Page 1

INSTRUCTION

MANUAL

Model

Model 85

ModelModel

EEEElectronic Load

lectronic Load

lectronic Loadlectronic Load

8511110 600W

85 85

0 600W Programmable

0 600W 0 600W

MODEL 8510

Programmable DC

Programmable Programmable

DC

DC DC

1

Page 2

Instruction Manual

for

Model 8510

PROGRAMMABLE DC ELECTRONIC LOAD

2

Page 3

TABLE OF CONTENTS

QUICK REFERENCE ............................................. 6

The Front Panel .............................................. 6

The Rear Panel............................................... 7

Front Panel Display......................................... 7

Immediate Action Keys ................................... 8

Front Panel Menus.......................................... 8

Key Pad .......................................................... 8

Menu Operation .............................................. 9

GENERAL INFORMATION.................................. 11

Document Orientation ................................... 11

Getting Started Map...................................... 11

Options and Accessories .............................. 11

Options.................................................. 11

Accessories ........................................... 12

Description.................................................... 12

Features and Capabilities.............................. 12

Front Panel Controls ..................................... 12

Remote Programming ................................... 13

Operating Modes........................................... 13

Constant Current (CC) Mode................. 13

Constant Resistance (CR) Mode ........... 13

Constant Voltage (CV) Mode.................. 13

Constant Power (CW) Mode.................. 14

Transient Operation ...................................... 14

Continuous ............................................ 14

Pulse ..................................................... 15

Trigger Mode ......................................... 15

List Operation .............................................. 16

Triggered Operation...................................... 16

Input Control ................................................. 16

Short On/Off .......................................... 16

Input On/Off........................................... 17

Operation Range ................................... 17

Protection Features....................................... 17

Remote Sense Function................................ 18

Saving and Recalling Settings....................... 19

Battery Testing.............................................. 20

Von/Voff Operation........................................ 21

INSTALLATION ................................................... 22

Inspection...................................................... 22

Damage................................................. 22

Items Supplied....................................... 22

Cleaning ................................................ 22

Location............................................................................... 22

Installation ....................................................................... 23

Bench Operation.................................................................. 23

Input Connections................................................................ 23

Power Cord...................................................................... 23

Trigger and Remote Sensing Connections ...................... 24

TURN-ON CHECKOUT........................................................... 24

Introduction.......................................................................... 24

Checkout Procedure............................................................ 24

In Case of Trouble ........................................................... 25

FRONT PANEL OPERATION................................................. 25

Example .............................................................................. 26

I-set ................................................................................ 26

P-set ................................................................................ 27

R-set ................................................................................ 27

V-set ................................................................................ 28

Shift + Store..................................................................... 28

Shift + Recall ................................................................... 28

In On/Off input setting...................................................... 28

Transition Testing Operation ............................................... 28

Transition Parameter Setting ........................................... 29

Continuous Transient Operation ...................................... 29

Pulse Transient Operation ............................................... 29

Toggled Transient Operation ........................................... 30

List Operation .................................................................. 31

Quick Recall Function.......................................................... 32

Automatic Testing Function of Electronic Load.................... 32

Edit the Testing File......................................................... 32

Automatic Testing ............................................................ 34

Select the Precision between Low Range & High Range. 35

SPECIFICATIONS .................................................................. 35

REMOTE OPERATION MODE ............................................... 36

1 Communication Cable ...................................................... 36

2 Communication between Electronic Load and PC ............ 37

3 Frame Format................................................................... 37

4 Communication Protocol................................................... 39

SERVICE / WARRANTY INFORMATION............................... 55

3

Page 4

Warranty Information

Certification

We certify that this product met its published specifications at time of shipment from the factory.

Assistance

The above statements apply only to the standard product warranty. Warranty options product

maintenance agreements and customer assistance agreements are also available.

Safety Summary

The following general safety precautions must be observed during all phases of operation of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the instrument .We

assumes no liability for the customer’s failure to comply with these requirements.

Environmental Conditions

This instrument is intended for indoor use in a pollution degree 2 environment. It is designed to

operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the

specifications tables for the ac mains voltage requirements and ambient operating temperature

range.

Before Applying Power

Verify that all safety precautions are taken. Note the instrument's external markings described under

"Safety Symbols".

Ground the Instrument

This product is a Safety Class 1 instrument (provided with a protective earth terminal). To minimize

shock hazard, the instrument chassis and cover must be connected to an electrical ground. The

instrument must be connected to the ac power mains through a grounded power cable, with the

ground wire firmly connected to an electrical ground (safety ground) at the power outlet. Note: Any

interruption of the protective (grounding) conductor or disconnection of the protective earth terminal

will cause a potential shock hazard that could result in personal injury.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of fumes or flammable gases.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers except as instructed in this Guide for

installing or removing electronic load modules. Component replacement and internal adjustments

must be made only by qualified service personnel. Do not replace components with power cable

connected. Under certain conditions dangerous voltages may exist even with the power cable

removed. To avoid injuries always disconnect power, discharge circuits, and remove external voltage

sources before touching components.

DO NOT SERVICE OR ADJUST ALONE

Do not try to do some internal service or adjustment unless another person capable of rendering first

aid resuscitation is present.

4

Page 5

Safety Symbols

Direct current

Alternating current

Both direct and alternating current

Protective earth (ground) terminal

Caution (refer to accompanying documents)

WARNING

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the indicated

conditions are fully understood and met.

CAUTION

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not correctly

performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed beyond a

CAUTION sign until the indicated conditions are fully understood and met.

5

Page 6

Quick Reference

The Front Panel

1

3 4

1

16-character display shows voltage and current measurements.

2

Rotary knob

3

Power switch ON/OFF

4

Entry keys:((((numeric keys))))

Enter values.

Increasing or decreasing the setup values.

Menu commands.

5

Keypad:

Enable/disable input.

Setup the current, resistance and voltage modes.

Set and reset protection functions.

Scroll through front panel.

6

Input terminals.

Note: Each terminal is able to sink 120A, the maximum current supported by

the instrument. Either one of the 2 negative or 2 positive terminals can be

used, it is not necessary to double up on the wires when driving a high

current.

5

2

6

6

Page 7

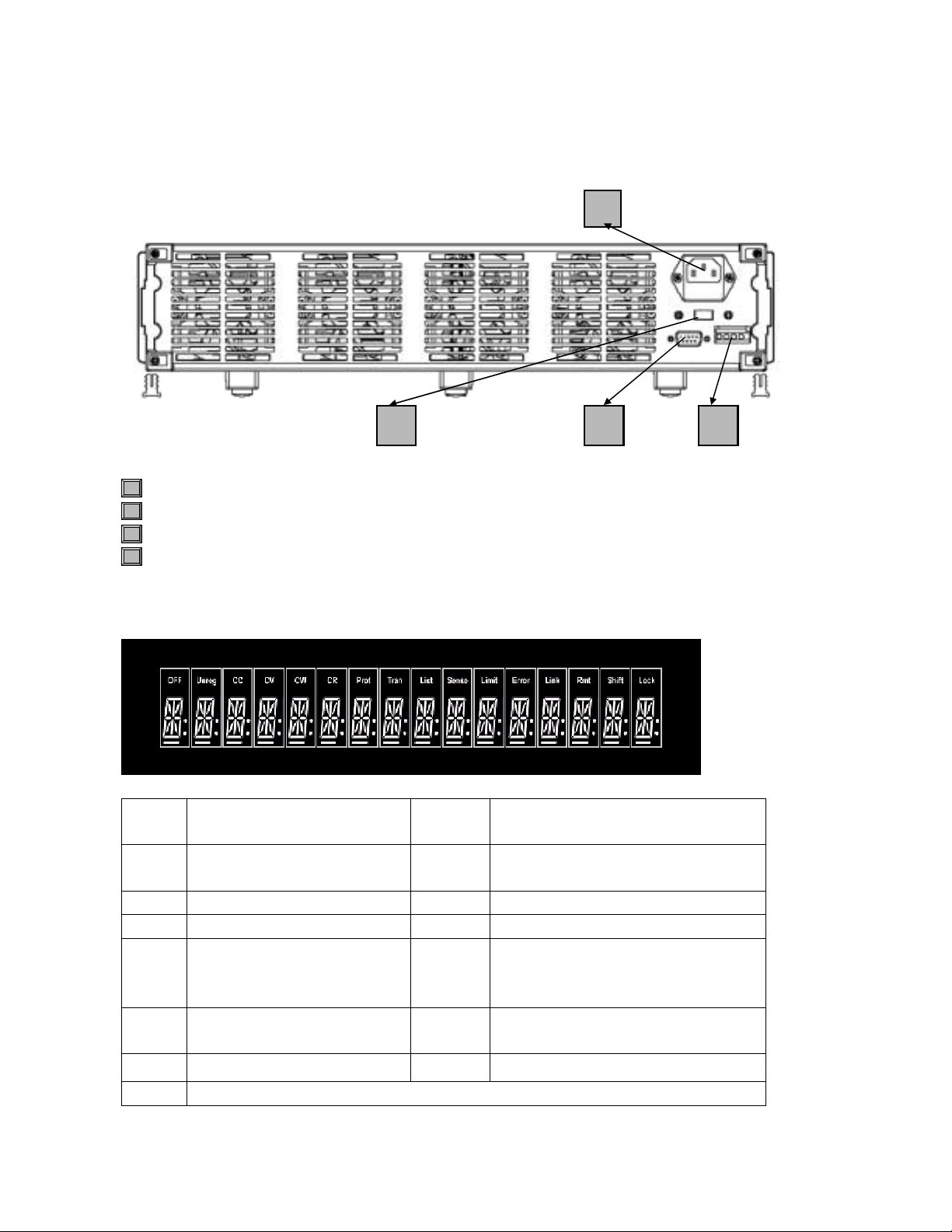

The Rear Panel

1

4

1

3 Pin IEC320 ac input connector. (Power code requires ground conductor).

2

4 Pin Trigger and Remote sensing connectors.

3

9-Pin COM port interface connector.

4

Power switch (110V / 220V)

Front Panel Display

OFF

CC

CV

CW

CR

Tran

List

power off

Constant current (CC) mode.

Constant voltage (CV) mode.

Constant power (CW) mode.

Resistance (CR) mode.

The input channel is enabled for

transient operation.

List mode is initiated or running.

Trigger

Sense

Error

Link

Rmt

Shift

Lock

Indicates that the electronic load is waiting an

initiate and trigger to occur.

Indicates that the electronic load is in Remote

sensing state

A errors have occurred

In the communication state

Indicates that the electronic load is in remote

state (RS-232). In the remote state, only the

active key is the Local key.

Indicates that the shift key has been pressed.

keyboard is locked by password

23

Unreg

The input is unregulated.

7

Page 8

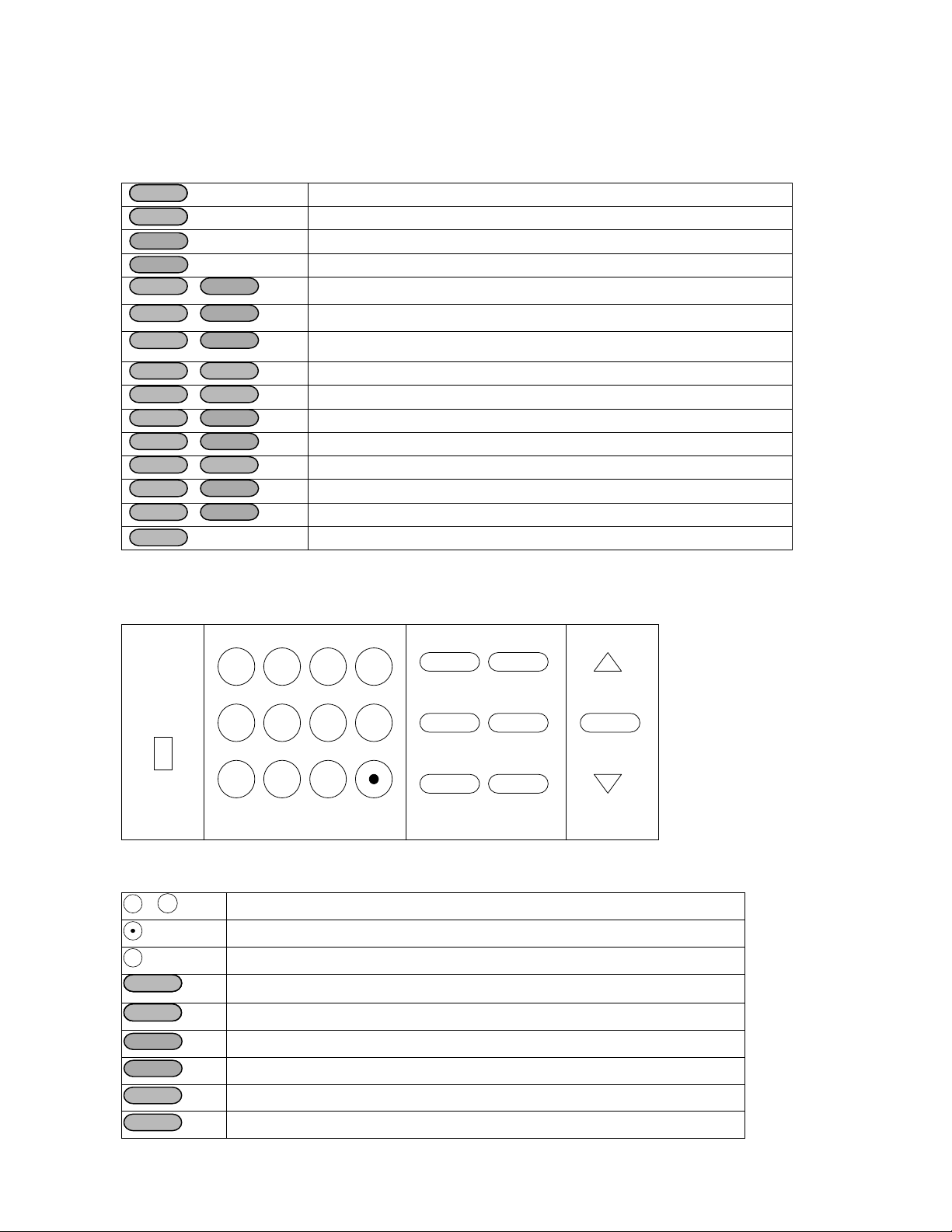

Immediate Action Keys

V-setV-set

I-setI-set

P-set

R-set

Shift

Shift

Shift

Shift

Shift

Shift

Shift

Shift

Shift

Shift

On/Off

+

+

+

+

+

+

+

+

+

+

A

B

Store

Recall

Menu

Short

Tran

Trigger

Battery

S-Tran

Choosing CV mode and setting the input of regulation voltage mode

Choosing CI mode and setting the input of regulation current mode

Choosing CP mode and setting the input of regulation power mode

Choosing CR mode and setting the input of regulation resistor mode

Switch to A setting value

Switch to B setting value

Press to store an existing electronic load state in non-volatile Memory.

Press to recall an existing electronic load state in non-volatile Memory.

Enter operation Menu.

Turn on or turn off short circuit Test.

Start /Stop transition operation

Causes a trigger to occur. Change the trigger source is IMMIDIATE

Battery discharge electronic operation

Set the transition operation parameter

Enable or disable load input.

Front Panel Menus

POWER

Store Recall S-Tran Menu

Local Battery Short Trigger

Key Pad

0

~~~~9

ESC

I-setI-set

V-setV-set

P-set

R-set

Shift

On/Off

1

A B

4

7

2

Tran

8 9

3 ESC

6 05

I-set V-set

P-set ENTER

Shift

R-set

Input on/off

0 through 9 are used for entering numeric values.

Decimal point.

The escape key. It may used to exit any working state.

Choosing CC mode and setup the input current of regulation current mode.

Choosing CV mode and setup the input voltage of regulation voltage mode.

Choosing CW mode and setup the input watt of regulation power mode.

Choosing CR mode and setup the input resistor of regulation resistance mode.

Shift keys.

Power ON/OFF

8

Page 9

△△△△

n

n

Scrolling keys let you move through the commands in the presently selected function me

up the next command in the list. Function menus are circular; you can return to the starti

position by continuous pressing the key.

▽▽▽▽

Enter

Go back to the previous command in the list .Function menus are circular; you can return

to the starting position by continuous pressing the key.

Confirmation key.

Menu Operation

Press Menu to indicate operation mode .View the menu in VFD and use ▽ and △ to scroll through the complete

menu listed below. When pressing the

return to the previous menu selection page.

Enter

MENU

CONFIG

INITIAL CONFIG

POWER-ON RECALL

ON

OFF<DEFAULT>

INPUT RECALL

ON

OFF<DEFAULT>

KEY SOUND SET

ON<DEFAULT>

OFF

KNOB LOCK SET

ON

OFF<DEFAULT>

SHORT CUT RECALL

ON

OFF>

RANG SELECT

ON

Return to the factory default setup value.

Setting Power-on state of Load.

When users turn on the electronic load; the electronic load setup value will

keep the state of last time when users turn off the electronic load.

Disable this function.

Setup of the electronic load input state in Power on.

When users turn on the electronic load; the electronic load input will keep

the state of last time when users turn off the electronic load.

When users turn on the electronic load, the electronic load input will keep

the state off.

Keypad sound setting.

Enable key sound.

Disable key sound.

Setup Rotary knob lock state.

Lock Rotary knob.

Unlock Rotary knob.

Quickly recall the data stored before

Change the measure precision of voltage and current

OFF>

REMOTE SENSE

ON

OFF<DEFAULT>

Setup voltage measurement Mode.

The electronic load will measure input voltage from the remote sense

connector.

The electronic load will measure input voltage from the front panel

connector.

key, you could get the selected menu function. Press

ESC

to

9

Page 10

ADC UPDATE RATE

HIGH

LOW<DEFAULT>

TRIGGER SOURCE

IMMEDIATE<DEF>

EXTERNAL

BUS

CONNECT MODE

MAXTIDLEXING

SEPARATE<DEF>

BAUDRATE SET

4800<DEFAULT>

9600

19200

38400

COMM. PARITY SET

NONE<DEFAULT>

EVEN

ODD

ADDRESS SET

KEY LOCK SET

EXIT

SYSTTEM SET

MAX CURRENT SET

MAX POWER SET

MAX VOLTAGE SET

VOLTAGE ONSET

VOLTAGE OFFSET

EXIT

LIST SET

MODE SET

FIXED MODE

LIST MODE

CALL LIST FILE

EDIT LIST FILE

LIST STORE MODE

8 X 120 STEPS

4 X 250 STEPS

2 X 500 STEPS

1 X 1000 STEPS

EXIT

LOAD ON TIMER

TIMER STATE

Choosing the trigger signals source.

Trigger signals from

Trigger signals from the TRIG connector in the rear panel.

Communication command trigger mode.

Setting baud rate.

Command parity setting.

Setting communication Flow mode

Setting keypad password.

Press

Setup the Maximum current.

Setup the Maximum Power.

Setup the Maximum Voltage.

Setting operation mode.

Recall list operation file.

Edit list operation file.

Users can choose 4 kind of memory space to save the list file.

Setting LOAD ON timer state

Enter

Fixed mode.

Choosing List mode.

Total 8 files and each file have120 list steps.

Total 4 files and each file have250 list steps.

Total 2 files and each file have500 list steps.

Total 1 file and each file have1000 list steps.

directly to disable the key lock function.

Shift

Trigger

+

key

10

Page 11

ON

OFF<DEFAULT>

TIMER SET

EXIT

EXIT

When users choose the timer state ON, and then turn on the electronic

load input, the LOAD ON TIMER will start working, and when the LOAD

ON TIMER is reach the setup time, the electronic load input will turn off

automatically,.

Setting time of LOAD ON timer.

General Information

Document Orientation

This manual describes the operation of the model 8510 DC Electronic Load. Unless otherwise noted, all units will be

referred to by the description "electronic load" throughout this instruction manual. The following documents and

software are shipped with your electronic load. This User's Guide (this document), contains installation, checkout, front

panel information and detailed programming information.

The Getting Started Map will help you find the information you need to complete the specific task that you want to

accomplish. Refer to the table of contents or index of each guide for a complete list of the information contained within.

Getting Started Map

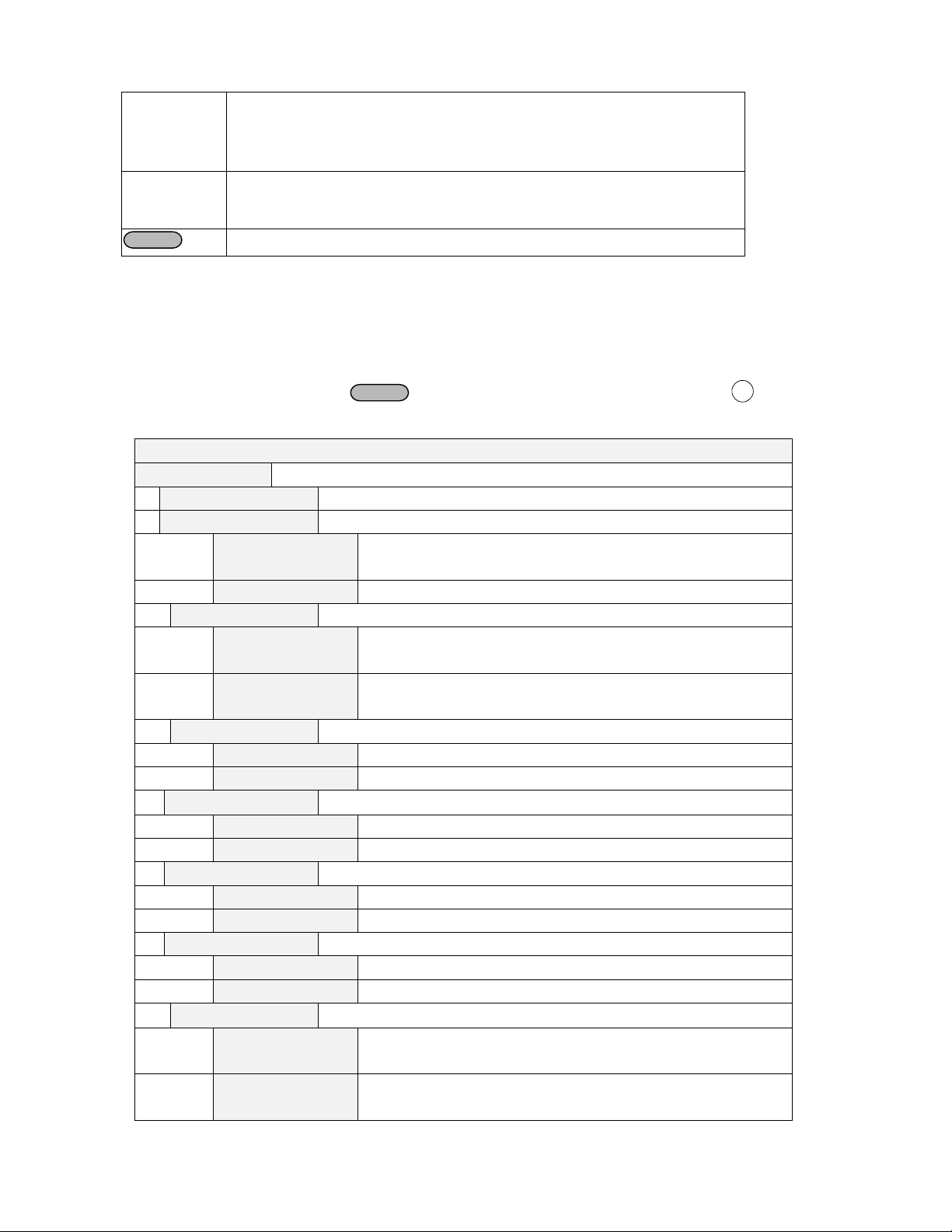

Task Where to find information

Checking out the unit

Verifying proper operation

Using the front panel

Calibrating the unit

Using the front panel

Front panel keys

Front panel examples

Using the programming interface

RS-232 interface

Remote operation mode

Protocol information

Controller Program and Software driver:

Power View PV-8500 software

Calibration PC-8500 software

Instruction manual

Instruction manual

Instruction manual

Instruction manual

CD-ROM

Options and Accessories

Options

11

Page 12

IT-E151 Rack mounts kit: for installation of one or two 8500 series load on the 19 inch rack.

IT-E131 isolated communication cable: This cable converts the electronic load’s serial port (TTL 5V level) to PC

RS232 interface.

IT-E132 isolated communication cable: This cable converts the electronic load’s serial port (TTL 5V level) to PC

USB interface.

Accessories

Power cord

User’s manual

Software CD-Rom

Calibration test report

IT-E132 isolated communication cable

Description

The 8500 series electronic loads are used for the design, manufacturing, and evaluation of DC power supplies, batteries, and

power components. The electronic load contains a processor, serial port connector, front-panel keypad and VFD, and other

circuits common to the other entire load module.

The model 8510 serial electronic load operates in constant current (CC) mode, constant voltage (CV) mode, or constant

resistance (CR) mode and constant power (CW) Mode.

Features and Capabilities

• High accuracy and high resolution

• Capable to work with constant current (CC), constant voltage (CV), constant resistance (CR) mode and constant power

(CW) operation.

• Serial port interface-DB9-RS232 port.

• Triggered input and measurement functions.

• Built-in pulse generator for continuous, pulsed, and toggled transient mode operation.

• Over voltage, over current, overpower, and over temperature protection.

• Electronic load calibrate by Software.

• Fan speed control by temperature.

• VFD display

• Short circuit test

• Battery testing function.

Front Panel Controls

The front panel has keyboard controls for setting the input voltage, current and resistance. The panel display provides

digital readouts of a number of functions including the inputs. The VFD display indicates the operating status of the

electronic load.

12

Page 13

Remote Programming

The electronic load may be remotely programmed from the computer via the IT-E131 isolated communication cable

.

Operating Modes

The four modes of operation are:

1: Constant current (CC).

2: Constant voltage (CV).

3: Constant resistance (CR).

4: Constant power (CW)

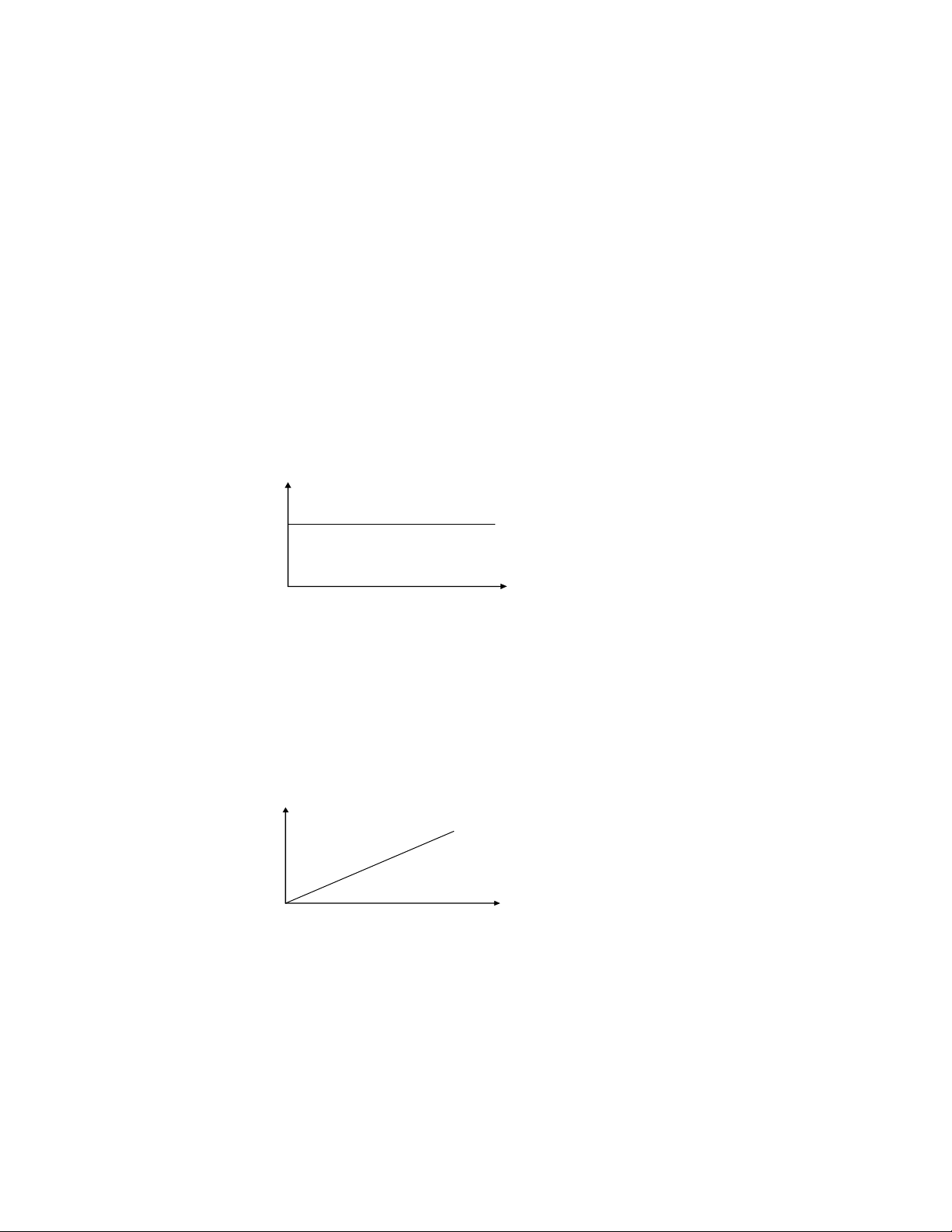

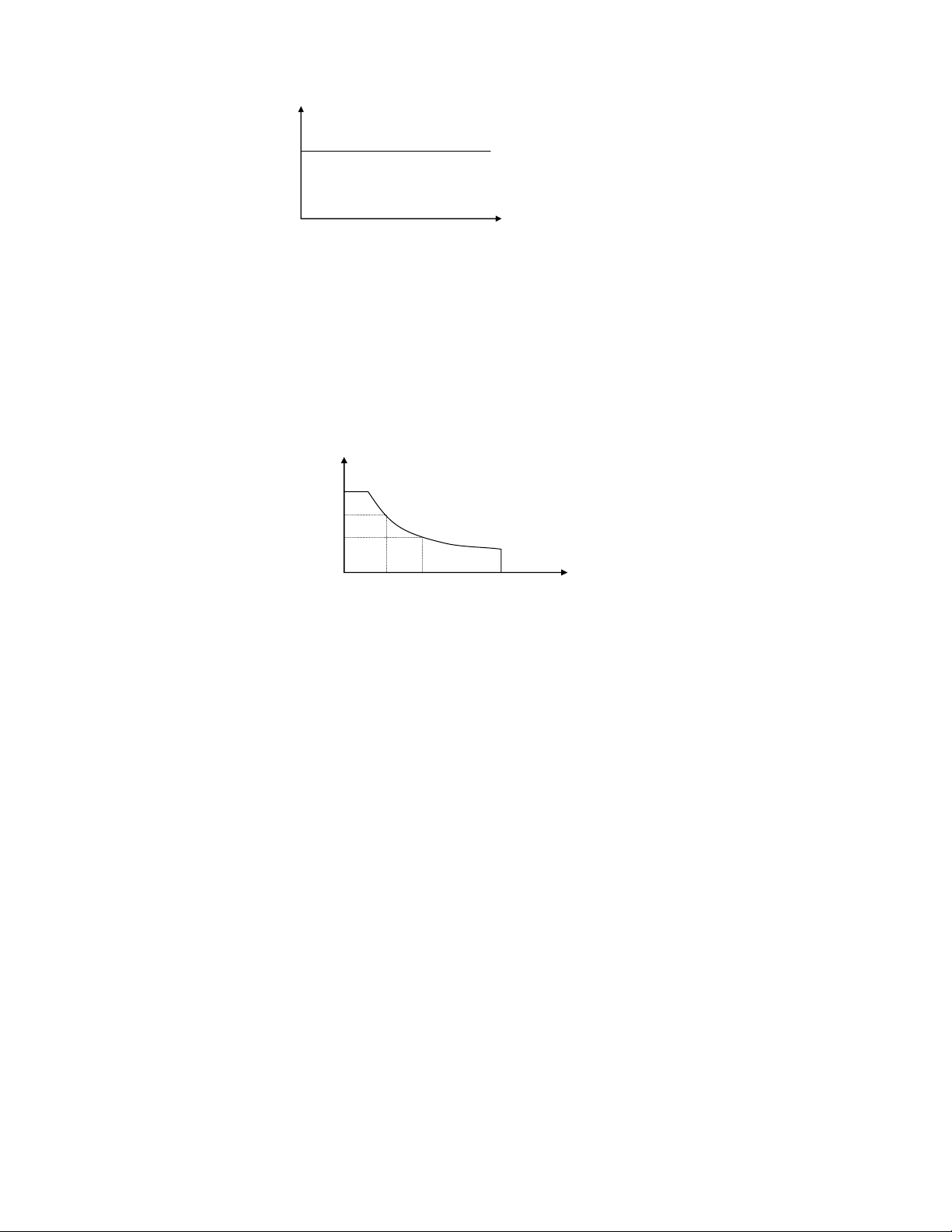

Constant Current((((CC))))Mode

In this mode, the electronic load will sink a current in accordance with the programmed value regardless of the input

voltage. CC mode can be set with front panel keys. The CC mode parameters are discussed in the following paragraphs.

I

LOAD

CURRENT

CURRENT

SETTING

LOAD INPUT

V

VOLTAGE

CONSTANTCURRENT MODE

Constant Resistance (CR) Mode

In this mode, the module will sink a current linearly proportional to the input voltage in accordance with the programmed

resistance. The CR mode can be set at the front panel. The CR mode parameters are described in the following paragraph.

I

LOAD

CURRENT

LOAD INPUT

VOLTAGE

CONSTANT RESISTANCE MODE

SLOPE

RESISTANCE

SETTING

V

Constant Voltage (CV) Mode

In this mode, the electronic load will attempt to sink enough current to control the source voltage to the programmed value.

The module acts as a shunt voltage regulator when operating in the CV mode. The CV mode can be set at the front panel.

The CV mode parameters are described in the following paragraphs.

13

Page 14

V

LOAD INPUT

VOLTAGE

VOLT

SETTING

LOAD CURRENT

CONSTANT VOLTAGE MODE

I

Constant Power (CW) Mode

In this mode, the electronic load’s power consumption will be in accordance with the programmed value, regardless of the

input voltage. The CW mode can be set with front panel keys. The CW mode parameters are discussed in the following

paragraphs.

LOAD INPUT

VOLTAGE

CONSTANT POWER MODE

V2

V3

V

I2

I2 I3

I3

I2I2

I3I3

LOAD

CURRENT

POWER

SETTING

I

Transient Operation

Transient operation enables the electronic load to periodically switch between two load levels, as might be required for

testing power supplies. A power supply's regulation and transient characteristics can be evaluated by monitoring the supply's

output voltage under varying combinations of load levels, frequency, and duty cycle.

Transient operation can be turned on and off at the front panel or via PC control using the IT-E131 isolated communication

cable. Before turning on transient operation, you should set the desired mode of operation as well as all of the parameters

associated with transient operation. Transient operation may be used in the CC, CR, or CV or CW modes and can be setup

in continuous, pulsed, or toggled operation mode.

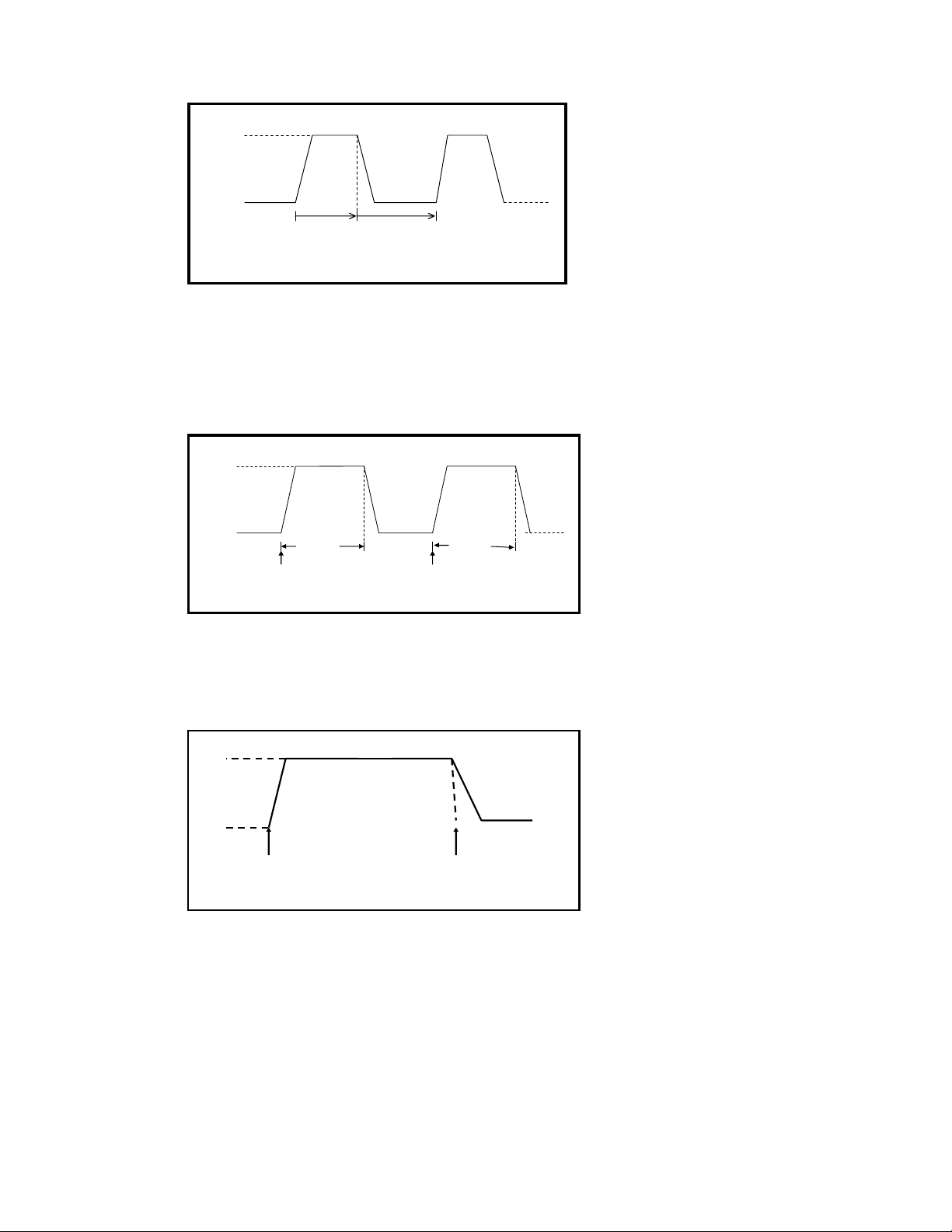

Continuous

Generates a repetitive pulse stream that toggles between two load levels and changes the state between value A and

value B.

14

Page 15

10A

5A

2.0ms 3.0ms

Continuous Transient Operation

Pulse

Switch to value B upon receiving one trigger signal , after taking the pulse time(TWD) of value B, the load will return to

Value A .

10A

5A

TWD

10ms

TRIG TRIG

Pulsed Transient Operation

TWD

10ms

Trigger Mode

Switches the state between value A and value B once trigger signal is received.

10A

5A

TRG

Toggled Transient Operation

TRG

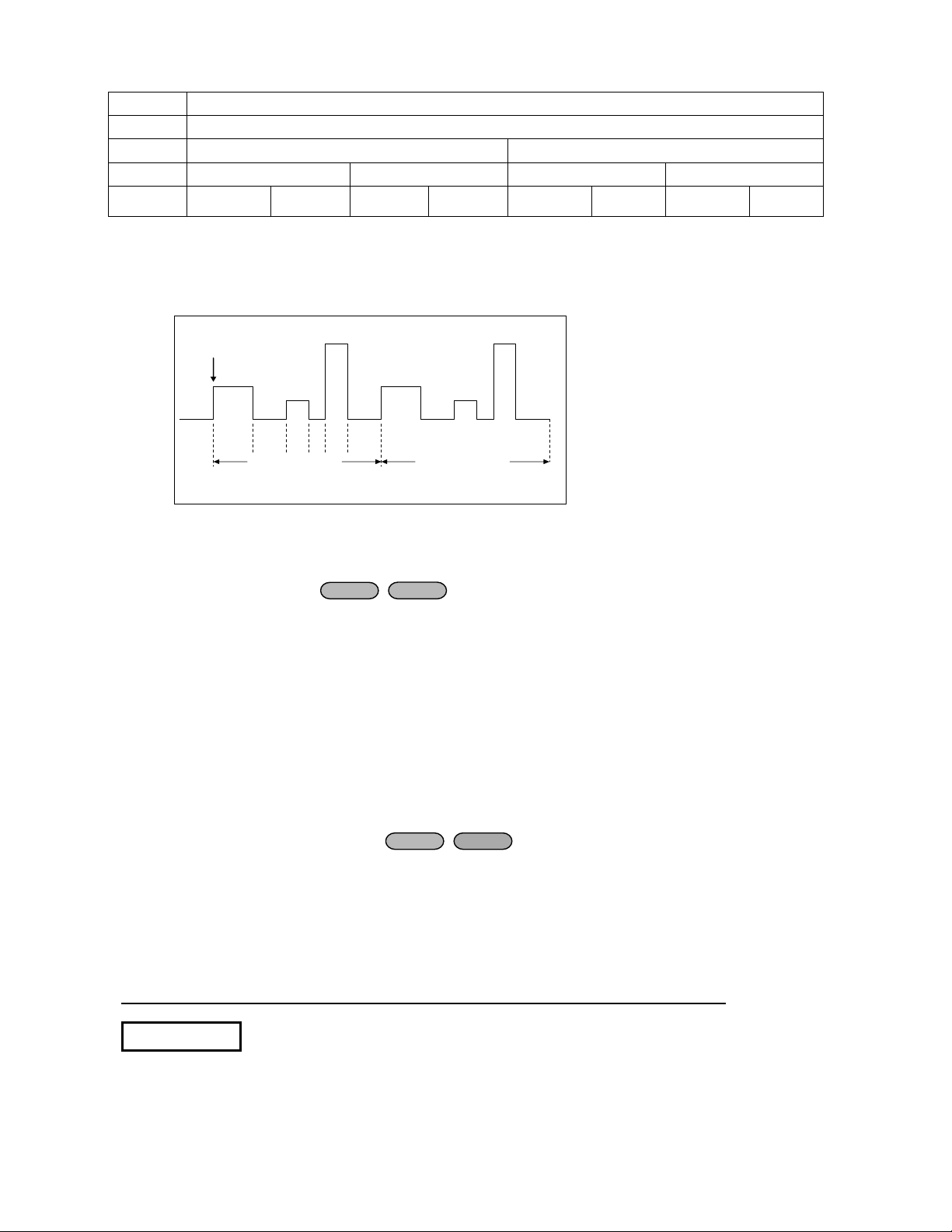

List Operation

List mode lets you generate complex sequences of input changes with rapid, precise timing, which may be synchronized with

internal or external signals. List operation can be changed by editing every step value and time in list operation. The

parameter of list operation include the group file name, input step setting (the max steps is 1000 steps),time of one step

(1mS~6000mS)and setting value of one step. In CC mode, dwell time range is 1mS to 6S, which also have an associated

value. Note that lists data can only be saved in total 1000 steps memory of 4 situations.

15

Page 16

GROUP Total = 1000 steps

1 1000 steps

500

2

4 250 steps 250 steps 250 steps 250 steps

8 120 steps 120 steps 120 steps 120 steps 120 steps 120steps 120 steps 120 steps

00 steps

0000

500 steps

When receiving one trigger signal, it will start the list operation until receiving another trigger signal or finish the List

operation.

Trigger

102345

List count=1 List count=2

List sequence

Triggered Operation

The electronic load has various triggering modes to allow synchronization with other test equipment or events. Such as:

Keypad triggering mode: Press

TTL triggering mode: Send a high pulse with a constant time more than 5m Sec to the trigger terminals in rear panel

to trigger the electronic load.

Command triggering mode: Send triggering command to the electronic load via the serial port.

Shift

Trigger

+

to trigger the electronic load.

Input Control

Short On/Off

The DC Load can simulate a short circuit at its input by turning the load on with full-scale current. The short circuit can

be toggled on/off at the front panel using the

operation setting current value , When short operation is on OFF state , the Load reverts back to the original setting

state.

The actual value of the electronic short is dependent on the mode and current range that are active when the short

is turned on.

In CC, CW and CR mode, the max short-circuit current value is 1.2 times of the current range. In CV mode, short-circuit

operation is same as the operation of setting CV to 0V.

Shift

+

Short

keys. Short

operation is not influence the

NOTE

Turning the Short Test on in CV mode may cause the load to draw so much current that the software current

limit is triggered, which may turn the input off. Turning the short circuit on does not affect the programmed

settings, and the load input will return to the previously programmed values when the short is turned off.

16

Page 17

Input On/Off

t

Electronic load's input can be toggled on/off at the front panel. Turning the input off (zero current) does not affect the

programmed settings. The input will return to the previously programmed values when the input is turned on again.

NOTE

The Input On/Off command supersedes the mode commands and Short Test

On/Off command.

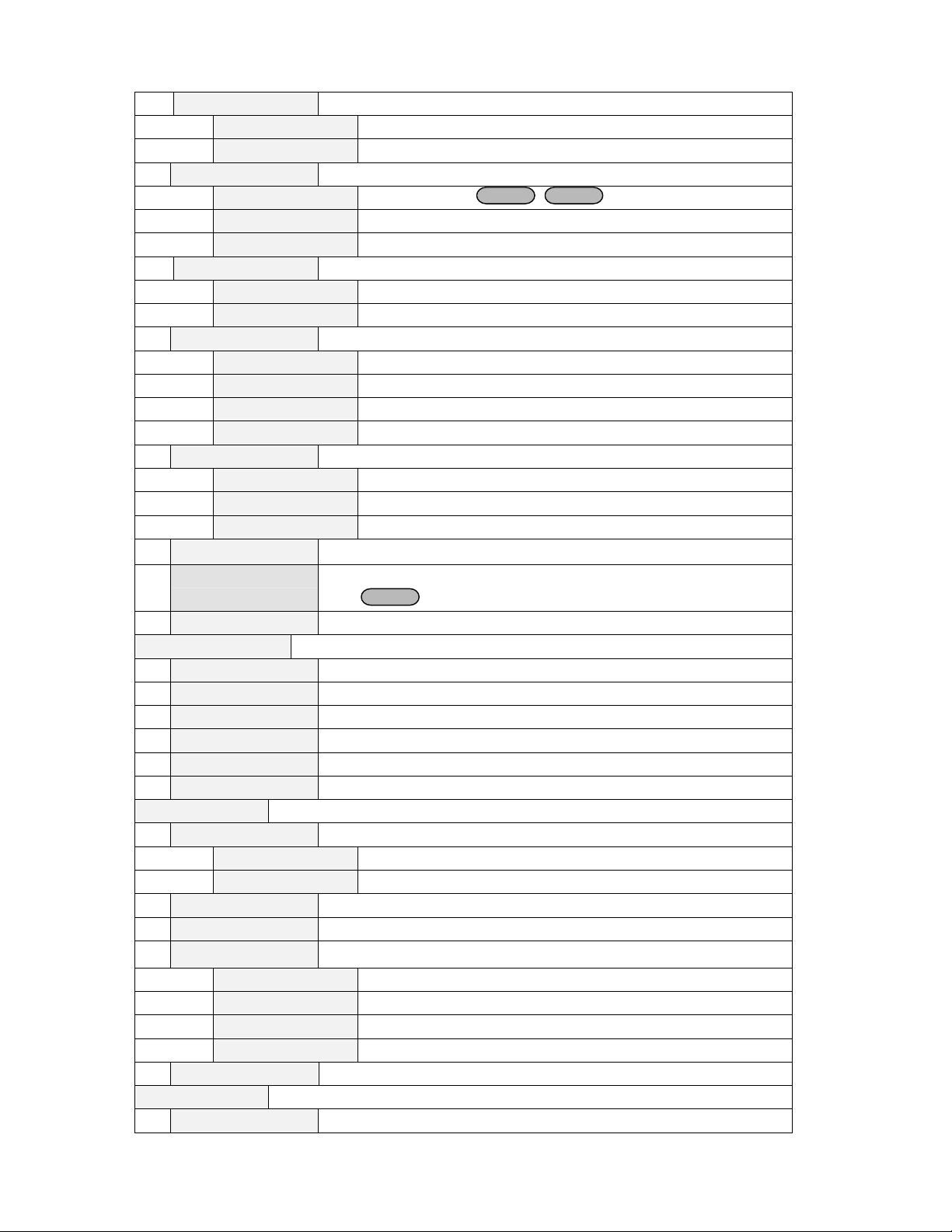

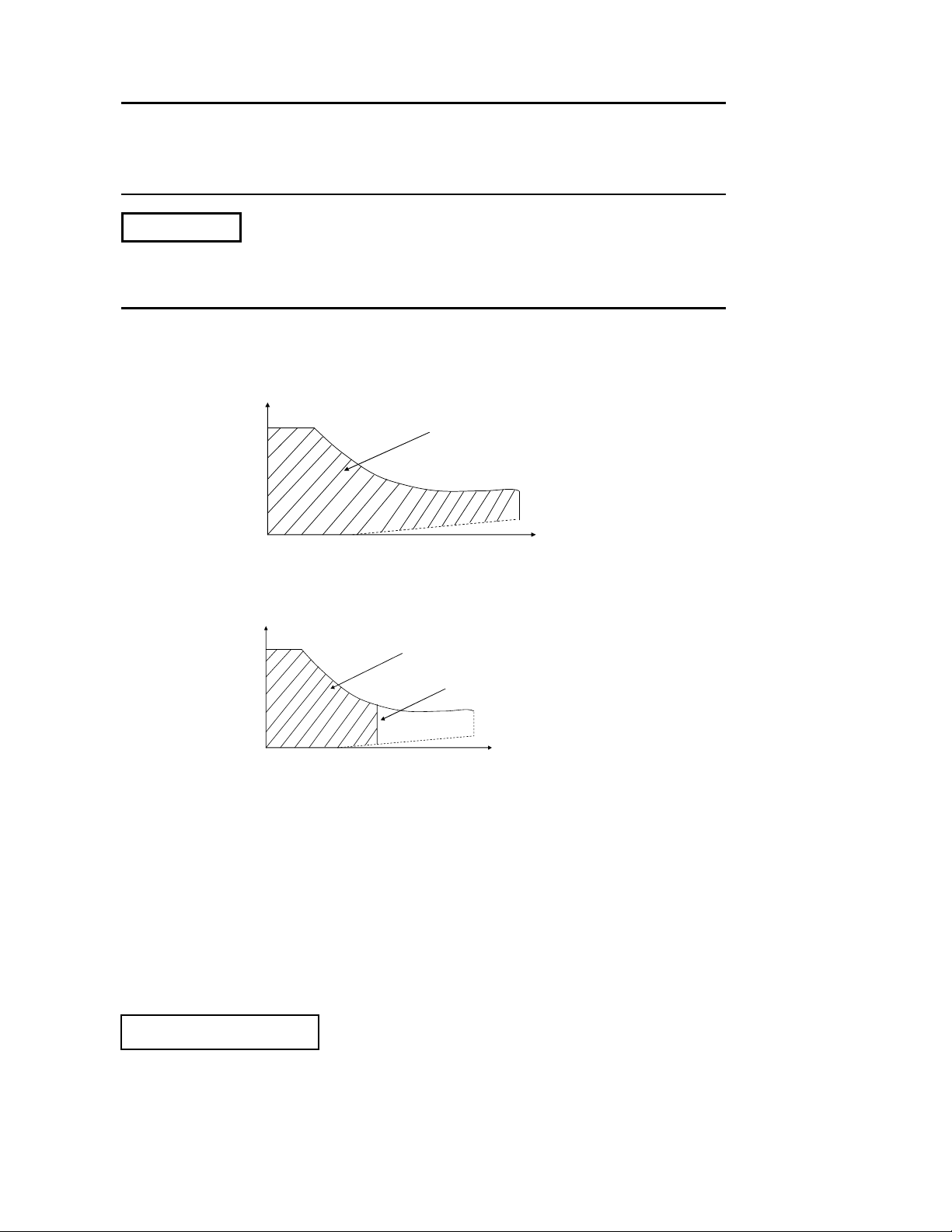

Operation Range

Work in the range of Rated Current, Rated voltage and Rated Power, The figure is as following:

Rated voltage

Operation mode change state

Rated voltage

INPUT VOLTAGE V

INPUT VOLTAGE V

Rated power

Input current I Rated current

C

Software Power Limit

Software Current Limi

A

Input current I Rated current

Protection Features

This Electronic Load includes the following protection features:

Over Voltage

If input voltage exceeds the voltage limit, Load will turn OFF the input and a buzzer turns on. VFD displays the

following:

OVER VOLTAGE

Over Current

17

Page 18

When working in CR, CC and CP mode, input current is ascending continuously, the load current will be limited by a

current limit circuit, Load will work in the over current protection state , VFD display the information as CC.

When work in CV mode, transition mode and List mode, Input current exceeds the current limit, Buzzer is mooing,

VFD display the flashing current value.

Over Power

If the input power exceeds the power limit in the normal operation mode, Load will work in the over power protection

state. VFD displays the information as CW.

When work in transition mode and list mode, if the input power exceeds the power limit. Buzzer is mooing, VFD display

the flashing current value and voltage value.

Reverse Voltage

This feature protects the load module in case the input DC voltage lines are connected with wrong polarity, if a reverse

voltage condition is detected, Buzzer is mooing. VFD display as following:

REVERSE VOLTAGE

Over Temperature

If internal power components ‘s temperature exceeds safe limits (80℃), Over temperature protection will be

activated . Load will turn off the input and Buzzer is mooing, VFD display as following:

OVER HEAT

Remote Sense Function and Trigger Function

When working in CV, CR and CP mode, if load consumes a large current, it will cause depressed voltage in the

connection line between the UUT (Unit Under Test) and the load’s terminals. In order to assure testing precision, this

DC load provides remote testing terminals in the rear panel. Users could test the output terminals voltage of the UUT

through it. Users should set the Load to REMOTE mode before using the function.

4 Pin trigger and remote sensing connectors:

+

..

Remote Sensing: SENSE (+)

inevitable voltage drop in the load leads, remote sensing provides greater accuracy by allowing the load to regulate

directly at the source's output terminals.

_ IN

Sense

A

Trigger

B

and

SENSE (–)

are the remote sensing inputs. By eliminating the effect of the

18

Page 19

TRIG:

used to change settings (voltage, current, resistance, etc.), toggle between settings in transient-toggle mode, or

generate a pulse in transient-pulse mode.

You must set the remote sense mode in the menu before using the remote sense function.

A TTL-compatible input that responds to external edge trigger signal. A trigger applied to this input can be

Action:

(1) Press

(2) VFD displays >CONFIG, press

Shift

+

Menu

key into the menu

Enter

key to confirm

(3) Press

(4) Press

key to choose>REMOTE SENSE, press

/ to choose>ON, press

Enter

Enter

key to confirm. And the remote sense function has been set.

key to confirm

Wiring diagram for remote sense

Input port in front panel

+

-

Sense port in rear panel

+

-

+

UUT

-

Saving and Recalling Settings

The electronic load has internal registers in which settings (mode, current, voltage, resistance, transient level, etc.) are

stored. Users could use

following:

CC value /CW value /CR value /CV value

Transition current A value /Transition current B value /Transition voltage A value /Transition voltage B value /

Transition power A value /Transition power B value /Transition Resistance A value /Transition Resistance B value

Current A pulse width time/ Current B pulse width time/Voltage A pulse width time/ Voltage B pulse width time /Power

A pulse width time/Power B pulse width time /Resistance A pulse width time /Resistance B width time

Transition current testing mode/Transition voltage testing mode/Transition power testing mode /Transition resistance

testing mode

Max current value / Max voltage value / Max power value

Shift

+

Store

and

Example:

Shift

+

Recall

to save and recall the relative data as

1) Press

2) Press

3) Press

I-setI-set

Shift

Shift

the number stored.

, set a value of current or voltage, press

Store

+

+

Recall

set a store code at random, press

, set the store code that you set before, press

19

Enter

to confirm.

Enter

to confirm.

Enter

to confirm, then you can get

Page 20

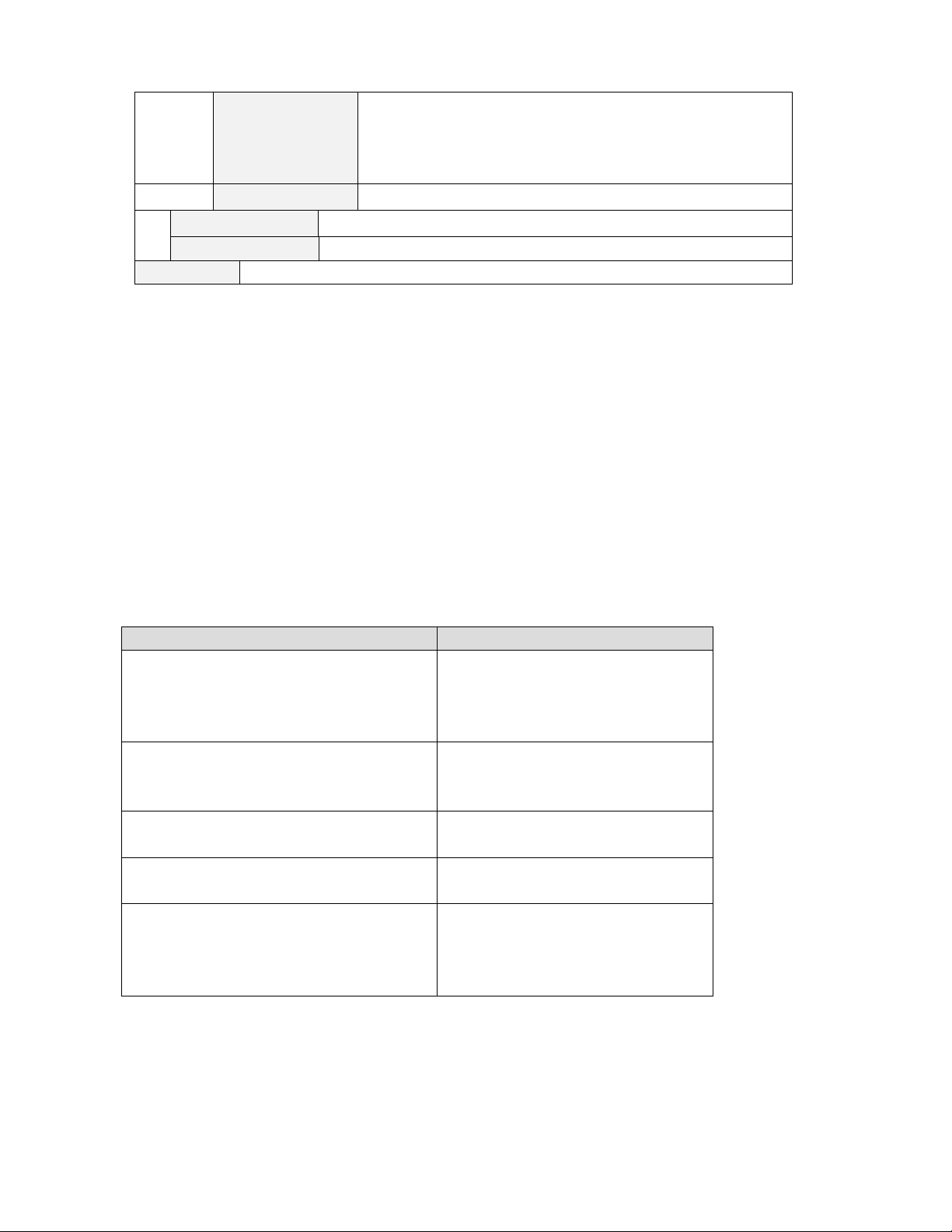

Battery Testing

A DC load is well suited to verify that a battery is working properly. Only with the correct load testing, the battery can

be confirmed if it was being the expectant life curve location. The electronic loads can be used to test any type of

battery.

As the accumulator is used by any sheltered equipment or the uninterrupted service system, it is necessary to use

load testing. Because the battery is the weakest component, load testing should be used periodically to ensure the

security of the battery.

Capability test

For the capability test CC mode is used. Generate a program to set the voltage in off state. If the accumulator’s voltage

is too low, the electronic load will interrupt the test if system checks the accumulator which is near to one rating or in

insecurity state. In testing procedure, you could see the accumulator voltage, discharge current, electronic load power

and spare capability of accumulator. If connecting with PC software, the battery’s discharge curve could be displayed in

window. This test can reflect the reliability and usage time of accumulator.

Operation:

(1) Turn off the input of electronic load, then connect the load with battery.

(2) Press

Note: the discharge current should not be more than the current that the battery can supply.

(3) Press

(4) Press

I-setI-set

confirm.

the test. When the battery voltage reaches as the min voltage, the battery test will stop. During the testing, press

the down key▼and up key▲ to observe the voltage, current and discharge capacity of the battery, and the power

of the load.

on the panel, VFD displays "CURRENT= A", set discharge current value and press

Shift

Shift

Battery

+

+

Battery

, VFD displays "MIN VOLT= V", set the min voltage value, press

to stop battery test.

Enter

Enter

to

to start

20

Page 21

V

Battery Voltage

Min voltage

t

I

Load Sink Current

t

Von/Voff Operation

You can set voltage value Von/Voff to control the input state on/off for electronic load. When the input voltage reaches

the Von value, the load’s input state is on. When the input voltage reaches the Voff value, the load’s input state is off.

Action for set Von/Voff value:

press

Shift

Enter

Enter

(1)

Press

(2)

VFD displays >CONFIG, press key to choose >SYSTEM SET, press

(3)

VFD displays >MAX CURRENT SET, press key to choose>VOLTAGE ON SET, press

confirm

(4)

VFD displays

press

(5)

Press key to choose

(6)

VFD displays

Menu

+

>VOLT.ON=0.00V, press numeric keys to set Von value

to confirm

>VOLT.OFF=0.00V, press numeric keys to set Voff value

to confirm

into menu

>VOLTAGE OFF SET, press

21

Enter

Enter

(0.1V to max voltage value),

to confirm

to confirm

Enter

(0V to max voltage value),

key to

Page 22

Installation

Inspection

Damage

When you receive your electronic load, inspect it for any obvious damage that may have occurred during shipment. If

there is damage, notify the shipping carrier and nearest Agent office and Support Office immediately.

Items Supplied

The following user replaceable items are included with your electronic load.

Item

Power Cord Users will get one of the power cords

Description

appropriate for your location.

Instruction manual

Software CD-Rom Programming information

Calibration Report The Instrument calibration report.

Contains installation, checkout, and

front panel information

Cleaning

Use a dry cloth or one slightly dampened with water to clean the external case parts. Do not attempt to clean internally.

WARNING

To prevent electric shock, unplug unit before cleaning.

Location

The outline diagram in following figure gives the dimensions of your electronic load. The electronic load must be

installed in a location that allows sufficient space at the sides and back of the unit for adequate air circulation.

Installation

Dimension :

429mmW x88.2mm H x 354.6mm D

22

Page 23

Outline Diagram

Unit (mm)

Bench Operation

A fan cools the electronic load by drawing air through the button and sides and exhausting it out the back.

Minimum clearances for bench operation are 25 mm along the sides.

CAUTION

Do not block the fan exhaust at the rear of the Load.

Input Connections

Power Cord

Connect the power cord to the IEC 320 connector on the rear of the unit.

WARNING

SHOCK HAZARD:

outlet is of the three-conductor type with the correct pin connected to earth ground.

NOTE

The detachable power cord may be used as an emergency disconnecting device. Removing the power cord from the

ac input connector will disconnect ac input power to the unit.

the power cord provides a chassis ground through a third conductor. Be certain that your power

23

Page 24

Trigger and Remote Sensing Connections

A 4-pin connector and a quick-disconnect mating plug are provided on rear panel for accessing input signals and

remote sensing, all leads connected to the connector should be twisted and shielded to maintain the instrument's

specified performance.

Remote Sensing:

sense ( ++++ )

)

and

sense (((( ---- ))))

) )

Used to connect the remote sensing leads to the power source.

TRIG IN: TRIG (IN)

input can be used to change settings (voltage, current, resistance, etc.), toggle between settings in transient-toggle

mode, or generate a pulse in transient-pulse mode.

A TTL-compatible input that responds to external edge trigger signal. A trigger applied to this

)

TRIG GND: TRIG (

Provides the common connection for the trigger signals.

Turn-On Checkout

Introduction

Successful tests in this chapter provide a high degree of confidence that the electronic load is operating properly.

Checkout Procedure

The test in this section checks for proper operation of the electronic load. If you have not already done so, connect the

power cord to the unit and plug it in

Procedure Display Explanation

1. Turn the unit on. The

electronic Load undergoes a

self-test when you First turn it

on.

2. Wait for 1s after turn on

electronic load.

3. Wait for another 2S. ERROR CAL.DATA

4. Press Shift button and

keys .

5. Press

ESC

button

△▽

.

EPROM ERROR

LOAD MODEL:85XX

:

XXX-XXX-XXX

SN

VER x.xx

0.000V 0.000A

During self test, all segments are briefly

lit

EEPROM damage or Lost data of last

power off

Run well if no such display, system will

go to the step 3 directly.

EEPROM Lost calibration data

Run well if no such display, system will

go to the step 4 directly.

Display the information of the product

Type, series number version of

software.

Display the actual input voltage and

current value.

24

Page 25

6.Press △▽

0.000W I: 0.000A

Display the actual power value and

setting value.

In Case of Trouble

Should the power-on self test of the Electronic Load fail, you may try the following: When turning on the power, make

sure the power cord to the unit is plugged in and the power switch is in the on position.

1) Check the power voltage setting.

Work voltage of load have two type 110V or 220V , Please make sure it is right voltage accordance to the voltage

in your area. You could change the voltage setting through dial the switch in the rear panel.

2) Check the fuse.

If fuse is blown, please replace it according to the following specification.

Model Fuse specification

(110VAC)

8510 T0.5A 250V T0.3A 250V

3) Location of Fuse

Fuse specification

(220VAC)

Fuse

Front Panel Operation

Display

16-character fluorescent display for showing measurements and programmed values.

Front Panel Display

Indicators for operating modes and status conditions:

OFF

CC

CV

CW

power off

The selected input channel is in the

constant current (CC) mode.

The selected input channel is in the

constant voltage (CV) mode.

The selected input channel is in the

constant power (CW) mode.

Trigger

Sense

Error

Link

Indicates that the electronic load is waiting an

initiate and trigger to occur.

Indicates that the electronic load is in sense

state

A errors have occurred

In the communication state

25

Page 26

CR

Tran

List

The selected input channel is in the

resistance (CR) mode.

The selected input channel is enabled

for transient operation.

A list is initiated or running.

Function keys

Main Function:

Set up a constant current input.

Set up a constant power input.

Set up a constant resistance input

Select CC, CR and CV and CW modes.

Select Current, Resistance and Voltage levels.

Set Trigger and Transient levels.

Set up front panel measurements.

Recall the stored data

Battery testing

Short-circuit testing

Rmt

Shift

Lock

Indicates that the electronic load is in remote

state (RS-232). In the remote state, only the

active key is the Local key.

Indicates that the shift key has been pressed.

keyboard is the mode for password

Entry Keys

Entry keys let you:

Enter programming values.

Increasing or decreasing setup values.

Press

△

or ▽ select the front panel menu parameters.

Power

The Power switch turns the electronic load power on or off.

Example

I-set (set up a constant current from 0 to Max current )

Set up a constant DC current input is the first main function of programmable DC electronic load,

8500 serial electronic load provides two methods to set up the constant DC current input by using the number

keyboard and the rotary button. Please see the following operation procedure.

Procedure Operation details VFD display

STEP 1

Press

I-setI-set

CURRENT=0.000A

STEP 2

Enter the password or jump the step 4 if

your password for reentering

26

PASSWORD:

Page 27

STEP 3

STEP 4

Enter the original value which displayed in

the VFD or enter a new value by using

number keys or Rotary knob to adjust the

voltage value

Press

Enter

to confirm

Setup the input current at 4.33A.

Method 1: To set up by using number keyboard

CURRENT=*.***A

0.000V *.***A

Step1. Press

Step2. Press numeric button to enter the current value 4.33.

Step3. Press

I-setI-set

Enter

button.

button to confirm the current value.

Method 2: To set up

(1) If the key board is unlocked by password, directly adjust the Rotary SW button, and voltage will be continually

changed from the previews value according the rotation. At the beginning, the cursor will be shown on the last number

of the value which is indicated on the VFD, you can move the cursor to the first number, second number etc by using

number buttons, and then adjust the Rotary SW to change each number, and let it stay at *.** A. Please see the

following description. Then press I-set to confirm the value.

0.00A 0.00V

0.0W 4.33A

I-setI-set

by using Rotary SW

Procedure:

Step1. Press

Step2. Adjust the Rotary knob to change the value, the operation is as the same as item (1)

Step5. Press

I-setI-set

Enter

button,

button to confirm the current value.

P-set (set up a constant power from 0 to Max power)

8500 series electronic load can be set up for a constant power.

Constant power setup procedure is as following:

Procedure Operation details VFD display

Step 1

Step 2

Step 3

P-set

Press

Enter a new value by using numeric keys or

Rotary knob to adjust the voltage value

Enter

Press

to confirm.

POWER =0.000W

POWER=*.***W

0.000W P:*.000W

R-set (set up a constant resistance from 0.1Ω to 4000Ω)

8500 series electronic load can be setup for a constant resistance.

Constant resistance setup procedure is as following:

Procedure Operation details VFD display

27

Page 28

Step 1

Step 2

R-set

Press

enter a new value by using numeric keys or Rotary

knob to adjust the resistance value

RESISTANCE =0000R

RESISTANCE=*****R

Step 3

Press

Enter

to confirm.

0.000W R:0000R

V-set (set up a constant voltage from 1.5V to Max voltage)

8500A electronic load can be setup for a constant voltage.

Constant voltage setup procedure is as following:

Procedure Operation details VFD display

Enter

V-setV-set

to confirm.

VOLTAGE=1.500V

VOLTAGE=*.***V

0.000W V:3.000V

Step 1

Step 2

Step 3

Press

enter a new value by using numeric keys or Rotary

knob to adjust the resistance value

Press

Shift + Store

Procedure Operation details VFD display

Press

Shift

Enter

Step 1

Step 2

Press

Store

and

to confirm.

STORE 1

Store the relative data

Shift + Recall

Procedure Operation details VFD display

Step 1

Step 2

Press

Press

Shift

Enter

Recall

and

to confirm

RECALL 1

Recall the saving data

On/Off input setting

Use

On/Off

to change the state of electronic load. Switch on to off state by press

On/Off

.

Transition Testing Operation

Users could switch between the two different current and voltage level settings in the transition mode; it could test the

(

transition specialty of power supply. Users could use front panel or communication interface

)

to make it work or not, please setting parameters before transition operation. Include Transition setting value,

OFF

Constant pulse width setting and Transition Pulse width setting and Transition testing mode. The mix pulse width is

500uS.The Max pulse width is 6S. Transition Operation only could work in CC and CV mode.

Users can choose one of the three operation modes: Continuous, Pulse and Toggling mode.

TRAN ON AND TRAN

28

Page 29

Transition Parameter Setting

Users could press

Shift

+

Enter

Enter

Enter

Enter

Shift

S-Tran

S-Tran

+

LEVEL A = *****

to set the transition parameter.

WIDTH A = ******

LEVEL B=*****

WIDTH B= *****

CONTINUOUS

PULSE

Setup value A

Setup time width of value A

Setup value B

Setup time width of value B

Choose one of the three transition

modes

TOGGLED

Enter

Finish transition setting

Continuous Transient Operation

In this mode, electronic load will generates a repetitive pulse stream that toggles between two load levels. ;

Load could switch the state between two setting value (value A and value B).

In this following example, assume that the CC mode is active; the applicable transient operation parameters have

been set as follows.

For example:

Continuous mode, current level A =5A, width = 2mS. Current level B =10A, width = 3ms. Testing machine input

voltage is 12V.

10A

5A

2.0ms 3.0ms

Continuous Transient Operation

Action

1. Select the operation mode (

2. Press

LEVER B=10A, press

3.Transition mode now is

4. Press

5. Press

6. Press

Shift

On/Off

Shift

+

Shift

+

+

, the input of load is powered on.

CC,CV,CR or CP

S-Tran

Enter

CONTINOUS

Tran

Tran

,

set LEVEL A=5A, press

, set WIDTH B=2mS, press

, press

to activate the transient mode.

again to stop the transient operation.

Pulse Transient Operation

), and set a proper value, press

Enter

Enter

to confirm.

, set WIDTH A=3mS, press

Enter

to confirm.

On/Off

to turn off the load input.

Enter

, set

In this mode, generates a transient pulse of programmable width when pulsed transient operation is in effect.

29

Page 30

For example: When load receiving one trigger signal, it will switch to 10A current value, and taking 10mS to return the

current value of 5A.

10A

5A

TRIG TRIG

Pulsed Transient Operation

Action

1. Select the operation mode (

2. Press

CONTINOUS

3. Press

4. Press

5. Press

6. Press

7. Press

8. Press

▼ till >PULSE

On/Off

Shift

Enter

Shift

Shift

Shift

S-Tran

+

.

.

, set transient mode is

Tran

+

Trigger

+

Tran

+

, the input of load is powered on.

.

TWD

10ms

TWD

10ms

Trigger

On/Off

to turn off the load input.

, get more pulse.

CC,CV,CR or CP

,

set LEVER A=5A, LEVER B=10A, WIDTH B=10mS. Transition mode now is

to activate the transient mode.

to start another pulse. Press

again to stop the transient operation.

), and set a proper value, press

PULSE

.

Shift

+

Toggled Transient Operation

In this mode, after transition operation start, Load could change the input between the main level and the

transient level when toggled transient operation is in effect.

For example:

When Load receives one trigger signal, Load current will switch between 5A and 10A.

10A

5A

TRG

30

Steps

1. Press

2. Press

Shift

Shift

TRG

Toggled Transient Operation

S-Tran

+

+

, Setting LEVER A=5A, LEVER B=10A, transition mode is TOGGLED.

Tran

to activate the transient mode.

Page 31

3. Press

Shift

+

Trigger

switch to the current value of 10A.

4. Press

5. Press

Shift

Shift

+

+

Trigger

Tran

, switch between 5A and 10A.

again to stop the transient operation.

List Operation

Users can use the front panel keypad or the included software (PV 8500) to program the list sequence. Please refer

to the software user’s guide.

The following example will help you how to do the list operation in front panel.

Trigger

102345

List count=1 List count=2

Steps

1) Press the button of

On/Off

List sequence

, execute the input of Load I in

OFF

state.

2) Press

menu, move cursor to

trigger source mode is panel

3) Press

4) Press

5) Press

6) Press

7) Press

8) Press

9) Press

10) Press

11) Repeat 7) and 8) operation , set current and width of one step 0A, 5mS;2A, 4mS;6A,2mS;0A,5mS.

12) Press

13) Move cursor to Mode Set , press

14) Press

15) Press

16) Press

17) Stop the list operation mode. Move cursor to

menu, press

Shift

Enter

ESC

to the previous menu, move cursor to

Enter

Enter

Enter

Enter

Enter

Enter

Enter

Enter

ESC

,Press

Shift+Trigger

Menu

+

to confirm.

into the next step menu .move cursor to

into the next step menu, move cursor to

, move cursor to REPEAT. Setup LIST is in cycle mode.

to confirm, setup the list steps = 5.

to confirm, setup step 1 current =3A.

to confirm, setup step 1 width=6mS.

to confirm, Menu STORE LIST FILE 1. save file in group1.

to confirm

On/Off

Enter

,

move cursor to the option of menu of

TRIGGER SOURCE

IMMEDIATE

,Make Load in ON state.

, make list operation run or stop.

, enter into next step menu. Select mode is

Enter

. Press

mode.

to enter into the next step menu to set mode is

LIST SET

Enter

LIST SET

EDIT LIST FILE.

CURRENT LIST,

, press

31

and move cursor to

.

CONFIG

Enter

<FIXED MODE>

, Press

select

,

move cursor to

Enter

IMMEDIATE <DEF>,

CURRENT MODE

.

into the next step

<LIST MODE >

Mode

Set in option

setting

.

Page 32

18) Press

Enter

to confirm.

Quick Recall Function

This function allows you to recall 10 groups numbers which were stored previously.

Steps:

1) Press

2) Press

3) Press

4) Press

5) Press

you can get the tenth group number. And if there is not stored number, VFD will show

Shift

▼to CONFIG

Enter

ESC

two times and quit the menu.

1

and you can get the first group number. Pr ess2, you can get the second group number. Press0,

Menu

+

, press

, select

Enter

>>>>ON

into submenu, press▼ to

and press

Enter

to confirm.

SHORTCURT RECALL

NO EEPROM DATA

Automatic Testing Function of Electronic Load

The CD load’s firmware provides an automatic testing function that is convenient for testing various

parameters of power supplies with different load conditions. Now we take a kind of charger as an

example to explain the usage of the automatic testing of the electronic load.

The test proceeding of R35 charger

Work produce process method

The second step None

The first step CC

The third step CC 5

The fourth step CV 3

The fifth step CV 2

The sixth step

Mode Voltage(V) Current(mA) Power(W) Ripple

counter(mVpp)

5.8

~

6.15

5.9

~

6.4

Short

circuit

0 ≤245

210 ≤4(input175VAC)

0 ≤1.2(input175VAC)

205

205

205

~

~

~

245

245

245

≤50mVpp

.

Edit the Testing File

1) Press

2) Press

3) Press

Shift

▼ to >>>>LIST SET

Enter

Menu

+

.

into submenu, press▼ to

into menu, VFD displays

>>>>EDIT LIST FILE

32

>>>>CONFIG

.

Page 33

4) Press

Enter

and begin to edit the automatic testing file, , VFD shows

MAX CURR= ****....**

**A

****

, which means

setting the maximum of voltage. The maximum is bigger than

the maximum is

5) VFD displays

18V

, which means CV is in high value, here ,the maximum is

press

6) VFD displays

1

Press

7) VFD displays

they are 6 steps. Press

8) Setting the mode of current procedure, press

VOLTAGE、、、、CONST POWER、、、、CONST RESIS

CURRENT

9) VFD shows

3A

. Press3and press

MAX VOLT=****....**

Enter

to confirm.

MAX POWER=****....**

+5+0 to set

TEST COUNT=**

6

SETTTT**

**=****....**

****

Enter

**

****

, press

**V

****

**W

****

MAX POWER=150W,

**,

****

to set

to confirm.

, which means setting the current procedure. Here, the first sis

Enter

, which means setting the maximum of voltage, the maximum is bigger than

, which means setting the maximum of power, here, it is150W,

which means setting steps of testing,20 steps are permitted at most, here,

TEST COUNT=6

▲、

. Here, the first step is CC mode, press ▲、▼to

3A

, which means CC mode is in high value, here,

to confirm.

18V

. Press1+8 to set

press

, press

▼to choose one mode in

Enter

Enter

to confirm.

to confirm.

MAX VOLT=18V

CONST CURRENT、、、、CONST

>CONST

0.21A

, press

,

0

、

、2、

10) Setting whether the current procedure is short circuit or not, press ▲、▼to choose one in

SHORT OFF.

11) Select the test number of this step, press▲、▼ to choose

12) VFD displays

、

13) VFD displays

6

、 、1、

14) VFD shows

testing value after inputting the value we settled. To wait for testing after the input stable, the range of prolong

time is

press

press

1

, then press

Here the first step is

MINNNN**

**=****....**

****

8

, press

0~25....

Enter

MAX**

**=****....**

****

5

,then press

DELAY**

**=****....**

****

5 seconds, when the setting is 25

Shift+Trigger

Enter

to confirm.

Enter

**

, which means setting the lower limit. Here, the first step is 5.8V. Press

****

to confirm.

**

, which requests setting the upper limit. Here, the first step is 6.15V, press

****

**

, which means setting the prolong time, that is how long we can read the

****

,the testing will continue. Here, the first step is 1 second, press1and then

to confirm.

SHORT OFF

Enter

SHORT ON

. Press

SHORT OFF

>READBACK V

to confirm.

....

5 seconds, automatic testing will be pause, only the user

, press

Enter

, PRESS

to confirm.

Enter

to confirm.

or

5

、

33

Page 34

15) Repeat 9

A.

B.

C.

D.

E.

16) VFD displays

files and

)~14),

CONST CURRENT,0A,SHORT OFF, READ BACK V, 5.9V, 6.4V,1S

CONST VOLTAGE, 5V, SHORT OFF,READ BACK A, 0.205A, 0.245A,1S

CONST VOLTAGE, 3V, SHORT OFF, READ BACK A, 0.205A,0.245A,1S

CONST VOLTAGE, 2V,SHORT OFF, READ BACK A, 0.205A,0.245A, 1S

CONST CURRENT, 0A, SHORT ON, READ BACK A,0A,0.245A, 1S

LIST

and set the other process step by step as follows:

SHORT TEST FILE*,

files use a common memory area, and the area can contain 8 groups of automatic testing files for

which requests saving the files edited to

EEPROM,

automatically testing

1

next usage. Here, the testing file could be saved in the first group, press

17) When the edition of automatic testing file is finished, press

Enter

and press

two times to back the menu.

Taking out the Testing File Rapidly

1) Press

2) Pr ess▼ and move the menu to

3) Pr ess

4) Press

5) Press

Shift

Enter

▼

and move the menu to

Enter

Menu

+

to enter into submenu, VFD displays

and recall the file edited

to enter into menu, VFD displays

>LIST SET

>CALL TEST FILE

>MODE SET

>>>>CONFIG

Automatic Testing

After editing the automatic testing file, the automatic testing could be carried out by the below steps.

1) Pr ess

FILE1

2) Pr ess

Shift

Enter

I-setI-set

+

to observe the voltage and current we inputted, and also can observe the step number of testing.

to enter into automatic testing, VFD displays the name of current file:

Enter

NAME: TEST

to confirm.

3) Pr ess

one step is 25.5S), press

4) When the automatic testing is finished, the buzzer will hint by tweet (buzzer), VFD reads the result of testing. If the

5) Press

Shift+Trigger

testing passed, VFD reads PASS, or reads FAULT. Pres

of every step.

ESC

to back the automatic testing.

and begin to operate, when the automatic testing is pause (the current prolong time of

Shift

Trigger

+

also can make the testing continue.

s▲、▼

also to observe the numerical value and result

Setting the Resolution and number of decimal points

By selecting the low range and high range, you can measure the voltage and current more precisely.

34

Page 35

Steps:

1) Pr ess

2) Pr ess

3) Pr ess▼to make VFD display

4) Pr ess

5) Pr ess

6) Pr ess

Voltage range: Now you can press

resolution. If the former maximum voltage value was 120V with a resolution of 10mV, it will change to 18V range/

1mV resolution when pressing

decimal points. If the former maximum voltage was 18V, you can press

range, with this setting the resolution will change accordingly to 10mV.

Current range: Press +▼ to select the maximum current range. If the former maximum current value is

12A and the resolution is 1mA, it will now be set to 120A max/10mA resolution. By pressing

will get 2 decimal points (xx.xx) compared to 3 decimal points. To toggle from the 120A to the 12A range, press

Shift

Enter

Enter

Enter

ESC

to exit menu

+▲, now the resolution will be set to 1mA.

Menu

+

into the submenu, VFD displays

to confirm, and press▼to choose ON

to confirm

to enter into menu, VFD displays

>INITIAL CONFIG

RANGE SELECT

+▲ , and the display will show 3 decimal points (xx.xxx) as opposed to 2

+▲ to switch from the maximum range to the lower range and high

>CONFIG

+▼ to set the instrument to 120V

+▼, you

Specifications

Parameter 8510

Voltage 0 to 120V

Input rating

Load

Regulation

Regulation

Regulation

CR Mode Regulation

Input current ≥FS 10%

Input Voltage≥FS 10%

Current 1mA to120A

Power 600 W

Range Accuracy Resolution

0-18V ±(0.05%+0.02%FS) 1mV

0-120V ±(0.05%+0.025%FS) 10mV

0-12A ±(0.1%+0.1%FS) 1mA

0-120A ±(0.2%+0.15%FS) 10mA

0.1-18V ±(0.05%+0.02%FS) 1mV CV Mode

0.1-120V ±(0.05%+0.025%FS) 10mV

0-12A ±(0.1%+0.1%FS) 1mA CC Mode

0-120A ±(0.2%+0.15%FS) 10mA

0.1 -10Ω ±(1%+0.3%FS) 0.001Ω

10-99Ω ±(1%+0.3%FS) 0.01Ω

100-999Ω ±(1%+0.3%FS) 0. 1Ω

1K-4KΩ ±(1%+0.8%FS) 1Ω

35

Page 36

CW Mode Regulation

Input current ≥FS 10%

Input Voltage≥FS 10%)

Current Measurement

Voltage Measurement

Power Measurement

Input current≥FS 10%

Input Voltage≥FS 10%

Battery testing function

Transition Mode

Weight 30.8 lb. (14kg)

0-100W ±(1%+0.1%FS) 1mW

100-600W ±(1%+0.1%FS) 100mW

0-12A ±(0.1% + 0.1%FS) 1mA

0-120A ±(0.2%+0.15%FS) 10mA

0-18V ±(0.02% + 0.02%FS) 1mV

0-120V ±(0.02% + 0.025%FS) 10mV

0-100W ±(1%+0.1%FS) 1mW

100-600W ±(1%+0.1%FS) 100mW

)

Range o Frequency 0.1Hz-1kHz Frequency error rate<0.5%

NOTE:

the most current product information.

Specifications and information are subject to change without notice. Please visit www.bkprecision.com for

Input=0.8-120V Max measurement capacity= 999A/H

Resolution =10mA Timer range=1~60000sec

Remote Operation Mode

The DB9 connector in the rear panel of the electronic load can be connected to a RS-232 or USB

interface via a communication cable. The following information may help you to know how to control

the input of electronic load through PC.

1 Communication cable

IT-E131 RS232 Communication cable

The DB9 interface connector on the rear panel of electronic load is TTL voltage level; you can use the communication

cable (IT-E131) to connect the DB9 interface connector of the electronic load and the RS-232 interface connector of

computer for the communication.

IT-E131 communication

cable

PC Load

COMPUTER

IT-E131 ISOLATED

IT

COMMUNICATION CABLE

859666668889942311

RX

TTL(5V)RS232 ISOLATION

TX

INSTRUMEN T

IT-E132 USB Communication cable

36

Page 37

The DB9 interface connector on the rear panel of electronic load is TTL voltage level; you can use the communication

cable (IT-E132) to connect the DB9 interface connector of the electronic load and the USB interface connector of

computer for the communication.

IT-E131 communication

IT-E132 communication

cable

PC Load

Note:

Do not connect the DB9 connector of the electronic load directly to a PC or other RS232 port.

COMPUTER

IT-E131 ISOL ATED

IT

COMMUNICATION CABLE

859666668889942311

RX

TTL(5V)RS232 ISOLATION

TX

INSTRU MENT

2 Communication between electronic load and PC

Before using the remote operation mode, please make sure that the baud rate and communication address in

electronic load are the same as in the computer software, otherwise, the communication will fail, you can change the

baud rate and communication address from the front panel or from computer.

.

Address: the range is from 0 to 254,default setting is 0

1

.

Baud rate: 4800,9600,19200 and 38400 are selectable, default setting is 4800

2

.

Data bit:8 bit

3

.

Stop bit:1

4

.

Parity:None

5

Parity=None

Start Bit

8 Data Bits

Stop Bit

Stop Bit

3. Frame Format

Frame length is 26 bytes. Details as following:

AAH Address Command 4—25bytes are information content Parity code

Description ::::

1. Start bit is AAH,occupies one byte.

2

.

Address range from 0 to FE, occupies one byte.

.

Each command occupies one byte. Following is the command details.

3

20H Selecting the Remote control mode

21H Selecting the input on/off state

22H Setting the max input voltage

23H Reading the max setup input voltage.

24H Setting max input current

37

Page 38

25H Reading the max setup input current.

26H Setting max input power.

27H Reading the max setup input power.

28H Selecting CC/CV/CW/CR operation mode of Electronic load.

29H Reading the operation mode.

2AH Setting CC mode current value

2BH Reading CC mode current value

2CH Setting CV mode voltage value

2DH Reading CV mode voltage value

2EH Setting CW mode watt value

2FH Reading CW mode watt value

30H Setting CR mode resistance value

31H Reading CR mode resistance value

32H Setting CC mode transient current and timer parameter.

33H Reading CC mode transient parameter

34H Setting CV mode transient voltage and timer parameter.

35H Reading CV mode transient parameter

36H Setting CW mode transient watt and timer parameter

37H Reading CW mode transient parameter

38H Setting CR mode transient resistance and timer parameter

39H Reading CR mode transient parameter

3AH Selecting the list operation mode (CC/CV/CW/CR)

3BH Reading the list operation mode.

3CH Setting the list repeat mode (ONCE / REPEAT)

3DH Reading the list repeat mode.

3EH Setting the number of list steps.

3FH Reading the number of list steps

40H Setting one of the step’s current and time values.

41H Reading one of the step’s current and time values.

42H Setting one of the step’s voltage and time values.

43H Reading one of the step’s voltage and time values

44H Setting one of the step’s power and time values

45H Setting one of the step’s power and time values.

46H Setting one of the step’s resistance and time values

47H Reading one of the step’s resistance and time values

48H Setting list file name.

49H Reading list file name.

4AH Selection the memory space mode for storing list steps.

4BH Reading the memory space mode for storing list steps.

4CH Save list file in appointed area.

4DH Get the list file from the appointed area.

4EH Setting min voltage value in battery testing mode.

4FH Reading min voltage value in battery testing mode

50H Setting timer value of FOR LOAD ON

38

Page 39

51H Reading timer value of FOR LOAD ON

52H Disable/Enable timer of FOR LOAD ON

53H Reading timer state of FOR LOAD ON

54H Setting communication address

55H Enable/Disable LOCAL control mode.

56H Enable/Disable remote sense mode.

57H Reading the state of remote sense mode.

58H Selecting trigger source.

59H Reading trigger source.

5AH Sending a trigger signal to trigging the electronic load.

5BH Saving user’s setting value in appointed memory area for recall.

5CH Recall user’s setting value in appointed memory area.

5DH Selecting FIXED/SHORT/TRAN/LIST/BATTERY function mode.

5EH Getting function mode state.

5FH Reading input voltage, current, power and relative state

60H Enter the calibration mode

61H Getting the calibration mode state.

62H Calibrate voltage value.

63H Sending the actual input voltage to calibration program.

64H Calibrate current value.

65H Sending the actual input current to calibration program.

66H Store the calibration data to EEPROM.

67H Setting calibration information.

68H Reading calibration information.

69H Restore the factory default calibration data.

6AH Reading product’s model, series number and version information.

6BH Reading the information of bar code.

6CH Setting information of bar code

12H The return information of command operation in electronic load.

NOTE

If control output of electronic through PC, please setting Electronic load is on

PC control state. Command is 20H. Make a calibration on input of electronic

Load, Ensure the calibration protection mode is OFF state when setting calibration information.

If electronic load in calibration mode, user’s can’t change the input and operation mode of electronic load

4. From 4th byte to 25th byte are information contents.

.

26th is sum code, is the sum of the former 25 bytes.

5

4. Communication Protocol

1. Selecting the Remote control mode

1st byte Start bit ( AAH )

((((

20H

39

))))

Page 40

2nd byte Address (0—0XFE)

3rd byte

Command

(

20H)

4th .byte

From 5th to 25th byte System reserve

26th byte Sum code

Operation mode

(

0 is front panel operation mode ,1 is remote operation mode )

NOTE

Front panel operation state is not in effect if electronic load is in calibration mode.

2. Selecting the input on/off state

1st byte Start bit ( AAH )

2nd byte Address(0—0XFE)

3rd byte

4th byte

From 5th to 25th byte System reserve

From26th byte Sum code

Command

Input state

(

(

((((

21H

))))

21H)

0 is OFF,1is ON)

((((

3. Setting / Reading max input voltage

1st byte Start bit ( AAH )

2nd byte Address (0—0XFE)

3rd byte

Command

(

22H/23H)

22H/23H

))))

4th byte The Lowest byte of max voltage value

5th byte The lower byte of max voltage value.

6th byte The higher byte of max voltage value.

7th byte The highest byte of max voltage value.

From 8th to 25th byte System reserve.

26th byte Sum code.

NOTE

Represent a voltage upper limit value by 4 bytes of Hex. Lower bytes are in the front location, higher bytes are in the

later location. 1 represent 1mV.For Example : The voltage upper limit is 16.000V

the 4th byte is 0XB0

,

5th byte is 0X3E,6th byte is 0X00,7TH byte is 0X00.

,

the hex code is 0X00003EB0,then

4. Setting / Reading the max input current .

1st byte Start bit ( AAH )

2nd byte Address(0—0XFE)

40

((((

24H/25H

))))

Page 41

3rd byte

4th byte The Lowest byte of max current value

5th byte The Lowest byte of max current value

6th byte The higher byte of max current value

7th byte The highest byte of max current value

From 8th to 25th byte System reserve

26th bye Sum code

Command

(

24H/25H)

NOTE

Represent an current value by 4 bytes of Hex .Lower bytes are in the front location, higher bytes are in the later

location.1 represent 0.1mA,If setting upper limit is

5th is

0X75,

6th is 0X00,7th is

0X00。

3.0000A,

the hex code is

0X00007530,

then the 4th byte is

((((

5. Setting / Reading max input power

1st byte Start bit ( AAH )

2nd byte Address (0—0XFE)

3rd byte

4th byte The lowest byte of max power value.

5th byte The lower byte of max power value

6th byte The higher byte of max power value.

7th byte The highest byte of max power value.

From 8th to 25th byte System reserve

26th byte Sum code

Command

(

26H/27H)

26H/27H

))))

NOTE

Represent power value by 4 bytes of Hex. Lower bytes are in the

Front location, higher bytes are in the later location. 1 represents 1mW. If setting upper value is

0X00030d40,

code is

5th is

0X40,

0X0d,

then the 4th byte is

6th is 0X03,7th is

0X00.

200.000W,

the hex

6. Selecting / Reading CC/CV/CW/CR operation mode of Electronic load.

1st byte Start bit ( AAH )

2nd byte Address (0—0XFE)

3rd byte

Command

(

28H/29H)

((((

28H/29H

0X30,

))))

4th byte

From 5th to 25th byte System reserve

26th byte Sum code

Mode

(

0 is CC mode, 1 is CV mode , 2 is CW mode , 3 is CR mode )

41

Page 42

7. Setting / Reading CC mode current value

1st byte Start bit ( AAH )

2nd byte Address (0—0XFE)

3rd byte

4th byte The lowest byte of current value

5th byte The lower byte of current value.

6th byte The higher byte of current value.

7th byte The highest byte of current value.

From 8th To 25th byte System reserve

27th byte Sum code

Command

(

2AH/2BH)

((((

2AH/2BH

))))

NOTE

Represent current by 4 bytes of Hex. Lower bytes are in the front location, higher bytes are in the later location. For

example: current is

NO. 7 bye is

0X00。

3.0000A,

Hex code is

0X00007530,

NO. 4 bye is

0X30,

NO. 5 bye is

0X75,

NO. 6 bye is 0X00

8. Setting / Reading CV mode voltage value.

1st byte Start bit ( AAH )

2nd byte Address (0—0XFE)

3rd byte

4th byte The lowest byte of voltage value.

5th byte The lower byte of voltage value.