Bison Gear & Engineering Multi-Tech Reducers Catalog Page

Specifications

185 & 385 Multi-Tech Reducers

Gearing: Hardened steel, AGMA Class 9

Housing: Precision machined die cast

aluminum

Lubrication: Grease filled, sealed and

gasketed

Bearings: Needle and thrust ball

Multi-Tech Reducers

REDUCERS UP TO 350 IN-LBS

Add your own stepper or servomotor to our NEMA gearboxes.

Highly efficient - helical-spur geartrains transmit 96% of

the available power per stage, leading the industry. Low

backlash ratings - less than 60 arc-minutes, create the ideal

gear reducer for applications such as process conveyors,

pumps, and dispensers. Shock load capability 200% - is

standard in the Multi-Tech product offering, as it is in all of

Bison’s products. Gloss black powder coat finish - provides

the durability needed for demanding environments. Grease

lubricated for all position mounting.

Optional Features

Shafts: Hardened steel

Mounting: Face or base, any angle

Input Features: • 1/4” diameter, for

NEMA 23 mounting

• 3/8” or 1/2” diameter,

for NEMA 34 mounting

input speed

• 3000 RPM maximum

input speed

• Footplate

185 series

Part number: P125-100-9998

385 series

Part number: P125-287-0200

Additional Information

See pages 86-87 for additional

accessories

185 NEMA 23 Input

Part Number Ratio In-Lbs N-m lb kg lb kg oz-in-sec2 kg-m2 arc-min

060-185-0003 3.0065 20 2.26 200 90.9 25 11.4 4X10-4 6X10-6 60

GEAR

REDUCERS

060-185-0005 4.9573 32 3.62 200 90.9 25 11.4 9X10-5 6X10-7 60

060-185-0007 6.6667 45 5 200 90.9 25 11.4 7X10-5 5X10-7 60

060-185-0013 12.9411 90 10.16 200 90.9 25 11.4 5X10-5 4X10-7 60

060-185-0025 25.2381 90 10.16 200 90.9 25 11.4 4X10-5 3X10-7 60

060-185-0049 48.9916 150** 16.95 130 59.1 25 11.4 4X10-5 3X10-7 60

060-185-0096 95.5442 150** 16.95 150 68.2 25 11.4 3X10-5 4X10-7 60

385 NEMA 34 Input

Part Number Input Ratio In-Lbs N-m lb kg lb kg oz-in-sec2 kg-m2 arc-min

060-385-0003 3/8” Input Shaft 3.0625 88 9.94 170 77.3 40 18.2 1X10-3 9X10-6 60

060-385-0005 3/8” Input Shaft 4.5208 130 14.69 170 77.3 40 18.2 1X10-3 8X10-6 60

060-385-0011 3/8” Input Shaft 10.8889 300** 34 200 90.9 40 18.2 8X10-4 6X10-6 60

060-385-0015 3/8” Input Shaft 15.3013 300** 34 220 100 40 18.2 7X10-4 5X10-6 60

060-385-0021 3/8” Input Shaft 20.7958 300** 34 230 104.5 40 18.2 7X10-4 5X10-6 60

060-385-0030 3/8” Input Shaft 29.8324 300** 34 250 113.6 40 18.2 7X10-4 5X10-6 60

060-385-0050 3/8” Input Shaft 50.0889 350** 40 250 113.6 40 18.2 6X10-4 5X10-6 60

060-385-1003 1/2” Input Shaft 3.0625 88 9.94 170 77.3 40 18.2 1X10-3 9X10-6 60

060-385-1005 1/2” Input Shaft 4.5208 130 14.69 170 77.3 40 18.2 1X10-3 8X10-6 60

060-385-1011 1/2” Input Shaft 10.8889 300** 34 200 90.9 40 18.2 8X10-4 6X10-6 60

060-385-1015 1/2” Input Shaft 15.3013 300** 34 220 100 40 18.2 7X10-4 5X10-6 60

060-385-1021 1/2” Input Shaft 20.7958 300** 34 230 104.5 40 18.2 7X10-4 5X10-6 60

060-385-1030 1/2” Input Shaft 29.8324 300** 34 250 113.6 40 18.2 7X10-4 5X10-6 60

060-385-1050 1/2” Input Shaft 50.0889 350** 40 250 113.6 40 18.2 6X10-4 5X10-6 60

** Gear limited.

Rated Torque Radial Load Axial Load Inertia Backlash

Rated Torque Radial Load Axial Load Inertia Backlash

76

Gear & Engineering Corp.

ROBUSTICITY

3.38

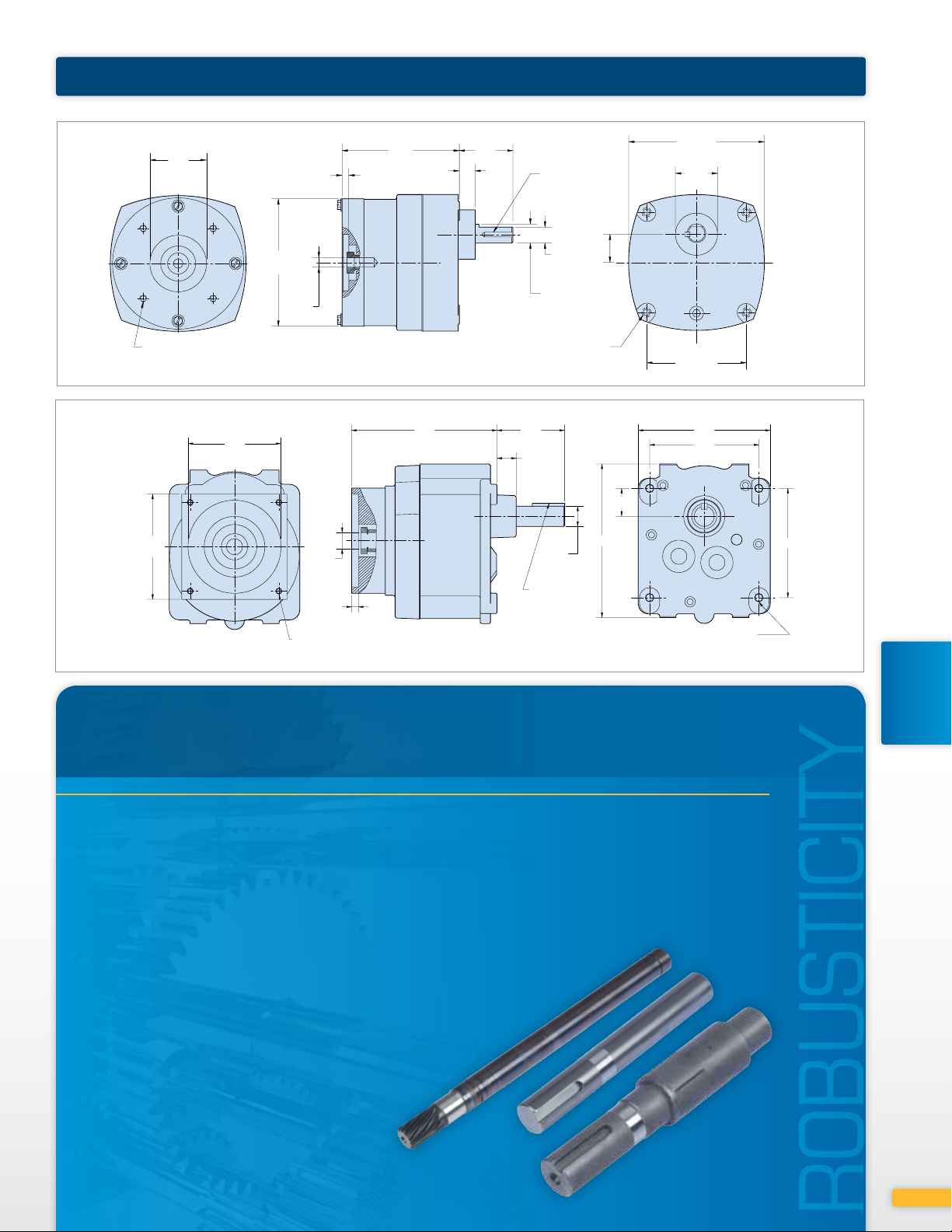

Multi-Tech Reducers

185 NEMA 23

1.50

PILOT

DIA.

(4) #10-32 TAPPED HOLES SOCKET

HEAD SCREW ON A ø2.625 B.C.

385 NEMA 34

3.25

SQ.

2.88

PILOT DIA.

3.38

DIA.

0.25

DIA.

3/8"

1/2'

#10-32 UNF-2B TAP (4)

HOLES ON A 3.875 B.C.

3.12

0.18

or

0.21

1.42

.42

1/8 SQ. KEY

X 0.75 LONG

0.75

0.46

FLAT

0.50

DIA.

#10-32 TAP (4) PLACES

2.004.50

0.59

0.62

DIA.

3/16 SQ. KEY

1.00 LONG

0.86

4.74

3.60 SQ.

1.12

DIA.

C

L

2.65 TYP.

SQUARE

4.08

3.38

1/4-28 UNF-2B TAP (4) HOLES

Superior Seals

DID YOU

KNOW?

Since most Bison gearboxes are oil lubricated for life, we understand the importance

of precision ground seal areas. Bison shafts are hardened prior to grind in order to

minimize wear on the seal journal. After heat treat, shafts are plunge ground on an

automated grinding wheel, maintaining tight tolerances on grind diameter, lead,

surface finish, and roundness. This superior seal grind coupled with spring loaded lip

seals provides dependable, leak-free performance and the flexibility to mount all Bison

gearmotors in any orientation.

Perfection

DRIVEN

GEAR

REDUCERS

77

Loading...

Loading...