Page 1

Frey M1 Module

18 July 2016

Version 2.0

Page 1

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 2

Contents

Charpt 1. Revision History ..................................................................... 4

Charpt 2. Introduction ............................................................................ 5

Charpt 3. Product Concept ................................................................ .... 6

3.1. Main Feature .......................................................................... 6

3.1.1. Chipset on module ................................................................. 6

3.1.2. Memory .................................................................................. 6

3.1.3. Multimedia ............................................................................. 6

3.1.4. Audio (PM8952 codec ) ......................................................... 7

3.1.5. Expansion Slot Interface ........................................................ 7

3.1.6. USB ....................................................................................... 7

3.1.7. Keypad................................................................................... 7

3.1.8. Dimension .............................................................................. 7

3.1.9. Operation temperature ........................................................... 7

3.2. Module Block Diagram ........................................................... 8

3.3. Pin Definition .......................................................................... 8

3.4. Pad assignments (Top view) ................................ ................ 27

3.5. Electrical Specification ......................................................... 28

3.5.1. Input power specification ..................................................... 28

3.5.2. Output power specification ................................................... 29

3.5.3. Current consumption ........................................................... 32

3.5.4. Digital logic characteristics ................................................... 32

3.5.5. Coin-cell charging ................................................................ 34

3.5.6. Audio ................................................................................... 34

3.5.7. Vibrator ................................................................................ 37

3.5.8. Display ± bias ...................................................................... 37

3.5.9. Flash drivers (including torch mode) .................................... 38

3.5.10. Display backlight (WLEDs) .................................................. 39

3.5.11. System clock (BB_CLK)....................................................... 40

3.5.12. RF Transmit and Receiver Specifications ............................ 40

3.5.13. Electrostatic Discharge ........................................................ 42

Charpt 4. Module Mounting Issues ...................................................... 44

4.1. Solder Paste ........................................................................ 44

4.2. Stencil Printing ..................................................................... 44

Page 2

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 3

4.2.1. General Stencil Considerations ........................................... 44

4.2.2. Used Parameters and Recommendations ........................... 45

4.2.3. Pick and Place ..................................................................... 45

4.2.4. Reflow Profile ....................................................................... 45

4.3. Soldering Conditions and Temperature ............................... 47

4.3.1. Reflow Profile ....................................................................... 47

4.3.2. Maximum Temperature and Duration .................................. 48

4.4. Soldering Process Evaluation .............................................. 48

4.4.1. Visual Inspection .................................................................. 48

4.4.2. X-Ray Inspection and Void Content ..................................... 48

4.5. Board Level Reliability Investigation .................................... 49

4.6. Desoldering Process ............................................................ 50

4.6.1. Preparation of LGA Module ................................................. 51

4.6.2. Baking of Application Board ................................................. 51

4.6.3. Removal of LGA Module ...................................................... 51

Charpt 5. Packaging ............................................................................ 52

5.1. Mechanical Dimensions of Frey M1 ..................................... 52

5.2. Shipping Materials ............................................................... 54

5.2.1. Moisture Barrier Bag ............................................................ 56

5.3. Packing Label ...................................................................... 58

5.4. Storage Conditions .............................................................. 62

5.5. Moisture Sensitivity Level .................................................... 63

5.6. Durability and Mechanical Handling ..................................... 63

5.6.1. Storage Life ......................................................................... 63

5.6.2. Processing Life .................................................................... 63

5.6.3. Electrostatic Discharge ........................................................ 63

Charpt 6. Regulatory and Type Approval Information.......................... 64

6.1. Safety Precautions ............................................................... 66

6.2. Safety .................................................................................. 68

Charpt 7. Appendix .............................................................................. 70

7.1. Abbreviations ....................................................................... 70

7.2. Mounting Advice Sheet ........................................................ 70

Page 3

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 4

Version

Date

Description

1.00

2016/06/21

Initial release

2.00

2016/7/18

Update FCC statement

Charpt 1. Revision History

Changes to the original manual are listed below:

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 4

Page 5

Charpt 2. Introduction

This document defines the specification for FREY M1. FREY M1 is a smart module for

handheld device and builds in Bluetooth, WiFi and GPS function. It also can support SD

card, LCM , Touch Screen , Audio , dual camera , Flash LED , Accelerometer /

Magnetometer / Gyroscope / Proximity & Light Sensor functions through application design

board.

Page 5

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 6

Charpt 3. Product Concept

3.1. Main Feature

3.1.1. Chipset on module

Digital processor : APQ8052 (ARM Cortex-A53 octa cores)

Quad core at 1.516 GHz, 512 kB L2 cache

Quad core at 1.209 GHz, 512 kB L2 cache

Power management : PM8952 and PMI8952

WLAN/BT/FM : WCN3680B

WLAN IEEE 802.11a/b/g/n/ac dual bands

Bluetooth V2.1BER/EDR+3.0HS+4.1 LE

FM RDS & RBDS, RX only

GPS : WGR7640

GPS, Glonass , Galileo or Beidou

3.1.2. Memory

eMCP , 2GB LPDDR3 RAM plus 16GB eMMC Flash ROM

3.1.3. Multimedia

Display interface:

Support one 4-lane MIPI DSI port , FHD (1920 × 1200) 60 fps

Camera interface:

Support 4-lane + 4-lane or 4-lane + 2-lane + 1-lane MIPI CSI port

Two Flash LED interface

Graphics:

Qualcomm® Adreno™ 405

Touch screen:

Capacitive panels via external IC by I2C

Page 6

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 7

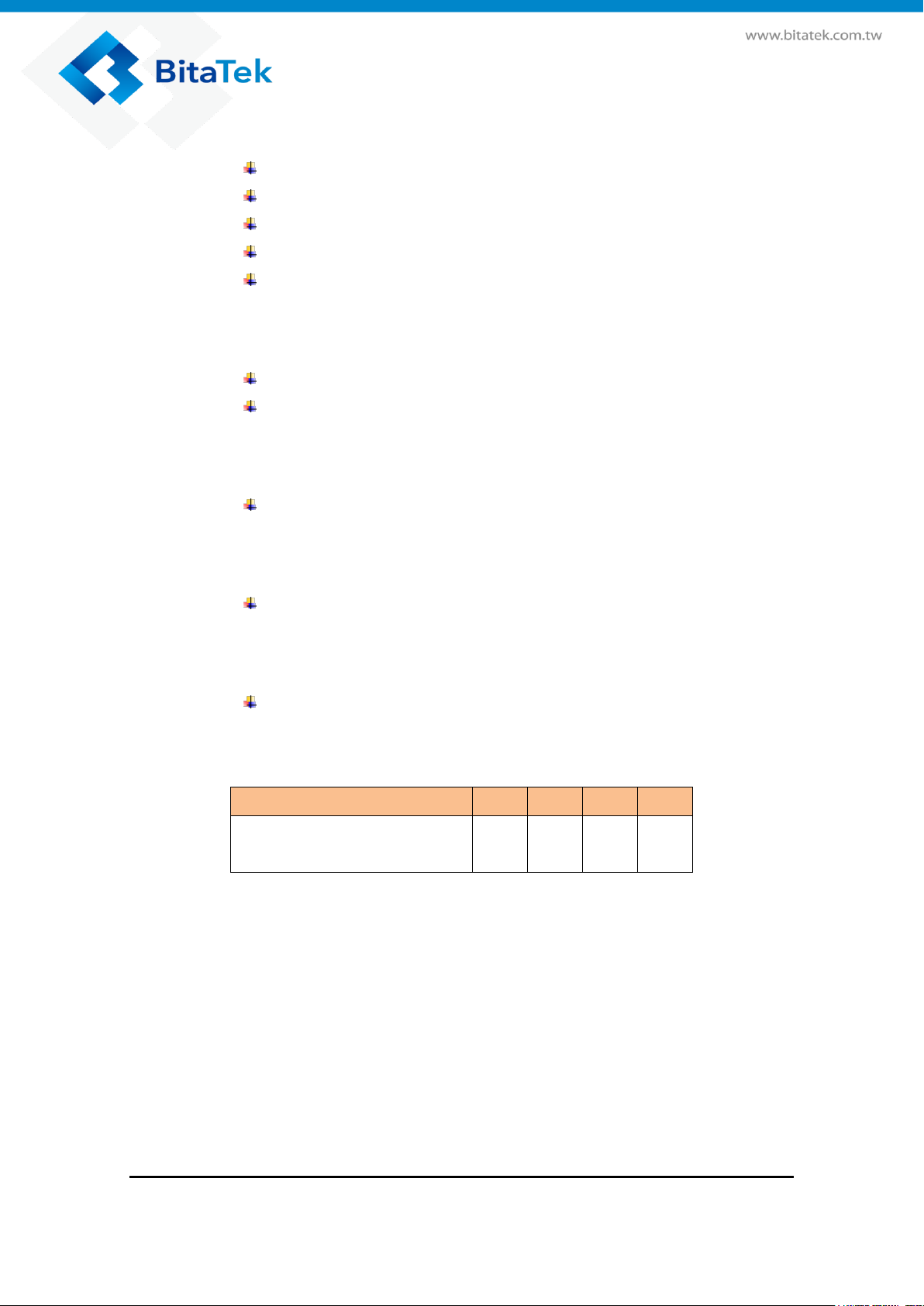

Item

Min.

Typ.

Max.

Unit

Normal temperature range

Extreme temperature range

+15

-30

+25 +55

+70

°C

°C

3.1.4. Audio (PM8952 codec )

Support two Microphones interface with noise cancellation

Support one speaker interface

Support one receiver interface

Support one audio jack interface

Support one vibrator control interface

3.1.5. Expansion Slot Interface

One micro SD Memory slot interface with SDHC

UIM interface x1

3.1.6. USB

Support one USB OTG

3.1.7. Keypad

Support 5x5 Key matrix

3.1.8. Dimension

44 x 33.6 x 2.7 mm

3.1.9. Operation temperature

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 7

Page 8

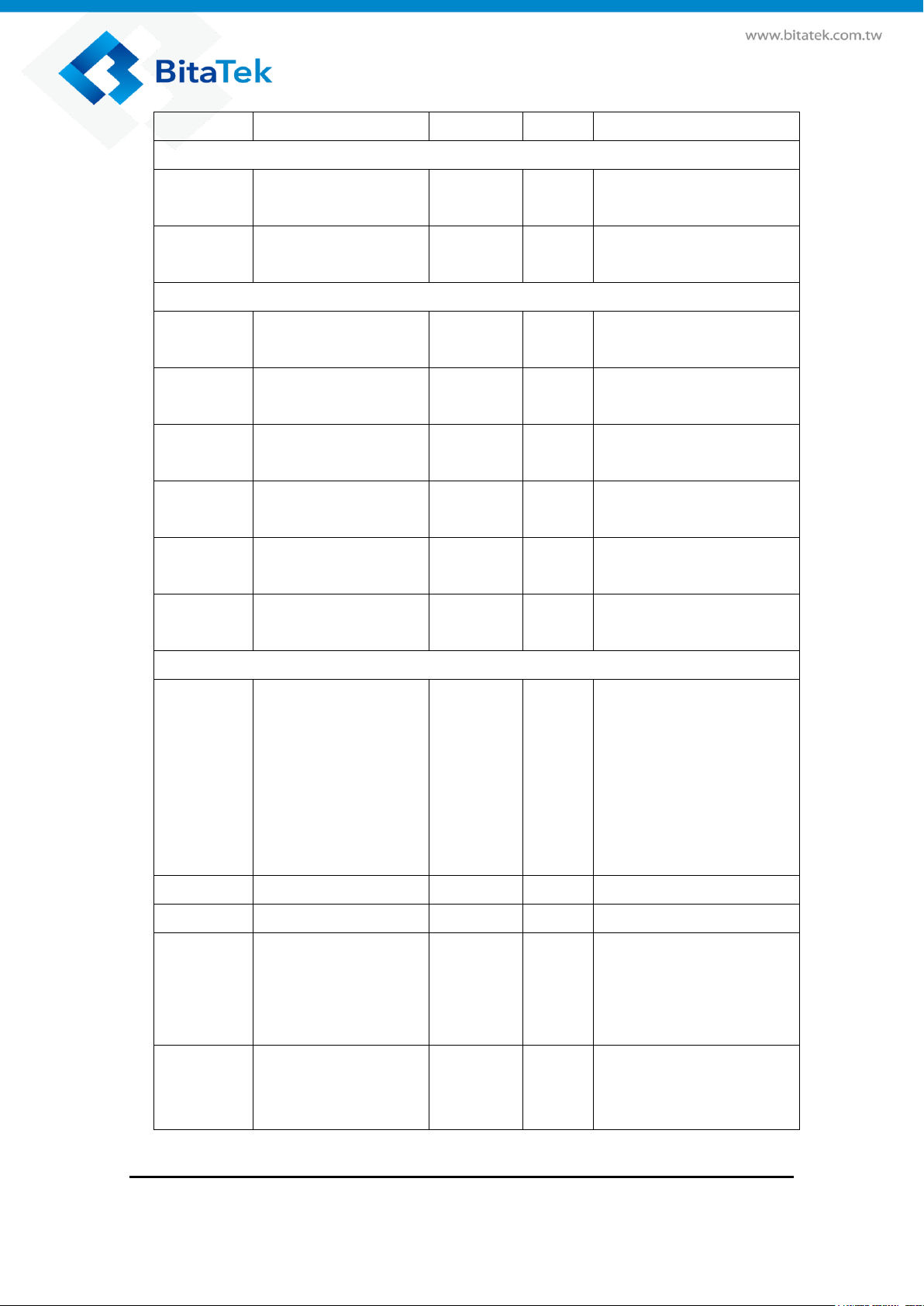

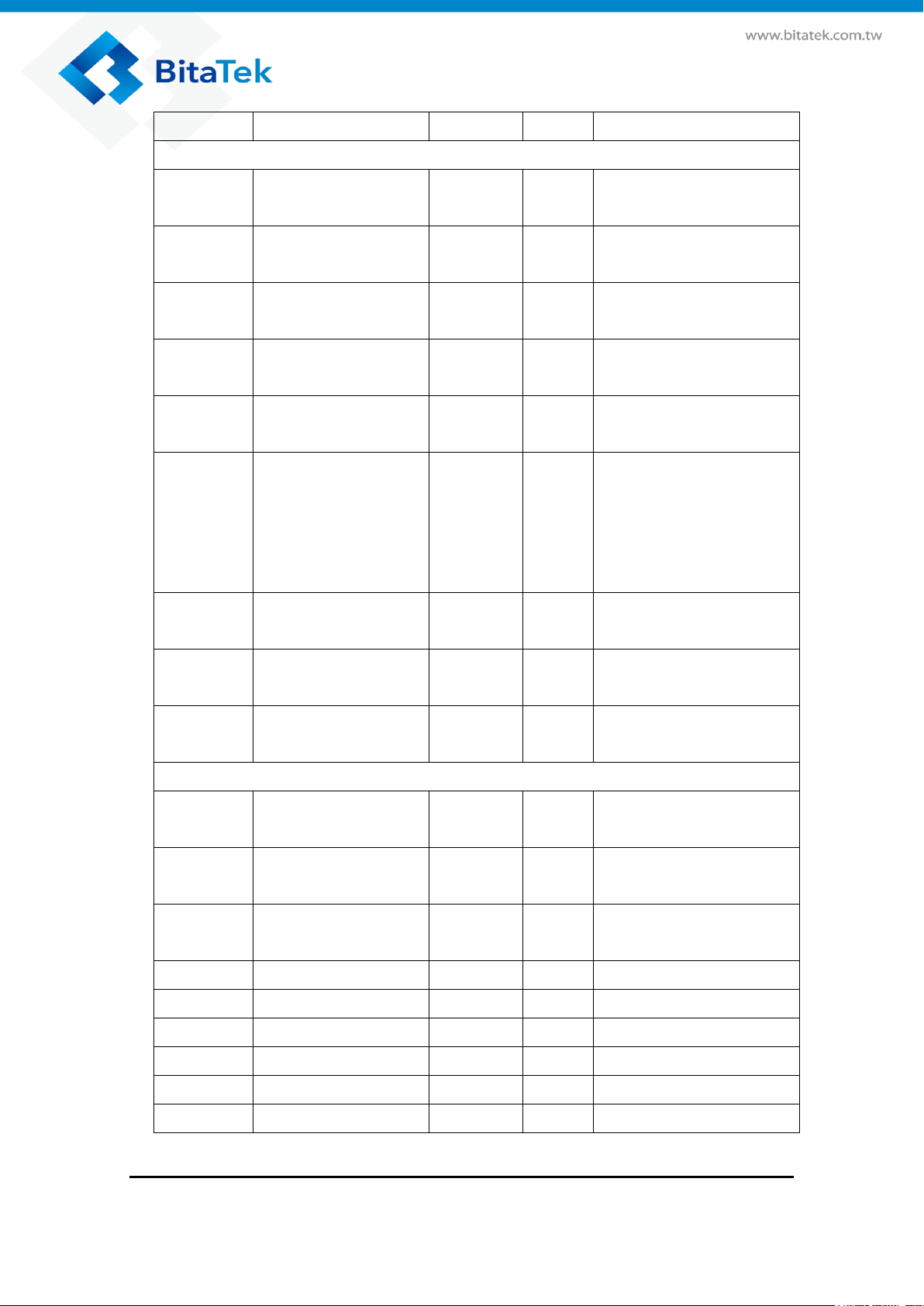

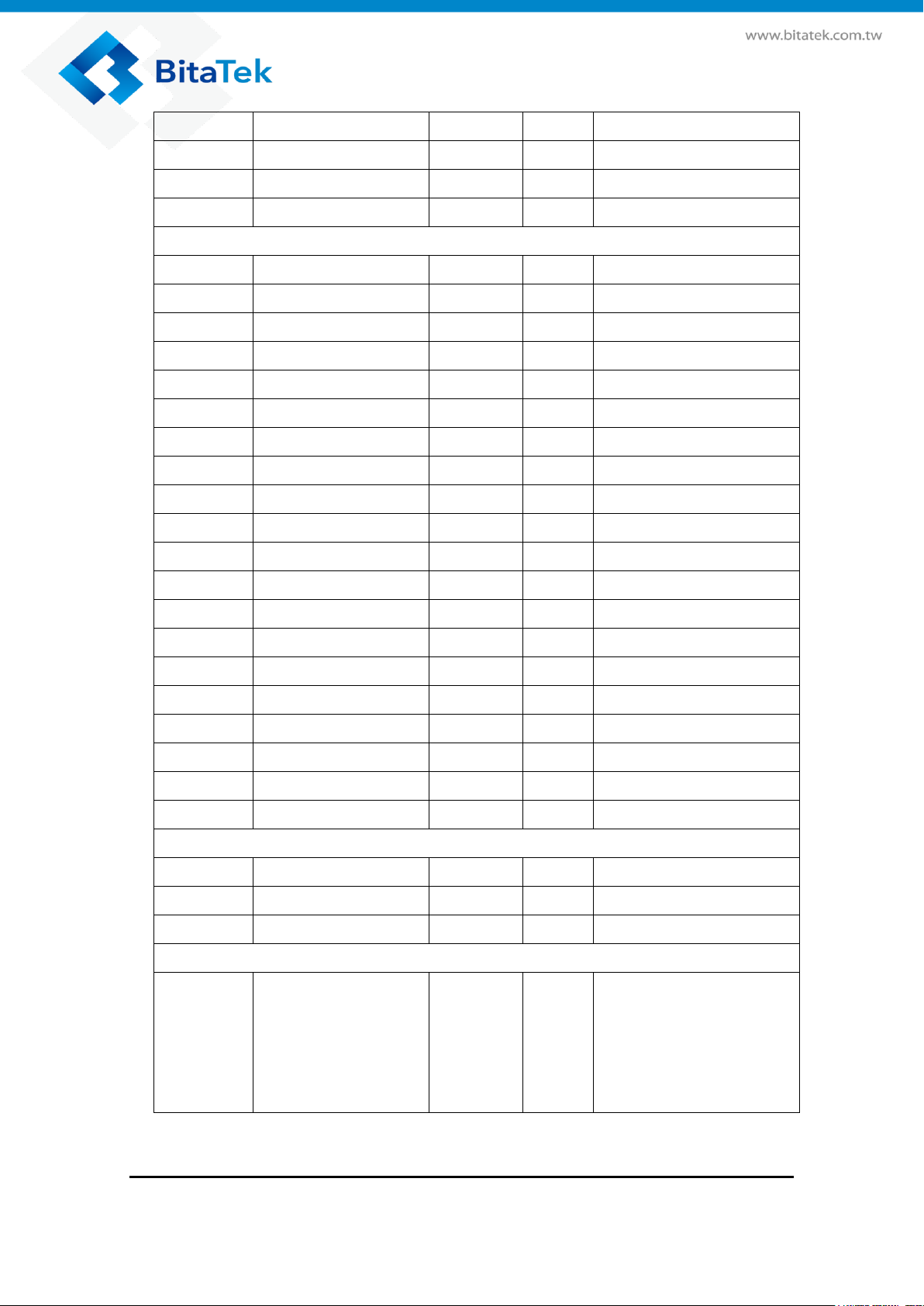

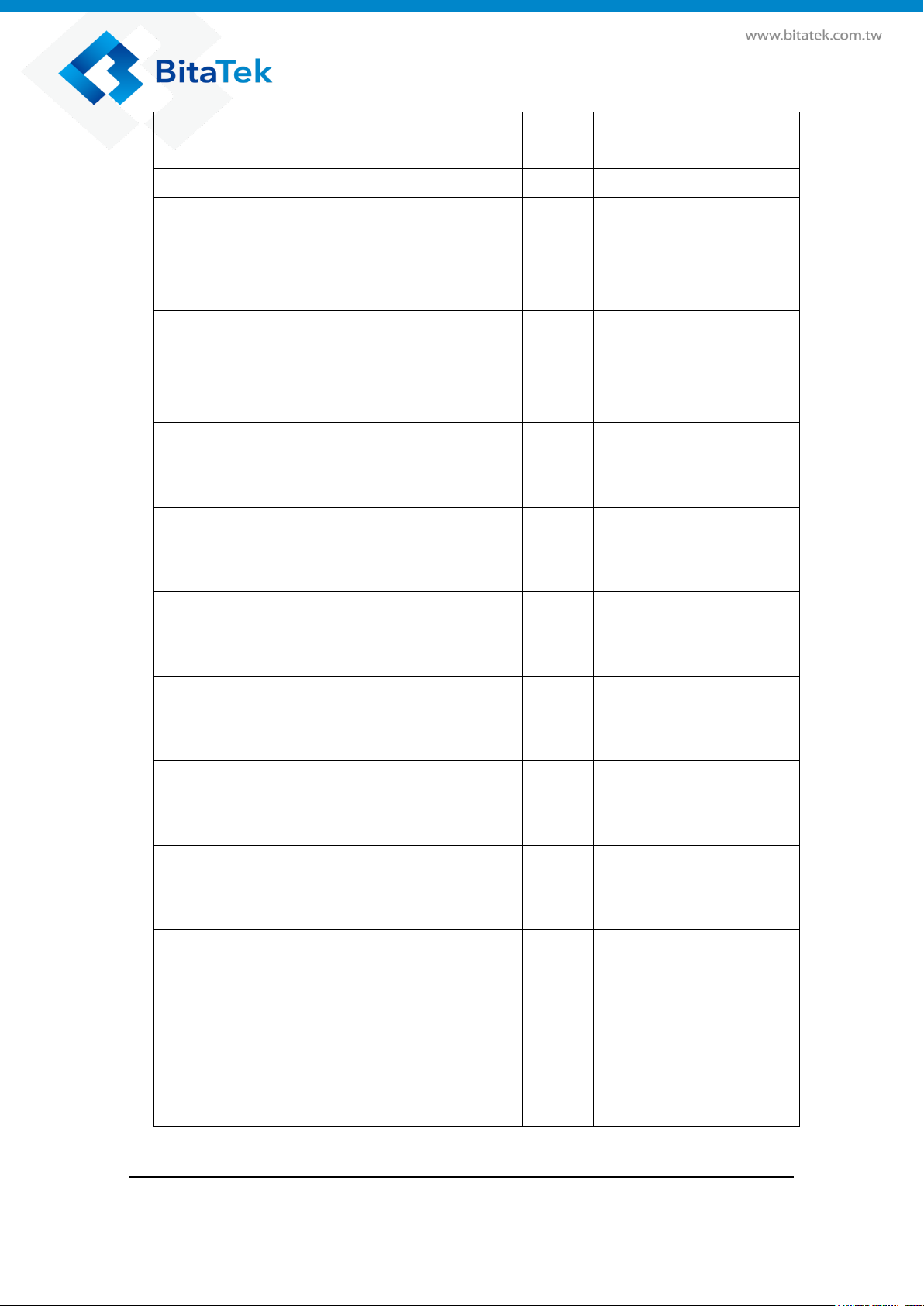

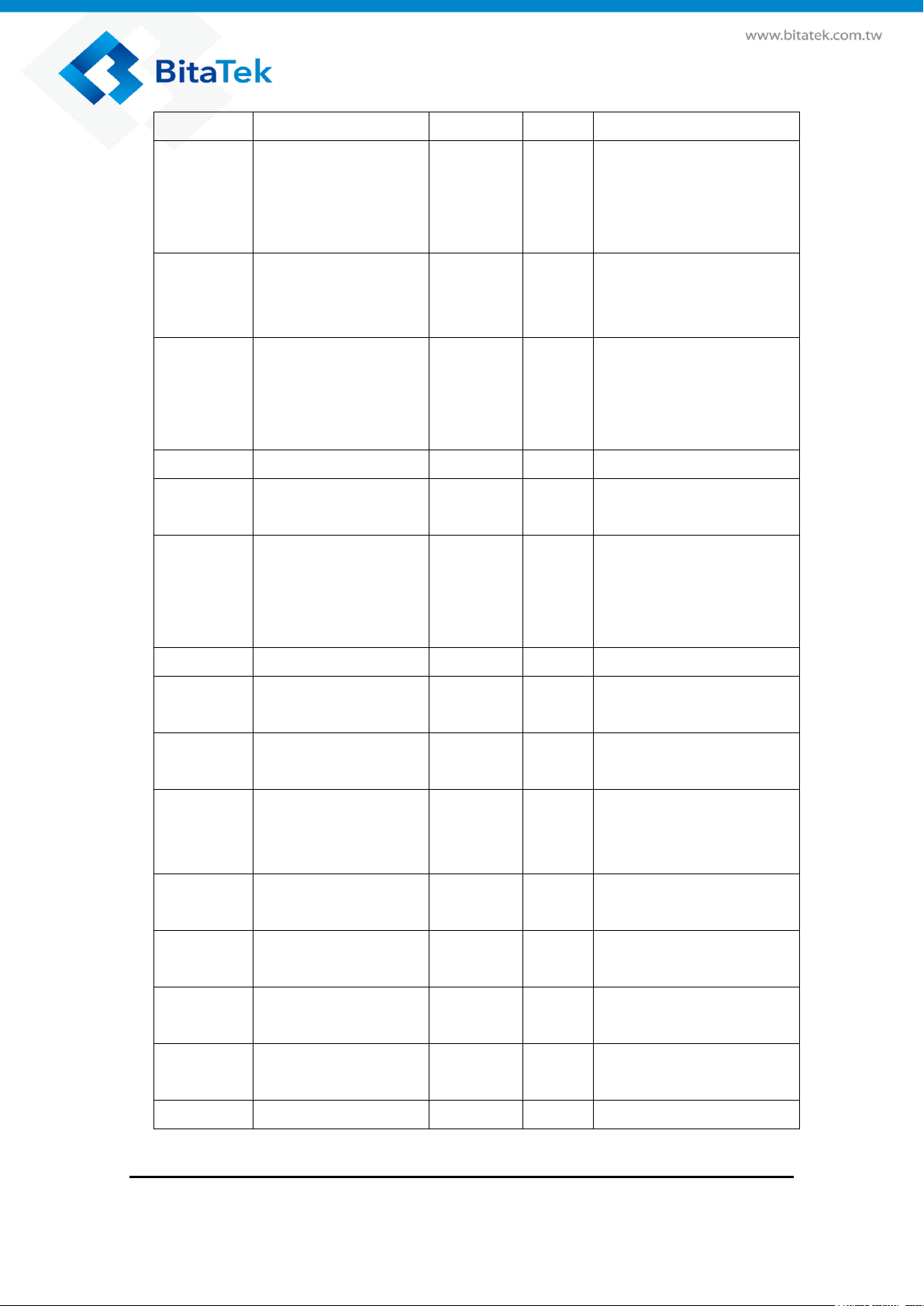

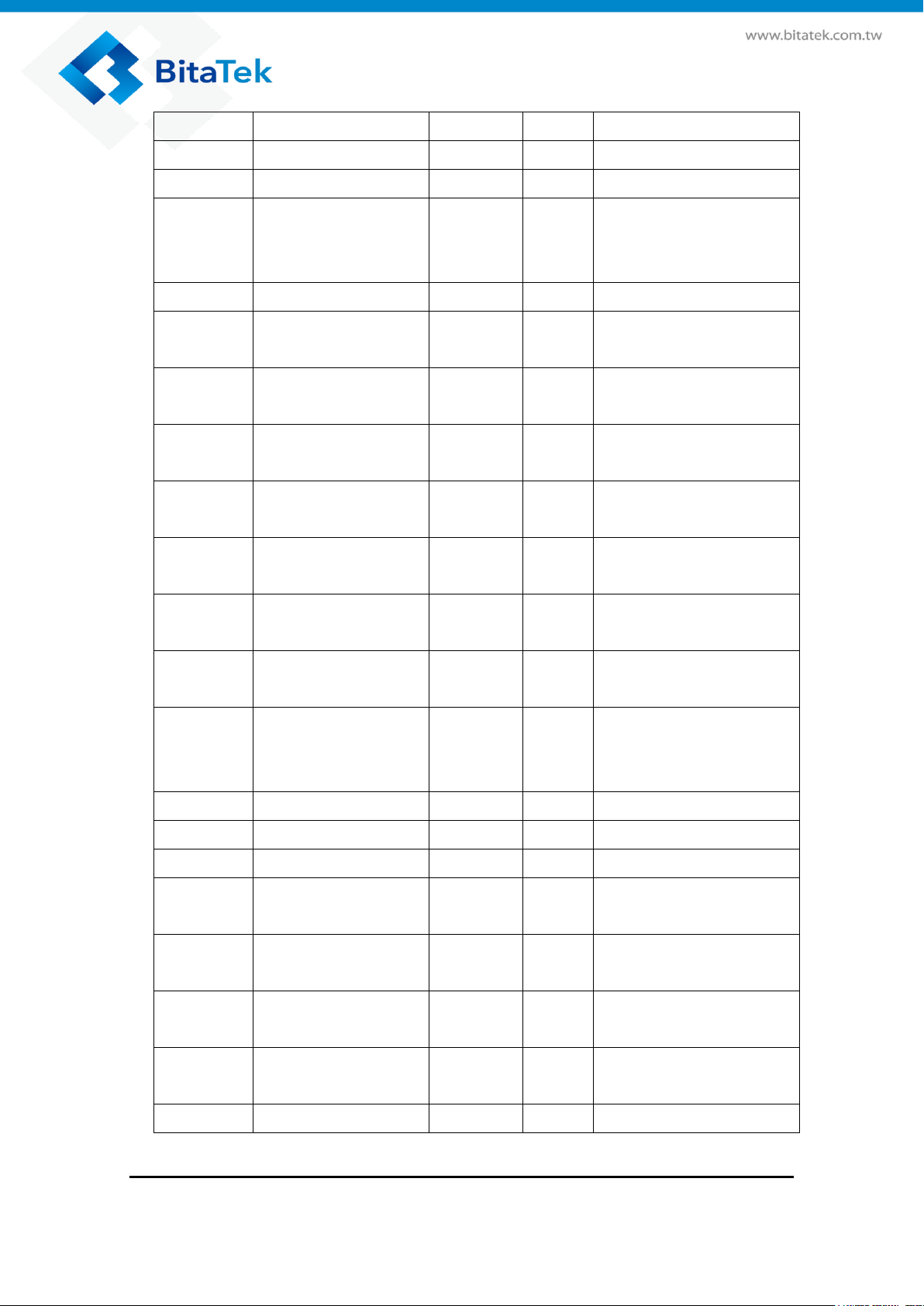

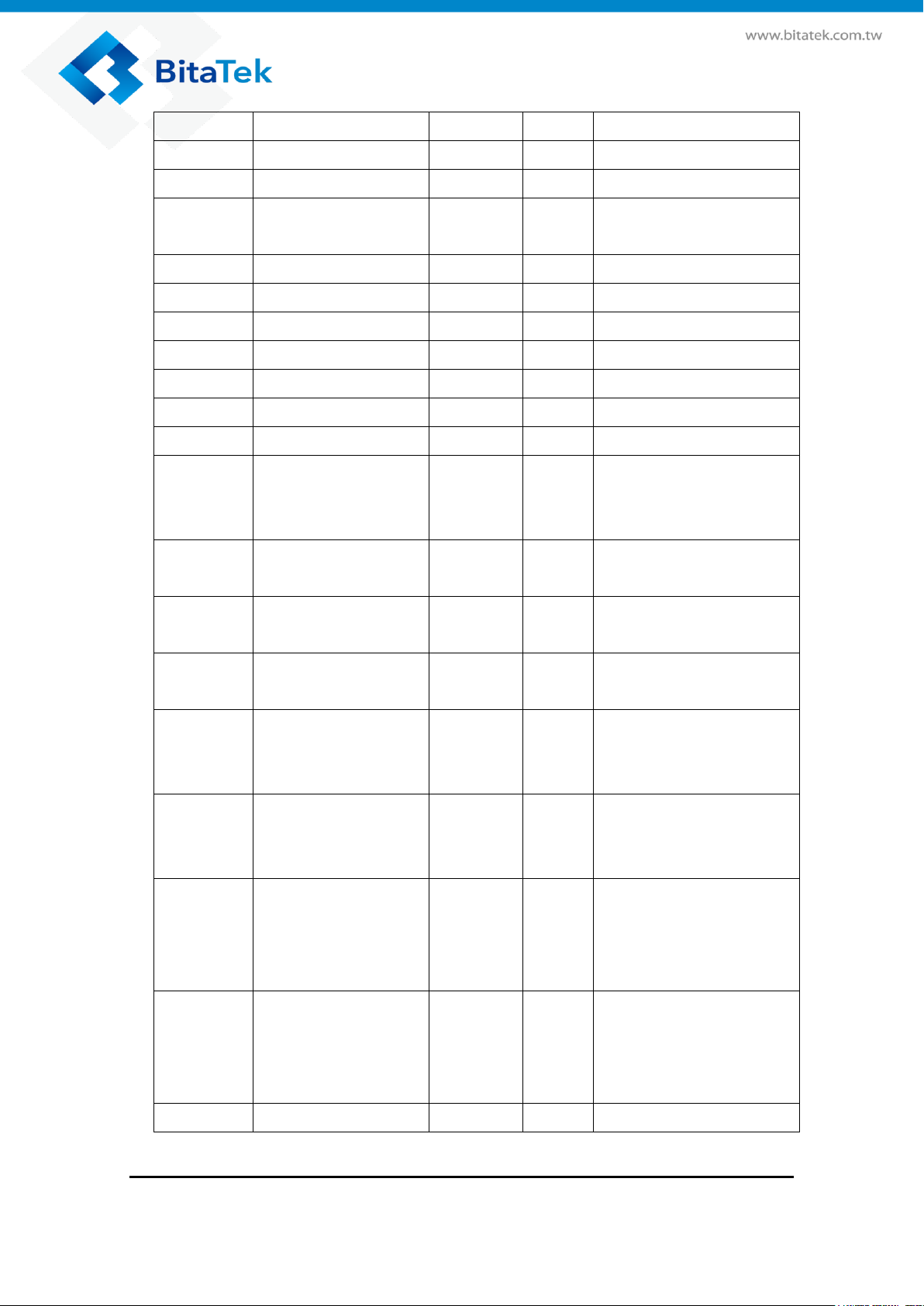

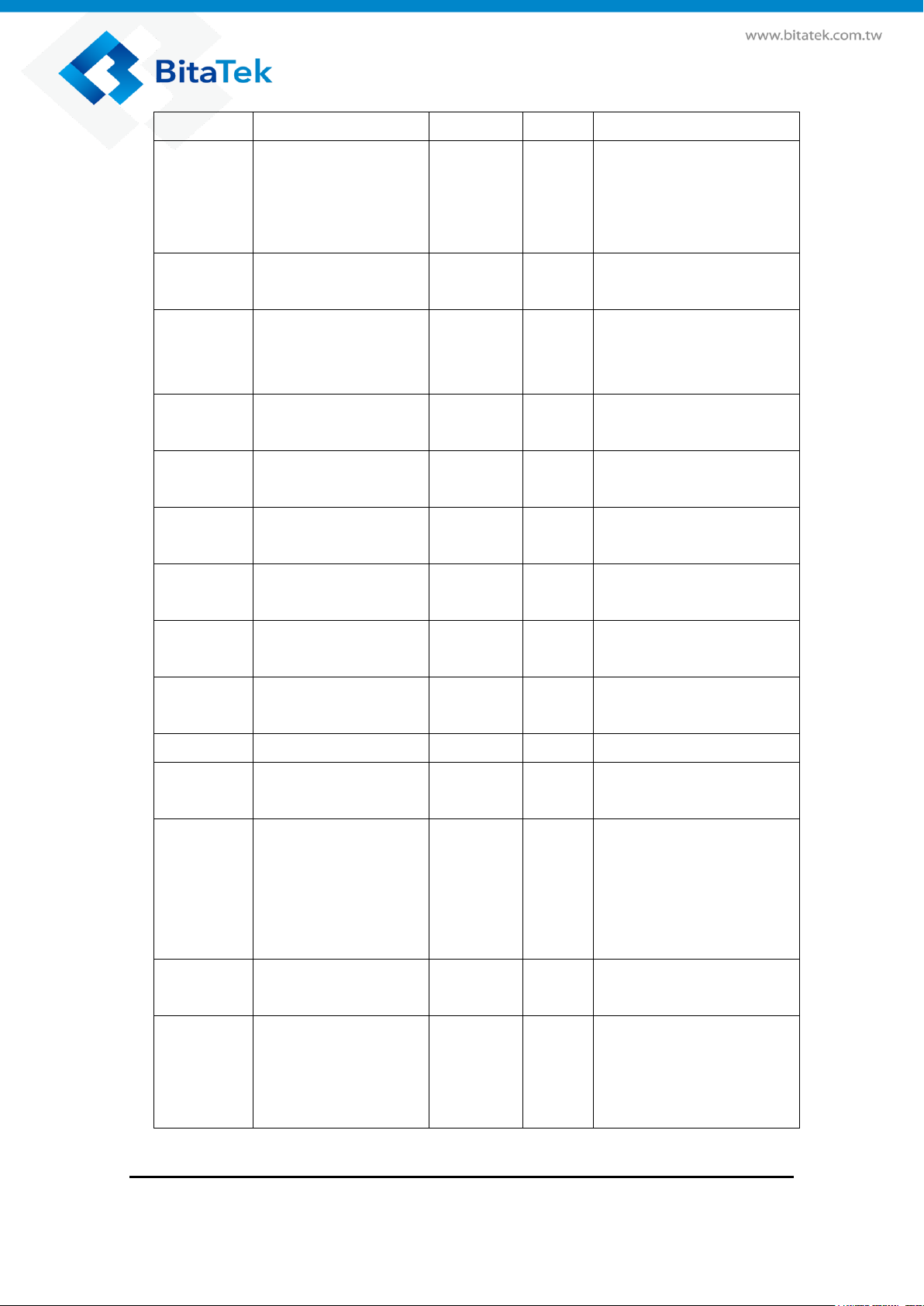

Pin

Number

Pin Name

Wakeup

Pad

Type

Functional description

Power

W18

USB_VBUS_IN

PI, PO

Input power from selected

source, or output during

USB-OTG.

W19

USB_VBUS_IN

PI, PO

Input power from selected

source, or output during

USB-OTG.

X18

USB_VBUS_IN

PI, PO

Input power from selected

source, or output during

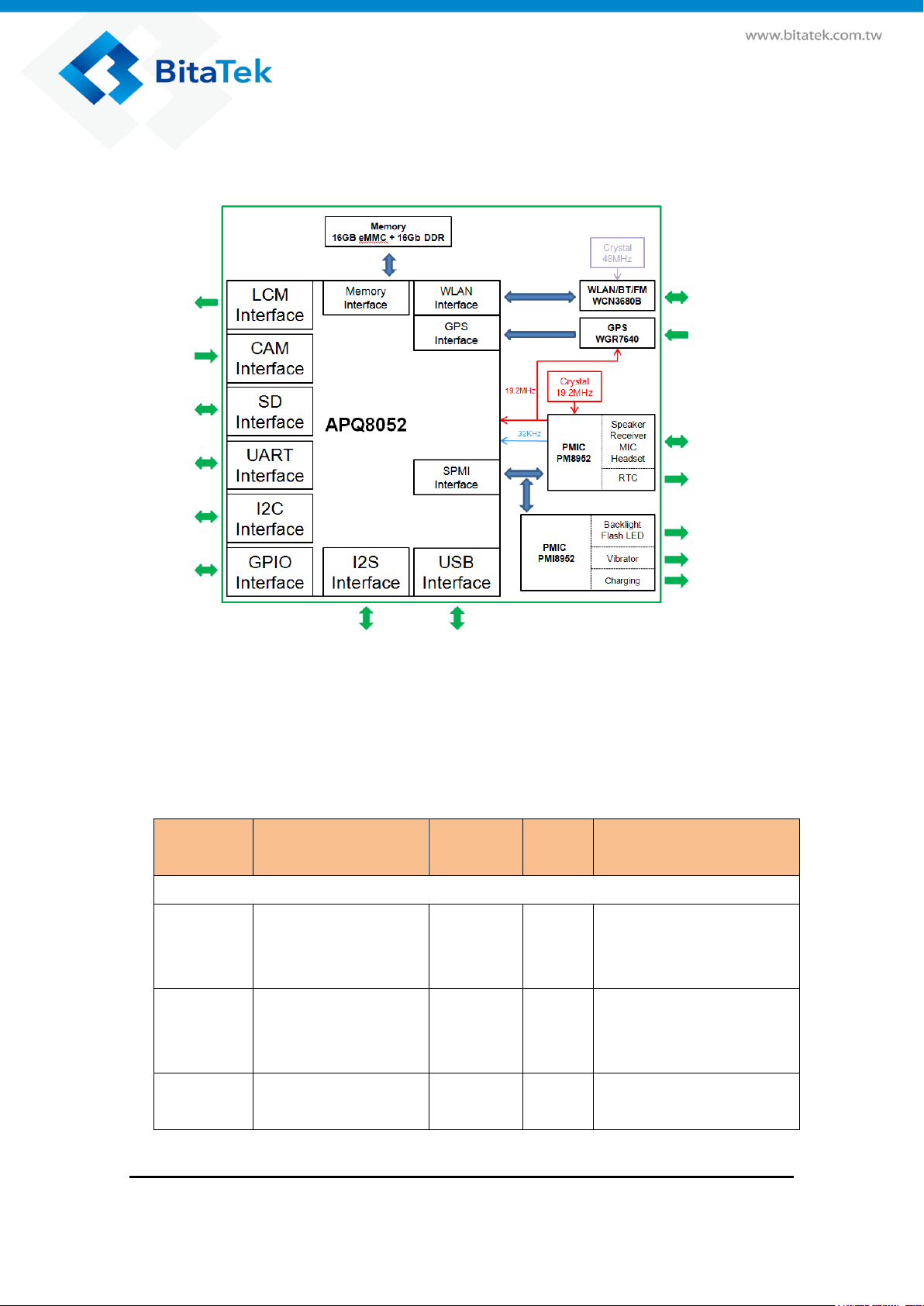

3.2. Module Block Diagram

3.3. Pin Definition

AI : Analog input ; AO : Analog output ;

DI : Digital input ; DO : Digital output

PI : Power input ; PO : Power output

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 8

Page 9

USB-OTG.

X19

USB_VBUS_IN

PI, PO

Input power from selected

source, or output during

USB-OTG.

T18

VBATT

PI, PO

Battery power supply

T19

VBATT

PI, PO

Battery power supply

U18

VBATT

PI, PO

Battery power supply

U19

VBATT

PI, PO

Battery power supply

Z18

VPH_PWR

PI, PO

Primary system power

supply node

Z19

VPH_PWR

PI, PO

Primary system power

supply node

AA18

VPH_PWR

PI, PO

Primary system power

supply node

AA19

VPH_PWR

PI, PO

Primary system power

supply node

U16

VREG_L1

PO

LDO output

F16

VREG_L4

PO

LDO output

C15

VREG_L5

PO

LDO output

F12

VREG_L6

PO

LDO output

C19

VREG_L10

PO

LDO output

D17

VREG_L11

PO

LDO output

E13

VREG_L12

PO

LDO output

C18

VREG_L14

PO

LDO output

C16

VREG_L16

PO

LDO output

E16

VREG_L17

PO

LDO output

D19

VREG_L18

PO

LDO output

D18

VREG_L22

PO

LDO output

T17

VREG_L23

PO

LDO output

U17

PMI8952_VBIAS

PO

Dedicated voltage source

for battery-related resistor

networks, not use for other

purpose.

X20

SYSON

PO

LDO output that supplies

SCHG FET drivers

RTC Battery

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 9

Page 10

P20

VCOIN

PI, PO

For RTC battery.

Clock

F17

PM8952_BB_CLK2

DO

Buffered baseband

(low-power) XO clock 2

System

W17

KYPD_PWR_N

DI

Internal pull-up to dVdd;

keep C load < 10 pF. Dual

function:

1. Keypad power on;

initiates power on when

grounded

2. Can be configured as

stage 2 or stage 3 reset if

held LOW longer

X15

RESIN_N

DI

PMIC reset input ; initiates

stage 2 or stage 3 reset if

held LOW

W20

PMI8952_CHG_EN

DI

Charger enable

V20

CHG_VBAT_SNS

AI

Sensed battery voltage for

charger circuits

T20

BATT_ID

AI

Battery ID input to ADC;

also detects missing

battery

Y16

CS_MINUS

AI

Current sense resistor —

minus side (low side)

V15

CS_PLUS

AI

Current sense resistor —

plus side (high side)

V16

BATT_MINUS

AI

Battery minus (-) terminal

sense input

U15

BATT_PLUS

AI

Battery plus (+) terminal

sense input

X17

BATT_THERM

AI

Battery temperature input

to ADC (measures pack

temperature) , default NTC

is 47KΩ±1% in EVB

battery .

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 10

Page 11

V17

PA_THERM

AI

AMUX input – PA

thermistor divider

V19

PMI8952_USB_EN

DO

Enable USB path from

external power multiplexer

Y18

PMI8952_USB_SNS

AI

USB input voltage sense

pin from external power

multiplexer

V18

PMI8952_DC_EN

DO

Enable 2nd power path

from external power

multiplexer

Y19

PMI8952_DC_SNS

AI

2nd power voltage sense to

determine in or out of valid

range

Z16

NC NC

Keep it floating and doesn't

connect to GND.

Audio

H18

MIC_BIAS1

AO

Microphone bias #1

I18

MIC_BIAS2

AO

Microphone bias #2

H19

MIC1_IN_M

AI

Microphone input 1, minus

H20

MIC1_IN_P

AI

Microphone input 1, plus

M19

MIC2_IN

AI

Microphone input 2

L18

MIC3_IN

AI

Microphone input 3

K18

GND_CFILT

GND

Microphone bias filter

ground

J19

HPH_L

AO

Headphone output, left

channel

J20

HPH_R

AO

Headphone output, right

channel

K20

HPH_REF

AI

Headphone ground

reference

N18

HS_DET

AI

Headset detection

L20

EARO_M

AO

Earpiece output, minus (-)

L19

EARO_P

AO

Earpiece output, plus (+)

N20

SPKR_DRV_M

AO

Class-D speaker driver

output, minus (-)

N19

SPKR_DRV_P

AO

Class-D speaker driver

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 11

Page 12

output, plus (+)

Vibrator

Y15

HAP_OUT_N

AO

Vibrator driver output

negative

Y14

HAP_OUT_P

AO

Vibrator driver output

positive

SD

V1

SDC2_CLK

DO

Secure digital controller 2

clock

X2

SDC2_CMD

DI,DO

Secure digital controller 2

command

W1

SDC2_DATA_0

DI,DO

Secure digital controller 2

data bit 0

V2

SDC2_DATA_1

DI,DO

Secure digital controller 2

data bit 1

V3

SDC2_DATA_2

DI,DO

Secure digital controller 2

data bit 2

W2

SDC2_DATA_3

DI,DO

Secure digital controller 2

data bit 3

USB

Z15

PMI8952_USB_ID

AI, AO

Dual function:

1. OTG mode enable

(programmable polarity;

can also be controlled by

OTG enable bit)

2. OTG ID monitor to detect

the OTG ID resistor value.

H13

USB_HS_DM

DI,DO

USB HS data minus

H14

USB_HS_DP

DI,DO

USB HS data plus

R19

PMI_USB_DM

DI

USB data minus for power

source detection only;

modem IC handles data

transactions

R18

PMI_USB_DP

DI

USB data plus for power

source detection only;

modem IC handles data

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 12

Page 13

transactions

LED driver

X9

VREG_WLED_ANOD

E

PO

LCM WLED boost output

Y13

WLED_SINK1

AO

WLED low-side current sink

input, string 1

Z14

WLED_SINK2

AO

WLED low-side current sink

input, string 2

Y12

WLED_SINK3

AO

WLED low-side current sink

input, string 3

Z12

WLED_SINK4

AO

WLED low-side current sink

input, string 4

W14

WLED_CABC

DI

Content adaptive backlight

control (CABC); PWM

signal from display

controller for dynamic

dimming of LCD

X16

FLASH_LED1

AO

High-side current source

for flash/torch LED1 anode

Z17

FLASH_LED2

AO

High-side current source

for flash/torch LED2 anode

Y17

CHARGE_LED_RED

AO

Current sink for charging

indication

Display

V14

VREG_DISP_N5V

PO

Regulated output for the

display’s negative bias

V13

VREG_DISP_P5V

PO

Regulated output for the

display’s positive bias

U14

NC NC

Keep it floating and doesn't

connect to GND.

K2

MIPI_DSI_CLK_N

DO

MIPI DSI clock negative

K3

MIPI_DSI_CLK_P

DO

MIPI DSI clock positive

J2

MIPI_DSI_LN0_N

DO

MIPI DSI data0 negative

J3

MIPI_DSI_LN0_P

DO

MIPI DSI data0 positive

I2

MIPI_DSI_LN1_N

DO

MIPI DSI data1 negative

I1

MIPI_DSI_LN1_P

DO

MIPI DSI data1 positive

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 13

Page 14

K1

MIPI_DSI_LN2_N

DO

MIPI DSI data2 negative

J1

MIPI_DSI_LN2_P

DO

MIPI DSI data2 positive

L2

MIPI_DSI_LN3_N

DO

MIPI DSI data3 negative

L3

MIPI_DSI_LN3_P

DO

MIPI DSI data3 positive

CAMERA

P3

MIPI_CSI0_CLK_N

DI

MIPI CSI clock negative

P2

MIPI_CSI0_CLK_P

DI

MIPI CSI0 clock positive

Q2

MIPI_CSI0_LN0_N

DI

MIPI CSI0 data0 negative

Q3

MIPI_CSI0_LN0_P

DI

MIPI CSI0 data0 positive

R2

MIPI_CSI0_LN2_N

DI

MIPI CSI0 data1 negative

S2

MIPI_CSI0_LN2_P

DI

MIPI CSI0 data1 positive

S1

MIPI_CSI0_LN3_N

DI

MIPI CSI0 data2 negative

R1

MIPI_CSI0_LN3_P

DI

MIPI CSI0 data2 positive

Q1

MIPI_CSI0_LN4_N

DI

MIPI CSI0 data3 negative

P1

MIPI_CSI0_LN4_P

DI

MIPI CSI0 data3 positive

N3

MIPI_CSI1_CLK_N

DI

MIPI CSI1 clock negative

N2

MIPI_CSI1_CLK_P

DI

MIPI CSI1 clock positive

O3

MIPI_CSI1_LN0_N

DI

MIPI CSI1 data0 negative

O2

MIPI_CSI1_LN0_P

DI

MIPI CSI1 data0 positive

N1

MIPI_CSI1_LN2_N

DI

MIPI CSI1 data1 negative

O1

MIPI_CSI1_LN2_P

DI

MIPI CSI1 data1 positive

M3

MIPI_CSI1_LN3_N

DI

MIPI CSI1 data2 negative

M2

MIPI_CSI1_LN3_P

DI

MIPI CSI1 data2 positive

L1

MIPI_CSI1_LN4_N

DI

MIPI CSI1 data3 negative

M1

MIPI_CSI1_LN4_P

DI

MIPI CSI1 data3 positive

Antenna

A2

WLAN_BT_ANT

ANT

WLAN/BT antenna

A19

GPS_ANT

ANT

GPS antenna

A13

FM_ANT

ANT

FM RX antenna

MPP(Multi-Purpose Pin)

X14

PMI8952_MPP_1

MPP

1. Configurable as digital

I/Os

2. Analog multiplexer inputs

3. Even MPPs configurable

as current sinks; odd MPPs

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 14

Page 15

configurable as analog

outputs

X13

PMI8952_MPP_2

MPP

1. Configurable as digital

I/Os

2. Analog multiplexer inputs

3. Even MPPs configurable

as current sinks; odd MPPs

configurable as analog

outputs

W13

PMI8952_MPP_3

MPP

1. Configurable as digital

I/Os

2. Analog multiplexer inputs

3. Even MPPs configurable

as current sinks; odd MPPs

configurable as analog

outputs

G16

PM8952_MPP_02

MPP

1. Configurable as digital

I/Os

2. Level-translating

bidirectional I/Os

3. Analog multiplexer inputs

4. Even MPPs can be

current sinks and odd

MPPs can be VREF buffer

outputs

F15

PM8952_MPP_03

MPP

1. Configurable as digital

I/Os

2. Level-translating

bidirectional I/Os

3. Analog multiplexer inputs

4. Even MPPs can be

current sinks and odd

MPPs can be VREF buffer

outputs

G15

PM8952_MPP_04

MPP

1. Configurable as digital

I/Os

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 15

Page 16

2. Level-translating

bidirectional I/Os

3. Analog multiplexer inputs

4. Even MPPs can be

current sinks and odd

MPPs can be VREF buffer

outputs

GPIO

E2

GPIO_0

GPIO

1. Configurable I/O

2. BLSP1_SPI_MOSI

3. BLSP1_UART_TX

F2

GPIO_1

GPIO

1. Configurable I/O

2. BLSP3_SPI_CS_N

3. BLSP3_I2C_SDA

4. GP_CLK_2B

E3

GPIO_2

V

GPIO

1. Configurable I/O

2. BLSP8_SPI_MISO

F3

GPIO_3

GPIO

1. Configurable I/O

2. BLSP1_SPI_CLK

3. BLSP1_UART_RFR_N

4. BLSP1_I2C_SCL

U4

GPIO_4

GPIO

1. Configurable I/O

2. BLSP2_SPI_MOSI

3. BLSP2_UART_TX

T4

GPIO_5

V

GPIO

1. Configurable I/O

2. BLSP2_SPI_MISO

3. BLSP2_UART_RX

4. LDO_EN

X3

GPIO_6

GPIO

1. Configurable I/O

2. BLSP2_SPI_CS_N

3. BLSP2_UART_CTS_N

4. BLSP2_I2C_SDA

5. GP_CLK_1B

W3

GPIO_7

GPIO

1. Configurable I/O

2. BLSP2_SPI_CLK

3. BLSP2_UART_RFR_N

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 16

Page 17

4. BLSP2_I2C_SCL

5. GP_PDM_2A

I3

GPIO_8

GPIO

1. Configurable I/O

H2

GPIO_9

GPIO

1. Configurable I/O

G3

GPIO_10

V

GPIO

1. Configurable I/O

2. BLSP1_SPI_MISO

3. BLSP1_UART_RX

G2

GPIO_11

GPIO

1. Configurable I/O

2. BLSP3_SPI_CLK

3. BLSP3_I2C_SCL

4. GP_CLK_3B

D4

GPIO_12

V

GPIO

1. Configurable I/O

2. BLSP4_SPI_MOSI

3. MI2S_2_D0

D1

GPIO_13

V

GPIO

1. Configurable I/O

2. BLSP4_SPI_MISO

3. MI2S_2_D1

F1

GPIO_14

GPIO

1. Configurable I/O

2. BLSP4_SPI_CS_N

3. BLSP4_I2C_SDA

E1

GPIO_15

GPIO

1. Configurable I/O

2. BLSP4_SPI_CLK

3. BLSP4_I2C_SCL

E4

GPIO_16

GPIO

1. Configurable I/O

2. BLSP5_SPI_MOSI

3. BLSP5_UART_TX

G4

GPIO_17

V

GPIO

1. Configurable I/O

2. BLSP5_SPI_MISO

3. BLSP5_UART_RX

B4

GPIO_18

GPIO

1. Configurable I/O

2. BLSP5_SPI_CS_N

3. BLSP5_UART_CTS_N

4. BLSP5_I2C_SDA

C4

GPIO_19

GPIO

1. Configurable I/O

2. BLSP5_SPI_CLK

3. BLSP5_UART_RFR_N

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 17

Page 18

4. BLSP5_I2C_SCL

V9

GPIO_20

GPIO

1. Configurable I/O

2. BLSP6_SPI_MOSI

3. BLSP6_UART_TX

4. GP_PDM_1B

W9

GPIO_21

V

GPIO

1. Configurable I/O

2. BLSP6_SPI_MISO

3. BLSP6_UART_RX

T15

GPIO_22

GPIO

1. Configurable I/O

2. BLSP6_SPI_CS_N

3. BLSP6_UART_CTS_N

4. BLSP6_I2C_SDA

T16

GPIO_23

GPIO

1. Configurable I/O

C1

GPIO_24

GPIO

1. Configurable I/O

2. SDE_VSYNC_P

G1

GPIO_25

V

GPIO

1. Configurable I/O

2. SDE_VSYNC_S

3. PRI_MI2S_MCLK_A

4. SEC_MI2S_MCLK_A

T12

GPIO_26

GPIO

1. Configurable I/O

Y9

GPIO_27

GPIO

1. Configurable I/O

2. CAM_MCLK1

T13

GPIO_28

1. Configurable I/O

2. CAM_MCLK2

Y11

GPIO_29

GPIO

1. Configurable I/O

2. BLSP6_SPI_CS2_N

3. GP_CLK1

Z11

GPIO_30

GPIO

1. Configurable I/O

2. CCI_I2C0_SCL

W10

GPIO_31

V

GPIO

1. Configurable I/O

2. CCI_I2C1_SDA

Y8

GPIO_32

GPIO

1. Configurable I/O

2. CCI_I2C1_SCL

T8

GPIO_33

GPIO

1. Configurable I/O

2. CCI_TIMER0

X10

GPIO_35

V

GPIO

1. Configurable I/O

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 18

Page 19

W11

GPIO_36

V

GPIO

1. Configurable I/O

W8

GPIO_37

V

GPIO

1. Configurable I/O

V8

GPIO_38

V

GPIO

1. Configurable I/O

Z8

GPIO_39

GPIO

1. Configurable I/O

2. CCI_ASYNC0

3. GP_MN

Z13

GPIO_40

GPIO

1. Configurable I/O

X11

GPIO_41

GPIO

1. Configurable I/O

2. SD_WRITE_PROTECT

Z10

GPIO_42

V

GPIO

1. Configurable I/O

2. GP_CLK_1A

Y10

GPIO_43

V

GPIO

1. Configurable I/O

2. GP_CLK_2A

V12

GPIO_44

V

GPIO

1. Configurable I/O

2. GP_CLK_3A

T9

GPIO_45

V

GPIO

1. Configurable I/O

2. GP_PDM_1A

V10

GPIO_46

V

GPIO

1. Configurable I/O

2. GP_CLK0

X12

GPIO_47

GPIO

1. Configurable I/O

2. CCI_I2C0_SDA

U9

GPIO_48

V

GPIO

1. Configurable I/O

2. BLSP6_SPI_CS2_N

3. GP_PDM_0B

W12

GPIO_50

GPIO

1. Configurable I/O

F14

GPIO_51

GPIO

1. Configurable I/O

F13

GPIO_52

GPIO

1. Configurable I/O

H12

GPIO_53

GPIO

1. Configurable I/O

2. UIM1_RESET

B11

GPIO_54

V

GPIO

1. Configurable I/O

2. UIM1_PRESENT

G9

GPIO_57

GPIO

1. Configurable I/O

2. UIM2_RESET

F11

GPIO_58

V

GPIO

1. Configurable I/O

2. UIM2_PRESENT

E14

GPIO_59

GPIO

1. Configurable I/O

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 19

Page 20

E12

GPIO_60

GPIO

1. Configurable I/O

G12

GPIO_61

GPIO

1. Configurable I/O

G11

GPIO_62

V

GPIO

1. Configurable I/O

T11

GPIO_63

GPIO

1. Configurable I/O

2. CAM_MCLK0

U13

GPIO_64

GPIO

1. Configurable I/O

H6

GPIO_65

V

GPIO

1. Configurable I/O

T14

GPIO_67

V

GPIO

1. Configurable I/O

H3

GPIO_68

GPIO

1. Configurable I/O

H4

GPIO_85

V

GPIO

1. Configurable I/O

D5

GPIO_86

GPIO

1. Configurable I/O

E5

GPIO_87

GPIO

1. Configurable I/O

C5

GPIO_88

GPIO

1. Configurable I/O

2. BLSP8_I2C_SDA

3. BLSP8_SPI_CS_N

F6

GPIO_89

GPIO

1. Configurable I/O

2. DMIC0_CLK

H8

GPIO_90

V

GPIO

1. Configurable I/O

2. DMIC0_DATA

A4

GPIO_91

GPIO

1. Configurable I/O

2. MI2S_1_SCK

B5

GPIO_92

GPIO

1. Configurable I/O

2. BLSP7_SPI_MOSI

3. MI2S_1_WS

A5

GPIO_93

V

GPIO

1. Configurable I/O

2. BLSP7_SPI_MISO

3. MI2S_1_D0

D2

GPIO_94

GPIO

1. Configurable I/O

2. WSA_IO_DATA

3. BLSP7_SPI_CS_N

4. BLSP7_I2C_SDA

D3

GPIO_95

GPIO

1. Configurable I/O

2. WSA_IO_CLK

3. BLSP7_SPI_CLK

4. BLSP7_I2C_SCL

C2

GPIO_96

GPIO

1. Configurable I/O

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 20

Page 21

2. BLSP8_SPI_MOSI

C6

GPIO_97

GPIO

1. Configurable I/O

2. BLSP1_SPI_CS_N

3. BLSP1_UART_CTS_N

4. BLSP1_I2C_SDA

D6

GPIO_98

GPIO

1. Configurable I/O

2. MI2S_1_D1

C3

GPIO_99

GPIO

1. Configurable I/O

2. BLSP8_I2C_SCL

3. BLSP8_SPI_CLK

D12

GPIO_100

GPIO

1. Configurable I/O

2. GRFC_0

E11

GPIO_101

GPIO

1. Configurable I/O

2. GRFC_1

C10

GPIO_102

GPIO

1. Configurable I/O

2. GRFC_2

D11

GPIO_103

GPIO

1. Configurable I/O

2. GRFC_3

D10

GPIO_104

GPIO

1. Configurable I/O

2. GRFC_4

H10

GPIO_105

GPIO

1. Configurable I/O

2. GRFC_5

B10

GPIO_106

GPIO

1. Configurable I/O

H11

GPIO_110

GPIO

1.Configurable I/O

2. GRFC_10

E10

GPIO_115

GPIO

1.Configurable I/O

2. GRFC_15

3.

GSM_TX_PHASE_TXDAC

1

F10

GPIO_116

GPIO

1. Configurable I/O

2. GRFC_28

G10

GPIO_117

GPIO

1.Configurable I/O

2.

SM_TX_PHASE_TXDAC0

3. GRFC_27

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 21

Page 22

F8

GPIO_118

GPIO

1.Configurable I/O

2. RFFE1_CLK

E8

GPIO_119

GPIO

1.Configurable I/O

2. RFFE1_DATA

G8

GPIO_120

GPIO

1. Configurable I/O

2. RFFE2_CLK

G7

GPIO_121

GPIO

1. Configurable I/O

2. RFFE2_DATA

G6

GPIO_122

GPIO

1. Configurable I/O

2. RFFE4_CLK

G5

GPIO_123

GPIO

1. Configurable I/O

2. RFFE4_DATA

H5

GPIO_124

GPIO

1. Configurable I/O

2. RFFE5_CLK

F5

GPIO_125

GPIO

1. Configurable I/O

2. RFFE5_DATA

H7

GPIO_126

GPIO

1. Configurable I/O

2. RFFE3_CLK

F4

GPIO_127

GPIO

1. Configurable I/O

2. RFFE3_DATA

W4

GPIO_128

GPIO

1. Configurable I/O

V4

GPIO_129

GPIO

1. Configurable I/O

T3

GPIO_130

GPIO

1. Configurable I/O

X8

GPIO_131

GPIO

1. Configurable I/O

U8

GPIO_132

GPIO

1. Configurable I/O

Z9

GPIO_133

GPIO

1. Configurable I/O

W15

PMI8952_GPIO_1

GPIO

1. Configurable I/O

W16

PMI8952_GPIO_2

GPIO

1. Configurable I/O

D16

PM8952_GPIO_01

GPIO

1. Configurable I/O

D15

PM8952_GPIO_02

GPIO

1. Configurable I/O

H16

PM8952_GPIO_04

GPIO

1. Configurable I/O

C17

PM8952_GPIO_05

GPIO

1. Configurable I/O

E15

PM8952_GPIO_06

GPIO

1. Configurable I/O

P18

PM8952_GPIO_07

GPIO

1. Configurable I/O

P19

PM8952_GPIO_08

GPIO

1. Configurable I/O

GND

Page 22

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 23

A1

GND

GND A3

GND

GND A6

GND

GND A7

GND

GND A8

GND

GND A9

GND

GND A10

GND

GND A11

GND

GND A12

GND

GND A14

GND

GND A15

GND

GND A16

GND

GND A17

GND

GND A18

GND

GND A20

GND

GND B1

GND

GND B2

GND

GND B3

GND

GND

B6

GND

GND

B7

GND

GND B8

GND

GND B9

GND

GND B12

GND

GND B13

GND

GND B14

GND

GND B15

GND

GND B16

GND

GND B17

GND

GND B18

GND

GND B19

GND

GND B20

GND

GND C7

GND

GND C8

GND

GND

C9

GND

GND

C11

GND

GND

Page 23

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 24

C12

GND

GND C13

GND

GND C14

GND

GND C20

GND

GND D7

GND

GND D8

GND

GND D9

GND

GND D13

GND

GND D14

GND

GND D20

GND

GND E6

GND

GND E7

GND

GND E9

GND

GND E17

GND

GND E18

GND

GND E19

GND

GND E20

GND

GND F7

GND

GND

F9

GND

GND

F18

GND

GND F19

GND

GND F20

GND

GND G13

GND

GND G14

GND

GND G17

GND

GND G18

GND

GND G19

GND

GND G20

GND

GND H1

GND

GND H9

GND

GND H15

GND

GND H17

GND

GND I19

GND

GND

I20

GND

GND

J18

GND

GND

Page 24

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 25

K19

GND

GND M18

GND

GND M20

GND

GND O18

GND

GND O19

GND

GND O20

GND

GND Q18

GND

GND Q19

GND

GND Q20

GND

GND R3

GND

GND R20

GND

GND S3

GND

GND S18

GND

GND S19

GND

GND S20

GND

GND T1

GND

GND T2

GND

GND T5

GND

GND

T6

GND

GND

T7

GND

GND T10

GND

GND U1

GND

GND U2

GND

GND U3

GND

GND U5

GND

GND U6

GND

GND U7

GND

GND U10

GND

GND U11

GND

GND U12

GND

GND U20

GND

GND V5

GND

GND V6

GND

GND

V7

GND

GND

V11

GND

GND

Page 25

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 26

W5

GND

GND W6

GND

GND W7

GND

GND X1

GND

GND X4

GND

GND X5

GND

GND X6

GND

GND X7

GND

GND Y1

GND

GND Y2

GND

GND Y3

GND

GND Y4

GND

GND Y5

GND

GND Y6

GND

GND Y7

GND

GND Y20

GND

GND Z1

GND

GND Z2

GND

GND

Z3

GND

GND

Z4

GND

GND Z5

GND

GND Z6

GND

GND Z7

GND

GND Z20

GND

GND AA1

GND

GND AA2

GND

GND AA3

GND

GND AA4

GND

GND AA5

GND

GND AA6

GND

GND AA7

GND

GND AA8

GND

GND AA9

GND

GND

AA10

GND

GND

AA11

GND

GND

Page 26

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 27

AA12

GND

GND AA13

GND

GND AA14

GND

GND AA15

GND

GND AA16

GND

GND AA17

GND

GND AA20

GND

GND

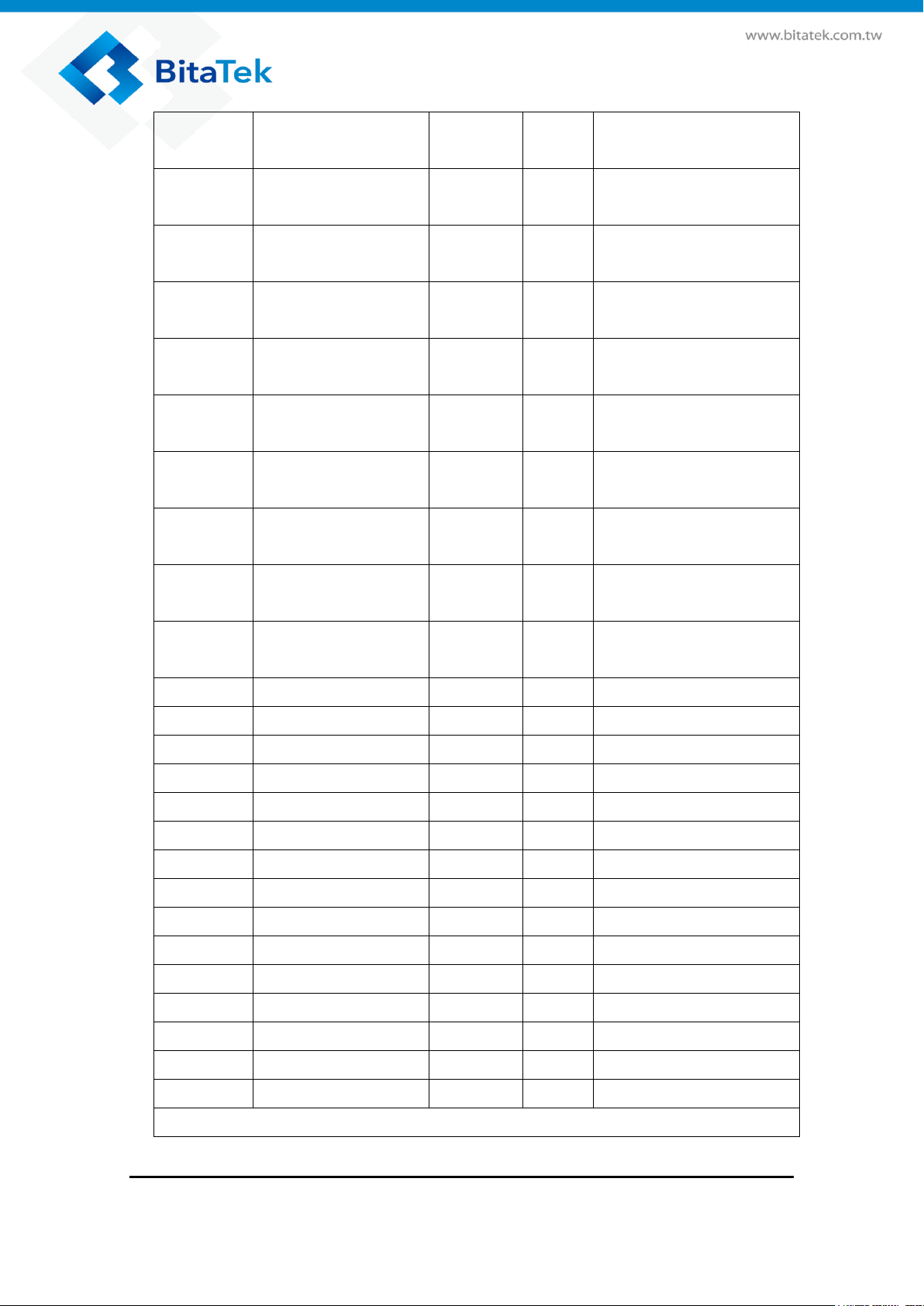

3.4. Pad assignments (Top view)

Page 27

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 28

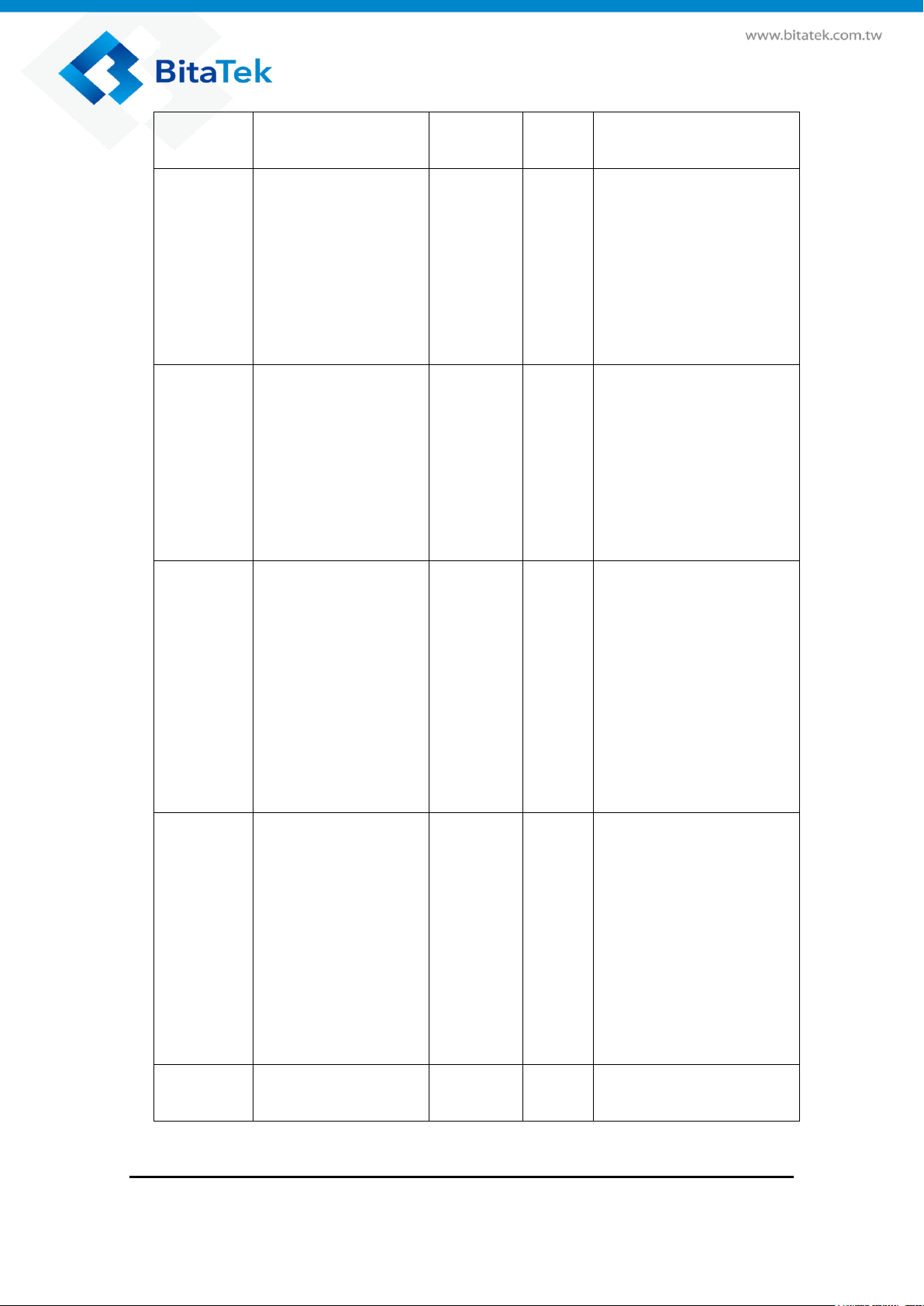

Parameter

Min.

Max.

Units

USB_VBUS_IN

0

25 V VPH_PWR

0

6

V

CHG_OUT (VBAT)

Steady state

0

5

V

CHG_OUT (VBAT)

Transient (< 10 ms)

0

6

V

Parameter

Min.

Max.

Units

USB_VBUS_IN

4.0

10 V VPH_PWR

3.5

4.5

V

CHG_OUT (VBAT)

3.5

4.5

V

3.5. Electrical Specification

3.5.1. Input power specification

Absolute maximum rating:

Operating FREY M1 under conditions beyond its absolute maximum ratings may damage

the device. Absolute maximum ratings are limiting values to be considered individually

when all other parameters are within their specified operating ranges. Functional operation

and specification compliance under any absolute maximum condition, or after exposure to

any of these conditions, is not guaranteed or implied. Exposure may affect device reliability.

Operation condition:

Operating conditions include parameters that are under the control of the user : power supply

voltage and ambient temperature. The FREY M1 meets all performance specifications listed in

this document when used and/or stored within the operating conditions, unless otherwise noted

in those sections (provided the absolute maximum ratings have never been exceeded).

Note : There is battery detection algorithm in FREY M1 , user need to implement battery ID and

thermal pin on the system , otherwise system can't be powered on successfully .

Page 28

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 29

Parameter

Conditions

Min

Typ

Max

Units

Peak switching current

USB_IN = 9.0 V

- 4 -

A

Maximum DC output

current

USB_IN = 9.0 V

- 3 -

A

Switching frequency

0.95

1.0

1.05

MHz

OTG output voltage

4.85

5.00

5.15

V

Charger-specific digital I/O characteristics

High-level input voltage

(VIH)

All charger digital

interface pads except

CHG_EN

1.5 - -

V

Low-level input voltage

(VIL)

- - 0.5

V

CHG_EN high-level input

voltage (VIH)

1.3 - -

V

CHG_EN low-level input

voltage (VIL)

- -

0.3

V

Output

power

Circuit

type

Default

voltage (V)

Specified

voltage range

(V)6

Rated

current

(mA)

Expected use

VREG_L1

NMOS

LDO

1.000

1.000

200

RFICs

VREG_L4

PMOS

LDO

1.800

1.800

450

RFICs and

GPS eLNA

VREG_L5

PMOS

LDO

1.800

1.800

300

Most digital

I/Os, LPDDR

and eMMC

Battery charger:

The FREY M1 features a fully programmable switch-mode battery charger, input power and

output power controller for terminal devices. The device is designed to be used in

conjunction with systems using single-cell Li-ion and Li-polymer battery packs.

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

3.5.2. Output power specification

Page 29

Page 30

VREG_L6

PMOS

LDO

1.800

1.800

300

APQ DSI PLL

and OTP,

Camera,

Touch screen,

Display, and

sensors

VREG_L10

PMOS

LDO

2.850

2.850

150

Sensors

VREG_L11

PMOS

LDO

2.950

2.950

800

Micro SD

VREG_L12

PMOS

LDO

2.950

1.800/2.950

150

APQ pad

group 2 and

SDC2

VREG_L14

PMOS

LDO

1.800

1.800/3.300

50

APQ pad

group 5,

dual-voltage

UIM1, and

NFC

VREG_L16

PMOS

LDO

1.800

1.800

5

PMIC HKADC

VREG_L17

PMOS

LDO

2.850

2.850

600

Camera,

Display, and

Touch screen

VREG_L18

PMOS

LDO

2.700

2.700

150

QTI RF

front-end

VREG_L22

PMOS

LDO

2.800

2.800

300

Camera –

analog

VREG_L23

NMOS

LDO

1.200

1.200

300

Camera –

digital

Page 30

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 31

Parameter

Comments

Min

Typ

Max

Units

Output voltage

All NMOS

All PMOS

12.5 mV steps

12.5 V steps

0.375

1.75

-

-

1.5375

3.3375

V

V

Overall DC voltage output

error

Normal mode

At default voltage

At non-default

voltages

Low-power mode

At default voltage

At non-default

voltages

Over-voltage,

temperature, and process

variations plus load and

line regulation

-2

-3

-4

-5

-

-

-

-

2

3

4

5

%

%

%

%

Temperature coefficient

-100

-

100

ppm/°C

NMOS power-supply ripple

rejection

Normal mode

50 Hz–1 kHz

1–10 kHz

10–100 kHz

Low-power mode

50 Hz–1 kHz

1–100 kHz

PSRR

60

-

-

-

-

70

60

50

50

40

-

-

-

-

-

dB

dB

dB

dB

dB

PMOS power-supply ripple

rejection

50 Hz–1 kHz

1–10 kHz

10–100 kHz

43

35

13

-

-

-

-

-

-

dB

dB

dB

LDO performance specifications

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 31

Page 32

Item

Test condition

Max.

Units

Off mode current

Module is turned off

250

uA

Flight mode current

Module is turned on and in sleep mode

and all RF is turned off

4.5

mA

WiFi TX current

2.4G, 11b, 11 Mbps, 15 dBm

250

mA

WiFi RX current

2.4G

130

mA

WiFi TX current

5G, 11a, 54 Mbps, 15 dBm

250

mA

WiFi RX current

5G

130

mA

BT TX current

class 2 , 2dBm

150

mA

BT RX current

130

mA

Pad voltage

Usage

Table

1.8 V

Most digital I/Os

Table 3.5.4.1

Dual-V (1.8 V/2.95 V)

SDC2, UIM

Table 3.5.4.2

Dual-V (1.8 V/3.05 V)

USB

Table 3.5.4.3

Parameter

Min.

Max.

Unit

VIH

High-level input voltage

0.65 × VDD_P3

-

V

VIL

Low-level input voltage

-

0.35 × VDD_P3

V

VOH

High-level output voltage

VDD_P3 - 0.45

-

V

VOL

Low-level output voltage

-

0.45

V

3.5.3. Current consumption

Note 1. The measurement is at VBAT of module and VBAT=3.8V .

Note 2. WiFi & BT current is measured with IQexl 160.

3.5.4. Digital logic characteristics

Digital I/Os specification

Table 3.5.4.1 Digital I/O (VDD_P3= VREG_L5)

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 32

Page 33

Parameter

Min.

Max.

Unit

Common to UIM pads at either voltage (VDD_PX= VREG_L14)

VIH

High-level input voltage

0.7 × VDD_PX

VDD_PX + 0.3

V

VIL

Low-level input voltage

0

0.2 × VDD_PX

V

VOH

High-level output voltage

0.8 × VDD_PX

VDD_PX

V

VOL

Low-level output voltage

0

0.4

V

SDC2 pads at 2.95 V only(VDD_PX= VREG_L12)

VIH

High-level input voltage

0.625 ×

VDD_PX

VDD_PX + 0.3

V

VIL

Low-level input voltage

0

0.25 × VDD_PX

V

VOH

High-level output voltage

0.75 × VDD_PX

VDD_PX

V

VOL

Low-level output voltage

0

0.125 × VDD_PX

V

SDC2 pads at 1.8 V only

VIH

High-level input voltage

1.27

2

V

VIL

Low-level input voltage

0

0.58

V

VOH

High-level output voltage

1.4

-

V

VOL

Low-level output voltage

0

0.45

V

Parameter

Min.

Typ.

Max.

Unit

Supply voltages

Dual-supply

- - 1.80

3.075

- - V

USBPHY_SYSCLK

Frequency

-

19.2

-

MHz

Duty cycle

40 - 60

%

Low-level input voltage (VIL)

- - 0.85

V

High-level input voltage (VIH)

1.27 - -

V

USBPHY_VBUS

Valid USB_HS_VBUS detection

voltage

2.0 - 5.25

V

Table 3.5.4.2 SDC2,UIM

Table 3.5.4.3 USB

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 33

Page 34

Parameter

Condition

Min

Typ

Max

Unit

Target regulator

voltage(*)

VIN > 3.3 V, ICHG = 100 µA

2.50

3.10

3.25

V

Parameter

Conditions

Min

Typ

Max

Units

Microphone amplifier gain = 0 dB (minimum gain)

Input referred noise

Analog input = -200 dBV,

A-weighted, bandwidth 20

Hz–20 kHz

-

19.0

25.1

µVrms

Signal-to-noise

ratio

Analog input = 0 dBV,

A-weighted, bandwidth 20

Hz–20 kHz

92.0

94.0

-

dB

Microphone amplifier gain = 24 dB (maximum gain)

Input referred noise

Analog input = -200 dBV,

A-weighted, bandwidth 20

Hz–20 kHz

-

2.7

4.2

µVrms

Signal-to-noise

ratio

Analog input = -24 dBV,

A-weighted, bandwidth 20

Hz–20 kHz

84.0

88.0

-

dB

General requirements

Power supply

rejection

100 mVpp sine wave

imposed on PMIC vph_pwr

3.5.5. Coin-cell charging

(*) Valid regulator voltage settings are 2.5, 3.0, 3.1, and 3.2 V.

3.5.6. Audio

All audio codec performance data are collected above Vbatt of 3.7 V, unless otherwise

specified.

Inputs and Tx processing

All Tx performance parameters are measured with a 1.02 kHz sine wave input signal,

capless differential or single-ended inputs, Fs = 48 kHz, 24-bit data, and MCLK = 9.6 MHz

or 12.288 MHz.

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 34

Page 35

input; analog input = 0

Vrms, terminated with 0 Ω

Terminate inputs with 0 Ω;

gain = 0 dB

75

75

60

95

95

97

-

-

-

dB

dB

dB

Input impedance

Input disabled

3 - -

MΩ

Input capacitance

Capless input

- - 15

pF

Parameter

Conditions

Min

Typ

Max

Units

Earpiece

Output power

f = 1.02 kHz, 0 dBFS input,

6 dB gain mode, 32 Ω

120.0

127.0

-

mW

f = 1.02 kHz, -1.5 dBFS

input, 6 dB gain mode, 16

Ω

160.0

172.0

-

mW

f = 1.02 kHz, -3.5 dBFS

input, 6 dB gain mode,

10.67 Ω

150.0

160.0

-

mW

Output load

Supported output load

10.7

32.0

50000

Ω

Output

capacitance

Total capacitance between

EARO_P and EARO_M,

including PCB capacitance

and EMI

- - 500

pF

Disabled

output

impedance

Measured externally with

amplifier disabled

1.0 - -

M Ω

Output

common mode

voltage

Measured externally with

amplifier disabled

1.52

1.60

1.68

V

Headphone

Outputs and Rx processing

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 35

Page 36

Output power

f = 1.02 kHz, 0 dB FS, 16 Ω

load; VDD_CP = 1.95 V, 0 dB

gain mode

60.0

63.0

-

mW

f = 1.02 kHz, 0 dB FS, 32 Ω

load; VDD_CP = 1.95 V, 0 dB

gain mode

27.0

30.8

-

mW

Output load

Supported output load

13.0

16.0

50000

Ω

Output

capacitance

Total capacitance on HPH

output (single-ended),

including PCB capacitance

and EMI

- - 1000

pF

Disabled output

impedance

Measured externally, with

amplifier disabled

1.0 - -

MΩ

Mono speaker

Output power

Vdd = 5 V , f = 1 kHz

THD + N < 8.7%; 15 µH + 8 Ω

+15 µH

THD+N ≤ 1%; 15 µH + 8 Ω +

15 µH

THD+N ≤ 1%; 15 µH + 4 Ω +

15 µH

1200

1500

1700

1400

2150

-

-

-

mW

mW

mW

Power supply

rejection

200 mVpp sine wave imposed

on PMIC_VBATT; digital input

= -999 dBFS2

1 kHz

60.0

60.0

40.0

40.0

85.0

86.0

86.0

82.0

-

-

-

-

dB

dB

dB

dB

Efficiency

Vdd = 5 V

Pout = 1 W, 15 µH + 8 Ω + 15

µH

Pout = 2 W, 15 µH + 4 Ω + 15

µH

73.0

60.0

82.0

77.0

-

-

%

%

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 36

Page 37

Parameter

Conditions

Min

Typ

Max

Units

Operational input

voltage

Connected at VDD_HAP (VH

below)

2.5

3.6

4.75

V

Output voltage

Peak, no load

Average (V_HA)

Maximum drive

Accuracy

At HAP_OUT_P and

HAP_OUT_N

Differential, over one PWM

cycle

Differential, over one PWM

cycle

Duty cycle < 95%

-

0

1.2

-

-

-

-

50

VH

3.6

3.6

-

V

V

V

mV

Output current limit

R_ERM or R_load

R_load = 10

Cycle-to-cycle limit

300

600

400

800

500

1000

mA

mA

Internal PWM

frequency

Programmable

options

Accuracy

253 kHz, 505 kHz, 739 kHz,

1076 kHz

253

-

503

-

1076

+/-16

KHz

%

Parameter

Conditions

Min

Typ

Max

Units

Operational input voltage

Connected at VDD_DIS_P

2.5 - 4.75

V

Output voltage

(VDIS_P_OUT)

5.0 5.5 6.1 V

3.5.7. Vibrator

3.5.8. Display ± bias

FREY M1 provides the plus and minus bias voltages for LCD displays; pertinent

performance specifications are listed as below.

Display plus bias

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 37

Page 38

Range, no load to 150 mA

Resolution

- 100

-

mV

Output current

- -

150

mA

Efficiency

I_out = 30 mA

-

92 - %

Switching frequency

(default)

- 1.48

-

MHz

Parameter

Conditions

Min

Typ

Max

Units

Operational input voltage

Connected at VDD_DIS_N

2.5 - 4.75

V

Output voltage

(VDIS_N_OUT)

Range, no load to 150

mA

Resolution

-1.4

-

-

100

-6.0

-

V

mV

Output current

- -

150

mA

Efficiency

I_out = 50 mA

-

84 - %

Switching frequency

(default)

- 1.48

-

MHz

Parameter

Conditions

Min

Typ

Max

Units

Driver input voltage

VDD_FLASH

Flash disabled

Flash enabled

VDD_TORCH

Expected source is PMI’s

DC_IN_OUT

2.5

-

-

-

-

3.6

10

5.8

5.5

V

V

V

NOTE: All specifications apply at VDD_DIS_x = 3.6 V , T = -30 to +85ºC, VDIS_P_OUT = 5.5 V, L

= 4.7 µH, and C = 10 µF (capacitance value de-rated from 22 µF nominal) .

Display minus bias

NOTE: All specifications apply at VDD_DIS_x = 3.6 V, T = -30 to +85ºC, VDIS_N_OUT = -5.5 V,

L = 4.7 µH, C = 10 µF (capacitance value de-rated from 22 µF nominal) .

3.5.9. Flash drivers (including torch mode)

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 38

Page 39

Expected source is PMI’s

VREG_BST_BYP

Output current per

LED

Flash

Torch

-

-

-

-

1000

200

mA

mA

Parameter

Conditions

Min

Typ

Max

Units

Operational input voltage

VPH_PWR

2.5 - 4.75

V

Input voltage for full

brightness

2 strings (~16 WLEDs)

4 strings (~28 WLEDs)

I_led = 20 mA per string

V_out = 28 V across panel

V_out = 24 V across panel

2.8

3.6

-

-

-

-

V

V

Output voltage

6.0 - 28.5

V

Over-current protection

Programmable, set to 980 mA

830

980

1200

mA

Switching frequency

0.6

0.8

1.6

MHz

Efficiency

Peak

Average

Light load

VDD = 3.6 V, 25°C, F_sw = 0.8

MHz

I_out = 15 mA/string (x4), 13.5 V

out

I_out = 5 to 25 mA/string (x4)

I_out = 1 to 5 mA/string (x4); PSM

en

-

-

-

86

80

75

-

-

-

%

%

%

Full-scale current range

Programmable range, 2.5 mA

step

0 - 30

mA

CABC frequency

20 - 40

KHz

NOTE: All specifications apply at VPH_PWR = 3.6 V, T = -30 to +85ºC unless noted otherwise.

3.5.10. Display backlight (WLEDs)

The FREY M1 supports WLEDs with a boost converter that generates the high voltage needed

for powering a string of WLEDs, plus four output drivers for sinking the current from WLED

strings.

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 39

Page 40

Parameter

Comment

Min

Typ

Max

Units

Operating frequency

19.2

MHz

Output levels

Logic high (VOH)

Logic low (VOL)

1.17

-

-

-

-

0.63

V

V

Band

Min

Max

WIFI 2.4G

2412MHz

2472MHz

WiFi 5G

5180MHz

5825MHz

BT

2402MHz

2480MHz

GPS

1574.40MHz

1576.44MHz

Glonass

1598MHz

1606MHz

Parameter

Bandwidth

Mode

Rate

(Mbps)

Data Rate

2.4G

Unit

Min

Typical

Max

TX output

power level

HT20

11b

11

CCK-11

13

15

17

dBm

11g

54

OFDM-54

11

13

15

dBm

11n

65

MCS7

10

12

14

dBm

Constellation

Error (EVM)

HT20

11b

11

CCK-11

-

-18 - dB

11g

54

OFDM-54

-

-24 - dB

11n

65

MCS7

-

-26 - dB

Sensitivity

HT20

11b

11

CCK-11

-

-89

-

dBm

11g

54

OFDM-54

-

-74

-

dBm

11n

65

MCS7

-

-70

-

dBm

3.5.11. System clock (BB_CLK)

3.5.12. RF Transmit and Receiver Specifications

RF Operation Frequency Band

WIFI

Considering SAR regulatory, limit WiFi Tx power at certain level.

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 40

Page 41

Parameter

Bandwidth

Mode

Rate

(Mbps)

Data Rate

5G

Unit

Min

Typical

Max

HT20

11a

54

OFDM-54

13

15

17

dBm

TX output

power level

11n

65

MCS7

10

12

14

dBm

11ac

78

MAC8

10

12

14

dBm

HT40

11n

135

MCS7

10

12

14

dBm

11ac

180

MCS9

10

12

14

dBm

HT80

11ac

433

MCS9

9

11

13

dBm

Constellation

Error (EVM)

HT20

11a

54

OFDM-54

-

-24 - dB

11n

65

MCS7

-

-25 - dB

11ac

78

MCS8

-

-28 - dB

HT40

11n

135

MCS7

-

-25 - dB

11ac

180

MCS9

-

-28 - dB

HT80

11ac

390

MCS9

-

-32 - dB

Sensitivity

HT20

11a

54

OFDM-54

-

-70

-

dBm

11n

65

MCS7

-

-68

-

dBm

11ac

78

MCS8

-

-58

-

dBm

HT40

11n

135

MCS7

-

-58

-

dBm

11ac

180

MCS9

-

-53

-

dBm

HT80

11ac

380

MCS9

-

-51

-

dBm

Parameters

Min

Typ

Max

Uint

RCV/CA/01/C (Single Sensitivity)

-

-87 - dBm

RCV/CA/07/C (EDR Sensitivity)

-

-87 - dBm

2Mbps Packet Length: 2-DH1

RCV/CA/07/C (EDR Sensitivity)

-

-87 - dBm

Bluetooth

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 41

Page 42

3Mbps Packet Length: 3-DH1

TRM/CA/01/C Output power(class1)

0 8 12

dBm

TRM/CA/01/C Output power(class2)

-6 0 4

dBm

Test Items

Test condition

Min

Typical

Max

Unit

CN ration

Satellites@-130dBm

-

38

40

dBm

Sensitivity

- -145

-

dBm

Specification

ANSI/ESDA/JEDEC JS-001-2011

± 1KV Human Body Model (HBM)

JESD22-A114-F

± 500V Charge Device Model (CDM)

EN301-489

± 4KV (Indirect discharge) *

± 8KV (Air discharge) **

GPS

3.5.13. Electrostatic Discharge

The module is not protected against Electrostatic Discharge (ESD) in general.

Consequently, it is subject to ESD handling precautions that typically apply to ESD

sensitive components. Proper ESD handling and packaging procedures must be applied

throughout the processing, handling and operation of any application that incorporates a

FREY M1 module.

Electrostatic discharge (ESD) may lead to irreversible damage for the module. It is

therefore advisable to develop measures and methods to counter ESD and to use these to

control the electrostatic environment at manufacturing sites.

Note * : Indirect discharge with coupling metal plane .

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 42

Page 43

Note ** : Air discharge on location 1,2,3,4,5 on module , module is mounted on EVB .

Page 43

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 44

Charpt 4. Module Mounting Issues

Frey M1 modules have been designed with an easy integration into SMT processes in mind.

Some module mounting issues are discussed in more detail in the sections below.

Please note that Frey M1 modules are specified for one soldering cycle only. Once removed

from the application, the module will very likely be destroyed and cannot be soldered onto

another application. Please also note that the modules are not sealed and should therefore

not be subjected to any post SMT wash or to any environments where condensation could

occur.

4.1. Solder Paste

A variety of solder paste types can be used to realize connections to external applications.

Soldering using lead free eutectic SnAgCu alloy can be done without any special restrictions,

because of its maximum allowed temperature of 245°C.

ENIG finish of the modules soldering pads ensures good wetting properties even after 12

month of storage.

However, there are some restrictions that should be noted before selecting the solder paste:

Due to the fact that the top side of the modules is assembled using standard eutectic SnAgCu

alloy, no higher melting alloys should be used (even though remelting of top side solder joints

also happens with eutectic SnAgCu).

Higher temperatures mean more stress to materials than lower temperatures: Increasing the

reflow temperature increases the growth of intermetallics, especially if the temperature lies

above the melting point of that alloy. Large intermetallics are commonly considered a

reliability risk. They should therefore be kept as small as possible.

4.2. Stencil Printing

4.2.1. General Stencil Considerations

The higher the stand off formed by the solder paste volume, the better the reliability for land

grid array (=LGA) based connections. The solder paste volume in a stencil printing process is

formed by aperture size (area) and stencil height:

VolumeSolder paste = AreaAperture x HeightStencil

Page 44

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 45

It is recommended that customers do their own testing to determine the optimal solder paste

volume. This volume can be applied by stencil printing with different stencil heights to fit your

existing assembly needs. The volume is kept constant by varying the aperture size

accordingly.

The most common thicknesses 110μm and 150μm (stainless steel, laser cut) have been

tested with good results with regard to printing process, soldering process and reliability

testing. Similar results are expected with stencil thicknesses in between.

Different solder paste volumes have been tested too but with much lower volume there is a

trend to poor solder joints and a risk for open joints. Much larger solder joints tend to form

solder balling in the vicinity of the solder joints.

4.2.2. Used Parameters and Recommendations

For stencil printing, a stainless steel stencil, laser cut (or similar technology) should be used.

Parameters must be optimized depending on actual application board design, equipment und

solder paste.

To simulate different applications, two different stencil thicknesses of 110μm and 150μm

were used while keeping the solder paste volume constant by variation of the apertures.

If the results for all tested versions were found to be good. For exact pad and aperture

dimensions, as well as module geometry and footprint design

4.2.3. Pick and Place

FREY M1 well be put into the antistatic tray plate. One antistatic tray plate will have 15 Frey

M1 modules, and one moisture barrier bag will have max 5 antistatic tray plates

4.2.4. Reflow Profile

Short profiles are recommended for reflow soldering processes in order to prevent top side

solder joints from growing large intermetallic compounds. Peak zone temperature should be

adjusted high enough to ensure proper wetting and optimized forming of solder joints. On the

other hand, a plateau during preheating can help to reduce voiding behavior. Generally

speaking, unnecessary long exposure and exposure to more than 245°C should be avoided.

Page 45

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 46

As an example and during Frey M1 internal tests, forced convection machines were able to

realize a good reflow soldering profile, so there was no need for using vapor phase

equipment.

For analyzing and adapting solder profiles a carrier board was prepared with thermocouples

(TC) .

In order to get a good overall performance the resulting voiding and the formation of

intermetallics as well as other thermal induced degradations must be well balanced. As

mentioned above a longer preheating phase can help gasses to escape from solder joints

before solidification. To not overstress the assembly, the complete reflow profile should be as

short as possible.

Here an optimization considering all components on the application must be performed. The

optimization of a reflow profile is a gradual process. It needs to be performed for every paste,

equipment and product combination. The presented profiles are only samples and valid for the

used pastes, reflow machines and test application boards. Therefore a "ready to use" reflow

profile can not be given.

Page 46

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 47

Profile Feature

Pb-Free Assembly

Preheat & Soak

Temperature Minimum (T

smin

)

Temperature Maximum (T

smax

)

Time (T

smin

to T

smax

) (tS)

150°C

200°C

60-120 seconds

Average ramp up rate (T

smax

to Tp)

3K/second max.

Liquidous temperature (TL)

Time at liquidous (tL)

217°C

60-90 seconds

Peak package body temperature (Tp)

245°C +0/-5°C

Time (tP) within 5 °C of the peak package body

temperature (TP)

30 seconds max.

Average ramp-down rate (TP to T

Smax

)

3 K/second max.

4.3. Soldering Conditions and Temperature

4.3.1. Reflow Profile

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 47

Page 48

Time 25°C to maximum temperature

8 minutes max.

4.3.2. Maximum Temperature and Duration

The following limits are recommended for the SMT board-level soldering process to attach

the module:

• A maximum module temperature of 245°C. This specifies the temperature as

measured at the module’s top side.

• A maximum duration of 30 seconds at this temperature.

Please note that while the solder paste manufacturers' recommendations for best

temperature and duration for solder reflow should generally be followed, the limits listed

above must not be exceeded.

Frey M1 is specified for one soldering cycle only. Once Frey M1 is removed from the

application, the module will very likely be destroyed and cannot be soldered onto another

application.

4.4. Soldering Process Evaluation

4.4.1. Visual Inspection

As a rule, automated optical inspection (AOI) of solder joints is not suitable for evaluating LGA

modules, because most of the I/O pins are hidden underneath the module. Inspection of the

outermost I/Os is not sufficient to evaluate soldering. Please reference IPC-A-610 standard.

4.4.2. X-Ray Inspection and Void Content

X-Ray inspection is an appropriate method for evaluating solder joints after reflow. X-Ray

images can show wetting problems, missing solder volume or of course bridging.

X-Ray inspection is made somehow more difficult by overlaying module components and by

possible bottom side (application) assemblies. However, module connections are

characterized by their shape and size, so in most cases they can easily be distinguished from

the mentioned overlaying structures.

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 48

Page 49

Item No

Test case

International standard

1

Storage Test

IEC60068-2-1

IEC60068-2-2

2

Thermal Cycle

IEC60068-2-3

IEC60068-2-56

IEC60068-2-38

IEC60068-2-30

3

Thermal Stress

IEC60068-2-3

The set shows typical X-Ray images of sample modules soldered to an assumed application

board including some failure samples. The images are taken from assembly and BLR testing

and comprise two different stencil versions (110μm and 150μm thickness).

A good solder joint at Frey M1 signal pins in X-Ray inspection is characterized by a

rectangular shape, described by the dimensions of the pad at the module.

Solder joints which have a round footprint in X-Ray image are found in areas with high stand

off and are more column like instead of flat. These are good from electrical point of view but

indicate processing problems like aslope standing of the module or warpage.

It is recommended to use X-Ray to determine level of voiding. Entrapments of gases can

often not be completely avoided, if large flat solder joints are used. Currently there are no

standards available defining limits for void content. The available IPC610 standard for ball

grid arrays (=BGA) must not be applied to LGAs and hence to the Frey M1 SMT modules.

As seen from the X-Ray images above there is no significant difference in reflow result for the

110μm and 150μm stencils. This is mainly due to the fact, that the resulting volume was kept

constant by varying the apertures accordingly. The resulting shape of the solder joint is only

influenced by the volume.

Only if solder paste spreading is limited, which can occur with lead free solder on Cu-OSP or

immersion tin PCB surfaces, a little difference in solder joint shape can be expected but with

no effect on quality or yield. This is a characteristic of lead free solders and not a wetting

issue.

4.5. Board Level Reliability Investigation

The board level reliability tests described as follow table

BitaTek Co., Ltd. Copyright protected. All rights reserved.

NO. 115 Wugong 3rd Rd., Tel +886 2 2298 8588

Wugu Dist., New Taipei City 248, Taiwan (R.O.C.) Fax+886 2 2290 0029

Page 49

Page 50

IEC60068-2-56

IEC60068-2-38

IEC60068-2-30

4

Thermal Shock

IEC60068-2-14

5

Vibration

IEC60068-2-6

IEC60068-2-59

6

Mechanical Shock

IEC60068-2-27

7

Micro Drop

IEC60068-2-32

8

ESD

IEC61000-4-2

9

Low temperature start test

IEC60068-2-1

10

High temperature start test

IEC60068-2-2

4.6. Desoldering Process