is greater

than 5-10 TH it is recommended to lower the value by P404. (For example: 20-25 hours for

20°f). WATER SOFTENER IS ALWAYS RECOMMENDED

Page 37

TECHNICAL TRAINING COURSE

Co

Rigenerazione

Cottura manuale Rigenerazione

Service

P500 - HACCP enabling:

0 = disabled (default)

1 = enabled only for probe cooking (WITH USB pen-drive connected)

2 = enabled for all cooking (WITH USB pen-drive connected)

37

ONLY:

Ver 344 : NEW BOARD

3 = enabled only for probe cooking (WITHOUT USB pen-drive connected,download after)

4 = enabled for all cooking (WITHOUT USB pen-drive connected,download after)

P501 = Maximum time between HACCP data (1-20 minutes): default ‘5’

P502 = Maximum temperature difference (at core if cooking with probe or chamber if

timed cooking between HACCP data saves (1-20° C): default ‘5’

P980 =DEMO Mode

0 = normal operation (oven)

1 = DEMO mode (showroom)

2 = DEMO mode (demo unit - demonstration panel)

3 = DEMO WASH mode (showroom/fair)

To change the value of a parameter:

1. Select the parameter by rotating the encoder knob.

2. Press the knob button to enter “parameter change” mode.

3. Rotate the encoder knob to change the value of the parameter.

4. Press the knob button to enter conrm the change.

5. Press the “esc” key to exit the “parameters” menu.

5.12

STEP 1 :

Insert USB pendrive

with les

‘V344Rxxx.MD5’ and

‘V344xxx.s19

FIRMWARE UPGRADE

STEP 2 : SELECT

“

Service

” TO OPEN:

“

Service functions

”

Service functions

Date and Time

ttura manuale

Manual

Cooking

Rigenerazione

Regeneration

Recipe

Ricette

Service

Parameters

System info

Language

Advanced functions

Wash log - Download

USB

STEP 3 :

SELECT

“

USB

”

STEP 4 :

SELECT

“

Firmware upgrade”

USB

Download log HACCP

Upload recipes

Download recipes

Firmware upgrade

WAIT UNTIL

JOB IS ENDED!

A pop-up will appear on the

screen

Upgrading procedure will be

approximately 45-60 seconds

Page 38

38

Rigenerazione

Cottura manuale Rigenerazione

Service

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

5.13.1

STEP 1 : SELECT

“

Service

“

Service functions

ttura manuale

Ricette

5.13.2

STEP 1 :

INSERT A EMPTY

USB PENDRIVE

UPLOAD NEW PARAMETERS

STEP 2 : SELECT

“

” TO OPEN:

Advanced functions

”

INSERT PASSWORD ‘114’

” AND

Service functions

Manual

Cooking

Recipe

Service

Wash Program

Descaling

Date and Time

Password

Parameters

114

System info

Language

Advanced functions

DOWNLOAD PARAMETERS FROM THE OVEN

STEP 2 : SELECT

“

“

Service

” TO OPEN:

“

Service functions

”

Advanced functions

Ver 250 : OLD BOARD

STEP 3 :

PRESS KNOB

TO CONFIRM

Ver 250 : OLD BOARD

STEP 3 : SELECT

INSERT PASSWORD ‘12’

A pop-up stating that

the transfer is complete

appears

Log & USB

Upload recipes

Download recipes

USB UPDATE

Download HACCP log

Download parameters

Upload parameters

OK

Firmware upgrade

” AND

OK!

STEP 4 :

PRESS KNOB

TO CONFIRM

Service functions

Download recipes

STEP 5 :

SELECT

“

Download recipes”

Wash Program

Descaling

Parameters

System info

Language

Advanced functions

ttura manuale

Ricette

Manual

Cooking

Recipe

Service

STEP 6 :

PRESS KNOB

TO CONFIRM

Service functions

Wash Program

Descaling

Date and Time

Password

Parameters

System info

Language

Advanced functions

12

A pop-up stating that

the transfer is complete

appears

Service functions

Upload recipes

Download recipes

USB UPDATE

Download HACCP log

Download parameters

Upload parameters

OK

Firmware upgrade

OK!

Page 39

TECHNICAL TRAINING COURSE

Rigenerazione

Cottura manuale Rigenerazione

Service

39

5.13.3

STEP 1 :

Insert USB pendrive

with parameters le

‘parxxxx.csv’

UPLOAD NEW PARAMETERS

Touch version

STEP 2 : SELECT

“

Service

” TO OPEN:

“

Service functions

Cottura manuale

Manual

Cooking

Rigenerazione

Regeneration

Recipe

Service

”

Ricette

Ver 344 : NEW BOARD

STEP 3 : SELECT

“

Advanced functions

INSERT PASSWORD ‘156’

Service functions

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

” AND

STEP 4 :

PRESS KNOB

TO CONFIRM

STEP 5 :

SELECT

“

Log & USB

”

Service functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

STEP 6 :

SELECT

“

Upload parameters

Log & USB

Upload recipes

Download recipes

Download HACCP log

Download parameters

Upload parameters

Firmware upgrade

ERROR

pop-up appears

if no le or wrong le

A pop-up stating that

the transfer is complete

”

appears

Log & USB

Upload recipes

Download recipes

USB UPDATE

Download HACCP log

Download parameters

Upload parameters

OK

Firmware upgrade

OK!

ERROR!

OK

Page 40

40

Co

Rigenerazione

Cottura manuale Rigenerazione

Service

TECHNICAL TRAINING COURSE

5.13.4

Insert a EMPTY

USB pendrive

DOWNLOAD PARAMETERS FROM THE OVEN

STEP 1 :

STEP 2 : SELECT

“

Service

“

Service functions

ttura manuale

Manual

Cooking

Rigenerazione

Regeneration

” TO OPEN:

Recipe

Ricette

Service

Ver 344 : NEW BOARD

STEP 3 : SELECT

“

Advanced functions

”

INSERT PASSWORD ‘156’

” AND

STEP 4 :

PRESS KNOB

TO CONFIRM

Service functions

Wash Program

Descaling

Password

Date and Time

156

Parameters

System info

Language

Advanced functions

STEP 5 :

SELECT

“

Log & USB

”

Service functions

Wash Program

Descaling

Test service

Date and Time

Gas test

Parameters

I/O Check

System info

Log & USB

Language

Advanced functions

STEP 6 :

SELECT

“

Download parameters

Log & USB

Upload recipes

Download recipes

Download HACCP log

Download parameters

Upload parameters

Firmware upgrade

A pop-up stating that

the transfer is complete

”

appears

Log & USB

Upload recipes

Download recipes

USB UPDATE

Download HACCP log

Download parameters

Upload parameters

OK

Firmware upgrade

OK!

Page 41

TECHNICAL TRAINING COURSE

41

6.0

6.1

Boiler descaling is activated by choosing the appropriate entry from the service menu:

(Service – descaling) (insert part of the instructions manual)

At this point a sequence of pop-ups will appear that will guide the user until the end of the

procedure. The procedure consists in the following phases:

MAINTENANCE

BOILER DESCALING

1 Stand-by phase to conrm you want to carry out descaling:

Press Esc to exit and return to the service menu

2 Boiler discharge phase:

You must wait for the boiler to drain completely

3 Reactant loading phase:

As per instructions, insert the reactant in the boiler via the appropriate inlet

4 Reactant working phase:

There is an indication of how much is left to the end of the phase.

The duration of this phase depends on the value of parameter P400 with default value: 360

minutes (6 Hours).

If you wish to use a different type of reactant you can change the value of this parameter.

With the ON/OFF key you can interrupt the “stand-by with reactant” phase to go directly

to the rinsing phase. In the event of no line power, upon reactivation the timer will restart

counting from the residual time left.

Page 42

42

TECHNICAL TRAINING COURSE

5 Rinsing phase:

In this phase, after having drained the reactant, 3 rinsing cycles are carried out in this manner:

a) Water loading with discharge open for 60 seconds.

b) Water loading for 20 seconds past the level.

c) Water discharge for 10 seconds below the level.

During the rinsing phase a lack of water may be diagnosed; in this case the procedure is

suspended and the following message appears:

By pressing the encoder button the procedure restarts from phase c) and if the lack of water

persists the water missing signal returns.

6 End of procedure

To exit and return to normal operation, press on the pop-up area of the touch screen, or press

Esc or the encoder key.

Decalcication request

To prevent the boiler being ruined because the user forgets to descale, there is a warning signal

every time the oven is switched on if over P404 hours of operation of the boiler have gone by

since the last descaling (default 250 hours). The following pop-up appears that can be removed

via key conrmation or touch screen:

Page 43

TECHNICAL TRAINING COURSE

43

6.2

At the end of a working day, clean the equipment, both for hygienic reasons and to avoid

malfunctionings.

The oven must never be cleaned using direct or high pressure water jets. In the same manner,

to clean the appliance do not use pan-scrubbers, steel brushes or scrapers; it is eventually

possible to use stainless steel wool, rubbing it in the direction of the sheets satin nish.

Manual cleaning

Wait for the cooking compartment to cool down.

Remove the side tray racks.

Remove the manually removable residues and place the removable parts inside dishwashers.

To clean the cooking compartment use soapy warm water. Subsequently, all interested surfaces

must be thoroughly rinsed, being careful to ensure no detergent residues remain.

To clean the oven external parts, use a damp cloth and a non-aggressive detergent.

CLEANING OVEN CAVITY

Automatic Washing System

In ovens equipped with Automatic washing function, the above described phases happen

automatically.

With this type of ovens, to perform washing, connect the pump oat to a detergent tank and

select Washing (See the instructions manual). The 4 automatic washing levels for the touch

screen version (Hard, Intense, Normal, Soft) are selected according to the cleaning necessary

to remove the cooking residue in the compartment (Hard=deep clean, for

very resistant dirt, Soft=light wash).

Washing can be interrupted at any moment, by pressing the button Start/Stop until loading

the detergent. After loading, one must wait for the washing cycle to nish.

To perform best results in automatic whashing system is recommended to use:

BKI OVEN CLEANER AND RINSE AGENT

Technician can inTerrupT The washing cycle by pressing The knob for 10

seconds and inserT password 222

Page 44

44

TECHNICAL TRAINING COURSE

6.3

CLEANING PANEL AIR FILTER

The lter is located under the

panel.

Pull it downward to remove it,

so the two clips unhook.

Separate the lter from the l-

ter holder and

wash it with water and soap.

Then reassam-

ble the lter in

the holder and

install it under

the oven panel.

Hi temp

6.4

the oven is more or less 13-14 mm with a new gasket.

see page 33

ADJUSTMENT OF THE HINGES AND THE CLOSING PIVOT OF THE DOOR

The door hinges must be adjusted to assure maximum

seal of the oven door during its functioning. It is possible

to adjust both the upper and lower hinges.

If required, to adjust the door seal, loosen the bolt

and move the door in wanted position. Once adjusted,

fasten the bolt again.

The door’s closing pin can be adjusted in depth to

eliminate any steam emissions during cooking.

It is possible to adjust pressure applied by the door

on the gasket by tightening the pin to increase or

loosening the pin to decrease it.

Once adjusted, fasten the bolt again ensuring to have

positioned the lock closing anchoring downwards.

The standard distance between door and front part of

Page 45

TECHNICAL TRAINING COURSE

45

6.5

6.6

CHANGING DOOR LIGHTS AND GLASS CLEANING

The door glass can be cleaned externally and internally.

For this purpose, turn the stop holding the internal

glass in position clockwise and, once the glass is opened, clean it with suitable detergent. Never use abra-

sive materials. The glass must be correctly closed and

locked in position by turning the stop anti-clockwise.

To replace the bulbs remove the protective glass and

replace the defective bulb with same type (Halogen 12

Volt).

WASHING SPRINKLER CLEANING

2. push up and

1.

4. 5. clean sprinkler

turn left

3. pull down

6. push up and

turn left

6. pull down to verify

it is xed

Page 46

46

TECHNICAL TRAINING COURSE

7.0

7.1

SPECIAL MAINTENANCE

BOILER OPENING AND CHECK

STEP 1:

turn the boiler bottom part to left and the upper part

to the right.

STEP 2:

Pull down the bottom part of the boiler

STEP 3:

Verify the probe status and clean the boiler with a

special product if needed.

Page 47

TECHNICAL TRAINING COURSE

47

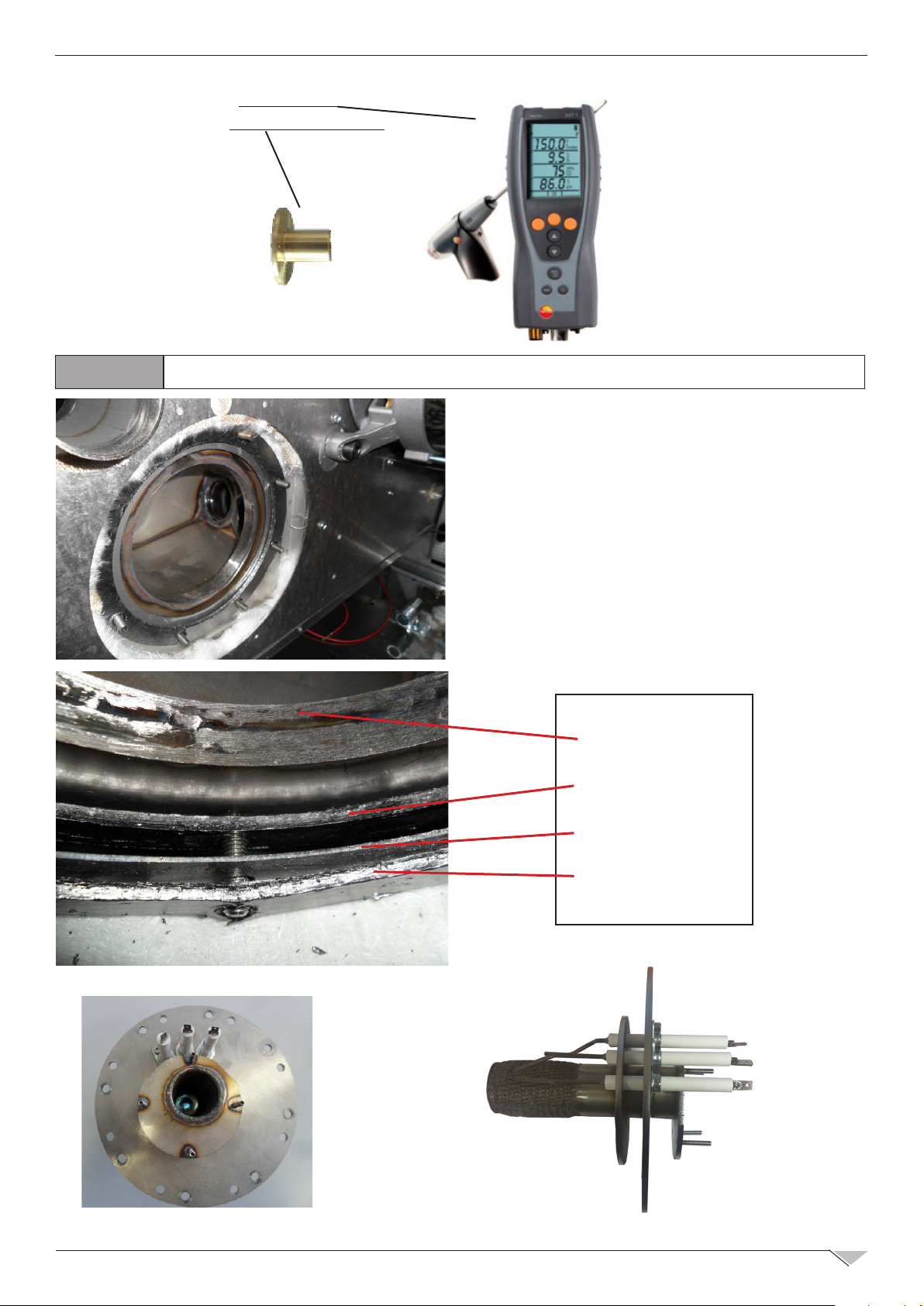

7.2

TOOLS SET

FANS REPLACEMENT

1.

Page 48

48

TECHNICAL TRAINING COURSE

2.

5. RIGHT SCREW

3.

6. LEFT SCREW

4.

7.

8.

9.

10.

Page 49

TECHNICAL TRAINING COURSE

49

11.

14.

12.

15.

13.

16.

17.

18.

19.

Page 50

50

TECHNICAL TRAINING COURSE

20.

23.

21.

24.

22.

26.

27.

25.

28.

29.

Page 51

TECHNICAL TRAINING COURSE

51

7.3

NECESSARY: SILICONE, CUTTER AND 1 NEW GASKET

2. CAREFULLY CLEAN THE SEAT OF THE GASKET

DOOR GASKET REPLACEMENT

1. REMOVE THE OLD GASKET

3. PREPARE THE SEAT WITH SILICONE ALL ALONG THE PERIMETER, IN ALL RIVETS AND

IN THE CORNERS

4. FIX THE NEW GASKET.

FIRST ON TOP

5. THEN ON THE BOTTOM

6. PUSH THE GASKET IN

SEAT ALL ALONG THE PERIMETER

Page 52

52

7. PULL THE GASKET IN ITS

SEAT OF ABOUT 2 mm.

LOWER SIDE ONLY

TECHNICAL TRAINING COURSE

8. CAREFULLY COVER THE LOWER FESSURE WITH SILICONE

9. CAREFULLY PUSH THE

GASKET BACK IN SEAT

7.4

COMPLETE DOOR HANDLE REPLACEMENT

10. CLEAN THE EXCEEDING

SILICONE

11. WAIT 8 HOURS WITH

DOOR OPENED

TOOLS NEEDED

Page 53

TECHNICAL TRAINING COURSE

53

1.

3.

2.

4.

5.

7.

6.

8.

Page 54

54

TECHNICAL TRAINING COURSE

8.0

ELECTRICAL DRAWINGS

LEGEND

C,C1,,, Capacitor

EU,EU1,EU2 Electrovalve for humidier

EA Steam kill solenoid valve

EL Washing electrovalve

ES Boiler discharge electrovalve

ESH Hand shower electrovalve

EV Boiler load electrovalve

EVG Gas solenoid valve

FM1,FM2 Motor thermic protection (incor.)

FU1,FU2… Fuse

FLC Filter E.M.C.

FR1,FR2… Cooling fan

FS1 Chamber safety thermostat

FS2 Bolier safety thermostat

IGN,IGN1,IGN2 Burner control

INV,INV1,INV2 Motor inverter

K0 Inverter line relay

KØA,KØB Auxiliary power line contactor

Keyboard Keyboard electronic card

KR1/3,…. Chamber resistance contactor

L1, L2 Chamber lighting lamp

M1, M2.. Motor

MB1,MB2.. Gas Blower

MS Discharge valve motorized

MV Humidity discharge valve

P1,P2.. Burner air pressure switch

PA Water pressure switch

PB Rinsing agent pump

PFC PFC

PD Detergent pump

PL Washing pump

PWM Gas blower speed control board

R1,R2…. Resistance

S0 Main switch

SC Chamber probe

SCHF Oven control electronic card

SP Door microswitch

SS Core Probe

SU1, SU2 Umidity probe

TR1 Trasformer 230V/12V, 12VA - 5VA

TR2,TR3 Trasformer 230V/24V AC

TRAL Chamber light trasformer 230V/12V AC

X./.. Power plug

Z1 Boiler level control probe

Page 55

TECHNICAL TRAINING COURSE

55

Page 56

56

TECHNICAL TRAINING COURSE

Page 57

TECHNICAL TRAINING COURSE

57

Page 58

58

TECHNICAL TRAINING COURSE

Page 59

TECHNICAL TRAINING COURSE

59

Page 60

60

TECHNICAL TRAINING COURSE

Page 61

TECHNICAL TRAINING COURSE

61

Page 62

62

ABTE062R

Rev. 00

Pg. 1/3

7

2

20

31

30

26

9

25

24

10

11

15

14

4

Pg.3

Pg.2

5

6

8

29

28

27

13

Pg.2

16

18

17

19

1

TECHNICAL TRAINING COURSE

9.0

SPARE PARTS EXPLODED VIEW

Page 63

TECHNICAL TRAINING COURSE

2

20

27

3

4

5

Pg 2

Pg 2

Pg. 3

6

8

13

14

22

15

29

19

21

23

28

31

30

1

SBHE061W

Rev. 02

Pg. 1/3

7

16

17

18

11

12

10

9

24

25

63

Page 64

64

ABTE062R

Rev. 00

Pg. 3/3

50

51

64

56

52

53

54

55

57

58

60

59

61

62

62

63

TECHNICAL TRAINING COURSE

Page 65

TECHNICAL TRAINING COURSE

ABTE062R

Rev. 00

Pg. 2/3

46

39

40

41

42

43

44

43

45

47

48

32 33 34 35 36

37

38

65

Page 66

66

26

18

19

23

24 25

ABTG062R

Rev. 00

Pg. 1/3

2

1

6

34

35

17

4

Pg.2

5

27

Pg.2

7

8

13

15

16

20

14

22

21

Pg.3

18

31

9

32

11

10

33

37

38

TECHNICAL TRAINING COURSE

Page 67

ABTG062R

Rev. 00

Pg. 3/3

57

58

59

60

61

62

66

67

68

69

71

27

27

64

63

65

70

TECHNICAL TRAINING COURSE

67

Page 68

68

ABTG062R

Rev. 00

Pg. 2/3

53

46

47

48

49

50

51