Page 1

Remote Filter

MODELS FKF, FKF-H

Service Manual

Serial Numbers 122085 and higher

CS-TM-023.01 Revised 3/26/13

Page 2

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS

WHO IS

COVERAGE PERIOD

WARRANTY COVERAGE

EXCEPTIONS

EXCLUSIONS

INSTALLATION

REPLACEMENT PARTS

COVERED

COVERED

BKI LIMITED W ARRANTY

2812 Grandview Dr. • Simpsonville, SC 29680 • USA

This warranty covers defects in material and workmanship under normal use, and applies only to the

original purchaser providing that:

The equipment has not been accidentally or intentionally damaged, altered or misused;

The equipment is properly installed, adjusted, operated and maintained in accordance with

national and local codes, and in accordance with the installation and operating instructions provided

with this product.

The serial number rating plate affixed to the equipment has not been defaced or removed.

This

warranty

purchased

Warranty claims must be received in writing by BKI within one (1) year from date of

installation or within one (1) year and three (3) months from data of shipment from the

factory, whichever comes first.

COB Models: One (1) Year limited parts and labor.

COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a two (2)

year door warranty.

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door warranty.

BevLes Products: Two (2) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after

shipment date from BKI, whichever comes first.

This

authorized

performed during regular, weekday business hours.

door warranty on convection ovens years 3 through 5 is a parts only warranty and does not include

labor, travel, mileage or any other charges.

Thermostat calibrations

Air and gas

Light

Glass doors and

Fuses,

Adjustments

Tightening

Failures

Unauthorized

Damage

Alteration,

Thermostats

Freight –

Ordinary

Failure to follow

Events

appropriate installation

manufacturer.

BKI genuine

installation

for use in the U.S.A.

warranty

covers on-site labor, parts and

service

representative

Any exceptions must be pre-approved in advance and in writing by BKI. The extended

Negligence

adjustments,

bulbs,

beyond control

Leveling, as well as

by a BKI F

door adjustments,

to

burner

of screws or

caused

by erratic

repair by

in

shipment,

misuse or

and safety valves with

other than normal UPS charges,

wear and

Factory OEM parts receive a (90) day

tear,

installation and/or operating instructions,

actory Authorized

is

extended

or acts of

after (30) days

flames and

fasteners,

anyone other than

improper installation,

of the

proper installation

and use materials – is the responsibility of the

to the original

up to (100) miles

God,

cleaning of

voltages

or gas

broken

company.

purchaser

reasonable

from equipment installation date,

Service

round

pilot

burners,

suppliers,

a BKI F

actory Authorized

capillary tubes,

and check out of all

materials warranty

Center.

and applies only to

travel

time

trip and (2)

and travel e

new equipment -

equipment

hours

dealer

effective from the date of

xpenses

travel time and

Service Center,

or installer, not the

of the

per

CS-TM-023.01 Revised 3/26/13

Page 3

Remote Filter Table of Contents

Table of Contents

Table of Contents ........................................................................................................................................1

Introduction..................................................................................................................................................2

Safety Precautions ....................................................................................................................................2

Safety Signs and Messages .................................................................................................................2

Safe Work Practices .............................................................................................................................3

Safety Labels ........................................................................................................................................5

Operation......................................................................................................................................................6

Controls and Indicators .............................................................................................................................6

BLF/FKM Filtering Procedure....................................................................................................................6

DNF Filtering Procedure ...........................................................................................................................8

Filter Pad Replacement...........................................................................................................................10

Replacement Parts ....................................................................................................................................11

1

Page 4

Remote Filter Introduction

Introduction

Congratulations! You have chosen an FKF Remote Filter that will give you many years of fine service

from the original manufacturer, BKI. The FKF Remote Filter is designed to filter shortening used in BKI’s

Electric Pressure Fryer (model BLF and FKM only) and Donut Fryer (model DNF only).

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has

been built with care and dedication -- using the best materials available. Attention to the operating

instructions regarding proper installation, operation, and maintenance will result in long lasting

dependability to insure the highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

you have any questions, please contact your BKI Distributor. If they are unable to

answer your questions, contact the BKI Technical Service Department, toll free:

1-800-927-6887. Outside the U.S., call 1-864-963-3471.

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know and

understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other special

data.

2

Page 5

Remote Filter Introduction

Safe Work Practices

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling the fryer basket or

touch any hot metal surfaces. You received a pair of insulated mitts

with your fryer. If you lose or damage your mitts, you can buy new

ones at your local restaurant equipment supply store or from your

local BKI Distributor.

Always wear non-skid shoes when working around the fryer or any

other equipment that uses shortening. Never wear loose clothing

such as neckties or scarves while operating your fryer. Keep loose

hair tied back or in a hair net while operating your fryer.

Always wear appropriate personal protection equipment during the

filtering process to guard against possible injury from hot oil.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it

near for easy access.

If you need to replace this manual, contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Or download from our website:

http://www.bkideas.com/na/service.htm

Protect Children

Keep children away from this equipment. Children may not

understand that this equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

3

Page 6

Remote Filter Introduction

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep

all safety labels clean and in good condition. Replace any damaged

or missing safety labels. Refer to the Safety Labels section for

illustration and location of safety labels on this unit.

If you need a new safety label, obtain the number of the specific

label illustrated on page 5, then contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You

must use a 40-pound Type BC fire extinguisher and keep it within

25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services,

hospitals, and the fire department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the

equipment.

• Make certain your employees are aware of the safety

precautions on the equipment and in this manual.

• Make certain that you have thoroughly trained your employees

about operating the equipment safely.

• Make certain the equipment is in proper working condition. If you

make unauthorized modifications to the equipment, you will

reduce the function and safety of the equipment.

4

Page 7

Remote Filter Introduction

Safety Labels

5

Page 8

Remote Filter Operation

Operation

Controls and Indicators

The FKF and FKF-H have a power switch to turn the pump motor on or off. It also contains a pump motor

reset switch. If the motor overheats while filtering, it will automatically shut off. To reactivate the pump

motor, wait 15 minutes to allow the motor to cool then press the switch. The FKF-H also has a heater

mounted on the pump that melts residual solid shortening within the pump. This heater has a power

switch used to turn it on or off.

BLF/FKM Filtering Procedure

Always wear appropriate personal protection equipment during the filtering

process to guard against possible injury from hot oil.

1. Set the FILTER/OFF/FRY switch on the fryer to OFF.

2. Turn the thermostat to the off position and remove the fryer basket.

3. Make certain that the FKF filter unit filter pad is clean and not torn.

4. Position the FKF filter unit under the main drain valve and make sure it’s filter screen is in

place.

5. If solid shortening has been used and needs to be melted in the pump, follow the instructions

below, otherwise skip to the next step:

a. Plug the pump heater power cord into the BLF/FKM receptacle.

b. Turn the pump heater power switch on.

c. Position the FILTER/OFF/FRY switch to FILTER. The heater will begin to melt the

shortening in the pump.

d. Wait 30 minutes to ensure all shortening in the pump has melted.

e. Position the FILTER/OFF/FRY switch to OFF.

f. Turn the pump heater power switch off.

g. Unplug the pump heater power cord from the BLF/FKM receptacle.

6. Plug the FKF pump motor power cord into the BLF/FKM receptacle.

7. Place the pump motor power switch on.

8. Move the DRAIN handle on the fryer slowly to the OPEN position until the shortening starts to

flow evenly. This will prevent excessive splashing of hot shortening.

9. When the pot is empty, place the DRAIN handle in the CLOSED position.

To refill the pot through the drain valve, use the steps below:

1. Make certain that the braided hose (located on the drain valve) is connected to it’s mating

part on the FKF filter unit.

6

Page 9

Remote Filter Operation

Hot shortening may splash out of the pot causing severe injury when filling the

pot if the lid is not closed. To prevent shortening splashes, close the lid before

filling.

2. Close the lid to prevent shortening splashes.

3. Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump into

the pot.

4. After 1 minute carefully open the lid to check the level of the shortening.

5. Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached or

until air starts bubbling through the shortening.

6. As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to

prevent shortening degradation and prevent the filter pump and lines from filling up with

shortening.

7. Add new shortening if the fill mark has not been reached.

8. Disconnect the braided hose.

9. Remove the FKF unit from under the BLF/FKM fryer and place in a storage location.

To refill the pot through the filter hose, use the steps below:

1. Make certain that the filter hose is connected to it’s mating part on the FKF filter unit.

2. Holding the hose by the handle, place hose nozzle inside the pot.

Hot shortening may splash out of the pot causing severe injury when filling the

pot if the lid is not held down over the hose nozzle. To prevent shortening

splashes, hold the lid down over the hose nozzle.

3. Hold the lid down over the hose nozzle to prevent shortening splashes.

4. Position the FILTER/OFF/FRY switch to FILTER and shortening will automatically pump into

the pot.

5. After 1 minute, hold the hose by the handle and carefully raise the lid to check the level of the

shortening.

6. Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached or

until air starts bubbling through the shortening.

7. As soon as air is seen in the shortening, position the FILTER/OFF/FRY switch to OFF to

prevent shortening degradation.

8. Add new shortening if the fill mark has not been reached.

9. Disconnect the filter hose. Hold the filter hose, with nozzle down, over the pot to drain all

excess oil from the hose.

10. Remove the FKF unit from under the BLF/FKM fryer and place in a storage location.

7

Page 10

Remote Filter Operation

DNF Filtering Procedure

Always wear appropriate personal protection equipment during the filtering

process to guard against possible injury from hot oil.

1. Set the fryer POWER switch to the ON position.

2. Set the FILTER MOTOR switch on the fryer to OFF.

3. Turn the thermostat to the off position and remove the screen lifter.

4. Make certain that the FKF filter unit filter pad is clean and not torn.

5. Position the FKF filter unit under the main drain valve and make sure it’s filter screen is in

place.

6. If solid shortening has been used and needs to be melted in the pump, follow the instructions

below, otherwise skip to the next step:

a. Plug the pump heater power cord into the fryer power receptacle.

b. Turn the pump heater power switch on.

c. Position the FILTER MOTOR switch to ON. The heater will begin to melt the

shortening in the pump.

d. Wait 30 minutes to ensure all shortening in the pump has melted.

e. Position the FILTER MOTOR switch to OFF.

f. Turn the pump heater power switch off.

g. Unplug the pump heater power cord from the fryer power receptacle.

7. Plug the FKF pump motor power cord into the fryer power receptacle.

8. Place the pump motor power switch on.

9. Move the DRAIN handle on the fryer slowly to the OPEN position until the shortening starts to

flow evenly. This will prevent excessive splashing of hot shortening.

10. When the pot is empty, place the DRAIN handle in the CLOSED position.

11. Make certain that the filter hose is connected to it’s mating part on the FKF filter unit.

12. Holding the hose by the handle, place hose nozzle inside the pot.

Hot shortening may splash out of the pot causing severe injury when filling the

pot if the lid is not held down over the hose nozzle. To prevent shortening

splashes, hold the lid down over the hose nozzle.

13. Hold the lid down over the hose nozzle to prevent shortening splashes.

14. Position the FILTER MOTOR switch to ON and shortening will automatically pump into the

pot.

8

Page 11

Remote Filter Operation

15. After 1 minute, hold the hose by the handle and carefully raise the lid to check the level of the

shortening.

16. Let the filter continue to pump the shortening until the fill mark in the fryer pot is reached or

until air starts bubbling through the shortening.

17. As soon as air is seen in the shortening, position the FILTER MOTOR switch to OFF to

prevent shortening degradation.

18. Add new shortening if the fill mark has not been reached.

19. Disconnect the filter hose. Hold the filter hose, with nozzle down, over the pot to drain all

excess oil from the hose.

20. Remove the FKF unit from under the fryer and place in a storage location.

9

Page 12

Remote Filter Operation

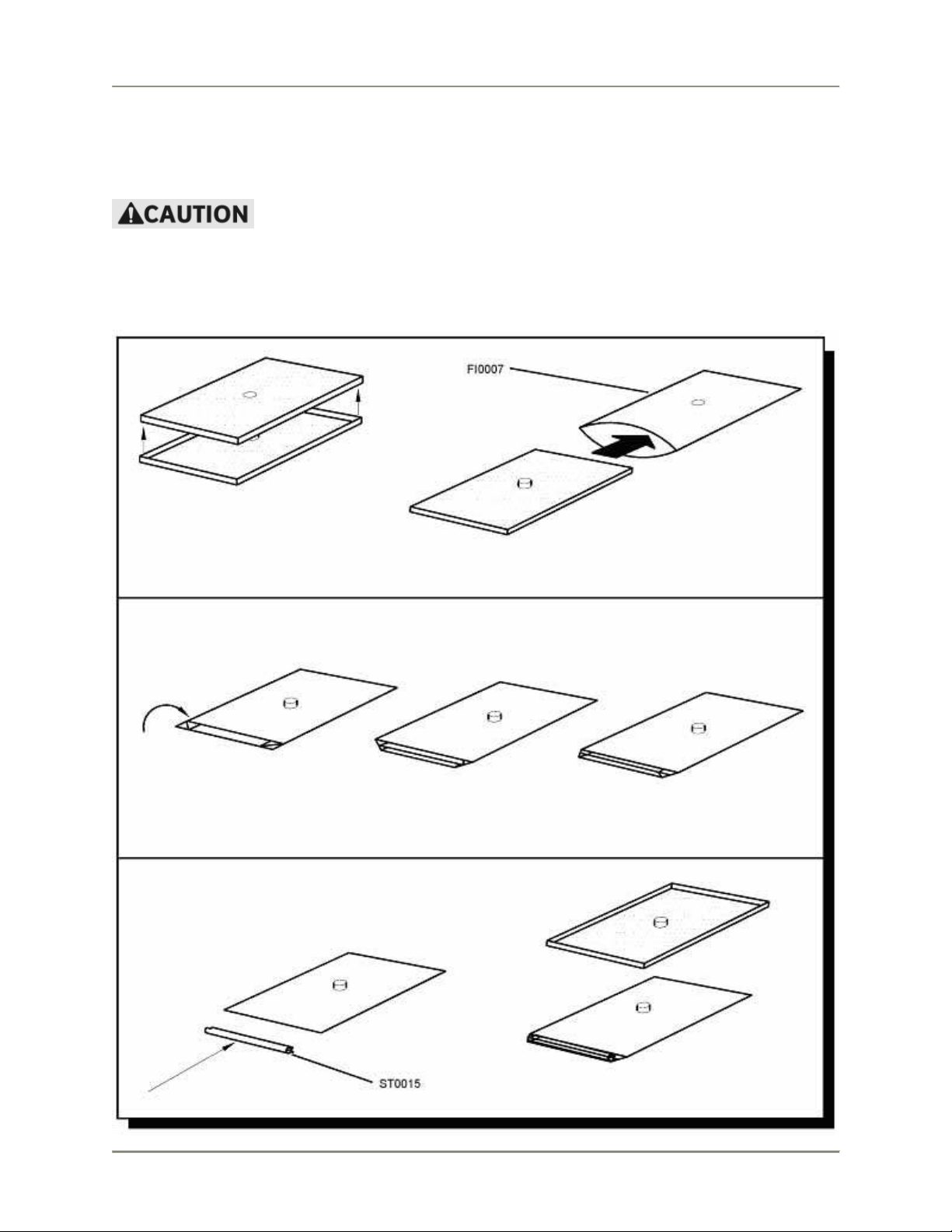

Filter Pad Replacement

The filter pad must be replaced daily. If the shortening has a milky color when it is pumped into the pot,

the filter pad should be replaced immediately.

If the filter pad is not properly closed, breading crumbs will get through the pad

opening and clog the pump. Ensure that the filter pad is properly closed upon

replacement.

1. Place the filter screen inside the filter pad.

2. Fold the end of the pad and seal with the bag clip.

10

Page 13

Remote Filter Replacement Parts

Replacement Parts

Use the information in this section to identify replacement parts. To order replacement parts, call your

local BKI sales and service representative. Before calling, please note the serial number, model number

and voltage on the rating tag affixed to the unit.

ITEM # PART # QTY DESCRIPTION

1 WFKFA006 1 FKF BASE UNIT WELDMENT

2 C0400 4 CASTER, 121-2R FKF

3 SB2306 1 S/S CRUMB BASKET WELD, FKF

4 SB2307

or

SB7704

5 SB2319 1 FILTER HEATING ASSY, HAIGHT (ACCESSORY)

6 FT0105 1 UNION, 3/8 HANDLE BAR

7 FKFA058 1 TUBING, SCREEN TO UNION FKF

8 FC0003 1 FEMALE COUPLING

9 SB7659 1 FILTER SCREEN FITTING SPOTWELD

10 O0013 1 O-RING, FLUOROCARBON V680-70

11 FS0002 1 FILTER SCREEN, INTERCEPTOR

12 FC0004 1 NUT SCREEN RETAINING FKM-F &

13 FS0001 1 FILTER SCREEN, BOTTOM

14 FS0003 1 FILTER SCREEN, TOP

15 FT0506 2 ELL, 5/8 TUBE TO 1/2NPT FEMALE

16 P0081 1 PLUG, F-H4F4-7-7 QUIK DISCONN

17 FKFA061 1 TUBING, PUMP TO DISCONNECT,FKF

18 B0851 1 BUSHING, BLK HEX REDUCING

19 M0053 1 MOTOR, LEESON LESS CORD/PUMP

20 FI0007 1 FILTER, FKM-F 13.5 X 20.5

21 ST0015 1 FILTER BAG CLIP FKM-F

22 FKFA068 1 MOTOR COVER, FKF

23 FKFA069 1 CORD NEST, FKF

24 S0103 1 SWITCH, RKR DPST 15A 250V LAMP

25 FKFA063 1 SWITCH ENCLOSURE, FKF

26 CS0006 1 CORD SET, 250V 23" BLK FKF

27 FT0195 2 NIPPLE, 1/2 X 2 BLK

28 P0070 1 PUMP ONLY FOR HAIGHT MOTOR

29 FKFA060 1 TUBING, PUMP TO UNION, FKF

30 SB2332 1 FILTER HOSE, FEMALE SOCKET (ACCESSORY)

1 OIL CONTAINER WELD, FKF

or

OVERSIZE OIL VAT WELD, FKF

11

Page 14

Remote Filter Replacement Parts

12

Page 15

2812 Grandview Dr., Simpsonville, S.C. 29680, USA

http://www.bkideas.com

Made and printed in the U.S.A

LI0171/0407

CS-TM-023.01 Revised 3/26/13

Page 16

Remote Filter Replacement Parts

REVISION HISTORY

REVISION

DATE REVISED BY DESCRIPTION

01 03/26/13 KW Initial Release-Supersedes all previous

releases

2

Loading...

Loading...