Bishamon L2K-2848 User Manual

HYDRAULIC LIFT TABLES

Models Lift2K®, Lift3K™, Lift5K™

Please note: This manual was current at the time of printing.

To obtain the latest, most updated version, please contact

Bishamon’s customer Service Department or go to our website:

Date Placed in Service:

Serial Number:

Dealer:

Version 1.00

www.Bishamon.com

BISHAMON INDUSTRIES CORPORATION

5651 East Francis Street

Ontario, California 91761, USA

(909) 390-0055 (800) 231-3187

Table of Contents

Contents Page

Getting Started ........................................................................................................................................................................................................1

Inspection ................................................................................................................................................................................................................1

Safety Defi nitions.....................................................................................................................................................................................................1

Dangers, Warnings and Cautions ............................................................................................................................................................................1

Safety Warning Label Locations .............................................................................................................................................................................. 2

Responsibilities of Owners/Users ............................................................................................................................................................................ 3

Specifi cations ..........................................................................................................................................................................................................4

Recommended Floor Area.......................................................................................................................................................................................6

Functional Description ............................................................................................................................................................................................. 6

Maintenance Bar Operating Instructions ................................................................................................................................................................. 7

Installation Instructions ............................................................................................................................................................................................ 7

Operating Instructions .............................................................................................................................................................................................8

Routine Maintenance...............................................................................................................................................................................................9

Troubleshooting ......................................................................................................................................................................................................16

Replacement Parts ................................................................................................................................................................................................. 16

List of Figures

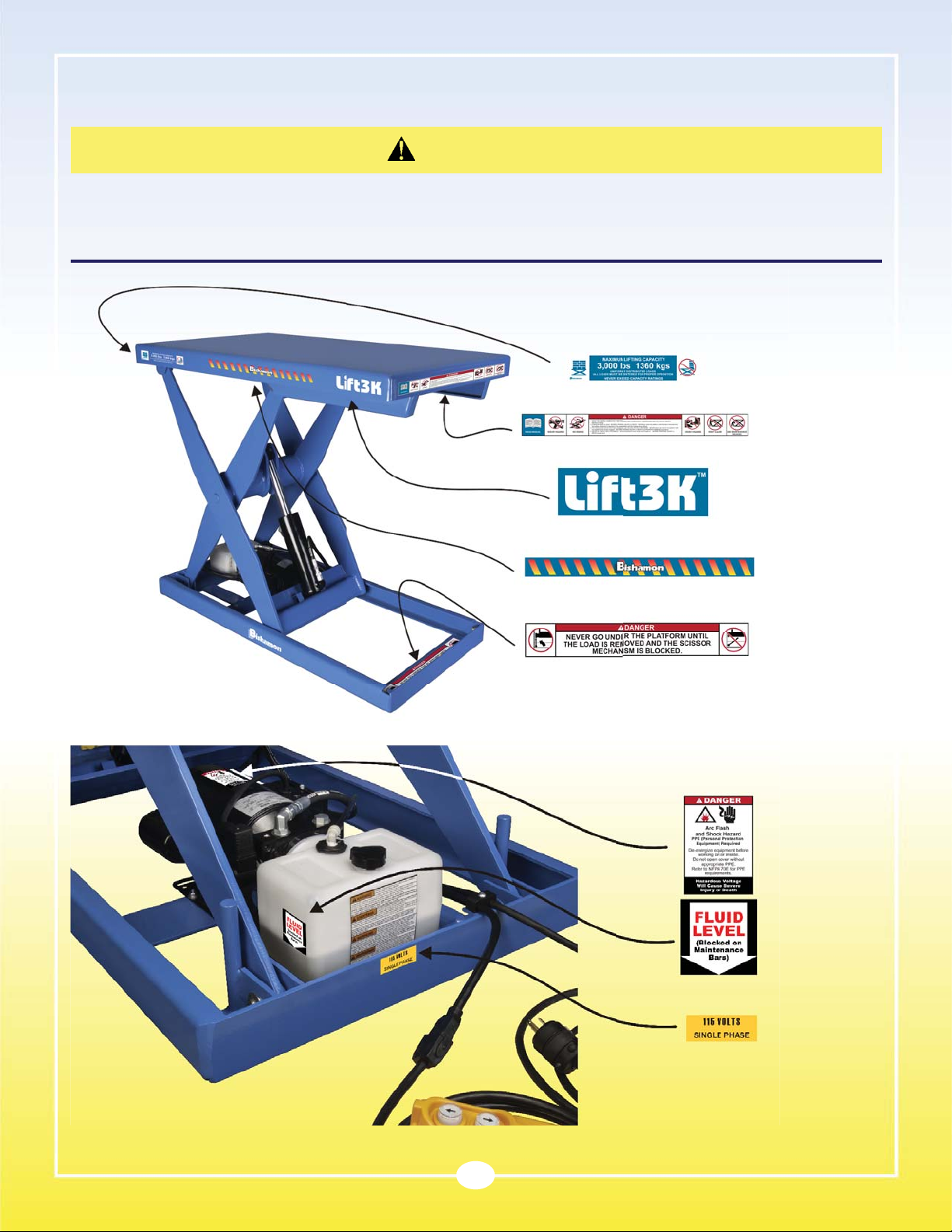

Figure 1 - Safety Warning Label Locations .......................................................................................................................................................2

Figure 2 - Fixed Platform Model Specifi cation Drawing ....................................................................................................................................4

Figure 3 - Turntable Model Specifi cation Drawing ............................................................................................................................................5

Figure 4 - Recommended Floor Area ................................................................................................................................................................6

Figure 5 - Maintenance Bar Operation .............................................................................................................................................................. 7

Figure 6 - Maintenence Bar in Stored Position ................................................................................................................................................. 7

Figure 7 - Installation Components ................................................................................................................................................................... 7

Figure 8 - Handling the OPTIMUS Lift .............................................................................................................................................................. 8

Figure 9 - Anchor Bolt Detail .............................................................................................................................................................................8

Figure 10 - Hand Control Operation .................................................................................................................................................................... 9

Figure 11 - Foot Control Operation ..................................................................................................................................................................... 9

Figure 12 - Reservoir Fluid Level .......................................................................................................................................................................10

Figure 13 - Hydraulic Schematic - Plumbing Diagram ....................................................................................................................................... 11

Figure 14 - Lift2K 115 Volt Wiring Diagram ........................................................................................................................................................12

Figure 15 - Lift3K , Lift5K 115 Volt Wiring Diagram ............................................................................................................................................ 12

Figure 16 - Lift3K, Lift5K 208/230 Volt 3 Phase Wiring Diagram ....................................................................................................................... 13

Figure 17 - Lift3K, Lift5K 480 Volt 3 Phase Wiring Diagram .............................................................................................................................. 13

Figure 18 - Lift3K, Lift5K 230 Volt Single Phase Wiring Diagram ...................................................................................................................... 14

Figure 19 - Hand Control Wiring Diagram .......................................................................................................................................................... 14

Figure 20 - Foot Control Wiring Diagram - 20A ..................................................................................................................................................15

Figure 21 - Foot Control Wiring Diagram - 15A ..................................................................................................................................................15

List of Charts

Chart 1 - Recommended Hydraulic Fluid .......................................................................................................................................................11

Chart 2 - Troubleshooting ...............................................................................................................................................................................16

GETTING STARTED

PLEASE READ THIS MANUAL CAREFULLY BEFORE USING THE OPTIMUS™ Scissor Lift Table. The safety of all persons installing, using or

servicing the OPTIMUS™ scissor lift is of utmost importance to Bishamon. All OPTIMUS™ series lifts are capable of supporting heavy loads and

are capable of causing SEVERE PERSONAL INJURY if used improperly or certain safety precautions are not taken. When properly used and

maintained, OPTIMUS™ lifts will provide many years of safe, trouble free service. If you have any questions about any of the instructions in this

manual or about the use of this product, PLEASE contact your DEALER or Bishamon Industries Corporation.

®

OPTIMUS™ LK series refers Lift2K

referred to as the “lift table” or the “lift”.

, Lift3K™ and Lift5K™ scissor lift tables. Throughout this service manual the OPTIMUS™ scissor lift may be

INSPECTION

IMMEDIATELY upon receipt of the lift table, remove all packing and strapping material and visually inspect the unit for damage. Any damage

to the unit MUST BE NOTED on the delivery receipt. After the preliminary inspection is conducted, the unit should be thoroughly inspected for

any concealed damage that was not readily apparent during the preliminary inspection. Any concealed damage found that was not noted on the

delivery receipt should be IMMEDIATELY reported in writing TO THE DELIVERING CARRIER.

SAFETY DEFINITIONS

Bishamon uses the following system to identify the degree of risk associated with hazards and unsafe practices.

DANGER - Immediate hazard which will result in SEVERE PERSONAL INJURY or DEATH.

WARNING - Hazard or unsafe practice which could result in SEVERE PERSONAL INJURY or DEATH and PROPERTY DAMAGE.

CAUTION - Hazard or unsafe practice which could result in MINOR PERSONAL INJURY and PROPERTY DAMAGE.

DANGERS

1. READ THIS MANUAL COMPLETELY BEFORE USING AND THOROUGHLY UNDERSTAND AND FOLLOW ALL SAFETY

INSTRUCTIONS.

2. A falling lift table can cause SEVERE PERSONAL INJURY or DEATH. NEVER go under the platform until the load is removed and the

scissor mechanism is secured in the raised position with the maintenance bars.

3. The maintenance bars have been designed for use only when the lift is UNLOADED. NEVER place any load on the platform with the

maintenance bars engaged. SEVERE PERSONAL INJURY or DEATH and PROPERTY DAMAGE could result.

4. NEVER sit, stand or ride on the platform. Moving components could cause loss of balance. SEVERE PERSONAL INJURY or DEATH

could result.

5. The lifts electrical circuits use voltages, which can cause SEVERE PERSONAL INJURY or DEATH. DO NOT work with the electrical

components unless you are a QUALIFIED ELECTRICAN

6. The lift’s electrical components can create sparks. DO NOT install the lift in an area where potentially explosive dusts, gases, or vapors

may be present. Failure to comply may result in an explosion and cause SEVERE PERSONAL INJURY or DEATH.

WARNINGS

1. The OPTIMUS lift table is designed for use with stable, uniformly distributed loads on a solid level fl oor. DO NOT concentrate the load at

one point on the platform or pallet. ALWAYS uniformly distribute each layer of load over the supporting surface. DO NOT use the lift for

any purpose other than its intended use.

2. DO NOT install the lift table on an unlevel or soft surface. The lift base frame must be supported along its entire length and width. Failure

to completely support the base frame could result in damage to the lift.

3. DO NOT use the lift table with an unstable, unbalanced or loosely stacked load. Unbalanced loads may become unstable and fall.

SEVERE PERSONAL INJURY and PROPERTY DAMAGE could result.

4. DO NOT overload the lift table. ALWAYS stay within the designated capacity ratings. SEVERE PERSONAL INJURY and PROPERTY

DAMAGE could result.

5. SHEARING HAZARD. ALWAYS keep hands and feet clear of the scissor mechanism and all moving components. DO NOT put hands or

fi ngers under the platform when in use. SEVERE PERSONAL INJURY could result.

6. CRUSHING HAZARD. ALWAYS keep hands and feet clear of all moving components. DO NOT put feet on the base frame when in use.

SEVERE PERSONAL INJURY could result.

7. PINCH POINT HAZARD. ALWAYS keep feet, hands and fi ngers away from the underside of the platform and all moving components.

SEVERE PERSONAL INJURY could result.

8. DO NOT change the relief valve setting. The relief valve is installed to protect the operator and the lift table. Changing the relief valve

setting may compromise the performance and safety of the lift. SEVERE PERSONAL INJURY and PROPERTY DAMAGE could result.

9. NEVER leave the loaded lift table unattended unless the platform is in the fully-lowered position.

10. ALL lift servicing must be performed by qualifi ed personnel only. Unauthorized modifi cations to this lift table, its hydraulic power unit or its

control system may compromise the performance and safety of the system. UNDER NO CIRCUMSTANCES should you attempt any repair

or service that is not covered in this manual.

11. The release of fl uids under high pressure can cause SEVERE PERSONAL INJURY. Before servicing the lift, ALWAYS remove all load,

engage the maintenance bars and RELEASE THE HYDRAULIC PRESSURE.

1

12. ALWAYS ensure all safety warning labels are in place and legible. If not, remove the lift table from service and replace the required labels.

Refer to Figure 1 for label descriptions and locations.

13. ALWAYS securely anchor the base frame to the fl oor to ensure maximum stability.

CAUTIONS

1. DO NOT continue to operate the pump if a squealing noise is heard coming from the pump. The pressure relief valve is operating.

Continued use of the pump with the relief valve operating may cause permanent damage the pump. REDUCE the load to prevent the relief

valve from operating.

SAFETY WARNING LABEL LOCATIONS

Figure 1 Safety Warning Label Locations

2

RESPONSIBILITIES OF OWNERS/USERS

The following section is taken directly from section 5 of ANSI MH29.1-2012. Please note the following:

• Manufacturer refers to Bishamon’s authorized representative the “DEALER” or to “Bishamon Industries Corporation”.

• Industrial scissors lift refers to the OPTIMUS series lifts – models Lift2K, Lift3K and Lift5K.

• Operating and maintenance manual refers to this manual – “OPTIMUS LK Series Lift2K, Lift3K and Lift5K Series Operation and Service

Manual”.

Basic Principles - Owners/users shall apply sound principles of safety, training, inspection, maintenance, and expected operating environment. It

shall be the responsibility of the owner/user to advise the manufacturer where defl ection may be critical to the application.

Manuals - Owners/users shall keep and maintain a copy of the operating and maintenance manual and ensure its availability to operating and

maintenance personnel.

Inspection and Maintenance - It shall be the responsibility of the users to inspect and maintain the industrial scissors lift as required to ensure

proper operation. The frequency of inspection and maintenance shall be based upon the manufacturer’s recommendations and be compatible

with operating conditions and the severity of the operating environment. Industrial scissors lifts that are not in proper operating condition shall

be immediately removed from service until repaired. Maintenance and repairs shall be made by a qualifi ed person and the repairs shall be in

conformance with the manufacturer’s recommendations.

Maintenance Safety Precautions - Before adjustments and repairs are started on an industrial scissors lift, the following precautions shall be

taken as applicable:

1. Remove the load from the platform.

2. Lower platform to the fully-lowered position if possible or secure by maintenance device and/or blocking as described by the manufacturer

to prevent unintended platform movement.

3. Relieve system pressure from all hydraulic circuits before loosening or removing any components.

4. All controls in the “Off’ position and all operating features secured from inadvertent motion by brakes, blocks, or other means.

5. Disconnect power and follow established owner/user lockout/tagout policies.

6. Follow precautions and directions as specifi ed by the manufacturer.

Replacement Parts - When parts or components are replaced, they shall be replaced with parts or components approved by the original

manufacturer of the industrial scissors lift.

Maintenance Training - The user shall ensure only qualifi ed personnel inspect and maintain the industrial scissors lift in accordance with section

5.3, 5.4, and 5.6 of MH29.1-2012 and with the manufacturer’s recommendations as described in the maintenance manual.

Operator Training - An owner/user, who directs or authorizes an individual to operate an industrial scissors lift, shall ensure that the individual has

been:

1. Trained in accordance with the manufacturer’s operating manual.

2. Made aware of the responsibilities of operators as outlined in section 6 of ANSI MH29.1-2012.

3. Retrained, if necessary, based on the owners/user’s observation and evaluation of the operator.

Modifi cations - Modifi cations and additions shall not be performed without the manufacturer’s prior written approval. Where such authorization is

granted, capacity, operation, and maintenance instruction plates, tags, or decals shall be changed accordingly.

3

Loading...

Loading...