Biro VTS-500 Installation Manual

MODEL VTS-500

VACUUM TUMBLER

OPERATION MANUAL & PARTS LIST

The BIRO VTS-500 VACUUM TUMBLERS are versatile machines used for vacuum

tumbling all types of meats with marinaded blends of herbs and spices. All marinades should be FDA approved and meet F.S.I. standards. The BIRO VTS-500 produces equally impressive results with beef, pork, poultry and fish.

The unit is both easy to clean and maintain as well as sanitary in design and construction. The entire machine is built to give many years of trouble free service while

providing a unique line of marinated products for your customers.

ITEM No. VTS583-307

STARTING WITH SERIAL No. 544

ITEM No. VTS583-307

307-1-09-4

TABLE OF CONTENTS

Page

NOTICETOOWNERSANDOPERATORS......................................... 1

SAFETYTIPS............................................................... 2

OPERATION................................................................ 3

CLEANING................................................................. 4

MAINTENANCE ............................................................. 5

PUMPFILTER.......................................................... 5-7

VACUUMPUMP......................................................... 8-9

GEARREDUCER ......................................................10-11

TOPROGRAMTIMER.....................................................12

TIMERPROGRAMNOTES..................................................13

PHOTOELECTRICEYE .................................................14-15

CONTROLPANEL–COMPONENTS.............................................16

CONTROLPANEL–REARVIEW ................................................17

DRUMASSEMBLY ...........................................................18

FRAMEASSEMBLYANDCOMPONENTS..........................................19

VACUUMHOSESANDFITTINGS.............................................20-21

COMPONENTCOVERANDREARDOOR .........................................22

OPERATORNOTES..........................................................23

WIRINGDIAGRAMS........................................................24-25

SPAREPARTSRECOMMENDATION .............................................26

OPERATOR’SSIGNATUREPAGE................................................27

LIMITEDWARRANTY.........................................................28

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should read and be thoroughly familiar with the procedures contained in this Manual. Even so

BIRO cannot anticipate every circumstance or environment in which its products will be used.

You, the owner and operator, must remain alert to the hazards posed by the function of this equipment. No one under eighteen (18) years of age should operate this equipment. If you are uncertain about a particular task, ask your supervisor.

This Manual contains a number of safe practices in the SAFETY TIP section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

Warnings related to possible damage to equipment are indicated by:

BIRO also has provided warning labels on the equipment. If any warning label, instruction label

or Manual becomes misplaced, damaged, or illegible, please contact your nearest Distributor or

BIRO directly for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

1

NOTICE TO OWNERS AND OPERATORS

OR

– NOTE –

A copy of this manual is included with each MODEL VTS-500 VACUUM TUMBLER.

The descriptions and illustrations contained in this manual are not binding.

The manufacturer reserves the right to introduce any modification

without updating the manual.

SAFETY TIPS

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

ALWAYS Read Operation and Service Manual BEFORE Operating, Cleaning or Servicing.

ALWAYS Keep Hands Clear of the Rotating Drum and Other Moving Parts.

NEVER Attempt to Remove the Drum Lid Unless Vacuum Has Been Released and the Drum is

Positioned Vertically With the Lid at the Top.

NEVER Operate Vacuum Pump Unless Properly Connected to Tumbler Drum.

ONLY Operate Vacuum Pump in Recommended Vacuum Range (15-20 Inches of Mercury)

NEVER TO EXCEED 20 INCHES Hg.

ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

ONLY Install on Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away From

Children and Visitors.

DO NOT Allow Food Particles, Liquids or Any Other Foreign Material to Enter the Vacuum

Pump or Vacuum Hose.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Cleaning or Servicing.

NEVER Leave Machine Unattended While Operating.

PROMPTLY REPLACE Any Worn or Illegible Warning and/or Instruction Labels.

USE ONLY BIRO Parts and Accessories Properly Installed.

FOOD HANDLING TO PREVENT CONTAMINATION

1. ALWAYS wash hands thoroughly with warm soap and water before and after handling raw fish, poultry or

meats.

2. ALWAYS clean and sanitize all utensils and surfaces that have been in contact with raw products.

3. ALWAYS store cold foods at or below 45 deg. F (7.2 deg. C).

2

OPERATION

ROTATING DRUM

ONLY Properly Trained Personnel Should Use This Equipment.

ALWAYS Keep Hands Clear of the Rotating Drum and Other Moving Parts.

DO NOT Tamper With, Bypass, Alter, or Modify This Equipment in Any Way From Its Original

Condition.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine Before Cleaning, Servicing, or When Not In Use.

NEVER Leave Unattended While Operating.

NEVER Turn Drum by Hand, Jog Machine Until Drum is in Desired Position.

ALWAYS Comply With All Regulation for Food Handling, Packaging, and Storage.

NEVER Operate Without All Warning or Instruction Labels Attached.

TO PROCESS PRODUCT AND MACHINE OPERATION

1. Weigh product to be vacuum tumbled.

2. Refer to your ingredient chart for proper amount of marinade seasoning and water.

3. Use jog switch to position drum opening upright.

4. Place product, marinade and water into tumbler drum.

5. Install gasket on drum and place cover on drum and secure with four latches.

6. Connect vacuum hose to valve on drum. Be sure valve handle is in the open position, Parallel with the valve

body.

7. Turn vacuum pump to “ON”. (Vacuum gauge will start indicating a vacuum is being pulled in the drum.) If

needle in vacuum gauge does not indicate vacuum is being pulled, turn “OFF” vacuum pump and

disconnect vacuum hose from drum. Remove drum lid and check that the lid gasket is properly installed and

seated, then repeat this procedure.

8. When vacuum gauge does indicate that a vacuum is being pulled, allow to continue running until gauge

reads between 15 and 20 inches Hg. NEVER TO EXCEED 20" Hg.

9. Close valve handle on drum, Perpendicular to valve body. Turn vacuum pump to “OFF” position. Remove

vacuum hose from valve. Drum contents are now sealed in a vacuum.

10. Program timer to desired tumble time, and press green button to start, drum will start turning.

11. Turn speed control knob to desired RPM.

12. Drum will stop when time runs out.

13. Turn off motor, jog drum until opening is in upright position. NEVER TURN DRUM BY HAND.

14. Turn valve handle to open position Parallel with valve body to release vacuum. Remove drum lid.

15. Remove product from drum.

16. Unplug machine and refer to cleaning instructions.

3

CLEANING

ROTATING DRUM

TO AVOID PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Cleaning or Servicing.

ONLY Use Recommended Cleaning Equipment, Materials and Procedures.

NEVER Spray Water or Other Liquid Substances Directly at Motor, Power Switch or any Other

Electrical Components.

ALWAYS Thoroughly Clean Equipment at Least Daily.

DO NOT Use Harsh Chemicals, Scouring Pads or Cleansers. Ordinary Liquid Detergent for

Manual Dish Washing or Pot/Pan Washing Will Not Harm the Machine. Dish Machine

Chemicals Will Cause Brown Stains, as will Chlorine Bleach and Similar Products if Allowed

to Stand in or on the Machine for Any Length of Time.

CLEANING THE BIRO VACUUM TUMBLER:

1. Turn “OFF”, unplug machine from power source, and perform lockout/tagout procedures.

2. The drum, drum lid, and gasket can be removed and washed in utensil sink. Be sure to flush the vacuum

valve on drum with warm soapy water and rinse with clean water thoroughly. The drum, drum lid, and

gasket should be sanitized with an appropriate sanitizer approved by your local Health Dept. All parts should

be air dried before reassembly and storage.

3. The exterior of the tumbler base and drum can be pressure washed with the same type soap solution followed

by a rinse water wiping.

4. If food stains are not removed, use a product such as “Bon Ami” or “Soft Scrub”. Be sure to scrub with the

grain of the Stainless Steel with a soft cloth or sponge.

5. Streaks or water spots can usually be removed with a solution of vinegar and water.

4

MAINTENANCE

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Servicing.

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

PROMPTLY REPLACE Any Worn or Illegible Labels.

USE ONLY GENUINE BIRO Parts and Accessories Properly Installed.

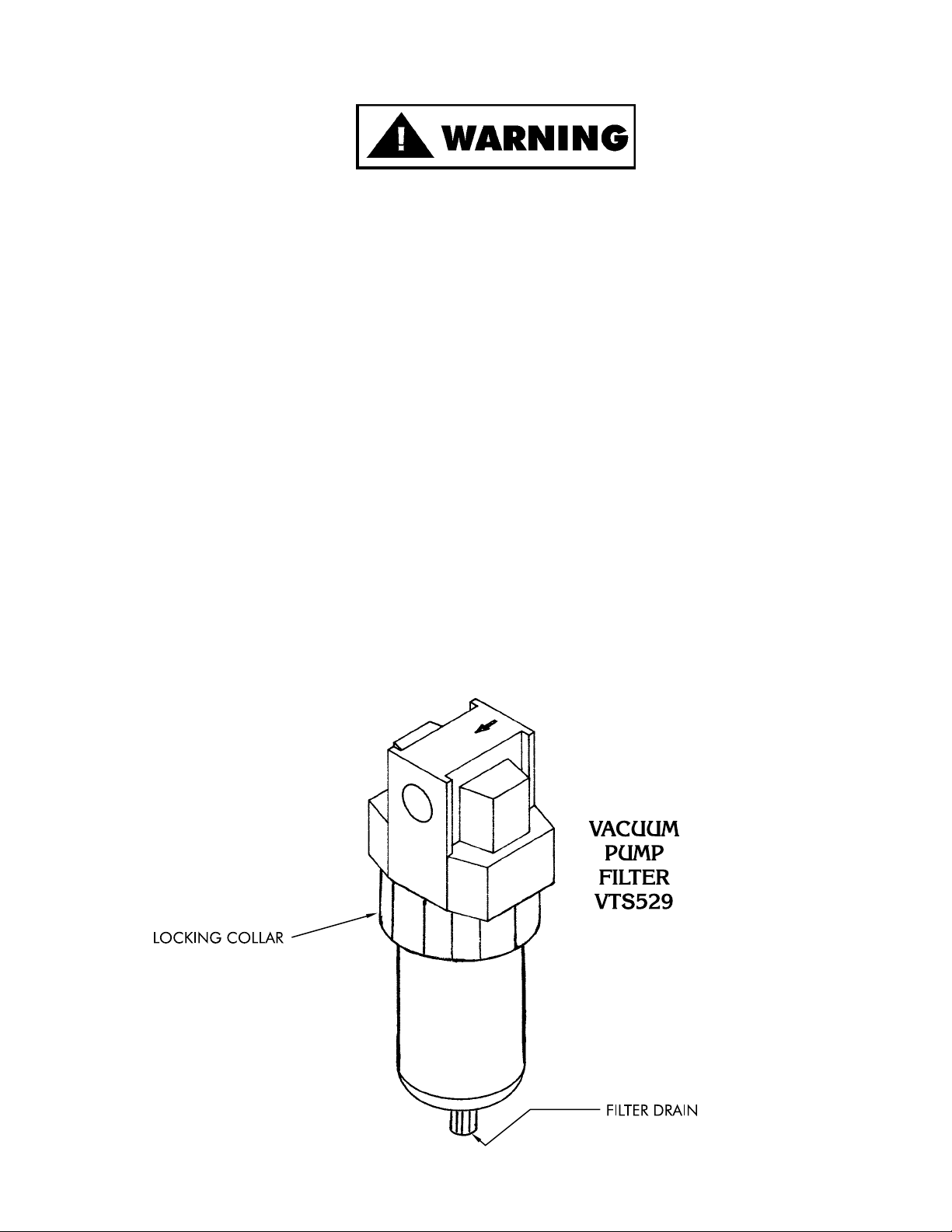

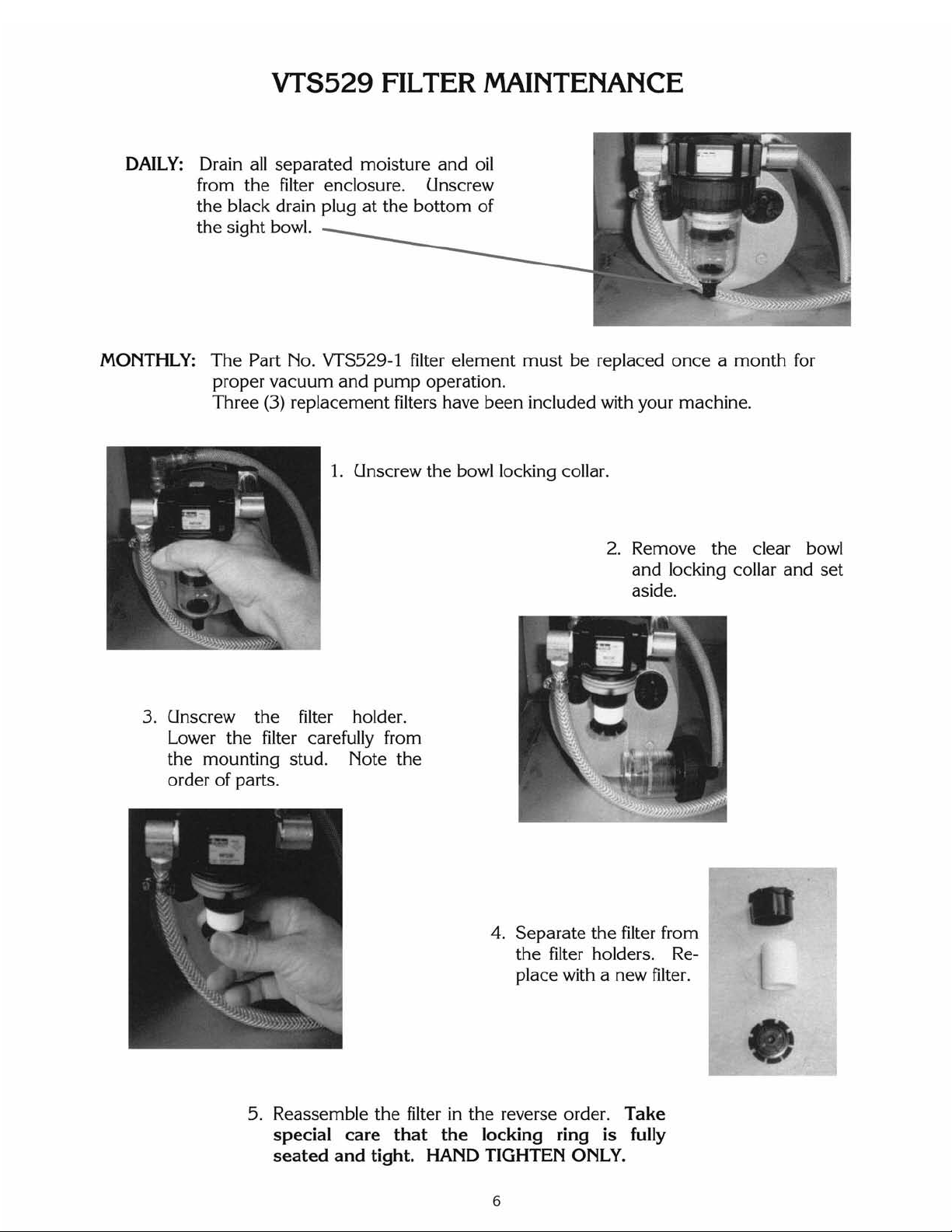

A. PUMP FILTER No. VTS529

1. Check filter daily. Filter must be drained before the separated moisture and oil reaches the bottom of the

lower black baffle. Drain by unscrewing the black drain plug in bottom of sight bowl.

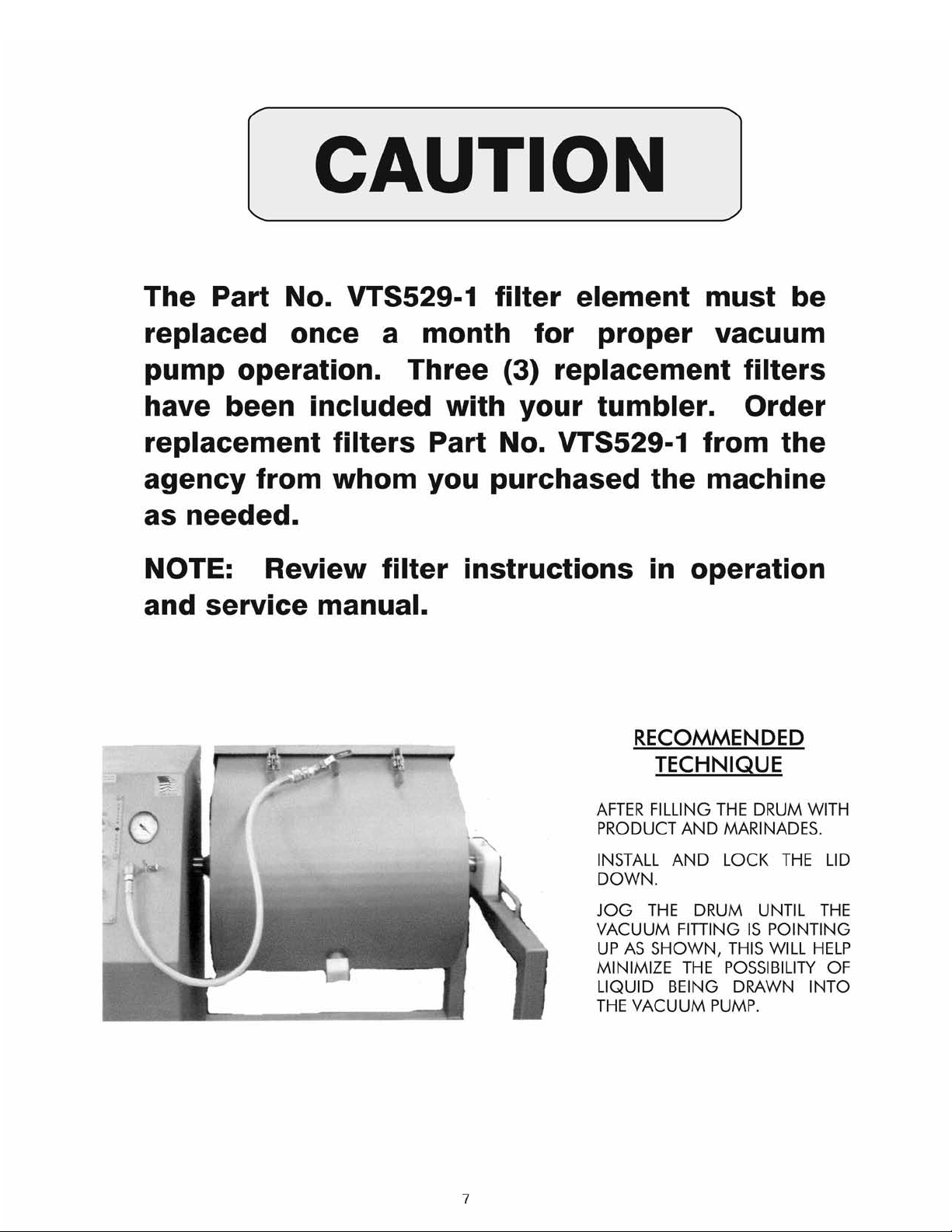

2. The filter element No. VTS529-1 should be removed and cleaned monthly.

a. Unscrew the black locking collar.

b. Remove bowl and locking collar.

c. Unscrew the black baffle at the bottom of the filter.

d. Clean bowl and filter element. Reinstall the filter element. Clean bowl with mild soap and water only. Do

not use detergents, cleansing agents, such as acetone, alcohol, benzene or gasoline, which are damaging

to plastic.

e. Lubricate bowl lip to assist initial sealing. Use only mineral based oils or grease. Do not use synthetic oils

or silicones.

5

Loading...

Loading...