BKI BLF-F Owner’s Manual

Extra-Large Electric

Auto-Lift Fryer

SERIES: BLF

Operation Manual

BKI LIMITED WARRANTY

2812 Grandview Dr. • Simpsonville, SC 29680 • USA

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the

WHO IS COVERED This

COVERAGE PERIOD

WARRANTY COVERAGE This

EXCEPTIONS Any exceptions must be pre-approved in advance and in writing by BKI. The extended door warranty

EXCLUSIONS

INSTALLATION Leveling, as well as

REPLACEMENT PARTS

original purchaser providing that:

The equipment has not been accidentally or intentionally damaged, altered or misused;

The equipment is properly installed, adjusted, operated and maintained in accordance with national

and local codes, and in accordance with the installation and operating instructions provided with this

product.

The serial number rating plate affixed to the equipment has not been defaced or removed.

warranty

for use in the U.S.A.

Warranty claims must be received in writing by BKI within one (1) year from date of

installation or within one (1) year and three (3) months from data of shipment from the

factory, whichever comes first.

COB Models: One (1) Year limited parts and labor.

COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a two (2)

year door warranty.

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door warranty.

BevLes Products: Two (2) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after

shipment date from BKI, whichever comes first.

warranty

authorized

performed during regular, weekday business hours.

on convection ovens years 3 through 5 is a parts only warranty and does not include labor, travel,

mileage or any other charges.

Negligence

Thermostat calibrations

Air and gas

Light

Glass doors and

Fuses,

Adjustments

Tightening

Failures

Unauthorized

Damage

Alteration,

Thermostats

Freight –

Ordinary

Failure to follow

Events

installation

BKI genuine

installation

Warranty

liabilities on the

consequential damages,

unit. The repair or

obligations under

is

extended

covers on-site labor, parts and

service

representative

or acts of

adjustments,

bulbs,

caused

beyond control

is in lieu of all

door adjustments,

to

burner

of screws or

by erratic

repair by

in

shipment,

misuse or

and safety valves with

other than normal UPS charges,

wear and

installation and/or operating instructions,

and use materials – is the responsibility of the

by a BKI F

proper installation

Factory OEM parts receive a (90) day

manufacturer’s

replacement

the terms of this

to the original

God,

after (30) days

flames and

fasteners,

voltages

anyone other than

improper installation,

tear,

of the

company.

actory Authorized

other warranties, expressed

part. BKI shall in no

or in any

of

purchaser

up to (100) miles

event

proven defective

warranty.

reasonable

from equipment installation date,

cleaning of

or gas

suppliers,

a BKI F

broken

capillary tubes,

and check out of all

Service

for

damages

and applies only to

travel

round

pilot

burners,

actory Authorized

materials warranty

Center.

or implied, and all

event

parts shall

time

trip and (2)

new equipment -

dealer

be liable for any

in excess of the

equipment purchased

and travel e

hours

Service Center,

or installer, not the

effective from the date of

constitute a

xpenses

travel time and

per

appropriate

other obligations

special, indirect

purchase

fulfillment of all

of the

manufacturer.

or

or

price of the

SS-OM-011.05 Revised 09/12/2018

Electric Autolift Fryer Table of Contents

1

Table of Contents

Table of Contents ........................................................................................................................................ 1

Introduction ................................................................................................................................................. 2

Safety Precautions .................................................................................................................................... 2

Safety Signs and Messages ................................................................................................................. 2

Specific Precautions ............................................................................................................................. 3

Equipotential ground plane .............................................................................................................. 3

Full Disconnection ............................................................................................................................ 3

Safe Work Practices ............................................................................................................................. 4

Safety Labels ........................................................................................................................................ 8

Installation ................................................................................................................................................... 9

Unpacking and Handling ........................................................................................................................... 9

Installation Procedure ............................................................................................................................... 9

Wiring ...................................................................................................................................................... 10

Initial Test and Adjustment ..................................................................................................................... 11

Operation ................................................................................................................................................... 12

Controls and Indicators ........................................................................................................................... 12

Care of the Shortening ............................................................................................................................ 15

BLF-F Operation ..................................................................................................................................... 16

Start-Up (BLF-F) ................................................................................................................................. 16

Cooking (BLF-F) ................................................................................................................................. 17

BLF-FC Operation .................................................................................................................................. 18

System Programming ......................................................................................................................... 18

Product Programming ........................................................................................................................ 21

Start-Up (BLF-FC) .............................................................................................................................. 24

Cooking (BLF-FC) .............................................................................................................................. 25

Maintenance .............................................................................................................................................. 27

Scheduled Maintenance ......................................................................................................................... 27

Filtering Procedure ............................................................................................................................. 28

Boil-Out Procedure ............................................................................................................................. 29

Filter Pad Replacement ...................................................................................................................... 31

Troubleshooting ...................................................................................................................................... 32

Notes .......................................................................................................................................................... 33

BKI Worldwide is a wholly owned subsidiary of Standex International Corporation.

Electric Autolift Fryer Introduction

2

Introduction

The BLF Fryer is compact, attractive and functional in design. It is constructed of a stainless steel fryer

pot for cleaning ease. Exclusive BKI patented features and safety devices offer flexibility, efficiency and

reliability plus PERFECTION IN FRYING!

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has

been built with care and dedication -- using the best materials available. Attention to the operating

instructions regarding proper installation, operation, and maintenance will result in long lasting

dependability to insure the highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

you have any questions, please contact your BKI Distributor. If they are unable to

answer your questions, contact the BKI Technical Service Department, toll free:

1-800-927-6887. Outside the U.S., call 1-864-963-3471.

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know and

understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other special

data.

Electric Autolift Fryer Introduction

Risk of fire exists if the oil level drops below 5mm of the maximum oil level.

Use of oil/shortening older than the manufacturers recommendations for life of

the oil is prone to surge boiling and flash fires. Follow the oil manufacturers

guidelines for the life cycle of oil/shortening.

Do not open the drain valve or the fill valve while the fryer is under pressure.

Serious burns may result.

Follow operator instructions regarding effects of surge boiling of over-wet foods

and proper load size.

This unit may incorporate components that contain Mercury. The use of Mercury

relays is an industry standard.

Equipotential ground plane

When a high current flows through a conductor, differences in potential appear

between the conductor and nearby metallic surfaces near the appliance. As a

result, sparks may be produced between the appliance and surrounding metal

surfaces. These sparks could cause serious injury, damage, or fire.

BKI provides an Equipotential ground terminal for the connection of a bonding

conductor after the installation of the appliance per lEC60417-1. This terminal is

located on the inside of the Power Entry Supply box near the Earth connection

and is marked with this symbol.

Full Disconnection

In accordance with Local and/or National wiring codes, the installer must provide

a means of full disconnection under over voltage Category III conditions. An IEC

approved cord and plug combination will meet this requirement.

Units not provided with a cord and plug do not meet this requirement. In

accordance with Local and/or National wiring codes, the installer must provide

the means of full disconnection.

The fryer is designed to hold a maximum of 75 lb (34 kg) of oil/shortening.

Specific Precautions

California Residents Only. This product can expose you to chemicals

including chromium, and lead which are known to the State of California

to cause cancer and birth defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

3

Electric Autolift Fryer Introduction

4

Safe Work Practices

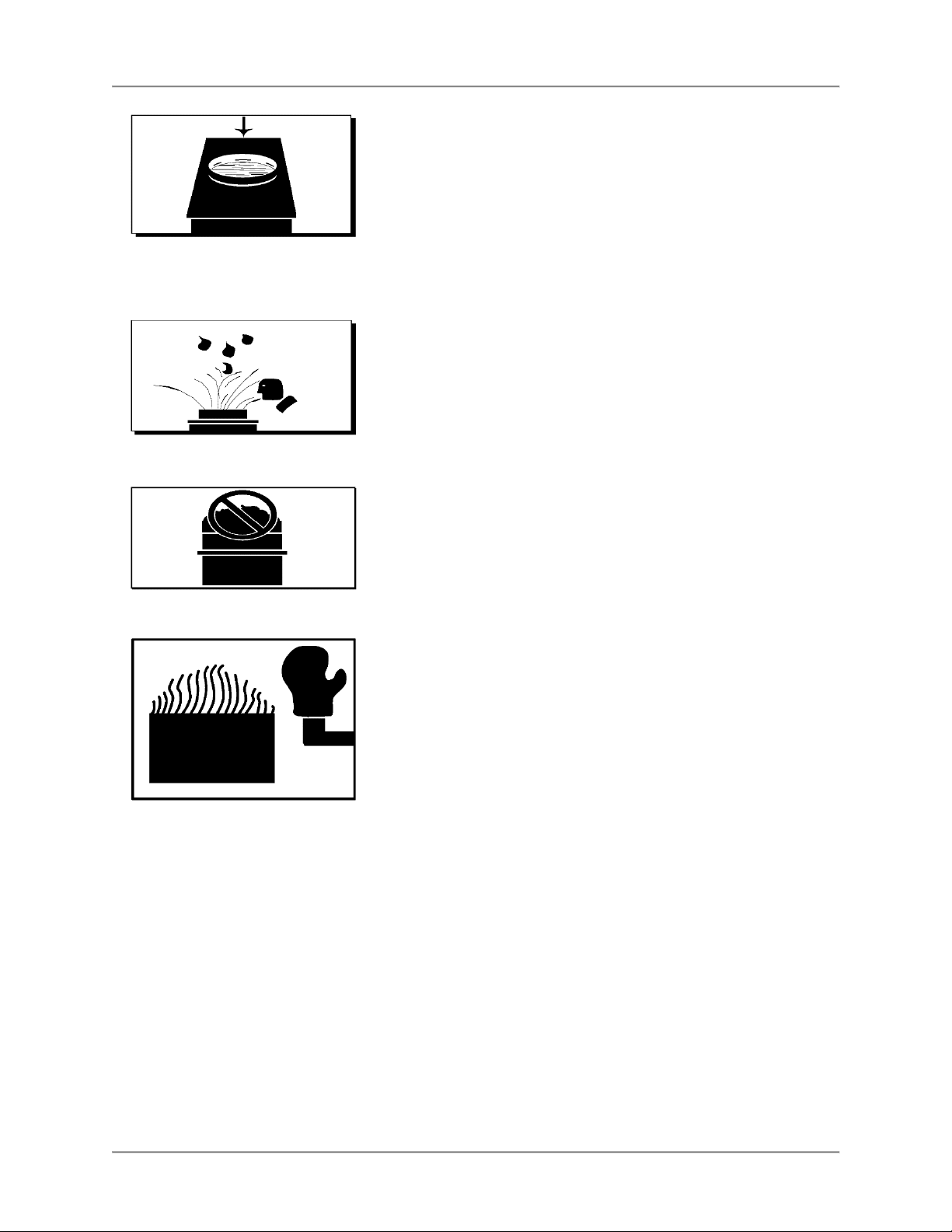

Keep The Casters Locked

To avoid spilling shortening, keep the casters locked. If any

shortening spills near your fryer, clean it up immediately.

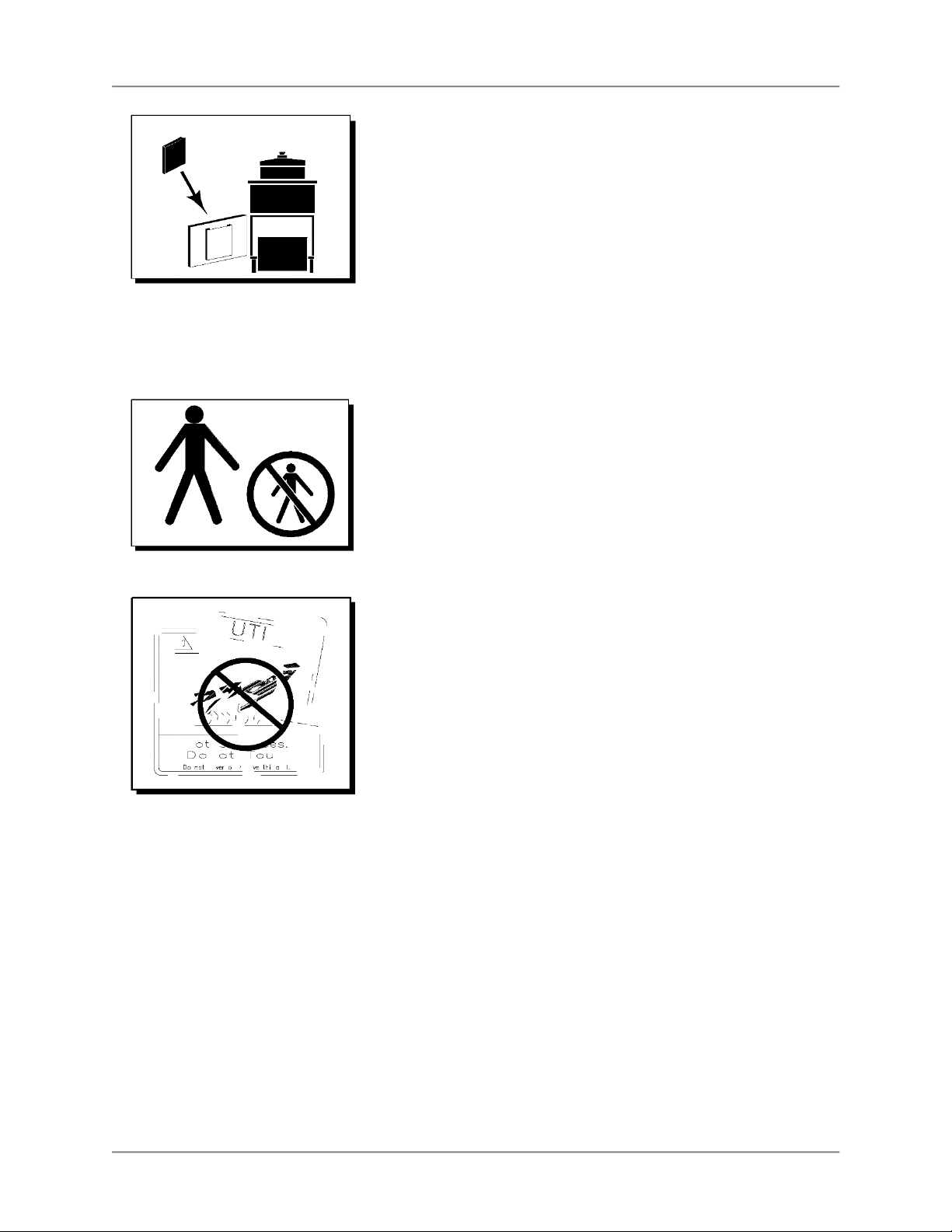

Noncombustible Floors Only

Make sure your floor is noncombustible. Do not operate your fryer

on floors that are wood, carpeted or have rubber mats.

• Placing your fryer on a combustible floor could cause a

fire. Serious injury could result.

• Examples of noncombustible floors where you can safely

place your fryer are concrete, tile, and ceramic.

Keep The Area Around Your Fryer

Uncluttered

Make sure to keep the area around your fryer clear of any

obstacles.

Serious injury can occur if you trip or fall near the fryer. You could

be burned by hot shortening that splashes out of the fryer or by

falling against the hot metal of the fryer.

Keep The Floor Around Your Fryer Clean Of

Shortening

Make sure to keep the floor around your fryer clean of shortening

and other liquids.

Serious injury can occur if you slip near your fryer. You could be

burned by hot shortening that splashes out of the fryer or by

falling against the hot metal of the fryer.

Electric Autolift Fryer Introduction

5

Do Not Overfill The Fryer With Shortening

Hot shortening and steam may escape and burn you if you put

too much shortening in the fryer. Fill the fryer to approximately

one inch below the fill marks that are inside the fryer pot. Heat the

shortening. If needed, carefully add more shortening to bring the

level to the fill marks.

Do Not Let Any Water Get Into The Fryer

Always remove excess moisture from food before placing it into

the fryer basket. Water will cause the hot shortening to spatter.

You could be burned.

Do Not Overload The Basket With Food

Hot shortening and steam may escape and burn you if you place

too much food in the basket.

Wear Safe Clothing Appropriate To Your

Job

Always wear your insulated mitts when handling the fryer basket

or touch any hot metal surfaces. You received a pair of insulated

mitts with your fryer. If you lose or damage your mitts, you can

buy new ones at your local restaurant equipment supply store or

from your local BKI Distributor.

Always wear non-skid shoes when working around the fryer or

any other equipment that uses shortening. Never wear loose

clothing such as neckties or scarves while operating your fryer.

Keep loose hair tied back or in a hair net while operating your

fryer.

Always wear appropriate personal protection equipment during

the filtering process to guard against possible injury from hot oil.

Always wear appropriate personal protection equipment during

the boil-out process to guard against possible injury from hot

cleaning solution.

Electric Autolift Fryer Introduction

6

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep

it near for easy access.

If you need to replace this manual, contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not

understand that this equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

Keep Safety Labels Clean and in Good

Condition

Do not remove or cover any safety labels on your equipment.

Keep all safety labels clean and in good condition. Replace any

damaged or missing safety labels. Refer to the Safety Labels

section for illustration and location of safety labels on this unit.

If you need a new safety label, obtain the number of the specific

label illustrated on page 8, then contact:

BKI

Technical Services Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Electric Autolift Fryer Introduction

7

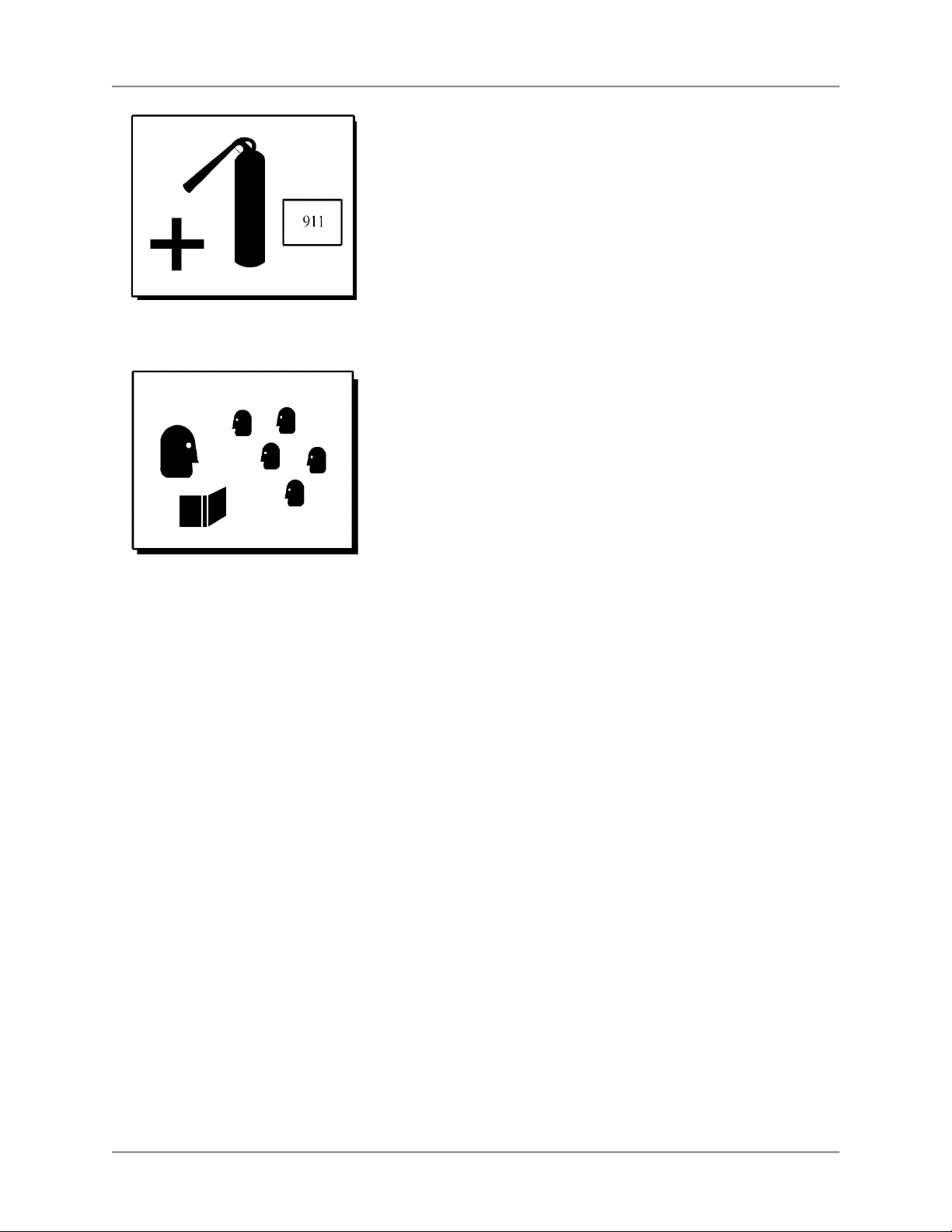

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

Keep a first aid kit and a fire extinguisher near the equipment.

You must use a 40-pound Type BC fire extinguisher and keep it

within 25 feet of your equipment.

Keep emergency numbers for doctors, ambulance services,

hospitals, and the fire department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the

equipment.

• Make certain your employees are aware of the safety

precautions on the equipment and in this manual.

• Make certain that you have thoroughly trained your employees

about operating the equipment safely.

• Make certain the equipment is in proper working condition. If

you make unauthorized modifications to the equipment, you

will reduce the function and safety of the equipment.

Electric Autolift Fryer Introduction

8

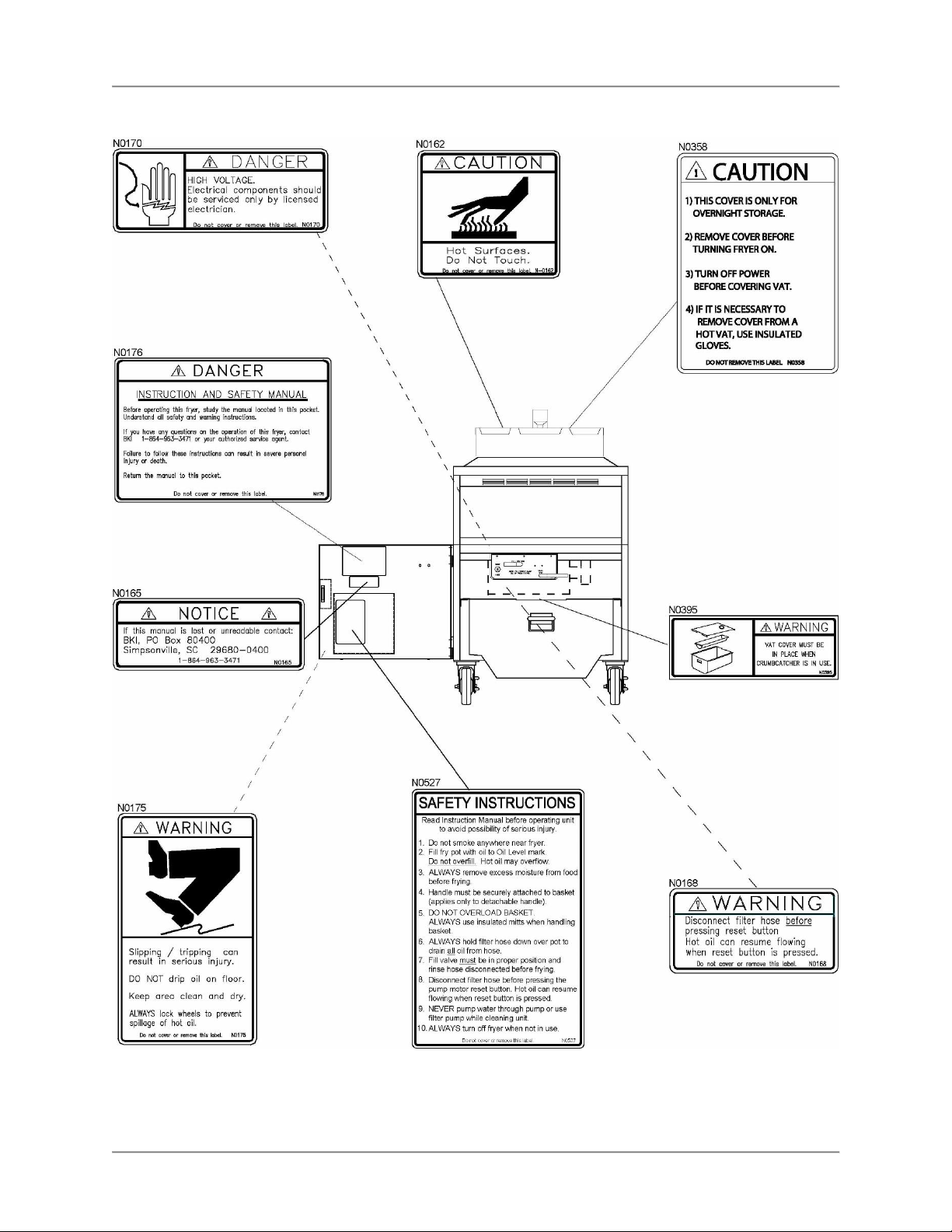

Safety Labels

Electric Autolift Fryer Installation

9

Installation

Serious injury, equipment damage or death could result if attempting to install

this fryer yourself. Ensure that an authorized BKI service agent installs the fryer.

Unpacking and Handling

It is the owners’ responsibility to file all freight claims with the delivering truck line. Inspect all cartons and

crates for damage as soon as they arrive. If damage to cartons or crates is found, or if a shortage is

found, note this on the bill of lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the delivering truck line and follow up

the call with a written report indicating concealed damage to your shipment. Ask for an immediate

inspection of your concealed damage item. Packaging material MUST be retained to show the inspector

from the truck line.

Installation Procedure

1. Remove the shipping packing materials from the interior and exterior of the fryer.

Risk of electric shock – Fryer must be secured to building structure. Follow

restraining device instructions for proper installation.

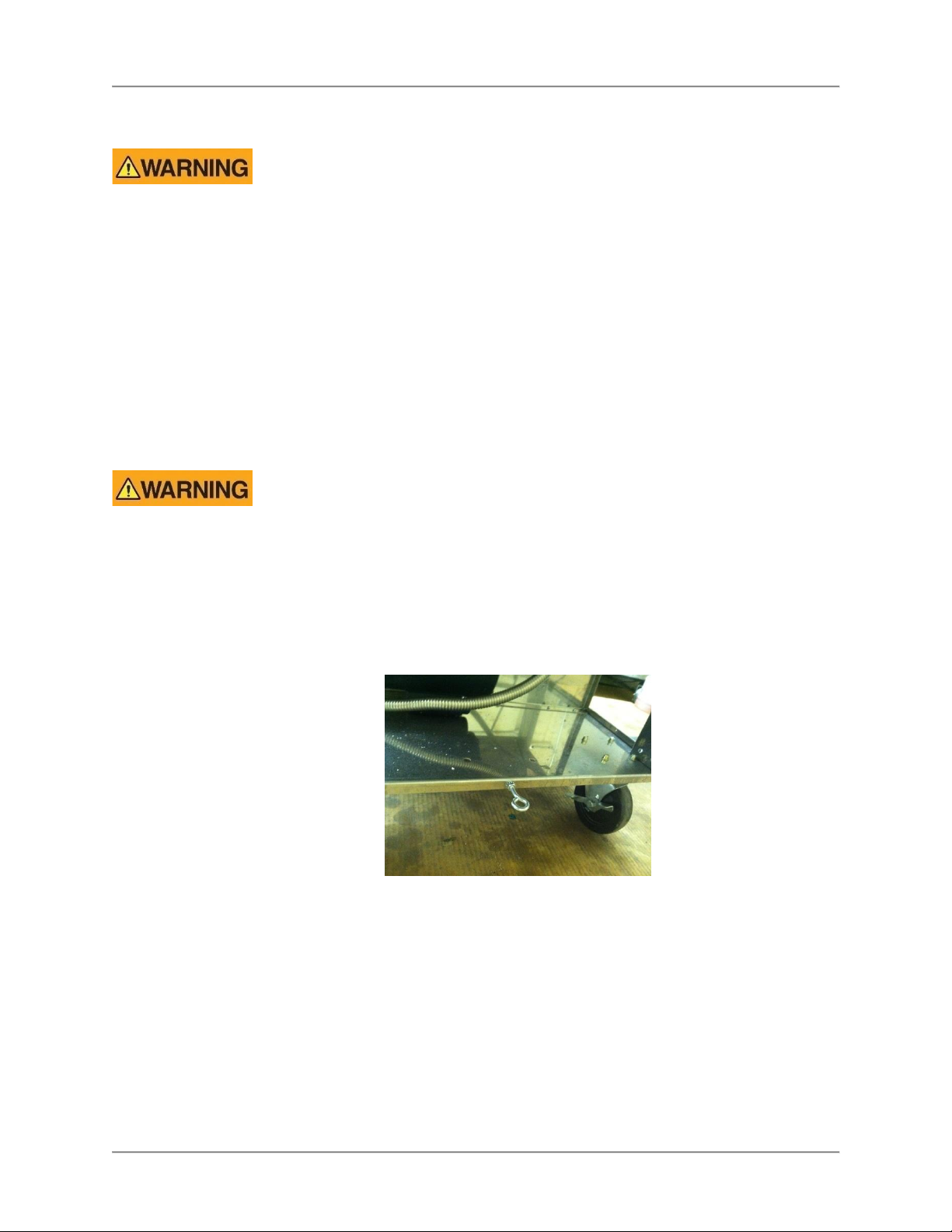

2. Install an ANSI Z83.11/CGA 1.8 compliant restraining device (such as BKI part number FT0279)

per the instructions below:

• Mount the wall attachment according the restraining device manufacturer instructions.

• Attach the spring-loaded hook on the restraining device to the eye-bolt mounted to the fryer

then attach the other spring-loaded hook to the wall attachment.

3. Lock the casters so the fryer does not move. Every time the fryer is used, make sure the casters

are locked so the fryer cannot move.

4. Clean the fryer pot before filling with shortening.

5. Place the DRAIN handle in the CLOSED position.

Electric Autolift Fryer Installation

10

Wiring

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs the electrical installation. Ensure that a licensed electrician

perform the electrical installation in accordance with local codes, or in the

absence of local codes, with the National Electrical Code, ANSI NFPA 70-20XX.

This unit, when installed by an authorized BKI service agent, must be wired for use in accordance with all

applicable local, state, and federal codes. For specific electrical requirements and connections refer to the

wiring diagram attached to the unit or provided in the Service Manual.

Loading...

Loading...