160-tonne mine haulage truck

Mine haulage reimagined

Rexx is the latest product to join the Bis haulage fleet, providing

increased efficiency and productivity to our customers’

operations through our integrated haulage services.

Rexx delivers:

Lower mine development costs

Rexx’s 4.8m width, even weight distribution, and ability to haul efficiently on 12%

gradients means it can operate on narrower and steeper haul roads and in tighter

cutbacks, reducing development costs, rehabilitation and environmental disturbance.

Superior fuel efficiency

Up to 40% less fuel burn leading to

significant fuel cost savings for your project.

Better safety outcomes

Rexx comes equipped with world-class

fatigue detection and driver monitoring

systems, and operators experience better

visibility and cabin access than ever before.

Increased range

With the ability to efficiently travel

up to four times further than conventional

dump trucks.

Mining for the future

Rexx’s smart design has the ability to

house proprietary automation hardware.

1 REXX

Lower mine

development costs

Mine development costs are optimised,

thanks to Rexx’s unique attributes.

Rexx has been designed with multiple

steering and driving axles, enabling it to

handle gradients of up to 12% when fully

loaded.

At 4.8m wide, haul roads and inclines can

be narrower.

The ability to haul efficiently on 12% inclines

reduces incline length and significantly

improves strip ratio, while Rexx’s

evenly-distributed weight allows for

lower-specification haul road construction.

In addition, the Bis steering system enables

a turning radius of less than 12.6m, which

allows Rexx to easily manoeuvre in smaller

spaces and turn around sharp corners.

This reduces the haul road infrastructure

costs of your operations, as well as

environmental disturbance and associated

rehabilitation works.

The unique five-axle drive and 20-tyre design

of Rexx distributes the load more evenly,

delivering an increased surface area and

reduced ground pressure. This enables Rexx

to operate in even the toughest of terrains,

including all pit environments and wet

underfoot conditions.

With its superior traction, gradeability and

narrow width – Rexx enables you to optimise

your mine design – from concept

to completion.

2

40% more fuel efficient

With patented on-demand power that lowers

fuel consumption, Rexx is up to 40% more

fuel efficient than its competitors, delivering

significant cost savings to miners, as well as

reduced greenhouse gas emissions.

Rexx’s empty-weight advantage means

less fuel is needed to move more of your

product.

Rexx’s design incorporates both durability

and lightness. At a loaded weight of 227

tonnes, Rexx’s 160-tonne payload represents

70% of gross vehicle mass. This weight

advantage maximises tonnes delivered

and drives big savings on fuel and related

emissions.

A second source of Rexx’s fuel efficiency

is its dual-engine design. During sections

of low power demand in a haul cycle, such

as the empty leg, Rexx can operate on one

engine, optimising fuel consumption.

Rexx is equipped with heavy duty road train

tyres which are smaller in size, and do not

experience tyre-heating issues to the same

extent.

With the power to haul directly from pit-toplant over a much longer distance without

the need for the rehandle step – Rexx

delivers cost savings and a reduction in ore

loss/dilution at your site.

Driving better safety

in mine site haulage

The safety of our people, environment and

communities is our core value at Bis and we

are proud of our industry-leading safety record.

Rexx has a range of proprietary safety features

to keep operators safe.

Greater visibility for operators

With a large format front window and a cabin

that sits at the front of the profile, operators of

Rexx experience significantly greater visibility of

their surrounds.

Rexx is the single haulage solution that

solves the niche haul-distance equation

of mining projects – with the ability to

efficiently transport a 160-tonne payload

for 40km at a normal operating speed of

60km per hour.

This industry-leading distance is at least

four times further than conventional dump

trucks, which are limited in range due to

tyres heating.

3 REXX

Four times more range

While most standard heavy vehicles of this

scale would have extended blind spots in

front of their windshields of up to 6m, Rexx’s

unique window design enables operators

to see obstructions as close as 2.5m ahead.

Rexx’s cabin is compliant with FOPS and

ROPS.

360° Biscam view

With four on-board cameras, Rexx

operators have constant visibility of

all sides of the vehicle.

The camera system can be customised,

allowing operators to select the visual angles

best suited to their mirror setup and seating

position, resulting in a full 360° view of their

working environment.

Improved access and egress

Mining for the future

Bis has more than a century of operational

experience and has developed leading

monitoring and preventative maintenance

systems.

When compared with 6-7m access height and

standard ladder-style access for conventional

dump trucks – Rexx has really ‘stepped up’

the game – providing significantly-improved

access and egress for operators due to the

reduced cab height of just 2.4m from ground,

as well as pneumatically-controlled stairway

access to the cab.

Vehicle monitoring

All Rexx vehicles have a real-time in-cabin

monitoring solution installed. This includes

proprietary artificial intelligence and monitoring

systems that alert drivers and fleet managers to

non-compliant driving behaviour. This helps to

ensure adherence to your company’s guidelines

and policies, and drive safety improvement

initiatives.

Smaller mechanical components and tyres

Smaller machinery components reduce the

risk to safety. From hydraulic pumps and the

transmission engine, to the tyres that weigh

just 800kg – all the components of Rexx are

smaller than most, reducing the risks of injury

associated with changing and working with

large, heavy components.

We have embarked on a digital journey to

improve how we manage and deliver safely

throughout our operations.

Our assets are equipped with technology

features with an ability to improve safety in

both real-time and in the future, using data

analytics techniques.

Our technology suite is proactive, using

both Artificial Intelligence (AI) and human

data analytics to gain meaningful and

valuable insights.

This software will consolidate all of the above

data sources to create and develop insights

that alert managers and vehicle operators on

operational risks and issues in real-time.

Bis’ monitoring technology also captures

daily operational data to help identify

areas for improvement and drive business

efficiencies.

With Rexx’s intelligent in-cab systems, you

receive valuable information to optimise your

production and improve on-site operational

costs.

Rexx’s smart design has adequate space to

house automation hardware to align with

your site’s pathway to automation.

Rexx can be easily retrofitted for automation

with the inclusion of a broad range of sensors

to report on wheel stability, bin tipping,

suspension control and engine operation.

4

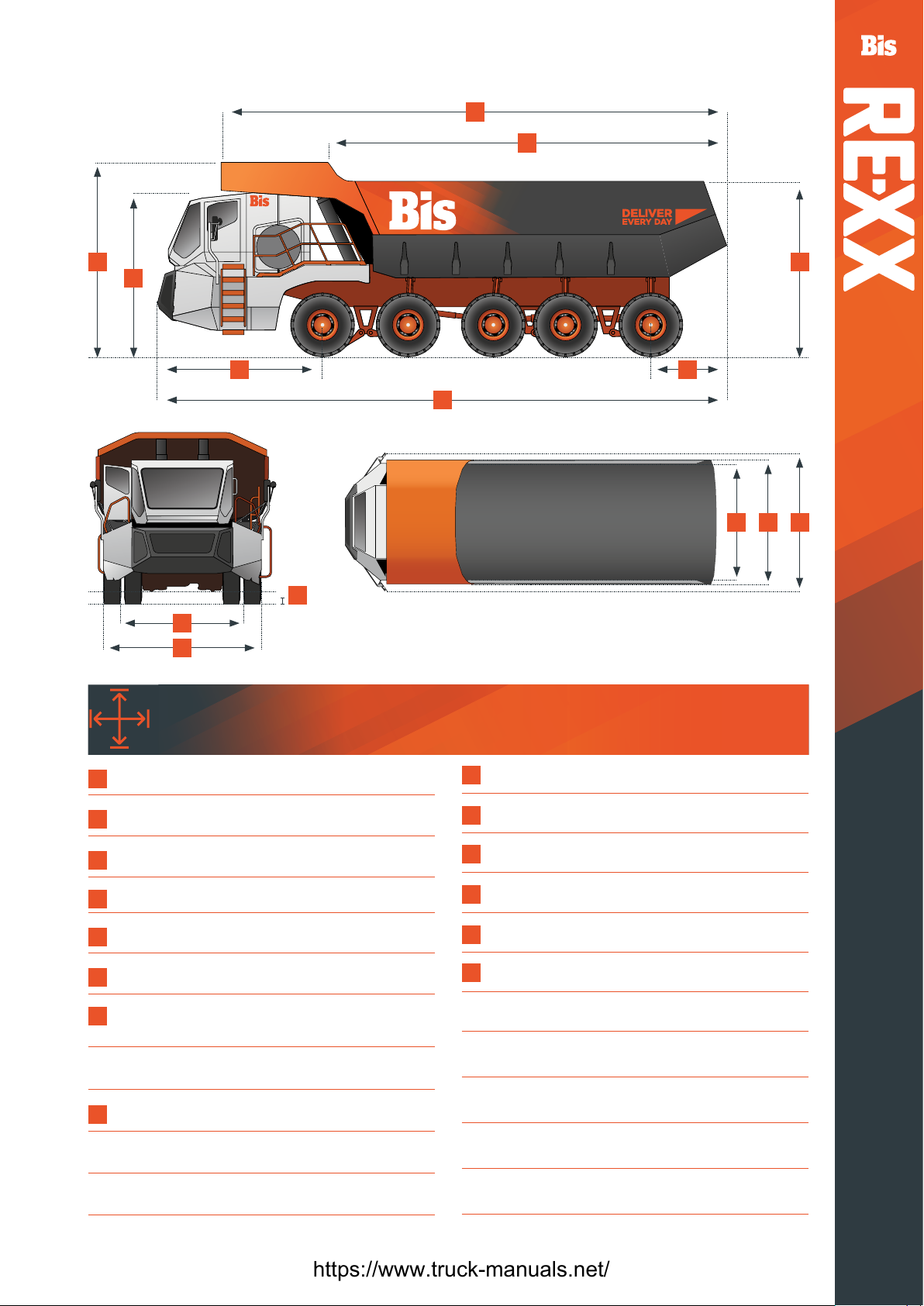

Specifications

Specifications

Length 14.3m

Height 4.9m

Operating width 4.8m

Tare weight (approximate) 67 tonne

Payload capacity 160 tonne

Gross weight < 227 tonne

Maximum speed 60km/h

Turning radius (outside wheel) < 12.6m

Transmission

Manufacturer Allison

Layout Side by side

Gears 6 speed, 1 reverse

control type Electronic gear

Dumping system/bin

Raise time 60 seconds

Lowering time 40 seconds

(Cycle time 100 seconds)

Engine

Manufacturer dual-powered Cummins

15L engine

Gross Power 1100 horsepower

Wheels

Rims 5 piece

Type Custom bold pattern,

standard size

Tyre 18.00R25

Tipping angle 50°

Rear clearance

during tipping

Bin capacity Can be customised to suit any

Customisation Rexx has a range of

Total envelope

dimensions

(bins up/access

panels open)

1.4 to 1.6m (depending

on bin requirement)

material between 89-130m

interchangeable bins that

are customisable by our

in-house engineering department

to suit the specific needs of

your operation.

Length 17.5m

Height 12.4m

Width 8.4m

3

5 REXX

B

C

N H

A

FE

D

MLK

G

I

J

Dimensions (with standard 80m3 bin)

A

Height to top of rops - empty

B

Overall bin length

C

Inside bin length

D

Overall length

E

Front axle to front

F

Rear axle to tail

G

Front axle clearance

loaded height

Dump clearance height 1,381mm

H

Loading height empty

Inside bin depth - maximum 2,545mm

4,105mm

12,731mm

10,043mm

14,331mm

4,167mm

1,916mm

355mm

4,405mm

I

Centreline tyre width

J

Overall tyre width

K

Inside bin width

L

Outside bin width

Overall width including mirrors

M

N

Height to top of canopy

3,400mm

4,500mm

4,476mm

4,816mm

5,306mm

4,857mm

Bin angle – fully raised 50°

Turning circle

- inside bin clearance

Turning circle

- inside wheels track

Turning circle

- outside wheels track

(R6,650mm)

13,200mmø

(R6,800mm)

13,600mmø

(R12,645mm)

25,290mmø

Overall height - bin raised 12,440mm

Turning circle

- inside bin clearance

(R14,145mm)

28,290mmø

6

About Bis

Bis is a leading resources logistics

company, providing innovative

logistics, materialshandling and

specialised equipment solutions to

the global mineral resources sector.

Since 1915, Bis has built a reputation as a

leader in efficiently moving large volumes of

raw materials and commodities through the

full mining value chain, by applying patented

solutions, advanced technology and deep

industry experience.

Today, we haul, transport, process and handle

millions of tonnes of raw materials and

commodities for our customers every year.

We have grown our business alongside yours,

focusing on proprietary technology solutions

designed to make your operations more

productive, more efficient and reassuringly safe.

Innovation and problem-solving are in our DNA.

We aspire to serve our customers globally and

to innovate every day – lifting safety,

productivity and sustainability.

That’s how we help our customers

to DeliverEvery Day.

Contact Bis to discuss how Rexx can deliver

efficiencies at your site as part

of our integrated haulage solutions:

Contact us

Head Office

Level 1, Brightwater House

Garden Office Park

355 Scarborough Beach Road

Osborne Park WA 6017

T: (08) 9202 5800

E: enquiries@bisindustries.com

bisindustries.com

Loading...

Loading...