Page 1

X-Large, Double-Rotating

Rotisserie Oven Series

Series: DRGV with TouchTEC controls

Operation Manual

Page 2

CS-TM-051.04 09/25/18

NOTICE

The purchaser must post, in a prominent location, instructions to be followed

in the event the user smells gas. This information shall be obtained by

consulting the local gas supplier.

Gas Rotisserie Oven

MODEL DRGV (with TouchTEC Controller)

Service Manual

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operation and

maintenance instructions thoroughly before installing or servicing this

equipment.

Page 3

CS-TM-051.04 09/25/18

BKI LIMITED WARRANTY

2812 Grandview Dr. • Simpsonville, SC 29680 • USA

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the

original purchaser providing that:

The equipment has not been accidentally or intentionally damaged, altered or misused;

The equipment is properly installed, adjusted, operated and maintained in accordance with national

and local codes, and in accordance with the installation and operating instructions provided with this

product.

The serial number rating plate affixed to the equipment has not been defaced or removed.

WHO IS COVERED This

warranty

is

extended

to the original

purchaser

and applies only to

equipment purchased

for use in the U.S.A.

COVERAGE PERIOD

Warranty claims must be received in writing by BKI within one (1) year from date of

installation or within one (1) year and three (3) months from data of shipment from the

factory, whichever comes first.

COB Models: One (1) Year limited parts and labor.

COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a two (2)

year door warranty.

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door warranty.

BevLes Products: Two (2) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after

shipment date from BKI, whichever comes first.

WARRANTY COVERAGE This

warranty

covers on-site labor, parts and

reasonable

travel

time

and travel e

xpenses

of the

authorized

service

representative

up to (100) miles

round

trip and (2)

hours

travel time and

performed during regular, weekday business hours.

EXCEPTIONS Any exceptions must be pre-approved in advance and in writing by BKI. The extended door warranty

on convection ovens years 3 through 5 is a parts only warranty and does not include labor, travel,

mileage or any other charges.

EXCLUSIONS

Negligence

or acts of

God,

Thermostat calibrations

after (30) days

from equipment installation date,

Air and gas

adjustments,

Light

bulbs,

Glass doors and

door adjustments,

Fuses,

Adjustments

to

burner

flames and

cleaning of

pilot

burners,

Tightening

of screws or

fasteners,

Failures

caused

by erratic

voltages

or gas

suppliers,

Unauthorized

repair by

anyone other than

a BKI F

actory Authorized

Service Center,

Damage

in

shipment,

Alteration,

misuse or

improper installation,

Thermostats

and safety valves with

broken

capillary tubes,

Freight –

other than normal UPS charges,

Ordinary

wear and

tear,

Failure to follow

installation and/or operating instructions,

Events

beyond control

of the

company.

INSTALLATION Leveling, as well as

proper installation

and check out of all

new equipment -

per

appropriate

installation

and use materials – is the responsibility of the

dealer

or installer, not the

manufacturer.

REPLACEMENT PARTS

BKI genuine

Factory OEM parts receive a (90) day

materials warranty

effective from the date of

installation

by a BKI F

actory Authorized

Service

Center.

Warranty

is in lieu of all

other warranties, expressed

or implied, and all

other obligations

or

liabilities on the

manufacturer’s

part. BKI shall in no

event

be liable for any

special, indirect

or

consequential damages,

or in any

event

for

damages

in excess of the

purchase

price of the

unit. The repair or

replacement

of

proven defective

parts shall

constitute a

fulfillment of all

obligations under

the terms of this

warranty.

Page 4

Rotisserie Oven Table of Contents

1

Table of Contents

Table of Contents ............................................................................................................................................................... 1

Introduction ......................................................................................................................................................................... 2

Safety Precautions ........................................................................................................................................................... 2

Safety Signs and Messages ........................................................................................................................................ 2

Specific Precautions .................................................................................................................................................... 2

Safe Work Practices .................................................................................................................................................... 4

Safety Labels ............................................................................................................................................................... 5

Health and Sanitation Practices ....................................................................................................................................... 5

Food Handling .............................................................................................................................................................. 6

Storage of Raw Meats ................................................................................................................................................. 6

Coding Cooked Foods ................................................................................................................................................. 6

Storage of Prepared Foods ......................................................................................................................................... 6

Operation ............................................................................................................................................................................. 7

Controls and Indicators .................................................................................................................................................... 7

Hardware Controls ....................................................................................................................................................... 7

Software Controls – Operation Screens ...................................................................................................................... 8

Software Controls – Programming Screens .............................................................................................................. 10

Programming the Controller Using the Touchscreen Interface ...................................................................................... 12

Edit a Recipe .............................................................................................................................................................. 12

Edit the Basic Setup................................................................................................................................................... 12

Operation with the Controller ......................................................................................................................................... 13

Viewing Recipes ........................................................................................................................................................ 13

Cooking ...................................................................................................................................................................... 13

Operation After a Gas or Power Outage ........................................................................................................................ 14

Normal Shutoff ............................................................................................................................................................... 14

Installing Rotor System .................................................................................................................................................. 14

Preparing and Loading Chickens ................................................................................................................................... 14

Trussing Chickens ..................................................................................................................................................... 15

V-Spits ....................................................................................................................................................................... 16

Baskets ...................................................................................................................................................................... 17

Installation ......................................................................................................................................................................... 18

Unpacking and Handling ................................................................................................................................................ 18

Location and Clearance ................................................................................................................................................. 18

Specific Instructions ....................................................................................................................................................... 18

Counter Top and Stand .................................................................................................................................................. 19

Mounting ......................................................................................................................................................................... 20

Stacking Ovens .............................................................................................................................................................. 22

Locking Ovens in Place .................................................................................................................................................. 27

Gas Supply Connection ................................................................................................................................................. 28

Gas Manifold Pressure Test ........................................................................................................................................... 28

Maintenance ...................................................................................................................................................................... 29

Scheduled Maintenance ................................................................................................................................................. 29

Daily Cleaning & Maintenance ................................................................................................................................... 29

Troubleshooting.............................................................................................................................................................. 32

Accessories....................................................................................................................................................................... 35

Replacement Parts ........................................................................................................................................................... 36

Wiring Diagram ................................................................................................................................................................. 41

Notes .................................................................................................................................................................................. 42

BKI Worldwide is a wholly owned subsidiary of Standex International Corporation.

Page 5

Rotisserie Oven Introduction

2

Introduction

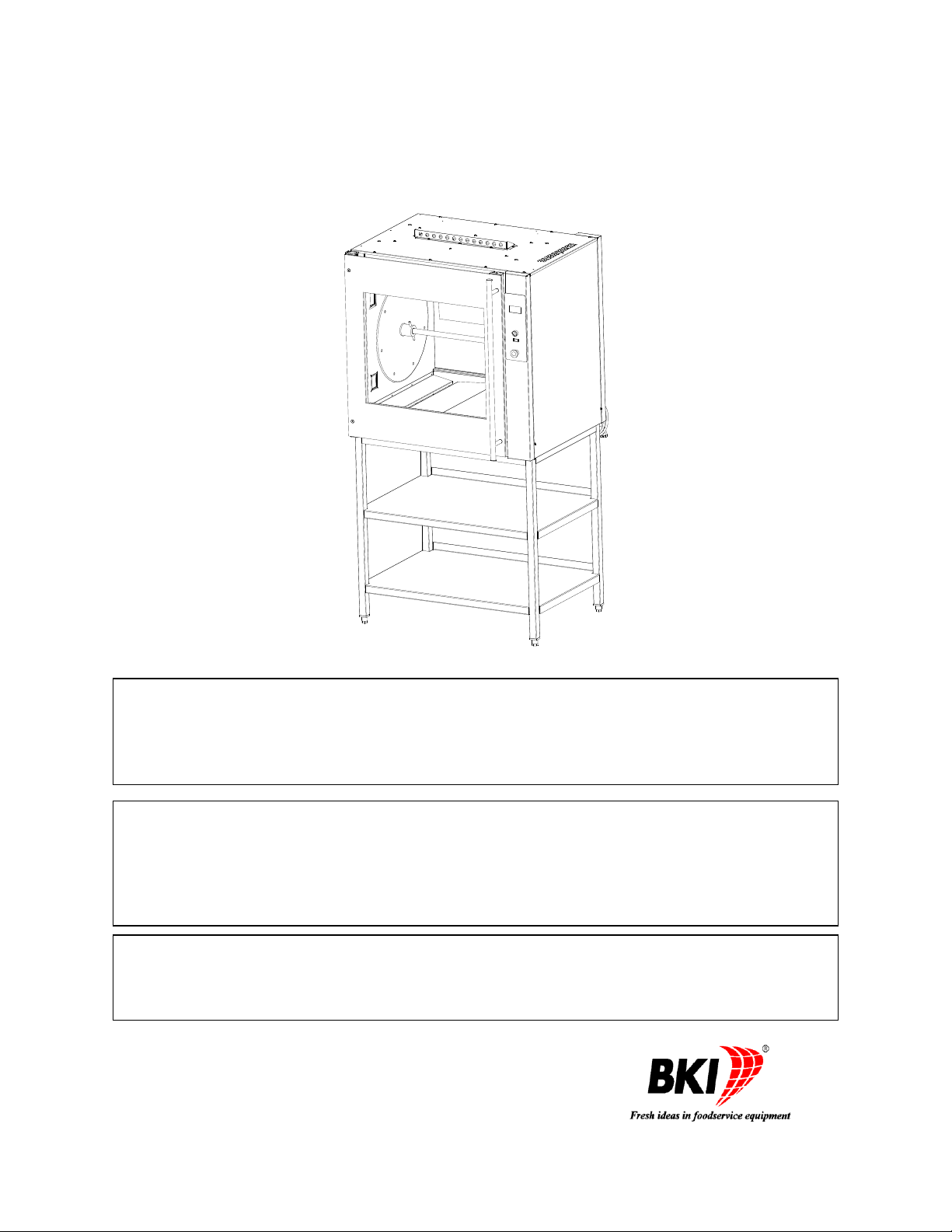

Your BKI DRGV is a computer controlled gas rotisserie oven. It utilizes a double revolving mechanism and infrared

burner that ensure even product cooking. A touchscreen control and switches are provided to allow for quick setup and

operation. Removable components allow for easy maintenance and cleaning.

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has been built

with care and dedication -- using the best materials available. Attention to the operating instructions regarding proper

installation, operation, and maintenance will result in long lasting dependability to ensure the highest profitable return on

your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you have

any questions, please contact your BKI Distributor. If they are unable to answer your

questions, phone the applicable BKI Technical Services Department:

BKI North America: (864) 963-3471

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol. When you see

this symbol on your equipment, be alert to the potential for personal injury or property damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify specific areas

where potential hazards exist and special precautions should be taken. Know and understand the meaning of these

instructions, signs, and messages. Damage to the equipment, death or serious injury to you or other persons may result

if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe practices.

This message is used when special information, instructions or identification are required

relating to procedures, equipment, tools, capacities and other special data.

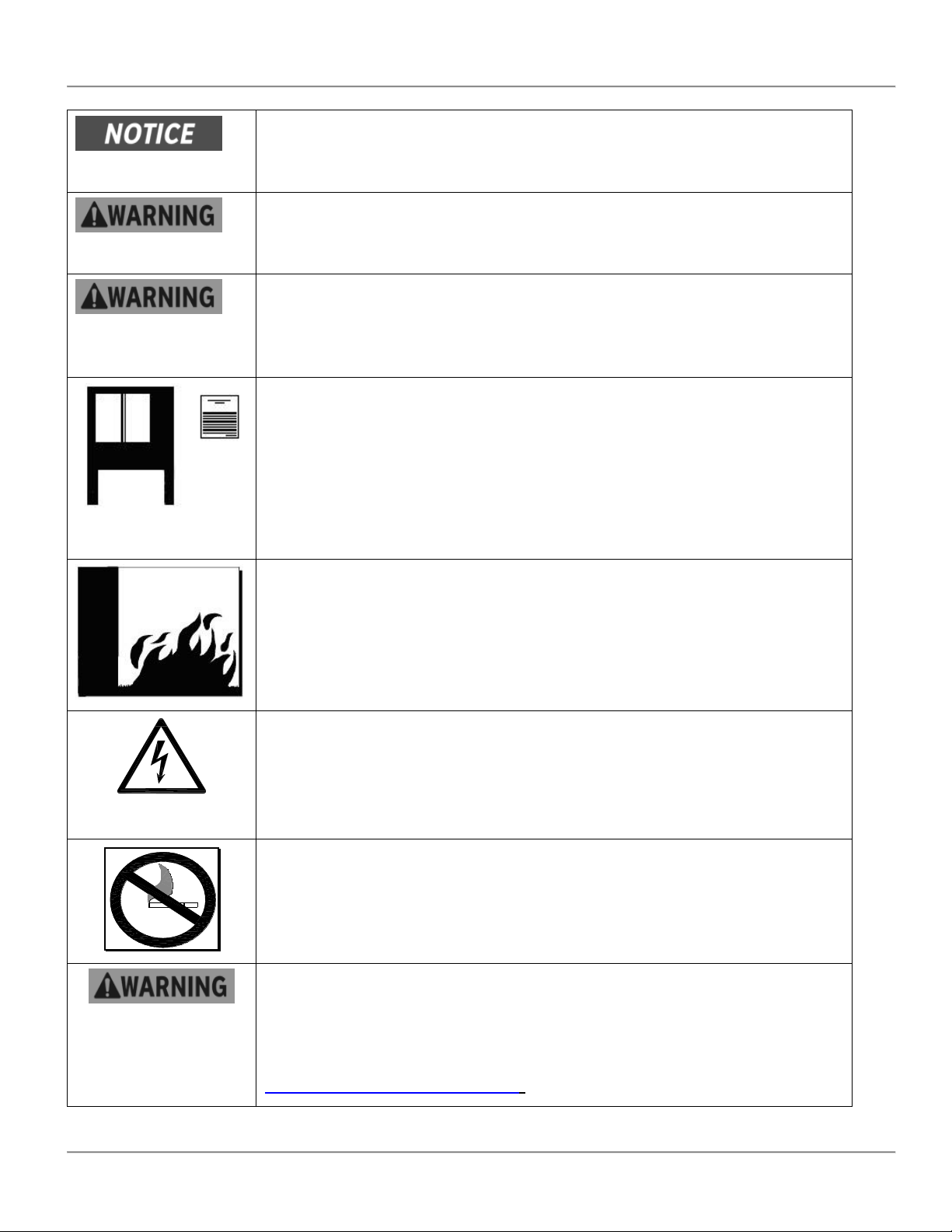

Specific Precautions

Page 6

Rotisserie Oven Introduction

3

The purchaser must post, in a prominent location, instructions

to be followed in the event the user smells gas. This information

shall be obtained by consulting the local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read

the installation, operation and maintenance instructions

thoroughly before installing or servicing this equipment.

Use Gas Safely-- Avoid Danger

Gas can be a dangerous fuel if not handled safely.

Make sure to ventilate the oven properly. If the oven is not

properly ventilated, carbon monoxide can be released around

the oven. Asphyxiation or suffocation can occur if gas is not

ventilated properly.

Clearance to Combustibles

Observe proper clearance to combustibles as noted on the oven

rating tag. Never place anything on top of the oven.

Keep the area around the oven free and clear from combustibles.

WARNING – DANGEROUS VOLTAGE

This equipment uses high voltage. Serious injury can occur if

you or any untrained or unauthorized person installs, services,

or repairs this equipment. Always Use an Authorized Service

agent to Service Your Equipment.

Do Not Smoke Near the Oven

This oven uses combustible fuels to operate. Smoking near this

oven could possibly cause a fire. Do not allow anyone to smoke

near this oven.

California Residents Only. This product can expose you to

chemicals including chromium, and lead which are known

to the State of California to cause cancer and birth defects

or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

Page 7

Rotisserie Oven Introduction

4

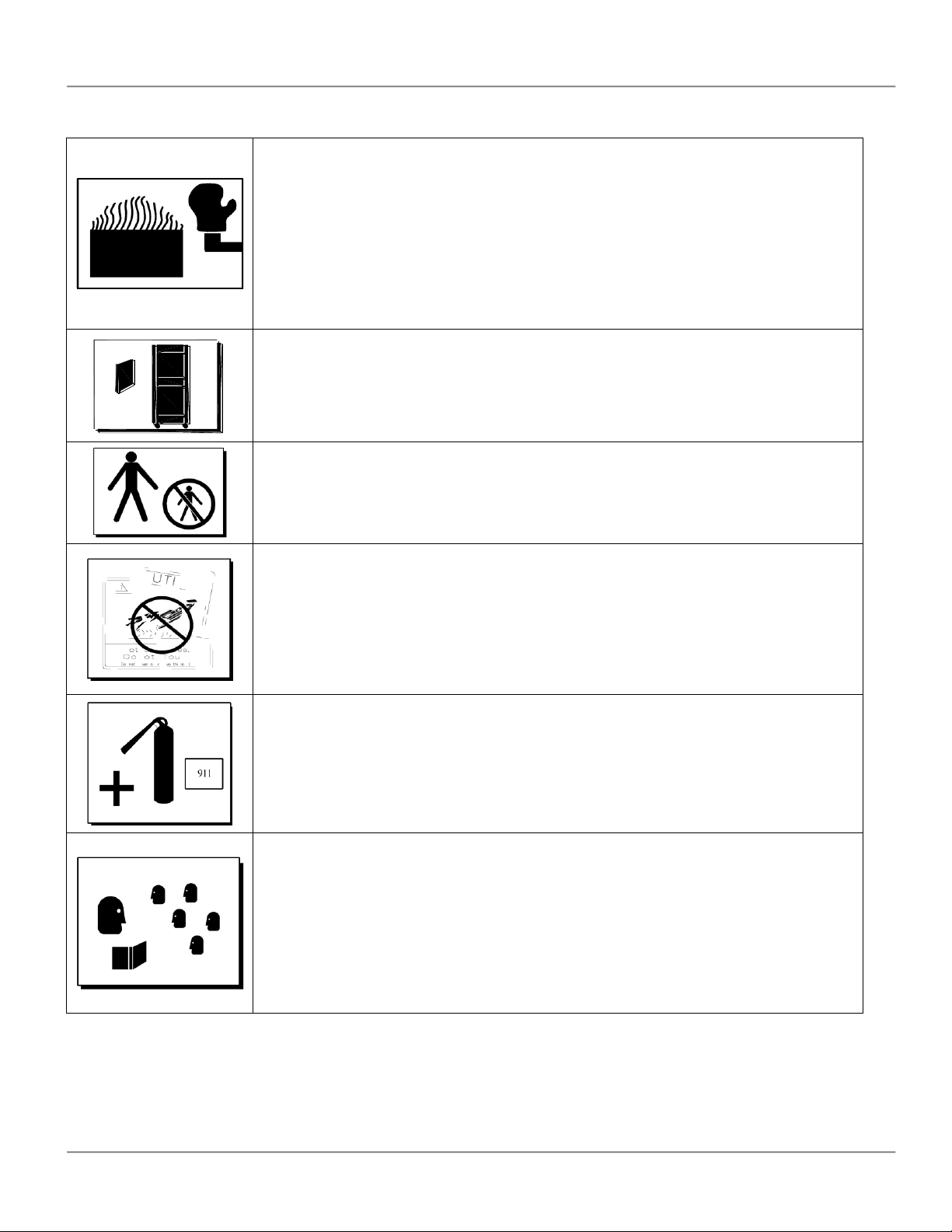

Safe Work Practices

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling hot oven parts or touch any hot metal

surface. If you lose or damage your mitts, you can buy new ones at your local

restaurant equipment supply store or from your local BKI Distributor.

Always wear non-skid shoes when working around the oven or any other equipment.

Never wear loose clothing such as neckties or scarves while operating this

equipment. Keep loose hair tied back or in a hair net while operating this equipment.

Always wear appropriate personal protection equipment during the cleaning process

to guard against possible injury.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it near for easy

access. If you need to replace this manual, phone the applicable BKI Technical

Services Department:

BKI North America: (864) 963-3471

Protect Children

Keep children away from this equipment. Children may not understand that this

equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep all safety labels

clean and in good condition. Replace any damaged or missing safety labels. Refer to

the Safety Labels section for illustration and location of safety labels on this unit. If

you need a new safety label, obtain the number of the specific label illustrated on

page 5, then phone the applicable BKI Technical Services Department:

BKI North America: (864) 963-3471.

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You must use a 40-

pound Type BC fire extinguisher and keep it within 25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services, hospitals, and the fire

department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the equipment.

• Make certain your employees are aware of the safety precautions on the

equipment and in this manual.

• Make certain that you have thoroughly trained your employees about operating the

equipment safely.

Make certain the equipment is in proper working condition. If you make unauthorized

modifications to the equipment, you will reduce the function and safety of the

equipment.

Page 8

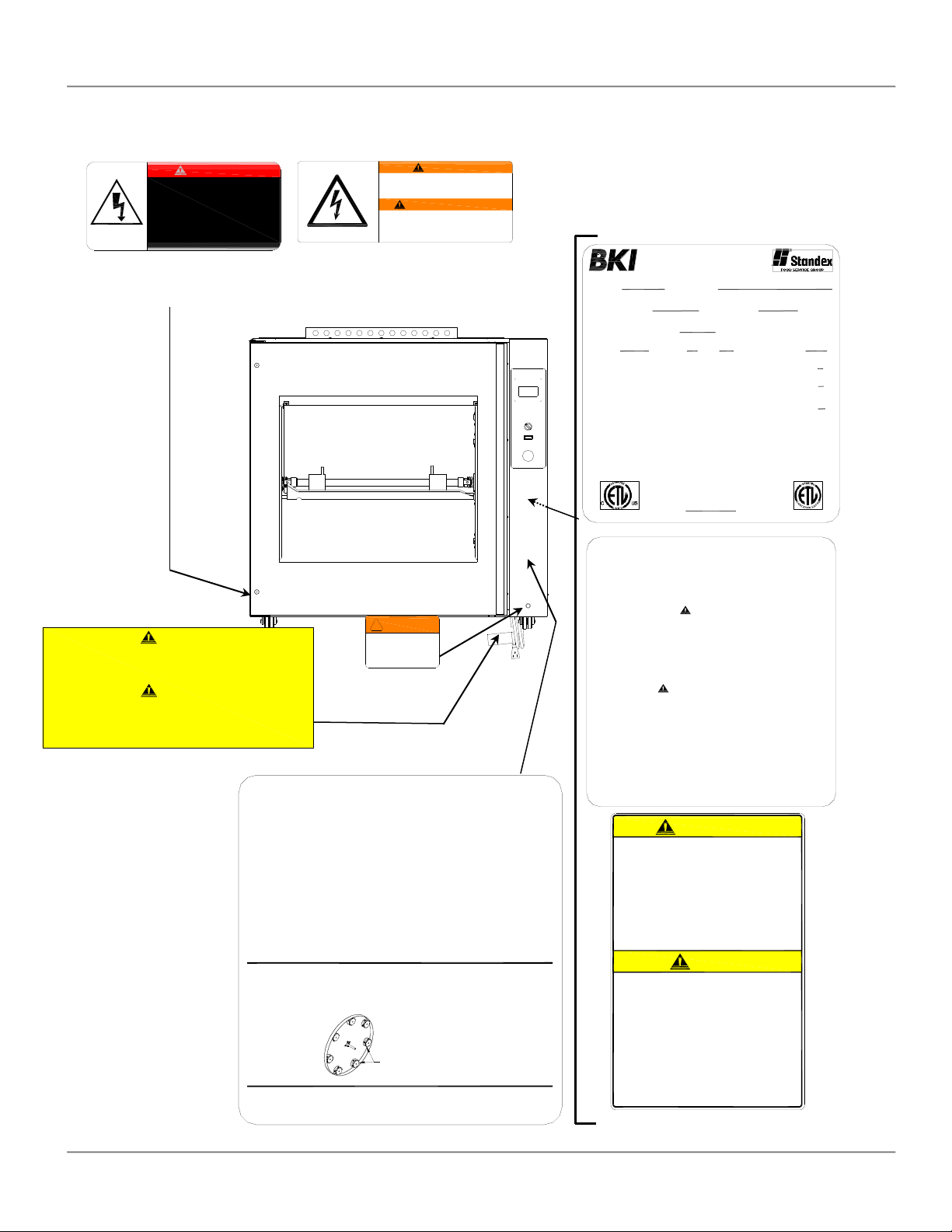

Rotisserie Oven Introduction

Electrical Grounding Instructions - This appliance is equipped with a

three-prong (grounding) plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle. Do not cut or

remove the grounding prong from this plug.

Mise à la terre - Cet appareil est pourvu d’une fiche à trois broches dont une

mise à la terre assurant une protection contre les chocs électriques. La prise dans

laquelle elle est branchée doit être correctement mise à la terre. Ne pas couper ni

enlever la broche de mise à la terre de la fiche.

CAUTION

AVERTIR

DO NOT COVER or REMOVE THIS LABEL NE RECOUVREZ PAS ou ENLEVEZ PAS CETTE ÉTIQUETTE

DANGER

HIGH VOLTAGE.

Turn power off before

servicing. May have more than

one disconnect switch.

HAUTE TENSION.

Mettez l'appareil hors tension avant

de proceder a l'entretien. Peut-etre

d'u commutateur de deconnexion.

®

"Experts In Heat Transfer Technology"

www.bkideas.com

DRGV-7

123456789012-12345678

PHASE

1

VOLTS

115

AMPS / Ampère

2.2

Hz

60

EQUIPPED FOR

Equipé pour

NATURAL

GAS

Gaz

INPUT

Énergie

72,000

BTU / Hr

BTU / H

MANIFOLD PRESSURE

Pression le Collecteur

4.5

INCHES of WATER

Pouces d'eau

Minimum spacing to a wall or adjacent unit.

L'espacement minimum sur un mur ou unité

adjacente.

6

Back

Arrière

Side

Côté

in.

3

in.

Minimum spacing above mounting surface.

L'espacement minimum au-dessus de la

surface de montage.

Bottom

Bas

4

in.

12345678

SIMPSONVILLE, SC, USA

DATE OF MANUFACTURE

DATE DE FABRICATION

ANS Z83.11 • CSA 1.8-2007 Food Service Equipment

MODEL

Modele

SERIAL NO

Nº de Serie

Suitable for installation on combustible floors.

Convient à l’installation sur un plancher combustible.

N0656 -1

Intended for other than household use.

Non destiné à l’usage domestique.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or

death. Read the installation, operating and

main-tenance instructions thoroughly before installing

or servicing this equipment.

L’installation, le réglage, la modification, la réparation

ou l’entretien incorrect de cet appareil peut causer des

dommages matériels, des blessures ou la mort. Lire

attentivement les instructions d’installation, de

fonctionnement et d’entretien avant de procéder à son

installation ou entretien.

WARNING

L'AVERTISSEMENT

For installation under ventilation hood only.

Installer en dessous d’une hotte de ventilation seulement.

N0656 -2

NORMAL OPERATION -

1.) Turn main POWER switch on.

2.) Touch controller screen to activate.

3.) Select desired cook recipe.

4.) Touch Cook or Preheat to start oven.

TO CANCEL COOK PROGRAM -

1.) Touch on upper right of controller

screen and hold for 3 seconds.

NORMAL SHUT DOWN -

1.) Cancel any activate cook program.

2.) Wait 30 seconds for fans to stop.

3.) Turn POWER switch off.

AFTER POWER or GAS OUTAGE -

the oven will shut of automatically.

To restart the oven, turn the POWER

switch off and wait 5 minutes.

Then follow NORMAL OPERATION

procedures above.

FONCTIONNEMENT NORMAL -

1.) Allumez INTERRUPTEUR principal.

2.) Écran tactile de commande pour activer.

3.) Sélectionner le programme de cuisson

désirée.

4.) Toucher Cook ou Preheat pour

commencer four.

D'ANNULER LE PROGRAMME de CUISSON -

1.) Toucher sur le contrôle et pendant

3 secondes.

ARRÊT NORMAL -

1.) Annuler le programme de cuisson actif.

2.) Attendre 30 secondes pour les fans

d'arrêter.

3.) Couper le courant interrupteur.

APRÈS MISE SOUS TENSION ou

de GAZ PANNE -

le four automatically arrêter.

Redémarrer le four, Couper le courant

interrupteur et attendre 5 minutes.

Puis suivre FONCTIONNEMENT

NORMAL procédure ci-dessus.

NE PAS utiliser de nettoyants

caustique pour nettoyer cette unité.

DO NOT use caustic cleaners

when cleaning this unit.

Lubricate rotor gears with BKI L0200

Lubricant each day after cleaning. Failure

to clean and lubricate the gears can

damage the drive motor or warp the gear

assembly.

LUBRICATE HERE

LUBRIFIEZ ICI

Lubrifier les engrenages du rotor avec BKI

L0200 lubrifiant chaque jour aprè le

nettoyage. Défaut de nettoyer et lubrifier

les engrenageseut peut endommager le

moteur d'entraînement ou dedéformer

l'engrenage.

N0657

When this appliance is installed with

casters, it must be installed with the

casters supplied, a connector complying

with either ANSI Z21.69 • CSA 6.16 and a

quick-disconnect device complying with

ANSI Z21.41 • CSA 6.9. It must also be

installed with restraining means to guard

against transmission of strain to the

connector, as specified in the appliance

manufacturer’s instructions.

Les appareils sur roulettes doivent être

pourvus des roulettes fournies, d’un tuyau

de raccordement conforme à la norme

ANSI Z21.69 ou CAN/CGA-6.16 et d’un

raccord à débranchement rapide

satisfaisant les exigences de la norme

ANSI Z21.41 ou CAN1-6.9. Ils doivent

aussi être munis d’un dispositif de

retenue pour empêcher toute

transmission de tension au tuyau de

raccordement confromément aux

instructions du fabricant.

NOTICE

AVIS

L'AVERTISSEMENT

WARNING

For continued protection against risk of fire and

electrical shock, replace with 8 amp fuse only.

Pour la protection continuée le risque de feu et

la décharge électrique, remplace avec 8 fusible

d'Ampli seulement.

Do not cover or remove label

Ne pas couvrir ou supprimer l'étiquette

N0658

FRONT of OVEN

BACK of OVEN

BOTH SIDES of OVEN

CONTROL SIDE of

OVEN ONLY

! WARNING

WHEN LIT UNIT IS

MALFUNCTIONING.

TURN OFF and CALL

FOR SERVICE.

N0536

Safety Labels

5

Page 9

Rotisserie Oven Introduction

6

Health and Sanitation Practices

BKI Rotisserie Ovens are manufactured to comply with health regulations and are tested and certified to NSF and FSA

standards. You must operate the equipment properly, using only quality products and use meat thermometers to insure

meats are thoroughly cooked.

Food Handling

• Wash hands thoroughly in warm, soapy water after handling raw poultry or meats.

• Clean and sanitize all utensils and surfaces that have been in contact with raw products. Clean and sanitize the

meat forks or baskets between cooking.

• Never place cooked meats on the same surfaces used to prepare raw meats, unless the area has been

thoroughly cleaned and sanitized.

Storage of Raw Meats

• Designate an area or shelf strictly for the storage of all raw meats to be used in the rotisserie.

• Raw product must always be stored at temperatures below 38° F. (3° C.).

• Never store or mix raw foods above cooked foods, as this is a health hazard. The drippings from raw foods

contaminate cooked or processed foods.

• All chicken and chicken parts to be stored overnight must be thoroughly iced down and refrigerated.

Coding Cooked Foods

All products cooked during the day should be sold the same day.

NOTE: It is not the intent of the rotisserie program to have unsold merchandise at the end of the cooking day. Follow

your company’s procedures for the handling of any leftover product.

Storage of Prepared Foods

• Cold foods should be kept at or below 38° F. (3° C.).

• Hot foods must be maintained to meet local health codes, usually a minimum 145° F. (63° C.).

Page 10

Rotisserie Oven Operation

7

Operation

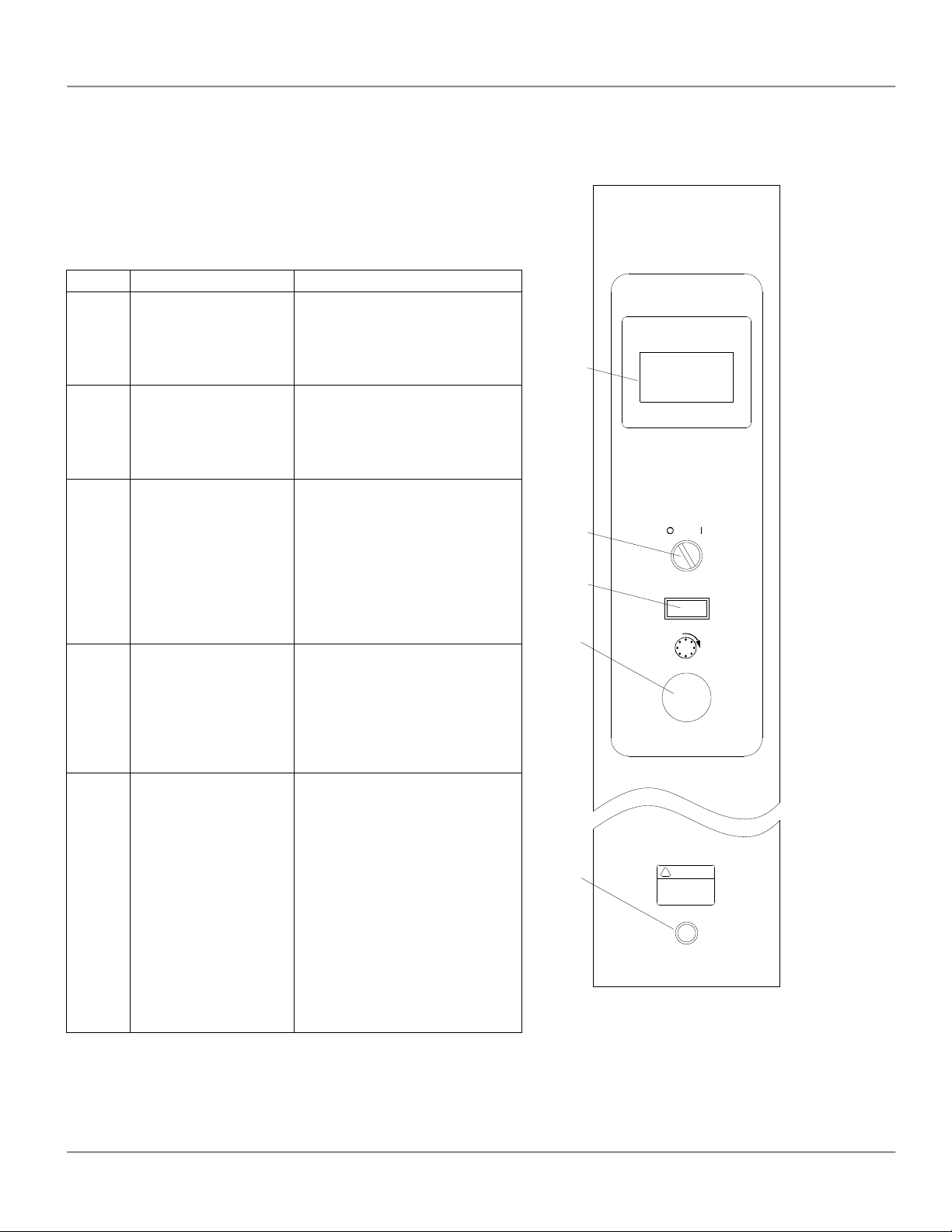

Controls and Indicators

Hardware Controls

Item #

Description

Function

1

Rotor Switch

Depressing the switch allows

the operator to “jog” the rotor

position when the door is

open. Releasing the switch

stops the rotor.

2

Main Power Isolator

Light

This light illuminates to

indicate that power is being

applied to the oven from the

Main Power Isolator (Circuit

Breaker).

3

Main Power Switch

Turns power to the entire unit

on or off. When placed in the

on position, the Touchscreen

controller is powered, lights

illuminate and the rotor motor

engages (if both doors are

closed). When placed in the

off position, power is removed

from the entire unit.

4

Analog Touchscreen

Controller

Used for operation and

programming of the oven. A

built-in beeper is used to

indicate touchscreen presses

and other oven functions. It

has 15 programmable cooking

recipes.

5

Cooling Fan

Indicator Light

This light illuminates to

indicate there is a malfunction

of the cooling fan in the

control compartment. Call a

qualified BKI service

technician to repair the oven.

The oven can still be operated

with when this light is

illuminated. However,

operating the oven for an

extended period of time may

result in oven failure and

damage to additional

components.

3

2

1

4

OPERATOR SIDE

Power

TouchTEC ________

5

! WARNING

WHEN LIT UNIT IS

MALFUNCTIONING.

TURN OFF and CALL

FOR SERVICE.

Page 11

Rotisserie Oven Operation

8

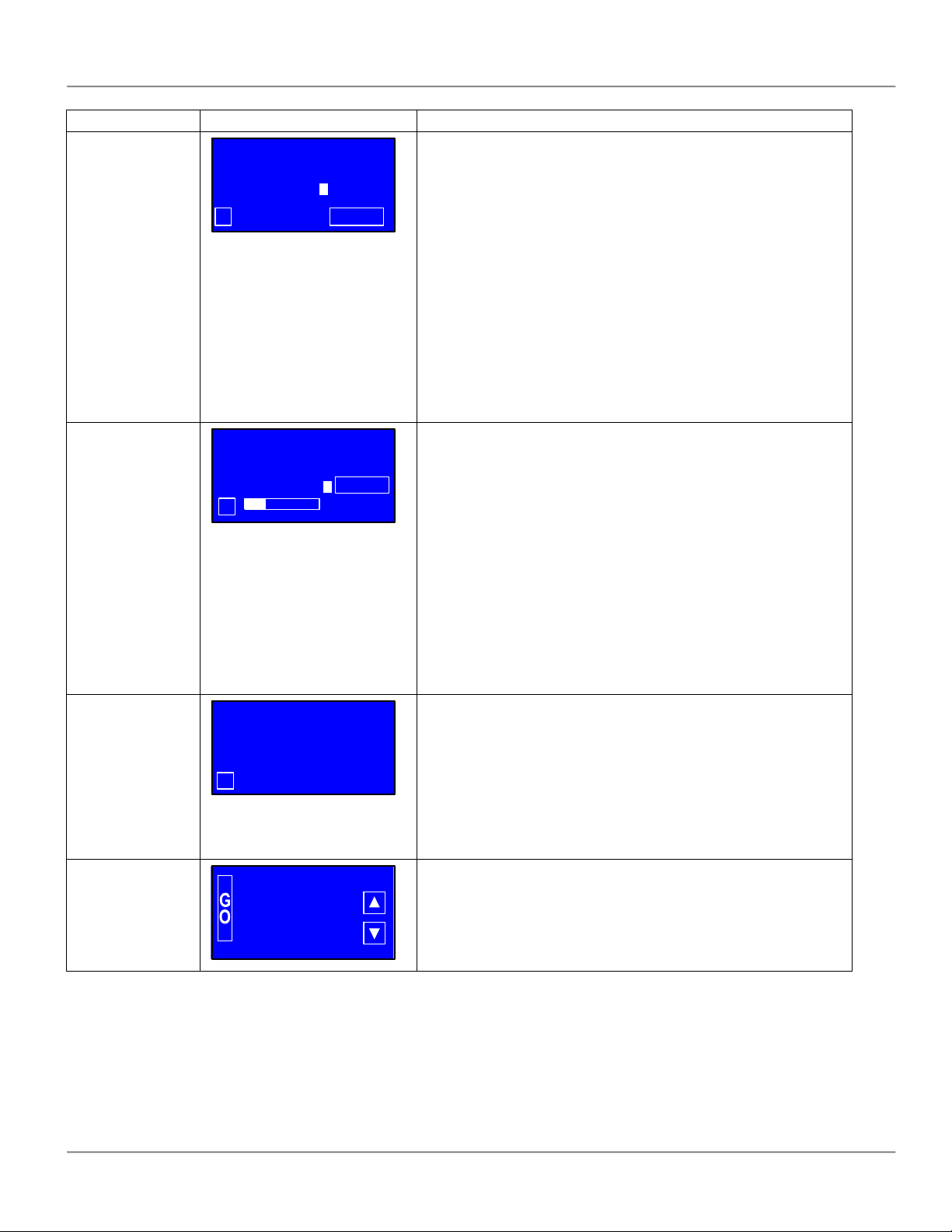

Software Controls – Operation Screens

Screen Name

Screen

Description

Startup

Appears when the Main Power Switch is placed in the on

position.

Controller Off

OFF

TOUCH TO START

Appears after the Startup screen displays. This screen

Indicates that the controller is turned off. Touching anywhere

on the screen will turn the controller on and display the

Recipe Selection screen.

Recipe

Selection

RECIPE 01

RECIPE 03

RECIPE 04

RECIPE 02

Displays a the list of available recipes. The up and down

arrow buttons move the highlight box from one recipe to the

next. Once the desired recipe is highlighted the user

touches the GO button to start the cook cycle. Touching the

X button for 3 seconds turns the controller off. Touching any

recipe will show the settings for that recipe.

Recipe Settings

Preheat Temp: 360F

Cook Temp: 360F

Cook Time: 1:10

RECIPE 02

Displays Preheat Temperature, Cook Temperature, Cook

Time, Hold Temperature and Cook To settings for a

selected recipe. Touching the up and down arrow buttons

scroll the screen to view more settings. Touching the X

button momentarily returns you to the previous screen.

Preheat/Cook

Selection

T

Preheat

Cook

RECIPE 02

RECIPE 02

Displays once the user highlights a recipe and touches the

GO button if the recipe has a preheat temperature

programmed. The user selects where to start the cooking

cycle by touching Preheat or Cook. Touching Preheat

displays the Preheat screen. Touching Cook displays the

Ready To Cook screen. If the Preheat temperature is set to

OFF the controller goes directly to the Ready To Cook

screen. The T button can be used to display the current

oven temperature. Touching the T button displays the

temperature, then automatically returns to the previous

screen in 2 seconds. Touching the X button momentarily

returns you to the previous screen.

Preheat

T

Preheating

250F

H

RECIPE 02

Displays once the user touches the Preheat option from the

Preheat/Cook Selection screen. The Preheat cycle heats the

cooking cavity up to the pre-defined preheat temperature.

Once this temperature is reached the unit automatically

switches to the Ready To Cook mode. A small highlighted

letter H will appear to the right of the temperature display to

indicate that the controller has energized the heating

elements. The absence of the letter H indicates that the

controller has de-energized the heating elements as the

oven temperature has reached the set temperature limit.

The T button works as described for the Preheat/Cook

Selection screen. Touching the X button for 3 seconds

returns you to the Recipe Selection screen.

Page 12

Rotisserie Oven Operation

9

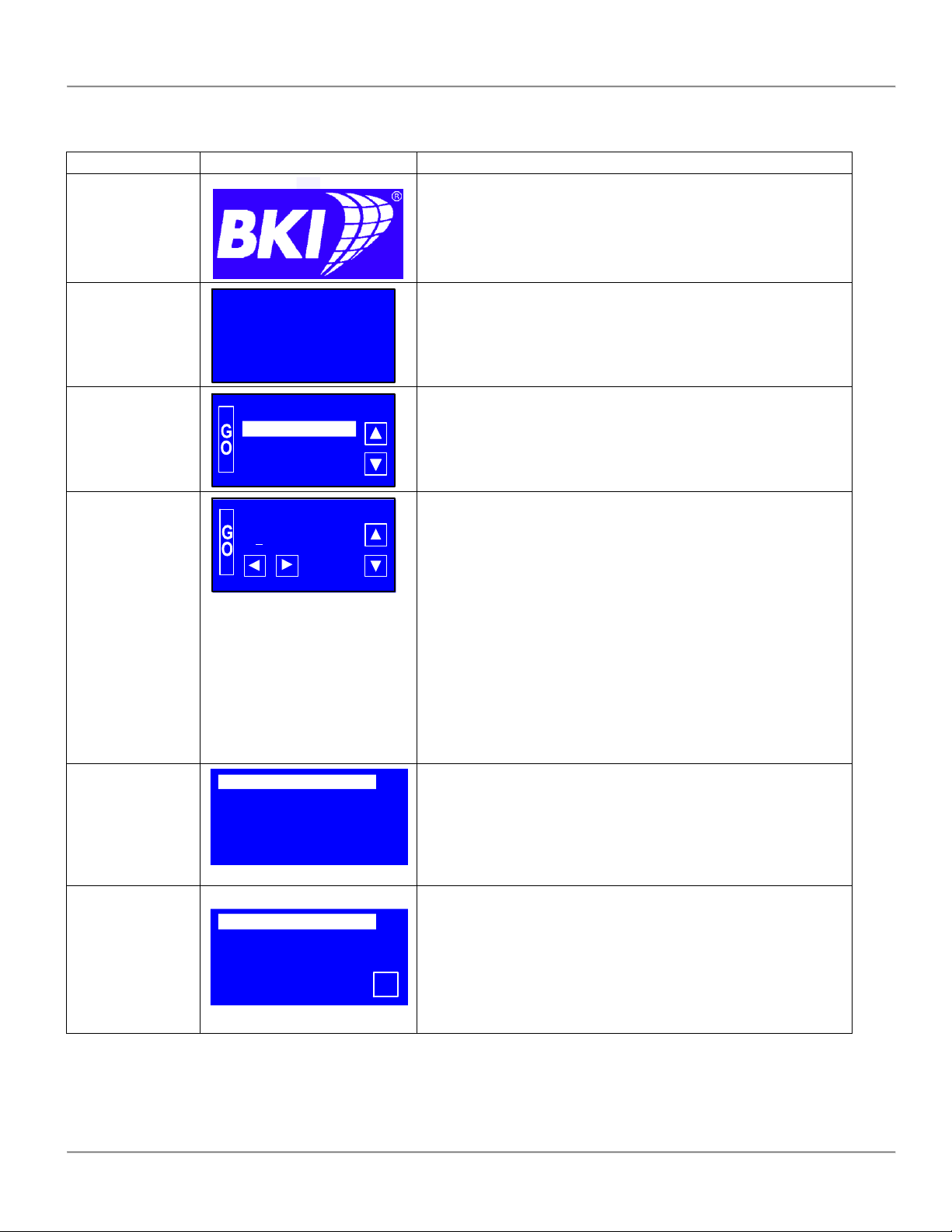

Screen Name

Screen

Description

Ready to Cook

READY

350F

T COOK

RECIPE 02

H

Displays once the user touches the Cook option from the

Preheat/Cook selection screen or once the preheat cycle is

finished or directly from the Recipe Selection screen if no

preheat temperature was programmed. When the

temperature is within 5° of the cook temperature the

controller will emit three 2 second beeps indicating that the

product can be loaded. The user places the product to be

cooked into the cooking cavity and touches the COOK

button to start the cooking process. If the door is opened

and/or the temperature drops below 25° below the preheat

temperature, the screen will flash and beep every 30

seconds until the COOK button is touched. The highlighted

letter H works as described for the Preheat screen. The T

button works as described for the Preheat/Cook Selection

screen. Touching the X button for 3 seconds returns you to

the Recipe Selection screen.

Cooking

RECIPE 02

350F

EXTRA

Time

H

T

0:50

Displays once the COOK button is touched from the Ready

To Cook screen. This screen shows the cooking

temperature, the time remaining in the cook cycle, and the

elapsed time shown with the progress bar at the bottom of

the screen. Hold the X button for 2 seconds to stop the cook

in progress. The EXTRA button can be used to add more

cook time to the cycle. The cook cycle ends when the cook

time elapses. This is indicated by three 2 second beeps. If a

hold temperature was programmed then the Hold screen is

displayed. If no hold temperature was programmed then the

screen will flash and beep until touched. The highlighted

letter H works as described for the Preheat screen. The T

button works as described for the Preheat/Cook Selection

screen. Touching the X button for 3 seconds returns you to

the Preheat/Cook Selection screen.

Hold

RECIPE 02

T

350F

EXTRA

Time

0:09

Holding

Displays once the cook cycle is complete if a hold

temperature was programmed. This screen displays the

hold temperature (or nothing if set to OFF), and the elapsed

time in the hold mode. The EXTRA button is available here

so the product can be cooked for more time if required. The

highlighted letter H works as described for the Preheat

screen. The T button works as described for the

Preheat/Cook Selection screen. Touching the X button for 3

seconds returns you to the Recipe Selection screen.

Extra Cook

EXTRA COOK

5

Appears when the EXTRA button is touched from the

Cooking or Hold screens. Use the up and down arrow

buttons to set the amount of additional cook or hold time in 5

minute increments. Touch the GO button to add the

additional time you set. Touch the X button to return to the

previous screen without adding any extra cook or hold time.

Page 13

Rotisserie Oven Operation

10

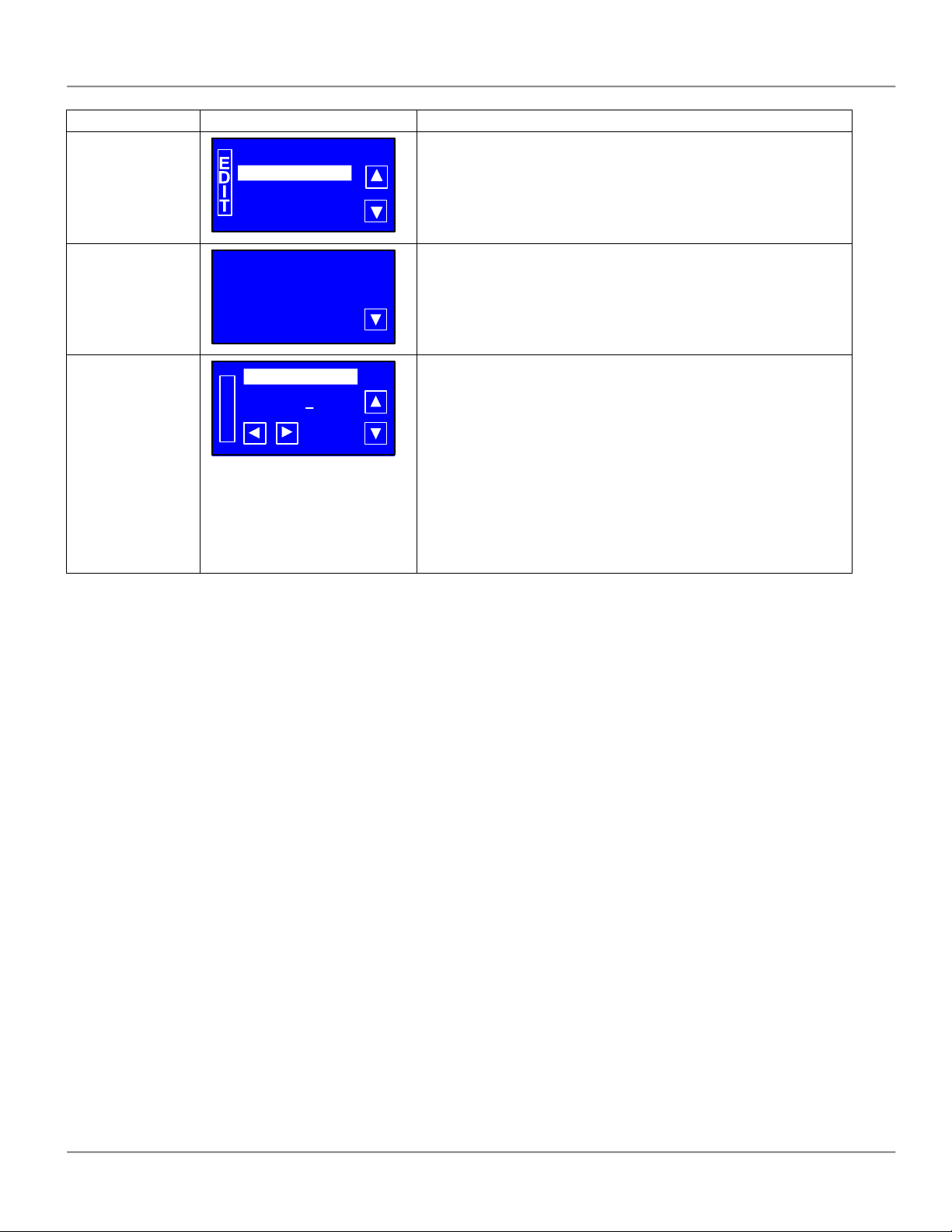

Software Controls – Programming Screens

Screen Name

Screen

Description

Startup

Appears when the Main Power Switch is placed in the on

position.

Controller Off

OFF

TOUCH TO START

Appears after the Startup screen displays. Indicates that the

controller is turned off. Touching anywhere on the screen

will turn the controller on and display the Recipe Selection

screen.

Recipe

Selection

RECIPE 01

RECIPE 03

RECIPE 04

RECIPE 02

Appears once the Controller Off screen is touched. Touch

any recipe for 3 seconds to enter the programming mode.

Touch the X button for 3 seconds to turn the controller off.

Program

Security

ENTER CODE

0 0 0 0

Appears upon entering the programming mode and is used

to enter a 4 digit passcode. When the controller is first

powered, 0000 is used to access the programming mode.

Upon subsequent access, if you don’t want to use a special

passcode but want to leave it 0000 just press the GO button.

If you do want to use a special passcode, configure one

using the Basic Setup screen. Use the left and right arrow

buttons to move the cursor under the digit to be changed.

The up and down arrow buttons increase or decrease the

digit as desired. Touch the GO button to submit the security

passcode. If the passcode is valid the Programming mode

Selection screen will appear. If the passcode is invalid the

Program Security screen will reappear showing the

passcode you entered. Touch the X button to return to the

previous screen.

Program Mode

Selection

BASIC SETUP

COOK PROGRAMS

PROGRAMMING MODE

Appears once a valid passcode is entered from the Security

screen. Touch the BASIC SETUP option to change basic

controller parameters. Touch the COOK PROGRAMS

option to change cook parameters for a specific recipe.

Touch the X button to return to the Recipe Selection screen.

Basic Setup

CHANGE CODE

UNITS: F

BASIC SETUP

SIGNAL MODE: Cont

E

Appears when the BASIC SETUP option is touched from

the Programming Mode Selection screen. Use this screen to

configure the controller to display temperature in Fahrenheit

of Centigrade, to use short or long beeps at the end of a

cook cycle and to modify the four digit passcode. The E in

the bottom right corner toggles between English and

Spanish on the display. Touch the X button to return to the

previous screen.

Page 14

Rotisserie Oven Operation

11

Screen Name

Screen

Description

Recipe Edit

Selection

RECIPE 01

RECIPE 03

RECIPE 04

RECIPE 02

Appears when the COOK PROGRAMS option is touched

from the Programming Mode Selection screen. This screen

is used to select the recipe you want to edit. Use the up and

down arrow buttons to highlight the recipe then touch the

EDIT button. Touch the X button to return to the previous

screen.

Recipe

Parameter

Selection

Preheat Temp: 360F

Cook Temp: 360F

Cook Time: 1:10

RECIPE 02

Appears when a recipe is selected and the EDIT button is

touched from the Recipe Edit Selection screen. This screen

is used to select a specific recipe parameter to edit. Use the

up and down arrow buttons to scroll through the list of

parameters and touch the parameter you want to change.

Touch the X button to return to the previous screen.

Recipe

Parameter Edit

Ck Temp: 360F

S

A

V

E

RECIPE 02

Appears when a recipe parameter is touched from the

Recipe Parameter Selection screen. This screen is used to

edit a specific recipe parameter. The editable parameters

are: Recipe name, Preheat Temp, Cook Temp, Cook Time

and Hold Temp. The left and right arrow buttons are used to

move the cursor under the character to be changed. The up

and down arrow buttons changes the character as desired.

The Preheat Temp and Hold Temp parameters can be

turned off by scrolling the temperature below 150°. Touch

the SAVE button to save the changed parameter. Touch the

X button to abort all changes and return to the previous

screen.

Page 15

Rotisserie Oven Operation

12

Programming the Controller Using the Touchscreen Interface

Use the procedures below to edit a separate recipe or to change the basic controller configuration.

Edit a Recipe

1. Turn on the Power Switch. The Startup screen will briefly appear then the Controller Off screen will display.

2. Touch anywhere on the touchscreen. The Recipe Selection screen will appear displaying a list of recipes.

3. Touch any recipe for 3 seconds. The Security screen will appear.

4. Use the up/down and left/right arrow buttons to enter the passcode and touch the GO button. The Program Mode

Selection screen will appear if a valid passcode is entered.

5. Touch the COOK PROGRAMS option. A Recipe Edit Selection screen will appear.

6. Highlight the recipe you want to edit using the up/down arrow buttons then touch the EDIT button. The Parameter

Selection screen will appear.

7. Use the up/down arrow buttons to view the recipe parameters and touch the parameter you want to edit. The

Parameter Edit screen will appear.

8. Change the parameter value using the left/right and up/down arrow buttons then touch the SAVE button to save

your changes. You will return to the Parameter Selection screen.

9. Repeat the process to change any other parameters.

10. Touch the X button as necessary to return to the Recipe Selection screen.

Edit the Basic Setup

1. Turn on the Power Switch. The Startup screen will briefly appear then the Controller Off screen will display.

2. Touch anywhere on the touchscreen. The Recipe Selection screen will appear displaying a list of recipes.

3. Touch any recipe for 3 seconds. The Security screen will appear.

4. Use the up/down and left/right arrow buttons to enter the passcode and touch the GO button. The Program Mode

Selection screen will appear if a valid passcode is entered.

5. Touch the BASIC SETUP option. A Basic Setup Selection screen will appear.

6. Touch the parameter that needs to be changed. A Basic Setup Parameter Edit screen appears.

7. Change the parameter value using the left/right and up/down arrow buttons then touch the SAVE button to save

your changes. You will return to the Basic Setup Selection screen.

8. Repeat the process to change any other parameters.

9. Touch the X button as necessary to return to the Recipe Selection screen.

Page 16

Rotisserie Oven Operation

13

Operation with the Controller

Use the procedures below to view a separate recipe or to activate a cook cycle using a one of the preprogrammed

recipes.

Viewing Recipes

1. Turn on the Power Switch. The Startup screen will briefly appear then the Controller Off screen will display.

2. Touch anywhere on the touchscreen. The Recipe Selection screen will appear displaying a list of recipes.

3. Use the up/down arrow buttons to highlight the recipe you wish to view then touch it. A Recipe Settings screen will

appear.

4. Use the up/down arrow buttons to view any settings for the recipe selected.

5. Touch the X button momentarily to return to the previous screen.

Cooking

1. Turn on the Power Switch. The Startup screen will briefly appear then the Controller Off screen will display.

2. Touch anywhere on the touchscreen. The Recipe Selection screen will appear displaying a list of recipes.

3. Use the up/down arrow buttons to highlight the recipe you wish to use then touch the GO button. If a preheat

temperature was programmed then the Preheat/Cook Selection screen will appear. If no preheat temperature was

programmed then the controller enters the Ready To Cook mode displaying the Ready To Cook screen.

• If the Preheat/Cook Selection screen appears, do either of the following:

• Touch the Preheat option to enter the Preheat mode. The controller will display the Preheat screen.

Once the preheat temperature is reached the controller enters the Ready To Cook mode.

• Touch the Cook option to enter the Ready to Cook mode.

Once the temperature is within 5° of the cook temperature in the Ready To Cook mode the controller will emit

three 2 second beeps indicating that the oven can be loaded with product.

4. Load the product into the oven. Use the Rotor Switch on the front panel to operate the rotors during loading.

5. Close the door.

6. Touch the COOK button. The controller now enters the cook mode and displays the cooking temperature, time

remaining in the cook cycle and the elapsed time. If necessary, use the EXTRA button to add more cook time to

the cycle. At the end of a cook cycle the controller will emit three 2 second beeps and enter the Hold mode and

display the Hold screen if a Hold temperature was programmed. If a Hold temperature was not programmed the

screen will flash and beep until touched.

7. Open the oven door and check the product for proper internal temperature. If necessary, use the EXTRA button to

add more cook time.

8. Unload the product if it is done.

Page 17

Rotisserie Oven Operation

14

Operation After a Gas or Power Outage

The oven will shut off automatically if the gas supply is interrupted or the power goes out. If either of these conditions

occur you should perform the following procedure:

For your safety, if there is an interruption in the gas or power supply, make sure to wait

for at least five minutes before restarting your oven. This allows time for any unburned

gas to dissipate. (LP gas may take longer than five minutes.) If you smell gas, do not start

your oven.

1. Place the Main Power Switch to the “OFF” position.

2. Wait at least 5 minutes to allow gas that may have accumulated in the burner compartment to escape.

3. Follow normal operating procedures once the power or gas is restored.

Normal Shutoff

1. Stop cooking and remove all food products from the oven.

2. Turn the Main Power Switch to the “OFF” position.

3. Allow oven cavity to cool before cleaning.

Installing Rotor System

ROTOR

GUIDE

PIN

STEP 1

Install the Rotor Disks by first

inserting the guide pin into the

shaft center hole. The Rotor

Disk with gears goes on the

control side of the oven. It will

be necessary to rotate this

Rotor Disk while pushing in to

engage the gears and the

drive hub. When properly

installed there will be

approximately ¼” [6 mm]

space between the Rotor Disk

and cavity side.

STEP 2

Rotate both Rotor Disks

so that the wide side of

the T-slot in the hubs is

facing up as shown.

Hold the Rotor Shaft with

wide side of the Tshaped tabs in end hubs

facing up. Slide the Tshaped tabs in the Rotor

Shaft ends into the

corresponding slots in

the hubs.

STEP 3

Slide the Retaining Cups

on each end of the Rotor

Shaft completely onto the

Rotor Hubs. The grooves

in the Rotor Shaft end

hubs must be visible.

STEP 4

Slide the Retaining

Washers onto the

Rotor Hubs and seat

them in the grooves

in the Rotor Shaft

end hubs.

Page 18

Rotisserie Oven Operation

15

Preparing and Loading Chickens

Trussing Chickens

It is recommended that whole chickens be trussed before cooking. Trussing holds the wings and legs of the chicken

tightly against the body. This improves the visual appeal of the chickens while they are cooking. In addition trussing

keeps the chicken moist by retaining more of the natural juices and helps prevent the wing tips from burning.

Using 6 ½” – 7” elastic ties, follow these simple steps to truss the chickens.

1. Fold wing tips back under the chicken.

2. With the back of the chicken up slip

the tie under the wings and pull back.

3. Pull and twist the tie over the back of the

chicken to form an “X”. Make sure wing

tips are under tie.

4. Turn the chicken over and pull the tie

over the ends of the legs.

Page 19

Rotisserie Oven Operation

16

V-Spits

Up to four (4) whole chickens can be placed on a DRGV-7 v-spit. Insert the tapered (square pin) end of the v-spit under

the legs and through the cavity of the trussed chicken as shown below. Orient the spit with the “V” toward the breast side

of the chicken. The legs and thighs of the chicken should be on the same side of the v-spit as the breast.

Make sure the chickens are evenly spaced on the v-spit. Do not place more than four chickens on a v-spit. Chickens

that are pushed tightly together on the v-spit will not brown properly during cooking leaving “blonde” areas where the two

chickens were touching.

The DRGV-7 will hold up to 7 v-spits. When loading less than 7 spits, space the spits as evenly as possible on the

rotors. Balancing the load on the rotors will extend the life of the rotor drive system. When loading only 2 or 3 spits DO

NOT place them in adjacent mounting locations on the rotors.

Load the first v-spit on the rotors as described below. Use the rotor jog button to advance the rotors while loading

additional v-spits.

STEP 1

Orient the V-spit with the round

pin to the left. Insert the round

pin completely into the hole in

the passive (left) side rotor.

STEP 2

Rotate the V-spit so that the flats

of the square pin align with the

square opening in the drive (right)

rotor. Insert the square pin

completely into the square

opening in the rotor.

STEP 3

Verify that rotor disk slips into

the slot in the round pin on the

left end of the V-spit.

Page 20

Rotisserie Oven Operation

Lower Tray

Intermediate Tray

Upper Tray

Thumb Screw Wrench

(FA55313800)

Baskets

The optional tiered clamping baskets can be used to cook a wide variety meat portions and proteins. By using the

intermediate trays two layers of smaller portions can be cooked in a single basket. Note that these baskets will not

produce an even browning on the exterior of the cooked products.

Place the portions to be cooked in the Lower Tray of the baskets. The portions should be evenly distributed in the

Lower Tray with some space between each portion for adequate heat circulation.

Slide the Upper Tray over the vertical pins in the Lower Tray. Push the Upper Tray down onto the portions to be cooked

firmly enough that the portions do not move in the basket. Tighten the thumb screws securely on each end with the

thumb screw wrench. For larger portions, the Intermediate Tray can be used in place of the Upper Tray.

To cook two layers of portions in the basket, load the first layer in the Lower Tray and secure this layer with the

Intermediate Tray as described above. In similar fashion place the second layer of portions in the Intermediate Tray and

secure this layer with the Upper Tray.

Load the baskets onto the ovens rotor system as described above for the V-spits.

17

Page 21

Rotisserie Oven Installation

Serious injury, equipment damage or death could result if attempting to install this oven

yourself. Ensure that an authorized BKI service agent installs the oven.

The oven must be installed under a ventilation hood. If the oven is not properly

ventilated, carbon monoxide can be released around the oven. Asphyxiation or

suffocation can occur if gas is not ventilated properly.

Installation of this appliance must conform with local codes, or in the absence of local

codes, with the National Fuel Gas Code ANSI Z223.11/NFPA 54 or Natural Gas and

Propane Code CSA B149.1 as applicable.

• This appliance and its individual shutoff valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test

pressures in excess of ½ psi (3.5kPa).

• The appliance must be isolated from the gas supply piping system by closing its

individual shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than ½ psi (3.5kPa).

When installed, this appliance must be electrically grounded in accordance with local

codes, or in the absence of local codes, the National Electric Code ANSI/NFPA 70 or the

Canadian Electrical Code CSA C22.2, as applicable.

A wiring diagram is located on the inside of the appliance’s right side panel.

This appliance is equipped with a 3-prong (grounding) plug for your protection against

shock hazard and should be plugged directly into a properly grounded 3-prong

receptacle. Do not cut or remove the grounding prong from the plug.

When this appliance is installed with casters, it must be installed with the casters

supplied, a connector complying with either ANSI Z21.69 • CSA 6.16 and a quick-

disconnect device complying with ANSI Z21.41 • CSA 6.9. It must also be installed with

restraining means to guard against transmission of strain to the connector, such as BKI

part number FT0279.

Installation

Unpacking and Handling

It is the owners’ responsibility to file all freight claims with the delivering truck line. Inspect all cartons and crates for

damage as soon as they arrive. If damage to cartons or crates is found, or if a shortage is found, note this on the bill of

lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the delivering truck line and follow up the call with a

written report indicating concealed damage to your shipment. Ask for an immediate inspection of your concealed

damage item. Packaging material MUST be retained to show the inspector from the truck line.

Remove all packing from the interior and exterior of the oven.

Location and Clearance

Install your oven in a well-ventilated area. This will ensure that the gas burns properly and will help prevent any fires.

The oven must be mounted on a level surface capable of supporting the fully loaded oven. Refer to Chart 1 for oven

weight.

Adequate clearance must be provided around the oven for safety, proper operation and ventilation. Refer to

Chart 1 for required minimum clearances. Note that these are minimum clearances. If the oven is to be permanently

mounted near other immovable objects additional clearance must be provided for connection and service of the oven on

both sides.

All ventilation slots must be kept free from obstruction. The area around oven must be kept free and clear from

combustibles.

Specific Instructions

18

Page 22

Rotisserie Oven Installation

19

> 18in

[457.2mm]

> 3in

[76.2mm]

> 6in

[152.4mm]

30 3/4in

[781.0mm]

34 5/8in

[879.1mm]

34 1/16in

[865.0mm]

40 11/16in

[1033.7mm]

3in

[76.2mm]

1 7/8in

[47.6mm]

38in

[964.8mm]

4in

[101.6mm]

TECHNICAL SPECIFICATIONS:

Net Weight: 450 lbs [204 kg]

Floor Space: 13.2 sq ft [1.2 sq m]

Voltage: 115V

Phase: 1

Frequency: 60 Hz

Amperage: 4.5A

Electrical Power: 540W

Electrical Plug: NEMA 5-15P

Gas Power: 75,000 BTU Max.

Gas Types: Natural & Propane

Min. Gas Pressure: 5 inch W.C.

Max. Gas Pressure:14 inch W.C.

Gas Inlet: 3/4" NPTM

for SERVICE

ACCESS

FOR PROPER OPERATION

Use a minimum 3/4" pipe and

3/4" ID flexible gas connector

for gas supply connection.

2 11/16in

[67.9mm]

Chart 1. Location and Clearance

Counter Top and Stand

Model DRGV-7 Gas Rotisserie Oven

Page 23

Rotisserie Oven Installation

20

> 3in

[76.2mm]

34 1/16in

[865.0mm]

1 7/8in

[47.6mm]

30 3/4in

[781.0mm]

34 5/8in

[879.1mm]

40 11/16in

[1033.7mm]

3in

[76.2mm]

79 3/4in

[2025.4mm]

> 6in

[152.4mm]

32 15/16in

[836.6mm]

TECHNICAL SPECIFICATIONS:

Net Weight: 900 lbs [408 kg]

Floor Space: 13.9 sq ft [1.3 sq m]

(2) Ovens Connect Independently

Specifications for Single Oven

Voltage: 115V

Phase: 1

Frequency: 60 Hz

Amperage: 4.5A

Electrical Power: 540W

Electrical Plug: NEMA 5-15P

Gas Power: 75,000 BTU Max.

Gas Types: Natural & Propane

Min. Gas Pressure: 5 inch W.C.

Max. Gas Pressure:14 inch W.C.

Gas Inlet: 3/4" NPTM

1 5/8in

[41.6mm]

> 3in

[76.2mm]

43 1/16in

[1093.5mm]

DRAIN

VALVE

2 5/8in

[66.7mm]

FLUE DUCTS ARE

REMOVABLE TO

ALLOW FOR

INSTALLATION

UNDER A HOOD

BUT MUST BE

REATTACHED

AFTER

INSTALLATION

FOR PROPER OPERATION

Use a minimum 3/4" pipe and

3/4" ID flexible gas connector

for gas supply connection.

2 5/8in

[66.6mm]

Model DRGV-14 Gas Rotisserie Oven

Page 24

Rotisserie Oven Installation

21

Mounting

This appliance cannot be mounted directly on a counter top. Air must be able to circulate

under the appliance. To prevent equipment damage the appliance must be mounted on

legs, casters or a stand with an open appliance mounting surface.

Screw Legs or Stand

mounting screws into

larger 3/8"-16 Thread

Inserts on each corner

of the oven base.

(4) SCR068

3/8"-16 x 3/4"

Hex Head Screw

(4) WSH046

3/8" Lock

Washer

Use inner Stand

Mounting holes

in front of oven.

Use outer Stand

Mounting holes

in front of oven.

L0154 4 in.

Adjustable

Leg - (4) req'd.

Page 25

Rotisserie Oven Installation

22

Stacking Ovens

Serious injury, equipment damage or death could result if attempting to install

these ovens yourself. Special equipment is required to lift and stack two ovens.

Ensure that an authorized BKI service agent installs the oven.

A DRGV-14 two cavity oven is shipped from the factory as two individual ovens along with the components required to

assemble them into a single unit. The lower oven will have casters installed, the upper oven will not.

Prepare the top oven by attaching the mounting angle to the bottom as illustrated below.

Prepare the lower oven by first removing the two side panels. Then attach the stacking channels, flue duct and baffle as

detailed in the following illustrations.

Page 26

Rotisserie Oven Installation

23

Remove front (3) Top Panel mounting

Screws. Position Front Trim over mounting

holes and secure with Screws.

FB55308003

Front Trim orient as

shown.

(2) BLT257

1/4"-20 x 5/8"

Carriage Bolts

(2) WSH248

1/4"-20 Keps

Nuts

(4) SCR059

1/4"-20 x 3/4"

Hex Screws

&

(4) WSH044

1/4" Lock

Washers

(2) FB55307803 Channels

(with factory installed

thread inserts)

PREPARING LOWER OVEN

ATTACH FRONT TRIM

ATTACH STACKING CHANNELS

Page 27

Rotisserie Oven Installation

24

Lift the top oven and set it in place on the lower oven as shown in the following illustration. Ensure the lifting equipment

has a rated capacity of at least 500 lb. [250 kg].

The angles on the bottom of the top oven slide over the outside of the channels attached to the top of the lower oven.

ATTACH FLUE BAFFLE

ATTACH FLUE DUCT

Flue Ducts slides over the

outside of the Oven Flue

WB55306700

Flue Duct

(4) SCR138

#10 x 1/2"

Screws

Remove existing (3)

Screws, position Flue

Baffle & re-install Screws.

(4) SCR138

#10 x 1/2"

Screws

FB55308203

Flue Baffle

PREPARING LOWER OVEN (cont.)

Page 28

Rotisserie Oven Installation

25

Secure the two ovens to each other with the fasteners noted on the illustration.

(4) SCR059 1/4"-20 x 3/4"

Hex Head Screws &

(4) WSH2661/4" Flat

Washer &

(4) WSH044 1/4" Lock

Washer

(4) 1/4"-20 Threaded Inserts in

top may be used to attach lifting

hardware. Minimum capacity

of lifting hardware is 500 lb. [250 kg].

Page 29

Rotisserie Oven Installation

26

Lower oven Flue Duct

slides inside of Chimney

(4) SCR138

#10 x 1/2"

Screws

Lower Oven

Flue Chimney

Assembly

(4) SCR138

#10 x 1/2" Screws

installed thru Top

Panel of lower

oven into Side Trim

Tab on front

flange of Side

Trim fits into

slot in end of

Front Trim

It will be necessary

to remove the cooling

fan on this side of the

lower oven to install

the Side Trim screw.

Re-install cooling fan

after installing Side

Trim.

(2) FB55308103

Side Trim - fit between

top panel of lower oven

and base plate of

upper oven

Upper Oven

Flue Chimney

(4) SCR138

#10 x 1/2" Screws

install in top two

holes in ends of

Flue Chimey

Attach Lower and Upper Oven Flue Chimneys and Side Trims as illustrated below.

Page 30

Rotisserie Oven Installation

27

Locking Ovens in Place

For ovens equipped with casters, injury or equipment damage could result if the

ovens are not locked in position to prevent movement during normal operation.

Locking casters are provided on ovens with 3” diameter and larger casters. To prevent movement of the ovens once

they are in their installed position depress the caster locking lever on the side of the two front casters with your foot.

Low profile ovens with 2” diameter casters are provided with two legs in the front of the base of the lower oven. Once

the ovens are moved to their installed position, lower these legs to firmly contact the floor, preventing movement of the

ovens.

LEG LEVELERS TO BE LOWERED

TO CONTACT FLOOR TO PREVENT

MOVEMENT WHEN OVEN IN

OPERATING POSITION.

DRGV-14 LOWER OVEN with 2" CASTERS

Page 31

Rotisserie Oven Installation

28

COMBINATION GAS VALVE

Gas Supply Connection

Installation of this appliance must conform with local codes or in the absence of

local codes with the National Fuel Gas Code ANSI Z223.11/NFPA 54 or Natural

Gas and Propane Code CSA B149.1 as applicable.

The gas supply connection for the oven is located on the back of

the oven as shown. A separate gas supply must be provided

for each oven cavity for stacked ovens (DRGV-14).

A 3/4” NPT nipple is provided for the gas supply

connection. For proper oven operation the gas supply piping

and connector must have a minimum capacity of 80,000 BTU per

Hr. If a flexible connector with quick disconnect device is utilized,

a minimum 3/4” ID flexible connector and quick

disconnect devise must be used.

Gas Manifold Pressure Test

The gas manifold pressure is preset at the factory. Due to

variations in gas supply pressures, the manifold pressure

should be checked after installation of the oven.

Refer to the oven’s rating plate for the required manifold

pressure setting. Typically the manifold pressure will be

4 1/2 in W.C. for natural gas and 7 in W.C. for lp gas.

To check the manifold pressure connect a manometer to the

OUTLET PRESSURE TAP (see diagram at right). Connect the

oven’s gas supply and electric cord, turn the oven on and start

a cook program so that the oven burner lights. With the burner

lit compare the manifold pressure on the manometer to the

rated manifold pressure.

If the actual manifold pressure is different than the rated pressure use the PRESSURE REGULATOR ADJUSTMENT on

the valve to correct the manifold pressure. It will be necessary to remove the CAP SCREW to access the PRESSURE

REGULATOR ADJUSTMENT (see diagram at above).

Be sure to disconnect the manometer and reinstall the plug in the valve’s OUTLET PRESSURE TAP after the

competition of gas manifold pressure test.

Gas Supply

Connection

(3/4” NPT)

Page 32

Rotisserie Oven Maintenance

29

Maintenance

The restraining device must always be connected when the appliance is in service.

Disconnect for movement, such as servicing or cleaning. Reconnect the restraining

device after appliance has been returned to its normal position.

Failure to comply with the maintenance below could result in a serious accident or

equipment damage.

Failure to remove power from this unit before performing maintenance may cause severe

electrical shock. This unit may have more than one disconnect switch.

Scheduled Maintenance

Use the following table to help manage scheduled maintenance activities.

Frequency

Performed By

Part

Activity

Daily

User

Entire Oven

Perform oven-cleaning procedure.

Daily

User

Drive Rotor

Gears

Lubricate planetary gear teeth.

6 months

User

Fan Blade

Remove and replace.

Cleaning is not only necessary for sanitary reasons, but will increase sales appeal and maximize operating efficiency.

Failure to remove power from this unit may cause severe electrical shock. This

unit may have more than one disconnect switch.

Always wear appropriate personal protection equipment (googles, rubber glove &

long sleeved garments) when cleaning the oven to guard against possible injury.

Using abrasive cleaners will damage the cabinet finish. Use only a mild soap and

water solution or approved cleaner.

DO NOT USE OVEN CLEANER on this machine. Caustic cleaners will cause

damage to the machine.

NEVER USE A WATER HOSE OR A STEAM CLEANER TO WASH THIS UNIT.

Excess water can get into the interior of the cabinet and cause damage.

BKI Approved Cleaning Solutions

ECOLAB Greasestrip Plus

Proctor & Gamble DCT Oven Cleaner

J. Wilson Marketing Combi Brite Cleaner

Daily Cleaning & Maintenance

1. Allow oven to cool below 50o C-55o C (120o F-130o F).

2. Turn the Main Power Switch off and unplug the appliance.

3. Empty the Dripping Drawer using the drain valve or fat pump (refer to Figure 1 below).

4. Remove all food products from the unit.

5. Remove V-spits, or Baskets from the unit and place them in a large sink to soak in hot cleaning solution. Clean

the components with warm water, a sponge and an approved cleaning solution. Wipe dry with a clean cloth.

Page 33

Rotisserie Oven Maintenance

30

6. Remove the Rotor System as described below:

Orientation

Button

7. Place the Rotor System components in a large sink to soak in hot cleaning solution. Clean the components with

warm water, a sponge and an approved cleaning solution. Wipe dry with a clean cloth.

8. Remove the Fan Guard by pulling it straight out of the top of the oven cavity (refer to Figure 1 below).

Tabs on Fan Guard insert

into these slots.

Fan Guard

sits on pin,

both sides

Burner Cover - lift

up to cover Burner

during cleaning.

Fan Guard - pull

straight out to remove,

reinstall as shown.

Fan Blades under

Fan Guard

Wire Rack or Drip Tray

sits on pins in the front

& back of the cavity

Dripping Drawer

Figure 1

9. Remove the Wire Racks or Drip Tray and the Dripping Drawer from the oven (refer to Figure 1 above).

STEP 1

Rotate the rotor assembly until the

orientation button in the center of the

shaft is on top.

Lift the Retaining Washers on each

end of the shaft up & out of the

grooves in the Hubs.

STEP 2

Slide the Retaining

Cups off of the Hubs

on each end of the

shaft.

STEP 4

Remove the Rotor Disks

from the oven by pulling

out on the outside of the

disks while rotating them

back and forth.

STEP 3

Lift the Rotor Shaft

assembly out of the

Hubs on the Rotors.

Page 34

Rotisserie Oven Maintenance

ROTOR

GUIDE

PIN

Lubricate gear teeth.

STEP 1

Install the Rotor Disks by first

inserting the guide pin into the

shaft center hole. The Rotor

Disk with gears goes on the

control side of the oven. It will

be necessary to rotate this

Rotor Disk while pushing in to

engage the gears and the

drive hub. When properly

installed there will be

approximately ¼” [6 mm]

space between the Rotor Disk

and cavity side.

STEP 2

Rotate both Rotor Disks

so that the wide side of

the T-slot in the hubs is

facing up as shown.

Hold the Rotor Shaft with

wide side of the Tshaped tabs in end hubs

facing up. Slide the Tshaped tabs in the Rotor

Shaft ends into the

corresponding slots in

the hubs.

STEP 3

Slide the Retaining Cups

on each end of the Rotor

Shaft completely onto the

Rotor Hubs. The grooves

in the Rotor Shaft end

hubs must be visible.

STEP 4

Slide the Retaining

Washers onto the

Rotor Hubs and seat

them in the grooves

in the Rotor Shaft

end hubs.

10. Clean the Fan Guard, Wire Racks or Drip Tray and Dripping Drawer with mild soap and water solution or

approved cleaning solution and a sponge. Wipe dry with a clean cloth.

11. Clean in interior oven cavity with mild soap and water solution or approved cleaning solution and a sponge.

Wipe dry with a clean cloth.

12. Carefully clean the fan blades using a mild soap and water solution or approved cleaning solution and a scrub

brush. Do not bend or disfigure the fan blades.

13. Clean the outside of the oven with mild soap and water solution or approved cleaning solution and a sponge.

Wipe dry with a clean cloth.

14. Replace the Fan Guard, Wire Racks or Drip Tray and Dripping Drawer in the oven cavity (refer to Figure 1

above).

15. Lubricate the gears on the Drive Rotor as shown below with Permatex® Super Lube® Synthetic Lubricant with

PTFE (BKI part number L0200).

16. Reinstall Rotor System as shown below.

31

Page 35

Rotisserie Oven Maintenance

32

Oven will not turn on,

Main Power Light

IS iluminated

Is there continuity across

the High Limit Thermostat

contacts?

Reset the Thermostat then

operate the oven to

diagnose & repair the cause

of the Thermostat trip.

NO

Is there continuity across

the Power Switch

contacts with the switch

in the On position?

YES

YES

NO

Diagnose & repair fault

in internal oven wiring

Verify the Switch operator

cam rotates with switch. If it

does replace Contact Block.

Rotors will not rotate with Door closed but

will rotate when Jog Switch is pushed.

Is the Door

completely closed?

Close door.

NO

Is there continuity across

the Door Switch COM &

NO terminals with the

Door closed?

YES

YES

NO

Diagnose & repair fault in

internal oven wiring

Replace Door

Switch

Rotors will not rotate with Door closed

OR when the Jog Switch is pushed.

With the Power on &

the Door closed, is

there 120V present

between Rotor Motor

wires #2 & #11?

YES

NO

Diagnose & repair fault

in internal oven wiring

Replace R2 Relay

With the Power on &

the Door closed, is

there 120V present

between R2 Relay

wires #2 & #12?

NO

YES

Defective Rotor Motor

or Capacitor

Rotors rotate but have a jerky motion.

Adjust rotor drive chain

tension and alignment.

Troubleshooting

YES

Is Power Cord

plugged in?

Plug Cord into

115V receptacle.

NO

YES

Is there 115V across

the receptacle power

terminals?

Is the Main Power

pilot light faulty?

Is the oven’s circuit

breaker in building

panel tripped?

Diagnose & repair fault

in internal oven wiring.

NO

Contact building’s

electrician to repair

receptacle wiring.

YES

Diagnose & repair

cause then reset

the circuit breaker.

Replace Pilot Light

NO

YES

Oven will not turn on,

Main Power Light

is NOT illuminated.

NO

Rotors rotate with Door closed but will

not rotate when Jog Switch is pushed.

When depressing the Jog

Switch, is there continuity

between the contact

terminals?

YES

NO

Diagnose & repair fault in

internal oven wiring

Replace Jog

Switch

Page 36

Rotisserie Oven Maintenance

33

Oven Burner Will Not Light

The oven will try to ignite the burner for 6 seconds. If it fails to ignite the Spark / Ignition Control will lockout.

The Power Switch will have to be cycled off & back on to reset the Spark / Ignition Control.

Turn oven Power Switch off and then back on. Make certain the Door is closed & start Controller and initiate a

Preheat or Cook program.

With the Door closed, watch the Spark / Flame Sense Probe and Burner as the Controller calls for heat.

Troubleshoot the problem as described below based on your observations.

ALL measurements described below are made with the Door closed & when the Controller is calling for heat.

Is the Gas Supply

connected to the

oven?

Connect Gas

Supply

NO

YES

YES

Replace the

Gas Valve

NO

YES

Insufficient gas

pressure to

operate oven.

Spark is observed but the

Burner does not ignite.

NO

Is pressure at the

Valve INLET above

7 in. W.C. for natural

gas or 10 in. W.C.

for lp gas?

Is there any pressure

at the Valve OUTLET?

Check for

obstructions in the

flexible gas tube or

Burner Orifice.

Is the Combustion

Blower inlet free of

obstructions?

YES

Remove

obstruction

NO

Is pressure at the

Valve OUTET

4 1/2 in. W.C. for

natural gas or

7 in. W.C. for lp gas?

Adjust Valve

manifold

pressure

NO

YES

Is there 24V

across the Gas

Valve terminals?

Replace the

Spark / Ignition

Control

NO

YES

Vacuum Switch

tube is obstructed

or disconnected.

Is there 120V across

the white & black

Transformer wires?

Replace the

Controller

NO

Disconnect Spark Cable

from Control & Probe.

YES

No Spark is observed when

Controller calls for heat.

YES

Replace the

Spark Cable

NO

YES

Replace the

Transformer

NO

Is there is 24V

between the yellow

Transformer wire &

wire #8 on Vacuum

Switch SW4?

Is there continuity

through the Spark

Cable?

Is there continuity

between the Spark

Rod on the Probe

Assembly & ground?

Replace the

Spark / Ignition

Control

NO

Replace the Spark /