Page 1

Electric Pressure Fryer

MODELS FKM, FKM-F, & FKM-FC

SERVICE MANUAL

Serial Numbers 121836 and higher

Page 2

Warranty Information

LIMITED ONE YEAR WARRANTY

BKI (The “Company”) warrants to the original purchaser/user, that at time of shipment from the Company

factory, this equipment will be free from defect in materials and workmanship. Written notice of a claim

under this Warranty must be given within ONE YEAR AND THREE MONTHS from date of shipment from

the factory. Defective conditions caused by abnormal use or misuse, lack of maintenance, damage by

third parties, alterations by unauthorized personnel, acts of God, failure to follow installation instructions

or any other events beyond the control of the company will NOT be covered under Warranty. The

obligation of the Company under this Warranty shall be limited to repairing or replacing (at the option of

the company) any part which is defective in reasonable opinion of the Company. The user will have the

responsibility and expense of removing and returning the defective part to the Company as well as the

cost of reinstalling the replacement or repaired part.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, LOSS OF REVENUE OR

LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT OR CONSEQUENTIAL DAM AGES INCLUDING

BUT NOT LIMITED TO, FOOD SPOILAGE OR PRODUCT LOSS. WARRANTY DOES NOT COVER

GLASS BREAKAGE. THE ABOVE WARRANTY IS EXCLUSIVE AND ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY SHALL

APPLY ONLY WITHIN THE CONTINENTAL UNITED STATES, ITS TERRITORIES, AND

POSSESSIONS AND IN CANADA.

LIMITED NINETY DAY LABOR WARRANTY

All labor necessary to repair or replace factory defective parts will be performed, without charge, to the

end user, by service personnel of a BKI Authorized Distributor during the first ninety days after the date of

installation of the new equipment.

Replacement parts: Any appliance replacement part, except lamps and fuses, which proves to be

defective in material or workmanship within 90 days from date of original installation will be repaired or

replaced without charge F.O.B. Factory, Simpsonville, S.C. or F.O.B. authorized distributor.

Page 3

Electric Pressure Fryer Table of Contents

Table of Contents

Table of Contents........................................................................................................................................1

Introduction .................................................................................................................................................2

Safety Precautions....................................................................................................................................2

Safety Signs and Messages.................................................................................................................2

Specific Precautions.............................................................................................................................3

Safe Work Practices.............................................................................................................................3

Safety Labels........................................................................................................................................7

Installation ...................................................................................................................................................8

Unpacking and Handling...........................................................................................................................8

Assembly and Mounting ...........................................................................................................................8

Wiring........................................................................................................................................................8

Initial Test and Adjustment .......................................................................................................................9

Maintenance ..............................................................................................................................................10

Scheduled Maintenance.........................................................................................................................10

Safety Pop Valve Procedure..............................................................................................................11

Filtering Procedure.............................................................................................................................12

FKM-F and FKM-FC.......................................................................................................................12

FKM................................................................................................................................................13

Boil-Out Procedure.............................................................................................................................14

Filter Pad Replacement......................................................................................................................16

Troubleshooting......................................................................................................................................17

Replacement Parts....................................................................................................................................19

Assemblies..............................................................................................................................................19

Accessories.............................................................................................................................................38

Components............................................................................................................................................39

Wiring Diagrams........................................................................................................................................41

1

Page 4

Electric Pressure Fryer Introduction

Introduction

The FKM Pressure Fryer is compact, attractive and functional in design. It is constructed of a stainless

steel fryer pot for cleaning ease. Exclusive BKI patented features and safety devices offer flexibility,

efficiency and reliability plus PERFECTION IN PRESSURE FRYING!

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has

been built with care and dedication -- using the best materials available. Attention to the operating

instructions regarding proper installation, operation, and maintenance will result in long lasting

dependability to insure the highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

you have any questions, please contact your BKI Distributor. If they are unable to

answer your questions, contact the BKI Technical Service Department, toll free:

1-800-927-6887. Outside the U.S., call 1-864-963-3471.

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know a nd

understand the meaning of these instructions, signs, and messages . Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other spe cial

data.

2

Page 5

Electric Pressure Fryer Introduction

Specific Precautions

Lids for FKM Pressure Fryers manufactured prior to May 27, 1980 (or units with

serial numbers lower than 3613) could be manually opened while under pressure

resulting in serious injury or death. If you have one of these units, please contact

the BKI Technical Services Department toll-free at 1-800-927-6887 for urgent

update information.

Safe Work Practices

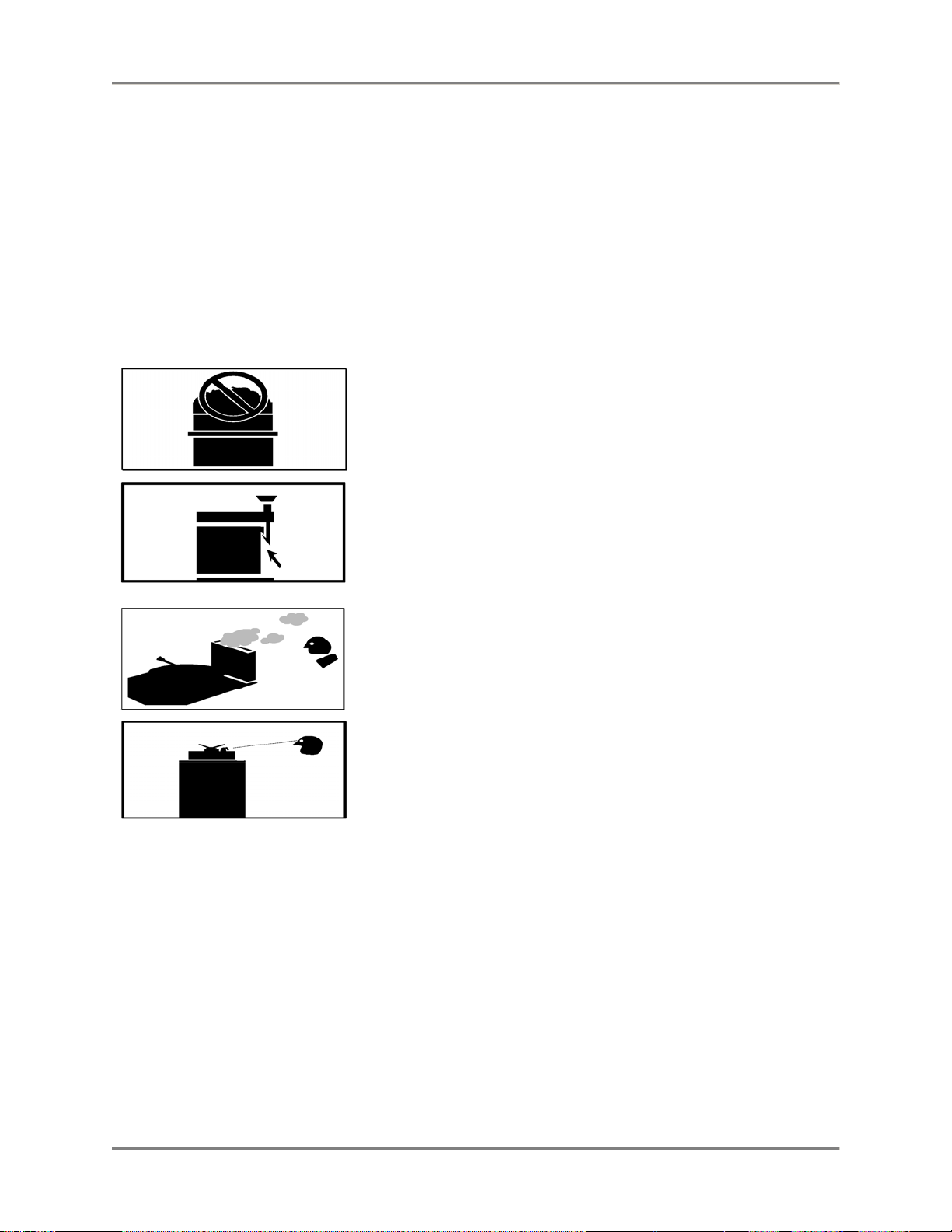

Noncombustible Floors Only

Make sure your floor is noncombustible. Do not operate your fryer

on floors that are wood, carpeted or have rubber mats.

• Placing your fryer on a combustible floor could cause a fire.

Serious injury could result.

• Examples of noncombustible floors where you can safely

Keep The Area Around Your Fryer Uncluttered

Make sure to keep the area around your fryer clear of any

obstacles.

Serious injury can occur if you trip or fall near the fryer. You could

be burned by hot shortening that splashes out of the fryer or by

falling against the hot metal of the fryer.

Keep The Floor Around Your Fryer Clean Of Shortening

Make sure to keep the floor around your fryer clean of shortening

and other liquids.

Serious injury can occur if you slip near your fryer. You could be

burned by hot shortening that splashes out of the fryer or by falling

against the hot metal of the fryer.

place your fryer are concrete, tile, and ceramic.

Keep The Lid Closed When The Fryer Is Not In Use

Hot shortening can splash if someone moves the fryer or bumps

into it. Serious injury can occur if hot shortening splashes out of the

fryer.

Do not lean, sit or stand on the fryer or perform any maintenance or

cleaning duties while the fryer or the shortening is hot. You could

be burned.

Keep The Casters Locked

To avoid spilling shortening, keep the casters locked. If any

shortening spills near your fryer, clean it up immediately.

3

Page 6

Electric Pressure Fryer Introduction

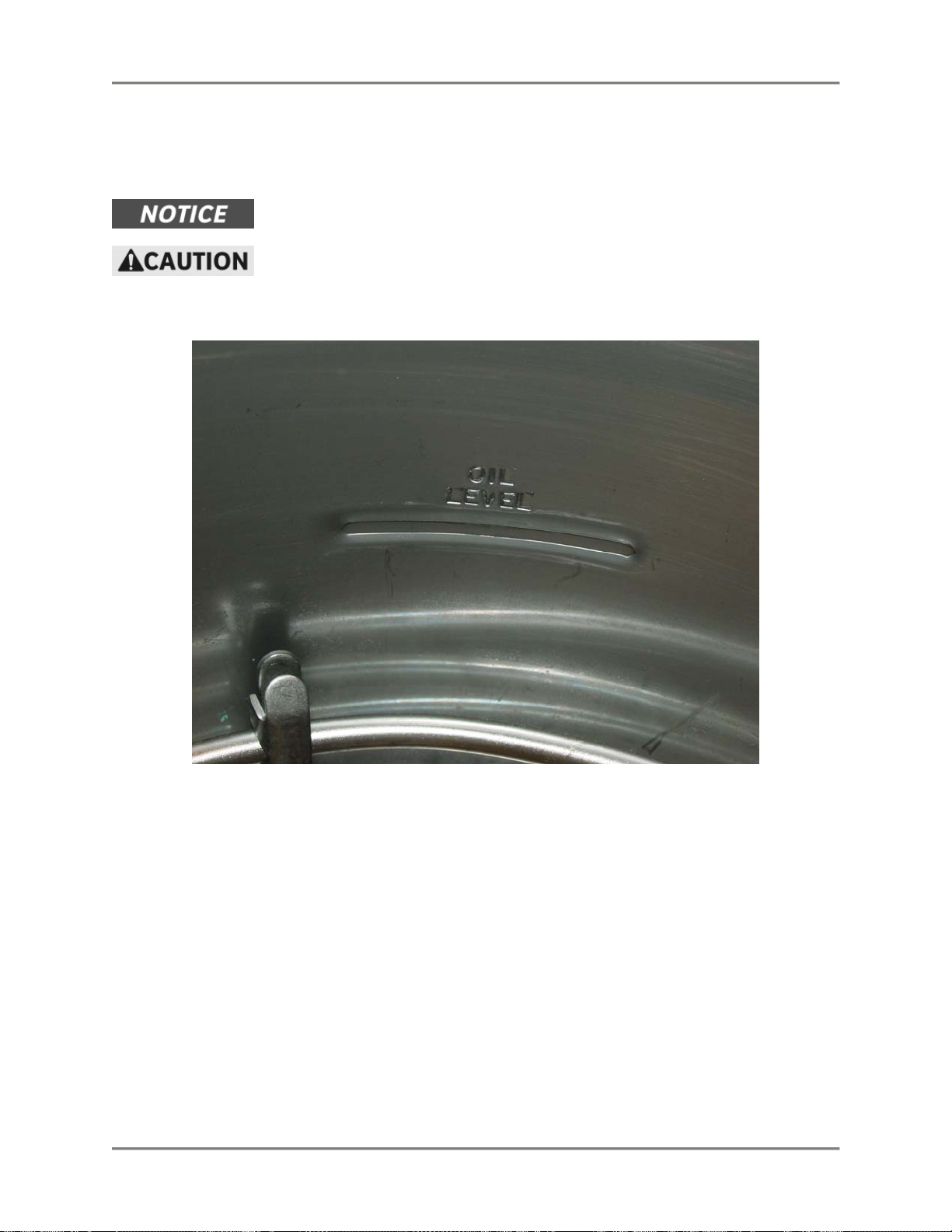

Do Not Overfill The Fryer With Shortening

Hot shortening and steam may escape and burn you if you put too

much shortening in the fryer. Fill the fryer to approximately one inch

below the fill marks that are inside the fryer pot. Heat the

shortening. If needed, carefully add more shortening to bring the

level to the fill marks.

Do Not Let Any Water Get Into The Fryer

Always remove excess moisture from food before placing it into the

fryer basket. Water will cause the hot shortening to spatter. You

could be burned.

Do Not Overload The Basket With Food

Hot shortening and steam may escape and burn you if you place

too much food in the basket.

Always Make Sure The Lid Hook Is Latched When Closing The

Fryer

To make sure the lid hook is latched properly, press down the lid

until the hook snaps shut. Hot shortening and steam can escape if

the lid hook is not latched properly. You could be burned.

Keep Away From The Vent

Hot steam escapes from the vent continuously when you are using

your fryer. You could be burned if you get too close to the vent.

Seal The Safety Valve Properly

To seal the safety valve, lift the arm on the side of the valve. Then

release it. The valve should snap closed. Hot steam can escape

from the valve and you could be burned if you do not seal the valve

properly.

Always Tighten The Spin Handle When Closing The Fryer

Hot shortening and steam can escape if you do not tighten the spin

handle properly. You could be burned. Line up the orange knobs on

the fryer lid handle and the front hook when tightening.

Do Not Over-Tighten The Spin Handle

You could damage the fryer.

4

Page 7

Electric Pressure Fryer Introduction

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling the fryer basket or

touch any hot metal surfaces. You received a pair of insulated mitts

with your fryer. If you lose or damage your mitts, you can buy new

ones at your local restaurant equipment supply store or from your

local BKI Distributor.

Always wear non-skid shoes when working around the fryer or any

other equipment that uses shortening. Never wear loose clothing

such as neckties or scarves while operating your fryer. Keep loose

hair tied back or in a hair net while operating your fryer.

Always wear appropriate personal protection equipment during the

filtering process to guard against possible injury from hot oil.

Always wear appropriate personal protection equipment during the

boil-out process to guard against possible injury from hot cleaning

solution.

Never Loosen The Spin Handle Until The Pressure Gauge Is At

Zero

Steam may escape suddenly if you loosen the spin handle before

the gauge is at zero. If steam escapes suddenly, you could be

burned.

After the pressure gauge is at zero, wait 5 seconds. Then loosen

the spin handle slowly to open the lid of the fryer. By doing this, the

steam will escape slowly and there is less change of being burned.

Always use extreme caution when working around the fryer with the

lid open.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it

near for easy access.

If you need to replace this manual, contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not

understand that this equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

5

Page 8

Electric Pressure Fryer Introduction

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep

all safety labels clean and in good condition. Replace any damaged

or missing safety labels. Refer to the Safety Labels section for

illustration and location of safety labels on this unit.

If you need a new safety label, obtain the number of the specific

label illustrated on page 7, then contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You

must use a 40-pound Type BC fire extinguisher and keep it within

25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services,

hospitals, and the fire department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the

equipment.

• Make certain your employees are aware of the safety

precautions on the equipment and in this manual.

• Make certain that you have thoroughly trained your employees

about operating the equipment safely.

• Make certain the equipment is in proper working condition. If you

make unauthorized modifications to the equipment, you will

reduce the function and safety of the equipment.

6

Page 9

Electric Pressure Fryer Introduction

Safety Labels

7

Page 10

Electric Pressure Fryer Installation

Installation

Serious injury, equipment damage or death could result if attempting to install

this fryer yourself. Ensure that an authorized BKI service agent installs the fryer.

Unpacking and Handling

It is the owners’ responsibility to file all freight claims with the delivering truck line. Inspect all cartons and

crates for damage as soon as they arrive. If damage to cartons or crates is found, or if a shortage is

found, note this on the bill of lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the delivering truck line and follow up

the call with a written report indicating concealed damage to your shipment. Ask for an immediate

inspection of your concealed damage item. Packaging material MUST be retained to show the inspector

from the truck line.

Assembly and Mounting

1. Remove the shipping packing clip from underneath the dead weight cap and discard.

2. Replace the dead weight and cover.

3. If your fryer has casters, lock them so the fryer does not move.

4. Clean the fryer pot before filling with shortening.

5. Place the DRAIN handle in the CLOSED position

Wiring

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs the electrical installation. Ensure that a licensed electrician

performs the electrical installation.

The fryer, when installed by an authorized BKI service agent, must be wired in accordance with local

codes, or in the absence of local codes, with the National Electrical Code, ANSINFPA 70-2002. You can

obtain this code from:

The National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

8

Page 11

Electric Pressure Fryer Installation

Initial Test and Adjustment

1. Fill pot with shortening to about one inch below the mark.

Use only high-quality shortening that has low moisture content, a high smoke

point and no additives.

Overfilling the fryer pot with shortening could lead to serious injury. Ensure that

the fryer pot is filled with shortening only to the fill mark when shortening is hot.

Do not use any shortening other than what is specified in this manual and do not

overfill the fryer pot.

2. Place the FILTER/OFF/FRY switch to the FRY position. The shortening should begin to heat and

begin to reach the fill mark inside the pot. Add more shortening as required to reach the fill mark.

Refer to the troubleshooting section if this does not occur.

9

Page 12

Electric Pressure Fryer Maintenance

Maintenance

Failure to comply with the maintenance below could result in a serious accident.

Do not over-tighten the spindle assembly. (Only tighten to hold pressure.)

Your fryer will need periodic maintenance and servicing. We strongly suggest

that you use only a service company that is authorized by BKI to do this work.

Scheduled Maintenance

Use the following table to help manage scheduled maintenance activities.

FREQUENCY PERFORMED BY PART ACTIVITY

Each Fry Cycle

Daily

Weekly

User Pressure Gauge Check for proper display of

cooking vat pressure. Contact

authorized BKI service agent if

adjustment or replacement is

required.

User Lid Gasket Check for unusual wear such

as cracks and deformation,

and pressure leaks. Contact

authorized BKI service agent if

adjustment or replacement is

required.

User Dead Weight

Assembly

User Filter Pad Replace filter pad. Refer to the

User Condensation

Pan

User Filter system Filter the shortening using the

User Safety Pop Valve Check for release of pressure

Clean weight and orifices daily

and check for wear.

procedure in this manual.

Remove and drain.

procedure in this manual.

and proper seal. Refer to the

procedure in this manual.

Every 6 Months

Authorized BKI

Authorized BKI

Authorized BKI

User Fryer Pot Perform the boil-out procedure

Authorized BKI

service agent

service agent

service agent

service agent

Acme Screw and

Nut

Solenoid Valve Check that the valve is holding

Hook, Catch,

Spring

Connections,

Fittings

10

in this manual.

Check for wear on the threads.

and releasing pressure when

the timer or computer activates

it.

Check for wear and ease of

operation.

Check for leakage while oil is

pumping.

Page 13

Electric Pressure Fryer Maintenance

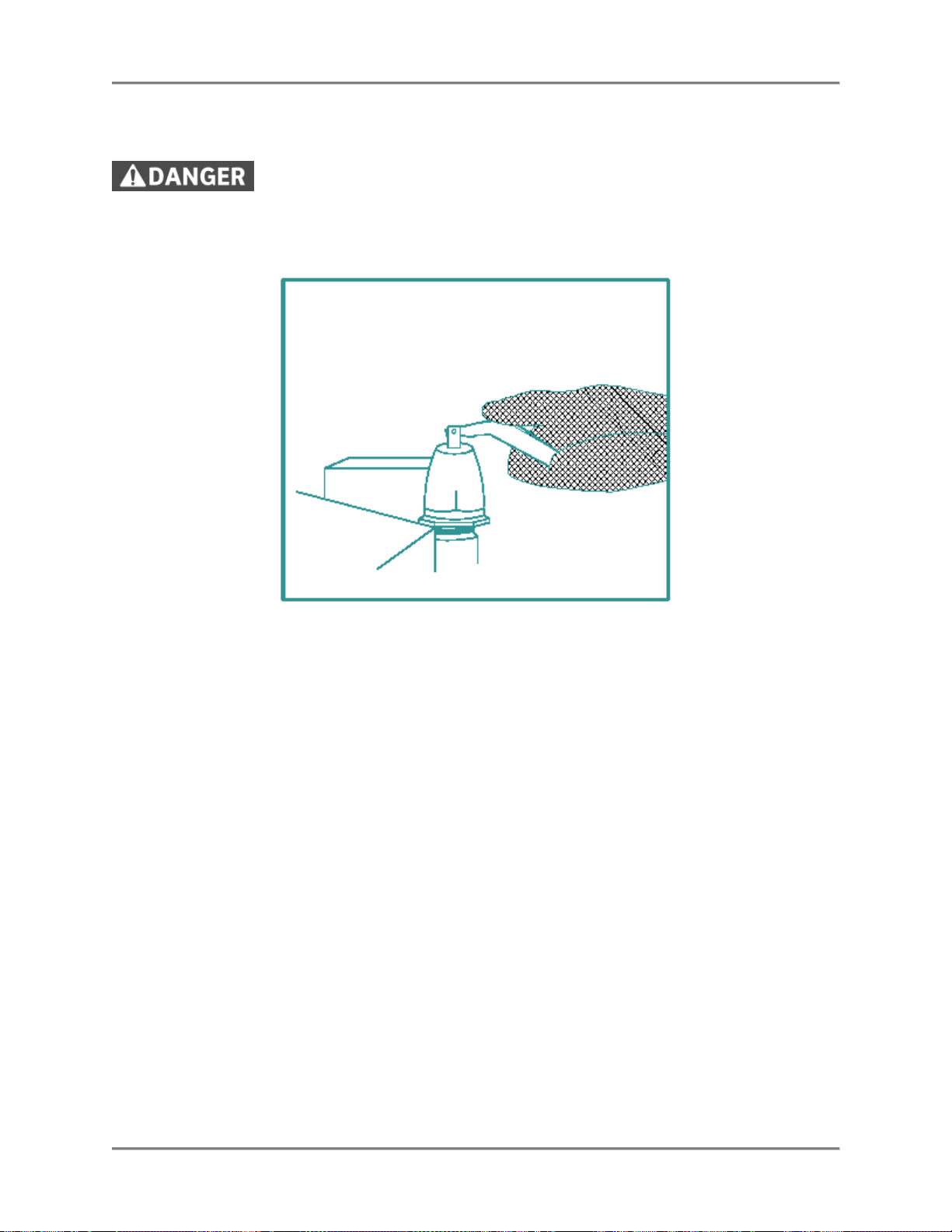

Safety Pop Valve Procedure

The safety pop valve should be blown under pressure periodically to prevent the seat from sticking.

Failure to use the insulated mitts will result in injury. Always use the insulated

mitts when handling the arm on the safety valve.

1. After the pressure is up during a cooking cycle, use the insulated glove to lift the arm on the edge

of the safety valve and let some steam escape. This will clean the valve.

2. Release the lever on the valve, and let it slam shut to seal the valve.

11

Page 14

Electric Pressure Fryer Maintenance

Filtering Procedure

Breaded foods require frequent filtering. An excess amount of breading left in the fryer pot will reduce the

life of the shortening. We recommend the shortening be filtered after every three frying cycle loads. When

the shortening starts to show signs of foaming and has a bad taste, do not use it. The fryer pot should be

cleaned before refilling with new shortening. Best results for filtering are obtained while the shortening is

hot. You should filter at the end of every business day. You should also remove and drain the

condensation pan daily.

Always wear appropriate personal protection equipment during the filtering

process to guard against possible injury from hot oil.

FKM-F and FKM-FC

1. Set the FILTER/OFF/FRY switch to OFF.

2. Remove the fryer basket.

3. Make certain that the filter pad is clean and not torn.

IMPORTANT: Make certain the vat cover is properly positioned underneath the drain valve.

Also make certain the filter vat and filter screen is under the main drain valve before starting

the filtering process.

4. Move the DRAIN handle slowly to the OPEN position so that the shortening starts to flow

evenly. This is to prevent excessive splashing of hot shortening.

5. When the pot is empty, place the DRAIN handle in the CLOSED position.

To refill the pot automatically, use the steps below:

Hot shortening may splash out of the pot causing severe injury when filling the

pot if the lid is not closed. To prevent shortening splashes, close the lid before

filling.

• Close the lid to prevent shortening splashes.

• Place the FILL handle to the THRU POT position.

• Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump

into the pot.

• After 1 minute carefully open the lid to check the level of the shortening.

• Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached

or until air starts bubbling through the shortening.

• As soon as air is seen in the shortening, first place the FILL handle to the THRU HOSE

position then position the FILTER/OFF/FRY switch to OFF to prevent shortening

degradation and prevent the filter pump and lines from filling up with shortening.

• Add new shortening if the fill mark has not been reached.

12

Page 15

Electric Pressure Fryer Maintenance

To refill the pot through the rinse hose, use the steps below:

• Make certain that the rinse hose is connected to rinse hose connector.

• Holding the hose by the handle, place hose nozzle inside the pot.

Hot shortening may splash out of the pot causing severe injury when filling the

pot if the lid is not held down over the hose nozzle. To prevent shortening

splashes, hold the lid down over the hose nozzle.

• Hold the lid down over the hose nozzle to prevent shortening splashes.

• Position the FILL lever in the THRU HOSE position.

• Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump

into the pot.

• After 1 minute, hold the hose by the handle and carefully raise the lid to check the level of

the shortening.

• Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached

or until air starts bubbling through the shortening.

• As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to

prevent shortening degradation.

• Add new shortening if the fill mark has not been reached.

FKM

1. Set the FILTER/OFF/FRY switch to OFF.

2. Remove the fryer basket.

3. Make certain that the FKF filter unit or portable filter unit filter pad is clean and not torn.

4. Position the FKF filter unit or portable filter unit under the main drain valve and make sure it’s

filter screen is in place.

5. Ensure that the FKF filter unit or portable filter unit is powered.

6. Move the DRAIN handle slowly to the OPEN position until the shortening starts to flow

evenly. This will prevent excessive splashing of hot shortening.

7. When the pot is empty, place the DRAIN handle in the CLOSED position.

To refill the pot through the drain valve, use the steps below:

• Make certain that the braided hose (located on the drain valve) is connected to it’s mating

part on the FKF filter unit or portable filter unit.

Hot shortening may splash out of the pot causing severe injury when filling the

pot if the lid is not closed. To prevent shortening splashes, close the lid before

filling.

• Close the lid to prevent shortening splashes.

13

Page 16

Electric Pressure Fryer Maintenance

• Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump

into the pot.

• After 1 minute carefully open the lid to check the level of the shortening.

• Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached

or until air starts bubbling through the shortening.

• As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to

prevent shortening degradation and prevent the filter pump and lines from filling up with

shortening.

• Add new shortening if the fill mark has not been reached.

To refill the pot through the rinse hose, use the steps below:

• Make certain that the rinse hose is connected to it’s mating part on the FKF filter unit or

portable filter unit.

• Holding the hose by the handle, place hose nozzle inside the pot.

Hot shortening may splash out of the pot causing severe injury when filling the

pot if the lid is not held down over the hose nozzle. To prevent shortening

splashes, hold the lid down over the hose nozzle.

• Hold the lid down over the hose nozzle to prevent shortening splashes.

• Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump

into the pot.

• After 1 minute, hold the hose by the handle and carefully raise the lid to check the level of

the shortening.

• Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached

or until air starts bubbling through the shortening.

• As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to

prevent shortening degradation.

• Add new shortening if the fill mark has not been reached.

Boil-Out Procedure

Boil-outs remove microscopic particles o f carbon that build up on the walls of the fryer pot. To avoid

eventual carbon build-up, off flavors, and shortening breakdown, boil-outs should be done once a week

on each fryer following these procedures.

Always wear appropriate personal protection equipment during the boil-out

process to guard against possible injury from hot cleaning solution.

1. Position the FILTER/OFF/FRY switch to OFF.

2. Drain the clean shortening into an adequate storage container. (Allow the shortening to cool to

room temperature before attempting storage.)

14

Page 17

Electric Pressure Fryer Maintenance

3. CLOSE the drain and fill the fryer pot with HOT water to the shortening level fill mark. Do not

overfill by allowing the water level higher than the fill mark.

4. Add ½ cup (4 ounces) of BKI cleaner.

5. Wash down the inside of the pot and lid with the pot brush to loosen the sediment.

6. Set the temperature of the solution as follows:

• For an FKM or FKM-F – Position the FILTER/OFF/FRY switch to ON. Set the thermostat to

a temperature of 190º F.

• For an FKM-FC – Position the FILTER/OFF/FRY switch to ON. Press PROG (program), type

1733, and press ENTER. The fryer pot will heat to a temperature of 190º F during the CLEAN

cycle to allow the CLEAN function to be performed. NOTE: The fryer pot must be below 255º

F to enter the CLEAN mode.

7. Bring the cleaning solution to a rolling boil and maintain the boil for 5 minutes.

8. Place the FILTER/OFF/FRY switch to OFF.

9. Scrub the inside of the fryer pot and inside of the lid again.

10. Before draining the cleaning solution, remove the filter bag, screen and pipe connections from

the filter vat. This must be done before draining the cleaning solution. NEVER pump water or

detergent through the filter system.

11. After 15 minutes, slowly open the drain valve. Drain the solution into the filter vat and discard.

12. Rinse the pot with hot water, using the pot brush to remove remaining sediment, drain and

discard.

13. Close the drain and refill the fryer pot with hot water to the proper level.

14. Add approximately 4 to 6 ounces of distilled (white) vinegar to develop a neutralizing solution. Stir

the solution briefly. Leave in the pot for three to five minutes and discard. NOTE: Foaming of

shortening after boil-outs is caused by failure to follow proper neutralizing procedures.

15. Repeat steps 12 through 14 as needed to remove all traces of cleaning solution.

16. Rinse the pot again with Cool water, drain and discard.

Damage to the fryer could result if the fryer pot is not completely dry before filling

with shortening. Refill the fryer pot with shortening ONLY when it is completely

dry.

17. Dry the fryer pot, lid, and filter vat COMPLETELY.

18. Close the main drain and fill with new shortening to the proper level.

15

Page 18

Electric Pressure Fryer Maintenance

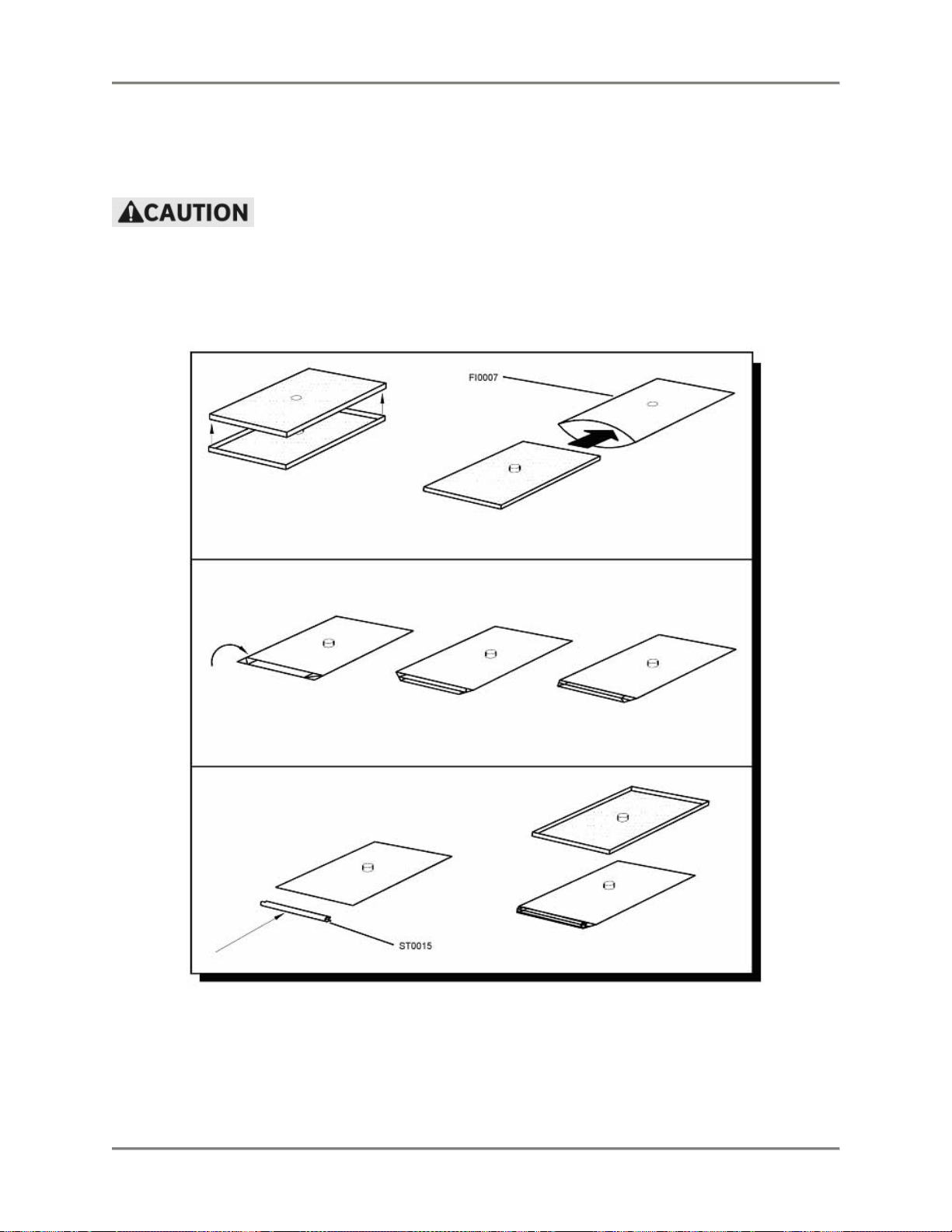

Filter Pad Replacement

The filter pad must be replaced daily. If the shortening has a milky color when it is pumped into the pot,

the filter pad should be replaced immediately.

If the filter pad is not properly closed, breading crumbs will get through the pad

opening and clog the pump. Ensure that the filter pad is properly closed upon

replacement.

1. Place the filter screen inside the filter pad.

2. Fold the end of the pad and seal with the bag clip.

16

Page 19

Electric Pressure Fryer Maintenance

Troubleshooting

Refer to the table below for troubleshooting information.

Problem Cause Possible Solution

Pressure Loss or Not Releasing

Pressure

Shortening Heating Too Slowly

Bad thermostat or loose

Weak heating elements or

Coil on contactor is bad Contact an authorized BKI

Breading build-up on heating

Filter System Not Working

Connections not tight Tighten the connections. If

Dead Weight Valve Leaking Clean the weight and orifice. If

problems persist, contact an

authorized BKI service agent for

corrective action.

Lid Gasket Leaking Contact an authorized BKI

service agent for corrective

action.

Solenoid Valve Leaking or

Stuck

Safety Valve not seating Contact an authorized BKI

Low voltage or improper

voltage

wires

heating elements breaking

down

elements

Uncertain Press the reset button on end of

After a period of time, it is

possible that the valve seat

and/or plunger may stick or wear.

Activate the valve by starting a

cook cycle. You should hear a

solid metallic CLICK sound from

the solenoid valve. If you should

hear no sound (or a slow

BUZZING CLICK), contact an

authorized BKI service agent for

corrective action.

service agent for corrective

action.

Contact an authorized BKI

service agent for corrective

action.

Contact an authorized BKI

service agent for corrective

action.

Contact an authorized BKI

service agent for corrective

action.

service agent for corrective

action.

Clean heating elements. If

problems persist, contact an

authorized BKI service agent for

corrective action.

pump and hi-limit reset button

under control panel. If problems

persist, contact an authorized

BKI service agent for corrective

action.

problems persist, contact an

authorized BKI service agent for

corrective action.

17

Page 20

Electric Pressure Fryer

Problem Cause Possible Solution

Filter valve not open Contact an authorized BKI

service agent for corrective

action.

Filter paper on screen

clogged with crumbs

Motor hums, but does not

pump

Motor and pump coupling

worn

No power to control panel Make sure drain valve is

Computer Hangs

Computer malfunction. Press and hold the Toggle/Clear

Change filter paper. If problems

persist, contact an authorized

BKI service agent for corrective

action.

Check for clogged pump. If

problems persist, contact an

authorized BKI service agent for

corrective action.

Contact an authorized BKI

service agent for corrective

action.

completely closed. If problems

persist, contact an authorized

BKI service agent for corrective

action.

button while moving the

FRY/OFF/FILTER switch from

FRY to OFF and back to FRY. If

problems persist, contact an

authorized BKI service agent for

corrective action.

18

Page 21

Electric Pressure Fryer Replacement Parts

Replacement Parts

Use the information in this section to identify replacement parts. To order replacement parts, call your

local BKI sales and service representative. Before calling, please note the serial number, model number

and voltage on the rating tag affixed to the unit.

Assemblies

Description Assembly # Figure # Table #

DEAD WEIGHT ASSEMBLY AN19104100 Figure 1 Table 1

DOOR ASSEMBLY SB1910

DRAIN/MOTOR/PIPING ASSEMBLY N/A Figure 3 Table 3

DRAIN VALVE & PLUGS SB1999S Figure 4 Table 4

DOMESTIC FRONT PANEL FKM/FKM-F

EUROPEAN FRONT PANEL FKM/FKM-F

FRONT PANEL FKM-FC AN19106400 Figure 6 Table 6

LID/TOP ASSEMBLY SB1992S Figure 7 Table 7

OIL VAT ASSEMBLY AN16010200 Figure 8 Table 8

QUICK DISCONNECT ASSEMBLY

DOMESTIC REAR PANEL FKM/FKM-F

EUROPEAN REAR PANEL FKM/FKM-F

REAR PANEL FKM-FC AN19106200 Figure 11 Table 11

SOLENOID VALVE AN19104300 Figure 12 Table 12

AN19108100

AN19108200

AN19103300

SB1997S

AN19106100

AN19106500

Figure 2

Figure 5 Table 5

Figure 9 Table 9

Figure 10 Table 10

Table 2

19

Page 22

Electric Pressure Fryer Replacement Parts

Figure 1. Dead Weight Assembly

Table 1. Dead Weight Assembly Parts

ITEM # PART # QTY DESCRIPTION

1 FT0395 1 PIPE, POPOFF VALVE BAFF BOX

2 FT0396 1 PIPE, DEAD WT TO BAFFLE BOX

3 O0001 1 ORIFICE, SS

4 O0002 1 GASKET, O-RING #2-222

5 PV0001 1 VALVE, POP SAFETY 1321148

6 FT0066 1 ELL, REDUCER 3/4 X 1/2 90 DEG

7 FT0235 1 NIPPLE, 1/2 X C SS

8 FT0190 1 ELL, STREET 1/4 90 DEG CP

9 FT0084 1 COUPLING, BRASS 1/4

10 FT0563 1 FITTING, COMPRESSION ¾”

11 FT0067 1 BUSHING, C110JO 3/4 X 1/2 CP

12 FT0234 1 NIPPLE, 1/4 X 1 1/2 SS 304

13 C0657 1 COVER, DEAD WEIGHT VALVE FKM

14 B0969 1 BODY, DEAD WEIGHT VALVE FKM

15 W0201 1 WEIGHT, VALVE FKM 12#

16 G0064 1 GAUGE, PRESSURE 30 PSI

20

Page 23

Electric Pressure Fryer Replacement Parts

Figure 2. Door Assembly

21

Page 24

Electric Pressure Fryer Replacement Parts

Table 2. Door Assembly Parts

ITEM # PART # QTY DESCRIPTION

1 F0083 2 THREAD INSERT 10-24 STEEL

2 ST0013 1 BRACKET, BRUSH HOLDER FKM, LPF,LGF

3 H0010 2 HINGE, LH PIN HALF

4 N0059 1 DECAL, SMALL BRUSH/

5 N0165 1 DECAL, NOTICE LOST MANUAL

6 N0527 1 DECAL, SAFETY INSTR FRYERS

7 N0175 1 DECAL, SLIPPING ADMONITIONS

8 N0176 1 DECAL, INSTR & SAFETY MANUAL

9 P0022 1 HANDLE, PULL SS P60-1010

10 RIV172 3 RIVET, 1/8 X 1/4 CS PLT POP

11 SB1951 1 INSIDE DOOR POCKET/MAGNET WELD FKM

12 SCR008 6 SCREW, 10 X 1/2 PHIL TRUSS HD

13 SCR383 2 SCREW, 10-24 X 1/2" PHIL TRUSS HD

14 WFKMA178 1 DOOR, FRYER OUTSIDE WELD

15 N0153 1 DECAL, FKM WARNING ACME SCREW

16 H0009 1 HINGE, DOOR,RH,PIN SIDE FRY.D OORS

22

Page 25

Electric Pressure Fryer Replacement Parts

Figure 3. Drain/Motor/Piping Assembly

23

Page 26

Electric Pressure Fryer Replacement Parts

Table 3. Drain/Motor/Piping Assembly Parts

ITEM # PART # QTY DESCRIPTION

1 MB19101000 1 DRAIN VALVE REPLACEMENT

2 FT0044 1 ELL, STREET 3/8 90 DEG BLACK

3 FT0412 2 NIPPLE, 3/8 NPT X 1 1/2 SCH 40

4 SB1314 1 BALL VALVE ASSY, FRYERS

5 FT0538 1 TEE, 1/2 X 1/2 X 3/8 BLK

6 FT0507 1 CONNECTOR, MALE 10FBU-S NKL PLTD

7 FT0536 3 COUPLING, 5/8 45¦ FLARE TO

8 FT0543 1 DRAIN VALVE BRACKET, FRYERS

9 TU0206 1 TUBING, 29" 1/2" ID

10 TU0205 1 TUBING, 12" 1/2" ID

11 P0070 1 PUMP ONLY FOR HAIGHT MOTOR

12 F0254 2 PIN, COTTER HAIRPIN #213

13 F0255 1 PIN, CLEVIS 3/16 X 1-1/4

14 F0253 1 PIN, CLEVIS 3/16 X 1 3/4

15 SP0014 2 SPACER, ALUM .5 X .125

16 SP0034 2 SPACER, DRAIN VALVE BRKT FRYERS

17 NUT253 2 NUT, 6-32 S/S 18-8 NYLON

18 F0158 1 BUSHING, BLK 1/2 HEYCO SNAP

19 LZ0130 1 SWITCH,ACT. COVER FKMA247

20 S0054 1 SWITCH, MICRO BZ-2RW822-A2

21 H0089 1 HANDLE SUPPORT PLA TE

22 N0285 1 DECAL, FKM-F DRAIN HNDL PLATE

23 SCR194 2 SCREW, 6-32 X 1 SL RD HD MS

24 H0215 1 HANDLE, DRAIN VALVE FKM BLF

25 C0672 1 COVER, DR A IN HAN DLE RED

26 SCR006 3 SCREW, 8 X 1/2 PHIL PAN HEAD

27 MA19100508 1 FILL VALVE HANDLE, FRYERS

28 C0668 1 COVER, FILL HANDLE BLACK

29 P0081 1 PLUG, F-H4F4-7-7 QUIK DISCONN

30 B0851 1 BUSHING, BLK HEX REDUCING

31 MA19100800 1 TUBING, TEE TO DISCONNECT

32 FT0132 1 ELL, STREET 1/2 90 DEG BLACK

33 M0053 1 MOTOR, LEESON LESS CORD/PUMP

24

Page 27

Electric Pressure Fryer Replacement Parts

Figure 4. Drain Valve & Plugs

Table 4. Drain Valve & Plugs Parts

ITEM # PART # QTY DESCRIPTION

1 MB19101000 1 DRAIN VALVE REPLACEMENT

2 FT0243 2 PLUG, 3/8" SQ HEAD PIPE

25

Page 28

Electric Pressure Fryer Replacement Parts

Figure 5. Domestic/European Front Panel FKM/FKM-F

Table 5. Domestic/European Front Panel FKM/FKM-F Parts

ITEM # PART # QTY DESCRIPTION

1 N0522 1 DECAL, CTL PNL FKM FKMF

2 S0104 1 SWITCH, RKR DPDT 15A 250V LAMP

3 TI0032 1 TIMER, 230V DIGITAL 4 BUTTON

4 PL0004 1 PILOT LIGHT, ROUND 250V

5 T0075 1 THERMOSTAT, SOLID STATE FRYER

6 K0040 1 KNOB, S/S STRAT T0075

26

Page 29

Electric Pressure Fryer Replacement Parts

Figure 6. Front Panel FKM-FC

Table 6. Front Panel FKM-FC Domestic Parts

ITEM # PART # QTY DESCRIPTION

1 N0524 1 DECAL,CTL PNL FKMFC

2 S0104 1 SWITCH, RKR DPDT 15A 250V LAMP

3 CP0039 1 CONTROLLER, VFD LESS HARNESS

27

Page 30

Electric Pressure Fryer Replacement Parts

Figure 7. Lid/Top (sheet 1 of 4)

28

Page 31

Electric Pressure Fryer Replacement Parts

Figure 7. Lid/Top (Sheet 2 of 4)

29

Page 32

Electric Pressure Fryer Replacement Parts

Figure 7. Lid/Top (Sheet 3 of 4)

30

Page 33

Electric Pressure Fryer Replacement Parts

Figure 7. Lid/Top (Sheet 4 of 4)

31

Page 34

Electric Pressure Fryer Replacement Parts

Table 7. Lid/Top Parts

ITEM # PART # QTY DESCRIPTION

Figure 7 (sheet 1) SB1992S LID/TOP

Figure 7 (sheet 2) SB3481 1 HANDLE ASSY, SPIN

1 FT0332 3 STUD, 5.5” TIGHTEN DN HN

2 K0003 2 KNOB, BLACK #85C

3 K0020 1 HUB, TIGHTEN DOWN

4 K0043 1 KNOB, ORANGE

Figure 7 (sheet 3) AB19103900 1 ARM ASSY, FKM

1 A0120 1 ARM COMPLETE FKM LGF

2 H0155 1 HANDLE, BLK DELRIN FKM LPF LGF

3 P0094 1 PIN, HOOK FKM, LPF, LGF

4 H0024 1 HOOK, LID 1018 ALLOY

5 K0043 1 KNOB, ORANGE

6 N0160 1 DECAL, WARNING BEFORE USING

7 NUT128 2 NUT, 5/16-18 SS 18-8 CAP

8 S0091 1 SPRING, HOOK LGF LPF FKM

9 SCR122 2 SCREW, 1/4-20 X 1/2 FLAT HD

10 SCR259 2 SCREW, 1/4-20 X 1/2 PHIL RD HD

11 TB0020 1 BUSHING, BRONZE 1"

12 H0156 2 HANDLE SIDE FOR H0155 FKM LPF LGF

13 WSH045 2 WASHER, 5/16 LOCK ZINC PLTD

14 WSH102 2 WASHER, 1/4 INT LOCK

15 FT0407 1 PLUG, HOLE 3/8" SHORT PRONG

16 F0026 1 ROLL PIN, 5/32 X 3/4

Figure 7 (sheet 4) SB1989 1 LID LOCKING ASSY W/INSERT FKM

1 F0353 1 PIN, LOCKING FKM LGF LPF

2 G0016 1 GASKET, FKM LID BONDED SILICON

3 S0155 1 SPRING, LOCKING PIN W/LID INSERT

4 B0857 1 BUSHING, BRONZE 3/8X9/16X5/8

5 P0115 1 LID INSERT, FKM

6 FK0010 1 LID, FKM CAST ALUM

7 C0674 1 LID COVER AND ARM GUIDE FKM

8 F0107 1 LOCK KEY PIN, FRYERS

9 FKMA016 1 PIN, HINGE

10 FKMA152 1 KEY, TIGHTEN DOWN SCREW

11 FKMA201 1 PLATE, TIGHTEN DOWN FKM

12 FT0049 2 COLLAR, 1/2" SET BRIGHT

13 N0153 1 DECAL, FKM WARNING ACME SCREW

14 N0345 1 DECAL, HOOK LID INSTRUCTIONS

15 SCR383 2 SCREW, 10-24 X 1/2" PHIL TRUSS HD

16 SCR176 2 SCREW, 8-32 X 3/8 SLOT BINDING

17 SCR178 1 SCREW, 5/16-18 X 1 FLAT HD

18 TB0021 1 TIGHTEN DOWN BASE COLD ROLLED

19 TC0003 1 COLLAR, THREADED SHAFT

20 TC0005 1 COLLAR, LOCKING RING

21 TS0010 1 SCREW, TIGHTEN DOWN

22 S0071 1 SPRING, TORSION

23 LZ0107 1 PLATE, LID FOR LOCKING DEVICE

32

Page 35

Electric Pressure Fryer Replacement Parts

Figure 8. Oil Vat Assembly

33

Page 36

Electric Pressure Fryer Replacement Parts

Table 8. Oil Vat Assembly Parts

ITEM # PART # QTY DESCRIPTION

1 SB1991 1 QUIK DISCONNECT BRACKET WELDMENT

2 O0013 1 O-RING, FLUOROCARBON V680-70

3 WB16010600 1 FILTER VAT WELD QUIK DISC

4 WB16010400 1 FILTER VAT TUBE WELD, BLF

5 SB7659 1 FILTER SCREEN FITTING SPOTWELD

6 FS0003 1 FILTER SCREEN, TOP

7 FS0002 1 FILTER SCREEN, INTERCEPTOR

8 FS0001 1 FILTER SCREEN, BOTTOM

9 FKMA357 1 COVER, FILTER VAT

10 FC0004 1 NUT SCREEN RETAINING FKM-F &

11 N0395 1 DECAL, VAT COVER SAFETY WARN

12 SB7675 1 CRUMB BASKET WELD, LG VAT ASSY

Figure 9. Quick Disconnect Assembly

Table 9. Quick Disconnect Assembly Part s

ITEM # PART # QTY DESCRIPTION

1 B0996 1 BALL, 11/16" STEEL BEARING

2 FT0429 1 QUICK DISCONNECT, PUMP SIDE

3 FT0500 1 QUICK DISCONNECT, VAT SIDE

4 FT0536* 1 COUPLING, 5/8 45¦ FLARE TO

5 O0013 2 O-RING, FLUOROCARBON V680-70

6 O0014 1 O-RING, PARKER #2-124 LARGE

7 S0138 1 SPRING, FOR QUICK DISCONNECT

8 SCR4531* 2 SCREW, #10 24X3/8" WASHERED

* - Not included with SB1997S

34

Page 37

Electric Pressure Fryer Replacement Parts

Figure 10. Domestic/European Rear Panel FKM/FKM-F

Table 10. Domestic/European Rear Panel FKM/FKM-F Parts

ITEM # PART # QTY DESCRIPTION

1 T0036 1 THERMOSTAT, HI LIMIT 540 DEG

2 TB0064 1 TERM BLOCK 4 CONDUCTOR CTR

3 TB0065 2 TERM BLOCK 4 CONDUCTOR W/MTG FOOT

4 TB0068 1 TERM BLOCK END PLATE

5 TB0069 1 TERM BLOCK JUMPER BAR (not shown)

6 R0148 1 RELAY, 3 POLE 42CF35AG

7 F0158 1 BUSHING, BLK 1/2 HEYCO SNAP

8 F0097 2 FUSE, 15A 300V SC15 TIME DELAY

9 R0134 3 RELAY, MERCURY MDI 60NO220A

10 F0154 2 BUSHING, BLK 1-3/16 HEYCO SNAP

11 F0342 3 CLAMP, CABLE 3/16"

12 FH0001 2 FUSE HOLDER, 15A 300V HPF-EE

13 FT0080 1 CONNECTOR, BOX #7483 1"

14 FT0277 1 PLUG, HOLE 7/8" (1/2" CONDUIT)

35

Page 38

Electric Pressure Fryer Replacement Parts

Figure 11. Rear Panel FKM-FC

Table 11. Rear Panel FKM-FC Parts

ITEM # PART # QTY DESCRIPTION

1 T0036 1 THERMOSTAT, HI LIMIT 540 DEG

2 R0148 1 RELAY, 3 POLE 42CF35AG

3 TB0064 1 TERM BLOCK 4 CONDUCTOR CTR

4 TB0065 2 TERM BLOCK 4 CONDUCTOR W/MTG FOOT

5 TB0068 1 TERM BLOCK END PLATE

6 R0134 3 RELAY, MERCURY MDI 60NO220A

7 W0054 1 TRANSFORMER ASSY 240V

8 TB0069 1 TERM BLOCK JUMPER BAR (not shown)

9 F0154 2 BUSHING, BLK 1-3/16 HEYCO SNAP

10 R0044 2 RELAY, X-40, SGL FRYER

11 F0097 2 FUSE, 15A 300V SC15 TIME DELAY

12 F0158 1 BUSHING, BLK 1/2 HEYCO SNAP

13 F0342 3 CLAMP, CABLE 3/16"

14 FH0001 2 FUSE HOLDER, 15A 300V HPF-EE

15 FT0080 1 CONNECTOR, BOX #7483 1"

16 FT0277 1 PLUG, HOLE 7/8" (1/2" CONDUIT)

36

Page 39

Electric Pressure Fryer Replacement Parts

Figure 12. Solenoid Valve Assembly

Table 12. Solenoid Valve Assembly Parts

ITEM # PART # QTY DESCRIPTION

1 FT0249 1 CONNECTOR, 3/8 STR FLEX LIQUIDTITE

2 FT0396 1 PIPE, DEAD WT TO BAFFLE BOX

3 SV0001 1 VALVE, SOLENOID HV-214-761-2 240V

4 FT0563 1 FITTING, COMPRESSION ¾”

37

Page 40

Electric Pressure Fryer Replacement Parts

Accessories

Description Accessory # Figure # Item #

BASKET, LARGE FKM BAIL HANDLE B0114 Figure 13 1

BRUSH, DRAIN (LONG WHITE) B0075 Figure 13 2

BRUSH, L TIPPED 40152 B0063 Figure 13 3

BRUSH, LONG #5702 B0051 Figure 13 4

BRUSH, POT SCRUBBER, WHITE B0049 Figure 13 5

BRUSH, SHORT #6175 B0052 Figure 13 6

CORD SET, FKM-FC 7' SB7655 Figure 13 7

FILTER HOSE, FEMALE SOCKET SB2332 Figure 13 8

FILTER VAT DOLLY FKM-F SB7650 Figure 13 9

INSULATED MITT 13" G0052 Figure 13 10

Figure 13. Accessories

1 2 3

4 5 6

7 8 9

10

38

Page 41

Electric Pressure Fryer Replacement Parts

Components

Description Component # Figure # Item #

ARM ADJUSTABLE STOP /FKM A0101 Figure 14 1

BAFFLE BOX ASSEMBLY AN19102800 Figure 14 2

BRACKET, CALROD FKMA258 LZ0006 Figure 14 3

CALROD, 208V 5675W FKM-F C0030 Figure 14 4

CALROD, 240V 5675W FKM-F C0031 Figure 14 5

CASTER, W/TOP PLATE 5" C0406 Figure 14 6

CLAMP, HOSE #6207 #4 HF0009 Figure 14 7

COLLAR, 1/2" SET BRIGHT FT0049 Figure 14 8

CONDENSATION PAN WELDMENT WFKMA341 Figure 14 9

DRAIN PIPE, CONDENSATE FKM FKMA260 Figure 14 10

FILTER, FKM-F 13.5 X 20.5 FI0007 Figure 14 11

OUTLET BOX, (ON FKM ONLY FOR POWERING FKF) SB1953 Figure 14 12

PROBE ASSEMBLY KIT, COMPUTER SB1938 Figure 14 13

SEMI AUTOMATIC HOSE ASSEMBLY (FKM only) SB1990 Figure 14 14

SIDE CABINET, L&R FKM/DNF FKMA399 Figure 14 15

SLIDE, UHMW U-SHAPE .5 X 1/8ID S0106 Figure 14 16

STRIKER PLATE (DOOR CATCH) FKMA167 Figure 14 17

SWITCH, ACT. COVER FKMA247 LZ0130 Figure 14 18

THERMISTER PROBE/FTGS ASSEMBLY SB7656 Figure 14 19

BRACKET BACK PLATE FKMA259 LZ0007 Figure 14 20

FILTER BAG CLIP FKM-F ST0015 Figure 14 21

Figure 14. Components

1 2 3

4 5 6

39

Page 42

Electric Pressure Fryer Replacement Parts

7 8 9

10 11 12

13 14 15

16 17 18

19 20 21

40

Page 43

Electric Pressure Fryer Wiring Diagrams

Wiring Diagrams

Refer to the table below to find the wiring diagram associated with your unit.

Wiring Diagram Figure # Page #

Domestic FKM & FKM-F 208V/220V/240V Figure 15 42

European FKM & FKM-F 220V/380V, 230V/400V, 240V/415V Figure 16 46

FKM-FC 208V/220V/240V Figure 17 50

FKM-FC 220V/380V, 230V/400V, 240V/415V Figure 18 54

41

Page 44

Electric Pressure Fryer Wiring Diagrams

Figure 15. Domestic FKM & FKM-F 208V/220V/240V (Sheet 1 of 4)

42

Page 45

Electric Pressure Fryer Wiring Diagrams

Figure 15. Domestic FKM & FKM-F 208V/220V/240V (Sheet 2 of 4)

43

Page 46

Electric Pressure Fryer Wiring Diagrams

Figure 15. Domestic FKM & FKM-F 208V/220V/240V (Sheet 3 of 4)

44

Page 47

Electric Pressure Fryer Wiring Diagrams

Figure 15. Domestic FKM & FKM-F 208V/220V/240V (Sheet 4 of 4)

45

Page 48

Electric Pressure Fryer Wiring Diagrams

Figure 16. European FKM & FKM-F 220V/380V, 230V/400V, 240V/415V (Sheet 1 of 4)

46

Page 49

Electric Pressure Fryer Wiring Diagrams

Figure 16. European FKM & FKM-F 220V/380V, 230V/400V, 240V/415V (Sheet 2 of 4)

47

Page 50

Electric Pressure Fryer Wiring Diagrams

Figure 16. European FKM & FKM-F 220V/380V, 230V/400V, 240V/415V (Sheet 3 of 4)

48

Page 51

Electric Pressure Fryer Wiring Diagrams

Figure 16. European FKM & FKM-F 220V/380V, 230V/400V, 240V/415V (Sheet 4 of 4)

49

Page 52

Electric Pressure Fryer Wiring Diagrams

Figure 17. FKM-FC 208V/220V/240V (Sheet 1 of 4)

50

Page 53

Electric Pressure Fryer Wiring Diagrams

Figure 17. FKM-FC 208V/220V/240V (Sheet 2 of 4)

51

Page 54

Electric Pressure Fryer Wiring Diagrams

Figure 17. FKM-FC 208V/220V/240V (Sheet 3 of 4)

52

Page 55

Electric Pressure Fryer Wiring Diagrams

Figure 17. FKM-FC 208V/220V/240V (Sheet 4 of 4)

53

Page 56

Electric Pressure Fryer Wiring Diagrams

Figure 18. FKM-FC 220V/380V, 230V/400V, 240V/415V (Sheet 1 of 4)

54

Page 57

Electric Pressure Fryer Wiring Diagrams

Figure 18. FKM-FC 220V/380V, 230V/400V, 240V/415V (Sheet 2 of 4)

55

Page 58

Electric Pressure Fryer Wiring Diagrams

Figure 18. FKM-FC 220V/380V, 230V/400V, 240V/415V (Sheet 3 of 4)

56

Page 59

Electric Pressure Fryer Wiring Diagrams

Figure 18. FKM-FC 220V/380V, 230V/400V, 240V/415V (Sheet 4 of 4)

57

Page 60

P.O. Box 80400, Simpsonville, S.C. 29680-0400, USA

http://www.bkideas.com

Made and printed in the U.S.A

LI0192/0504

Loading...

Loading...