Page 1

®

Page 2

The

®

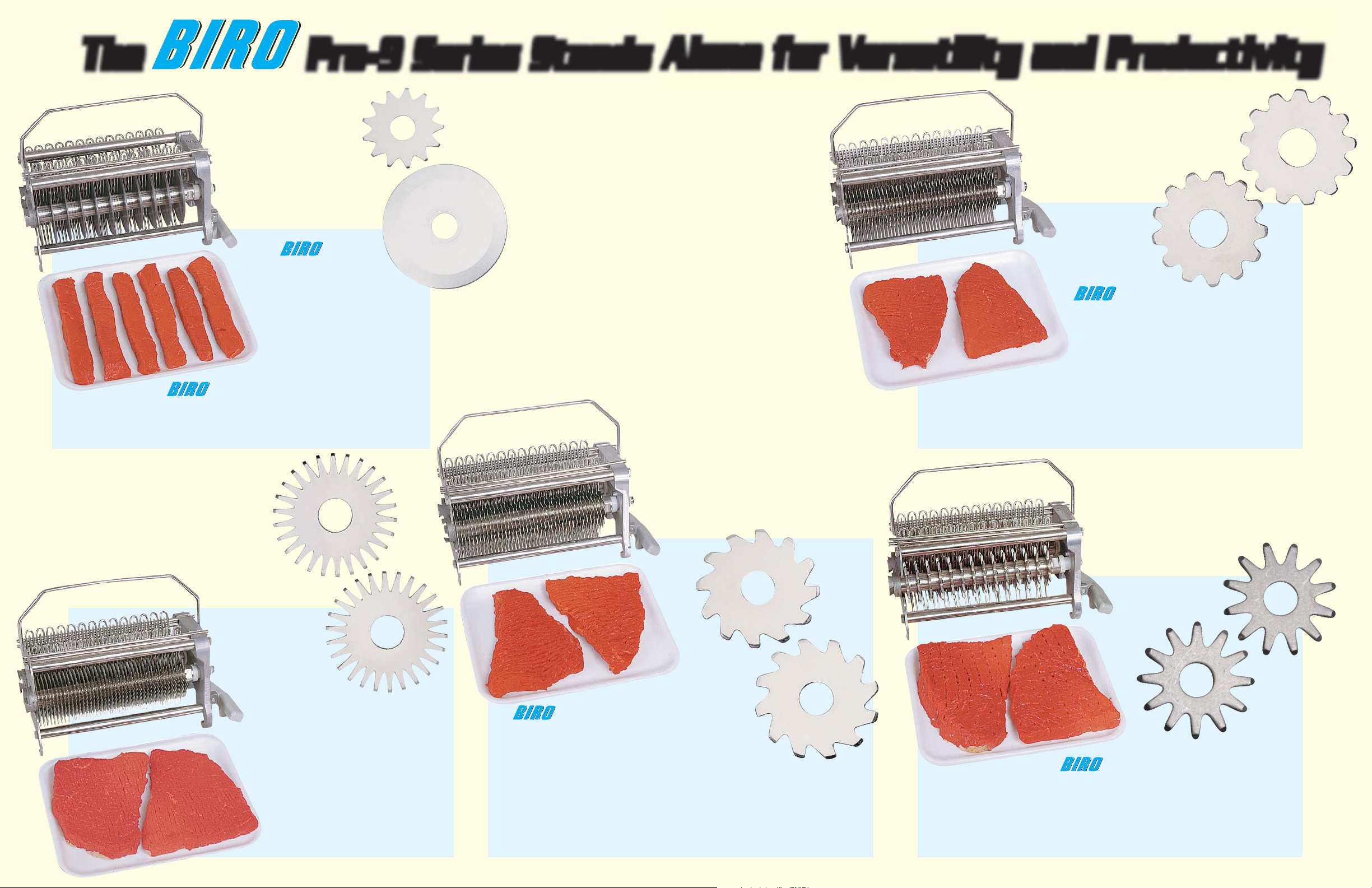

Pro-9 Series Stands

STRIP

Alone for Versatility and Productivity

Nothing surpasses the

Pro-9 Tenderizer for

versatility. Use the

SCORING

CUTTING

• Use a strip

cutting group to make such diverse

products as strips for stir fry or fajitas,

julienne for salads, and beef jerky strips.

Use two passes to make cubes for stew

or soup meat. Cut your valuable production

time significantly while making those

value-added products your customers want.

• strip cutting groups are available in 1/4”, 3/8”, 9/16”, 3/4”,

1”, 1 1/4”, 1 9/16”, and 2” strip widths. Choose the sizes which work best for you to help you

merchandise less expensive cuts for higher profit.

®

®

CUTLET

TENDERIZING

Pro-9 to tenderize,

knit, score, cut strips,

cut stew, and star

punch. Merchandise

less expensive, less

tender cuts to create

value-added products

which add to your

bottom line.

TENDERIZING/

KNITTING

• scoring rollers cut just the surface of

the steak or patty, which creates an eye-appealing product

which cooks quicker. Create a value-added product which can

• You can tailor your scoring roller set to the size of the

product by choosing the blade diameter which works for you. Choose

from 5 different sizes of gap between rollers to stretch or thicken your product so you get the mix

of value-added products which makes the most profit for you.

®

improve your gross profit by enabling you to profitably

merchandise less expensive cuts.

STAR

PUNCHING

• Designed specially

for thin or delicate

products such as veal,

chicken breast, or squid,

the cutlet tenderizer set

gently pierces the product

without tearing it. You can

create value-added products such as veal scaloppine or

veal parmigiana which will broaden your product mix

and enhance your sales and profit.

• Use the cutlet tenderizer set with the no charge

optional 140 rpm roller speed. Attain maximum

productivity while making value-added products.

• standard tenderizer blades cut deep into the product

to sever fiber and sinew. Two passes are all you need to create

value-added product from less expensive, hard to merchandise cuts.

Improve your product mix and gross profit and increase productivity.

• You can turn your tenderizing set into a knitting set just by changing

the position of the rear stripper. Take two smaller pieces of hard to

merchandise meat and convert them into one value-added product.

®

• The star punching group uses 1/8” star rollers to punch

lasting holes into the meat patty or steak to break down fiber. This makes the product more

tender and reduces the cooking time of the product by up to 40%. Use the star punching group to

merchandise those less expensive, less tender cuts as value-added products for higher profit.

®

Page 3

Stands alone for quality

2”

(50.8

16” (406.4 mm)

”

8

⁄

1

7

(180.975 mm)

71⁄2” (190.5 mm) 13⁄8” SLOT WIDTH

mm)

1

7

⁄

4

”

(184.1 mm)

7

13

⁄

8

”

(352.425 mm)

”

3

8

⁄

5

(136.5

mm)

1

10

⁄

2

”

(266.7 mm)

1

16

⁄

2

”

(419.1 mm)

34.925 MM

13” (330.2 m

®

and value since 1921

SPECIFICATIONS

PRO-9 SD PR

ELECTRICAL SUPPLY 115V, 1 PHASE – 5 FOOT – 3 WIRE CORD, 3 PRONG MOLDED, GROUNDED PLUG,

230V, 1 PHASE – 5 FOOT – 3 WIRE CORD, NO PLUG

CASE STAINLESS STEEL

CASE TOP STAINLESS STEEL

CUTTING GROUPS STAINLESS STEEL WITH STAINLESS STEEL SPACERS AND COMBS

ROLLER SPEEDS 105 R.P.M. STANDARD 115 R.P.M. STANDARD

13” (330.2 mm)

TRANSPARENT SAFETY COVER LEXAN TRANSPARENT

TRANSMISSION OIL BATH GEAR BOX

TRANSMISSION DRIVE POLY FLEX DOUBLE-V BELT POLY FLEX DOUBLE-V BELT STEEL GEAR SYSTEM

)

m

FIBER GEAR SYSTEM

SAFETY SWITCH MOTOR SHUTS OFF WHEN SAFETY COVER IS RAISED

STANDARD FEATURES DUAL PURPOSE TENDERIZER/KNIT ASSEMBLY, CORD AND/OR PLUG

(SEE ELECTRICAL) OPERATING AND SAFETY MANUAL

OPTIONS (EC) HEAVY DUTY RIGID SS COMBS, SS SAFETY COVER,

CRADLE STORAGE CONTAINER, SS CART

CERTIFICATIONS N.S.F., U.S.D.A., U.L., C.S.A., C.F.I.A.

WEIGHTS – APPROX. UNPACKED: 69 LBS. (31 KG.) 70 LBS. ( 32 KG.) 73 LBS. (33.1 KG.)

PACKED: 74 LBS. (33.6 KG.) 75 LBS. (34 KG.) 78 LBS. (35 KG.)

DIMENSIONS PACKED: L = 20” (508 MM) X W = 20” (508 MM) X H = 19” (483 MM)

O-9 HD - 1/2 HP PRO-9 HD - 3/4 HP

140 R.P.M. OPTIONAL– NO COST

MOTORS

HP KW TYPE VOLTS AMPS CYCLE PH STATUS

1/2SD .38 TEFC DP 115/230 7.5/3.8 60 1 STD

1/2HD .38 TEFC DP 115/230 7.5/3.8 60 1 STD

3/4HD .56 TEFC DP 115/230 8.8/4.4 60 1 STD

1/2SD .38 TEFC DP 115/230 7.5/3.8 50 1 EC

1/2HD .38 TEFC DP 115/230 7.5/3.8 50 1 EC

3/4HD .56 TEFC DP 115/230 8.8/4.4 50 1 EC

SD=STANDARD DUTY HD=HEAVY DUTY

STD=STANDARD TEFC DP=TOTALLY ENCLOSED

FAN COOLED, DRIP PROOF

LEGEND: HP = HORSEPOWER, SD = STANDARD DUTY,

HD = HEAVY DUTY, L = LEXAN, SS = STAINLESS STEEL,

STD = STANDARD, EC = EXTRA COST, NA = NOT AVAILABLE

ITEM NO.: LIT-PRO9-131 FORM NO.: MD PRO SRS 131-10-09-32-MARK PRINTED IN U.S.A.

STANDARD AND OPTIONAL CUTTING GROUPS REQUIRED SD 1/2 HP HD 1/2 HP HD 3/4 HP

HOPPER TYPE PRO-9 PRO-9 PRO-9

TA3130-50 CUTLET (TENDERIZING) CRADLE ASSEMBLY SS EC EC EC

TA3130 STD (TENDERIZING) CRADLE ASSEMBLY L STD STD STD

TA3130-9A 1/4” STEW-STRIP CRADLE ASSEMBLY L NA EC EC

TA3130-5A 3/8” STEW-STRIP CRADLE ASSEMBLY L NA EC EC

TA3130-4A 9/16” STEW-STRIP CRADLE ASSEMBLY L NA EC EC

TA3130-1A 3/4” STEW-STRIP CRADLE ASSEMBLY L EC EC EC

TA3130-14A 7/8” STEW-STRIP CRADLE ASSEMBLY L EC EC EC

TA3130-2A 1” STEW-STRIP CRADLE ASSEMBLY L EC EC EC

TA3130-3A 1 1/4” STEW-STRIP CRADLE ASSEMBLY L EC EC EC

TA3130-7A 1 9/16” STEW-STRIP CRADLE ASSEMBLY L EC EC EC

TA3130-8A 2” STEW-STRIP CRADLE ASSEMBLY L EC EC EC

TA3130-36 STAR ROLLER CRADLE ASSEMBLY L EC EC EC

TA3130-20 SCORING CRADLE ASSEMBLY, 0 ROLLER GAP L NA EC EC

TA3130-21 SCORING CRADLE ASSEMBLY, 1/16” ROLLER GAP L NA EC EC

TA3130-22 SCORING CRADLE ASSEMBLY, 1/8” ROLLER GAP L EC EC EC

TA3130-23 SCORING CRADLE ASSEMBLY, 3/16” ROLLER GAP L EC EC EC

TA3130-24 SCORING CRADLE ASSEMBLY, 1/4” ROLLER GAP L EC EC EC

CALL FACTORY FOR MORE INFORMATION

ALL SPECIFICATIONS CONTAINED HEREIN ARE SUBJECT TO CHANGE WITHOUT NOTIFICATION.

Service is available from over 245 locations worldwide

Loading...

Loading...