Page 1

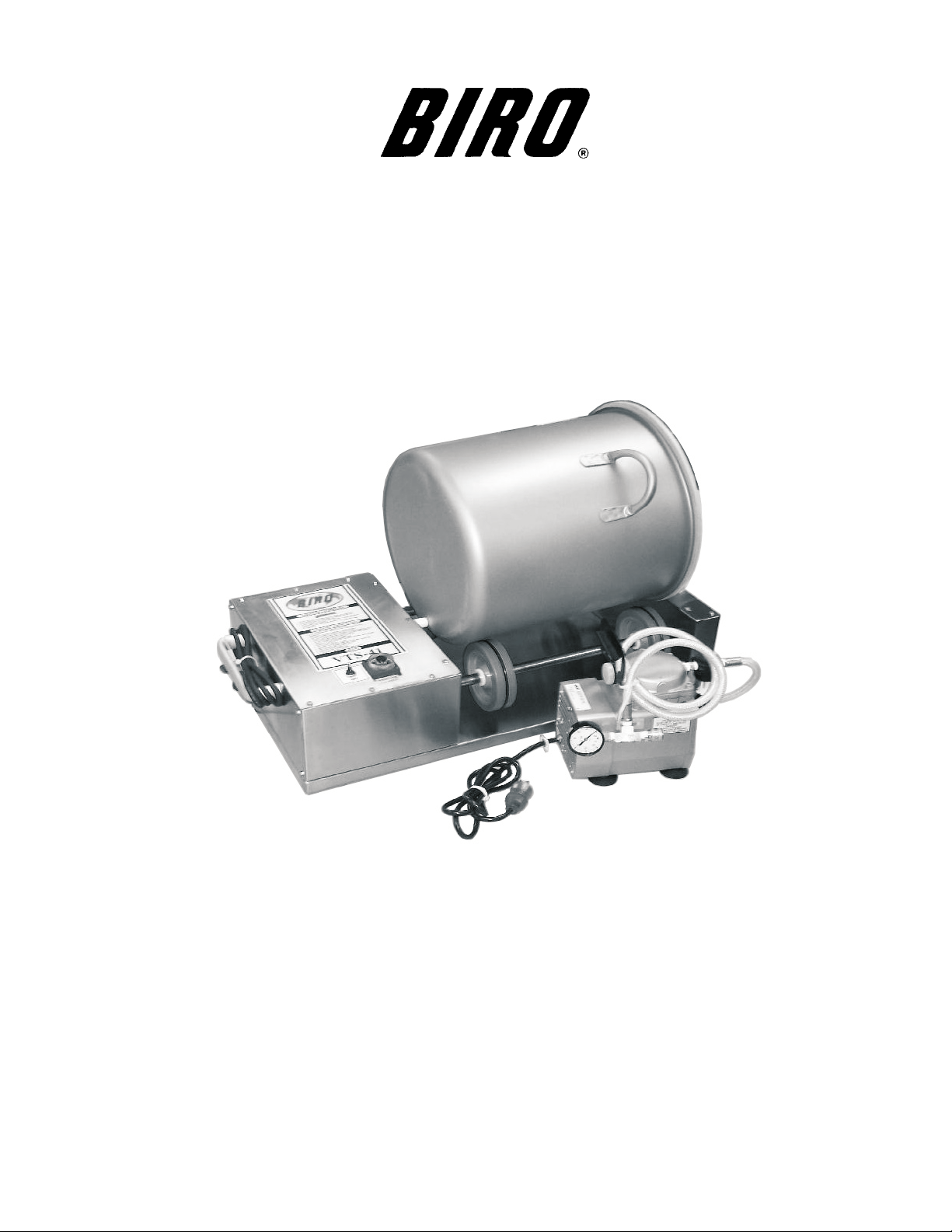

VACUUM TUMBLER

OPERATION MANUAL & PARTS LIST

MODEL VTS-41

REMOTE PUMP

MODEL VTS-42

INTERNAL PUMP

The BIRO VTS-41 & VTS-42 VACUUM TUMBLERS are versatile machines used for

vacuum tumbling all types of meats. The BIRO VTS-41 & VTS-42 produce equally

impressive results with beef, pork, poultry and fish.

The units are both easy to clean and maintain as well as sanitary in design and construction. The entire machine is built to give many years of trouble free service while

providing a unique line of marinated products for your customers.

The BIRO VTS-41 & VTS-42 have the following agency approval:

ULc (U.S. & CANADA)

Page 2

TABLE OF CONTENTS

Page

NOTICETOOWNERSANDOPERATORS......................................... 1

SAFETYTIPS............................................................... 2

OPERATION................................................................ 3

TOPROCESSPRODUCT.................................................... 3

OPERATIONOFVTS-41ONLY ............................................... 4

OPERATIONOFVTS-42ONLY ............................................... 5

VTS-41PARTSDIAGRAMS ................................................. 6&7

VTS-42PARTSDIAGRAMS ................................................. 8&9

VACUUM PUMP OPERATING AND MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . 10

INLETFILTEROPERATIONANDSERVICE ........................................11

VTS-41WIRINGDIAGRAM.................................................12&13

VTS-42WIRINGDIAGRAMS....................................................14

GENERALMAINTENANCE.....................................................15

CLEANING.................................................................16

OPERATOR'SSIGNATUREPAGE................................................17

LIMITEDWARRANTY.........................................................18

NOTICE TO OWNERS AND OPERATORS .................................................. 1

SAFETY TIPS .............................................................................. 2

OPERATION .............................................................................. 3

TO PROCESS PRODUCT ................................................................. 3

OPERATION OF VTS-41 ONLY ........................................................... 4

OPERATION OF VTS-42 ONLY ........................................................... 5

INSTRUCTIONS FOR PULLING A VACUUM ................................................ 6

OPERATOR’S NOTES ...................................................................... 7

VTS-41 PARTS DIAGRAMS ............................................................... 8, 9

VTS-42 PARTS DIAGRAMS ............................................................. 10-14

INLET FILTER OPERATION AND SERVICE ............................................ 12, 14

VACUUM PUMP OPERATION AND SERVICE ............................................. 15

VTS-41 WIRING DIAGRAM ............................................................ 16, 17

VTS-42 WIRING DIAGRAMS .............................................................. 18

GENERAL MAINTENANCE ............................................................... 19

CLEANING ............................................................................... 20

OPERATOR’S SIGNATURE PAGE ...........................................................21

LIMITED WARRANTY .....................................................................22

Page 3

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should be thoroughly familiar with the procedures contained in this Manual. Even so BIRO

cannot anticipate every circumstance or environment in which its products will be used. You, the

owner and operator, must remain alert to the hazards posed by the function of this equipment.

No one under eighteen (18) years of age should operate this equipment. If you are uncertain

about a particular task, ask your supervisor.

This Manual contains a number of safe practices in the SAFETY TIP section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

Warnings related to possible damage are indicated by:

BIRO also has provided warning labels on the equipment. If any warning label or Manual becomes misplaced, damaged, or illegible, please contact your nearest Distributor or BIRO directly

for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

This Manual applies to Model VTS-41 with Serial Number 41100 and higher; Model VTS-42

with Serial Number 42100 and higher.

1

NOTICE TO OWNERS AND OPERATORS

OR

Page 4

SAFETY TIPS

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

ALWAYS Read Operation and Service Manual BEFORE Operating, Cleaning or Servicing.

ALWAYS Keep Hands Clear of the Rotating Drum and Other Moving Parts.

NEVER Attempt to Remove the Drum Lid Unless Vacuum Has Been Released and the Drum is

Positioned Vertically with the Lid at the Top.

NEVER Operate Vacuum Pump Unless Properly Connected to Tumbler Drum.

ONLY Operate Vacuum Pump in Recommended Vacuum Range (15-20 Inches of Mercury)

NEVER TO EXCEED 20 INCHES Hg.

ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

ONLY Install on Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away From

Children and Visitors.

DO NOT Store or Operate Machine in Meat Cooler.

DO NOT Allow Food Particles, Liquids or Any Other Foreign Material to Enter the Vacuum

Pump or Vacuum Hose.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Attempting to Unjam or Unclog, Cleaning or Servicing.

NEVER Leave Machine Unattended While Operating.

PROMPTLY REPLACE Any Worn or Illegible Warning and/or Instruction Labels.

USE ONLY BIRO Parts and Accessories Properly Installed.

NEVER Use the Motor Cover Plate for Preparing the Product.

2

Page 5

OPERATION

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

ONLY Properly Trained Personnel Should Use This Equipment.

ALWAYS Keep Hands Clear of the Rotating Drum and Other Moving Parts.

DO NOT Tamper With, Bypass, Alter, or Modify This Equipment in Any Way From Its Original

Condition.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine Before Cleaning, Servicing, or When Not In Use.

NEVER Leave Unattended While Operating.

DO NOT Store or Operate Machine in Meat Cooler.

NEVER Operate Without All Warning or Instruction Labels Attached.

NEVER Use the Motor Cover Plate for Preparing the Product.

A. FOOD HANDLING TO PREVENT CONTAMINATION

1. ALWAYS wash hands thoroughly with warm soap and water before and after handling raw fish, poultry or

meats.

2. ALWAYS clean and sanitize all utensils and surfaces that have been in contact with raw products.

3. ALWAYS store cold foods at or below 45 deg. F (7.2 deg. C).

B. TO PROCESS PRODUCT

1. Insert baffles into Stainless Steel drum. Be sure that baffles are fully engaged on mounting buttons.

2. Weigh product to be vacuum tumbled.

3. Refer to your ingredient chart for proper amount of marinade seasoning and water.

4. Place product, marinade and water into tumbler drum.

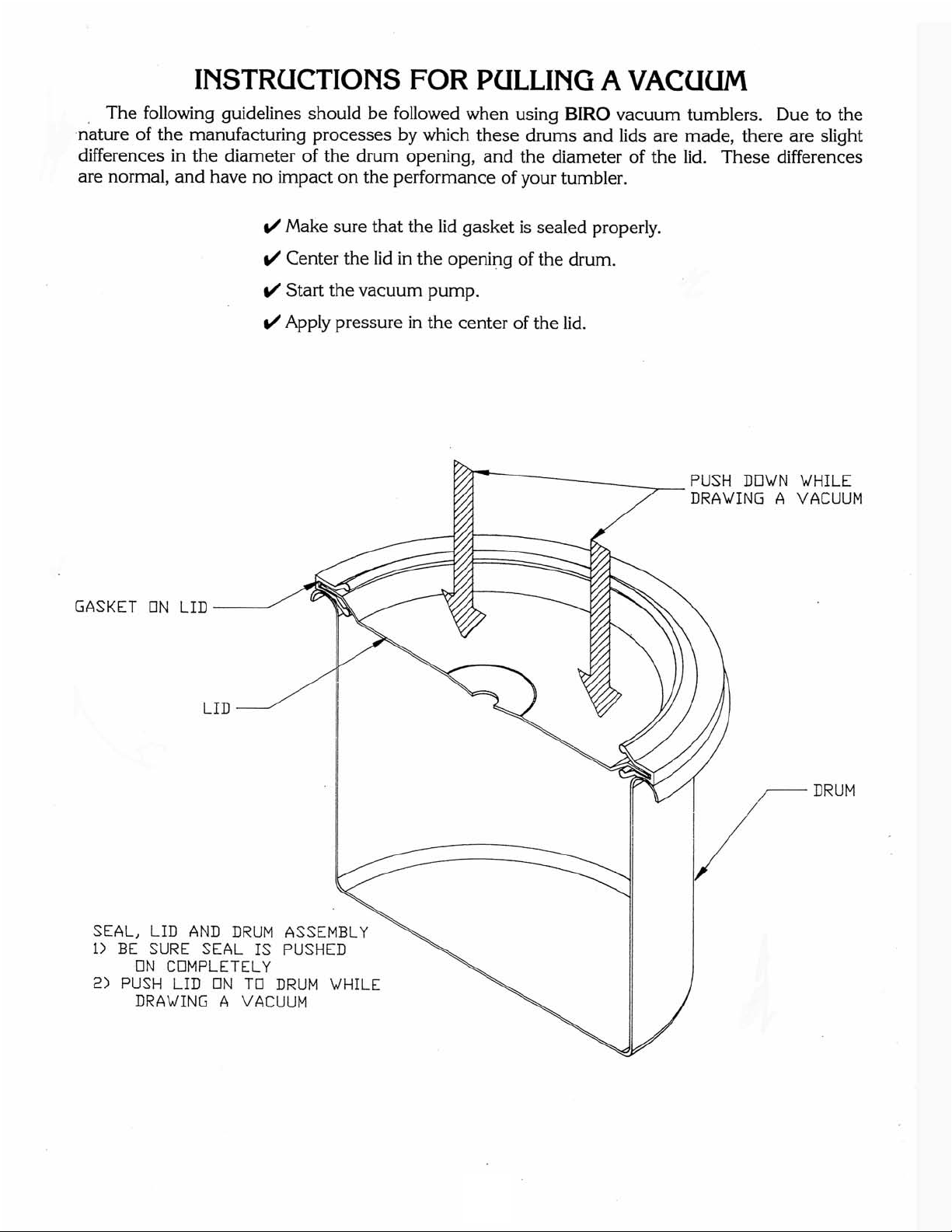

5. Install gasket on drum lid and place lid on drum.

6. Connect vacuum hose to valve on drum lid. Be sure valve handle is in the open position, parallel with the

valve body.

3

Page 6

OPERATION OF VTS-41 ONLY

7. Plug vacuum pump into a grounded 60HZ: 115 volt, 10 amp power source. Turn vacuum pump to “ON”

while pressing down on center of lid. (Vacuum gauge will start indicating a vacuum is being pulled in the

drum.) If needle in vacuum gauge does not indicate vacuum is being pulled, turn “OFF” vacuum pump and

disconnect vacuum hose from drum lid. Remove drum lid and check that the lid gasket is properly installed

and seated.

8. When vacuum gauge does indicate that a vacuum is being pulled, allow to continue running until gauge

reads between 15 and 20 inches Hg. NEVER EXCEED 20 Hg.

9. Close valve handle on drum lid, Perpendicular to valve body. Turn vacuum pump to “OFF” position and

unplug from power source. Remove vacuum hose from valve. Drum contents are now sealed in a vacuum.

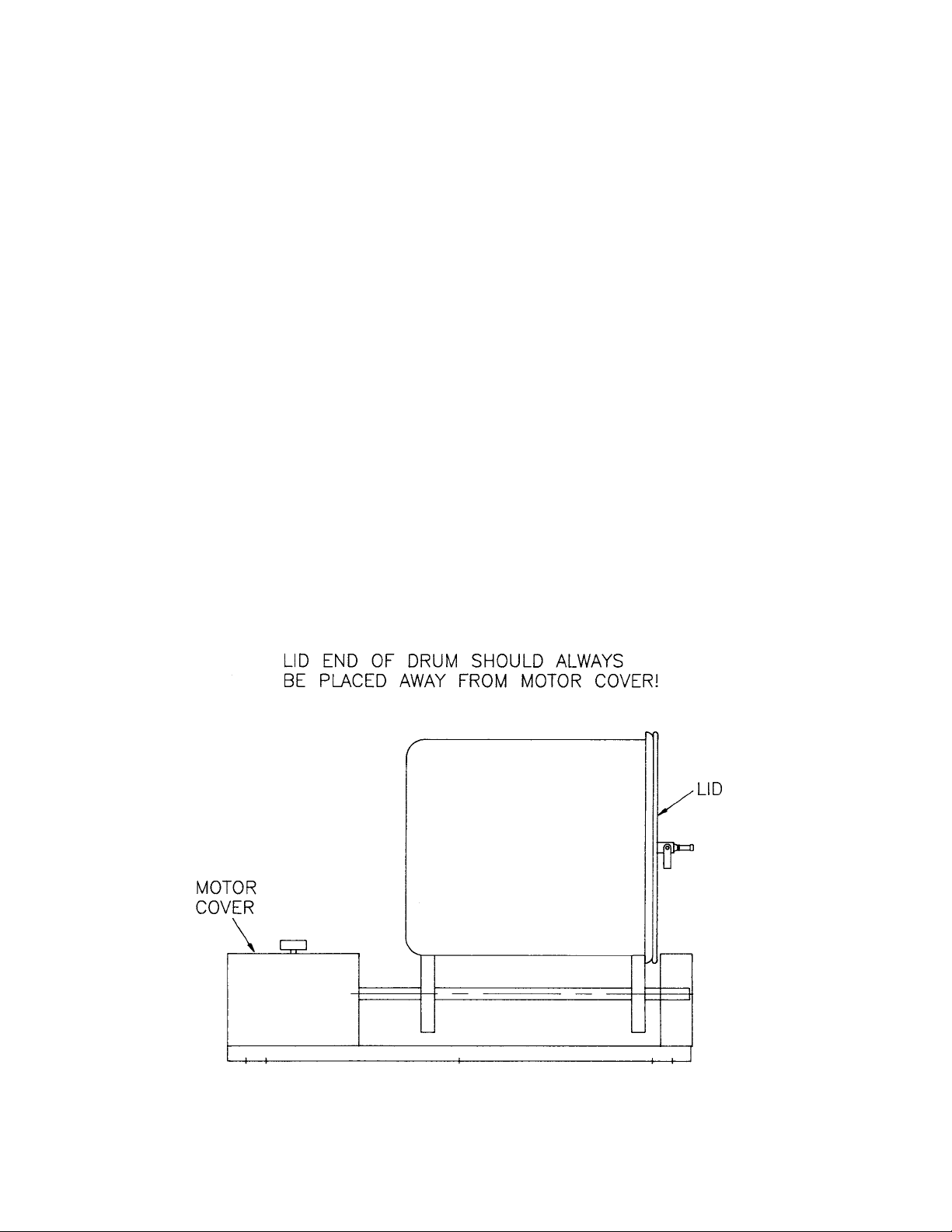

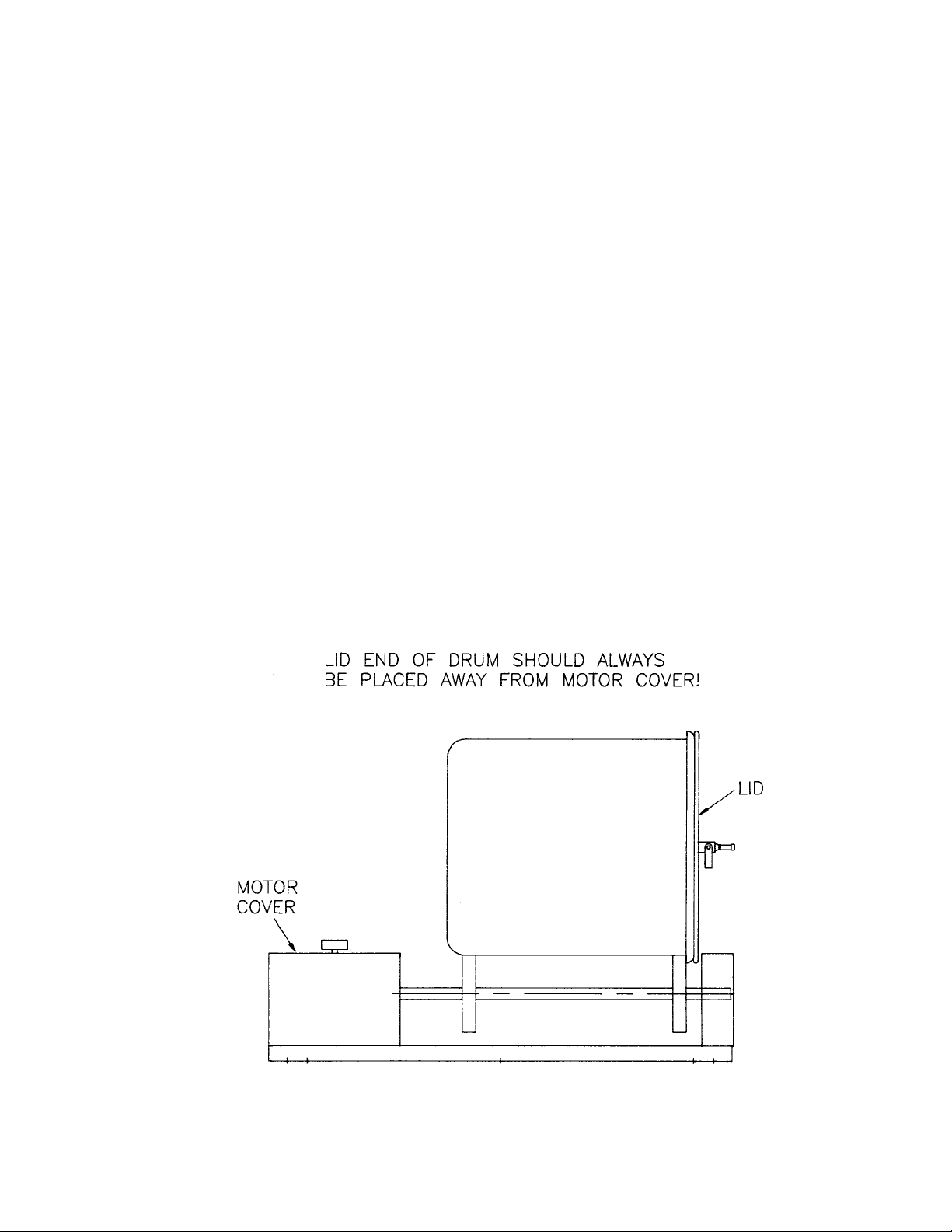

10. Lay drum horizontally on roller with lid end facing away from machine timer controls.

11. Plug tumbler motor into a grounded 60HZ, 115 volt, 10 amp power source.

12. Turn timer control dial to desired time, and turn toggle switch to "ON TIMER" position.

13. When drum stops, turn toggle switch to “OFF” position, unplug tumbler motor from power source.

14. Remove drum and place on table with lid up. Turn valve handle to open position Parallel with valve body to

release vacuum. Remove drum lid.

15. Remove product from drum.

4

Page 7

OPERATION OF VTS-42 ONLY

7. Plug tumbler power cord into a grounded 60HZ: 115 volt, 10 amp OR 50HZ: 220 volt, 5 amp power source.

Turn toggle switch to “VACUUM PUMP” while pressing down on center of lid. (Vacuum gauge will start

indicating a vacuum is being pulled in the drum.) If needle in vacuum gauge does not indicate vacuum is

being pulled, turn toggle to “OFF” and disconnect vacuum hose from drum lid. Remove drum lid and check

that the lid gasket is properly installed and seated.

8. When vacuum gauge does indicate that a vacuum is being pulled, allow to continue running until gauge

reads between 15 and 20 inches Hg. NEVER EXCEED 20 Hg.

9. Close valve handle on drum lid, Perpendicular to valve body. Turn toggle switch to “OFF” position. Remove

vacuum hose from valve. Contents are now sealed in a vacuum.

10. Lay drum horizontally on roller with lid end facing away from machine timer controls.

11. Turn timer control dial to desired time, and turn toggle switch to "ON TIMER" position.

12. When drum stops turn toggle switch to “OFF” position, unplug tumbler motor from power source.

13. Remove drum and place on table with lid up. Turn valve handle to open position Parallel with valve body to

release vacuum. Remove drum lid.

14. Remove product from drum.

5

Page 8

6

Page 9

– OPERATOR’S NOTES –

7

Page 10

VTS-41

IMPORTANT: Always Advise Model & Serial Number When Ordering Parts

6

Part

No. Description

155-1 Guide for 16" high drum

311-1 Rubber foot

HHS010S Hex head screw, 10-32

´

3

8

,SS

HHS035S Hex head screw,

1

4

-20

´

5

8

,SS

HN15S

1

4

-20 hex nut

HN20S Hex nut

5

16

-18 SS

LW10S Lock washer,

1

4

,SS

LW15S Lock washer

5

16

SS

VT402 Motor, HP,

1

25

115-60-1, 17.7RPM. 90:1

VT408 Flange bearing

VT411 Set collar

VT412 Rivet chain before serial no. 41322

VT412-1 Rivet chain after serial no. 41321

VT412ML Master link – spring clip

VT413 Sprocket

VT414-1 Guide for 15" high drum

VT438S Tumbler base plate

VT439S Sprocket & chain box less cover

VT441S Driving shaft

VT442S Driven shaft

Part

No. Description

VT443S Sprocket & chain cover

VT445S-1 Drive wheel, with O-ring

VT448S Label, VTS-41 control panel

VT449S Timer with pushbutton start, 0-50 minute

VT450S Timer socket

VT461S Motor box less cover

VT462S Motor box cover

VT474S Terminal strip, 4 circuit

VT478S Strain relief, 90 deg.

VT492S Timer without pushbutton start, 0-50 minute

VT740S O-ring

VTS7154 Oval handle

VTS7164 Toggle switch w/boot, ON-OFF

VTS7170 Power cord w/120V plug, 8’, 16/3

VTS7179 Toggle switch boot

WS005S Weld stud 8-32´¾, SS

WS012S Weld stud 10-32´½. SS

NOT SHOWN

VT418 Vacuum pump w/toggle, 110-60-1

VT479S Vacuum pump w/toggle, 220-50-1

p ,

VT740S O-ring

VTS7154 Oval handle

VTS7164 Toggle switch w/boot, ON-OFF

VTS7170 Power cord w/120V plug, 8’, 16/3

VTS7179 Toggle switch boot

WS005S Weld stud 8-32´¾, SS

WS012S Weld stud 10-32´½. SS

NOT SHOWN

VT418 Vacuum pump w/toggle, 110-60-1

VT479S Vacuum pump w/toggle, 220-50-1

VT513S Shaft Seal

8

Page 11

VTS-41

IMPORTANT: Always Advise Model & Serial Number When Ordering Parts

7

Part

No. Description

VT418 Vacuum pump w/toggle, 110V-60-1

VT422 Vacuum gauge

VT435 Coupler,

1

4

MPT

VT436 Tee,

14141

4

´´

FPT, brass

VT437 Hose, 5’ with

1

4

MPT crimped ends

VT447S Hex nipple,

1

4

NPT

VT479S Vacuum pump w/toggle, 220V-50-1

VTS7121 Inlet filter

Part

No. Description

VT415S-2 Drum & lid assembly, SS with

guide 155-1

VT425S Baffle only for 15" high drum

VT425S-1 Baffle only for 16" high drum

VT428S-2 Drum with baffles & guide

155-1

VT429S-2 Drum only, without baffles but

with guide 155-1

VT430S-1 Lid assembly with ball valve

VT432S Welded boss SS

VT434S-1 Lid gasket

VT453S Nipple only

VT454S Ball valve only

9

Page 12

VTS-42

IMPORTANT: Always Advise Model & Serial Number When Ordering Parts

8

Part

No. Description

155-1 Guide for 16" high drum

311-1 Rubber foot

HHS010S Hex head screw, 10-32

´

3

8

,SS

HHS035S Hex head screw,

1

4

-20

´

5

8

,SS

HHS049S Hex head screw

5

16

-18´½SS

HN15S

1

4

-20 Hex nut

HN20S Hex nut

5

16

-18 SS

LW10S Lock washer,

1

4

,SS

LW15S Lock washer

5

16

SS

VT402 Motor, HP,

1

25

115-60-1, 17.7RPM. 90:1

VT408 Flange bearing

VT411 Set collar

VT412 Rivet chain before serial no. 42563

VT412-1 Rivet chain after serial no. 42562

VT412ML Master link – spring clip

VT413 Sprocket

VT414-1 Guide for 15" high drum

VT421 Muffler

VT438S Tumbler base plate

VT439S Sprocket & chain box less cover

VT440S Motor & pump box less cover

VT441S Driving shaft

VT442S Driven shaft

VT443S Sprocket & chain cover

VT444S Motor & pump cover

VT445S-1 Drive wheel, with O-ring

VT449S Timer with pushbutton start, 0-50 minute

VT450S Timer socket

Part

No. Description

VT453S Nipple quick release ¼ MPT – brass

VT464S Label, filter

VT467S Label, VTS-42 control panel

VT468S Elbow 45°´¼´¼FPT–SS

VT470S Elbow, 90 deg.,

1

4

FPT, SS

VT474S Terminal strip, 4 circuit

VT476S Toggle switch w/boot, ON-OFF-ON

VT477S Sight window

VT478S Strain relief, 90 deg.

VT481S Lock knob

VT482S Access door

VT487S Coupling

1

4

FPT brass

VT488S Nipple 6"

´

1

4

MPT brass

VT488S-1 Nipple 6½"´¼ MPT – brass

VT491S Ventilation fan

VT492S Timer without pushbutton start, 0 – 50 minute

VT498S Bushing ¼ MPT

´

1

8

FPT – brass

VT740S O-ring

VTS7154 Oval handle

VTS7160 90° street

1

4

MPT

´

1

4

FPT brass

VTS7162 Vacuum pump, 115-60-1

VTS7162-50 Vacuum pump, 220-50-1

VTS7170 Power cord w/120V plug, 8’, 16/3

VTS7179 Toggle switch boot

VTS7209 Spring clip holder

WS005S Weld stud 8-32´¾, SS

WS012S Weld stud 10-32´½. SS

WW15S Washer – SS

Part

No. Description

VT453S Nipple quick release ¼ MPT – brass

VT464S Label, filter

VT467S Label, VTS-42 control panel

VT468S Elbow 45°´¼´¼FPT–SS

VT470S Elbow, 90 deg.,

1

4

FPT, SS

VT474S Terminal strip, 4 circuit

VT476S Toggle switch w/boot, ON-OFF-ON

VT477S Sight window

VT478S Strain relief, 90 deg.

VT481S Lock knob

VT482S Access door

VT487S Coupling

1

4

FPT brass

VT488S Nipple 6"

´

1

4

MPT brass

VT488S-1 Nipple 6½"´¼ MPT – brass

VT491S Ventilation fan

VT492S Timer without pushbutton start, 0 – 50 minute

VT498S Bushing ¼ MPT

´

1

8

FPT – brass

VT740S O-ring

VTS7154 Oval handle

VTS7160 90° street

1

4

MPT

´

1

4

FPT brass

VTS7162 Vacuum pump, 115-60-1

VTS7162-50 Vacuum pump, 220-50-1

VTS7170 Power cord w/120V plug, 8’, 16/3

VTS7179 Toggle switch boot

VTS7209 Spring clip holder

WS005S Weld stud 8-32´¾, SS

WS012S Weld stud 10-32´½. SS

WW15S Washer – SS

VT513S Shaft Seal

10

Page 13

VTS-42

11

Page 14

12

Page 15

13

Page 16

VTS-42

Taking special care that the sight bowl is fully seated and locked.

14

Page 17

15

Page 18

VTS-41

WIRING DIAGRAM

IMPORTANT: Always Advise Model & Serial Number

12

TIMER

CONNECTIONS 2, 7 – COIL

CONNECTIONS (3, 1) (8, 6) N.O. CONTACTS

16

Page 19

VTS-41

WIRING DIAGRAM

FOR VARIABLE SPEED

IMPORTANT: Always Advise Model & Serial Number

13

TIMER

CONNECTIONS 2, 7 – COIL

CONNECTIONS (3, 1) (8, 6) N.O. CONTACTS

17

Page 20

VTS-42

WIRING DIAGRAM

IMPORTANT: Always Advise Model & Serial Number

14

TIMER: INTERVAL MODE – 50 MINUTES

CONNECTIONS 2, 7 – COIL, 24 – 240 VAC

CONNECTIONS (3, 1) (8, 6) N.O. CONTACTS

TIMER: INTERVAL MODE – 50 MINUTES

CONNECTIONS 2, 7 – COIL, 24 – 240 VAC

CONNECTIONS (3, 1) (8, 6) N.O. CONTACTS

18

Page 21

GENERAL MAINTENANCE

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Servicing.

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

PROMPTLY REPLACE Any Worn or Illegible Labels.

USE ONLY GENUINE BIRO Parts and Accessories Properly Installed.

A. PUMP FILTER

1. Check filter daily. Filter must be drained before the separated moisture and oil reaches the bottom of the

lower filter element. Drain by unscrewing the black drain plug in bottom of sight bowl.

2. The filter element should be removed and cleaned monthly.

a. Unscrew clear threaded bowl.

b. Unscrew filter element assembly.

c. Clean bowl and filter element. Reassemble or replace filter element. Clean bowl with mild soap and water

only. Do not use detergents, cleansing agents, such as acetone, alcohol, benzene or gasoline, which are

damaging to plastic.

d. Lubricate or replace bowl gasket to assist initial sealing. Use only mineral based oils or grease. Do not

use synthetic oils or silicones.

e. Screw bowl into body of filter. Close black drain plug.

B. VACUUM PUMP

WARNING: THE MOTOR IS THERMALLY PROTECTED AND CAN AUTOMATICALLY RESTART WHEN THE

OVERLOAD RESETS. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING. PERSONAL

INJURY COULD BE THE RESULT.

1. Do not at any time lubricate any parts of the vacuum pump with oil, grease or petroleum products or clean

with acids, caustics or chlorinated solvents. Never allow the diaphram to contact any petroleum products.

This can reduce greatly the service life of the vacuum pump.

2. To clean or replace the internal filters and/or rubber gasket. Remove the five screws in the top of the pump.

The filter and gasket are located beneath this top plate. Remove the filters and wash them in solvent and

blow off with air or replace. The gasket may be cleaned with water. Replace the filters in proper position and

replace the gasket. The gasket and top plate will fit in one position only.

3. To replace the diaphram, remove the socket cap screws from the head of the pump. The diaphram is held in

place by two phillips head screws. Remove screws, retainer plate and diaphram. The diaphram will fit in any

position on the connecting rod. Replace the plate and the two phillips head screws. Torque to 30 inch

pounds.

CAUTION: DO NOT RAISE ANY BURRS OR NICKS ON THE HEADS OF THESE SCREWS. THESE

BURRS COULD CAUSE DAMAGE TO THE INLET VALVE.

15

19

Page 22

CLEANING

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Cleaning or Servicing.

ONLY Use Recommended Cleaning Equipment, Materials and Procedures.

NEVER Spray Water or Other Liquid Substances Directly at Motor, Power Switch or any Other

Electrical Components.

ALWAYS Thoroughly Clean Equipment at Least Daily.

DO NOT Use Harsh Chemicals, Scouring Pads or Cleansers. Ordinary Liquid Detergent for Manual Dish or Pot/Pan

Washing Will Not Harm the Machine. Harsh Machine Chemicals Will Cause Brown “Rusty” Stains, as will Chlorine

Bleach and Similar Products if Allowed to Stand in or on the Machine for Any Length of Time.

CLEANING THE BIRO VACUUM TUMBLER:

1. Turn “OFF”, unplug machine from power source,and perform lockout/tagout procedures.

2. The drum, drum lid, baffles in Stainless Steel drum and gasket can be removed and washed in utensil sink.

Be sure to flush the vacuum valve with warm soapy water and rinse with clean water thoroughly. The drum,

drum lid, baffles from Stainless Steel drum and gasket should be sanitized with an appropriate sanitizer

approved by your local Heath Dept. All parts should be air dried before reassembly and storage.

3. The exterior of the tumbler base can be wiped down with the same type soap solution followed by a rinse

water wiping.

4. If food stains are not removed, use a product such as “Bon Ami” or “Soft Scrub”. Be sure to scrub with the

grain of the Stainless Steel with a soft cloth or sponge.

5. Streaks or water spots can usually be removed with a solution of vinegar and water.

16

20

Page 23

OPERATOR'S SIGNATURE PAGE

MY SIGNATURE ATTESTS THAT I HAVE COMPLETELY READ AND UNDERSTAND THIS MANUAL.

I REALIZE THAT THIS MACHINE, IF OPERATED CARELESSLY, CAN CAUSE SERIOUS INJURY TO

MYSELF AND OTHERS.

NAME (PRINT) SIGNATURE

SUPERVISOR’S

INITIALS

DATE

17

21

Page 24

LIMITED WARRANTY

WARRANTY: The BIRO Manufacturing Company warrants that the BIRO Vacuum Tumbler will be

free from defects in material and workmanship under normal use and with recommended service.

BIRO will replace defective parts, which are covered by this limited warranty, provided that the defective parts are authorized for return, shipping charges prepaid, to a designated factory for inspection and/or testing.

DURATION OF WARRANTY: The warranty period for all parts covered by this limited warranty is

one (1) year from inspection/demonstration advised on returned warranty registration card, or

eighteen (18) months from original factory shipping date, whichever occurs first, except as noted

below.

PARTS NOT COVERED BY WARRANTY: The following are not covered by this limited warranty:

VTS7121 vacuum pump inlet filter, VT434S-1 drum lid gasket, and VT454S ball valve on drum lid.

This limited warranty does not apply to machines sold as used, rebuilt, modified, or altered from

the original construction in which the machine was shipped from the factory. Water contaminated

electrical systems and vacuum pump are not covered under this limited warranty. BIRO is not responsible for electrical connection of equipment, adjustments to switch components or any other

electrical requirements, which must be performed only by a certified electrician. BIRO is not responsible for service charges or labor required to replace any part covered by this limited warranty

or for any damages resulting from misuse, abuse, lack of proper or recommended service.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no warranties

other than those expressly stated in this limited warranty. THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR PROCESSING OF FOOD PRODUCTS, AND ALL OTHER IMPLIED WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT

LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE

REMEDIES PROVIDED IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S SOLE AND EXCLUSIVE REMEDIES AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete the warranty registration card supplied with each machine. The warranty registration card must be returned to The Biro Manufacturing Company for proper registration. If no warranty registration card is returned to BIRO, the

warranty period will begin from the date the machine was originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the agency from whom you purchased the machine; or

2. Consult the yellow pages of the phone directory for the nearest authorized dealer; or

3. Contact Biro Mfg. Company for the nearest authorized service entity (250 plus worldwide) in

your area.

THE BIRO MANUFACTURING COMPANY

1114 Main Street

Marblehead, Ohio 43440-2099

Ph. 419-798-4451

Fax 419-798-9106

E-mail: service@birosaw.com

Web: http://www.birosaw.com

18

ITEM NO. VT480S-274

Form No. VTS41/42-274-10-04-4 COMM

ITEM NO. VT480S-274

Form No. VTS41/42-274-7-08-5 PPD

22

Loading...

Loading...