Bison Gear & Engineering 26 Frame Permanent Magnet DC Motors Catalog Page

26 Frame Permanent Magnet DC Motors

PMDC MOTORS

Motors are available in 12, 24, or 90 volts.

Power range from 1/53 to 1/9 HP.

Specifications

Additional Information

Armatures: Dynamically balanced

Commutators: Tang-type, diamond turned

Varnishing: Class H polyester trickle

varnishing

Magnets: Highest grade ceramic

Finish: Gloss black powder coat

Brushes: Oversized with integral shunts

Replaceable, pg. 86

Bearings: Double shielded ball

Shafts: Carbon steel

Casting: Zinc alloy

Mounting: Base and face

Insulation: Class F

Wiring diagram pages 88-91

26 Frame Permanent Magnet DC Motors

Part Number Volts HP RPM Watts Amps

051-206-4005

051-206-4015

051-206-5005 90 1/53 2475 26 0.29 1.3 7.6 42.578 41.594 31.508 3.75 G

051-206-5015 90 1/27 1810 41 0.46 1.3 20.8 59.621 24.908 44.120 5.25 G

12

24

12

24

1/44

1/18

1/20

1/9

1870

4246

1800

4000

31

63

54

108

2.61 1.3 12.7 6.713 1.069 4.963 3.75 F

4.51 1.3 28.8 7.796 0.458 5.769 5.25 F

Form

Factor

Torque

(oz-in)

Torque

Contant

Terminal

Resistance

Voltage

Contant

Shipping

Wt.

Brush

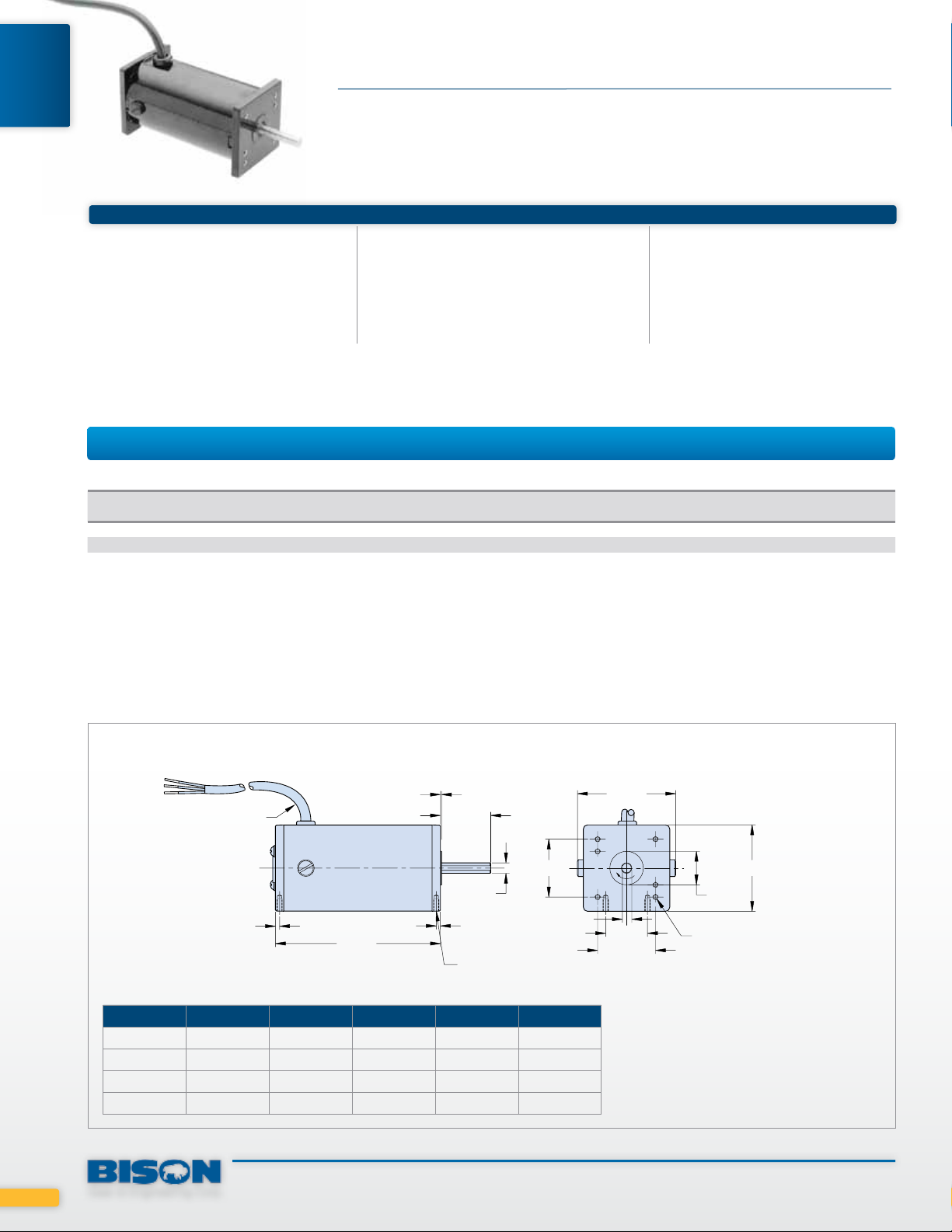

26 Frame PMDC

E

36" CORDSET

1.500

1.729

C

0.125

0.125

D- OVER FLAT

A

8-32 UNC-2B X 0.375

TAPPED HOLE (4) PLACES

Part Number A B C D E

051-206-4005 3.750 0.875 0.250 0.218 .080

051-206-4015 4.930 1.000 0.312 0.281 .031

051-206-5005 3.750 0.875 0.250 0.218 .080

051-206-5015 4.930 1.000 0.312 0.281 .031

8

Gear & Engineering Corp.

2.935

1.250

1.729

2.582 SQ.

B

8-32 UNC-2B X 0.25

TAPPED HOLE

(4) PLACES

32 Frame Permanent Magnet DC Motors

2.625

Motors are available in 12, 24, 90, or 180 volts.

Power range from 1/18 HP to 1/3 HP.

Specifications

Additional Information

Armatures: Dynamically balanced

Commutators: Tang-type, diamond turned

Varnishing: Class H polyester trickle

varnishing

Magnets: Highest grade ceramic

Finish: Gloss black powder coat

Brushes: Oversized with integral shunts

Replaceable, pg. 86

Bearings: Double shielded ball

Shafts: Carbon steel

Casting: Zinc alloy

Mounting: Base and face

Insulation: Class F

Wiring diagram pages 88-91

See pages 86-87 for additional

accessories

32 Frame Permanent Magnet DC Motors

Form

Part Number Volts HP RPM Watts Amps

051-203-4025

051-203-4035

051-203-4045

051-203-5025 90 1/18 1800 61 0.68 1.3 31.2 57.070 19.7576 74.6886 42.199 0.0174 8.25 D

051-203-5035 90 1/8 1800 115 1.28 1.3 70.0 61.478 6.6323 34.2597 45.459 0.0411 9.25 D

051-203-5045 90 1/6 1800 155 1.72 1.3 90.0 61.197 5.1412 27.3643 45.251 0.0515 10.75 D

051-203-7005 180 1/14 2350 81 0.45 1.2 31.2 92.349 52.4115 195.5731 68.285 0.0174 8.25 D

051-203-7015 180 1/8 1800 115 0.64 1.3 70.0 122.957 29.4829 137.0389 90.917 0.0411 9.25 D

051-203-7025 180 1/6 1800 155 0.86 1.3 93.4 119.48 19.5003 104.3069 88.347 0.0515 10.75 D

12241/14

12241/7

12241/6

1/6

1/4

1/3

1750

420080164

1750

143

3580

292

1948

170

4124

345

Factor

6.69

6.83

11.95

12.18

14.17

14.36

Torque

(oz-in)

1.0 41.0 7.260 0.2913 1.1393 5.368 0.0195 8.25 A

1.0 90.0 8.294 0.1563 0.6367 6.133 0.0423 9.25 A

1.0 93.4 7.209 0.1033 0.3939 5.33 0.0524 10.75 A

KT

(oz-in/A)

RT

(ohms)

Arm.

Induct.

(mh)

KE

(V/krpm)

Arm

Inertia

(oz-in-sec2)

Shipping

Wt.

PMDC MOTORS

Brush

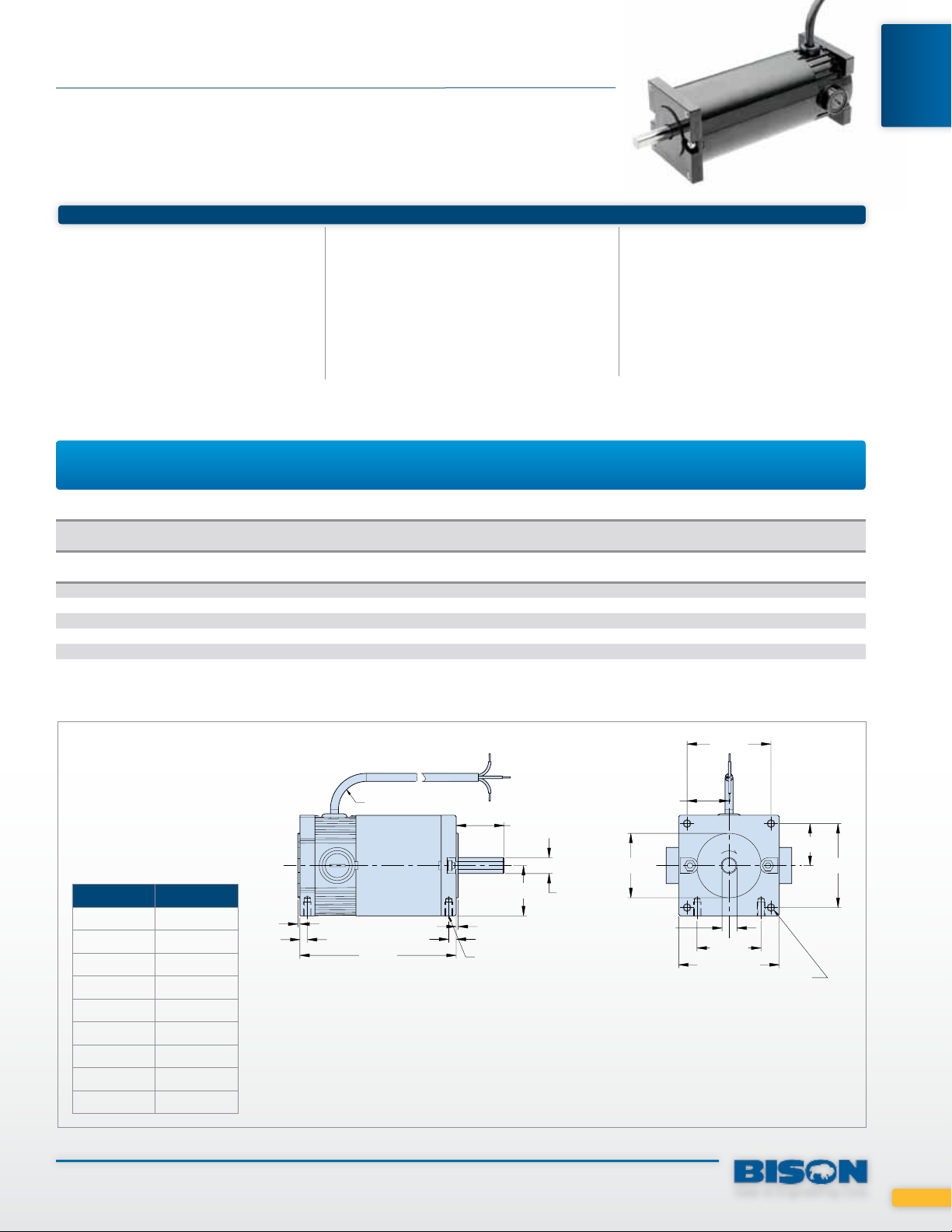

32 Frame PMDC

Part Number A

051-203-4025 4.890

051-203-4035 6.890

051-203-4045 7.890

051-203-5025 4.890

051-203-5035 6.890

051-203-5045 7.890

051-203-7005 4.890

051-203-7015 6.890

051-203-7025 7.890

0.062

0.234

36" CORDSET

0.062

A

1.500

1.572

0.234

1/4-20 UNC-2B X 0.437

DEEP (4) PLACES FOR

BASE MOUNTING

0.500

DIA.

0.468 OVER FLAT

ø2.015

1.313

1.313

2.000

3.145 SQ.

1/4-20 UNC-2B

THRU (4) PLACES

Gear & Engineering Corp.

2.625

9

Loading...

Loading...