Page 1

CS-TM-049.01 Revised 05/04/2018

Gas Pressure Fryer

MODELS FKG-TC

Service Manual

Page 2

Page 3

Gas Pressure Fryer Table of Contents

2

BKI LIMITED WARRANTY

2812 Grandview Dr. • Simpsonville, SC 29680 • USA

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the

original purchaser providing that:

The equipment has not been accidentally or intentionally damaged, altered or misused;

The equipment is properly installed, adjusted, operated and maintained in accordance with national and

local codes, and in accordance with the installation and operating instructions provided with this product.

The serial number rating plate affixed to the equipment has not been defaced or removed.

WHO IS COVERED This

warranty

is

extended

to the original

purchaser

and applies only to

equipment purchased

for

use in the U.S.A.

COVERAGE PERIOD

Warranty claims must be received in writing by BKI within one (1) year from date of

installation or within one (1) year and three (3) months from data of shipment from the factory,

whichever comes first.

COB Models: One (1) Year limited parts and labor.

COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a two (2) year

door warranty.

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door warranty.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after

shipment date from BKI, whichever comes first.

WARRANTY COVERAGE This

warranty

covers on-site labor, parts and

reasonable

travel

time

and travel e

xpenses

of the

authorized

service

representative

up to (100) miles

round

trip and (2)

hours

travel time and

performed

during regular, weekday business hours.

EXCEPTIONS Any exceptions must be pre-approved in advance and in writing by BKI. The extended door warranty on

convection ovens years 3 through 5 is a parts only warranty and does not include labor, travel, mileage or

any other charges.

EXCLUSIONS

Negligence

or acts of

God,

Thermostat calibrations

after (30) days

from equipment installation date,

Air and gas

adjustments,

Light

bulbs,

Glass doors and

door adjustments,

Fuses,

Adjustments

to

burner

flames and

cleaning of

pilot

burners,

Tightening

of screws or

fasteners,

Failures

caused

by erratic

voltages

or gas

suppliers,

Unauthorized

repair by

anyone other than

a BKI F

actory Authorized

Service Center,

Damage

in

shipment,

Alteration,

misuse or

improper installation,

Thermostats

and safety valves with

broken

capillary tubes,

Freight –

other than normal UPS charges,

Ordinary

wear and

tear,

Failure to follow

installation and/or operating instructions,

Events

beyond control

of the

company.

INSTALLATION Leveling, as well as

proper installation

and check out of all

new equipment -

per

appropriate

installation

and use materials – is the responsibility of the

dealer

or installer, not the

manufacturer.

REPLACEMENT PARTS

BKI genuine

Factory OEM parts receive a (90) day

materials warranty

effective from the date of

installation

by a BKI F

actory Authorized

Service

Center

Warranty

is in lieu of all

other warranties, expressed

or implied, and all

other obligations

or liabilities

on the

manufacturer’s

part. BKI shall in no

event

be liable for any

special, indirect

or

consequential

damages,

or in any

event

for

damages

in excess of the

purchase

price of the unit. The repair or

replacement

of

proven defective

parts shall

constitute a

fulfillment of all

obligations under

the terms

of this

warranty.

.

Page 4

Gas Pressure Fryer Table of Contents

1

Table of Contents

Table of Contents ...............................................................................................................................................1

Introduction ........................................................................................................................................................2

Safety ...............................................................................................................................................................2

Safety Signs and Messages ........................................................................................................................2

Specific Precautions ....................................................................................................................................3

Equipotential ground plane .....................................................................................................................3

Full Disconnection ...................................................................................................................................3

Safe Work Practices ....................................................................................................................................4

Installation ....................................................................................................................................................... 10

Operation ......................................................................................................................................................... 11

Start-Up (FKG-TC) ........................................................................................................................................ 11

Product Programming ................................................................................................................................... 14

Set Oil Temp ................................................................................................................................................. 18

Set Clock ....................................................................................................................................................... 19

Settings ......................................................................................................................................................... 20

Frying Log ..................................................................................................................................................... 21

Machine Log ................................................................................................................................................. 22

Import/Export ................................................................................................................................................ 23

Change Code ................................................................................................................................................ 26

System I/O .................................................................................................................................................... 27

Cap Touch .................................................................................................................................................... 29

Options .......................................................................................................................................................... 30

Screen ........................................................................................................................................................... 31

Maintenance .................................................................................................................................................... 33

Scheduled Maintenance ............................................................................................................................... 33

Safety Pop Valve Procedure .................................................................................................................... 34

Troubleshooting ............................................................................................................................................ 35

Gas Alarm ................................................................................................................................................. 36

Filter Pump Reset ..................................................................................................................................... 36

Replacement Parts .......................................................................................................................................... 38

Assemblies .................................................................................................................................................... 38

Components.................................................................................................................................................. 55

Accessories ................................................................................................................................................... 57

Wiring Diagram ................................................................................................................................................ 59

Notes ................................................................................................................................................................ 60

Page 5

Gas Pressure Fryer Introduction

2

Introduction

The FKG Pressure Fryer is compact, attractive and functional in design. It is constructed of a stainless steel

fryer pot for cleaning ease. Exclusive BKI patented features and safety devices offer flexibility, efficiency and

reliability plus PERFECTION IN PRESSURE FRYING!

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has

been built with care and dedication -- using the best materials available. Attention to the operating instructions

regarding proper installation, operation, and maintenance will result in long lasting dependability to insure the

highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you

have any questions, please contact your BKI Distributor. If they are unable to answer

your questions, contact the BKI Technical Service Department, toll free: 1-800-927-

6887. Outside the U.S., call 1-864-963-3471.

Safety

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol. When

you see this symbol on your equipment, be alert to the potential for personal injury or property damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know and understand

the meaning of these instructions, signs, and messages. Damage to the equipment, death or serious injury to

you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe

practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other special data.

Page 6

Gas Pressure Fryer Introduction

3

Specific Precautions

Risk of fire exists if the oil level drops below 5mm of the maximum oil level.

Use of oil/shortening older than the manufacturer’s recommendations for life of

the oil is prone to surge boiling and flash fires. Follow the oil manufacturer’s

guidelines for the life cycle of oil/shortening.

Do not open the drain valve or the fill valve while the fryer is under pressure.

Serious burns may result.

The appliance and its individual shutoff valve must be disconnected from the gas

supply system during any pressure testing of that system at test pressures in

excess of ½ psi (3.5 kPa).

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operation and

maintenance instructions thoroughly before installing or servicing this equipment.

Follow instructions regarding effects of surge boiling of over-wet foods and

proper load size.

Equipotential ground plane

When a high current flows through a conductor, differences in potential appear

between the conductor and nearby metallic surfaces near the appliance. As a

result, sparks may be produced between the appliance and surrounding metal

surfaces. These sparks could cause serious injury, damage, or fire.

BKI provides an Equipotential ground terminal for the connection of a bonding

conductor after the installation of the appliance per lEC60417-1. This terminal is

located on the inside of the Power Entry Supply box near the Earth connection

and is marked with this symbol.

Full Disconnection

In accordance with Local and/or National wiring codes, the installer must provide

a means of full disconnection under over voltage Category III conditions. An IEC

approved cord and plug combination will meet this requirement.

Units not provided with a cord and plug do not meet this requirement. In

accordance with Local and/or National wiring codes, the installer must provide

the means of full disconnection.

The fryer is designed to hold a maximum of 75lbs (34KG) of oil/shortening.

The purchaser must post, in a prominent location, instructions to be followed in

the event the user smells gas. This information shall be obtained by consulting

the local gas supplier.

Page 7

Gas Pressure Fryer Introduction

4

Safe Work Practices

Do Not Store or Use Anything Flammable

Near the Fryer

Your pressure fryer is powered by either natural gas or LP gas. Do

not store or use gasoline or any flammable liquids or vapors near

this or any other appliance. Flammable materials will burn easily.

Letting any flammable liquid or vapor get too close to the fryer

could cause an explosion or fire. Serious injury could result.

Examples of flammables that you should not store near the fryer

are gasoline, paint, thinners or removers, gas tanks, and cleaning

materials.

Use Gas Safely-- Avoid Danger

Gas can be a dangerous fuel if not handled safely.

Make sure to ventilate the fryer properly. If the fryer is not properly

ventilated, carbon monoxide can be released around the fryer.

Asphyxiation or suffocation can occur if gas is not ventilated

properly.

Before using this appliance for the first time, contact your local gas

supplier for instructions about what to do if you smell gas. Post

those instructions somewhere near the fryer, so that everyone who

uses or works near the fryer knows what to do if they smell gas.

Beware of High Voltage

This equipment uses high voltage. Serious injury can occur if you

or any untrained or unauthorized person installs, services, or

repairs this equipment. Always Use an Authorized Service agent to

Service Your Equipment.

Noncombustible Floors Only

Make sure your floor is noncombustible. Do not operate your fryer

on floors that are wood, carpeted or have rubber mats.

• Placing your fryer on a combustible floor could cause a

fire. Serious injury could result.

• Examples of noncombustible floors where you can safely

place your fryer are concrete, tile, and ceramic.

Page 8

Gas Pressure Fryer Introduction

5

Keep the Area Around Your Fryer

Uncluttered

Make sure to keep the area around your fryer clear of any

obstacles.

Serious injury can occur if you trip or fall near the fryer. You could

be burned by hot shortening that splashes out of the fryer or by

falling against the hot metal of the fryer.

Keep the Floor Around Your Fryer Clean Of

Shortening

Make sure to keep the floor around your fryer clean of shortening

and other liquids.

Serious injury can occur if you slip near your fryer. You could be

burned by hot shortening that splashes out of the fryer or by falling

against the hot metal of the fryer.

Keep the Lid Closed When The Fryer Is Not

In Use

Hot shortening can splash if someone moves the fryer or bumps

into it. Serious injury can occur if hot shortening splashes out of the

fryer.

Do not lean, sit or stand on the fryer or perform any maintenance

or cleaning duties while the fryer or the shortening is hot. You

could be burned.

Keep the Casters Locked

To avoid spilling shortening, keep the casters locked. If any

shortening spills near your fryer, clean it up immediately.

Do Not Overfill the Fryer with Shortening

Hot shortening and steam may escape and burn you if you put too

much shortening in the fryer. Fill the fryer to the fill marks that are

inside the fryer pot. Heat the shortening.

Page 9

Gas Pressure Fryer Introduction

6

Do Not Let Any Water Get into The Fryer

Always remove excess moisture from food before placing it into the

fryer basket. Water will cause the hot shortening to spatter. You

could be burned.

Do Not Overload the Basket With Food

Hot shortening and steam may escape and burn you if you place

too much food in the basket.

Always Make Sure the Lid Hook Is Latched

When Closing The Fryer

To make sure the lid hook is latched properly, press down the lid

until the hook snaps shut. Hot shortening and steam can escape if

the lid hook is not latched properly. You could be burned.

Always Tighten the Spin Handle When

Closing The Fryer

Hot shortening and steam can escape if you do not tighten the spin

handle properly. You could be burned. Line up the orange knobs

on the fryer lid handle and the front hook when tightening.

Do Not Over-Tighten the Spin Handle

You could damage the fryer.

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling the fryer basket or

touch any hot metal surfaces. You received a pair of insulated mitts

with your fryer. If you lose or damage your mitts, you can buy new

ones at your local restaurant equipment supply store or from your

local BKI Distributor.

Always wear non-skid shoes when working around the fryer or any

other equipment that uses shortening. Never wear loose clothing

such as neckties or scarves while operating your fryer. Keep loose

hair tied back or in a hair net while operating your fryer.

Always wear appropriate personal protection equipment during the

filtering process to guard against possible injury from hot oil.

Always wear appropriate personal protection equipment during the

boil-out process to guard against possible injury from hot cleaning

solution.

Page 10

Gas Pressure Fryer Introduction

7

Never Loosen the Spin Handle Until The

Pressure Gauge Is At Zero

Steam may escape suddenly if you loosen the spin handle before

the gauge is at zero. If steam escapes suddenly, you could be

burned.

After the pressure gauge is at zero, wait 5 seconds. Then loosen

the spin handle slowly to open the lid of the fryer. By doing this, the

steam will escape slowly and you will not be burned.

Seal the Safety Valve Properly

To seal the safety valve, lift the arm on the side of the valve. Then

release it. The valve should snap closed. Hot steam can escape

from the valve and you could be burned if you do not seal the valve

properly.

Keep Away From the Vent

Hot steam escapes from the vent continuously when you are using

your fryer. You could be burned if you get too close to the vent.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it

near for easy access.

If you need to replace this manual, contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not

understand that this equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Page 11

Gas Pressure Fryer Introduction

8

Keep Safety Labels Clean and in Good

Condition

Do not remove or cover any safety labels on your equipment. Keep

all safety labels clean and in good condition. Replace any

damaged or missing safety labels. Refer to the Safety Labels

section for illustration and location of safety labels on this unit.

If you need a new safety label, obtain the number of the specific

label illustrated on page Error! Bookmark not defined., then

contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You

must use a 40-pound Type BC fire extinguisher and keep it within

25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services,

hospitals, and the fire department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the

equipment.

• Make certain your employees are aware of the safety

precautions on the equipment and in this manual.

• Make certain that you have thoroughly trained your employees

about operating the equipment safely.

• Make certain the equipment is in proper working condition. If

you make unauthorized modifications to the equipment, you will

reduce the function and safety of the equipment.

Page 12

Gas Pressure Fryer Introduction

9

Do Not Smoke Near The Fryer.

Electrical Grounding Instructions:

This appliance is equipped with a three-prong (grounding) plug for

your protection against shock hazard and should be plugged

directly into a properly grounded three-prong receptacle. Do not

cut or remove the grounding prong from this plug.

Page 13

Gas Pressure Fryer Installation

10

Installation

For installation information refer to Gas Pressure Fryer, MODEL FKG-TC, Installation and Operation Manual.

Page 14

Gas Pressure Fryer Operation

11

Operation

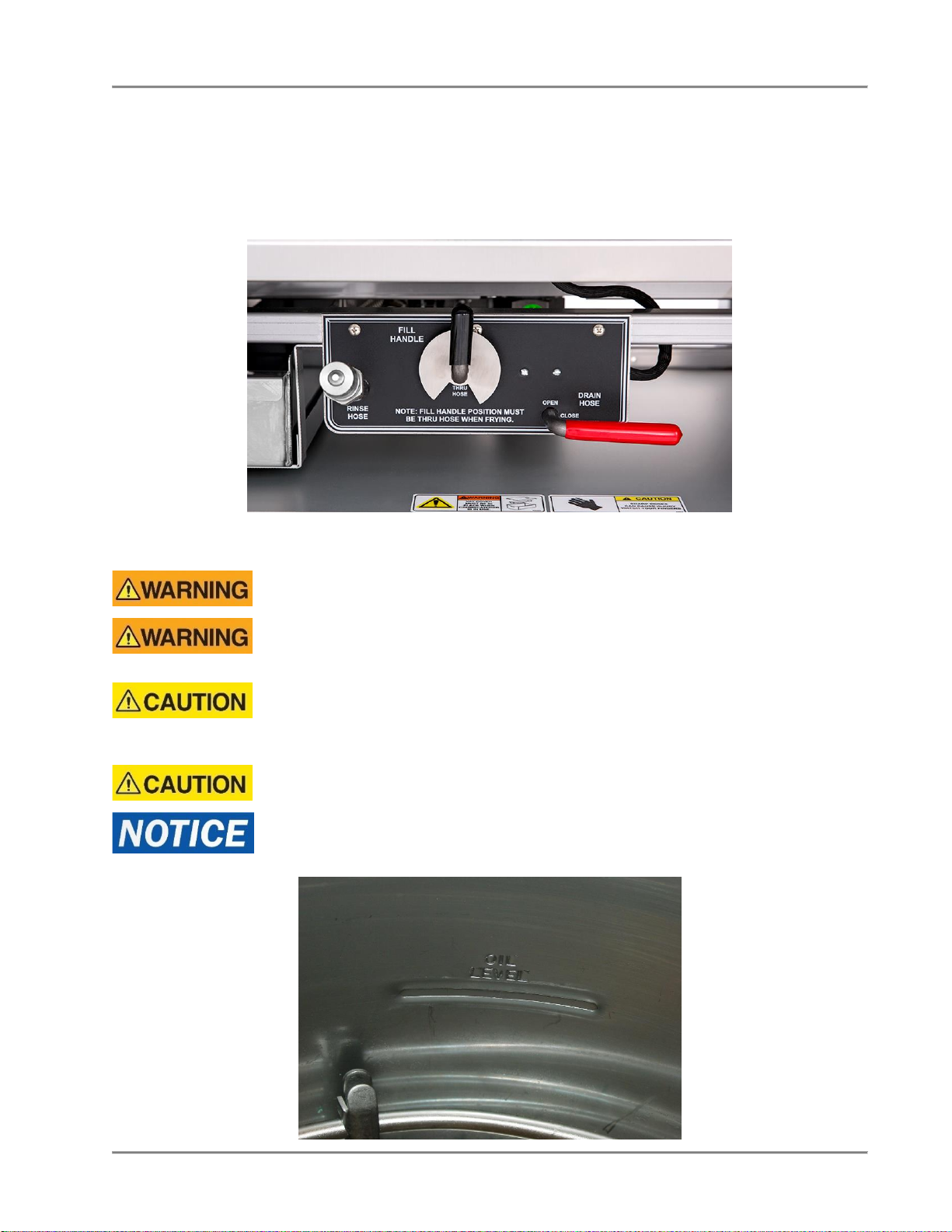

Start-Up (FKG-TC)

1. Turn fryer on by touching the ON button for 3 seconds.

2. Make sure the main drain valve is closed.

3. Fill pot with shortening to about one inch below the mark.

Risk of fire exists if the oil level drops below the minimum oil level. The level of oil

within the pot must not fall below 5mm of the maximum oil level.

Use of oil/shortening older than the manufacturers recommendations for life of

the oil is prone to surge boiling and flash fires. Follow the oil manufacturers

guidelines for lifecycle of oil/shortening.

Overfilling the fryer pot with shortening could lead to serious injury. Ensure that

the fryer pot is filled with shortening only to the fill mark when shortening is hot.

Do not use any shortening other than what is specified in this manual and do not

overfill the fryer pot.

The fryer has a maximum temperature setting of 375º F/191º C. Do not use

oil/shortening with a flashpoint less than 554º F (290º C)

Use only high-quality shortening that has low moisture content, a high smoke

point and no additives.

Page 15

Gas Pressure Fryer Operation

12

1. Once the fryer is filled with shortening, press the FRY button.

2. Confirm the oil level by pressing the green check mark.

3. The fryer will start heating up by going into a melt cycle. It will pulse the elements until the oil gets to

225° F (107° C) and then goes into heat mode until it reaches the setpoint temperature. The recipes

will be greyed out and inaccessible until the fryer reaches setpoint temperature. (If the burner does

not light and you get a Gas Alarm, see the Gas Alarm instructions in the Troubleshooting section.)

Page 16

Gas Pressure Fryer Operation

13

4. When the fryer is ready to cook the recipes will be activated.

IMPORTANT! Before the first cooking operation each day, stir the shortening freely while it is heating

to provide a balanced shortening temperature for excellent results with the first cooking. Failure to do

this can result in a crusty skin on the product surface with an undercooked product internally. In

addition, in some cases, failure to stir the shortening while it is initially heating may cause the HILIMIT safety device to disable the power due to a false overtemperature condition.

Page 17

Gas Pressure Fryer Operation

14

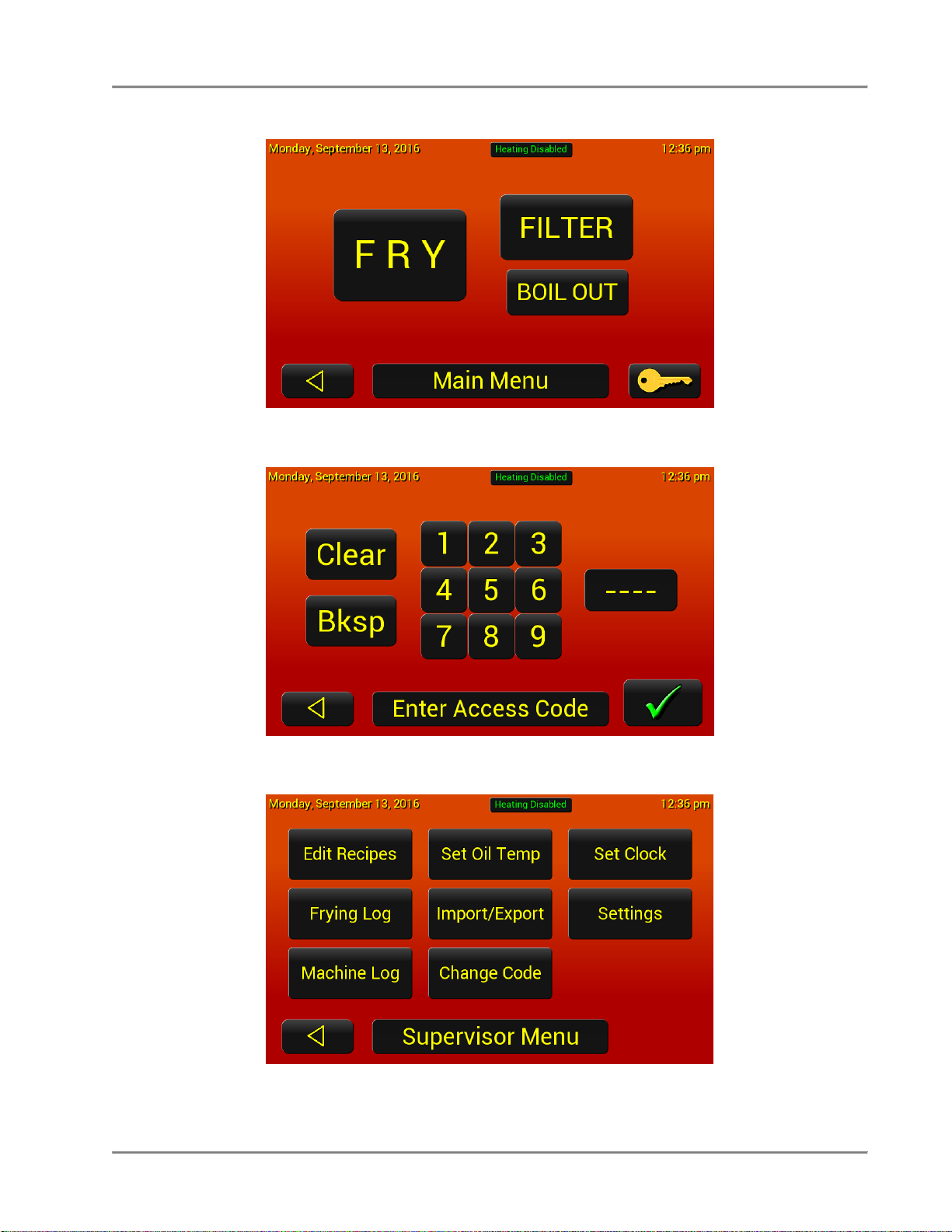

Product Programming

1. Press the Key button to get into the settings menus.

2. Enter code 1234 and then pres the green check mark.

3. Select the Edit Recipe button

Page 18

Gas Pressure Fryer Operation

15

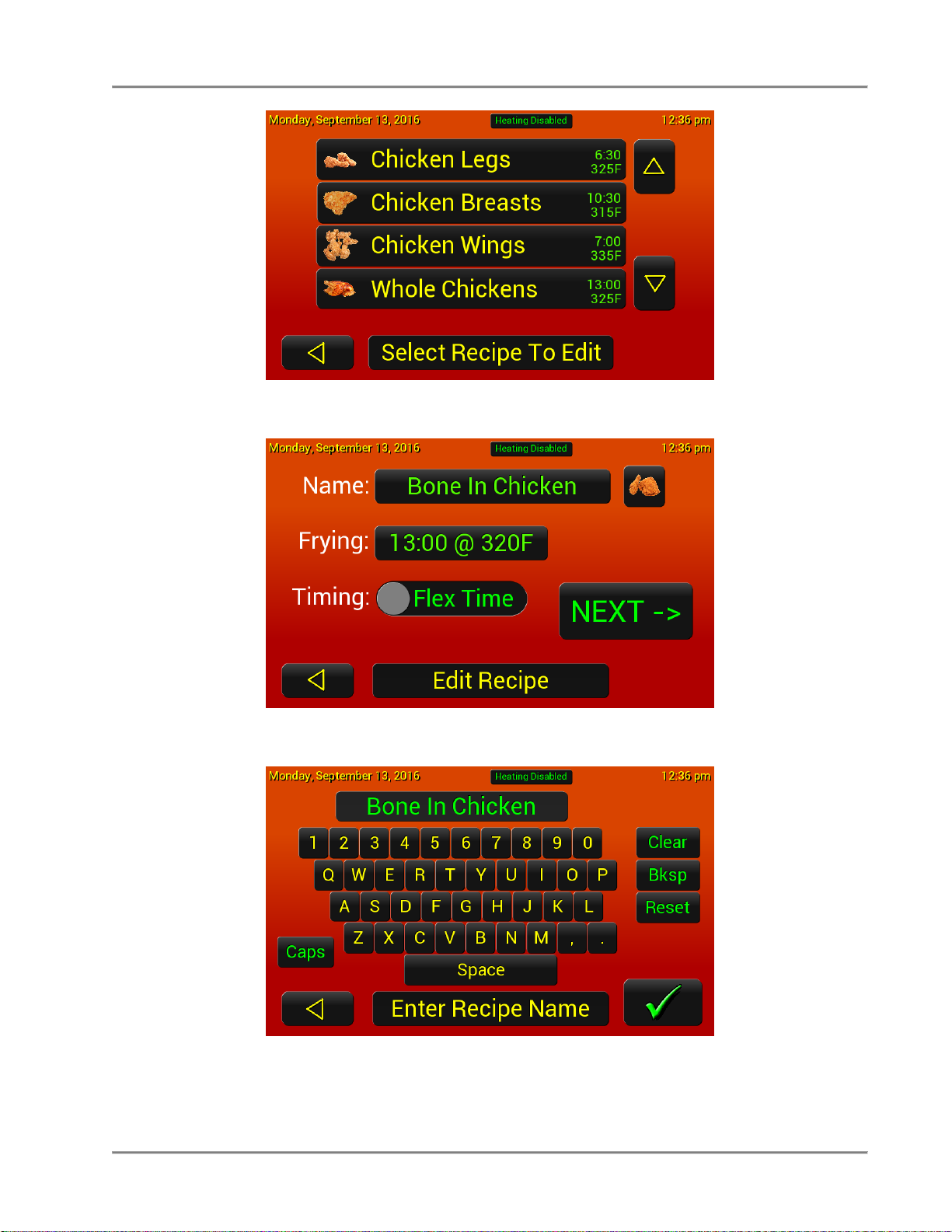

4. Select the Recipe that needs edited.

5. In the Edit Recipe screen the name, cook time, temperarture, timing type, & picture can be edited.

6. Select Name to change the name and press the green check mark to save.

Page 19

Gas Pressure Fryer Operation

16

7. Select Frying to edit the time and temperature of the recipe. Press the green check mark to save.

8. Pressing the Next button will bring you to the second page where the shake/stir, alarm, if the program

is active, and the filter weight can be edited.

9. Press the Shake/Stir time to edit the time & numer of beeps. Press the green check mark to save.

Page 20

Gas Pressure Fryer Operation

17

10. Press the alarm time to edit the time. Press the green check mark to save.

11. Make sure the program is active and set the filter weight (1.0-12.0 by 0.5 increments, if using global

filtering).

12. When done, press the SAVE button to save the program.

13. If you want to cancel the recipe or accidently press the back button, the message above will display.

You can save by pressing the SAVE or cancel by pressing the back arrow.

Page 21

Gas Pressure Fryer Operation

18

Set Oil Temp

1. Get into the supervisor menu and select the Set Oil Temp button

2. Set the oil temperature to the desired ready to cook temperature between 250° F and 375° F.

3. Press the green check mark to save.

Page 22

Gas Pressure Fryer Operation

19

Set Clock

1. Get into the supervisor menu and select the Set Clock button

2. Set the date & time.

3. Press the green check mark to save.

Page 23

Gas Pressure Fryer Operation

20

Settings

1. Get into the supervisor menu and select the Settings button

2. Set the Beeper Volume (Low or High), Pattern (1, 2, or 3), the Filter Lockout* can be turned off & on,

the Filter Lockout Value can be set (2-20), and the Temperature Units can be set (C or F).

*The filter lockout is a global counter used to determine when to force filter. Set the total filter

value in settings and then in the recipes, the weight of each recipe can be set. (i.e. Fresh

breaded product can have a value of 3 and french fries a value of 1.) When the values of the

recipes cooked adds up to the global value (or over), the control will require a filter.

3. Press the green check mark to save.

Page 24

Gas Pressure Fryer Operation

21

Frying Log

1. Get into the supervisor menu and select the Frying Log button

2. The frying log will record the following events:

• Recipe Cooked with elapsed time and average temperature

• Basic Filter with filtering time, refill time, and number of pump lockouts

• Filter With Rinse Hose with filtering time, refill time, and number of pump lockouts

• Boil Out with heating time

3. Press the back button to exit.

Page 25

Gas Pressure Fryer Operation

22

Machine Log

4. Get into the supervisor menu and select the Machine Log button

5. The frying log will record the following events:

• Touchscreen Error

• Probe Error

• Nonvolatile Memory read, write, or data errors

• Factory Reset

• Touchscreen Calibration

• Configuration Change

• Password Error

• Password Reset

• Password Change

• Recipe Saved

• Recipes Imported

• Recipes Exported

• Configuration Import

• Configuration Export

• Frying Log Export

• Machine Log Export

• USB Drive read, write, and file open errors

• Touch Configuration Change

• Fryer Options Changed

• Firmware Update

6. Press the back button to exit.

Page 26

Gas Pressure Fryer Operation

23

Import/Export

1. Get into the supervisor menu and select the Import/Export button

2. Insert a USB drive.

3. Press the import/export recipes button to save the recipes to a USB or copy to the fryer.

Page 27

Gas Pressure Fryer Operation

24

1. To add up to 8 additional Recipe Icons, press the Import Icons button with the USB inserted.

2. Importable Image Requirements:

a. JPG images only, standard 24 bit color with any amount of image compression.

b. Recipe icons must be 64 pixels wide and 64 pixels tall.

c. The maximum file size is 54k bytes.

d. File names can be any combination of letters and numbers up to a maximum of 8 characters, the

extension must be “.jpg”. The name is case insensitive.

3. Touch the Find Files … button, the controller will look through the entire USB drive and find all jpg

files which are 64x64 pixels and below the maximum file size, displays the file name and image of the

first file found meeting those criteria, and shows the number of files found in the Find Files … button.

The 8 locations to the right will now be available, locations which already have an icon stored in them

will display the stored image. Use the up and down arrows to scroll through all the files the controller

found until the file wanted is displayed.

4. Select the location in which they want to store the icon, they can choose any of the eight locations

including those which are already in use, that location will be overwritten. The selected location

button turns green and the green check button is now available. Touching the green check button

stores the selected image into that location in the controller image format along with the name and

size of the file and the original jpg file data so it can be exported at some other time.

5. When the import is completed the controller chirps twice indicating that it has stored that icon. Select

other icon files and other icon locations and store as many of the images as desired.

6. Press the back button to exit.

Page 28

Gas Pressure Fryer Operation

25

1. To copy any or all 8 Recipe Icons, press the Export Icons button with the USB inserted.

2. The eight button on the left side display all the imported user icons. Select or deselect any of the 8

images to be exported just by touching the icon buttons. Touch once to select, touch again to

deselect. The Select All button can be used tol select all imported icons.

3. Touch the green check button to export all of the selected icons with their original file names and data

to the USB drive. NOTE: Files already on the flash drive which have the same name as the original

files will be overwritten with the stored image data.

4. Press the back button to exit.

Page 29

Gas Pressure Fryer Operation

26

Change Code

1. Get into the supervisor menu and select the Change Code button

2. Enter the new 4 digit access code. We recommend an easy to remember number, like the store

number.

3. Press the green check mark to save.

Page 30

Gas Pressure Fryer Operation

27

System I/O

1. Enter code 5142 and then pres the green check mark to get into the technician menus.

2. Select the MORE button.

3. Select the System I/O button.

Page 31

Gas Pressure Fryer Operation

28

4. The System I/O let you see which out puts are open or closed and the oil temperature. The text in

the yellow are the state of the output.

The bottom half of the screen are inputs and the individual components can be turned off and on by

pressing the assiciated button. This can be used to aid in the troubleshooting of the components.

Do not turn on Heat [K1][DO1] without the elements being fully covered with oil

or water. Damage to the elements and/or fryer may occur.

Page 32

Gas Pressure Fryer Operation

29

Cap Touch

1. Select the Cap Touch button to configure and callibrate the touch screen.

2. The screen sensitivity can be adjusted by using the +/- buttons. Also, the glass thickness can be

changed to fine tune the sensitivity.

3. To calibrate the screen, press the Calibrate Touch button and follow the instructions on the screen.

Page 33

Gas Pressure Fryer Operation

30

Options

1. Select the Options button to configure the control for the type of fryer you have.

2. The “Outputs” & “Inputs” indicates what is active (green) and inactive (red).

3. Set the fryer up using the HEAT, LID SOL, LIFT, & MODEL buttons.

a. HEAT: Elec or Gas

b. LID SOL: On (pressure fryer) or Off

c. LIFT: None or Manual (lift assist) or Auto (auto lift fryer)

d. MODEL: Type in the model of fryer

4. Press the green check mark to save.

Page 34

Gas Pressure Fryer Operation

31

Screen

1. Select the Screen button to configure the background color and the spalsh screen logo.

2. Insert the USB flash drive containing the files if you want to import images.

3. Changing the Background - The Background button has the following options, touch the button to

toggle between them and see how they look:

a. BKI Image – Displays the standard BKI background image.

b. Imported – Displays the imported image if present. Touch the [Import Background] button

and the controller imports the BGROUND.RAW image and displays it. The progress bar will

show the importing process.

c. Black – Displays a solid black background

d. Dk Grey – Displays a dark grey background

e. Dk Red – Displays a dark red background and screen title bar

f. Dk Green - Displays a dark green background and screen title bar

g. Dk Blue - Displays a dark blur background and screen title bar

h. Gradient – Displays an orange to red gradient background

4. Keep touching the Background button and it will wrap around to the beginning of the list.

5. Changing the Splash Logo - The Splash Logo button has the following options:

a. BKI Logo – Displays the standard BKI logo in the splash screen

b. Imported – Displays the imported logo in the splash screen

Page 35

Gas Pressure Fryer Operation

32

6. Before importing the logo you must set the image width and height. If the width and height shown in

the button below the Import Logo button are not correct touch the [W x H] button and the following

window appears:

7. Use the [+] and [-] buttons to set the image width and height and then touch the green check mark

button to save the new values and return to the Screen Settings window.

8. Once the image size has been set touch the Import Logo button and the LOGO.RAW file will be

imported and stored along with the image size. The progress bar will show the importing of the file

data.

9. Press the green check mark to save.

Page 36

Gas Pressure Fryer Maintenance

33

Maintenance

Failure to comply with the maintenance below could result in a serious accident.

Do not over-tighten the spindle assembly. (Only tighten to hold pressure.)

Your fryer will need periodic maintenance and servicing. We strongly suggest that

you use only a service company that is authorized by BKI to do this work.

The restraining device must always be connected when the appliance is in service.

Disconnect for movement, such as servicing or cleaning. Reconnect the restraint

when fryer has been returned to its normal position.

The FKG appliance is not intended to be cleaned with a water jet.

Scheduled Maintenance

Use the following table to help manage scheduled maintenance activities.

FREQUENCY

PERFORMED BY

PART

ACTIVITY

Each Fry Cycle

User

Pressure Gauge

Check for proper display of cooking vat

pressure. Contact authorized BKI service

agent if adjustment or replacement is

required.

User

Lid Gasket

Check for unusual wear such as cracks

and deformation, and pressure leaks.

Contact authorized BKI service agent if

adjustment or replacement is required.

Daily

User

Dead Weight

Assembly

Clean weight and orifices daily and check

for wear.

User

Filter Pad

Replace filter pad. Refer to the procedure

in this manual.

User

Condensation Pan

Remove and drain.

User

Filter system

Filter the shortening using the procedure

in this manual.

Weekly

User

Safety Pop Valve

Check for release of pressure and proper

seal. Refer to the procedure in this

manual.

User

Fryer Pot

Perform the boil-out procedure in this

manual.

Every 6 Months

Authorized BKI

service agent

Acme Screw and

Nut

Check for wear on the threads.

Authorized BKI

service agent

Solenoid Valve

Check that the valve is holding and

releasing pressure when the timer or

computer activates it.

Authorized BKI

service agent

Hook, Catch, Spring

Check for wear and ease of operation.

Authorized BKI

service agent

Connections,

Fittings

Check for leakage while oil is pumping.

Page 37

Gas Pressure Fryer Maintenance

34

FREQUENCY

PERFORMED BY

PART

ACTIVITY

Authorized BKI

service agent

Fryer Pot

Fittings/Connections

Check for leakage around fry pot top deck

and fittings (heaters, hi-limit, thermostat,

etc.).

Safety Pop Valve Procedure

The safety pop valve should be blown under pressure periodically to prevent the seat from sticking.

Failure to use the insulated mitts will result in injury. Always use the insulated mitts

when handling the arm on the safety valve.

1. After the pressure is up during a cooking cycle, use the insulated glove to lift the arm on the edge of

the safety valve and let some steam escape. This will clean the valve.

2. Release the lever on the valve, and let it slam shut to seal the valve.

Page 38

Gas Pressure Fryer

35

Troubleshooting

Refer to the table below for troubleshooting information.

Problem

Cause

Possible Solution

Pressure Loss or Not

Releasing Pressure

Dead Weight Valve Leaking

Clean the weight and orifice. If

problems persist, contact an authorized

BKI service agent for corrective action.

Lid Gasket Leaking

Contact an authorized BKI service

agent for corrective action.

Solenoid Valve Leaking or

Stuck

After a period of time, it is possible that

the valve seat and/or plunger may stick

or wear. Activate the valve by starting a

cook cycle. You should hear a solid

metallic CLICK sound from the solenoid

valve. If you should hear no sound (or a

slow BUZZING CLICK), contact an

authorized BKI service agent for

corrective action.

Safety Valve not seating

Contact an authorized BKI service

agent for corrective action.

Shortening Heating Too

Slowly

Gas pressure is low or isn’t

adjusted properly

Contact an authorized BKI service

agent for corrective action.

Bad thermostat or loose

wires

Contact an authorized BKI service

agent for corrective action.

Filter System Not Working

Uncertain

Press the hi-limit reset button under

control panel. If problems persist,

contact an authorized BKI service

agent for corrective action.

Connections not tight

Tighten the connections. If problems

persist, contact an authorized BKI

service agent for corrective action.

Filter valve not open

Contact an authorized BKI service

agent for corrective action.

Filter paper on screen

clogged with crumbs

Change filter paper. If problems persist,

contact an authorized BKI service

agent for corrective action.

Motor hums, but does not

pump

Check for clogged pump. If problems

persist, contact an authorized BKI

service agent for corrective action.

Motor and pump coupling

worn

Contact an authorized BKI service

agent for corrective action.

No power to control panel

Make sure drain valve is completely

closed. If problems persist, contact an

authorized BKI service agent for

corrective action.

Computer Hangs

Computer malfunction.

Turn the power OFF then back ON. If

problems persist, contact an authorized

BKI service agent for corrective action.

Page 39

Gas Pressure Fryer

36

Gas Alarm

If the fryer tries 3 times to light the burner without success the gas control system will lock out and a Gas

Alarm will pop up on the screen. Press the green RESET button to reset the gas control system and try to

light again. If the problem persists, contact an authorized BKI service agent for corrective action.

Filter Pump Reset

If the filter pump overheats a PUMP TOO HOT alert will pop up and a timer will start to count up.

Page 40

Gas Pressure Fryer

37

Once the pump has cooled, the screen will indicate that the pump is ready. Press the green Check Mark to

start the pump back up.

Page 41

Gas Pressure Fryer Replacement Parts

Description

Assembly #

Figure #

Table #

DEAD WEIGHT ASSEMBLY

AN19312300

Figure 1

Table 1

SOLENOID VALVE

AN19312400

Figure 2

Table 2

DOOR ASSEMBLY

AB19311700

Figure 3

Table 3

LID/TOP ASSEMBLY

SB1992S

Figure 4

Table 4

OIL VAT ASSEMBLY

AN19313000

Figure 5

Table 5

QUICK DISCONNECT ASSEMBLY

AN19103300

SB1997S

Figure 6

Table 6

COMPONENT PANEL FKG-TC

AN19317600

Figure 7

Table 7

FRONT PANEL FKG-TC

AB19112700

Figure 8

Table 8

GAS SYSTEM ASSEMBLY

N/A

Figure 9

Table 9

DRAIN/MOTOR/PIPING ASSEMBLY

N/A

Figure 10

Table 10

Replacement Parts

Use the information in this section to identify replacement parts. To order replacement parts, call your local

BKI sales and service representative. Before calling, please note the serial number, model number, gas type

and voltage on the rating tag affixed to the unit.

Assemblies

38

Page 42

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

1

FT0396

1

PIPE, DEAD WT TO BAFFLE BOX

2

FT0414

1

NIPPLE, 1/2" x 3 3/4", SS SCH 80

3

O0001

1

ORIFICE, SS

4

O0002

1

GASKET, O-RING #2-222

5

PV0001

1

VALVE, POP SAFETY 1321148

6

FT0066

1

ELL, REDUCER 3/4 X 1/2 90 DEG

7

FT0235

1

NIPPLE, 1/2 X C SS

8

FT0190

1

ELL, STREET 1/4 90 DEG CP

9

FT0084

1

COUPLING, BRASS 1/4

10

FT0563

1

FITTING, COMPRESSION ¾”

11

FT0067

1

BUSHING, C110JO 3/4 X 1/2 CP

12

FT0234

1

NIPPLE, 1/4 X 1 1/2 SS 304

13

C0657

1

COVER, DEAD WEIGHT VALVE FKM

14

B0969

1

BODY, DEAD WEIGHT VALVE FKM

15

W0201

1

WEIGHT, VALVE FKM 12#

16

G0136

1

GAUGE, PRESSURE 30 PSI

Figure 1. Dead Weight Assembly

Table 1. Dead Weight Assembly Parts

39

Page 43

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

1

FT0249

1

CONNECTOR, 3/8 STR FLEX LIQUIDTITE

2

FT0414

1

NIPPLE, 1/2" x 3 3/4", SS SCH 80

3

SV0004

1

VALVE, SOLENOID HV-214-761-2 120V

4

FT0563

1

FITTING, COMPRESSION ¾”

Figure 2. Solenoid Valve Assembly

Table 2. Solenoid Valve Assembly Parts

Figure 3. Door Assembly Parts

40

Page 44

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

1

F0083

2

THREAD INSERT 10-24 STEEL

2

ST0013

1

BRACKET, BRUSH HOLDER FKM, LPF,LGF

3

H0010

2

HINGE, LH PIN HALF

4

N0059

1

DECAL, SMALL BRUSH/

5

N0165

1

DECAL, NOTICE LOST MANUAL

6

N0527

1

DECAL, SAFETY INSTR FRYERS

7

N0175

1

DECAL, SLIPPING ADMONITIONS

8

N0176

1

DECAL, INSTR & SAFETY MANUAL

9

P0022

1

HANDLE, PULL SS P60-1010

10

RIV172

3

RIVET, 1/8 X 1/4 CS PLT POP

11

SB1951

1

INSIDE DOOR POCKET/MAGNET WELD FKM

12

SCR008

6

SCREW, 10 X 1/2 PHIL TRUSS HD

13

SCR383

2

SCREW, 10-24 X 1/2" PHIL TRUSS HD

14

WFKMA178

1

DOOR, FRYER OUTSIDE WELD

15

N0153

1

DECAL, FKM WARNING ACME SCREW

16

H0009

1

HINGE, DOOR,RH,PIN SIDE FRY.DOORS

Table 3. Door Assembly Parts

Figure 4. Lid/Top (sheet 1 of 4)

41

Page 45

Gas Pressure Fryer Replacement Parts

42

Page 46

Gas Pressure Fryer Replacement Parts

43

Figure 6. Lid/Top (Sheet 2 of 4)

Page 47

Gas Pressure Fryer Replacement Parts

44

Figure 6. Lid/Top (Sheet 3 of 4)

Page 48

Gas Pressure Fryer Replacement Parts

45

Figure 6. Lid/Top (Sheet 4 of 4)

Page 49

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

Figure 6 (sheet 1)

SB1992S

LID/TOP

Figure 6 (sheet 2)

SB3481

1

HANDLE ASSY, SPIN

1

FT0332

3

STUD, 5.5” TIGHTEN DN HN

2

K0202

2

KNOB, BLACK

3

K0020

1

HUB, TIGHTEN DOWN

4

K0203

1

KNOB, ORANGE

Figure 6 (sheet 3)

AB19103900

1

ARM ASSY, FKM

1

A0120

1

ARM COMPLETE FKM LGF

2

H0155

1

HANDLE, BLK DELRIN FKM LPF LGF

3

P0094

1

PIN, HOOK FKM, LPF, LGF

4

H0024

1

HOOK, LID 1018 ALLOY

5

K0203

1

KNOB, ORANGE

6

N0160

1

DECAL, WARNING BEFORE USING

7

NUT128

2

NUT, 5/16-18 SS 18-8 CAP

8

S0091

1

SPRING, HOOK LGF LPF FKM

9

SCR122

2

SCREW, 1/4-20 X 1/2 FLAT HD

10

SCR259

2

SCREW, 1/4-20 X 1/2 PHIL RD HD

11

TB0020

1

BUSHING, BRONZE 1"

12

H0156

2

HANDLE SIDE FOR H0155 FKM LPF LGF

13

WSH045

2

WASHER, 5/16 LOCK ZINC PLTD

14

WSH102

2

WASHER, 1/4 INT LOCK

15

FT0407

1

PLUG, HOLE 3/8" SHORT PRONG

16

F0026

1

ROLL PIN, 5/32 X 3/4

Figure 6 (sheet 4)

SB1989

1

LID LOCKING ASSY W/INSERT FKM

1

F0353

1

PIN, LOCKING FKM LGF LPF

2

G0016

1

GASKET, FKM LID BONDED SILICON

3

S0155

1

SPRING, LOCKING PIN W/LID INSERT

4

B0857

1

BUSHING, BRONZE 3/8X9/16X5/8

5

P0115

1

LID INSERT, FKM

6

FK0010

1

LID, FKM CAST ALUM

7

C0674 *

1

LID COVER AND ARM GUIDE FKM

8

F0107

1

LOCK KEY PIN, FRYERS

9

FKMA016

1

PIN, HINGE

10

FKMA152

1

KEY, TIGHTEN DOWN SCREW

11

FKMA201

1

PLATE, TIGHTEN DOWN FKM

12

FT0049

2

COLLAR, 1/2" SET BRIGHT

13

N0153 *

1

DECAL, FKM WARNING ACME SCREW

14

N0345 *

1

DECAL, HOOK LID INSTRUCTIONS

15

SCR383

2

SCREW, 10-24 X 1/2" PHIL TRUSS HD

16

SCR176

2

SCREW, 8-32 X 3/8 SLOT BINDING

17

SCR178

1

SCREW, 5/16-18 X 1 FLAT HD

18

TB0021

1

TIGHTEN DOWN BASE COLD ROLLED

19

TC0003

1

COLLAR, THREADED SHAFT

20

TC0005

1

COLLAR, LOCKING RING

21

TS0010

1

SCREW, TIGHTEN DOWN

22

S0071

1

SPRING, TORSION

23

LZ0107

1

PLATE, LID FOR LOCKING DEVICE

Table 4. Lid/Top Parts

* - These parts constitute Lid Cover Assembly, AN1910840S.

46

Page 50

Gas Pressure Fryer Replacement Parts

47

Figure 5. Oil Vat Assembly

2

7

5

3

4

8

6

10

9

1

11

13

12

12

Table 5. Oil Vat Assembly Parts

Page 51

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

AN19313000

1

FILTER SCREEN ASSY,FKG

1

WB16010600

1

WELDMENT, FILTER VAT QUICK DISCONNECT

2

WB16022100

1

WELDMENT, FILTER TUBE, BLF

3

FS0002

1

FILTER SCREEN, INTERCEPTOR

4

FS0003

1

FILTER SCREEN, TOP

5

FS0001

1

FILTER SCREEN, BOTTOM

6

SB7659

1

FILTER SCREEN FITTING SPOTWELD

7

FC0004

1

NUT SCREEN RETAINING FKM-F & FKM-FC

8

O0013

1

O-RING, FLUOROCARBON V680-70

9

SCR344

1

SCREW, SET, SOC, 8-32 X 1/4

10

SB7675

1

CRUMB BASKET WELD, LG VAT ASSY

11

FB19312904

1

COVER, FILTER VAT, SHEET METAL FRAME

12

N0395

1

DECAL, VAT COVER SAFETY WARN

13

N0694

2

DECAL, CAUTION, SHARP EDGES

ITEM #

PART #

QTY

DESCRIPTION

1

B0996

1

BALL, 11/16" STEEL BEARING

2

FT0429

1

QUICK DISCONNECT, PUMP SIDE

3

FT0500

1

QUICK DISCONNECT, VAT SIDE

4

FT0536*

1

COUPLING, 5/8 45¦ FLARE TO

5

O0013

2

O-RING, FLUOROCARBON V680-70

6

O0014

1

O-RING, PARKER #2-124 LARGE

7

S0138

1

SPRING, FOR QUICK DISCONNECT

8

SCR453*

2

SCREW, #10 24X3/8" WASHERED

Figure 6. Quick Disconnect Assembly

Table 6. Quick Disconnect Assembly Parts

* - Not included with SB1997S

48

Page 52

Gas Pressure Fryer Replacement Parts

49

Figure 7. Component Panel FKG-TC

1

3

18

25

16

15

21

8

17

7

22

10

5

12

4

6

9

11

11

13

2

20

19

14

23

13

26

24

27

28

Page 53

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

1

FB16004210

1

RELAY PANEL, BLF/FKM

2

FB16201910

1

BRACKET, FUSE HOLDER, FKG/BLG

3

CP0110

1

MOTOR CONTROL BOARD, COMBUSTION BLOWER

4

SP0047

4

SPACER, .250 OD x .312 L x #6 ID, NYLON

5

SCR118

6

SCREW, 6-32 X 5/8 SLTD RD ZINC PLATED

6

WSH089

10

WASHER, #6 INT LOCK ZINC PLATED

7

NUT048

10

NUT, 6-32 HEX ZINC PLTD

8

FH0001

1

FUSE HOLDER, 15A 300V HPF-EE

9

T0036

1

THERMOSTAT, HI LIMIT 540 DEG

10

SCR006

11

SCREW, 8 X ½ PHIL PAN TYPE “B” NKL PLTD

11

TF0005

2

TRANSFORMER, 120-24V LGF

12

SCR138

4

SCREW, #10 X ½” PHIL TRUSS HD

13

R0196

2

RELAY, DPDT 220/240V FLANGE MOUNT

14

FU004UK

2

FUSEHOLDER, 5 x 20 mm, PANEL MOUNT, 0.188 TAB TERMINALS

15

F0158

1

BUSHING, BLK ½ HEYCO SNAP

16

F0154

1

BUSHING, BLACK 1-3/16 HEYCO SNAP

17

FT0080

1

CONNECTOR, BOX #7483, 1”

18

F0097

1

FUSE, 15A 300V SC15 TIME DELAY

19

F0177

1

FUSE, HOUNO 3.15A, #061417

20

F0417

1

FUSE, 5 x 20mm, 1A 250V, TIME DELAY

21

F0342

2

CLAMP, CABLE 3/16”

22

RIV180

2

RIVET, 1/8” SS (0.063-0.125)

23

CP0118

1

BOARD, POWER RELAY, I/O

24

SP0013

4

SPACER, FOR #8 X 1/2" LG.

25

SCR194

4

SCREW, 6-32 X 1 SLTD RD

26

R0197

1

RELAY, DPDT, 110/120V, FLANGE MOUNT

27

USB001

1

CORD, USB, WATERPROOF, PANEL MOUNT, FEMALE-MALE, 0.5M LONG

28

USB002

1

CAP, USB

29*

MA19101700

1

CONDUIT, 1"" FLEX 21.50

30*

F0315

2

BUSHING, CONDUIT 1" PLASTIC

31*

S0063

1

SPRING GUARD, 6 ½” FRYERS

32*

HF0013

2

CLAMP, HOSE, #62M10

Table 7. Component Panel FKG-TC Parts

* Not Shown

50

Page 54

Gas Pressure Fryer Replacement Parts

3

4

7

6

1

2

5

8

ITEM #

PART #

QTY

DESCRIPTION

1

FB19112600

1

STUD ASSEMBLY, CONTROL PANEL, TOUCH SCREEN

2

CP0117

1

CONTROLLER, TOUCH SCREEN, FRYER

3

S0712

1

SWITCH, CAPACITIVE TOUCH, 2-BUTTON, ON/OFF

4

NUT048

8

NUT, 6-32 HEX ZINC PLTD

5

WSH089

8

WASHER, #6 INT LOCK ZINC PLATED

6

SP0052

4

SPACER, 5/16 OD, 1/4 L, #10 ID ALUMINUM

7

SP0013

4

SPACER, FOR #8 X 1/2" LG.

8

WSH271

4

WASHER, #8 FLAT S/S

9*

N0702

1

DECAL, CONTROL PANEL, FRYER, TOUCH SCREEN

10*

T0184

1

PROBE, TEMPERATURE, 100 OHM RTD

11*

FT0286

1

THERMOCOUPLE FITTING W/FERRULE & NUT

12*

FT0287

1

BUSHING, REDUCING 3/8" x 1/8"

Figure 8. Front Panel FKG-TC

Table 8. Front Panel FKG-TC Parts

* Not Shown

51

Page 55

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

1

G0327

2

GASKET, BURNER & FLUE, FKG/BLG

2

WB19306600

1

WELDMENT, BLOWER DUCT (STRAIGHT), FKG/BLG

3

2015768

1

GASKET, COMBUSTION BLOWER

4

AB19310900

1

ASSEMBLY, COMBUSTION BLOWER, FKG/BLG

5

7020204

1

VALVE, GAS, FKG/BLG

6

2015652

1

FITTING, GAS VALVE TO ORIFICE

7

2019975

1

FITTING, GAS VALVE TO GAS CONNECTION

8

7070142

2

GASKET, ALUMINUM WASHER

9

O0029

1

ORIFICE, NATURAL GAS, 3.8 MM

O0030

1

ORIFICE, LP GAS, 3.2 MM

10

S0097

1

SWITCH, VACUUM 0.14"W.C. FH

11

FB19315900

1

ASSEMBLY, GAS BURNER, 5.00”, FKG/BLG

12

I0511

1

IGNITER, ELECTRODE

13

I0512

2

INSULATOR, BOOT, STRAIGHT SPARK PLUG

14

G0328

1

GASKET, IGNITER, FKG/BLG

15

7020217

1

IGNITION MODULE, IGNITION BOOST

16

WSH248

6

WASHERED LOCKNUT, 1/4-20 ZINC EXTERNAL TOOTH

17

NUT276

2

NUT, #8-32, KEPS, ZINC PLATED STL

18

SCR426

4

SCREW, 10-24 X 3/4, HEX CAP, SS

19

NUT286

6

NUT, #10-24 KEPS, ZINC PLATED STL

20

H0218

1

HOSE, GAS LINE, FKG/BLG

21

SCR462

2

SCREW, 10-24 x 1/2 HEX SER WSHR ZINC PLATED STEEL

22

6041095

1

TRANSFORMER, IGNITION BOOST

14

6

3

15

12

13

17 USE ANTI-SEIZE

19

18

16 USE ANTI-SEIZE

10

5

7

9

11

1

2

20

21

4

8

22

Figure 9. Gas System Assembly

Table 9. Gas System Assembly Parts

52

Page 56

Gas Pressure Fryer Replacement Parts

53

Figure 10. Drain/Motor/Piping Assembly

16

2

23

24

17

22

21

19

28

30

26

27

29

35

10

1

3

8

14

37

4

34

31

13

12

15

11

33

32

15

2

25

8

9

20

18

6

57

57

13

36

40

38

4

39

39

Page 57

Gas Pressure Fryer Replacement Parts

ITEM #

PART #

QTY

DESCRIPTION

1

AB15507900

1

ASSEMBLY, PUMP DISCONNECT, FILTER VAT, FKG/BLG

2

FT0312

2

ELL, STREET 1/2 90 DEG BLACK

3

FT0619

1

NIPPLE, 1/2" x 1-1/2" LG, SS 304

4

SCR463

8

SCREW, 1/4-20 X 5/8, HEX SER FLNGD

5

FT0153

2

CONNECTOR, BOX 3/8 X 90

6

LPFFA035

1

CONDUIT, 3/8" FLEX 17"

7

F0312

2

BUSHING, CONDUIT 3/8" PLASTIC

8

FT0536

2

COUPLING, 5/8" 45° FLARE TO 1/2" MPT STRAIGHT ELECTROLESS

NICKEL 9 TU0206

1

TUBING, 29" 1/2" ID

10

D0060

1

VALVE, DRAIN, SS BALL & PLT. CAR. STEM

11

FT0543

1

DRAIN VALVE BRACKET FRYERS

12

FT0044

1

ELL, STREET 3/8 90 DEG, BLACK

13

FT0412

2

NIPPLE, 3/8" NPT x 1 1/2" SCH 40 BLACK PIPE

14

FT0538

1

TEE, 1/2" x 1/2" x 3/8", BLACK PIPE

15

SB1314

1

BALL VALVE ASSY, FRYERS

16

FT0507

1

CONNECTOR, MALE 10FBU-S, NICKEL PLATED 5/8" TUBE TO 1/2" NPT

17

FKMA224

1

HANDLE SUPPORT PLATE FKM

18

MA19100508

1

FILL VALVE HANDLE

19

H0215

1

DRAIN VALVE HANDEL FKM & BLF

20

C0672

1

COVER, DRAIN HANDLE RED

21

C0668

1

COVER, FILL HANDLE BLACK

22

MA19100800

1

TUBING, TEE TO DISCONNECT FKM

23

P0081

1

PLUG, D-H4F4-SV-8, QUIK DISCONNECT

24

B0851

1

BUSHING, BLACK HEX REDUCING 1/2 x 3/8 NPT 150LB

25

SCR138

3

SCREW, #10 X 1/2" PHIL TRUSS HD

26

LZ0130

1

COVER, MICROSWITCH FKM & BLF

27

F0158

1

BUSHING, BLK 1/2 HEYCO SNAP

28

SCR194

2

SCREW, 6-32 x 1" RND HD, ZINC SLOTTED

29

NUT253

2

NUT, 6-32 S/S 18-8 NYLON

30

S0054

1

SWITCH, MICRO BZ-2RW822-A2

31

F0253

1

PIN, CLEVIS, 3/16 x 1 3/4

32

F0254

2

PIN, COTTER HAIRPIN #213 .080 WIRE DIA

33

F0255

1

PIN, CLEVIS, 3/16 x 1-1/4

34

SP0014

2

SPACER, ALUM .5 X .125

35

SP0034

2

SPACER, DRAIN VALVE BRKT FRYERS

36

WB19315400

1

WELDMENT, FILL HANDLE INDICATIOR

37

M0121

1

MOTOR W/PUMP, 115-208/230/50-60Hz

38

FB19313405

1

BRACKET, PUMP MOTOR MOUNT, FKG/BLG

39

F0140

8

AVK, HEX INSERT, ¼”-20

40

N0695

1

DECAL, DRAIN HANDLE PLATE, FKM

Table 10. Drain/Motor/Piping Assembly Parts

54

Page 58

Gas Pressure Fryer Replacement Parts

Description

Component #

Figure #

Item #

ARM ADJUSTABLE STOP /FKM

A0101

Figure 11

1

CASTER, SWIVEL, W/TOP PLATE 5" W/BRAKE

C0406

Figure 11

2

BAFFLE BOX ASSEMBLY

AN19302600

Figure 11

3

CONDENSATION PAN WELDMENT

WB19311100

Figure 11

4

DRAIN PIPE, CONDENSATE FKM

MB19310600

Figure 11

5

FILTER BAG CLIP FKM-F

ST0015

Figure 11

6

COLLAR, 1/2" SET BRIGHT

FT0049

Figure 11

7

SLIDE, UHMW U-SHAPE .5 X 1/8ID

S0106

Figure 11

8

SIDE CABINET, L&R FKM/DNF

FKMA399

Figure 11

9

HINGE, SLIP WING RH

H0051

Figure 11

10

HINGE, SLIP WING LH

H0052

Figure 11

11

PROBE, TEMPERATURE, 100 OHM RTD

T0184

Figure 11

12

THERMOCOUPLE FITTING W/FERRULE & NUT

FT0287

Figure 11

13

BUSHING, REDUCING 3/8" x 1/8"

FT0286

Figure 11

14

1 2 3

4 5 6

7 8 9

Components

Figure 11. Components

55

Page 59

Gas Pressure Fryer Replacement Parts

56

10

11

12

13

14

Page 60

Gas Pressure Fryer Replacement Parts

Description

Accessory #

Figure #

Item #

BASKET, LARGE FKM BAIL HANDLE

B0114

Figure 12

1

BASKET, FKM, (GRANDE)

B0128

Figure 12

2

BRUSH, DRAIN (LONG WHITE)

B0075

Figure 12

3

BRUSH, L TIPPED 40152

B0063

Figure 12

4

BRUSH, LONG #5702

B0051

Figure 12

5

BRUSH, SHORT #6175

B0052

Figure 12

6

FILTER HOSE, FEMALE SOCKET

SB2332

Figure 12

7

FILTER VAT DOLLY FKM-F

SB7650

Figure 12

8

BRUSH, POT SCRUBBER, WHITE

B0049

Figure 12

9

BRUSH, POT SCRUBBER, HIGH TEMP., WHITE

B1102

Figure 12

9

POT STIR STICK FOR 75# BLF

P0149

Figure 12

10

RESTRAINT

FT0279

Figure 12

11

GLOVE, NEOPRENE

G0089

Figure 12

12

FILTER, FKM-F 13.5 X 20.5

FI0007

Figure 12

13

CLEANER, FRYER, OSG BOIL OUT COMPOUND

LC0006

Figure 12

14

1 2 3

4 5 6

7 8 9

Accessories

Figure 12. Accessories

57

Page 61

Gas Pressure Fryer Replacement Parts

58

10

11

12

13

14

Page 62

Gas Pressure Fryer Wiring Diagram

59

Wiring Diagram

TYPE SIZE

DRAWING No.

REV. No.

S

B

AMPS.

KILOWATTS

BREAKER SIZE

VOLTAGEMODEL No.

PHASE

No. OF WIRES

DATE

DRAWN BY

JDS

06/26/17

FKG-TC

1 3

120

5.0

0.6 15

1939030002 - ECO 18-009

LEGEND

L1

8

14

15

9

8

11

10

12

13

14

15

16

14

16

7 9

12

11

7

N

L1

N

G

YE

L

BLUE

BLK

WHT

15

4

3

2 1

6

5

2 1

8 7

4 3

J5

J6

P1

RELAY

R0196

S1

SW2

SW4

DETAIL A

WHT

BRN

YEL

RED

RBY

DETAIL A

AIR PRESSURE

SWITCH

S0097

8

4

ON

OFF

SW1

SW2

SW4

MOTOR CNTL

CP0110

BLK

ORG

BLU

GRY

31

31

32

33

1515

14

15

15

14

29

30

29

18

R

B

Y

3

4

1

1

3

4

5

5

5

14

14

LOW

SPEED

HIGH

SPEED

TRANSFORMER,

120VAC PRIMARY,

230VAC SEC,

TF0504

FUSE, 1.0A

F0417

BLOWER,

120VAC

AB19310900

14

13

IGNITION MODULE

7020217

29

12

11

10

9

8

7

6

5

4

3

2

1

33

19

18

17

FLAME

IGNITIER

I0511

WHT

WHT

WHT

SOLENOID

VALVE, 120V

SV0004

FUSE, 3.15A

F0177

4-CONDUCTOR

NUT

TRANSFMR,

120VAC

24VAC SEC,

TF0005

FUSE,15A

F0097

HI-LIMIT, 540°

T0036

DRAIN, 250V

S0054

9-PIN CAP/P LUG

CONNECTOR

GAS VALVE

(NOT SHOWN)

7020204

IGNITION

TRANSFORMER

6041095

WHT

FUSE, 1.0A

F0417

35

34

3

1

2

3-PIN CAP/ PLUG

CONNECTOR

34 WHT

35 BLK

GGG

RTD ASSY,

T0184

8

9

10

9

11

12

13

141516

8

16

12

15

OPERATOR

CONTROL PANEL

NO2

NO1

NO3

NO4

COM1

COM2

POWER, ON/OFF,

S0712

8

14

9

11

P1

P2

P4

P5

P8

P7

P6

J3

J4

P3

DIGITAL

OUTPUTS

DIGITAL

INPUTS

RELAY

OUTPUTS

ANALOG

INPUTS

ANALOG

OUTPUTS

AC

POWER

TO USER

INTERFACE

10

11

9

8

YE

L

BLUE

BLK

WHT

RELAY

R0196

19

29

13

M

L1

T1

PS

T8

TS

L2

11

PUMP MOTOR,

120V

M0121

COM

NO

NC

COM

NO

NC

RELAY

R0197

30

TRANSFMR,

120VAC

24VAC SEC,

TF0005

COM

NO

NC

RELAY BOARD

CP0118

TOUCH SCREEN

BOARD

(NOT SHOWN)

CP0117

36

36

36

36

37

37

14

38

38

39

17

18

39

18

40

12

11

1114

13

11

T2T4T5

P1

T3

10

10

10

P

Page 63

Gas Pressure Fryer Notes

60

Notes

Page 64

CS-TM-049.01 Revised 05/04/2018

2812 Grandview Dr., Simpsonville, S.C. 29680, USA

http://www.bkideas.com

Made and printed in the U.S.A

Loading...

Loading...