Page 1

Revised 6.4.2018

Combi-King® Combination

Oven Series

Series: ETG & EHG

Installation Manual

Page 2

DEAR CUSTOMER

COMBI OVEN INSTALLATION MANUAL

Congratulations on the purchase of your new

Combi-King Plus Combination Oven. By purchasing

this new oven, you have entered into a new era of

cooking. With the new technology and simplicity

built into the Combi-King Combination Oven, you

will receive excellent results in no time at all. The

oven’s ease and simplicity of operation will help you

realize savings in training dollars.

With the Combi-King one touch, simply identify

the relevant food, push start, and you are cooking.

The simplicity of operation guarantees consistently

produced products without having to set times,

temperatures, and finishes.

For the Chef, the Combi-King oers a wide array of

functions and steps that once tested can be saved

and recreated by experienced kitchen sta as well

as the first time operator.

NOTICE

Please read the operations manual in full before

starting up the appliance to make sure all the

benefits and safety information is understood.

For more information, culinary support, and

customer service please contact 1- 800-927-6887

Appliance Model _______________________________

S/N ___________________________________________

Dealer ________________________________________

Installer _______________________________________

Date of Install _________________________________

2

Page 3

COMBI OVEN INSTALLATION MANUAL

TABLE OF CONTENTS

INTRODUCTION ......................................................................................................................................................................... 4

INTENDED USE .................................................................................................................................................................... 4

SAFETY INFORMATION ............................................................................................................................................................. 4

SAFETY PRECAUTIONS ...................................................................................................................................................... 4

SAFETY SIGNS AND MESSAGES ....................................................................................................................................... 4

SAFE WORK PRACTICES .................................................................................................................................................... 5

SPECIFIC PRECAUTIONS ................................................................................................................................................... 6

GENERAL SAFETY GUIDELINES FOR INSTALLERS, USERS, AND SERVICE TECHNICIANS .................................. 7

HEALTH AND SANITATION PRACTICES ................................................................................................................................ 8

SPECIFICATIONS ........................................................................................................................................................................9

PRE-INSTALLATION CHECKLIST .......................................................................................................................................... 21

VENTILATION REQUIREMENTS ............................................................................................................................................ 22

WATER QUALITY ....................................................................................................................................................................... 23

INSTALLATION ..........................................................................................................................................................................24

GENERAL INFORMATION ................................................................................................................................................24

UNPACKING AND HANDLING ........................................................................................................................................ 24

REQUIRED CLEARANCES/POSITIONING ........................................................................................................................... 25

DOOR ADJUSTMENT ..............................................................................................................................................................26

ELECTRICAL CONNECTION .................................................................................................................................................. 27

WATER CONNECTION ............................................................................................................................................................28

DRAIN CONNECTION .............................................................................................................................................................29

GAS CONNECTION ................................................................................................................................................................. 30

PRODUCT REGISTRATION/INSTALLATION CHECKLIST ............................................................................................... 32

WIRING DIAGRAMS .................................................................................................................................................................34

BKI LIMITED WARRANTY ........................................................................................................................................................ 37

3

Page 4

COMBI OVEN INSTALLATION MANUAL

INTRODUCTION/SAFETY INFORMATION

Intended Use

BKI Combi-King Plus Combination Ovens are solely

intended for use in commercial kitchens.

The units may only be used for cooking food using

the correct racks, containers, baking sheets, and

slide in pans. Roll in rack dollies and cassettes must

only be supplied by BKI.

Units should only be used with purest quality

drinking water for unit protection. The owner of the

oven should test water for filtration needs. Water

quality needs can be found in the manual under

“Water Quality.”

Your new Combi-King oven should not be used for

the following purposes, among others:

• As a dishwasher

• Drying towels, paper, or dishes

• As a storage container

• Heating brines, oils, or other chemicals

• Heating closed containers (i.e. canned goods)

• Heating flammable liquids

Safety Precautions

Always follow recommended safety

precautions listed in this manual. To the

left is the safety alert symbol. When you

see this symbol on your equipment, be alert to the

potential for personal injury or property damage.

Safety Signs and Messages

The following safety signs and messages are placed

in this manual to provide instructions and identify

specific areas where potential hazards exist and

special precautions should be taken. Know and

understand the meaning of these instructions, signs,

and messages.

DANGER

This message indicates an imminently

hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

This message indicates a potentially hazardous

situation, which, if not avoided, could result in

death or serious injury.

• Deep frying

• Cleaning air filters or equipment parts

CAUTION

This message indicates a potentially hazardous

situation, which, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

This message is used when special information,

instructions or identification are required

relating to procedures, equipment, tools,

capacities and other special data.

4

Page 5

COMBI OVEN INSTALLATION MANUAL

+

911

SAFETY INFORMATION–SAFE WORK PRACTICES

Beware of High Voltage

This equipment uses high

voltage. Serious injury can

occur if you or any untrained

or unauthorized person

installs, services, or repairs this

equipment. ALWAYS use an

AUTHORIZED SERVICE AGENT

to service your equipment.

Beware of Hot Surfaces–

DO NOT Touch

The door on this unit reaches

temperatures that can cause

burns. Use caution when

opening and closing the

door. Do not touch any of

the surfaces when the unit is

heated.

Protect Children

Keep children away from

this equipment. Children

may not understand that this

equipment is dangerous for

them and others.

Know Your Responsibilities

as an Employer

• Make certain your

employees know how to

operate the equipment.

• Make certain your

employees are aware of the safety precautions on

the equipment and in this manual.

• Make certain that you have thoroughly trained

your employees about operating the equipment

safely.

• Make certain the equipment is in proper working

condition. If you make unauthorized modifications

to the equipment, you will reduce the function

and safety of the equipment as well as void the

warranty.

Keep this Manual With the

Equipment

This manual is an important

part of your equipment.

Always keep it nearby for easy

access.

NEVER allow children to play

near or operate your equipment.

Be Prepared for Emergencies

Be prepared for fires, injuries,

or other emergencies.

Keep a first aid kit and a

fire extinguisher near the

equipment. You must use

a 40-pound type BC fire

extinguisher and keep it

within 25 feet of your equipment. Keep emergency

numbers for doctors, ambulance services, hospitals,

and the fire department near your telephone.

+

911

If you need to replace this manual, contact:

BKI

Technical Services Department

2812 Grandview Dr.

Simpsonville, SC 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Or visit www.bkideas.com

5

Page 6

COMBI OVEN INSTALLATION MANUAL

WARNING

WARNING

NOTICE

NOTICE

NOTICE

SAFETY INFORMATION–SPECIFIC PRECAUTIONS

CAUTION

Equipotential Ground Plane

When a high current flows through a conductor,

dierences in potential appear between the

conductor and nearby metallic surfaces near the

appliance. As a result, sparks may be produced

between the appliance and surrounding metal

surfaces. These sparks could cause serious

injury, damage, or fire.

BKI provides an Equipotential ground

terminal for the connection of a bonding

conductor after the installation of the

appliance per lEC60417-1. This terminal

is located on the inside of the Power

Entry Supply box near the Earth connection

and is marked with this symbol

WARNING

Disconnect power before servicing.

Improper installation, adjustment, alteration,

service, or maintenance can cause property

damage, injury, or death. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

For Your Safety

DO NOT store or use gasoline or other

flammable vapors or liquids in the vicinity of this

or any other appliance.

For Your Safety

All service must be performed by a qualified BKI

authorized technician.

For Your Safety

This manual is a part of your new Combi-King

Plus Combination oven. You must keep and

maintain it for the entire life span of your

Combi-King and pass it on to the next owner

of the unit.

Retain this manual for reference, keep it where

you can use it.

This manual may be subject to new technical

developments, modifications, and unforeseen

errors.

DO NOT operate or attempt to operate this

appliance or any accessories without reading

completely and fully understanding this manual.

DO NOT connect Combi Steamer-oven drain

connection to any drain material that cannot

sustain 175° F.

6

Page 7

COMBI OVEN INSTALLATION MANUAL

SAFETY INFORMATION

General Safety Guidelines for Installers, Users, and

Service Technicians

• Read, understand, and follow the instructions, and

heed and obey the warnings of the Installation

Manual, the Operator’s Manual, and the labels

on the Combi oven, accessories, and supporting

products.

• Improper installation, maintenance, cleaning, or

modifications to the Combi oven can lead to injury

or death of the operator(s), and equipment and

property damage.

• Steam – To avoid steam burns, open the Combi

door by turning the handle to the left or clockwise

(“airing”) position and waiting for the steam and

condensate to clear. Then, turn to the right or

counterclockwise and slowly open the door. Never

breathe steam, superheated steam, or hot air.

NOTE: The cooking program is interrupted

whenever the door is opened.

• Heat – The Combi, cooking containers, shelves,

and inner door and anything else inside the

cooking compartment are HOT, as are many of

the component parts. Wear DRY heatproof gloves

or mitts.

• Exhaust Vents – The top of the Combi, and the

gas and steam exhaust vents are very hot during

operation and remain hot for some time. Never

breathe gas or steam from the exhaust vents.

Use extreme caution when working on or near

this area and component parts.

• Grease Spatter – Hot grease will spatter and cause

burns if sprayed with water. Locate fryers and

similar appliances outside the range of the Combi

hand shower.

• Electric Shock – Use the hand shower only on

the inside of the oven. Use of the hand shower,

hoses, power cleaners, or pressure washers on

the outside of the Combi can cause electric

shock and/or damage to electrical and electronic

components.

• Cleaning and Daily Maintenance – Wait for the

Combi to cool before cleaning and performing

daily maintenance. DO NOT spray water in a hot

cooking compartment. Do not use hoses, power

cleaners, pressure washers, or harsh or abrasive

cleaning agents inside OR outside the cooking

compartment.

• Cleaning Agents – Use only BKI approved

cleaning and descaling products. Follow the

instructions and heed and obey the warnings on

the labels. Other products can damage the Combi,

cause injury, or present health hazards.

• Wear appropriate shoes/boots to the work area to

help protect feet and to help prevent slips

and falls.

• Use non-slip, draining, anti-fatigue FLOOR MATS

(not included) rated for use in wet, greasy, and dry

work areas to help prevent slipping and / or falling

injuries. Obtain the best mats for your needs from

your local supplier.

• Scalds – DO NOT place containers with liquid

contents or contents that become liquid on oven

racks higher than you can see. You must be able to

see into the container. Cover containers (individual

or on trolleys) containing hot or hot liquid items

to help prevent spills during transport. Observe

and heed, and obey the additional warning labels

posted on the Combi.

7

Page 8

COMBI OVEN INSTALLATION MANUAL

HEALTH AND SANITATION PRACTICES

BKI Combi Ovens are manufactured to comply with

health regulations and are tested and certified to

UL®, cUL®, and NSF® standards. You must operate

the equipment properly using only quality products

and use meat thermometers to insure meats are

thoroughly cooked.

Food Handling

• Wash hands thoroughly in warm, soapy water after

handling raw poultry or meats.

• Clean and sanitize all utensils and surfaces that

have been in contact with raw products. Clean

and sanitize the meat forks or baskets between

cooking.

• Never place cooked meats on the same surfaces

used to prepare raw meats, unless the area has

been thoroughly cleaned and sanitized.

Storage of Raw Meats

• Designate an area or shelf strictly for the storage

of all raw meats to be used in the oven.

• Raw product must always be stored at

temperatures below 38° F. (3° C.).

Coding Cooked Foods

• All products cooked during the day should be sold

the same day.

NOTE: Follow your company’s procedures for the

handling of any leftover product.

Storage of Prepared Foods

• Cold foods should be kept at or below

38° F. (3° C.).

• Hot foods must be maintained to meet local

health codes, usually a minimum 145° F (63°).

• Never store or mix raw foods above cooked foods,

as this is a health hazard. The drippings from raw

foods contaminate cooked or processed foods.

• All chicken and chicken parts to be stored

overnight must be thoroughly iced down

and refrigerated.

8

Page 9

66,5 29.13” (740 mm) 56,5

33.98” (863 mm)

31.34” (796 mm)

33.66” (855 mm)

71,5 22.05” (560 mm)

77

32.87” (835 mm)

34.68” (881 mm)

Ă

50

115

R574

241

129

290

204,5

298,5

610

30.43” (773 mm)

63 75

126,5

128,5

139

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN MICROBOILER TOUCHSCREEN CONTROLS

Model EHG061R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 34.68" (881 mm) 40.25" (1023 mm)

Width 33.98" (863 mm) 36.75" (934 mm)

Depth 33.66" (855 mm) 36" (915 mm)

Weight 300 lb (137 kg) 344 lb (157 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 1.2 10 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

6 ea. 12" x 20" x 2.5" (65 mm) Steam table pans

6 ea. 13" x 18" half size sheet pans

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

• Reversible doors

(consult with factory

about additional width

considerations)

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

REQUIRED CLEARANCES

Left 0" (20” (508 mm) for service)

Right 0"

Front 23" (585 mm) for door swing

Back 3” (75 mm) for plumbing

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

BTUH

• Tablet detergent

• Water filtration systems

• Culinary components

41,000

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

Visit bkideas.com to view all

accessories available for this model.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

Cooking Solutions Group

5.18.2018

Page 10

34.09” (866 mm)

36.42” (925 mm)

34.61” (879 mm)

32.87” (835 mm)

77,5

Ă

50

67 27.17” (690 mm)

39.57” (1005 mm) 5464

115

A

R834

53,5

90,5

251

88,5

220

55 75

441

75,5

70,5

697

44.21” (1123 mm)

33.19” (843 mm)

196,5

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN MICROBOILER TOUCHSCREEN CONTROLS

Model EHG062R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 34.61" (879 mm) 40.25" (1022 mm)

Width 44.21" (1123 mm) 45.5" (1156 mm)

Depth 36.42" (925 mm) 38.5" (978 mm)

Weight 448 lb (204 kg) 492 lb (224 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 1.2 10 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

12 ea. 12" x 20" x 2.5" (65 mm) steam table pans

12 ea. 13" x 18" half size sheet pan

6 ea. 18" x 26" full size sheet pan

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

• Reversible doors

(consult with factory

about additional width

considerations)

Visit bkideas.com to view all

accessories available for this model.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

REQUIRED CLEARANCES

Left 0" (20” (508 mm) for service)

Right 0"

Front 28" (705 mm) for door swing

Back 3" (75 mm) for plumbing

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

• Tablet detergent

• Water filtration systems

• Culinary components

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

BTUH

68,200

Cooking Solutions Group

5.18.2018

Page 11

R574

241

129

290

204,5

298,5

610

30.433” (773 mm)

63 75

126,5

128,5

139

33.98” (863 mm)

66,5

29.13” (740 mm) 56,5

33.66” (855 mm)

31.34” (796 mm)

45.71” (1161 mm)

77

Ă

50

115

71,5

22.05” (560 mm)

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN MICROBOILER TOUCHSCREEN CONTROLS

Model EHG101R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 45.71" (1161 mm) 51.25" (1302 mm)

Width 33.98" (863 mm) 36.75" (934 mm)

Depth 33.66" (855 mm) 36" (915 mm)

Weight 362 lb (164 kg) 413 lb (188 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 1.5 12.5 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

10 ea. 12” x 20” x 2.5” (65 mm) Steam table pans

10 ea. 13" x 18" half size sheet pan

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

• Reversible doors

(consult with factory

about additional width

considerations)

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

REQUIRED CLEARANCES

Left 0" (20” (508 mm) for service)

Right 0"

Front 23" (585 mm) for door swing

Back 3" (75 mm) for plumbing

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

BTUH

• Tablet detergent

• Water filtration systems

• Culinary components

65,000

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

Visit bkideas.com to view all

accessories available for this model.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

5.18.2018

Cooking Solutions Group

Page 12

39.567” (1005 mm) 5464

36.42” (925 mm)

43.90” (1115 mm)

45.63” (1159 mm)

77,5

67

27.17” (690 mm)

115

Ă

50

34.09” (866 mm)

R834

53,5

90,5

251

88,5

220

55 75

441

75,5

70,5

697

44.21” (1123 mm)

33.19” (843 mm)

196,5

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN MICROBOILER TOUCHSCREEN CONTROLS

Model EHG102R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 45.63" (1159 mm) 51.25" (1302 mm)

Width 44.21" (1123 mm) 45.5" (1156 mm)

Depth 36.42" (925 mm) 38.5" (978 mm)

Weight 466 lb (212 kg) 514 lb (234 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 2.3 19 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

20 ea. 12" x 20" x 2.5" (65 mm) Steam table pans

20 ea. 13" x 18" half size sheet pan

10 ea. 18" x 26" full size sheet pan

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

• Reversible doors

(consult with factory

about additional width

considerations)

Visit bkideas.com to view all

accessories available for this model.

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front 28" (705 mm) for door swing

Back 3" (75 mm) for plumbing

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

• Tablet detergent

• Water filtration systems

• Culinary components

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

BTUH

95,000

5.18.2018

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

Cooking Solutions Group

Page 13

59 25.79” (655 mm)

72.56” (1843 mm)

149

33.66” (855 mm)

36.46” (926 mm)

74.25” (1886 mm)

56,5 56,5

39.29” (998 mm)

33.66” (855 mm)

R695

32.52” (826 mm)

259

Ă

50

129,8

106,2

208,5

283,5

628,5

714

79

75,6

138

323,3

33

15588

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN MICROBOILER TOUCHSCREEN CONTROLS

Model EHG201R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 74.25" (1886 mm) 83" (2108 mm)

Width 39.29" (998 mm) 45.5" (1156 mm)

Depth 36.46" (926 mm) 41.75" (1061 mm)

Weight 781 lb (355 kg) 847 lb (385 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 2.5 21 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

20 ea. 12" x 20" x 2.5" (65mm) Steam table pans

20 ea. 13" x 18" half size sheet pan

OPTIONS & ACCESSORIES

• Trolley configuration for

baking trays (600 x 400 mm)

• Core probe

• Tablet detergent

• Water filtration systems

• Culinary components

Visit bkideas.com to view all

accessories available for this model.

REQUIRED CLEARANCES

Left 0" (20” (508 mm) for service)

Right 0"

Front

Back 3" (75 mm) for plumbing

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

• Hot & cold smoker

• Leveling plate for trolley

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

39.3" (1000 mm) for trolley exit

BTUH

130,000

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

5.18.2018

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

Cooking Solutions Group

Page 14

42.62” (1083)59.1 56.4

47.17” (1198 mm)

34.72” (882 mm)

259

Ă50

111.3

134.5

208.5

283.5

770

79

138

275.9

114.3100

59 28.19” (716 m

72.56” (1843 mm)

74.25” (1886 mm)

149

36.06” (916 mm)

38.86” (987 mm)

27.20” (691 mm)

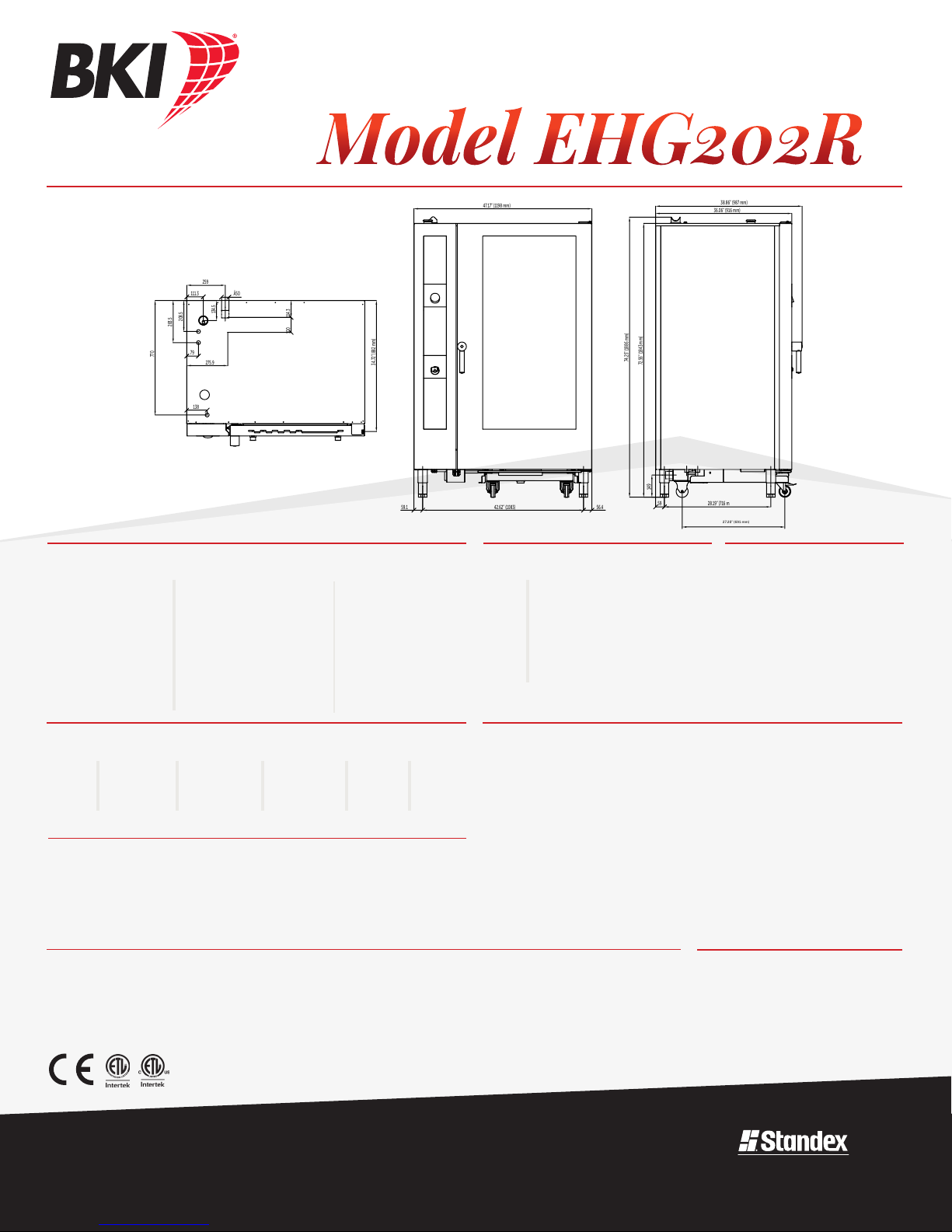

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN MICROBOILER TOUCHSCREEN CONTROLS

Model EHG202R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 74.25" (1886 mm) 83" (2108 mm)

Width 47.17" (1198 mm) 52" (1321 mm)

Depth 38.86" (987 mm) 44.5" (1131 mm)

Weight 860 lb (391 kg) 926 lb (421 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 3.1 26 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

40 ea. 12" x 20" x 2.5" (65mm) Steam table pans

40 ea. 13" x 18" half size sheet pans

20 ea. 18" x 26" full size sheet pans

OPTIONS & ACCESSORIES

• Hot & cold smoker

• Leveling plate for trolley

• Trolley configuration for

baking trays (600mm x

400mm)

• Core probe

• Tablet detergent

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front

Back 3" (75 mm) for plumbing

43.4" (1100 mm) for trolley exit

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

BTUH

• Water filtration systems

• Culinary components

191,000

Visit bkideas.com to view all

accessories available for this model.

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

5.18.2018

Cooking Solutions Group

Page 15

66,5 29.13” (740 mm) 56,5

33.98” (863 mm)

31.34” (796 mm)

33.66” (855 mm)

71,5 22.05” (560 mm)

77

32.87” (835 mm)

34.68” (881 mm)

Ă

50

115

R574

241

129

290

204,5

298,5

610

30.43” (773 mm)

63 75

126,5

128,5

139

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN BOILERLESS TOUCHSCREEN CONTROLS

Model ETG061R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 34.68" (881 mm) 40.25" (1023 mm)

Width 33.98" (863 mm) 36.75" (934 mm)

Depth 33.66" (855 mm) 36" (915 mm)

Weight 300 lb (137 kg) 344 lb (157 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 0.4 3.5 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

6 ea. 12" x 20" x 2.5" (65 mm) Steam table pans

6 ea. 13" x 18" half size sheet pans

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

• Reversible doors

(consult with factory

about additional width

considerations)

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front 23" (585 mm) for door swing

Back 3" (75 mm) for plumbing

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

BTUH

• Tablet detergent

• Water filtration systems

• Culinary components

41,000

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

Visit bkideas.com to view all

accessories available for this model.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

Cooking Solutions Group

5.18.2018

Page 16

34.09” (866 mm)

36.42” (925 mm)

34.61” (879 mm)

32.87” (835 mm)

77,5

Ă

50

67 27.17” (690 mm)

39.57” (1005 mm) 5464

115

A

R834

53,5

90,5

251

88,5

220

55 75

441

75,5

70,5

697

44.21” (1123 mm)

33.19” (843 mm)

196,5

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN BOILERLESS TOUCHSCREEN CONTROLS

Model ETG062R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 34.61" (879 mm) 40.25" (1022 mm)

Width 44.21" (1123 mm) 45.5" (1156 mm)

Depth 36.42" (925 mm) 38.5" (978 mm)

Weight 448 lb (204 kg) 492 lb (224 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 0.4 3.5 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

12 ea. 12" x 20" x 2.5" (65 mm) steam table pans

12 ea. 13" x 18" half size sheet pan

6 ea. 18" x 26" full size sheet pan

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

• Reversible doors

(consult with factory

about additional width

considerations)

Visit bkideas.com to view all

accessories available for this model.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front 28" (705 mm) for door swing

Back 3" (75 mm) for plumbing

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

• Tablet detergent

• Water filtration systems

• Culinary components

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

BTUH

68,200

Cooking Solutions Group

5.18.2018

Page 17

R574

241

129

290

204,5

298,5

610

30.433” (773 mm)

63 75

126,5

128,5

139

33.98” (863 mm)

66,5

29.13” (740 mm) 56,5

33.66” (855 mm)

31.34” (796 mm)

45.71” (1161 mm)

77

Ă

50

115

71,5

22.05” (560 mm)

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN BOILERLESS TOUCHSCREEN CONTROLS

Model ETG101R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 45.71" (1161 mm) 51.25" (1302 mm)

Width 33.98" (863 mm) 36.75" (934 mm)

Depth 33.66" (855 mm) 36" (915 mm)

Weight 362 lb (165 kg) 413 lb (188 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 0.7 6 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

10 ea. 12” x 20” x 2.5” (65 mm) Steam table pans

10 ea. 13" x 18" half size sheet pan

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

• Reversible doors

(consult with factory

about additional width

considerations)

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front 23" (585 mm) for door swing

Back 3" (75 mm) for plumbing

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

BTUH

• Tablet detergent

• Water filtration systems

• Culinary components

65,000

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

Visit bkideas.com to view all

accessories available for this model.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

5.18.2018

Cooking Solutions Group

Page 18

39.567” (1005 mm) 5464

36.42” (925 mm)

43.90” (1115 mm)

45.63” (1159 mm)

77,5

67

27.17” (690 mm)

115

Ă

50

34.09” (866 mm)

R834

53,5

90,5

251

88,5

220

55 75

441

75,5

70,5

697

44.21” (1123 mm)

33.19” (843 mm)

196,5

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN BOILERLESS TOUCHSCREEN CONTROLS

Model ETG102R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 45.63" (1159 mm) 51.25" (1302 mm)

Width 44.21" (1123 mm) 45.5" (1156 mm)

Depth 36.42" (925 mm) 38.5" (978 mm)

Weight 466 lb (212 kg) 514 lb (234 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 0.8 6.5 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

20 ea. 12" x 20" x 2.5" (65 mm) Steam table pans

20 ea. 13" x 18" half size sheet pan

10 ea. 18" x 26" full size sheet pan

OPTIONS & ACCESSORIES

• Stands

• Stacking system

• Hot & cold smoker

• Reversible doors

(consult with factory

about additional width

considerations)

Visit bkideas.com to view all

accessories available for this model.

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front 28" (705 mm) for door swing

Back 3" (75 mm) for plumbing

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

• Rack configuration for

baking trays (600 x 400 mm)

• Core probe

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

• Tablet detergent

• Water filtration systems

• Culinary components

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

BTUH

95,000

5.18.2018

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

Cooking Solutions Group

Page 19

59 25.79” (655 mm)

72.56” (1843 mm)

149

33.66” (855 mm)

36.46” (926 mm)

74.25” (1886 mm)

56,5 56,5

39.29” (998 mm)

33.66” (855 mm)

R695

32.52” (826 mm)

259

Ă

50

129,8

106,2

208,5

283,5

628,5

714

79

75,6

138

323,3

33

15588

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN BOILERLESS TOUCHSCREEN CONTROLS

Model ETG201R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 74.25" (1886 mm) 83" (2108 mm)

Width 39.29" (998 mm) 45.5" (1156 mm)

Depth 36.46" (926 mm) 41.75" (1061 mm)

Weight 781 lb (355 kg) 847 lb (385 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 1.0 8 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

20 ea. 12" x 20" x 2.5" (65mm) Steam table pans

20 ea. 13" x 18" half size sheet pan

OPTIONS & ACCESSORIES

• Trolley configuration for

baking trays (600 x 400 mm)

• Core probe

• Tablet detergent

• Water filtration systems

• Culinary components

Visit bkideas.com to view all

accessories available for this model.

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front 40" (1016 mm) for trolley exit

Back 3" (75 mm) for plumbing

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

• Hot & cold smoker

• Leveling plate for trolley

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

BTUH

130,000

5.18.2018

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

Cooking Solutions Group

Page 20

42.62” (1083)59.1 56.4

47.17” (1198 mm)

34.72” (882 mm)

259

Ă50

111.3

134.5

208.5

283.5

770

79

138

275.9

114.3100

59 28.19” (716 m

72.56” (1843 mm)

74.25” (1886 mm)

149

36.06” (916 mm)

38.86” (987 mm)

27.20” (691 mm)

EQUIPMENT DIMENSIONS

COMBIKING COMBINATION OVEN BOILERLESS TOUCHSCREEN CONTROLS

Model ETG202R

MECHANICAL SPECIFICATIONS

Dimension Uncrated Crated

Height 74.25" (1886 mm) 83" (2108 mm)

Width 47.17" (1198 mm) 52" (1321 mm)

Depth 38.86" (987 mm) 44.5" (1131 mm)

Weight 860 lb (391 kg) 926 lb (421 kg)

ELECTRICAL OPTIONS

Volts Phase Cycle/Hz kW Amps Wires

120 1 60 1.6 13 2+Grnd

NOTE: Cord and plug are included with the unit

PAN CAPACITY

40 ea. 12" x 20" x 2.5" (65mm) Steam table pans

40 ea. 13" x 18" half size sheet pans

20 ea. 18" x 26" full size sheet pans

OPTIONS & ACCESSORIES

• Hot & cold smoker

• Leveling plate for trolley

• Trolley configuration for

baking trays (600mm x

400mm)

• Core probe

• Tablet detergent

REQUIRED CLEARANCES

Left 0" (20" (508 mm) for service)

Right 0"

Front 44" (1118 mm) for trolley exit

Back 3" (75 mm) for plumbing

WATER CONNECTIONS

3/4" standard cold water

connection

3/4" soft water connection

2" (50 mm) drain

WATER REQUIREMENTS

Pressure (min-max): 35 • 87 PSI

Hardness (CaC03) = Less than 7.5 GPG (Grains per Gallon)

TDS (Total Dissolved Solids)= Less than 100.0 mg/L (Milligrams per Liter

Free Chlorine = Less than 0.5 mg/L (Milligrams per Liter)

Chlorides =Less than 20 mg/L (Milligrams per Liter)

Chloramines = Less than 0.5 mg/L (Milligrams per Liter)

Total Alkalinity= Less than 20 mg/L (Milligrams per Liter)

Total Silica = Less than 10mg/L (Milligrams per Liter) pH level= 7.0 to 8.0

Conductivity (Boiler Models only) = Minimum of 20 µS/ecm (microSiemens per cm)

• Not maintaining water quality to factory requirements voids warranty

BTUH

• Water filtration systems

• Culinary components

191,000

Visit bkideas.com to view all

accessories available for this model.

bkideas.com

© BKI LI0283C/08-06

Specifications are subject to

change without notice.

BKI Worldwide, Inc.

2812 Grandview Drive

Simpsonville, SC 29680

Telephone: (864) 963-3471

Toll Free: (800) 927-6887

BKI Worldwide, Inc. is a wholly owned subsidiary

of Standex International Corporation.

Dimensions nominal.

Shipping Class: #110

FOB Simpsonville, SC

5.18.2018

Cooking Solutions Group

Page 21

COMBI OVEN INSTALLATION MANUAL

PRE-INSTALLATION CHECKLIST

The following points are a listing of requirements that should be verified prior to the installation of the BKI

Combi Oven. For more specific installation requirements, refer to instruction manual that comes with the

oven.

1. Verify ventilation requirements. Will the installation use an existing hood or ventless hood?

2. Verify ventilation height requirements. What is the clearance under the hood?

3. If a ventilation hood is installed above the oven, it should project 19.69” (500 mm) over the front of the

oven. The suction eect should be 400 to 800 m3/h (523 to 1046 yd3/h).

4. Verify the drain is accessible and will not be located directly under the oven.

5. Verify the drain for the oven is made of stainless steel or an equally temperature-resistant material,

minimum 175° F.

6. Verify the drain for the oven is at least 1.97” (50 mm) in diameter and a fall of at least 3° or 5%.

7. Verify correct power supply (1 Phase, 3 wire, 120V, Amperage) is available and within 10 feet of oven

location. Power cord exits oven on right hand side (facing the unit).

8. Verify proper Electrical Supply Voltage, Amperage, and Phase. Typical requirements are 120VAC, 3 Phase,

60 Hz with 3 wires (2 legs with a ground).

NOTE: There is no NEUTRAL.

9. Verify gas supply pressure and volume capacity.

10. Verify the installation area for the oven will have minimum clearances of 3” (75 mm) from the rear wall,

0” from any objects on the right side of the oven and 0” for clearance on the left side of the oven while

in operation. The left side requires 20” (508 mm) clearance for servicing (page 23).

NOTE: High heat source equipment should not be located to the left of the oven.

11. Verify cold water supply to the oven will be between 40-60 PSI (flowing).

12. Verify the water concentrations:

____ Hardness (GPG of CaCO3), ____ Iron, ____ pH, ____ TDS, ____ Chlorine, ____ Chloride.

NOTE: If water hardness exceeds the allowable limit noted, an approved water treatment system capable

of removing Chlorine and Chloramines should be installed in the water supply line to the oven. Installing

a water treatment system will extend the life the oven and minimize the potential for future corrosion.

Potential Install Location: _______________________________ Store Number: ____________________________

Customer Name: _______________________________________ Customer Title: ____________________________

Phone Number: _______________________________________ Date: _____________________________________

21

Page 22

COMBI OVEN INSTALLATION MANUAL

DANGER

VENTILATION REQUIREMENTS

Gas combi ovens must be located under an

exhaust hood. Information on the construction and

installation of ventilating hoods may be obtained

from Vapor Removal from Cooking Equipment,

NFPA Standard No. 96 (latest edition).

• Kitchen ventilation must include a provision for

an adequate flow of fresh air for gas combustion

and to prevent a negative-pressure condition. The

bottom of the oven provides air supply access

for gas combustion and must be kept clear at all

times. DO NOT obstruct or restrict ventilation nor

the air flow required to support combustion.

• DO NOT obstruct the flow of the exhaust flue at

the top rear of the oven. It is especially critical that

gas supply piping and electrical support cord and/

or receptacle be routed away from the path of the

hot combustion fumes.

Exhaust Hood

NOTE: all hood and ducting of ovens must comply

to local codes interpreted by fire and building

inspectors in the municipality where the oven is

installed.

Ventilation hoods must ensure an adequate amount

of incoming air during operation and must be

operated whenever the Combination oven/steamer

is used in order to avoid the accumulation of

condensation in the hood area.

FAILURE TO VENT THIS APPLIANCE PROPERLY

MAY BE HAZARDOUS TO THE HEALTH

OF THE OPERATOR. Equipment damage,

operational problems, and unsatisfactory baking

performance may also be the consequence of

improper venting. Any damages sustained by a

failure to properly vent this oven are not

covered under warranty.

22

Page 23

WATER QUALITY

COMBI OVEN INSTALLATION MANUAL

As with all steam related products, water filtration

and regular filter replacements may be necessary

with the Combi. It is strongly recommended to have

a water analysis performed prior to installing the

Combi. Poor water quality can have a big impact

on cook quality, performance, and longevity of

the Combi. Varying combinations of pH; alkalinity;

hardness; chlorides; total dissolved solids; and other

chemical characteristics, when subjected to high

temperatures, will cause water to have a tendency

to either scale or corrode.

There are a number of dierent water filter/

treatment systems available and each has its own

benefits and specialties. Below are a dierent styles

and their benefits. Multiple styles may need to be

used to get the water to proper levels.

• Particle Filter

When the water contains sand, iron particles, or

suspended matter, we recommend a 5-15 µm

(micrometer) particle filter.

• Active Carbon Filter

When the level of chlorine (Cl) in the water

exceeds 0.5 mg/L (ppm) (information available

from the water company), an active carbon filter

should be installed.

• Phosphate Additive System

A Phosphate Additive (Feeder) System is

recommended for steam generator units

only when a moderate level of scale (not

containing chloride) is experienced. The system

recommended is Kleensteam from Everupure.

• Ion Exchange System

An ion exchange system is recommended for a

steam generator based unit when a high level of

scale (not containing chloride) is experienced and

for a spritzer based unit when any scale (not

containing chloride) is experienced. Systems

recommended: Claris from Everpure (H+ Ion

Exchanger). Sodium ion exchangers (as used in

dishwashers) must not be used.

• Blended Reverse Osmosis (RO)

When the water has a chloride (Cl) concentration

above 20 mg/L (= 20 ppm), a blended RO system

should be installed to avoid corrosion.

NOTE: Make sure a minimum conductivity of 20

µS/cm (microSiemens) remains in the water for

steam generator units.

Water quality must conform to the below

requirements. If water does not meet the minimum

quality and damage to the oven is determined to

be due to water quality, it will be considered nonwarranty and will not be covered under the stated

warranty policy.

BKI Minimum Water Quality Requirements

– Hardness (CaCO3) = Less than

7.5 GPG (Grains per Gallon)

– TDS (Total Dissolved Solids) = Less than

100.0 mg/L (Milligrams per Liter)

– Free Chlorine = Less than 0.5 mg/L

(Milligrams per Liter)

– Chlorides = Less than 20 mg/L

(Milligrams per Liter)

– Chloramines = Less than 0.5 mg/L

(Milligrams per Liter)

– Total Alkalinity = Less than 20 mg/L

(Milligrams per Liter)

– Total Silica = Less than 10 mg/L

(Milligrams per Liter)

–pH level = 7.0 to 8.0

– Conductivity (Boiler Models only) = Minimum

of 20 µS/cm (microSiemens per cm)

Water Usage

Average Water Flow = 8.5 gal/hour at 36 psi inlet

pressure for half size 6 grid oven; 9.8 gal/hour at

36 psi inlet pressure for half size 10 grid oven; 11.6

gal/hour at 36 psi inlet pressure for full size 10 grid

oven; Peak Water consumption = 2.6 gal/min

23

Page 24

INSTALLATION

WARNING

WARNING

COMBI OVEN INSTALLATION MANUAL

General Information

Serious injury, equipment damage or death

could result if attempting to install this Combi

oven yourself. Ensure that an authorized BKI

service agent installs the Combi oven.

Only qualified, professional plumbers, pipe

fitters, and electricians should install this

equipment.

• The installation of this Combi must conform with:

– The Basic Plumbing Code of the Building

Ocials and Code Administrators

International, Inc. (BOCA).

– The National Fuel Gas Code, ANSI Z223.1 /

NFPA 54 (latest edition) or the Natural Gas

and Propane Installation Code CSA B1 49.1 as

applicable.

– The National Electrical Code, ANSI/NFPA 70

(latest edition), or the Canadian Electrical

Code, CSA C22.2 as applicable.

Unpacking and Handling

It is the owners’ responsibility to file all freight

claims with the delivering truck line. Inspect all

cartons and crates for damage as soon as they

arrive. If damage to cartons or crates is found, or if a

shortage is found, note this on the bill of lading (all

copies) prior to signing.

If damage is found when the equipment is opened,

immediately call the delivering truck line and

follow up the call with a written report indicating

concealed damage to your shipment. Ask for an

immediate inspection of your concealed damage

item. Packaging material MUST be retained to show

the inspector from the truck line.

Remove all packing from the interior and exterior of

the oven.

– The Food Service Sanitation Manual of the

Food and Drug Administration (FDA).

– All applicable national, state, and local laws,

codes, and regulations.

Death, injury, and equipment damage can

result from improper lifting. Use adequate

workers with training and experience lifting

heavy equipment to place the Combi oven on

the supporting surface.

24

Page 25

COMBI OVEN INSTALLATION MANUAL

INSTALLATION–REQUIRED CLEARANCES/POSITIONING

Required Clearances

BB

AA

D

D

A. Left Side – 0" and 20" (servicability)

B. Rear – 3" (utilities)

C. Right Side – 0"

D. Front – Dependent on model door swing

– If next to a high heat source (i.e. fryer or broiler),

ensure that there is adequate distance or a heat

shield is installed.

– Allow for adequate clearance on left side for

service.

C

C

Positioning

Follow the criteria below when selecting a location

for your Combi oven:

• Ensure the Combi oven will go through any

doorways or passages (see Shipping Weights and

Dimensions table below).

• If Combi oven is going on a counter top or

stand not supplied by BKI, ensure the supporting

structure can hold the weight of the Combi oven

fully loaded with food (see Shipping Weights and

Dimensions table below).

• The floor/stand must be level to ensure proper

door sealing and operation.

• The position of the Combi oven should be that the

Combi oven will not slide or tip.

• The area around the Combi oven should be free

from combustibles.

• The ambient temperature should be within

40° F to 95° F.

• Ensure the Combi oven air vents are not blocked.

NOTE: Do not install the Combi over a drain. Rising

steam out of the drain can have adverse aects

on operation, impede cooling air circulation, and

damage electrical and electronic components.

SHIPPING WEIGHTS & DIMENSIONS

Steam Generator Model Weight Lbs (kg) Width in (mm) Depth in (mm) Height in (mm)

ETG & EHG 061R 344 (157) 36.75 (934) 36 (915) 40.25 (1023)

ETG & EHG 062R 492 (224) 45.5 (1156) 38.5 (978) 40.25 (1023)

ETG & EHG 101R 413 (188) 36.75 (934) 36 (915) 51.25 (1302)

ETG & EHG 102R 514 (234) 45.5 (1156) 38.5 (978) 51.25 (1302)

ETG & EHG 201R 847 (385) 45.5 (1156) 41.75 (1061) 83 (2108)

ETG & EHG 202R 926 (421) 52 (1321) 44.5 (1131) 83 (2108)

25

Page 26

COMBI OVEN INSTALLATION MANUAL

INSTALLATION–POSITIONING/DOOR ADJUSTMENT

1

1

2

Move the Combi oven into final position. Level front

to back and side to side by turning lower legs for

proper operation.

33

2

2

2

1 3

To adjust the door seal, loosen the hinge bolts and

move the door to desired position. Once adjusted,

tighten the hinge bolts again. See dimensions on

door gap.

Door Adjustment

Once the oven has been correctly positioned in its

designated place for installation, check the oven

compartment door closing and

seal of the gaskets.

The door hinges must be

adjusted to assure maximum

seal of the oven door during its

operation. See dimensions on

door gap.

The door’s catch can be

adjusted in depth to eliminate

any steam leaks during cooking.

12-14 mm

Door Gap

3-5 mm

NOTE: Both the upper and lower hinges should be

adjusted.

3

1

2

2

To adjust pressure applied by the door on the

gasket, open the oven door and locate the catch

pin. Using a 1/2" wrench, loosen the nut on the

back of the pin. Turn the pin clockwise to increase

the pressure or turn the pin counterclockwise to

decrease the pressure. Retighten the nut.

26

Page 27

COMBI OVEN INSTALLATION MANUAL

INSTALLATION–ELECTRICAL CONNECTION

Check to make sure the electrical rating on the

rating plate (located on the back of the Combi

oven) matches the supplied electrical connection.

The Combi oven must be properly grounded

and have the electrical power lines installed in

accordance to all applicable codes, regulations, and

laws.

A dedicated main disconnect switch and a separate

fuse or breaker for each Combi oven should be

installed.

The customer connection terminals are located

behind the left side panel.

T ELECTRICAL OPTIONS

ETG061R

ETG062R

ETG101R

ETG102R

ETG201R

ETG202R

Volts

120

120

120

120

120

120

Phase

1

1

1

1

1

1

Cycle/Hz

60

60

60

60

60

60

4

Remove the left side panel. Connect the wiring

to the termial as shown. For all other models, #8

electrical wires are required.

kW

0.4

0.4

0.7

0.8

1.0

1.6

Amps

3.5

3.5

6

6.5

8

13

Wires

2+Grnd

2+Grnd

2+Grnd

2+Grnd

2+Grnd

2+Grnd

H ELECTRICAL OPTIONS

Volts

EHG061R

EHG062R

EHG101R

EHG102R

EHG201R

EHG202R

120

120

120

120

120

120

Phase

1

1

1

1

1

1

Cycle/Hz

60

60

60

60

60

60

27

kW

1.2

1.2

1.5

2.3

2.5

3.1

Amps

10

10

12.5

19

21

26

Wires

2+Grnd

2+Grnd

2+Grnd

2+Grnd

2+Grnd

2+Grnd

Page 28

ELECTRIC COMBI OVEN

INSTALLATION–WATER CONNECTION

The Combi oven requires two 3/4" GHT (Garden

Hose Thread) cold water connections. One is for

treated water that feeds the spritzer and/or steam

generator, and one for untreated water that feeds

the hand shower, drain quench, and cleaning

system. Both connections need to be connected

to a cold water supply for proper operation of the

Combi oven.

• If the water supply meets the minimum water

quality requirements, then a single water supply

configuration may be used. If a single water

connection is used, a water distributor or tee

should be sized appropriately to handle both water

connections.

• The minimum water temperature for the correct

functioning of the oven is 43° F. The maximum

water temperature for the correct functioning of

the oven is 80° F.

• Dynamic Pressure = minimum of 35 PSI. Should

the incoming water pressure be lower than

the minimum value, install a pump or adjust

the pressure regulator upstream of the oven to

achieve the required minimum pressure.

• Static Pressure = maximum 87 PSI. Should the

incoming water pressure be higher than maximum

value, install a pressure reducer upstream of the

Combi oven.

Before connecting, let sucient amount of water

flow to clean the pipes from any residues.

5

Shut o valve

Treated

Water

Connect the cold water supply lines to Combi oven

water connection outlets. Make sure there is a shut

o between the lines and the oven, placed in an

area where it can be seen and reached in case of

emergency.

• Install the water supply lines before positioning

the Combi oven.

• Water supply lines should be located so that the

Combi oven can be easily moved for servicing.

• Check that the check valve of the solenoid valve is

clean.

• Backflow Prevention — The equipment must be

installed with adequate backflow protection to

comply with applicable federal, state, and local

codes.

28

Page 29

COMBI OVEN INSTALLATION MANUAL

NOTICE

INSTALLATION–DRAIN CONNECTION

The Combi oven is supplied with a 50 mm (2”)

drain pipe out the back of the unit. The drain line

is to be installed in compliance with the Basic

Plumbing Code of the Building Ocials and Code

Administrators International, Inc. (BOCA) and the

Food Service Sanitation Manual of the Food and

Drug Administration (FDA) and any other applicable

national, state, or local codes and regulations.

Do Not install the Combi oven directly over a drain.

Steam rising up out of the drain will adversely aect

operation, impede cooling air circulation, and

damage electrical and electronic components.

Improper installation of drain outlet line voids

the Combi oven warranty.

The following requirements are critical to the safety

of personnel and equipment and must be adhered

to under any circumstances.

• The drain for the Combi oven should be made of

stainless steel or an equally temperature-resistant

material (minimum 175° F).

The total length of pipe and number of bend

fittings required to reach the open drain determines

the pipe size used to extend the drain line to an

open drain.

6a

2" pipe

(6' or less connection)

For drain pipe connections of 6 feet or less

(requires no more than two elbows), connect

2” drain pipe to outlet extension on lower back

of Combi oven. Use a hose clamp, as required, to

secure the drain pipe to the oven drain.

• Do Not connect drains from any other equipment

to the drain line of the Combi oven.

• Do Not connect the drain outlet extension line

directly into a floor drain or a sewer line.

• The drain line must be free air vented, have gravity

flow from the Combi oven, and terminate outside

the perimeter of the Combi oven.

Note: Free air venting requires minimum 1”

clearance between the end of the drain line and

the top of the floor drain.

• The drain line must have gravity flow from the

Combi drain outlet to floor drain.

• Do Not install a trap in the drain line.

6b

2 1/2" pipe

(6' to 12' connection)

For drain pipe connections of 6 to 12 feet

(requires three elbows), connect 2 1/2” drain pipe to

outlet extension on lower back of Combi oven.

29

Page 30

COMBI OVEN INSTALLATION MANUAL

DANGER

INSTALLATION–GAS CONNECTION

Death, injury, and equipment damage can

result from improper lifting. Use adequate

workers with training and experience lifting

heavy equipment to place the Combi oven

on the supporting surface.

If the installer smells gas, or suspects there is

gas leak, immediately refer to posted gas leak

instructions. The posted instructions are provided

by the local gas supplier and supersede any

other instructions.

Install Gas Supply Lines

Installer/owner is responsible for furnishing and

installing gas supply lines, valves, regulators,

and accessories.

When installing gas supply lines and accessories,

observe the following:

• The installation must conform with local codes, or

in absence of local codes, with National Fuel Gas

Code, ANSI Z223.1 / NFPA 54 (or latest edition), or

Natural Gas and Propane Installation Code, CSA

B1 49.1, and any other applicable national, state, or

local codes and regulations.

Observe the following precautions in addition to

the posted instructions:

• DO NOT light or start any appliance.

• DO NOT touch any electrical switch.

• DO NOT use any phone in the building.

• Immediately call the gas supplier from a phone

away from the building. Follow the gas supplier’s

instructions.

• I f the gas supplier cannot be reached, call the fire

department

Gas Supply

• Make sure gas supply type matches type of gas

shown on the rating plate.

• Make sure that gas supply pressure does not

exceed 14" water column (1/2 psi), and falls within

acceptable gas pressure range shown below:

– Natural gas pressure must be between

5 1/2" – 7" water column

• GAS SUPPLY PRESSURE TO THE COMBI MUST

NEVER EXCEED 14" WATER COLUMN (1/2 psi). If

the gas supply pressure exceeds 14” water column,

a pressure regulator must be installed in gas supply

plumbing to reduce pressure to the Combi.

7

Gas

shut o valve

3/4" NPT gas inlet

Gas line

– Propane gas pressure must be between

11" – 14" water column

Install the gas line on the 3/4" NPT gas inlet. It is

located on the bottom right of the Combi.

• Install main manual shut o valve between gas

supply and the Combi.

30

Page 31

COMBI OVEN INSTALLATION MANUAL

INSTALLATION–GAS CONNECTION

• Install sediment trap (drip leg) in gas supply line.

• Use a pipe sealant resistant to LP gas.

Leak Test Gas Supply

• Before turning on gas to the Combi or after any

service to gas supply:

– Test all pipe joints for leaks with soap and

water solution.

– All leaks must be corrected before attempting

to operate the Combi.

Pressure Testing the Gas Supply Lines

If any pressure testing is required, the Combi must

be isolated from the gas supply system

during any pressure testing as follows:

• HIGH PRESSURE TESTING:

The Combi and its main manual shut-o valve

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 14" Water Column

(1/2 psi or 3.45 kPa). Leak test all joints and fittings

with a soap and water solution after reconnecting

gas supply

• LOW PRESSURE TESTING:

The COMBI must be isolated from the gas supply

piping system by closing its main manual shut-o

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less

than 14" water column (1/2 psi or 3.45kPa). Leak

test all joints and fittings with a soap and water

solution after opening the main manual shut-o

valve.

31

Page 32

COMBI OVEN INSTALLATION MANUAL

PRODUCT REGISTRATION/INSTALLATION CHECKLIST

In order for the oven to qualify for warranty, this checklist must be filled out by an Authorized Service

Technician and returned to BKI within 30 days of the date of installation. The Authorized Service Technician

must sign this document, obtain the customer’s signature, and send this form via fax to 864-963-5316 or via

e-mail to: customerservice@bkideas.com. Referto instruction manual for all specific installation requirements.

Model #: ______________________________________ Serial #: _________________________________________

Machine Voltage & Phase: _______________________ Installed by (Name): ______________________________

Company Name/Address: _______________________ Gas Type: _______________________________________

Start-Up by (Name): ____________________________ Date of Installation: ______________________________

Date of Start-Up: ______________________________ Company Name/Address: _________________________

Store Name: ___________________________________ Install Location: __________________________________

Customer Title: ________________________________ Customer Name: _________________________________