Page 1

User’s Manual

SRP-F310/312/313II

Front Exit Thermal Printer

IFJ-W, IFJ-Bi(Equipped Interface card)

Rev. 1.00

http://www.bixolon.com

Page 2

SRP-F310/312/313II

■

Do not bend the cable by force or leave it under any

Do not plug in or unplug with your hands wet.

Keep the plastic bag out of children’s reach.

Do not pull the cable to unplug.

can damage the cable, which is the origin of a fire or a

You must use only the supplied adapter.

Do not plug several products in one multi-outlet.

PROHIBITED

PROHIBITED

PROHIBITED

PROHIBITED

PROHIBITED

ONLY SUPPLIED ADAPTER

PROHIBITED

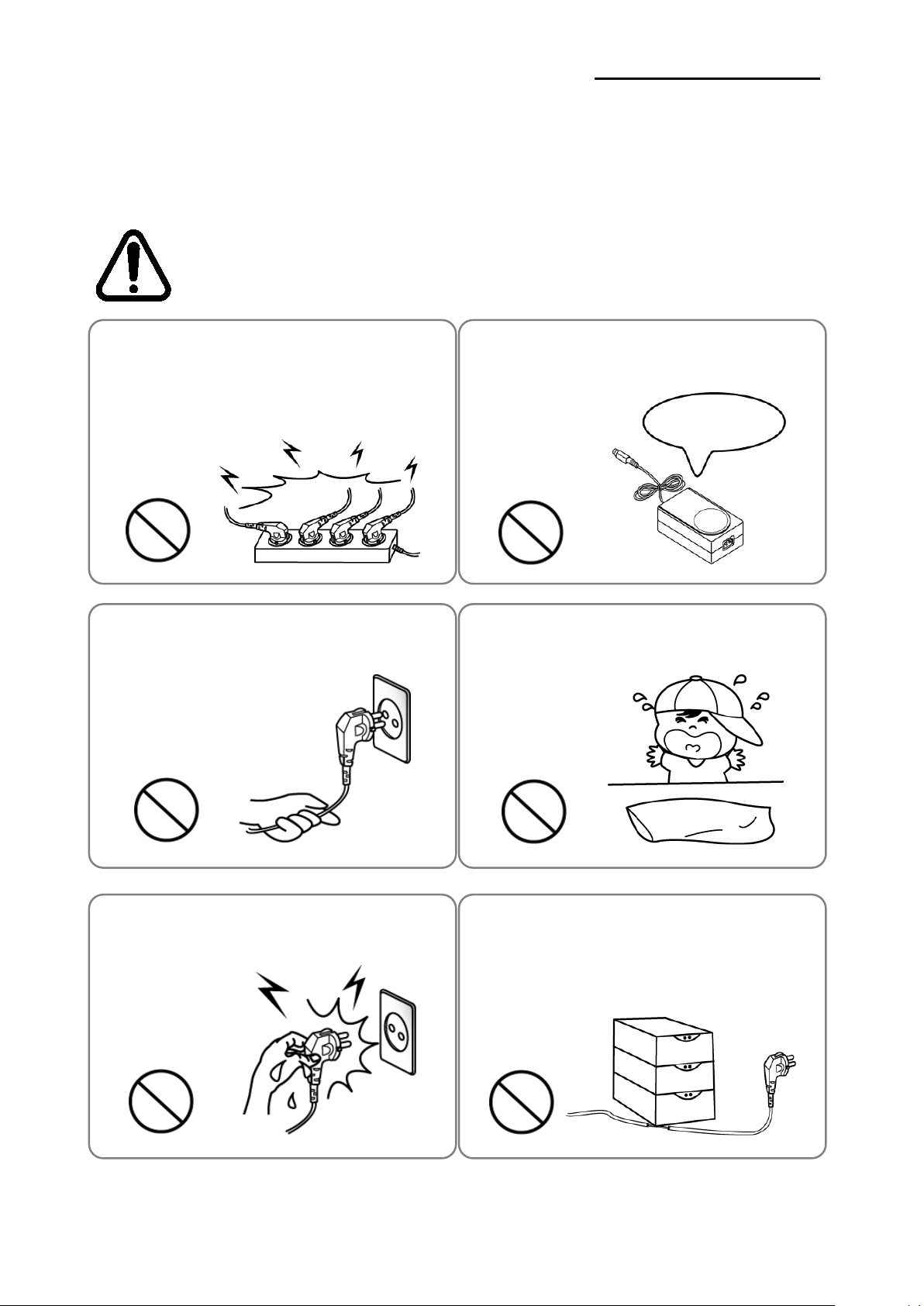

Safety Precautions

In using the present appliance, please keep the following safety regulations in order to

prevent any hazard or material damage.

WARNING

Violating following instructions can cause serious injury or death.

• This can provoke over-heat i ng and a fire.

• If the plug is wet or dirty, dry or wipe it before usage.

• If the plug does not fit perfectly with the outlet, do not plug in.

• Be sure to use only standardized multi-outlets.

• This

breakdown of the printer.

• It is dangerous to use other adapters.

• If not, a child may put the bag on his head.

• You can be electrocuted.

Rev. 1.00

heavy object.

• A damaged cable can cause a fire.

- 2 -

Page 3

SRP-F310/312/313II

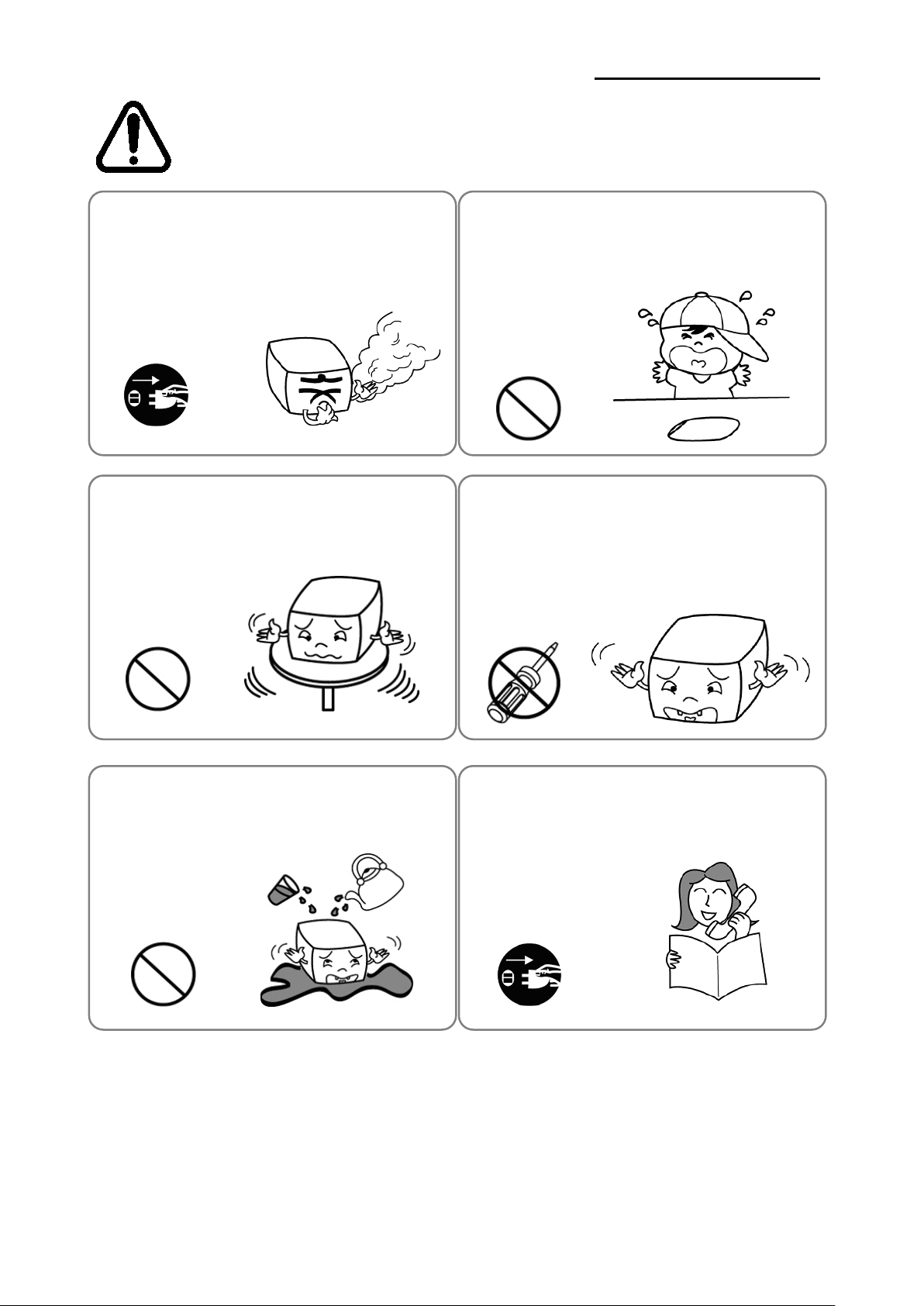

Do not use the printer when it is out of order. This

Do not let water or other foreign objects in the

If this happened, switch off and unplug the printer before

Use only approved accessories and do not try to

Install the printer on the stable surface.

If the printer falls down, it can be broken and you can hurt

Keep the desiccant out of children’s reach.

If you observe a strange smoke, odor or noise from

printer, unplug it before taking following

After the disappearance of the smoke, call your dealer to

TO

PROHIBITED

DISASSEMBLING

PROHIBITED

PROHIBITED

TO

PRINTER

PRINTER

PRINTER

DEALER

PRINTER

CAUTION

Violating following instructions can cause slight wound or damage the appliance.

the

measures.

• Switch off the printer and unplug the set from the mains.

•

repair it.

UNPLUG

•

yourself.

• If not, they may eat it.

disassemble, repair or remodel it for yourself.

• Call your dealer when you need these services.

• Do not touch the blade of auto cutter.

PROHIBITED

PRINTER

printer.

•

calling your dealer.

can cause a fire or an electrocution.

• Switch off and unplug the printer before calling your dealer.

UNPLUG

Rev. 1.00

- 3 -

Page 4

SRP-F310/312/313II

■

■

■

Warning - U.S.A

i) Class B Digital Device

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications, However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

- Consult the dealer or an experienced radio/TV technician for help.

ii) Changes or modifications not expressly approved by the manufacturer could void the

user’s authority to operate the equipment.

iii) Cation: Exposure to Radio Frequency Radiation.

To comply with FCC RF exposure compliance requirements, a separation distance of at

least 20 cm must be maintained between the antenna of this device and all persons.

Notice - Canada

This Apparatus complies with class “B” limits for radio interference as specified in the

Canadian department of communications radio interference regulations.

Get appareil est conforme aux normes class “B” d’interference radio tel que specifier par

ministre canadien des communications dans les reglements d’interference radio.

Caution

Some semiconductor devices are easily damaged by static electricity. You should turn the

printer “OFF”, before you connect or remove the cables on the rear side, in order to guard

the printer against the static electricity. If the printer is damaged by the static electricity, you

should turn the printer “OF F” .

Rev. 1. 00

- 4 -

Page 5

SRP-F310/312/313II

■

■

■

■

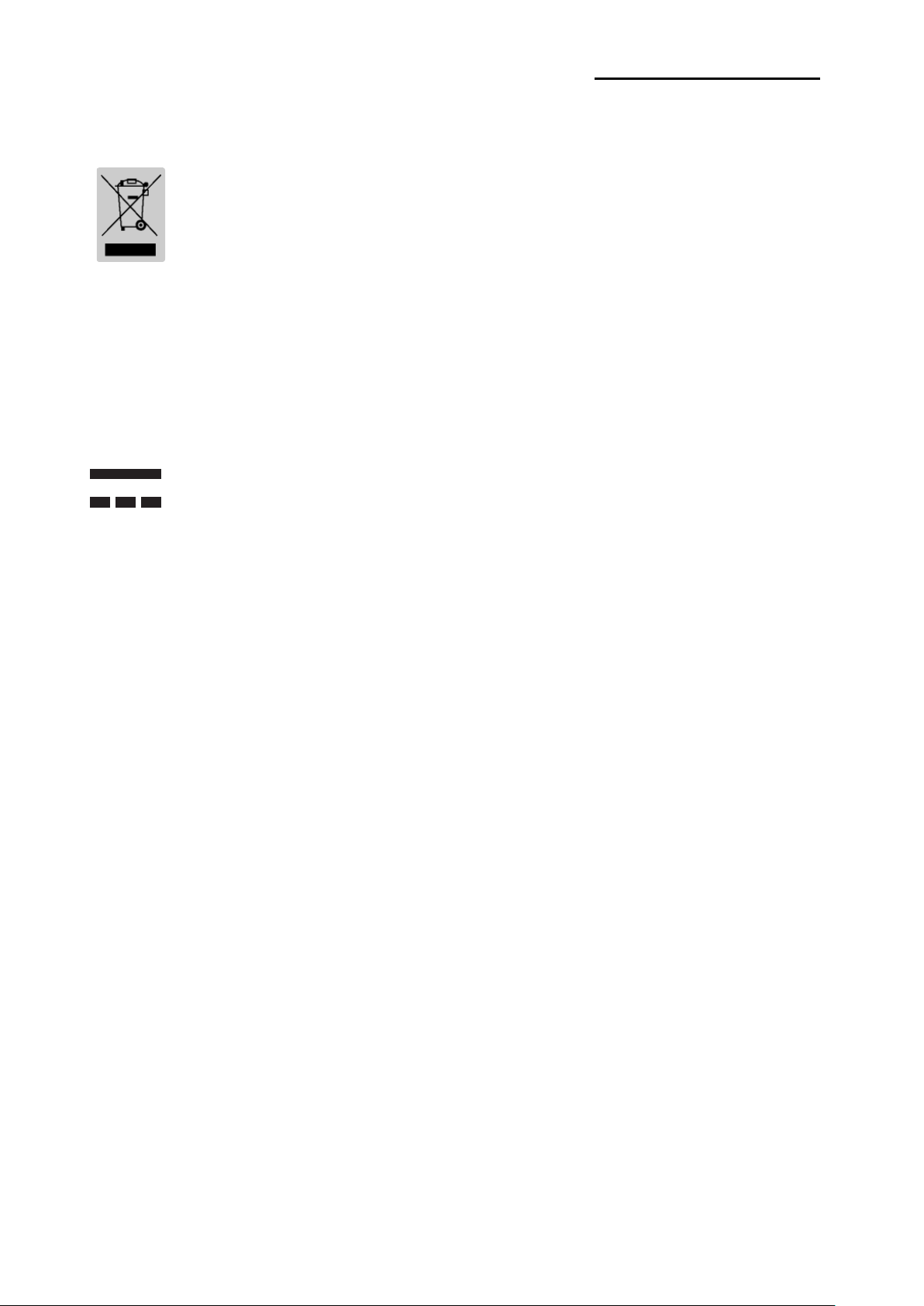

Waste Electrical and Electric Equipment (WEEE)

This marking shown on the product or its literature, indicates that is should not

be disposed with other household wastes at the end of its working life, To

prevent possible harm to the environment or human health from uncontrolled

waste disposal, please separate this from other types of wastes and recycle it

responsibly to promote the sustainable reuse of material resources. Household

users should contact either the retailer where they purchased this product, or

their local government office, for details of where and how they can take this item for

environmentally safe recycling. Business users should contact their supplier and check the

terms and conditions of the purchase contract. This product should not be mixed with other

commercial wastes for disposal.

Rating Label Symbol Information

DC (Direct current)

Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the fol lowing

two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that

may cause undesired operation.

Label Material

* Control Label: PC

* Other Labels: PET

Rev. 1. 00

- 5 -

Page 6

SRP-F310/312/313II

■

※

Introduction

SRP-F310/312/313II series printers have been designed to be connected to various types

of electronic devices such as ECR (Electronic Cash Register), POS (Point Of Sales), and

computer peripheral dev i c es.

1. High speed printing: 82.74/93.33 li nes per second.

2. Low noise thermal printing.

3. Support of USB & Ethernet (built-in type), serial, parallel, POWERED USB,

Wireless LAN, and Bluetooth interfaces

4. The data buffer allows the unit to receive print data even during printing.

5. Peripheral units drive circuit enables control of external devices such as cash drawer.

6. Bar code printing is possible by using a bar code command.

7. Different print densities can be selected by DIP switches.

※ For network information, refer to the ‘Network user manual’

Please be sure to read the instruction in this manual carefully before using your new

SRP-F310/312/313II

Use only authorized supplies that can be trusted!

- We are not responsible for quality and service for damage caused by the use of

unauthorized products(or recycled ones).

- The following Bluetooth mark and QD ID B021701 is only applicable to models with the

Bluetooth SIG qualification.

We at BIXOLON maintain ongoing efforts to enhance and upgrade the functions and

quality of all our products. In following, product specifications and/or user manual content

may be changed without prior notice.

Rev. 1. 00

- 6 -

Page 7

SRP-F310/312/313II

■

Table of Contents

1. Setting Up the Printer .................................................................................................. 8

1-1 Unpacking ................................................................................................................. 8

1-2 Interface .................................................................................................................... 9

1-2-1 USB Interface ............................................................................................... 9

1-2-2 Ethernet Interface ......................................................................................... 9

1-2-3 Serial Interface (RS-232C) ......................................................................... 10

1-2-3-1 Single Interface .................................................................................. 10

1-2-3-2 Dual Interface ..................................................................................... 10

1-2-4 Parallel Interface (IEEE1284) ..................................................................... 12

1-2-5 Powered USB Interface .............................................................................. 13

1-2-6 Bluetooth / WLAN Interface ........................................................................ 13

1-2-6-1 Bluetooth Interface ............................................................................. 13

1-2-6-2 Wireless LAN Interface ...................................................................... 14

1-3 Connecting the Drawer ........................................................................................... 14

1-4 Setting the Dip Switches ......................................................................................... 15

1-4-1 Serial Interface ........................................................................................... 15

1-4-2 Parallel / USB / Ethernet / Wireless LAN / Powered USB Interface ............ 15

1-4-3 Bluetooth Interfac e ..................................................................................... 15

1-5 Installing or Replacing the Paper ............................................................................ 16

1-6 Using 83mm Paper ................................................................................................. 18

1-7 Recommended Papers ........................................................................................... 18

1-8 Adjustments and Settings ....................................................................................... 19

1-9 Using the Printer ..................................................................................................... 19

1-10 Connecting the Computer ..................................................................................... 20

1-11 Connecting the Power Supply............................................................................... 20

2. Self Test ...................................................................................................................... 21

3. Hexadecimal Dumping .............................................................................................. 22

4. Specification .............................................................................................................. 23

5. Appendix .................................................................................................................... 24

5-1 Cleaning Printer ...................................................................................................... 24

Rev. 1. 00

- 7 -

Page 8

SRP-F310/312/313II

1. Setting Up the Printer

1-1 Unpacking

Your printer box should include these items.

If any items are damaged or missing, please contact your dealer for assistance.

SRP-F310/312/313II CD

Roll Paper Manual Power Cord

Rev. 1. 00

- 8 -

Page 9

SRP-F310/312/313II

1-2 Interface

※

Pin No.

Signal Name

Assignment (Color)

Function

Shell

Shield

Drain Wire

Frame Ground

1

VBUS

Red

Host Power

2

D-

White

Data Line (D-)

3

D+

Green

Data Line (D+)

4

GND

Black

Signal Ground

Pin No.

Signal Name

Color

Function

1

TD+

WHITE ORANGE

Transmit +

2

TD-

ORANGE

Transmit -

3

TCT

WHITE GREEN

Receive +

4

NC

BLUE

-

5

NC

WHITE BLUE

-

6

RCT

GREEN

Receive -

7

RD+

WHITE BROWN

-

8

RD-

BROWN

-

ETHERNET

connector

USB connector

You can connect up the three cables to the printer.

They all connect to the connector panel on the back of the printer, which is shown below:

CAUTIONS

Before connecting any of the cables, make sure that both the printer and the host are

turned off.

1-2-1 USB Interface

1-2-2 Ethernet Interface

* IP and MAC information can be obtained from the self-test. Refer to the Ethernet User’s

Manual that is available from the BIXOLON website for more detailed information.

* For using this interface in the Bluetooth or WLAN applied product, Printer wiring requires

to use double shielded (Cat 7) Ethernet cable.

Rev. 1. 00

- 9 -

Page 10

SRP-F310/312/313II

1-2-3 Serial Interface (RS-232C)

USB connector

Interface connector

USB connector

ETHERNET

connector

ETHERNET

connector

Interface connector

1-2-3-1 Single Interface

1-2-3-2 Dual Interface

Rev. 1. 00

- 10 -

Page 11

SRP-F310/312/313II

Pin No.

Signal Name

Direction

Function

Main

Frame GND

-

Frame Ground

2

TXD

Output

Data Tr ansmiss ion

3

RXD

Input

Data Reception

6 DSR Input

This signal shows whether the host computer can

printer does not confirm this signal.

7

Signal GND

-

Signal Ground

This signal shows whether the printer works or not

printer does not confirm this signal.

Shield

Frame GND

-

Frame Ground

20 DTR Output

receive data (hardware flow control).

1) MARK (Logic 1): The host computer can

receive data.

2) SPACE (Logic 2): The host computer cannot

receive data.

3) After checking the signal in the printer, it

transmits data to the host.

4) When XON / XOFF flow control is selected, the

(hardware flow control).

1) MARK (Logic 1): Printer is working.

2) SPACE (Logic 2): Printer is not working.

3) After checking the signal in the printer, it

transmits data to the host.

4) When XON/XOFF flow control is selected, the

Rev. 1. 00

- 11 -

Page 12

SRP-F310/312/313II

1-2-4 Parallel Interface (IEEE1284)

Pin No.

Source

Compatibility Mode

Nibble Mode

Byte Mode

1

Host

nStrobe

HostClk

HostClk

2

Host / Printer

Data 0 (LSB)

-

Data 0 (LSB)

3

Host / Printer

Data 1

-

Data 1

4

Host / Printer

Data 2

-

Data 2

5

Host / Printer

Data 3

-

Data 3

6

Host / Printer

Data 4

-

Data 4

7

Host / Printer

Data 5

-

Data 5

8

Host / Printer

Data 6

-

Data 6

9

Host / Printer

Data 7 (MSB)

-

Data 7 (MSB)

10

Printer

nAck

PtrClk

PtrClk

11

Printer

Busy

PtrBusy / Data3,7

PtrBusy

12

Printer

Perror

AckDataReq / Data2,6

AckDataReq

13

Printer

Select

Xflag / Data1,5

Xflag

14

Host

nAutoFd

HostBusy

HostBusy

15 - NC

NC

NC

16 - GND

GND

GND

17 - FG

FG

FG

18

Printer

Logic-H

Logic-H

Logic-H

19~30 - GND

GND

GND

31

Host

nInit

nInit

nInit

32

Printer

nFault

nDataAvail / Data0,4

nDataAvail

33 - GND

ND

ND

34

Printer

DK_Status

ND

ND

35

Printer

+5V

ND

ND

36

Host

nSelectIn

1284-Active

1284-Active

USB connector

ETHERNET

connector

Interface connector

Rev. 1. 00

- 12 -

Page 13

SRP-F310/312/313II

1-2-5 Powered USB Interface

Pin No.

Signal Name

Function

Shield

Shield

Frame Ground

1

PGND

Main Power Ground

2

VPP24V

Main Power

3

GND

Signal Ground

4

D+

Data Line (D+)

5

D-

Data Line (D-)

6

VBUS

Hose Power

7

VPP24V

Main Power

8

PGND

Main Power Ground

Item

Specifications

Frequency

2.402~2.480 GHz

Version

2.1 + EDR

Module T y pe

Class 1

USB connector

Interface connector

USB connector

Interface connector

ETHERNET

connector

ETHERNET

connector

* For cable and connector information, refer to the web-site (www.powered.org)

* In case of using Powered USB interface, the other USB interface provided by default is

not useful. (In this case, USB communication is only available through the Powered USB)

1-2-6 Bluetooth / WLAN Interface

1-2-6-1 Bluetooth Interface

1) Bluetooth Communication Specifications

2) Bluetooth Connection

Printer can be connected to terminal devices with Bluetooth communication capability

(PDA, PC, smartphone, tablet PC, etc.)

* Refer to the Bluetooth Connection Manual for more detailed instructions about how to

establish the connection.

Rev. 1. 00

- 13 -

Page 14

SRP-F310/312/313II

Item

Specifications

Frequency

2.412~2.484 GHz

Channel

Channel 1~13

Protocol

802.11b, 802.11g, 802.11n

※

※

Pin No.

Signal name

Direction

1

Frame ground

-

2

Drawer kick- out drive signal 1

Output

3

Drawer open/close signal

Input

4

+24V - 5

Drawer kick- out drive signal 2

Output

6

Signal ground

-

1-2-6-2 Wireless LAN Interface

1) Wireless LAN Communication Specifications

2) Connecting Wireless LAN

Printer can be connected to terminal devices with wireless LAN communication

capability (PDA, PC, smar tp ho ne, t a bl et PC , et c.) .

* Refer to the Wireless LAN Connection Manual for more detailed instructions about how

to establish the connection.

1-3 Connecting the Drawer

Connect the cash drawer connecting cable to the cash drawer connection in the rear of the

printer.

WARNING

Use a drawer that matches the printer specification.

Using an improper drawer may damage the drawer as well as the printer.

CAUTIONS

Do not connect a telephone line to the drawer kick-out connector.

Otherwise, the telephone line and the computer may be damaged.

Rev. 1. 00

- 14 -

Page 15

SRP-F310/312/313II

1-4 Setting the Dip Switches

SW

Function

ON

OFF

Default

1-1

Auto-Cutter Selection

Disable

Enable

OFF

1-2

Handshaking

XON / OFF

DTR / DSR

OFF

1-3

Word length

7 bits

8 bits

OFF

1-4

Parity check

Yes

No

OFF

1-5

Parity selection

EVEN

ODD

OFF

1-6

OFF

1-7

ON

1-8

OFF

SW

Function

ON

OFF

Default

1-1

Auto-Cutter Selection

Disable

Enable

OFF

1-2

1-8

SW

Function

ON

OFF

Default

1-1

Auto-Cutter Selection

Disable

Enable

OFF

1-2

Reserved

-

-

OFF

1-3

Reserved

-

-

OFF

1-4

Reserved

-

-

OFF

1-5

Bluetooth mode

iOS

Normal

OFF

1-6

Reserved

-

-

OFF

1-7

Reserved

-

-

ON

1-8

Reserved

-

-

OFF

Transmission speed

SW1 – 6

SW1 – 7

SW1 – 8

Default

2400 baud

ON

OFF

OFF

4800 baud

ON

OFF

ON

9600 baud

OFF

ON

OFF

19200 baud

OFF

OFF

OFF

38400 baud

OFF

ON

ON

57600 baud

OFF

OFF

ON

115200 baud

ON

ON

ON

※

Dip Switch Set 1

ON

Auto Cutter Disable

OFF

Auto Cutter Enable

Application

Ignores Auto Cutter error for continuous printing

1-4-1 Serial Interface

• DIP Switch 1

Baud rate selection Refer to the Following Table 1

1-4-2 Parallel / USB / Ethernet / Wireless LAN / Powered USB Interface

• DIP Switch 1

~

Reserved - - OFF

1-4-3 Bluetooth Interfac e

• DIP Switch 1

9600

Table 1 - Baud Rate Selection

Auto Cutter Enable / Disable selection

SW1 - 1

Rev. 1. 00

- 15 -

Page 16

SRP-F310/312/313II

1-5 Installing or Replacing the Paper

※

※

CAUTIONS

Be sure to use paper rolls that meet the specifications. Do not use paper rolls that have

the paper glued to the core because the printer may not detect the paper end correctly.

Do not use paper wider than 80 mm or plastic paper tube when using a printer that

specifies 80 mm paper.

1-5-1 Make sure that the printer is not receiving data; otherwise, data may be lost.

1-5-2 Open the paper roll cover by pressing the Push button.

CAUTIONS

Do not open the print cover while the printer is operating. This may damage the printer.

1-5-3 Remove any existing used paper roll core when replacing the paper roll

1-5-4 Insert the paper roll as shown.

Rev. 1. 00

- 16 -

Page 17

SRP-F310/312/313II

1-5-5 Check the orientation of the roll paper when inserting it into the printer.

※

1-5-6 Pull out a small amount of paper, as shown. Then close the cover.

CAUTIONS

When closing the cover, press the center of printer cover firmly to prevent

paper miss-loading.

1-5-7 Tear off the paper as shown.

Rev. 1. 00

- 17 -

Page 18

SRP-F310/312/313II

1-6 Using 83mm Paper

※

※

※

Use of the partition depends on the width of the paper.

1-6-1 Remove the partition as shown in the following picture when using 83 mm paper.

NOTE

Partition is installed at the factory for 80 mm paper .

Fig 1 Fig 2

CAUTIONS

Do not rotate the partition while removing it from the printer as shown in Fig 1 because the

holder may be damaged. Lift up the partition as shown in Fig 2 to remove it safely.

1-6-2 The rest of the installation process after this step is the same as the procedure

described in 1-5.

1-7 Recommended Papers

- TF50KS-E (Paper Thickness: 65μm): Nippon Paper Industries Co., Ltd.

- PD 160R (Paper Thickness: 75μm): New Oji Paper Mfg. Co., Ltd.

- P350 (Paper Thickness: 62μm): Kansaki Specialty Paper, Inc. (USA)

CAUTIONS

Use of papers other than those recommended above may damage TPH or degrade the

printing quality and our company is not responsible for the damage caused by nonrecommended papers. If you have to use other products, we recommend that you use

papers with a similar level of quality to the recommended ones.

Rev. 1. 00

- 18 -

Page 19

SRP-F310/312/313II

1-8 Adjustments and Settings

The SRP-F310/F312/F313II is set up at the factory to be appropriate for almost all users. It

does, however, offer some settings for users with special requirements.

It has DIP switches that allow you to change communication settings, such as

handshaking and parity check, as well as print density.

One of the features of the SRP-F310/F312/F313II is to detect the remaining level of paper.

Paper LED will be turned on if the paper sensor detects that the remaining level of paper is

lower than the preset level. This warning level can be changed by rotating the paper

sensor tab forwar d or back ward (refer to the followi ng pictur e) .

1-9 Using the Printer

Control Panel

○ POWER

The POWER light is on whenever the printer is on.

○ ERROR

This indicates an error.

○ PAPER

This light indicates the near end of the paper roll. Install a new paper roll and the printer

will continue printing. W hen the light blinks, it indicates the self-test printing standby state

or macro execution Standby state when the macro execution command is used.

○ FEED

Press the FEED button once to advance paper one line. You can also hold down the FEED

button to feed paper continuously.

Rev. 1. 00

- 19 -

Page 20

SRP-F310/312/313II

1-10 Connecting the Computer

※

※

You need an appropriate interface cable.

1-10-1 Plug the cable connector securely into the printer’s interface connector.

1-10-2 Tighten the screws on both sides of the cable connector.

1-10-3 Attach the other end of the cable to the computer.

1-11 Connecting the Power Supply

CAUTIONS

When connecting or disconnecting the power supply from the printer, make sure that the

power supply is not plugged into an electrical outlet. Otherwise you may damage the

power supply or the printer.

If the power supply’s rated voltage and your outlet’s voltage do not match, contact your

dealer for assistance. Do not plug in the power cord. Otherwise, you may damage the

power supply or the printer.

1-11-1 Make sure that the printer’s power switch is turned off, and the power supply’s

power cord is unplugged from the electrical outlet.

1-11-2 Check the label on the power supply to make sure that the voltage required by the

power supply matches that of your electrical outlet.

1-11-3 Plug in the power supply’s cable as shown below. Notice that the flat side of the

plug faces down.

NOTE

To remove the DC cable connector, make sure that the power supply’s power cord is

unplugged; then grasp the connector at the arrow and pull it straight out.

Rev. 1. 00

- 20 -

Page 21

SRP-F310/312/313II

2. Self Test

The self-test checks whether the printer has any problems. If the printer does not function

properly, contact your dealer. The self-test checks the following:

2-1 Make sure paper roll has been installed properly.

2-2 Turn on the power while holding down the FEED button with beep. The self-test begins.

2-3 The self-test prints the current printer status, which provides the control ROM version

and the DIP switch setting.

2-4 After printing the current printer status, self-test printing will print the following,

and pause (The PAPER LED light blinks).

SELF-TEST PRINTING.

PLEASE PRESS THE FEED BUTTON.

2-5 Press the FEED button to continue printing.

The printer prints a pattern using the built-in character set.

2-6 The self-test automatically ends and cuts the paper after printing the following.

*** COMPLETED ***

2-7 The printer is ready to receive data as soon as it completes the self-test.

Rev. 1. 00

- 21 -

Page 22

SRP-F310/312/313II

3. Hexadecimal Dumping

1B 21 00 1B 26 02 40 40 40 40

. ! . . & . @ @ @ @

02 0D 1B 44 0A 14 1E 28 28 28

. . . D . . . . ( ( (

00 01 0A 41 0D 42 0A 43 43 43

. . . A . B . C C C

This feature allows experienced users to see exactly what data is coming to the printer.

This can be useful in finding software problems. When you turn on the hexadecimal dump

function, the printer pri nts all commands and dat a in hexadecimal format along w it h a

guide section to help you find specific commands.

To use the hexadecimal dump func ti on, foll o w these steps.

3-1 After you make sure that the printer is off, open the cover.

3-2 Turn on the printer, while holding down the FEED button with beep.

3-3 Close the cover, then the printer enters the hexadecimal dump mode.

3-4 Run any software program that sends data to the printer. The printer will print all the

codes it receives in a two-column format. The first column contains the hexadecimal

codes and the second column gives the ASCII characters that corresponds to the

codes.

A period (.) is printed for each code that has no ASCII equivalent.

During the hex dump, all commands except DLE EOT and DLE ENQ are disabled.

3-5 When the printing finishes, turn off the printer.

3-6 Turn on the printer and then the hexadecimal mode is off.

Rev. 1. 00

- 22 -

Page 23

SRP-F310/312/313II

4. Specification

Printing method

Thermal line printing

SRP-F310II: 180dpi(7dots/mm)

SRP-F313II: 203dpi(8dots/mm)

SRP-F310II: 72mm

SRP-F313II: 80mm

Paper width

79.5±0.5mm/82.5±0.5mm

SRP-F310II: 42(Font A), 56(Font B)

SRP-F313II :53(Font A), 71(Font B)

SRP-F310II: 82.74 lines/sec, Max. 350 mm/sec

SRP-F313II: 93.33 lines/sec, Max. 350mm/sec

Receive Buffer Size

4K Bytes

※ NOTE: Printing speed may be slower, depending on the data

transmission speed andthe combinat ion of control commands.

SMPS Input voltage

100~240VAC

Frequency

50/60Hz

SMPS Output voltage

24VDC

0~45 ℃ (Operating)

-20~60

10~80 % RH (Operating)

Printer Head *)

150 Km

Auto Cutter

1,800,000 Cut

MCBF *

Printer Mechanism *)

70,000,000 lines

Dot density

Printing width

Characters per line (default)

Printing speed

Supply voltage

Environmental

Conditions

Temperature

Humidity

SRP-F312II: 203dpi(8dots/mm)

SRP-F312II: 72mm

SRP-F312II: 48(Font A), 64(Font B)

SRP-F312II: 93.33 lines/sec, Max. 350mm/sec

℃ (S to ra g e )

10~90 % RH (Storage)

; Except for paper

LIFE *

*) The specifications were determined based on operation at normal temperature

using designated paper on default settings. They are subject to change

depending on temperature or printing level.

*) The specifications were tested according to standard reliability.

If you want to test the product to determine its life cycle, please contact us for

more details and comply with the standard reliability for testing.

** The switch is the disconnecting device. Turn off switch from any hazard.

Rev. 1. 00

- 23 -

Page 24

SRP-F310/312/313II

5. Appendix

5-1 Cleaning Printer

Paper dust inside the printer may lower the print quality. In this case clean the printer as

follows:

5-1-1 Open the printer cover and remove any paper.

5-1-2 Clean the print head with a cotton swab moistened with alcohol solvent.

5-1-3 Clean the paper sensor and paper roller with a cotton swab and a dry cloth.

5-1-4 Insert a paper roll and close the printer cover.

The remaining amount of paper detected by paper near-end sensor varies with the

diameter of the paper core. To set the paper near-end sensor, contact your dealer.

Rev. 1. 00

- 24 -

Loading...

Loading...