Bixs MTB/Cross, Pedelec/E-bike, Mariposa, Cougar, Sauvage Operating Instructions Manual

...

SWISS ENGINEERED

ATTENTION!

Please read pages 13-18 before your first ride!

Please perform the functional check on pages 19-22 before every ride!

Please observe bike card!

Your BiXS bicycle and this translation of these original operating instructions comply with the safety

requirements laid down in the European standard EN 14766 mountain bike and EN 15194 are referred

to as pedelecs.

MTB / CROSS

PEDELEC / E-BIKE

OPERATING INSTRUCTIONS

www.bixs.com

Rahmen:

a

Oberrohr

b

Unterrohr

c

Sitzrohr

d

Kettenstrebe

1 Sattel

2 Sattelstütze

3 Sattelstützenklemme

4 Bremse hinten

5 Bremsscheibe

6 Umwerfer

7 Zahnkranz

8 Schaltwerk

9 Kette

10 Kettenblatt

Frame:

a

Top tube

b

Down tube

c

Seat tube

d

Chainstay

1 Saddle

2 Seat post

3 Seat post clamp

4 Rear brake

5 Rotor

6 Front derailleur

7 Cassette sprockets

8 Rear derailleur

9 Chain

10 Chainring

Cadre :

a

Tube supérieure

b

Tube diagonale

c

Tube de selle

d

Base

1 Selle

2 Tige de selle

3 Collier de serrage

de selle

4 Frein arrière

5 Disque de frein

6 Dérailleur avant

7 Jeu de pignons

8 Dérailleur arrière

9 Chaîne

e

Sitzstrebe

f

Steuerrohr

g

Stoßdämpfer

e

Rear stay

f

Head tube

g

Rear Shock

e

Hauban

f

Tube de direction

g

Amortisseur

BAUTEILBESCHREIBUNG

Federgabel:

I

Gabelkopf

II

Standrohr

III

Tauchrohr

IV

Ausfallende

11 Tretkurbel

12 Pedal

13 Vorbau

14 Lenker

15 Bremshebel

16 Schalthebel

17 Lenkungslager

18 Frontscheinwerfer

19 Gabel

A

B

C

Bedieneinheit

20 Bremse vorne

21 Bremsscheibe

Laufrad:

22 Schnellspanner/

Steckachse

23 Speiche

24 Felge

25 Reifen

26 Nabe

COMPONENTS

11 Crankset

12 Pedal

13 Stem

14 Handlebar

15 Brake lever

16 Shifter

17 Headset

18 Front light

19 Fork

Suspension fork:

I

Fork crown

II

Stanchion tube

III

Lower leg

IV

Drop-out

A

B

C

control element

20 Front brake

21 Rotor

Wheel:

22 Quick-release/

thru axle

23 Spoke

24 Rim

25 Tyre

26 Hub

DESCRIPTION DES COMPOSANTS

Fourche suspendue :

I

Té de fourche

II

Plongeur

III

Fourreau

IV

Patte de fi xation

10 Plateau

11 Manivelle

12 Pédale

13 Potence

14 Cintre

15 Levier de frein

16 Manette de vitesse

17 Jeu de direction

18 Phare avant

19 Fourche

A

B

C

et visuel

20 Frein avant

21 Disque de frein

Roue :

22 Attache rapide/

Axes traversants

23 Rayon

24 Jante

25 Pneumatique

26 Moyeu

Motor

Akku

Display und

Motor

Rechargeable battery

Display and

Moteur

Batterie

Unité de commande

10

11

12

4, 5

10

11

12

13

1

14

15

2

3

a

6

4

5

e

g

c

7

8

d

f

I

II

b

III

IV

9

16

17

20

21

22

23

24

25

26

13

1

2

C

3

a

f

14

15

16

17

18

19

e

c

6

7

8

A

d

9

B

b

20

21

22

23

24

25

26

SOME NOTES ON THESE ORIGINAL

OPERATING INSTRUCTIONS

The illustration shows a typical mountain bike and an E-bike/pedelec

– this type corresponds to the BiXS bicycle or BiXS pedelec that you

have just purchased. Today’s bicycles and e-bikes/pedelecs come in a

great many types that are designed for specific uses and are equipped

accordingly.

In the present operating instructions bicycles with drive support and

described as EPACs in the European standard EN 15194 are referred to

as pedelecs. For a precise description of the different EPAC types see

the chapter “Intended Use”.

In these operating instructions the term “bicycle” will always be used

in general descriptions if this refers to mountain bikes and pedelecs. If

the warnings or information relate only to pedelecs then these will be

marked with a special symbol.

Pay particular attention to the following symbols:

e

This symbol indicates an imminent risk to your life or health

g

unless you comply with the corresponding handling in-

structions given or take preventive measures.

This symbol warns you of incorrect actions that could result

a

in damage to property and the environment.

This symbol provides you with information about how to

I

handle the product or refers to a passage in the operating

instructions that deserves your special attention.

The following symbols always appear if it is necessary to bring your

attention to special points concerning pedelecs. If you have purchased

a BiXS pedelec then you should pay special attention to this information

and these warnings. Please note as well in all cases the general warning information given in these operating instructions.

f

g

h

1

TABLE OF CONTENTS

This symbol indicates an imminent risk to your life or health

H

unless you comply with the corresponding handling instructions given or take preventive measures when using your

BiXS pedelec. Please note as well in all cases the general

warning information given in these operating instructions.

This symbol warns you of incorrect actions that could re-

S

sult in damage to property and the environment when using

your BiXS pedelec. Please note as well in all cases the gen-

a

eral warning information given in these operating instructions.

This symbol provides you with information about how to

u

handle the BiXS pedelec or refers to a passage in the operating instructions that deserves your special attention.

Please note as well in all cases the general warning information given in these operating instructions.

The described possible consequences will not be repeated in these operating instructions every time one of the symbols appears.

b

This translation of the operating instructions is not intended to help you

assemble a BiXS bicycle from individual components, to repair it or to

make a partly assembled bicycle ready for use.

These operating instructions are not applicable to any other than

the displayed bicycle types.

These operating instructions correspond to the requirements of the

European standards EN 14766 for mountain bikes and EN 15194 for

Cycles – Electrically power assisted cycles– EPAC bicycles and the

c

Machinery Directive 2006/42/EU.

Comply also with the instructions of the parts manufacturers, which you

can find on the enclosed CD.

The present operating instructions are subject to European law. If your

BiXS bicycle is to be delivered to countries outside Europe, supplementary information has to be provided by the bicycle manufacturer as the

case may be.

Technical details in the text and illustrations of these operating instructions are subject to change.

d

SOME NOTES ON THESE ORIGINALOPERATING INSTRUCTIONS 1

TABLE OF CONTENTS 3

GENER AL SAFETY NOTES 6

INTENDED USE 9

BEFORE YOUR FIRST RIDE 13

Additional information “Before Your First Ride” with your BiXS Pedelec ........................................................... 17

BEFORE EVERY RIDE 19

Additional information “Before Ever y Ride” with your BiXS Pedelec ..................................................................22

AFTER AN ACCIDENT 23

Additional information “After an Accident” with your BiXS Pedelec ..................................................................26

HOW TO USE QUICK-RELEASES AND THRU AXLES 27

Quick-releases ..................................................................................................................................................27

How to Fasten Components Securely with a Quick-Release

Thru Axles ......................................................................................................................................................... 30

Notes on How to Mount Front Wheels

Notes on How to Mount Rear Wheels

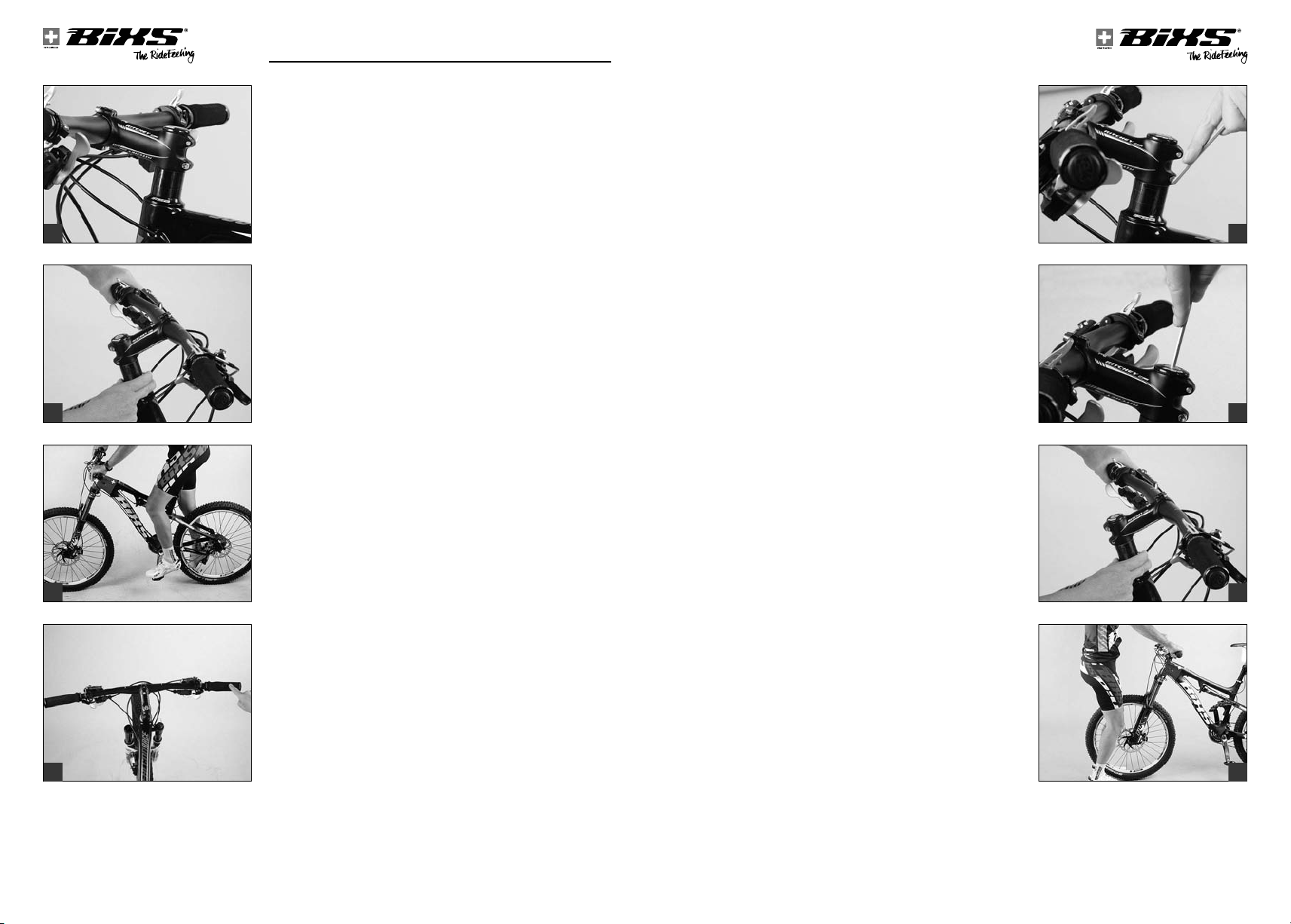

ADJUSTING THE BiXS BICYCLE TO THE RIDER 33

Setting the Saddle Height ..................................................................................................................................34

Adjusting the Height of the Handlebars .............................................................................................................36

Adjustable Stems ..............................................................................................................................................37

Stems for Threadless Systems, the Aheadset

Adjusting the Tilt of the Handlebars, Bar Ends and Brake Levers ......................................................................39

Adjusting the Brake Lever Reach....................................................................................................................... 41

Correcting the Fore-To-Aft Position and Tilt of the Saddle ................................................................................ 42

Adjusting Saddle Position and Tilt ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... 43

Patent clamping with one bolt or two parallel bolts ........................................................................................43

Clamping with t wo bolts in line ..................................................................................................................... 44

Single bolt system........................................................................................................................................45

Ritchey “Mast Topper” . ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .. 46

Seat post Monorail ... ... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... .. 46

CARBON – IMPORTANT INFORMATION 47

BiXS DIRT, FREERIDE, DOWNHILL BIKES – SPECIAL FE ATURES 49

Adjusting the saddle to the correct height

BRAKE SYSTEM 51

General Information on Brakes .......................................................................................................................... 51

Rim Brakes........................................................................................................................................................ 53

V-Brakes

..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... .53

Operation and Wear . ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... 53

Functional Check ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... .. 53

Synchronising and Readjusting ... ... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... .... 54

Disc Brakes ....................................................................................................................................................... 55

Operation and Wear . ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... 55

Hydraulic Disc Brakes ... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... .... 56

Functional Check ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... .. 56

Wear and Maintenance .. ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ... 56

Mechanical Disc Brakes ... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... 57

Functional Check ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... .. 57

Wear and Maintenance .. ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ... 57

... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... .30

... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... .32

®

System .....................................................................................37

..... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... .... 50

.... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... 28

2

3

GEARS 58

Derailleur Gears ................................................................................................................................................58

Operation and Control ..................................................................................................................................58

Checking and Readjusting

.... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... .... 60

Adjusting the Rear Derailleur ... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... 61

Adjusting the Limit Stops . .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... .61

Adjusting the Front Derailleur .. ... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ... 62

CHAIN – CARE AND WE AR 63

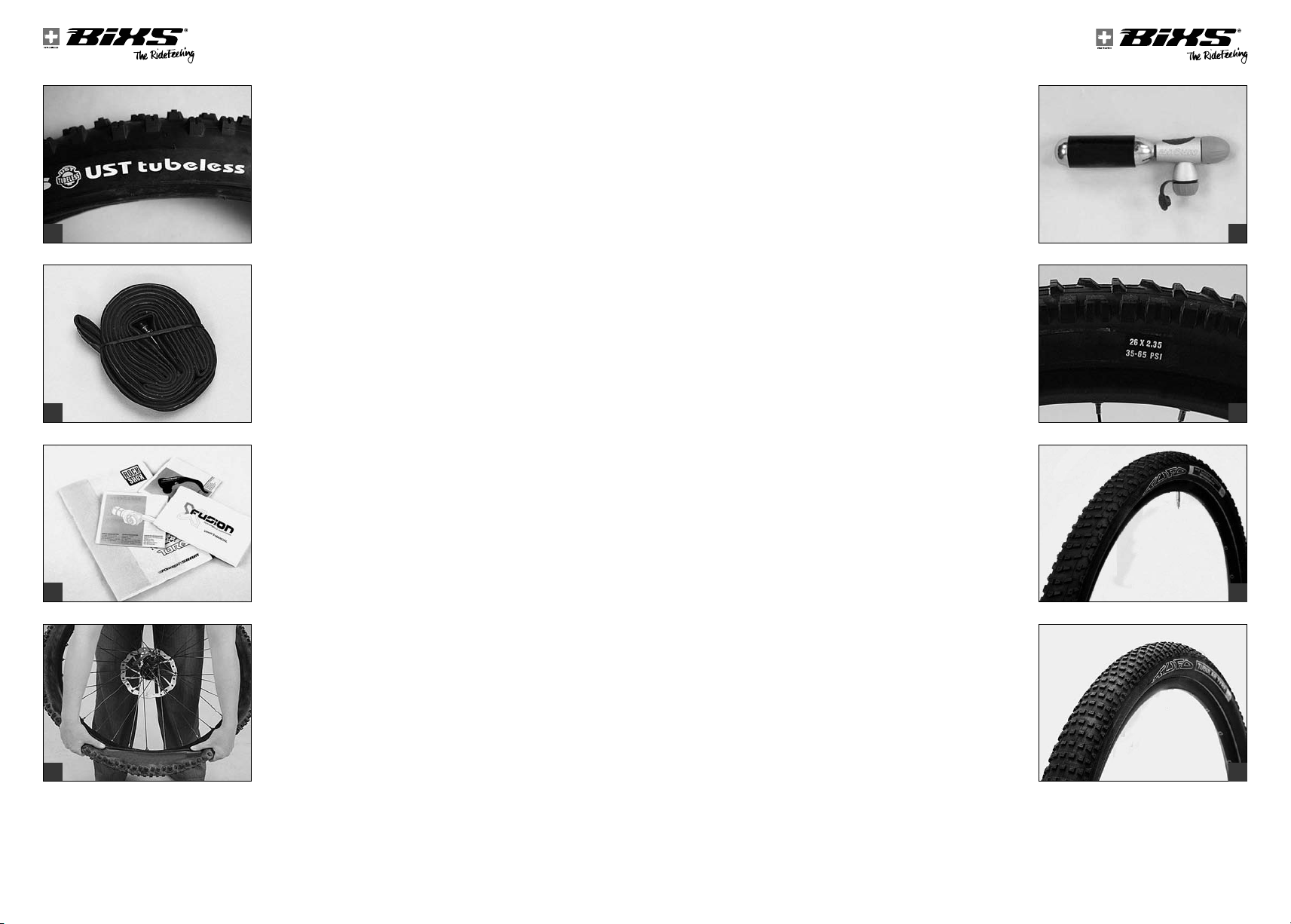

WHEELS AND T YRE EQUIPMENT 64

Tyres, Inner Tubes, Rim Tape, Inflation Pressure ............................................................................................... 64

Valves................................................................................................................................................................ 65

Rim Trueness and Spoke Tension ......................................................................................................................67

TYRE PUNCTURE 68

Wheel Removal .................................................................................................................................................68

Clincher and Folding Tyres ................................................................................................................................69

Tyre Removal

..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... .... 69

Tyre Mounting ... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... .... 70

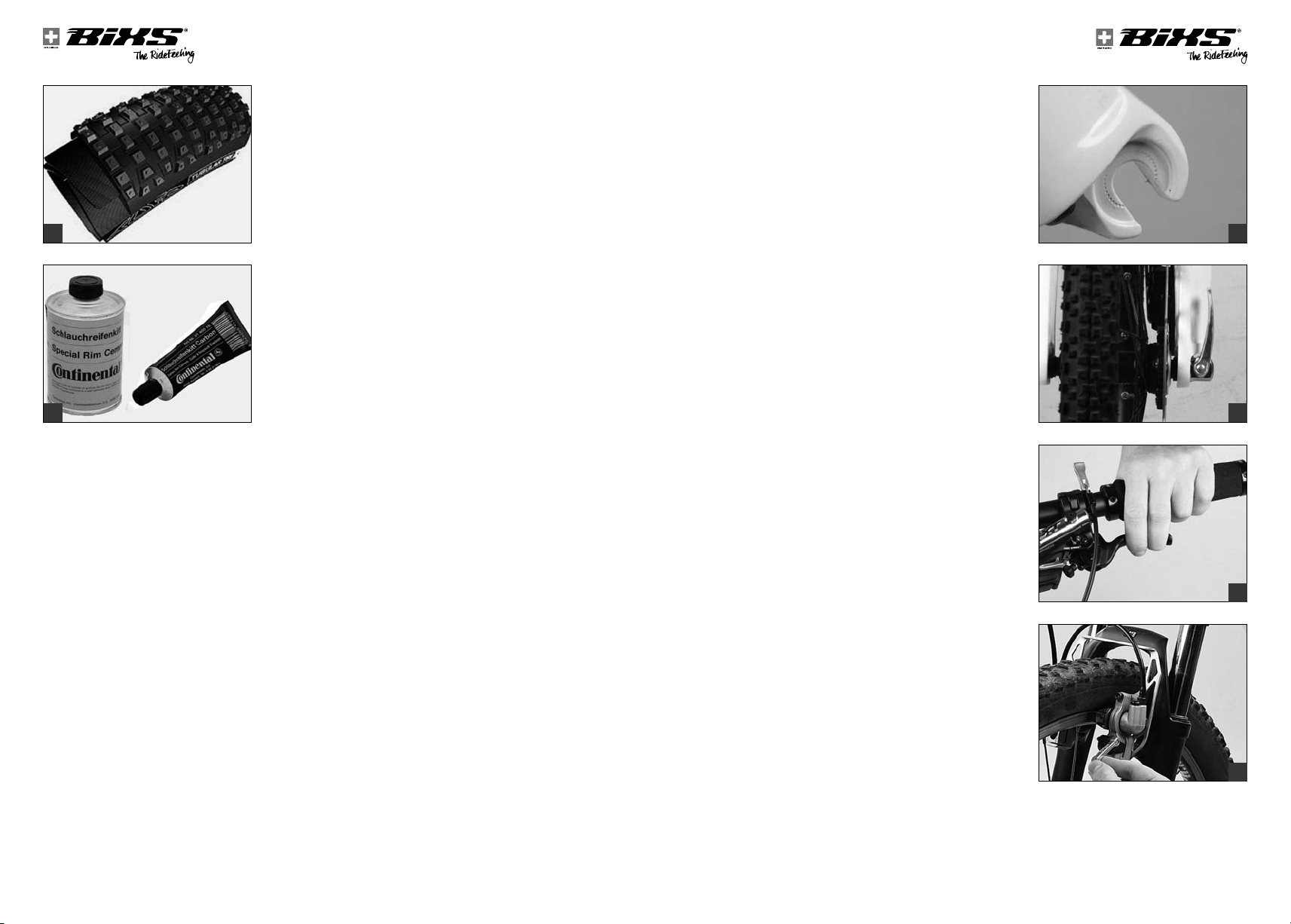

Tubeless/UST tyres ...........................................................................................................................................72

Tyre Removal

Repair

..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... .... 72

.. ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... 72

Tyre Mounting ... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... .... 72

Tubular Tyres ..................................................................................................................................................... 73

Tyre Removal .... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... 73

Tyre Mounting

.... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .73

Wheel Mounting ................................................................................................................................................ 75

HEADSET 76

Checking and Readjusting .................................................................................................................................76

Threadless Headset – Aheadset

®

.................................................................................................................... 77

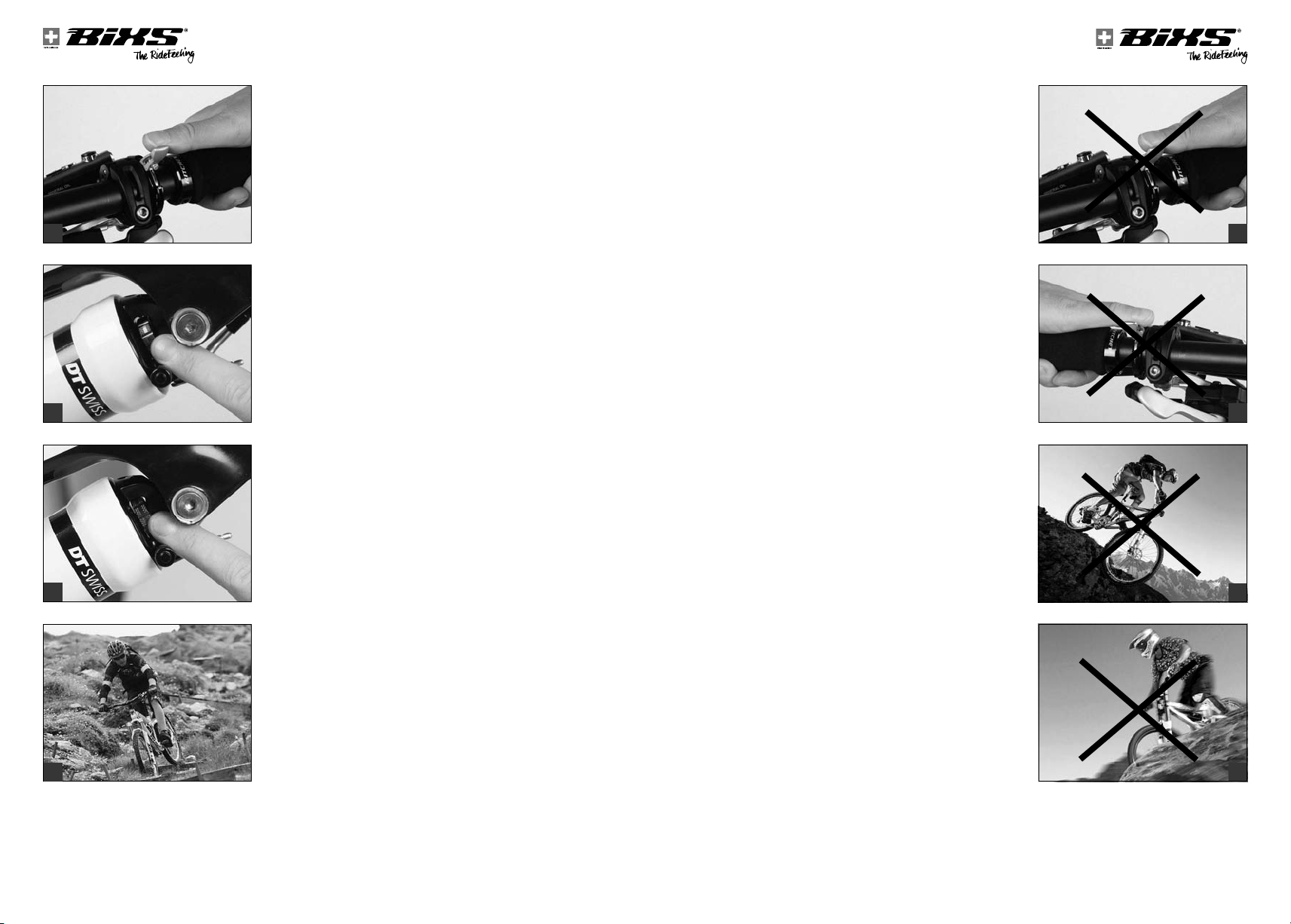

SUSPENSION 78

Glossary ............................................................................................................................................................ 78

Suspension Forks .............................................................................................................................................. 79

Adjusting the Spring Rate

.... ... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ...... 79

Damping and Lockout .... ... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... 81

Maintenance . ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... .... 82

Rear Shock ........................................................................................................................................................ 83

What to Bear in Mind when Adjusting the Seating Position . ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... .. 83

Adjusting the Spring Rate .. ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ... 84

Adjusting the Damping Control .... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... .86

Adjusting the Travel .. ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... .... 87

Maintenance . ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... .... 87

PEDELECS 89

Useful Tips for Riding a BiXS Pedelec ................................................................................................................ 89

Riding with Drive Assistance

.... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... .. 89

Range – Useful Information for a Long Ride .... ... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... .... 91

Riding Without Drive Assistance . ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... .92

Riding a BiXS Speed Pedelec – Special Features ..............................................................................................93

Useful Information for Proper Handling of the Battery .......................................................................................95

LIGHTING SYSTEM 98

Battery-Powered Lighting .................................................................................................................................98

THINGS YOU NEED TO KNOW ABOUT BICYCLES AND CYCLING 99

Cycling Helmets and Glasses ............................................................................................................................99

Clothing ............................................................................................................................................................. 99

Pedals and Shoes ............................................................................................................................................ 100

Accessories ..................................................................................................................................................... 101

TRANSPORTING BAGGAGE 104

TAKING CHILDREN WITH YOU 105

Child-Carrier seats .......................................................................................................................................... 105

Child Trailers ...................................................................................................................................................105

Children’s bicycle Towing Devices / Towing Systems ......................................................................................106

TRANSPORTING YOUR BiXS BICYCLE 107

By Car .............................................................................................................................................................107

By Public Transpor t ......................................................................................................................................... 108

Special points concerning transpor t of your BiXS pedelec .............................................................................. 109

By Car

.... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... .... 109

By Train / By Public Transport ... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... . 110

By Plane ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... ....... ..... ..... ....... ..... ..... ....... ..... ..... ..... .... ... ..... ..... .... ... ..... ..... .... ... ..... ..... 110

GENER AL NOTES ON CARE AND SERVICING 111

Maintenance and Servicing ............................................................................................................................. 111

Cleaning and maintaining your BiXS bicycle or pedelec................................................................................... 112

SERVICE AND MAINTENANCE SCHEDULE 114

RECOMMENDED TORQUE SETTINGS FOR COMPONENTS 116

Recommended Torque Settings for Disc Brakes.............................................................................................. 117

LEGA L REQUIREMENTS FOR RIDING ON PUBLIC ROADS 118

WARRANT Y AND GUARANTEE 120

A Note on Wear ............................................................................................................................................... 121

WARRANT Y / GUARANTEE FOR BiXS MODELS 122

DISTRIBUTOR – BiXS 123

SERVICE SCHEDULE (TO BE STAMPED) 124

BIKE CARD 130

HANDOVER REPORT 131

Edition 1, September 2012

© No part of this publication may be reprinted, translated, copied or transmitted in any form or by any means,

electronic, mechanical, by hand or otherwise for another business purpose without prior written permission of

Zedler – Institut für Fahrradtechnik und -Sicherheit GmbH.

© Text, concept, photos and graphic design

Zedler – Institut für Fahrradtechnik und -Sicherheit GmbH

www.zedler.de

4

5

GENERAL SAFETY NOTES

Dear Customer,

In purchasing this BiXS bicycle

high quality and technology. Each component of your new BiXS bicycle

has been designed, manufactured and assembled with great care and

expertise. Your BiXS bicycle dealer gave the bicycle its final assembly

and adjustment to guarantee proper operation and many enjoyable riding experiences with complete peace of mind from the very first metres.

a

b

c

These operating instructions contain a wealth of information on the

proper use of your BiXS bicycle, its maintenance and operation as well

as interesting information on bicycle design and engineering. Please

read these instructions thoroughly. We are sure that even if you have

been cycling all your life you will find useful and detailed information.

Bicycle and pedelec technology has developed at a very rapid pace during recent years. Therefore, before setting off on your new BiXS bicycle,

be sure to read at least the chapter “Before Your FIRST Ride” first.

To have as much fun as possible during cycling, be sure to carry out the

functional check described in chapter “Before EVERY Ride” before

setting off.

Even a manual as big as an encyclopaedia could not describe every

possible combination of bicycle models and components or parts on

the market. These operating instructions therefore focus on your newly

purchased BiXS bicycle and standard components and provide useful

information and warnings. In addition to this, your BionX system operating instructions give important information and warnings on handling

your new BiXS pedelec.

When doing any adjusting or servicing, be aware that the detailed instructions and information provided in these operating instructions only

refer to this BiXS mountain bike or BiXS pedelec.

(a-d)

you have chosen a product of

The information included here is not applicable to any other bicycle

type. As bicycles and pedelecs come in a wide variety of designs with

frequent model changes, the routines described may require complementary information. Comply also with the instructions of the parts

manufacturers, which you can find on the enclosed CD.

Be aware that these instructions may require further explanation, depending on the experience and/or skills of the person doing the work.

(e)

For some jobs you may require additional (special) tools

(f)

plementary instructions

a bicycle mechanic.

Before you set off, let us point out a few things that are very important to

every cyclist: Never ride without a properly adjusted helmet and without

(g)

glasses

a minimum you should wear straight cut trousers and shoes fitting the

pedal system. Always ride carefully on public roads and observe the

traffic rules so as not to endanger yourself or others.

This manual cannot teach you how to ride. Please be aware that cycling

is a hazardous activity that requires the rider to stay in control of his or

her BiXS bicycle at all times.

Like any sport, cycling involves the risk of injury and damage. Keep

this in mind. When you decide to ride a bicycle or pedelec you need

to accept the risk inherent to cycling. Please note that on a bicycle you

have no protection technique around you (e.g. bodywork, ABS, airbag)

like you have in a car. Therefore, always ride carefully and do respect

the other road users. Never ride under the influence of drugs, medication, alcohol or when you are tired. Do not ride with a second person

on your BiXS bicycle and never ride without having both hands on the

handlebars

and take care to always wear suitable, bright clothing. As

(h)

.

. This manual cannot teach you the skills of

or sup-

e

f

g

d

6

h

7

INTENDED USE

13

14

15

16

17

20

21

22

23

24

25

26

a

b

d

e

f

I

II

1

2

3

6

4

5

7

8

9

10

11

12

c

III

IV

g

Observe the legal regulations concerning off-road cycling

pedelecs). These regulations may differ in each country. Please respect

nature when riding off-road. Only use your pedelec on signposted, well

maintained trails and hard-surface roads.

Always bear in mind that you travel rapidly and quietly when you are

(b)

riding a BiXS pedelec

. Do not startle pedestrians or other cyclists.

Always make others aware of your presence well ahead of time and by

ringing your bell or make use of the brakes so as to avoid accidents.

a

Familiarize yourself with your BiXS pedelec. You can fi nd further information in the chapters “Useful Tips for Riding a BiXS Pedelec“ and

“Riding a BiXS Speed Pedelec – Special Features”.

(a)

(also for

Keep in mind that every bicycle type is built for a specifi c intended use

(e-g)

. Be sure to use your BiXS bicycle only according to its intended

use, as it may otherwise not withstand the stress and would fail and

cause an accident with unforeseeable consequences!

1. Cross bikes are equipped with 28”-wheels (inner diameter 622

mm) and intended for hard-surface roads. They are also suitable

for off-road cycling on gravel fi eld tracks, however, not for rough

terrain.

2. Cross-country, marathon and touring mountain bikes are also

suitable for off-road use, but not for extreme terrain, jumps, drops

e

and competitive use in the categories freeride, dual slalom, down-

First of all, we would like to familiarize you with your BiXS bicycle or

hill-races, etc.

pedelec. Please unfold the cover of this manual. A BiXS mountain bike

(c)

and a BiXS pedelec

necessary components are described. Leave the page unfolded as you

read so that you can easily locate the components as they are referred

(d)

are shown as examples in which all the

3. Enduro and all-mountain bikes are suitable for off-road use (Alpcross etc.); they are, however, not designed for dual, dirt, downhill

and freeride cycling etc.

to in the text.

4. Dirt/fourcross, urban and dual slalom bikes are intended for

b

For your own safety, never do work on your pedelec unless

g

you feel absolutely sure about it. If you are in doubt or if

you have any questions, please contact your BiXS bicycle

1

2

3

6

4

5

7

8

9

10

11

12

e

d

f

a

I

II

g

b

c

III

IV

13

14

15

16

17

20

21

22

23

24

25

26

dealer.

c

1

2

3

c

6

4, 5

7

8

9

10

11

12

d

e

A

d

C

a

f

B

b

13

14

15

16

17

18

19

20

21

22

23

24

25

26

hard use on secured terrain. There are different types which are

either equipped for trick and show cycling, for jumps and freestyle

in special obstacle courses or for races.

5. Downhill bikes are designed for high level downhill races.

6. Freeride bikes are suitable for jumps and drops in most challenging terrains and in bicycle parks.

Be sure to use your bicycle only for its intended purpose,

g

as it may otherwise not withstand the stress and fail! Risk

of accident!

For your own safety, do not overestimate your cycling skills.

g

Please note that though looking easy the tricks of a profes-

sional are hazardous to your life and limb. Always protect

(h)

yourself with suitable clothing

.

f

g

h

8

9

7. Pedelecs (Pedal Electric Cycles)

Assisted Cycles) are bicycles with an auxiliary motor that only

switches on when the pedals are moved by the rider. When you

stop pedalling, the motor switches off.

A driving licence is not required for riding a pedelec

tor assistance switches off automatically at a speed of 25 kmh/15

mph. You do not need an operating licence and need not insure the

a

pedelec either. Please do not confuse your pedelec with a speed

pedelec (S-Pedelec) (see item 9).

All regulations that apply to bicycles, also apply to pedelecs, i.e.

they are allowed to or must use cycle paths without any restrictions. Wearing a helmet is recommended, but not compulsory.

Most pedelecs are designed for cycling exclusively on lanes and

roads with a smooth surface

bicycles. In general, typical pedelecs are not suitable for off-road

use. Using pedelecs off-road can result in crashes with unforeseeable consequences.

b

If your pedelec does not look like a typical mountain bike (see the

cover), then please read the chapter “Before Your First Ride”.

Please note that there are different types of pedelecs and e-

U

bikes which are subject to different overall legal conditions.

Check the class of your BiXS pedelec or e-bike in the bicycle

card. Keep the specific regulations for your pedelec/e-bike

class in mind when riding on public roads and also through

the countryside.

(a)

or EPACs (Electrically Power

(b)

if the mo-

(c)

. Only use trails that are allowed for

The starting or pushing aid provides assistance during pushing or

when doing a hill start, even without pedalling, up to a speed of 6

kmh / 3.7 mph.

These BiXS pedelecs are not required to be insured for riding on

public roads.

If you were born after 1st April 1965 you will require a

U

moped driving licence (driving licence class M) or a driving

licence for motor vehicles according to the German Bicycle

Association (ZIV).

The laws and regulations concerning pedelecs, speed

U

pedelecs and e-bikes are currently being revised. Read the

daily press to keep yourself informed about current legislative changes.

The other regulations do not differ from those relating to pedelecs

(see item 7.).

9. Speed pedelecs are bicycles with an auxiliary motor which provide assistance to the rider even beyond a speed of 25 kmh / 15

mph, as long as you continue pedalling. Without pedalling a speed

pedelec provides assistance to a maximum speed of 20 kmh/12

mph.

Speed pedelecs are regarded as motor vehicles, have an operat-

ing licence or EU type approval, and are therefore subject to strict

guidelines regarding the replacement of components or making

any conversions.

e

f

10

(d+e)

c

8. Pedelecs

trically Power Assisted Cycles) with starting or pushing aid are

considered as motor vehicles with special authorization. Nevertheless, you do not need an operating licence and need not insure the

pedelec either. Wearing a cycle helmet is not compulsory either,

but highly recommended.

d

(Pedal Electric Cycles) as well as EPACs (Elec-

It is mandatory to wear a helmet

If you are riding a speed pedelec you may not use cycle paths

within built-up areas in Germany. The only exception to this is in

cases where the cycle path or lane has been approved for use

by mopeds (this is marked by an additional sign). Outside built-up

areas it is permissible to ride a speed pedelec on cycle paths and

(g+h)

lanes

These speed pedelecs are required to have an operating licence

and to be insured as motor vehicle when riding on public roads. If

you were born after 1st April 1965 you will require a moped license

(driving license class M) or a driving license for motor vehicles. You

can obtain a moped license if you are aged 15 or over. Enquire at

your driving license agency.

.

(f)

in Germany and Switzerland.

g

h

11

BEFORE YOUR FIRST RIDE

a

Manufacturer

Model

Bike-ID

Frame no.

Rear shock - Manufacturer/Model

Suspension fork - Manufacturer/Model

- Serial no

Frame type

Frame size

Size of wheels and tyres

Colour

Special features

Permissible overall load

(bicycle, rider and baggage) ____ kg

Pannier rack £ yes £ no

Permissible load ____ kg

Child carrier allowed £ yes £ no

Trailer allowed £ yes £ no

Permissible trailer load ____ kg

b

BIKE CARD

(Hint to the dealer: Please copy the bike card and the handover report

and keep one copy in your customer file. Send another copy to the

manufacturer.)

Brake levers

g

Brakes assignment

Right lever

£ front wh eel brake

£ rear wheel b rake

Left lever

£ front wh eel brake

£ rear wheel b rake

HANDOVER REPORT

The above-described bicycle was delivered to the customer ready for use, i. e. after completion of assembly, inspection, and operational checks as described below (additionally required routines in parentheses):

£ Lighting

£ Brakes rear a nd front

£ Suspension fo rk, rear shock (adjusted to suit customer)

£ Wheels ( trueness/spoke tension/tyre pressure)

£ Handlebar s/stem (position/bolts checked wit h

torque wrench)

£ Pedals (adjustment of r elease force, if necessary)

£ Saddle /seat post (height and position of saddle

adjusted to suit customer, bolts checked with

torque wrench)

£ Gears ( limit stops!)

£ Acces sory fastenings (check with torque wrench)

£ Other rou tines performed

£ Test ride

Dealer name ____________________________

Street ___________________________

Town ____________________________

Deli very date, dealer stamp and signature

Customer name ____________________________

first name _________________________

Street ___________________________

ZIP code/town _____________________

£ Manual/operating instructions

Additional instructions:

£ Brake system

£ Suspension seat post

£ Pedal system

£ Rear shock

£ Suspension fork

£ Seat post, stem

£ Gear system

£ System operating instructions BionX

£ Others

Phone ___________________________

Fax _____________________________

E-mail ___________________________

Phone ___________________________

Fax _____________________________

E-mail ___________________________

In Switzerland you may ride your speed pedelec on paths and

tracks where mopeds are not allowed if you ride without drive assistance to maximum 20 km/h (12 mph), with drive assistance to

maximum 25 km/h (15 mph) or with the motor switched off completely.

Be sure to also read the chapter “Riding a BiXS Speed Pedelec –

Special Features”.

(a)

Most of the speed pedelecs

are designed for cycling exclusively on

lanes and roads with a smooth surface. Only use trails that are allowed

for speed pedelecs / e-bikes. Typical speed pedelecs are generally not

suitable for off-road use. Using speed pedelecs off-road can result in

crashes with unforeseeable consequences.

Comply also with the instructions of the parts manufactur-

I

ers, which you can find on the enclosed CD.

For more information about the intended use of your BiXS

U

pedelec as well as the permitted overall weight (rider,

pedelec and baggage) see the BionX system operating in-

(b)

structions and the bicycle card

and read the chapter

“Before Your First Ride”.

For more information on approval for the use of trailers and

U

child-carrier seats on your BiXS pedelec please refer to the

BionX system operating instructions and the bicycle card.

1. Your BiXS bicycle is designed for a maximum overall weight, including rider, baggage and BiXS bicycle all together.

The maximum overall weight is specified in the following table and in the bicycle card enclosed with these operating instructions; if it is not, then contact your BiXS bicycle dealer.

Model name Frame Vehicle Rider’s Total Weight Child-carrier Trailer

weight weight weight guaranteed seat allowed allowed

Mariposa FS Carbon 11-15 75 86-90 130 no no

Mariposa FS Alloy 12-16 75 87-91 130 no no

Mariposa HT Alloy 11-15 75 86-90 130 no 25

Mariposa HT Alloy EQ 14-18 75 89-93 130 no 25

Cougar FS Carbon 12-16 75 87-91 130 no no

Cougar FS Alloy 14-18 75 89-93 130 no no

Sauvage FS Carbon 11-15 75 86-90 130 no no

Sauvage FS Alloy 13-17 75 88-92 130 no no

Chamois FS Carbon 12-16 75 87-91 130 no no

Chamois FS Alloy 13-17 75 87-91 130 no no

Pace 29 FS Carbon 11-15 75 86-90 130 no no

Sign 29 FS Carbon 11-15 75 86-90 130 no no

Sign 29 FS Alloy 14-18 75 89-93 130 no no

Core 29 HT Carbon 9-13 75 84-88 130 no 25

Core 29 HT Alloy 12-16 75 87-91 130 no 25

Storm HT Alloy 13-17 75 88-92 130 no 25

Sportivo HT Alloy 12-16 75 87-91 130 no 25

12

c

d

13

2. If you want to use your pedelec on public roads, it has to comply

with the respective legal requirements. These requirements may

vary in each country. The fittings of your bicycle are, therefore,

not necessarily complete. Ask your BiXS bicycle dealer concerning the laws and regulations applicable in your country or in the

country you intend to use your BiXS bicycle. Have your BiXS bicycle

equipped accordingly before using it on public roads.

We very strongly recommend you to take out private liability

a

b

c

i

insurance. Ensure that your insurance covers you for damage caused while riding the bicycle or pedelec. Contact an

insurance company or broker.

(a)

3. Are you familiar with the brake system

cle card and check whether the brake lever

on the side you are used to (right or left). If it is not, ask your BiXS

bicycle dealer to switch the brake levers before you set off for the

first time.

Your new BiXS bicycle is equipped with modern brakes

may be far more powerful than those that you were used to before.

Be sure to first practise using the brakes on a level, non-slip surface off public roads!

You can find further information in the chapter “Brake System”

and in the instructions from the parts manufacturers, which you

can find on the enclosed CD.

4. Are you familiar with the type and functioning of the gears

your BiXS bicycle dealer to explain you the gear system and make

yourself familiar with your new gears in an area free of traffic, if

necessary.

You can find further information in the chapter “Gears” and in the

instructions from the parts manufacturers, which you can find on

the enclosed CD.

? Have a look at the bicy-

(b)

of the front brake is

(c)

which

(d)

? Ask

5. Are both the saddle and handlebars properly adjusted? The saddle

should be set to a height from which you can just reach the pedal

(e)

in its lowest position with your heel

reach to the floor when you are sitting on the saddle. Your BiXS

bicycle dealer will be pleased to help you if you are not happy with

your seating position.

For more information see the chapter “Adjusting the BiXS Bicy-

cle to the Rider”.

6. If your BiXS bicycle is equipped with clipless or step-in pedals

Have you ever tried the shoes they go with? Do not set off until

you have practised engaging and disengaging the shoes from the

pedals when stationary. Ask your BiXS bicycle dealer to explain the

pedals to you.

You can find further information in the chapter “Pedals and

Shoes” and in the instructions from the parts manufacturers,

which you can find on the enclosed CD.

7. If you have bought a BiXS bicycle with suspension, you should ask

your BiXS bicycle dealer to adjust the suspension mechanism to

your needs before delivery. Improperly adjusted suspension components are liable to malfunction or damage. In any case they will

impair the performance of your bicycle as well as your safety and

pleasure whilst cycling.

You can find further information in the chapters “Suspension

(g)

Forks”

parts manufacturers, which you can find on the enclosed CD.

Be aware that the distance you need to stop your bicycle

G

and “Rear Shock”

increases if you are riding with your hands on the bar ends.

The brake levers are not always within easy reach.

. Check whether your toes

(h)

and in the instructions from the

(f)

e

:

f

g

14

d

h

15

Be sure to use your BiXS bicycle only for its intended use,

g

as it may otherwise not withstand the stress and fail! Dan-

ger of an accident!

Make particularly sure there is enough space between your

g

Please note that in wet conditions the brake performance is

a

G

g

a

b

a

c

(a)

crotch

if you have to get off your pedelec quickly.

less effective and the tyre grip is reduced. Keep this fact in

mind in particular when riding on a wet road and do not ride

as fast as you would in dry conditions.

Due to the specific intended use, some dirt bikes

fitted with only one brake. Do not ride these bikes on public

roads, but only on signposted tracks and lanes.

A lack of practice when using clipless pedals or too much

spring tension in the mechanism can lead to a very firm

connection, from which you cannot quickly step out! Dan-

ger of an accident!

Before hitching a trailer

child-carrier seat

contact your BiXS bicycle dealer.

and the top tube so that you do not hurt yourself,

(b)

are

(c)

to your bicycle or mounting a

(d)

, have a look at the bicycle card and

ADDITIONAL INFORMATION “BEFORE YOUR FIRST RIDE”

WITH YOUR BiXS PEDELEC

1. Have you ridden a pedelec

characteristics of this revolutionary hybrid drive concept. Set off

for your first ride by selecting the lowest level of drive assistance!

Slowly approach the potential of your BiXS pedelec in an area free

of traffic.

You can find further information in the chapters “Useful Tips for

Riding a BiXS Pedelec” and “Riding a BiXS Speed Pedelec

– Special Features” and in your BionX system operating instruc-

tions.

2. Your BiXS bicycle is designed for a maximum overall weight, including rider, baggage and pedelec. The maximum overall weight

is specified in your BionX system operating instructions; if it is not,

then contact your BiXS bicycle dealer.

The weight distribution on pedelecs differs markedly from

H

the weight distribution on bicycles without drive assistance. A pedelec is markedly heavier than a bicycle without

drive assistance. For this reason parking, pushing, lifting

and carrying the BiXS pedelec is more difficult. Bear this in

mind when loading your pedelec into a car and unloading it

or when mounting it on a bicycle carrier system.

3. The rechargeable battery

before you set off for the first time

handling and mounting of the rechargeable battery? Before you set

off for the first time, check whether the battery is properly mounted, that it has engaged audibly and that it is locked.

You can find further information in the chapter “Inserting and Re-

moving the Battery” in your BionX system operating instructions.

(e)

yet? Please note the particular riding

(f)

of your BiXS pedelec must be charged

(g)

. Are you familiar with the

e

f

g

16

Please note that the system switches itself off automatically

U

after 10 minutes without any actuation

how to switch the system on again in the chapter “Operat-

ing the BionX Propulsion System” in your BionX system

operating instructions.

d

(h)

. You can find out

h

17

BEFORE EVERY RIDE

We recommend that you charge your battery

H

during the day and only in dry rooms which have a smoke

or a fire detector; but not in your bedroom. Place the battery during the charging process on a big, non-inflammable

plate made of ceramics or glass! Unplug the battery once it

has been charged up.

Charge your battery only with the supplied charger. Do not

H

a

b

c

use the charger of any other manufacturer, not even when

the connector of the charger matches your rechargeable

battery. The rechargeable battery can heat up, catch fire or

even explode!

Do not park your BiXS pedelec in strong sunshine.

H

4. The functions of your pedelec are operated with the buttons of the

(c)

control element

functions and displays?

Check whether you know the functions of all the buttons. You can

find further information in the chapter “Operating the BionX Pro-

pulsion System” in your BionX system operating instructions.

Be aware that the brakes of your BiXS pedelec are always

H

more effective than the drive. If you face any problems with

your drive (e.g. because it pushes you forward before a

turn), slow down your BiXS pedelec carefully.

Pulling the brake lever of the rear brake stops the motor.

H

Emergency stop! However, if you have a front-mounted motor you must operate the front brake very carefully

When mounting your BiXS pedelec, make sure not to step

H

on the pedals until you sit in the saddle and grip the handlebars tightly, and that one pedal is at the lowest position

when you get on. The motor assistance might switch on

suddenly unexpectedly and result in an uncontrolled start of

your BiXS pedelec. Danger of an accident!

on the handlebars. Are you familiar with all the

(a+b)

(d)

only

.

Your BiXS bicycle has undergone numerous tests during production

and a final check has been carried out by your BiXS bicycle dealer.

Nevertheless, be sure to check the following points before every ride

to exclude any malfunctioning that may be due to the transport of your

BiXS bicycle or to the work a third person may have performed on your

BiXS bicycle before delivery:

(e)

1. Are the quick-release levers

rear wheel properly closed and the bolts of the seat post and other

components accurately tightened?

You can find further information in the chapter “How to Use

Quick-Releases and Thru Axles” and in the instructions from

the parts manufacturers, which you can find on the enclosed CD.

2. Are the tyres in good condition and do they have sufficient pressure? The minimum and maximum pressure (in bar or PSI)

indicated on the side of the tyre.

Note that the tyres of a BiXS pedelec typically require somewhat

more pressure than you are generally used to with your mountain

bike.

You can find further information in the chapter “Wheels and Tyre

Equipment” and in the instructions from the parts manufacturers,

which you can find on the enclosed CD.

3. Spin the wheels to check for true running

tween rim and brake pad or, in the case of wheels with disc brakes,

between frame and rim or tyre. Wheels which do not run true can

be an indication of tyres with ruptured sides or broken axles or

spokes.

You can find further information in the chapter “Wheels and Tyre

Equipment” and in the instructions from the parts manufacturers,

which you can find on the enclosed CD.

and thru axles

(f)

of the front and

(h).

Watch the gap be-

(g)

e

is

f

g

18

Check with your insurers that the pedelec as well as the

U

storekeeping and the charging of lithium-ion batteries are

d

covered by your household and fire insurance. Read the

daily press to keep yourself informed about current legislative changes.

h

19

4. Test the brakes when stationary by firmly pulling the brake levers

(a)

towards the handlebars

hit the rim evenly with their entire surface

tyre during braking or in the open state or in between. Make sure

you cannot pull the brake levers all the way to the handlebars and

check the cables for leaks in the case of hydraulic brakes. Check

the thickness of the brake pads, as well.

a

With disc brakes

sponse. If you have to actuate the brake lever more than once to

get a positive braking response, have your BiXS bicycle checked by

your BiXS bicycle dealer.

You can find further information in the chapter “Brake System”

and in the instructions from the parts manufacturers, which you

can find on the enclosed CD.

5. Let your BiXS bicycle bounce on the ground from a small height. If

there is any rattling, see where it comes from. Check the bearings

and the bolts,

(b)

(c)

if necessary.

. The brake pads of rim brakes must

without touching the

you should directly get a positive braking re-

b

6. If you want to ride on public roads, make sure your BiXS pedelec

is equipped according to the applicable regulations of your country

(d)

.

Riding without lights and reflectors in dark or dim conditions is very

dangerous. A lighting set that corresponds to the regulations is a

must on public roads. Turn on the lights as soon as dusk sets in.

For more information see the chapter “Legal Requirements for

Riding on Public Roads“.

c

7. If you have a BiXS bicycle with suspension, press down on your

bicycle and see whether the suspension components retract and

(e+f)

extend as usual

You can find further information in the chapters “Suspension

Forks” and “Rear Shock” and in the instructions from the parts

manufacturers, which you can find on the enclosed CD.

8. If your bicycle has a kick-stand

before you set off. Danger of an accident!

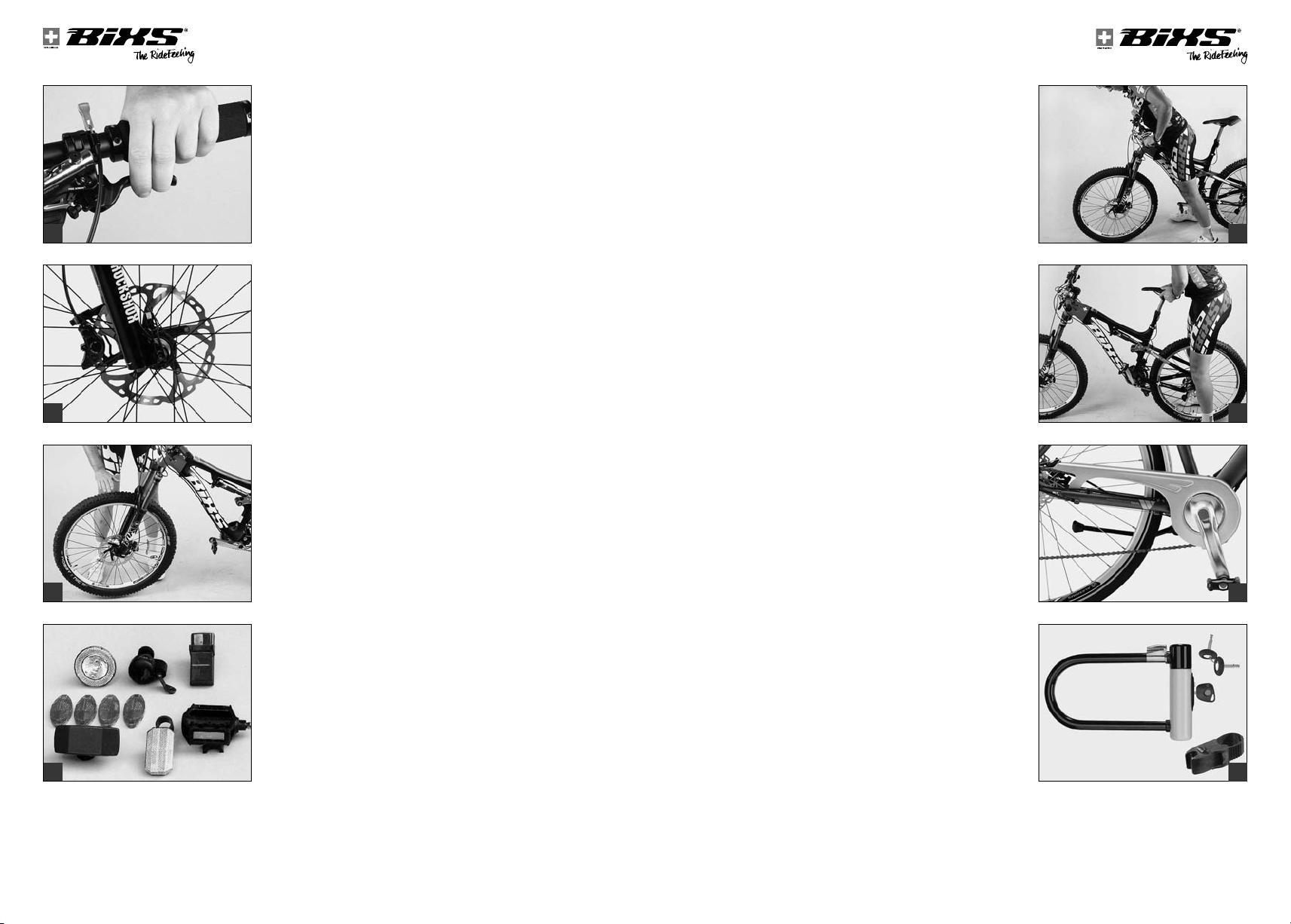

9. Do not forget to take a high-quality D-lock

you on your ride. The only way to effectively protect your BiXS bicycle against theft is to lock it to an immovable object.

10. Remove the cycle computer when you park your BiXS bicycle or

pedelec.

Improperly closed fastenings can cause parts of your BiXS

G

pedelec to come loose and result in serious accidents!

Do not use your BiXS bicycle if it fails on any one of these

G

points! Riding a defective BiXS bicycle can result in serious

accidents! If you are in doubt or if you have any questions,

please contact your BiXS bicycle dealer.

During use your BiXS bicycle or pedelec is undergoing

G

stress resulting from the surface of the road and through

the rider’s actions. Due to these dynamic loads, the different parts of your bicycle react with wear and fatigue. Please

check your BiXS bicycle or pedelec regularly for wear

marks, scratches, deformations, colour changes and any

indication of cracking. Components which have reached the

end of their service life may break without previous warning. Let your BiXS bicycle dealer maintain and service your

BiXS bicycle regularly and in cases of doubt it is always best

to replace components.

.

(g)

, make sure it is fully raised

(h)

or chain lock with

e

f

g

20

Be aware that the distance you need to stop your bicycle

G

increases if you are riding with your hands on the bar ends.

The brake levers are not always within easy reach.

d

h

21

AFTER AN ACCIDENT

ADDITIONAL INFORMATION “BEFORE EVERY RIDE” WITH

YOUR BiXS PEDELEC

1. Are the connections of the rechargeable battery, the control element on the handlebars and the drive system properly plugged in

(a)

?

You can find further information in the chapters “Inserting and

a

b

c

Removing the Battery” and “Operating the BionX Propulsion

System” in your BionX system operating instructions.

2. Is your battery fully charged

Remember to fully recharge the battery after each longer ride (e.g.

less than 50% charged). Modern lithium-ion batteries have no

memory effect. However, it does not matter if your BiXS pedelec

is left as it is for a short time (e.g. overnight) when less than 50%

charged. However, you should not wait until the battery is fully discharged!

For more information see the chapter “Useful Information for

Proper Handling of the Battery” and the chapter “Handling and

Charging the battery” in your BionX system operating instruc-

tions.

3. Does the display on the control element and the cycle computer on

the handlebars show all the values

Are there any error messages or warnings on the display? Check

the values are correct before every ride. Do not set off on your BiXS

pedelec under any circumstances if the control element shows a

warning.

You can find further information in the chapter “Operating the

BionX Propulsion System” in your BionX system operating instructions.

4. Is the battery tight in its holder and properly locked up

set off with a loose and unlocked battery.

You can find further information in the chapter “Inserting and Re-

moving the Battery” in your BionX system operating instructions.

(b)

?

(c)

?

(d)

? Never

1. Check whether the wheels are still firmly fixed in the drop-outs and

whether the rims are still centred with respect to the frame or fork

(e)

. Spin the wheels and observe the gap either between brake

pads and rim sides or between frame and tyre. If the width of the

gap changes markedly and you have no way to true the rim where

you are, you will need to open the rim brake a little so that the rim

can run between the brake pads without touching them. Please

note that in this case the brakes may not act as powerfully as you

are used to.

You can find further information in the chapters “Brake System”,

“How to Use Quick-Releases and Thru Axles” and “Wheels

and Tyre Equipment” and in the instructions from the parts man-

ufacturers, which you can find on the enclosed CD.

2. Check that handlebars and stem are neither bent nor broken and

(f)

that they are level and upright

fixed on the fork by trying to turn the handlebars relative to the front

wheel. Briefly lean on the brake levers to make sure the handlebars

are firmly fixed in the stem

sary, and carefully tighten the bolts to ensure reliable clamping of

the components. The maximum torque values are printed directly

on the components or specified in the enclosed operating instructions.

You can find further information in the chapters “Adjusting the

BiXS Bicycle to the Rider” and “Headset” and in the instructions

from the parts manufacturers, which you can find on the enclosed

CD.

3. Check whether the chain still runs on the chainrings and the

sprockets. If your BiXS bicycle fell over to the chain side, verify

the proper functioning of the gears. Ask somebody to lift the BiXS

bicycle by the saddle and carefully shift through all the gears. Pay

particular attention when shifting to the small gears and make sure

the rear derailleur does not get too close to the spokes as the chain

climbs onto the larger sprockets

. Make sure the stem is firmly

(g)

. Realign the components, if neces-

(h)

.

e

f

g

22

d

h

23

If the rear derailleur or the drop-outs/derailleur hanger are bent,

the rear derailleur may collide with the spokes. This can result in

damage to the rear derailleur, the rear wheel and the frame. Check

the function of the front derailleur, as a displaced front derailleur

(a)

can throw off the chain, thus interrupting the drive train of your

BiXS bicycle.

You can find further information in the chapter “Gears” and in the

a

b

instructions from the parts manufacturers, which you can find on

the enclosed CD.

4. Make sure the saddle is not out of alignment, using the top tube

or the bottom bracket shell as a reference. If necessary, open the

clamp, realign the saddle and retighten the clamp.

You can find further information in the chapters “Adjusting the

BiXS Bicycle to the Rider” and “Headset” and in the instructions

from the parts manufacturers, which you can find on the enclosed

CD.

5. Lift your BiXS bicycle up a few centimetres

(c)

the ground

bolts or components. Retighten them, if necessary.

6. Finally, take a good look at the whole BiXS bicycle to detect any

deformations, colour changes or cracks

. If this causes any sort of noise, search for loosened

and let it bounce onto

(d)

.

(b)

c

Ride back very carefully by taking the shortest route possible, only if

your BiXS bicycle or BiXS pedelec went through this check without any

(e)

problems

cle out of the saddle. If you are in doubt about the performance of your

BiXS bicycle, have yourself picked up by car, instead of taking any risks.

Back home you need to check your BiXS bicycle thoroughly once again.

The damaged parts must be repaired or replaced. Ask your BiXS bicycle

dealer for help.

For more information about carbon components see chapter “Carbon

– Important Information”.

G

G

. Do not accelerate or brake hard and do not ride your bicy-

Deformed components, especially those made of alumini-

um, can break without previous warning. They may not be

repaired, i.e. straightened, as the imminent risk of breakage

will remain. This applies in particular to the fork, the handlebars, the stem, the cranks, the seat post and the pedals.

When in doubt, it is always recommended that you have

these components replaced, as your safety comes first. Ask

your BiXS bicycle dealer for help.

If your BiXS bicycle is assembled with carbon components

(f+g)

, it is imperative that you have it checked by your BiXS

bicycle dealer after an accident or similar incident. Carbon

is an extremely strong material which combines high resistance with low weight. However, one of the inherent properties of carbon is that possible overstress may compromise

the inner carbon-fibre structure without showing any visible

deformation, as is the case with steel or aluminium. A damaged component can fail without previous warning. Danger

of an accident!

e

f

g

24

d

h

25

HOW TO USE QUICK-RELEASES AND

THRU AXLES

ADDITIONAL INFORMATION “AFTER AN ACCIDENT” WITH

YOUR BiXS PEDELEC

1. Check the rechargeable battery

no longer properly in its holder or shows any damage, do not use

your BiXS pedelec any longer, or at least, not in assistance mode.

Switch off the motor and the battery separately, if necessary. A

damaged battery can lead to a short-circuit or a sudden failure of

a

b

c

your BiXS pedelec assistance right at the moment when you need

it.

Damage to the outer housing of the rechargeable battery can result

in the entry of water or moisture and that can lead to short circuits

or electric shocks. The rechargeable battery could catch fire or

even explode! In such a case contact your BiXS bicycle dealer immediately.

(b)

2. Check the display

Do not use your BiXS pedelec if the display shows an error mes-

sage or a warning. If necessary, switch off the system completely

and wait at least 10 seconds before checking it again.

Do not set off on your BiXS pedelec with drive assistance if the

control element shows a warning. In such a case contact your BiXS

bicycle dealer immediately.

You can find further information in the chapter “Operating the

BionX Propulsion System” in your BionX system operating instructions.

3. Let your BiXS pedelec bounce on the ground from a low height. If

there is any rattling, see where it comes from. Check the bearings,

the bolts and the proper seating of the battery and the connectors

(c+d)

, as necessary.

You can find further information in the chapter “Inserting and Re-

moving the Battery” in your BionX system operating instructions.

. Are all the values displayed as usual?

(a)

. If the rechargeable battery is

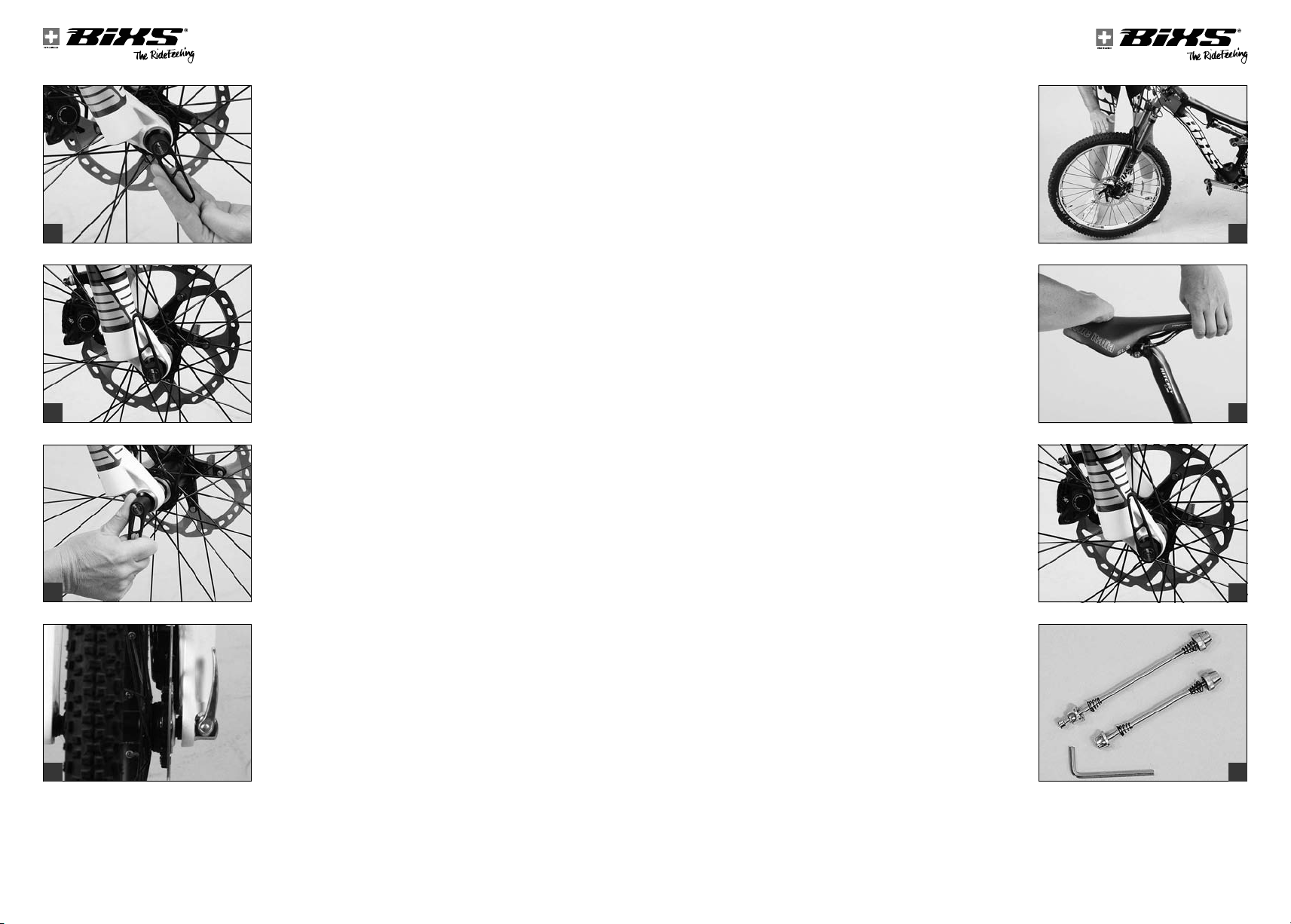

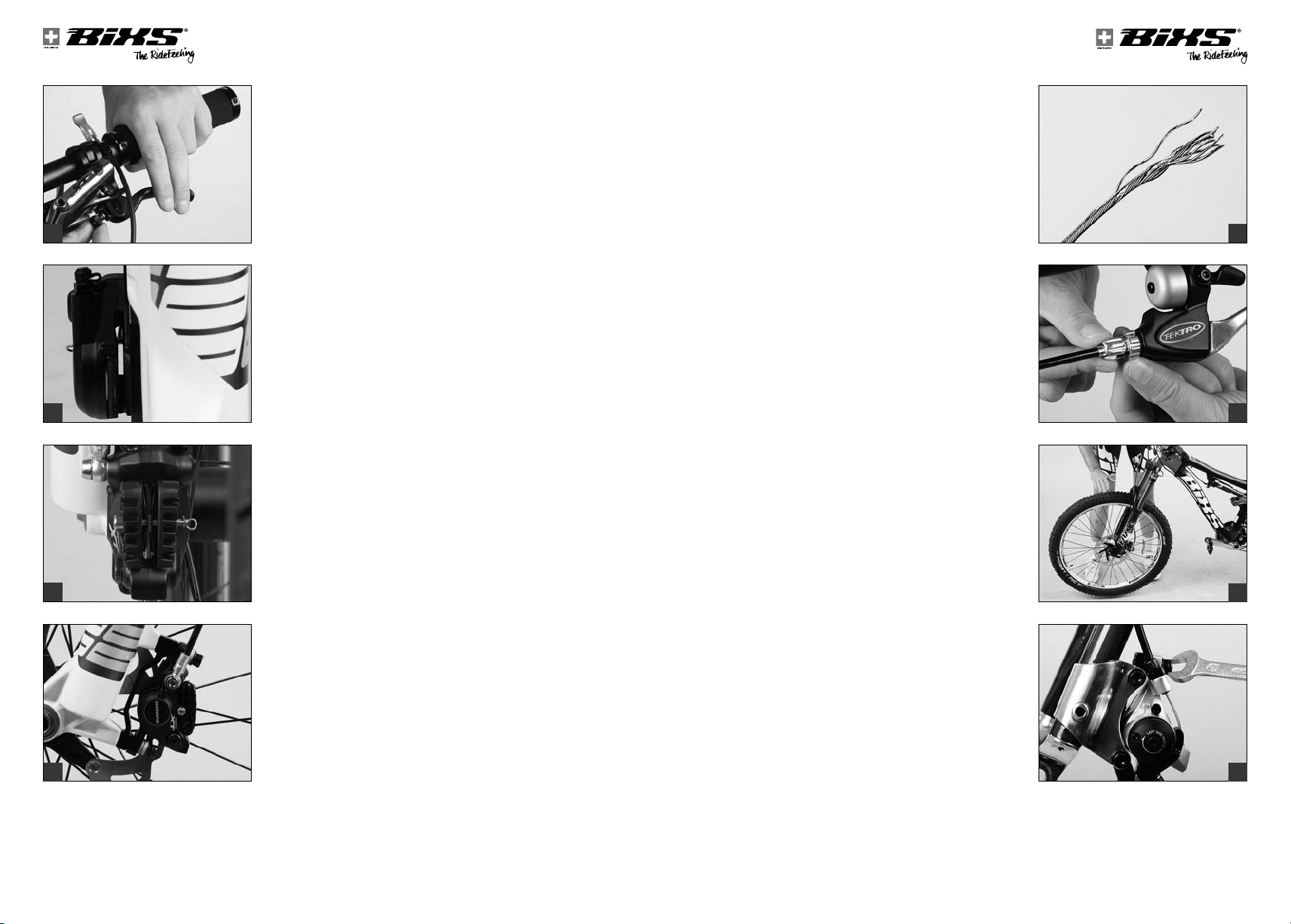

QUICK-RELEASES

Most mountain bikes are fitted with quick-releases to ensure fast adjustments, assembly and disassembly. Be sure to check that all the

quick-releases are tight before you set off on your BiXS bicycle. Quickreleases should be handled with the greatest care, as they directly affect your safety.

Practise the proper use of quick-releases to avoid any accidents.

Quick-release mechanisms essentially consist of two operative elements:

1. The hand lever on one side of the hub which creates a clamping

(e)

force via a cam when you close it

2. The tightening nut on the other side of the hub with which the initial

tension on the threaded rod (quick-release axle) is set

Make sure that the levers of both wheel quick-releases

G

are always on the side opposite the chain drive. This will

help you to avoid accidentally mounting the front wheel the

wrong way round. In the case of bicycles with disc brakes

and quick-releases having a 5-mm-axle, it may be reasonable to mount both quick-releases with the lever on the side

(g)

of the chain drive

contact with the rotor and prevent you from having your fingers burnt. If you are in doubt or if you have any questions,

then contact your BiXS bicycle dealer.

Never ride your BiXS bicycle without having checked first

G

whether the wheels are securely fastened

an accident!

Do not touch the rotor directly after having stopped – you

G

may burn your fingers! Always let the rotor cool down before opening the quick-release!

. This would help you not to come into

.

(f)

.

(h)

. Danger of

e

f

g

26

If your BiXS bicycle is equipped with quick-releases, be sure

A

to lock the wheels together with the frame to an immovable

object when you leave the bicycle outside.

d

h

27

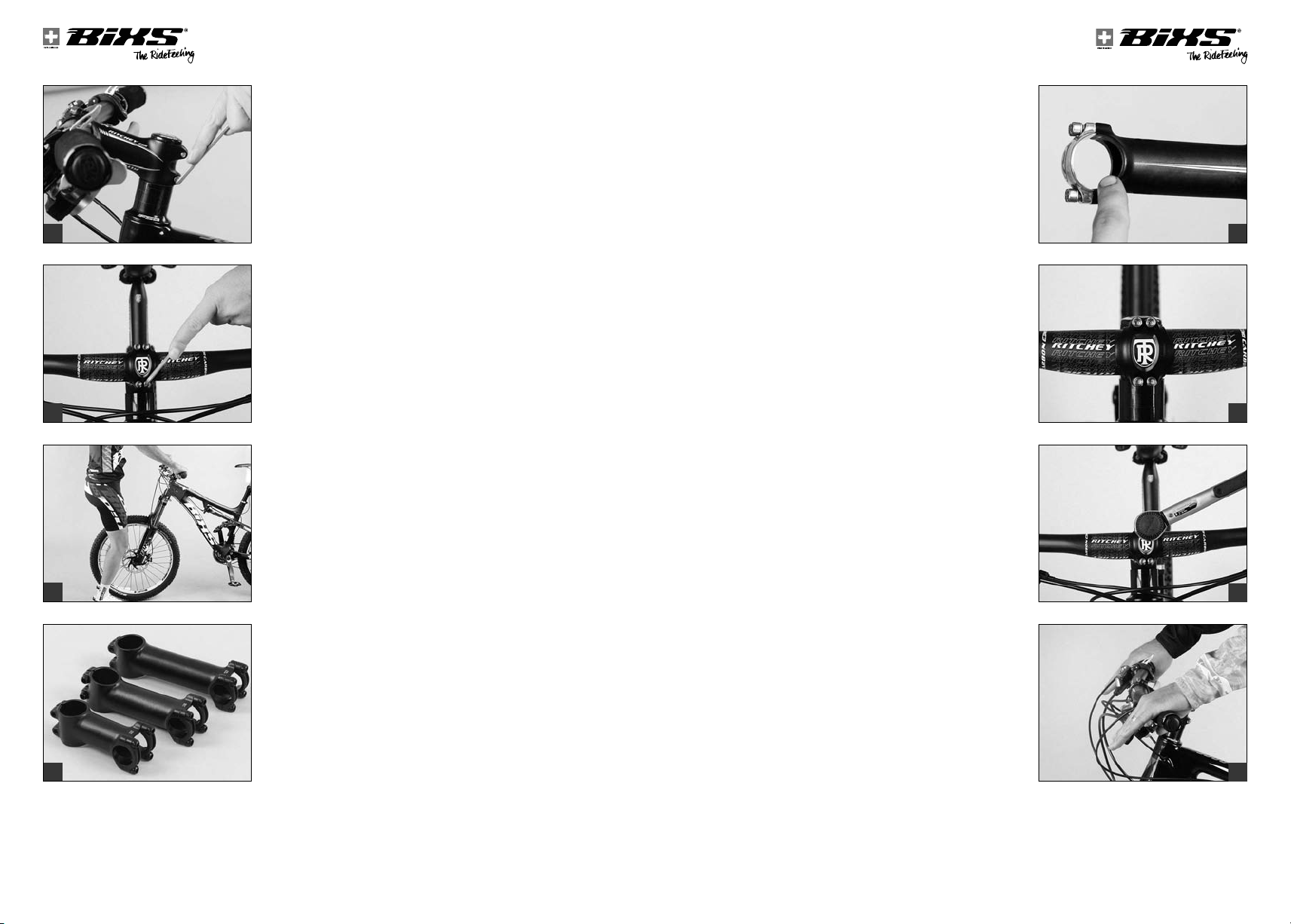

How to Fasten Components Securely with a Quick-Release

Open the quick-release. The marking “Open“ on the lever should be-

(a)

come visible now

Make sure the component to be fastened is in the correct position.

.

If your seat post is equipped with a quick-release mechanism, check

whether the saddle is firmly fixed by trying to twist it relative to the

(f)

.

frame

With the DT Swiss RWS system

via a cam, but by tightening a bolted connection with a lever.

(g)

the clamping force is not created

You can find further information in the chapters “Wheels and Tyre

a

b

c

Equipment” and “Adjusting the BiXS Bicycle to the Rider” and in

the instructions from the parts manufacturers, which you can find on

the enclosed CD.

Move the lever back, as if to close it. Now you should be able to read

(b)

”Close“ on the outside of the lever

you should feel virtually no resistance with your hand until half way.

Over the second half of its travel the resistance you feel should increase

(c)

significantly

much strength to close the lever. Use the ball of your thumb to push it

in all the way while your fingers pull on an immovable part, such as the

fork or the rear stay, but not on a brake rotor or spoke.

In its end position, the lever should be at right angles to the quickrelease axle

lie close to the frame or the fork so that it cannot be opened accidentally. Make sure, however, that the lever is easy to handle for actual

quick use.

To check whether the lever is securely locked, apply pressure to the end

of the lever and try to turn it while it is closed. If you can turn the lever

around, open it and increase the preload. Screw the tightening nut on

the opposite side clockwise by half a turn. Close the quick-release lever

and check it again for tightness.

Finally lift the bicycle a few centimetres so that the wheel no longer

touches the ground and hit the tyre from above

fastened, the wheel will remain firmly fixed in the drop-outs of the frame

or fork without producing any rattling.

. Towards the end of its travel you should need very

(d)

, i.e. it should not stick out to the side. The lever should

. When you start closing the lever

(e)

. If it is properly

Tighten the system by turning the lever clockwise and by keeping the

clamping nut tight.

Depending on frame or fork the lever may touch either frame or fork

during tightening. If it does, remove the lever, release it, let it engage

again before you retighten it.

In its end position the lever should lie close to the frame or the fork so

that it cannot be opened accidentally.

Do not touch the rotor directly after having stopped – you

g

may burn your fingers! Always let the rotor cool down be-

fore opening the quick-release!

With an insufficiently closed quick-release the wheel can

g

come loose , thus creating a serious risk of accident!

If your bicycle is equipped with quick-releases, be sure to

a

lock it to an immovable object together with the wheels

when you leave it outside.

To be on the safe side you can replace the quick-releases

i

by special locks

with a special, coded key or an Allen key. If you are in doubt

or if you have any questions, contact your bicycle dealer.

(h)

. They can only be opened and closed

e

f

g

28

d

h

29

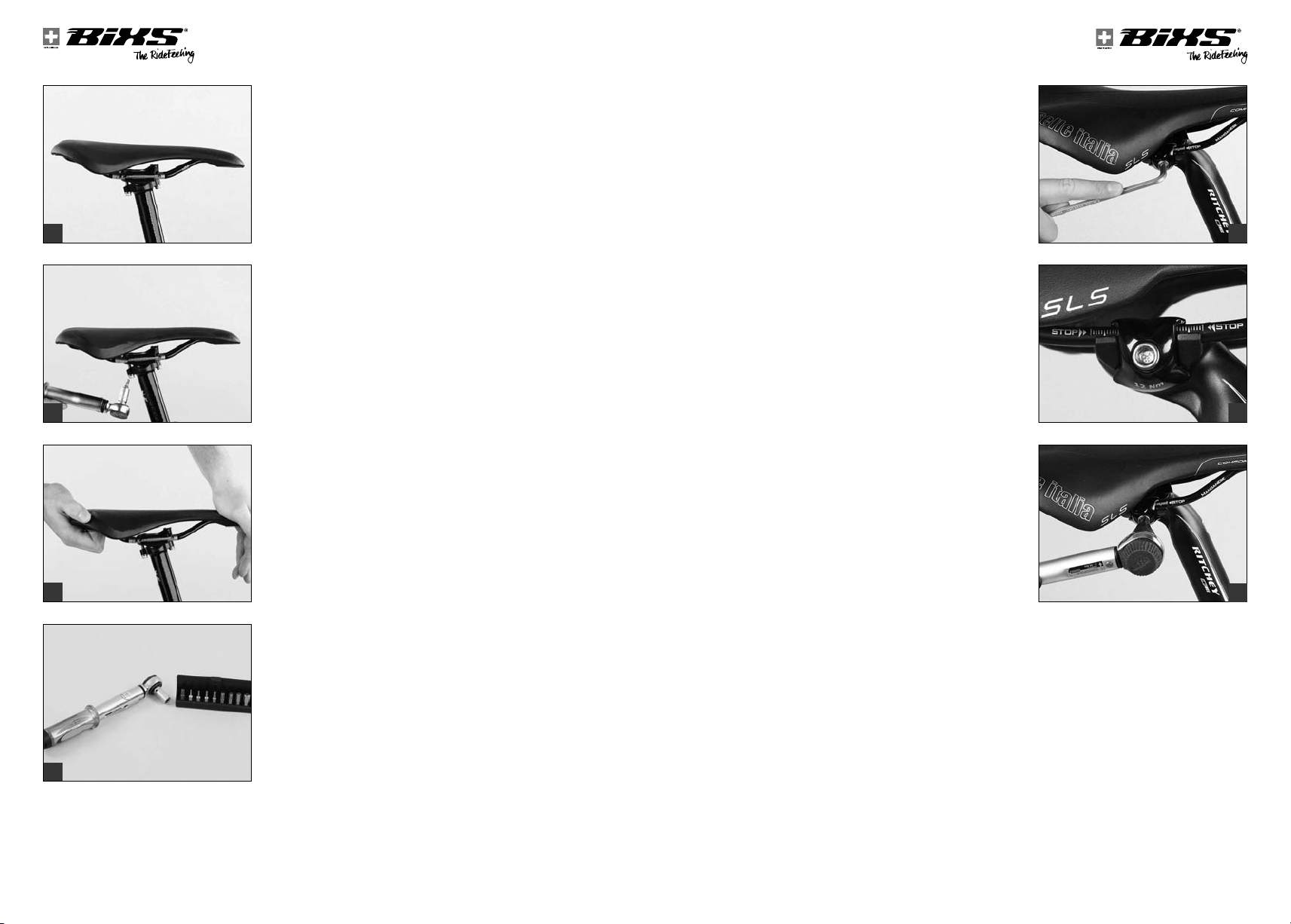

THRU A XLES

Thru axles

stress occurring e.g. during freeriding, cross-country, downhill riding or

jumps. They provide suspension forks with a suitable stiffness.

i

a

(a)

are mounted when BiXS bicycles have to withstand high

Before mounting or replacing a fork/wheel combination

with thru axle system, be sure to read the operating instructions of the respective suspension fork or wheel manufacturer first.

The QR15 or E-Thru system

Shimano and Fox and is a 15 mm thru axle that optimises weight. It

is mounted like the Maxle system and also operated with a quickrelease lever. The special feature of the QR15/E-Thru compared to

usual quick-release systems is the firm, bolted connection of the tightening nut to the fork leg on the opposite side of the quick-release lever.

For dismounting the front wheel you may need tools

fork manufacturer and thru axle system. To dismount the wheel, loosen

the axle support at the fork and remove the axle completely from the

hub.

(f)

has been developed jointly by

(g)

according to

e

Notes on How to Mount Front Wheels

There is a wide range of thru axle systems available now. Some systems are tightened with quick-releases. Other systems may require

(b+c)

special tools for assembly or disassembly

With the conventional thru axle system slide the thru axle through

the fork and the hub in a way that the head of the Allen bolt comes to

b

c

a rest on the right side (the chain side of the bicycle). Once the axle is

mounted, gently let the fork deflect a few times

chance of the axle getting jammed. Screw the nut onto the axle and

tighten it according to the enclosed instructions of the suspension fork

manufacturer. To lock the axle, finish by tightening the Allen bolts at the

front of the fork, according to the enclosed instructions of the suspension fork manufacturer.

If you are in doubt or if you have any questions, contact your BiXS

bicycle dealer.

Check the reliable fit of the bolts after one to two hours in use and then

every 20 hours.

If your bicycle is equipped with a Maxle thru axle system

quick-release lever, put the wheel into the fork and mount the rotor in

the brake calliper. Bring the wheel into the correct position between the

drop-outs and slide the axle with the open Maxle quick-release lever

from the right side through the drop-out and the hub. As soon as the

axle thread engages with the thread of the left drop-out, tighten it by

turning the whole Maxle clockwise. Close the Maxle thru axle quickrelease lever like a usual quick-release lever (see above section “How

to Fasten Components Securely“).

.

(d)

, thus excluding the

(e)

with

d

To remount the front wheel proceed in the reverse order. Make sure all

bolts/quick-release systems are tightened properly.

Check the reliable fit of the bolts after one to two hours in use and then

every 20 hours in use.

Improperly mounted wheels may throw you off your bicycle

g

or result in serious accidents!

To mount the axle only use the tools recommended by the

a

manufacturer. Make it a rule to use a torque wrench

Tighten carefully by approaching the prescribed maximum

torque in small steps (0.5 Nm increments) and check in between the proper fit of the component. Never exceed the

maximum torque value indicated by the manufacturer! A too

tight fixing of the axle can damage the axle or the fork leg.

(h)

f

.

g

h

30

31

ADJUSTING THE BiXS BICYCLE TO THE RIDER

Notes on How to Mount Rear Wheels

Besides the front thru axle systems, there are also rear thru axle sys-

(a)

. This system combines extreme stiffness with light weight.

tems

To dismount the rear wheel release the axle (with Allen key or RWS

quick-release, as provided by the system) and remove it, before dismounting the rear wheel as usually.