Page 1

Double Revolving Oven

MODEL DR-34

Installation & Operation Manual

Serial Numbers 100482 and Higher

Page 2

WHAT IS

WHO IS

COVERED

COVERAGE PERIOD

WARRANTY

EXCEPTIONS

EXCLUSIONS

INSTALLATION

REPLACEMENT PARTS

COVERED

COVERAGE

BKI LIMITED

PO Box

963-3471 • Toll

(864)

This warranty covers defects in material and workmanship under normal use, and applies only to the original

purchaser providing that:

The equipment has not been accidentally or intentionally damaged, altered or misused;

The equipment is properly installed, adjusted, operated and maintained in accordance with national and local

codes, and in accordance with the installation and operating instructions provided with this product.

The serial number rating plate affixed to the equipment has not been defaced or removed.

This

warranty

is

in the U.S.A.

extended

80400 • Simpsonville, SC

Free: (800)

to the original

purchaser

WARRANTY

29680-0400 • USA

927-6887 • Fax: (864) 963-5316

and applies only to

equipment purchased

Warranty claims must be received in writing by BKI within one (1) year from date of installation or

within one (1) year and three (3) months from data of shipment from the factory, whichever comes

first.

COB Models: One (1) Year limited parts and labor.

COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a two (2) year door

warranty.

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door warranty.

BevLes Products: Two (2) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after shipment date

from BKI, whichever comes first.

This

warranty

authorized

performed during regular, weekday business hours.

Any exceptions must be pre-approved in advance and in writing by BKI. The extended door warranty on

convection ovens years 3 through 5 is a parts only warranty and does not include labor, travel, mileage or

any other charges.

covers on-site labor, parts and

service

representative

reasonable

up to (100) miles

round

travel

trip and (2)

time

and travel

hours

expenses

travel time and

Negligence

Thermostat calibrations

Air and gas

Light

Glass doors and

Fuses,

Adjustments

Tightening

Failures

Unauthorized

Damage

Alteration,

Thermostats

Freight

Ordinary

Failure to follow

Events

Leveling, as well as

installation

BKI genuine

installation

Warranty

is in lieu of all

manufacturer’s

on the

damages,

or in any

replacement

warranty.

of this

or acts of

God,

after (30) days

adjustments,

bulbs,

to

of screws or

caused

repair by

in

shipment,

misuse or

and safety valves with

– other than normal UPS charges,

wear and

beyond control

proper installation

and use materials – is the responsibility of the

Factory OEM parts receive a (90) day

by a BKI F

actory Authorized

part. BKI shall in no

event

of

proven defective

door adjustments,

burner

flames and

fasteners,

by erratic

voltages

anyone other than

improper installation,

tear,

installation and/or operating instructions,

of the

other warranties, expressed

for

damages

parts shall

from equipment installation date,

cleaning of

or gas

suppliers,

a BKI F

broken

capillary tubes,

company.

and check out of all

Service

in excess of the

materials warranty

Center.

event

be liable for any

constitute a

or implied, and all

pilot

burners,

actory Authorized

new equipment -

dealer

or installer, not the

effective from the date of

other obligations

purchase

special, indirect

price of the unit. The repair or

fulfillment of all

Service Center,

per

appropriate

obligations under

of the

manufacturer.

or liabilities

or

consequential

the terms

for use

Asia Europe Latin America North America

Page 3

Double Revolving Oven Table of Contents

Table of Contents

Table of Contents........................................................................................................................................1

Introduction .................................................................................................................................................2

Safety Precautions....................................................................................................................................2

Safety Signs and Messages.................................................................................................................2

Safe Work Practices.............................................................................................................................3

Safety Decals .......................................................................................................................................4

Health And Sanitation Practices...............................................................................................................5

Food Handling......................................................................................................................................5

Storage Of Raw Meats.........................................................................................................................5

Coding Cooked Foods..........................................................................................................................5

Storage Of Prepared Foods.................................................................................................................5

Operation .....................................................................................................................................................6

Controls and Indicators.............................................................................................................................6

Turning the Oven “On”..............................................................................................................................7

Programming the Oven.............................................................................................................................7

Cooking.....................................................................................................................................................7

Reviewing Set Points................................................................................................................................8

Changing Set Points During Cooking.......................................................................................................8

Canceling the Cooking Cycle....................................................................................................................8

Power Failure During The Cooking Cycle ................................................................................................8

Probe (Thermocouple) Diagnostics..........................................................................................................8

Suggested Cooking Instructions...............................................................................................................9

Supplies Needed..................................................................................................................................9

Cooking Whole Chickens .....................................................................................................................9

Cooking Chicken Parts.........................................................................................................................9

Cooking Ribs......................................................................................................................................10

Suggested Times For Cooking.................................................................................................... ...........10

Installation .................................................................................................................................................11

Unpacking and Handling.........................................................................................................................11

Location and Clearance..........................................................................................................................11

Wiring......................................................................................................................................................11

Maintenance ..............................................................................................................................................12

Scheduled Maintenance.........................................................................................................................12

Oven Cleaning....................................................................................................................................12

Planet Gear Lubrication......................................................................................................................13

Troubleshooting......................................................................................................................................13

Notes ..........................................................................................................................................................15

1

Page 4

Double Revolving Oven Introduction

Introduction

The Double Revolving Oven is a compact, attractive and functional unit utilizing a double re volving

mechanism that ensures fast and even product cooking. It contains removable components and doors on

both sides for easy accessibility, maintenance and cleaning. A touch pad controller and switches are

provided to allow for quick setup and operation of the unit.

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has

been built with care and dedication -- using the best materials available. Attention to the operating

instructions regarding proper installation, operation, and maintenance will result in long lasting

dependability to insure the highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

you have any questions, please contact your BKI Distributor. If they are unable to

answer your questions, contact the BKI Technical Service Department, toll free:

1-800-927-6887. Outside the U.S., call 1-864-963-3471.

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

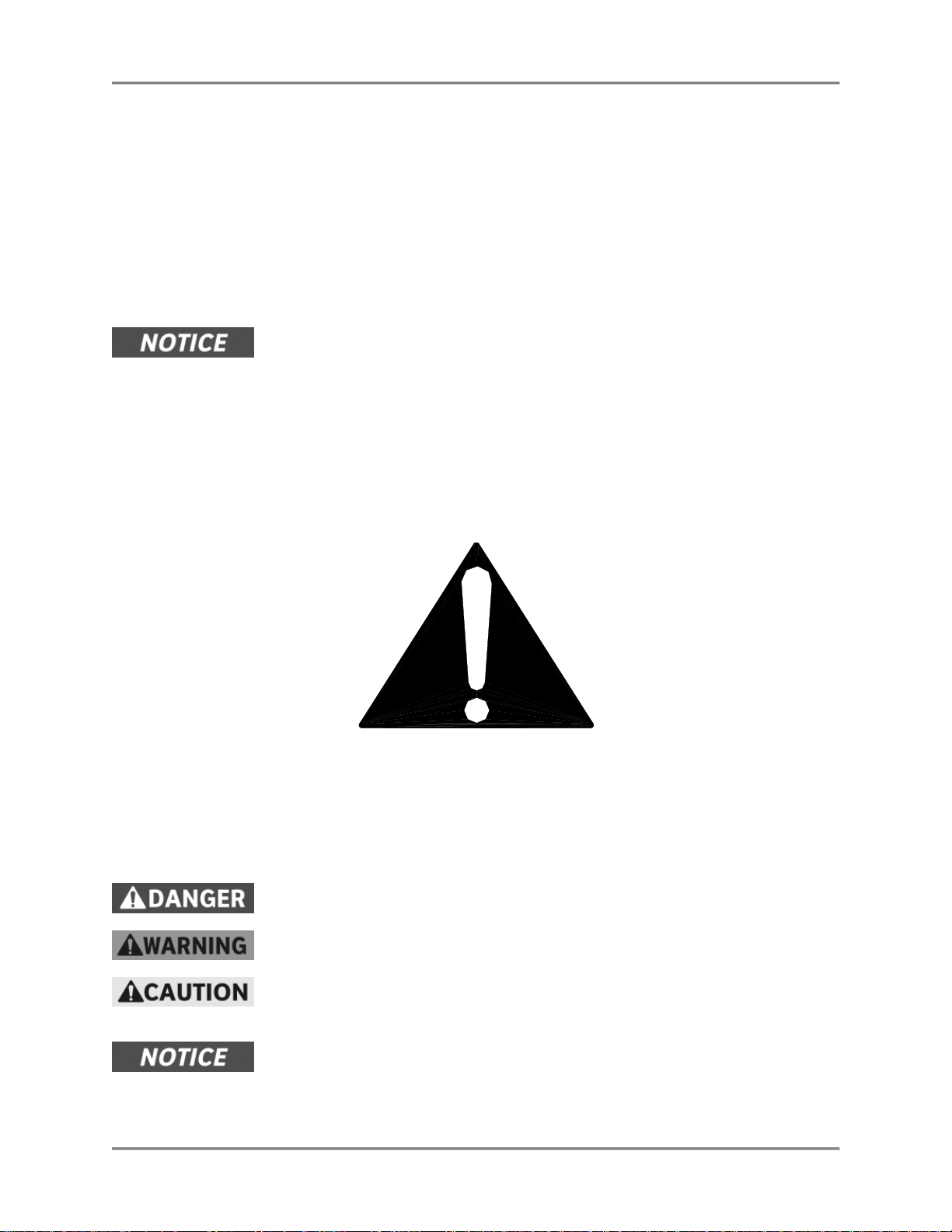

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know and

understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against unsafe

practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other special

data.

2

Page 5

Double Revolving Oven Introduction

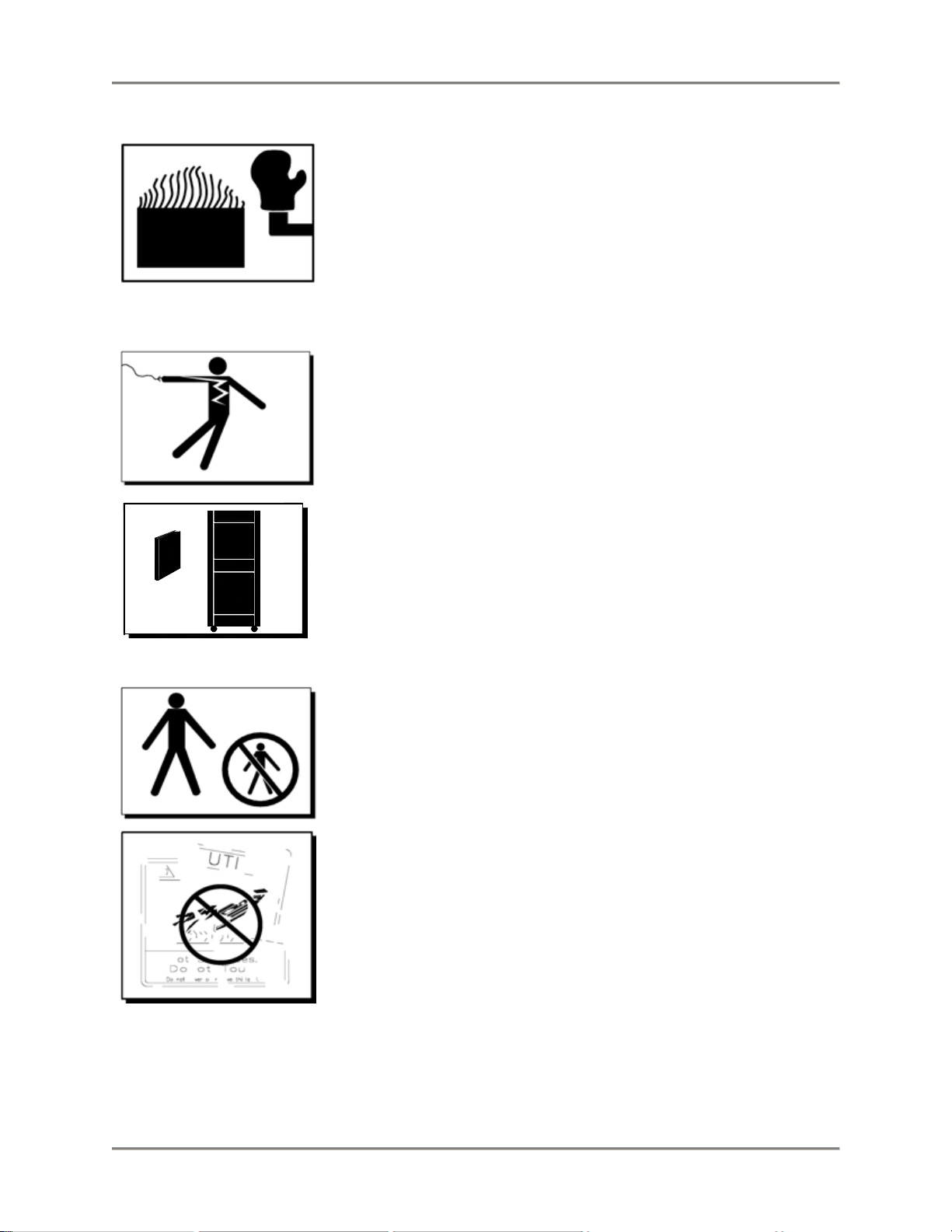

Safe Work Practices

Wear Safe Clothing Appropriate To Your Job

Always wear your insulated mitts when handling hot racks or touch any

hot metal surface. If you lose or damage your mitts, you can buy new

ones at your local restaurant equipment supply store or from your local

BKI Distributor. Never wear loose clothin g such as neckties or scarves

while operating this equipment. Keep loose hair tied back or in a hair

net while operating this equipment.

Always wear appropriate personal protection equipment during the

cleaning process to guard against possible injury from hot cleaning

solution.

Beware of High Voltage

This equipment uses high voltage. Serious injury can occur if you or

any untrained or unauthorized person installs, services, or repairs this

equipment. Always use an Authorized Service agent to service your

equipment.

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it

near for easy access. If you need to replace this manual, contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not understand

that this equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep all

safety labels clean and in good condition. Replace any damaged or

missing safety labels. Refer to the Safety Labels section for illustration

and location of safety labels on this unit.

If you need a new safety label, obtain the number of the specific label

illustrated on page 4, then contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

3

Page 6

Double Revolving Oven Introduction

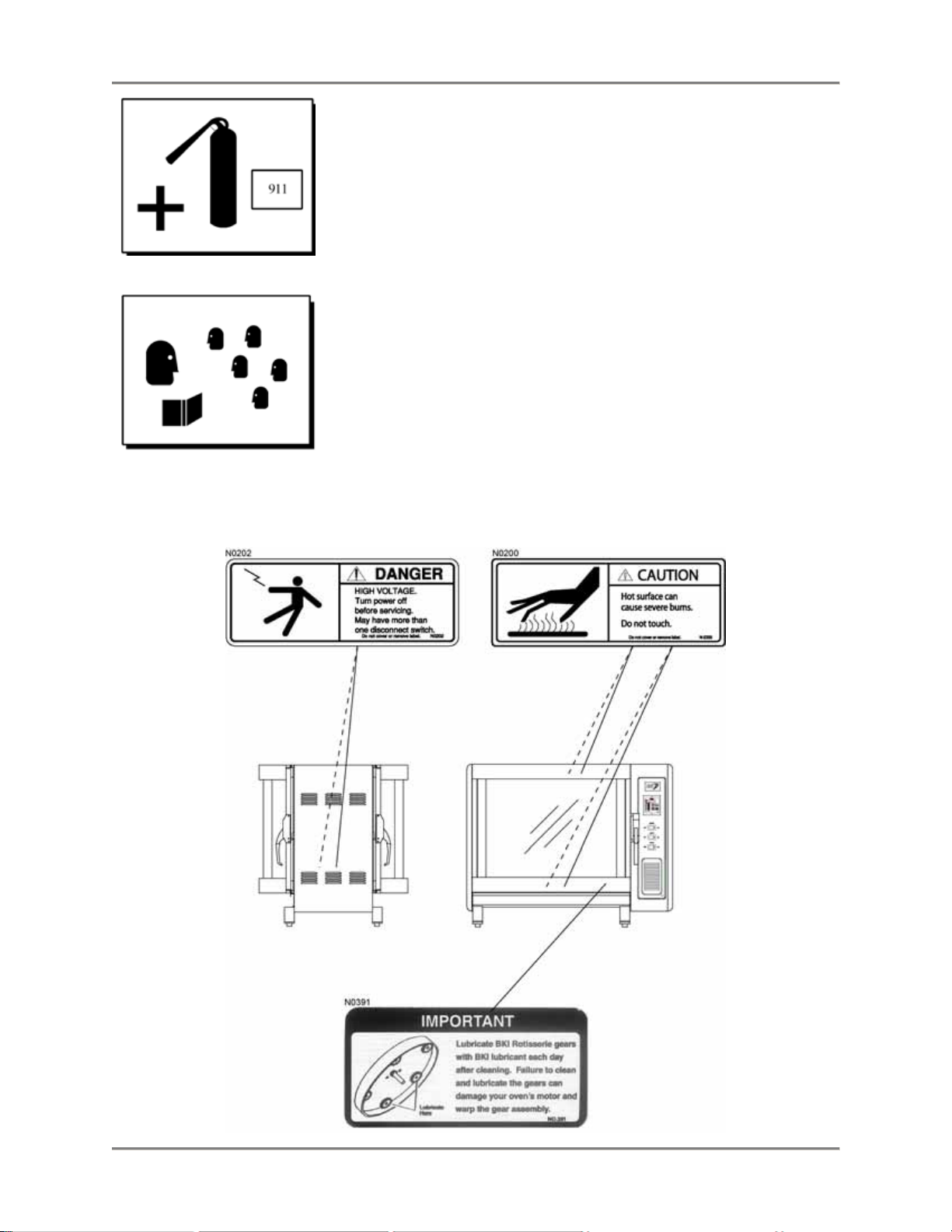

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment. You

must use a 40-pound Type BC fire extinguisher and keep it within 25

feet of your equipment.

Keep emergency numbers for doctors, ambulance services, hospitals,

and the fire department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the equipment.

• Make certain your employees are aware of the safety precautions on

the equipment and in this manual.

• Make certain that you have thoroughly trained your employees

about operating the equipment safely.

• Make certain the equipment is in proper working condition. If you

make unauthorized modifications to the equipment, you will reduce

the function and safety of the equipment.

Safety Decals

4

Page 7

Double Revolving Oven Introduction

Health And Sanitation Practices

BKI Rotisserie Ovens are manufactured to comply with health regulations and are tested and certified to

®

, cUL®, and NSF® standards. You must operate the equipment properly using only quality products

UL

and use meat thermometers to insure meats are thoroughly cooked.

Food Handling

• Wash hands thoroughly in warm, soapy water after handling raw poultry or meats.

• Clean and sanitize all utensils and surfaces that have been in contact with raw products. Clean

and sanitize the meat forks or baskets between cooking.

• Never place cooked meats on the same surfaces used to prepare raw me ats, unless the area

has been thoroughly cleaned and sanitized.

Storage Of Raw Meats

• Designate an area or shelf strictly for the storage of all raw meats to be used in the rotisserie.

• Raw product must always be stored at temperatures below 38° F. (3° C.).

• Never store or mix raw foods above cooked foods, as this is a health hazard.

raw foods contaminate cooked or processed foods.

• All chicken and chicken parts to be stored overnight must be thoroughly iced down and

refrigerated.

The drippings from

Coding Cooked Foods

All products cooked during the day should be sold the same day.

NOTE: It is not the intent of the rotisserie program to have unsold merchandise at the end of the cooking

day. Follow your company’s procedures for the handling of any leftover product.

Storage Of Prepared Foods

• Cold foods should be kept at or below 38° F. (3° C.).

• Hot foods must be maintained to meet local health codes, usually a minimum 145° F. (63° C.).

5

Page 8

Double Revolving Oven Operation

Operation

Controls and Indicators

The figure below depicts the oven’s controls and indicators. Refer to it as necessary while performing

operating procedures in this section.

6

Page 9

Double Revolving Oven Operation

Turning the Oven “On”

Press the POWER rocker switch, LIGHTS rocker switch, and ROTOR rocker switch located on the front

panel to “ON”.

Programming the Oven

1. Press and hold the “START/STOP” button until display alternates between “STOP” and the probe

sense temperature. The control is now ready for programming.

2. Press the “SELECT” button until the “PREHEAT TEMP” light turns on.

3. Press the “UP” or “DOWN” buttons to obtain the desired temperature. If a preheat cycle is not

required, press the “UP” or “DOWN” buttons until “OFF” is displayed. “OFF” is displaye d below

100° F. or above 325° F.

4. Press the “SELECT” button until the “COOK TEMP” light turns on. Press the “UP” or “DOWN”

buttons until the desired temperature is displayed.

5. Press the “SELECT” button until the “COOK TIME” light turns on. Press the “UP’ or “DOWN”

buttons until the desired time is displayed. The time is displayed in Hours and minutes.

6. Press the “SELECT” button until the “HOLD TEMP” light turns on. Press the “UP” or “DOWN”

buttons until the desired temperature is displayed. The hold function can be disabled by pressing

the “UP” or “DOWN” buttons until “OFF” is displayed below 100° F. or above 250° F.

7. Pressing the “SELECT” button again returns the control to the “STOP MODE”. The display will

alternate between “STOP” and the probe sense temperature. The control is ready for cooking.

Cooking

1. Ensure that the oven has been programmed. Always preheat the oven to 300° F before loading

the product.

2. Press the “START/STOP” button.

If a pre-heat temperature was programmed, the “CYCLE ON” light will turn on, the display will

alternate between “PrE” and the probe temperature and the controller will elevate the oven

temperature to the pre-heat value. When the oven temperature reaches the desired pre-heat

value, the “CYCLE ON” light begins flashing and a (5) second pulsing audible alert will be

activated. The control will maintain the oven temperature until the product is loaded into the

oven.

If pre-heat temperature was turned off, the oven will immediately enter a cook/hold mode.

3. Load product into the oven.

4. Press the “START/STOP” push button. The control will now regulate the oven to the desired cook

temperature and the cook timer will count down. The “CYCLE ON” light will be on and the display

will alternately show oven temperature and cook time remaining.

• If the hold temperature has been turned off, the oven will sound an audible alert when the

cook time reaches zero. This alarm will sound until the “START/STOP” button is pressed.

• If the hold temperature has been set, the control will beep eight (8) times at the end of the

cook cycle. It will regulate the programmed hold temperature. A count up timer will be

initiated to track the length of time in the hold mode. The display will alternately show

7

Page 10

Double Revolving Oven Operation

“HOLD”, actual oven temperature and hold elapsed time. The control will stay in the hold

mode until the “START/STOP” button is pressed again.

Reviewing Set Points

During the cooking cycle any programmed cooking parameter can be displayed.

1. Press the “SELECT” button until the desired parameter light turns on. The display will show the

value of the set point for five (5) seconds.

2. Reviewing set points during a cooking cycle will not alter them or interrupt the cooking cycle.

Changing Set Points During Cooking

1. Push the “START/STOP” momentarily. The “CYCLE ON” light will flash and the control will go

into pause. In this mode the control regulates at the pre-set points but the cook count down timer

will stop.

2. Change the cooking parameters by pressing the “SELECT” button until the desired indicator light

turns on. The display will show the pre-set value.

3. Press the “UP” and “DOWN” buttons to change the setting as desired.

4. Resume the cooking cycle by press the “START/STOP” button. The “CYCLE ON” light will come

on indicating that the cooking cycle has resumed.

Canceling the Cooking Cycle

Press and hold the “START/STOP” button until the “CYCLE ON” light turns off. (“STOP” will be

displayed).

Power Failure During The Cooking Cycle

The control will suspend operation retaining set points and cycle times. When power is restored,

operation will resume where left off when the power failed.

Probe (Thermocouple) Diagnostics

If the probe (thermocouple inside the oven) stops working, the control will cancel the cooking cycle and

the display will show “PROB”.

If the probe temperature goes below 50° F (10° C.) or, if the control fails, the display will show “EEEE”

and the control will go into “STOP” mode.

8

Page 11

Double Revolving Oven Operation

Suggested Cooking Instructions

Supplies Needed

• Meat thermometer - for testing the internal temperature of the product.

• Oven mitts - For handling hot items.

• Large pan - For barbecue sauce. Immediately after cooking the product, dip it in the barbecue

sauce for a delicious flavor.

Cooking Whole Chickens

1. Preheat the oven to 300° F.

2. Prepare whole chickens for cooking:

Cut off the excess skin along the neck so that it does not flap around.

Remove excess fat around the cavity opening.

Push down and break the breastbone.

Fold down the wings and lock them under the back.

3. Sprinkle Hi-Temp Seasoning into the cavity and over the outside of the chicken. Rub seasoning

thoroughly all over the chicken.

4. Secure the chickens on cooking forks or V-spits and load into the oven.

5. Cook at 325° F for approximately one hour. Check the internal temperature of the chicken with a

meat thermometer. Chicken is ready when the internal temperature is 175° F.

6. Cycle cook your foods. The oven must be in use at all times for the best merchandising results.

Regulate the number of chickens that you cook at one time in relation to the volume of business

that you expect.

Never mix raw chicken and cooked chicken together. Never place cooked chicken

in pans where raw chicken has been unless the pans have been thoroughly

washed and sanitized. Always wash and sanitize pans before reusing.

Cooking Chicken Parts

1. Marinate the chicken parts overnight in a five gallon covered container (Marinating is optional)

2. Preheat the oven to 300° F.

3. Sprinkle Hi-Temp Seasoning on the chicken pieces and rub seasoning in thoroughly.

4. Load chicken parts in clamshell baskets.

5. Cook at 325° F. for approximately 45 minutes.

6. Check the internal temperature of the chicken with a meat thermometer before removing from the

oven. The chicken is ready when the internal temperature is 175° F.

9

Page 12

Double Revolving Oven Operation

Cooking Ribs

1. Marinate the ribs overnight if desired. (Marinating is optional).

2. Preheat the oven to 300° F.

3. Cut the ribs into approximately 4” sections.

4. Rub Hi-Temp seasoning on the ribs.

5. Load ribs in clamshell baskets.

6. Cook at 325° F for approximately 45-50 minutes.

7. Check the internal temperature of the ribs with a meat thermometer before removing them from

the oven. Continue cooking until the internal temperature of the ribs is at least 170° F.

8. Dip the ribs in barbecue sauce after cooking.

Suggested Times For Cooking

Product Temperature Cook Time

Whole chickens (15 chickens)

- 2-1/2 to 2-3/4 lbs.

Chicken parts (baskets only)

Halves

Quarters

Pieces

Ribs (baskets only)

Baby Back Ribs

Short Ribs

325° F

325° F

325° F

325° F

325° F

325° F

55 to 65 minutes

1 Hour

55 Minutes

50 Minutes

50 Minutes

55 Minutes

10

Page 13

Double Revolving Oven Installation

Installation

Serious injury, equipment damage or death could result if attempting to install this

oven yourself. Ensure that an authorized BKI service agent install the oven.

Unpacking and Handling

It is the owners’ responsibility to file all freight claims with the delivering truck line. Inspect all cartons and

crates for damage as soon as they arrive. If damage to cartons or crates is found, or if a shortage is

found, note this on the bill of lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the delivering truck line and follow up

the call with a written report indicating concealed damage to your shipment. Ask for an immediate

inspection of your concealed damage item. Packaging material MUST be retained to show the inspector

from the truck line.

Remove all packing from the interior and exterior of the oven.

Location and Clearance

Place the oven no less than 10.5" (26.7 cm.) to combustible surfaces at the rear of the machine, and 1"

(2.54 cm.) on the sides.

Wiring

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs the electrical installation. Ensure that a licensed electrician

perform the electrical installation in accordance with local codes, or in the absence

of local codes, with the National Electrical Code, ANSI NFPA 70-20XX.

This unit, when installed by an authorized BKI service agent, must be wired for use in accordance with all

applicable local, state, and federal codes. For specific electrical requirements and conne ctions refer to the

wiring diagram attached to the unit or provided in the Service Manual.

11

Page 14

Double Revolving Oven Maintenance

Maintenance

Failure to comply with the maintenance below could result in a serious accident or

equipment damage.

Failure to remove power from this unit before performing maintenance may cause

severe electrical shock. This unit may have more than one disconnect switch.

Scheduled Maintenance

Use the following table to help manage scheduled maintenance activities.

Frequency Performed By Part Activity

Daily User Oven Clean the entire Oven.

Daily User Planet Gears Lubricate Planet Gears.

Oven Cleaning

Cleaning is not only necessary for sanitary reasons, but will increase sales appeal and maximize

operating efficiency.

Failure to remove power from this unit may cause severe electrical shock. This

unit may have more than one disconnect switch.

Using abrasive cleaners may damage the cabinet finish. Use only a mild soap

and water solution.

Never steam clean or get excess water in the interior of the cabinet as this can

damage unit.

DO NOT USE OVEN CLEANER on this machine. Caustic cleaners can cause

damage to the machine.

Always wear appropriate personal protection equipment during the cleaning

process to guard against possible injury from hot cleaning solution.

1. Turn off all switches and controls.

2. Empty the grease drawer.

3. Wearing your insulated mitts. remove all food products from the unit. Also remove V-spits, bottom

pans, meat baskets, and rotors from the unit and place them in a large sink to soak in hot

cleaning solution. (BKI Cleaner).

4. Let the oven cool until it is warm, but not hot enough to burn you.

5. Clean the outside and inside of the rotisserie oven with warm water, a sponge and approved

cleaner which is authorized for use on food surface areas.

6. Clean the rotors with warm water, a sponge and BKI Cleaner. Wipe dry with a clean cloth.

12

Page 15

Double Revolving Oven Maintenance

Planet Gear Lubrication

Lubricating the Planet Gears with BKI lubricant each day after cleaning will prevent motor damage and

warping of the rotor assembly.

1. Open the operator side door.

2. Lift the passive side rotor assembly off the shaft seat and out of the oven.

3. Wash the passive side rotor assembly with a mild grease cutting detergent and dry with a soft

cloth.

4. Slide the drive side rotor assembly off the rotor shaft and remove from oven.

5. Wash the drive side rotor assembly with a mild grease cutting detergent and dry with a soft cloth.

6. Apply a thin film of BKI lubricant to each planet gear on the drive side rotor assembly.

7. Slide the drive side rotor assembly on to the rotor shaft ensuring that the planet gears properly

align with the sun gear.

8. Place the passive side rotor assembly on the shaft seat inside the oven.

Troubleshooting

Refer to the table below for troubleshooting information. Additional troubleshooting information can be

found on our website at http://www.bkideas.com/

Problem Cause Possible Solution

Unit will not turn on Power to unit is not on. Problem

with building power panel,

circuit breaker or fuse.

Blown fuse on unit. Contact an authorized BKI service

Defective power switch. Contact an authorized BKI service

Unit operates for a period of

time, then, the control turns off

(no display).

Oven does not heat at all. Improper control settings. Reset the control.

Loose wire on heater circuit. Contact an authorized BKI service

Inlet to cooling fan has been

blocked, loss of power to

cooling fan or defective cooling

fan.

.

Check circuit breaker or fuses at

building power panel. If problem

persists, contact an authorized

BKI service agent for corrective

action.

agent for corrective action.

agent for corrective action.

Remove blockage from around

cooling fan inlet. If problem

persists, contact an authorized

BKI service agent for corrective

action.

agent for corrective action.

Defective relay. Contact an authorized BKI service

agent for corrective action.

Heating elements not

functioning.

13

Contact an authorized BKI service

agent for corrective action.

Page 16

Double Revolving Oven Maintenance

Problem Cause Possible Solution

Oven is very slow to heat up. Improper power line voltage. Contact an authorized BKI service

agent for corrective action.

Heating elements not

functioning.

Contact an authorized BKI service

agent for corrective action.

Control displays “PROB”. Damaged probe. Contact an authorized BKI service

agent for corrective action.

Thermocouple connection is

loose.

Control displays “EEEE”. Temperature inside the oven is

Contact an authorized BKI service

agent for corrective action.

Reprogram the controller.

below 50° F.

Time/Temperature controller

has failed.

Rotors not turning (Rotating). Dirty or greasy Planetary/Sun

gears.

Contact an authorized BKI service

agent for corrective action.

Clean and lubricate Planetary/Sun

gears.

Motor circuit breaker tripped. Press the reset button on front

panel.

Rotor switch not functioning. Contact an authorized BKI service

agent for corrective action.

Rotor Motor failure. Contact an authorized BKI service

agent for corrective action.

Drive Belt failure. Contact an authorized BKI service

agent for corrective action.

Product not cooked thoroughly Oven not preheated. Be sure to preheat the oven to

300 degrees before placing

product in oven.

Improper time and temperature. Check program for proper time

and temperature setting.

14

Page 17

Double Revolving Oven Notes

Notes

15

Page 18

Double Revolving Oven Notes

16

Page 19

Double Revolving Oven Notes

17

Page 20

P.O. Box 80400, Simpsonville, S.C. 29680-0400, USA

http://www.bkideas.com

Made and printed in the U.S.A

LI0119/0407

Loading...

Loading...