Specifications

Gearhead

Gearing: Hardened steel worm, forged

bronze gear

Housing: Precision machined die cast

aluminum

Lubrication: Lifetime oil bath, sealed

and gasketed

Bearings: Ball

Shafts: Hardened steel

Mounting: Face or base, any angle

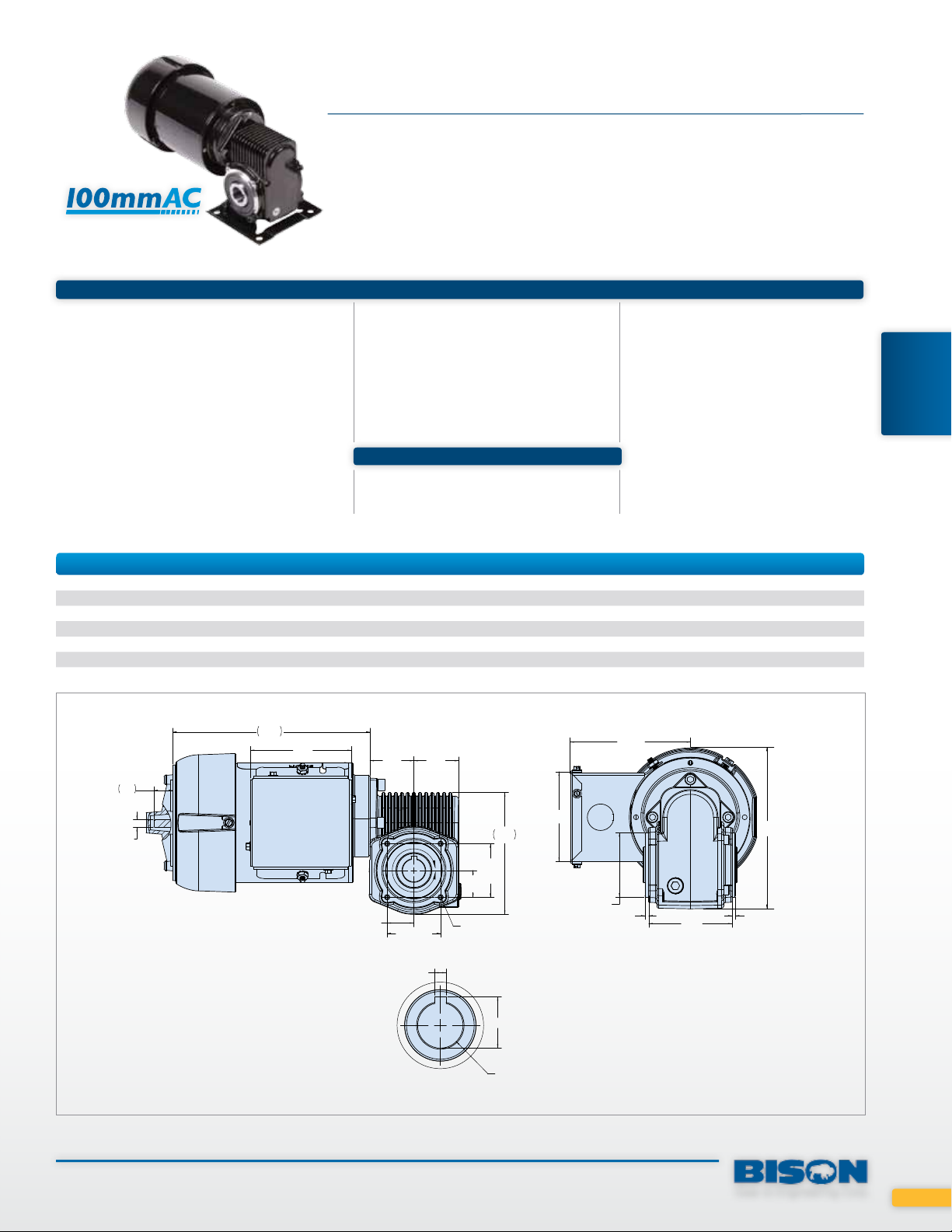

100mm 750 Series Right Angle AC

UP TO 100 IN-LBS CONTINUOUS

For tight-spaces requiring big power, Bison’s 100mmAC (4” dia.),

1/8 HP motors offer larger motor power in 30% less volume.

Motor

Motor Type: Permanent split capacitor

Rotation: Reversible

Bearings: Ball

Insulation: Class B minimum

Enclosure: TEFC

Finish: Gloss black powder coat

Capacitor included

Features

Motors are supplied with mounted

junction box and capacitor, and rear

shaft extension for brake

Additional Information

See pages 56-57 or 86-87 for

additional accessories

Footplate P/N P125-750-1000

Wiring diagram pages 88-91

RIGHT ANGLE

GEARMOTORS

750 Series PSC 115V

Part Number Speed (RPM) Torque (in-lbs) Input HP Gear Ratio Stages OHL Hz Shipping Wt.

026-756-3560 28 100 1/8 60.0 1 300 60 14.75

026-756-3545 37 80 1/8 45.0 1 300 60 14.75

026-756-3530 56 67 1/8 30.0 1 300 60 14.75

026-756-3520 82 43 1/8 20.5 1 300 60 14.75

026-756-3510 164 21 1/8 10.3 1 200 60 14.75

026-756-3505 327 11 1/8 5.2 1 270 60 14.75

750 PSC 115V

.64

ø 0.31

WITH .26

FLAT

6.52

3.33

1.45 1.48

.88

TYP.

1.77 TYP.

.1895

.1875

A

.88

TYP.

#10-32 UNF-2B

X .31 DEEP,

4-PLCS.

1.77

TYP.

3.07

4.03

Ø2.13

TYP.

3.97

.13

2.75

5.32

.13

DETAIL: HOLLOW SHAFT

SCALE 2 : 1

.847

.751

Ø

.750

Gear & Engineering Corp.

53

Specifications

Gearhead

Gearing: Hardened steel worm, forged

bronze gear

Housing: Precision machined die cast

aluminum

Lubrication: Lifetime oil bath, sealed and

RIGHT ANGLE

GEARMOTORS

Bearings: Ball

Shafts: Hardened steel

Mounting: Face or base, any angle

Finish: Gloss black powder coat

o-ringed

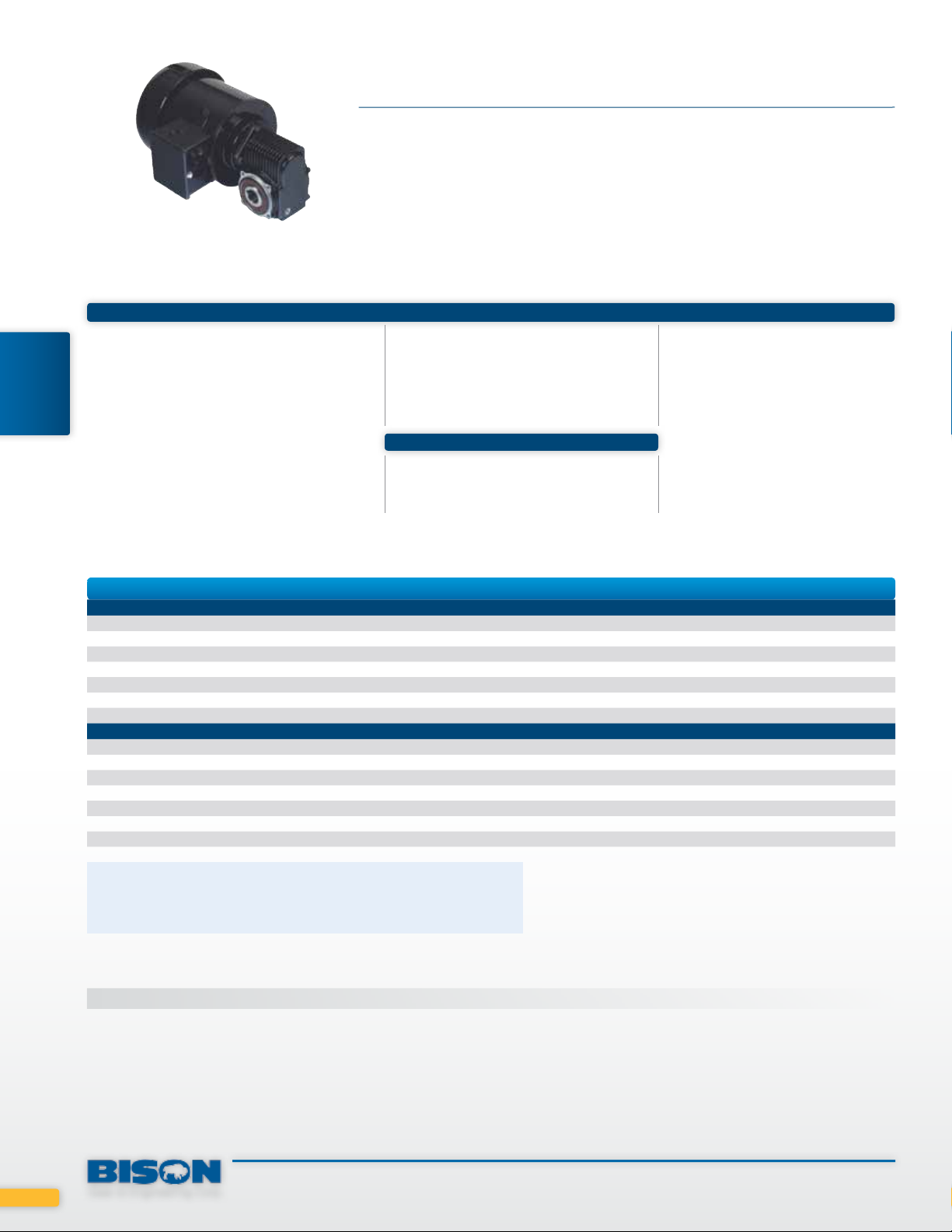

750 Series Right Angle AC

UP TO 130 IN-LBS CONTINUOUS

The 750 Series line of hollow shaft gearmotors allows hundreds

of mounting configurations enabling engineers to optimize their

assemblies. Industry standard mounts are available for drop-in

requirements, and a hollow shaft style is available to use with

optional accessories to meet your specifications.

Additional Information

Wiring diagram pages 88-91

Motor

Motor

Motor Type: Permanent split capacitor

Rotation: Reversible

Bearings: Ball

Insulation: Class B

Enclosure: TEFC

Finish: Gloss black powder coat

Features

Motors are supplied with mounted

junction box and capacitor, and rear

shaft extension for brake.

756 AC PSC 115V/230V

Part Number Speed (RPM) Torque (in lbs.) Input HP Gear Ratio Stages OHL* Amps Hz Shipping Wt.

Hollow / No Footplate

026-756-4460 28 120** 1/4 60.0 1 300 2.40/1.32 60/50 16.75

026-756-4445 36 120** 1/4 45.0 1 300 2.40/1.32 60/50 16.75

026-756-4430 55 130 1/4 30.0 1 300 2.40/1.32 60/50 16.75

026-756-4420 80 108 1/4 20.5 1 300 2.40/1.32 60/50 16.75

026-756-4413 124 76 1/4 1.3 1 300 2.40/1.32 60/50 16.75

026-756-4410 160 62 1/4 10.3 1 300 2.40/1.32 60/50 16.75

026-756-4405 330 30 1/4 5.2 1 270 2.40/1.32 60/50 16.75

Standard Shaft / With Footplate

026-756-4660 28 120** 1/4 60.0 1 300 2.40/1.32 60/50 19.75

026-756-4645 36 120** 1/4 45.0 1 300 2.40/1.32 60/50 19.75

026-756-4630 55 130 1/4 30.0 1 300 2.40/1.32 60/50 19.75

026-756-4620 80 108 1/4 20.5 1 300 2.40/1.32 60/50 19.75

026-756-4613 124 76 1/4 1.3 1 300 2.40/1.32 60/50 19.75

026-756-4610 160 62 1/4 10.3 1 300 2.40/1.33 60/50 19.75

026-756-4605 330 30 1/4 5.2 1 270 2.40/1.33 60/50 19.75

* Maximum overhung load located 2.5” from centerline of gearbox.

** Output torque is gear limited.

*** 60Hz speed shown

Also operable @ 50 Hz @ 5/6 of rated speed

750 Series 3-Phase Inverter Duty 230V

For more specifications see page 64

54

Gear & Engineering Corp.

750 Series Right Angle AC

756 PSC 115V/230V Hollow

0.64

ø0.31

WITH .26

FLAT

(4) #10-32 TAPPED HOLES

EQUALLY SPACED ON 2.50 B.C.

ON BOTH SIDES

6.56 1.45

1.45

1.77

756 PSC 115V/230V Standard Shaft

0.64

6.56 1.45

1.45

1.77

ø0.75

BORE

3/16 SQ.

KEY SEAT

3/16 SQ. KEY

X 1.00 LONG

3.13

2.13 DIA.

0.13

4.03

4.03

2.75

0.13

ø5.53

1.57

1.68

ø5.53

5.80

RIGHT ANGLE

GEARMOTORS

ø0.31

WITH .26

FLAT

0.30 DIA. THRU

HOLES (4) PLACES

3.00

3.75

0.59

OVER

FLAT

3.13

1.34

0.63

DIA.

3.25

1.68

3.25

4.07

Capacitor in junction box

Gear & Engineering Corp.

6.02

55

Inverter Duty AC Gearmotors (continued)

DESIGNED FOR ROBUSTICITY

Specifications

Gearhead

Gearing: AGMA class 9 heat treated steel

Geartrain: Engineered to handle up to 200%

shockloading

Housing: Precision machined die cast

aluminum

Lubrication: Lifetime oil bath

Bearings: Needle and thrust ball, or ball

bearing

Shafts: Precision ground shaft seal diameters

Mounting: All position

Additional Information

650 Series 3-Phase Inverter Duty 230V

Rated Speed

RPM @ 6hz

GEARMOTORS

INVERTER DUTY

Part Number

017-650-0029 6.0 60 90 222 222 148 1/4 28.9 0.75 23

017-650-0070 2.5 25 38 490 490 327 1/4 69.7 0.75 23

017-650-0090 1.7 17 26 722** 722** 442 1/4 89.8 0.75 23

017-650-0214 0.8 7.9 12 650** 650** 650** 1/4 214.5 0.75 23

017-651-0028 6.3 63 95 423 423 282 1/2 27.6 1.60 29

™

Rated Speed

RPM @ 60hz

Rated Speed

RPM @ 90hz

Motor

Motor Type: 230V, 3 phase, 6-90 Hz

Rotation: Reversible

Bearings: Double shielded ball

bearing support

Insulation: Class F (155ºC)

Enclosure: TEFC

Thermostat: Signal type; closed

Wiring diagram pages 88-91

Rated Torque

in-lbs @ 6hz

Rated Torque

In-lbs @ 60hz

Product Line Features

• Global safety recognition:

• Insulation system designed to

• Ambient temperature 0º to 40ºC

• Continuous duty

See pages 86-87 for additional

accessories

Rated Torque

In-lbs @ 90hz

UL, CUL

meet NEMA MG 1 Section 31

Input HPGear

Ratio

Amps

Shipping

Wt.

750 Series 3-Phase Inverter Duty 230V

Part Number

With Mounting Bracket & Output Shaft

027-756-4005 33 330 495 30 30 20 1/4 5.2 0.75 19.8

027-756-4010 16 160 240 58 58 39 1/4 10.3 0.75 19.8

027-756-4013 12.4 124 186 76 76 51 1/4 13.0 0.75 19.8

027-756-4020 8 80 120 108 108 72 1/4 20.5 0.75 19.8

027-756-4030 5.5 55 83 130 130 87 1/4 30.0 0.75 19.8

027-756-4045 3.8 38 57 120** 120** 80** 1/4 45.0 0.75 19.8

027-756-4060 2.8 28 42 100** 100** 67** 1/4 60.0 0.75 19.8

Hollow Shaft & Pilot Mount

027-756-4405 33 330 495 30 30 20 1/4 5.2 0.75 16.8

027-756-4410 16 160 240 58 58 39 1/4 10.3 0.75 16.8

027-756-4413 12.4 124 186 76 76 51 1/4 13.0 0.75 16.8

027-756-4420 8 80 120 108 108 72 1/4 20.5 0.75 16.8

027-756-4430 5.5 55 83 130 130 87 1/4 30.0 0.75 16.8

027-756-4445 3.8 38 57 120** 120** 80** 1/4 45.0 0.75 16.8

027-756-4460 2.8 28 42 100** 100** 67** 1/4 60.0 0.75 16.8

** Output torque is gear limited.

Rated Speed

RPM @ 6hz

Rated Speed

RPM @ 60hz

Rated Speed

RPM @ 90hz

Rated Torque

in-lbs @ 6hz

Rated Torque

In-lbs @ 60hz

Rated Torque

In-lbs @ 90hz

Input HPGear

Ratio

Amps

Shipping

Wt.

64

Gear & Engineering Corp.

650 3-Phase Inverter Duty 1/4 HP

6.56

10.77

0.64

2.00

3/16 SQ. KEY

X 1” LONG

1.71

4.03

0.91

4.78

3.63

ø5.53

ø0.31

WITH .26

FLAT

5.00

DIA.

J-BOX

0.75

DIA.

650 3-Phase Inverter Duty 1/2 HP

J-BOX

14.63

5.61

DIA.

2.00

0.75

DIA.

2.12

750 3-Phase Inverter Duty Standard Shaft 1/4 HP

.88

.64

1.45

1.45

2.12

3/16 SQ. KEY

X 1” LONG

3/16 SQ. KEY

X 1” LONG

3.26

3.13

ø6.76

1.75

1.60

0.44 THREAD DEPTH (6) PLACES

4.78

3.63

4.87

3.92

2.71

6.22

3.59

TAP 1/4-20 UNC-2B

1.71

0.91

2.72

3.59

TAP 1/4-20 UNC-2B

0.44 THREAD DEPTH (6) PLACES

6.22

GEARMOTORS

INVERTER DUTY

0.59

0.30 DIA. THRU

HOLES (4) PLACES

1.50

3.00

3.75

OVER

FLAT

750 3-Phase Inverter Duty Hollow Shaft 1/4 HP

0.64

ø0.31

WITH .26

FLAT

(4) #10-32 TAPPED HOLES

EQUALLY SPACED ON 2.50 B.C.

ON BOTH SIDES

6.56 1.45

1.77

1.45

1.77

ø0.75

BORE

3/16 SQ.

KEY SEAT

3.13

2.13 DIA.

0.63

DIA.

0.13

4.03

3.25

3.75

1.63

2.75

4.94

ø5.53

5.80

1.57

1.68

0.13

Gear & Engineering Corp.

65

Loading...

Loading...