BKI 1.06 Service Manual

Combi-Oven

MODELS 1.06, 1.10, 2.10

Service Manual

Warranty Information

Your new BKI Combi has a 12 month factory warranty covering oven cabinet and parts. However, heating

elements in oven chamber are guaranteed for 24 months.

The factory warranty does not include glass parts, including glass in oven door, glass cover, bulbs and

door gasket.

Moreover, the factory warranty will terminate upon:

• Errors that can be assigned to irregular installation e.g. electricity, water/drain, air exhaust,

according to BKI's current installation and service manual.

• Errors and interruptions of operation resulting from irregular operation according to the directions

in the user's manual.

Combi-Oven Table of Contents

Table of Contents

Table of Contents........................................................................................................................................1

Introduction .................................................................................................................................................2

Description................................................................................................................................................2

Safety Precautions....................................................................................................................................3

Installation ...................................................................................................................................................4

Unpacking the Oven.................................................................................................................................4

Positioning of oven ...................................................................................................................................5

Water Connection.....................................................................................................................................5

Exhaust.....................................................................................................................................................6

Electrical Connection................................................................................................................................6

Drain Connection......................................................................................................................................7

Adjusting Flaps .........................................................................................................................................8

Setting System Options for CVC Controller..............................................................................................9

Setting System Options for S Controller.................................................................................................10

Setting System Options for VS Controller ..............................................................................................15

Initial Checks and Adjustments...............................................................................................................17

Maintenance ..............................................................................................................................................18

Scheduled Maintenance.........................................................................................................................18

Troubleshooting......................................................................................................................................21

Replacement...........................................................................................................................................25

Replacement Parts....................................................................................................................................26

Assemblies..............................................................................................................................................26

Accessories.............................................................................................................................................53

Notes ..........................................................................................................................................................57

1

Combi-Oven Introduction

Introduction

We congratulate you on your new BKI Combi.

By the purchase of a BKI Combi, you now possess one of the market's leading oven products for

professional kitchens. All BKI Combis are currently subjected to intensive product development that

ensures that the products are always based on the latest technology as well as the most modern and

energy-saving techniques of preparation.

Moreover, the products from BKI are up-to-date with the latest development/technology as regards:

• ERGONOMICS AND SAFETY

• SIMPLE AND LOGICAL OPERATION

• EASY-TO-OPERATE DESIGN

• RELIABILITY AND SERVICE

To ensure our customers an optimum and reliable product, prior to dispatch, all BKI Combis have passe d

through an extensive test programme in which all functions are subjected to a continuous and extreme

load.

Before use and to make the best use of the many facilities and advanced technique of the BKI Combi, it is

important that you are aware of working ranges and possibilities of application of the steamer. We thus

recommend you study the user's manual thoroughly before using the steamer. By this, you can - as a

user - make sure that you achieve optimum cooking results through appropriate and safe operation. By

going through the user's manual, you will save time

Description

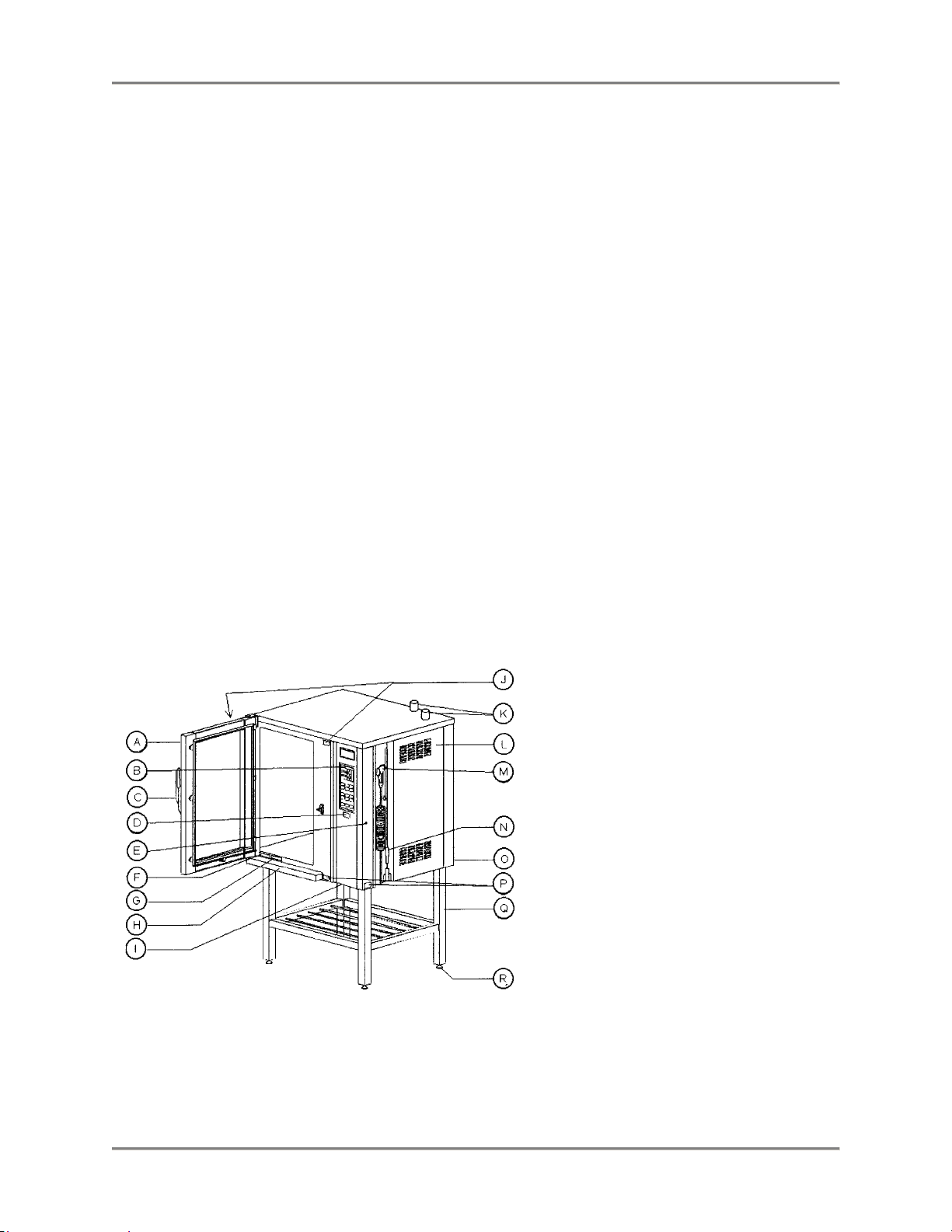

Refer to illustration below for a description of the unit.

(A) Oven door

(B) Operating panel

(C) 2-step safety handle

(D) Rethermalize on High Speed only!

(E) Plug for core temperature probe

(F) Serial plate

(G) Risk of fire - space oven a

minimum of 2 inches from the rear

and side wall

(H) Drip tray

(I) Ball valve for hand shower

(J) Hot surface

(K) Exhaust

(L) Cover for electri c parts

(M) Hand shower

(N) Core temperature probe

(O) Drain

(P) Risk of electric shock. Disconnect

power before servicing

(Q) Stand

(R) Adjustment legs

2

Combi-Oven

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know a nd

understand the meaning of these instructions, signs, and messages . Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other spe cial

data.

Specific Precautions

Risk Of Electric Shock Disconnect Power Before Servicing

For Continued Protection Against Risk Of Fire And Electric Shock, Replace With

Fuses Of Same Rating

Rethermalize on High Speed only!

Hot surface can cause severe burns. Do not touch.

Replace Oven Halogen Lamps with 12V, 20W maximum

3

Combi-Oven Installation

Installation

Unpacking the Oven

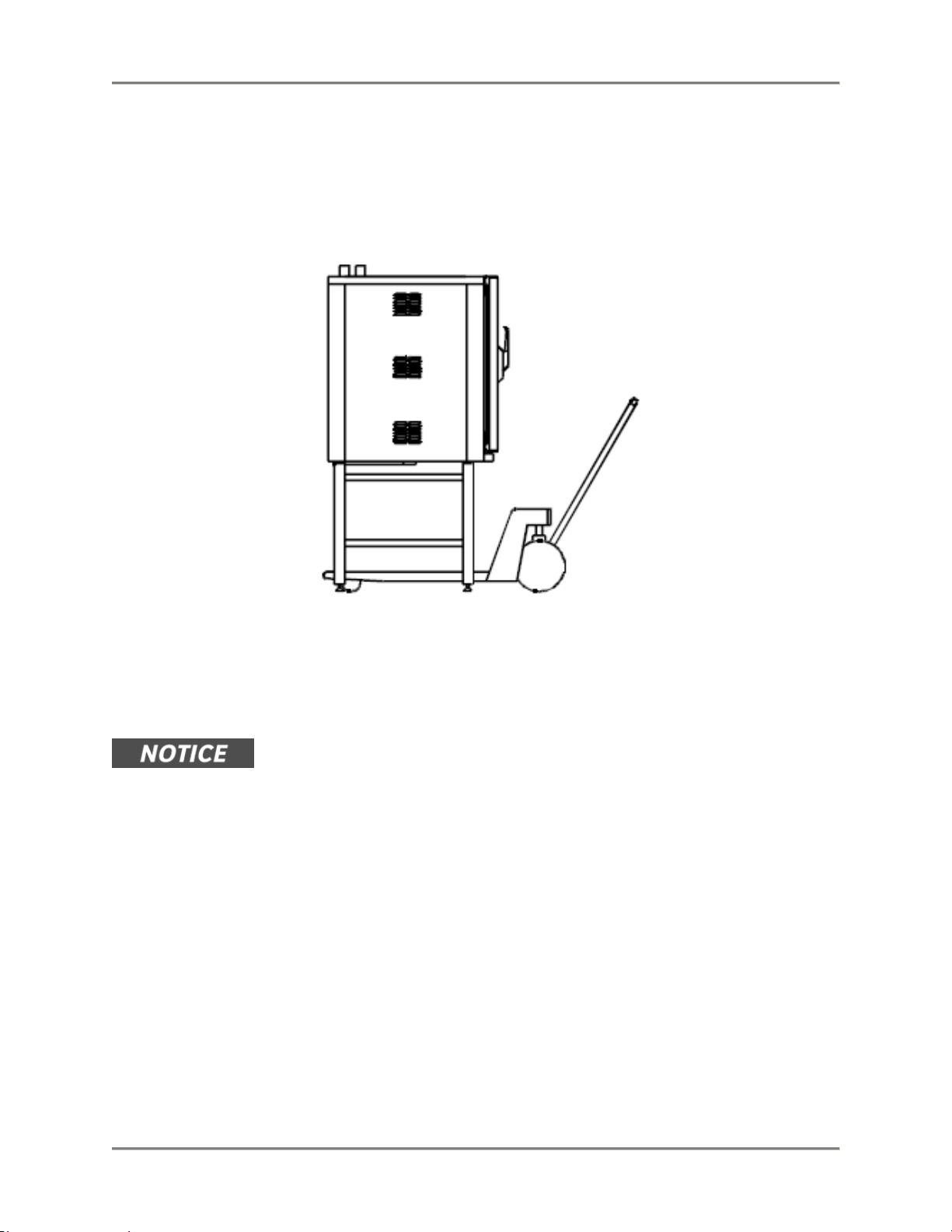

The oven is best handled while in its wrapping. Use a lifting trolley whenever possible. Introduce the lifting

trolley under the lower cross tube of the stand and place a couple of wooden blocks between the cross

tube and the lifting trolley.

To achieve the best possible balance, introduce the lifting trolley from the front of the oven or from the

motor side. Note that the oven can be lifted off the stand. Remove the original packaging from the oven.

Do not remove the foil that covers the surfaces until the oven has been installed, as the surfaces are

vulnerable to sharp objects such as tools, once the foil has been removed. Remove all protecting parts

that secure the racks in the oven compartment.

The packing must be destroyed in accordance with the rules and regulations

covering the disposal of rubbish in your country. Information on the packaging

material can be obtained from our technical department.

4

Combi-Oven Installation

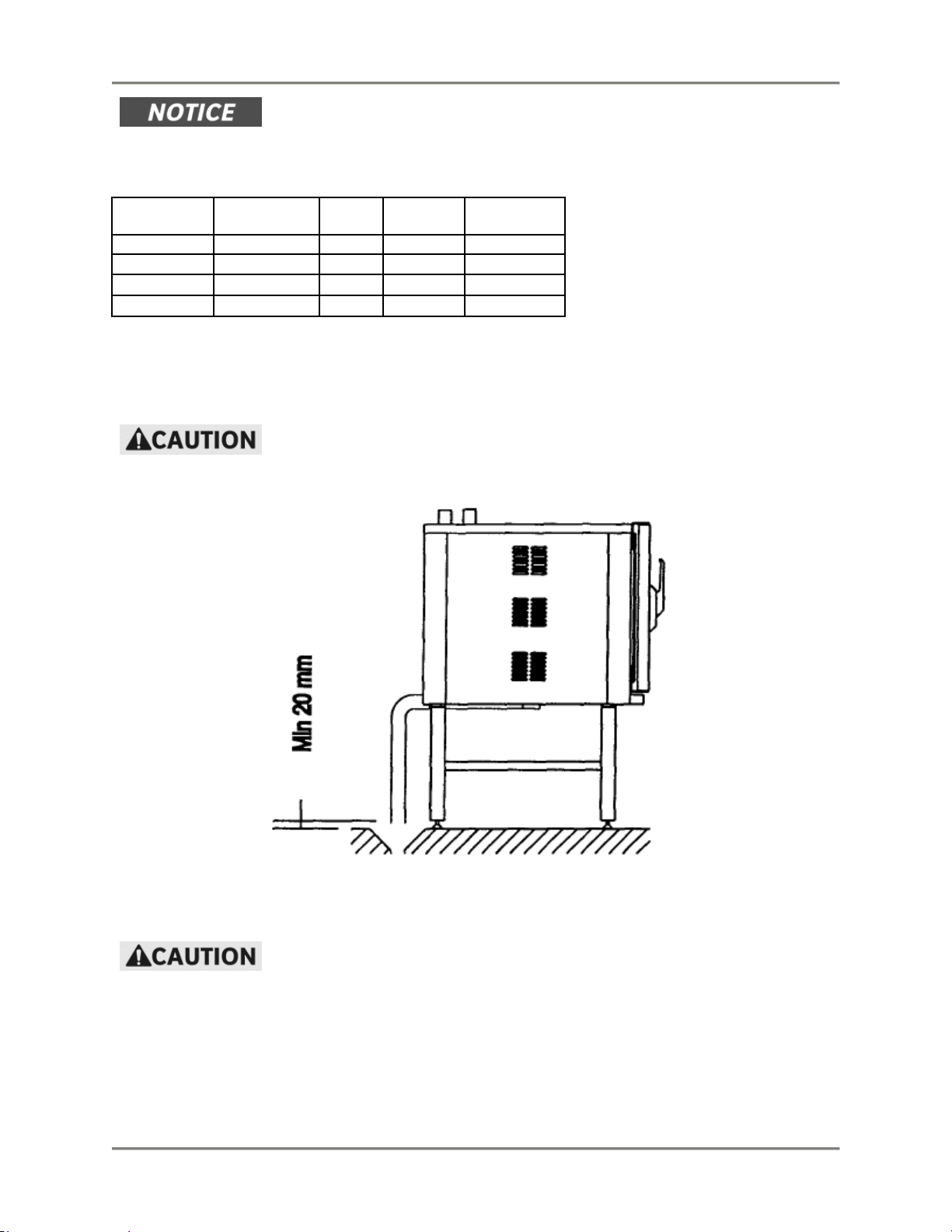

Positioning of oven

To ensure that the oven functions correctly when installed, it should be placed upright and level

(horizontally). This is measured at the front edge and side edge of the roof, and adjustment is made by

means of the adjusting screws on the stand or on the legs of table models. The height of the oven can

also be adjusted to fit the trolley for rack.

The oven should be placed at least 2 inches from the rear wall and the distance between the sides of the

oven and the nearest wall or piece of furniture, etc. should be at least 4 inches. This is to ensure the

necessary flow of cooling air to the oven. Strong sources of heat such as frying pans, fryers, etc. should

not be placed near the oven, especially not on its right side; otherwise the warranty may cease to apply.

Water Connection

As standard, the BKI Combi has one water connection. To facilitate cleaning and service, the oven should

be connected with an approved flexible 1/2"

stop-tap for the water supply to the oven.

Before connecting the oven to water, flush the water tubes thoroughly. Then fit the dirt filter and connect

the oven.

Water Requirements

Hardness: max. 3 dH

Conductivity: min. 75 microsiemens

Water pressure min. 1.5 bar (150 kP), max.6.0 bar (600 kP).

Water pressure Combi Clean: min. 2.5 bar dynamic pressure (CombiClean activated)

Water temperature: max. 20°C

Chloride concentration: max. 100 mg/litre

If the feeder is connected to the water distribution system with a flexible hose, this hose should be VA

approved.

A reversed osmosis plant must not be connected to ovens with a steam

generator as this may cause problems with respect to the registration of the

water level in the steam generator.

hose and the permanent installations should be fitted with a

5

Combi-Oven Installation

An authorized plumber in accordance with existing rules and regulations MUST

carry out the water connection.

Clogged up water filters and dirt in solenoid valves are not covered by the

warranty.

Alternatively, the oven can be supplied with two water connections (optional equipment):

1. for raw water for condensation nozzle (cold water)

2. for nozzle in oven cabinet and steam generator. Must meet the requirements made on water for

drain connection, however, the water temperature must not exceed 140°F.

Exhaust

The BKI Combis are equipped with an open/direct exhaust system that removes surplus humidity from

the oven compartment. The exhaust system has electrically or manually operated air exhaust.

The vent pipe can be connected to a ventilating system. In this case, a special extraction funnel is fitted to

avoid suction directly from the oven compartment. This extraction funnel can be ordered from BKI.

If an extraction hood is installed in the ceiling above the oven, it should project 50 cm over the front of the

oven. The suction effect should be 400 - 800m

The ventilation motor can be controlled directly from the oven. This means that the ventilation starts when

a program is started and runs for 5 minutes after the program is finished.

3

/h.

Electrical Connection

An authorized electrician in accordance with existing rules and regulations must carry out the electrical

connection.

There is a wiring diagram in the motor room.

Locate an approved plug outlet or a contact breaker close to the oven so that the oven can be

disconnected during repair and installation. The breaker must be able to cut off all poles with a length of

break of at least 3 mm. To facilitate cleaning and service, use an approved flexible connection cable, type

H05RN-F.

The oven may leak 1 mA current per kW.

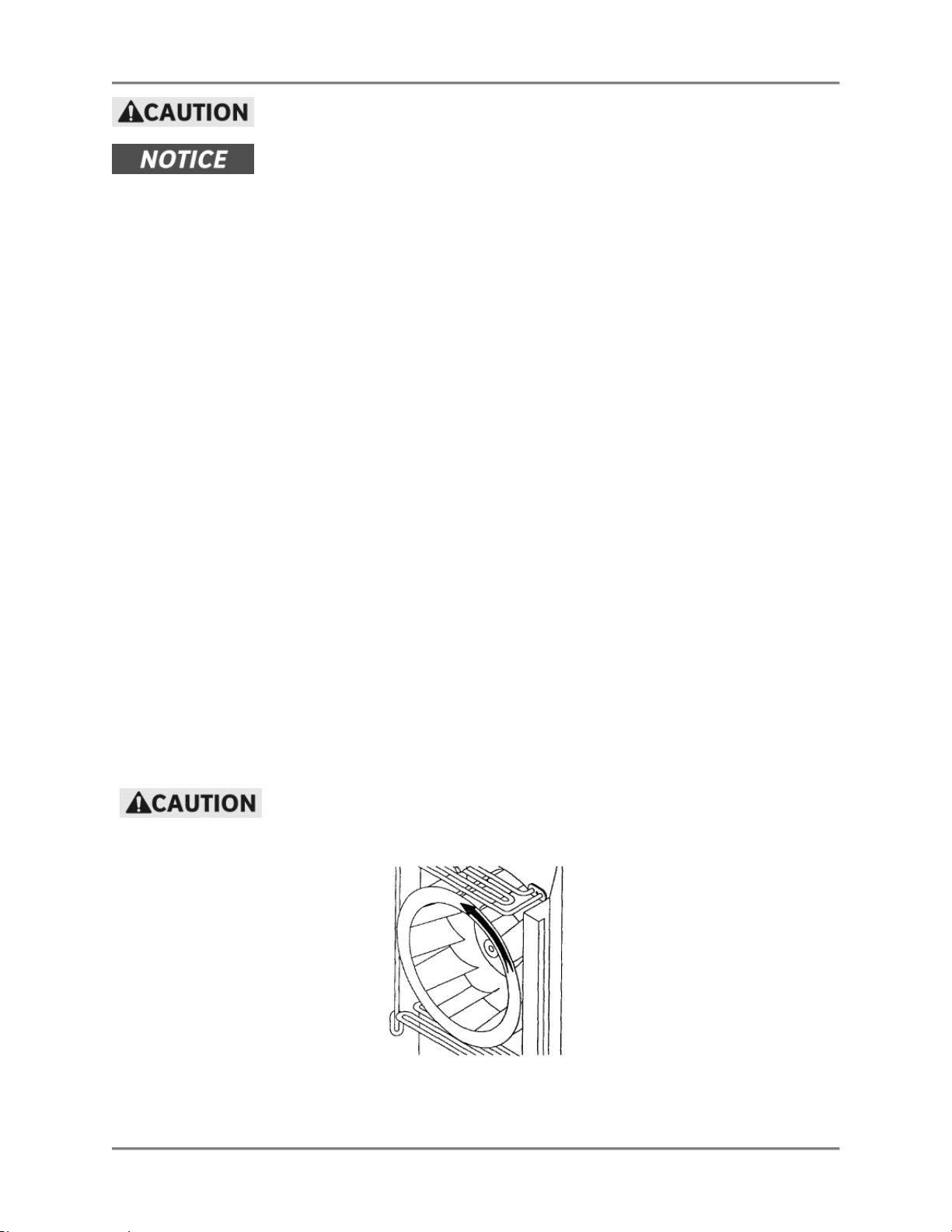

After connection, check that the fan rotates in the right direction, i.e. COUNTERCLOCKWISE.

If the fan rotates in the wrong direction, the oven does not operate correctly, which may cause damage to

the oven.

6

Combi-Oven Installation

The warranty does not cover incorrect connection.

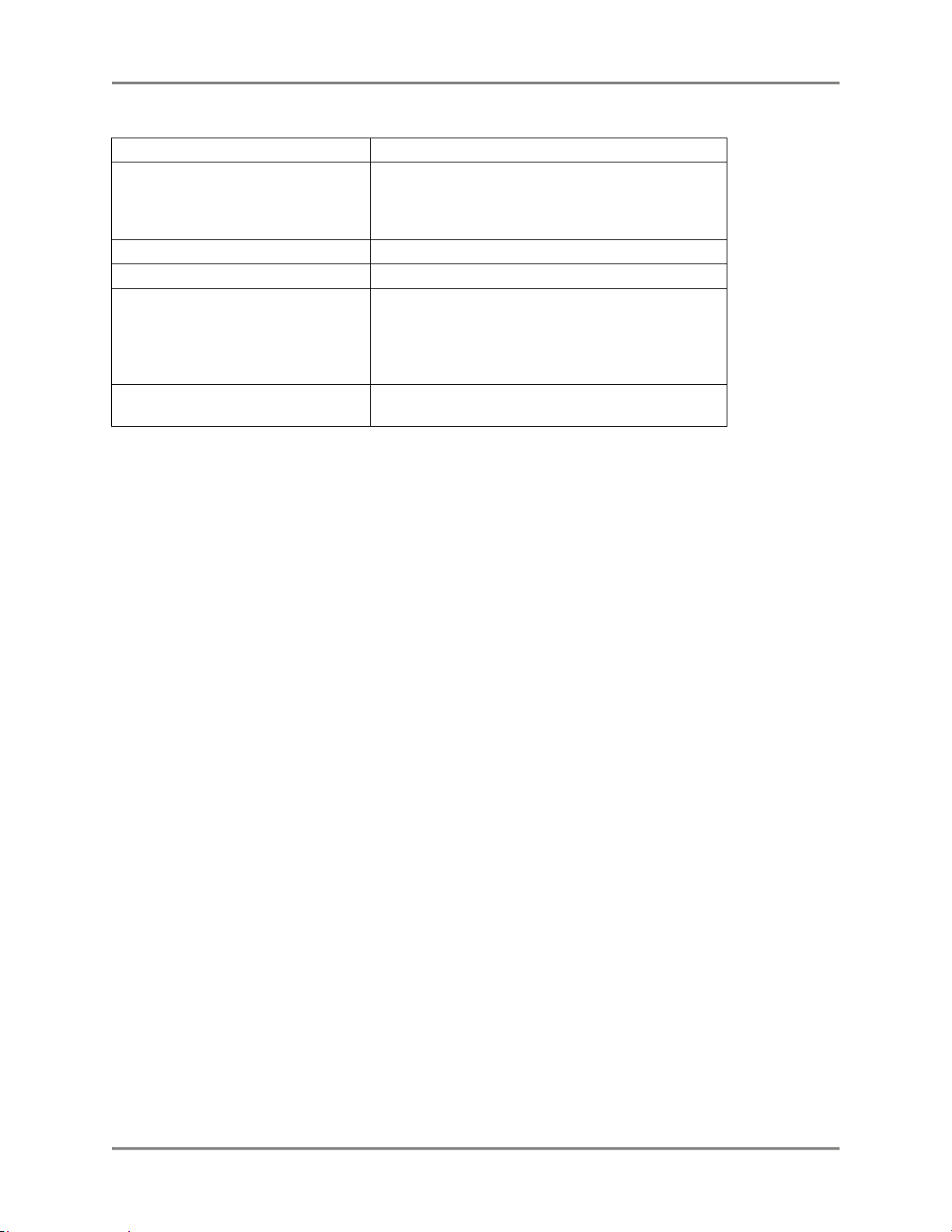

Knock out openings for supply connection

Open type Thread Size Amps Cable

2.10 - 2.14 1 1/2 70 2 AWG 50.0 mm

1.16 1 1/4 56 4 AWG 43.7 mm

1.10 1 42 6 AWG 34.5 mm

1.06 3/4 22 10 AWG 27.8 mm

Size /

opening

Drain Connection

As standard, The BKI Combi is equipped with a drain system that removes surplus water from the oven

compartment. Water may occur when steam is used in the oven and when the oven is cleaned.

An authorized plumber must carry out connection. The oven must be connected

to an open drain and the connection must end at least 20 mm above the outlet

grating or funnel.

The drain must never end directly under the oven. The drain tube must be of stainless steel, have a

diameter of at least 38 mm and a fall of at least 3° or 5%.

Never connect directly to a water trap so as to avoid obnoxious smells, bacteria

and possibly low pressure, suction or overflow.

7

Combi-Oven Installation

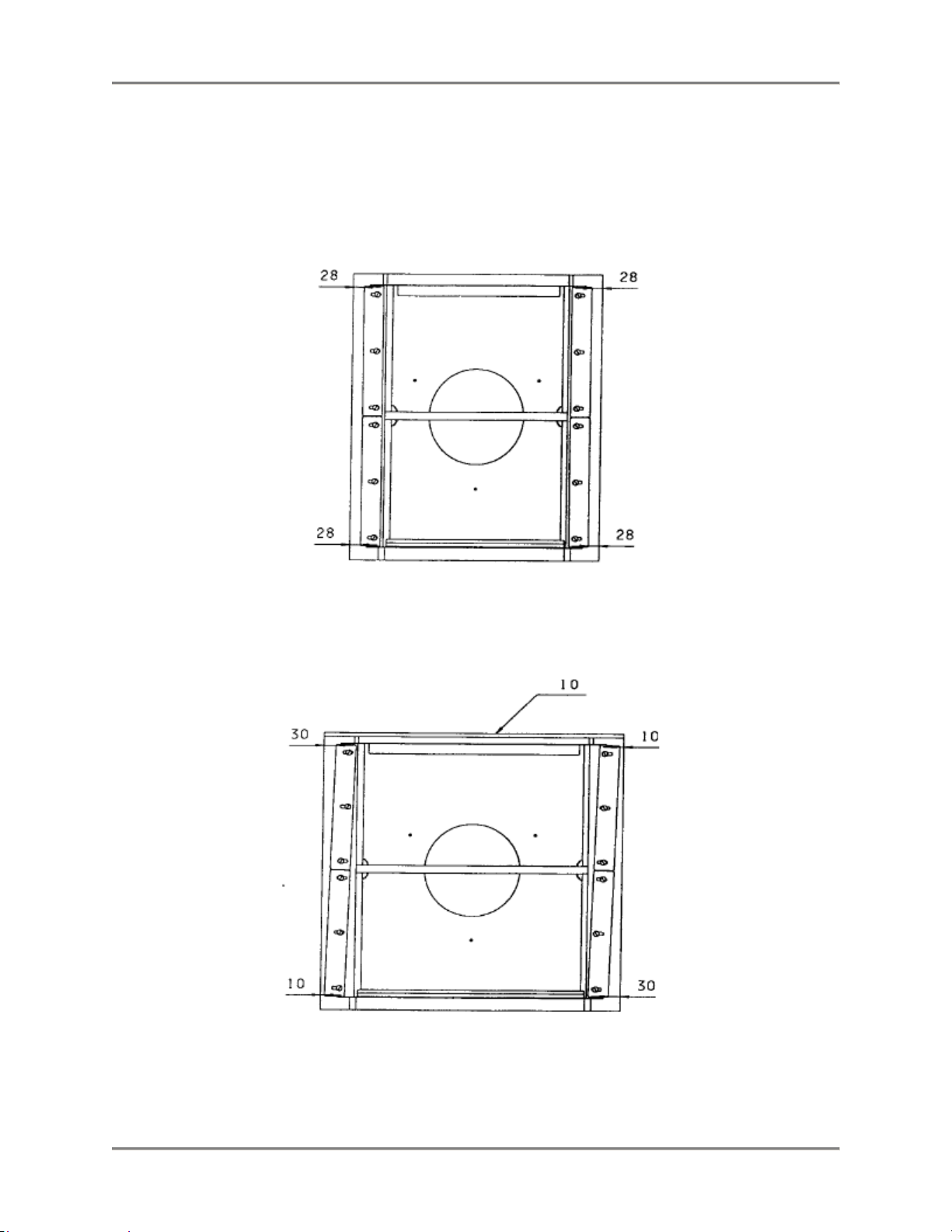

Adjusting Flaps

The flaps can be adjusted individually to achieve a uniform baking result. Experience shows that the

following basic setting produces the best result in the vast majority of cases Air gap setting in mm:

Type 1.06 and 1.10

Type 2.10

For types 2.10 we recommend that a 10 mm rail be fitted at the top (part no. O 11.588).

8

Combi-Oven Installation

Setting System Options for CVC Controller

System options are set through Engineering menus. To access these menus press and hold the F1 key

while pressing the START/STOP key. A list of menu commands will appear in the display. To see

additional menu commands press F1. To return to the main display, press the ENTER/STEP key. To

select a command, access it’s menu then press the numeric key associated with the command. Upon

selecting a command, its options will be displayed. To select/activate and navigate the comma nd options

use the keys specified on the display. Return to the Engineering menu by pressing F1. The following table

lists the command options that need to be set to enable proper operation of the BKI Combi.

CVC Controller System Settings

Menu Command Option Settings

1 = TEST FUNCTION

2 = ENCODE OVEN TYPE

3 = SELECT LANGUAGE

2 = Adjust PT100 sensors

3 = Set Restart Time

1 = Oven Light ON/OFF

2 = Phase Test

3 = Transfer all menus

1 = Setup

2 = Motor Alarm

3 = Cleaning mode

1 = Access Code

2 = Warm up in step 1

3 = Condensation ON/OFF

4 = Show empty tray

Only used to troubleshoot oven.

2 = Autorestart

4 = GB

The values are factory set by the manufacturer.

Consult manufacturer before adjusting.

Leave as is

1 = Oven light 5min.

OFF

Enter = OK

Oven type (2 = CVC)

Temperature mode (2 = Fahrenheit)

Keyboard (2 = BKI)

Special mode (1 = Normal)

Fan (1= Single direction)

Language (4 = GB)

OFF

1 = Normal 2 step

OFF

Normal 6 step

Leave as is

Leave as is

9

Combi-Oven Installation

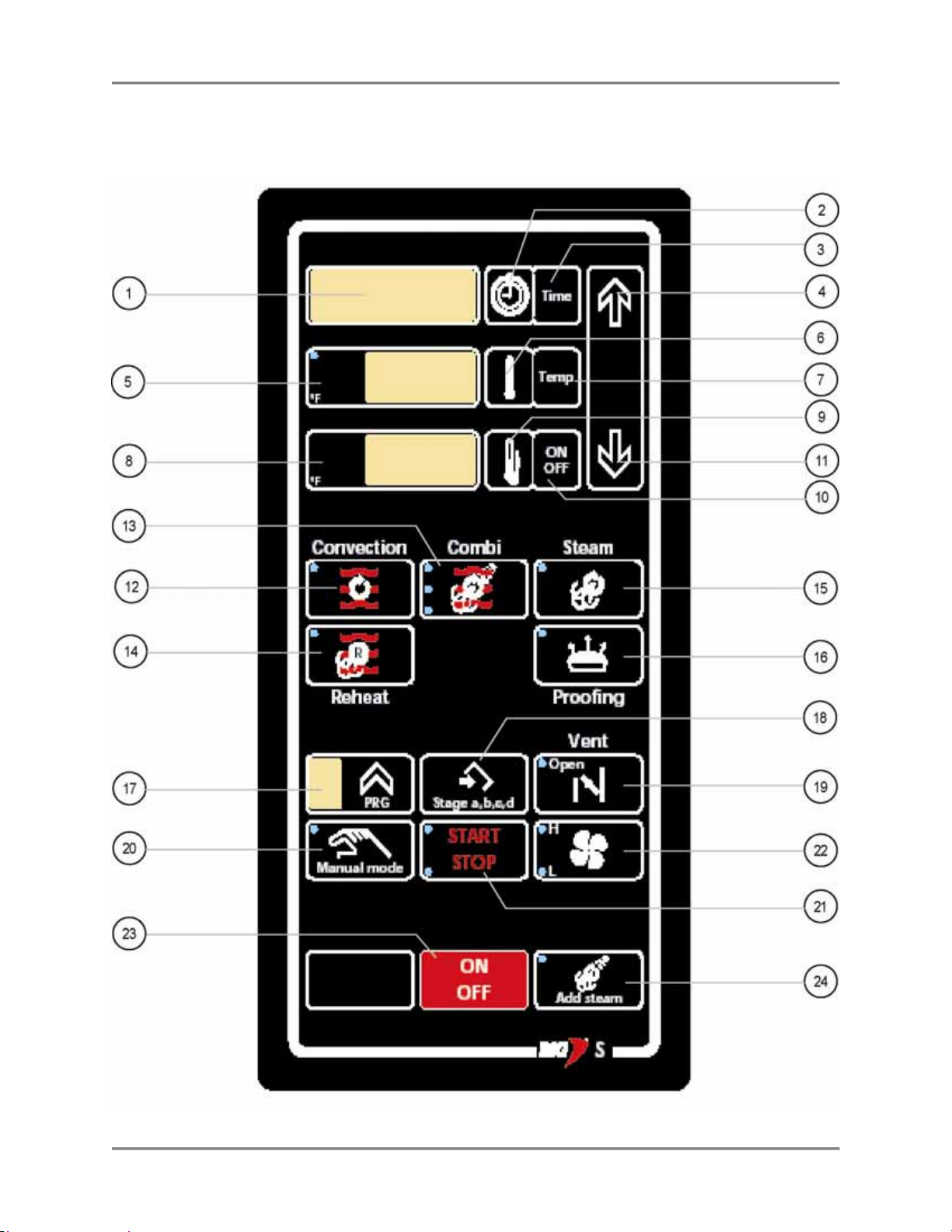

Setting System Options for S Controller

Refer to the figure below as necessary while using this section.

10

Combi-Oven Installation

Start-Up Window

When the computer is switched on, it checks all control lamps and segments to make sure that they work.

Figures appear in the displays:

• The time display shows how U1 is set.

• The temperature display shows the current EPROM version.

• The display for core temperature shows whether the computer includes CombiClea n (0 = without

CC, 1= with CC).

Accessing the Set-Up Mode

Select the set-up mode by pressing key (4) and key (2) simultaneously for 5 sec. U1 appears in the time

display. Shift to the next setting (max. U5) by pressing key (2). The set-up mode can be

interrupted/closed any time by pressing key (18).

U1: Selecting Automatic Restart, Oven Model And Voltage

Automatic restart

1 or 0 is shown in the time display (1).

0 = The oven will not restart a program that has been interrupted because of power cut.

1 = The oven will restart a program that has been interrupted because of power cut.

Shift by pressing key (3).

Oven model

A digit between 1 and 6 is shown in the program display (17).

1 = CM, 2 = CV, 3 = BM, 4 = ST, 5=S, 6=VS

Shift by pressing (17).

Voltage

1 or 2 is shown in the core temperature display (8).

1 = Voltage with 0

2 = Voltage without 0

Shift by pressing the core temperature key (9).

U2: Selecting Interior Light

When the program display (17) shows 5, the interior light is automatically switched off after 5 min.

When the program display (17) shows 0, the interior light will shine continuously.

When the program display (17) shows 6, the interior light is automatically switched off after 5 min. In

addition, the light in the oven door is switched off after 3 sec. when the door is opened.

When the program display (17) shows 1, the oven light will shine continuously. In addition, the light in the

oven door is turned off after 3 sec. when the door is opened.

Settings 1 and 6 are very useful on ovens with oven light in the door in order to avoid blinding while the

door is open.

Shift by pressing (17).

11

Combi-Oven Installation

U3: Adjusting Temperature Sensors (Pt-100)

The digit of the sensor in use is shown in the program display (17).

1 = oven chamber, 2 = probe, 3 = steam generator, 4 = condensation

Change the digit by pressing the program key (17).

The current temperature is shown in the temperature display (5).

The set point is shown in the core temperature display (8)

Standard set point = 100, which can be adjusted downwards to 80 and upwards to 120 with the arrow

keys.

Each temperature sensor can be adjusted/corrected by approx. +/-10°C, i.e. the temperature changes in

steps of 0.5°C.

The core temperature display holds only 2 digits, consequently 80 = 80, 00 = 100 and 20 = 120.

U4: Selecting Pre-Set/Current Temperature, Combiclean, Additional

Detergent, Showdisplay And Printer

Pre-set/current temperature

1 or 0 is shown in the time display (1).

0 = Pre-set temperature (standard)

1 = Current temperature during operation

Shift by pressing (3).

CombiClean

The oven size is shown in the temperature display (5).

You change between oven sizes by pressing the temperature key (7).

Additional Detergent

If the oven chamber is not properly clean when the cleaning program is completed, it is possible to add

additional detergent.

Press the key for manual humidity (24) until the control lamp is turned on. ”Additional detergent” is now

active.

Note that the programs are prolonged by 5 minutes + the detergent phase.

If the control lamp is off, this function is off.

Demo mode

It is possible to select a demo mode in which the oven rinses only.

Press the exhaust key (19)until the control lamp is turned on.

Showdisplay

Press (17) until the display shows 1.

The control lamps in (23) and (22) flash to indicate that the keys are active.

By pressing (23), you reserve memory in the showdisplay for the 16 programs.

12

Combi-Oven Installation

With (22), you enter a start text for each program. However, this is usually not necessary, as the

showdisplay is ready for use on delivery.

If you have deleted or ruined a program, press (9) and select the program you have just ruine d and then

to enter the start text again.

Note that there should be at least 20 characters in the program on the sho wdisplay in order for the

start text to be transferred.

Note! When the showdisplay is active, the printer cannot be used.

Printer

Press (17), until the display shows 0. The printer output is thus activated.

Press (18) to enter the start-up menu.

Press (20) for 5 seconds. The time display now shows PR*nt, “Yes” in the temperature display and “No” in

the display for core temperature probe.

Press (6).

The printer output is now activated.

To switch off the printer output, press (9)

.

Note! When the showdisplay is active, the printer cannot be used.

U5: Selecting Phase Sequence Test And Reversing

Phase sequence test

Phase sequence test is usually always active.

This alarm can be deactivated in the case of installation for demonstration purposes in order to avoid

error code 15.

The temperature display shows either ON or OFF. ON and OFF are selected by pressing (6).

Reversing

In the reversing function, it is possible to set the time before reversing as well as the time of the interval.

Change between 0, 1 and 2 by pressing (17).

0 = “Reversing” is switched off and the time is not shown (standard)

1 = “Reversing” is switched on and error code 5 “Fan too hot” works reversely because the thermo-switch

of the motor used is open and closes when the temperature is too high.

2 = “Reversing” is switched off and error code 5 “Fan too hot” works as usual, i.e. the thermo-switch is

closed and opens when the temperature is too high.

The time during which the fan is running is shown in the time display (1) and is set between 10 and 9 9

with the arrow keys (4, 11). Each step corresponds to 2 seconds, it is therefore possible to set the time of

the intervals between 20 and 198 seconds (standard is 50 = 100 seconds). The time of the interval is

shown in the core temperature display (8) and is set with the core temperature key (9) and the core

temperature ON/OFF key (10).

The time can be set between 1 and 30 seconds (standard = 10 seconds).

13

Combi-Oven Installation

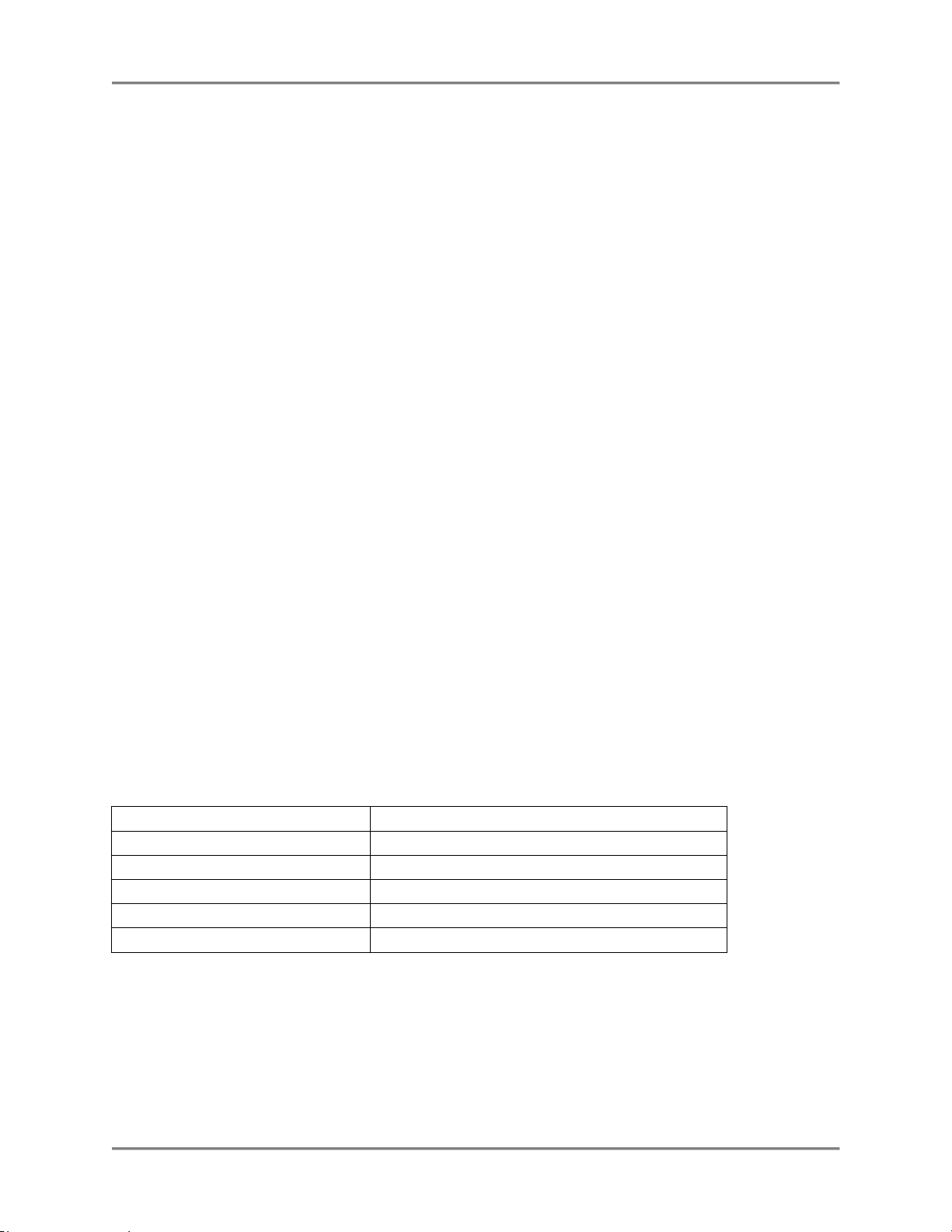

S Controller System Settings

Set-Up Mode Settings

U1 Automatic restart (1)

Voltage (1)

Oven Model (5)

U2 Interior light (5)

U3 Leave as is

U4 Pre-set/current temperature (1)

CombiClean (select your oven size)*

Additional Detergent (press manual humidity key

until lamp turns on)*

Printer (Not applicable)

U5 Phase Sequence Test (OFF)

Reversing (2)

* - Only with CombiClean models.

14

Combi-Oven Installation

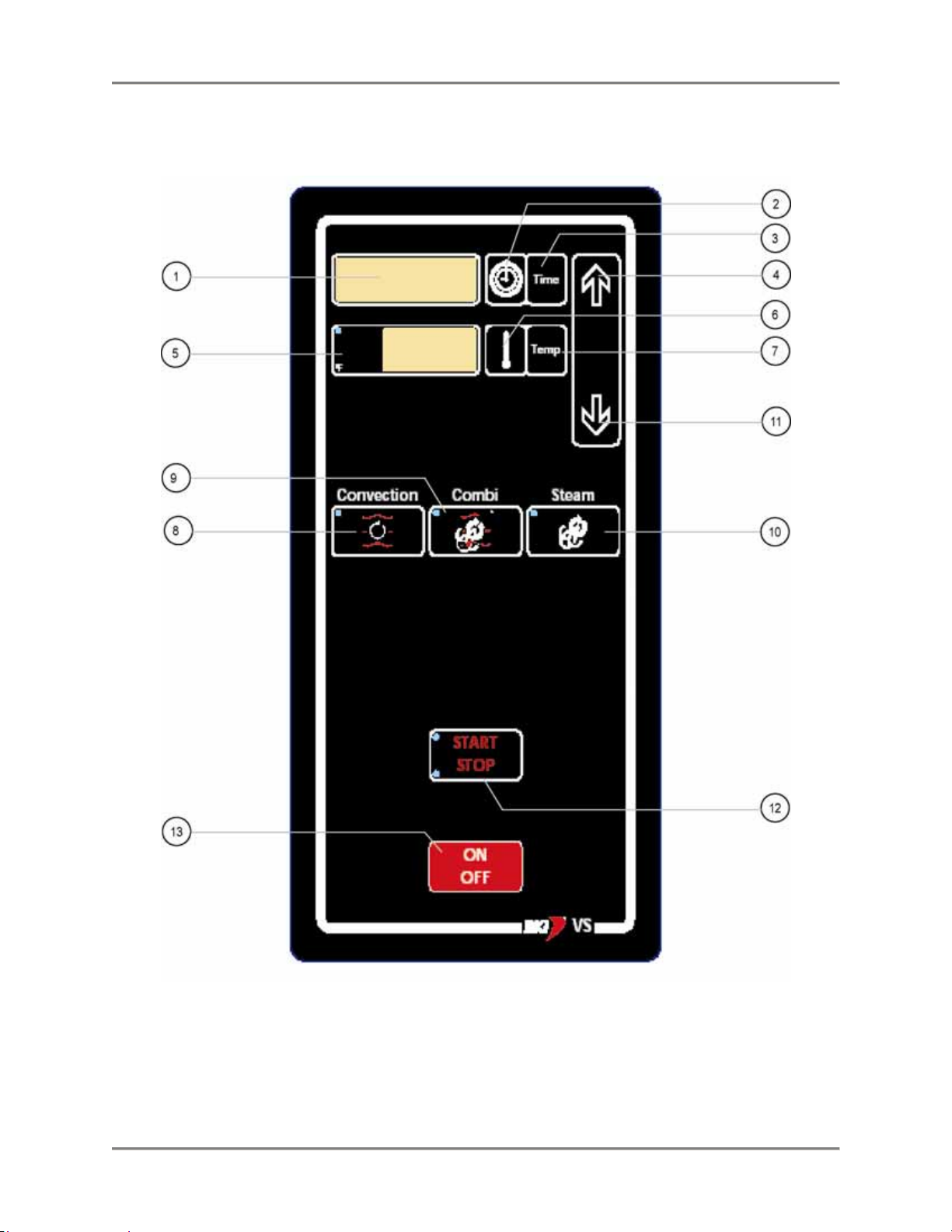

Setting System Options for VS Controller

Refer to the figure below as necessary while using this section.

Start-Up Window

When the computer is switched on, it checks all control lamps and segments to make sure that they work.

Figures appear in the displays:

• The time display shows how U1 is set.

• The temperature display shows the current EPROM version.

15

Combi-Oven Installation

Accessing the Set-Up Mode

Select the set-up mode by pressing key (4) and key (2) simultaneously for 5 sec. U1 appears in the time

display. Shift to the next setting (max. U5) by pressing key (2). The set-up mode can be

interrupted/closed any time by pressing key (12).

U1: Selecting Automatic Restart

Automatic restart

1 or 0 is shown in the time display (1).

0 = The oven will not restart a program that has been interrupted because of power cut.

1 = The oven will restart a program that has been interrupted because of power cut.

Shift by pressing key (3).

U4: Selecting Pre-Set/Current Temperature

Pre-set/current temperature

1 or 0 is shown in the time display (1).

0 = Pre-set temperature (standard)

1 = Current temperature during operation

Shift by pressing (3).

U5: Selecting Phase Sequence Test And Reversing

Phase sequence test

Phase sequence test is usually always active.

This alarm can be deactivated in the case of installation for demonstration purposes in order to avoid

error code 15.

The temperature display shows either ON or OFF. ON and OFF are selected by pressing (6).

VS Controller System Settings

Set-Up Mode Settings

U1 Automatic restart (1)

U2 Not Used

U3 Not Used

U4 Pre-set/current temperature (1)

U5 Phase Sequence Test (OFF)

16

Loading...

Loading...