BKI 1.06 Installation Manual

Combi-Oven

MODELS 1.06, 1.10, 2.10

Installation & Operation Manual

Warranty Information

LIMITED ONE YEAR WARRANTY

BKI (The "Company") warrants to the original purchaser that at time of shipment from the

Company factory, this equipment will be free from defect in materials and workmanship. Written

notice of a claim under this warranty must be received by the Company within ONE YEAR from

the date of installation, but no longer than ONE YEAR AND THREE MONTHS from date of

shipment from the factory. Defective conditions caused by abnormal use or misuse, lack of or

improper maintenance, damage by third parties, alterations by unauthorized personnel, acts of

God, failure to follow installation and/or operating instructions, or any other events beyond the

reasonable control of the Company will NOT be covered under this warranty. The obligation of

the Company under this warranty shall be limited to repairing or replacing (at the option of the

Company) any part, with the exception of lamps, fuses, and glass (which are not covered under

warranty), which is found defective in the reasonable opinion of the Company. Any part found

defective by the Company will be repaired or replaced without charge F.O.B. factory,

Simpsonville, South Carolina or F.O.B. authorized BKI Distributor. The Company and/or its

authorized representatives will assume the normal replacement labor expense for the defective

part for the period of the warranty as stated above, excluding travel and/or other expenses

incidental to the replacement of the defective part, where replacement work is performed during

standard business hours and not subject to overtime, holiday rates, and/or any additional fees. IN

NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, LOSS OF REVENUE OR

LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT OR CONSEQUENTIAL DAMAGES

INCLUDING BUT NOT LIMITED TO, FOOD SPOILAGE OR PRODUCT LOSS. WARRANTY

DOES NOT COVER GLASS BREAKAGE. THE ABOVE WARRANTY IS EXCLUSIVE AND ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

REPLACEMENT PARTS

Any appliance replacement part, with the exception of lamps, fuses, and glass, which proves to

be defective in material or workmanship within ninety (90) days of installation will be replaced

without charge F.O.B. Factory, Simpsonville, SC or F.O.B. authorized BKI Distributor. The user

shall have the responsibility and expense of removing and returning the defective part to the

Company as well as the cost of reinstalling the replacement or repaired part.

Combi-Oven Table of Contents

Table of Contents

Table of Contents........................................................................................................................................1

Introduction .................................................................................................................................................2

Description................................................................................................................................................2

Safety Precautions....................................................................................................................................3

Operation .....................................................................................................................................................4

General.....................................................................................................................................................4

CVC Controller Operation.........................................................................................................................6

S Controller Operation............................................................................................................................24

VS Controller Operation..........................................................................................................................32

Installation .................................................................................................................................................36

Unpacking the Oven...............................................................................................................................36

Positioning of oven .................................................................................................................................37

Water Connection...................................................................................................................................37

Exhaust...................................................................................................................................................38

Electrical Connection..............................................................................................................................38

Drain Connection....................................................................................................................................39

Adjusting Flaps .......................................................................................................................................40

Setting System Options for CVC Controller............................................................................................41

Setting System Options for S Controller.................................................................................................42

Setting System Options for VS Controller ..............................................................................................47

Initial Checks and Adjustments...............................................................................................................49

Maintenance ..............................................................................................................................................50

Scheduled Maintenance.........................................................................................................................50

Troubleshooting......................................................................................................................................53

Replacement...........................................................................................................................................57

1

Combi-Oven Introduction

Introduction

We congratulate you on your new BKI Combi.

By the purchase of a BKI Combi, you now possess one of the market's leading oven products for

professional kitchens. All BKI Combis are currently subjected to intensive product development that

ensures that the products are always based on the latest technology as well as the most modern and

energy-saving techniques of preparation.

Moreover, the products from BKI are up-to-date with the latest development/technology as regards:

• ERGONOMICS AND SAFETY

• SIMPLE AND LOGICAL OPERATION

• EASY-TO-OPERATE DESIGN

• RELIABILITY AND SERVICE

To ensure our customers an optimum and reliable product, prior to dispatch, all BKI Combis have passe d

through an extensive test programme in which all functions are subjected to a continuous and extreme

load.

Before use and to make the best use of the many facilities and advanced technique of the BKI Combi, it is

important that you are aware of working ranges and possibilities of application of the steamer. We thus

recommend you study the user's manual thoroughly before using the steamer. By this, you can - as a

user - make sure that you achieve optimum cooking results through appropriate and safe operation. By

going through the user's manual, you will save time

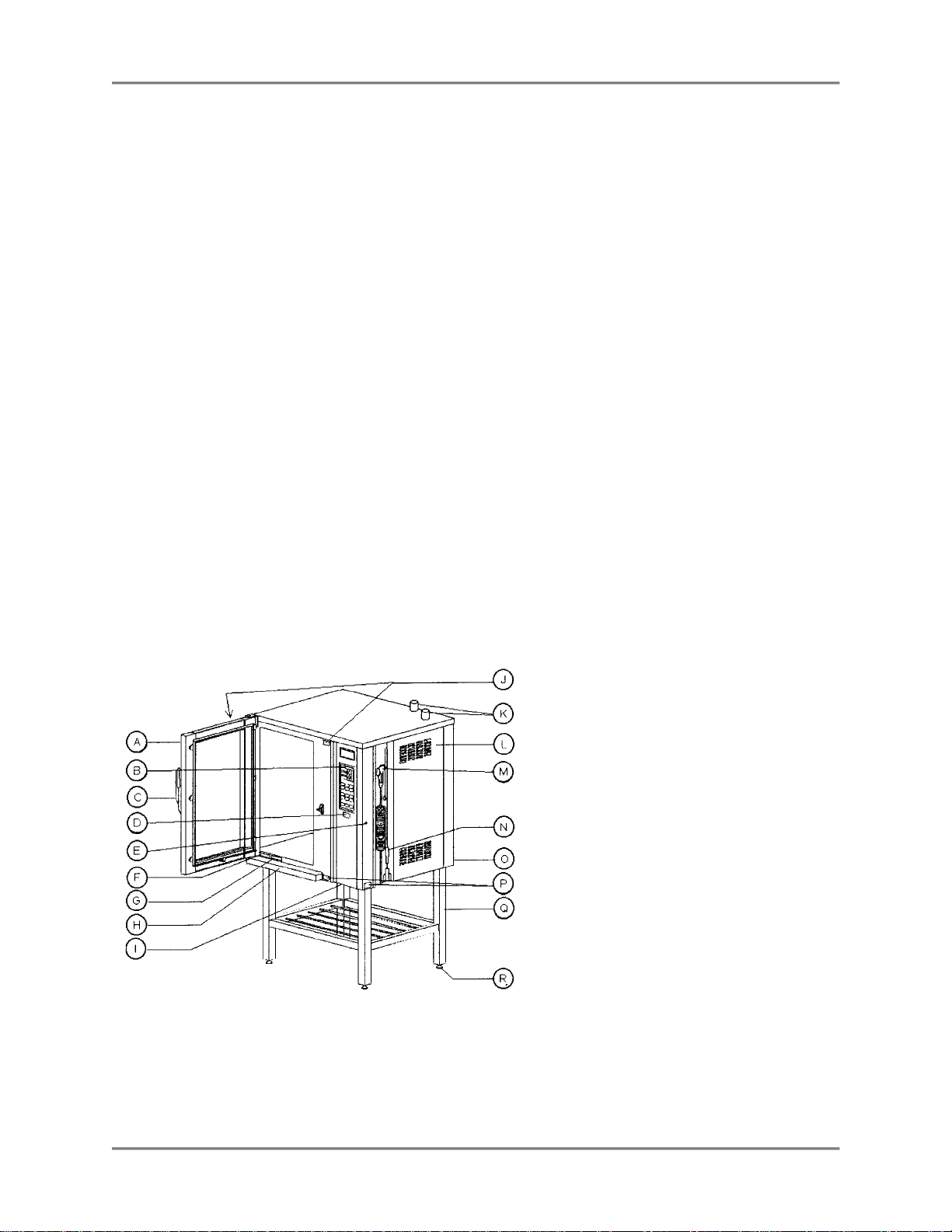

Description

Refer to illustration below for a description of the unit.

(A) Oven door

(B) Operating panel

(C) 2-step safety handle

(D) Rethermalize on High Speed only!

(E) Plug for core temperature probe

(F) Serial plate

(G) Risk of fire - space oven a

minimum of 2 inches from the rear

and side wall

(H) Drip tray

(I) Ball valve for hand shower

(J) Hot surface

(K) Exhaust

(L) Cover for electri c parts

(M) Hand shower

(N) Core temperature probe

(O) Drain

(P) Risk of electric shock. Disconnect

power before servicing

(Q) Stand

(R) Adjustment legs

2

Combi-Oven

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know and

understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other special

data.

Specific Precautions

Risk Of Electric Shock Disconnect Power Before Servicing

For Continued Protection Against Risk Of Fire And Electric Shock, Replace With

Fuses Of Same Rating

Rethermalize on High Speed only!

Hot surface can cause severe burns. Do not touch.

Replace Oven Halogen Lamps with 12V, 20W maximum

3

Combi-Oven Operation

Operation

General

The combination of circulating hot air and steam is the basic principle in the modern combi steamer. The

BKI Combi is supplied with a high-powered fan motor ensuring an optimum circulation. This gives a

number of advantages when preparing different products.

To achieve the optimum use of the oven there are some plain general principles and working techniques

during the day's work that we recommend. If these general tips are followed, the result will in most cases

be better final products.

Pre-heating

One of the most important basic rules in using the modern oven is PREHEATING. Generally, the oven

should be pre-heated for ALL TASKS. Leaving out the pre-heating may cause a reduced end product and

extra long process time. To make the best of the properties of the oven, pre-heating should become a

natural routine in the day's work.

Pre-heating is particularly important at the start of the workday when the oven is cold.

We also recommend extra pre-heating when the oven has maximum loading or when preparing chilled

and frozen products.

In the above cases, we recommend that the oven is pre-heated for approx.10-15 min. in the desired

operating mode- perhaps at a temperature 86 - 104°F above the operating temperature (does not apply to

STEAMING and PROOFING).

For PREHEATING in other situations, see description under each operating mode.

Loading and unloading

After pre-heating, the oven is ready for loading with products. The products are to be placed in the

containers so that the air can circulate freely around them.

To achieve an optimum air circulation we recommend that you always start placing canteens or baking

sheets in the rack from the centre and then upwards and downwards by turns. Generally, canteens,

baking sheets etc. are to be regularly dispersed in the rack.

Avoid temperature decline!

When loading, we suggest that the oven door be open for the shortest possible time to avoid a major

temperature decline in the oven compartment.

Hot surface can cause severe burns. Do not touch.

After the preparation, the products are to be unloaded from the oven. You have to be cautious as the

oven compartment in most cases contains steam.

Safety

As an extra precaution, the oven door is provided with a specially designed 2-step safety handle which

ensures that the oven door cannot be opened in one movement. Upon activating the handle into the first

step, the oven will automatically switch off and an automatic motor brake suspends the fan. The oven

door should remain in this step for a few seconds and in doing so, much of the steam will escape the

oven compartment and thereby reduce the scalding risk of the staff. The oven door can then be re-

4

Combi-Oven Operation

opened by activating the handle again and the products can be unloaded either by hand or with a trolley

for racks.

Applying air exhaust

The BKI Combi (with CVC or S controllers) has an open exhaust system. This means that the oven is

provided with a direct air exhaust that can be opened and closed automatically.

The air exhaust removes humidity and steam from the oven compartment quickly and efficiently. This

gives a dry heat in the oven compartment which may be used for browning and grilling steaks, omelet etc.

To obtain a crisp pastry the air exhaust is very useful in connection with baking. When baking dough

products, we recommend CONVECTION with open exhaust e.g. for the latter half of the baking process.

Manual humidity/steam pulsing

The BKI Combi with CVC or S controller has manual humidity steam pulsing capability.

By activating the appropriate key, the oven compartment is supplied with humidity/steam. This will go on

continuously as long as the key is activated.

The manual humidity pulsing is used for a quick admission of steam into the oven compartment

immediately after loading. The humidity pulsing can be applied for all operating modes.

As an example, when baking dough products in CONVECTION we recommend humidity pulsing for the

first approx. 10-15 seconds of the baking process. This gives a shiny and crisp surface to the baked

products.

As for roasting, the manual steam is very effective for closing the pores of the meat quickly and

effectively. This has the effect of keeping the humidity in the meat and the finished result becomes juicier.

Using the Fan

The BKI Combi with CVC or S controller has has fan speed selection capability.

The basic principle of the modern combi steamer is the circulating air and steam. In most working

processes, it is optimum that air and steam circulate at the highest possible speed - that is high fan

speed. However, in some processes a lower air circulation provide s a better result. It is possi ble manually

to change between high and low fan speed with the appropriate key.

HIGH fan speed should - as a principal rule - be used for CONVECTION and COMBI STEAMING

modes.

When baking light products e.g. meringue and chou (cream puff) and when preparing omelette and

souffle you may use low speed. By this, you avoid that light baking products "blow off the sheet" or that

omelette/souffle batter has an uneven thickness.

LOW fan speed should - as a principal rule - be used for the PROVING mode that is a rather

sensitive preparation process.

Any time during the preparation, you can change between high and low fan speed.

5

Combi-Oven Operation

CVC Controller Operation

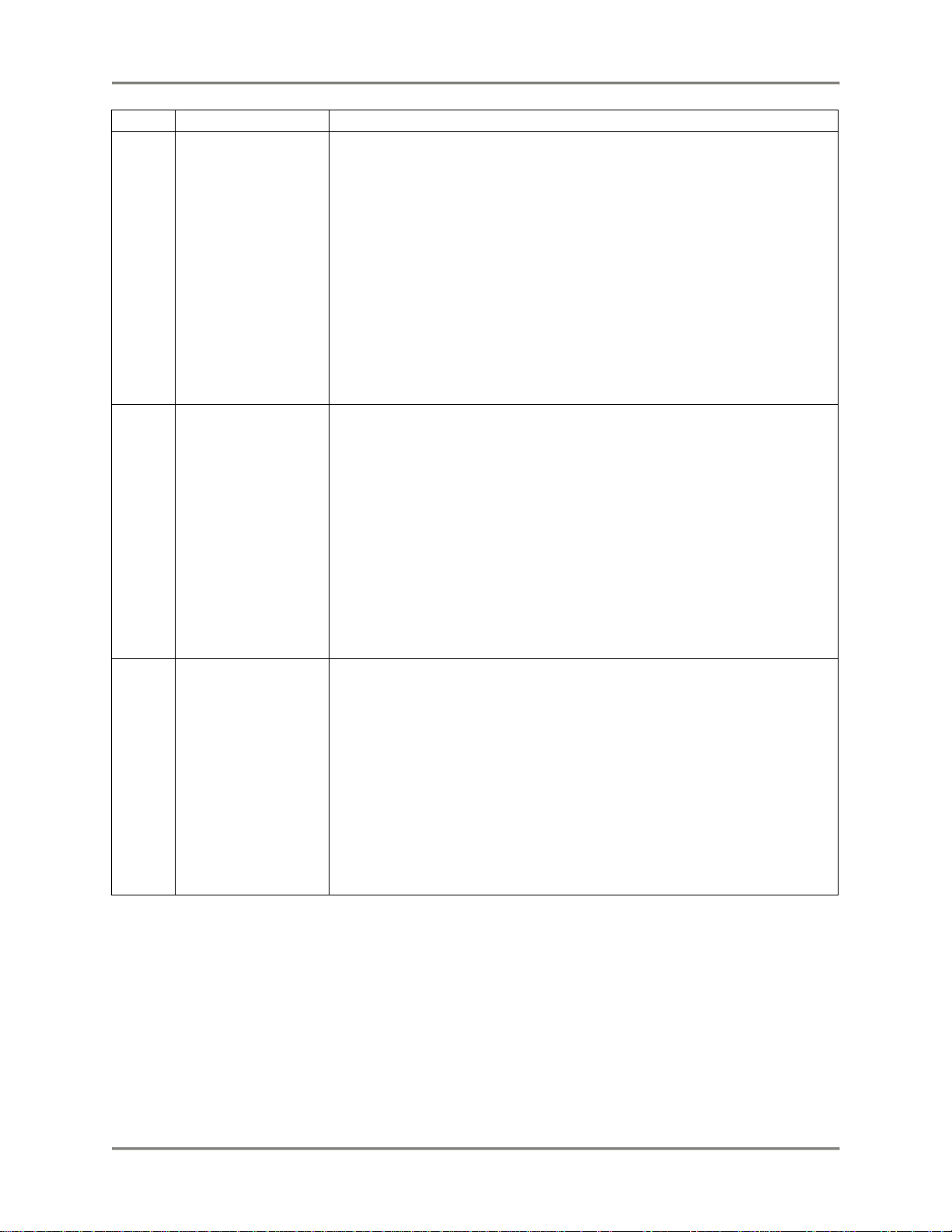

Controls and Indicators

Refer to the figure and table below for an explanation of controls and indicators.

6

Combi-Oven Operation

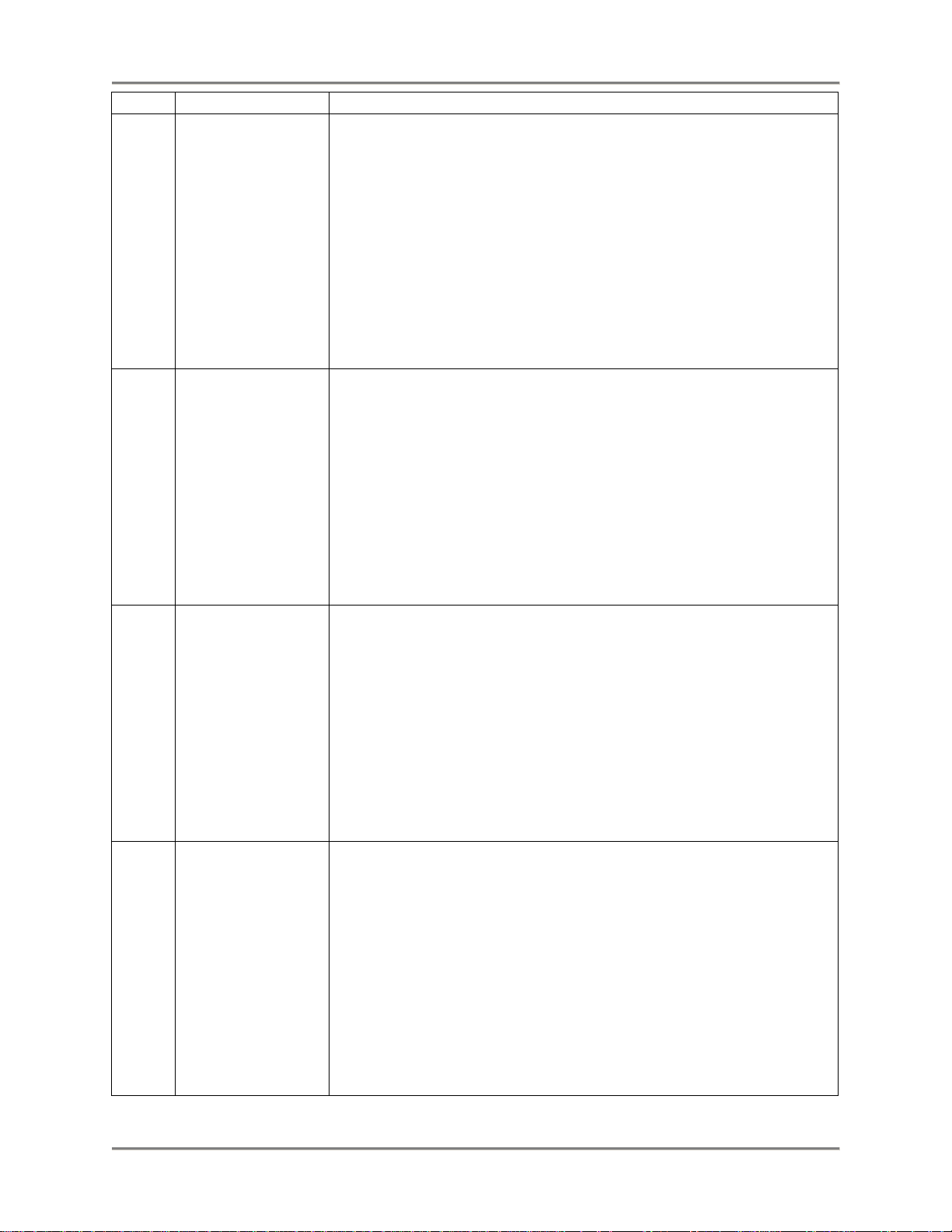

Item # Description Function

1 Time, Core

Temperature, Oven

Temperature and

Diagnostic

Message Display

Time Display - Upon setting of time, display (1) will show the time

requested. The remaining period is indicated during programme

performance.

Core Temperature Display - In this display, the set core temperature is

indicated upon connection of core temperature control.

Oven Temperature Display - This display shows the set oven

compartment temperature. The light diode in the upper left corner (12)

is lit when the heating elements of the oven are connected.

Diagnostic Message Display - The Combi is supplied with an automatic

diagnostic system. When a defect occurs, a message will appear in the

bottom line of the display

2 CONVECTION key The CONVECTION operating mode is selected by pushing

key (2).

Automatically, the oven is set to start on the pre-selected values of this

mode. These pre-selected values can be changed according to wishes,

needs and experiences, see (14).

The values of time (11), oven temperature (12) and e.g. core

temperature (13) are adjusted. The speed of the fan motor (9) can also

be set and the exhaust opened/closed (8). You can now start the oven

by pressing key (16).

The selection range of the oven compartment temperature is

68-482°F.

3 COMBI

STEAMING, low

key

In this mode, it is possible to select low humidity pulsing.

Automatically, the oven is set to start on the pre-selected values of

COMBI STEAMING. These pre-selected values can be changed

according to wishes, needs and experiences. See key (14).

The values of time (11), oven temperature (12) and e.g. core

temperature (13) are adjusted. The speed of the fan motor (9) can also

be set and the exhaust opened/closed (8). You can then start the oven

by pushing key (14).

The selection range of the oven compartment temperature is

68-482°F.

7

Combi-Oven Operation

Item # Description Function

4 REHEATING key The REHEATING operating mode is selected by touching key (4).

The oven is automatically set to start on the pre-selected values of this

mode. These pre-selected values can be changed according to wishes,

needs and experiences. See key (14).

The values of time (11), oven temperature (12) and e.g. core

temperature are adjusted. In the same way, the speed of the fan motor

(9) can be set and the exhaust opened/closed (8).

You can now start the oven by pressing key (16).

The selection range of the oven compartment temperature is

230-320°F.

5 COMBI

STEAMING,

medium key

In this mode, it is possible to select medium humidity pulsing.

Automatically, the oven is set to start on the pre-selected values of

COMBI STEAMING. These pre-selected values can be changed

according to wishes, needs and experiences. See key (14).

The values of time (11), oven temperature (12) and e.g. core

temperature (13) are adjusted. The speed of the fan motor (9) can also

be set and the exhaust opened/closed (8). You can then start the oven

by pushing key (14).

The selection range of the oven compartment temperature is

68-482°F.

6 COMBI

STEAMING, high

key

In this mode, it is possible to select high humidity pulsing.

Automatically, the oven is set to start on the pre-selected values of

COMBI STEAMING. These pre-selected values can be changed

according to wishes, needs and experiences. See key (14).

The values of time (11), oven temperature (12) and e.g. core

temperature (13) are adjusted. The speed of the fan motor (9) can also

be set and the exhaust opened/closed (8). You can then start the oven

by pushing key (14).

The selection range of the oven compartment temperature is

68-482°F.

7 PROOFING key The PROOFING operating mode is selected by touching key (7)

Automatically, the oven is set to start on the pre-selected values of this

mode. These pre-selected values can be changed according to wishes,

needs and experiences. See key (14).

The values of time (11) and oven temperature (12) are adjusted. In the

same way, the speed of the fan motor (9) is set and the exhaust

opened/closed (8).

You can now start the oven by pressing key (16).

The selection range of the oven compartment temperature is

68-104°F.

8

Combi-Oven Operation

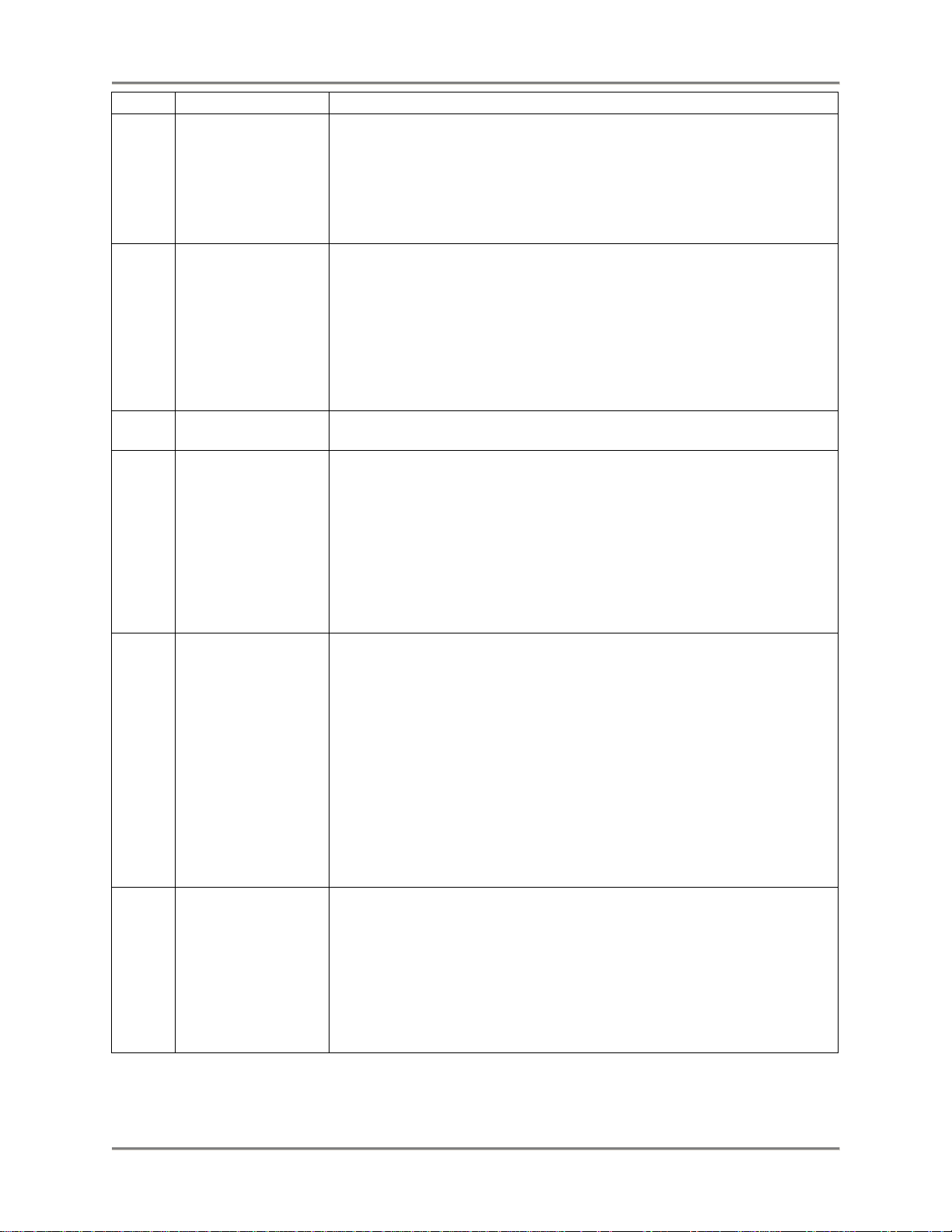

Item # Description Function

8 Exhaust key By pressing key (8), you can open (the light diode is on) and close (the

light diode is off) the exhaust from the oven room.

The exhaust can be opened and closed any time during the

programme performance. Concerning use of open and closed exh aust

respectively, please refer to the tables and the paragraphs of the

individual cooking modes.

9 Fan Speed key The fan of the oven can be set on two different rates of fan speed:

• HIGH (the upper light diode is lit)

• LOW (the lower light diode is lit)

Normally, the fan speed is high but you can change it anytime during

the programme performance. Concerning use of high and low speed

respectively please refer to the tables of preparing various products

and the paragraphs of the individual cooking modes.

10 Numeric keys The required values for time, oven temperature and core temperature

are set with the keys (10).

11 Time Function key The time requested is set by activating key (11) and display (1) will

flash. Now, the time can be set with the keys(10).The time range is 1

min. to 99 hours and 59min. After time setting, you push key (14)

again.

When the set time has run out the oven will automatically switch off

and an alarm will buzz.

The set time may be changed during the entire programme

performance.

12 Oven Temperature

Function key

The oven compartment temperature requested is set by touching key

(12) and display (1) will then start flashing. The oven compartment

temperature can now be set with the keys (10). After setting the oven

compartment temperature, push key (14) again.

The setting range of the oven compartment temperature:

CONVECTION 68-482°F

COMBISTEAMING 68-482°F

REHEATING 230 - 320°F

PROOFING 68-104°F

The selected oven compartment temperature may be changed any

time during programme performance.

13 Probe Temperature

Function key

When the core temperature control is on, the core temperature can be

adjusted by pushing key (13). Display (1) will then flash and the core

temperature can be set with the keys (10). After setting the value, push

key (14) again.

Automatically, the oven will switch off and an alarm will signal when the

set core temperature has been reached.

The setting range of the core temperature is 68 - 210°F.

9

Combi-Oven Operation

Item # Description Function

14 Receipt key

(Memory)

15 Memory Function

key (F1)

16 START/STOP key The programme performance is switched on and off by touching key

17 ON/OFF key The oven is switched on and off by pushing key (17). All displays and

18 Manual Humidity

Pulsing

This key has two functions:

• Storing settings in the memory function (see key (15))

• Storing changes of pre-selected values of Operating

modes(2)-(7).

Beyond the permanent operating modes, the BKI Combi oven contains

a memory function, in which it is possible to store up to 199 extra

programmes.

You change from manual operation to memory function by pushing key

(15). To change between the 199 programmes you touch key (15) until

the number of programme required appears.

(16).

light diodes will light up for a moment indicating that all functions are

automatically tested before start.

The oven will always start up in manual operation and the

CONVECTION mode.

Pressing key (18), humidity/steam is added into the oven compartment

as long as the key is activated.

Features

Some of the features of the computer control:

• 4-line display; 2 lines are used for menu headings

• Adjustable contrast and background light

• Choice between small letters and capital letters

• Display that always shows how many steps (max. 6) are contained in a menu and which step is

being performed at the moment.

• Menu numbers that can be retrieved either by pressing the number directly via the F1 key or by

"rolling" forwards or backwards in the menus with the arrow keys (2 and 8).

• Automatic cooling down to steaming temperature from, for instance, roasting temperature. At the

same time, the exhaust will open automatically.

• Automatic control of

o Breaking of phase (fuses)

o Correct direction of rotation of fan motor

o All temperature sensors

o Inductive sensor

o Automatic emptying of steam generator at least once a day

• If an error occurs, a message will show in the display. The control distinguishes between two

types of errors:

o Serious errors, ie the oven cannot start or it stops during operation

o Minor errors, ie the oven can still run.

10

Combi-Oven Operation

• With the function key F1, another 10 functions are available.

Press F1 once (I) Retrieve menu number

(2) Store changed menu

(3) Correct menu text

Press F1 twice (1) Store manual program

(2) Find vacant menu

(3) Delete menu/step

Press F1 3 times (I) Retrieve original menu

(2) Contrast adjustment

(3) Choose language

(4) Change pre-set values

How to Operate

Start-Up

The oven always starts in the manual menu with the CONVECTION mode automatically selected.

Manual Operation

Pressing START/STOP activates this function. The pilot lamps change from red to green to indicate that

the function is active.

Changing operating mode, time, etc.

If another operating mode than CONVECTION is required, this must be selected before selecting time,

temperature, etc. If not, these settings will be deleted by the pre-selected values of the new operating

mode.

Before starting or during program performance, you can change time, temperature, core temperature,

exhaust and fan speed as you wish.

Time, temperature and core temperature is selected by pressing the function key in question, and the text

in the display will flash. Changes can now be made by pressing the keys. Confirm with ENTER-STEP.

The exhaust is open when the pilot lamp is on. High fan speed is indicated by the upper pilot lamp, low

fan speed by the lower pilot lamp.

Timer

The computer control can also operate as a timer (countdown). This is indicated by both pilot lamps being

off. Now all other functions but the time are disconnected. When the time runs out, an alarm will sound

and the oven will continue in the next step.

Extending a program

To extend a program by another step, press ENTER-STEP and the vacant step is ready for programming.

General Procedure

1. Choose one of the six operating modes as step I.

2. Adjust the values for time, temperature and core temperature, if necessary. Perhaps, change the

settings for fan and exhaust.

3. Proceed to the next step or start the oven program.

11

Combi-Oven Operation

Programming

Retrieving a Menu

Press FI once and select the 1st line that reads "Retrieve menu number". Press the desired menu number

and conclude by pressing ENTER-STEP.

or

Press 2 (arrow upwards) and a new menu appears. If the key is kept activated, the menus roll forward - if

key 8 is activated, they roll backward.

NOTE: Use menu No 0 (between 199 and 1) only if you wish to run the oven manually.

Store changed menu

This function is used to store any changes that may have been made in one of the menus I - 199. A

program menu can be changed before, during or after its performance without affecting the original menu.

If you wish to store a change permanently, use the function "Store changed menu" as follows: Press F1

once, press 2 and conclude with ENTER-STEP.

Correct menu text

This function offers the possibility of constructing or changing a menu heading.

Press F1 once, press 3 and by means of the keys 2, 4, 6 and 8, you can "write" in the display.

Visualize a cylinder with letters and figures which can be rolled forwards and ba ckwards by pressing keys

2 (forwards) and 8 (backwards).

With keys 4 and 6, the cursor can be moved to the right and to the left.

With the key "7", you can change between capital letters and small letters.

With the key "0", you can delete a character.

Conclude with ENTER-STEP.

Store manual program

This function is used to set up a new menu.

Enter your program into the MANUAL menu (No 0). Select the function "Store manual program" by

pressing F1 twice and pressing 1. The computer control will automatically stop at the first vacant menu.

Accept this menu or press the desired number followed by ENTER-STEP.

If there are no vacant menus, delete an existing one (see below).

When the menu number has been chosen, conclude by writing the menu text as described above

("Correct menu text") and pressing ENTER-STEP.

Find vacant menu

This function finds the first vacant menu. Press Fl twice, press 2 and the display shows a vacant menu

number. Conclude by pressing ENTER-STEP.

Delete menu/step

With this function, you delete either the last step or the entire menu. Push FI twice, press 3 and conclude

by pressing ENTER-STEP.

12

Combi-Oven Operation

Retrieve original menu

With this function, you retrieve a copy of the original menus I - 199 which are pre-programmed in the

control. These original menus cannot be changed. Changes can only be made after entering into "Store

manual menu". Press F1 three times, press I and conclude by pressing ENTER-STEP.

Contrast adjustment

This function allows you to adjust background light and contrast in the display.

Press Fl three times, press 2 and the adjustment is made with keys 2 (lighter) and 8 (darker).

The background light is adjustable with keys 1 (lighter) and 8 (darker).

Conclude by pressing Fl.

Select language

Press F1 three times, press 3 and conclude by pressing ENTER-STEP.

Change pre-selected values

Every time one of the six operating modes (CONVECTION, COMBI, etc.) are selected, each will appear

with pre-selected values for temperature, time, maybe probe temperature, fan, and exhaust.

These values can be changed.

Select "Change preselected values" by pressing F1 three times and pressing 4. Enter the new/changed

values and conclude by pressing ENTER-STEP.

Using the Temperature Probe

To be able to use the many advantages/qualities of the modern combi oven to a full extent, as standard,

the Combi steamers from BKI are all equipped with digital core temperature control.

With the application of core temperature control and probe to match, the core temperature in the products

can be measured very exactly with which the optimum combination of time and temperature can be

obtained. In practice, this gives a reduced weight loss/shrinkage and makes uniform preparation possible

and thereby a high quality product.

Because of operation, cleaning and service, the probe is connected on the outside of the oven.

Operation

1. The oven is set on the operating mode required and time/manual time control, temperature etc.

are set. When set on manual time control, the oven will automatically switch off when the set core

temperature has been reached. If a time has been set at the same time as core temperature the

oven will switch off at the function to be reached first-time or core temperature.

2. The plug of the core temperature probe is inserted in the outlet on the front panel of the oven.

3. The probe is placed with the point in the middle of the thickest part of the product. The oven door

is closed and the door gasket will shut tight around the wire. Alternatively, the probe can with

advantage be placed in e.g. the joint at a separate worktable before placing it in the oven. Correct

placing of probe is herewith made simpler and easier and the risk of burn/scalding upon touching

of the hot oven is reduced considerably.

4. After pressing key (13), display (1) will flash and the core temperature required can be set with

keys (10). To accept the set core temperature, you press key (14) again. Automatically, the oven

will switch off when the set time is obtained.

13

Combi-Oven Operation

Keeping warm function

As a special feature, the core temperature control includes a specific keeping warm function. When the

set core temperature is reached the heating elements will automatically be disconnected. The special

keeping warm function will hereafter see to the maintenance of the reached core temperature in the joint

by connecting the heating elements again when the core temperature drops by 35.6°F below the set

temperature. When the set core temperature is reached again, the core temperature is retained as long

as required.

Pre-heating

By application of core temperature control, the oven should be pre-heated in standard ways.

Application

Core temperature can with advantage be applied for:

• Roasting incl. long-term roasting

• Reheating

• Steaming

• Forced steaming

• Preparation of sous-vide/Vacuum products

Long-term roasting

Long-term roasting in a BKI Combi is a gentle roasting process in which the used roasting temperatures

are often reduced by more than 50% compared to standard temperature. With considerably reduced

temperature and extended time, the meat becomes extra tender and juicy during this kind of roasting. The

shrinkage is also reduced considerably.

During long-term roasting e.g. below 212°F, it will often be unnecessary to add steam/humidit y as the

evaporation has already been reduced to a minimum. To reduce evaporation further, if any, low fan speed

can be used with advantage.

Long-term roasting/ core temperature control

To be able to regulate/control and subsequently maintain the set core temperature, it is a great advantage

applying core temperature control during long-term roasting. This obtains optimum roasting every time.

Advantages

• Obtaining of optimum core temperature in the products.

• Uniform products from time to time - even for products of different sizes.

• Shrinkage is reduced considerably as each degree, which goe s be yond the optimum core

temperature, means weight loss.

• Reduced energy consumption.

Suggestions and tips

• Probe to be placed in the middle of the thickest part of the product for measurement of the core

temperature.

• To obtain a uniform core temperature during simultaneous preparation of products of different

sizes the probe is first placed in the smallest product.

• In many cases, humidity/steam addition is not required during long-term roasting below 212°F.

• Low fan speed may be applied for long-term roasting to

14

Combi-Oven Operation

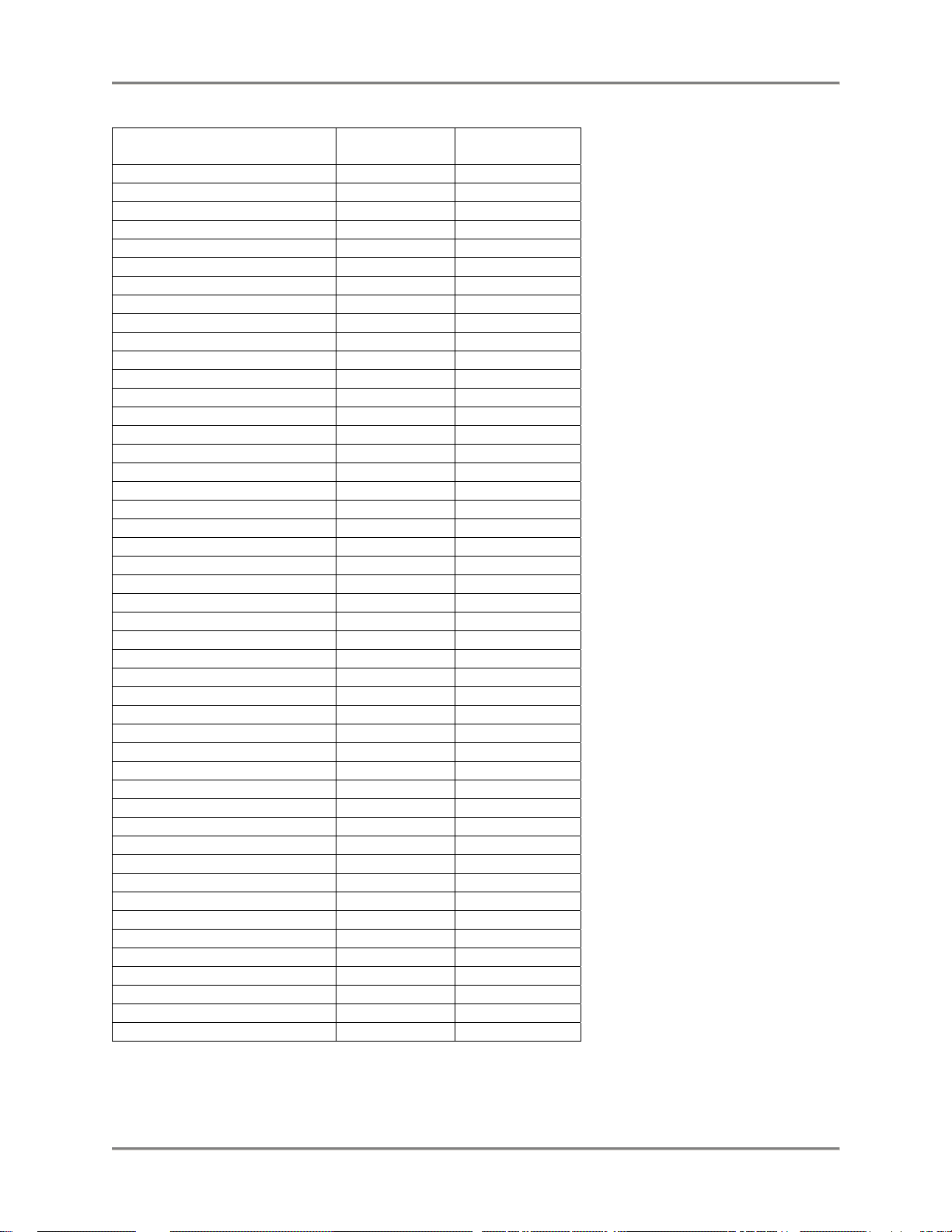

Recommended values for core temperature control

Product Level of

Preparation

Pork

Ham Well-done 167°F

Ham Under-done 149-154°F

Boiled ham Juicy 147-154°F

Cured saddle. of pork 149-158°F

Cured saddle of pork, cold 131-140°F

Loin Under-done 149-158°F

Loin Well-done 158-167°F

Shank Well-done 176-185°F

Shoulder of pork Well-done 167°F

Rib Well-done 149°F

Baked ham Well-done 149-158°F

Beef

Fillet Medium 131-140°F

Roast beef Medium 131-140°F

Joint of beef Well-done 185-194°F

Boiled beef Well-done 176-185°F

Veal

Saddle of veal Under-done 149-158°F

Leg of veal Well-done 167-176°F

Shoulder of veal Well-done 167-176°F

Brisket of veal Well-done 167-172°F

Mutton

Saddle of Iamb Under-done 158-185°F

Saddle of Iamb Well-done 176°F

Lamb

Lamb Well-done 174-185°F

Poultry

Chicken 185°F

Goose 167-176°F

Goose 194-197°F

Turkey, duck 176-185°F

Paste, pate etc.

Paste 161-165°F

Terrine 140-158°F

Foie gras (Pate de foie gras) 113°F

Fish

Salmon 131 °F

Pike 140°F

Fish pate 149°F

Core

Temperature

15

Combi-Oven Operation

Convection Mode

In this operating mode the products are prepared in constantly circulating hot air. The high-powered fan

ensures an optimum air distribution in the oven compartment. An optimum transfer of calories/energy to

the products is obtained this way. The temperature can infinitely be set within a range of 68-482°F.

Manually, humidity can be added by activating key (18).

Operation

By activating key (17), the oven will automatically startup in CONVECTION mode with the pre-selected

values of time, temperature etc. If the oven is set on a different operating mode you choose

CONVECTION by activating key (2). Correction of the time required is made with key (11), adjustment

with keys (10) and end with (14). The temperature is corrected by touching key (12), then adjusted with

the keys (10) and ended with (14).

Pre-heating

Generally, the oven is pre-heated for approx. 5-10 minutes in CONVECTION mode. Concerning use of a

cold oven and maximum loading of oven compartment please refer to the paragraphs under the heading

of GENERAL.

Application

The CONVECTION mode can be applied for:

• Roasting

• Grilling

• Baking

• Gratinating

• Breading

The mode can be applied alone or in combination with other modes. Below, you will find examples of

combination possibilities with other operating modes:

• CONVENTION + COMBI STEAMING, low or medium + CONVENTION

The preparation is started in CONVECTION to close the pores on the surface of the joint. You

then change to COMBI STEAMING, low or medium, and by this the actual roasting process is

accomplished with minimum shrinkage. Finally, the joint is browned in CONVECTION to make

the surface crisp.

• COMBISTEAMING, high + COMBI STEAMING, low or medium + CONVENTION

The initial steaming in COMBI STEAMING,high, closes the pores of the meat. You then roast in

COMBI STEAMING, low or, medium, and finally the joint is browned in CONVECTION. This

process is very common for e.g. joints that have to be juicy as well as crackled (e.g. roast pork).

Manual humidity pulsing

According to wishes/needs, injection steam can be added with key (18) e.g. to close the pores of the

meat or to make a crisp surface during baking.

Advantages

• Shorter roasting time

• Lower temperature

• Even temperature in the entire oven compartment

As the circulating hot air yields a quicker and more efficient addition of calories the roasting time is

considerably reduced compared to the traditional baking or roasting ovens with e.g. bottom heat and top

heat. Generally, the preparation requires lower temperature and combined with the possibility of adding

steam the shrinkage loss is substantially reduced. The effective air distribution ensures that the maximum

16

Loading...

Loading...