Page 1

SIR STEAK

MODEL PRO-9

MODEL PRO-9

with Solid State Relay

with Solid State Relay

Operation and Service Manual

Operation and Service Manual

Starting with Serial Number 30,000

Starting with Serial Number 30,000

Tenderizer Parts List

Biro Designed Biro Built

+

IMPORTANT NOTICE

This Manual contains important

safety instructions which must

be strictly followed when using

this equipment.

+

T3400-091

Part No.

2-09-37

1-06-38

Page 2

TABLE OF CONTENTS

Page

NOTICETOOWNERSANDOPERATORS......................................... 1

SAFETYTIPS............................................................... 2

INSTALLATION ............................................................. 3

OPERATION................................................................ 4

TOPROCESSPRODUCT ................................................ 4

TOUNJAMORUNCLOG................................................. 5

CLEANING................................................................. 6

CLEANINGTHESAFETYCOVERANDCASE................................. 6

CLEANINGTHECRADLEANDBLADEASSEMBLIES........................... 6

MAINTENANCE .............................................................13

WIRINGDIAGRAMS........................................................15-16

PARTSDIAGRAMS...........................................................17

PARTSLIST/ORDERING.......................................................27

OPERATOR’SSIGNATUREPAGE................................................30

LIMITEDWARRANTY.........................................................31

NOTICE TO OWNERS AND OPERATORS ..........................................1

SAFETY TIPS.......................................................................2

ALLATION.....................................................................3

INST

ERATION........................................................................4

OP

O PROCESS PRODUCT......................................................4

T

TO UNJAM OR UNCL

OG.....................................................5

CLEANING.........................................................................6

CLEANING THE SAFETY COVER AND CASE..................................6

MAINTENANCE....................................................................14

WIRING DIAGRAMS.......................................................... 16 & 17

PART

P

OP

LIMITED W

CLEANING THE CRADLE AND BLADE ASSEMBLIES..........................6

ASSEMBLY OF PRO-9 CRADLES...............................................9

S DIAGRAMS.................................................................. 18

ARTS LIST/ORDERING............................................................28

ERATOR’S SIGNATURE PAGE....................................................31

ARRANTY.............................................................. 32

Page 3

— NOTES —

Page 4

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should read and be thoroughly familiar with the procedures contained in this Manual. Even so,

BIRO cannot anticipate every circumstance or environment in which its products will be used.

You, the owner and operator, must remain alert to the hazards posed by the function of this equipment — particularly the SHARP ROTATING BLADES. No one under eighteen (18) years of age

should operate this equipment. If you are uncertain about a particular task, ask your supervisor.

This Manual contains a number of safe practices in the SAFETY TIPS section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

Warnings related to possible damage to the equipment are indicated by:

If any warning label, or Manual becomes misplaced, damaged, or illegible, please contact your

nearest Distributor or BIRO directly for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

This Manual applies to machines with serial number 30,000 and higher; to machines with redesigned SD gear box, serial number 52,902 and higher; and machines with redesigned heavy duty

gear box, serial number 52,884 and higher.

1

NOTICE TO OWNERS AND OPERATORS

OR

- NOTE -

A copy of this manual is included with each PRO-9 TENDERIZER

The descriptions and illustrations contained in this manual are not binding.

The manufacturer reserves the right to introduce any modification without

updating the manual.

Page 5

SAFETY TIPS

SHARP ROTATING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· NEVER Touch This Machine without Training and Authorization by Your Supervisor.

· ALWAYS Read Operation and Service Manual BEFORE Operating, Cleaning, or Servicing.

· ALWAYS Keep Hands Clear of Blades and Moving Parts.

· ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

· ONLY Install on Level, Non-Skid Surface in Clean, Well-Lighted Work Area Away from Children

and Visitors.

· DO NOT Tamper With, Bypass or Remove the Safety Cover, Interlock Switch, or Toggle

Switch.

· DO NOT Operate With the Safety Cover in Raised Position or Removed. Safety Cover MUST

Be Down During Operation.

· ONLY Operate Machine by Using the Machine’s ON/OFF Toggle Switch. ALWAYS Turn Off

Toggle Switch When Not in Use.

· DO NOT Wear Gloves While Operating.

· ALWAYS Turn Off and Unplug Machine From Power Source and Perform Lockout/Tagout

Procedures BEFORE Cleaning, Servicing, or Attempting to Unjam or Unclog.

· ALWAYS Wear Wire Mesh Safety Gloves When Touching or Handling Stew Cutter Attachments.

· NEVER Leave Machine Unattended While Running.

· PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

· USE ONLY BIRO Parts and Accessories Properly Installed.

2

Page 6

I. INSTALLATION

TO AVOID SERIOUS PERSONAL INJURY, PROPERLY INSTALL

EQUIPMENT IN ADEQUATE WORK AREA

· ALWAYS Use Qualified Technician and Electrician for Installation.

· ALWAYS Install Equipment in Work Area with Adequate Light and Space.

· ONLY Operate on a Solid, Level, Non-Skid Surface.

· NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

· NEVER Operate With Safety Cover in raised Position or Removed.

· NEVER Operate Without all Warnings Attached.

1. Read this Manual thoroughly before installation and operation. Do not proceed with installation and operation if

you have any questions or do not understand anything in this Manual. Contact your local Distributor, or BIRO

first.

2. Install machine on a level, solid, non-skid surface in a well-lighted work area away from children and visitors.

3. Machine must be properly grounded. Use a qualified electrician to install according to local building codes.

4. Make sure ON/OFF toggle switch is in “OFF” position.

5. Lower Safety Cover into operating position as shown in the picture on the front of this Manual.

6. Uncoil electrical cord and plug into specified, grounded outlet. (Specifications for this machine are found on the

plate located on the back of the case.)

7. With Safety Cover lowered into operating position, turn ON/OFF toggle switch to “ON” position. The blades will

begin to rotate. Make sure machine operates properly and is stable and secure on operating surface.

8. Raise Safety Cover to check safety interlock switch — machine should turn off.

9. Lower Safety Cover — machine should resume operating.

10. Turn toggle switch to “OFF” position.

11. Check placement of all warning labels. Machine is ready for trained operators to process product.

12. Contact your local distributor or BIRO directly if you have any questions or problems with the installation or

operation of the machine.

3

KEEP HANDS CLEAR OF SHARP ROTATING BLADES.

Page 7

II. OPERATION

SHARP ROTATING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· ONLY Properly Trained Pesonnel Should Use This Equipment.

· ALWAYS Keep Hands Clear of Blades and Other Moving Parts.

· NEVER Operate With Safety Cover in Raised Position or Removed. Safety Cover MUST Be

Down During Operation.

· DO NOT Tamper With, Bypass, or Remove Safety Cover, Interlock Switch, or Toggle Switch.

· ALWAYS Turn Off and Unplug Machine from Power Source and Perform Lockout/Tagout

Procedures Before Cleaning, Servicing, or Attempting to Unjam or Unclog.

· NEVER Leave Unattended While Running.

· ALWAYS Turn Off Toggle Switch When Not in Use.

· ONLY Operate Machine By Using ON/OFF Toggle Switch.

· DO NOT Wear Gloves While Running.

· ALWAYS Wear Wire Mesh Safety Gloves When Touching or Handling Stew Cutter Attachments

for Removal and Cleaning Purposes Only.

A. TO PROCESS PRODUCT

1. Have product prepared prior to using this machine by slicing to appropriate size.

NOTE: The dimensions of the feed slot in the Safety Cover are the maximum size of product which can be

processed.

2. Make sure Safety Cover is in the down position.

3. Turn ON/OFF toggle switch to “ON” position.

4. Insert the product through the feed slot in Safety Cover. Observe the processing through the Safety Cover.

5. Product will exit at machine output under Blade Assemblies.

4

DO NOT WEAR GLOVES WHILE OPERATING.

NEVER REACH OR GRAB FOR PRODUCT AT MACHINE

OUTPUT – ALLOW PRODUCT TO DROP AND FULLY CLEAR

ROTATING BLADES BEFORE REMOVING PRODUCT.

1. Have product prepared prior to using this machine by slicing to appropriate size.

NOTE A. The dimensions of the feed slot in the Safety Cover ar

which can be processed.

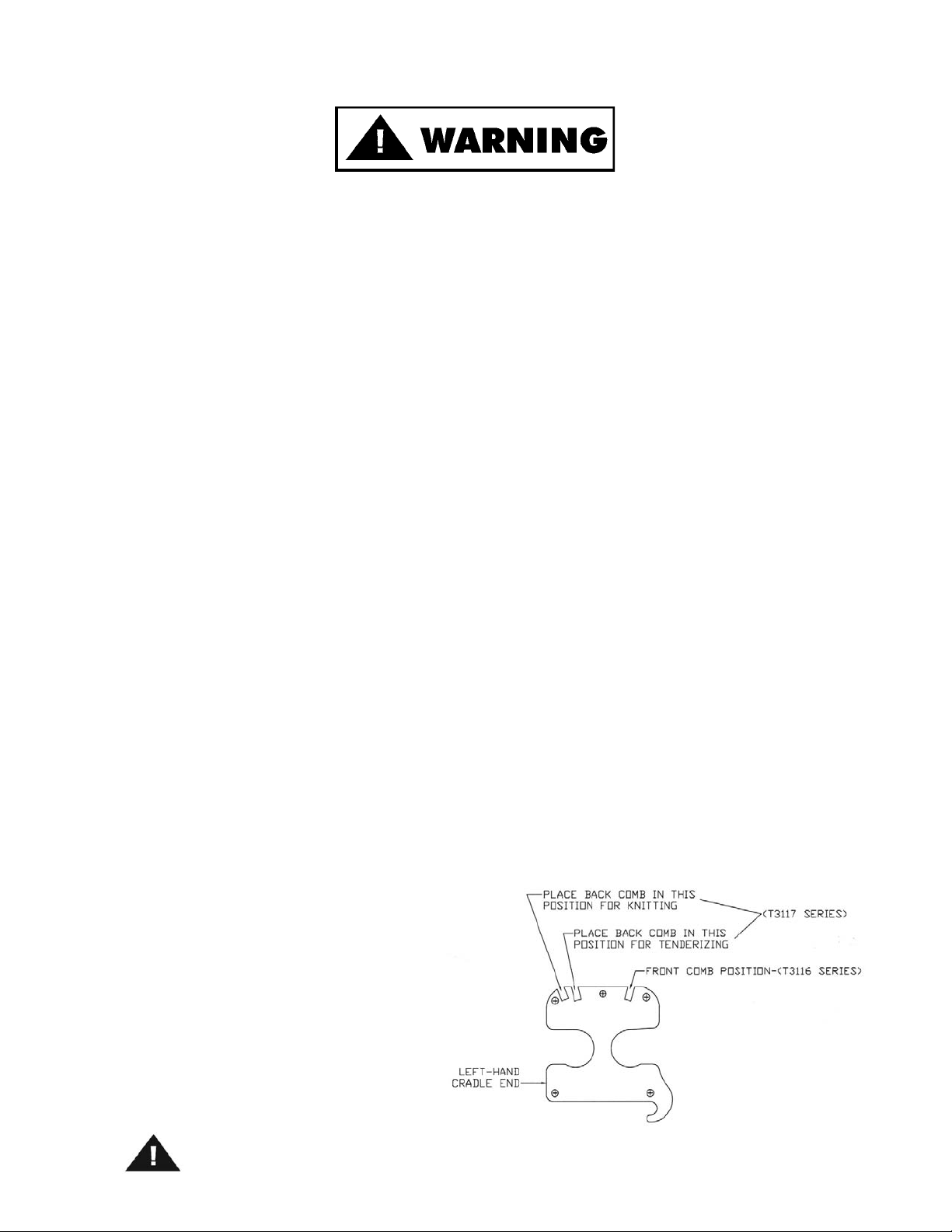

NOTE B. Position Rear Comb T3117 into one of the rear slots which is your processing requirement - tenderizing or knitting. See illustration below.

COMB POSITIONS FOR

TENDERIZING & KNITTING

e the maximum size of product

2. Make sure Safety Cover is in the down position.

DO NOT WEAR GLOVES WHILE OPERATING.

Page 8

DO NOT WEAR GLOVES WHILE OPERATING.

3. Turn ON/OFF toggle switch to “ON” position.

4. Insert the product through the feed slot in Safety Cover. Observe the processing through the Safety Cover.

5. Product will exit at machine output under Blade Assemblies.

NEVER REACH OR GRAB FOR PRODUCT AT MACHINE OUTPUT - ALLOW

PRODUCT TO DROP AND FULLY CLEAR ROTATING BLADES BEFORE

REMOVING PRODUCT.

6. Repeat procedure as necessary.

7. TURN MACHINE “OFF” BY MOVING TOGGLE SWITCH TO “OFF” POSITION WHEN FINISHED.

B. TO UNJAM OR UNCLOG

SHARP ROTATING BLADES

TO AVOID SERIOUS PERSONAL INJURY

• ALWAYS Keep Hands Clear of Blades and Moving Parts.

• ALWAYS Turn Machine “OFF” and Unplug From Power Supply and Perform Lockout/Tagout Procedures

BEFORE Attempting to Unjam or Unclog.

• NEVER Operate With Safety Cover in Raised Position or Removed. Safety Cover Must Be Down During

Operation.

• ALWAYS Wear Wire Mesh Safety Gloves When Touching or Handling Stew Cutter Attachments for

Removal and Cleaning Purposes Only.

1. If machine becomes jammed or clogged, turn ON/OFF toggle switch to “OFF” position and

UNPLUG machine from power source and perform lockout/tagout procedures.

ALWAYS WEAR WIRE MESH SAFETY GLOVES WHEN TOUCHING OR

HANDLING STEW CUTTER A

2. Raise Safety Cover.

nclog or unjam machine by disassembling Blade Assemblies following directions on pages 6 and 7 of

3. U

this manual.

TTACHMENTS.

DRIVE PINS MAY BE ENGAGED IN DRIVE COUPLING MAKING IT

DIFFICULT TO REMOVE CRADLE ASSEMBLY. CAREFULLY ROTATE DRIVE

BELT IN REVERSE TO DISENGAGE.

4. Reassemble machine according to directions on pages 9-13 of this Manual.

5. With Safety Cover lowered into operating position, plug machine into power source and resume normal

operation.

5

Page 9

III. CLEANING

SHARP ROTATING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· ALWAYS Turn Off and Unplug Machine from Power Source and Perform Lockout/Tagout

Procedures Before Cleaning or Servicing.

· ALWAYS Wear Wire Mesh Safety Gloves When Touching or Handling Stew Cutter Attachments

for Removal and Cleaning Purposes Only.

· ONLY Use Recommended Cleaning Equipment, Materials, and Procedures.

· ALWAYS Thoroughly Clean Equipment at Least Daily.

A. CLEANING SAFETY COVER AND CASE

1. BEFORE cleaning, turn toggle ON/OFF switch to “OFF” position and UNPLUG machine from power supply

and perform lockout/tagout procedures.

2. Raise Safety Cover and remove by sliding Cover to left and lifting off. Wash Safety Cover in a soapy bath of

120°-130°F and wipe with non-abrasive cloth.

3. Rinse thoroughly with hot water and allow to air dry.

4. Check to make sure all labels are intact and legible. Replace labels if they are worn or illegible.

B. CLEANING CRADLE AND BLADE ASSEMBLIES

1. Remove Cradle Assembly as follows:

a. While holding cradle safety lift handle with left hand, release Cradle Assembly lock on right end of Cradle

Assembly with right hand and slide Cradle Assembly to right.

b. Bring right end of Cradle Assembly forward first, then remove Cradle Assembly from machine.

2. Remove front wire comb by raising it by both ends and rolling it out in a forward motion.

Remove rear wire comb by raising it by both ends and rolling it out in a backward motion.

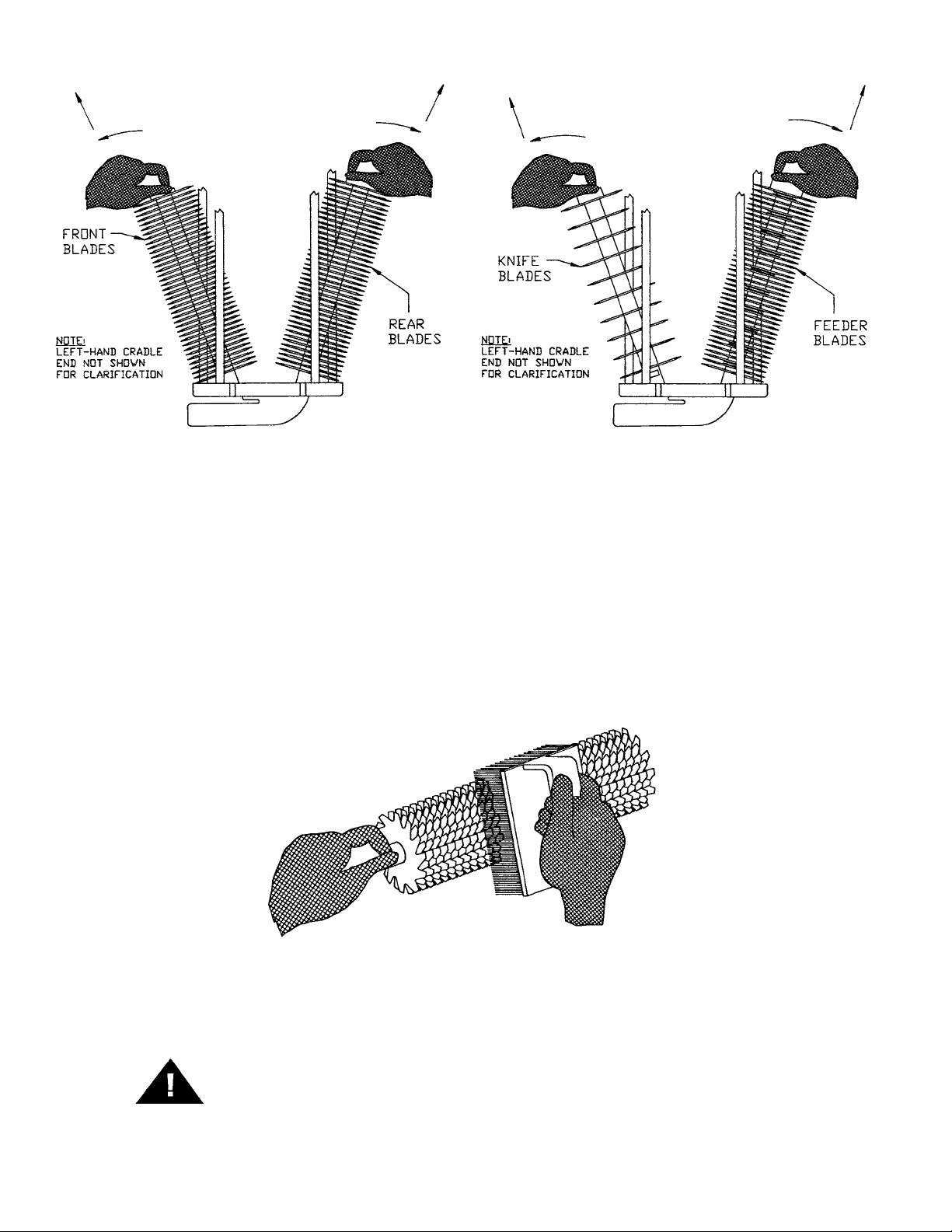

3. Next, remove the front and rear Blade Assemblies. Holding the drive coupling end of the front blade

assembly in your left hand, grasp the drive coupling end of the back blade assembly with your right hand.

Pivot both blade assemblies away from each other and slide the nylon bearing out of their pilot holes as

illustrated.

6

ALWAYS WEAR WIRE MESH SAFETY GLOVES WHEN

TOUCHING OR HANDLING STEW CUTTER ATTACHMENTS.

Page 10

4. With the parts disassembled, they should be cleaned and sanitized as follows:

7

STEP 1

Rinse Cradle Assembly, wire combs, and Blade

Assemblies in a water bath of 110°-115°F to loosen

particles.

STEP 2

Immerse all items in soapy bath of 120°-130°F and

clean using the BIRO Cleaning Brush, Part

#T3091-1

CLEANING TENDERIZER, SCORING, CUTLET AND STAR BLADE ASSEMBLIES

ALWAYS WEAR WIRE MESH SAFETY GLOVES WHEN

TOUCHING OR HANDLING STEW/STRIP CUTTER BLADE

ASSEMBLIES.

Page 11

8

CLEANING STEW/STRIP CUTTER BLADE ASSEMBLIES

ALWAYS WEAR WIRE MESH SAFETY GLOVES WHEN

TOUCHING OR HANDLING STEW/STRIP CUTTER BLADE

ASSEMBLIES.

Page 12

ASSEMBLY OF PRO-9 TENDERIZER, SCORING,

CUTLET AND STAR CRADLE ASSEMBLIES

NOTE: BIRO RECOMMENDS THE USE OF WIRE SAFETY CLEANING

GLOVES WHEN HANDLING CRADLE ASSEMBLIES.

STEP 1: Place the empty cradle on table top with plastic handle toward you, left hand cradle end away.

9

STEP 2:

Holding drive coupling end, insert back blade as-

sembly bearing #T3181-2, into large bearing hole on

right hand cradle end with bearing shoulder flat up.

Pivot shaft into the left hand cradle end slot.

STEP 4:

Holding the drive coupling end of the front blade

assembly in your left hand, grasp the drive coupling

end of the back blade assembly with your right hand

and pivot the rear tenderizer blades away from the

front knife blades.

STEP 5:

GENTLY pivot both blade assemblies together simultaneously. Make sure the front tenderizer blade

at the right hand cradle end is between the first two

rear tenderizer blades at the same end. Allow both

drive coupling ends to rest in the cradle supports.

NOTE:

STEP 3:

Holding drive coupling end, insert front blade as-

sembly #T3181-1, bearing slightly into small bearing

hole on right hand cradle end with bearing shoulder

flat up. CAUTION: DO NOT FORCE OR MAKE

CONTACT WITH REAR ASSEMBLY OR BOTTOM

OF CRADLE BAR OR BLADES WILL BE CHIPPED.

You must take extra care in this procedure

so as to match the back tenderizer blade as

sembly equally to the front cutting rollers in

the exact way it came from the factory. If as

sembled properly, no binding should occur

between the front and rear blade groups.

Page 13

ASSEMBLY OF PRO-9 TENDERIZER, SCORING, CUTLET

AND STAR CRADLE ASSEMBLIES (Cont.)

10

STEP 6:

Place back wire comb T3117 in right hand with

the short horizontal end away from you. Place the

comb finger closest to you (comb finger closest to

right hand cradle end) between the first two tenderizer blades on the back blade assembly.

STEP 7:

Place front wire comb T3116 in left hand with

short horizontal end away from you. Place the first

tenderizer blade (tenderizer blade closest to right

hand cradle end) between the first and second fin-

gers on the front comb. CAUTION: THERE

SHOULD BE NO COMB FINGERS BETWEEN THE

LEFT HAND CRADLE END AND THE KNIFE BLADE

NEXT TO IT.

STEP 8:

Unplug electrical cord. Holding the cutting group’s support handle, begin to insert the assembled cutting

group into PRO-9 Tenderizer. Open safety cover, insert coupling ends first and then rotate the right hand

cradle end back counter-clockwise onto the cutting group supports. Make sure coupling ends are locked into

the driving shafts and then pull down cradle lock lever to firmly secure the cutting group. Close safety cover,

plug in electrical cord, turn on toggle switch, and begin operation.

ASSEMBLY OF PRO-9 TENDERIZER, SCORING, CUTLET

AND STAR CRADLE ASSEMBLIES WITH WIRE

COMBS

STEP 7:

Place fr

horizontal end away from you. Place the comb finger

furthest end away from you (comb finger closest to left

handle cradle end) between the first two tenderizer

blades on the front blade assembly.

ont wire comb T3116 in left hand with short

CAUTION: THERE SHOULD BE NO COMB

FINGERS BETWEEN THE LEFT HAND CRADLE

END AND THE KNIFE BLADE NEXT TO IT.

Page 14

ASSEMBLY OF PRO-9 STEW/STRIP CUTTING CRADLES

12

STEP 6:

Place back comb T3117 in right hand with the

short horizontal end away from you. Place the comb

finger closest to you (comb finger closest to right

hand cradle end) between the first two feeder blades

on the back blade assembly.

CAUTION: IF COMB FINGERS ARE BENT OR DIS-

TORTED, REBEND SUSPECT COMB FINGER BACK

INTO POSITION USING THE COMB

STRAIGHTENER TOOL — PART No. TA3119.

STEP 7:

Place front comb T3116 in left hand with short

horizontal end away from you. Place the first knife

blade (knife blade closest to right hand cradle end)

between the second and third fingers on the front

comb. CAUTION: THERE SHOULD BE NO COMB

FINGERS BETWEEN THE LEFT HAND CRADLE

END AND THE KNIFE BLADE NEXT TO IT. Note:

this procedure varies upon using other stew blade as-

semblies with different spacing.

STEP 8:

Unplug the power cord then holding the cutting group’s support handle, begin to assemble completed

cutting group into PRO-9 Tenderizer. Open hopper cover, then assemble cutting group by inserting coupling

ends first and then rotating the right hand cradle end back counter-clockwise onto the cutting group sup

-

ports. Make sure coupling ends are locked into the driving shafts and then pull down plastic handle to firmly

secure the cutting group. Close hopper cover and begin operation.

ASSEMBLY OF PRO-9 TENDERIZER, SCORING, CUTLET

AND STAR CRADLE ASSEMBLIES WITH RIGID

RIGID

BACK

COMB

(T3117L)

Place back rigid comb T3117L in right hand with

the short horizontal end away from you. Place the

wide comb finger closest to you (wide comb finger

closest to right hand cradle end) between the last

tenderizer blade and right hand cradle end on the

back blade assembly.

COMBS

STEP 6:

STEP 7:

Place front rigid comb T3117L in left hand. With

short horizontal end away from you. Place the

wide comb finger closest to you (wide comb finger

closest to right hand cradle end) between the last

tenderizer blade and right hand cradle end on the

front blade assembly,

RIGID

FRONT

COMB

(T3116L)

STEP 8:

Unplug electrical cord. Holding the cutting group

group into PRO-9 Tenderizer. Open safety cover, insert coupling ends first and then rotate the right hand cradle end back counter-clockwise onto the cutting group supports. Make sure coupling ends are locked into the

driving shafts and then pull down the cradle lock lever to firmly secure the cutting group. Close safety cover,

plus in electrical cord, turn on toggle switch, and begin operation.

’s support handle, begin to insert the assembled cutting

11

Page 15

ASSEMBLY OF PRO-9 STEW/STRIP

CUTTING CRADLES

NOTE: BIRO RECOMMENDS THE USE OF WIRE SAFETY CLEANING

GLOVES WHEN HANDLING CRADLE ASSEMBLIES.

STEP 1: Place the empty cradle on table top with plastic handle toward you, left hand cradle end away.

11

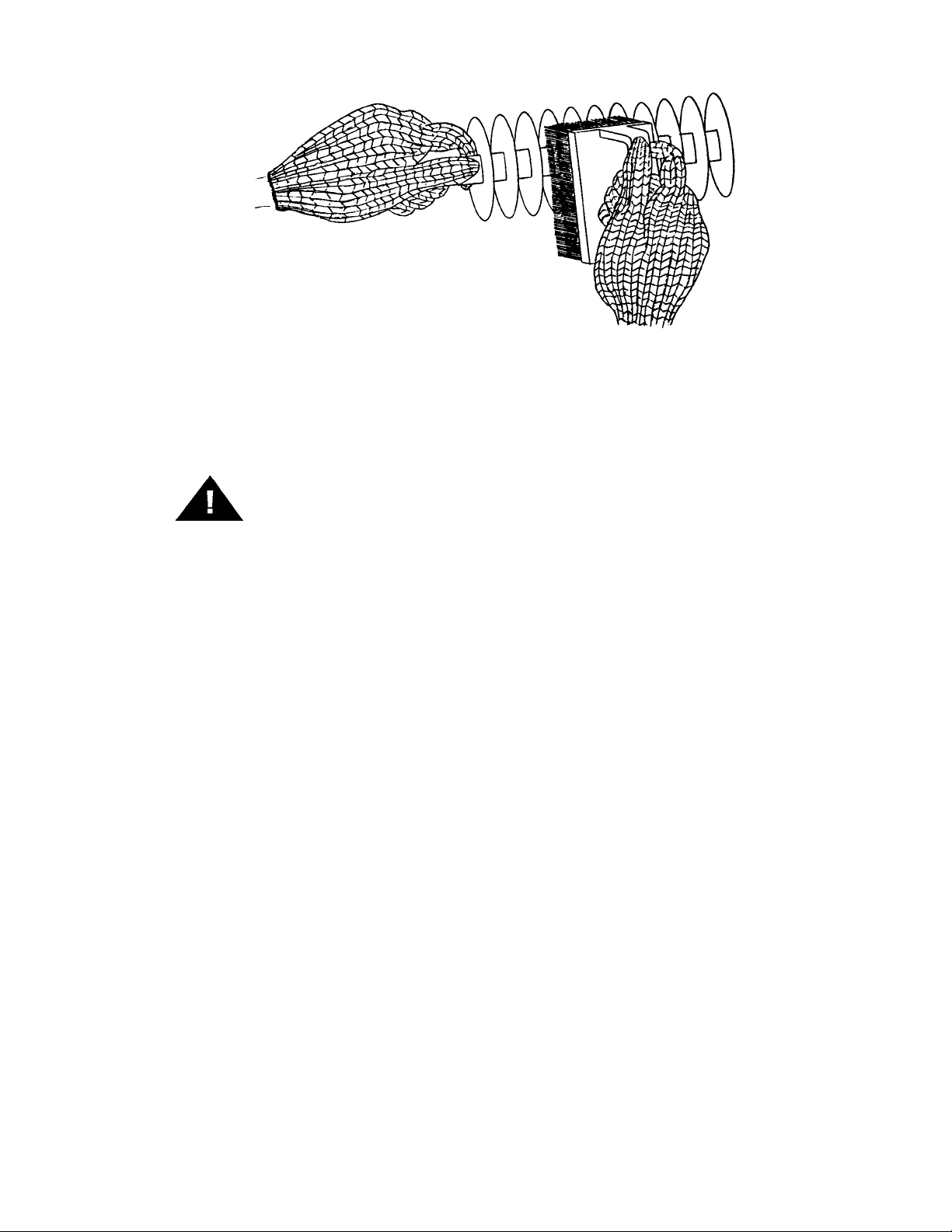

STEP 4:

Holding the drive coupling end of the front blade

assembly in your left hand, clutch the drive coupling

end of the back blade assembly with your right hand

and pivot the rear feeder blades away from the front

knife blades.

STEP 5:

For ¾² Stew Cradles

GENTLY pivot both blade assemblies together simultaneously. Make sure the knife blade at the right

hand cradle end is between the second and third

feeder blades at the same end. Note: other stew

blade assemblies with different spacing start at different points. Allow both drive coupling ends to rest in

the cradle supports. You must finish with the knife

blade between the last two feeder blades.

NOTE: You must take extra care in this procedure

so as to match the back feeder blade assem

bly equally to the front cutting rollers in the

exact way it came from the factory. If as

sembled properly, no binding should occur

between the front and rear blade groups.

STEP 3:

Holding drive coupling end, insert front blade as-

sembly T3181-1 bearing slightly into small bearing

hole on right hand cradle end with bearing shoulder

flat up. CAUTION: DO NOT FORCE OR MAKE

CONTACT WITH REAR ASSEMBLY OR BOTTOM

OF CRADLE BAR OR BLADES WILL BE CHIPPED.

STEP 2:

Holding drive coupling end, insert back blade as-

sembly T3181-2 bearing, into large bearing hole on

right hand cradle end with bearing shoulder flat up.

Pivot shaft into the left hand cradle end slot.

12

Page 16

ASSEMBLY OF PRO-9 STEW/STRIP CUTTING CRADLES

12

STEP 6:

Place back comb T3117 in right hand with the

short horizontal end away from you. Place the comb

finger closest to you (comb finger closest to right

hand cradle end) between the first two feeder blades

on the back blade assembly.

CAUTION: IF COMB FINGERS ARE BENT OR DISTORTED, REBEND SUSPECT COMB FINGER BACK

INTO POSITION USING THE COMB

STRAIGHTENER TOOL — PART No. TA3119.

STEP 7:

Place front comb T3116 in left hand with short

horizontal end away from you. Place the first knife

blade (knife blade closest to right hand cradle end)

between the second and third fingers on the front

comb. CAUTION: THERE SHOULD BE NO COMB

FINGERS BETWEEN THE LEFT HAND CRADLE

END AND THE KNIFE BLADE NEXT TO IT. Note:

this procedure varies upon using other stew blade assemblies with different spacing.

STEP 8:

Unplug the power cord then holding the cutting group’s support handle, begin to assemble completed

cutting group into PRO-9 Tenderizer. Open hopper cover, then assemble cutting group by inserting coupling

ends first and then rotating the right hand cradle end back counter-clockwise onto the cutting group sup

ports. Make sure coupling ends are locked into the driving shafts and then pull down plastic handle to firmly

secure the cutting group. Close hopper cover and begin operation.

13

Page 17

IV. MAINTENANCE

SHARP ROTATING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· ALWAYS Turn Off and Unplug Machine from Power Source and Perform Lockout/Tagout

Procedures Before Servicing.

· NEVER Touch This Machine Without Training and Authorization By Your Supervisor

· ALWAYS Keep Hands Clear of Blades and Moving Parts.

· DO NOT Tamper With, Bypass, or Remove the Safety Cover, Interlock Switch, or Toggle

Switch.

· ALWAYS Wear Wire Mesh Safety Gloves When Touching or Handling Stew Cutter or Stripper

Attachments for Removal and Cleaning Purposes Only.

· PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

· USE ONLY BIRO Parts and Accessories Properly Installed.

A. GENERAL

1. Machine should be generally inspected every time it is cleaned (at least daily) to ensure that it is in good

operating condition and has not been damaged or tampered with.

a. Safety Cover: The Safety Cover should be checked for cracks, gouges, or other damage. Replace if any

of these conditions exist.

b. Switches and Safety Interlock: All switches should be checked for proper operation. Check the rubber

cap nut on the toggle switch (Part #T3101-2) and the rubber cap nut on the interlock switch (Part

#T3105) for wear, tears, or damage. Replace if worn, torn, or damaged.

The Safety Cover interlock switch should be checked as follows:

i. Make sure ON/OFF toggle switch is in “OFF” position.

ii. Lower Safety Cover into operating position.

iii. Plug electrical cord into specified outlet.

iv. With Safety Cover lowered into operating position, turn ON/OFF toggle switch to “ON” position.

v. Raise Safety Cover to check safety interlock switch — machine should turn off.

vi. Lower Safety Cover — machine should resume operating.

vii. Turn toggle switch to “OFF” position. Unplug machine from power source and perform

lockout/tagout procedures.

13

KEEP HANDS CLEAR OF SHARP ROTATING BLADES.

14

Page 18

c. Cradle and Blade Assemblies: The blades and teeth of the Blade Assemblies should be checked for any

damage, including broken, bent, or missing teeth, or gouged or bent blades. Any damaged Blade

Assemblies should be replaced.

d. Machine Case: The machine case should be checked for damage beyond ordinary wear and tear. The

electrical cord should be checked for gouges, fraying, or other damage. Damaged cords should be

replaced.

e. Labels: The labels on the machine should be replaced if they are worn, torn, or illegible.

B. LUBRICATION

1. The Gear Box oil must be changed after the first four months of operation and, thereafter, at one-year

intervals.

2. The Motor has sealed bearings.

3. To change the Gear Box oil and to lubricate the Motor, follow these steps:

a. Remove the top of the case by removing the seven screws, which hold it in place.

b. Gear Box

i. Remove vent plug and turn machine upside down to drain oil.

ii. For standard duty unit, use 1.5 oz. of #30 wt. oil. For heavy duty unit, use 2 oz. of #30 wt. oil.

iii. Dispose of old oil in accordance with local, state, and federal law.

iv. Replace vent plug.

14

DO NOT USE THIS MACHINE IF ANY SWITCH FAILS TO

FUNCTION PROPERLY.

TURN OFF AND UNPLUG MACHINE FROM POWER SOURCE

AND PERFORM LOCKOUT/TAGOUT PROCEDURES BEFORE

PERFORMING ANY OTHER MAINTENANCE.

15

Page 19

15

MODEL PRO-9 TENDERIZER

WIRING DIAGRAM

115-220 VOLTS/1 PHASE

50-60 CYCLE

MODEL PRO-9 TENDERIZER

WIRING DIAGRAM

115-220 VOLTS/1 PHASE/50-60 CYCLE

WITH IN LINE CIRCUIT BREAKER

16

Page 20

16

WIRING DIAGRAM

115 or 220 VOLT: 1 PHASE, 50-60 HZ

WITH SOLID STATE RELAY

MODEL PRO-9 TENDERIZER

WIRING DIAGRAM

220-380-440 VOLTS/3 PHASE

50-60 CYCLE

17

Page 21

17

ITEM NO. TA3168-3

STANDARD DUTY TRANSMISSION ASSEMBLY

STARTING WITH SERIAL No. 52902

SERVICE REPLACEMENT

STARTING WITH S/N 40,299

ITEM NO. TA3168-4

HEAVY DUTY TRANSMISSION ASSEMBLY

STARTING WITH SERIAL No. 59094

SERVICE REPLACEMENT

STARTING WITH S/N 40,299

Item

Number Description

T3007-3 Gear Box Cover, (#52902 on)

T3008-1 Gear Box Cover Screw

T3009-3-4 Gear Box Cover Gasket (#52902 on)

*T3012 Knife Drive Gear & Pinion, SD

*T3014 Knife Drive Gear, Front, SD

T3015 Idler Fibre Gear & Pinion, SD

T3016-8 Driven Pulley Gear And Shaft (#59094 on)

SSS08NPS Key Lock Screw,

1

2

"

T3019-2 Driven Pulley Shaft Ball Bearing

T3019-8 Driven Pulley Shaft Bearing Washer

T3020-8-4 Driven Pulley Woodruff Key

T3020-9 Driven Pulley, 2V, 4

´

1

2

60HZ-SD 85 & 105 RPM

50HZ-SD 85 RPM

T3023-1-2 Idler Gear Shaft, (#52902 on)

T3023-1-2S Idler Gear Shaft Screw (#52884 on)

T3026-1 Coupling Shaft Bearing (#43479 on)

T3026-5 Seal, Beginning with Serial number 63718, SD

T3027 Pulley Set Screw

SSS03NPS Key Lock Screw,

1

4

"

T3052 Idler Gear Shaft Washer

T3078-1 Idler Gear Thrust Washer (#55020 on)

T3081 Idler Gear Bearing

T3088-1 Gear Box Vent

T3104-2 Silicon Washer (#43479 on)

T3106-1 Pulley Shaft Oil Seal

*T3169 Knife Drive Coupling, Front, w/Pin

*T3170 Knife Drive Coupling, Back, w/Pin

TA3168-3 Standard Duty Transmission Assembly

TA3169 Knife Drive Coupling & Gear Assembly, Front

TA3170 Knife Drive Coupling & Gear Assembly, Back

Item

Number Description

T3007-4 Gear Box Cover, (#52884 on)

T3008-1 Gear Box Cover Screw

T3009-3-4 Gear Box Cover Gasket (#52884 on)

T3012-1 Knife Drive Gear & Pinion

T3014-1 Knife Drive Gear, Front

T3015-2A Idler Gear & Pinion Assembly, HD

(#52537 on) with bushing

T3015-2A-R Idler Gear & Pinion, HD (#52537 on)

without bushing

T3016-8 Driven Pulley Gear And Shaft (#59094 on)

T3019-2 Driven Pulley Shaft Ball Bearing

T3019-3 Gear Box Ball Bearing

T3019-8 Driven Pulley Shaft Bearing Washer

T3020-8-4 Driven Pulley Woodruff Key

T3020-9 Driven Pulley, 2V, 4

´

1

2

60HZ-HD 115 & 140 RPM

50HZ-HD 140 RPM

T3020-9-1 Driven Pulley, 2V, 3

´

1

2

50HZ-SD 105 RPM

T3023-1-2 Idler Gear Shaft (#52884 on)

T3023-1-2S Idler Gear Shaft Screw (#52884 on)

T3027 Pulley Set Screw

T3052 Idler Gear Shaft Washer

T3078-1 Idler Gear Thrust Washer (#55022 on)

T3081 Idler Gear Bearing

T3088-1 Gear Box Vent

T3104-1 Silicon Washer

T3106-1 Pulley Shaft Oil Seal

T3106-2 Coupling Shaft Oil Seal

T3171 Knife Drive Coupling w/Pin

T3171-1 Coupling Shaft Key, Front

T3171-2 Coupling Shaft Key, Back

T3172 Knife Drive Coupling Retaining Ring

(#42583 on)

T3172-1 Knife Drive Coupling Spacer (#44186 on)

T3294 Gear Spacer, Front

T3294-1 Gear Spacer, Back

TA3168-4 Heavy Duty Transmission Assembly

*Gear — Couplings are supplied less the threaded key lock screw hole

when ordered separately due to thread misalignment.

18

Page 22

18

2V POLY FLEX BELT & PULLEY PARTS

STARTING WITH SERIAL NO. 63504

(See Parts List Below for Correct Motor)

Item

Number Description

T3020-8-4 Driven Pulley Woodruff Key

T3020-9 Driven Pulley, 2-V, 4

´

1

2

,SD&HD

60HZ-SD 85 & 105 RPM

60HZ-HD 115 & 140 RPM

50HZ-SD 85 RPM; 50HZ-HD 140 RPM

T3020-9-1 Driven Pulley, 2V, 3

´

1

2

,SD&HD

50HZ-SD 105 RPM

T3024-9 Motor Pulley, 2V, 2

´

5

8

60HZ-HD 115 RPM

T3024-9-1 Motor Pulley, 2V, 3

´

5

8

60HZ-SD 105 RPM

50HZ-SD 85 RPM; 50HZ-HD 140 RPM

T3024-9-2 Motor Pulley, 2V, 2

385

8

´

60HZ-HD 140 RPM

T3025 Motor Pulley Key

T3027 Motor Pulley Set Screw

T3045-3E-4 Motor,

3

4

HP, 115/230-60-1, HD

T3045-11E-3 Motor,

1

2

HP, 115/230-60-1, SD & HD

T3079-9 Motor Belt, 2V, 2/5M462

60HZ-HD 115 RPM, 50HZ-SD 105 RPM

T3079-9-1 Motor Belt, 2V, 2/5M475

60HZ-SD 85 RPM; 60HZ-HD 140 RPM

50HZ-HD 115 RPM

T3079-9-2 Motor Belt, 2V, 2/5M500

60HZ-SD 105 RPM

50HZ-SD 85 RPM; 50HZ-HD 140 RPM

TA3020-9K Poly Flex 2V Belt & Pulley Kit

60HZ-HD 115 RPM

Item

Number Description

TA3020-9K-2 Poly Flex 2V Belt & Pulley Kit

60HZ-SD 105 RPM

50HZ-SD 85 RPM; 50HZ-HD 140 RPM

TA3020-9K-3 Poly Flex 2V Belt & Pulley Kit

60HZ-SD 85 RPM, 60HZ-HD 140 RPM,

50HZ-HD 115 RPM

TA3020-9K-4 Poly Flex 2V Belt & Pulley Kit

50HZ-SD 105 RPM

BELT & PULLEY PARTS

BEFORE SERIAL NO. 63504

Item

Number Description

T3020 Driven Pulley,4

´

1

2

, SD-85 RPM

TA3020-8 HTD Driven Pulley w/Lock Collar, 4

´

1

2

,HD

SSS05S Driven Pulley Set Screw

T3020-8-4 Driven Pulley Woodruff Key

T3021-1 Driven Pulley Spring Pin, SD & HD

T3024-1 Motor Pulley, 3

´

5

8

, 50HZ, SD-85 RPM

T3024-2 Motor Pulley, 2

1

2

´

5

8

, 60HZ, SD-85 RPM

T3024-8 Motor Pulley, HTD 2

´

5

8

, 60HZ, HD-115 RPM

T3024-8-1 Motor Pulley, HTD, 2

1

2

´

5

8

, 50HZ, HD-115 RPM

60HZ, HD-140 RPM

Item

Number Description

T3024-8-2 Motor Pulley, HTD, 50HZ, HD-140 RPM

T3025 Motor Pulley Key

T3079A Motor Belt, 20" 50HZ-SD

T3079-2A Motor Belt 19" 60HZ-SD

T3079-3 Motor Belt 18

3

4

Special

T3079-8 Motor HTD Belt, 450mm, 60HZ-115

T3079-8-1 Motor HTD Belt, 465mm, 60HZ-140; 50HZ-115

T3079-8-2 Motor HTD Belt, 500mm, 50HZ-140

POLY FLEX PULLEY & BELT KITS

REPLACEMENT FOR ALL MACHINES

BEFORE SERIAL NO. 63504

Duty Cycle RPM Belt No. Kit No.

SD

SD

SD

SD

HD

HD

HD

HD

50

50

85

105

T3079-9-2

T3079-9

60

60

50

50

60

60

85

105

115

140

115

140

T3079-9-1

T3079-9-2

T3079-9-1

T3079-9-2

T3079-9

T3079-9-1

TA3020-9K-2

TA3020-9K-4

TA3020-9K-3

TA3020-9K-2

TA3020-9K-3

TA3020-9K-2

TA3020-9K

TA3020-9K-3

19

Page 23

19

WRAPAROUND CASE PARTS

Item

Number Description

T3005 Case, SS

LW10S Lock washer

1

4

T3059-5-3 Warning Label

PHS023S Case Top Side Screw (10-24)

T3069-1C Case Top Side Screw Clip

T3248-1 Cradle Rest Bar

T3248-4 Cradle Rest Thrust Plate

HHS040S Cradle Rest Bar Screw, RH

HHS046S Cradle Rest Bar Screw, LH

T3250 Case Joining Strip

CASE TOP PARTS

Item

Number Description

TA3006-2 Case Top Assy. w/o Switches

TA3006-2C CSA Case Top Assy. w/o Switches

HN15S Safety Cover Hinge Nut

HNNL15S Safety Cover Hinge Lock Nut (Nylock)

FFW05S Safety Cover Hinge Washer

T3064 Safety Cover Hinge Spring

T3066 Safety Cover Hinge RH

T3067 Safety Cover Hinge LH

PHS023S Case Top Screw 10-24

´

3

8

T3069-1C Case Top Side Screw Clip

54321 Waterproof Toggle Half Boot

T3103 On and Off Plate

T3105 Waterproof Cap Nut, Interlock

T3186-1A Toggle Switch, 3 Phase w/Cap Nut

T3186-4A Toggle Switch, 1 Phase w/Half Boot

T3187 Thermal Circuit Breaker, 8 Amp

T3187-1 Thermal Circuit Breaker, 10 Amp

T3187-2 Thermal Circuit Breaker, 12 Amp

T3187-3 Thermal Circuit Breaker, 5 Amp

T3188 Waterproof Reset Button Seal (not shown)

T3189 “Press to Reset” Plate (not shown)

T3190 Circuit Breaker Lock Washer (not shown)

T3200A Interlock Switch, 1 Phase w/Cap Nut

T3200-1A Interlock Switch, 3 Phase w/Cap Nut

LWET30S Shakeproof Washer UL

T3290-4A Switch Harness with Waterproof Half Boot,

15 Amp (1 PH) 115V (3 PH also available)

SAFETY COVER PARTS

Item

Number Description

T3059-3-2 Caution Decal

T3059-5-3 Warning Label

T3059-6 Cover removal label

T3076 BIRO SirSteak Decal *DNS

T3090 NSF Decal *DNS

T3096-0 Safety Cover, Stainless Steel

TA3096M-2 Safety Cover, Transparent

w/Decals

CASE TOP PARTS

Item

Number Description

TA3006-2 Case Top Assy. w/o Switches

TA3006-2C CSA Case Top Assy. w/o Switches

HN15S Safety Cover Hinge Nut

HNNL15S Safety Cover Hinge Lock Nut (Nylock)

FFW05S Safety Cover Hinge Washer

T3064 Safety Cover Hinge Spring

T3066 Safety Cover Hinge RH

T3067 Safety Cover Hinge LH

PHS023S Case Top Screw 10-24

´

3

8

T3069-1C Case Top Side Screw Clip

54321 Waterproof Toggle Half Boot

T3103 On and Off Plate

T3105 Waterproof Cap Nut, Interlock

T3186-1A Toggle Switch, 3 Phase w/Cap Nut

T3186-4A Toggle Switch, 1 Phase w/Half Boot

T3187 Thermal Circuit Breaker, 8 Amp

T3187-1 Thermal Circuit Breaker, 10 Amp

T3187-2 Thermal Circuit Breaker, 12 Amp

T3187-3 Thermal Circuit Breaker, 5 Amp

T3188 Waterproof Reset Button Seal (not shown)

T3189 “Press to Reset” Plate (not shown)

T3190 Circuit Breaker Lock Washer (not shown)

T3200A Interlock Switch, 1 Phase w/Cap Nut

T3200-1A Interlock Switch, 3 Phase w/Cap Nut

LWET30S Shakeproof Washer UL

T3290-4A Switch Harness with Waterproof Half Boot,

15 Amp (1 PH) 115V (3 PH also available)

CASE TOP PARTS

Item Number Description

TA3006-2 Case Top Assy. w/o Switches

TA3006-2C CSA Case Top Assy. w/o Switches

HN15S Safety Cover Hinge Nut

HNNL15S Safety Cover Hinge Lock Nut (Nylock)

FFW05S Safety Cover Hinge Washer

T3064 Safety Cover Hinge Spring

T3066 Safety Cover Hinge RH

T3067 Safety Cover Hinge LH

PHS023S Case Top Screw 10-24X 3/8

T3069-1C Case Top Side Screw Clip

54321 Waterproof Toggle Half Boot

T3103 On and Off Plate

T3105 Waterproof Cap Nut, Interlock

T3186-1A Toggle Switch, 3 Phase w/Cap Nut

T3186-4A Toggle Switch, 1 Phase w/Half Boot

T3187 Thermal Circuit Breaker, 8 Amp

T3187-1 Thermal Circuit Breaker, 10 Amp

T3187-2 Thermal Circuit Breaker, 12 Amp

T3187-3 Thermal Circuit Breaker, 5 Amp

T3188 Waterproof Reset Button Seal (not shown)

T3189 “Press to Reset” Plate (not shown)

T3190 Circuit Breaker Lock Washer (not shown)

T3200A Interlock Switch, 1 Phase w/Cap Nut

T3200-1A Interlock Switch, 3 Phase w/Cap Nut

LWET30S Shakeproof Washer UL

T3290-4A Switch Harness with Waterproof Half Boot,

The Lexan Safety Cover for the Pro-9 has been redesigned to

comply with current international standards. It is now 1-3/4

inch (44 mm) taller than the former design and completely

interchangeable with the previous safety cover which is no

longer available.

15 Amp (1 PH) 115V (3 PH also available)

Item Number Description Item Number Description

T3059-3-2 Caution Decal T3090 NSF Decal *DNS

T3059-5-3 Warning Label T3096-0-1 Safety Cover

T3059-6 Cover removal label Stainless Steel

T3076 BIRO SirSteak TA3096M-2 Safety Cover,

20

SAFETY COVER PARTS

,

Decal *DNS Transparent w/Decals

Page 24

20

Item

Number Description

T3001/04-4 Base Plate & Gear Housing Bracket

Assembly #52884 on

T3022-3A Frame Positioning Lock Screw (#40299 on)

CB74S Motor Screw (

5

16

´

3

4

carr.)

HN20S Motor Screw Nut (

5

16

-18)

FW16S Motor Screw Washer,

5

16

T3052 Idler Gear Shaft Washer

LW10S Lock Washer (

1

4

)

LW16S Lock Washer (

5

16

)

HNNL15S Safety Cover Hinge Lock Nut (

1

4

-20)

PHS002S Case Top Side Screw (8-32)

Item

Number Description

CB60S Case Screw (½)

CB61S Case Screw(¾)

HN15S Case Screw Hex Nut ¼-20

T3108-1 Motor Cord & Plug (115V-1PH)

T3108-4 Motor Cord & Plug (220V-1PH)

TA3111 Base Foot w/Nut Assembly

T3111-2 Base Leg, 4” SS (shpbrd)

HHS025S Hex head Cap Screw ¼-20 ´ ½

T3180 Cord Clamp

T3197-2 Motor Shim

LWET03S Grounding Shakeproof Washer

PRO-9 SD AND HD BASE FRAME PARTS LIST (REAR VIEW)

STARTING WITH S/N 40299 ON

21

Page 25

TENDERIZER CRADLE PARTS

21

TA3185M-115-TK SOLID STATE RELAY KIT FOR TRANSPARENT COVER

TA3185M-115-SK SOLID STATE RELAY KIT FOR STAINLESS STEEL SAFETY COVER

Item

number Description

TA3185M-K Harness with solid state switch and reed

110V-220V

TA3096M-0-1 SS safety cover w/magnet

TA3096M-2 Transparent safety cover w/magnet

54321 Toggle switch half boot

T3103 On & Off plate

TA3105M-2 Reed switch cap & spacer

T3105M Reed switch cap

T3105MS Spacer, switch cap

T3108-1 Power cord, 115V, 1PH

T3108-4 Power cord, 220V, 1PH

T3184-20-6LW Relay lock washer

T3184-20-6S Relay lock nut

T3184M-20 Switch & relay bracket

T3185M-120 Solid state relay, 115/220 volt

T3186-1A Toggle switch, On/Off, 3ph, 220V

T3186-4A Toggle switch, On/Off, 1 Ph 115V

T3200M Reed interlock switch

T3211M Reed switch lock washer

TA3096M-2 TRANSPARENT

SAFETY COVER

TA3096M-O-1 STAINLESS

STEEL SAFETY COVER

Solid state relay, 115/220 volt starting w/ SR# 72504SD

22

Page 26

22

STEW CRADLE PARTS ¼²

23

Page 27

23

1

4

"

S

TEW

C

RADLE

PARTS

L

ISTING

Item

Num

b

er

Descrip

tio

n

Qty.

TA3130-9A

Stew

Crad

le

Assembly

Co

mplete,

1

4

"1

TA3131-9 Stew Front Blade Assembly,

1

4

"1

TA3132-9 Stew Back Blade Assembly,

1

4

"1

T3031-11 Spacer,

5

8

ID

´

7

8

OD

´

.300 1

T3031-20 Spacer,

5

8

ID

´

7

8

OD

´

.200 28

T3031-21 Spacer,

5

8

ID

´

7

8

OD

´

.110 28

T3031-4 Aux. Spacer,

5

8

ID

´

1

9

16

OD

´

.035 29

T3031-5 Aux. Spacer,

5

8

ID

´

7

8

OD

´

.070 *

T3036-1 2" Notched Stew Feeder Blade 29

T3075 Bearing Snap Ring, SS 2

T3082 Front Knife Shaft End Nut, LH 1

T3083 Back Knife Shaft End Nut, RH 1

Item

Number Description Qty.

T3116-9 Stew Wire Comb, Front,

1

4

"1

T3117-9A Stew Wire Back Comb w/Al. Crossbar,

1

4

"1

T3130-1 Stew Cradle Less Blades & Combs 1

T3131-9 Front Knife Shaft w/Cplg. End, Less .088 spcr. 1

T3132 Back Knife Shaft w/Cplg. End 1

T3157 Cradle Lock Lever Shaft 1

T3178 Aux. Spacer.

5

8

ID

´

7

8

OD

´

.005 *

T3181-1 Knife Shaft Shoulder Bearing, Front 1

T3181-2 Knife Shaft Shoulder Bearing, Back 1

T3226A-1 Stew Cradle End, RH 1

T3227-1 Stew Cradle End, LH 1

Item

Number Description Qty.

T3228 Stew Cradle Bar, Bottom Back 1

T3228-1 Stew Cradle Bar, Bottom Front 1

T3228-3 Stew C r adle Bar, Top Back 1

T3228-3-1 Stew Cradle Bar, Top Front 1

T3229 Cradle End Screw, LH,

1

4

-20

´

3

4

4

T3230 Cradle End Screw, RH,

1

4

-20

´

1

1

4

4

T3247-1 Cradle Lock Lever, Nylon 1

T3247-5 Cradle Safety Lift Handle 1

T3247-9 Hand Feeder, Option, Nylon 0

T3300 Stew Blade, 3" O.D. 29

STAR CRADLE PARTS LISTING

Number Description

TA3130-36 Star Cradle Assembly, Complete

TA3331 Star Front Blade Assembly

TA3332 Star Back Blade Assembly

T3031-5 Star Auxiliary Spacer

5

8

ID

´

7

8

OD

´

.070

T3031-12 Front Knife Shaft Cap Spacer

T3075 Bearing Snap Ring, SS

T3082 Front Knife Shaft End nut, LH

T3083 Front Knife Shaft End Nut, LH

T3083 Back Knife Shaft End Nut, RH

T3130 Cradle

T3131A Front Knife Shaft w/Coupling End

T3132 Back Knife Shaft w/Coupling end

T3157 Cradle Lock Lever Shaft

T3181-1 Front Knife Shaft Shoulder Bearing

T3181-2 Back Knife Shaft Shoulder Bearing

T3226A Cradle End, Right Hand

T3227 Cradle End, Left Hand

T3228 Cradle Bar, Bottom Back & Front

T3228-3 Cradle Top Bar, Front & Back

T3229 Cradle End Screw, LH,

1

4

-20

´

3

4

T3230 Cradle End Screw, RH,

1

4

-20

´

1

1

4

T3247-1 Cradle Lock Lever

T3247-5 Cradle Lift Handle

T3316 Star Wire Comb, Front

T3317 Star Wire Comb, Back

T3331 Star Spacer

5

8

ID

´

7

8

OD

´

.405

T3331-1 Star Step Spacer, Front

5

8

ID

´

7

8

OD

´

.240

T3331-2 Star Step Spacer, Back

5

8

ID

´

7

8

OD

´

.075

T3331-3 Knife Shaft Extension Spacer, Back

1

2

ID

´

5

8

OD

´

3

16

T3336 Star Blade, 2

1

8

" Dia.

´

12 teeth

24

Page 28

24

NOTE: All No.’s ending in “A” have #T3031-4 Spacer omitted from their assemblies

starting with SR #57696 HD on 1-6-89.

STEW CRADLE PARTS LISTING

T3031-1 Stew, front spacer for ¾" width

T3031-2 Stew, front spacer for 1" width

T3031-3 Stew, front spacer for 1

1

4

" width

T3031-5 Aux spacer

5

8

ID

´

7

8

OD´.070

T3031-7 Knife shaft extension end spacer

1

2

´

5

8

´

1

8

T3031-8 Knife shaft extension end spacer

1

2

´

5

8

´

3

16

T3031-9 Stew, front spacer for

9

16

" width

T3031-11 Stew, front spacer for

3

8

" width

T3031-12 Front knife shaft cap spacer

T3031-14 Stew, front spacer for

7

8

" width

T3031-17 Stew, front spacer for 1

9

16

" width

T3031-18 Stew, front spacer for 2" width

TA3130-1A Stew cradle assembly, complete

3

4

" wide

TA3130-2A Stew cradle assembly, complete 1" wide

TA3130-3A Stew cradle assembly, complete 1

1

4

" wide

TA3130-4A Stew cradle assembly, complete

9

16

" wide

TA3130-5A Stew cradle assembly, complete

3

8

" wide

TA3130-7A Stew cradle assembly, complete 1

9

16

" wide

TA3130-8A Stew cradle assembly, complete 2" wide

TA3130-14A Stew, cradle assembly, complete

7

8

" wide

TA3131-1 Stew, front blade assembly,

3

4

" wide

TA3131-2 Stew, front blade assembly, 1" wide

TA3131-3 Stew, front blade assembly, 1

1

4

" wide

TA3131-4 Stew, front blade assembly,

9

16

" wide

TA3131-5 Stew, front blade assembly,

3

8

" wide

TA3131-7 Stew, front blade assembly, 1

9

16

" wide

TA3131-8 Stew, front blade assembly, 2" wide

TA3131-14 Stew, front blade assembly,

7

8

" wide

T3116 Wire front comb

T3116-9 Stew, wire front comb, ¼" wide

T3117-1 Stew, wire back comb,

3

4

" wide

T3117-2 Stew, wire back comb, 1" wide

T3117-3 Stew, wire back comb, 1

1

4

" wide

T3117-4 Stew, wire back comb,

9

16

" wide

T3117-5 Stew, wire back comb,

3

8

" wide

T3117-7 Stew, wire back comb, 1

9

16

" wide

T3117-8 Stew, wire back comb, 2" wide

T3117-9 Stew, wire back comb, ¼" wide

T3117-14 Stew, wire back comb,

7

8

" wide

TA3132-20 Stew/scoring back blade assembly, 2" O.D. for stew

cradles after Sr. No. 57696 & before Sr. No. 57696

TA3132-1 Replaced by TA3132-20

TA3132-2 Replaced by TA3132-20

TA3132-3 Replaced by TA3132-20

TA3132-4 Replaced by TA3132-20

TA3132-5 Replaced by TA3132-20

TA3132-7 Replaced by TA3132-20

TA3132-8 Replaced by TA3132-20

TA3132-14 Replaced by TA3132-20

T3036-1 Stew feeder/scoring blade, 2" O.D.

Requirement

29 for

1

4

"

43 for

3

8

"

43 for

9

16

"

43 for

3

4

"

43 for

7

8

"

43 for 1"

43 for 1

1

4

"

43 for 1

9

16

"

43 for 2"

T3300 Stew blade, 3" O.D.

Requirement

29 for

1

4

"

21 for

3

8

"

15 for

9

16

"

11 for

3

4

"

8 for

7

8

"

8 for 1"

7for1

1

4

"

5for1

9

16

"

4 for 2"

25

Page 29

SCORING CRADLE PARTS

25

SCORING CRADLE PARTS w/BLADES & COMBS

(See parts list for other items)

SCORING

BLADES

FT BK “A” – DIM

TA3130-20 Scoring Cradle Complete 2" 2" 0"

TA3130-21 Scoring Cradle Complete 2" 1

7

8

"

1

16

"

TA3130-22 Scoring Cradle Complete 1

7

8

"1

7

8

"

1

8

"

TA3130-23 Scoring Cradle Complete 1

7

8

"1

3

4

"

3

16

"

TA3130-24 Scoring Cradle Complete 1

3

4

"1

3

4

"

1

4

"

SCORING BLADES

“A” DIMENSION

Item

Number Description Diameter

T3036-1 Stew feeder scoring blade 2"

T3036-2 Scoring blade 1

7

8

"

T3036-3 Scoring blade 1

3

4

"

TA3131-20 Scoring, front blade assembly 2"

TA3131-22 Scoring, front blade assembly 1

7

8

"

TA3131-24 Scoring, front blade assembly 1

3

4

"

TA3132-20 Scoring, stew, back blade assembly 2"

TA3132-22 Scoring, back blade assembly 1

7

8

"

TA3132-24 Scoring, back blade assembly 1

3

4

"

26

Page 30

CUTLET PARTS LIST

26

Item

Number Description

TA3130-50 Cutlet cradle assembly complete

TA3131-50 Cutlet front blade assembly – 42 blades

TA3132-50 Cutlet back blade assembly – 43 blades

T3031 Spacer

5

8

ID

´

7

8

OD´.140

T3031-12 Front knife shaft cap spacer

T3036-50 Cutlet knife blade – 26 teeth

T3075 Bearing snap ring, SS

T3082 Front knife shaft end nut, left hand

T3083 Back knife shaft end nut, right hand

T3116 Wire comb, front

T3117 Wire comb, back

T3130 Cradle

T3131A Front knife shaft w/coupling end spacer

Item

Number Description

T3132 Back knife shaft w/coupling end

T3157 Cradle lock lever shaft

T3178 Auxiliary spacer

5

8

ID

´

7

8

OD´.005

T3181-1 Knife shaft shoulder bearing front

T3181-2 Knife shaft shoulder bearing back

T3226A Cradle end, right hand

T3227 Cradle end, left hand

T3228 Cradle bar, bottom back & front

T3228-3 Cradle bar, top front

T3229 Cradle bar end screw, left hand

1

4

-20

´

3

4

T3230 Cradle bar end screw, right hand

1

4

-20´1

1

4

T3247-1 Cradle lock lever, nylon

T3247-5 Cradle safety lift handle

CLEANING BRUSH

P/N T3091-1

(OPTION)

– NET EXTRA –

COMB STRAIGHTENER

P/N TA3119

(OPTION)

– NET EXTRA –

CLEANING BRUSH

P/N T3091-1

(OPTION)

– NET EXTRA –

27

Page 31

PARTS ORDERING

Important: Must have Serial Number when ordering parts.

Please contact yoru nearest authorized Biro service agency for any repair parts required on your Biro – Sir

Steak Model Pro-9 Tenderizer.

Additional information or authorized referral assistance may be obtained from:

The Biro Manufacturing Company

1114 West Main Street

Marblehead, Ohio 43440-2099

Phone: (419) 798-4451

FAX No. (419) 798-9106

27

Item No. Description

T3001/04-4 Base plate & gear bracket assembly #52884 on

T3005 Case, SS

T3007-3 Gear box cover, SD, #52902 on

T3007-4 Gear box cover, HD, #52884 on

T3008-1 Gear box cover screw, SD, #31600 on, also HD

T3009-3-4 Gear box cover gasekt, SD, #52902 on; HD

#52884 on

T3012 Knife drive gear & pinion, SD

T3012-1 Knife drive gear & pinion, HD

T3014 Knife drive gear front, SD

T3014-1 Knife drive gear, front, HD

T3015 Idler gear & pinion, SD, fibre

T3015A Idler gear & pinion, SD, steel

T3015-2A Idler gear & pinion, HD

T3016-1A Driven pulley gear & shaft (#52,884 to #59,094),

NA, replaced by T3016-8

T3016-8 Driven pulley gear & shaft (#59094 on) SD & HD

SSS08NPS Key lock screw,

1

2

"

T3019-2 Driven pulley shaft ball bearing #31600 on

T3019-3 Gear box ball bearing, HD

T3020 Driven pulley, 4

´

1

2

, SD only (85 RPM)

SSS05S Driven pulley lock set screw, HTD

T3020-8-4 Woodruff key

T3020-9 Driven Pulley, 2V, 4

´

1

2

,SD&HD

60HZ-SD 85 & 105 RPM

60HZ-HD 115 & 140 RPM

50HZ-SD 85 RPM; 50HZ-HD 140 RPM

T3020-9-1 Driven Pulley, 2V, 3

´

1

2

,SD&HD

50HZ-SD 105 RPM

T3021-1 Driven pulley roll pin, SD & HD

T3022-3A Frame positioning lock screw, #52884 on

T3023-1-2 Idler gear shaft, SD, #52902 on; HD #52884 on

T3023-1-2S Idler gear shaft screw, SD, #52902 on; HD #52884

on

T3024-1 Motor pulley, 3

´

5

8

, 50 cycle, SD only (85 RPM)

T3024-2 Motor pulley, 2

1

2

´

5

8

, 60 cycle, SD only (85 RPM)

T3024-6A Motor timing pulley, 2

´

5

8

, HD only, 60 cycle (115

RPM), obsolete order TA3024-8K

T3024-8 Motor pulley, HTD, 60 cycle, 115 RPM (2

´

5

8

)HD

only, 30 tooth

T3024-8-1 Motor pulley, HTD, (50 cycle – 115 RPM) (60 cycle –

140 RPM) (2

1

2

´

5

8

) HD only

T3024-8-2 Motor pulley, HTD (50 cycle – 140 RPM) HD only

T3024-9 Motor Pulley, 2V, 2

´

5

8

60HZ-HD 115 RPM

T3024-9-1 Motor Pulley, 2V, 3

´

5

8

60HZ-SD 105 RPM

50HZ-SD 85 & 105 RPM; 50HZ-SD 140 RPM

T3024-9-2 Motor Pulley, 2V, 2

385

8

´

60HZ-HD 140 RPM

T3025 Motor pulley key

T3026-1 Coupling shaft bearing, #43479 on

T3027 Motor pulley set screw

T3031 Spacer

T3031-1 Stew, front spacer for

3

4

" width (10) req’d

T3031-2 Stew, front spacer for 1" width (7) req’d

T3031-3 Stew, front spacer for 1

1

4

" width (6) req’d

T3031-4 Auxiliary spacer,

5

8

ID´1

9

16

OD´.035

T3031-5 Auxiliary spacer,

5

8

ID

´

7

8

OD´.070

T3031-6 Auxiliary spacer,

5

8

ID

´

7

8

OD´.035

T3031-7 Knife shaft extension end spacer

1

2

ID

´

5

8

OD

´

1

8

T3031-8 Knife shaft extension end spacer

1

2

ID

´

5

8

OD

´

3

16

Item No. Description

T3031-9 Stew, front spacer for

9

16

" width (14) req’d

T3031-11 Stew, front spacer for

3

8

" width (20) req’d

T3031-12 Front knife shaft cap spacer

T3031-14 Stew, front spacer for

7

8

" width (8) req’d

T3031-17 Stew, front spacer for 1

9

16

" width (4) req’d

T3031-18 Stew, front spacer for 2" width (3) req’d

T3031-20 Spacer, .200

´

5

8

´

7

8

, 28 required,

1

4

" stew frt.

T3031-21 Spacer, .110

´

5

8

´

7

8

, 28 required,

1

4

" stew bk.

SSS03NPS Key lock screw,

1

4

"

T3036 Tenderizer knife blade

T3036-1 Stew feeder/scoring blade, 2" O.D.

T3036-2 Scoring blade, 1

7

8

" O.D.

T3036-3 Scoring blade, 1

3

4

" O.D.

T3036-50 Cutlet knife blade, 26 teeth

T3045-3E-4 Motor, ¾HP, 115/220-50/60-1 HD

T3045-4C Motor, ¾HP, 220-50-1, SD & HD

T3045-11E-3 Motor, ½HP, 115/220-50/60-1, SD & HD

T3045-12 Motor, ¾HP, 230/460-60-3, HD

T3045-13A Motor, ¾HP, 220/440-50/60-3, HD

CB74S Motor screw,

5

16

´

3

4

carriage

HN20S Motor screw, nut,

5

16

-18

FW16S Motor screw washer,

5

16

T3052 Idler gear shaft washer

LW10S Lock washer,

1

4

"

LW16S Lock washer,

5

16

", motor bolt

T3059-3A Caution decal for safety cover, NC

T3059-4 Warning decal #42670 on, NC

HNNL15S Safety cover hinge nut (nylock)

FFW05S Safety cover hinge washer

T3064 Safety cover hinge spring

T3066 Safety cover hinge, RH

T3067 Safety cover hinge, LH

T3068 Safety cover hinge lock washer

PHS002S Case top screw, #8-32

PHS023S Case top side screw, #10-24

´

3

8

, #50420 on

T3069-1C Cover side screw clip, #50420 on

CB60S Case screw,

1

2

"

CB61S Case screw,

3

4

"

HN15S Case screw nut,

1

4

-20 hex

T3075 Bearing snap ring, SS

T3078-1 Thrust washer bearing, SD, #55020 on, HD

#55022 on

T3079A Motor belt, 20", 50 cycle only, #51093 on

T3079-2A Motor belt, 19", 60 cycle SD, 50 cycle HD

T3079-3 Motor belt, 18-

3

4

, 60 cycle, HD (special only)

T3079-6 Motor timing belt, 60 cycle (115 RPM), 47 teeth, HD

only

T3079-6-1 Motor timing belt, 50 cycle (115 RPM), 50 teeth, HD

only (also used on 60 cycle, 140 RPM)

T3079-8 Motor HTD belt, 60Cy-115RPM, 450 mm, HD

T3079-8-1 Motor HTD belt, 50CY-115RPM, 60Cy-140RPM,

465mm, HD

T3079-8-2 Motor HTD belt, 50Cy-140RPM, 500mm, HD

T3079-9 Motor Belt, 2V, 2/5M462

60HZ-HD 115 RPM

T3079-9-1 Motor Belt, 2V, 2/5M475

60HZ-SD 85 RPM; 60HZ-HD 140 RPM

50HZ-SD 105 RPM

T3079-9-2 Motor Belt, 2V, 2/5M500

60HZ-SD 105 RPM

50HZ-SD 85 RPM; 50HZ-HD 140 RPM

T3081 Idler gear bearing

28

Page 32

28

Item No. Description

T3082 Knife shaft end nut, left hand, front

T3083 Knife shaft end nut, right hand, back

T3088-1 Gear box vent, 1 psi

T3091-1 Cleaning brush

TA3096M-0 Safety cover, stainless

TA3096M-1 Safety cover, transparent

T3101-1 Waterproof cap nut, toggle

T3103 On & Off plate

T3104-1 Silicone washer, HD

T3104-2 Silicone washer, SD, #43479 on

T3105 Safety switch cap nut, waterproof

T3106-1 Pulley shaft oil seal, SD & HD

T3106-2 Coupling shaft oil seal, HD

T3108-1 Motor cord & plug, 115V

T3108-4 Motor cord & plug, 220V (3PH also available)

T3111-1 Base foot w/

1

4

-20 screw, order TA3111

T3116 Tenderizer wire front comb

T3116-L Tenderizer rigid front comb (laser)

T3116-1 Stew, wire front comb, SS,

3

4

" width

T3116-2 Stew, wire front comb, SS, 1" width

T3116-4 Stew, wire front comb, SS,

9

16

" width

T3116-5 Stew, wire front comb, SS,

3

8

" width

T3116-9 Stew, wire front comb,

1

4

" width

T3117 Tenderizer, wire back comb

T3117-L Tenderizer rigid back comb (laser)

T3117-1 Stew, wire back comb,

3

4

" width

T3117-2 Stew, wire back comb, 1" width

T3117-3 Stew, wire back comb, 1

1

4

" width

T3117-4 Stew, wire back comb,

9

16

" width

T3117-5 Stew, wire back comb,

3

8

" width

T3117-7 Stew, wire back comb, 1

9

16

" width

T3117-8 Stew, wire back comb, 2" width

T3117-9A Stew, wire back comb w/cross bar,

1

4

" width

T3117-14 Stew, wire back comb,

7

8

" width

T3119 Comb straightener

T3130 Cradle less blades & combs

T3130-1 Stew cradle less blades & combs

T3131A Front knife shaft w/coupling end & spacer

T3132 Back knife shaft w/coupling end

T3157 Cradle lock lever shaft

T3169 Knife drive coupling, front w/pin, SD

T3170 Knife drive coupling, back, w/pin, SD

T3171 Knife drive coupling, front and rear w/pin, HD

T3171-1 Coupling shaft key, front, HD

T3171-2 Coupling shaft key, back, HD

T3172 Knife drive coupling retaining ring, front and back

#42583 on, HD

T3172-1 Knife drive coupling spacer, front and back #44186

on, HD

T3175 Knife drive coupling pin (#30000 to

#32452-#42834 on)

T3175-1 Knife drive coupling pin (#32452 to #42834)

T3178 Auxiliary spacer

5

8

ID

´

7

8

OD´.005

T3078-1 Thrust washer bearing, SD, #55020 on, HD,

#55022 on

T3180 Cord clamp

Item No. Description

T3181-1 Knife shaft shoulder bearing, front

T3181-2 Knife shaft shoulder bearing, back

T3186-1A Toggle switch w/cap nut, 3 phase

T3186-4A Toggle switch w/half boot, 1 phase

T3187 Thermal circuit breaker, SD, 8 Amp, #46032 on

T3187-1 Thermal circuit breaker, HD, 10 Amp, #46032 on

T3187-2 Thermal circuit breaker, 12 Amp, #46032 on

T3187-3 Thermal circuit breaker, 5 Amp, #46032 on

T3188 Waterproof reset button seal, #46032 on

T3189 “Press to reset” plate, #46032 on

T3190 Circuit breaker lock washer, #46032 on *NSS

T3197-2 Motor shim

T3200A Interlock switch w/cap nut, 1 phase

T3200-1A Interlock switch w/cap nut, 3 phase

LWET30S Shakeproof washer

LWET03S Grounding shakeproof washer

T3226A Cradle end, right hand

T3226A-1 Stew cradle end, right hand

T3227 Cradle end, left hand – for wire comb

T3227-L Cradle end, left hand – for rigid comb

T3227-1 Stew cradle end, left hand

T3228 Cradle bar, bottom front & back

T3228-1 Stew cradle bar, bottom front

T3228-3 Cradle bar, top front & back

T3228-3-1 Stew cradle bar, top front

T3229 Cradle end screw, left side,

1

4

-20

´

3

4

T3230 Cradle end screw, right side,

1

4

-20´1

1

4

T3247-1 Cradle lock lever, nylon

T3247-5 Cradle safety lift handle

T3247-9 Hand feeder, nylon

T3248-1 Cradle rest bar

T3248-4 Cradle rest thrust plate

HHS040S Cradle rest bar screw, RH

HHS046S Cradle rest bar screw, LH

T3250 Case joining strip

T3290-4A Switch harness w/half boots 15Amp/1PH/115V

T3290-4A-5 Switch harness w/5 Amp breaker

T3290-4A-8 Switch harness w/8 Amp breaker

T3290-4A-10 Switch harness w/10 Amp breaker

T3290-4A-12 Switch harness w/12 Amp breaker

T3294 Gear spacer, front HD

T3294-1 Gear spacer, back HD

T3294-2 Gear thrust washer HD

T3300 Stew blade, 3.00 O.D.

T3316 Star dual rigid front comb

T3317 Star dual rigid back comb

T3331 Star spacer

5

8

ID

´

7

8

OD´.405

T3331-1 Star step spacer, front,

5

8

ID

´

7

8

OD´.240

T3331-2 Star step spacer, back,

5

8

ID

´

7

8

OD´.075

T3331-3 Knife shaft extension spacer, back,

1

2

ID

´

5

8

OD

´

3

16

T3336 Star blade, 2

1

8

" diameter´12 tooth

(

5

8

´

2

1

8

´

.120)

29

Page 33

ASSEMBLY NUMBERS FOR THE PRO-9 MACHINE

29

Item No. Description

TA3006-2 Case top assembly without switches, #50420 on

TA3006-2C CSA case top assembly w/o switches

TA3020-6 Obs. driven timing pulley w/bushing, HD, NLA order

TA3020-8K

TA3020-6K Obs. timing belt & pulley kit, HD only, NLA order

TA3020-8K

TA3020-8 HTD driven pulley w/lock collar (4

´

1

2

) HD only

TA3020-8K HTD pulley & belt kit, 60Cy-115RPM, HD only

TA3020-9K Poly Flex 2V Belt & Pulley Kit

60HZ-HD 115 RPM

TA3020-9K-2 Poly Flex 2V Belt & Pulley Kit

60HZ-SD 105 RPM

50HZ-SD 85 RPM; 50HZ-HD 140 RPM

TA3020-9K-3 Poly Flex 2V Belt & Pulley Kit

60HZ-SD 85 RPM, 60HZ-HD 140 RPM,

50HZ-HD 115 RPM

TA3020-9K-4 Poly Flex 2V Belt & Pulley Kit

50HZ-SD 105 RPM

TA3111 Base foot assembly

TA3130 Tenderizer cradle assembly, complete

TA3130-1A Stew, cradle assembly, complete

3

4

" width

TA3130-2A Stew, cradle assembly, complete 1" width

TA3130-3A Stew, cradle assembly, complete 1

1

4

" width

TA3130-4A Stew, cradle assembly, complete

9

16

" width

TA3130-5A Stew, cradle assembly, complete

3

8

" width

TA3130-7A Stew, cradle assembly, complete 1

9

16

" width

TA3130-8A Stew, cradle assembly, complete 2" width

TA3130-9A Stew, cradle assembly, complete

1

4

" width

TA3130-14A Stew, cradle assembly, complete

7

8

" width

TA3130-20 Scoring cradle complete FT 2" BK 2"

TA3130-21 Scoring cradle complete FT 2" BK 1

7

8

"

TA3130-22 Scoring cradle complete FT 1

7

8

"BK1

7

8

"

ItemNo. Description

TA3130-23 Scoring cradle complete FT 1

7

8

"BK1

3

4

"

TA3130-24 Scoring cradle complete FT 1

3

4

"BK1

3

4

"

TA3130-36 Star cradle assembly, complete

TA3130-50 Cutlet cradle assembly complete

TA3131 Tenderizing front blade assembly

TA3131-1 Stew, front blade assembly, complete

3

4

" width

TA3131-2 Stew, front blade assembly, complete 1" width

TA3131-3 Stew, front blade assembly, complete 1

1

4

" width

TA3131-4 Stew, front blade assembly, complete

9

16

" width

TA3131-5 Stew, front blade assembly, complete

3

8

" width

TA3131-7 Stew, front blade assembly, complete 1

9

16

" width

TA3131-8 Stew, front blade assembly, complete 2" width

TA3131-9 Stew, front blade assembly, complete

1

4

" width

TA3131-14 Stew, front blade assembly, complete

7

8

" width

TA3131-20 Scoring, front blade assembly, 2" O.D.

TA3131-22 Scoring, front blade assembly, 1

7

8

" O.D.

TA3131-24 Scoring, front blade assembly, 1

3

4

" O.D.

TA3131-50 Cutlet front blade assembly, 42 blades

TA3132 Tenderizing back blade assembly

TA3132-9 Stew, back blade assembly,

1

4

" width

TA3132-20 Universal stew and scoring, back blade assembly,

2" O.D.

TA3132-22 Scoring, back blade assembly, 1

7

8

" O.D.

TA3132-24 Scoring, back blade assembly, 1

3

4

" O.D.

TA3132-50 Cutlet back blade assembly, 43 blades

TA3168-3 Gear box assembly w/pulley, SD, #52902 on

TA3168-4 Gear box assembly 2/pulley, HD, #52884 on

TA3169 Knife drive coupling & gear box assembly, front, SD

TA3170 Knife drive coupling & gear box assembly, back, SD

TA3331 Star front blade assembly

TA3332 Star back blade assembly

30

Page 34

OPERATOR’S SIGNATURE PAGE

WARNING

READ AND UNDERSTAND THIS ENTIRE

MANUAL BEFORE SIGNING BELOW

MY SIGNATURE ATTESTS THAT I HAVE COMPLETELY READ AND UNDERSTAND THIS MANUAL.

I REALIZE THAT THIS MACHINE, IF OPERATED CARELESSLY, CAN CAUSE SERIOUS INJURY TO

MYSELF AND OTHERS.

NAME (PRINT) SIGNATURE DATE

30

SUPERVISOR’S

INITIALS

31

Page 35

LIMITED WARRANTY:

WARRANTY: The Biro Manufacturing Company warrants that the Model Pro-9 will be free from

defects in material and workmanship under normal use and with recommended service. BIRO will

replace defective parts, which are covered by this limited warranty, provided that the defective

parts are authorized for return, shipping charges prepaid, to a designated factory for inspection

and/or testing.

DURATION OF WARRANTY: The warranty period for all parts covered by this limited warranty is

one year from date of purchase, or eighteen months from factory ship date, whichever date occurs

first, except as noted below.

PARTS NOT COVERED BY WARRANTY: The following wearable parts are not covered by this

limited warranty: tenderizer blades, 3² stew blades, scoring blades, star blades, feeder blades, cutlet blades, and all front and rear wire combs This limited warranty does not apply to machines

sold as used, rebuilt, modified, or altered from the original construction in which the machine was

hipped from the factory. (Water contaminated electrical systems are not covered under this limited warranty). BIRO is not responsible for service charges or labor required to replace any part

covered by this limited warranty or for any damages resulting from misuse, abuse, lack of proper

or recommended service, or for electrical connection of equipment, adjustments to switch gear or

any other electrical requirements, which must be performed only by a certified electrician.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no warranties

other than those expressly stated in this limited warranty. THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR PROCESSING OF FOOD PRODUCTS, AND ALL OTHER IMPLIED WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT

LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE

REMEDIES PROVIDED IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S SOLE AND EXCLUSIVE REMEDIES AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete warranty registration card supplied

with each machine. The warranty card must be returned to The Biro Manufacturing Company for

proper registration. If no warranty card is returned to BIRO, the warranty period will begin from

the date the machine was originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the entity from whom you purchased the machine; or

2. Consult the yellow pages of the phone directory for the nearest authorized dealer; or

3. Contact BIRO Mfg. Company for the authorized service entity (250 plus worldwide) in your area.

THE BIRO MANUFACTURING COMPANY

1114 Main Street

Marblehead, Ohio

Ph. 419-798-4451

Fax 419-798-9106

E-mail: service@biro saw.com

Web: http://www.biro saw.com

31

ITEM NO: T3400-091

PTCT PRO9-091 1-06-38 COMM

PTCT PRO9-091 2-09-37 PPD

32

Loading...

Loading...