4

4-37

Model L Series

Thermal Shock plus Power Conditioning ∆R 0.70%

Short Time Overload ∆R 0.25%

Terminal Strength ∆R 0.25%

Moisture Resistance ∆R 0.50%

Mechanical Shock ∆R 0.25%

Vibration ∆R 0.25%

Low Temperature Storage ∆R 0.25%

High Temperature Exposure ∆R 0.50%

Load Life, 1,000 Hours ∆R 1.00%

Resistance to Solder Heat (Per MIL-STD-202, Method 210, Cond.B) ∆R 0.25%

Dielectric Withstanding Voltage 200V for 1 minute

Marking Permanency MIL-STD 202, Method 215

Lead Solderability MIL-STD 202, Method 208

Flammability UL-94V-O Rated

Storage Temperature Range -55°C to +150°C

MODEL L SERIES

Thick Film

Low Profile SIP

Conformal Coated

Resistor Networks

Specifications subject to change without notice.

ENVIRONMENTAL

ELECTRICAL

Standard Resistance Range, Ohms 22 to 1Meg

Standard Resistance Tolerance, at 25°C ±2%

Optional: ±1% (F Tol.), ±5% (J Tol.)

Operating Temperature Range -55°C to +125°C

Temperature Coefficient of Resistance ±100ppm/°C (<100 Ohms = ±250ppm/°C)

Temperature Coefficient of Resistance, Tracking ±50ppm/°C

Maximum Operating Voltage 100Vdc or √PR

Insulation Resistance ≥10,000 Megohms

4-38

Model L Series

-3 Circuit

(

Isolated Resistors

) &

-1 Circuits

(

Bussed Resistors

)

Ohms Code Ohms Code Ohms Code

22 220 820 821 33K 333

27 270 1K 102 39K 393

33 330 1.2K 122 47K 473

39 390 1.5K 152 51K 513

47 470 1.8K 182 56K 563

51 510 2K 202 68K 683

56 560 2.2K 222 82K 823

68 680 2.7K 272 100K 104

82 820 3.3K 332 120K 124

100 101 3.9K 392 150K 154

120 121 4.7K 472 180K 184

150 151 5.1K 512 200K 204

180 181 5.6K 562 220K 224

200 201 6.8K 682 270K 274

220 221 8.2K 822 330K 334

270 271 10K 103 390K 394

330 331 12K 123 470K 474

390 391 15K 153 510K 514

470 471 18K 183 560K 564

510 511 20K 203 680K 684

560 561 22K 223 820K 824

680 681 27K 273 1Meg 105

Ohms Code Ohms Code Ohms Code

R1/R2 R1/R2 R1/R2 R1/R2 R1/R2 R1/R2

180/390 181/391 330/390 331/391 3K/6.2K 302/622

220/270 221/271 330/470 331/471

220/330 221/331 330/680 331/681

MECHANICAL

Lead Material Steel Alloy (Standard)

Copper Alloy (Optional)

Lead Finish 90/10 Tin-Lead

Substrate Material Alumina

Resistor Material Cermet

Body Material Conformal Epoxy Resin

STANDARD RESISTANCE VALUES, OHMS

-5 Circuit

(Dual Terminators)

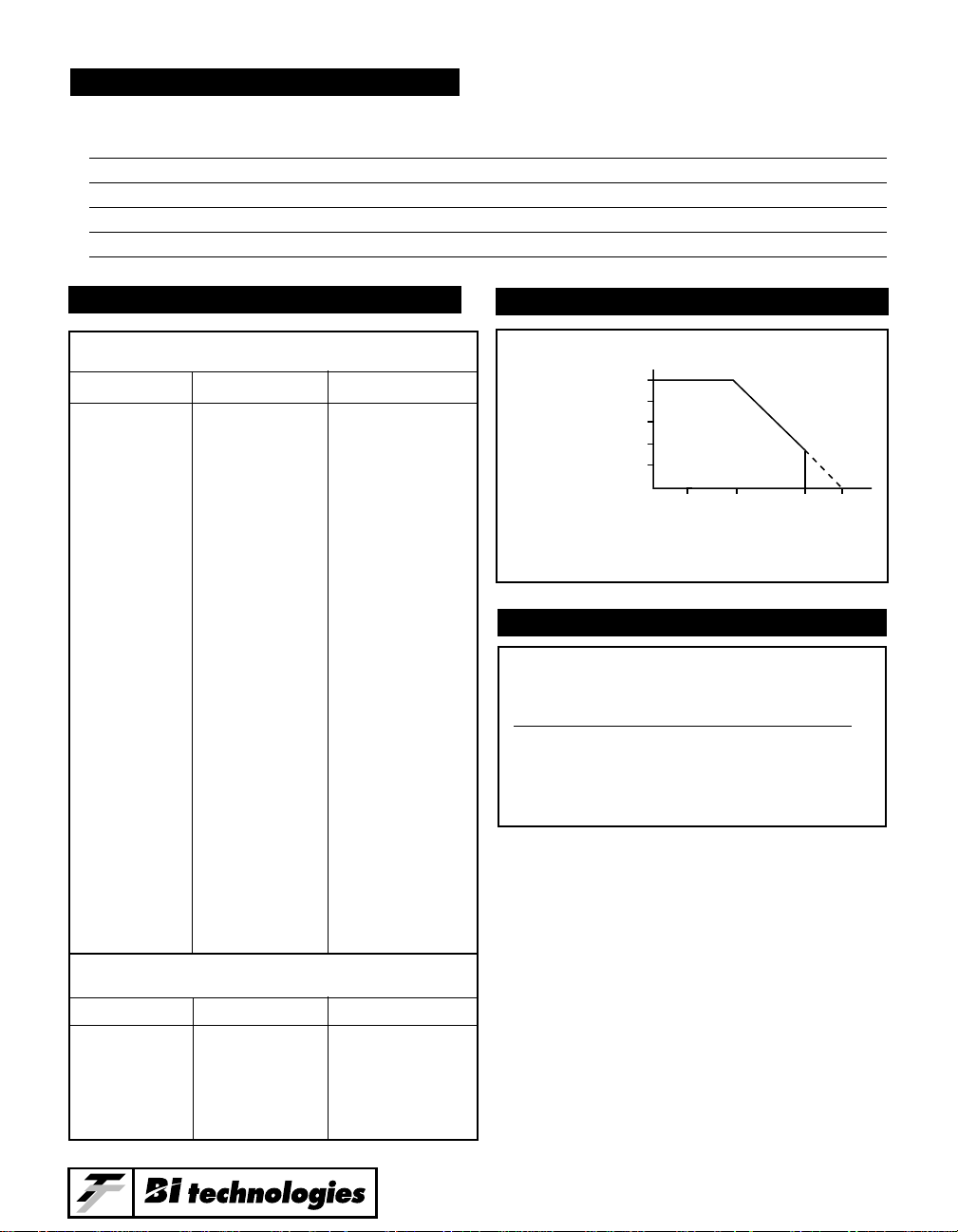

POWER DERATING CURVE

POWER DISSIPATION, WATTS AT 70°C

— Resistor (Per Circuit) —

Model Package -1 -3 -5

L06 .6 .125 .200 .125

L08 .8 .125 .200 .125

L10 1.0 .125 .200 .125

100

80

Percent of

Rated Power

60

40

20

0

15012570-0

Degrees C

4

4-39

Model L Series

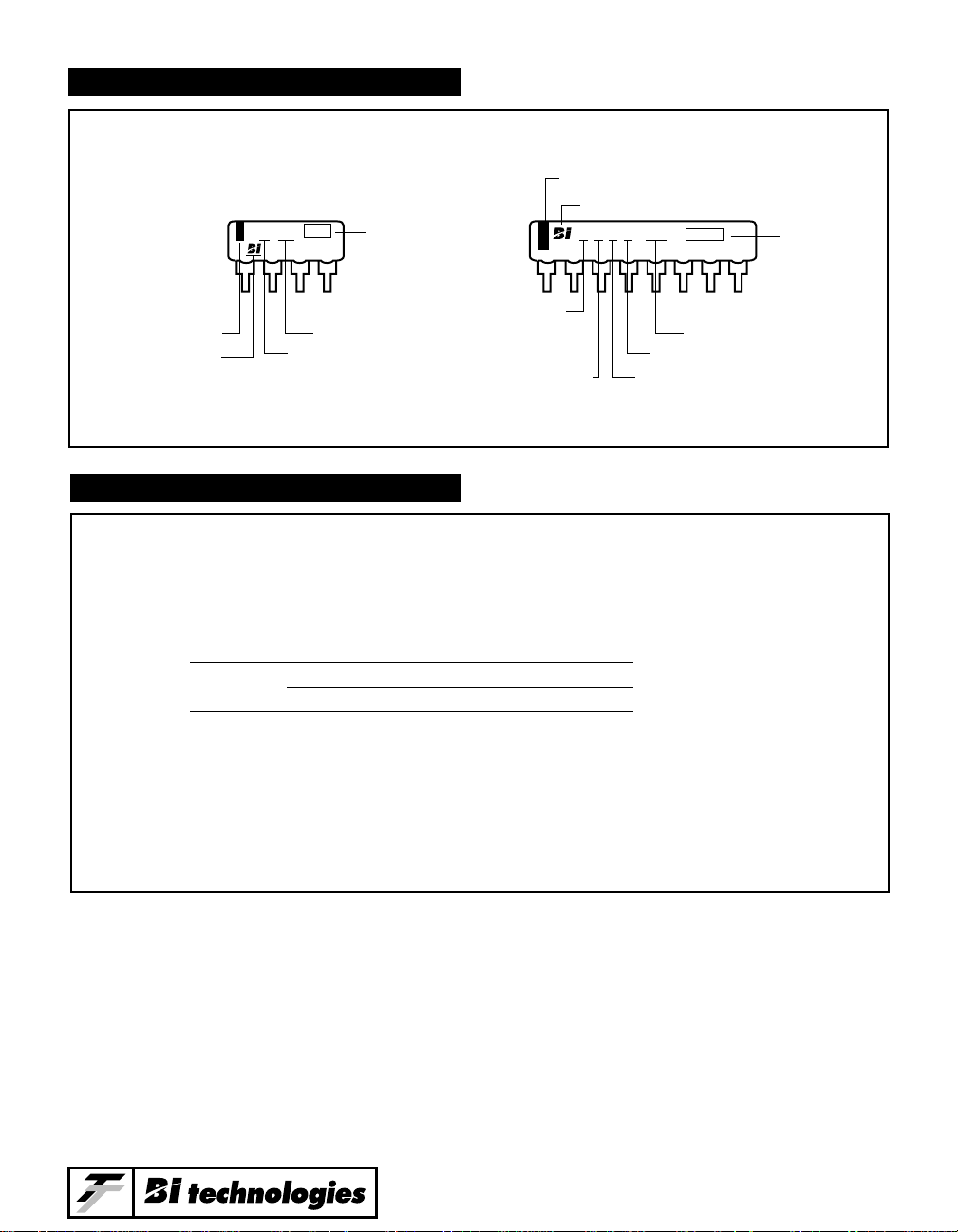

1234 n

-3 Circuit

Isolated Resistors

-5 Circuit

Dual Terminator

1234

R1

R2

n

1234 n

-1 Circuit

Bussed Resistors

No. of Leads

.100 ± .005

2.54 ± 0.13

Pitch. NonAccumulative

.020 ± .004

0.51 ± 0.10

.012 ± .003

0.31 ± 0.08

Centered

on Package

.140 ± .020

3.56 ± 0.51

.195

4.95

Max.

“L” Max.

.095

2.41

Max.

1.40

35.56

14

1.30

33.02

13

1.20

30.48

12

1.10

27.94

11

1.00

25.40

10

.90

22.86

9

.80

20.32

8

.70

17.78

7

.60

15.24

6

.50

12.70

5

.40

10.16

Dim. “L”

Max.

4# of Leads

OUTLINE DIMENSIONS (Inch/mm)

SCHEMATICS

4-40

Model L Series

TYPICAL PART MARKING

PACKAGING

Standard: Bulk: Quantity = 500 (Europe)

200 Units (USA/Asia)

Option: Tape in Ammo Box (Steel pins only).

All Units oriented with lead #1 to the left of direction of feed.

Tape: Width = 18mm

Pitch = 12.7mm

Ammo Box: Capacity = 1,000 Units

Option: Magazine

Dimensions conform to EIA & JEDEC standards.

All Units oriented with lead #1 to the same side.

Magazine: Material = Antistatic Plastic

4 Leads Only

Date

Code

Resistance Code

Lead #1 Indicator

Logo

B 104

Circuit Type & I.D. Code

Lead #1 Indicator

Model

Series

Number

Of Leads

Logo

L

8 3 C 103

Date

Code

Resistance Code

Factory Code

Circuit Type

4

4-41

Model L Series

ORDERING INFORMATION

APPLICABLE DOCUMENTS

MIL-R-83401 — Resistor Networks, Fixed, Film, General Specifications

MIL-STD-105 — Sampling Procedures and Tables for Inspection by Attributes

MIL-STD-202 — Test Methods for Electronic and Electrical Component Parts

L 08 5 C 331 / 471 F XX

Model Series

Number of Leads:

4 thru 14

Circuit Type:

3 = Isolated

1 = Bussed

5 = Dual Terminator

Lead Code:

S = Steel Leads

C = Copper Leads

Packaging Option:

AP = Ammo Pack, Steel Leads only

All leads attached to tape.*

G3T = Ammo Pack, Steel Leads only

3 leads only attached to tape.*

M1 or M2 = Tube **

(No code used for standard bulk packaging.)

Tolerance Code:

F = ±1%

J = ±5%

(No code used for 2% standard.)

R2 Resistance Code:

(Add for -5 circuit only)

Resistance Code:

First 2 digits are significant.

Last digit denotes number of trailing zeros.

For "F" tolerance first 3 digits are significant.

Fourth digit denotes number of trailing zeros.

* Refer to Packaging for Automation section (Page A-3) for Ammo Pack capacity and dimensions.

** Refer to Packaging for Automation section (Page A-4) for M1 and M2 tube capacity and dimensions.

Loading...

Loading...