Page 1

INSTRUCTION

MANUAL

El Manual de la Instrucción

Manual de Instruccion

MODEL 1735A

MODELO 1735A

0-30V, 0-3A

DC POWER SUPPLY

With Dual 4-Digit LED Displays

Fuente de poder DC

Con doble LED indicador

Page 2

TEST INSTRUMENT SAFETY

WARNING

Normal use of test equipment exposes you to a certain amount of danger from electrical shock because testing must sometimes be

performed where exposed high voltage is present. An electrical shock causing 10 milliamps of current to pass through the heart will stop

most human heartbeats. Voltage as low as 35 volts dc or ac rms should be considered dangerous and hazardous since it can produce a

lethal current under certain conditions. Higher voltages are even more dangerous. Your normal work habits should include all accepted

practices to prevent contact with exposed high voltage, and to steer current away from your heart in case of accidental contact with a

high voltage. Observe the following safety precautions:

1. There is little danger of electrical shock from the dc output of this power supply. However, there are several other possible test

conditions using this power supply that can create a high voltage shock hazard:

a. If the equipment under test is the “hot chassis” type, a serious shock hazard exists unless the equipment is unplugged (just turning

off the equipment does not remove the hazard), or an isolation transformer is used.

b. If the equipment under test is “powered up” (and that equipment uses high voltage in any of its circuits), the power supply outputs

may be floated to the potential at the point of connection. Remember that high voltage may appear at unexpected points in

defective equipment. Do not float the power supply output to more than 100 volts peak with respect to chassis or earth ground.

c. If the equipment under test is “off” (and that equipment uses high voltage in any of its circuits under normal operation), discharge

high-voltage capacitors before making connections or tests. Some circuits retain high voltage long after the equipment is turned

off.

2. Use only a polarized 3-wire ac outlet. This assures that the power supply chassis, case, and ground terminal are connected to a good

earth ground and reduces danger from electrical shock.

3. Don’t expose high voltage needlessly. Remove housings and covers only when necessary. Turn off equipment while making test

connections in high-voltage circuits. Discharge high-voltage capacitors after removing power.

(continued on inside back cover)

2

Page 3

Instruction Manual

for

Model 1735A

0-30 V, 0-3 A

DC POWER SUPPLY

With Dual LED Display

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

3

Page 4

Page

Page

TABLE OF CONTENTS

TEST INSTRUMENT SAFETY ----------------inside front cover

INTRODUCTION------------------------------------------------------5

FEATURES -------------------------------------------------------------6

SPECIFICATIONS ----------------------------------------------------7

CONTROLS AND INDICATORS----------------------------------9

OPERATING INSTRUCTIONS---------------------------------- 11

Safety Precautions--------------------------------------------------11

Equipment Precautions--------------------------------------------11

Hook-Up -------------------------------------------------------------11

Typical Constant Voltage Operation -------------------------- 14

Setting Current Limit ----------------------------------------------15

Typical Constant Current Operation--------------------------- 16

Constant Voltage/Constant Current Characteristic----------17

Connecting Two Power Supplies in Series------------------- 17

Connecting Two Power Supplies in Parallel------------------20

APPLICATIONS----------------------------------------------------21

General--------------------------------------------------------------21

Electronics Servicing --------------------------------------------21

Electronics Manufacturing--------------------------------------21

Electronics Design Lab ------------------------------------------22

Electronics Education--------------------------------------------22

Battery Charging--------------------------------------------------22

MAINTENANCE ----------------------------------------------------23

Fuse Replacement ------------------------------------------------23

Line Voltage Conversion----------------------------------------23

Adjustments --------------------------------------------------------23

1735A Calibration ------------------------------------------------26

Instrument Repair Service --------------------------------------25

WARRANTY SERVICE INSTRUCTIONS--------------------27

LIMITED TWO-YEAR WARRANTY--------------------------28

SPANISH MANUAL-----------------------------------------------30

4

Page 5

The

B+K Precision

Model

1735A

DC Power Supply is a high

Current limits are adjustable from 5% to 100% of maximum.

INTRODUCTION

quality, general purpose dc power source. It provides 0-30 volts

dc output, adjustable with both coarse and fine voltage controls

for precise settability. The current output is 0-3 amps, adjustable

with both coarse and fine current controls. Two large LED

meters continuously monitor the output voltage and current. The

VOLTAGE meter is green, while the CURRENT meter is red.

The Model 1735A exhibits excellent regulation and low ripple

characteristics. The circuit design incorporates a pre-regulator,

which greatly reduces internal power dissipation at low output

voltages. The styling is both attractive and functional. The

mechanical configuration conserves bench space and allows for

easy portability.

This instrument may be used in constant voltage or constant

current applications. The crossover from constant voltage to

constant current modes is smooth and automatic. LED’s indicate

the “CV” (constant voltage) or “CC” (constant current) mode of

operation. In constant voltage applications, a current limit may

be preset. When load variations cause the current to reach the

preset limit, the unit then regulates output current rather than

output voltage.

In constant current applications, the maximum voltage may

be preset. When load variations cause current to drop below

the regulated value, the unit reverts to regulated voltage

operation at the preset value.

Reverse polarity protection prevents accidental damage to

the power supply from improper connection to an external

voltage, and current limiting protects the equipment being

powered, as well as the power supply.

The output is isolated from chassis and earth ground,

which permits full flexibility of connections. When needed,

the (+) or (-) polarity may be strapped to ground, or either

polarity may be floated to an external voltage. Two sup plies

may be connected in series as a 0-to-60 volt power source, or

two supplies may be connected in parallel, with suitable

balancing resistors, for up to twice the output current.

This power supply is well suited for a wide variety of

electrical and electronics applications, including service

shops, engineering labs, production testing, school

laboratories, and home use by hobbyists.

5

Page 6

0-30 VOLTS

LED INDICATORS

Continuously variable over 0-to-30 volt range with coarse and fine

controls.

0-3 AMPS

0-to-3 amp current rated for continuous duty at full output current.

Coarse and fine current adjust controls.

LABORATORY QUALITY

Excellent regulation, low ripple.

CONSTANT VOLTAGE OR CONSTANT CURRENT

Provides regulated dc voltage output or regulated dc current output.

Crossover is smooth and automatic.

LED DISPLAYS

Two large, easy -to-read LED digit displays monitors output voltage

and output current, and provides good visibility in bright or low

light.

FEATURES

Act as pilot light and identify mode of operation and

metering.

PRE -REGULATOR

Limits internal dissipation for higher reliability.

ISOLATED OUTPUT

Either polarity may be floated or grounded.

OVERLOAD PROTECTION

Fully adjustable current limiting (from 5% to 100% of

maximum output current) protects circuit under test and the

power supply.

REVERSE POLARITY PROTECTION

Prevents damage to power supply from external voltage of

reverse polarity.

STYLING

Modern functional styling. Configuration conserves bench

space and aids portability. Logical, convenient layout of

controls.

6

Page 7

SPECIFICATIONS

OUTPUT VOLTAGE:

0 to 30

VDC, coarse and fine

Line (108

-

132

V): 0.2% + 3mA

adjustment.

OUTPUT CURRENT: 0 to 3A, coarse and fine adjustment.

CONSTANT VOLTAGE OPERATION

Voltage Regulation

Line (108-132 V): 0.01% + 3mV.

Load (no load to full load): 0.01% + 3mV.

Recovery Time: 100 µs typical.

Ripple Voltage

Peak-to-Peak: 2mV, typical

RMS: 1mV.

Temperature Coefficient

(0° to +35 °C): 300 PPm/°C

CONSTANT CURRENT OPERATION

Adjustable Current Limits: 5% to 100%

Current Regulation

Load 0.2% + 3mA

Current Ripple: 3mA typical.

METERING

Voltmeter 4 digit Green LED Display

Range: 0 to 99.99 V.

Accuracy: (0.5% + 9 digits)*.

Ammeter 4 digit Red LED Display

Range: 0 to 9.999A.

Accuracy: (0.5% + 9 digits)*.

(* = see note 1 at end of specifications)

POWER REQUIREMENTS:

Domestic: 120 VAC ±10%, 60 Hz

International: 120/220/230/240 VAC - 10%, 50/60 Hz

POWER CONSUMPTION: Approximately 180W or less at

full load.

PROTECTION: Reverse polarity protection,

Current limiting.

7

Page 8

SPECIFICATIONS

TEMPERATURE RANGE

WEIGHT:

10.5 lb.

Operation: 0° to +40° C, 75% R.H.

Storage: -15° to +70° C, 85% R.H.

DIMENSIONS (HxWxD): 6.2 x 5.5 x 12.5"

NOTE: Specifications and information are subject to change without notice. Please visit www.bkprecision.com for the most current product

information.

Note 1:

Important: Even with noticeable Thermal Drift, this high resolution power supply will be considerably more accurate than any standard

three digit display bench power supply.

Thermal Drift: Since this power supply has greater resolution than standard bench power supplies they are more susceptible to Thermal

Drift. Thermal Drift occurs on almost every type of power supply but is more apparent on high resolution types. Thermal Drift results in

the metering of the power supply to either slowly increase or decrease with the change in the power supply’s internal temperature. As the

power supply outputs more power its internal temperature will increase causing the metering (primarily the current) to slowly increase. As

the power demand is deceased the power supply will cool causing the metering (primarily the current) to slowly decrease. If the power

supply remains with a constant output of power for more than fifteen minutes the power supply metering will remain constant and should

not continue to drift.

ACCESSORIES SUPPLIED: Instruction Manual,

Spare Fuse

8

Page 9

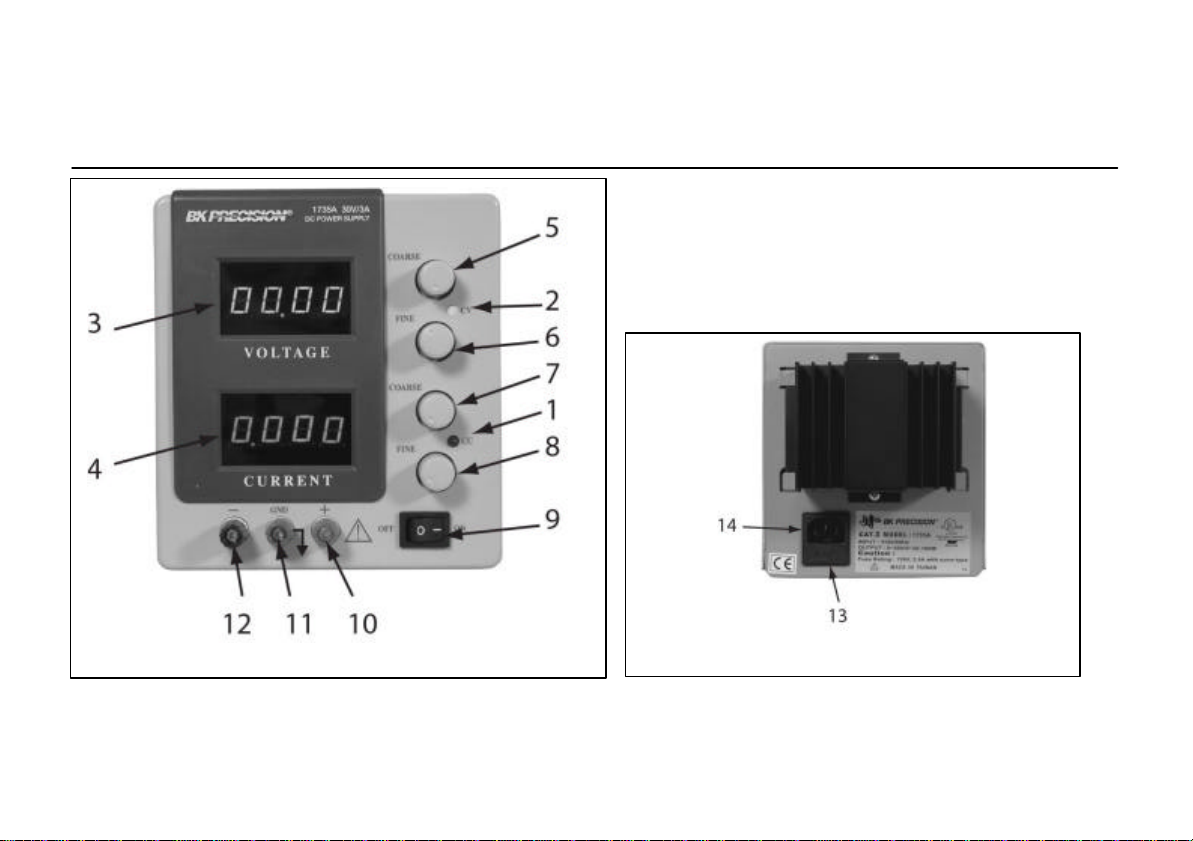

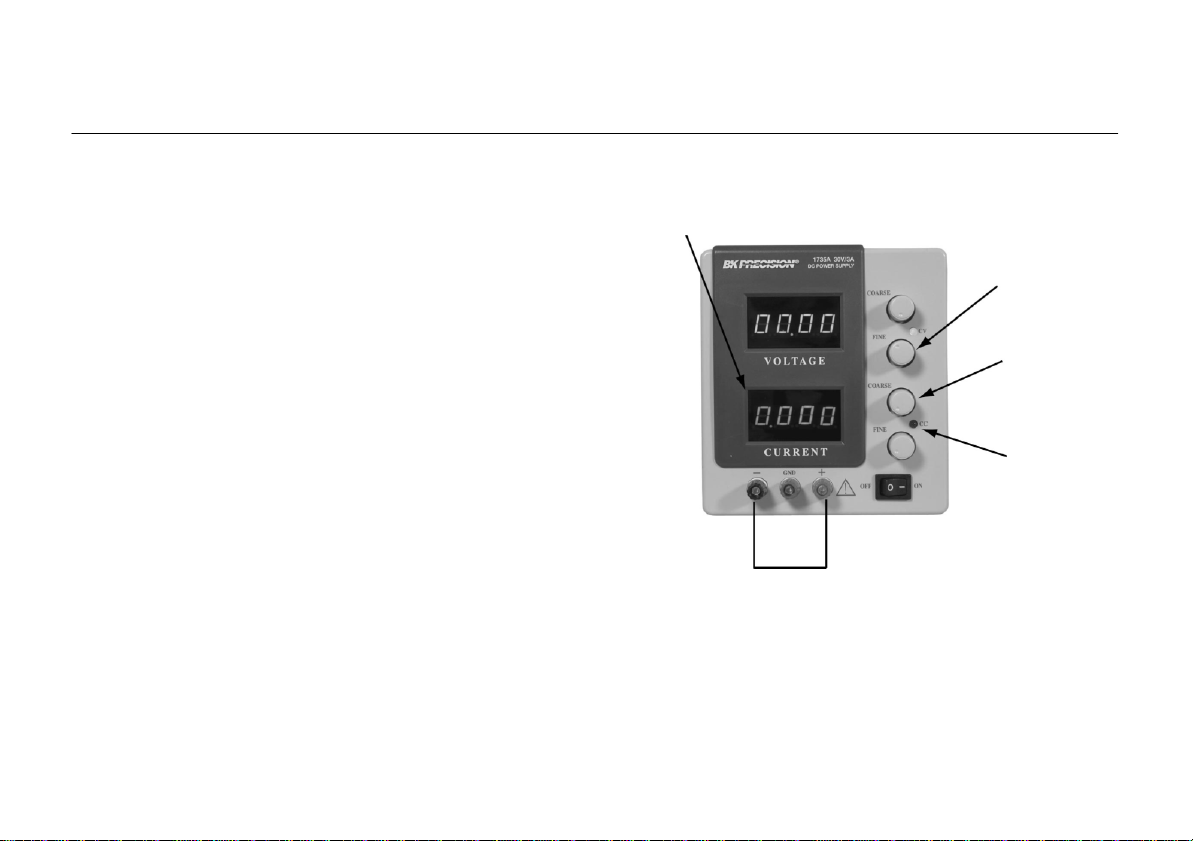

INDICATORS

CURRENT CONTROL

CONTROLS AND INDICATORS

Either the “CC” or “CV” and the LED indicators will be lit

whenever the unit is operating, thus serving as a pilot light. The unit

automatically changes from CV to CC operation when the preset

current limit is reached.

1. C.C. (Constant Current) Indicator. Red LED lights in constant

current mode. Unit regulates output current at value set by CURRENT controls.

2. C.V. (Constant Voltage) Indicator. Green LED lights in

constant voltage mode. Unit regulates output voltage at value set

by VOLTAGE controls.

3. GREEN LED Display. 4 digit display continuously monitors

voltage.

4. RED LED Display. 4 digit display continuously monitors

current.

VOLTAGE CONTROLS

5. Coarse Control. Coarse adjustment of output voltage. Read value

on GREEN LED display.

6. Fine Control. Fine adjustment of output voltage. Read value on

GREEN LED display.

7. Coarse CURRENT Control. Adjusts current limit in

constant voltage mode. Adjusts constant current value in

constant current mode. Current can be read from RED

LED display.

8. Fine Control. Adjusts current limit in constant voltage

mode. Adjusts constant current value in constant current

mode. Current can be read from RED LED display.

POWER CONTROLS

9. ON-OFF Switch.

OUTPUT TERMINALS

10. “+” Terminal (Red). Positive polarity output terminal.

11. GND Terminal. Earth and chassis ground.

12. “-” Terminal (Black). Negative polarity output

terminal.

9

Page 10

Figure 1. Front Panel Controls and Indicators.

Figure 2.

Rear Panel

REAR PANEL CONTROLS

CONTROLS AND INDICATORS

13. Fuse.

14. Power Cord.

15. 110/220 Line Voltage Conversion Switch.

10

Page 11

SAFETY PRECAUTIONS

the equipment under test.

Do not exceed the voltage rating of the circuit being powered.

OPERATING INSTRUCTIONS

Use only a polarized 3- wire ac outlet. This assures that the power

supply chassis, case, and ground terminal are connected to a good

earth ground and reduces danger from electrical shock.

There is little danger of electrical shock from the power supply

output, which produces a maximum of 30 volts dc. However, there

may be great danger of electrical shock if the power supply

output is connected to an external high voltage. Some equipment

being powered may contain high voltage and present a shock

hazard. Observe caution. If the power supply output is floated

(referenced to a voltage rather than earth ground) turn off the power

supply and the equipment under test when making connections.

Never float the power supply to a potential greater than 100 volts

peak with respect to earth ground.

EQUIPMENT PRECAUTIONS

Avoid using the power supply in ambient temperatures above

+40° C. Always allow sufficient air space around the heat sink at

the rear of the power supply for effective radiation to prevent

internal heat build- up.

Although the power supply is protected against reverse polarity

damage, the circuit being powered may not include such protection.

Always carefully observe polarity; incorrect polarity may damage

Many transistors and integrated circuits will not withstand

voltage of 30 volts.

There is no need to worry about voltage spikes or overshoot

damaging the equipment under test. The voltage between the

output terminals of the power supply never exceeds the preset

value as the POWER switch is turned on or off.

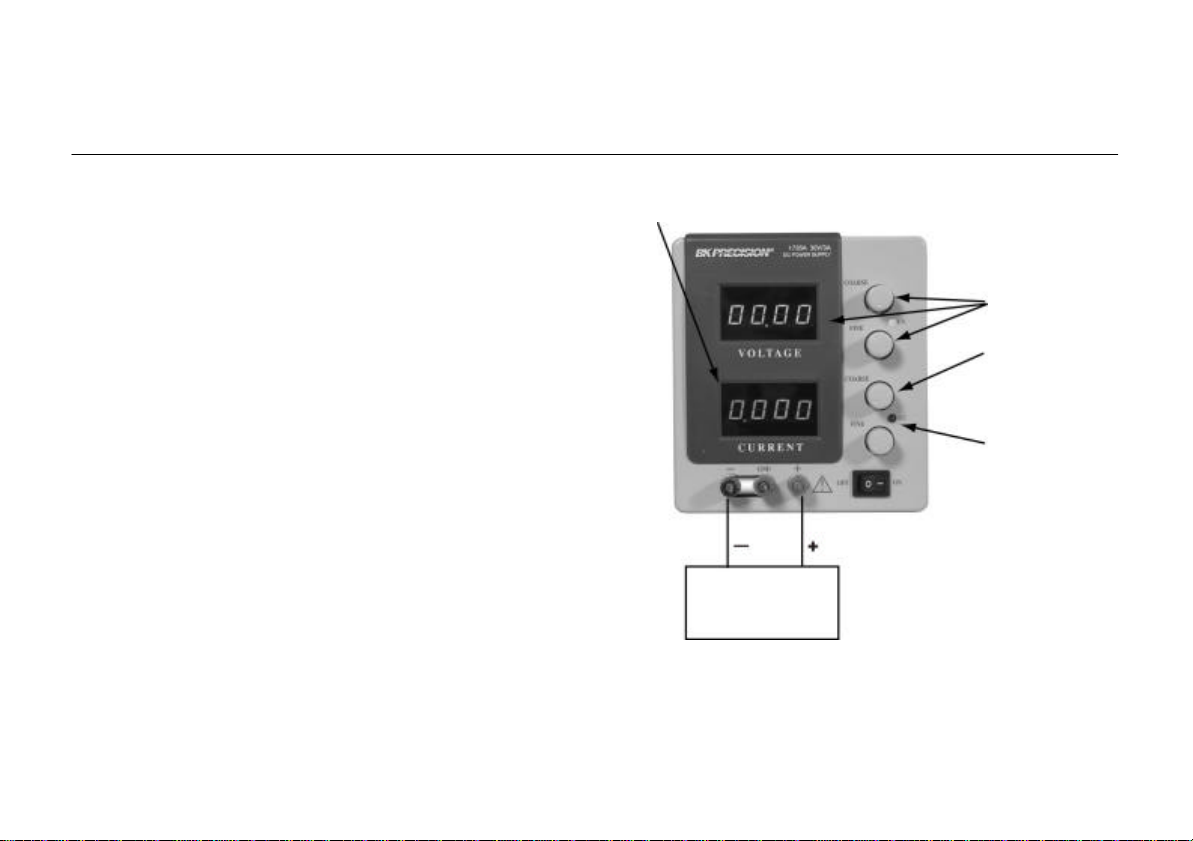

HOOK- UP

1. Turn off the power supply and the equipment to be powered

during hook- up.

2. Connect the positive polarity of the device being powered to

the red (+) terminal of the power supply.

3. Connect the negative polarity of the device being powered

to the black (-) terminal of the power supply.

4. Fig. 3 illustrates the grounding possibilities.

a. If the negative polarity of the equipment or circuit being

powered is also the chassis or common, it may be

grounded to earth by strapping the black (-) terminal to

the green ( ) terminal as shown in Fig. 3A.

b. Similarly, the positive polarity can be grounded by

strapping the red (+) terminal to the green ( ) terminal as

shown in Fig. 3B.

11

Page 12

OPERATING INSTRUCTIONS

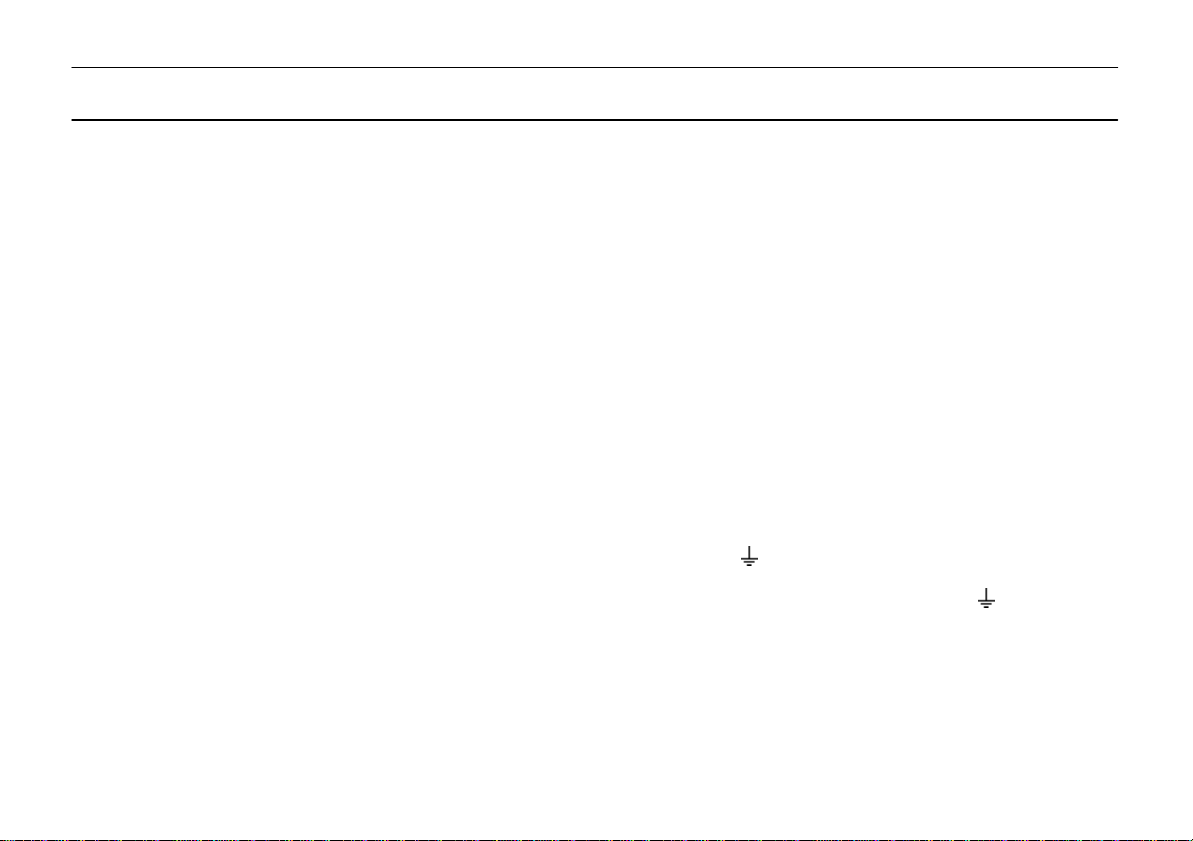

Figure 3 (A and B). Grounding Possibilities.

B. Grounded, common with

A. Grounded, common with

Equipment

Equipment

Strap

negative polarity

Being Powered

Strap

positive polarity

12

Being Powered

Page 13

OPERATING INSTRUCTIONS

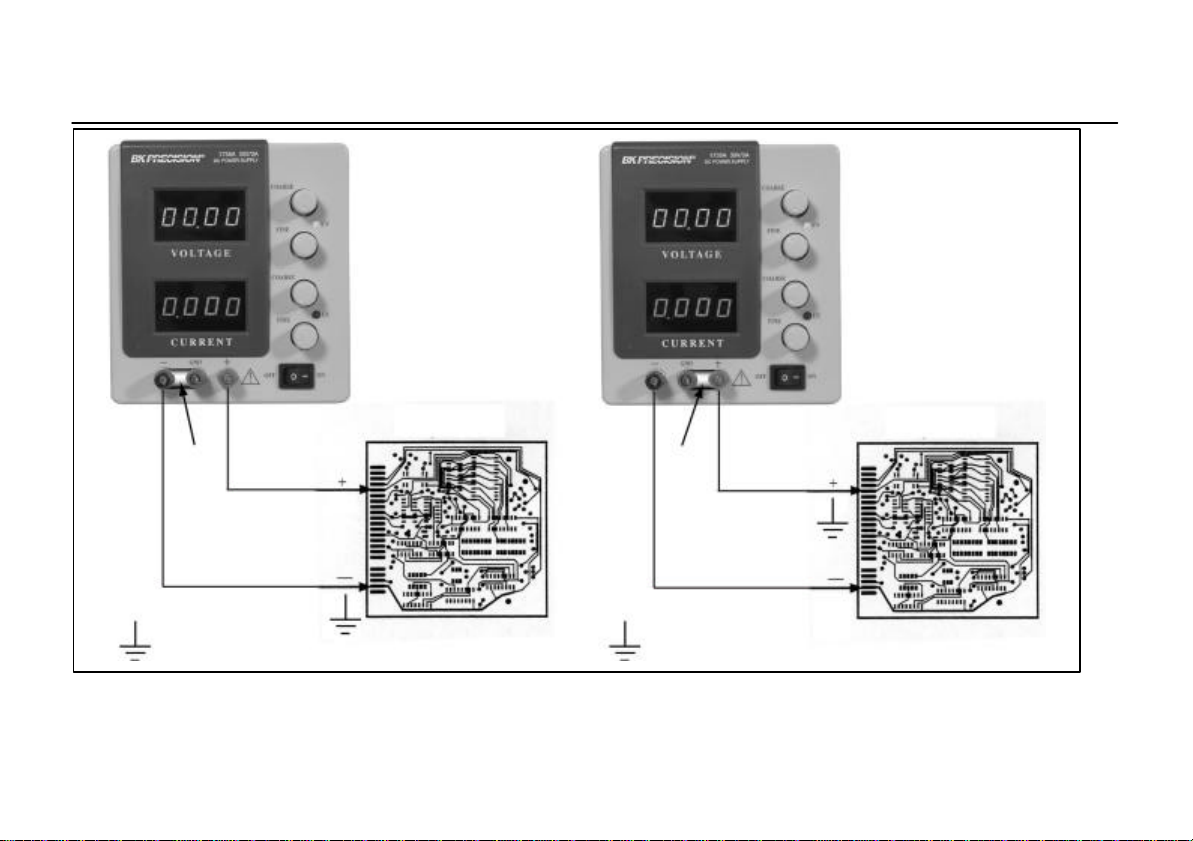

Figure 3 (C and D). Grounding Possibilities.

D. Grounded, not common with

No

No

Equipment

Equipment

Strap

Being Powered

Strap

Being Powered

C. No ground reference

Negative or positive polarity.

13

Page 14

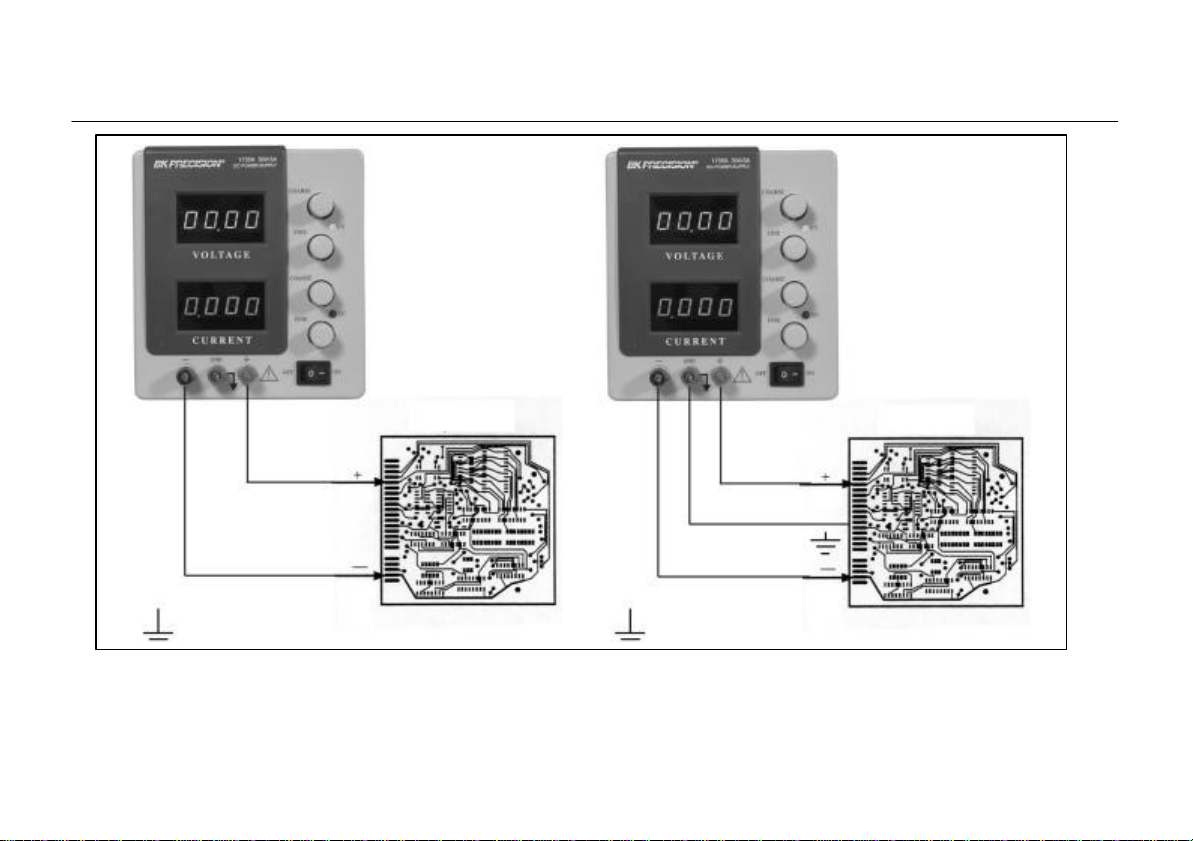

Figure 4. Typical Constant Voltag

e Operation.

c. If an earth ground reference is not required, the

Read output voltage and

Adjust to

CV Indicator on

OPERATING INSTRUCTIONS

configuration of Fig. 3C may be used. The scheme in Fig.

3C should also be used where it is not known whether the

chassis is common with either the positive or negative

polarity.

d. If the chassis or common of the equipment being powered is

separate from both the positive and negative polarity power

inputs, use the connection shown in Fig. 3D.

6. Observe proper polarity. If the circuit being powered is not

equipped with reverse polarity protection, damage to the circuit

can result from reverse polarity. Use color coded hook-up leads,

for conven ience in identifying polarity, red for (+) and black for

(-).

7. Make sure that the hook-up leads offer sufficient current

capability and low resistance between the power supply and the

circuits being powered.

TYPICAL CONSTANT VOLTAGE OPERATION

1. Before connecting the device to be powered to the power

supply, determine the maximum safe load current for the device

to be powered and set the current limit value (see “Setting

Current Limit” procedure in this section).

2. Set Fine VOLTAGE control to center and Coarse VOLTAGE

control to minimum (fully counterclockwise).

3. Turn off power supply and connect it to the device to be

powered (see “Hook -Up” procedure in this section).

4. Turn on POWER switch. The CV indicator should light.

14

Current meters

Desired voltage

Present current

limiting

Load

Page 15

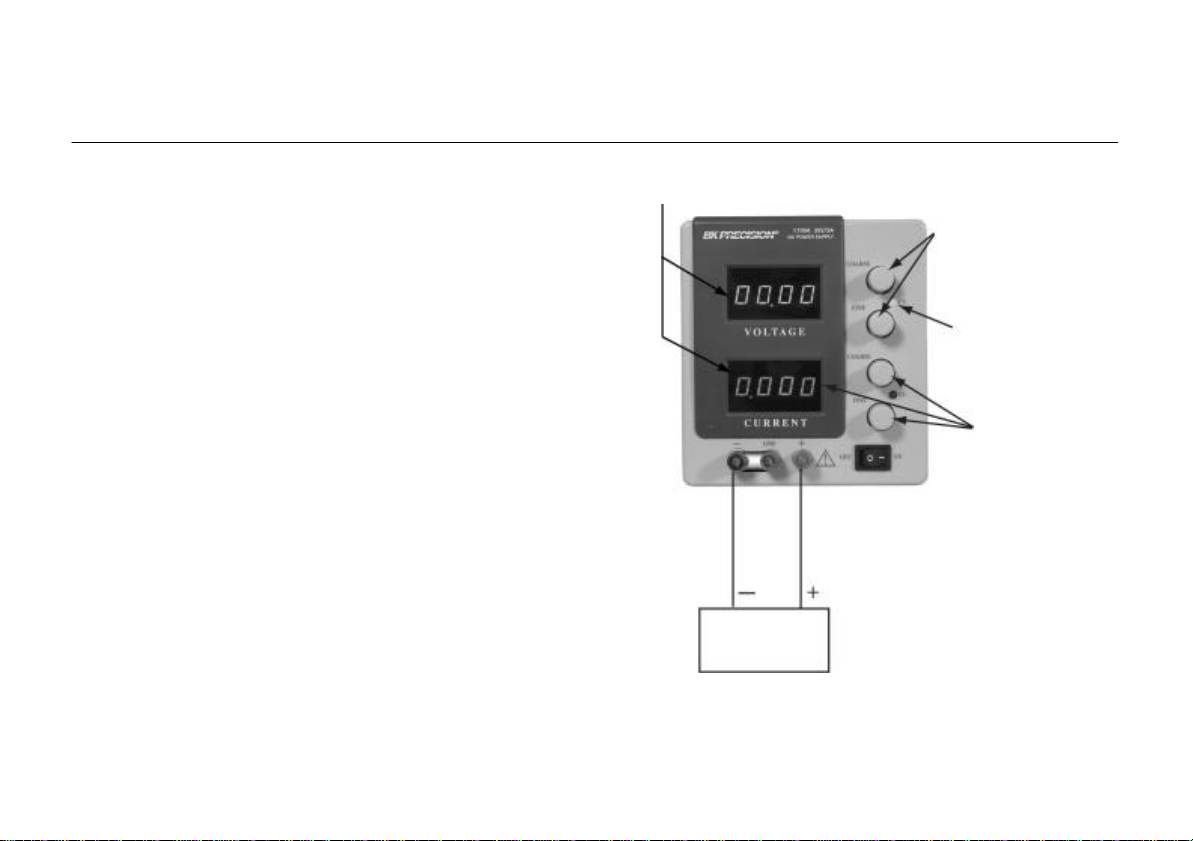

Figure 5. Settin

g Current Limit.

5. Increase the

VOLTAGE

setting until the Voltage LED display

Midrange

CC

Read current limit

Temporarily short

reads the desired value. The FINE control permits easier setting

to a specific value.

6. Note the load current on the Current LED display.

7. If the load current exceeds the preset current limit, the CV

indicator will go off and the CC indicator will light. In this case,

the power supply automatically switches to the constant current

mode, and further rotation of the VOLTAGE control will not

increase the output voltage.

SETTING CURRENT LIMIT

1. Determine the maximum safe current for the device to be

powered.

2. Temporarily short the (+) and (-) terminals of the power

supply together with a test lead.

3. Rotate the Coarse VOLTAGE control away from zero

sufficiently for the CC indicator to light.

4. Adjust the Coarse and Fine CURRENT control for the desired

current limit. Read the current value on the Current LED

display.

5. The current limit (overload protection) has now been preset. Do

not change the CURRENT controls settings after this step.

6. Remove the short between the (+) and (-) terminals and hook

up for constant voltage operation.

OPERATING INSTRUCTIONS

Value from meter

Adjust to

desired

current limit

(+) to (-)

15

Page 16

Figure 6. Typical Constant Current Operation.

TYPICAL CONSTANT CURRENT OPERATION

Read output current

Preset voltage limit

OPERATING INSTRUCTIONS

1. Before connecting the device to be powered to the power supply,

determine the maximum safe voltage to be applied, and set the

VOLTAGE controls to obtain that voltage reading on the Voltage

LED display.

2. Determine the desired constant current value.

3. Set the Coarse and Fine CURRENT control to minimum (fully

counterclockwise).

4. Turn off the power supply and connect it to the device to be

powered.

5. Turn on the power supply. The CC indicator should light.

6. Increase the Coarse and Fine CURRENT control setting until the

desired constant current value is read on the display, or set the

current limit in advance (before connecting the load) as prescribed

in the earlier “Setting Current Limit” procedure.

7. If the load current drops below the constant current value, the CC

indicator will go off and the CV indicator will light. In this case,

the power supply automatically switches to the constant voltage

mode, and further rotation of the CURRENT controls will not

increase the output current.

on meter

Adjust to desired

current

CC Indicator on

Load

16

Page 17

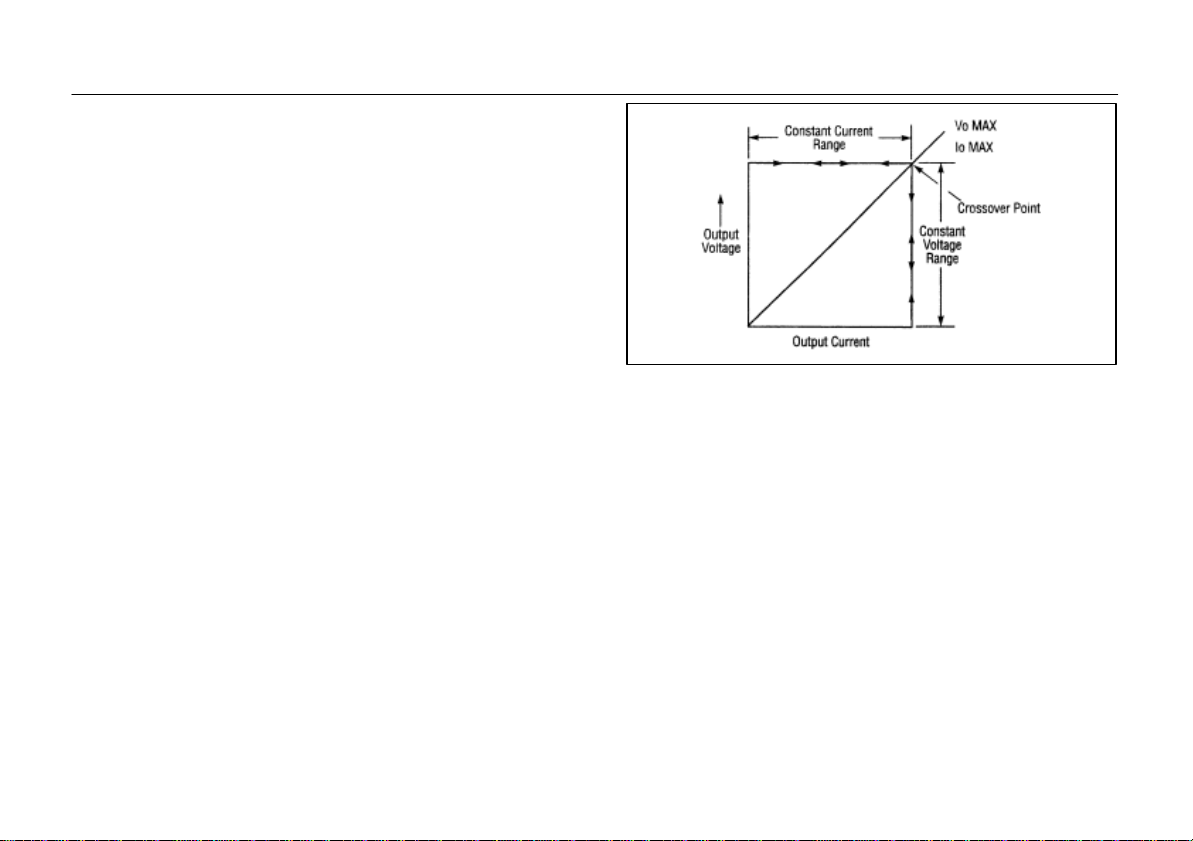

Figure 7. Constant Voltage/Constant Current Characteristic.

CONSTANT VOLTAGE/CONSTANT CURRENT

When connected in series, the

VOLTAGE

controls of

CHARACTERISTIC

The working characteristic of this power supply is called a constant

voltage/constant current automatic crossover type. This permits

continuous transition from constant current to constant voltage modes in

response to the load change. The intersection of constant voltage and

constant current modes is called the crossover point. Fig. 7 shows the

relationship between this crossover point and the load.

For example, if the load is such that the power supply is operating in

the constant voltage mode, a regulated output voltage is provided. The

output voltage remains constant as the load increases, up until the point

where the preset current limit is reached. At that point, the output current

becomes constant and the output voltage drops in proportion to furt her

increases in load. The crossover point is indicated by the front panel LED

indicators. The crossover point is reached when the CV indicator goes off

and the CC indicator comes on.

Similarly, crossover from the constant current to the constant voltage

mode automatically occurs from a decrease in load. A good example of

this would be seen when charging a 12-volt battery. Initially, the open

circuit voltage of the power supply may be preset for 13.8 volts. A low

battery will place a heavy load on the supply and it will operate in the

constant current mode, which may be adjusted for a 1 amp charging rate.

As the battery becomes charged, and its voltage approaches 13.8 volts, its

load decreases to the point where it no longer demands the full 1 amp

charging rate. This is the crossover point where the power supply goes

into the constant voltage mode.

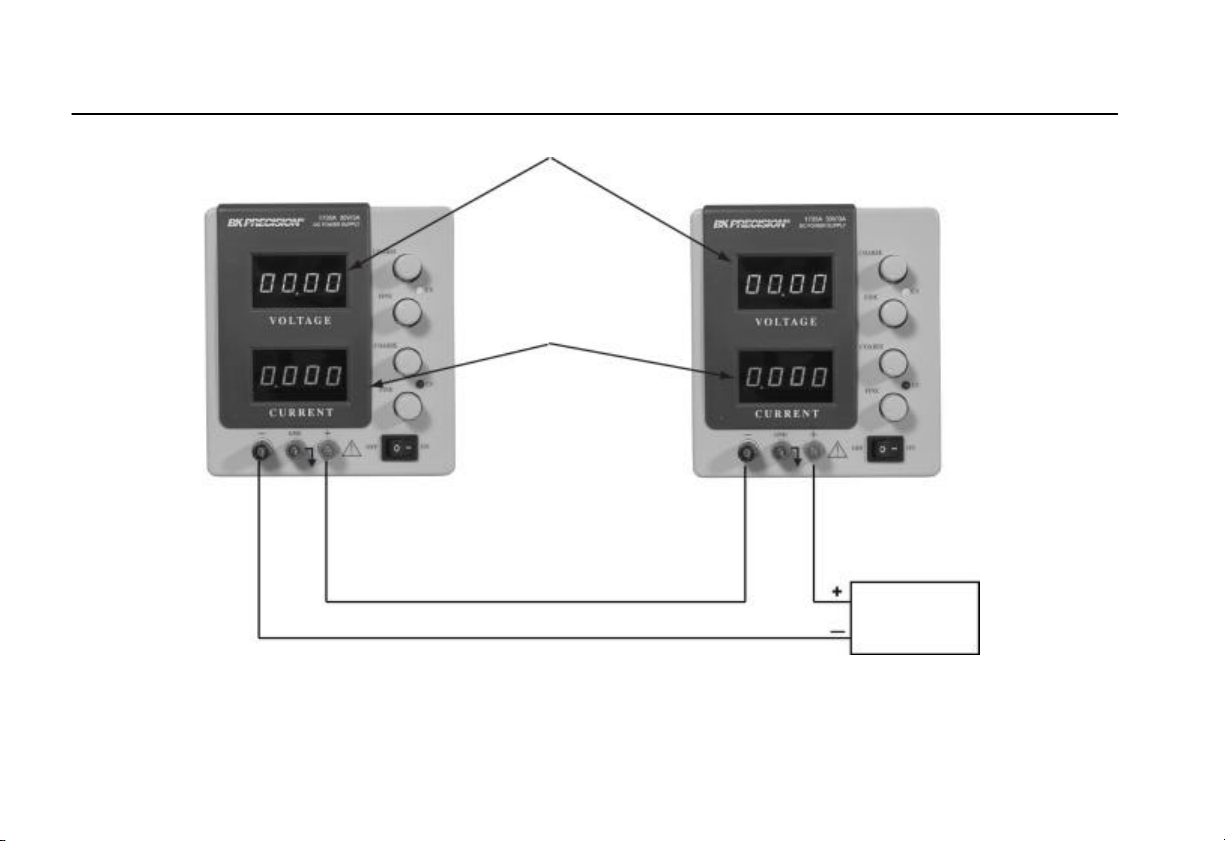

CONNECTING TWO POWER SUPPLIES IN SERIES

Two Model 1735A power supplies may be connected in series to

provide a variable 0-60 volt output. In this configuration the power

supply can supply up to 3 amps. See Fig. 8 for the connection scheme.

17

OPERATING INSTRUCTIONS

each power supply exercise control over a 0-30 volt range.

Add the LED display readings together or connect

external voltmeter across the load to determine the total

output voltage.

Load current may be monitored from either supply; the

readings will be identical since they are connected in

series. Also, since the supplies are connected in series, it is

only necessary to set the current limit on one of the

supplies; the other may be set for maximum.

Page 18

OPERATING INSTRUCTIONS

Output current

Output voltage equals sum of both displays

“in voltage metering mode”

equals value on

either ammeter

(both read identical)

Load

Figure 8. Connecting Two Power Supplies in Series.

18

Page 19

OPERATING INSTRUCTIONS

Figure 9. Connecting

Two

Power Supplies in Parallel.

0.1Ω

0.1Ω

Adjust both power supplies

Output current

Use load equalizing

to same voltage

equals sum

of both displays

resisters

Load

19

Page 20

CONNECTING TWO POWER SUPPLIES IN PARALLEL

If the current equalizing resistors are not well matched, it is

OPERATING INSTRUCTIONS

Two power supplies may be connected in parallel to double the

maximum load current. In this configuration the two supplies will

provide two 0-30 volt output at up to 6 amps (heavier gauge hookup leads are advisable). Current equalizing resistors must be used

as shown in Fig. 9. However, the protective current limiting

feature will prevent damage if current is temporarily unbalanced

during set-up.

When connected in parallel and operating in the constant

voltage mode, determine the total load current limit and preset the

current limiting for each power supply to half the total load

current value. Then when the load is connected, set the

VOLTAGE controls on the two power supplies for equal voltage

readings. This should also provide approximately equal current

from each supply. Add the two current meter readings together for

total load current, or connect an external ammeter in series with

the load.

preferable that the voltages be slightly unbalanced to achieve

current balance. Be sure that the supplies are adequately

balanced so that both remain in the CV mode.

When connected in parallel and operating in the constant

current mode, the VOLTAGE controls of both supplies should

be preset to the same value. Then when the load is connected, the

CURRENT controls of the two supplies should be adjusted for

approximately equal current from each unit. Be sure that both

supplies remain in the CC mode.

20

Page 21

APPLICATIONS

GENERAL

The Model 1735A power supply has a very wide variety of

applications in electrical and electronics servicing, engineering

laboratories, manufacturing and testing facilities, schools, and

home hobbying. The power supply output is fully adjustable from

0 to 30 volts and 0 to 3 amps. This flexibility makes them

suitable for most applications requiring a dc power source.

ELECTRONICS SERVICING

Most electronics troubleshooting and repair is performed on a

test bench. This power supply can provide the dc power source to

operate a module or circuit board on the test bench when it is

removed from its parent equipment. It can be used to power

portable, battery -operated equipment and check the effect of low

battery voltage. It can power vehicular equipment such as tape

players, auto sound systems, CB radios, etc. on the test bench.

Most automobiles and other vehicles use 12-volt electrical

systems. Although the electrical system is normally referred to as

a 12-volt system, actual battery voltage when fully charged is

approximately 14 volts. The power supply may be set to 14 volts

for servicing equipment from vehicles with 12-volt electrical

systems. Some trucks use a 24-volt electrical system; bench

testing of equipment from these systems should be performed at

28 volts.

Some servicing applications require the injection of a variable

dc voltage for certain tests, such as checking the effect of AGC

bias in a television receiver. This requires an isolated dc power

supply, such as the Model 1735A.

The equipment being tested may contain its own power supply

and operate from ac power. A dc voltage may already be present

in the circuit. One polarity of the power supply output is floated

to an appropriate point in the circuit, such as the emitter of a

transistor. The other polarity of the power supply output is then

applied to another point in the circuit, such as the base of that

transistor. Varying the power supply voltage then varies the dc

bias on the stage, and the effects may be not ed. A series limiting

resistor is often used to protect the circuits from overdissipation.

ELECTRONICS MANUFACTURING

In electronics manufacturing facilities, the power supply is

often used as a dc power source while testing and adjusting

modules, subassemblies, and complete units in the production

and assembly area or in the quality control area. The instrument

can be used in incoming inspection as a dc power source for

testing purchased components and subassemblies.

This power supply is particularly well suited for manufacturing

applications because of its ease of operation and its continuous

duty rating. When load current or total power dissipation are

among the main characteristics to be measured, the total load

current and voltage are easily displayed on the LED displays. The

current limit can be set so that all units which do not meet the

load current specification will cause the CC indicator to light,

and the unit can be rejected.

21

Page 22

ELECTRONICS DESIGN LAB

BATTERY CHARGING

APPLICATION

The technician or engineer working in an engineering laboratory

requires a dc power supply to power breadboard and prototype

circuits. This power supply is ideal because it monitors output

current, output voltage, limits current to protect the circuit, is

adjustable over a wide range, and has excellent regulation and very

low ripple.

Use of the instrument in an engineering laboratory is very

similar to that described for servicing electronics equipment and

modules, except that lower currents may be prevalent when

powering individual circuits. The current limiting feature is very

valuable in this application because it can protect unproven circuits

from damage.

ELECTRONICS EDUCATION

The student in an electronics curriculum may use the power

supply for powering equipment and circuits as previously

described for all other applications. In addition, the power supply

can be used in the classroom laboratory to conduct experiments in

fundamental electronics. In learning Ohm’s law, for example, the

relationships of resistance, current, and voltage are easily

demonstrated by the use of a power supply.

The power supply can be used as a battery charger to

restore the charge in rechargeable batteries such as lead-acid,

nickel-cadmium, and some alkaline types. Refer to the

battery manufacturer’s charging specifications for proper

voltage and current settings. Charging information is

sometimes printed on the batteries. Battery charging, at least

initially, requires the constant current mode of operation.

Before connecting the power supply to the battery, preset the

VOLTAGE controls to the fully charged terminal voltage

specified by the battery manufacturer. Turn off the power

supply while connecting the battery. Observe proper polarity

and connect as for constant current operation. Adjust the

CURRENT control for the maximum charging current

specified by the battery manufacturer. (If the maximum

charging current is greater than the power supply’s maximum

load current, set the CURRENT control to maximum). The

CC indicator will light and the battery will charge at the

preset current limit. As the battery approaches full charge, its

terminal voltage will approach that of the power supply

output and the charging current will taper off. The power

supply may automatically switch to CV (constant voltage)

operation. When this occurs, the power supply will continue

to provide a trickle charge.

22

Page 23

WARNING

LINE VOLTAGE CONVERSION, INTERNATIONAL

2.5A

1.25A

MAINTENANCE

The following instructions are for use by qualified personnel only. To

avoid electrical shock, do not perform any servicing other than

contained in the operating instructions unless you are qualified to do

so.

FUSE REPLACEMENT

If the fuse blows, the CV or CC indicators will not light and the

power supply will not operate. The fuse should not normally open

unless a problem has developed in the unit. Try to determine and

correct the cause of the blown fuse, then replace only with a fuse of

the correct rating as listed b elow. The fuse is located on the rear panel

(see Fig. 2).

OPERATION FUSE VALUE TYPE

120V 3.5A SLOW BLOW

220/230/240V 1.75A SLOW BLOW

Table 1. Fuse Values.

UNITS

The primary winding of the power transformer is tapped to

permit operation from 120/220/230 or 240 VAC, 50/60 Hz line

voltage. Con version from one line voltage to another is done by

a simple position change of the fuse receptacle underneath the

line cord.

ADJUSTMENTS

This unit was accurately adjusted at the factory before

shipment. Readjustment is recommended only if repairs have

been made in a circuit affecting adjustment accuracy, or if you

have a reason to believe the unit is out of adjustment. However,

adjustments should be attempted only if a multimeter with an

accuracy of ±0.5% DCV or better is available (B+K Precision

Model 2703A or equivalent).

23

Page 24

1735A

CALIBRATION

6.

Set the front panel Coarse VOLTAGE control for a

MAINTENANCE

If readjustment is required, use the following procedure. Locations

of the adjustments are shown in Fig. 11.

1. Set the front panel controls of the Model 1735A as follows:

Coarse and Fine VOLTAGE controls fully clockwise. Coarse

and Fine CURRENT controls fully clockwise. Power switch to

On.

2. Connect the Multimeter to measure the voltage at pin 7 of IC2

with respect to the front panel red (+) output jack. Adjust R21

for -5.00 volts on the Multimeter.

3. Connect the Multimeter to measure the voltage at pin 1 of IC2

with respect to the front panel red (+) output jack. Adjust R63

for 0 + l 0 mV on the Multimeter.

4. Connect the Multimeter to measure the DC voltage between the

black (-) and red (+) output jacks. The voltage should be 30 to

32 volts, the green CV indicator should be lit, and the red CC

indicator should be off.

5. Set the front panel Fine VOLTAGE control for a reading of

30.00 volts on the Multimeter. Adjust upper GREEN R304 for a

front panel meter reading of 30.00 volts on the GREEN

VOLTAGE meter.

reading of 04.00 to 06.00 volts on the GREEN

VOLTAGE meter.

7. Connect the Multimeter to read the DC current

between the black (-) and red (+) output jacks, using

the 10 amp range. The red CC indicator should light

and the green CV indicator should go off.

8. Set the front panel Fine CURRENT control for a

reading of 3.000 amps on the Multimeter. Adjust lower

RED R304 for a front panel meter reading of 3.000

amps on the RED CURRENT meter.

INSTRUMENT REPAIR SERVICE

Because of the specialized skills and test equipment

required for instrument repair and calibration, many

customers prefer to rely upon B+K Precision for this

service. We maintain a network of B+K Precision

authorized service agencies for this purpose. To use this

service, even if the instrument is no longer under warranty,

follow the instructions given in the WARRANTY

SERVICE INSTRUCTIONS section of this manual. There

is a nominal charge for instruments out of warranty.

24

Page 25

MAINTENANCE

Figure 11. Location of Adjustments.

25

Page 26

NOTES

26

Page 27

Service Information

Warranty Service: Please return the product in the original packaging with proof of purchase to the address

below. Clearly state in writing the performance problem and return any leads, probes, connectors and accessories

that you are using with the device.

Non-Warranty Service: Return the product in the original pac kaging to the address below. Clearly state in writing

the performance problem and return any leads, probes, connectors and accessories that you are using with the

device. Customers not on open account must include payment in the form of a money order or credit card. For the

most current repair charges please visit www.bkprecision.com and click on “service/repair”.

Return all merchandise to B&K Precision Corp. with pre-paid shipping. The flat -rate repair charge fo r NonWarranty Service does not include return shipping. Return shipping to locations in North American is included for

Warranty Service. For overnight shipments and non-North American shipping fees please contact B&K Precision

Corp.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Include with the returned instrument your complete return shipping address, contact name, phone number

and description of problem.

27

Page 28

Limited Two-Year Warranty

B&K Precision Corp. warrants to the original purchaser that its products and the component parts thereof, will be

free from defects in workmanship and materials for a period of two years from date of purchase.

B&K Precision Corp. will, without charge, repair or replace, at its option, defective product or component parts.

Returned product must be accompanied by proof of the purchase date in the form of a sales receipt.

To obtain warranty coverage in the U.S.A., this product must be registered by completing a warranty registration

form online at www.bkprecision.com within fifteen (15) days of purchase.

Exclusions: This warranty does not apply in the event of misuse or abuse of the product or as a result of

unauthorized alterations or repairs. The warranty is void if the serial number is altered, defaced or

removed.

B&K Precision Corp. shall not be liable for any consequential damages, including without limitation damages

resulting from loss of use. Some states do not allow limitations of incidental or consequential damages. So the

above limitation or exclusion may not apply to you.

This warranty gives you specific rights and you may have other rights, which vary from state-to-state.

B&K Precision Corp.

22820 Savi Ranch Parkway

Yorba Linda, CA 92887

www.bkprecision.com

714-921-9095

Model Number: _______________ Date Purchased: __________________

28

Page 29

TEST INSTRUMENT SAFETY

4. If possible, familiarize yourself with the equipment being tested and the location of its high voltage points. However, remember

that high voltage may appear at unexpected points in defective equipment.

5. Use an insulated floor material or a large, insulated floor mat to stand on, and an insulated work surface on which to place

equipment; and make certain such surfaces are not damp or wet.

6. When testing ac powered equipment, the ac line voltage is usually present on some power input circuits such as the on-off

switch, fuses, power transformer, etc. “any time” the equipment is connected to an ac outlet.

7. B+K Precision products are not authorized for use in any application involving direct contact between our product and the

human body, or for use as a critical component in a life support device or system. Here, “direct contact” refers to any connection

from or to our equipment via any cabling or switching means. A “critical component” is any component of a life support device

or system whose failure to perform can be reasonably expected to cause failure of that device or system, or to affect its safety or

effectiveness.

8. Never work alone. Someone should be nearby to render aid if necessary. Training in CPR (cardio-pulmonary resuscitation) first

aid is highly recommended.

(continued from inside front cover)

29

Page 30

SEGURIDAD DE EL INSTRUMENTO DE PRUEBA

PRECAUCIONES

Uso normal de probado de prueba te espose a cierta cantidad de peligro por un choque eléctrico porque revisiones son algunas veces hechas

donde hay alto voltaje descubierto. Un choque eléctrico que cause 10 milliamps pasar a través del corazón pararía la mayoría de los corazones

humanos. Voltaje tan bajo hasta 30 voltios dc ou ac rms podría ser considerado peligroso porque puede producir una corriente letal bajo ciertas

condiciones. Voltajes mas altos pueden ser aun mas peligrosos. Tus hábitos normales de trabajo deben de incluir todas las practicas aceptadas

para prevenir contacto con alto voltaje descubierto, y dirigir corriente lejos de el corazón en caso de contacto accidental con un alto voltaje.

Observe las siguientes medidas de seguridad:

1. Hay poco peligro de un choque eléctrico de la salida de cd de esta fuente de poder. Pero, puede haber otras posibles condiciones de

prueba que cuando usando esta fuente de poder se puede crear un peligro de un choque de alto voltaje.

• Si el equipo bajo prueba es de el tipo “chasis caliente”, un serio peligro de choque existe al menos que el equipo este

desconectado ( nada mas apagando el equipo no remueve el peligro), o si un transformador de aislamiento es usado.

• Si el equipo bajo prueba esta “prendido” (y este equipo usa alto voltaje en cualquiera de sus circuitos), las salidas de la fuente de

poder pueden ser flotadas a el potencial al el punto de conexión. Recuerden que el alto poder puede aparecer en puntos

inesperados en equipo defectuoso. No flote la salida de la fuente de poder por mas de 100 voltios pico con respecto al chasis o

tierra.

• Si el equipo bajo prueba esta “apagado” (y este equipo usa alto voltaje en cualquiera de sus circuitos cuando en operación normal),

descarga alto-voltaje capacitares antes de hacer conexiones o pruebas. Algunos circuitos conservan alto voltaje mucho después

que el equipo es apagado.

2. Solo use una enchufe polarizada de 3-conductores. Esto asegura que el chasis de la fuente de poder, cubierta, y la terminal de tierra

están conectadas a una buena tierra y reduce el peligro de un choque eléctrico.

3. No se expone a alto poder innecesariamente. Remueva cubiertas solo cuando mas necesario. Apague el equipo cuando este haciendo

conexiones de prueba en circuito de alto-voltaje. Descargue los capacitadotes después de que remueva el poder.

(continua el la parte de atrás)

30

Page 31

Manual de instrucciones

Modelo 1735A

Fuente de poder DC

Con doble LED indicador

31

Page 32

SEGURIDAD DE EQUIPO DE PRUEBA

Conectando dos fuentes d

e poder e

n paralelo

..............

48

INTRODUCCION..............................................................33

CARACTERISTICAS .......................................................34

ESPECIFICACIONES .......................................................35

CONTROLES & INDICADORES..................................37

INTRODUCIONES DE OPERACIÓN..........................39

precauciones de segundad.................................................39

precauciones del equipo .....................................................39

Conexión................................................................................39

Típica operación de voltaje constante............................42

Estableciendo el limite de corriente.................................43

Típica operación de corriente constante ..........................44

Voltaje constante / corriente constante

Características .....................................................................45

Conectando dos fuentes de poder en series....................45

TABLA DE CONTENDIDO

APLICACIONES..............................................................49

General................................................................................49

servicio electrónico...........................................................49

electrónica en manufactura ..............................................49

laboratorio de diseño electrónico...................................50

educación en electrónica..................................................50

cargado de baterias/pilas..................................................50

MANTENIMIENTO........................................................51

Remplazo de fusibles .......................................................51

conversión de línea de voltaje .......................................51

Ajustamiento......................................................................51

Calibración .........................................................................52

Information de Servicio ...................................................54

Dos-anos de Garantia Limitada......................................55

32

Page 33

INTRODUCCION

El B & K Precision Modelo 1735 CD Fuente de Poder es de una alta calidad, propósito general cd fuente de poder. Provee 0 –30 voltios cd

salida, ajustable con ambos grueso y fino controles de voltaje para precisos ajustes. La salida de corriente es 0-3 amperios, ajustable grueso y

fino controles de corriente. Dos grandes LED medidores continuamente observan el voltaje y corriente de salida. El medidor de VOLTAJE si

verde, cuando el medidor de corriente es rojo.

El modelo 1735 exhibe excelente regulación y baja ondulación características. El diseño de el circuito incorpora un pre-regulador , cual

grandemente reduce disipación de poder interna a bajos voltajes de salida. El estilo es ambo atractivo y funcional. La configuración mecánica

conserva espacio y permite fácil portabilidad.

Este instrumento puede ser usado en constante voltaje o constante corriente aplicaciones. El cambio de constante voltaje a constante corriente

modo es suave y automático. LED’s indican el “VC” (voltaje constante) o CC( constante corriente) modo de operación. En aplicaciones de

voltaje constante, un limite de corriente esta presente. Cuando variaciones de carga causan la corriente alcanzar el limite presente, la unidad

entonces regula la corriente de salida en vez de el voltaje de salida. Limites de corriente son ajustables desde 5% hasta 100% máximo. En

aplicaciones de constante corriente, el voltaje máximo puede estar presente. Cuando variaciones de carga causan una baja de corriente por

debajo de el valor regulado, la unidad cambia a operación de voltaje regulado a el prerregulado valor.

Polaridad reversa protección previene daño accidental a la fuente de poder de conexiones inapropiadas a un voltaje externo, y la corriente de

limitación protege el equipo que esta siendo prendido, como también a la fuente de poder.

La salida esta aislada de el chasis y tierra, cual permite total flexibilidad de conexiones. Cuando necesitado, el (+) o (-) polaridad puede estar

atados a tierra, o la polaridad puede estar flotando a un voltaje externo. Dos fuentes pueden estar conectadas en series como a 0-60 voltios fuente

de poder, o dos fuentes pueden ser conectadas en paralelo, con adecuados resistores balanceadores, por hasta doble la corriente de salida.

Esta fuente de poder esta muy adecuada para una amplia variedad de aplicaciones eléctricas y electrónicas, incluyendo talleres de servicio,

laboratorios de ingeniería, pruebas de producción, laboratorios de escuela, y uso de casa por aficionados.

33

Page 34

0-30 VOTIOS

LED INDICADOVES

CARACTERÍSTICAS

Continuamente variable sobre 0 a 30 voltios rango con grueso y

fino controles

0-3 AMPERIOS

0 a 3 amps corriente probada para continuo servido al la completa

salida de corriente .

Grueso y fino controles de ajuste de corriente

CALIDAD DE LABORATORIO

Excelente regulacio,baja onduracio

VOLTAJE CONSTANTE O CORRIETE CONSTANTE

Provees regulado cd voltaje de salida o salida regulada de corriente

cd .Cruce es suave

Y automático

LED PANTALLAS

Dos grandas,fael-de-leer LED pantallas de dígitos observa el

voltaje de salida y la

Corriente de salida,y provee buena y isibilidad en brillante o baja

luz.

34

Medidores Permitas resolución de 0.1 voltios o 0.01 amperios

Actúa como piloto y identifica el modo de operación y medida

PRE-REGULADOR

Limita disipación interna para mas alta confiabilidad

SALIDA AISLADA

La polaridad puede ser flotadon o a tierra

PROTECCIÓN DE SOBRECARGA

Completamente ajuste de limitación de corriente(desde 5% a

100% de máximo

Salida de corriente )protege circuitos bajo prueba y la fuente de

poder

PROTECCIÓN DE POLARIDAD VOLTEADA

Previene daño ala fuente de energía de volltaje externos de

polaridad volteada

ESTILO

Estilo de funcionalidad moderna.Configuración conuerva espacio

de banca y ayuda a

Si poryabilidad.Lógico,converniente layout de controles

Page 35

VOLTAJE DE SALIDA

:

0.01% + 3 mv

Corriente de ondu

lación:

3mA típ

ico

MIDIEDO

ESPECIFICACIONES

35

0 a 30VDC grueso y fino ajuste

CORRIENTE DE SALIDA:

0 a 3A grueso y fino ajuste

OPERACIÓN DE CONSTANTE VOLTAJE

Regulación de voltaje

Línea (108-132V): 0.01%+3mv

Carga (no carga a carga completa):

Tiampo de reoperación: 100us típico

Voltaje deondulación

Pico a pico: 2mv típico

RMS: 1mv

Coeficiente de temperatura

(0 a +35 C): 300PPm/o C°

OPARACION DE CONSTATE

Limites ajustables de corriente: 5% a100%

Regulación de corriente

Línea (108-132V): 0.2% + 3mA

Carga: 0.2% + 3mA

Voltímetro: 4 dígitos verde LED pantalla

Rango: 0 a 9.99V

Precisión: (0.5%+9 digita)

Amperímetro 4 dígitos rojo LED pantalla

Rango: 0 a 9.99V

Precisión: (0.5% + 9 digita)

REQUERIMIENTE DE PODER

Domestico: 120VAC +/- 10%,60Hz

Internacional: 120/220/230/240VAC+/-

CONSUMO DE PODER: Aproximadamente 180W

PROTECCIÓN: Protección de polaridad

10%,50/60Hz

o meros a carga

Completa

volteada, limitación de

corriente

Page 36

ESPECIFICACIONES

RANGO DE TEMPERATURA

Operación: 0° a +40°C, 75%R.H

Almacenamiento: -15° a +70°C, 85% R,H

DIMENSIONES (AxAxP): 6.2x5.5x12.5”

PESO: 10.5 LB

ACCESORIOS INCLUIDOS: Fusible extra, Manual de instrucciones

NOTA: Las especificaciones y la información están conforme a cambio sin el aviso de B&K Precision Corp. Por favor visite

www.bkprecision.com para las especificaciones más corriente y información de nuestros productos.

Nota 1:

Importante: Aún con variación térmica significativa, esta fuente de poder de alta resolución es considerablemente más precisa que

cualquier fuente de poder de escritorio de pantalla de 3 dígitos.

Variación térmica: Dado que esta fuente de poder posee mayor resolución que fuentes de escritorio estándar, es más

susceptible a variación térmica. La variación térmica ocurre en todo tipo de fuentes pero es más aparente en las de alta

resolución. La variación causa que la medición se incremente o disminuya lentamente con los cambios de temperatura interna

de las fuentes de poder. Conforme la fuente provee mayor potencia su temperatura interna aumenta, causando que la medición

(sobre todo de corriente) aumente lentamente. Conforme la demanda disminuye se enfría la fuente causando que la medición

(sobre todo de corriente) disminuya gradualmente. Si la fuente provee una potencia constante por más de 15 minutos la

medición permanece constante y no deberá mostrar variación.

36

Page 37

INDICADORES

CONTROLES DE VOLTAJE

CONTROLES Y INDICADORES

Sea el “CC” o “CV” y los LED indicadores pueden

ser prendidos cuando sea que la unidad este operando,

de este modo sirviendo como una luz piloto. La unidad

automáticamente cambia de CV a CC operación

cuando el preseleccionado limite de corriente es

alcanzado.

1. C.C. (corriente constante) Indicador. Roja LED

prende en constante corriente modo. La unidad

regula la corriente de salida at un valor establecido

por los CURRENT (corriente )controles.

2. C.V. (voltaje constante) indicador. Verde LED

prende en constante voltaje modo. La unidad

regula el voltaje de salida establecido por los

VOLTAGE(voltaje) controles.

3. GREEN (verde)LED pantalla. 4 dígitos

continuamente muestran voltaje.

4. RED (rojo) LED pantalla. 4 dígitos muestran

continuamente corriente.

37

5. Grueso Control (Control grueso) . Ajustes gruesos de

el voltaje de salida. Lea valor en la GREEN(VERDE)

LED pantalla.

6. Fine Control (control fino). Ajuste fino de salida de

voltaje. Lea el valor en GREEN (verde) LED

pantalla.

CONTROLES DE CORRIENTE

7. Grueso CURRENT(corriente) control. Ajuste el limite

de corriente en constante voltaje modo. Ajusta

constante valor de corriente en el constante corriente

modo. Corriente puede ser leída de la RED (roja)

LED pantalla.

CONTROLES DE PODER

8. Prendido-apagado switch.

TERMINALES DE SALIDA

9. “+” Terminal (rojo). Positiva polaridad terminal de

salida.

10. GND Terminal. Tierra y chasis tierra.

11. “-“ Terminal (negra). Negativa polaridad terminal de

salida

Page 38

CONTROLES DEL PANEL TRASERO

Figura 1.Controles e indicadores de el panel

delante

ro

CONTROLES E INDICADORES

13. Fusible

14. Cordón de poder

Figura 2.Panel trasero

38

Page 39

PRECAUCIONES DE SEGURIDAD

No exceda los voltajes recomendados de los circuitos que

INSTRUCCIONES DE OPERACION

Use solo a polarizado 3-conductores ca enchufe. Esto

asegure que la fuente de poder chasis, caja, y la terminal de

tierra son conectada a una buena tierra y reduce el peligro de

un choque eléctrico.

Hay un pequeño peligro de choque eléctrico dela salida de

la fuente de poder, cual produce un máximo de 30 voltios

cd. Pero, puede haber un gran peligro de choque eléctrico si

la salida de la fuente de poder es conectada a un extremado

alto voltaje. Algún equipo siendo prendido puede contener

alto voltaje y presenta un peligro de choque. Observe

precaución. Si la salida de la fuente de poder es flotada

(referencia a un voltaje en vez que la tierra) apague la fuente

de poder y el equipo bajo prueba cuando este haciendo

conexiones. Nunca flote la fuente de poder a un potencial

mas grande que 100 voltios pico con respecto a la tierra.

PRECAUCIONES DEL EQUIPO

Evite usar la fuente de poder en temperaturas ambientales

arriba de +40 C. Siempre permita suficiente espacio de aire

alrededor de el disipador de calor en al parte trasera de la

fuente de poder para una radiación efectiva para prevenir

calor interno atrapado.

Aunque la fuente de poder esta protegida enconara de daño

de polaridad volteada, el circuito que esta prendido no puede

incluir tal protección. Siempre cuidadosamente observe la

polaridad; polaridad incorrecta puede dañar el equipo bajo

39

prueba.

son prendidos. Muchos transistores y circuitos integrados

no pueden tolerar voltajes de 30 voltios.

No hay necesidad de preocuparse acerca de brincos de

voltaje o sobresaltos dañando el equip bajo prueba. El entre

las terminales de salida de la fuente de poder nunca excede

el establecido valor cuando el (Power) switch de poder es

apagado o endendido.

CONEXIÓN

1. Apague la fuente de poder y el equipo que va ha ser

prendido cuando este conectando

2. Conecte la polaridad positive a el dispositivo que va a

ser prendido a la terminal roja de la fuente de poder.

3. Conecte la polaridad negative de el dispositivo que va a

ser prendido a la terminal negra de la fuente de poder.

4. Fig. 3 ilustra las posibilidades de tierra.

a. Si la polaridad negativa de el equipo o el

circuito que esta encendido es también el

chasis o común, puede ser conectado a tierra

por medio de atando la terminal negra a la

verde como en Fig. 3A.

b. Similarmente, la polaridad positiva puede ser

conectada a tierra atando la terminal roja a la

verde como es mostrado en la Fig. 3B.

Page 40

Equipo encendido

Equipo encendido

Figura A y B .Posibilidades de conecciones etierra

INSTRUCCIONES DE OPERACIÓN

Corto Corto

A. Tierra,comun con B. Tierra,comun con

Polaridad negativas polaridad positiva

40

Page 41

Sin

Equipo encendido

Sin

Equipo encendido

Figura 3 (C y D)

C.

No referencia a tierra

D.

A tierra,no comun con

INSTRUCCIONES DE OPERACIÓN

Corto Corto

Polaridades Negativas o positivas

41

Page 42

c.

Si la referencia de tierra no es requerida, la configuración de

Lectura de voltaje de salida en

INSTRUCCIONES DE OPERACIÓN

Fig. 3C puede ser usada. El diagrama in Fig.3C debería

también ser usado donde no es conocido si el chasis es común

con la polaridad positiva o negativa.

d. el chasis o común de el equipo encendido es separado de ambas

polaridades negativa y positiva entradas de poder, use la conexión

en Fig. 3D.

5. Observe polaridad apropiada. Si el circuito encendido no esta equipado

con protección de polaridad reversa, daño a el circuito puede resultar de

una polaridad reversada. Use sondas de color codeé, para conveniencia

en identificar polaridad, roja para (+) y negra para (-).

6. Asegúrese que las sondas de conexión ofrecen suficiente capacidad de

corriente y baja resistencia entre la fuente de poder y el circuito que esta

siendo prendido.

OPERACION TIPICA DE VOLTAJE CONSTANTE

1. Antes de conectar el dispositivo para ser encendido por la fuente de

poder, determine la máxima carga de corriente segura para el dispositivo

que va ha ser encendido y establezca el valor de el limite de corriente

(vea “Establecer el limite de corriente” procedimiento en esta sección)

2. Coloque el control de VOLTAJE fino en el centro y el control de

VOLTAJE grueso al mínimo (completamente en la dirección en contra

de las anejillas de reloj)

3. Apague la fuente de poder y conéctela a el dispositivo que va ha ser

prendido. (vea “Conectado” procedimiento en esta sección).

4. Prenda el POWER switch. La CV luz de el indicador debe de prender.

42

Medidores de voltaje y corriente

Ajust al voltaje

Deseado

CV indicador

Prendido

Preestablecido

Limite de corriente

Carga

Figura 4. Típica operación de voltaje constante

Page 43

5.

xAumente la posición de el VOLTAJE hasta que la Voltaje

Lectura de valor del limite de corriente

Rango medio

Corto circuito temporal

INSTRUCCIONES DE OPERACIÓN

LED pantalla lea el valor deseado. El control FINO permite

mas fácil colocación a un valor especifico.

6. Note la carga de la corriente en la Corriente LED pantalla.

7. Si la carga de corriente excede el limite de corriente

ESTABLECIENDO EL LIMITE DE CORRIENTE

1. Determine la máxima corriente permitida para el

2. Temporalmente toque la (+) y (-) terminales de la fuente de

3. Rote el control de Voltaje gureso lejos de el cero

4. Ajuste el grueso y fino CORRIENTE control para el

5. El limite de corriente (sobrecarga portección) ha sido

6. Remueva el corto circuito entre la (+) y (-) terminales y

establecido, el CV indicador se apagara y el indicador de

CC prendera. En este caso, la fuente de poder

automáticamente cambiara a el modo de constante corriente,

y mas rotación de el control de VOLTAJE no aumentara la

salida de voltaje.

dispositivo que va ha ser encendido.

poder con una sonda de prueba.

suficientemente para encender el indicador de CC.

deseado limite de corriente. Lea el valor de la Corriente

LED pantalla.

establecido. No-camble la posición de los controles de

CORRIENTE después de este paso.

conecte para la operación de constante voltaje.

43

De el medidor

Figura 5. Estableciendo el limite de correinte

Adjuste al limite

De corriente deseado

CC indicado

Encendido

Page 44

OPERACION TIPICA DE CORRIENTE

CONSTANTE

Lea corriente de salida

en el medidor

1. Antes de conectar el dispositivo que va ha ser encendido por la

fuente de poder, determine el voltaje máximo seguro que va ha

ser aplicado, y coloque los controles de VOLTAJE para

obtener esa lectura de voltaje en la Voltaje LED pantalla.

2. Determine el valor deseado de corriente constante.

3. Ponga el Grueso y Fino conteo de CORRIENTE al mínimo

(completamente en contra de la dirección de las anejillas del

reloj)

4. Apague la fuente de poder y conéctela al dispositivo que va ha

ser encendido

5. Prenda la fuente de poder. El indicador de CC debe de prender.

6. Aumente el Grueso y Fino control de CORRIENTE posición

hasta que el valor deseado de constante corriente sea leído en la

pantalla, o ponga él limite de corriente en avanzado (antes de

conectar la carga) como fue prescribid en el previo

“Estableciendo el Limite de Corriente “ procedimiento.

7. Si la corriente de carga cae debajo de el valor de corriente

constante, el CC indicador se apagara y el CV indicador

prendera. En este caso, la fuente de poder automáticamente

cambiara a el modo de voltaje constante, y más rotaciones de

los controles de CORRIENTE no aumentaran la salida de

corriente.

Preestablecido

Limite de voltaje

Ajuste a la corriente

Deseada

CC indicador

Encendido

Carga

Figura 6.Tipica operación de corriente

44

Page 45

VOLTAJE CONSTANTE/ CORRIENTE CONSTANTE

Rango de corriente constante

CONECTANDO DOS FUENTES DE PODE EN SERIES

Corriente de salida

Figura 7

. Voltaje constante/Corriente constante características

Volta

je

CARACTERISTICAS

La característica de trabajo de esta fuente de poder es llamada un

constante voltaje/ constante corriente automático cruce tipo. Esto

permite continua transición de constante corriente a con stante voltaje

modo en respuesta al cambio de carga. La intersección de constante

voltaje y constante corriente modos es llamada él punte de cruce. Fig.

7 muestra la relación entre punto de cruce y la carga.

Por ejemplo, si la carga es tal que la fuente de poder este operando en

el modo de constante voltaje, una salida de voltaje regulada si

proveída. La salida de voltaje permance constante cuando la carga

aumenta, hacia arriba hasta el punto donde el establecido limite de

corriente es alcanzado. En este punto, la corriente de salida se hace

constante y la salida de voltaje cae en proporción al aumento en la

carga. El punto de cruce es indicado por los LED indicadores en el

tablero frontal. El punto de cruce es alcanzado cuando el CV indicado

se apaga y el CC indicador se prende.

Similarmente, cruce desde la constante corriente al el made de

constante voltaje ocurre automáticamente de una disminución de la

carga. Un buen ejemplo de esto puede ser vist cuando se carga una

batería de 12- voltios. Inicialmente, el voltaje de el circuito abierto de

la fuente de poder pudo se establecido para 13.8 voltios. Una batería

baja pone una carga pesada en la fuente y operara en el modo de

corriente constante, cuando puede ser ajustada a un velocidad de

cargado de 1 amp. Cvando la batería se carga, y su voltaje

aproxima13.8 voltios, su carga disminuye a el punto donde no mas

demanda el completo 1 amp velocidad de carga. Este es el punto de

cruce donde la fuente de poder va al modo de constante voltaje.

Ponto de gruce

de salida

Rango de voltaje

constante

Dos Modelo 1735 fuentes de poder pueden ser conectadas en serie para

proveer un variable 0-60 voltios salida. En esta configuración la fuente de

poder puede dar hasta 3 amps. Vea Fig. 8 por e diagrama reco

Cuando conectado en series, los controles de VOLTAJE de cada fuente de

poder ejercen control sobre an rango de 0-30 voltios. nexión

Sume las lecturas de las LED pantallas juntas on conecte un voltímetro

externo a través de al carga para determinar el voltaje total de salida.

La corriente de carga puede ser observada desde cualquier fuente; las

lecturas serán idénticas porque están conectados en serie. También, porque

las fuentes están conectadas en serie, solo es necesario establecer un limite

de corriente en una de las fuentes; la otra puede ponerse al máxi m

45

Page 46

Voltaje de salida es igual a la suma de ambas pantallas

Lea la corriente de cualquier

Los dos lean idénticamente

Carga

Figura 8 .Conectando dos fuentes de poder en serie

46

Page 47

Ajuste ambas

fuentes de

salida de corriente es

Figura 9. Conectando dos fuentes de poder en paralelo

poder a el mismo voltaje

igual a la suma de las

dos pantallas

Uso de resistores igualadores

0.1? 0.1?

1W 1W

Carga

47

Page 48

CONECTANDO DOS FUENTES DE PODER EN PARALELO

Dos fuentes de poder pueden ser conectadas en paralelo para

doblar la corriente máxima de corriente. En esta configuración

las dos fuentes proveerán dos 0-30 voltios salida hasta 6 amps

(mas grueso de sondas es recomendable). Resistor igualador de

corriente debe de ser usados como se muestra en la Fig. 9.

Pero, la característica protectiva de la limitación de corriente

prevendrá daño si la corriente es temporalmente disbalanceada

en el arreglo.

Cuando conecte en paralelo y opere en constante voltaje mode,

determine el limite total de corriente de la carga y preestablezca

la limitación de corriente para cada fuente de poder a la mitad de

el valor total de la corriente de la carga. Entonces cuando la

carga es conectada, ponga los controles de VOLTAJE en las dos

fuentes de corriente para lecturas iguales de voltaje. Esto

también debe proveer aproximadamente la misma corriente de

cada fuente. Sume las dos lecturas de el medidor de corriente

para una corriente total de carga, o conecte un ammetro externo

en serie con la carga.

Si los resistores igualadores de corriente no están bien parejos, es

preferible que los voltajes estén ligeramente desbalanceados para

lograr un balance de corriente. Asegúrese que las fuentes estén

adecuadamente balanceadas para que ambos permanezcan en el

modo CV.

Cuando este conectado en paralelo y operando el modo de

constante voltaje, los controles de VO LTAJE de ambas fuentes

deben de ser preestablecidos a el mismo valor. Entonces cuando

la carga es conectada, los controles de CORRIENTE de las dos

fuentes deben de ser ajustados para aproximadamente la misma

corriente de cada unidad. Asegúrese que las dos fuentes

permanezcan el el modo CC.

48

Page 49

APLICACIONES

GENERAL

El modelo 1735A fuente de poder tiene una muy ancha variedad de

aplicaciones en el servicio eléctrico y electrónico, laboratorios de

ingeniería, manufactura y lugares de prueba, escuelas, para el

aficionado. La salida de la fuente de poder es totalmente ajustable

desde 0 a 30 voltios y de 0 a 3 amps. Esta flexibilidad las hace

adecuadas para la mayoría de las aflicciones que requieran una fuente de

poder de cd.

SERVICIO ELECTRONICO

La mayoría de el revisado electrónico o reparación es hecho en la

banca de prueba. La fuente de poder puede proveer la fuente de poder

cd para operar un modulo o tablero de circuito en la banca de prueba

cuando es removido de su equipo mayor. Puede ser usado para

encender portátil, batería-operado equipo y ver el efecto de bajo voltaje

de batería. Puede encender equipo de carro como tocadores de cases,

equipos de sonido de carro, CB radios, etc. en la banca de prueba.

La mayoría de los automóviles y otros vehículos usan un sistema

eléctrico de 12-voltios. Aunque el sistema eléctrico es normalmente

referido como un sistema de 12-voltios, el voltaje actual de batería

cuando esta totalmente cargada es de aproximadamente 14 voltios. La

fuente de poder puede ser puesta a 14 voltios para servir equipo de

vehículos con el sistema eléctrico de 12- voltios. Algunas camionetas

usan un sistema eléctrico de 24-voltios; pruebas de banca de este

equipo con estos sistemas debe de hacerse a 28 voltios.

Algunas aplicaciones de servicio requieren la infección de un voltaje

cd variable para ciertas pruebas, como revisar los efectos de el AGC

bias en un receptor de televisión. Esto requiere un cd fuente de poder

49

aislada, como el modelo 1735A. El equipo bajo prueba puede contener

su propio fuente de poder y operar de ca energía. Un voltaje cd puede

estar ya presente en el circuito. Una polaridad de la salida de la fuente

de poder es flotada a un punto apropiado en el circuito, como el emisor

de un transistor. La otra polaridad de la salida de la fuente de poder es

entonces aplicada a otro punto en el circuito , tal como la base de el

transistor. Variando el voltaje de la fuente de poder cuando varia el

nivel cd en esa etapa, y los efectos pueden ser notados. Un resistor

limitador en serie es frecuentemente usado para proteger los circuitos de

sobre disipación.

MANUFACTURA DE ELECTRONICA

En los talleres de manufactura electrónica, la fuente de energía es

frecuentemente usado como una fuente de energía cd cuando revisando

y ajustando módulos, subsanables, y las unidades completas en las

arreas de producción y ensamblado o en la arrea de control de calidad.

El instrumento puede ser usado en inspecciones como una fuente de

energía para revisar componentes comprados y subasembles.

Esta. Fuente de poder es particularmente muy adecuada para las

aplicaciones de manufactura por su facilidad de operación y su continuo

grado de servicio. Cuando la corriente de carga o el poder disipado total

están entre la principales característica que van ha ser medidas, la

corriente total de carga y voltaje son fácilmente mostrados en las

pantallas LED. El limite de corriente puede ser establecido para que

todas la unidades cuales no tengan las especificaciones de la corriente

de carga hagan que el indicador CC prenda, y la unidad puede ser

rechazada

Page 50

.

APLICACIONES

LABORATORIO DE DISENO ELECTRONICO

El técnico o el ingeniero trabajando en un laboratorio de

ingeniería recrié de una fuente de energía cd para prender

tableros y circuitos. Esta fuente de poder es ideal porque ve la

corriente de salida, el volare de salida, limita la corriente para

proteger el circuito, y es ajustable sobre un ancho rango, además

tiene excelente regulación y muy baja ondulación.

Uso de este instrumento en un laboratorio de ingeniería es muy

similar a lo descrito para el servicio de equipo de electrónica y

módulos, excepto que mas bajas corrientes prevale en cuando

encendiendo circuitos individuales. La característica de

limitación de corriente es muy importante en esta aplicación

porque puede proteger no-probados circuitos de daño.

EDUCACION DE ELECTRONICA

Los estudiantes de un currículo en electrónica pueden usar la

fuente de poder para encender equipo y circuito come

previamente descrito para todas las otras aplicaciones.

Adicionalmente, la fuente de poder puede ser usada en el salón

de laboratorio para conducir experimentos en los principios de

electrónica. En aprender la ley de Ohm, por ejemplo, la

relaciones de resistencia, corriente y voltaje son fácilmente

demostradas con el uso de la fuente de poder.

CARGADO DE BATERIA

La fuente de energía también puede ser usada como un cargador

de baterías para reemplazar la carga en pilas recargables tal como

plomo-ácido, nicol-cadium, y otras tipo alcalino. Refiérase a el

fabricante de las baterías para especificaciones de carga para el

voltaje y corriente apropiados. Información de carga esta

algunas veces escrita en las baterías. El cargado de baterías. Al

menos inicialmente, recrié el made de operación de corriente

constante. Antes de conectar la fuente de energía a la batería,

establezca los controles de VOLTAJE a el completo terminal

voltaje cargado especificado por el fabricador de la batería.

Apague la fuente de poder cuando la este conectando a la

batería. Observe polaridad apropiada y conecte como para

operación de corriente constante. Ajuste el control de

CORRIENTE para el máximo cargado de corriente especificado

por el fabricante de la batería.( Si la máxima corriente de cargado

es mas grande que la máxima corriente de carga de la fuente de

energría, ponga el control de CORRIENTE al máximo). El

indicador de CC prendera y la pila se cargara a el preestablecido

limite de corriente. Cuando la pila se aproxime a carga

completa, el voltaje en sus terminales se aproximara a el de

salida de la fuente de energía y la corriente empezara a decaer.

La fuente de energía puede automáticamente cambiar a

operación CV (Voltaje constante). Cuando esto ocurra, la fuente

de poder continuara dando una carga triple.

50

Page 51

MANTENIMIENTO

PRECAUCION

Las siguientes instrucciones son solo para el uso de personal

calificado. Para evitar choque eléctrico, no haga ningún servicio

otro que el contenido en las instrucciones de operación al menos

que este calificado para hacerlo.

REMPLAZO DE FUSIBLE

Si el fusible se quema, la CV,CC o LED medidores indicadores

se encenderán y la fuente de energía no funcionara. El fusible no

debe de estar normalmente abierto al menos que un problema se

haya desarrollado en la unidad. Trate de deterimar y corregir la

causa de el fusible quemado, entonces cambie solo con un

fusible de el adecuado ratina. Para 120 V operación uno de

2.5A, 250V fusible debe de ser usado y para 220/230 o 240V

operación un 1.5A, 250V fusible debe de ser usado. El fusible

esta localizado en el panel trasero. (vea Fig.2)

CONVERSION DE LINEA DE VOLTAJE, LINEAS

INTERNACIONALES

El 1735A Modelo fuente de poder puede ser cambiado de 110

VCA a 220/230/240VCA por un switch localizado en el panel

trasero. Para convertir a una línea de voltaje diferente, haga el

siguiente procedimiento.

1. Asegúrese que el cordón de poder este desenchufado

2. Determine el voltaje deseado y cambie el switch de bajada a

el voltaje apropiado

3. Para cambiar el CA tapón para un especifico país, use el

siguiente diagrama para la correcta conexión

Verdee tierra

Blanco=220VCA (neutral)

Negro =220/230/240VCA (caliente)

4. Asegúrese que el tapón este conectado correctamente antes

de usar la fuente de poder.

5. Llame la fabrica si esta inseguro acerca de el método de

alambrado.

AJUSTES

Esta unidad fue precisamente ajustada en la fabrica antes de

enviarla. Reajustamiento es solo recomendado si reparaciones

han sido hechas en un circuito que afecte el ajuste de precison, o

si usted tiene una razón de creer que la unidad esta fuera de

ajuste. Pero ajustes solo deben de ser intentados si un milímetro

con una precisión de 0.1% cdv o mejor esta disponible (B & K

Precision Modelo 390 o equivalente).

51

Page 52

1735A CALIBRACION

Si ajustes son requeridos, use el siguiente procedimiento.

Lugares de ajuste son mostrados en Fig. 11.

1. Ponga el panel delantero de controles de el Modelo 1735

como sigue:

Grueso y Fino VOLTAJE controles completamente en la

dirección de la anejillas del reloj

Grueso y Fino CORRIENTE controles completamente en la

dirección de las manejillad del reloj

Switch de poder en encendido