Page 1

MODEL FBC-4800SS

STAINLESS STEEL

FROZEN MEAT CHIPPER

Operating Manual and Parts List

Applicable on Machines Starting with Serial No. 10200

Biro Designed Biro Built

+

IMPORTANT NOTICE

This Manual contains important

safety instructions which must

be strictly followed when using

this equipment.

+

FBC-4800

029-10-05-16

029-5-07-17

PTCT

Page 2

Page 3

TABLE OF CONTENTS

Page

NOTICETOOWNERSANDOPERATORS......................................... 1

SAFETYTIPS ............................................................... 2

INSTALLATION ............................................................. 3

UNCRATINGANDSETUP.............................................. 3-4

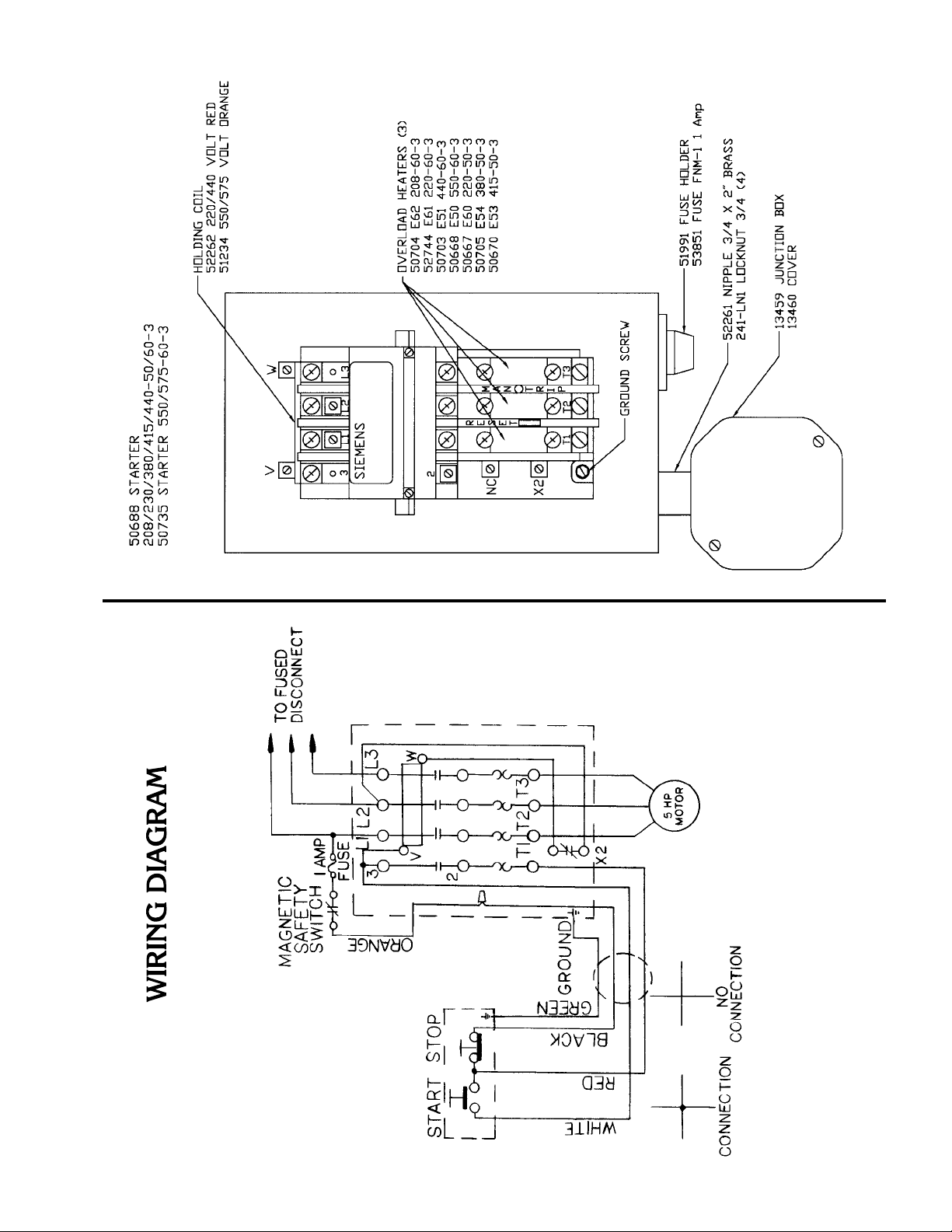

WIRINGDIAGRAM...................................................... 5

OPERATION................................................................ 6

TOPROCESSPRODUCT ................................................ 6

TROUBLESHOOTINGMACHINEOPERATION ............................... 7

MAINTENANCE ............................................................. 8

CLEANING................................................................. 9

PARTSDIAGRAMS...........................................................10

RUNNER AND GUILLOTINE BLADE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

LUBRICATION ..............................................................14

GROVE GEAR REDUCER DIAGRAM & LUBRICATION. . . . . . . . . . . . . . . . . . . . . . 16-17-18-19-20

MORSEGEARREDUCERDIAGRAM&LUBRICATION................................21

OPERATOR'SNOTES.........................................................22

OLD AND NEW STYLE BLADES AND OPERATOR’S NOTES

OPERATOR’SSIGNATUREPAGE................................................23

LIMITEDWARRANTY.........................................................24

Page 4

Page 5

NOTICE TO OWNERS AND OPERATORS

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should be thoroughly familiar with the procedures contained in this Manual. Even so BIRO

cannot anticipate every circumstance or environment in which its products will be used. You, the

owner and operator, must remain alert to the hazards posed by the function of this equipment —

particularly the MOVING SHUTTLE WITH SHARP CHIPPING BLADES, which can severly injure an

inattentive operator amputating fingers and limbs. No one under eighteen (18) years of age

should operate this equipment. If you are uncertain about a particular task, ask your supervisor.

This Manual contains a number of safe practices in the SAFETY TIPS section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

OR

Warnings related to possible damage are indicated by:

BIRO also has provided warning labels on the equipment. If any warning label or Manual becomes misplaced, damaged, or illegible, please contact your nearest Distributor or BIRO directly

for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

This Manual applies to SANITARY TIN machines with serial numbers 3100 to 5297, and

STAINLESS STEEL machines with serial numbers 10200 to present.

- NOTE -

A copy of this manual is included with each MODEL FBC-4800SS

THE BIRO MANUFACTURING COMPANY

FROZEN MEAT CHOPPER MACHINE.

1114 Main Street

MARBLEHEAD, OHIO 43440-2099 U.S.A.

The descriptions and illustrations contained in this manual are not

Phone (419) 798-4451

binding. The manufacturer reserves the right to introduce any

modification without updating the manual.

Fax (419) 798-9106

E-mail: service@birosaw.com

Web: http://www.birosaw.com

1

Page 6

SAFETY TIPS

MOVING SHUTTLE WITH SHARP CHIPPING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· NEVER Touch This Machine without Training and Authorization by Your Supervisor.

· ALWAYS Keep Hands Clear of Sharp Chipping Blades and Other Moving Parts.

· ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

· ONLY Install on Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away from

Children and Visitors.

· DO NOT Tamper With or Remove Product Chute Cover.

· NEVER Operate With the Product Chute Cover in the Open Position.

· ALWAYS Close Product Chute Cover Completely Before Operating Machine.

· ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to

This Machine BEFORE Cleaning or Servicing.

· NEVER Leave Machine Unattended While Operating.

· PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

· ALWAYS Read Operation and Service Manual BEFORE Operating, Cleaning, or Servicing.

· USE ONLY BIRO Parts and Accessories Properly Installed.

2

Page 7

INSTALLATION

TO AVOID SERIOUS PERSONAL INJURY, PROPERLY INSTALL

EQUIPMENT IN ADEQUATE WORK AREA

· ALWAYS Use Qualified Technician and Electrician for Installation.

· ALWAYS Connect to Proper Voltage & Phase.

· ALWAYS Install Equipment in Work Area with Adequate Light and Space Away From Children

and Visitors.

· ONLY Operate on a Solid, Level, Non-Skid Surface.

· NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

· NEVER Operate With Product Chute Cover in Open Position.

· NEVER Operate Without all Warning Labels Attached and Owner/Operator Manual Available to

the Operator.

UNCRATING AND SET UP

1. Read this Manual thoroughly before installation and operation. Do not proceed with installation and operation if

you have any questions or do not understand anything in this Manual. Contact your local Distributor, or BIRO

FIRST.

2. Carefully remove cardboard crate wraparound. Remove meat lug dolly and set aside.

3. Remove

4. Remove Meat Lug (Item No. 51199-MHD) from top of machine.

5. Install casters (3 ea. Item No. 51165 less brake and 1 ea. Item No. 51164 with brake) on the stainless steel Meat

Lug Dolly (Item No. 51582) with supplied fasteners. Set Meat Lug and Dolly aside.

6. With assistance of mechanical devices lift machine and block up. Remove machine legs from side of machine.

Replace legs to same mounting holes in vertical position, tightening the acorn nuts on the carriage bolts.

7. Remove stainless steel Chute Cover (Item No. 51597) from top of machine. Turn over and mount to stand offs at

top of chute opening. Tighten Chute Cover Hinge Pins (Item No. 51563). Do not over tighten. Chute should be

centered and still have free movement to open and close. Magnet should be centered over safety switch.

Tighten jam nuts on hinge pins.

8. Install Chute Cover Support (Item No. 51404) to Chute Cover. Be sure bushing is used to allow free movement

of chute support. Be sure chute support is in lock bracket welded to side of chute.

9. Place machine on a level, solid, non-skid surface in a well-lighted work area away from children and visitors.

10. Install floor stops over the front leg pads (opposite motor end). It is recommended that floor stops be anchored

to the floor with two

3

bolt and nut holding machine to wood crate bottom.

8

3

8

-16´1

1

" expansion anchors per floor stop.

2

3

Page 8

11. After checking and making sure that the power supply is correct, plug in your machine.

12. Machine must be properly grounded. Use qualified electrician to install according to local building codes.

13. With rear motor cover removed and chute cover in the closed position, push the green “start” button located on

the side of the rear cover. Be sure that the motor and transmission are rotating in the proper direction. Should

be COUNTERCLOCKWISE when viewing the transmission output shaft and machine crank arm, as indicated by

the arrow on crank arm. Should machine be operating backwards, push red “stop” button. Disconnect machine

from incoming power source and interchange two lead wires.

14. When machine is operating in proper direction, replace rear motor cover. Machine is now ready for trained

operators to process product.

MOTOR WIRING AND ELECTRICAL REQUIREMENTS

(1) Interchange of current is made in motor outlet box. Leads are properly marked. Changing instructions are on

the motor plate or motor outlet box.

(2) All chippers are wired 220 volts unless otherwise specified. Be sure motor specifications (voltage, cycle, phase)

match power supply line. Be sure line voltage is up to specification.

(3) Electrical connections to be in accordance with safety codes and National Electrical Code.

(4) Rated voltage of the unit shall be identical with full supply voltage.

(5) Voltage drop on the supply line shall not exceed 10% of full supply voltage.

(6) The feederline conductor size in the raceway from the branch circuit to the unit must be correct to assure

adequate voltage under heavy starting and short overload conditions.

(7) The feederline conductor shall only be used for the supply of one unit of the relevant horsepower. For

connections of more than one unit on the same feederline, a local electrician will have to be consulted to

determine the proper conductor size.

(8) The size of the electrical wiring required from the power source to the frozen block chipper is a MINIMUM OF

No. 10 WIRE if the distance from the machine to electrical box is 25 feet or less. Over 25 feet a MINIMUM OF

No. 8 WIRE is to be used.

(9) The BIRO Manufacturing Company is not responsible for permanent wiring, connection or installation.

NOTE TO OWNER AND ELECTRICIAN: IF THIS MACHINE IS NOT CORD

AND PLUG CONNECTED TO THE ELECTRICAL SUPPLY SOURCE, THEN IT

SHOULD BE EQUIPPED WITH, OR CONNECTED TO, A LOCKABLE,

MANUALLY-OPERATED DISCONNECT SWITCH (OSHA 1010.147).

MOTOR SPECIFICATIONS FURNAS HEATER ELEMENTS

VOLTS HERTZ AMPS CODE NO. BIRO ITEM NO.

208 60 16.2 E62 50704

230 60 14.0 E61 52744

460 60 7.0 E51 50703

575 60 6.0 E50 50668

190 50 16.7 E62 50704

220 50 14.4 E60 50667

380 50 8.7 E54 50705

415 50 8.0 E53 50670

4

Page 9

5

Page 10

OPERATION

MOVING SHUTTLE WITH SHARP CHIPPING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· ONLY Properly Trained Personnel Should Use This Equipment.

· ALWAYS Keep Hands Clear of Sharp Chipping Blades and Other Moving Parts.

· NEVER Operate With Product Chute Cover in the Open Position.

· DO NOT Tamper With or Remove Product Chute Cover.

· ALWAYS Close Product Chute Cover Completely Before Operating Machine.

· DO NOT Tamper With, Bypass, Alter, or Modify This Equipment in Any Way From Its Original

Condition.

· ALWAYS Turn Off, Unplug from Power Source and Perform Lockout/Tagout Procedure to This

Machine Before Cleaning or Servicing, or When Not in Use.

· NEVER Leave Unattended While Operating.

· NEVER Operate Without All Warnings Attached.

A. TO PROCESS PRODUCT

1. Place Meat Lug under machine to catch chipped product.

2. Prepare for processing a 60 pound tempered meat block. For optimum chipping the recommended block

temperature is 15 to 25 degrees F. With a maximum block size of 8"´16

product chips approx. 3

Plate (Item No. 51526).

3. Lift the Chute Cover slightly to release the Chute Support. Close the chute cover completely. The magnet

attached to the chute must contact the safety switch. The machine will not operate with the Chute Cover in

the open position.

4. Push the green “START” button. When the machine is finished chipping, which should be approx. 60

seconds, push the red “STOP” button. Unplug machine from power source and perform lockout/tagout

procedures.

5. Remove meat lug from under machine. Product is now ready for grinding or mixing/grinding.

1

"´3

2

1

1

"

". For narrower meat blocks there is available an optional Chute Filler

´

2

4

1

"´19

2

1

". This will yield finished

2

6

Page 11

B. TROUBLE SHOOTING MACHINE OPERATION

1. Machine is not chipping properly. Check the following items:

A. Product block may be frozen too hard (temperature should be 15 to 25 degrees).

B. Product block may be too soft.

C. Either the Guillotine Knife (Item No. 51380) or the Runner Blades (Item No. 51379) may be dull or broken.

D. Chute Spring (Item No. 51416) may be missing, broken, or have lost its temper.

E. Product block may be too narrow, install optional Chute Filler (Item No. 51526).

F. The machine may be running in the wrong direction. Check rotation arrow on the Crank Arm (Item No.

51387) for proper direction. COUNTERCLOCKWISE — looking at transmission output shaft.

G. Slide bearings in shuttle may be worn (Item No’s. 51502 & 51503, two each).

H. Guillotine Knife (Item No. 51380) may have been installed backwards.

I. Guillotine Knife and Runner Blades may have been resharpened beyond their life span.

J. Slide Rods (Item No. 51382) may be dry. Lubricate with good grade food machine oil.

2. Machine is not operating properly. Check the following mechanical items:

A. Crank Arm Pin sheared (Item No. 51054). Replace.

B. Transmission Bronze Drive Gear damaged or stripped (Item No. 51074-7). Replace.

C. Transmission Shaft Key sheared (Item No. 51074-16). Replace.

D. Motor Shaft Key sheared (Item No. 51074-28). Replace.

7

Page 12

MAINTENANCE

MOVING SHUTTLE WITH SHARP CHIPPING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· ALWAYS Turn Off, Unplug from Power Source and Perform Lockout/Tagout Procedures to

This Machine BEFORE Servicing.

· NEVER Touch This Machine Without Training and Authorization By Your Supervisor

· NEVER Place Hands Into Machine Input or Output Openings.

· NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

· PROMPTLY REPLACE Any Worn or Illegible Labels.

· USE ONLY GENUINE BIRO Parts and Accessories Properly Installed.

LUBRICATION

1. SLIDE RODS: Lubricate daily or after each cleaning with a good grade food oil.

2. CRANK PIN: Soak Felt Wick (Item No. 51285) once a year with 90 weight oil.

3. TRANSMISSION: Change after first month of operation, then every one year after.

For room temperatures above 20 deg. F. use SAE90 multi-purpose gear oil.

For room temperatures below 20 deg. F. use SAE80 multi-purpose gear oil.

4. MOTOR: Grease Zerk fitting on top and bottom of motor once a year.

5. GEAR BOX: Grease Zerk fitting on top of gearbox once a year.

SHUTTLE ASSEMBLY

1. GUILLOTINE KNIFE: Check for wear and dulling. Resharpen or replace as necessary.

2. RUNNER BLADES: Check for wear and dulling. Resharpen or replace as necessary. Replace any broken

blades.

3. SLIDE BEARINGS: Check for excessive free play. Replace as necessary.

8

Page 13

CLEANING

MOVING SHUTTLE WITH SHARP CHIPPING BLADES

TO AVOID SERIOUS PERSONAL INJURY

· ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedures to

This Machine Before Cleaning or Servicing.

· ONLY Use Recommended Cleaning Equipment, Materials and Procedures.

· NEVER Spray Water or Other Liquid Substances Directly at Motor, Power Switch or Any Other

Electrical Components.

· ALWAYS Thoroughly Clean Equipment at Least Daily.

CLEANING THE BIRO FROZEN BLOCK CHIPPER:

1. Turn “OFF”, unplug machine from power source, and perform lockout/tagout procedures.

2. Lift Chute Cover until notch in Chute Cover Support is in line with bracket on the side of the chute.

Disengage Chute Cover Support from bracket by pulling outward. Lift Chute Cover to fully open position and

allow to rest on top of the Drive Cover.

3. Loosen Hand Wheel (Item No. 51048) securing the Upper Frame Assembly (Item No. 51558). Move the

Hand Wheel and Catch Rod down to the unlock position. The Upper Frame Assembly is hinged to facilitate

cleaning. Lift to open Upper Frame Assembly. Assembly must be opened fully and resting against welded

Chute Cover hinge.

DO NOT SPRAY DIRECTLY AT ELECTRICAL COMPONENTS

4. Machine is now ready to be cleaned using warm soapy water and rinsed with clean water. Machine may be

cleaned by power spray washing, taking care not to spray directly at any electrical controls.

5. The shuttle may be removed for cleaning. This is accomplished by removing the hex head screws holding

the shuttle to the bearing bars.

6. After machine has been cleaned and allowed to air dry, the Slide Rods (Item No. 51382) should be coated

with a good food grade light oil or grease.

9

Page 14

RECOMMENDED

FLOOR ANCHOR

SUPPLIED

3

-16´1½²

8

EXPANSION

ANCHORS FOR

EACH (2)

FLOOR CHOCK,

FIGURE No. 17

10

Page 15

PARTS LIST

For: SANITARY TIN MACHINES starting with Serial No. 3100 to Serial No. 5297

&

For: STAINLESS STEEL MACHINES starting with Serial No. 10200

IMPORTANT: ALWAYS ADVISE SERIAL NUMBER WHEN ORDERING PARTS

FIG. NO. ITEM NO. DESCRIPTION

14 HHS129S Hex Head Screw,

Upper to Lower Frame

14A 0909 Acorn Nut,

15 50721 Lower Frame Assembly, Stainless Steel (NSS)

16 54279 Front Leg, Stainless Steel

16A 51338 Leg Carriage Bolt,

16B FW11S Flat Washer,

16C LW30S Lock Washer,

16D 0909 Acorn Nut,

17 50604 Floor Stop

18 51194 Front Leg Pad

19 51193 Rear Leg Pad

20 54285 Right Rear Leg, Stainless Steel

22 51387 Crank

22A 1161 Allen Screw,

22B 53783 Rotation Decal

23 51074G Transmission (see page 16-20) Grove gear reducer

23 51074 Transmission, (See Page 21) Morse reducer

23A 72251 Transmission Oil, 2 qts. (90 weight) for Morse reducer

23B HHS128S Hex Head Screw,

23C LW30S Lock Washer,

24 51054 Crank Pin

24A 16501WB Thrust Washer, Brass

25 51384 Pitman Arm Assembly with Bushings,

Wick & Pipe Plug, SS

25A 51051 Pitman Arm Bushings, Bronze

25B 0143 Pipe Plug,

1

25C 51285 Felt Wick

26 50688 Magnetic Starter, 208/230/380/415/460-50/60-3

26 50735 Magnetic Starter, 575-60-3

26A See Page 4 for Item No. Overload Heater Coils

27 51075 Motor, 5HP, 208/230/380/415/460-50/60-3

27 51192 Motor, 5HP, 575-60-3

27A 51074-28 Motor Shaft Key,

28 51991 Fuse Holder

28A 53851 Fuse, 1 Amp, FNM-1

29 50639 Magnet for Safety Switch

29A FNS24S Flat Head Screw, 10-32

29B 1116 Acorn Nut, 10-32

30 42MC-Y64 Magnetic Safety Switch, to 240V

31 51404 Chute Cover Support

31A 51581 Chute Cover Support Bushing

31B 19CB Carriage Bolt,

31C FW05S Flat Washer,

31D AN15S Acorn Nut,

32 51558 Upper Frame Assembly, Stainless Steel

33 13459 Junction Box

33A 13460 Junction Box Cover

34 51563 Chute cover hinge pin SS

34 HN30S Hex nut

3

-16 SS

8

35 51074G-1 Sub-plate (grove gear reducer)

36 51597 Chute cover

37 51784 Rubber bumper

46A 50690 Push Button Junction Box

1

-13´2, SS, Attach

2

1

-13; Attach Upper Frame to Lower Frame

2

1

-13´1, SS

2

1

", SS

2

1

", SS

2

1

-13, SS

2

1

-13´2"

2

1

2

"

2

1

4

1

", SS

4

1

-20, SS

4

1

2

", SS

3

16

-20

-13´1

3

,SS

4

3

1

´

8

5

´

8

3

,SS

´

4

11

Page 16

12

Page 17

PARTS LIST

IMPORTANT: ALWAYS ADVISE SERIAL NUMBER WHEN ORDERING

FIG. NO. ITEM NO. DESCRIPTION

1 51382 Slide Rod

2 51547 Front Bearing Bar Assembly w/Bearings

2A 51503 Front Slide Bearings

2B HHS135S Hex Bolt,

2C LW30S Lock Washer,

3 51340 Runner Blade Retainer

3A FHS36S Flat Head Screw,

3B 51454 Runner Blade Adjusting Set Screw

3C SSS13 Runner Blade Adjusting Set Screw ¼-20

3D SSS10 Locking Set Screw,

4 51378 Runner Support

4A HHS080S Hex Head Screw,

4B LW25S Lock Washer,

5 51379 Runner Blade, Tapered Ends

6 51380 Guillotine Knife

7 51377 Knife Clamp, Rear

8 51550 Bare Slide, Stainless Steel

8A 51549 Slide Assembly Complete

9 RHS23S Round Head Screw,

10 51540 Rear Bearing Bar w/Slide Bushings

10A 51502 Rear Slide Bearing

10B HHS135S Hex Bolt,

10C LW30S Lock Washer,

11 51557 Pitman Arm Pin

12 51383 Slide Rod Bushing, SS

13 51093 Slide Rod Washer

13A HHS125S Hex Head Screw,

13B LW30S Lock Washer,

21 54284 Left Rear Leg, Stainless Steel

34 51165 Caster Less Brake

35 51164 Caster With Brake

35A 51269 Caster Assembly, (4 caster w/fasteners)

36 51582 Lug Dolly Assembly w/Casters, Stainless Steel

36A 51335 Lug Dolly Less Casters, Stainless Steel

37 51199-MHD Meat Lug

38 72334 Groove Pin for Catch Rod

38A 51348 Catch Rod, Stainless Steel

39 51048 Hand Wheel

40 51416 Chute Spring

40A CB74S Chute Spring Carriage Bolt,

40B HNNL20S Chute Spring Nylok Nut,

41 51784 Rubber Bumper for Chute Cover

42 51597 Chute Cover Assembly, Stainless Steel

43 51575 Drive Cover Door

44 51563 Chute Cover Hinge Pins, SS

44A HN30S Hex Nut,

45 50757 Drive Cover, Stainless Steel

45A HHS025S Hex Head Screw ¼-20´½SS

45B LW10S Lock Washer ¼ SS

45C FW06S Flat Washer ¼ SS

46 50761 Push Button Plate w/Hood

46B 50681 Gasket

46E 42MC-Y73 Green Start Button

46F 42MC-Y74 Red Stop Button

47 50766 Switch Hole Filler Plate

48 51338 Leg carriage bolt ½-13´1SS

48 FW11S Flat washer ½ SS

48 LW30S Lock washer ½ SS

48 0909 Acorn nut ½-13 SS

49 54279 Front leg SS

NOT SHOWN 50777 Operating Manual & Parts List

1

-13"´2

2

1

-13´2

2

3

-16 light jam, SS

8

1

",SS

2

3

,SS

8

1

", SS

2

1

", SS

2

1

3

1

1

", SS

2

-20´1, SS

4

1

-20´¼

4

-16´1

8

1

-20

4

1

,SS

2

-13´1, SS

2

1

,SS

2

3

, SS, Brg. Retainer

´

8

5

-18

16

5

-18, SS

16

3

´

8

3

,SS

´

4

13

Page 18

RUNNER BLADE AND GUILLOTINE BLADE

REPLACEMENT PROCEDURE

1. Remove the slide assembly hex head mounting bolts (3 ea.)

2. Remove Item No. 51549 slide assembly from the machine.

3. Place on workbench.

4. Remove the runner support hex head bolts (4 ea.)

5. Remove Item No. 51378 runner support and Item No. 51377 knife clamp.

6. Clean the runner blade mounting grooves in the knife clamp.

7. Remove Item No. SSS10 locking set screws (4 ea.) and back out Item No. 51454 and No. SSS13S runner

blade adjusting screws (5 ea.)

8. Do not remove Item No. 51340 runner blade retainer.

9. Remove Item No. 51379 runner blades (5 ea.) and Item No. 51380 guillotine knife.

10. Clean the grooves.

11. Slide new Item No. 51379 runner blades into the slide frame under the Item No. 51340 runner blade retainer.

12. Lay new Item No. 51380 guillotine knife on the slide frame.

13. Push Item No. 51379 runner blades into the knife clamp.

14. Assemble Item No. 51377 knife clamp and Item No. 51378 runner support and bolt to the slide frame using

the 4 ea.

15. Be sure Item No. 51379 runner blades are sitting square and flush against Item No. 51380 guillotine knife

and Item No. 51377 knife clamp.

16. Tighten the mounting bolts.

17. Re-tighten the 5 ea. Item No. 51454 and No. SSS13S runner blade adjusting set screws until they are snug.

Do not over-tighten. Insert and tighten the 4 ea. ¼-20´¼ locking set screws in all adjusting set screw holes

except the middle one.

18. This assembly will prevent putting the runner blades in a bind.

19. Remount the slide assembly into the machine.

3

-16´1½'' hex bolts and lock washers.

8

SHUTTLE ASSEMBLY

1. GUILLOTINE KNIFE: Check for wear and dulling. Resharpen or replace as necessary.

2. RUNNER BLADES: Check for wear and dulling. Resharpen or replace as necessary. Replace any broken

blades.

3. SLIDE BEARINGS: Check for excessive free play. Replace as necessary.

LUBRICATION

1. SLIDE RODS: Lubricate daily or after each cleaning with a good grade food oil.

2. CRANK PIN: Soak Felt Wick (Item No. 51285) once a year with 90 weight oil.

3. MOTOR: Grease Zerk fitting on top and bottom of motor once a year.

4. GEAR BOX: Grease Zerk fitting on top of gearbox once a year.

14

Page 19

No. 51549 Slide Assembly Complete

With Blades and Without Bearing Bars

15

Page 20

INSTALLATION INSTRUCTIONS

ALTERNATE

GROVE GEAR REDUCER

REPLACING

MORSE GEAR REDUCER

· ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedures to

the Machine Before Any Service is Performed.

REMOVAL

A. Remove Item No. 51575 Drive Cover Door.

B. Remove four bolts holding the Item No. 50690 Pushbutton box to the Item No. 50757 Drive Cover and let

box hang free.

C. Remove the Item No. 50757 Drive Cover.

D. Open the motor junction box and disconnect the electrical leads. Remove the switch wires and conduit from

the motor.

E. Remove the motor from the OEM gear reducer (Morse), taking care to locate the motor key.

F. Remove the Item No. 51054 Crank Pin and Item No. 16501WB Thrust Washer from the Item No. 51384

Pitman Arm and rest at the bottom of the base access slot.

G. Loosen the Item No. 1161 Allen Screw in the Item No. 51387 Crank. Remove the Crank from the gear

reducer output shaft. This may require a puller. Keep track of the Crank Key.

H. Remove the four bolts holding the Gear Reducer to the machine frame and remove the Gear Reducer.

16

Page 21

INSTALLATION

A. Put the four ½-13´1¾ bolts and lock washers in the mounting plate first. Attach the mounting plate to the

Gear Reducer (Grove) using the four

7

-14´1¾ bolts and lock washers.

16

B. Mount the Gear Reducer and Mounting Plate combination to the machine frame and tighten the four ½-13

bolts. Remove the factory plug and replace with the plastic vented plug in the filler plug hole shown in the

drawing.

C. Reinstall the Motor into the Gear Reducer. Be sure the Motor Key is properly in place, Tighten the Motor

Bolts.

D. Reinstall the Motor wires and conduit. Reattach the wires. Taking care that the Motor wiring diagram is

followed for proper voltage.

E. Being aware of location of all other personnel while the Motor is being tested for proper rotation, plug the

machine into power source. Push the start button and note rotation of Gear Reducer output shaft. It should

rotate counterclockwise when viewing from shaft side. If not, interchange two lead wires. Unplug the

machine from power source for final installations.

F. Reinstall the Item No. 51387 Crank and Crank Key. Tighten the Item No. 1161 Allen Screw.

G. Reinstall the Item No. 51384 Pitman Arm using the Item No. 51054 Crank Pin and Item No. 16501WB

Thrust Washer. If the Crank and Pitman Arm do not line up, move the Pitman Arm by sliding the Slide

Assembly forward or backward until alignment is achieved.

H. Reinstall the Item No. 50757 Drive Cover.

I. Reinstall the Item No. 50690 Drive Cover.

J. Reinstall the Item No. 51575 Drive Cover Door.

K. Plug machine into power source and check for proper operation.

17

Page 22

LUBRICATION FOR GROVE GEAR REDUCER

1. Factory Filling

The speed reducers are oil filled at the factory to the proper level for the standard mounting position. The oil

level should be checked and adjusted (if necessary) prior to operation, using the oil level plug provided and

while the unit is oriented in its operating position.

2. Oil Changing

WHEN CHANGING OIL FOR ANY REASON,

DO NOT MIX DIFFERENT OILS IN THE REDUCER.

OILS SHOULD BE COMPATIBLE WITH

VITON®SEAL MATERIAL.

Therefore, when changing to a different oil, it is recommended that the housing be completely drained and

thoroughly flushed with a light flushing oil prior to refilling with the appropriate lubricant. The oil level should

be rechecked after a short period of operation and adjusted, if necessary.

OIL SHOULD BE CHANGED MORE OFTEN IF THE

REDUCER IS USED IN A SEVERE ENVIRONMENT

(i.e., DUSTY, HUMID)

A. Initial Oil Change

The oil in a new speed reducer should be changed at the end of 250 hours of operation. (30 days for 8

hour per day service, 15 days for 16 hour service, 10 days for 24 hour service.)

All standard reducers ordered from the factory are filled with lubricant to operate within a 30° to 100°F

ambient temperature range.

B. Subsequent Oil Changes

Under normal conditions, after the initial oil change, the oil should be changed after every 2500 hours of

operation, or every six months, whichever occurs first. Under severe conditions (rapid temperature

changes, moist, dirty or corrosive environment) it may be necessary to change oil at intervals of one to

three months. Periodic examination of oil samples taken from the unit will help establish the appropriate

interval.

C. Synthetic Oils

Synthetic lubricants can be advantageous over mineral oils in that they generally are more stable, have a

longer life, and operate over a wider temperature range. These oils are appropriate for any application but

are especially useful when units are subjected to low start-up temperatures or high operating

temperatures. Use of synthetics can cause problems if they are not compatible with the seals or the

conventional lubricants they replace. For continuous duty at normal ambient temperatures (-10°F to

105°F) we recommend the use of Mobile SCH 634

shipped in our product and the Viton® seal material used through size 252.

3. Overfilling or Underfilling

If a speed reducer is overfilled with oil, the energy used in churning the excessive oil can result in overheating.

If this occurs, shut down the drive, remove the oil level plug and allow oil to drain until oil ceases to drain

from the level hole, reinstall the oil level plug and restart the drive. if the speed reducer is underfilled, the

resultant friction can cause overheating and possible damage. If this occurs, fill the speed reducer to the oil

level plug hole and check the gearing for excessive wear. NOTE: Oil capacity is 1¾ pints.

4. Oil Seals

Although the speed reducer uses high quality oil seals and precision ground shafts to provide a superior seal

contact surface, it is possible that circumstances beyond the speed reducer's control can cause oil seal

leakage (damage during shipment or installation, etc.). When replacing a shaft oil seal, using the following

suggestions will help to insure leak-free operation and long seal life.

A. When installing a new seal, cover the keyway and any other surface discontinuity with smooth tape to

protect the seal lip from being damaged.

B. A sealant should be used between the O.D. of the seal and the I.D. of the bore into which the seal is

installed. The seal bore should also be free of any burrs, nicks, or scratches.

which is compatible with the standard compounded oil

C. Be sure that the seal is not cocked in the seal bore. The outer face of the seal should be flush with the

surface into which it is mounted.

18

Page 23

51074G GEAR REDUCER

LUBRICATION AND MAINTENANCE

LUBRICANTS FOR 51074G GEAR REDUCER

WORM GEAR REDUCERS

The precision-made gears and bearings in Grove Gear Speed Reducers require high-grade lubricants of the proper

viscosity to maintain trouble-free performance. For best results, use lubricants on the following chart for worm gear

reducers.

Manufacturer 30° to 100°F Ambient Temperature

AGMA Compounded No. 7

Amoco Oil Co. Worm Gear Oil Cylinder Oil #680

Chevron USA, Inc. Cylinder Oil #460X Cylinder Oil #680X

Exxon Co. USA Cylesstic TK-460 Cylesstic TK-680

Gulf Oil Co. Senate 460 Senate 680D

Mobile Oil Corp. 600 W Super Cylinder Extra Hecla Super

Shell Oil Co. Valvata Oil J460 Valvata Oil J680

Sun Oil Co. Gear Oil 7C Gear Oil 8C

Texaco Honor Cylinder Oil 650T Cylinder Oil

Union Oil Co. of CA Steaval A Worm Gear Lube 140

50° to 125°F Ambient Temperature

AGMA Compounded No. 8

Standard factory-installed lubricant is Mobile Oil Corp. 600 W Super Cylinder Oil (AGMA7).

Some gear lubricants contain E.P. additives that can be corrosive to gear bronze. Avoid lubricants that are com

pounded with sulfur and/or chlorine.

19

-

Page 24

No. 51074G GROVE GEAR REDUCER PARTS DIAGRAM

Item No. Description

51074G-1 Gear Housing

51074G-2 Pipe plug

51074G-3 Vent plug

51074G-5 Input cover

51074G-6 O-ring

51074G-7 Hex head cap screw

51074G-10 Input bearing

51074G-14 Output cover

51074G-15 O-ring

51074G-16 Output cover gasket (as required)

51074G-17 Output oil seal

Item No. Description

51074G-18 Output bearing (cup & cone)

51074G-19 Hex head cap screw

51074G-20 Single output shaft 1

3

dia.

8

51074G-22 Gear spacer

51074G-23 Gear key

50174G-24 Output gear

51074G-40 Quill motor flange

51074G-41 Input oil seal

51074G-42 Hex head cap screw

51074G-43 Retaining ring – shaft

51074G-45 Quill input shaft

20

Page 25

MORSE GEAR REDUCER

51074 — 1 Housing

51074 — 2 Motor Flange

51074 — 3 Brg. Ret. Input

51074 — 4 Cover Carr.

51074 — 5 Output Shaft

51074 — 6 Worm

51074 — 7 Gear

7

Bore

8

51074 — 8 Bearing Input

51074 — 9 Bearing Input

51074 — 10 Bearing Output

51074 — 11 Oil Seal Input

51074 — 12 Oil Seal Output

51074 — 13 Shim Input

51074 — 14 Shim Output

51074 — 15 Key Gear

51074 — 16 Key Output

51074 — 17 Oil Fill Plug

51074 — 18 Oil Plug

51074 — 19 Oil Plug

51074 — 20 Grease Fitting

51074 — 21 Grease Fitting

51074 — 22 Cap Screw

51074 — 23 Lock Washer

51074 — 24 Cap Screw

51074 — 25 Cap Screw

51074 — 26 Cap Screw

51074 — 27 Lock Washer

51074 — 28 Motor Shaft Key (

TRANSMISSION: Change after first month of operation, then every one year after.

TRANSMISSION: For room temperatures above 20 deg. F, use SAE90 multi-purpose gear oil.

TRANSMISSION: For room temperatures below 20 deg. F, use SAE80 multi-purpose gear oil.

3

3

1

)

´

16

8

21

Page 26

OLD STYLE AND NEW STYLE BLADES & KNIVES

Due to replacement of old style slide assemblies with the new style slide assemblies on the early

Model FBC-4800SS BIRO Frozen Block Chippers, it has become necessary that we ask you to

order your runner blades and guillotine knives by Style/Item Number.

Please see sketches below and order accordingly on all future orders.

51057 INSERT

- NOTES -

22

Page 27

OPERATOR’S SIGNATURE PAGE

WARNING

READ AND UNDERSTAND THIS ENTIRE

MANUAL BEFORE SIGNING BELOW

MY SIGNATURE ATTESTS THAT I HAVE COMPLETELY READ AND UNDERSTAND THIS

MANUAL. I REALIZE THAT THIS MACHINE, IF OPERATED CARELESSLY, CAN CAUSE

SERIOUS INJURY TO MYSELF AND OTHERS.

NAME (PRINT) SIGNATURE

SUPERVISOR’S

INITIALS

DATE

23

Page 28

LIMITED WARRANTY:

WARRANTY: The Biro Manufacturing Company warrants that Model FBC-4800 Meat Chipper will

be free from defects in material and workmanship under normal use and with recommended service. BIRO will replace defective parts, which are covered by this limited warranty, provided that

the defective parts are authorized for return, shipping charges prepaid, to a designated factory for

inspection and/or testing.

DURATION OF WARRANTY: The warranty period for all parts covered by this limited warranty is

one year from the date of puchase, except as noted below or 18 months from original ship date.

PARTS NOT COVERED BY WARRANTY: The following are not covered by this limited warranty:

wearable parts such as the meat lug, guillotine knife, runner blades,chute spring, and nylon bearings. This limited warranty does not apply to machines sold as used, rebuilt, modified, or altered

from the original construction in which the machine was shipped from the factory. (Water contaminated electrical systems are not covered under this limited warranty). BIRO is not responsible

for service charges or labor required to replace any part covered by this limited warranty or for any

damages resulting from misuse, abuse, lack of proper or recommended service.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no warranties

other than those expressly stated in this limited warranty. THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR PROCESSING OF FOOD PRODUCTS, AND ALL OTHER IMPLIED WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT

LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE

REMEDIES PROVIDED IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S SOLE AND EXCLUSIVE REMEDIES AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete warranty registration card supplied

with each machine. The warranty card must be returned to The Biro Manufacturing Company for

proper registration. If no warranty card is returned to BIRO, the warranty period will begin from

the date the machine was originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the entity from whom you purchased the machine; or

2. Consult the yellow pages of the phone directory for the nearest authorized dealer; or

3. Contact BIRO Mfg. company for the authorized service entity (250 plus worldwide) in your area.

THE BIRO MANUFACTURING COMPANY

1114 Main Street, Marblehead, Ohio 43440-2099

Ph. 419-798-4451 Fax 419-798-9106

E-mail: service@birosaw.com

Web: http://www.birosaw.com

ITEM NO. 50777

ITEM NO. 50777

PTCT FBC 4800-092-5-07-17-PPD

PTCT FBC 4800-092-10-05-16-COMM

24

Loading...

Loading...